Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Easy to cut and crush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

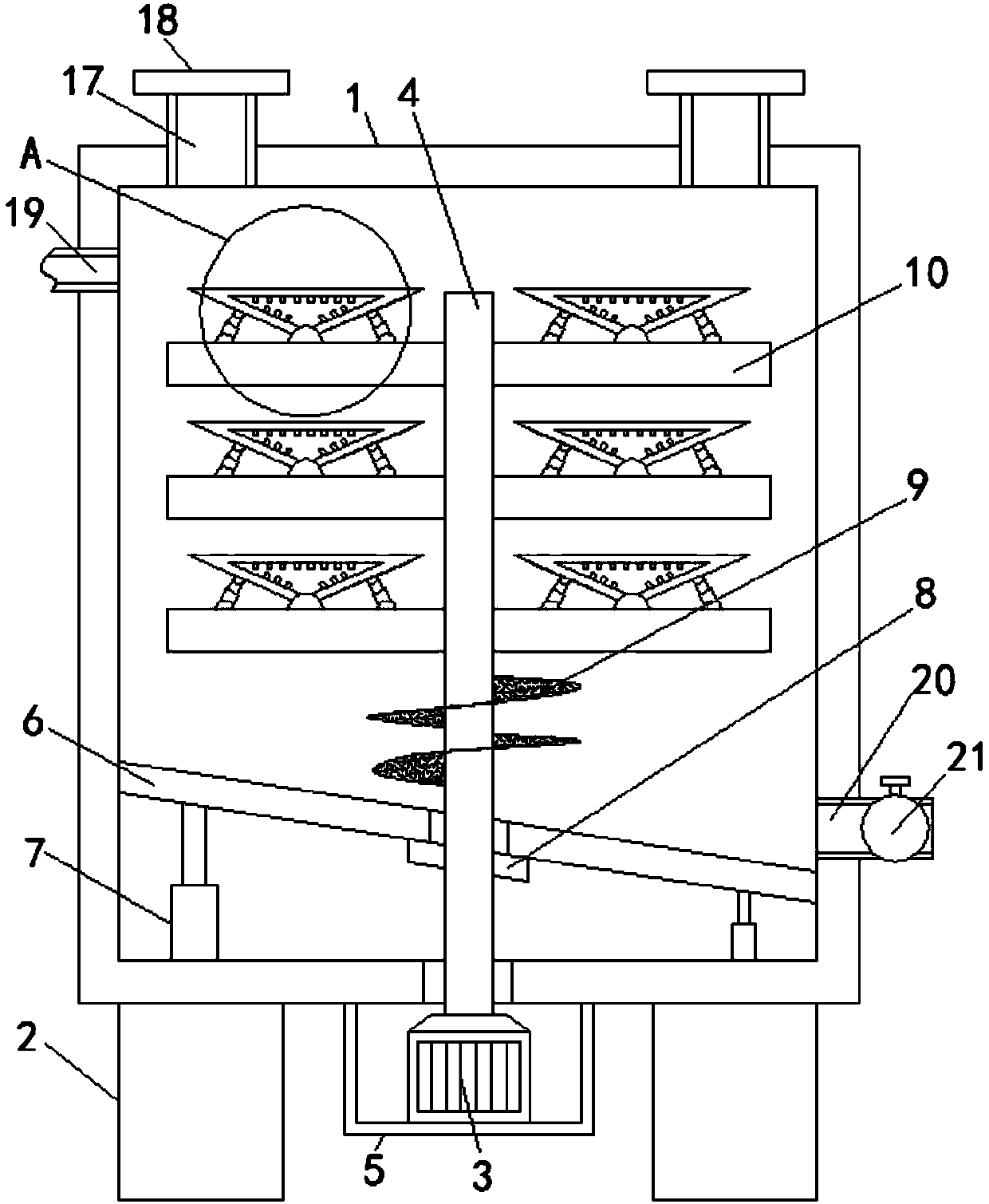

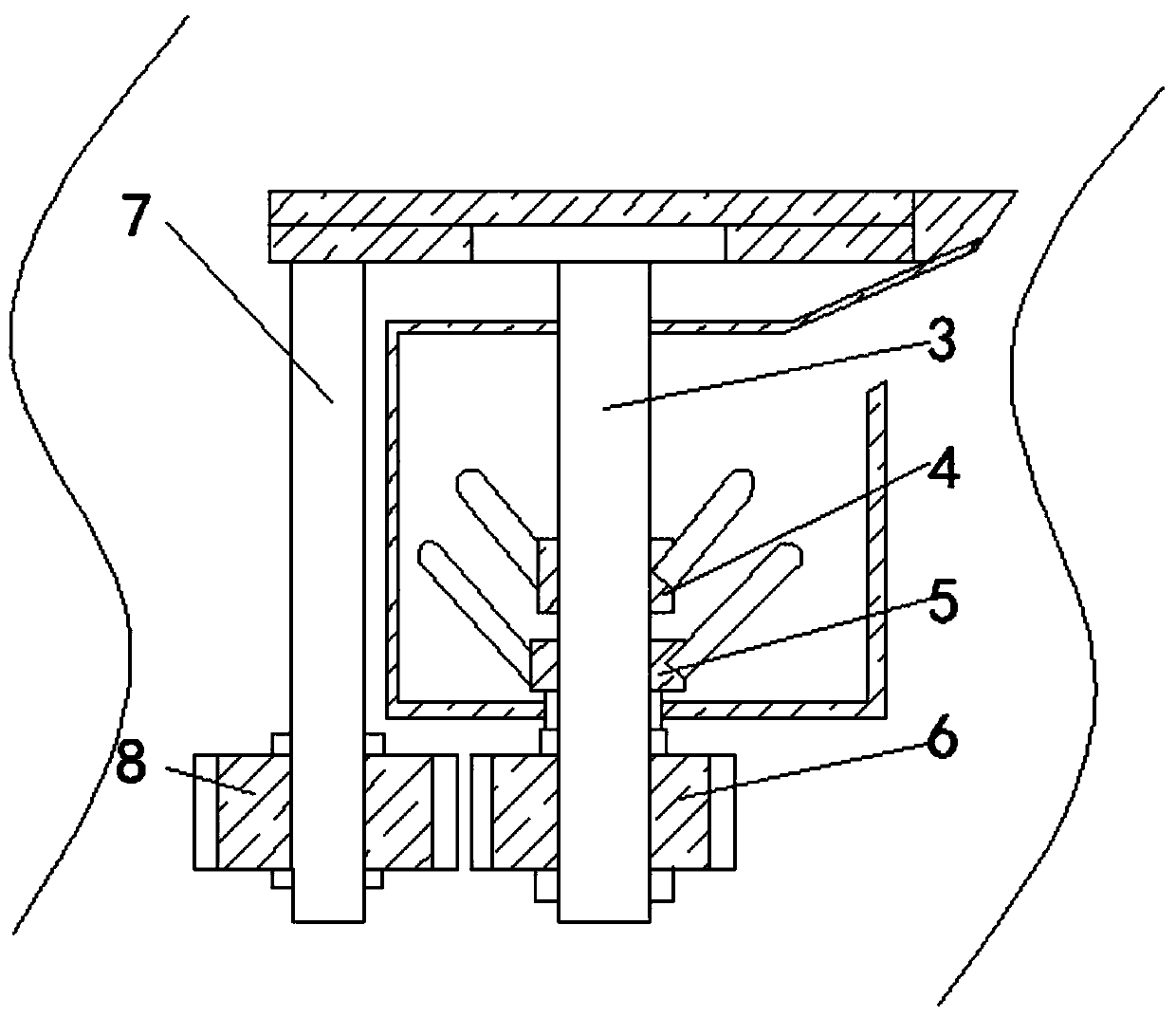

Safe and efficient medical waste compaction device

InactiveCN108380637AAvoid Breeding and SpreadingImprove securitySolid waste disposalMedical waste disposalEngineeringMedical treatment

The invention discloses a safe and efficient medical waste compaction device. The safe and efficient medical waste compaction device comprises a feeding pipe, a shell, a rotating rod, rakes, a slidingplate, a cutting box, a stirring motor, cutting blades, a gas collection tank, a compaction box, cutting teeth, a filter plate, a water collecting tank and a discharging door, wherein the rotating rod is arranged in the shell; the rakes are uniformly arranged on the rotating rod, the stirring motor is arranged at the top end of the cutting box, the top end of the cutting box is connected with thegas collection tank through a vent pipe, an ultraviolet light lamp is installed on the inner wall of the top end of the cutting box, the bottom end of the cutting box communicates with the compactionbox through a material conveying pipe, a hydraulic rod is arranged on the inner wall of the top end of the compaction box, a pressing plate is arranged at the bottom end of the hydraulic rod, the filter plate is arranged in the compaction box, one end of the filter plate is hinged to the inner wall of the compaction box, a lifting rod is arranged on the lower surface of the other end of the filter plate, and the lowest end of a water guide plate is connected with the water collecting tank. According to the safe and efficient medical waste compaction device, the breeding and the propagation ofharmful bacteria are avoided, the safety is improved, the pollution to outside ambient air is avoided, the medical waste can be prevented from being accumulated, the waste burning is facilitated, thestructure is simple, the use is convenient, and the popularization is facilitated.

Owner:合肥龙之韵医药技术有限公司

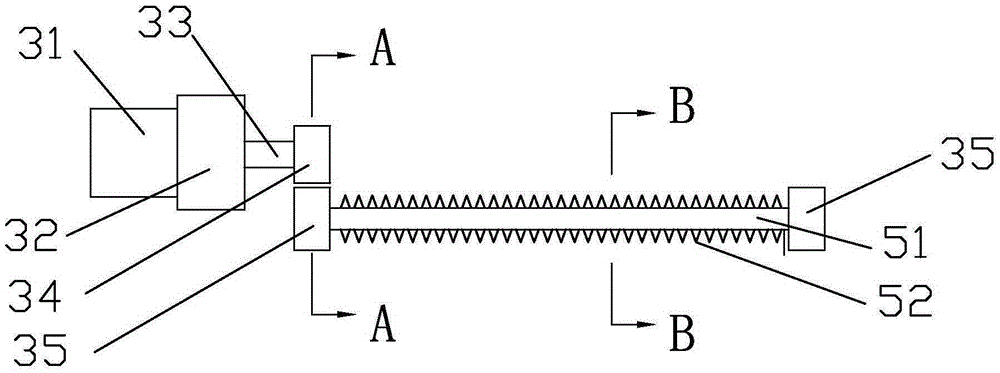

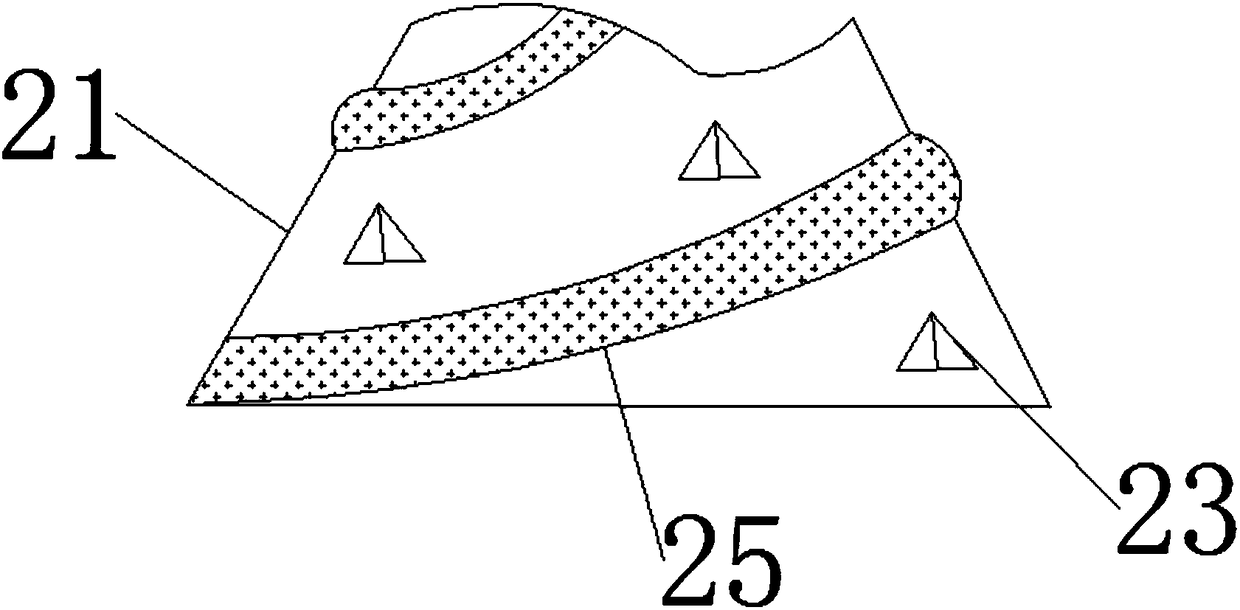

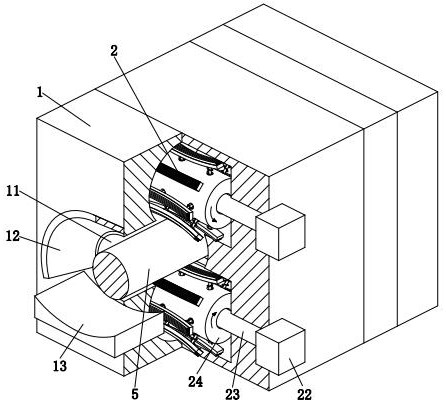

Coal gangue crusher

InactiveCN107029819AImprove crushing efficiencyEasy to cut and crushGrain treatmentsFixed bearingHigh humidity

The invention relates to the field of coal gangue brick making equipment, in particular to a coal gangue crusher. It includes a static tooth plate, a movable tooth plate, a camshaft, a bearing seat, a crusher bracket, a fixed bearing, a rotating shaft, a motor, and a feed bin; the fixed tooth plate is fixedly installed on the crusher bracket; the movable tooth The top of the plate is rotatably installed on the fixed bearing, and the fixed bearing is installed on the crusher bracket; the motor is connected to the camshaft through the rotating shaft; the camshaft is close to the movable tooth plate It is set on the back side, and the camshaft is installed on the bearing seat; the feed bin is connected with the crusher bracket, and is arranged above the space between the stationary tooth plate and the movable tooth plate. The object of the present invention is to provide a coal gangue crusher to solve the problems of poor crushing effect, low efficiency and inability to crush high humidity coal gangue in the existing coal gangue crusher.

Owner:怀宁县凉亭建材有限责任公司

Pulverizer applied to recycling of waste glass

InactiveCN105413798ASolve the crushing problemSimple structureGrain treatmentsGlass fragmentGlass recycling

The invention discloses a pulverizer applied to recycling of waste glass. The pulverizer comprises a pulverizing cavity. The pulverizing cavity comprises a transmission room and a pulverizing room. A transmission device is arranged in the transmission room. A pulverizing device is arranged in the pulverizing room. The transmission device comprises a first transmission device body and a second transmission device body. The pulverizing device comprises a first pulverizing device body and a second pulverizing device body. The first pulverizing device body comprises a pulverizing roller which is connected with the first transmission device body. The pulverizing roller comprises a first pulverizing roller body and a second pulverizing roller body. The second pulverizing device body comprises a center pulverizing main shaft which is connected with the second transmission device body. According to the pulverizer, the two levels of pulverizing device bodies are adopted, the first pulverizing device body, the first pulverizing roller and the second pulverizing roller are used for conducting primary pulverizing on waste glass, and then the second pulverizing device body is used. Small glass fragments can be pulverized further, and in addition, the glass fragments is evenly pulverized further to become aggregate capable of being used for concrete.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

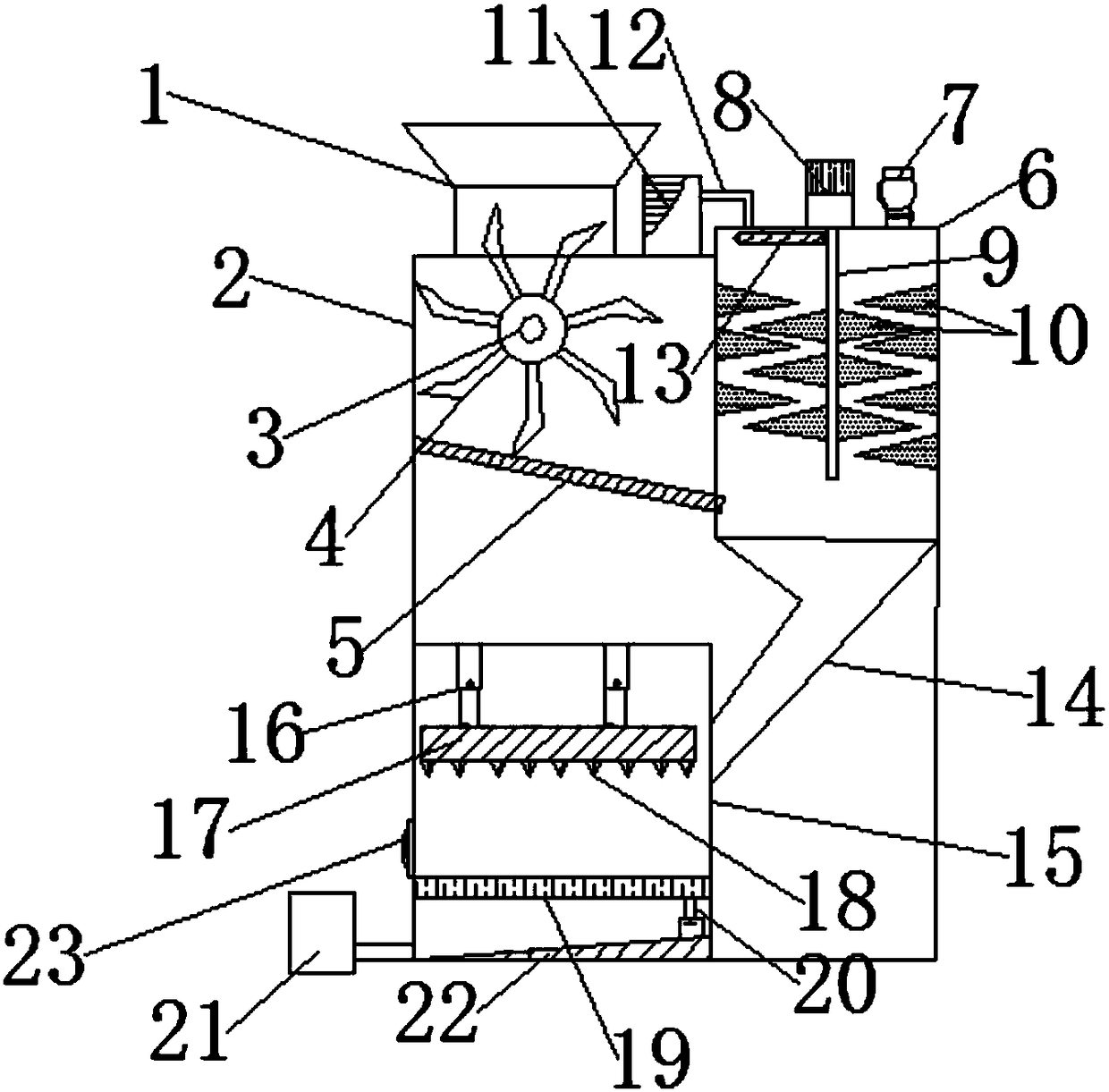

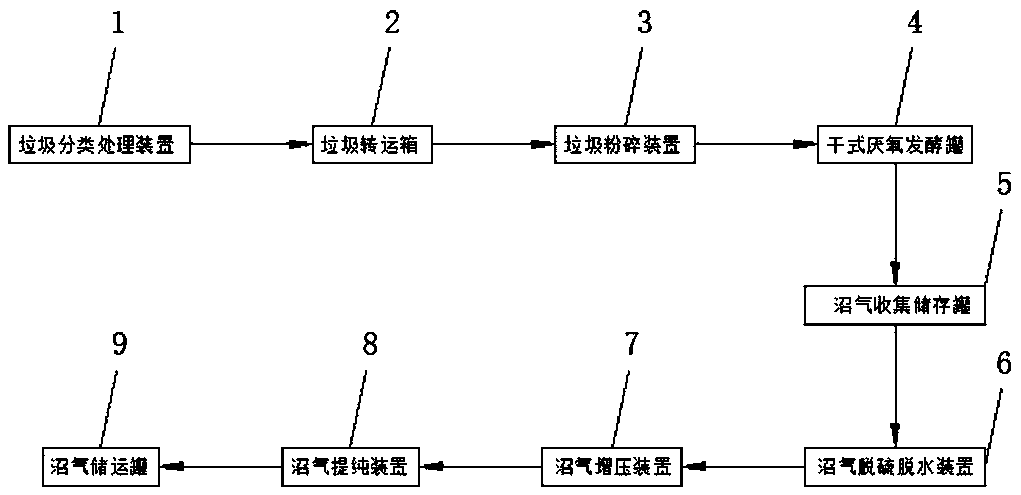

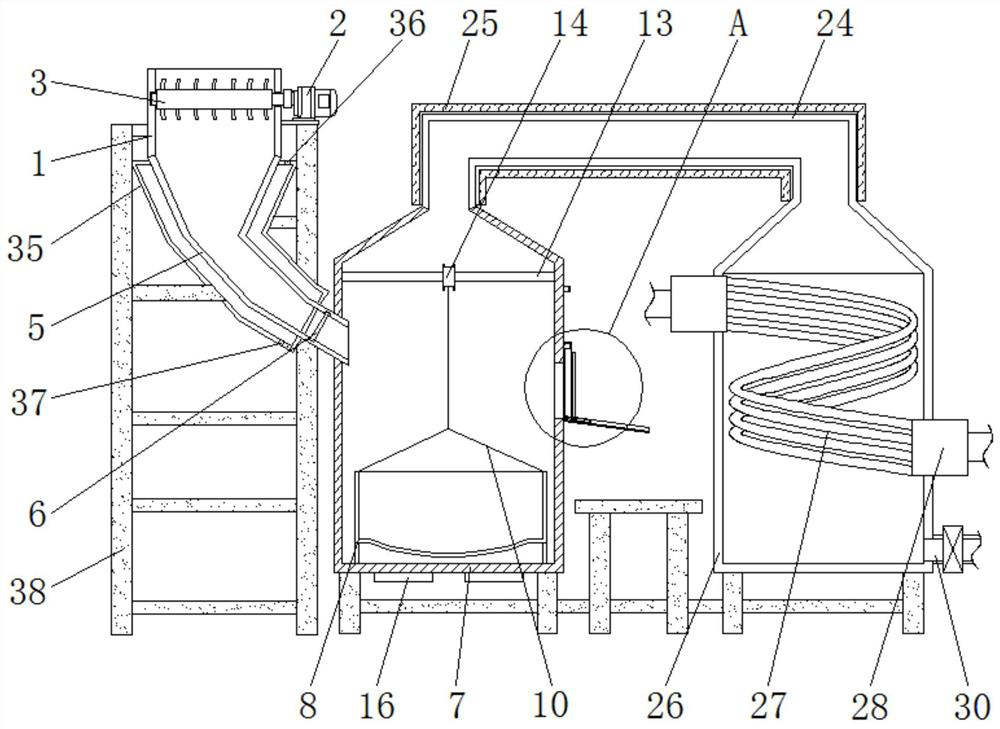

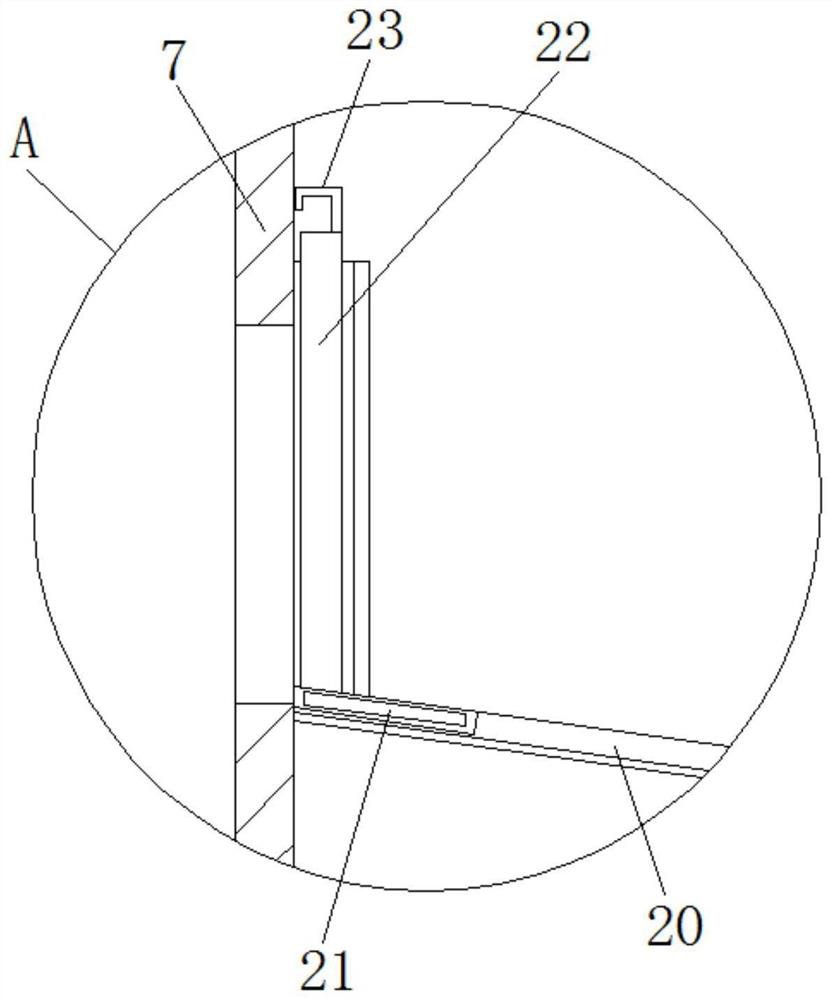

Reaction system for preparing methane from garbage

InactiveCN108018192AEasy to classifyImprove classification efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMethane

Owner:湖南三五二环保科技有限公司

Paper production method capable of recycling water

InactiveCN107513876ASave waterEasy to crushPulp beating/refining methodsRaw material divisionWater storageFiber

The invention discloses a paper production method capable of water recycling. The paper production equipment capable of water recycling includes a crushing box, the crushing box is fixedly connected with a stirring box through a material guide pipe fixedly connected at the bottom, and the bottom of the side of the stirring box is fixedly connected There is a discharge pipe, and the mixing tank is fixedly connected to the water storage tank through the catheter tube fixedly connected at the bottom. One end of the tube is fixedly connected to the top of the stirring tank. The invention crushes the trees through the crushing box, stirs the crushed trees through the stirring box to separate the plant fibers, collects the used water in the stirring box through the water storage tank, and then imports the water collected in the water storage tank into the stirring box through the water suction pump , to achieve the advantages of recycling water resources to stir the crushed trees, and has the advantage of saving water resources.

Owner:傅恺

Safe and efficient medical waste disposal incinerator

InactiveCN108397778AEasy to put inCheck it offAir/fuel supply for combustionIncinerator apparatusCombustionMedical waste

The invention discloses a safe and efficient medical waste disposal incinerator which comprises a feeding pipe, a housing, a rotary roller, a drawing rake, a sliding plate, a cutting box, cutting blades, a gas collecting tank, a combustion box, a combustion plate, an air blower, a rotary drum and a rotary motor, wherein the feeding pipe is arranged at the top end of the housing; the lowest end ofthe sliding plate is connected with the cutting box; a stirring motor is mounted at the top end of the cutting box; an output shaft of the stirring motor is connected with a stirring shaft; the cutting blades are arranged on the stirring shaft and on the inner wall of the cutting box; the top end of the cutting box is connected with the gas collecting tank through a breather pipe; the bottom end of the cutting box is connected with the combustion box through a conveying pipe; the combustion plate is arranged in the combustion box; a spraying grate is arranged below the combustion plate and communicates with the air blower through a vent pipe; and the side wall of the top end of the combustion box communicates with the cutting box through a hot-gas feeding pipe. The safe and efficient medical waste disposal incinerator avoids breeding and spread of harmful germs to improve security, prevents medical waste from polluting the external ambient air and being stacked, facilitates combustionof waste, is simple in structure and convenient to use and facilitates popularization.

Owner:合肥龙之韵医药技术有限公司

Paper manufacturing robot with water recycled

InactiveCN107604721ASave waterEasy to crushPulp beating/refining methodsRaw material divisionWater useFiber

The invention discloses a paper manufacturing robot with water recycled. The paper manufacturing equipment with the water recycled comprises a smashing box, a stirring box is fixedly connected with the smashing box through a material guiding pipe fixedly connected to the bottom of the smashing box, a material outlet pipe is fixedly connected to the bottom of the side surface of the stirring box, the stirring box is fixedly connected with a water storage tank through a liquid guiding pipe fixedly connected to the bottom of the stirring box, a water sucking pump is fixedly connected to the sidesurface of the water storage tank through a water sucking pipe, a drainage pipe is fixedly connected to one end of the water sucking pump through a water outlet pipe, and one end of the drainage pipeis fixedly connected to the top of the stirring box. According to the paper manufacturing robot with the water recycled, trees are smashed by the smashing box, the smashed trees are stirred by the stirring box to extract plant fibers, water used in the stirring box is collected by the water storage tank, then water collected in the water storage tank is guided into the stirring box through the water sucking pump, so that the purpose that water resources are recycled to stir the smashed trees is achieved, and the paper manufacturing robot has the advantage of water resource conservation.

Owner:傅恺

Processing method of red date grains

ActiveCN106473044AShorten working timeImprove work efficiencyFruit and vegetables preservationGrain treatmentsMicrowaveAdditive ingredient

The invention discloses a processing method of red date grains. The processing method of the red date grains comprises the following steps: preparing an anti-sticking antibacterial liquid, carrying out pre-treatments, carrying out soaking, carrying out grinding, carrying out grading, and carrying out drying. According to the processing method, the anti-sticking antibacterial liquid is adopted so as to reduce the cohesive force of the sugar in the red dates, so that shearing and crushing are facilitated, and bacteria and fungi are inhibited to a certain degree. A nitrogen-filled variable-frequency grinder is adopted, so that the contact points of the red dates with the blades can be maintained at an environment of 0-5 DEG C during the grinding processes, so that temperature rise of shear-type grinder is fundamentally suppressed, and automatic continuous low-temperature shearing is realized. Frequency control is adopted for controlling the rotate speed of the grinding machine, so that the frequency can be adjusted according to different raw materials, and the qualified rates of the grinded red date grains are thereby maximized. Vacuum microwave drying is adopted, so that the water contents in the red date grains can be rapidly reduced to lower than 15% after a short period of low-temperature drying; thus, re-bonding of the red date grains is avoided, and damages to the nutritional ingredients and browning of the red date grains are effectively inhibited.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Construction waste processing device based on dedusting technology

InactiveCN107457035AImprove crushing qualityGuaranteed shreddingUsing liquid separation agentMagnetic separationPre treatmentScrap

The invention discloses a construction waste processing device based on the dust removal technology, which comprises a sorting box, a transfer box and a crushing box. Corresponding to the feeding hole, the side wall of the sorting box is provided with a discharge hole, the middle part of the side wall of the sorting box is provided with a discharge hole, the discharge hole is connected to the transfer box, and the crushing box is close to the side of the sorting box There is a feeding hole at the end, a transmission device in the transmission box, a crushing rod in the crushing box, and a crushing tool matched with the extrusion roller at one end of the crushing rod. The top wall of the inner cavity of the crushing box is fixedly connected to the spray device, the bottom of the crushing box is evenly provided with a number of second legs; the invention sorts out the iron and metal waste products in the waste products by setting the sorting roller, so that the iron products can be recycled and reused; the extrusion roller can The waste products are pretreated and crushed, which is convenient for cutting and crushing by the crushing tool, so as to ensure that the waste products are completely crushed and the crushing quality is improved.

Owner:南宁众创空间科技有限公司

Environment-friendly stone production equipment

InactiveCN109513505AEasy to circulate crushingSmooth rotationTransportation and packagingMixersEngineeringIntegrated processing

The invention discloses environment-friendly stone production equipment and relates to the technical field of stone. The equipment comprises a pulverizing chamber, a crushing mechanism and a comprehensive treating chamber mechanism. Supporting columns are welded to the two sides of the lower portion of the pulverizing chamber correspondingly, and a pulverizing mechanism is arranged on the middle-lower portion of the interior of the pulverizing chamber. The crushing mechanism is mounted above the pulverizing mechanism, and a feed inlet is fixed above the crushing mechanism. The comprehensive treating chamber mechanism is mounted below one side of the pulverizing chamber, and an observation window is fixed to the outer side of the comprehensive treating chamber mechanism. A guide chute is formed in the upper end of the middle of the pulverizing mechanism, and a discharging outlet assembly is fixed below the pulverizing mechanism. A spiral feeding pipe is mounted below the discharging outlet assembly. A curing agent mixing mechanism is mounted on one side of the pulverizing chamber, and a conveying pipe is arranged below the curing agent mixing mechanism. The environment-friendly stone production equipment has the beneficial effect that by arranging a rotational rotary box body, waste stone can be repeatedly and circularly pulverized conveniently.

Owner:FOSHAN UNIVERSITY

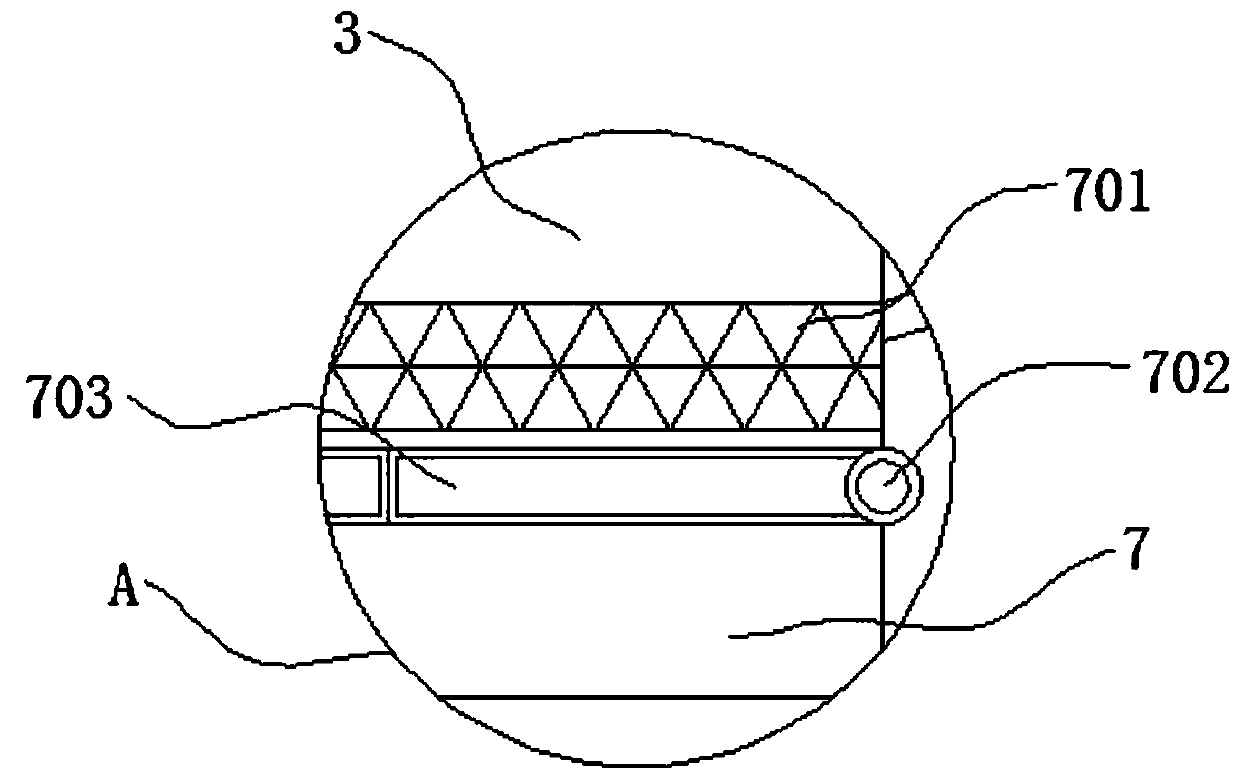

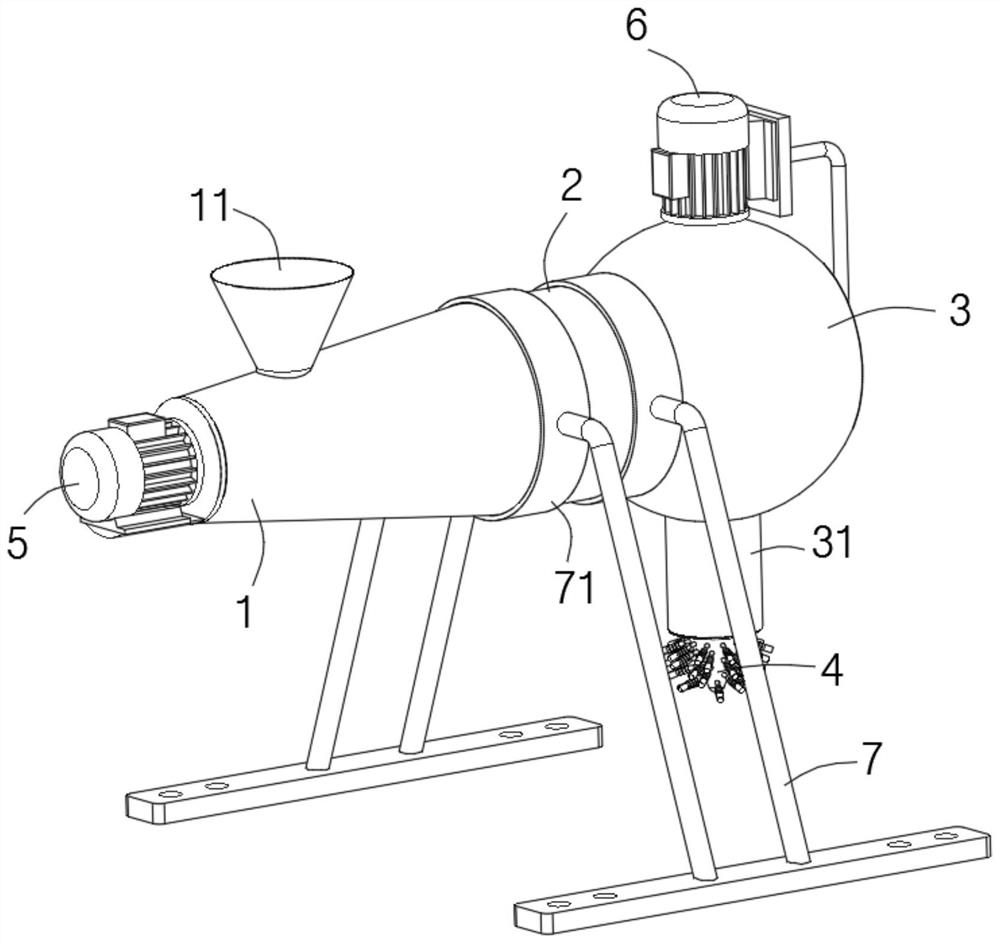

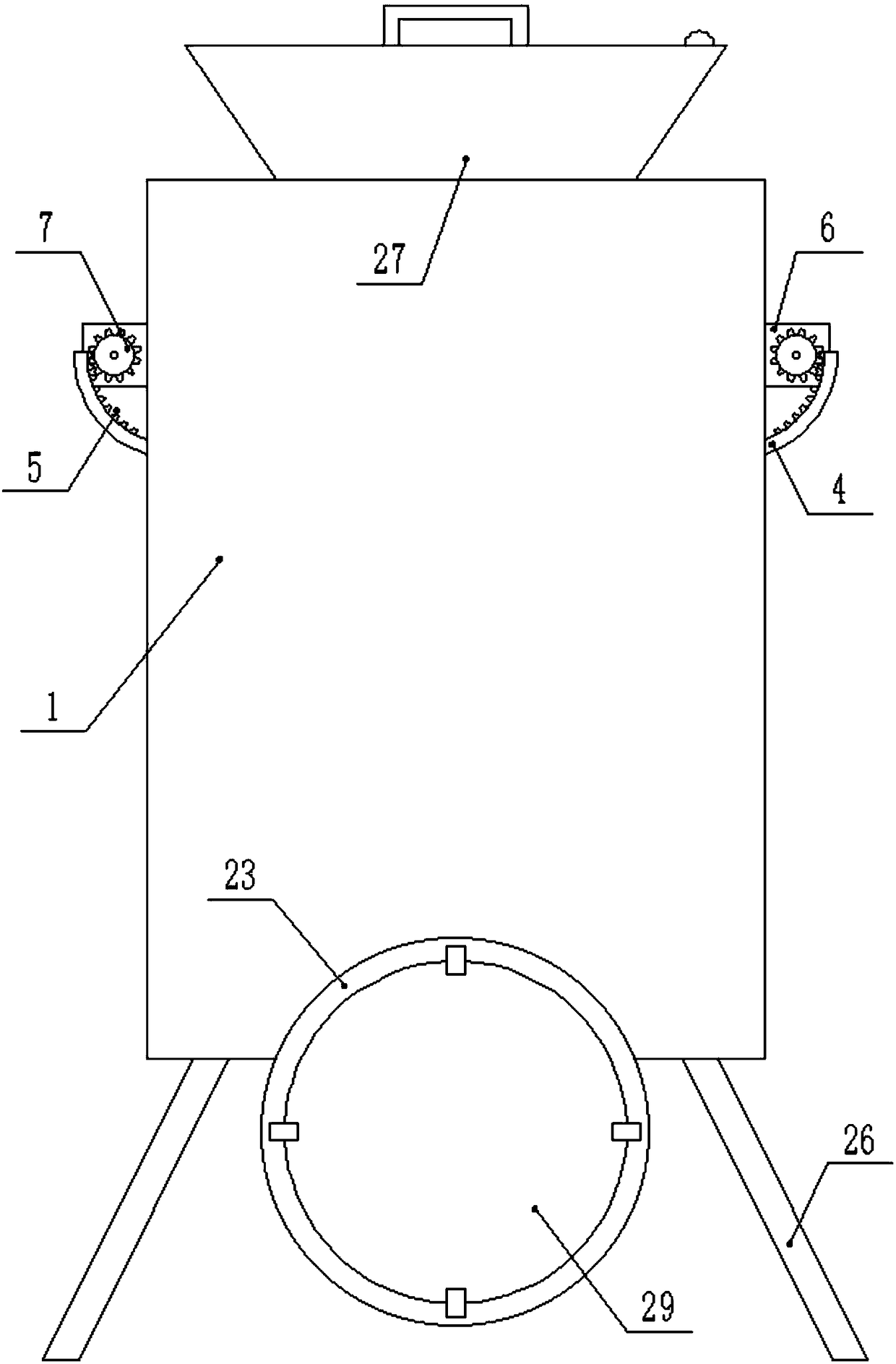

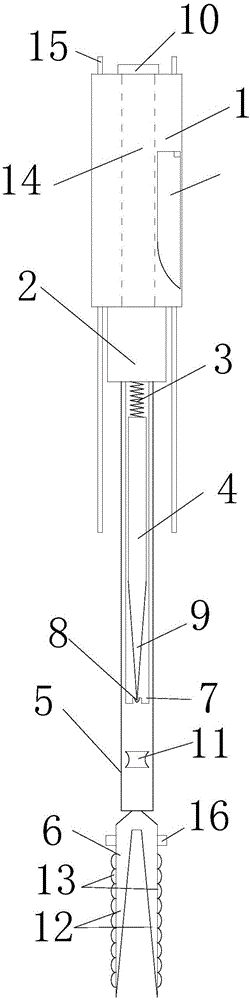

Feed puffing equipment

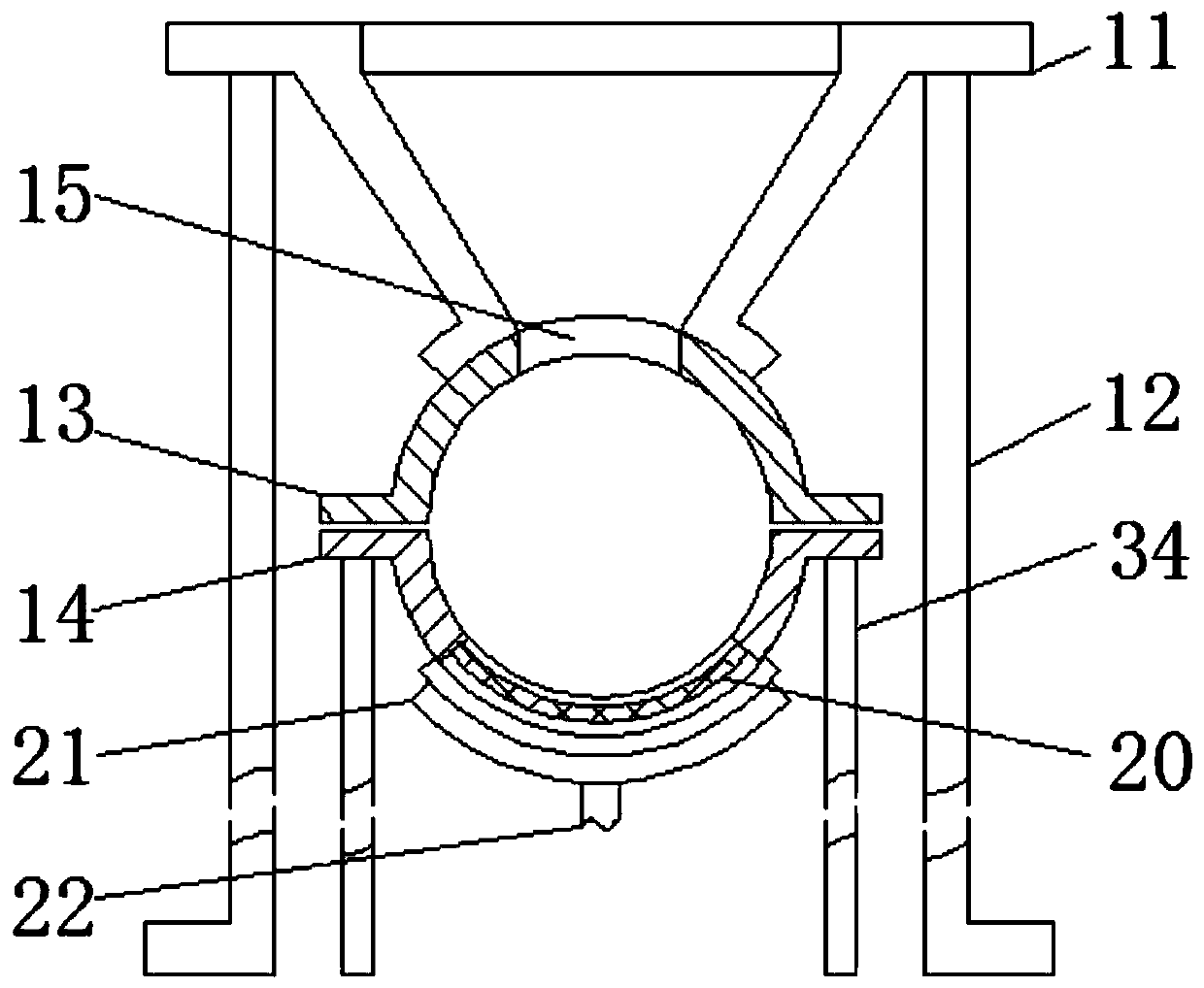

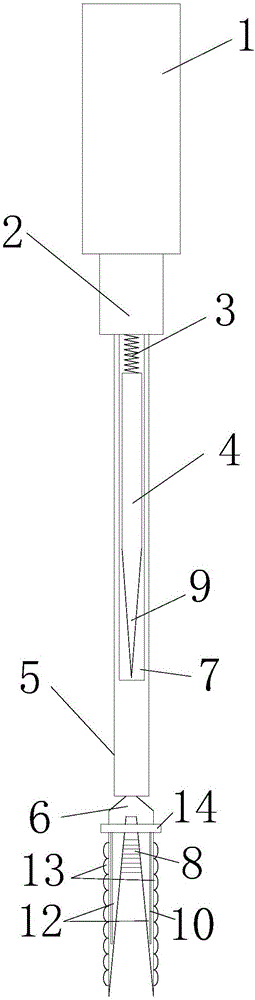

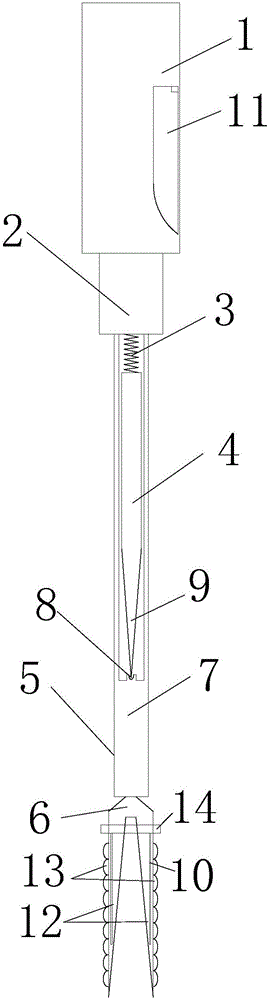

InactiveCN113545505AEasy to cut and crushEasy to refine particlesFeeding-stuffGrain treatmentsStructural engineeringFodder

The invention discloses feed puffing equipment. The feed puffing equipment comprises a conical feeding cylinder, wherein a feeding hopper is arranged on one side of the top of the conical feeding cylinder; a crushing cylinder is arranged at the large-diameter end of the conical feeding cylinder; a conveying cylinder is arranged at the end, away from the conical feeding cylinder, of the crushing cylinder; a connecting cylinder is connected to the bottom of the conveying cylinder; a conical discharging cylinder is arranged at the bottom end of the connecting cylinder; the large-diameter end of the conical discharging cylinder is located above the small-diameter end of the conical discharging cylinder; a plurality of puffing shaping pipes are uniformly distributed on the outer wall of the conical discharging cylinder; each puffing shaping pipe sequentially consists of an extruding pipe, a puffing pipe, a corrugated pipe section and a shaping pipe in a material discharging direction; each extruding pipe is in the shape of a circular truncated cone; and the diameter of an opening in the end, close to the corresponding puffing pipe, of each extruding pipe is smaller than that of an opening in the end, close to the conical discharging cylinder, of each extruding pipe. Through the adoption of the feed puffing equipment disclosed by the invention, the puffing quality of feeds is convenient to improve, and the circumstance that the feeds are broken in the puffing process can be reduced.

Owner:安徽皇佳生物工程技术有限公司

Baby diaper collecting treatment device and method

The invention discloses a baby diaper collecting treatment device and method. The baby diaper collecting treatment device comprises a box body; transverse plates are symmetrically hinged to the two ends of the inner wall of the box body, electric heating wires fixedly connected with the transverse plates are arranged in the transverse plates, the transverse plates are made of a ceramic material, and semi-circular rods which are concentric with the hinged positions the transverse plates and the semi-circular rods are fixed to the edges of the lower ends of the transverse plates; the semi-circular rods penetrate through the side wall of the box body and are slidably connected with the side wall of the box body; the portions, arranged outside the box body, of the semi-circular rods are provided with a plurality of uniformly distributed bulging teeth, and the bulging teeth are arranged on the inner arc surfaces of the semi-circular rods; first motors are symmetrically fixed to the two endsof the outer wall of the box body, and gears are fixed to rotary shafts of the first motors and engaged with the bulging teeth on the semi-circular rods; dried baby diapers can be conveniently subjected to smashing cutting, meanwhile, most of peculiar smell and germs can be eliminated, after the baby diapers are pressed and flattened by rollers and belts, crushing treatment is facilitated, the cut baby diapers can be conveniently smashed, the time is saved, the efficiency is improved, and the cost is reduced; and the baby diapers are thoroughly smashed through cutting blades rotating rapidly,the space is saved, and transporting, storing and recycling are facilitated.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

Extraction device for medicinal material distillation, facilitating full utilization

InactiveCN111804001AEasy to crushEasy to collectDistillation in boilers/stillsSolid solvent extractionHerb medicineMedicinal herbs

The invention discloses an extraction device for medicinal material distillation, which is beneficial to ensuring full utilization. The device comprises a crushing barrel, a first motor, a second motor, a heating plate, a refrigerator and a water pump, wherein the first motor is arranged at the top of the right side of the crushing barrel; a material accumulation hopper is connected to the lower part of the crushing barrel; a movable door is arranged on the right side of a herbal medicine frame, a supporting rod is arranged at the top of a distillation barrel, a ceramic heat preservation layeris arranged on the outer side of the distillation barrel, a condensation pipe is arranged in the condensation barrel, a protective shell is connected to the outer side of the bottom of the material accumulation hopper, and supports are connected to the lower portions of the crushing barrel, the distillation barrel and the condensation barrel. According to the extraction device for medicinal material distillation beneficial to ensuring full utilization, medicinal materials are conveniently crushed and collected, heating distillation treatment of the medicinal materials is facilitated, used medicinal material residues are conveniently discharged, new medicinal materials are conveniently added, distillation is facilitated, distilled heat can be recycled, and energy is conveniently saved.

Owner:李姗姗

Green grass crushing device used for animal husbandry

The invention relates to the technical field of animal husbandry, and discloses a green grass crushing device for animal husbandry, which includes a crushing box, four corners of the bottom of the crushing box are fixed with fixing feet, and the bottom of the crushing box is provided with a driving motor. The output shaft of the driving motor is fixedly connected to the transmission shaft, the outer side of the driving motor is provided with a protective cover, the bottom of the driving motor is fixedly connected to the inner bottom wall of the protective cover, and the top of the protective cover is fixedly connected to the crushing box . In this invention, the green grass can be put into the crushing box through the feed pipe, and the drive motor will be started to drive the transmission shaft to rotate, so that the spiral piece and the crushing piece can be rotated at the same time. Through the extension and shortening of the second hydraulic telescopic rod, it can The triangular slices move left and right to facilitate vertical cutting and crushing. The crushing teeth are convenient for cutting the green grass inside the triangular slices, which is more convenient and more thorough.

Owner:程建

Reaction kettle for accelerating reaction speed

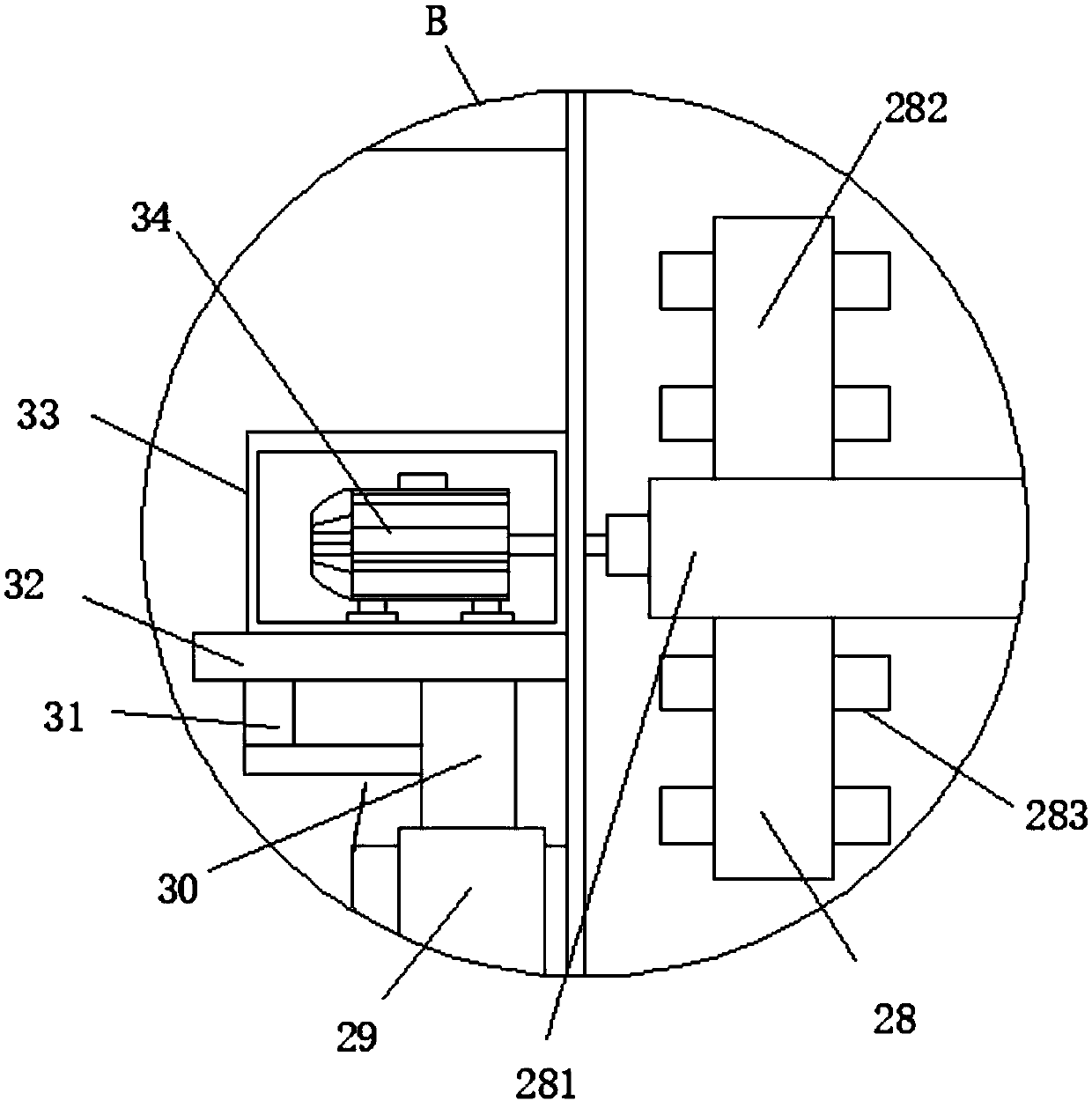

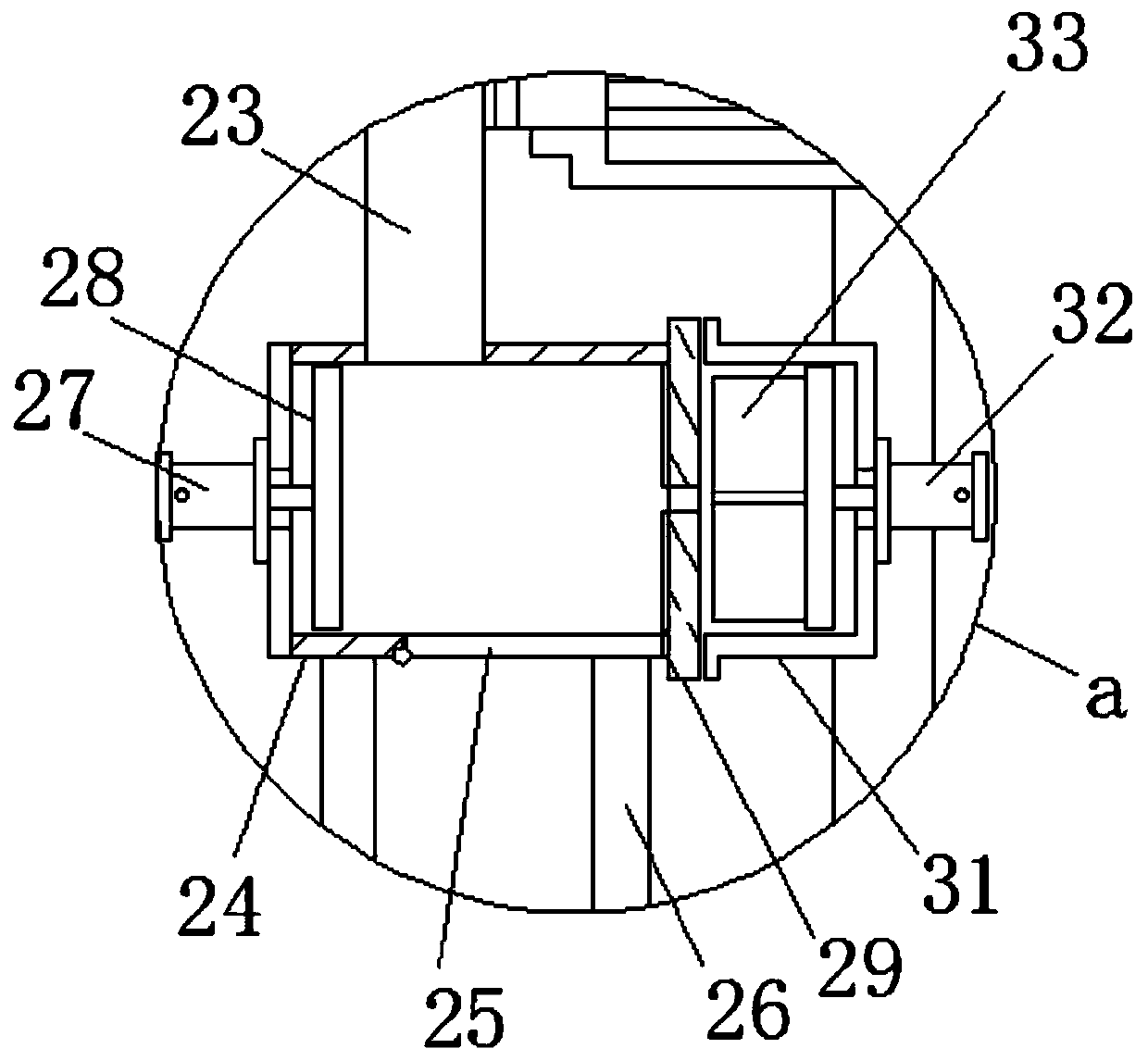

ActiveCN110721652AQuick responseEasy to cut and crushChemical/physical/physico-chemical stationary reactorsDrive wheelGear wheel

The invention relates to the technical field of reaction kettles and discloses a reaction kettle capable of increasing a reaction speed. The reaction kettle comprises a kettle body, wherein a crushingbox, a driving rotating shaft and an auxiliary rotating shaft are arranged in the kettle body; rotating shaft blades and gear blades are arranged out of the driving rotating shaft; a meshing gear, adriven wheel and a rotating wheel are fixedly installed out of the driving rotating shaft; a driving wheel is fixedly installed out of the auxiliary rotating shaft; a grinding box is arranged below the driving wheel; two grinding bodies meshed with each other are arranged in the grinding box; and a centrifugal box is arranged below the grinding box. According to the reaction kettle capable of accelerating the reaction speed, small holes are formed in the bottom and the outer side of the centrifugal box, and the driving rotating shaft rotates to drive the meshing gear to rotate, so the centrifugal box is driven to rotate reversely, reactants are thrown out of the small holes via centrifugal force, and materials are rapidly mixed after being added; and thus, uneven distribution after addition of the materials is prevented, and the reaction speed is effectively increased.

Owner:福建省沙县松川化工有限公司

Energy-saving and environmentally-friendly garbage disposal device for wasteyard

InactiveCN110043906AEasy to dryEasy to incinerateIncinerator apparatusSurface mountingArchitectural engineering

The invention discloses an energy-saving and environmentally-friendly garbage disposal device for a wasteyard. The energy-saving and environmentally-friendly garbage disposal device comprises a firstfixed base and a second fixed base, wherein a roller is rotatably mounted between the first fixed base and the second fixed base; a dryer is mounted on one side of the first fixed base; a charging hole is formed in the top of the first fixed base; a first motor is fixedly mounted on one side, away from the roller, of the second fixed base; an output end of the first motor penetrates through the second fixed base and is fixedly connected with a rotating shaft; a first spiral plate is fixedly welded with the surface of the rotating shaft; a second spiral plate is fixedly welded with the inner part of the roller; the second spiral plate and the first spiral plate are arranged in a staggering manner; a second motor is mounted at the bottom of the first fixed base through a supporting plate; agear is fixedly mounted at an output end of the second motor; a gear ring which is in meshed connection with the gear is mounted on the surface of the roller; and a discharging hole is formed in the bottom of the second fixed base in a penetrating manner. The energy-saving and environmentally-friendly garbage disposal device disclosed by the invention has the advantages that the working efficiencyis high and secondary pollution is avoided.

Owner:张英

A kind of processing method of jujube grain

ActiveCN106473044BShorten working timeImprove work efficiencyFood ingredient as viscosity modification agentFruit and vegetables preservationAdditive ingredientPass rate

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

food waste disposal equipment

ActiveCN108927269BImprove securityEnsure safetyHollow article cleaningMedical waste disposalHydraulic cylinderStructural engineering

A food waste treatment device is disclosed. The device includes a crushing bin, an upper end cover, a material guide bin and an extruding bin. A first filtration screen is embedded in the lower part of the inside of the crushing bin. The upper end cover is mounted on the crushing bin through screws. The outside of a main shaft is provided with crushing knives. The material guide bin is under the crushing bin. A tapered bar is mounted in an upper sleeve and a lower sleeve. Left and right sides of the tapered bar are provided with main shafts. The left side of the extruding bin is provided witha first hydraulic cylinder, and an output end of the first hydraulic cylinder is provided with an extruding plate. The right side of a protective shell is provided with a second hydraulic cylinder, acutter knife is mounted to an output end of the second hydraulic cylinder through screws. Third supporting bars are mounted to the lower parts of front and back sides of the lower sleeve. The device is provided with the extruding bin matching the extruding plate, a cavity plate and the cutter knife so that food in the extruding bin can be extruded and shaped so as to facilitate subsequent use.

Owner:芜湖英特杰智能科技有限公司

Construction waste recycling device and using method thereof

InactiveCN113385258AEasy to cut and crushGuaranteed separation effectDirt cleaningMagnetic separationRebarKnife blades

The invention relates to a construction waste recycling device. The construction waste recycling device comprises a machine body, the left side of the machine body communicates with a feeding base, a hydraulic cutting-off mechanism is arranged on the feeding base, an adjusting and crushing assembly is arranged in the machine body, a dustproof discharging assembly is arranged at the bottom of the machine body, a dust collecting mechanism connected with the hydraulic cutting-off mechanism and the dustproof discharging assembly is arranged on the right side of the machine body, the hydraulic cutting-off mechanism comprises a cutting-off tool rest fixedly mounted in the feeding base and a hydraulic push rod fixedly mounted at the top of the feeding base, a pressing plate making contact with the inner wall of the feeding base is fixedly mounted at the bottom of the hydraulic push rod, and a cutting-off blade corresponding to the cutting-off tool rest is fixedly mounted at the bottom of the pressing plate. According to the construction waste recycling device and the using method thereof, the hydraulic cutting-off mechanism is arranged, so that the hydraulic cutting-off mechanism can conveniently cut off and crush materials in the feeding base; meanwhile, concrete is crushed through cooperation with the adjusting and crushing assembly, separation of reinforcing steel bars is guaranteed, the separation effect is guaranteed, and secondary treatment is avoided.

Owner:盐城盛州禾润再生资源有限公司

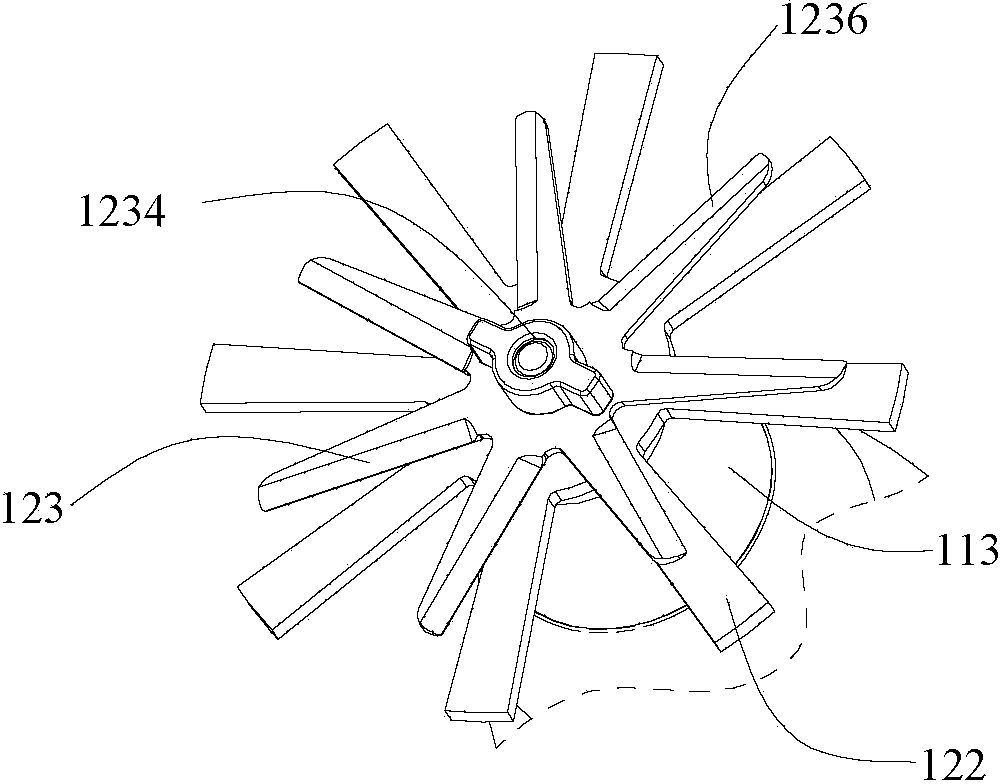

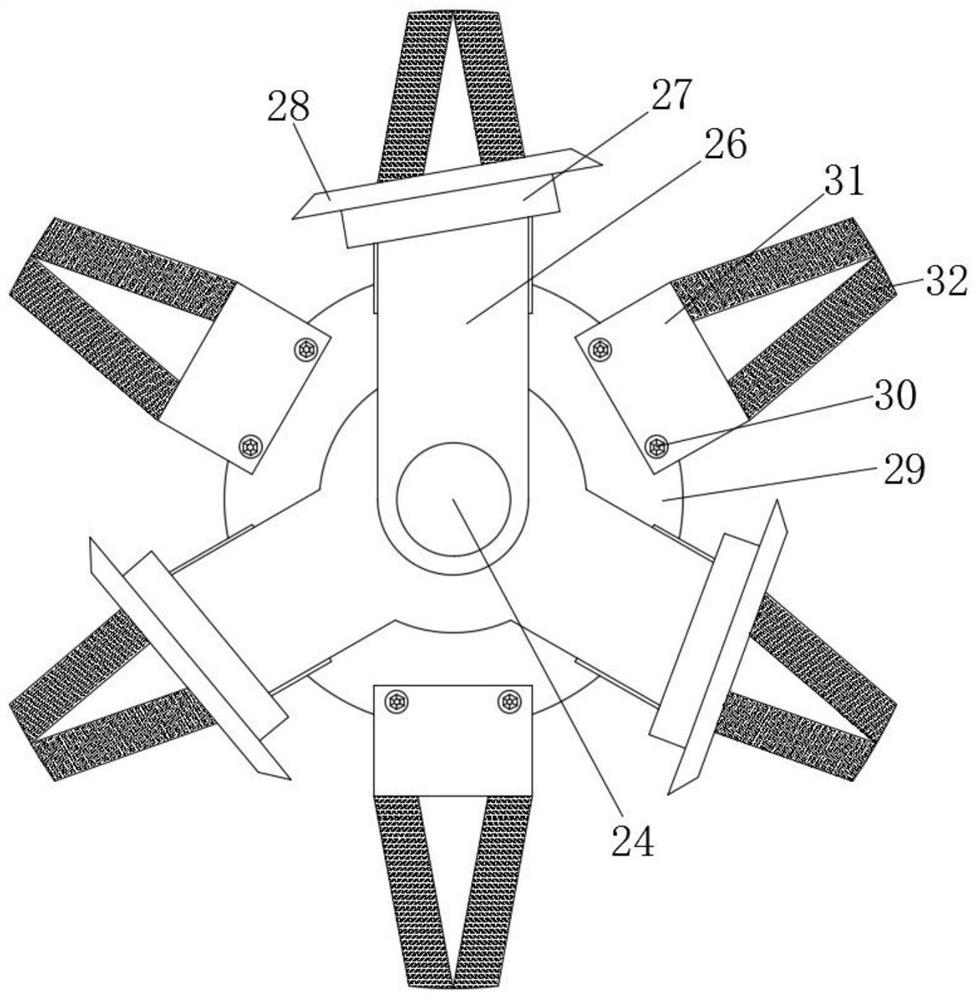

Soybean milk machine with efficient pulverization function

The invention relates to a soybean milk machine with the efficient pulverization function. The soybean milk machine with the efficient pulverization function comprises a motor, a fixed knife and a movable knife, wherein the motor is installed in a machine head, the fixed knife is fixed to the lower end of the machine head, the motor drives the movable knife to rotate, the fixed knife comprises a wing root and at least two shearing blades which are arranged on the same plane and are connected with the wing root of the fixed knife, the movable knife comprises a wing root and at least one shearing wing which is parallel to the shearing blades of the fixed knife and is connected with the wing root of the movable knife, the shearing wing is arranged below the shearing blades, a cutting edge is formed on the shearing wing, the cutting edge forming surface of the cutting edge faces the bottom of a cup body, the shearing wing and the shearing blades are used in cooperation to shear and pulverize materials, and the size of a gap between each shearing blade and the shearing wing ranges from 0.05 mm to 2 mm. According to the soybean milk machine with the efficient pulverization function, a traditional blade cutting type pulverization mode is changed, a shearing pair is formed by the fixed knife and the movable knife, and both large-grained materials and fine materials can be well sheared and pulverized.

Owner:JOYOUNG CO LTD

Biomass energy processing granulating device convenient for drying and smashing

InactiveCN112058180AEasy to handle with dust removalEasy to cut and crushCrop conditionersMowersElectric machineGear wheel

The invention discloses a biomass energy processing granulating device convenient for drying and smashing, which comprises a base, an electric telescopic rod, a sucking pump, a heating plate, a firstmotor, a second motor and a third motor, wherein a supporting table is fixedly connected to the upper end of the base, a limiting plate is fixedly installed at the upper end of the supporting table, extrusion hair rollers are rotatably connected to the left side and the right side of the lower surface of the limiting plate correspondingly, a conveying belt and the extrusion hair rollers are in transmission connection through an adjusting belt, the adjusting gear is mounted and connected to the rear end of a smashing roller, the crushing roller is rotatably connected to the interior of a smashing cylinder, and a sealing block is slidably connected to the interior of the lower end of the smashing cylinder. According to the biomass energy processing granulating device convenient for drying and smashing, straw can be fully dried conveniently, and dust prevention treatment can be conducted conveniently when the straw is processed. Meanwhile, biomass energy raw materials such as the straw can be cut off and smashed conveniently, the situation that the sizes are different is avoided, and granulating is convenient.

Owner:李姗姗

Safety efficient environment-friendly waste landfill apparatus

InactiveCN108568444AEasy feedingEasy to put inSolid waste disposalEnvironmental resistanceCombustion

The invention discloses a safety efficient environment-friendly waste landfill apparatus, comprising a feed pipe, a housing, a rotary rod, hooked rakes, a slide plate, a cutting box, a stirring motor,cutting blades, a gas collector cylinder, a compaction tank, cutting teeth, a filter plate, a water collection tank, and a discharge door; the rotary rod is arranged inside the housing; the hooked rakes are arranged evenly on the rotary rod; the stirring motor is mounted at the top end of the cutting box; the top end of the cutting box is connected with the gas collector cylinder through a vent pipe; an ultraviolet lamp is mounted on the inner wall of the top end of the cutting box; the lowest end of a guide plate is communicated with a landfill tank through a conveying pipe; the bottom end of the housing is fitted with a water collector box that is provided with a water guide pipe; the inlet end of the water guide pipe is provided with a water strainer; the landfill tank is provided witha timer; the top end of the landfill tank is provided with an accessories adding pipe and an inflow pipe. The safety efficient environment-friendly waste landfill apparatus prevents growth and propagation of harmful bacteria, has higher safety, prevents pollution of external ambient air, can avoid waste accumulation, is good for the combustion of waste, and is simple in structure, convenient to use and easy to popularize.

Owner:QUANZHOU HUIAN MINTOU TRADING CO LTD

Fork with storage function

The invention discloses a fork with a storage function. A hollow cylinder is arranged in the middle of an end rod, an internal thread is formed on the inner wall of the top of the hollow cylinder, the bottom of an end cover can extend into the hollow cylinder, an external thread is formed at the bottom of the end cover, a buffer block is arranged at a free end of the end rod, a spring is arranged in the buffer block, a through hole is formed in each of two sides of the hollow cylinder of the end rod, a chopstick is inserted into the through hole, and a cutter can be rotationally and movably connected onto the end rod and can be stored in a plane defined by the upper top surface of the end rod; a needle stick is connected to the bottom of the spring, a fork rod can be movably inserted into or extracted from the buffer block, a cavity is formed in the fork rod, the needle stick can be stored in the cavity of the fork rod, a fork head is arranged on the outer wall of the lower end of the fork rod and comprises fork blades on two side, end parts of the fork blades on the two side are combined on the outer wall of the lower end of the fork rod, and sawteeth are arranged on the outer side surface of each fork blade.

Owner:王伟民

High-strength fork with function of cutter

The invention discloses a high-strength fork with a function of a cutter. The cutter is rotatably and movably connected with an end rod, and the cutter can be contained in a plane enclosed by the upper top surface of the end rod; a buffer block is arranged at a free end of the end rod, a spring is arranged in the buffer block, the bottom of the spring is connected with a needle tag, the fork rod can be movably inserted into and pulled out from the buffer block, a cavity is formed in the fork rod, the needle tag can be contained in the cavity of the fork rod, a fork head is arranged on the outer wall of the lower end of the fork rod, the fork head comprises fork blades at the two sides, the fork blades at the two sides are combined on the outer wall of the lower end of the fork rod, a plurality of sawteeth convenient for cutting food are arranged on the outer side surface of each fork blade, multiple reinforcing ribs are arranged between the two fork blades, multiple reinforcing ribs are parallel to one another, and the lowest position of the reinforcing ribs is higher than the vertical central position of the fork blades.

Owner:祝敏

Clamping and cutting chopstick

The invention discloses a multifunctional clamping and cutting chopstick. A cutter is rotationally and movably connected on the rod body and can be contained in a plane formed by encircling of the upper top surface of the rod body; a spring is connected to the bottom of a fixed arm; a forked rod is arranged at the bottom of the spring; a fork head is arranged on the outer wall at the lower end of the forked rod; a rib is arranged on the fork blade on each side; the ribs extend along the fork blade length direction; a plurality of sawteeth convenient for food cutting are formed in the outer side face of the forked blade on each side; a cavity is formed in the upper part of the rod body; a buffer groove is formed in the inner wall of the bottom of the cavity; the end of the fork blade can stretch into the buffer groove; a clamp is arranged on the inner wall of the middle of the cavity of the rod body; a forked rod penetrates through the clamp and is locked and movably connected by the clamp; a wrapping layer is coated on the upper part of the rod body; a transverse anti-drop bulge is formed on the lower end of the rod body and is spiral; and an inner notch is formed in the side of the lower end of the rod body and positioned on one side of the transverse anti-drop bulge.

Owner:周言鑫

Fork with cutter and antiskid function

The invention discloses a fork with a cutter and an antiskid function. The cutter can be rotationally and movably connected to an end rod, and the cutter can be contained in the plane defined by the upper top face of the end rod. A buffer block is arranged at the free end of the end rod, a spring is arranged in the buffer block, the bottom of the spring is connected with a needle stick, a cavity is formed in a fork rod, the needle stick can be contained in the cavity of the fork rod, a clamping groove is formed in the inner wall of the lower end of the fork rod, and a needle head at the end of the needle stick can be inserted into the clamping groove for fixation. A fork head is arranged on the outer wall of the lower end of the fork rod and comprises two side fork blades, the ends of the two side fork blades are combined on the outer wall of the lower end of the fork rod, a flange is arranged on each fork blade, the flanges stretch in the length directions of the fork blades, multiple sawteeth are arranged on the outer side face of each fork blade, the sawteeth on the two sides are symmetrically arranged, a circle of buffer cushion is arranged on the outer edge faces of the fork blades on the two sides, the position of the buffer cushion is higher than the sawteeth on the topmost portions, and the buffer cushion is made of edible resin materials.

Owner:王伟民

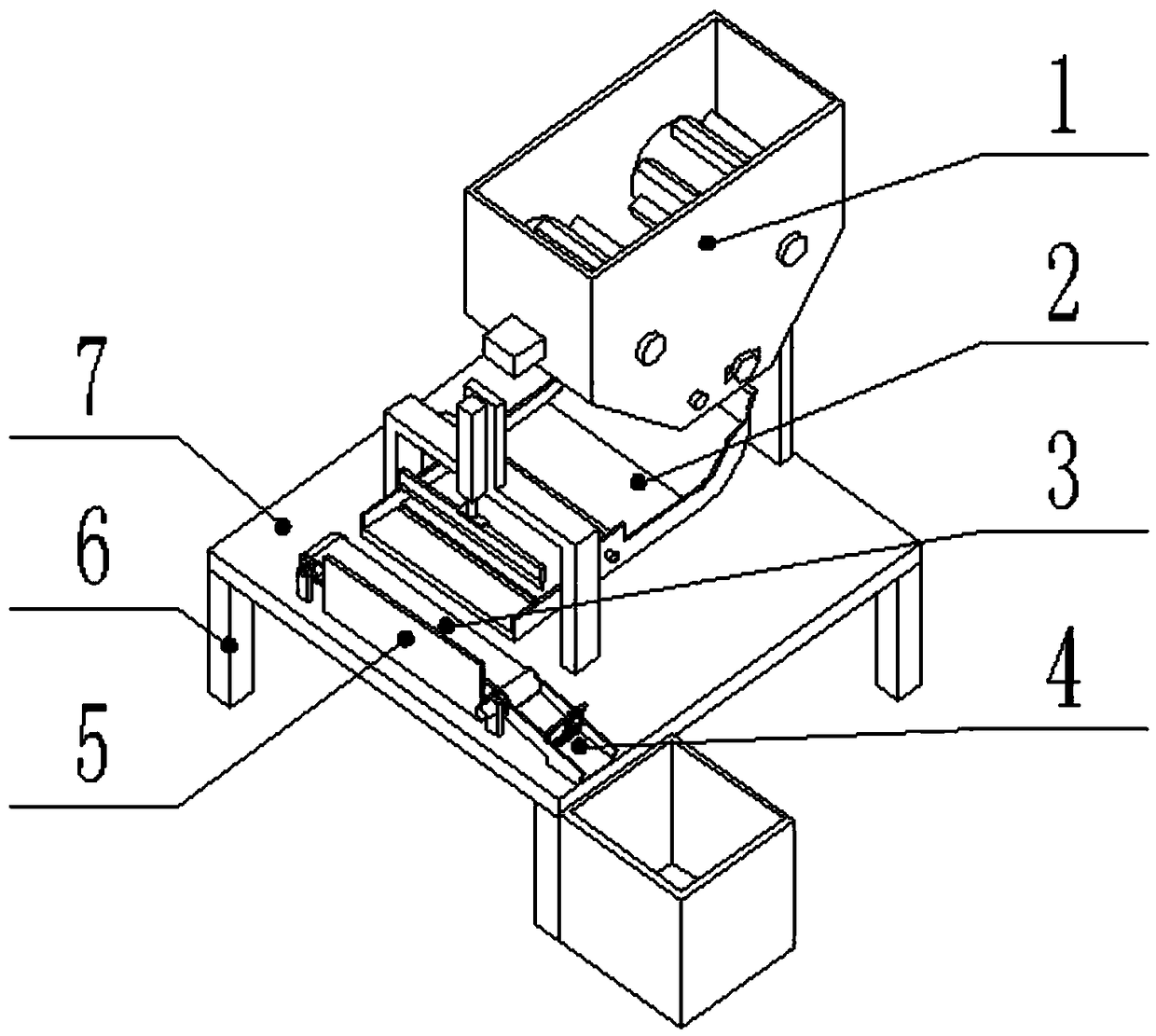

Automatic smashing device for agricultural waste

ActiveCN108126795AEasy to cut and crushEasy to handle manuallyGrain treatmentsDrive wheelCompression device

The invention discloses an automatic smashing device for agricultural waste, and belongs to the field of agricultural mechanical equipment. A compression device is fixedly connected with a first cutting device, a second cutting device is fixedly connected with a conveying device, a controller is fixedly connected with a compression device, a base of the first cutting device is fixedly connected with the first cutting device, a second motor is fixedly connected with a box body of the compression device, a fixing nut is fixedly connected with the box body of the compression device, a first roller is fixedly connected with the box body of the compression device, and a conveying roller is fixedly connected with a sliding groove of the first cutting device. By means of rotation of a motor in the compression device, the first roller and a second roller are driven to rotate so as to press agricultural waste into a driven roller and a driving roller, and cutting and smashing of agricultural waste are facilitated; by means of operation of a fourth motor in the conveying device, a driving wheel is driven to operate so as to drive a conveying belt to operate; and by means of cutting of the second cutting device, agricultural waste is cut into blocks which falling down into a storage vat, carrying is convenient, and working efficiency is improved.

Owner:凤阳清碳环保科技有限公司

Multifunctional straw chopping and crushing machine

A multifunctional straw chopping and crushing machine is disclosed. A crushing mechanism is arranged in a first working frame, a power mechanism for driving the crushing mechanism to rotate is fixedly mounted at the position, located on one side of the first working frame, of the top of a working table, and a penetrating groove is formed in the surface of a second working frame in a penetrating mode; and a second sealing mechanism for sealing the through groove is fixedly mounted on the surface of the second working frame and located on one side of the through groove. A first crushing cutter is arranged to crush materials put in from a discharging frame, a second crushing cutter rotates to cut off and crush the materials put in from one side of a penetrating groove, and the power mechanism is arranged to drive a first gear disc and a second rotating shaft on one side of the first gear disc to rotate through rotation of a servo motor. Therefore, the whole crushing mechanism is driven to rotate along the interior of the fixed bearing, and materials put in through the discharging frame and the through groove can be fully cut off and crushed.

Owner:ANHUI FUYANG SHENGDA MACHINERY CO LTD

A plywood manufacturing wood raw material pulverizer

ActiveCN113601641BImprove clamping effectImprove crushing effectWood working apparatusPulp and paper industryConveyor belt

The invention relates to the technical field of plywood processing, in particular to a wood raw material shredder for plywood manufacturing, which includes a processing shell, a conveying unit and a crushing unit. The conveying unit is installed on the left side of the processing shell, and the right side of the processing shell There is a crushing unit; the present invention can solve the following problems: the existing wood crushing equipment transports the wood raw materials to the interior of the equipment through a toothed conveyor belt, and the transmission effect of the wood raw materials is affected due to the line contact between the conveyor belt and the wood raw materials. And this type of equipment can only crush the wood raw material, but cannot effectively crush the wood raw material, thereby affecting the processing effect; The clamping effect of raw materials; the present invention can cut and pulverize wood chips that have been crushed and have unqualified sizes.

Owner:江苏星爵实业有限公司

Combination fork with containing function

The invention discloses a combination fork with containing function. The middle of an end rod is of hollow cylinder, an end cap is screwed to the top of the hollow cylinder through mating of an internal thread and an external thread, the free end of the end rod is provided with a buffer, a spring is disposed in the buffer, two sides of the hollow cylinder of the end rod are each provided with a through hole, a chopstick is inserted into each through hole, the bottom of the spring is connected with a needle tag, a fork rod is movably insertable into or removable from the buffer, a cavity is provided in the fork rod, the needle tag is receivable in the cavity of the fork rod, the fork rod is provided with a splayed through hole acting as a bottle opener, ends of fork blades on two sides are combined to the outer wall of the lower end of the fork rod, the outer side of each fork blade is provided with a plurality of saw teeth to facilitate food cutting, and the outer side of the middle of each fork blade is provided with a side cushion.

Owner:祝敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com