Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Easy post-assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

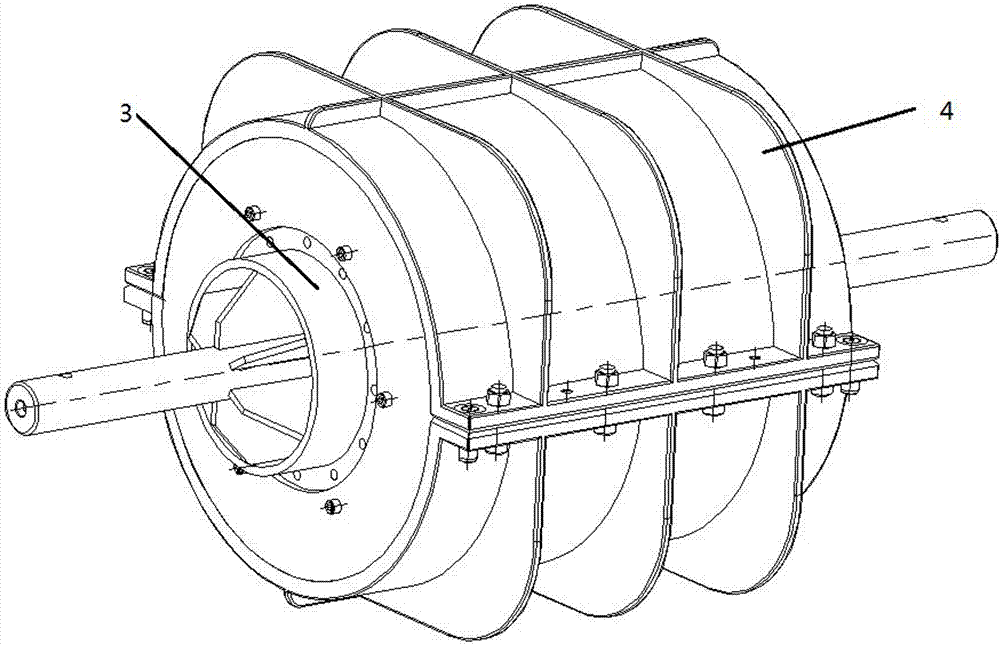

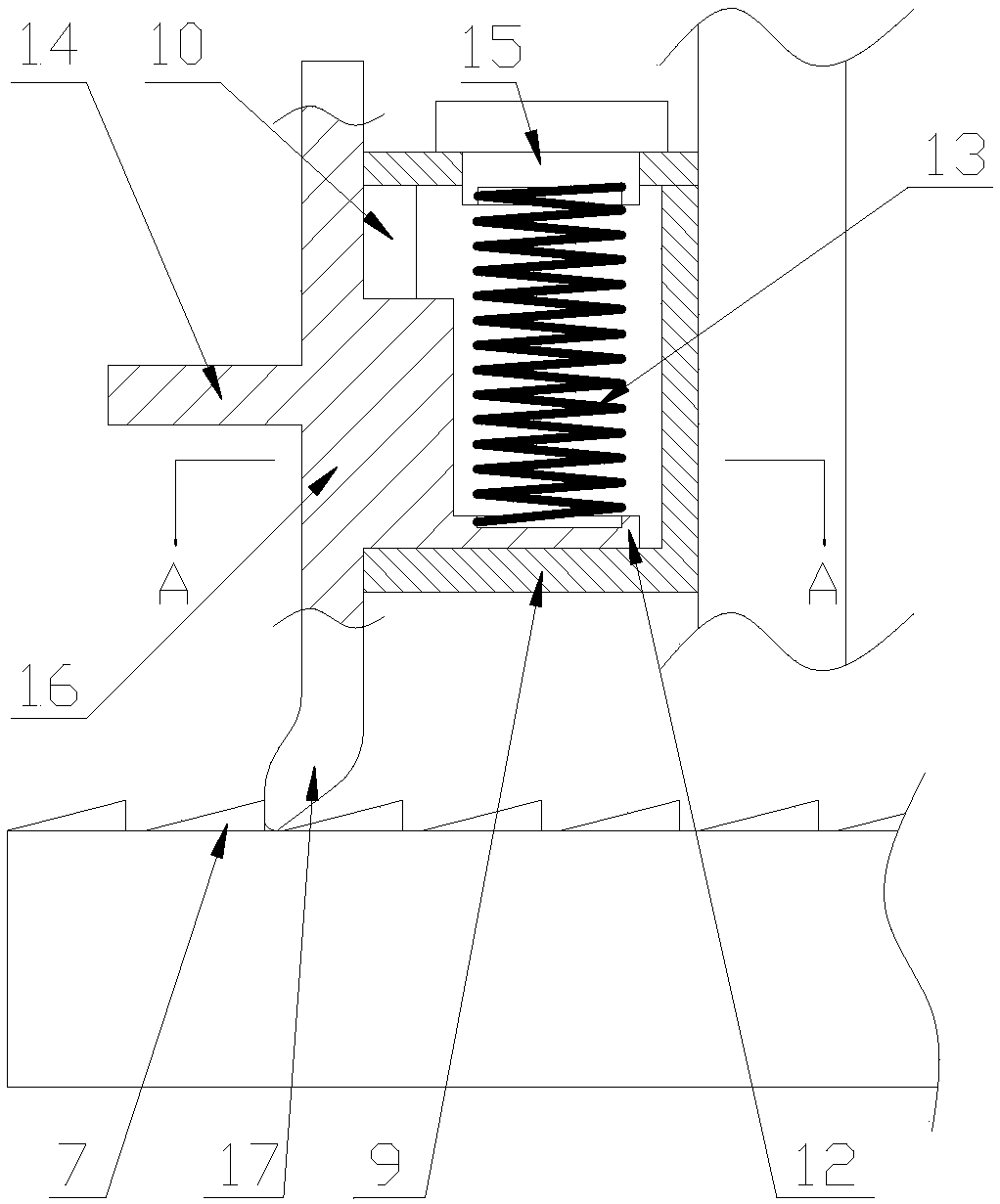

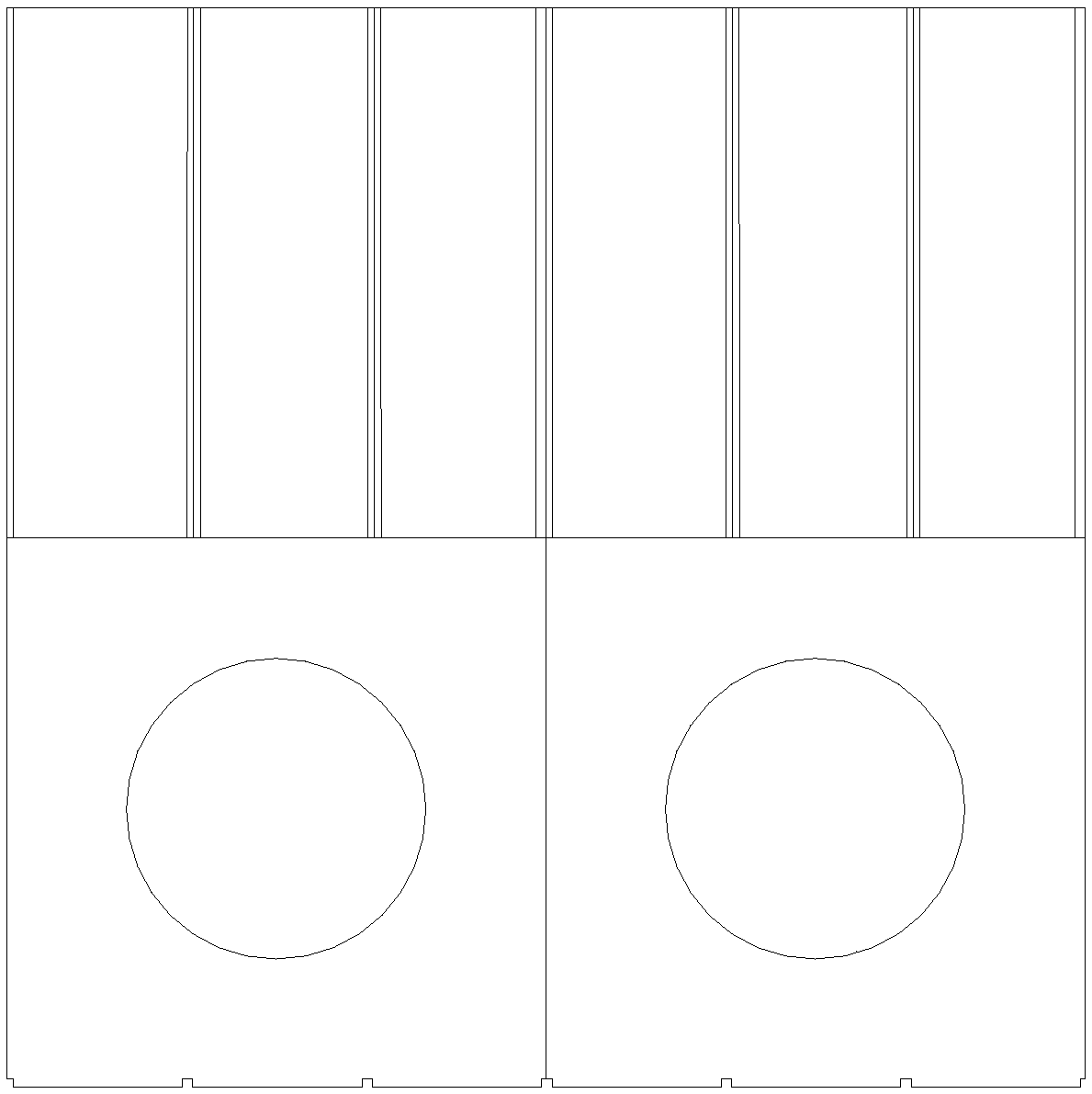

Winding die for molding interior grid stiffened cylindrical shell structure part and using step

InactiveCN106976250ASolve the difficulty of pressurization and demouldingImproved dimensional accuracy and positional accuracyDomestic articlesMesh gridEngineering

The invention relates to a winding die for molding an interior grid stiffened cylindrical shell structure part. The winding die comprises a body die, a core die and an outer die; evenly-arranged T-shaped grooves are formed in the two sides of the body die, the core die and the body die are assembled through T-shaped blocks, the outer die is arranged on the outer side of the core die and used for limiting the appearance of the molded part, end frame flanges facilitating turnup of the molded part are arranged at the two ends of the body die, and sealing heads are arranged on the outer side of the end frame flange. The using steps of the die comprises (1) cleaning and die assembling, (2) reinforcing rib winding, and vacuum bag hitting for pre-compaction; and (3) moving the die to a drying oven for curing, and demolding after curing is carried out. The winding die can be repeatedly used, grid reinforcing ribs of the molded product have the high size accuracy and position accuracy, the product quality consistency is good, and later period assembly of the product is facilitated.

Owner:HENGSHEN

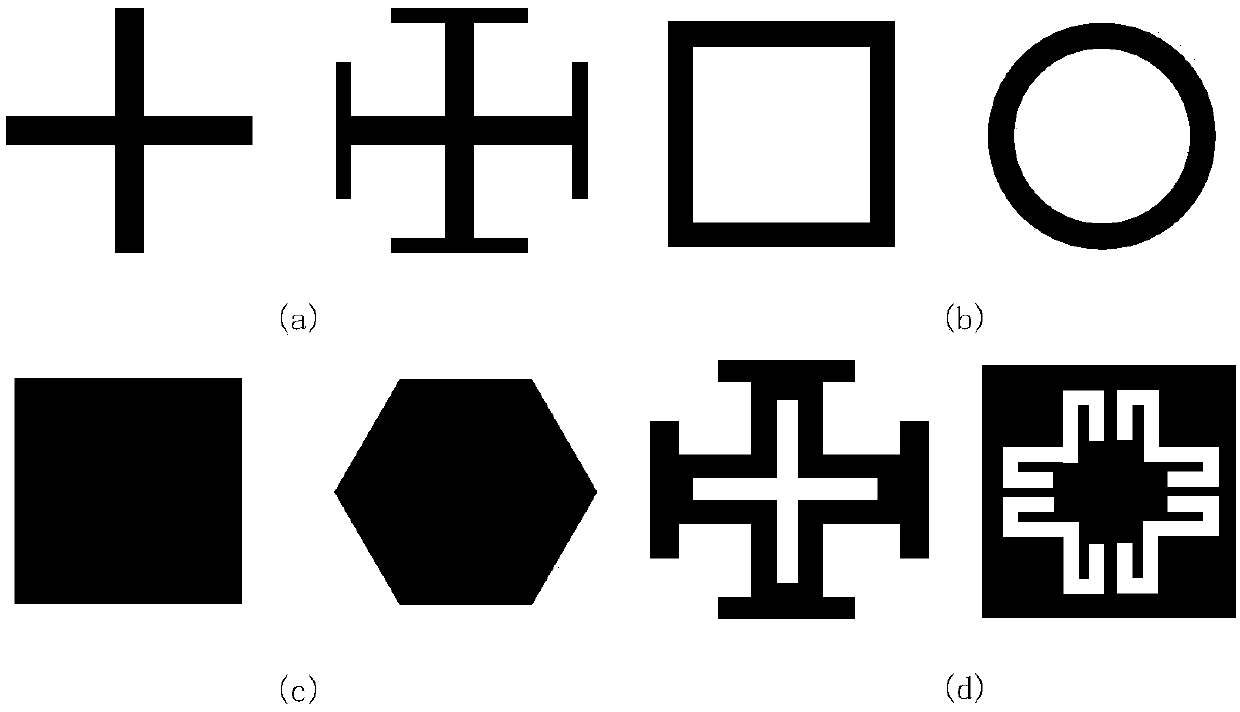

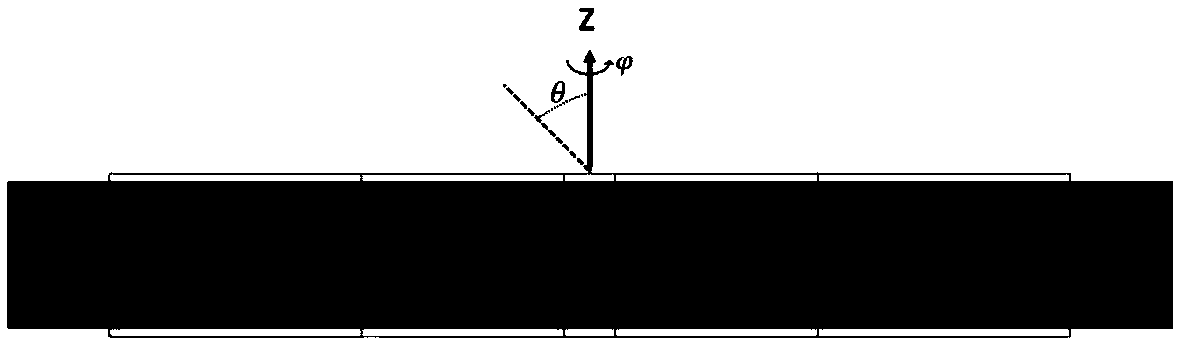

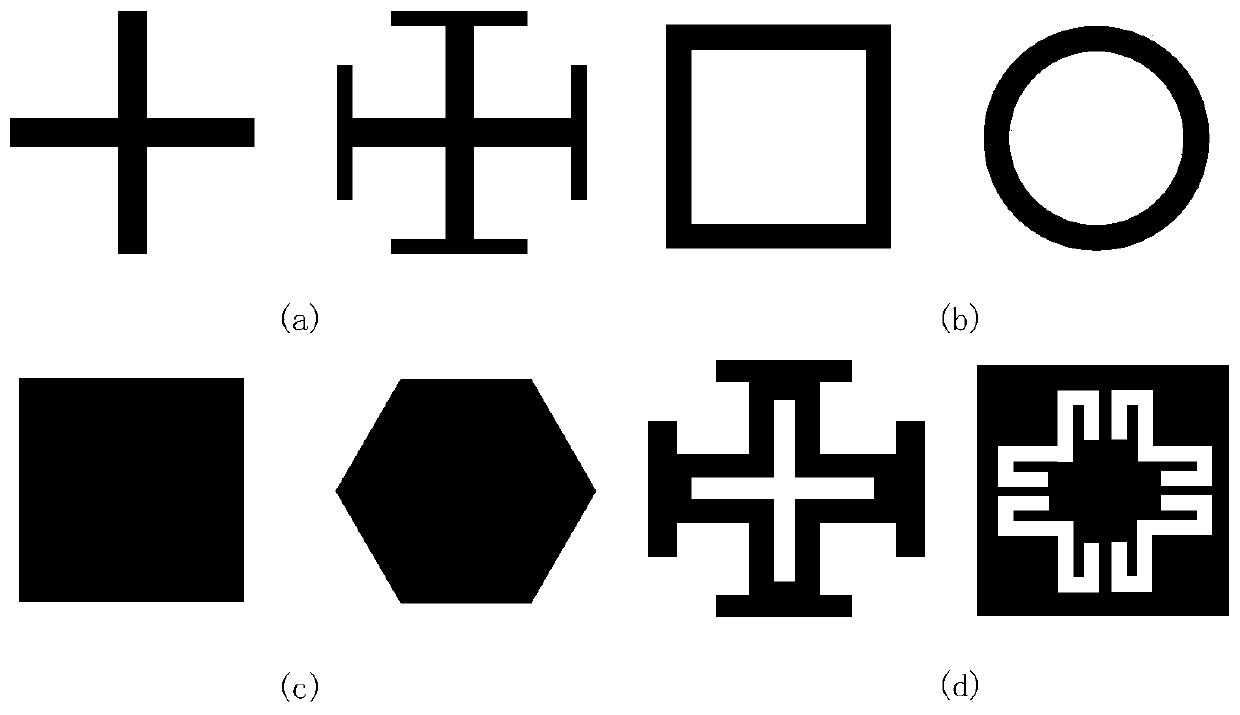

Miniaturized frequency selection surface based on double-opening resonance ring

ActiveCN109616724AGood spatial filteringCompatible with miniaturizationWaveguide type devicesTransmission zerosCoupling

The invention discloses a miniaturized frequency selection surface based on a double-opening resonance ring. A band-pass effect is formed through the combined action of the double-opening resonance ring and a middle coupling aperture. When electromagnetic wave is irradiated to the frequency selection surface, resonance is caused by the opening resonance ring. The frequency selection characteristicof the opening resonance ring is utilized, so that a high spatial filtering function is achieved, meanwhile, the miniaturization characteristic is realized; compared with a common frequency selectionsurface, the cell area is greatly reduced, and the size of the whole circuit unit is only 0.3lambda 0*0.3lambda 0; meanwhile, by virtue of mutual coupling between the opening gap of the resonance ring and an interlayer coupling window, a good out-of-band rejection effect is achieved; and a transmission zero point is arranged on each of the two sides of the band, so that the rectangular coefficient of the circuit is greatly improved. A symmetrical circuit structure is adopted, so that the structure is simple, and machining is easy; and meanwhile, the whole circuit is quite high in stability around the incident angle theta and a formula which is as shown in the specification, so that the practical value is increased.

Owner:四川众为创通科技有限公司

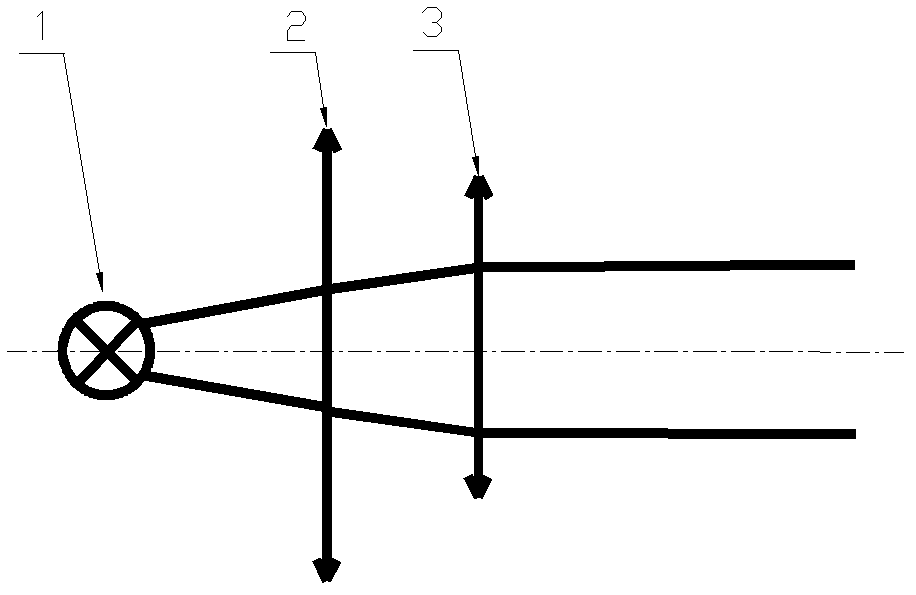

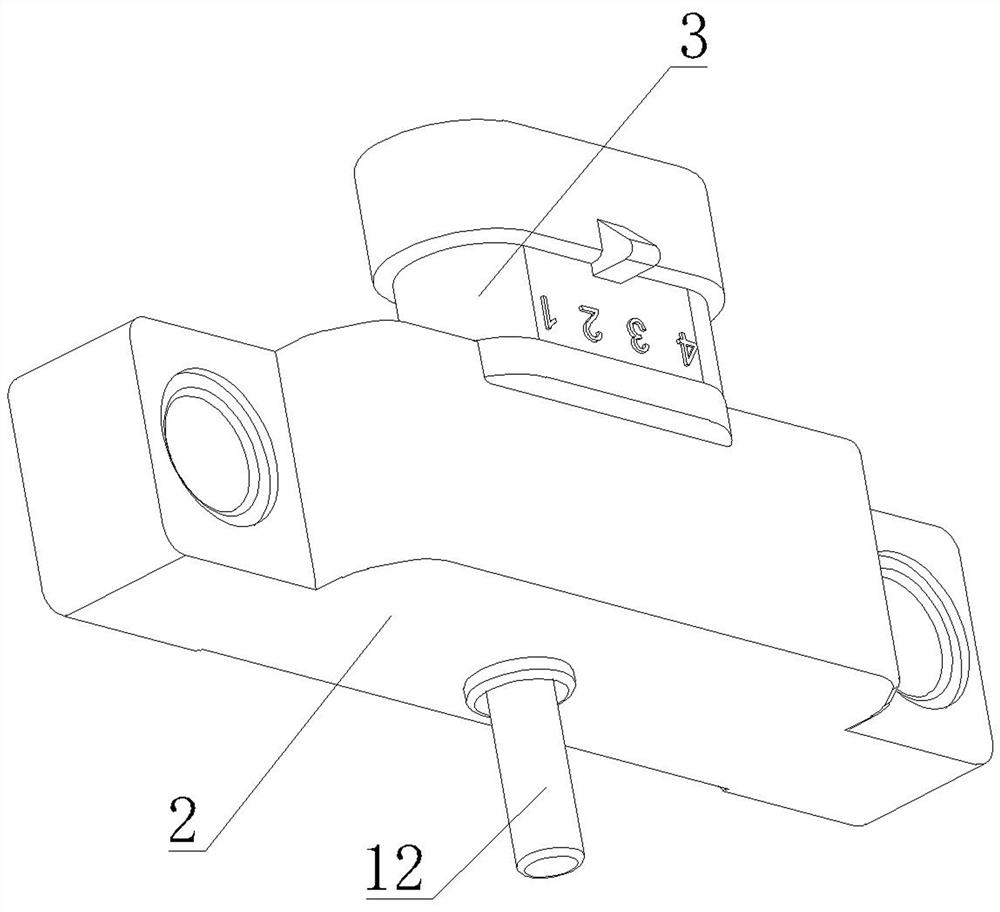

Camera night vision illuminating system and control method thereof

ActiveCN103186015AImprove effective utilizationSimple designTelevision system detailsColor television detailsCamera lensDivergence angle

The invention discloses a camera night vision illuminating system and a control method thereof, wherein the camera night vision illuminating system is high in optical utilization rate, large in divergence angle adjustment scope, and capable of achieving attention to both short-range and long-range targets. The camera night vision illuminating system comprises a control module, a power module, a light dependent resistor, an optical coupling switch and a stepping motor, wherein the power module, the light dependent resistor, the optical coupling switch and the stepping motor are connected with the control module. The power module is connected with an infrared source, an angle changing lens is arranged at the front end of the infrared source, and the stepping motor is connected with the angle changing lens. The camera night vision illuminating system is characterized by further comprising a laser distance measuring sensor which is connected with the control module. The night vision illuminating system is big in light-out divergence angle scope, capable of achieving attention to both short-range and long-range targets and meeting requirements for a camera market, high in optical effective utilization rate, simple in optical path design, good in long-distance illumination effects, low in cost, and easy to process and assemble in the later stage. Through adoption of a laser ranging linkage angle changing mode, the camera night vision illuminating system is safe, reliable, and capable of effectively avoiding potential safety hazards of laser products.

Owner:TIANJIN YAAN TECH CO LTD

Hard alloy sleeve type part inner hole key groove machining method

The invention discloses a hard alloy sleeve type part inner hole key groove machining method. A procedure original point is arranged in an inner hole of a sleeve type part, a first cutting falling point and a second cutting falling point are designed on the inner hole according to the width of a key groove, a working table (used for driving a to-be-machined product) and / or a linear cutting wire are / is moved to enable the linear cutting wire to generate relative displacement relative to the working table, the sleeve type part is machined at the first cutting falling point and the second cuttingfalling point firstly until the requirement for the depth of the key groove is met, then machining is continuously carried out from the depth position of the key groove in the width direction of thekey groove until chipping falling happens, and machining of the key groove is completed. According to the linear cutting wire walking manner, the two cutting falling points are arranged, the final chipping falling position in the machining process is adjusted, falling defects at a groove opening of the key groove are avoided, the key size accuracy of the key groove is guaranteed, and the user requirement is met.

Owner:ZIGONG CEMENTED CARBIDE CORP

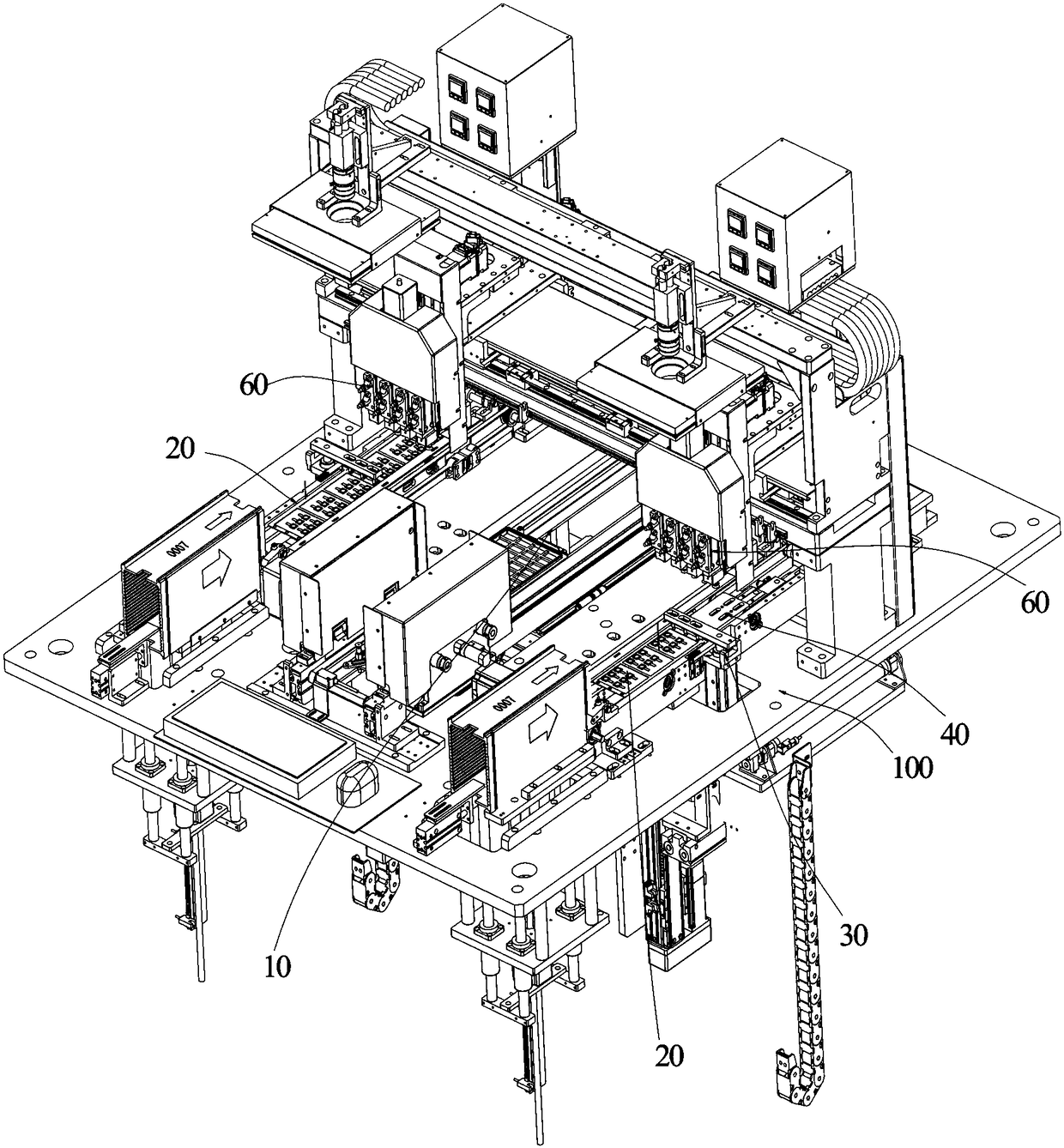

Fully-automatic film stripping machine

The invention discloses a fully-automatic film stripping machine. The fully-automatic film stripping machine comprises a rack, a first conveying mechanism, a second conveying mechanism, a film separating mechanism, a supporting mechanism and a workpiece clamping mechanism, wherein the film separating mechanism is arranged on the second conveying mechanism; the film separating mechanism comprises afilm jacking part and a film clamping part; the film jacking part is arranged above a film stripping station, and can get close to or get away from the film stripping station in a height direction ofthe rack; the film jacking part is used for downwards jacking a protective film at the bottom end of a tray for separating the protective film at the bottom end of the tray from the tray after getting close to the film stripping station; and the film clamping part gets close to the film stripping station and then clamps the protective film which is separated from the tray. The fully-automatic film stripping machine can realize stripping a workpiece from the protective film at the bottom end of the tray; and the workpiece separated from the protective film is loaded on a workpiece carrying disc.

Owner:深圳双十科技股份有限公司

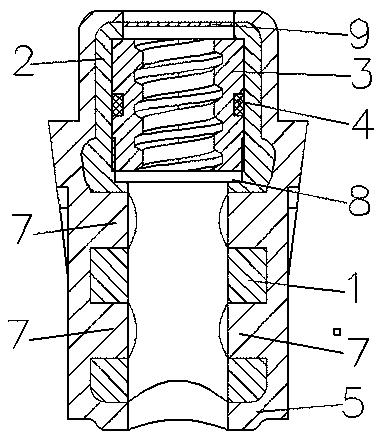

Liquid level sensor and compressor using the same

InactiveCN105067088ALiquid level detection is accurateEasy post-assemblyLevel indicators by floatsInductorMagnet

The invention provides a liquid level sensor of a compressor. The liquid level sensor comprises a compressor housing. An oil storing cavity of freezing lubricating oil is arranged in the compressor housing. An opening is arranged in the compressor housing. The liquid level sensor comprises a housing body with an opening which is in sealed connection with the opening of the compressor housing. The liquid level sensor also comprises a filtering screen which is arranged on the inner side of the opening of the housing body. The filtering screen surrounds at least parts of inner wall of the housing body, so a detection cavity communicated with the oil storing cavity via the filtering screen is formed. The liquid level sensor also comprises a floating ball which is arranged in the detection cavity and rises and descends along with change of liquid levels of the freezing lubricating oil. At least one permanent magnet is arranged on the floating ball. The liquid level sensor further comprises an inductor which is installed on the outer wall surface of the housing body. The inductor can be easily assembled later and pre-assembled for mass production, individually changed and more suitable for small semi-enclosed and fully-enclosed compressors.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Heat pipe type heat exchanger

InactiveCN110440617AEasy post-assemblyEasy to installIndirect heat exchangersPlate heat exchangerPorous medium

The invention provides a heat pipe type heat exchanger. Theheat pipe type heat exchanger comprises a porous medium material, an integrated heat pipe and a high-temperature heat exchanger, wherein theintegrated heat pipe comprises a heat pipe condensation section, a heat pipe heat insulation section and a heat pipe evaporation section which are connected in sequence, the heat pipe evaporation section is embedded in the porous medium material, and the heat pipe condensation section is embedded into the high-temperature heat exchanger. According to the heat exchanger, gas and air are mixed and burnt in the porous medium material, so that the heat exchange surface area is expanded by flue gas and the porous medium material, the heat transfer effect is enhanced, and the heat exchange coefficient is improved; and meanwhile, theintegrated heat exchange pipe is adopted, and high-temperature heat is uniformly conveyed into a heater of a power device, so that the high-efficiency, high-temperature and uniform heat exchange process of fuel in the power device is realized, the problems that a heating pipe is prone to being burnt out and heat exchange is difficult to strengthen due to the factthat at present, an engine is heated by directly utilizing the high-temperature flue gas are solved, and the later assembly and installation are facilitated.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

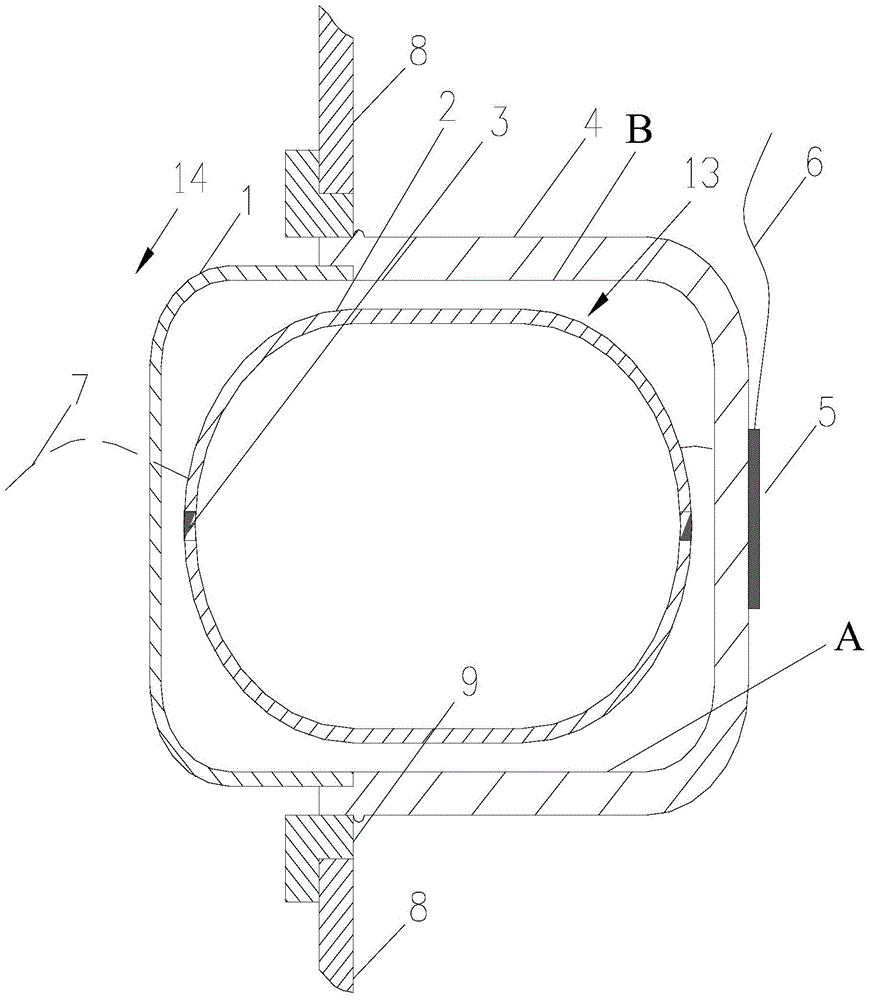

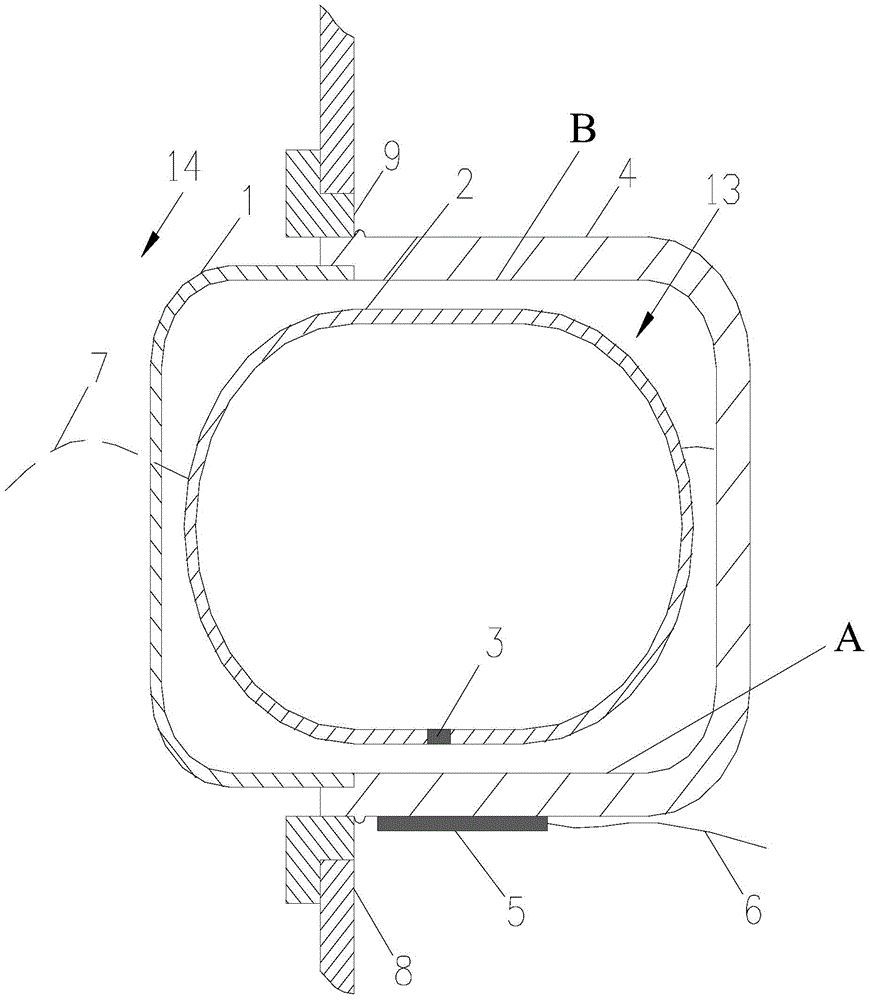

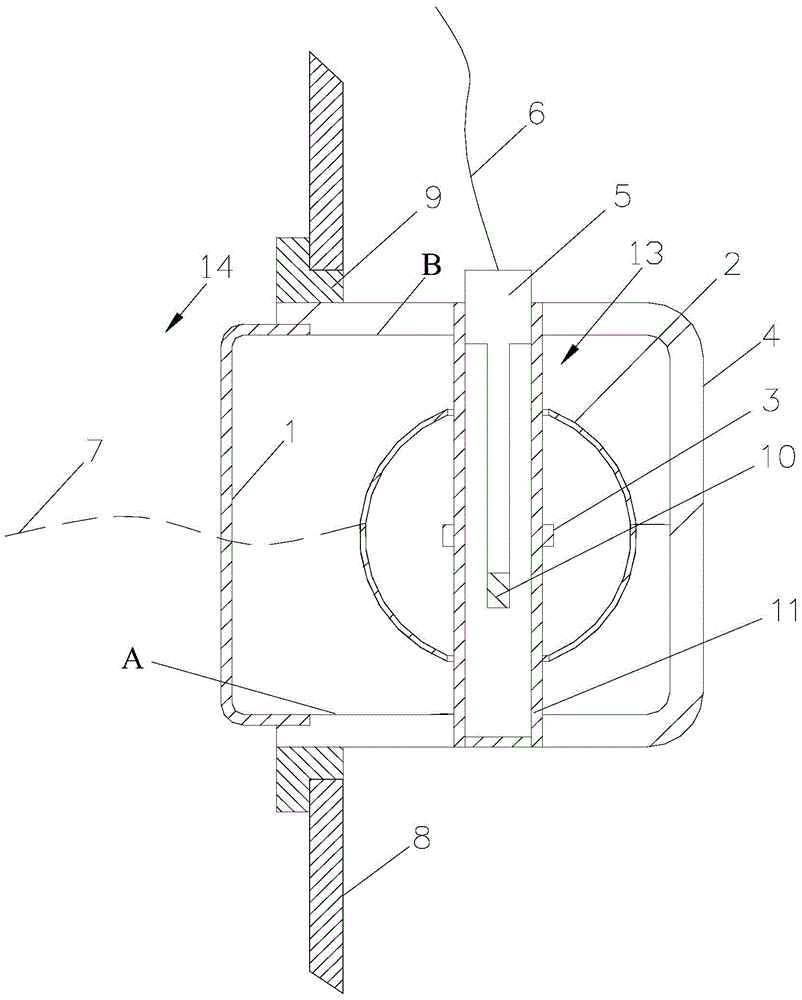

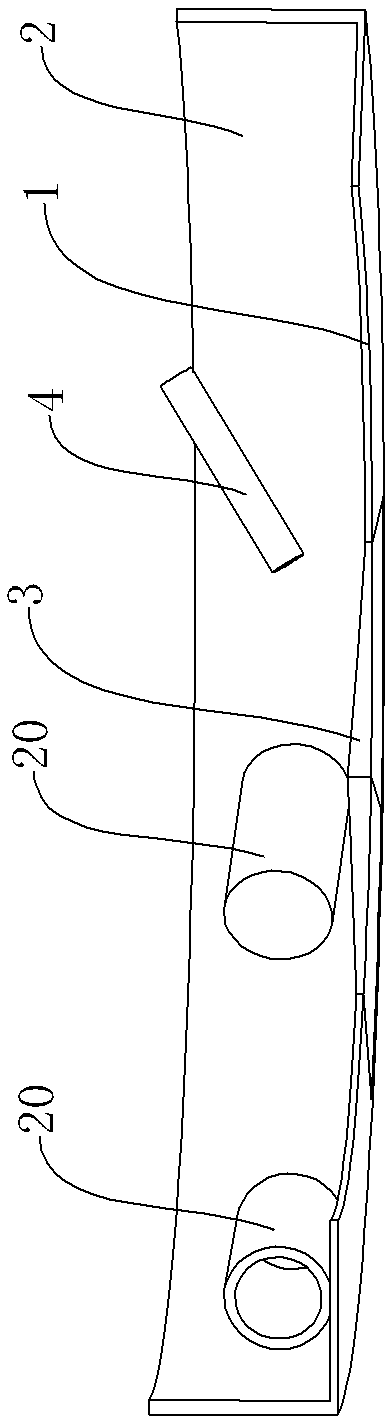

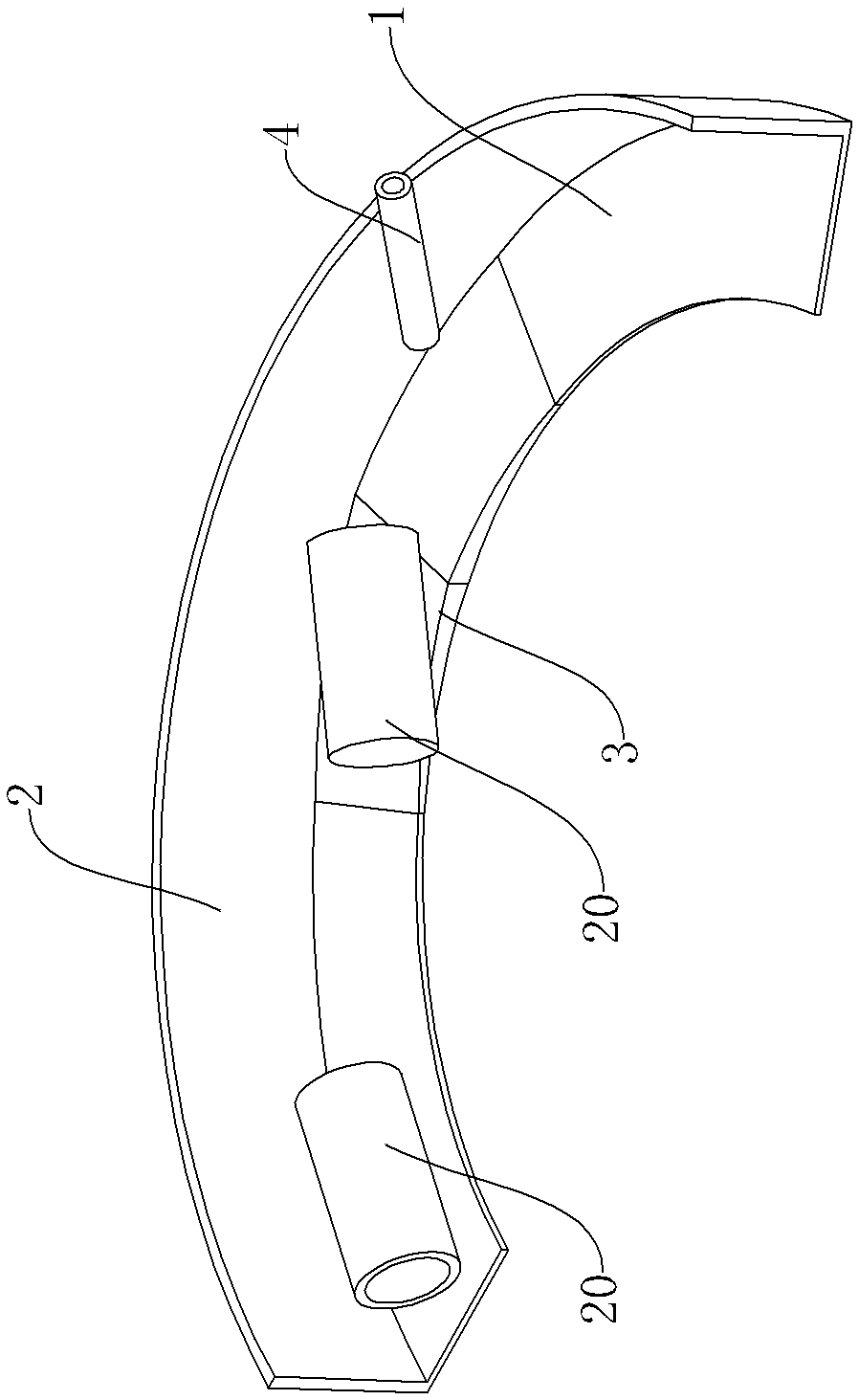

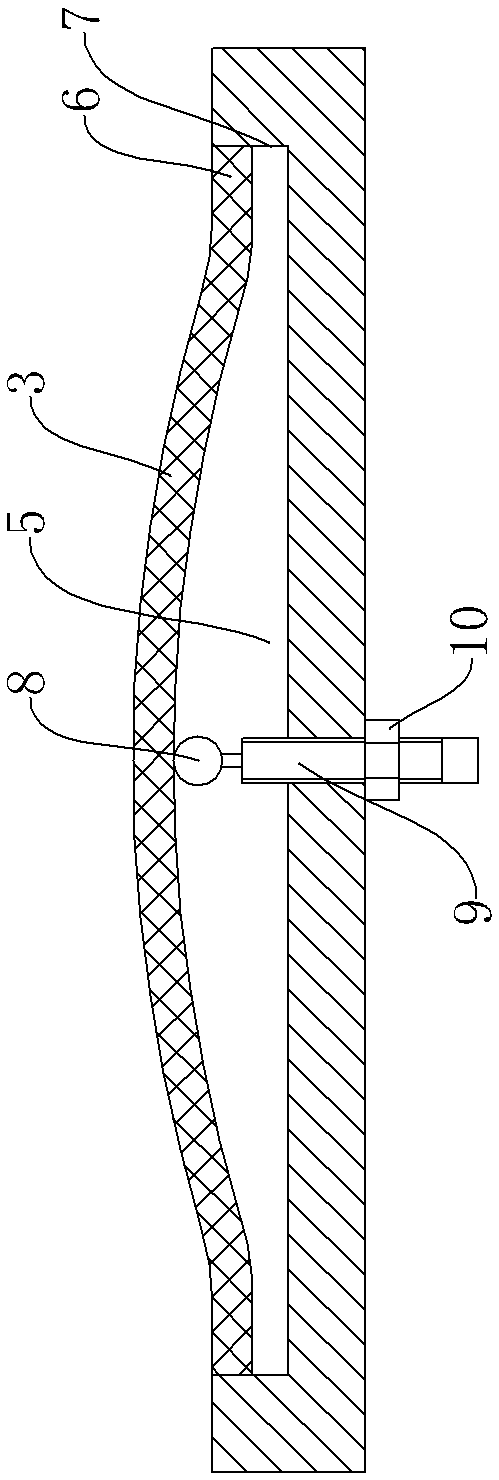

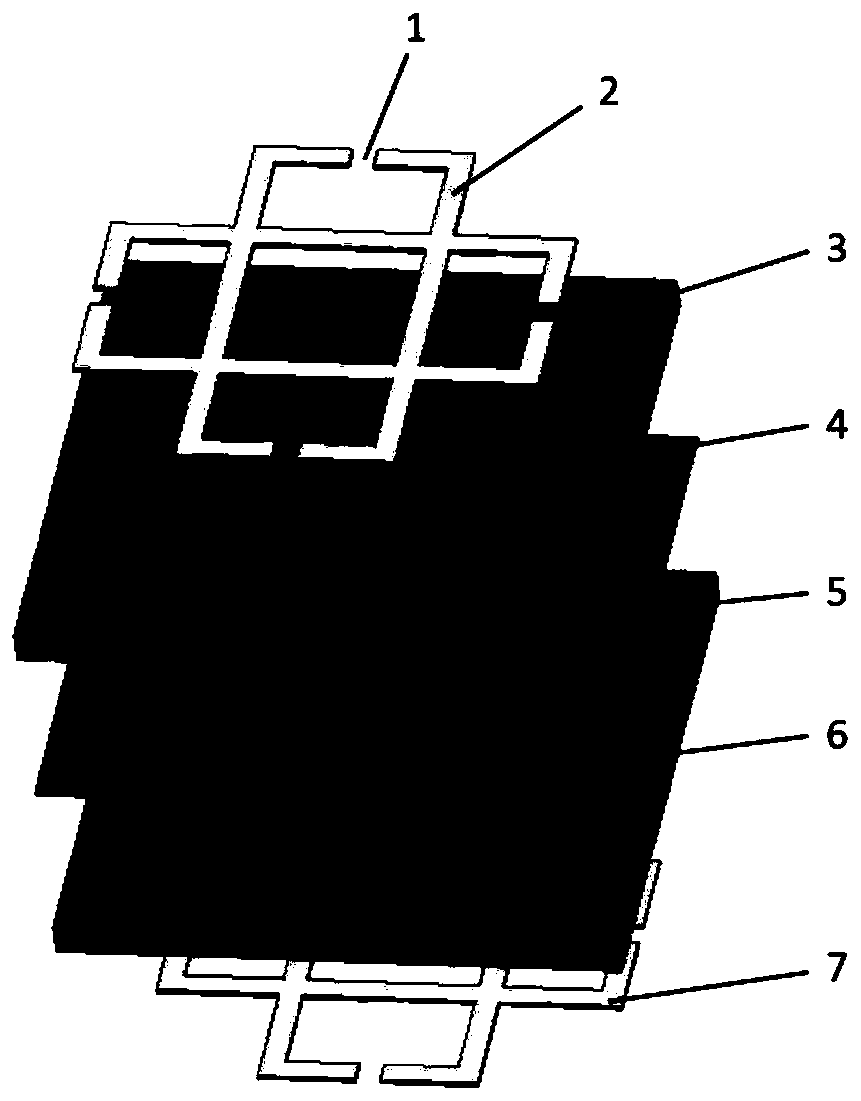

High-heat-conductivity niobium-tin superconducting coil and manufacturing method thereof

PendingCN114300213AImprove cooling effectImprove preparation safetySuperconducting magnets/coilsCoils manufactureNiobiumSuperconducting Coils

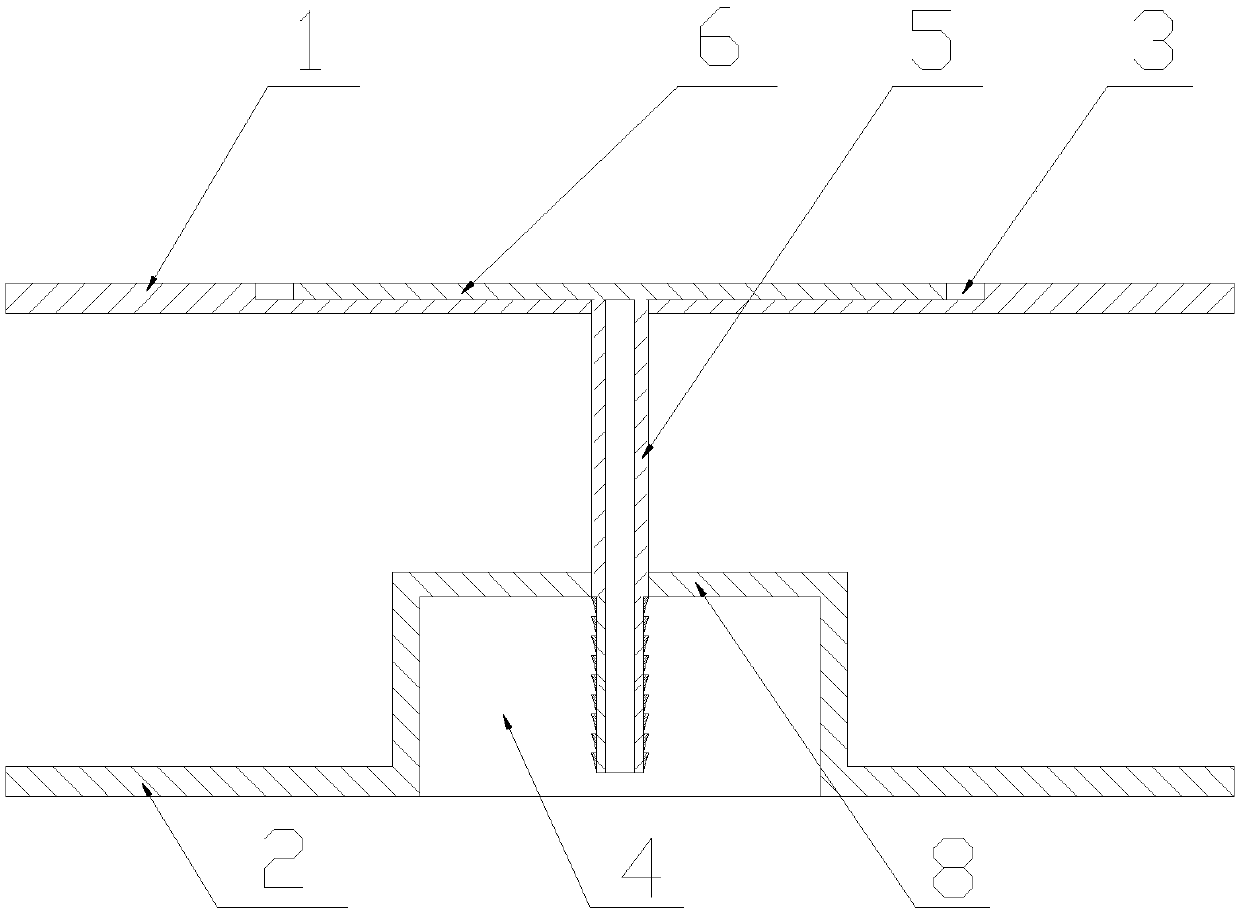

The invention provides a high-heat-conductivity niobium three-tin superconducting coil and a manufacturing method thereof. The high-heat-conductivity Nb3Sn superconducting coil comprises a stainless steel framework (1), an insulating layer (2), a Nb3Sn superconducting coil (3), aluminum nitride (4), sodium chloride (5) and a central support (6). The high-heat-conductivity Ni3Sn superconducting coil is adopted, the mechanical supporting structure of stainless steel is utilized, the high heat conductivity of aluminum nitride is combined, the cold conduction effect of the thin-wall stainless steel framework can be improved, the problem that the cooling capacity of the Ni3Sn coil is poor is effectively solved, the refrigeration effect of the Ni3Sn coil is improved, and the service life of the Ni3Sn coil is prolonged. Therefore, the current-carrying capacity of the Ni3Sn coil is improved, and the performance of the Ni3Sn superconducting coil is improved. Meanwhile, in order to solve the problem that thin-wall stainless steel is prone to deformation at high temperature, the gap between the stainless steel framework and the center heat-resistant steel support is filled with sodium chloride, radial shrinkage of the stainless steel at high temperature is effectively prevented, sodium chloride can be removed only through water dissolution after temperature returning, and the center heat-resistant steel support can be conveniently pulled out.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Self-locking type rubber outer tire positioning device and splicing type storing structure thereof

InactiveCN107867475AReduce workloadReduce the use effectContainers to prevent mechanical damageStorage devicesEngineeringSelf locking

Owner:重庆市万盛区安达橡胶制品有限责任公司

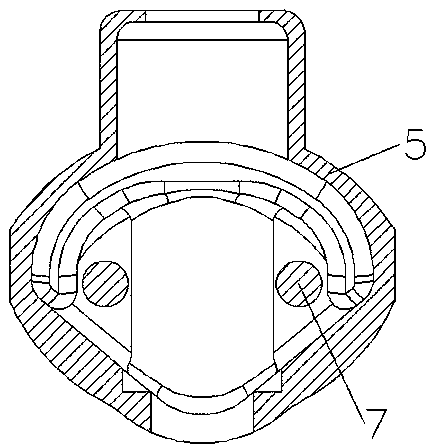

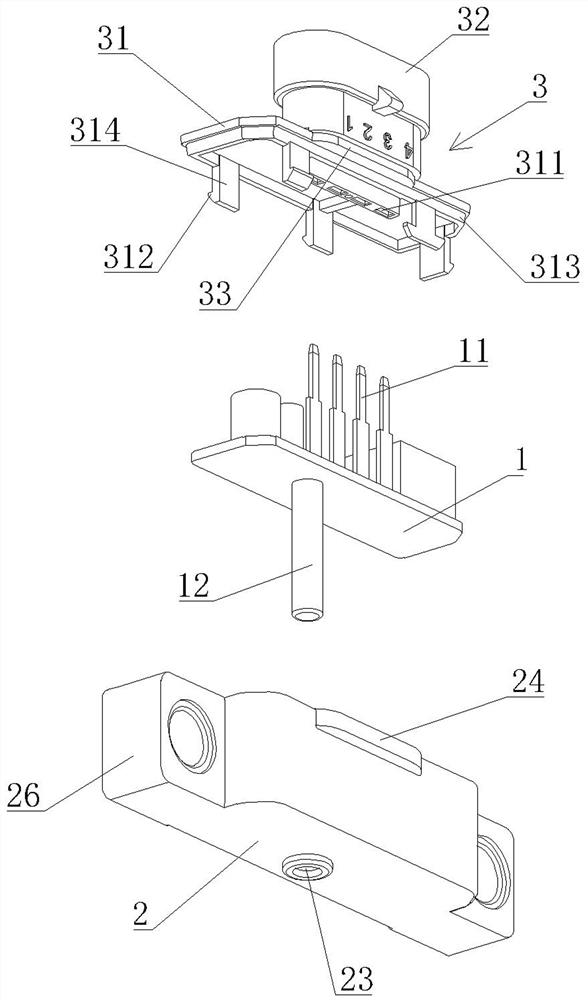

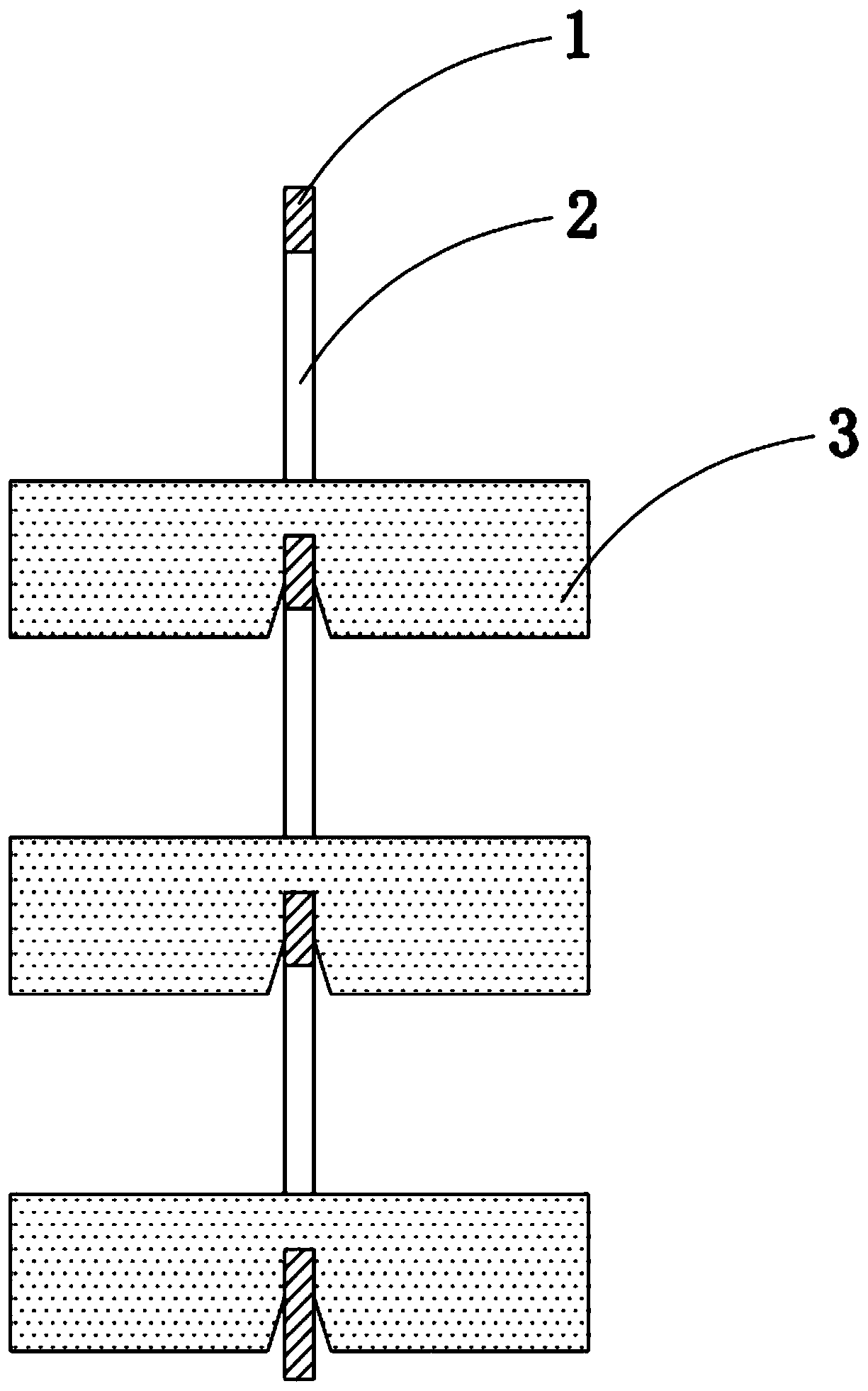

Arraying device of pin sleeves

InactiveCN108127361AGuaranteed directionalityEasy post-assemblyMetal working apparatusVulcanizationEngineering

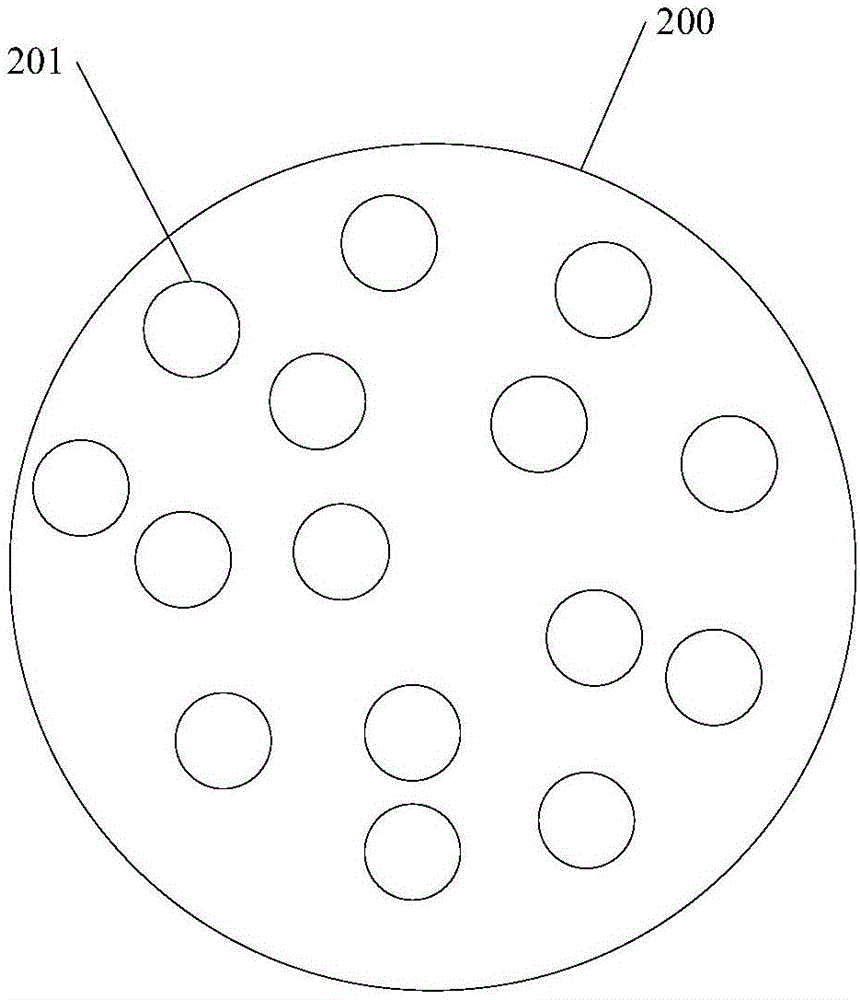

The invention provides an arraying device of pin sleeves. The problems that the direction of the pin sleeves can not be ensured and assembling is influenced in the conveying process are solved. The pin sleeves are of a hollow structure, and one end of each pin sleeve is packaged through a bottom plate. The arraying device of the pin sleeves is characterized by comprising a slide plate, a guide plate, a nozzle, an air source and a driving unit, the slide plate is horizontally arranged, the arc-shaped guide plate is fixed to one side of the slide plate, a slope plate of an up-down slope structure is arranged in the middle of the slide plate. The nozzle is fixed above the slide plate and is in the down slope direction of the slope plate. The nozzle is connected with the air source through a pipeline. The driving unit is used for providing the initial speed of the pin sleeves. The slide plate is fixed to the base and provided with a slide plate groove. The slope plate is a rubber plate. The two ends of the rubber plate are combined with the two side walls of the slide plate groove through vulcanization. The middle of the rubber plate is supported above the slide plate groove through afirst supporting mechanism.

Owner:WUXI CHANGZHISHENG MACHINERY MFG CO LTD

Valve gate disc made from novel environment-friendly material and production process thereof

The invention discloses a valve gate disc. The valve gate disc comprises a gate disc body and a nut, wherein the gate disc body is integrally formed by a valve plate and a valve rod, the interior of the gate disc body is of a hollow structure, the nut is positioned at the upper part of the gate disc body and is connected with a valve screw rod, a sealing ring is arranged between the outer side ofthe nut and the inner wall of the valve rod, the outer surface of the gate disc body is wrapped in a plastic body, positioning holes are formed in the two sides of the valve plate, and positioning columns corresponding to the positioning holes in position are arranged on the inner wall of the plastic body. According to the valve gate disc, the gate disc body is integrally formed by caprolactam, alight-resistant agent, a heat stabilizer, a fiber material and graphite through injection molding, wherein the light-resistant agent, the heat stabilizer, the fiber material and the graphite are addedin proportion, and the advantages that the energy-saving and environment-friendly effects are achieved, the processing technology is simple, the rate of finished products is high, the environment isnot polluted, and the labor intensity of workers is low are achieved; and the outside of the gate disc body is wrapped in the plastic body, so that the metal valve plate is isolated from a fluid, it is guaranteed that a water source is not polluted, processing is easy, materials are saved, and the cost is low.

Owner:黄长太

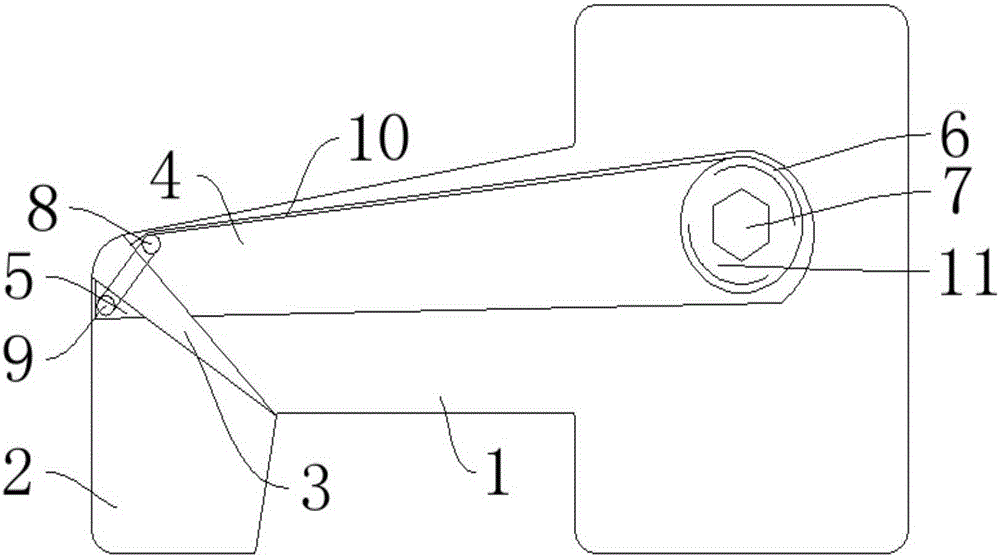

Clamping cover die with angle fine-adjustment structure

The invention relates to a clamping cover die with an angle fine-adjustment structure. The clamping cover die comprises a main base plate. The left side face of the main base plate is provided with a main inclined face. An auxiliary base plate is arranged on the left side of the main base plate. The upper surface of the auxiliary base plate is provided with an auxiliary inclined face matched with the main inclined face. The main inclined face and the auxiliary inclined face are fixedly connected through an adjusting rubber pad. According to the clamping cover die, the angle between the main base plate and the auxiliary base plate is changed through a main adjusting wheel in a first groove and a first driven adjusting wheel and a second driven adjusting wheel in a second groove in cooperation with an adjusting pull rope, and the university of the clamping cover die is improved greatly; tightening of the adjusting rope is kept through a torsional spring on the inner side of the main adjusting wheel, so that follow-up assembly is facilitated, and the safety of the adjusting pull rope is improved; and a locking block on the outer side of the main adjusting wheel is used for preventing the main adjusting wheel from rotating, the stability of the clamping cover die is improved greatly after the angle of the clamping cover die is adjusted, and follow-up assembling use is facilitated.

Owner:HUANGSHI GAOKE PLASTIC MOLD

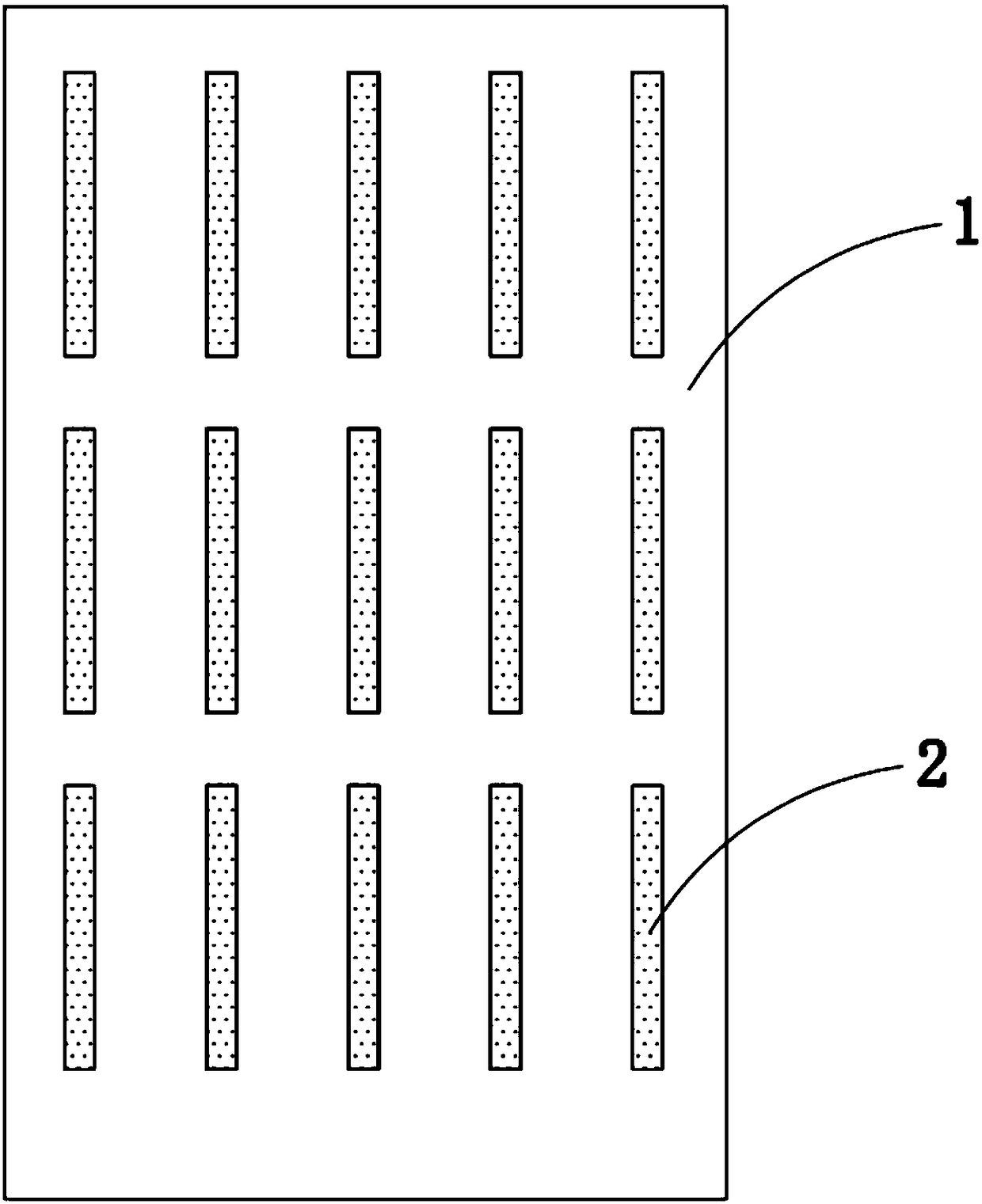

Combined-type heat radiation structure used for transformer and manufacture process thereof

The invention discloses a combined-type heat radiation structure used for a transformer. The structure comprises a vertical board. Through holes are uniformly arranged in the vertical board. Radiatingfins in snap joint with the vertical board are arranged in the through holes in a penetrating manner. The radiating fins are equipped with clamp grooves corresponding to the through holes. The overall heat radiation structure of a conventional transformer is changed. The through holes are uniformly arranged in the vertical board such that the radiating fins in snap joint with the vertical board are arranged in the through holes in the penetrating manner. The vertical board and the radiating fins are all copper aluminum alloy boards which hare low in cost and good in heat radiation performance. Manufacture process is optimized. Openings of the clamp grooves are equipped with chamfers in order to facilitate assembling in the late period. Polishing treatment comprises coarse grinding and precise grinding treatment such that burr and scraps on surfaces are processed clean, which is convenient for subsequent installation. Planeness errors of the vertical board and the radiating fins are nobigger than + / -0.01 mm so that assembly quality is increased. The combined-type heat radiation structure is simple in process so that the overall heat radiation area is increased. The heat radiationperformance is improved. The combined-type heat radiation structure shows great practicality.

Owner:安徽金环电气设备有限责任公司

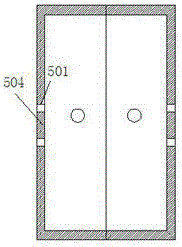

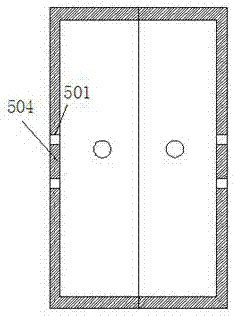

Plastic mold for wood-plastic wardrobe door

InactiveCN105216143AExtended service lifeEasy to assembleDomestic articlesMultiple bufferingCompressive strength

The invention relates to a plastic mold for a wood-plastic wardrobe door. The plastic mold comprises a mold body. The mold body comprises a base plate mold body, first buffering devices located on the outer side face of the base plate mold body, second buffering devices located on the outer side face of the base plate mold body, third buffering devices located on the outer side face of the base plate mold body and fourth buffering devices located on the outer side face of the base plate mold body. According to the plastic mold for the wood-plastic wardrobe door, the multiple buffering devices composed of outer side plates and inner side plates are arranged on the surface of the base plate mold body and are fixedly connected through a plurality of connecting plates, and insert devices which are convenient to clamp are arranged on the outer sides, so that latter assembly is facilitated while the production cost is greatly reduced. The service life of a wood-plastic wardrobe door plank is prolonged. The compressive strength is improved.

Owner:HUANGSHI DINGSHENG MOLD CO LTD

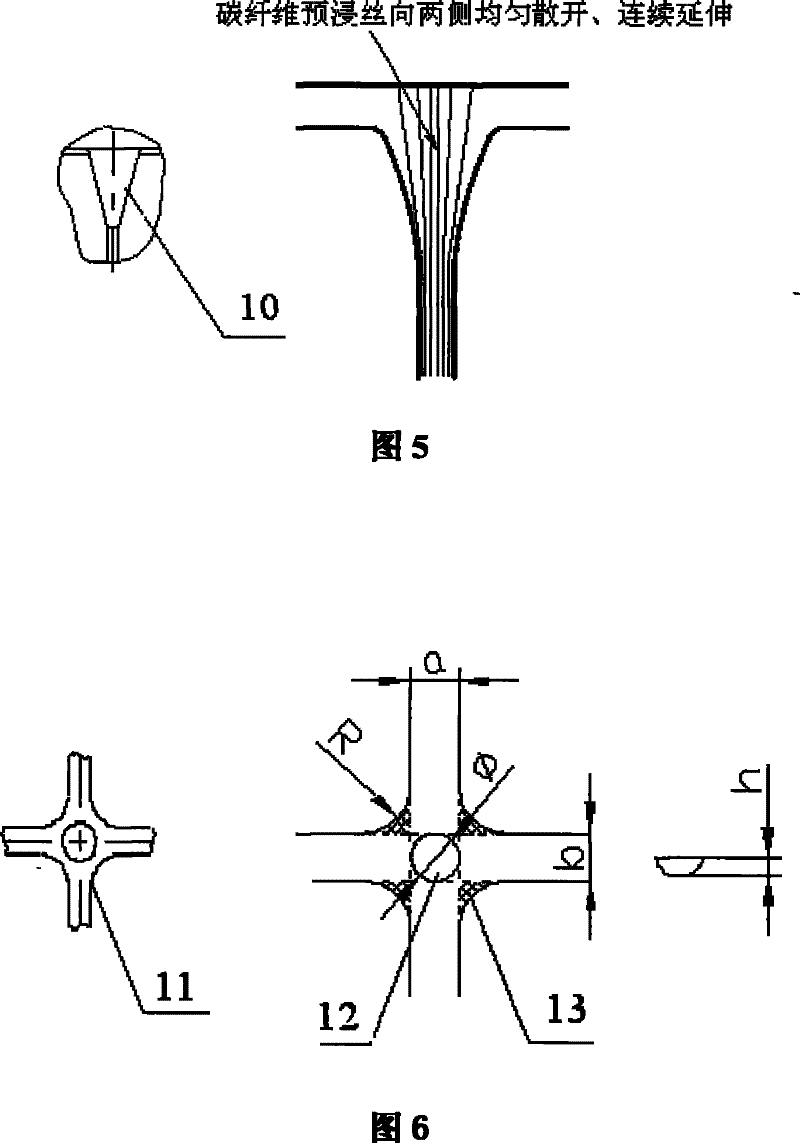

Carbon fiber reinforcement resin base composite material lattice structural-component conforming die and method

ActiveCN101450533BSolve the problem of continuous intersectionSolve the difficulty of demouldingCarbon fibersResin-Based Composite

The invention relates to a mould and a method for molding a carbon fiber reinforced resin-based composite material grid structural piece. The mould for molding the carbon fiber reinforced resin-based composite material grid structural piece consists of a main body mould, a splitting grid male mould and a splitting grid female mould sequentially from an inner layer to an outer layer; and two end frame pressure loops are arranged on the upper part and the lower part of the main body mould and the splitting grid male mould respectively. The mould can be repeatedly used for a plurality of times; a grid reinforced rib of a molded product has higher dimension precision and position precision; and the quality of the product has good consistency. The method for molding the carbon fiber reinforcedresin-based composite material grid structural piece is wholly co-cured and molded, is favorable for ensuring the consistency of the whole performance and quality of the composite material grid structural product so that the structure has good rigidity and bearing capacity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

A reinforced SMA composite material with low warpage and high dimensional stability for automobile structural parts and preparation method thereof

Owner:华合新材料科技股份有限公司

Wardrobe position fixing device

The invention discloses a wardrobe position fixing device which comprises a position fixing part for being connected with a wall. The two edges of the side, away from a position fixing head, of the position fixing part are symmetrically provided with two inserting parts. Main rods are matched with the inserting parts. Second screw thread position fixing parts are matched between the main rods and the inserting parts. A bent pipe is matched between the two main rods. First inserting parts are arranged at the two ends of the bent pipe and are inserted into the main rods. Third screw thread position fixing parts are matched between the main rods and the first inserting parts. A position fixing set is matched between the two main rods and comprises two wardrobe sleeves symmetrically arranged up and down. According to the device, the position fixing head is adopted for being matched with a joint head to complete position fixing and locking, decoration personnel can carry out later-stage assembling conveniently, the assembling speed is increased, by connecting the position fixing part with a position fixing groove in a matched manner, the first screw thread position fixing parts are connected with screw threads of screw thread grooves in a matched manner, the overall stability of the device is improved, two end points are adopted for fixing positions, position fixing is more reliable, and security is ensured.

Owner:JIANGSU TIANGANG PRECISION CASTING CO LTD

Rubber outer tyre storage structure

InactiveCN107867476AReduce workloadReduce the use effectContainers for annular articlesTyresPore diameterEngineering

The invention discloses a storage structure for rubber tires, which includes several positioning frames. The positioning frames include a first fixed plate and a second fixed plate in a square shape, and a rubber tire is formed between the first fixed plate and the second fixed plate. clamping space, the first fixed plate and the second fixed plate are respectively provided with weight-reducing via holes, the aperture of the weight-reducing via hole is smaller than the inner diameter of the rubber tire, and the hole of the first fixed plate weight-reducing via hole A number of fixing strips are evenly arranged along the circumference of the mouth, and each fixing strip extends toward the second fixing plate. The weight-reducing via hole on the second fixing plate is a stepped hole, and the outer diameter of the stepped hole is relatively large, so that the step The hole wall of the hole forms a positioning ladder, and the end of the fixing bar is provided with a wedge-shaped positioning clip, and the protrusion of the wedge-shaped clip is engaged with the positioning ladder to form the positioning of the rubber tire; several positioning frames are placed as several positioning frames layer, and the positioning frames of adjacent positioning frame layers are perpendicular to each other.

Owner:重庆市万盛区安达橡胶制品有限责任公司

Cabin temperature detector and manufacturing method thereof

PendingCN111707394AImprove quality and efficiencyImprove production efficiencyThermometer detailsTemperature measurement of flowing materialsAdhesive glueHemt circuits

The invention discloses a cabin temperature detector and a manufacturing method thereof. The cabin temperature detector comprises a circuit board, a lower shell and an upper cover, wherein a temperature detection circuit is arranged on the circuit board, a temperature probe is arranged on the lower surface of the circuit board, the temperature detection circuit comprises a temperature sensing element, one end, located at the circuit board, of the temperature probe makes contact with the temperature sensing element, a cavity for accommodating the circuit board is formed in the upper cover, an opening is formed in the top of the lower shell, the lower end of the temperature probe extends out of the lower shell from a through hole, the lower shell comprises a cover body used for sealing the opening, jacks corresponding to the wiring terminals on the circuit board are formed in the cover body, the circuit board is installed in the lower shell, a packaging glue is injected into the cavity,and the upper cover covers the lower shell. According to the cabin temperature detector, the manufacturing process is optimized, the production efficiency is improved, the product quality can be ensured in the batch manufacturing process, the qualification rate of products is improved, and the cabin temperature detector is long in service life and stable and reliable in the using process.

Owner:XINXIANG GUANGMING ELECTRIC APPLIANCE CO LTD

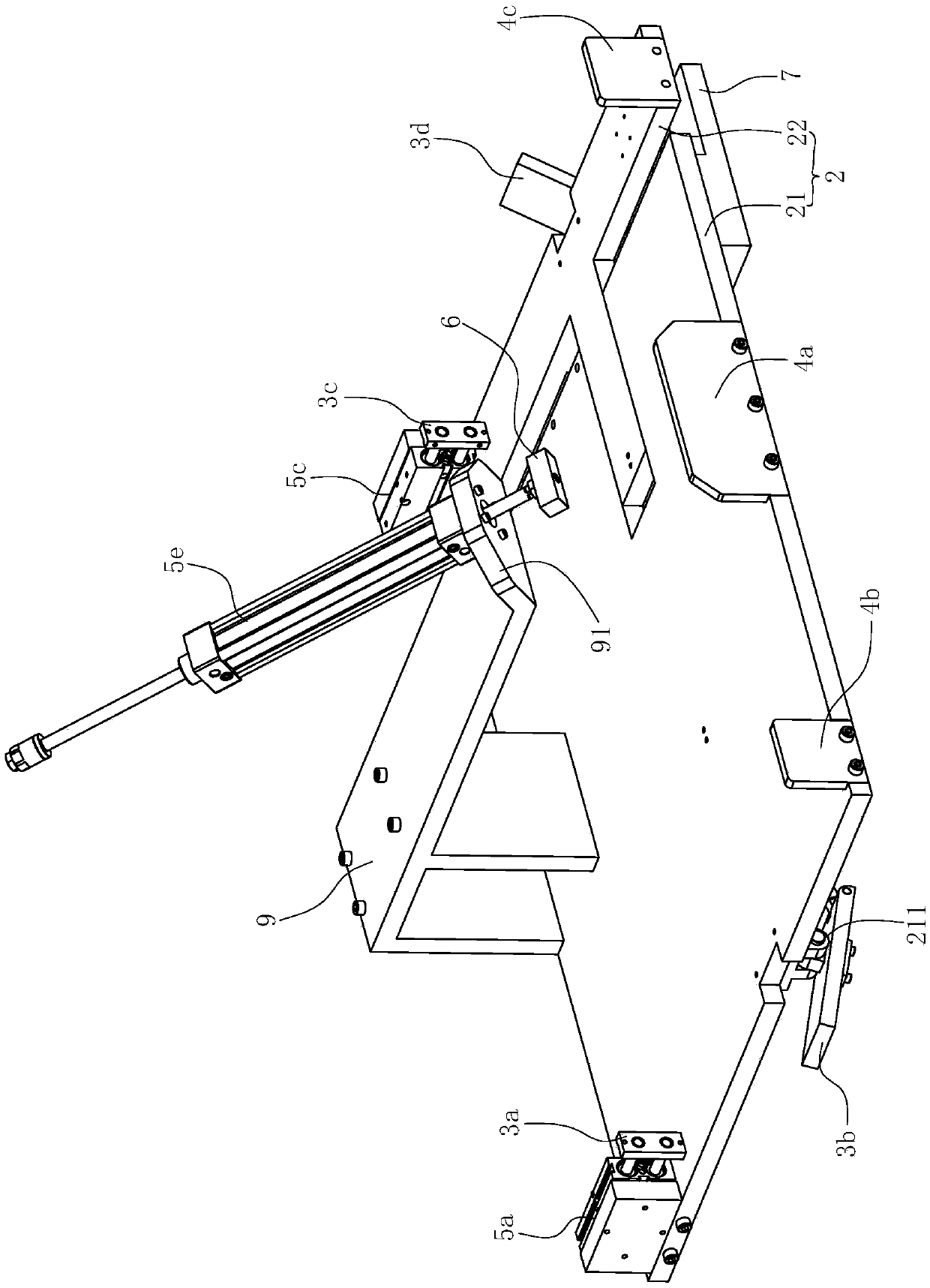

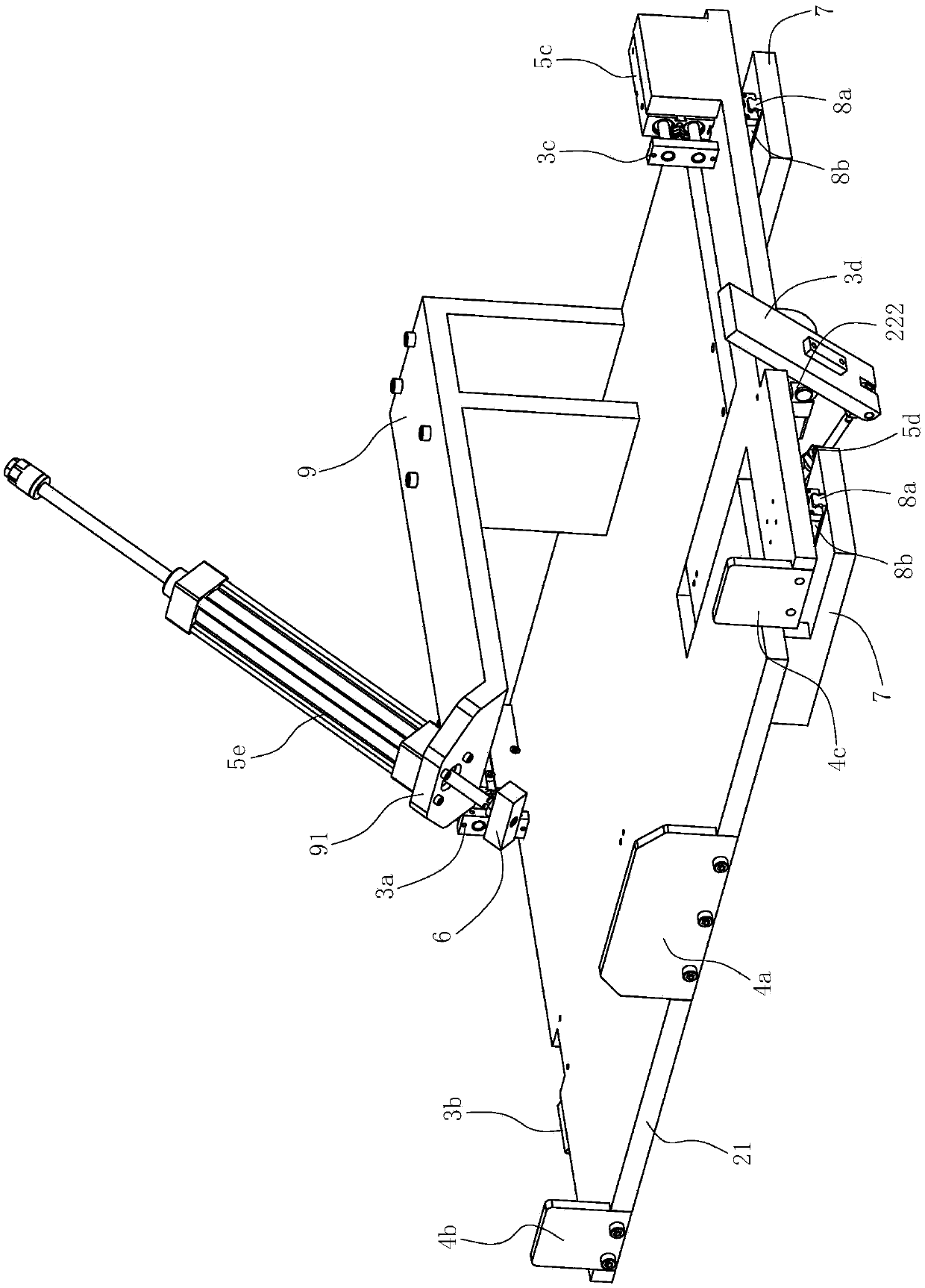

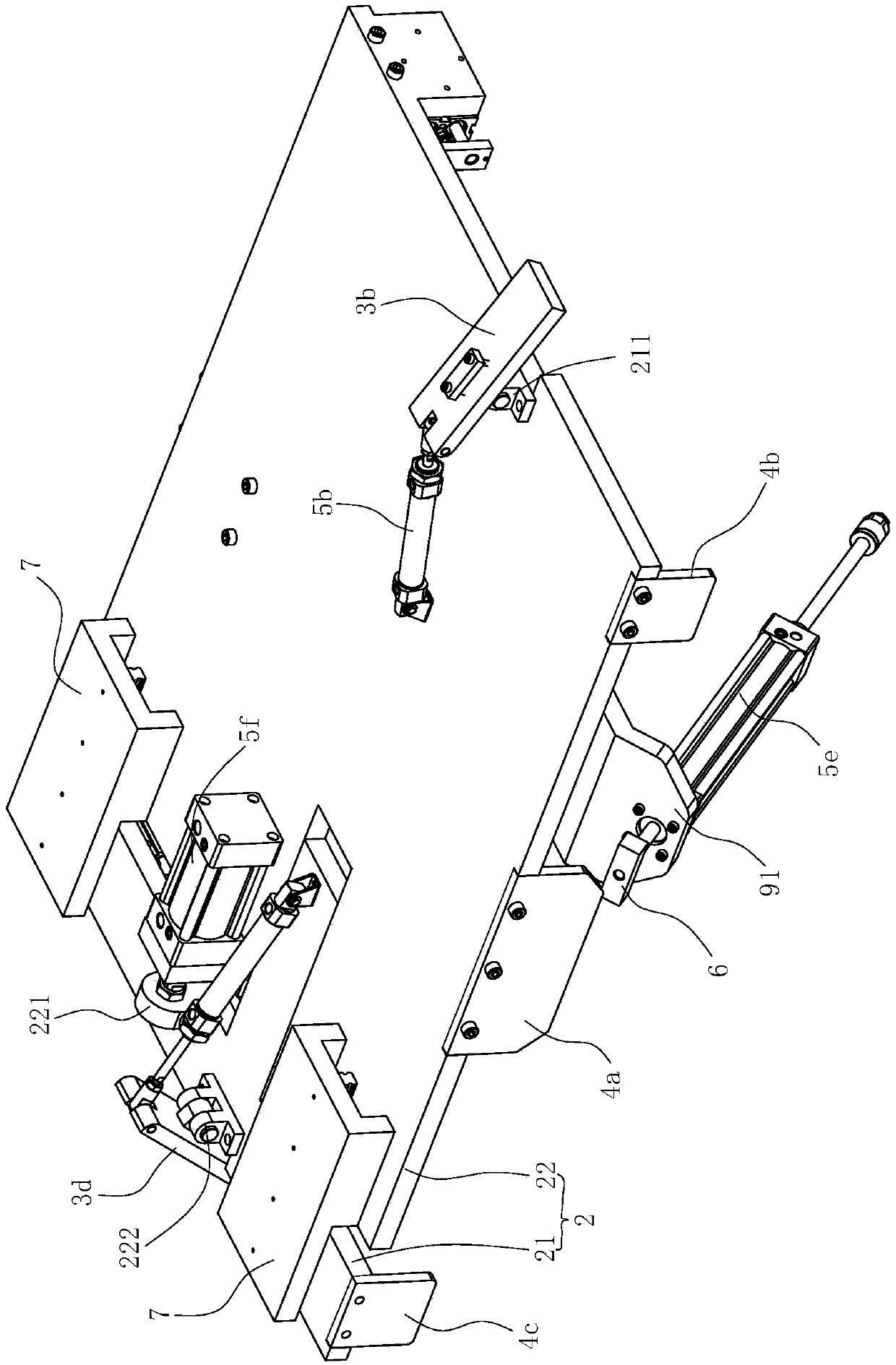

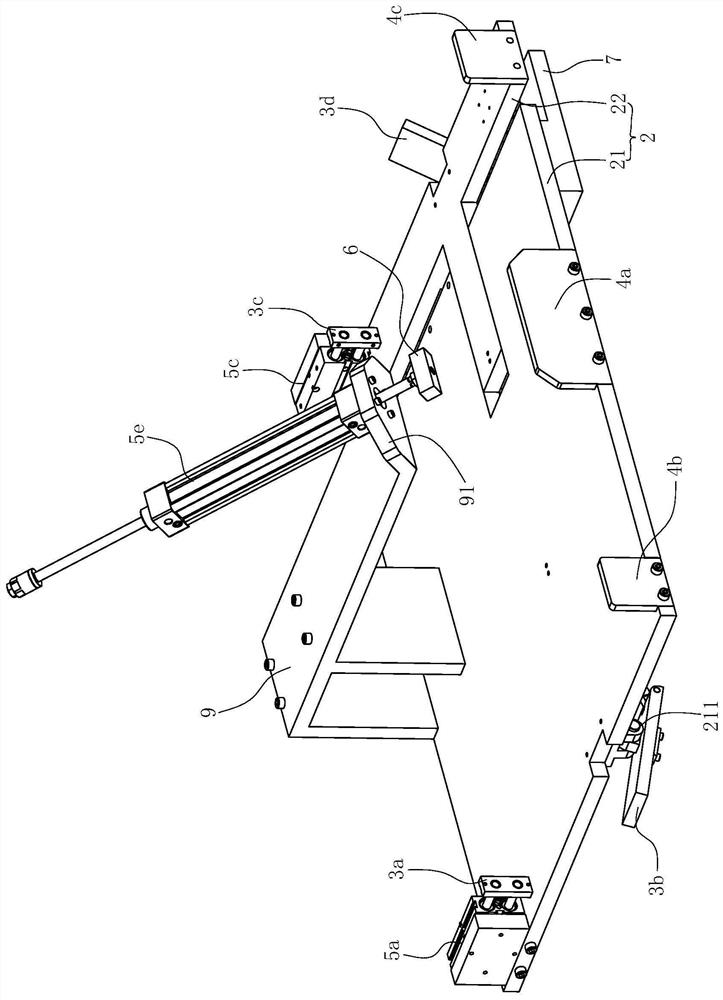

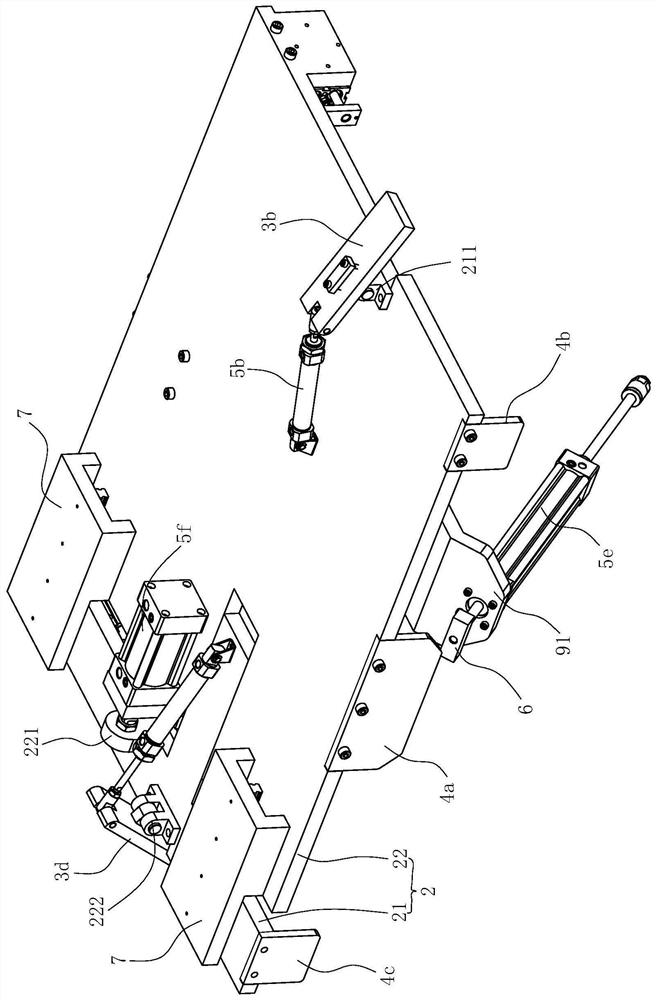

Automatic clamping and welding fixture with correction function suitable for exhaust fume collecting hoods of multiple specifications

ActiveCN110900063AGuaranteed flatnessCorrection of flatnessWelding/cutting auxillary devicesAuxillary welding devicesExhaust fumesEngineering

The invention relates to a welding fixture, in particular to an automatic clamping and welding fixture with a correction function suitable for exhaust fume collecting hoods of multiple specifications.The automatic clamping and welding fixture comprises a platform, wherein the platform is used for accommodating an exhaust fume collecting hood with a front folded edge, a left folded edge and a right folded edge. The automatic clamping and welding fixture is characterized in that the platform is composed of a main platen and a side platen, and a driving structure used for driving the side platento slide left and right is arranged at the bottom part of the main platen; a left rear pressing block, a left side pressing block and a front middle baffle plate are arranged on the main platen, theleft rear pressing block is driven by means of a left rear cylinder, the left side pressing block is used for making contact with the side surface of the left folded edge, and the front middle baffleplate is fixed to the front portion of the main platen and used for making contact with the middle portion of the front folded edge; a right rear pressing block and a right side pressing block are arranged on the side platen, the right rear pressing block is driven by means of a right rear cylinder, and the right side pressing block is driven by means of a right side cylinder; and an upper cylinder is arranged above the main platen, and a correction pressing block is fixed to a piston rod of the upper cylinder. The automatic clamping and welding fixture can be used for welding the exhaust fumecollecting hoods of different specifications, can further ensure the flatness of the front folded edge of the exhaust fume collecting hood after welding, and is beneficial to later assembly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

An automatic tire dewatering machine

ActiveCN105904679BIncrease productivityReduce manufacturing costMetal working apparatusMechanical equipmentWaste material

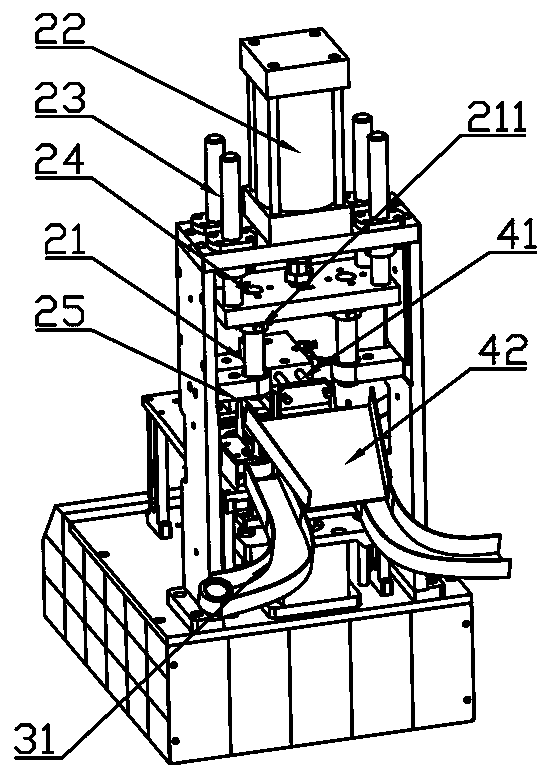

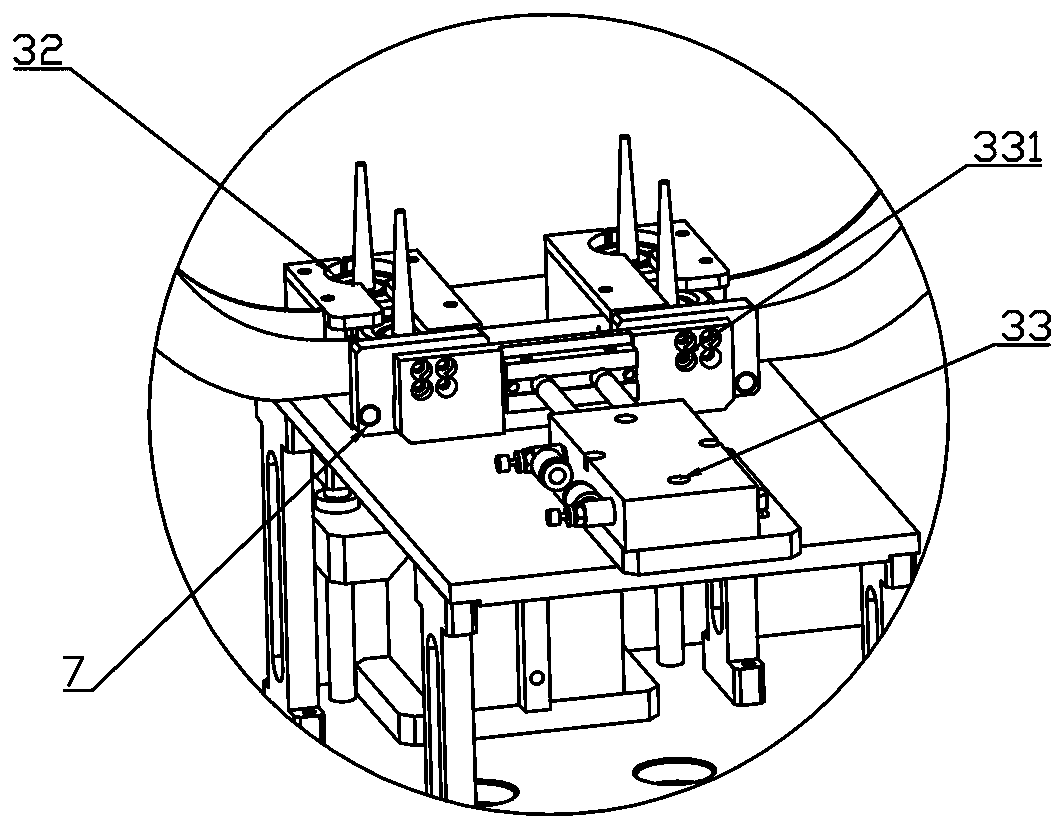

The invention relates to the field of toy mechanical equipment, in particular to an automatic tire drainage opening cutting machine. The automatic tire drainage opening cutting machine mainly comprises vibration conveying units, a stamping unit, a positioning unit and a discharging unit. The vibration conveying units are located on the two sides of a workbench and connected to positioning parts of the positioning unit through tracks. The stamping unit is located over the positioning unit. The discharging unit is located between the stamping unit and the positioning unit. Cutters are stamped to the positioning unit through a downward pressing air cylinder. A controller is arranged under the workbench. The automatic tire drainage opening cutting machine has the beneficial effects that the drainage opening cutting mechanism cuts tire drainage openings through the cutters of the stamping unit, and the cutters adsorb cut drainage opening waste materials to the discharging unit; and compared with traditional manual drainage opening cutting, not only is the product production efficiency improved by the design, but also the manufacturing cost and manpower are greatly reduced.

Owner:DONGGUAN SUMS MODEL GIFTS CO LTD

Self-locking rubber outer tire stacking structure

InactiveCN107867479AReduce workloadReduce the use effectContainers for annular articlesTyresEngineeringSelf locking

The invention discloses a self-locking rubber tire stacking structure, comprising several positioning frames, the positioning frame includes a first fixing plate and a second fixing plate, the end surface of the first fixing plate is provided with a first accommodating cavity, and the first accommodating A positioning plate is installed in the cavity, and the locking rod is fixed on the positioning plate. Several conical positioning ratchets are arranged on the circumferential surface of the locking rod. The locking rod passes through the first and second fixing plates and passes through the self-locking locking device. Cooperate with the positioning ratchet on the locking rod to axially position the locking rod. The second fixing plate is provided with a second accommodation cavity sunken toward the first fixing plate. The outer diameter of the second accommodation cavity is smaller than that of the rubber tire The inner diameter of the locking rod end and the self-locking locking device are integrally located in the second accommodating chamber, the self-locking locking device is fixed on the bottom wall of the second accommodating chamber, and the positioning plate is integrally located in the first accommodating chamber In the cavity; several positioning frames are placed into several positioning frame layers, and the positioning frames of adjacent positioning frame layers are perpendicular to each other.

Owner:重庆市万盛区安达橡胶制品有限责任公司

Integrated forming production method for firecrackers

The invention specifically discloses an integrated forming production method for firecrackers. The integrated forming production method includes the following steps that a base with a groove and a cylinder with multiple through holes are prepared from a mixed material of pond sludge and smashed straw; multiple lead struts are sequentially arrayed in the groove, wherein the distance between every two adjacent lead struts is equal to the distance between the centers of the corresponding two adjacent through holes in the cylinder, one end of each lead strut is inserted in the base and fixed, and the other end of each lead strut extends out of the base; a lead is coiled in the groove and is sequentially arranged on forks of the multiple lead struts in an erected manner; the cylinder is arranged on the base in a buckled manner and fixed after the multiple through holes correspond to the multiple lead struts one to one, and firecracker bodies are manufactured; and the firecrackers are prepared after the multiple through holes of the cylinder are filled with sound making firecracker cores and provided with covers. The firecrackers produced through the method are different from the structure of existing firecrackers, the structures between the firecrackers are more compact, the production process is simple, the produced firecrackers are convenient to transport and store and are convenient to remove after being set off, and environment protection is achieved.

Owner:北海市铁山港区营盘烟花厂

Wardrobe fixing device adopting fixing at two ends

The invention discloses a wardrobe fixing device adopting fixing at two ends. The wardrobe fixing device comprises a fixing part used for being connected with a wall, two inserting parts are symmetrically arranged on two sides of the side, far away from a fixing head, of the fixing part, main rods are arranged in a manner of being matched with the inserting parts, second spiral thread fixing parts are matched between each main rod and the corresponding inserting part, a curved tube is matched between the two main rods, first inserting parts are arranged at two ends of the curved tube, the first inserting parts are inserted into the main rods, third spiral thread fixing parts are matched between the main rods and the first inserting parts, a fixing group is matched between the two main rods, and the fixing group comprises two wardrobe sleeves arranged symmetrically up and down. For the device, fixing locking is completed by match of the fixing head and a jointing head, so that the later assembly of decoration personnel is facilitated, the assembling speed is improved, through the matched connection of the fixing part and a fixing groove, and the spiral thread matched connection of a first spiral thread fixing part and a spiral thread groove, the overall stability of the device is improved, two end points are adopted for fixing, so that the fixing is reliable, and the safety is ensured.

Owner:徐盈

Miniaturized Frequency Selective Surface Based on Double Split Resonator

ActiveCN109616724BGood spatial filteringSmall unit areaWaveguide type devicesCouplingOut of band rejection

The invention discloses a miniaturized frequency selection surface based on a double-opening resonance ring. A band-pass effect is formed through the combined action of the double-opening resonance ring and a middle coupling aperture. When electromagnetic wave is irradiated to the frequency selection surface, resonance is caused by the opening resonance ring. The frequency selection characteristicof the opening resonance ring is utilized, so that a high spatial filtering function is achieved, meanwhile, the miniaturization characteristic is realized; compared with a common frequency selectionsurface, the cell area is greatly reduced, and the size of the whole circuit unit is only 0.3lambda 0*0.3lambda 0; meanwhile, by virtue of mutual coupling between the opening gap of the resonance ring and an interlayer coupling window, a good out-of-band rejection effect is achieved; and a transmission zero point is arranged on each of the two sides of the band, so that the rectangular coefficient of the circuit is greatly improved. A symmetrical circuit structure is adopted, so that the structure is simple, and machining is easy; and meanwhile, the whole circuit is quite high in stability around the incident angle theta and a formula which is as shown in the specification, so that the practical value is increased.

Owner:四川众为创通科技有限公司

A wardrobe retainer

The invention discloses a wardrobe position fixing device which comprises a position fixing part for being connected with a wall. The two edges of the side, away from a position fixing head, of the position fixing part are symmetrically provided with two inserting parts. Main rods are matched with the inserting parts. Second screw thread position fixing parts are matched between the main rods and the inserting parts. A bent pipe is matched between the two main rods. First inserting parts are arranged at the two ends of the bent pipe and are inserted into the main rods. Third screw thread position fixing parts are matched between the main rods and the first inserting parts. A position fixing set is matched between the two main rods and comprises two wardrobe sleeves symmetrically arranged up and down. According to the device, the position fixing head is adopted for being matched with a joint head to complete position fixing and locking, decoration personnel can carry out later-stage assembling conveniently, the assembling speed is increased, by connecting the position fixing part with a position fixing groove in a matched manner, the first screw thread position fixing parts are connected with screw threads of screw thread grooves in a matched manner, the overall stability of the device is improved, two end points are adopted for fixing positions, position fixing is more reliable, and security is ensured.

Owner:JIANGSU TIANGANG PRECISION CASTING CO LTD

A manufacturing process of a combined heat dissipation structure for a transformer

The invention discloses a combined-type heat radiation structure used for a transformer. The structure comprises a vertical board. Through holes are uniformly arranged in the vertical board. Radiatingfins in snap joint with the vertical board are arranged in the through holes in a penetrating manner. The radiating fins are equipped with clamp grooves corresponding to the through holes. The overall heat radiation structure of a conventional transformer is changed. The through holes are uniformly arranged in the vertical board such that the radiating fins in snap joint with the vertical board are arranged in the through holes in the penetrating manner. The vertical board and the radiating fins are all copper aluminum alloy boards which hare low in cost and good in heat radiation performance. Manufacture process is optimized. Openings of the clamp grooves are equipped with chamfers in order to facilitate assembling in the late period. Polishing treatment comprises coarse grinding and precise grinding treatment such that burr and scraps on surfaces are processed clean, which is convenient for subsequent installation. Planeness errors of the vertical board and the radiating fins are nobigger than + / -0.01 mm so that assembly quality is increased. The combined-type heat radiation structure is simple in process so that the overall heat radiation area is increased. The heat radiationperformance is improved. The combined-type heat radiation structure shows great practicality.

Owner:安徽金环电气设备有限责任公司

Wardrobe fixing device rapid in assembly

The invention discloses a wardrobe fixing device rapid in assembly. The wardrobe fixing device rapid in assembly comprises a fixing piece used for being connected with the wall. Two insertion pieces are symmetrically arranged on the two sides of the side, far away from a fixing head, of the fixing piece. Main rods are arranged through matching of the insertion pieces. Second thread fixing pieces are arranged between the main rods and the insertion pieces in a matched manner. A bent pipe is arranged between the two main rods in a matched manner. The two ends of the bent pipe are provided with first insertion pieces. The first insertion pieces are inserted into the main rods. Third thread fixing pieces are arranged between the main rods and the first insertion pieces in a matched manner. A fixing set is arranged between the two main rods in a matched manner. The fixing set comprises two wardrobe sleeves which are vertically symmetrical. The wardrobe fixing device rapid in assembly completes fixing and locking through cooperation between the fixing head and a connection head, decoration personnel can conveniently conduct assembly in the later period, and the assembly speed is improved; through cooperative connection between the fixing piece and a fixing groove and threaded and cooperative connection between a first threaded fixing piece and a threaded groove, the overall stability of the wardrobe fixing device rapid in assembly is improved; and two-end-point fixation is adopted, so that fixation is more reliable, and the safety is ensured.

Owner:徐盈

Suitable for multi-standard fume collection hoods, automatic clamping welding fixture with correction function

ActiveCN110900063BGuaranteed flatnessCorrection of flatnessWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSmoke hood

An automatic clamping welding jig suitable for multi-standard fume collecting hoods and with a correction function. The invention relates to a welding jig, including a platform for placing a fume collecting hood with front folds, left folds and right folds; its features are: The platform is composed of the main platform and the side platform. The bottom of the main platform is provided with a drive structure for driving the side platform to slide left and right; The baffle, the left rear pressing block is driven by the left rear cylinder, the left pressing block is used to contact the side of the left flange, and the front middle baffle is fixed on the front of the main table to contact the middle of the front flange; There are right rear pressing block and right pressing block on the side table, the rear pressing block is driven by the right rear cylinder, and the right pressing block is driven by the right air cylinder; the upper cylinder above the main table, the upper cylinder A correction block is fixed on the piston rod. The fixture can weld the fume collection hoods of different specifications, and can also ensure the flatness of the front fold of the fume collection hood after welding, which is beneficial to later assembly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Rubber tyre casing stacking structure

InactiveCN107792486AReduce workloadReduce the use effectContainers for annular articlesTyresEngineeringTread

The invention discloses a stacking structure for rubber tires, which comprises a plurality of positioning frames. The positioning frame includes a first fixing plate and a second fixing plate, and a clamping space for the rubber tire is formed between the first fixing plate and the second fixing plate. The end surface of the first fixing plate facing away from the second fixing plate is provided with a first accommodation cavity, a positioning plate is installed in the first accommodation cavity, and an axially extending connecting screw is fixed on the positioning plate, and the connecting screw The screw rod passes through the through holes provided on the first fixing plate and the second fixing plate, and is locked by a nut. The second fixing plate is provided with a second accommodating cavity recessed toward the first fixing plate, and the second accommodating cavity The outer diameter of the outer diameter is smaller than the inner diameter of the rubber tire, the end of the connecting screw and the nut are integrally located in the second accommodating chamber, and the entirety of the positioning plate is located in the first accommodating cavity; several positioning frames are placed as several positioning frame layers, adjacently positioned The positioning frames of the shelf layers are perpendicular to each other.

Owner:重庆市万盛区安达橡胶制品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com