Automatic clamping and welding fixture with correction function suitable for exhaust fume collecting hoods of multiple specifications

A technology for welding fixtures and fume collecting hoods, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult gap adjustment, uneven gap, and gap tolerance, etc., so as to facilitate later assembly and plane degree correction, to ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

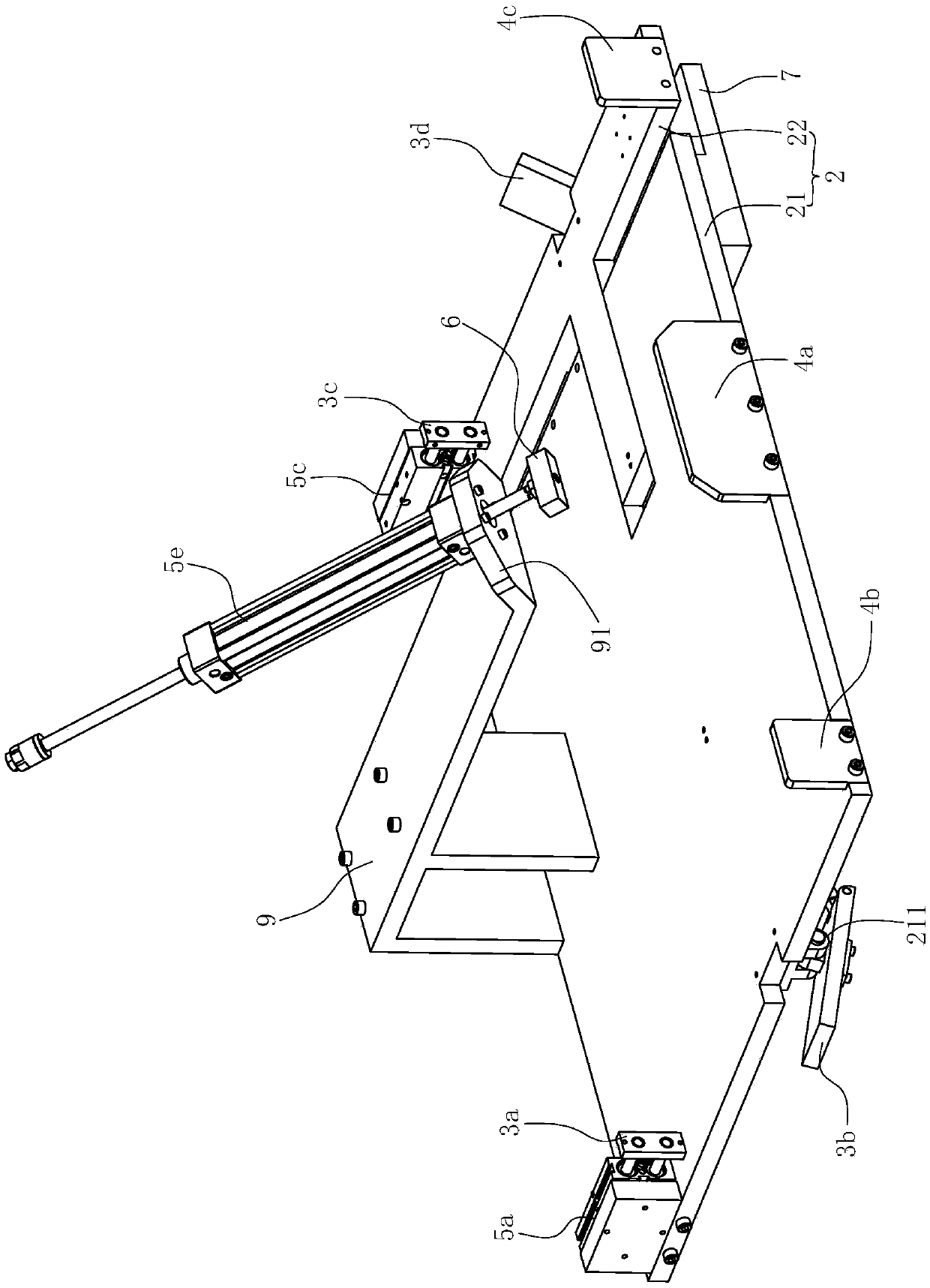

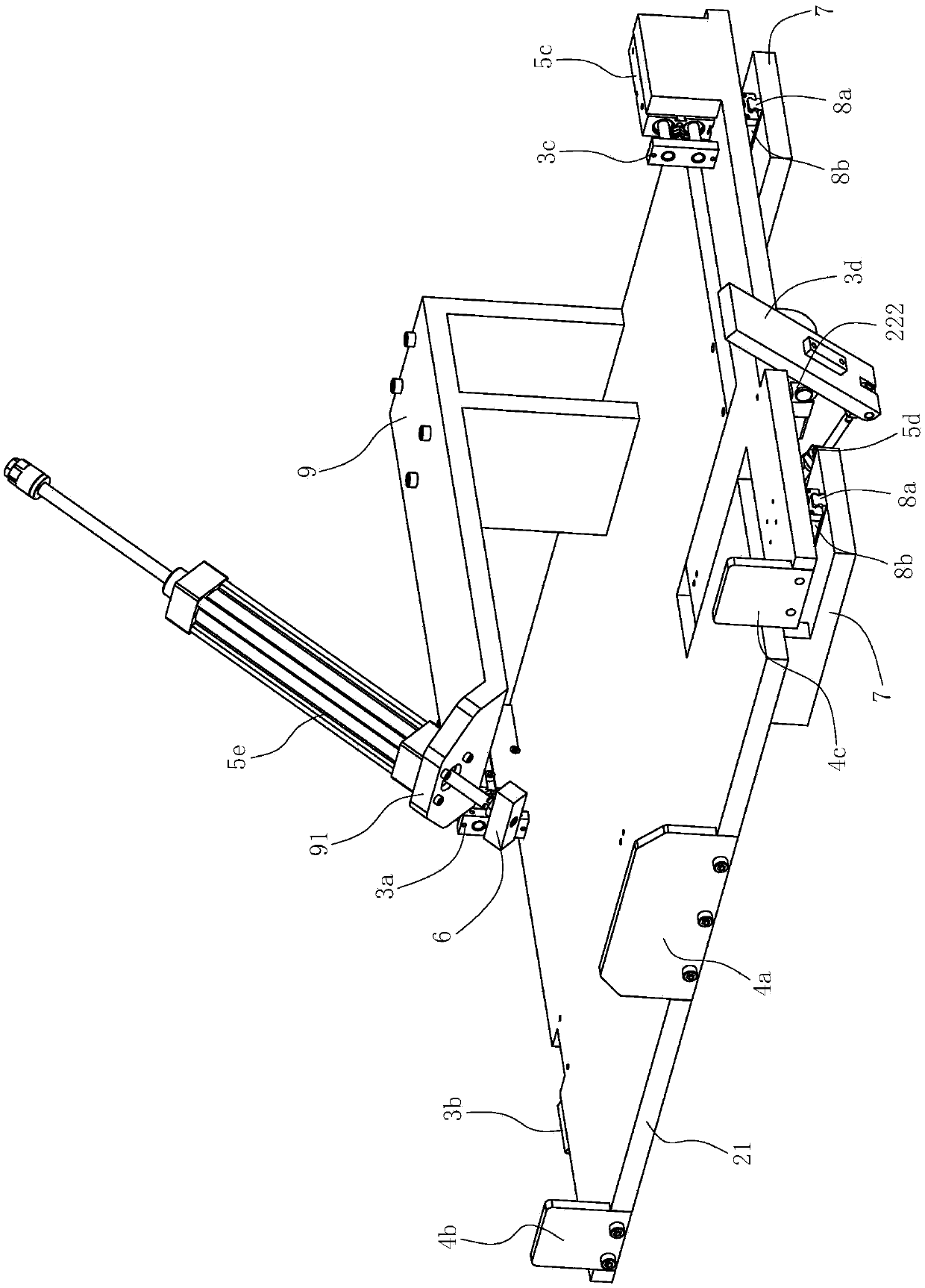

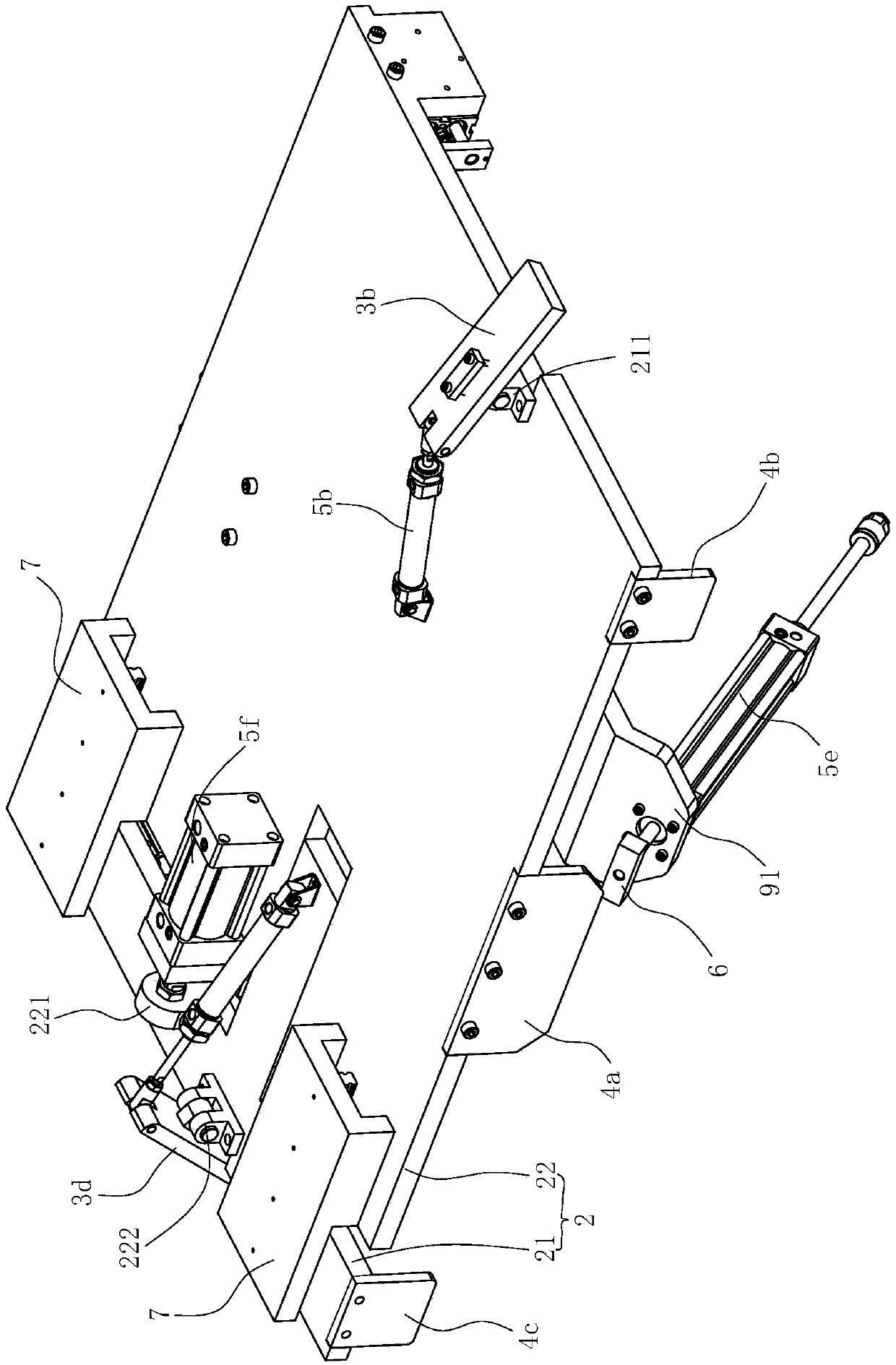

[0022] Such as Figure 1~6 Shown is a preferred embodiment of the present invention.

[0023] An automatic clamping and welding jig suitable for multi-standard fume collection hoods with a correction function, including a platform 2 for placing a fume collection hood 1 with a front fold 11, a left fold 12 and a right fold 13; the fixture is used for Two reinforcing strips 10 are welded between the front flange 11 and the top surface of the fume collecting hood, and L-shaped connectors 14 are welded on both sides of the fume collecting hood to ensure the strength of the fume collecting hood 1 .

[0024] The platform 2 is composed of a main platform 21 and a side platform 22, the upper surfaces of the main platform 21 and the side platform 22 are located on the same horizontal plane, and the side platform 22 is installed on the right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com