Fully-automatic film stripping machine

A stripping machine, fully automatic technology, applied in the field of mechanical processing equipment, can solve the problems of affecting efficiency, low degree of automation, poor continuity, etc., and achieve the effect of facilitating later assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

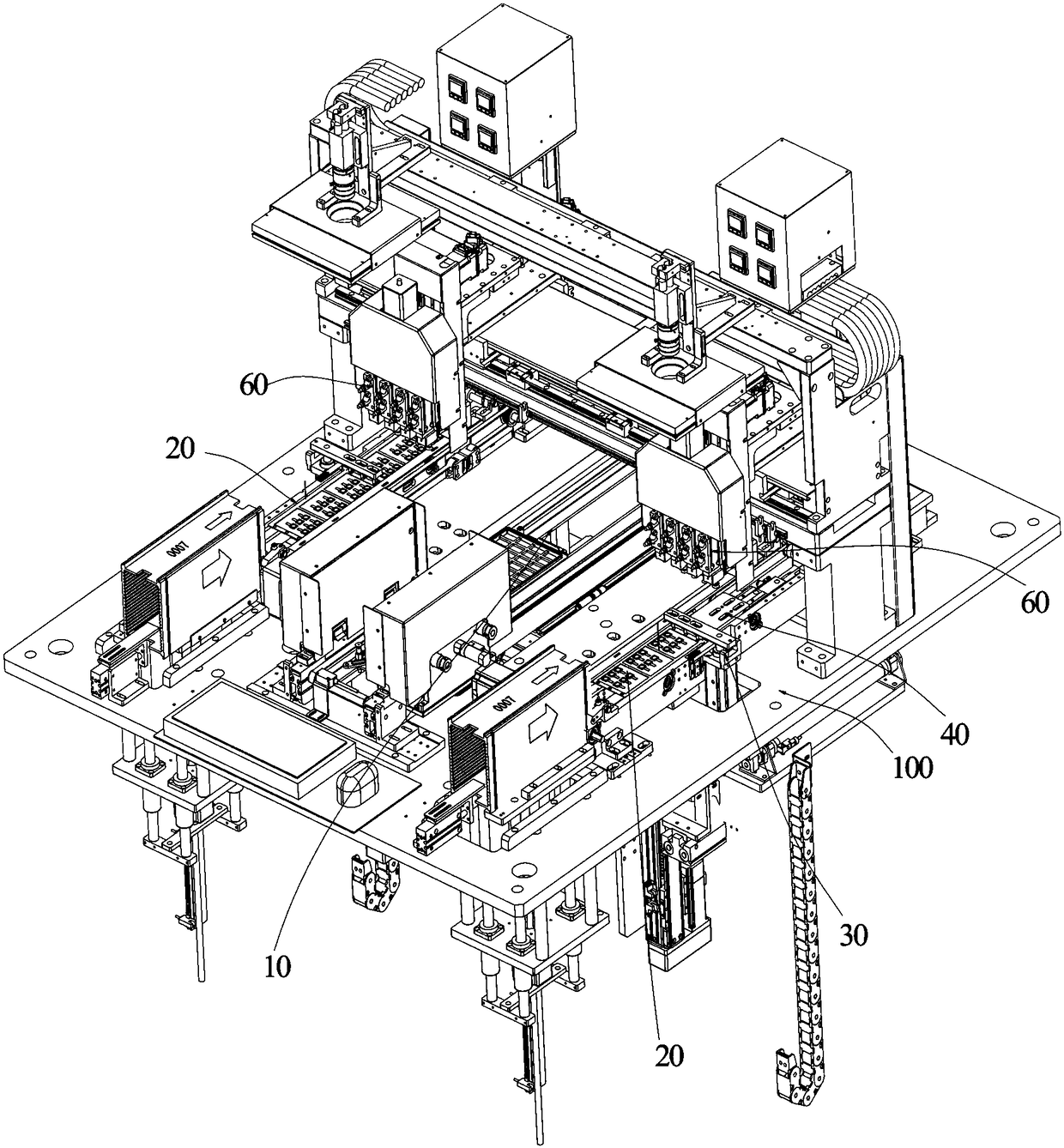

[0033] Such as Figure 1-9 A fully automatic film stripping machine shown includes a frame 100 , a first conveying mechanism 10 , a second conveying mechanism 20 , a film separating mechanism 30 and a material holding mechanism 40 . The first conveying mechanism 10 is arranged on the frame 100 and is used for conveying the workpiece carrier. The second conveying mechanism 20 is also arranged on the frame 100 and is located at one side of the first conveying mechanism 10 . The second conveying mechanism 20 is used for conveying the tray loaded with workpieces; a peeling station is formed on the conveying end surface of the second conveying mechanism 20 . It should be noted that the workpiece carrier is a tray with multiple small compartments for loading the workpiece after peeling off the film, while the material tray is a material frame whose bottom e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com