An automatic tire dewatering machine

An automatic tire and nozzle technology, which is applied in metal processing and other directions, can solve the problems of slow cutting operation speed, uneven nozzle cutting, rough manual operation, etc., to facilitate later assembly, improve accuracy, strengthen accuracy and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

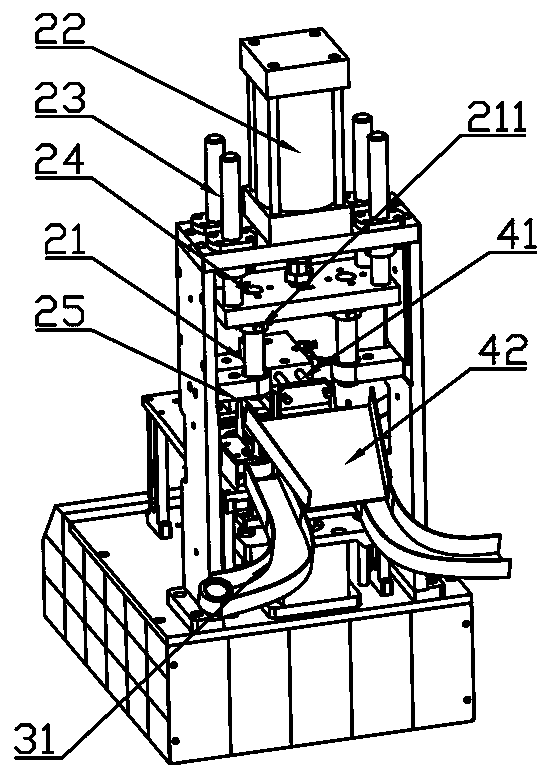

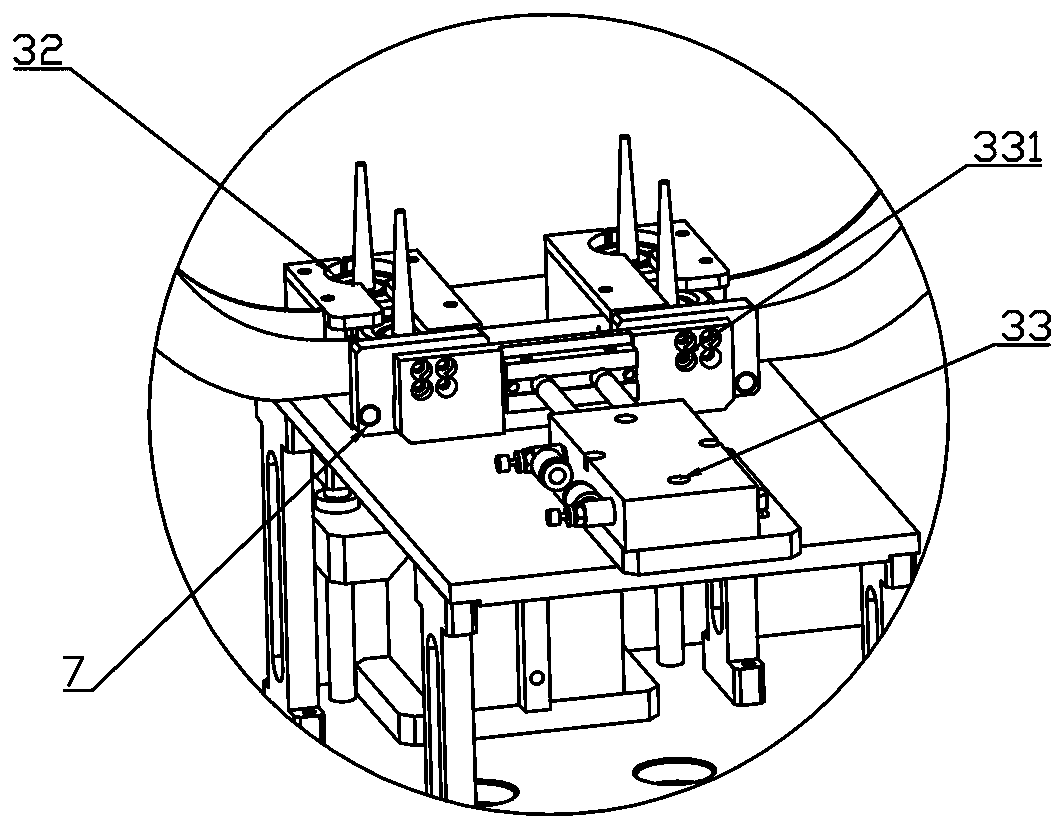

[0022] Figure 1~4 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention. The present invention is an automatic tire dewatering machine, which mainly includes: a vibrating conveying unit 1, a stamping unit 2, a positioning unit 3 and an unloading unit 4. The vibrating conveying unit 1 is located on both sides of the workbench 5, the vibrating conveying unit 1 is connected to the positioning part 32 of the positioning unit 3 through the rail 6, the stamping unit 2 is located above the positioning unit 3, and the unloading unit 4 is located between the stamping unit 2 and the positioning unit Between 3, the cutting knife 21 is stamped to the positioning unit 3 by pressing down the cylinder 22, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com