Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Controllable movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

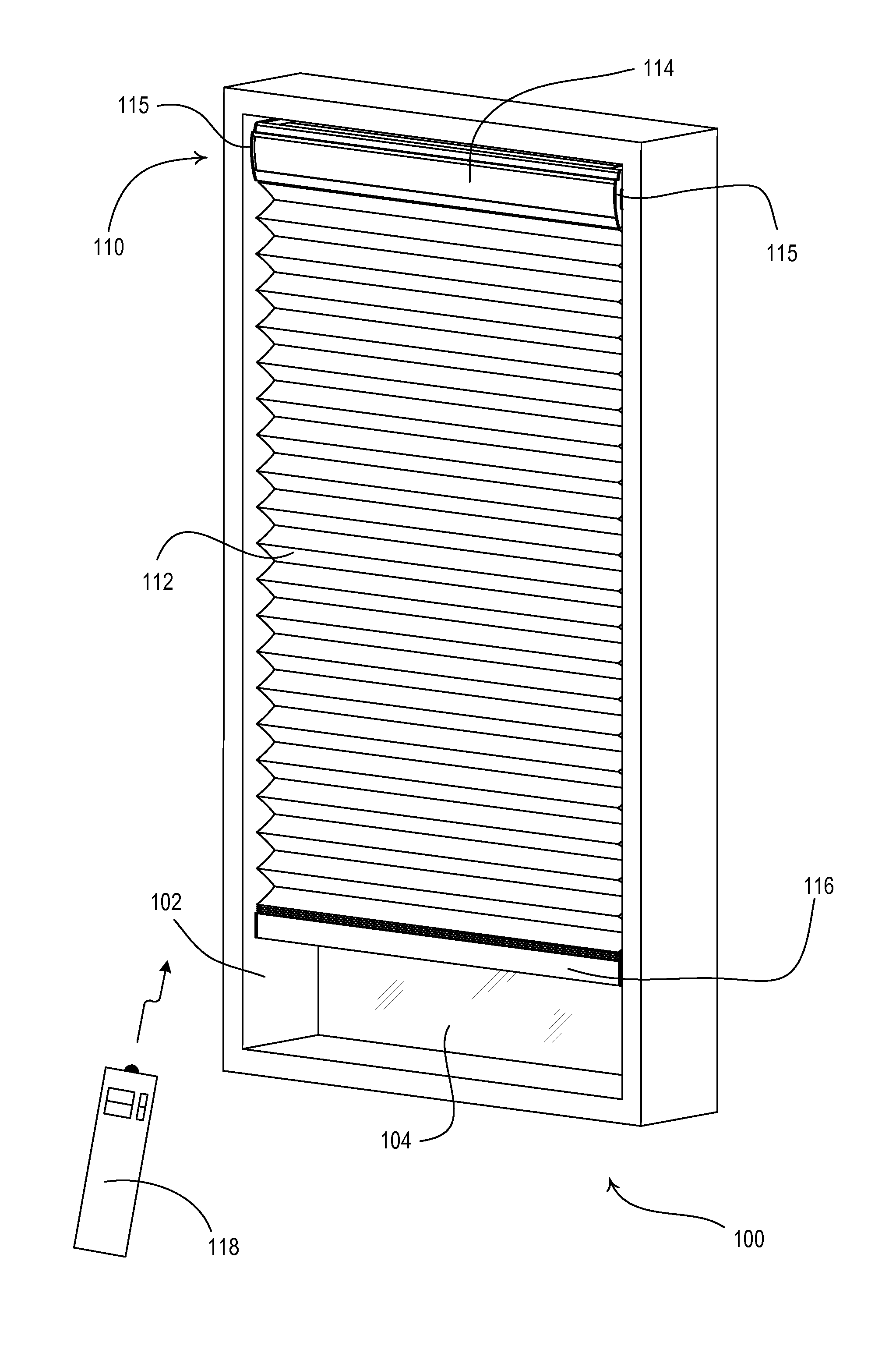

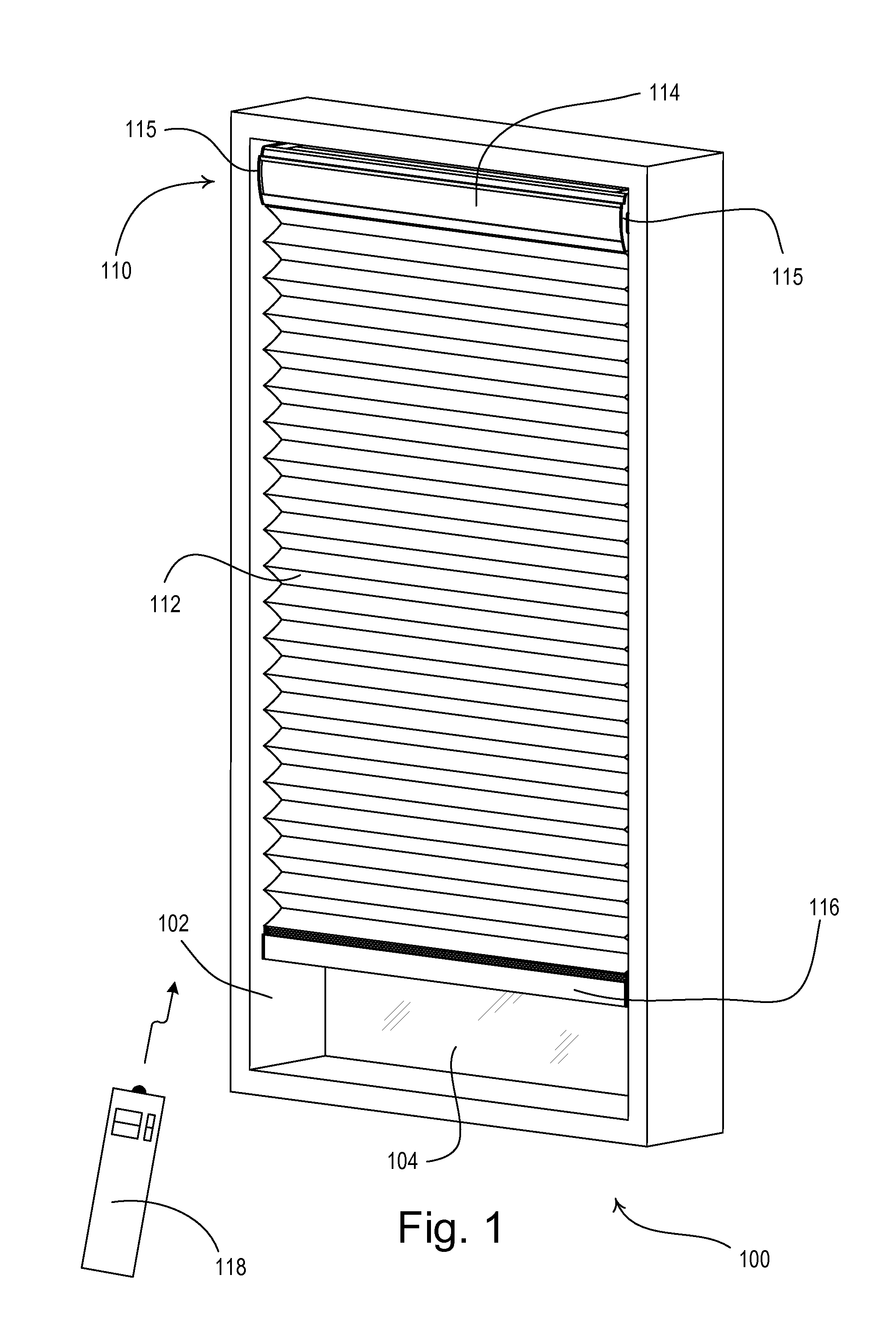

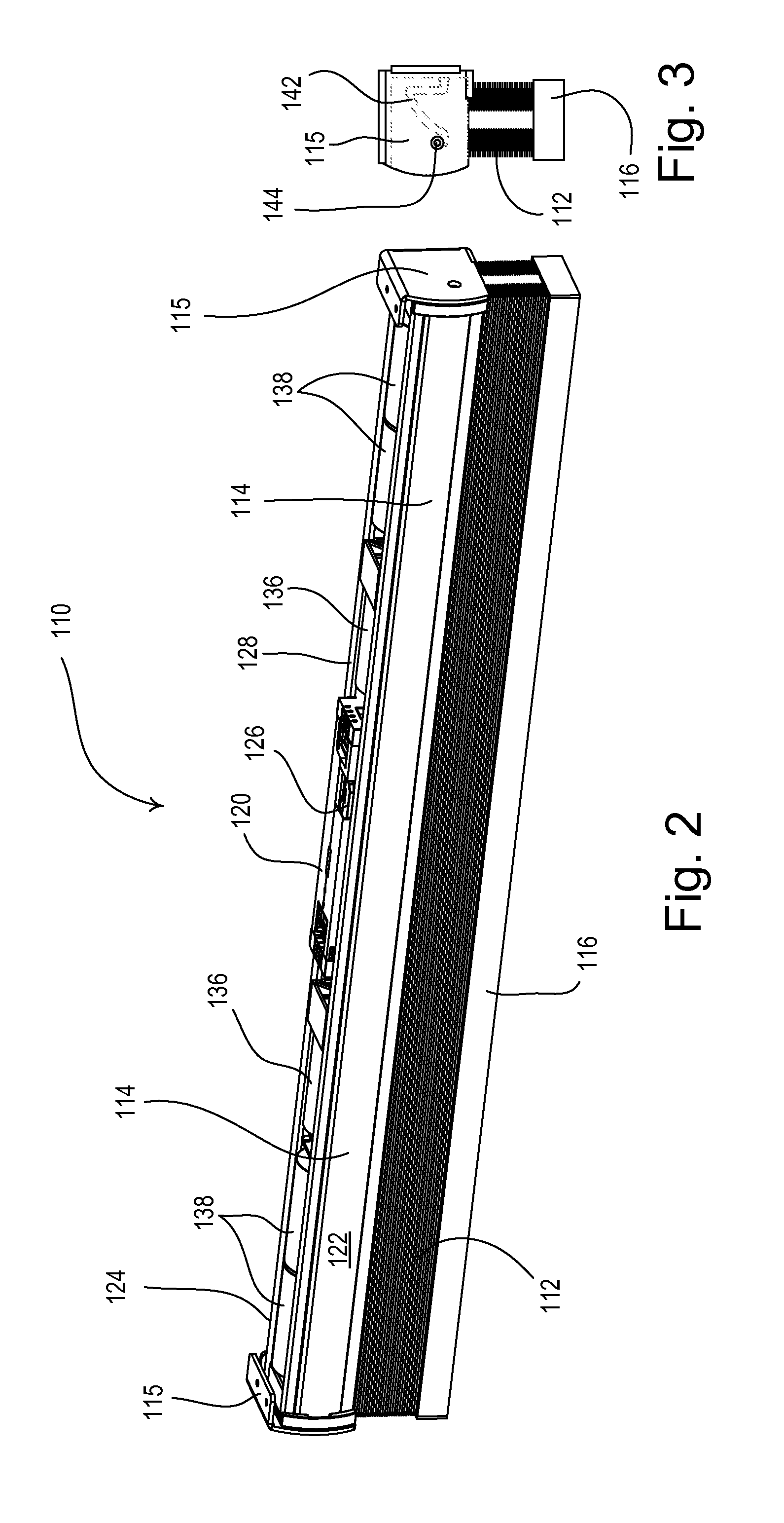

Battery-powered motorized window treatment having a service position

ActiveUS20120255689A1Cheap replacementLong life-timeLight dependant control systemsPower managementEmbedded system

Owner:LUTRON TECH CO LLC

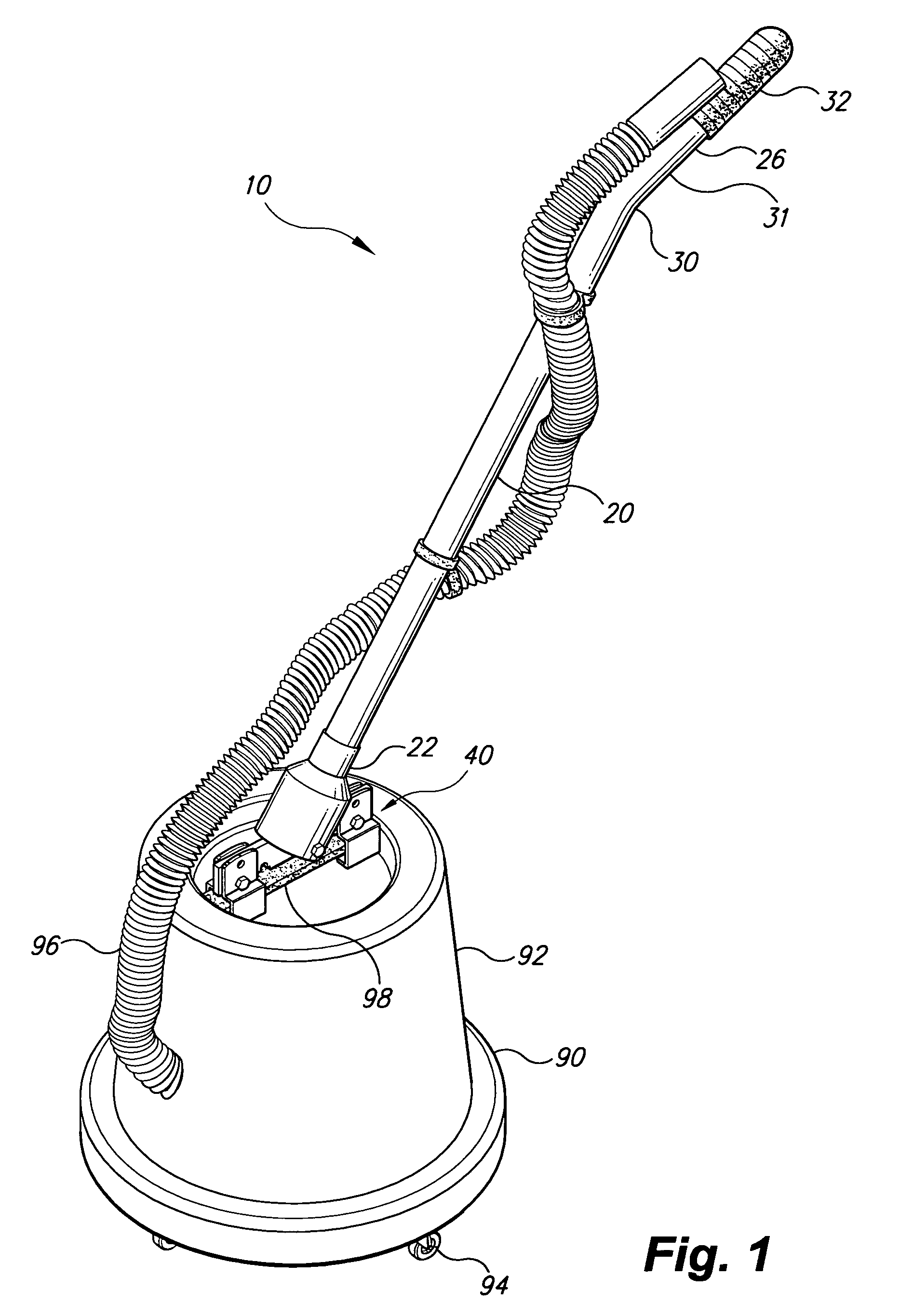

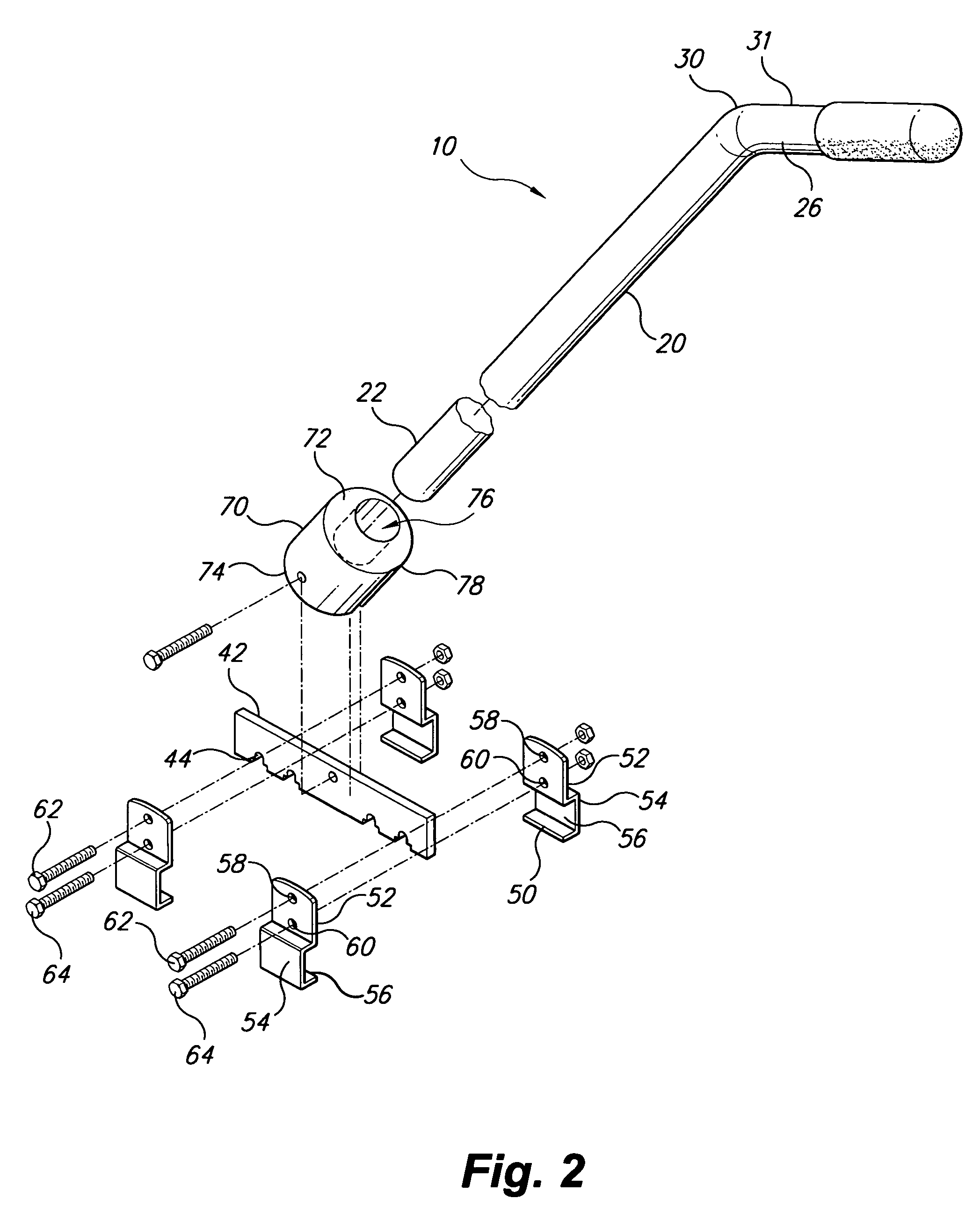

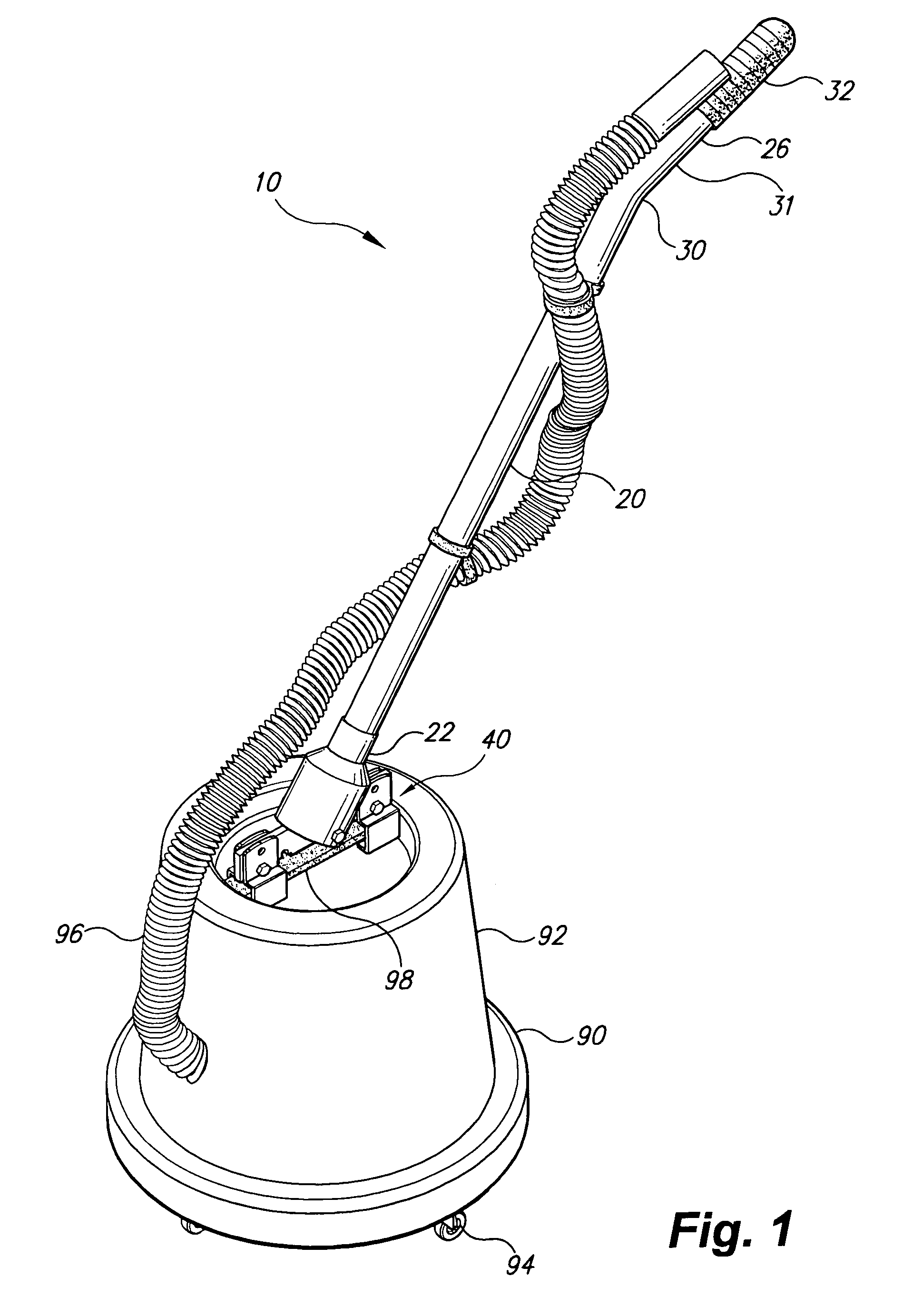

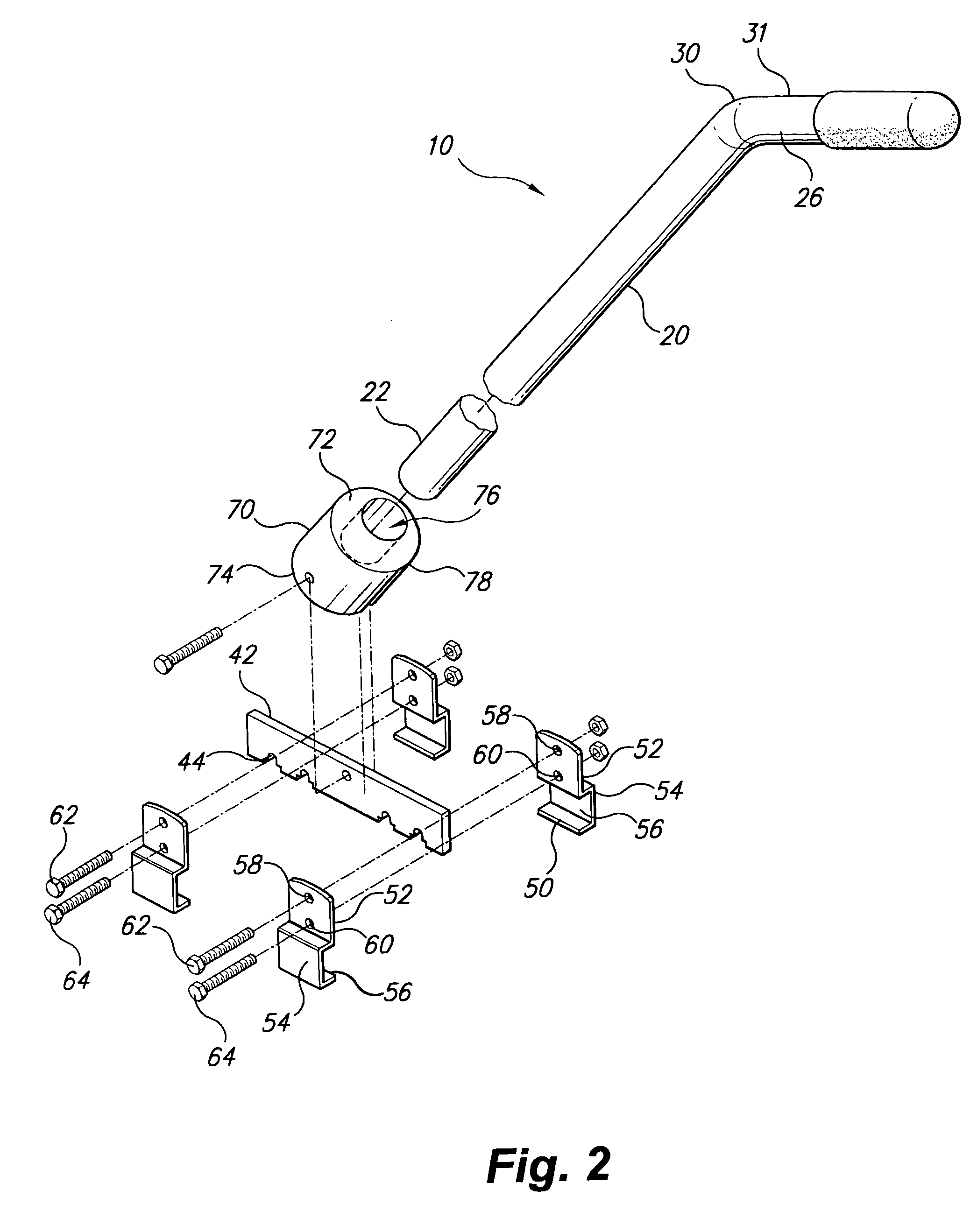

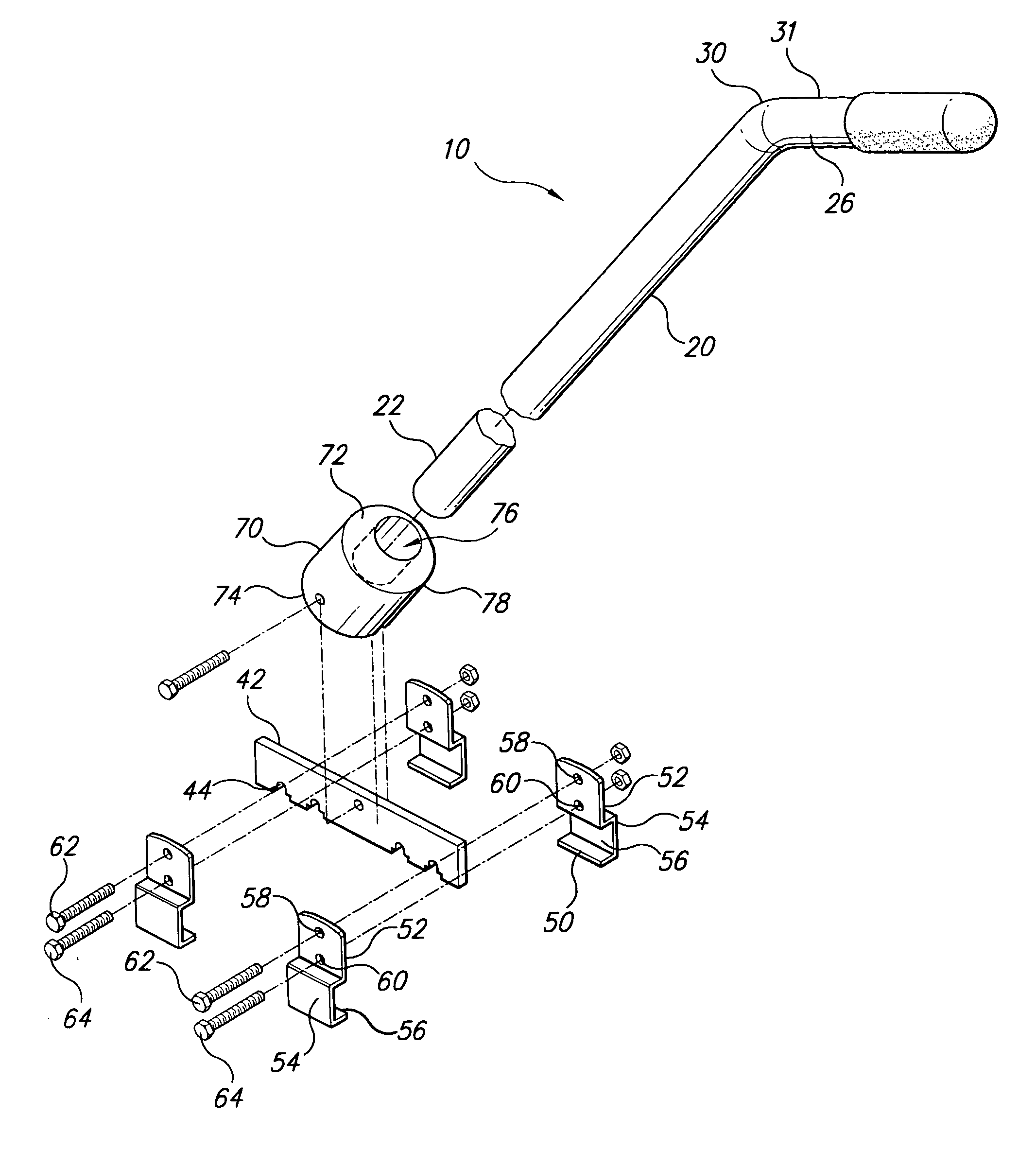

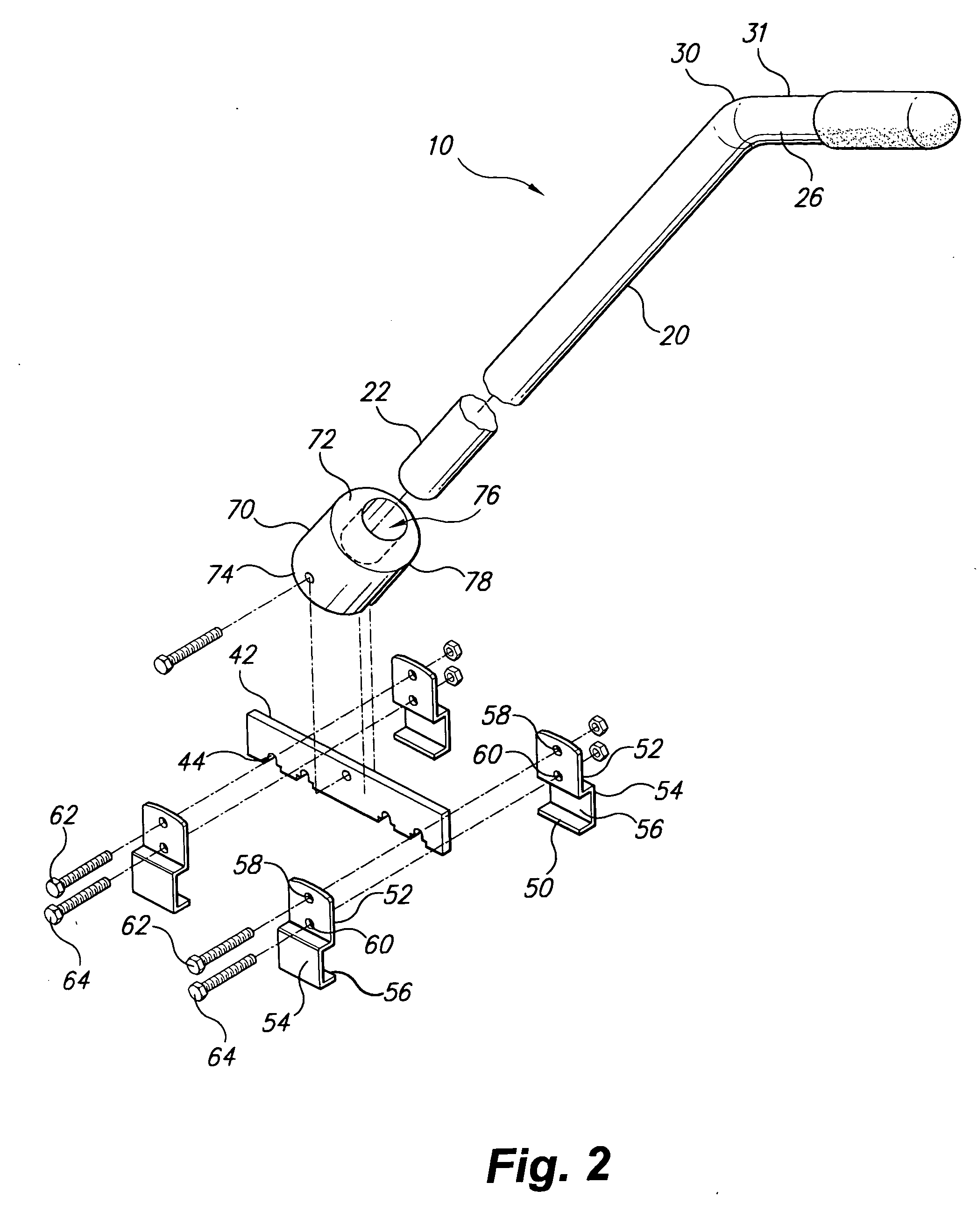

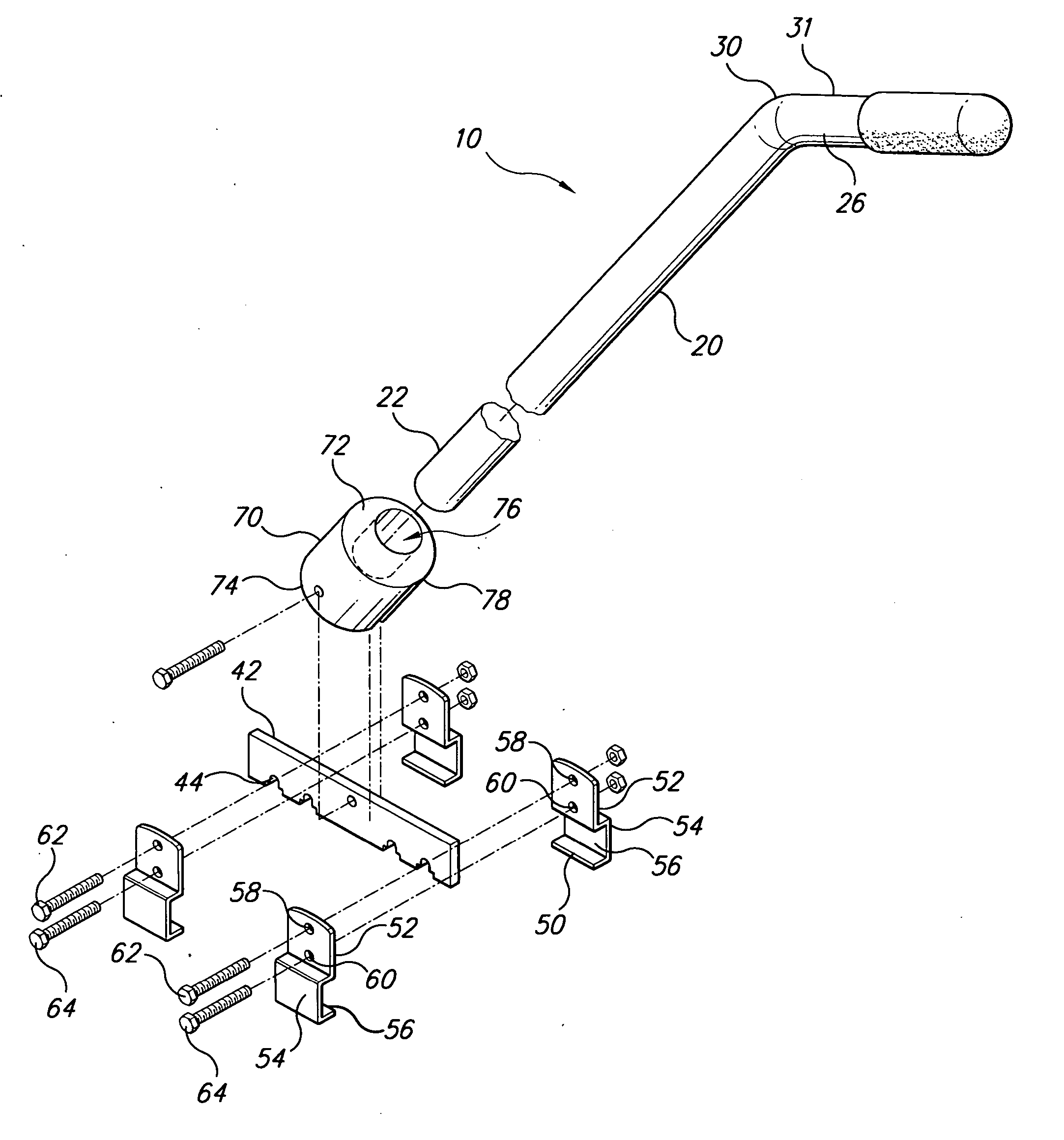

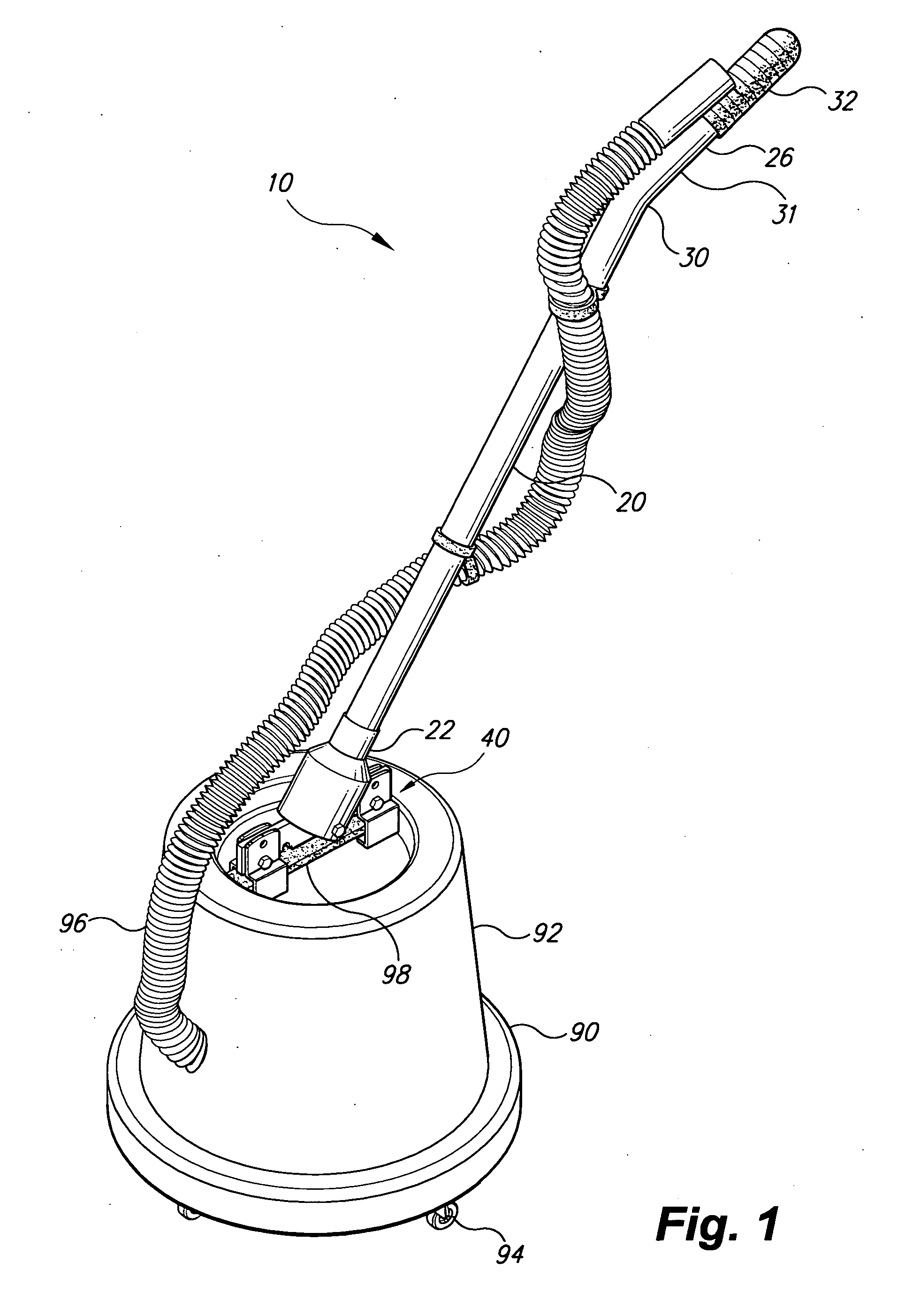

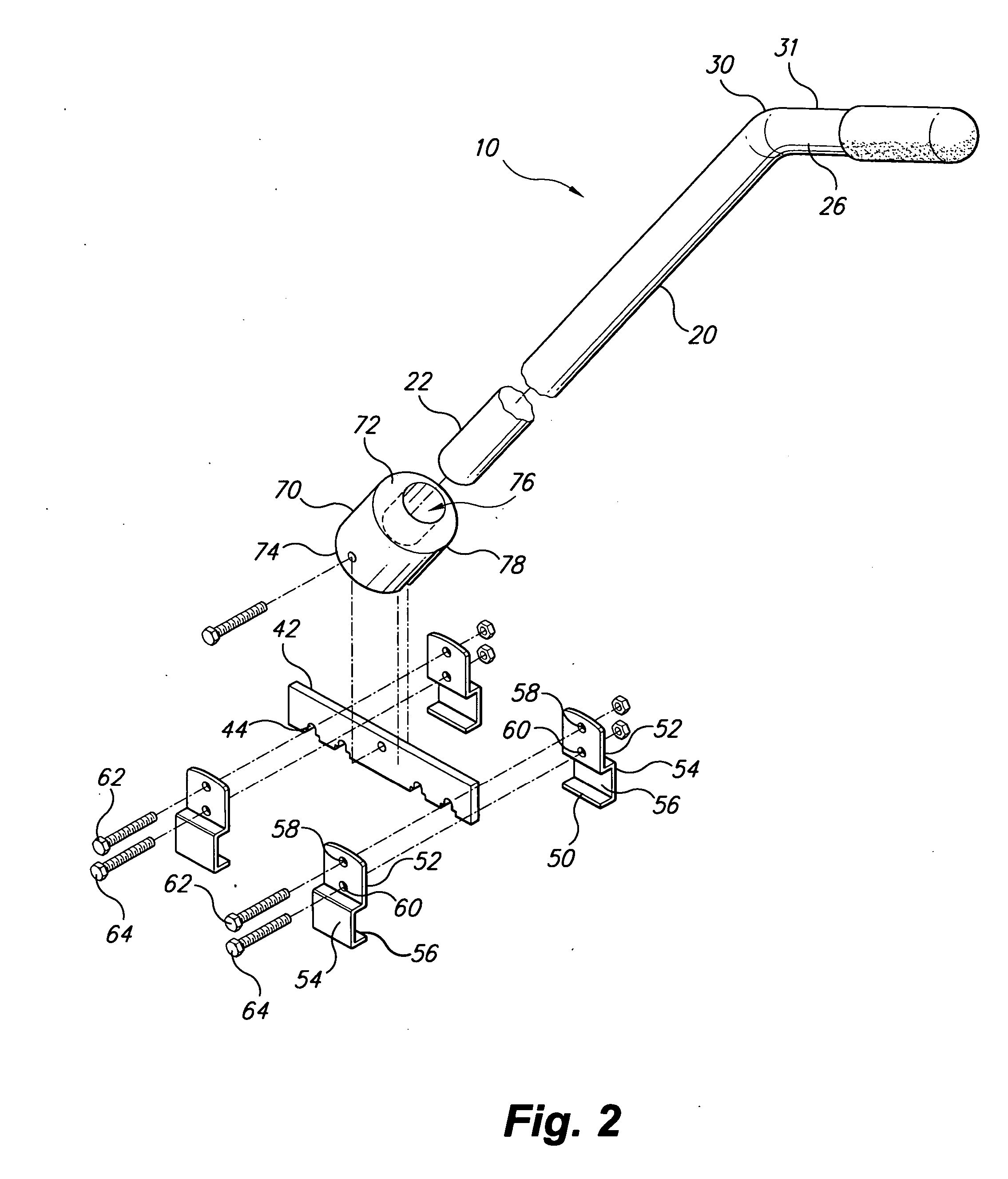

Ergonomic appliance handle

InactiveUS7216403B2Easy to operateEasy to moveTravelling carriersHoldersMechanical engineeringVacuum cleaner

Owner:DECKER DEBORAH

Endoscope and endoscope system

InactiveCN110367912AControllable movementReduce collisionUltrasonic/sonic/infrasonic diagnosticsGastroscopesHuman bodyTissue imaging

The invention is applicable to the technical field of endoscopes and provides an endoscope and an endoscope system. The endoscope and the endoscope system have the advantages that a flexible catheterwhose outer diameter is smaller than the outer diameter of an endoscope body is used to perform mechanical guidance and conveying on the capsule-shaped endoscope body to allow the movement of the endoscope body in a human body to be controllable, collision and rubbing of the catheter against the human body digestive tract can be reduced effectively, examination and diagnosis comfortableness and tolerance are increased, and operation convenience is achieved; the optical image data of the human body digestive tract is acquired through a camera module, the ultrasonic scanning data of the human body digestive tract is acquired through an ultrasonic imaging module, the optical image data and the ultrasonic scanning data are transmitted to an imaging system through data lines to perform real-time image processing to obtain an optical image and an ultrasonic image which are displayed, the multidimensional tissue imaging images in the human body digestive tract can be displayed in real time, tissue pathological change can be observed conveniently, deep tissue pathological change can be acquired, a visual and accurate diagnosis basis can be provided, and diagnosis completeness and accuracycan be increased.

Owner:SHENZHEN INST OF ADVANCED TECH

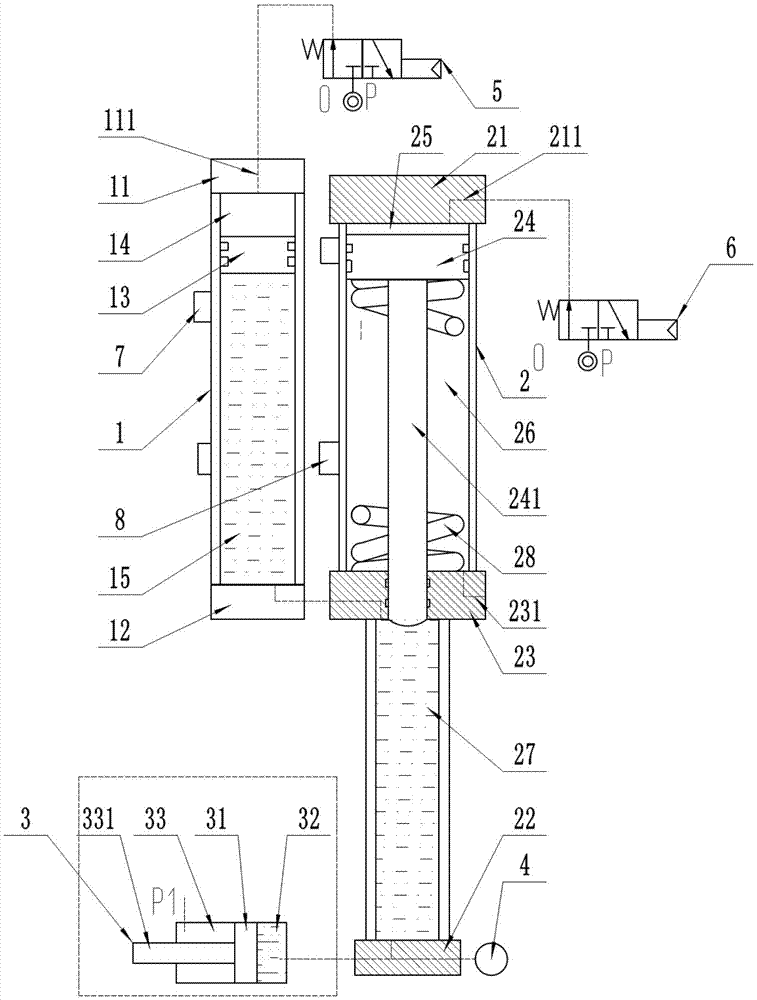

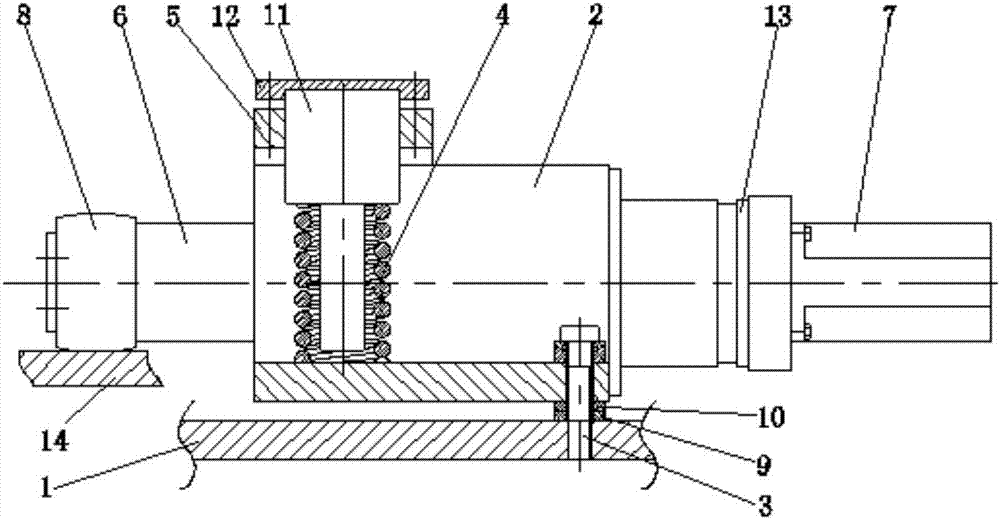

Single-acting pneumatic hydraulic intensifier

InactiveCN105443458ALow gas consumptionLow energy consumptionFluid-pressure convertersFluid-pressure actuatorsHigh pressureEnergy consumption

The invention provides a single-acting pneumatic hydraulic intensifier. The single-acting pneumatic hydraulic intensifier comprises an oil cylinder, a pressure cylinder and a pneumatic hydraulic cylinder, all of which are connected in sequence; the oil cylinder is provided with an upper cover, a lower cover and a piston; a pre-pressure cavity is formed between the piston and the upper cover, while an oil storage cavity is formed between the piston and the lower cover; the pressure cylinder is provided with an upper pressurization cover, a lower pressurization cover and a middle pressurization cover; a pressurization piston is arranged between the upper pressurization cover and the middle pressurization cover; a pressurization cavity is formed between the pressurization piston and the upper pressurization cover, while a return cavity is formed between the pressurization piston and the middle pressurization cover; a pressurization oil cavity is formed between the lower pressurization cover; a pressurization rod connected to the pressurization piston extends into the pressurization oil cavity; the pneumatic hydraulic cylinder interior is divided by a working piston into an oil cavity and a gas cavity; the pressurization oil cavity is connected with the oil storage cavity and the oil cavity, respectively. By means of such a solution, fast movement and pressurization are realized by using the pneumatic technology, and high pressure output is realized by means of hydraulic control, and therefore, the gas consumption is low, and so is the energy consumption; the single-acting pneumatic hydraulic intensifier is compact in structure, high in reliability and low in cost, and realizes complete gas-liquid isolation; besides, the working push rod is fast, steady and controllable in motion.

Owner:TIANJIN SHANGJI HYDRAULIC PRESSURE EQUIP

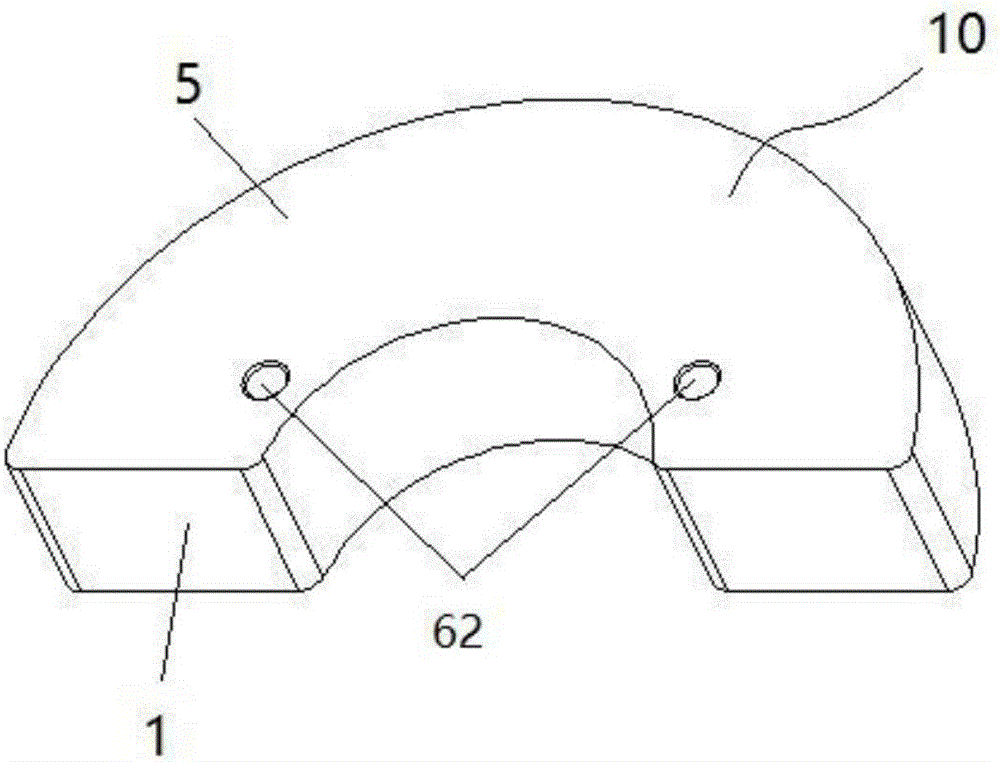

Balance block and rotor assembly, shaft assembly and compressor with balance block

InactiveCN106337812AIncrease centripetal forceOffset eccentricityRotary/oscillating piston pump componentsLiquid fuel engine componentsCentripetal forceEngineering

The invention provides a balance block and a rotor assembly, a shaft assembly and a compressor with the balance block. The balance block comprises a main body (1) and a movable block body (2), wherein the main body (1) is suitable for being installed on a rotatable piece; and the movable block body (2) is connected with the main body (1) through an elastic piece (3). When the rotatable piece rotates, the movable block body (2) can move in the direction that the elastic piece (3) is squeezed or stretched, so that the relative positions of the movable block body (2) and the main body (1) are changed, and then the distance between the center of mass of the balance block (10) and a rotation shaft of the rotatable piece is changed. According to the balance block, under the condition that the mass of the balance block is small, the centripetal force is improved by increasing the distance between the center of mass of the balance block and the rotation shaft of the rotatable piece, and the beneficial technical effects that the eccentric magnitude generated when a crankshaft rotates can be counteracted, and the situation that vibration of the compressor is caused during low-speed rotation due to the large mass of the balance block, and consequently abrasion of the compressor is accelerated is avoided are achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Rest for a snooker cue

InactiveUS7063621B2More controllablePrevent movementIndoor gamesBilliardsEngineeringMechanical engineering

Owner:BARRY MICHAEL ROY

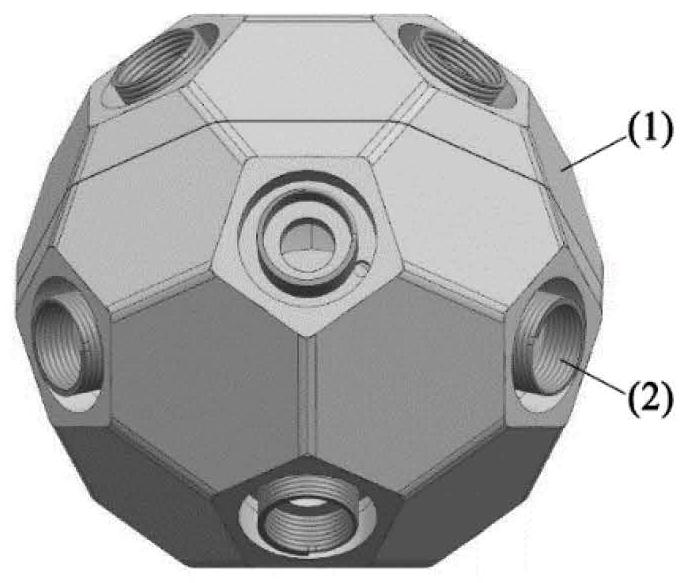

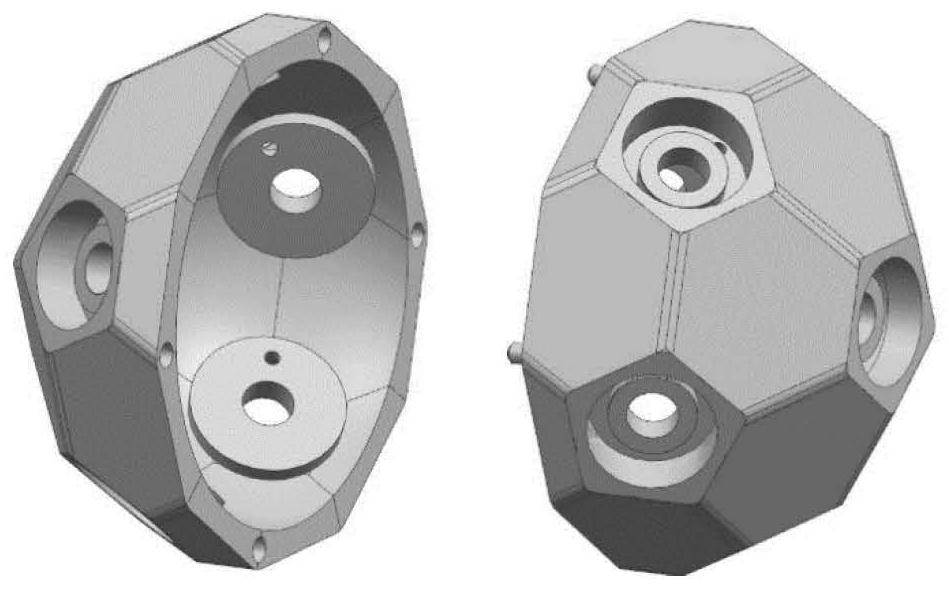

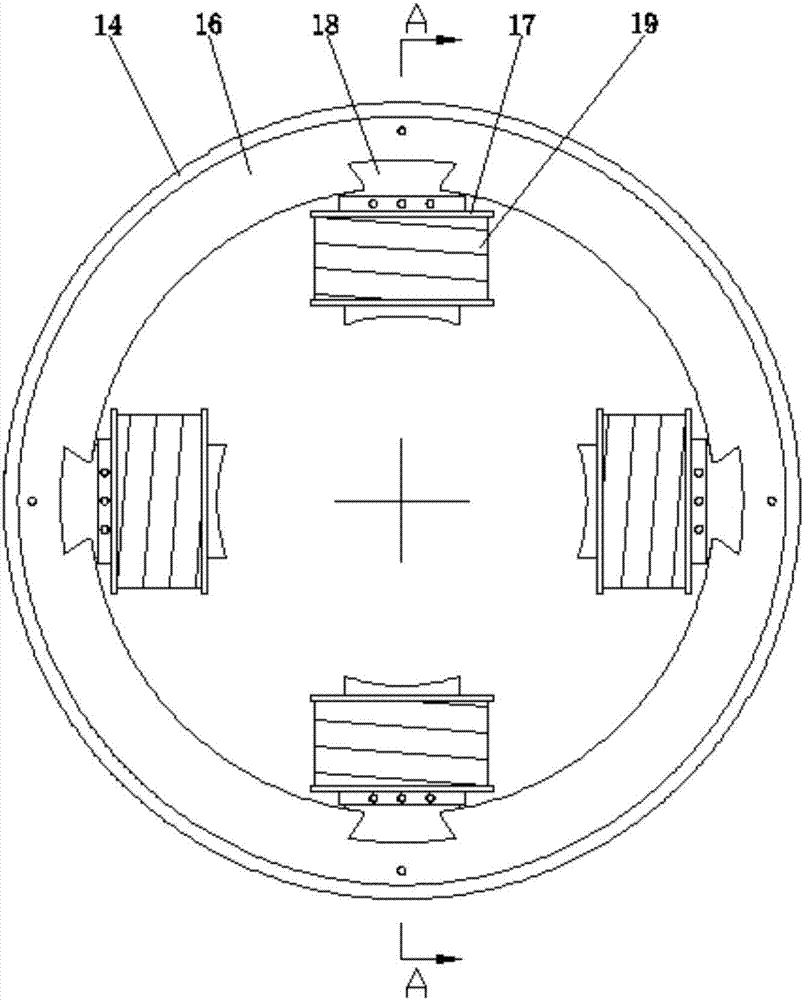

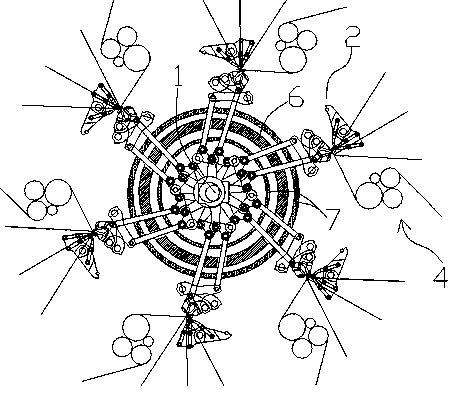

Spherical-like robot

The invention belongs to the field of mobile robots, and particularly discloses a sphere-like robot. The sphere-like robot comprises a sphere-like shell, a driving unit and a control unit, wherein thesphere-like shell is a sphere-like polyhedron composed of a hexagonal supporting surface and a pentagonal driving surface; the driving unit comprises a preset number of driving assemblies, and each driving assembly is installed on the corresponding pentagonal driving face; and the control unit is arranged in the sphere-like shell and used for controlling the driving assembly to stretch out and draw back so as to drive the sphere-like robot to move. According to the spherical-like robot, the control unit is used for controlling the driving unit to stretch out and draw back to drive the spherical-like robot to turn over, linear contact is kept between the spherical-like robot and a motion plane in the motion process, motion is controllable, motion resistance is small, surface contact is kept between the spherical-like robot and the motion plane in the static process, and high static stability is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

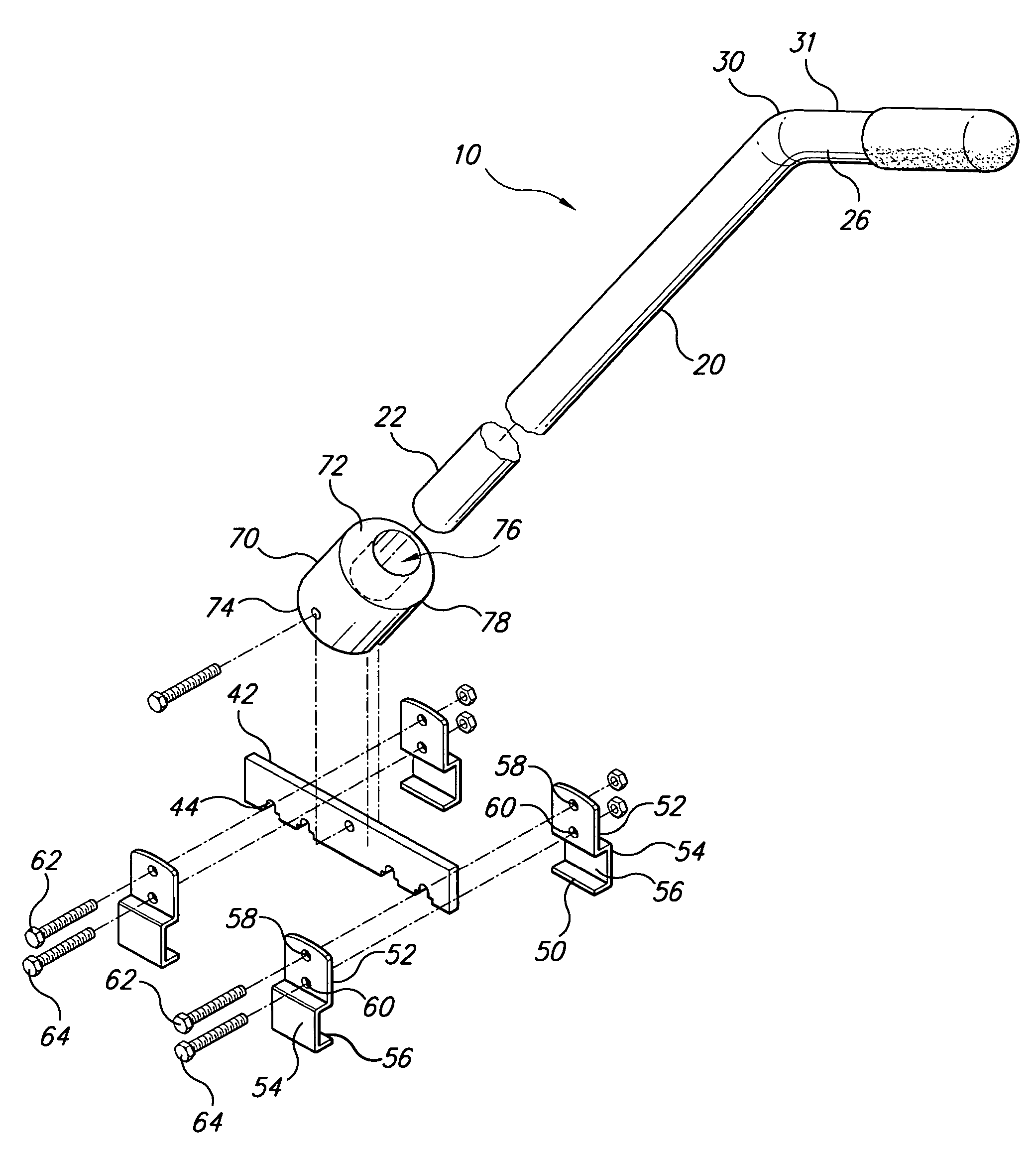

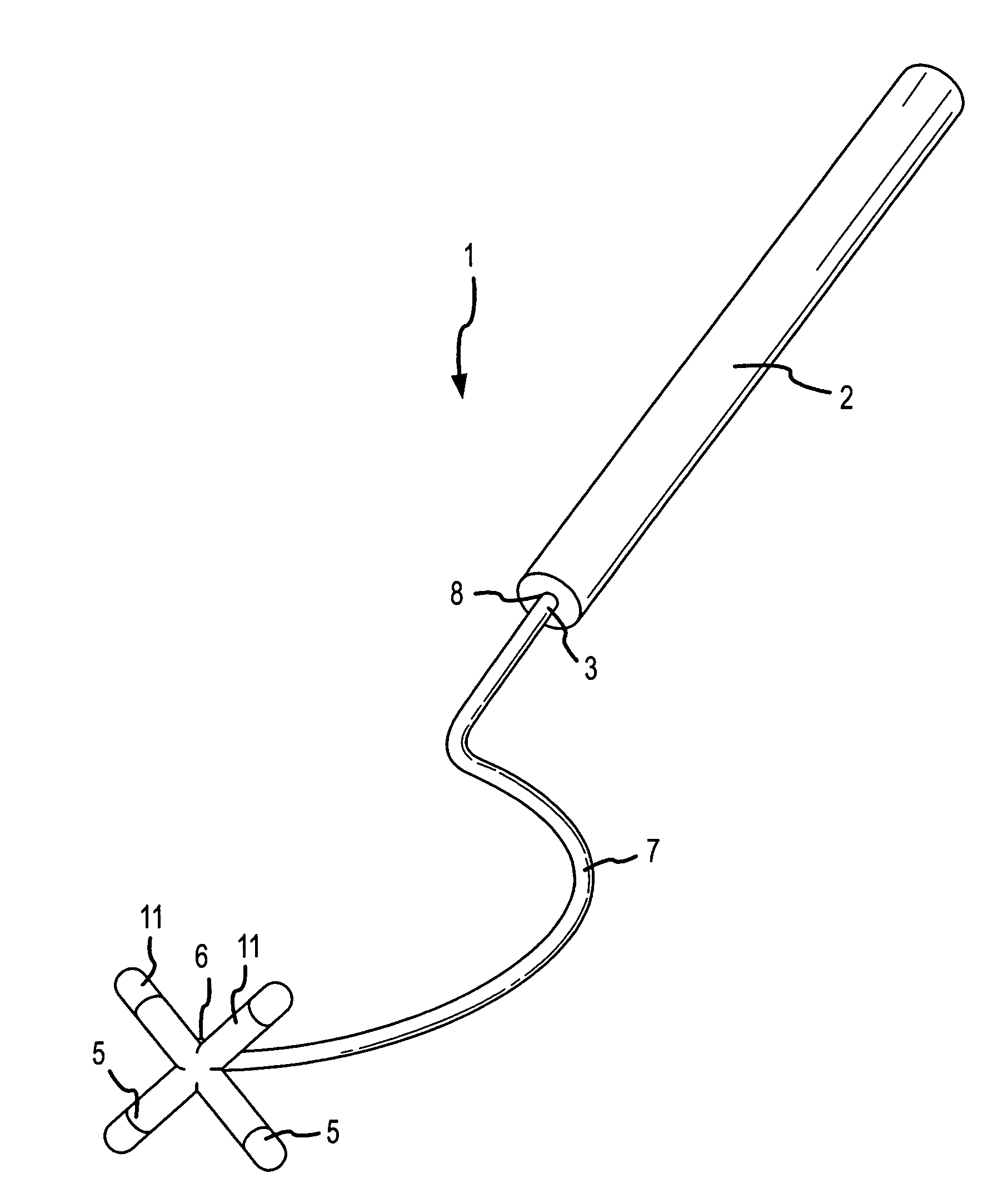

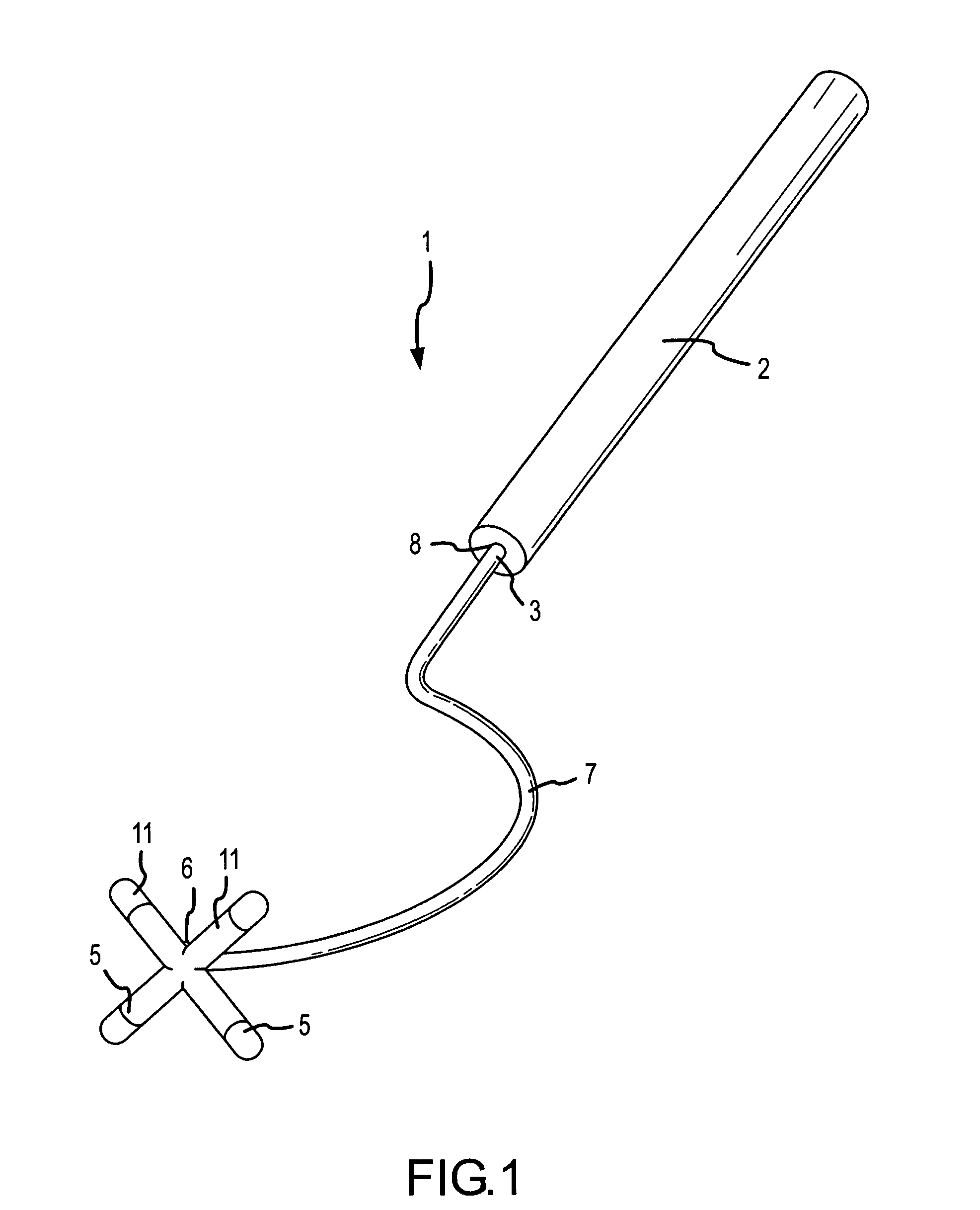

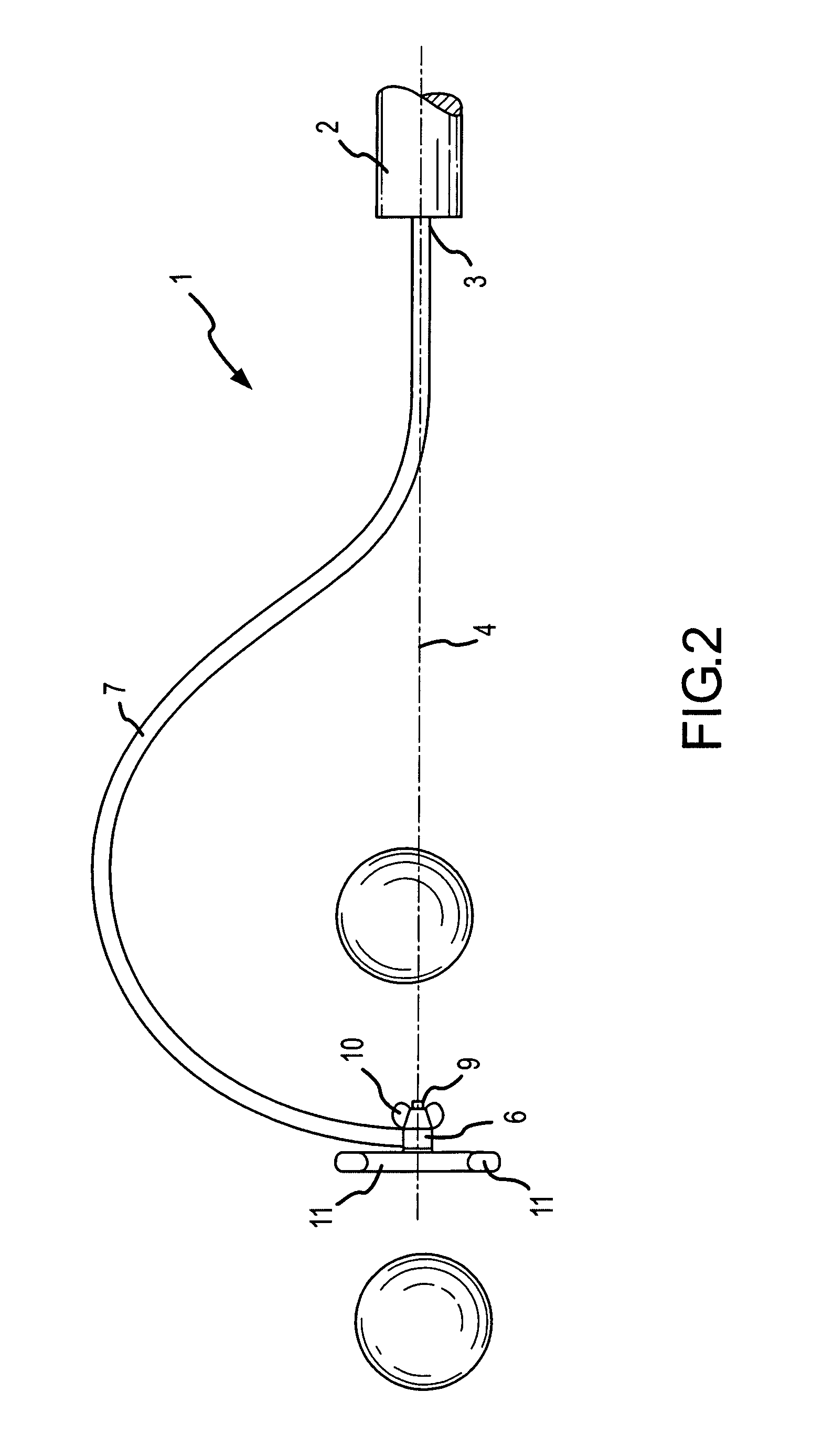

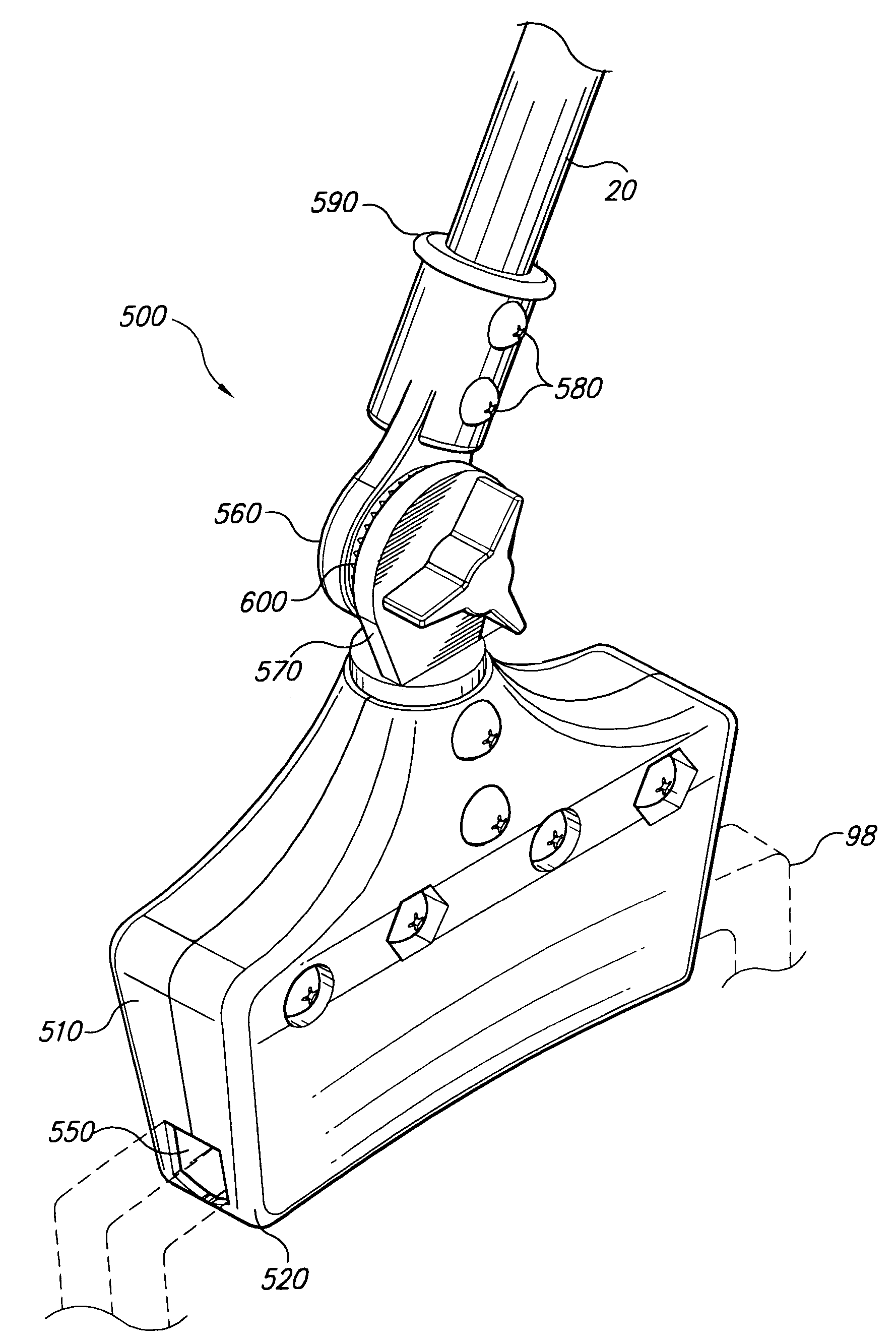

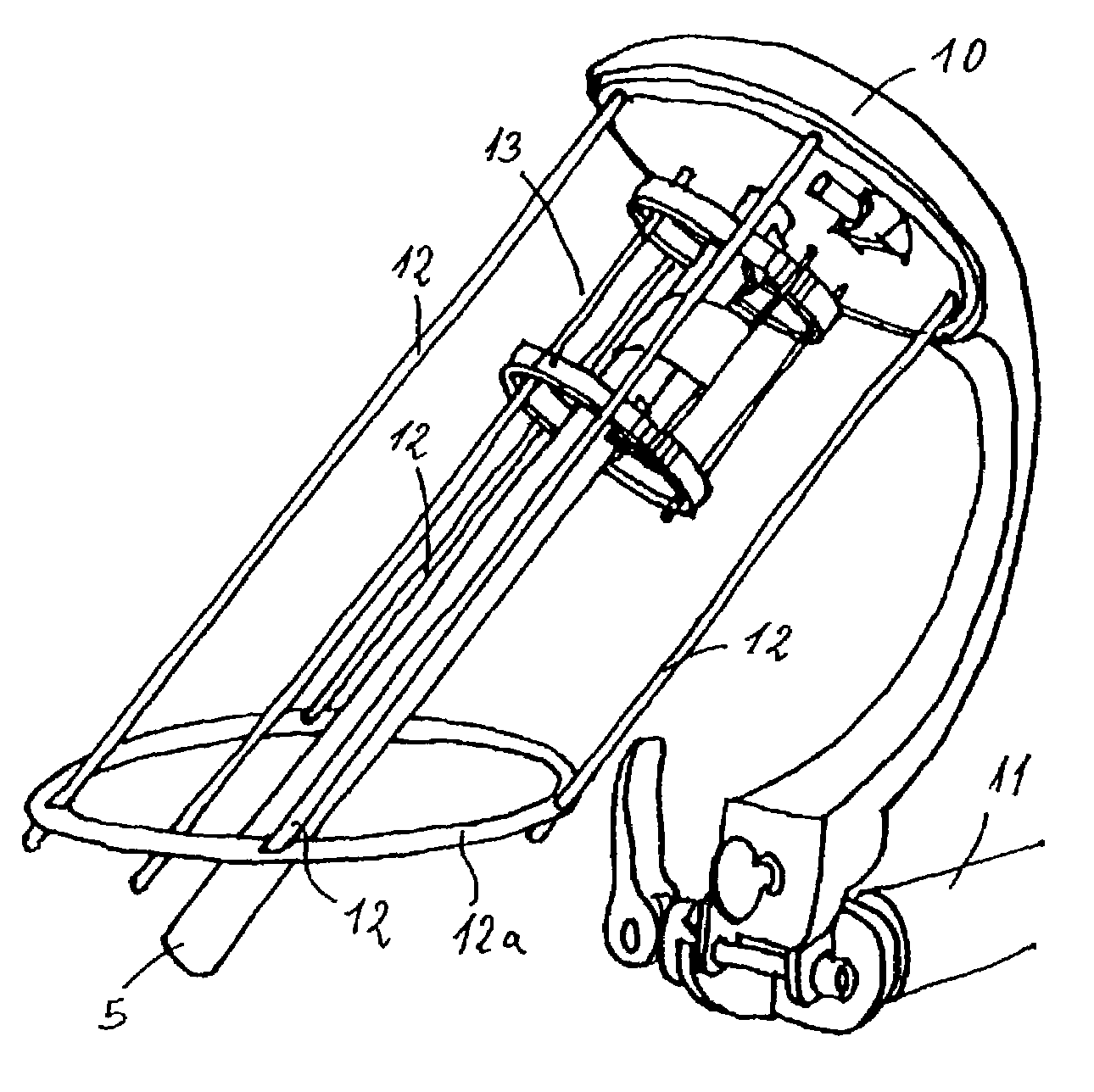

Ergonomic appliance handle

InactiveUS7464440B2Easy to operateEasy to moveTravelling carriersHoldersEngineeringMechanical engineering

The ergonomic appliance handle is an extension handle that is attachable to a carrying or transport handle on a canister style vacuum cleaner or similar floor appliance. The ergonomic appliance handle provides an elongated handle shaft that is attached to the canister vacuum's handle at a proximate end of the handle shaft by a mounting assembly. The handle shaft extends angled upward, away from the vacuum, placing a handgrip at the distal end of the handle shaft at an ergonomically comfortable height and position for a user to easily and conveniently operate the vacuum in a comfortable posture without subjecting the user to unnecessary bending, stooping, or twisting.

Owner:DECKER DEBORAH

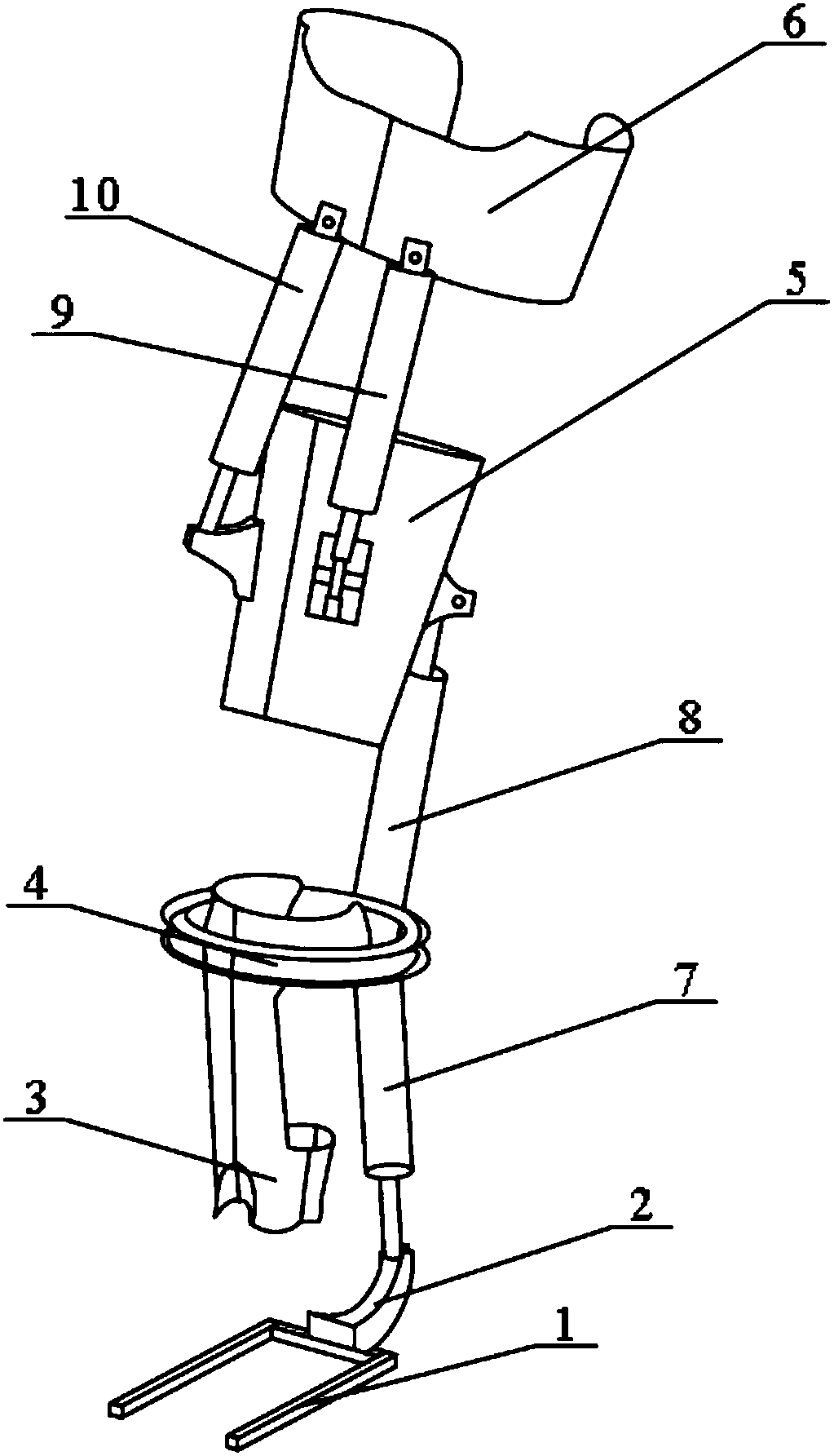

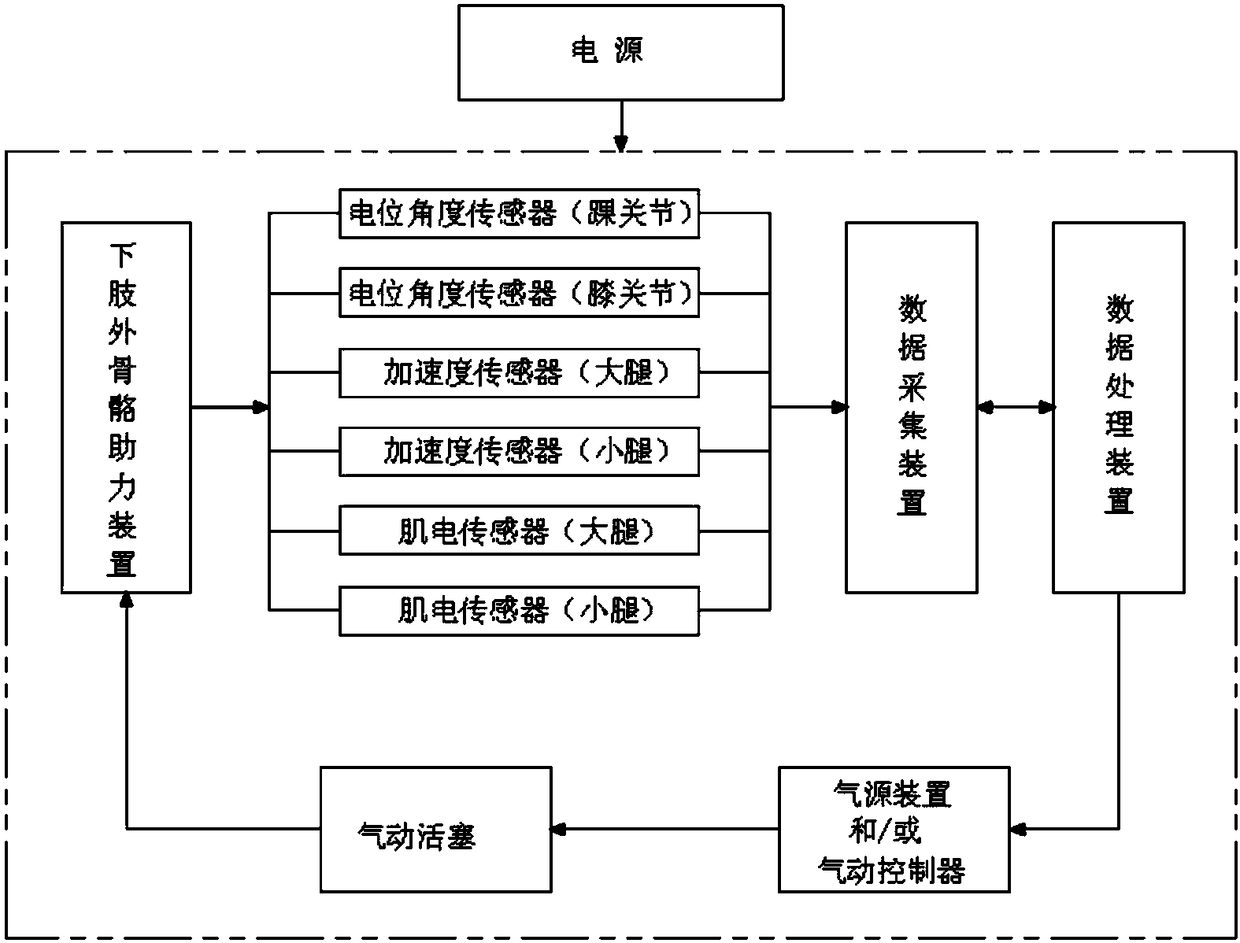

Lower limb exoskeleton power assisting device and control method thereof

PendingCN108098741AAchieving Human Strength and Athletic PerformanceGuaranteed accuracyProgramme-controlled manipulatorPistonExoskeleton

The invention relates to a lower limb exoskeleton power assisting device. The lower limb exoskeleton power assisting device comprises at least one of a left leg power assisting device body and a rightleg power assisting device body. Each leg power assisting device body comprises a pneumatic system, a foot fixing part, a crus connection part, an ankle fixing part, a crus fixing part, a thigh fixing part and a thigh root fixing part, wherein the foot fixing part is fixedly connected with the crus connection part; the crus connection part is movably connected with the crus fixing part through afirst pneumatic piston; the crus fixing part partially downwards extend and is connected with the ankle fixing part; the crus fixing part is movably connected with the thigh fixing part through a second pneumatic piston; and the thigh fixing part is movably connected with the thigh root fixing part through a third pneumatic piston and a fourth pneumatic piston. The invention further relates to a control method of the lower limb exoskeleton power assisting device. The lower limb exoskeleton power assisting device aims to simulate the effect of the human muscle action, a compressed air cylinderis installed at the leg part, the movement intention is read through a precision control sensor, proper assistance is given at the proper time, and improvement of human body strength and exercise performance is achieved.

Owner:水逸阳

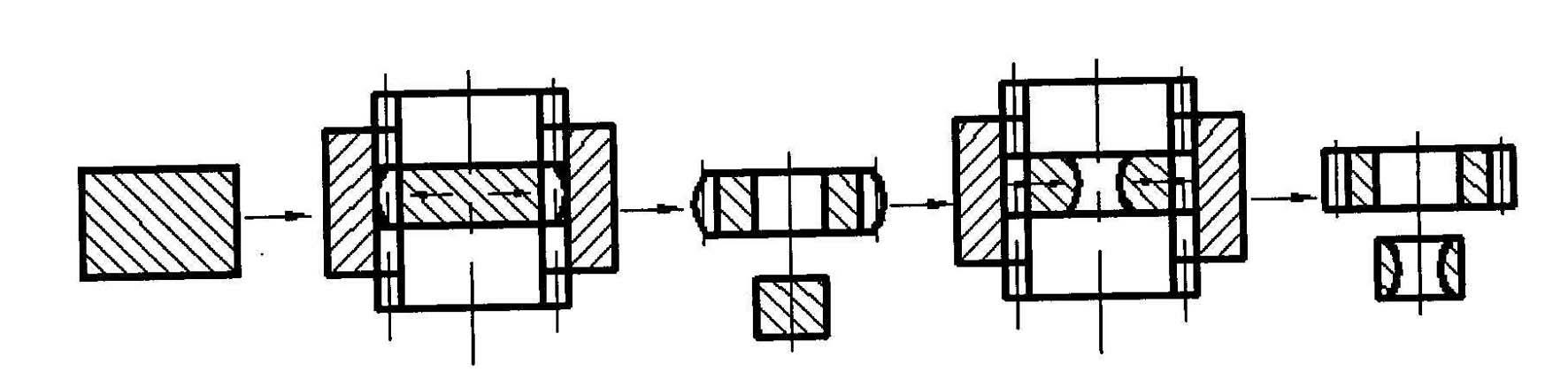

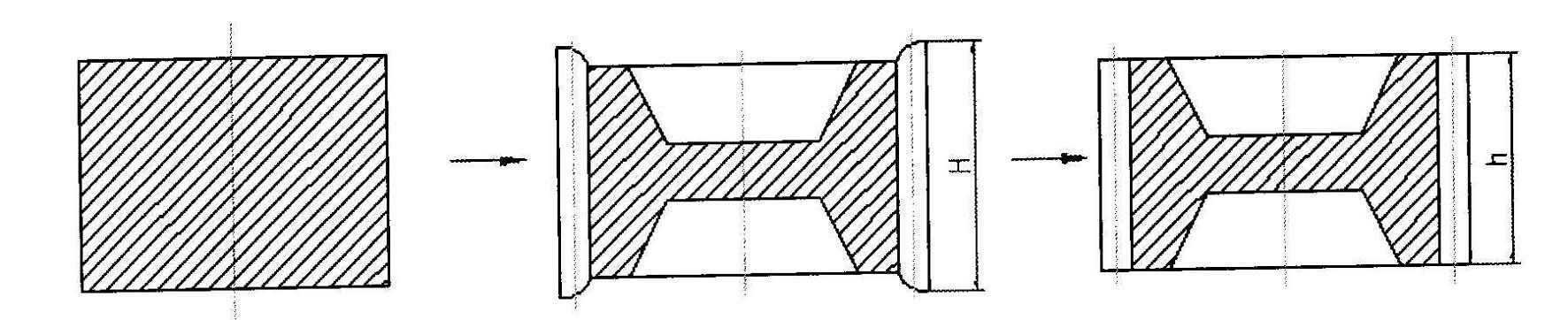

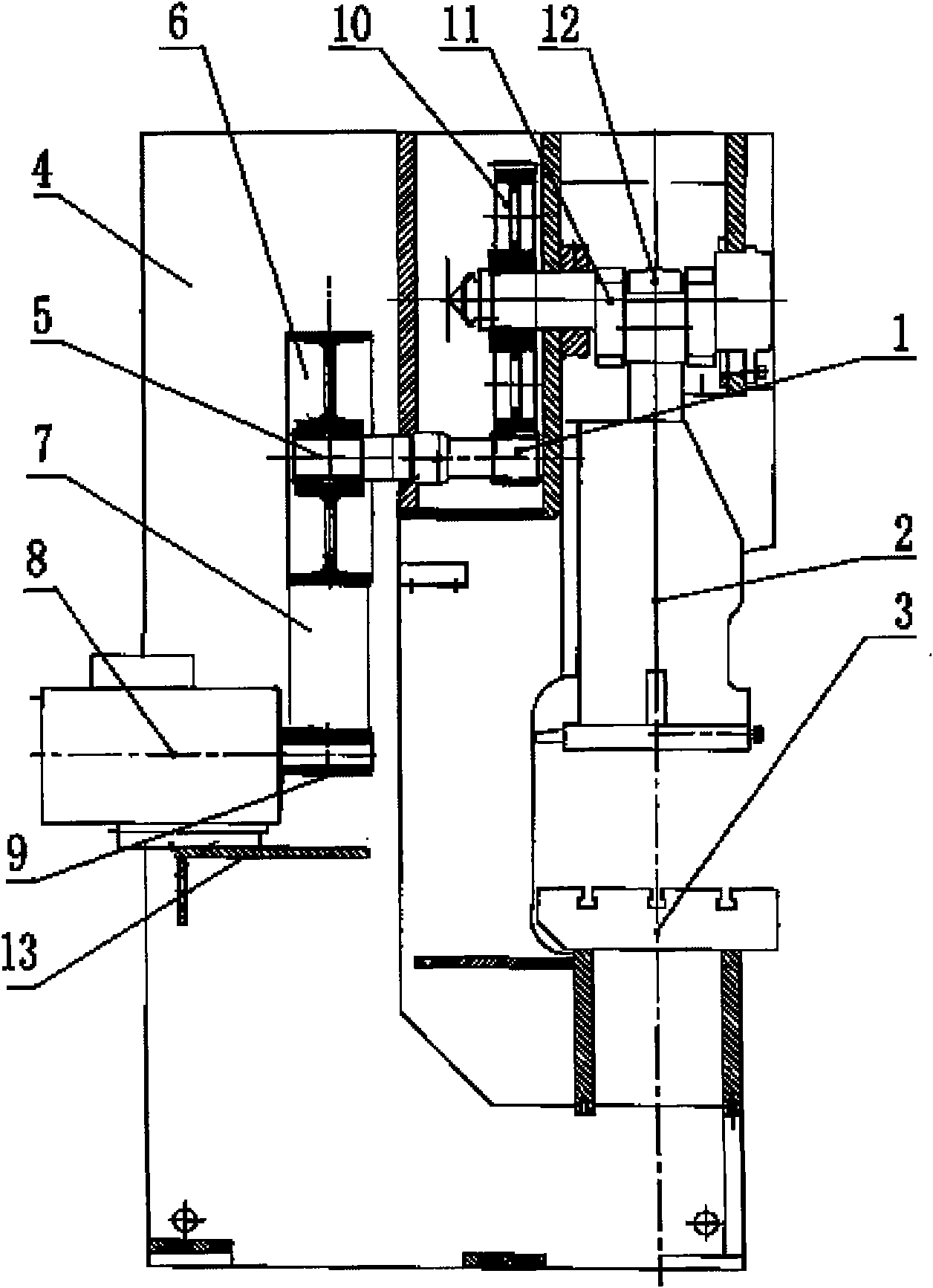

Cold precision forming device for asymmetric cylindrical gear

The invention discloses a cold precision forming device for an asymmetric cylindrical gear. The device comprises a lower die holder which is arranged on a base, a mobile female die which is positioned above the lower die holder, and an upper die holder which is arranged above the mobile female die, wherein a lower built-in oil cylinder and a lower external punching head with a hollow cylindrical structure are sequentially arranged in the lower die holder from bottom to top, and a lower internal punching head is arranged in a hollow cylindrical cavity of the lower external punching head; the mobile female die consists of a movable crossbeam and a forming female die which is arranged in a cavity at an intermediate position of the movable crossbeam, and two ends of the movable crossbeam are respectively combined with oil cylinders which are vertically arranged on two sides of the lower die holder and are used for controlling the vertical displacement of the movable crossbeam; an upper built-in oil cylinder and an upper external punching head with a hollow cylindrical structure are sequentially arranged in the upper die holder from top to bottom, and an upper internal punching head is arranged in a hollow cylindrical cavity of the upper external punching head; and the forming female die, the upper and lower external punching heads, and the upper and lower internal punching heads are arranged in a coaxial mode.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

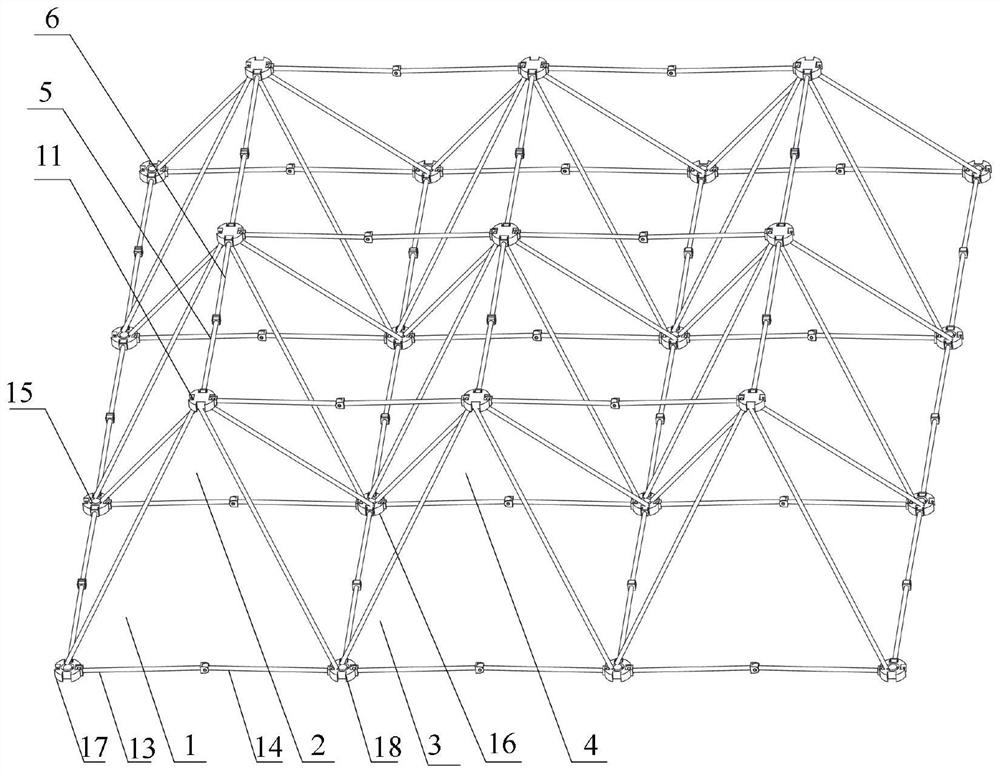

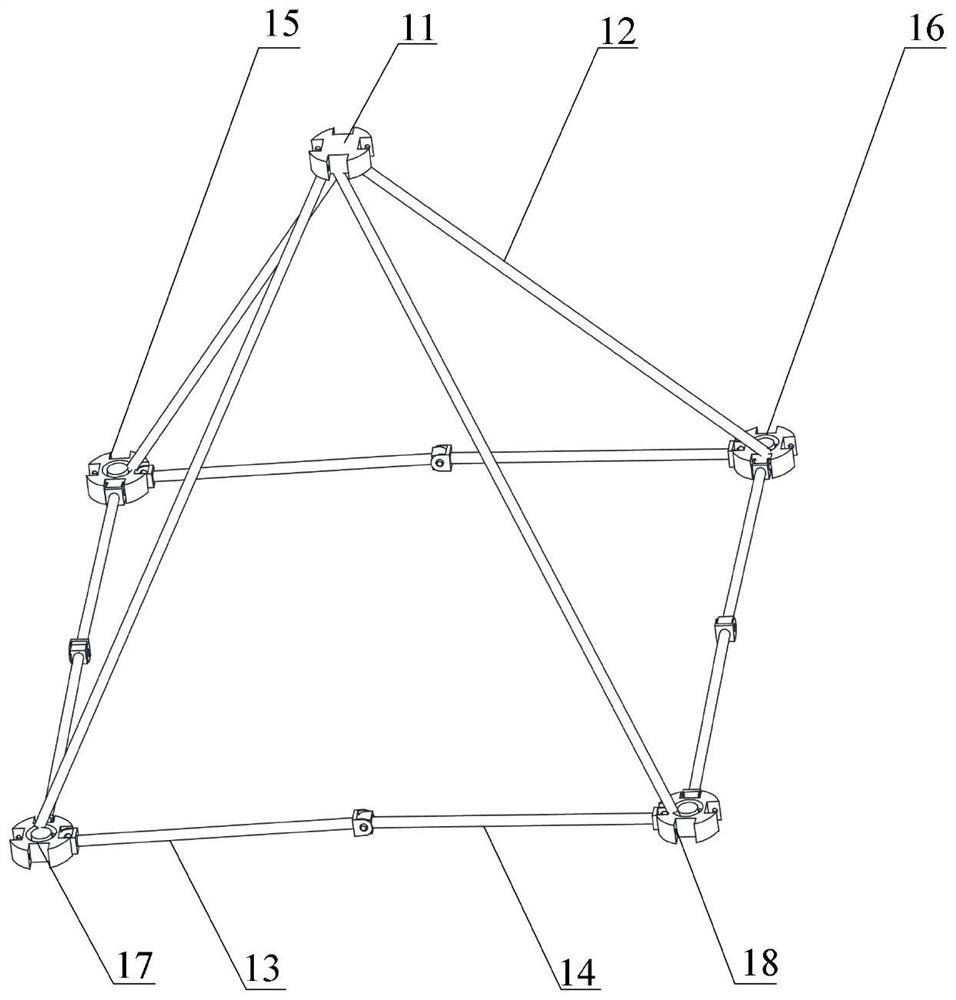

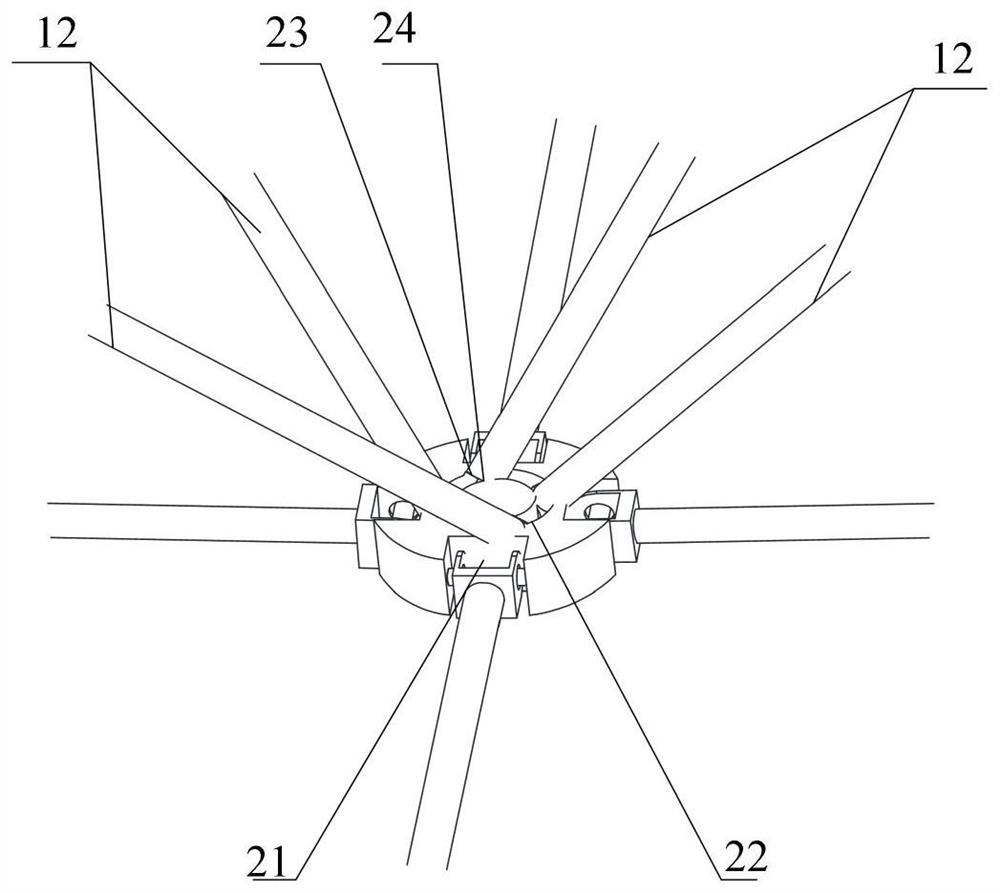

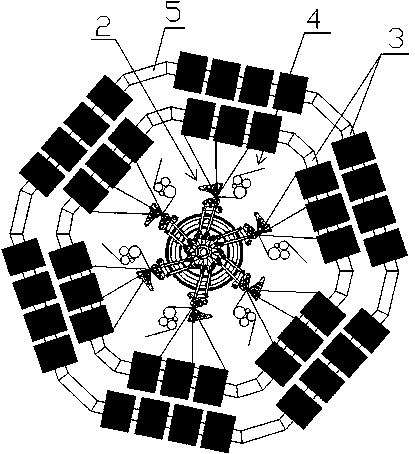

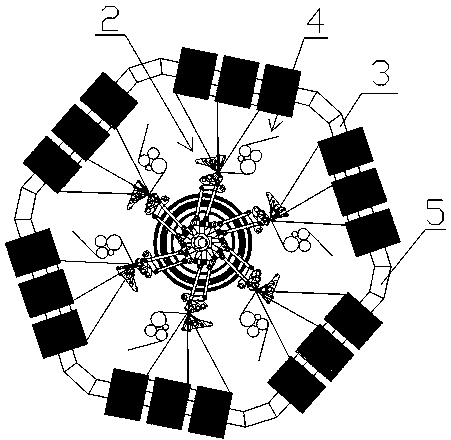

Array type folding and unfolding antenna mechanism based on rectangular pyramid unit

PendingCN114024121ASimple structureControllable movementAntenna supports/mountingsAntenna adaptation in movable bodiesStructural engineeringMechanical engineering

The invention discloses an array type folding and unfolding antenna mechanism based on a rectangular pyramid unit. The rectangular pyramid unit is composed of a top faceplate, a first bottom faceplate, a second bottom faceplate, a third bottom faceplate, a fourth bottom faceplate, four first bottom connecting rods, four second bottom connecting rods and four web members. According to the mechanism, a plurality of groups of tightly connected array type folding and unfolding antenna mechanisms are vertically and transversely combined in an array form, and every two top faceplates of the rectangular pyramid units after an array is formed are connected through a top end first connecting rod and a top end second connecting rod. According to the array type folding and unfolding antenna mechanism, by adding driving at a rotating pair, the faceplates are tightly leaned against one another, the shape of the faceplates is regular, and the faceplates are consistent in posture and are located in the same plane. The array type folding and unfolding antenna mechanism based on the rectangular pyramid unit has the comprehensive advantages of being high in rigidity, high in folding rate, high in supporting performance, adjustable in aperture size and the like.

Owner:JIANGSU UNIV OF SCI & TECH

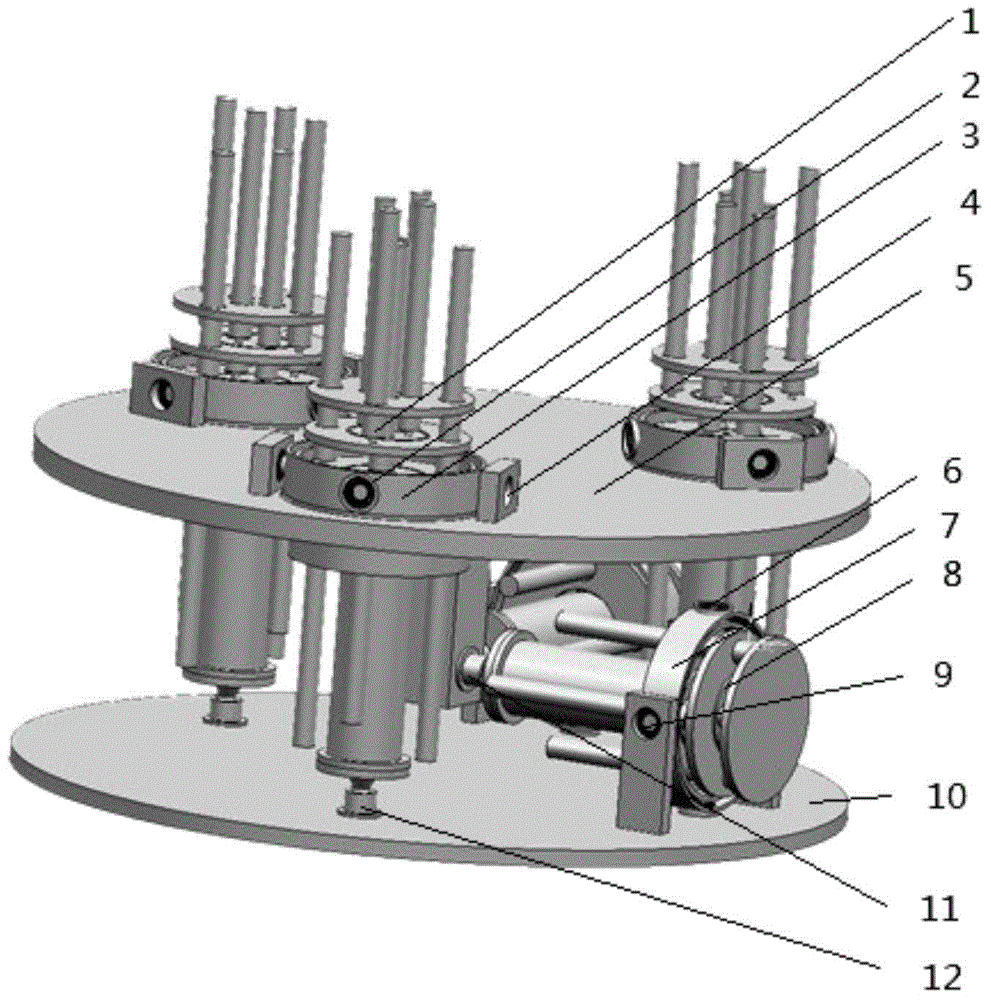

Five-freedom-degree auxiliary lens adjusting mechanism of astronomical telescope working in extreme environment

InactiveCN104090359AEasy to calculateControllable movementTelescopesElectric machineryDegrees of freedom

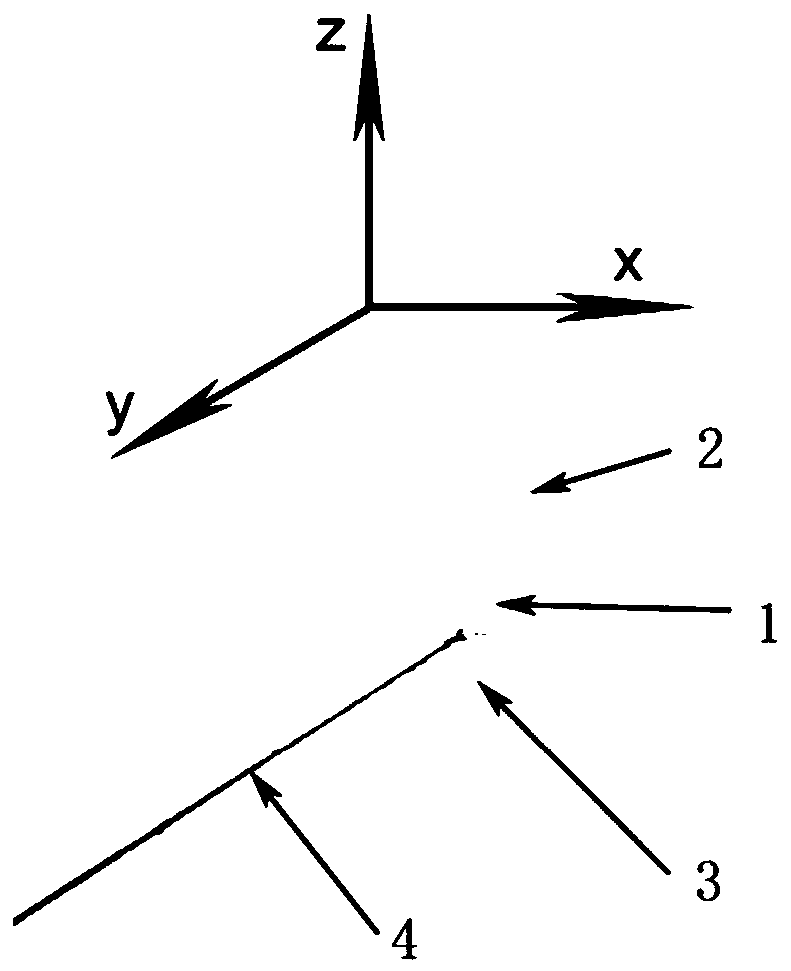

A five-freedom-degree auxiliary lens adjusting mechanism of an astronomical telescope working in an extreme environment is arranged between a telescope machine frame and an auxiliary lens of the telescope. The auxiliary lens adjusting mechanism is characterized by being provided with a five-dimensional parallel movement mechanism with three translation freedom degrees and two rotation freedom degrees and comprising a static platform, a dynamic platform, a first piezoelectric ceramic driving rod, a second piezoelectric ceramic driving rod, a third piezoelectric ceramic driving rod, a fourth piezoelectric ceramic driving rod and a fifth piezoelectric ceramic driving rod. The two ends of the five sets of piezoelectric ceramic driving rods are connected with the static platform and the dynamic platform respectively. Translation along a z axis and rotation around an x axis and a y axis can be generated through movement of the first piezoelectric ceramic driving rod, the second piezoelectric ceramic driving rod and the third piezoelectric ceramic driving rod, and translation along the x axis and the y axis can be generated through movement of the fourth piezoelectric ceramic driving rod and the fifth piezoelectric ceramic driving rod. The auxiliary lens adjusting mechanism can support work of the astronomical telescope working in the extreme environment and has the advantages that the driving mechanism is made of piezoelectric ceramics, so that the problem of a motor caused in the extreme environment is solved. No transmission mechanism is adopted in the whole set of mechanism, therefore, movement precision is improved, large lateral load can be borne, movement interference is eliminated, and control is convenient.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Ergonomic appliance handle

InactiveUS20060042047A1Easily and conveniently operateEasy to operateTravelling carriersHoldersEngineeringMechanical engineering

The ergonomic appliance handle is an extension handle that is attachable to a carrying or transport handle on a canister style vacuum cleaner or similar floor appliance. The ergonomic appliance handle provides an elongated handle shaft that is attached to the canister vacuum's handle at a proximate end of the handle shaft by a mounting assembly. The handle shaft extends angled upward, away from the vacuum, placing a handgrip at the distal end of the handle shaft at an ergonomically comfortable height and position for a user to easily and conveniently operate the vacuum in a comfortable posture without subjecting the user to unnecessary bending, stooping, or twisting.

Owner:DECKER DEBORAH

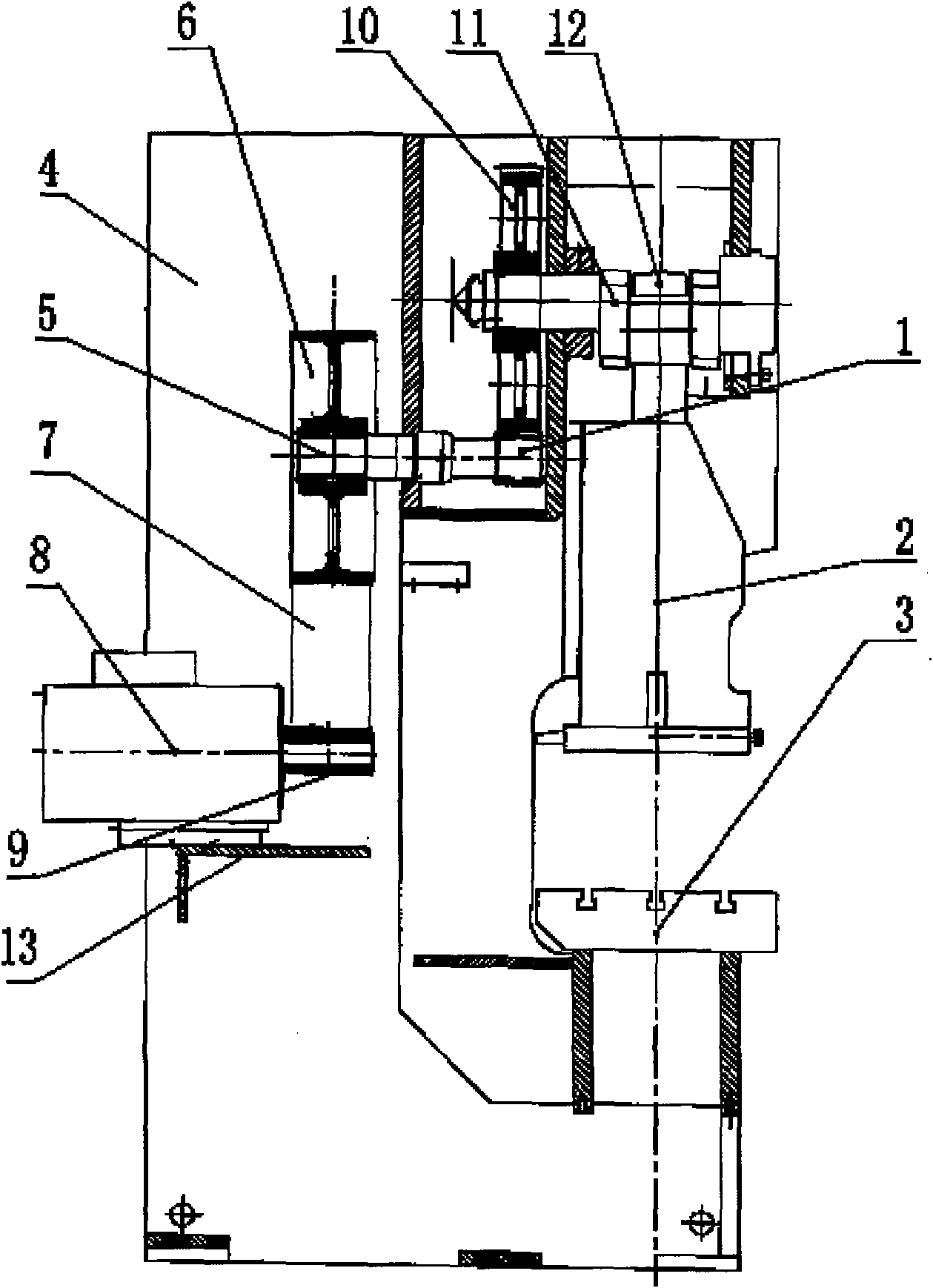

Automatic servo driving press machine

InactiveCN101837647APrecisely control where you areAchieve speed controlPress ramDrive wheelGear wheel

The invention relates to an automatic servo driving press machine, which comprises that: a sliding block is arranged above a worktable of the press machine, is connected with a connecting rod and can slide vertically; the other end of the connecting rod is hinged to a crankshaft; the crankshaft is connected with a driven gear supported on a frame; the driven gear is externally meshed with a driving gear; the center of the driving gear is fixed with a gear shaft; a shaft end of the gear shaft is provided with a driven wheel; a rear opening gear of the frame is provided with a motor base; a servo motor is arranged on the motor base; a shaft end of the servo motor is provided with a driving wheel; and the driving wheel and the driven wheel are connected by a synchronous belt. In working time, the servo motor rotates, a torque is transmitted to the gear shaft through the transmission of the driving wheel, the synchronous belt and the driven wheel, the gear shaft further drives the driving gear, the driven gear and the crankshaft to rotate, and the crankshaft drives the sliding block to move up and down when rotating. Relative sliding does not exist among the driving wheel, the synchronous belt and the driven wheel, so the position of the sliding block and an angle over which a rotor of the servo motor rotates correspond to each other.

Owner:杨茂召

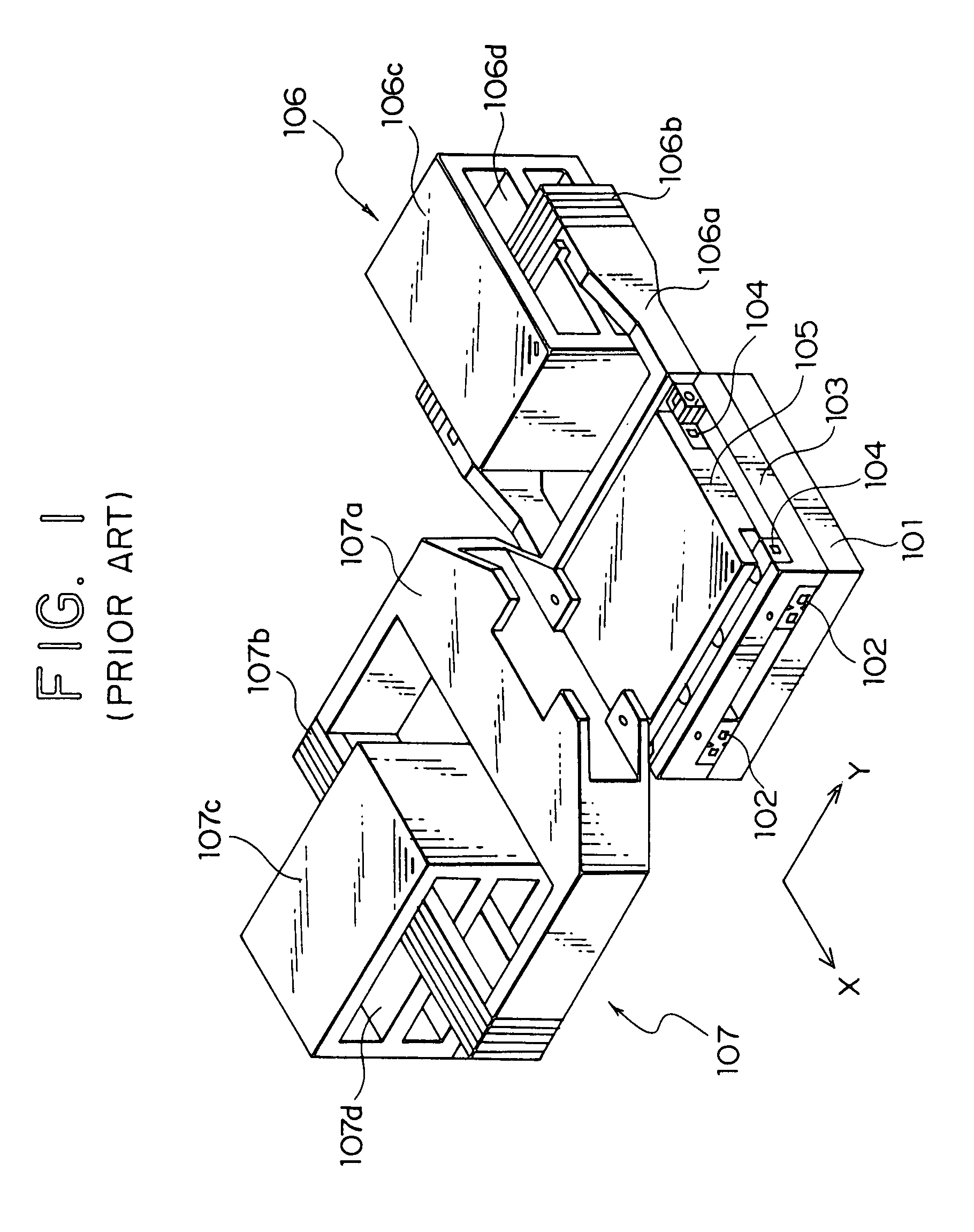

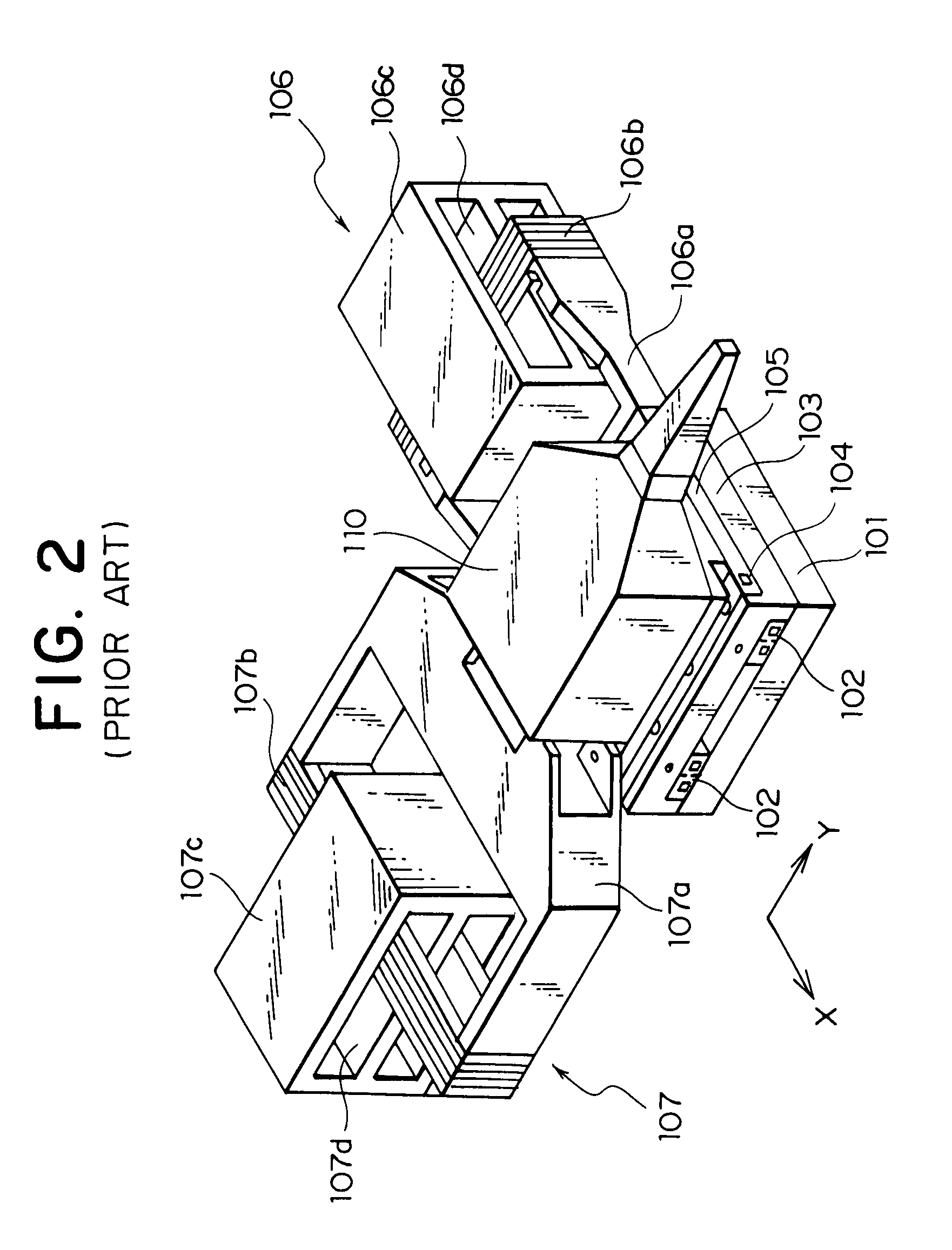

XY stage

InactiveUS7654207B1Sufficiently suppressEasy to move and controlAutomatic control devicesSolid-state devicesLinear motorGravitation

An XY stage comprises a base, a movable table which is disposed on the base so as to be movable in an X direction and a Y direction in an X-Y plane, and a work member which is provided on the movable table. The XY stage further comprises: a first linear motor for giving a driving force in the X direction to the movable table at the same height as the center of gravity of a movable section composed of the movable table and the work member; and a second linear motor for giving a driving force in the Y direction to the movable table at the same height as the center of gravity of the movable section.

Owner:NEC CORP

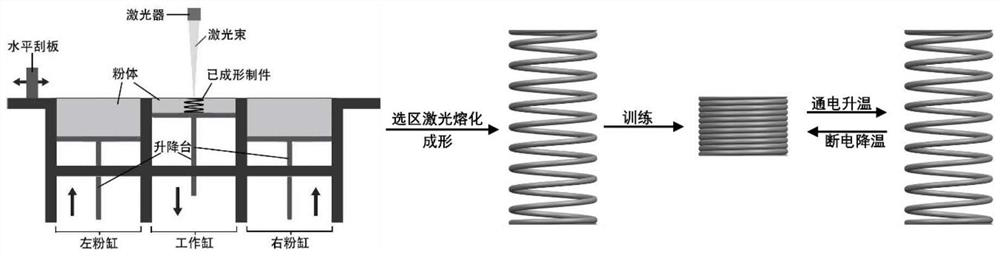

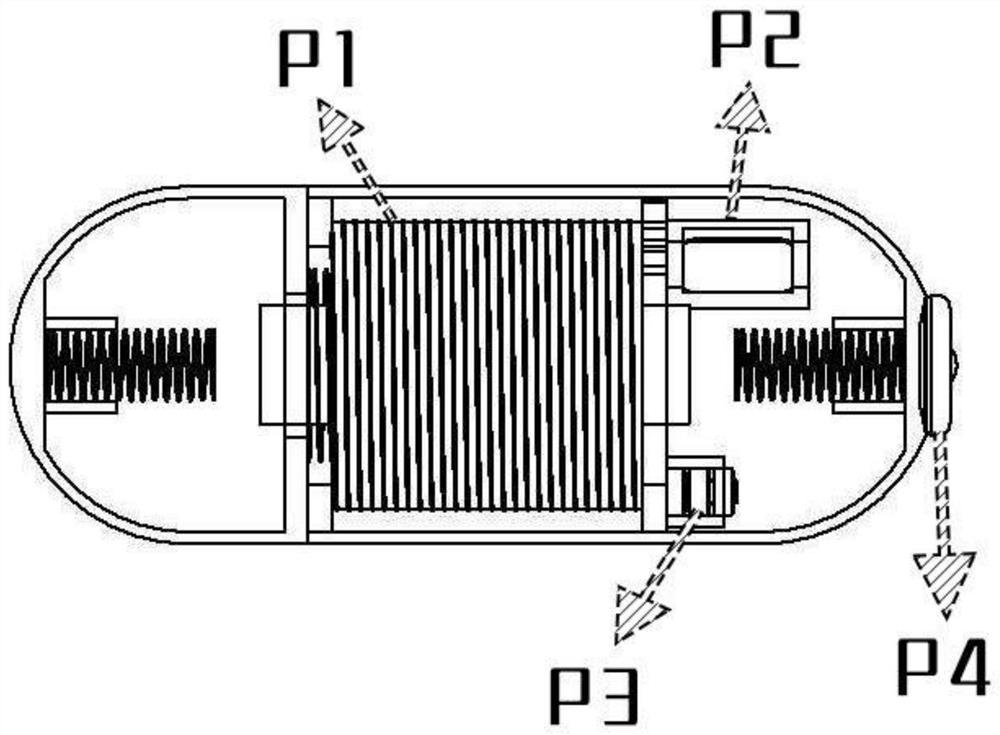

Self-propelled wireless detection capsule endoscope system

ActiveCN111938554AMobilityControllable movementGastroscopesOesophagoscopesMechanical engineeringWireless connectivity

The invention discloses a self-propelled wireless detection capsule endoscope system. The self-propelled wireless detection capsule endoscope system comprises a capsule body and a controller, whereinthe capsule body comprises a capsule shell; one end of the capsule shell is provided with a camera, the inner walls of the two ends of the capsule shell are each fixedly provided with a spring, and the two springs are oppositely distributed in the axial direction of the capsule shell; a shock excitation impact structure, an energy supply module and a microprocessor are further arranged in the capsule shell; the shock excitation impact structure is arranged between the two springs and comprises a solenoid coil and a shock excitation body; and the camera, the solenoid coil and the energy supplymodule are electrically connected with the microprocessor. The controller is wirelessly connected with the microprocessor. The microprocessor, the energy supply module and the solenoid coil are all fixed to the inner wall of the capsule shell, and the shock excitation body is inserted into the solenoid coil. The capsule endoscope system has the outstanding characteristics of being simple in structure and controllable in motion, and can be widely applied as a new generation of endoscope for digestive tract detection.

Owner:UNIV OF SCI & TECH BEIJING

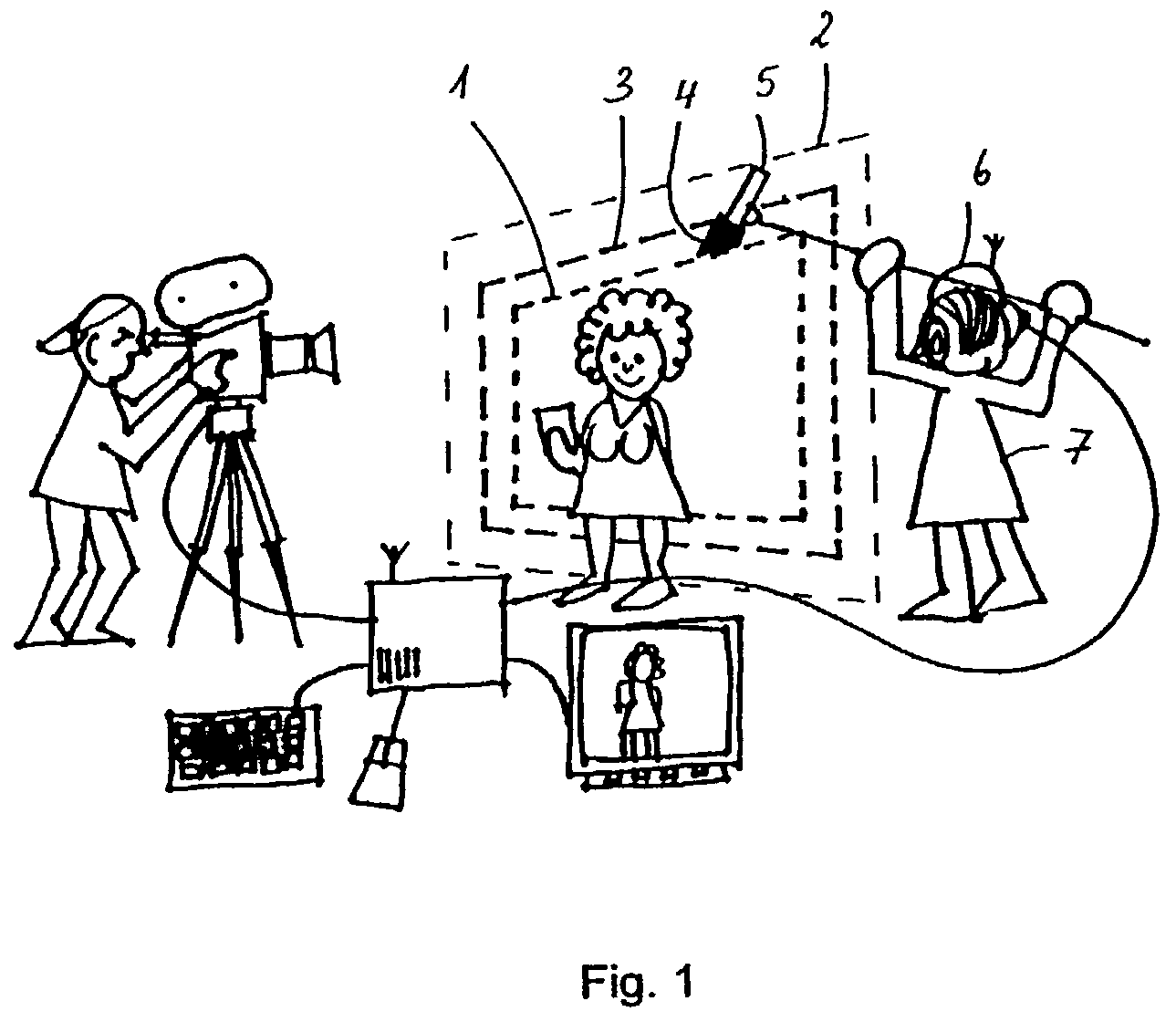

Suspension for microphones

InactiveUS7251340B2Controllable movementReduce wind effectPiezoelectric/electrostrictive microphonesTelevision system detailsEngineeringCantilever

A microphone suspension, particularly for absorbing the vibrations from a boom. The microphone suspension has a base member pivotable mounted to the boom. Bars extend substantially perpendicular to the base member and are adapted to hold an internal microphone holder by first elastic members. An oval ring-shaped member interconnects the bars in the ends opposite to the base member. At least one microphone can be suspended in the internal holder.

Owner:JAN JUHLER +1

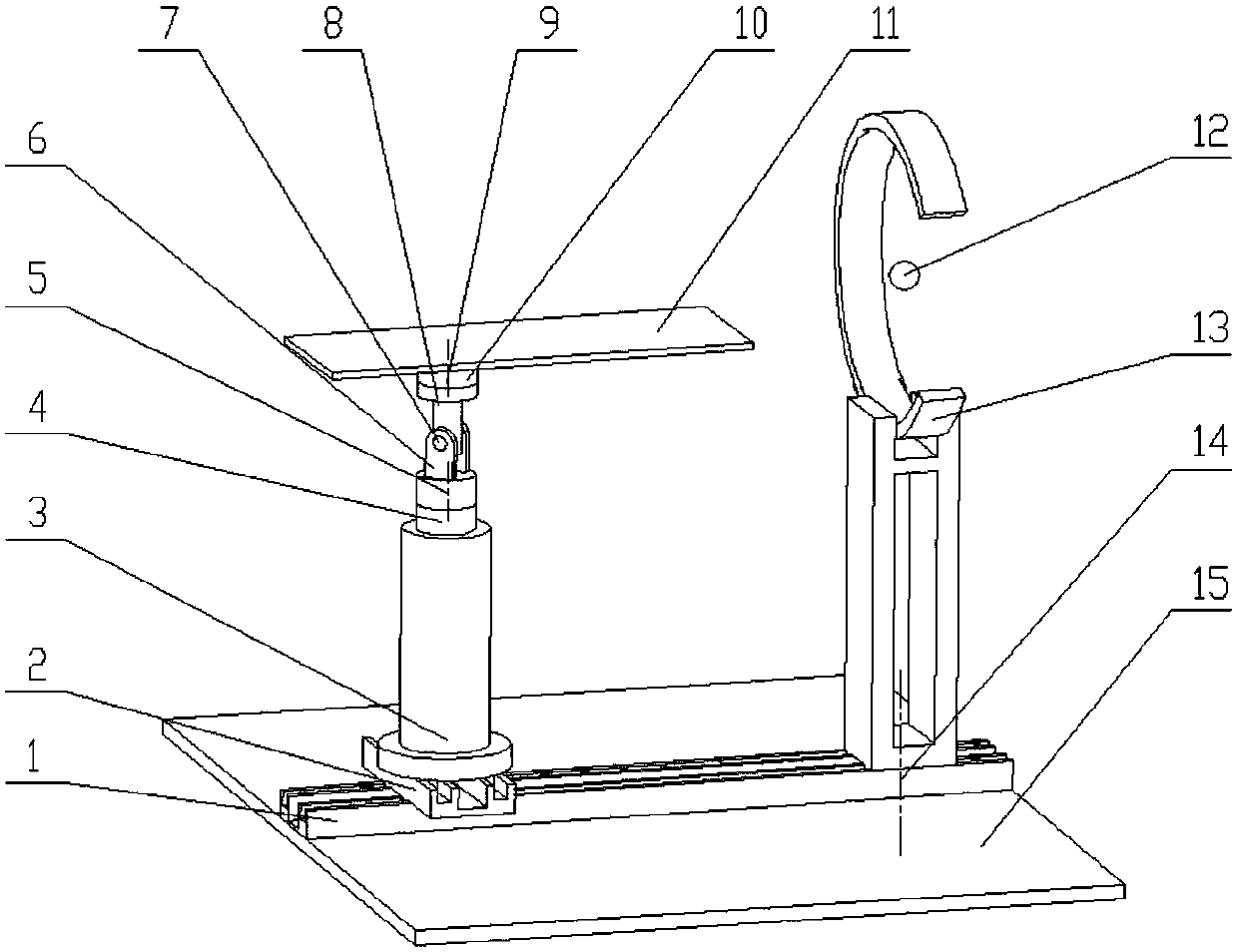

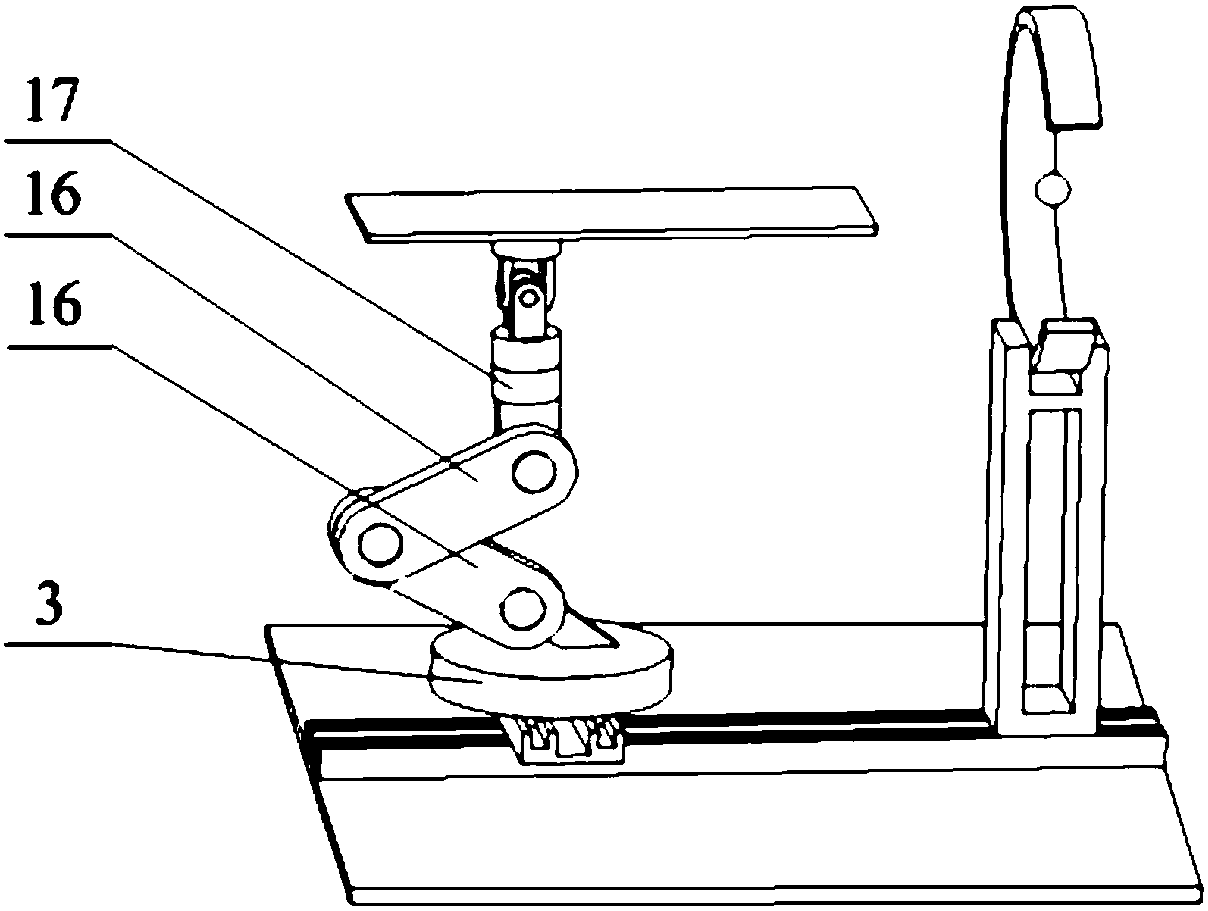

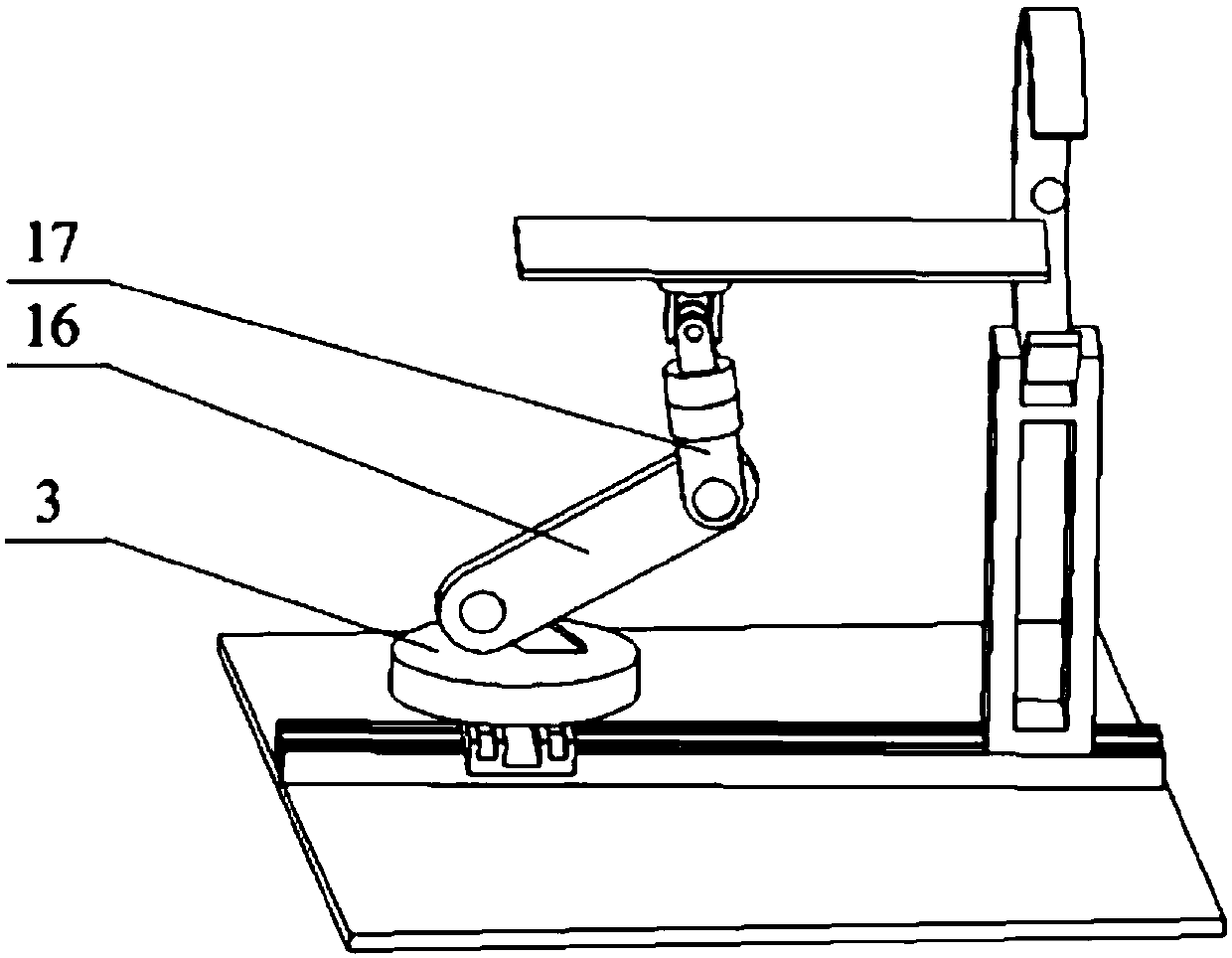

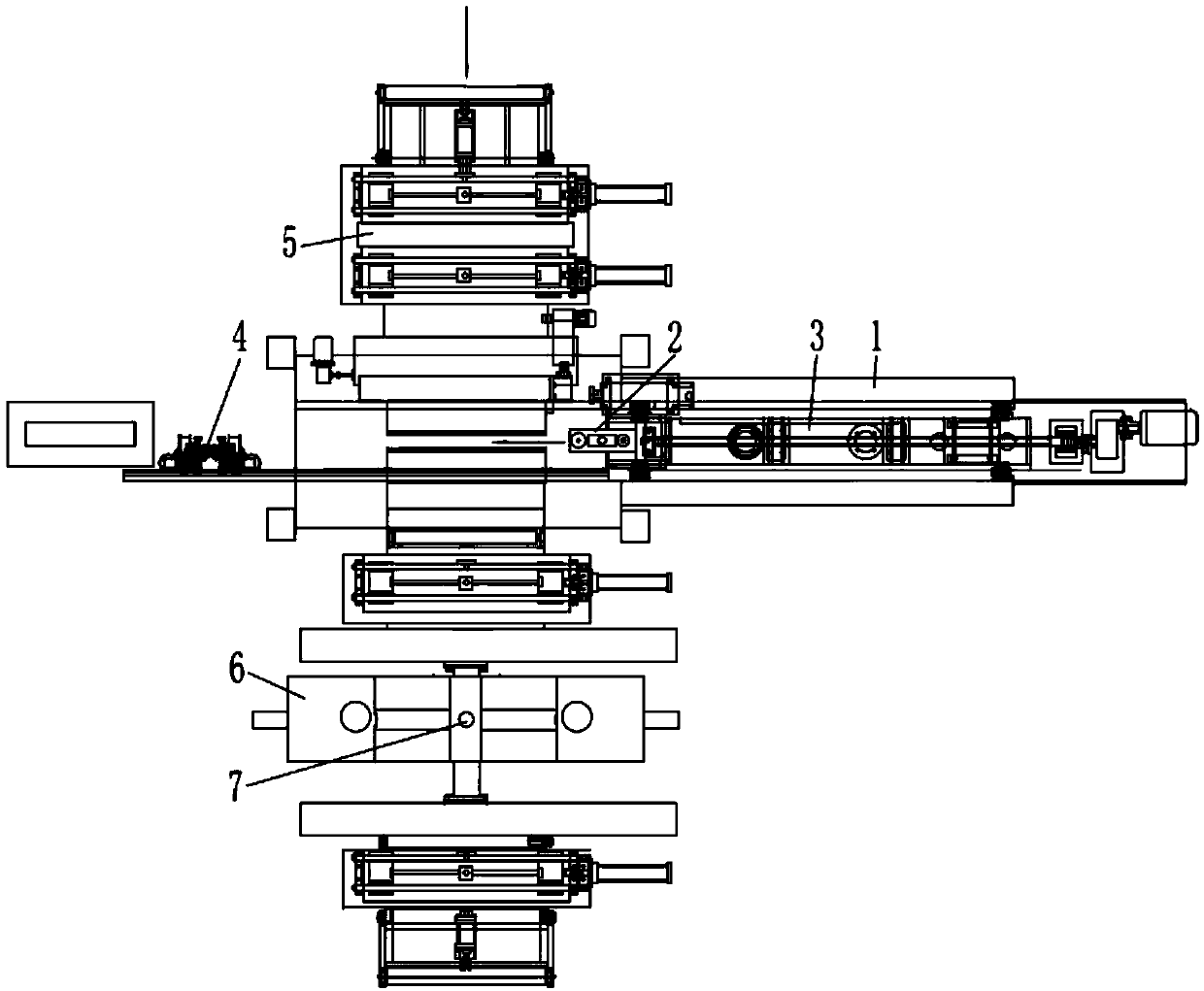

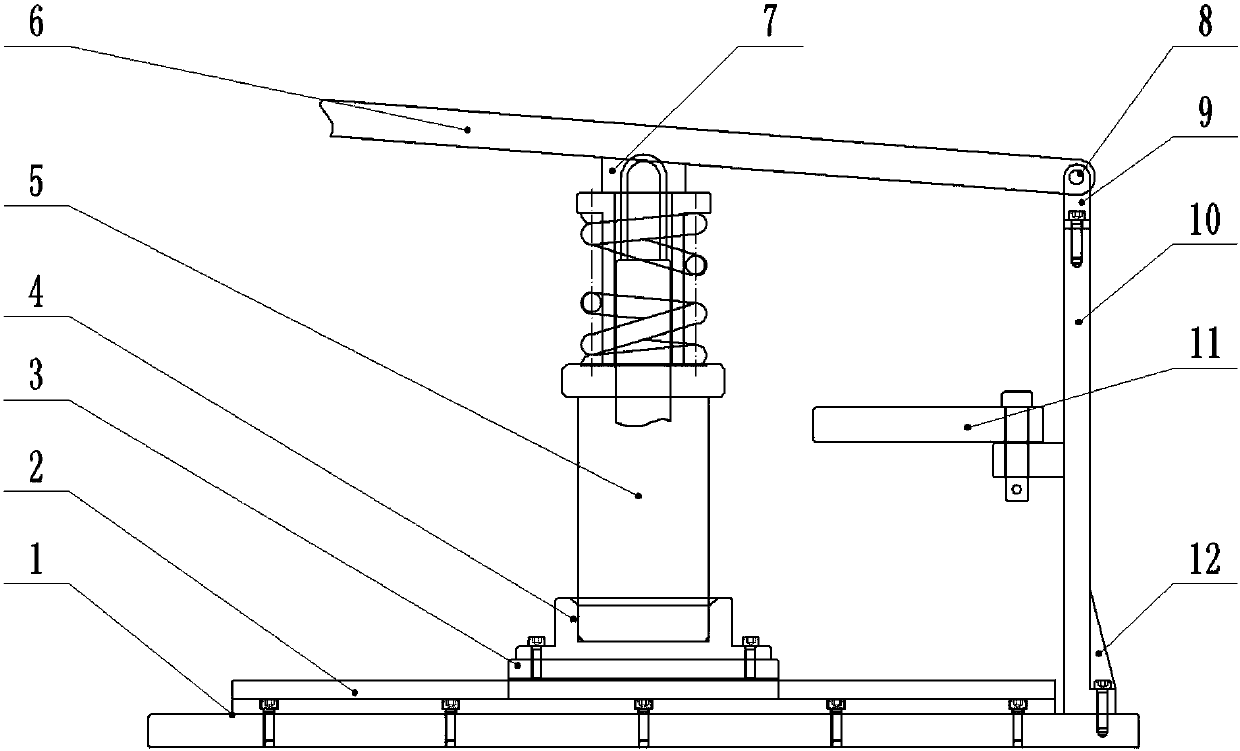

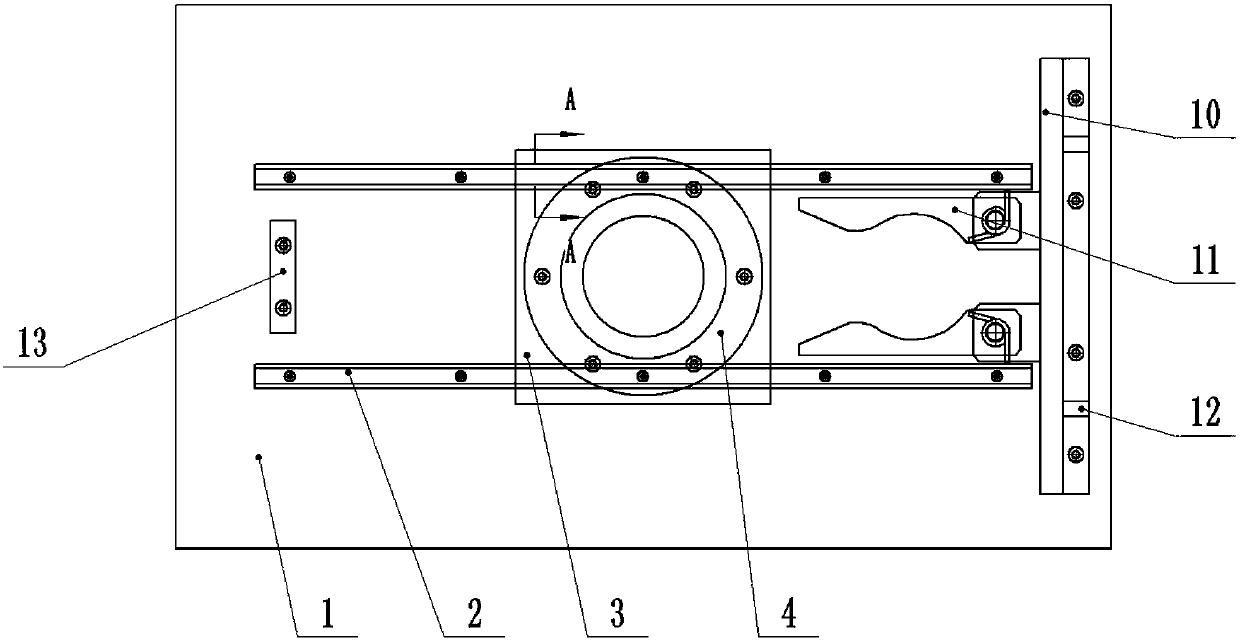

Treatment bed transfer device

PendingCN107617168ADifficulty of simplifying structure and controlSimple motion controlX-ray/gamma-ray/particle-irradiation therapyEngineeringMechanical engineering

The invention discloses a treatment bed transfer device. The device comprises a first guide rail (1) and a second guide rail (2), wherein the first guide rail (1) and the second guide rail (2) are fixed at an angle to an imaging device (13). The first guide rail (1) is arranged on the ground (15). The second guide rail (2) is arranged on the first guide rail (1) and can move along the first guiderail (1). An axial angle is between the first guide rail (1) and the second guide rail (2). The treatment bed transfer device further comprises a lifting assembly which is arranged on the second guiderail (2) and can move along the second guide rail, and an adjusting assembly which is arranged on the lifting assembly to adjust the posture of a treatment bed. A bed plate (11) is arranged on the upper end of the adjusting assembly. The problems of complex motion control of the treatment bed transfer device during a radiotherapy process and the like are effectively solved.

Owner:RADIATION THERAPY MEDICAL SCI & TECH CO LTD

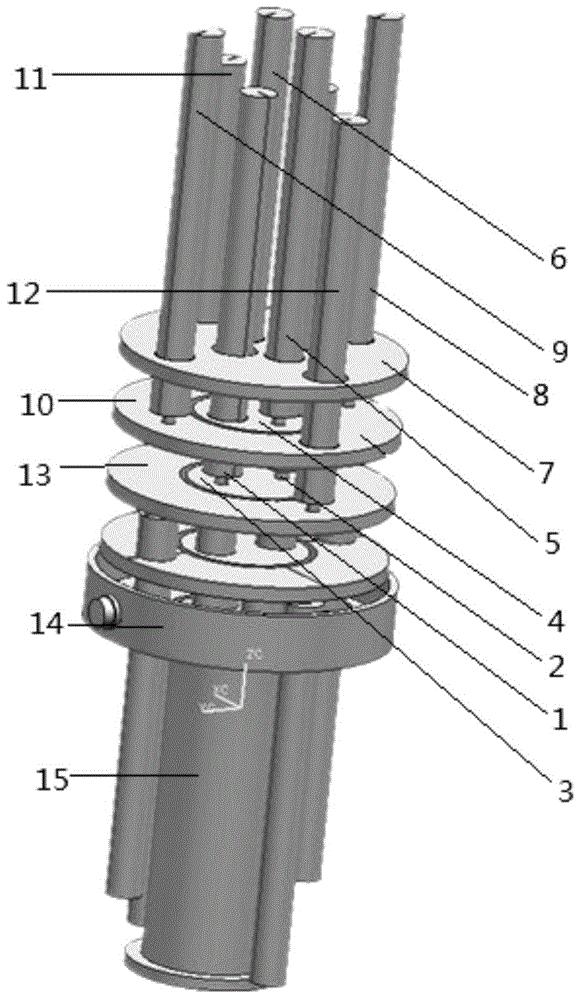

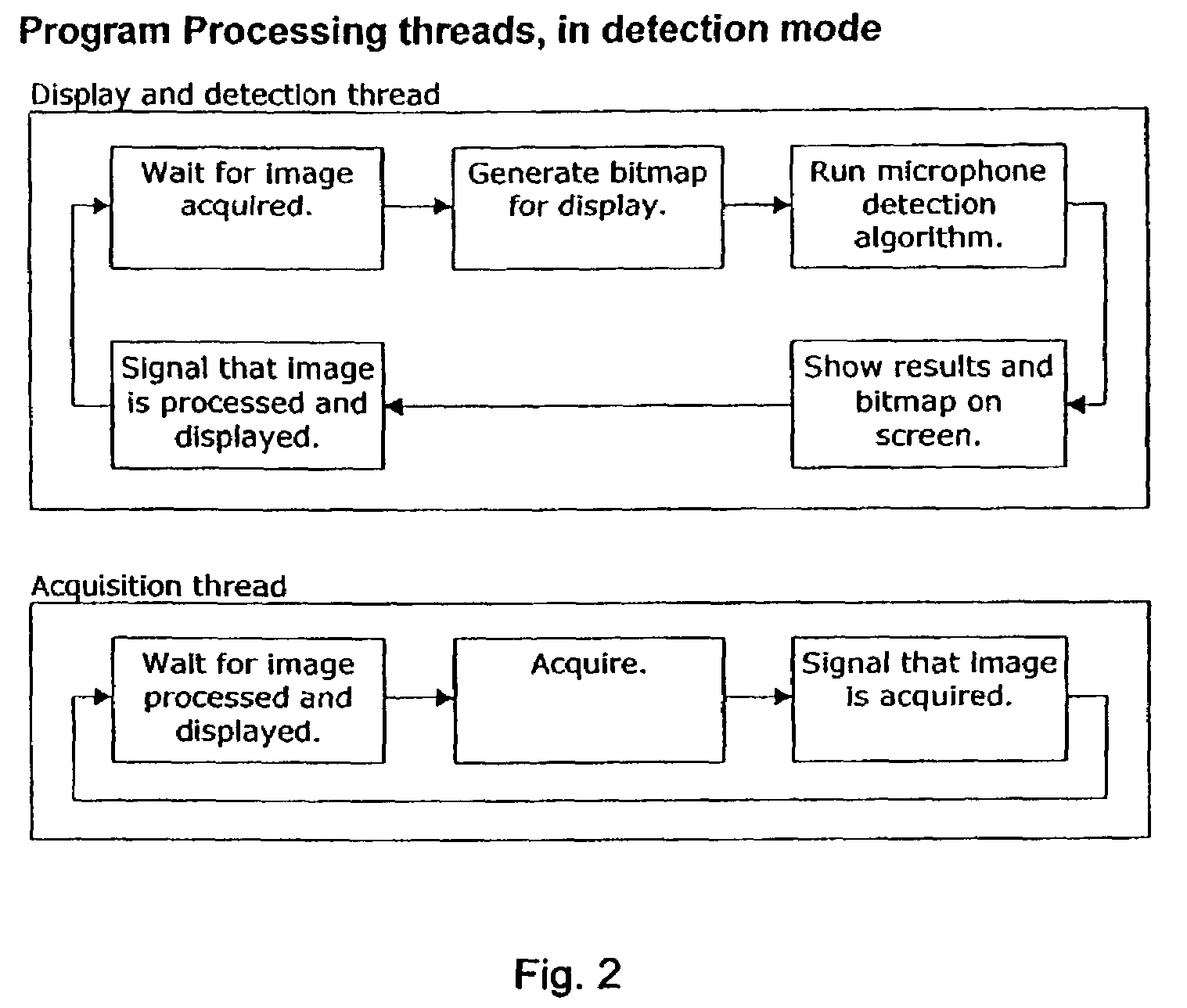

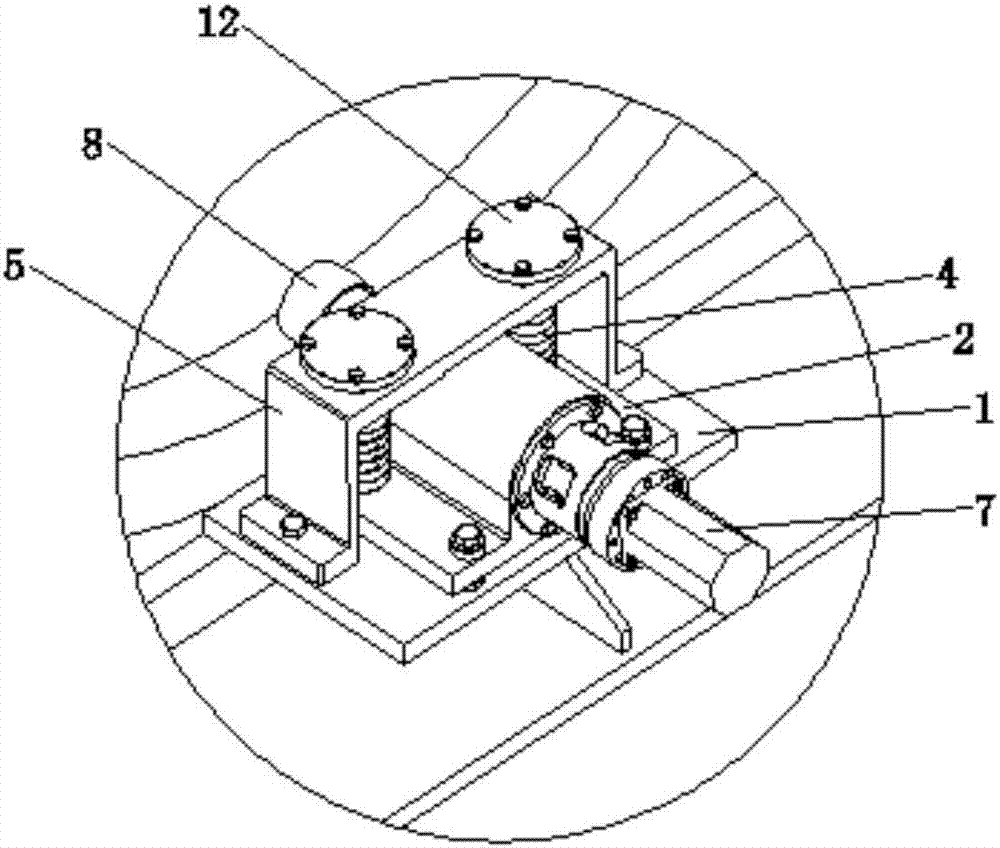

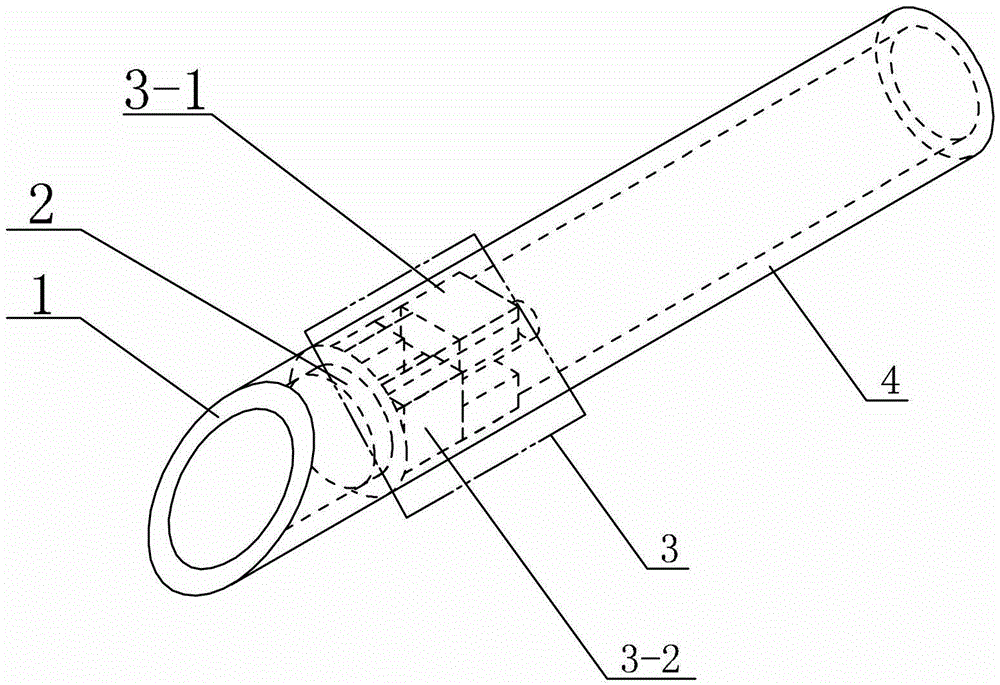

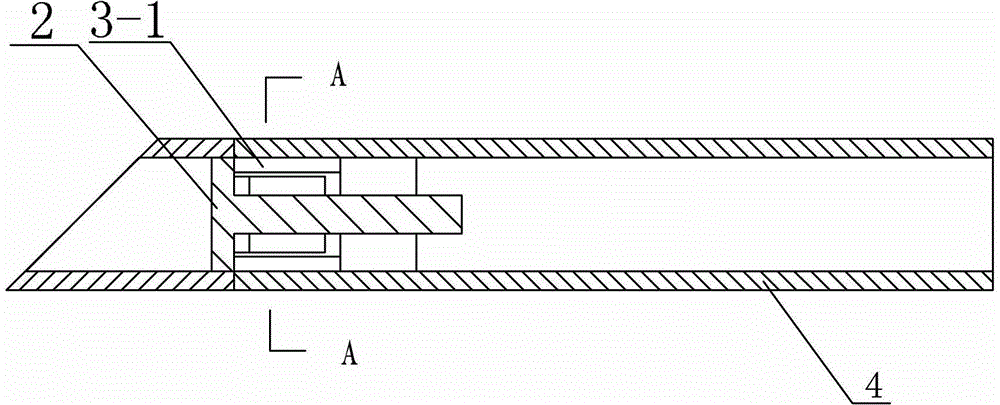

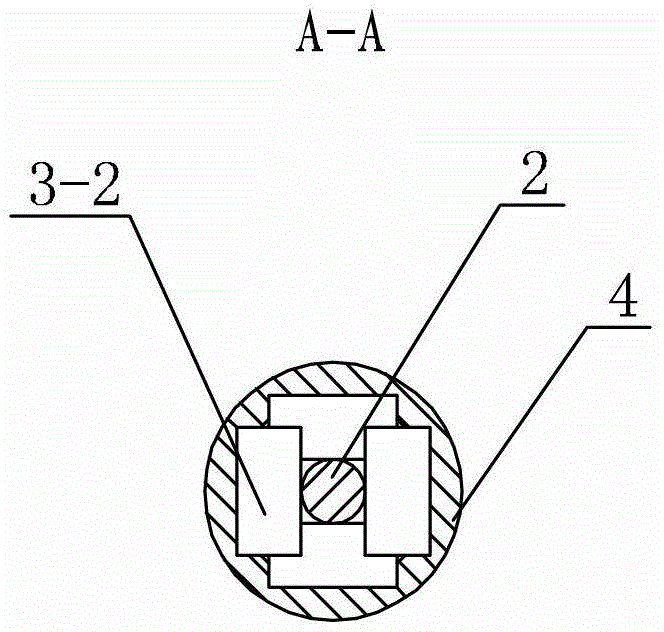

Motion control device for capsule endoscopy

ActiveCN107157430AChange strengthChange distributionGastroscopesOesophagoscopesCapsule endoscopyPower flow

The invention discloses a motion control device for a capsule endoscopy. A bearing seat is arranged on a base. The rear end of the bearing seat is connected with the base through two first bolts which are arranged side by side with one on the left and the other on the right. Spherical washer components are arranged between the head of each first bolt and the bearing seat, and between the bearing seat and the base. Compression springs are arranged on the left side and the right side of the front end of the bearing seat respectively. A driving shaft penetrates through the bearing seat in a rotary mode. The rear end of the driving shaft is connected with an output shaft of a motor. The front end of the driving shaft is sleeved with a friction wheel. The inner wall of a housing is pressed by the friction wheel. An annular magnet is fixedly arranged in the housing. Multiple coil holders which are evenly distributed in the circumferential direction are arranged in the magnet. A coil is arranged on each coil holder. The intensity and distribution of the magnetic field in the magnet are changed by controlling the current change of the electromagnetic coils, so that the stress magnitude and direction of the capsule endoscopy in the whole plane are controlled. The magnet can rotate, resulting in rotation of the magnetic field, so that the capsule endoscopy can move in the whole plane in a controllable mode.

Owner:重庆金山医疗技术研究院有限公司

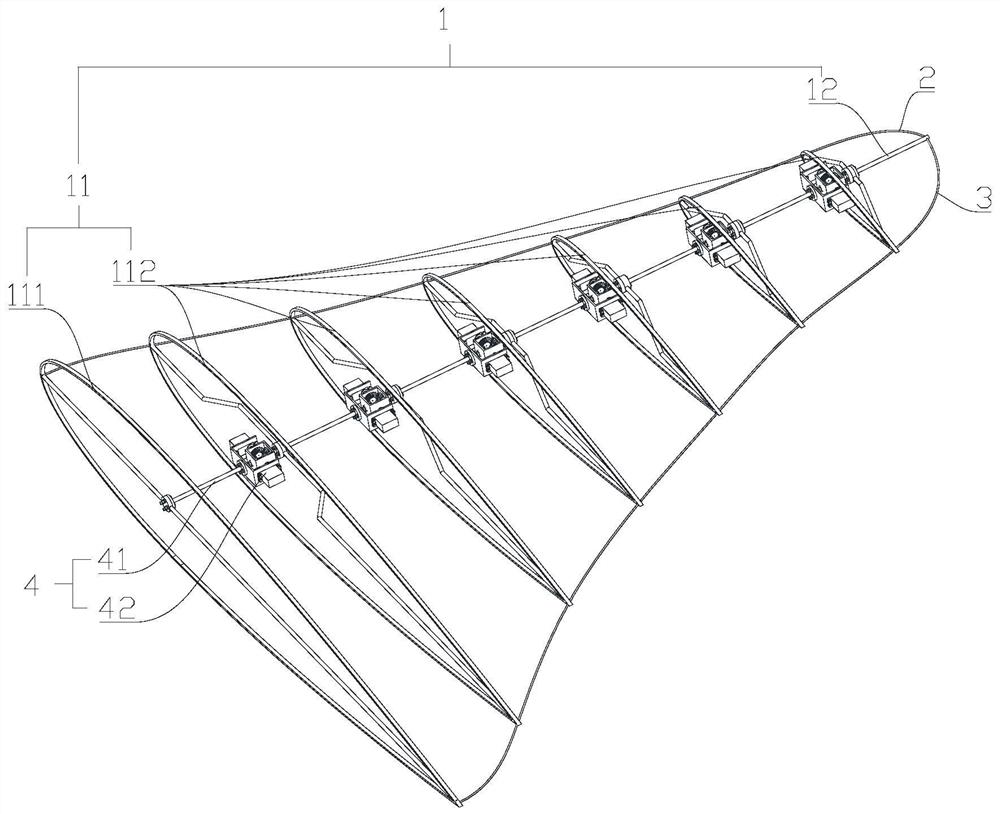

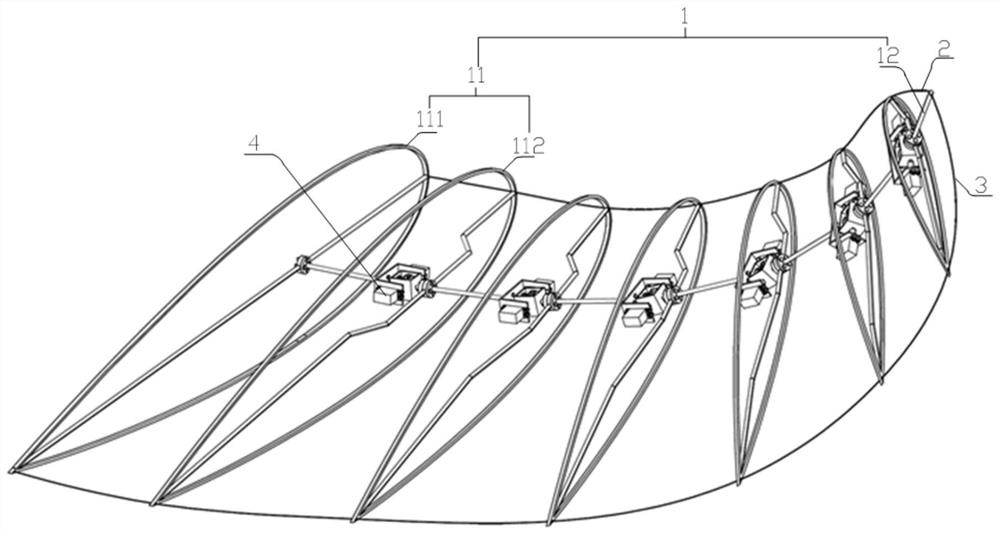

Manta ray imitating pectoral fin mechanism and manta ray imitating robot

ActiveCN113044194AMany degrees of freedomControllable movementPropulsive elements of non-rotary typeUnderwater equipmentPhysicsMultiple degrees of freedom

The invention relates to a manta ray imitating pectoral fin mechanism and a manta ray imitating robot. The manta ray imitating pectoral fin mechanism comprises a pectoral fin framework, a front edge rope, a rear edge rope and a flexible fin skin; the pectoral fin framework comprises a root supporting framework and a multi-stage swing supporting framework, each stage of swing supporting framework is correspondingly provided with a differential driving unit, and each stage of differential driving unit comprises a connecting piece and a driving assembly fixedly connected to the connecting piece; wherein the connecting piece of the first-stage differential driving unit is fixedly connected to the root supporting framework, and the connecting pieces of the other stages of differential driving units are fixedly connected to the upper-stage swing supporting framework; and the driving assembly of each stage of differential driving unit drives the swing supporting framework of the same stage to rotate with a straight line on the section of the pectoral fin supported by the swing supporting framework as the axis and rotate with a vertical line of the section of the pectoral fin as the axis. The manta ray imitating pectoral fin mechanism has multiple degrees of freedom, and movement of the manta ray imitating pectoral fin mechanism is completely controllable.

Owner:QINGDAO NAT LAB FOR MARINE SCI & TECH DEV CENT

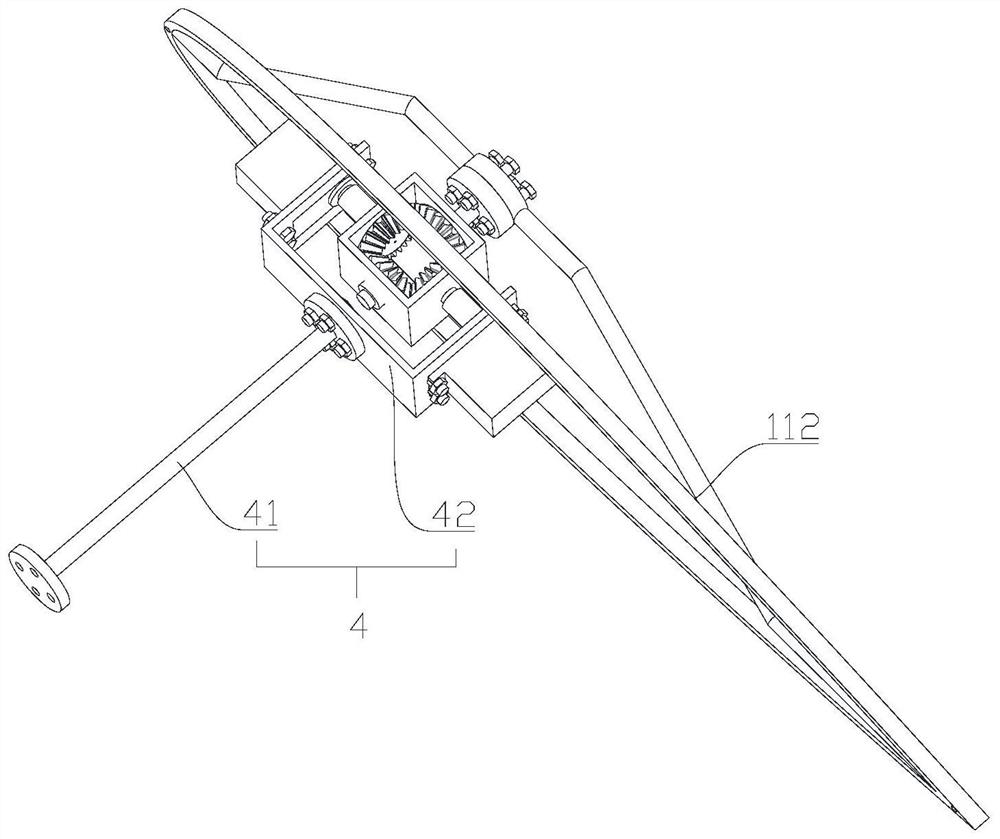

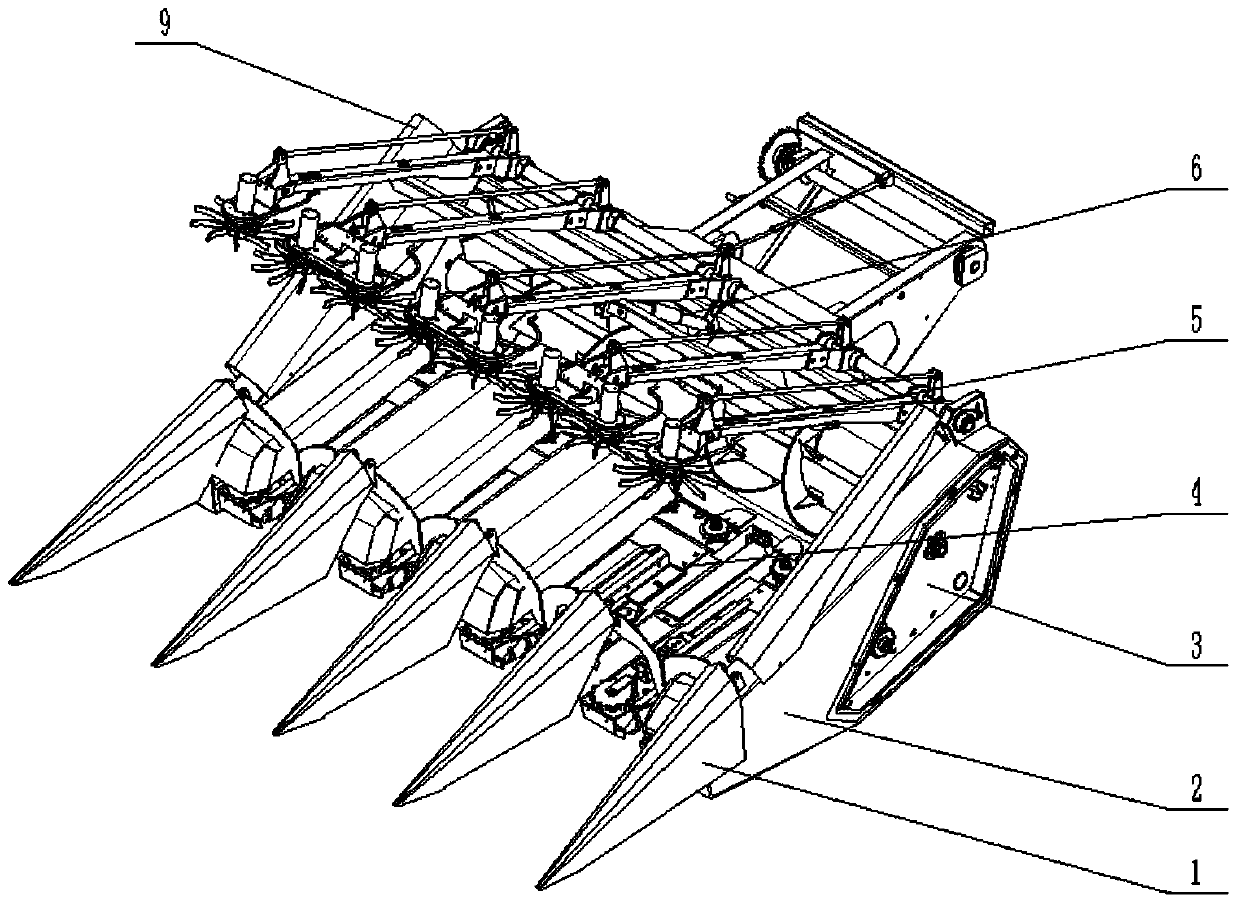

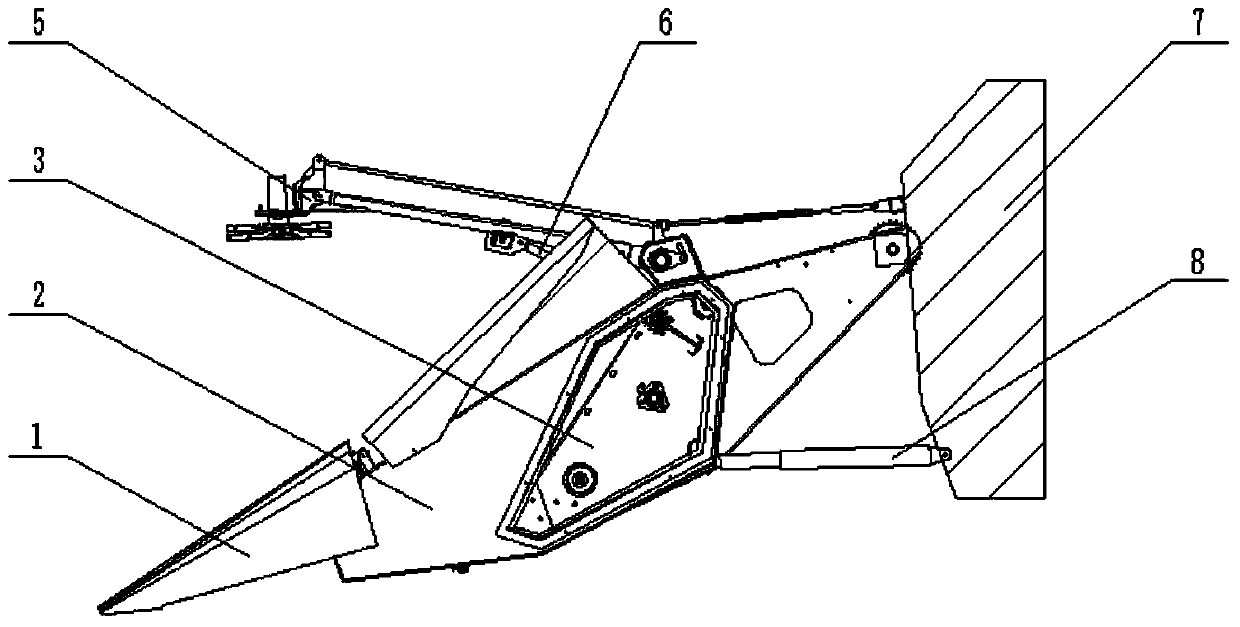

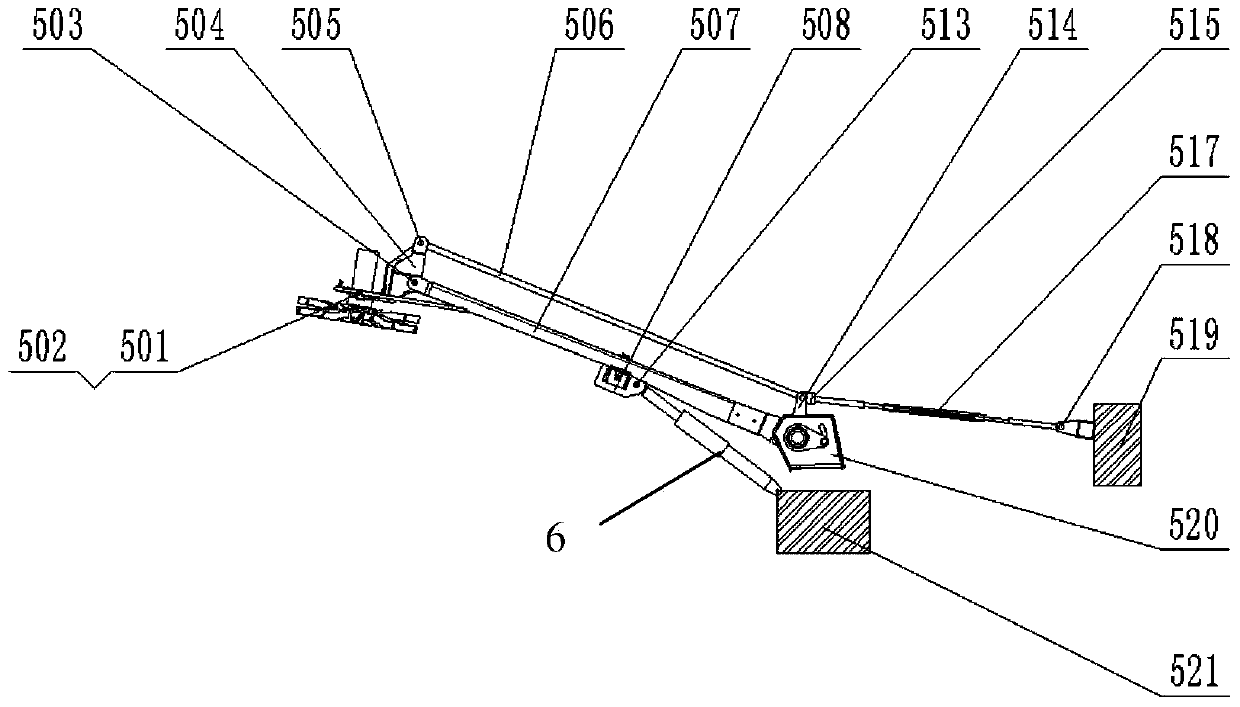

Crop poking tooth system and use method thereof

ActiveCN104186108AEasy to knock downHarvest failureHarvestersBalancing machineStructural engineering

The invention relates to the field of corn harvesting machines, in particular to a crop poking tooth system and a use method thereof. A side drive unit or a middle drive unit is connected with a third connection rod through a first pin shaft, the side drive unit or the middle drive unit is connected with a second connection rod through a first connection rod and a second pin shaft, a main rotating shaft penetrates through the third connection rod, is in clearance fit with the third connection rod and is limited through a positioning sleeve, a fourth connection rod is connected with the second connection rod through a pin shaft, the fourth connection rod is fixed to the main rotating shaft through a bolt, a fifth connection rod is connected with the second connection rod and the fourth connection rod simultaneously through pin shafts, the other end of the fifth connection rod is connected with a connection rod adjustment rod through threads, the two ends of the connection rod adjustment rod are provided with opposite threads, the connection rod adjustment rod is connected with a machine frame through another connection rod and a fourth pin shaft, and the first connection rod, the second connection rod, the third connection rod, the fourth connection rod and the fifth connection rod are connected together to form a five-connection-rod balance mechanism to support the side drive unit or the middle drive unit. According to the crop poking tooth system and the use method thereof, the situation that a common header knocks down straws during not-in-row harvesting is avoided and not-in-row harvesting is achieved.

Owner:SHENYANG YUANDA INTELLIGENT AGRI

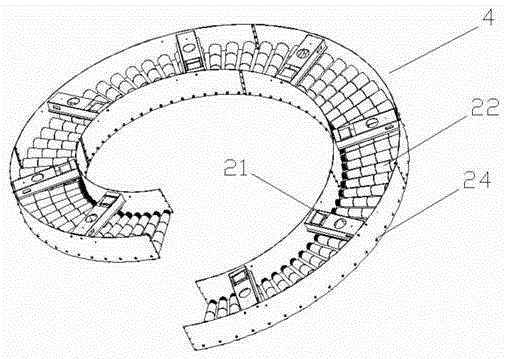

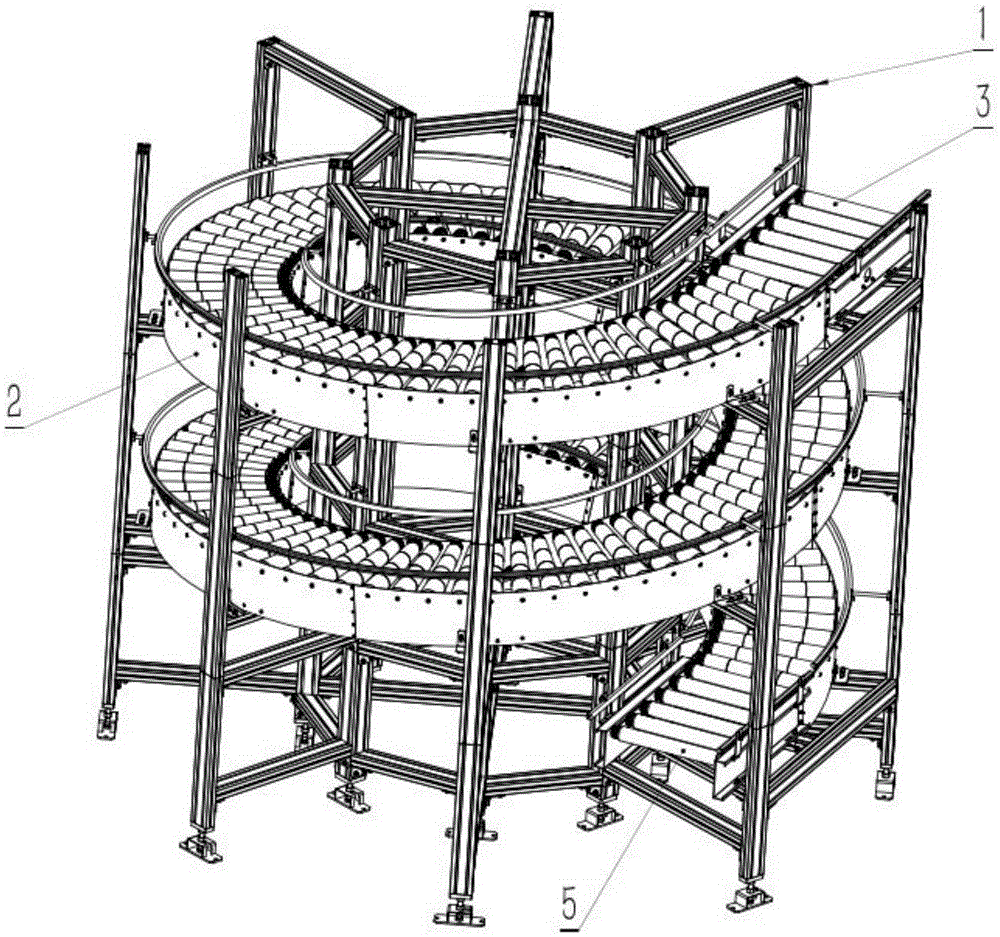

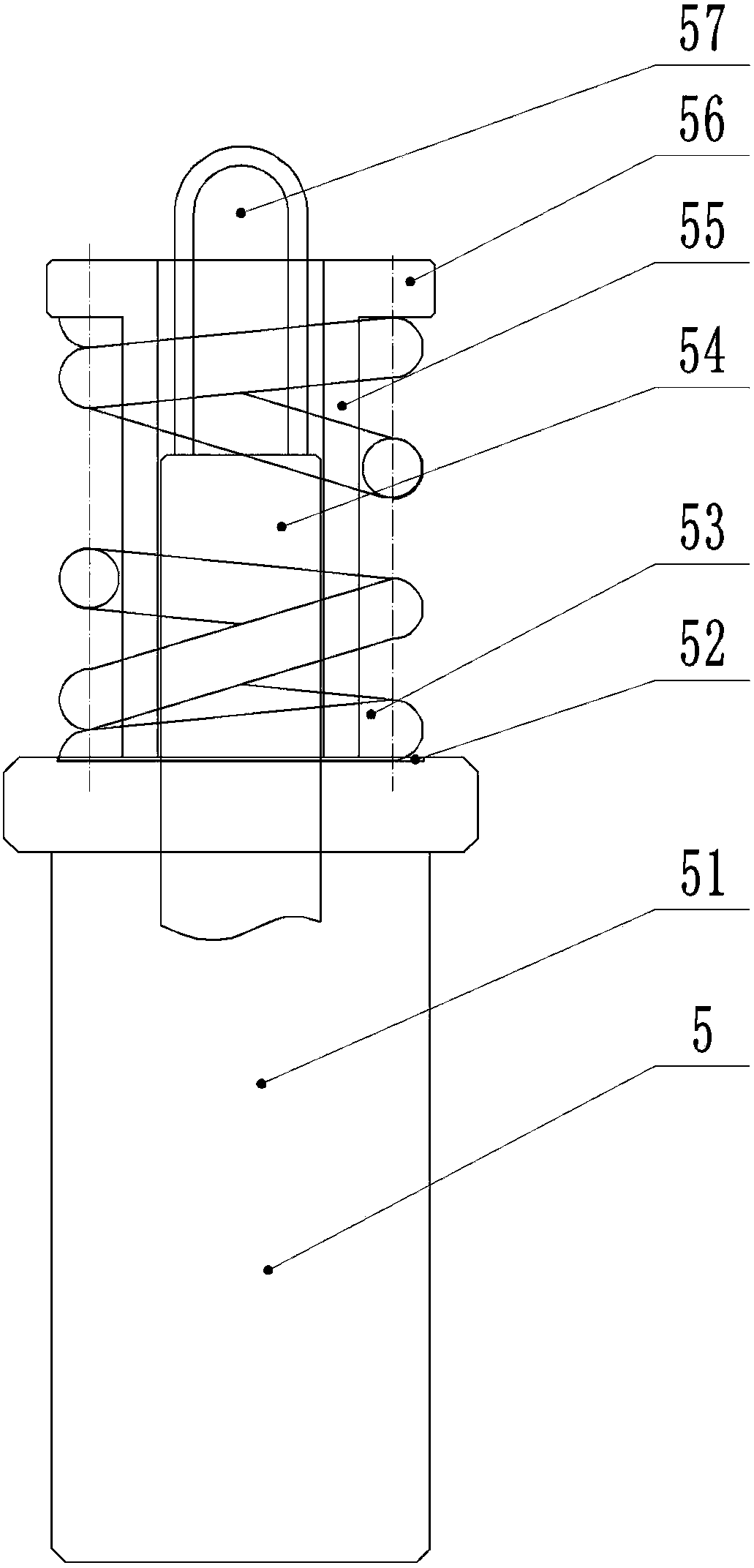

Screw elevator

InactiveCN105416980AControllable movementAchieve accumulationRoller-waysElectric machineryEngineering

The invention discloses a screw elevator. The screw elevator comprises a machine frame and a screw conveying line, wherein the screw conveying line is arranged in the machine frame and ascends in a screw mode in the axial direction of the machine frame; the screw conveying line comprises motors, rollers, a controller and screw side plates, wherein the controller is fixed to the machine frame or the screw side plates and is electrically connected to the motors, the motors are connected to the rollers in a driving mode, the rollers are connected through a driving belt, and the two ends of each roller are fixed to the screw side plates; the screw conveying line is divided into an upper port conveying section, a screw conveying section and a lower port conveying section, wherein the upper port conveying section, the screw conveying section and the lower port conveying section are sequentially connected, and the screw conveying section adopts the multi-section design and is formed by splicing a plurality of single screw conveying bodies. According to the screw elevator, the sectional design is adopted so that the movement of material can be controlled, and individual control over the motors is adopted so that the material can be accumulated.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

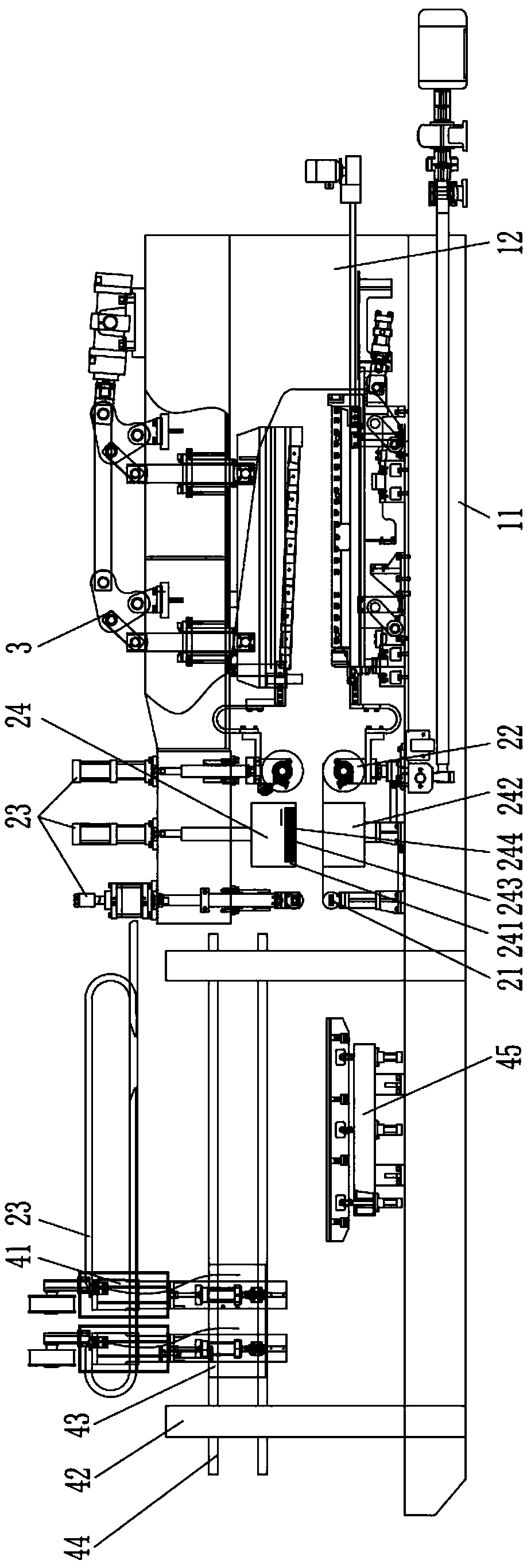

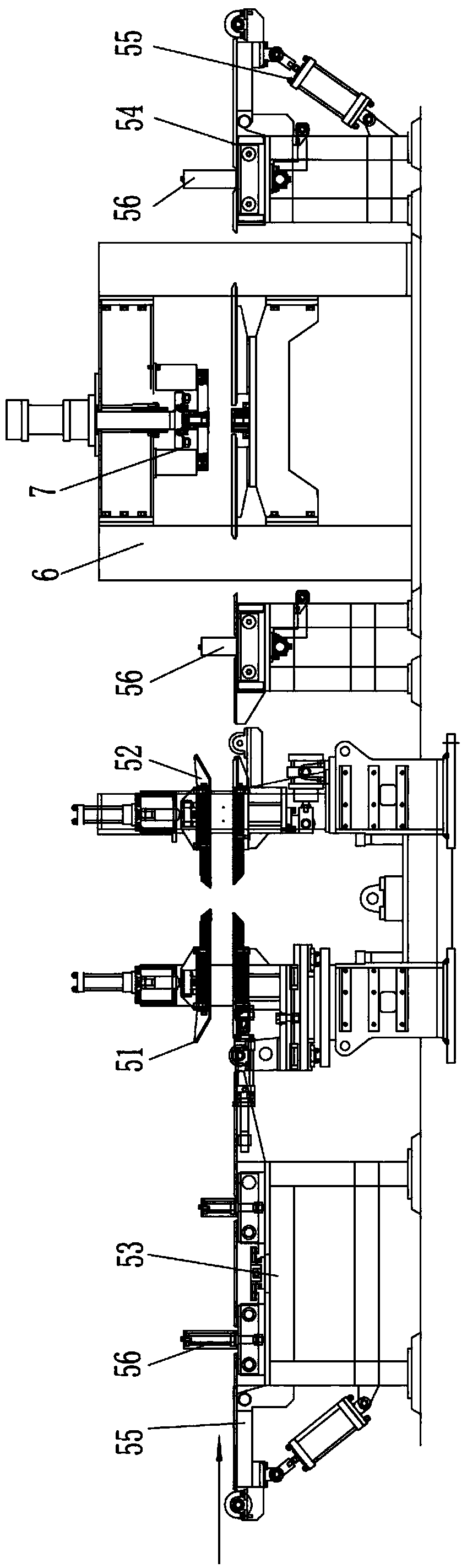

Resistance welding argon arc shielded welding combined welding machine

The invention discloses a resistance welding argon arc shielded welding combined welding machine. The resistance welding argon arc shielded welding combined welding machine comprises an operation sideand a transportation side; the operation side is provided with a vehicle frame, a resistance welding component, a double-blade shearing component and an argon arc welding component; the transportation side is provided with a centering conveying component, a crescent shearing component and a punching component; the resistance welding component comprises a rolling wheel, an electric welding wheel,a lifting device and a heating device; the argon arc welding component comprises at least one argon arc welding gun, an upright post and a moving component; the centering conveying component comprisesan inlet clap, an outlet clamp, a front centering sleeve picking element and a rear centering sleeve picking element; the rear centering sleeve picking element comprises two groups of centering parts; and the crescent shearing component and the punching component are arranged between the two groups of centering parts. The resistance welding argon arc shielded welding combined welding machine disclosed by the invention can be used for implementing different forms of welding according to strip steel different in thickness, lowers the equipment investment cost and the labor cost in a strip steelproduction process, eliminates the stress of a welding seam, improves the quality of the welding seam and meets the technical requirements of welding of the strip steel.

Owner:佛山市诚德新材料有限公司

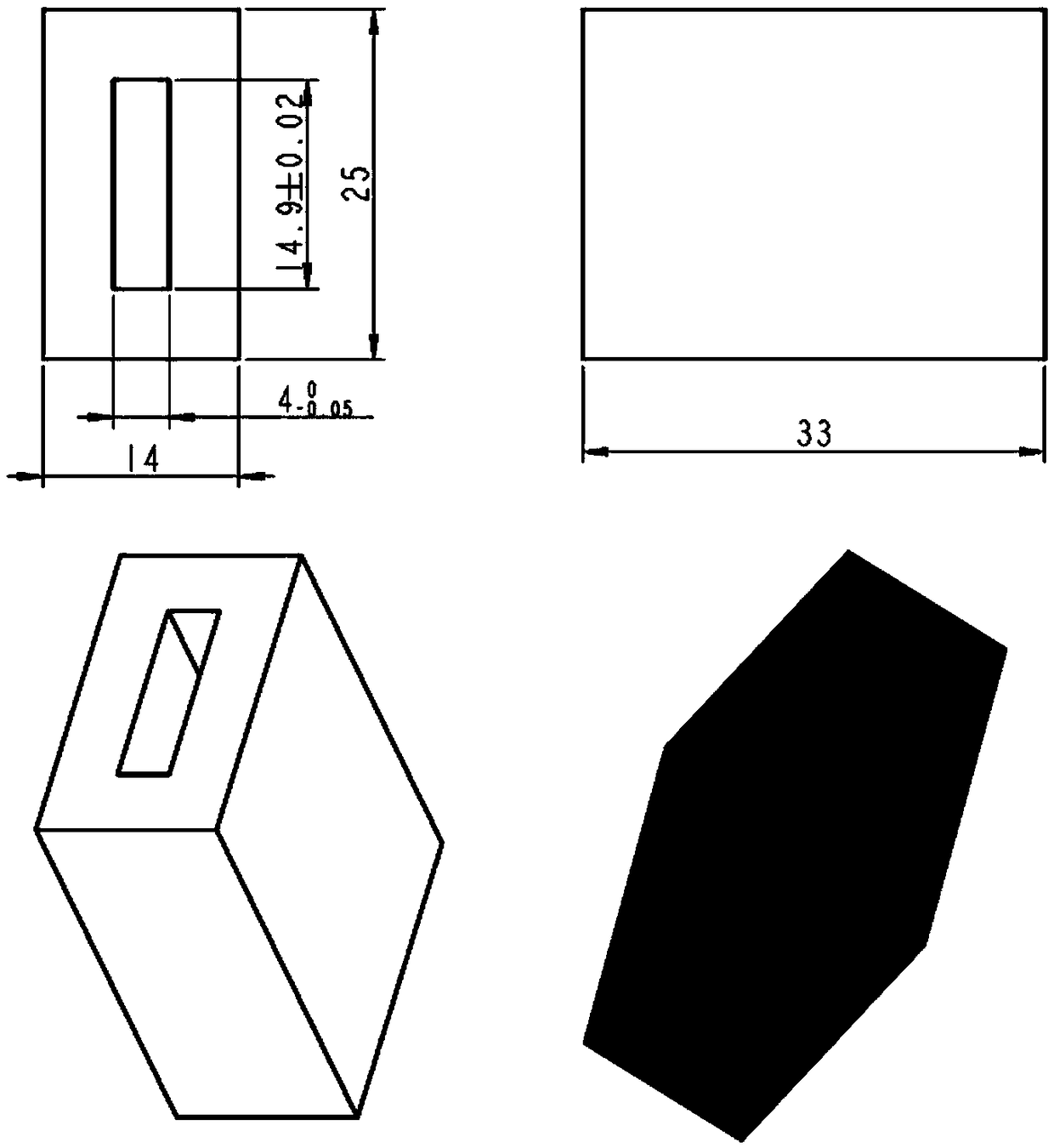

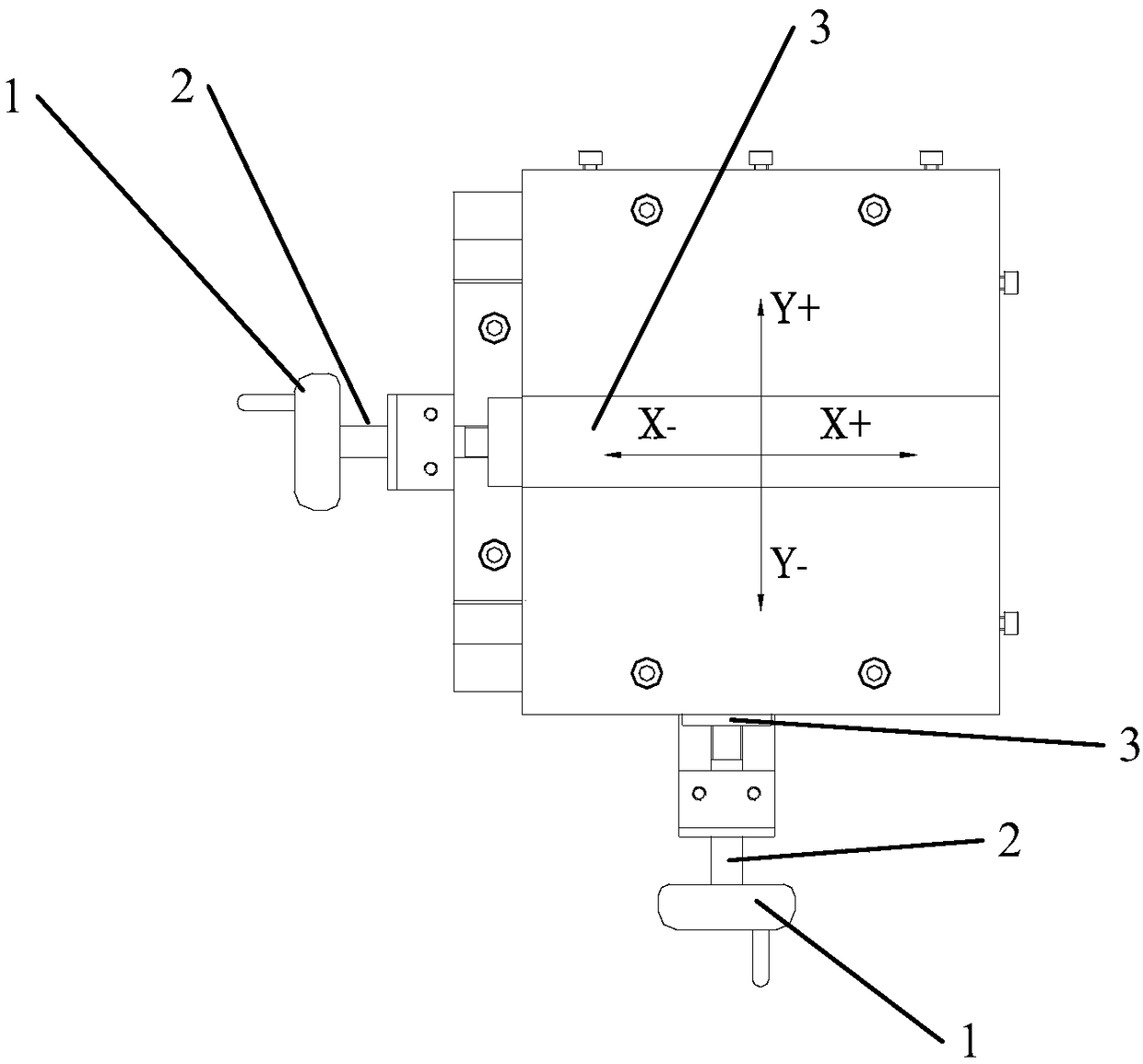

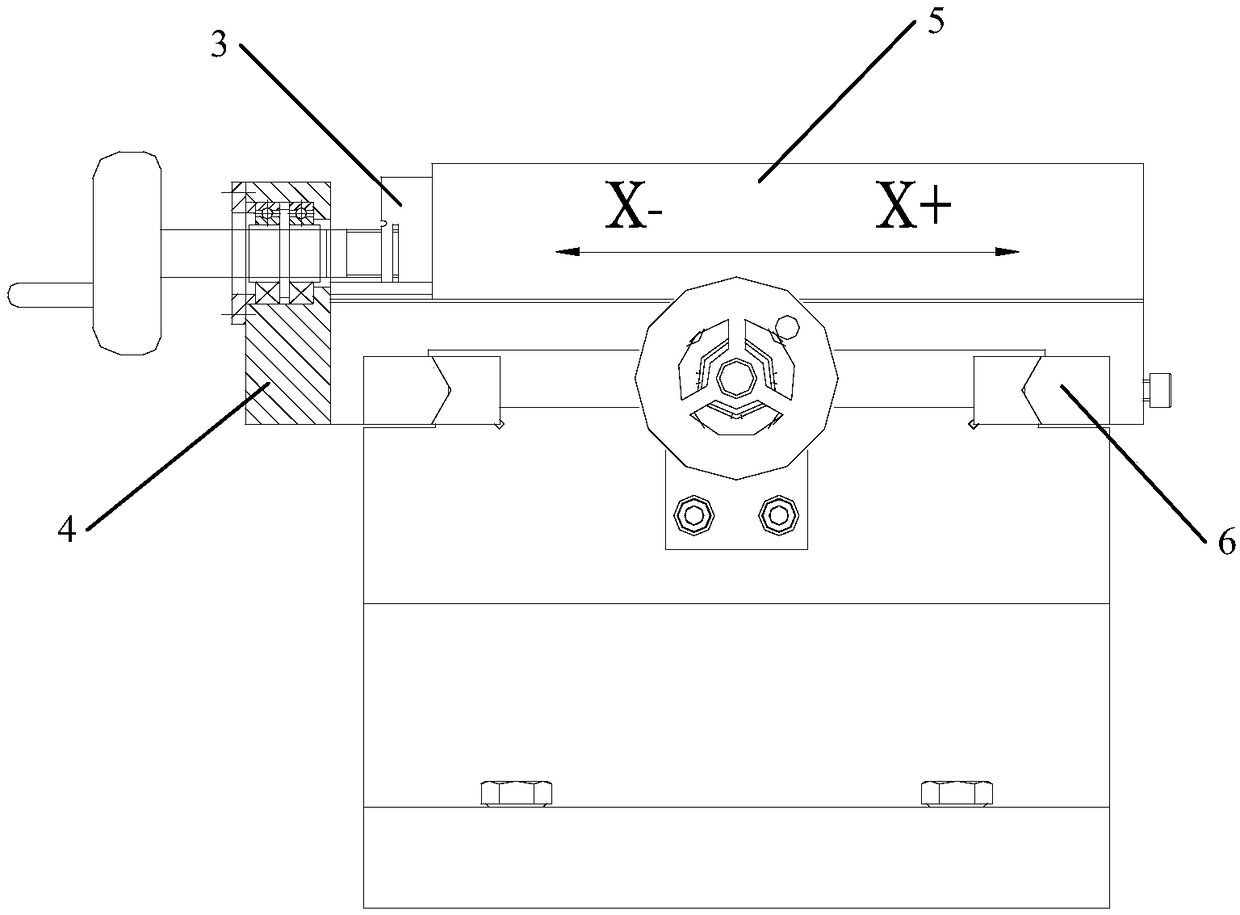

Ferrite hole channel machining device for phase shifter

InactiveCN109449558AImprove processing progressControllable movementWaveguide type devicesCompression moldingLinear motion

The invention provides a ferrite hole channel machining device for a phase shifter. The ferrite hole channel machining device comprises a first motion unit and a second motion unit; the first motion unit comprises a screw rod, a positioning block in thread fit with the screw rod, a recording unit and a movable supporting plate which is fixedly connected with the positioning block; and the second motion unit comprises a linear motion unit, a driving unit and a grinding tool fixed on the linear motion unit. A rotating force of the screw rod is converted into an indirect acting force in an XY-axis direction indirectly through the movable supporting plate; the motion in the XY-axis direction is easier to control due to the loss of the indirect acting force, so that the control precision is improved, the machining progress of a hole channel of a ferrite is accelerated, and the problem that the precision requirement of 0.05 mm cannot be met because the size precision of the hole channel of the ferrite manufactured by compression molding is relatively low at present is solved.

Owner:BEIJING INST OF RADIO MEASUREMENT

Inclined angle flexible needle robot auxiliary puncture system based on piezoelectric actuation

ActiveCN103083091BOvercoming complexityControllable movementDiagnosticsSurgical needlesEngineeringTrajectory planning

The invention provides an inclined angle flexible needle robot auxiliary puncture system based on piezoelectric actuation, relates to robot auxiliary puncture systems, and aims at resolving the problems that an existing flexible needle is complex in stress, brings difficulty to trajectory planning, and does not easily guarantee moving accuracy in the moving process inside tissue. According to the inclined angle flexible needle robot auxiliary puncture system, a support piece, a lead screw tail end bearing block, a lead screw head end bearing block and a motor installation base are sequentially arranged on a platform from left to right, an inserting needle motor is arranged on the motor installation base, an output shaft of the inserting needle motor is connected with a lead screw, a guide rail is arranged on the platform, a moving nut is arranged on the lead screw, a bearing support seat is arranged on the moving nut, a sliding block is arranged on the guide rail, the bearing support seat is connected with the guide rail, a sliding block nut connecting seat is arranged on a sliding block nut connecting piece, a flexible needle fixing piece is fixedly installed on the sliding block nut connecting seat, a support sleeve is arranged at the upper end of the support piece, one end of a feeding flexible needle is arranged inside the support sleeve in a penetrated mode, and the other end of the feeding flexible needle is connected with the flexible needle fixing piece. The inclined angle flexible needle robot auxiliary puncture system is applied to robot auxiliary puncturing.

Owner:HARBIN INST OF TECH

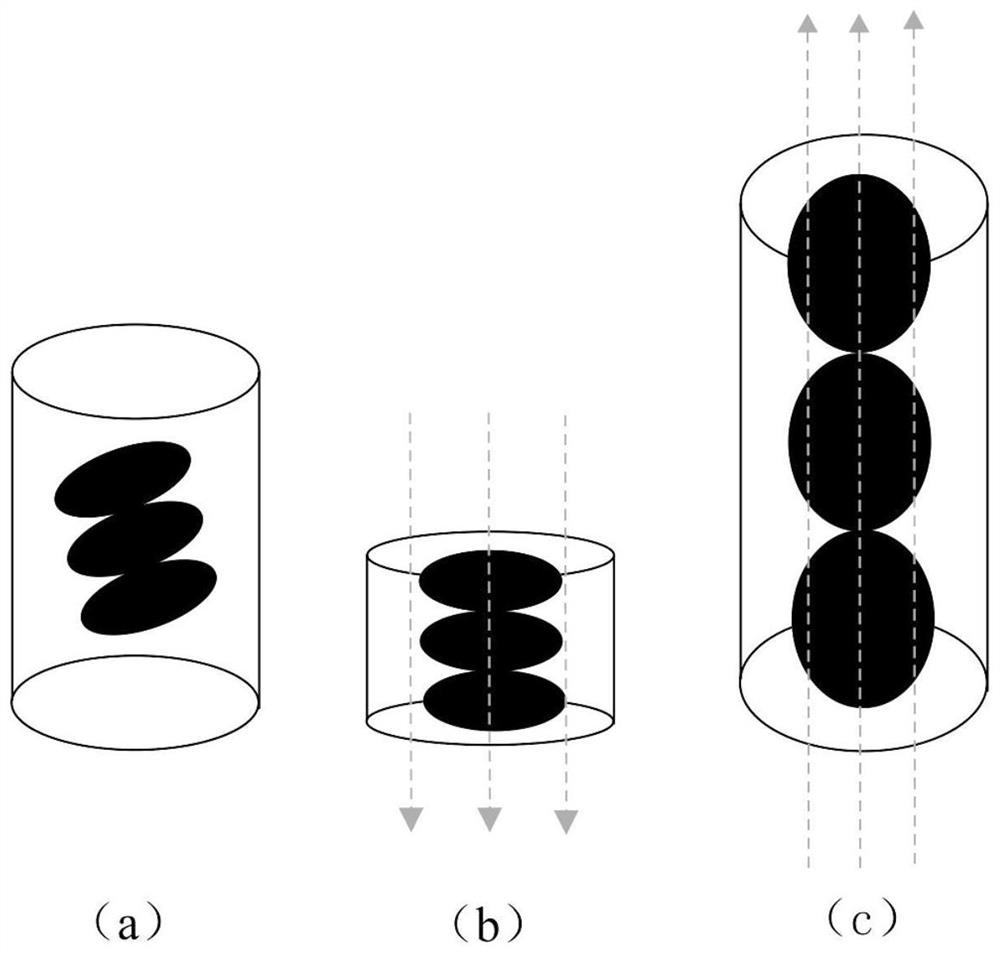

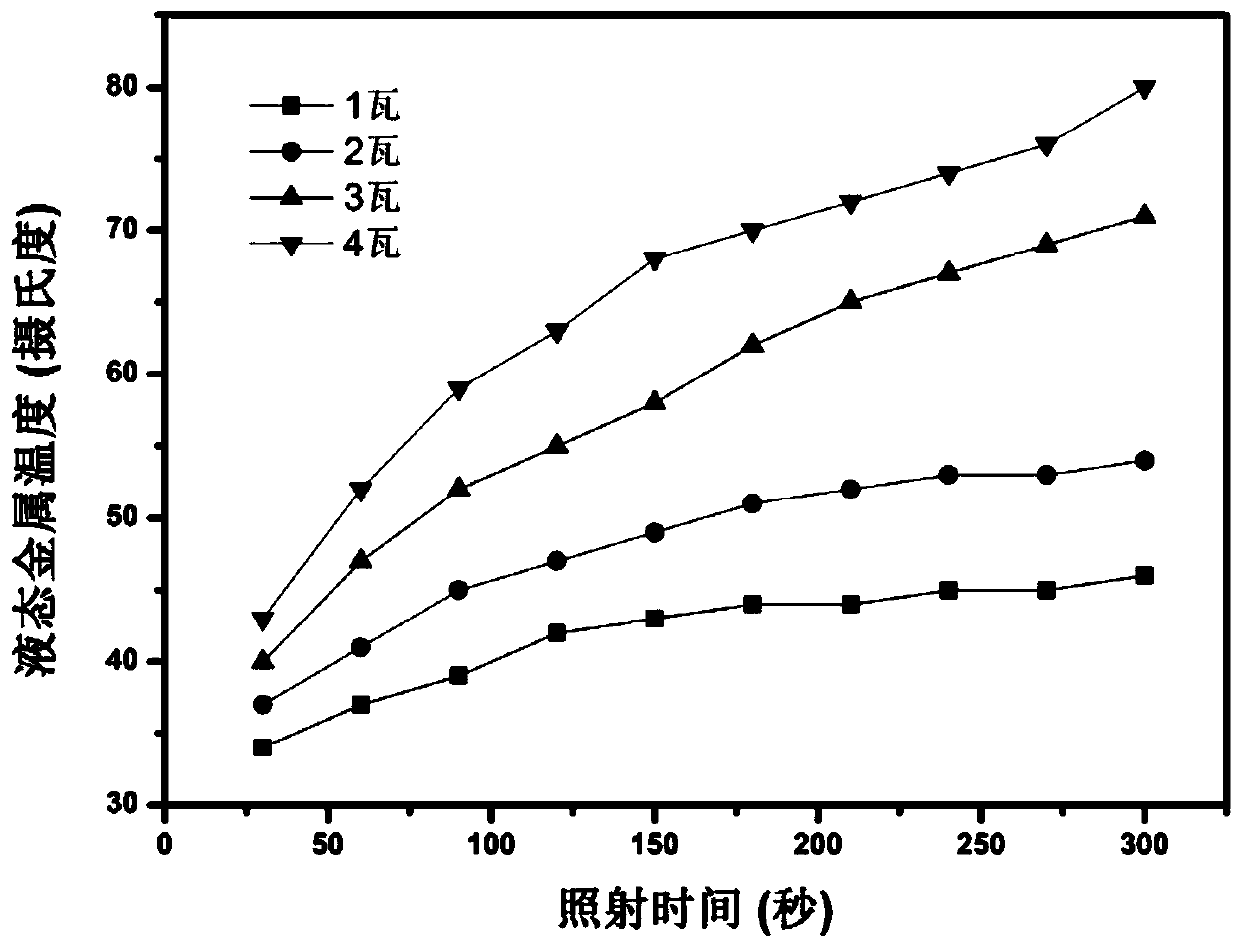

Method for controlling movement of liquid metal by using laser in ionic liquid

The invention relates to a method for controlling movement of a liquid metal by using a laser in an ionic liquid. The method comprises the following steps: step (1) immersing the liquid metal into a glass container containing the ionic liquid; step (2) allowing the laser to transmit the glass container to irradiate the liquid metal immersed in the ionic liquid; step (3) generating small bubbles onthe surface of the irradiated liquid metal, gradually gathering the small bubbles on the liquid metal to form large bubbles, and controlling a growth speed of the bubbles by adjusting laser intensityand irradiation time; and step (4) allowing the large bubble to carry the liquid metal to rise, and controlling a movement direction of a combination of the liquid metal and the bubbles by regulatingand controlling a laser irradiation portion. The method for controlling movement of the liquid metal by using the laser in the ionic liquid disclosed by the invention has the following beneficial effects: 1, the movement of the liquid metal in three-dimension directions is controllable; and 2, the movement of the liquid metal in the ionic liquid in three-dimension directions is controllable.

Owner:INNER MONGOLIA UNIV OF TECH

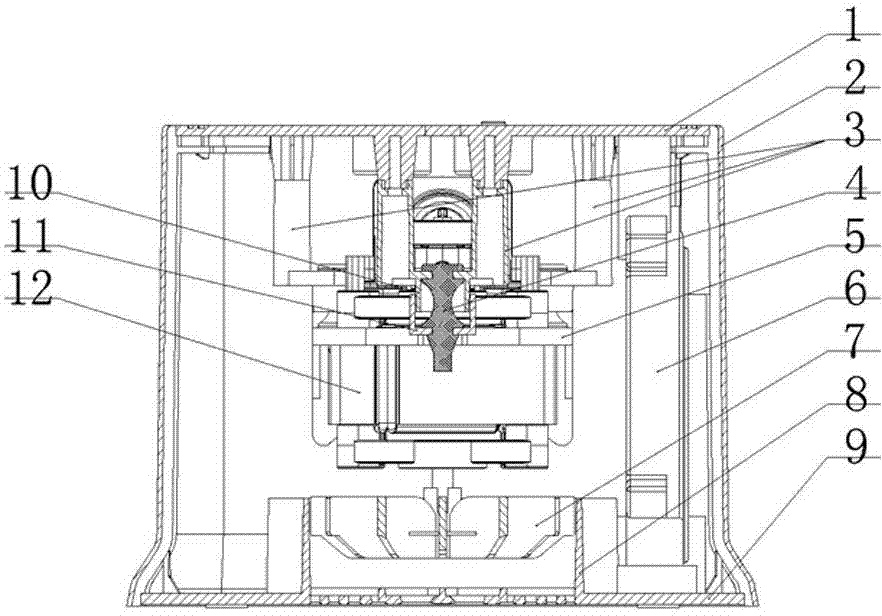

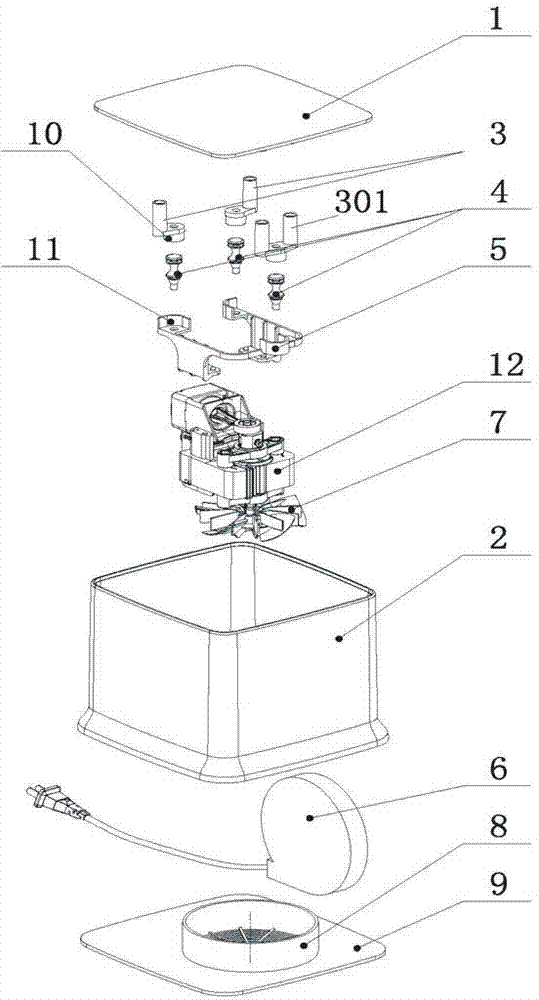

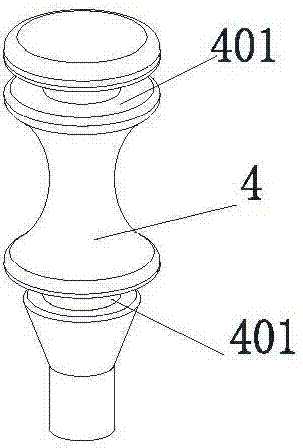

Compression type atomizer

ActiveCN103751890AReduce vibrationVibration does not passMedical atomisersComputer engineeringComputer fan

The invention discloses a compression type atomizer which comprises a main unit bottom shell, a compressing main unit and a coaxial fan. A middle shell is connected to the main unit bottom shell. An upper cover is disposed on the middle shell. A hanging device is disposed on the inner surface of the upper cover. The compression main unit is connected with the hanging device. An air drum is arranged at the bottom of the main unit bottom shell. The coaxial fan is disposed in the air drum. The hanging device can control the horizontal motion of the compression main unit. Reasonable gaps can be reserved among single- and double-column buffer circular tubes, positioning can be achieved while vibration is not transmitted. The radiating fan is used by the atomizer to improve radiation and enhance the performance of the drum, the air pumping force of the radiating fan is increased, the radiating capacity of the compression main unit is enhanced, and the service life of the compression main unit is prolonged.

Owner:江西晶康宇医疗科技有限公司

Ergonomic appliance handle

InactiveUS20060042046A1Easily and conveniently operateEasy to operateTravelling carriersHoldersEngineeringMechanical engineering

The ergonomic appliance handle is an extension handle that is attachable to a carrying or transport handle on a canister style vacuum cleaner or similar floor appliance. The ergonomic appliance handle provides an elongated handle shaft that is attached to the canister vacuum's handle at a proximate end of the handle shaft by a mounting assembly. The handle shaft extends angled upward, away from the vacuum, placing a handgrip at the distal end of the handle shaft at an ergonomically comfortable height and position for a user to easily and conveniently operate the vacuum in a comfortable posture without subjecting the user to unnecessary bending, stooping, or twisting.

Owner:DECKER DEBORAH

An assembly device for an insulating pull rod

ActiveCN105788918BReduce labor intensityImprove work efficiencyElectric switchesEngineeringMechanical engineering

Owner:ZHEJIANG DONGCHI SWITCH

Vertical multi-discharge warp knitting machine

PendingCN110699842AImprove weaving efficiencyReduce wearWarp knittingStructural engineeringMechanical engineering

The invention relates to a vertical multi-discharge warp knitting machine, which comprises a main shaft which is vertically arranged and a plurality of knitting mechanisms which are symmetrically distributed around the center of the main shaft and are also vertically arranged; the plurality of weaving mechanisms share the main shaft for radial power driving; the vertical multi-discharge warp knitting machine further comprises a plurality of creels corresponding to the knitting mechanisms and vertically arranged outside the knitting mechanisms; a plurality of beams are distributed on the creelsin a matrix form to feed yarns to the knitting mechanisms; the vertical multi-discharge warp knitting machine further comprises a plurality of traction reeling mechanisms corresponding to the knitting mechanisms and vertically arranged outside the knitting mechanisms; the vertical multi-discharge warp knitting machine further comprises a guide bar traversing mechanism; the main shaft and the knitting mechanisms of the vertical multi-discharge warp knitting machine are vertically distributed, at least three knitting mechanisms are symmetrically distributed around the main shaft in a central mode, the main shaft is shared for radial power driving, the knitting efficiency of the warp knitting machine is greatly improved, the temporary space is greatly reduced, and the space utilization rateis increased.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com