Cold precision forming device for asymmetric cylindrical gear

A cylindrical gear, precision forming technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problem of gear asymmetry, etc., to achieve the effect of high gear tooth shape accuracy, short process, and save processing and non-use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

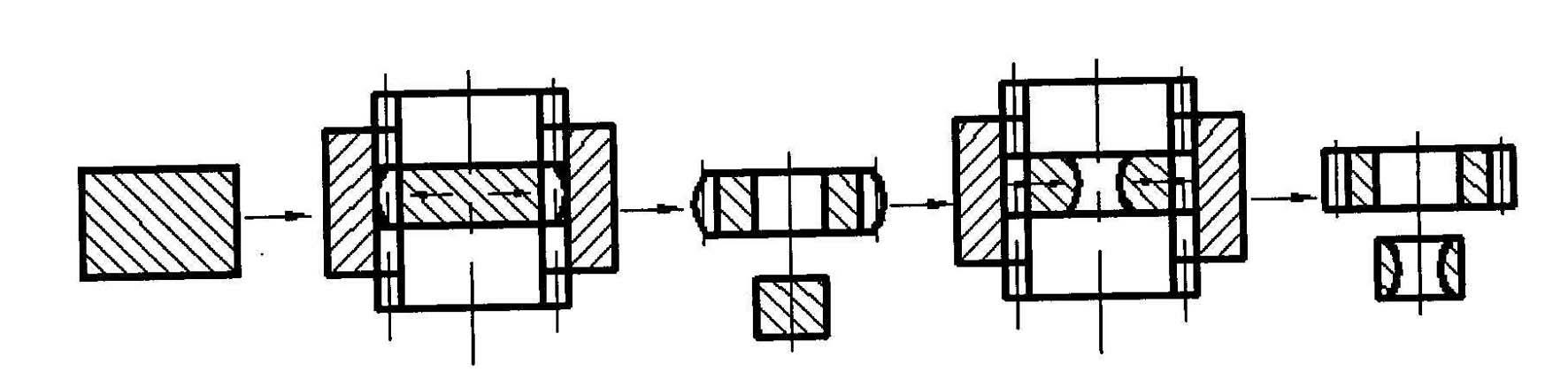

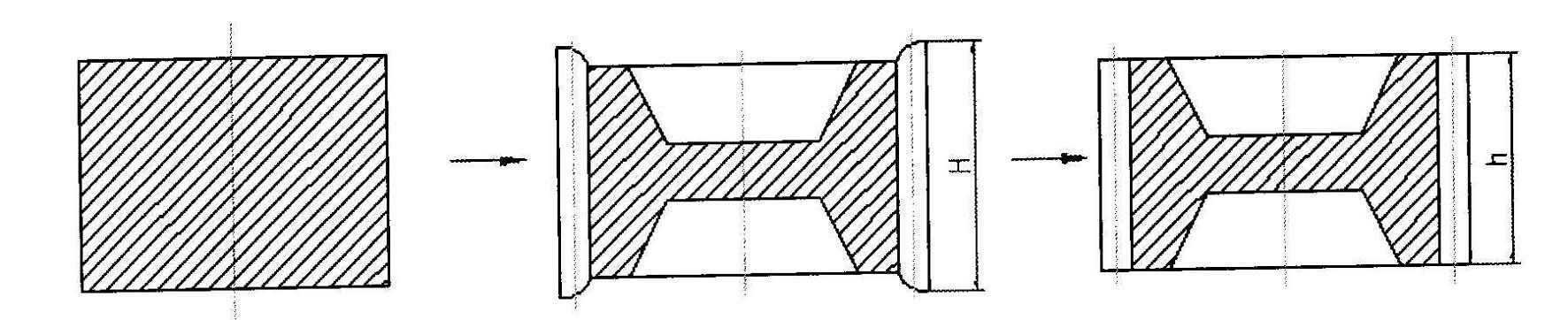

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0029] Such as Figure 4 , 5 Shown: the asymmetric cylindrical gear cold precision forming device of the present invention comprises the lower die frame 12 that is installed on the base, the moving die frame that is positioned at the lower die frame top, the upper die frame 1 that is arranged on the motion die frame top; The lower mold base is sequentially provided with a lower built-in oil cylinder 10 and a lower outer punch 9 of a hollow cylindrical structure from bottom to top, and a lower inner punch 8 is installed in the hollow column cavity of the lower outer punch 9; the moving die The forming die 5 is composed of a movable crossbeam 7 and a mold cavity installed at the middle position of the movable crossbeam 7. The oil cylinder 11 that moves up and down is combined; in the upper mold base, there are built-in oil cylinders 2 and upper and outer punche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com