Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Construction will not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

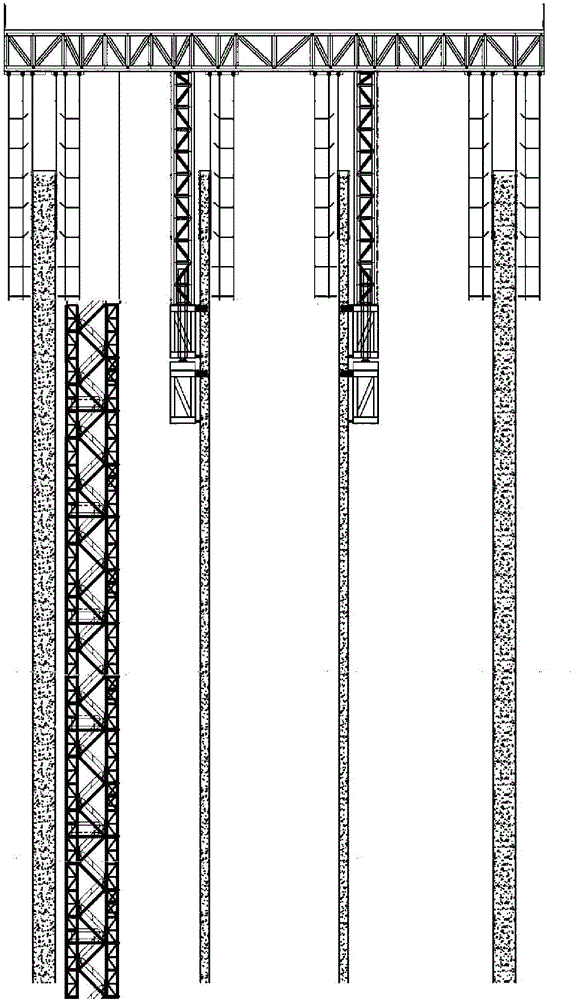

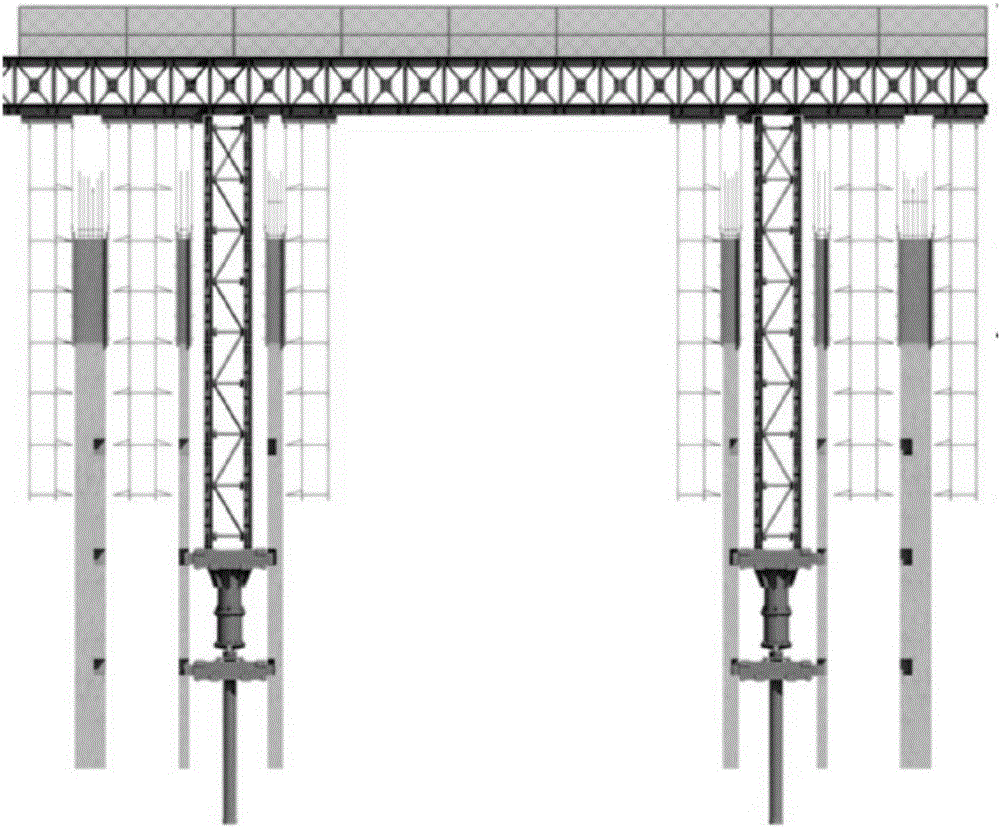

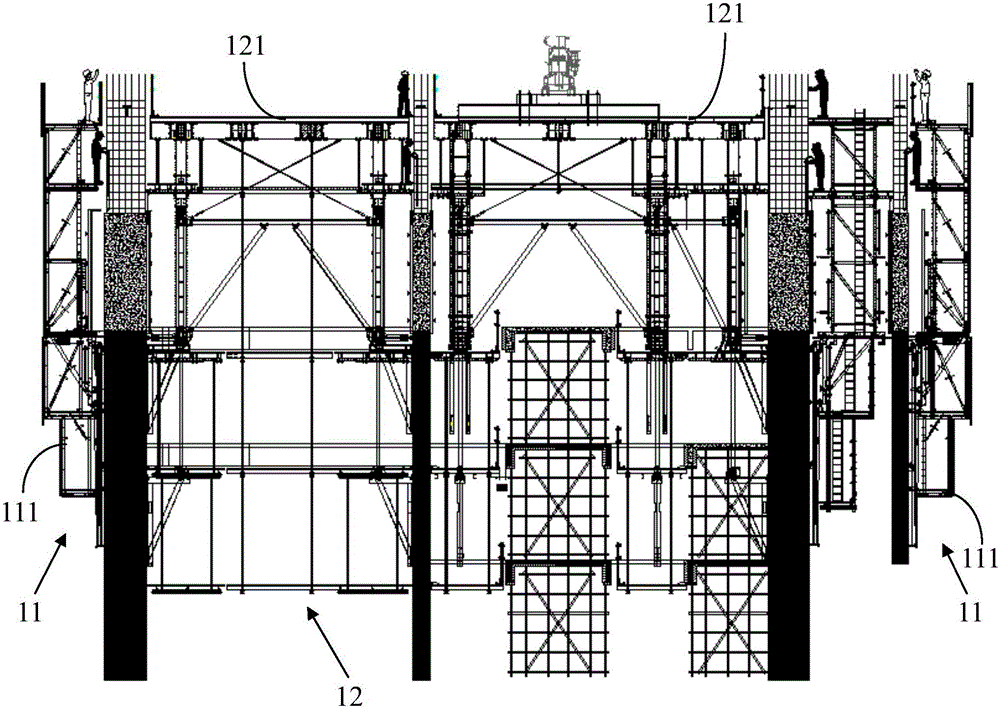

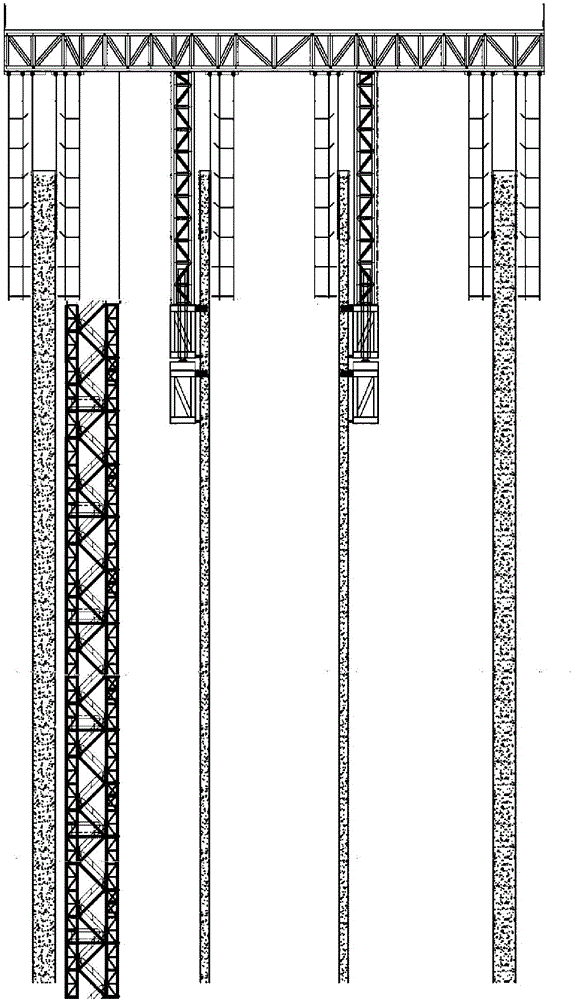

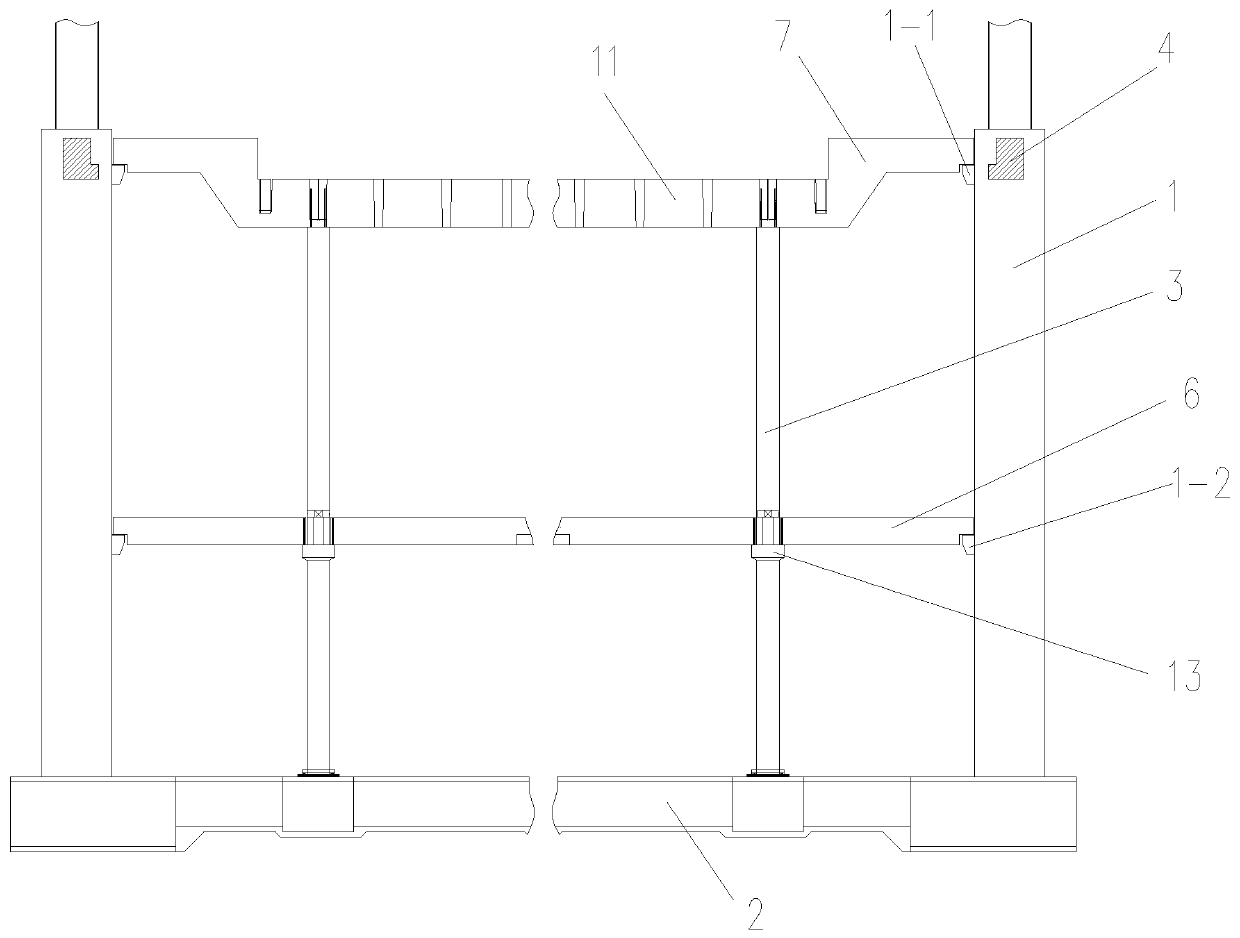

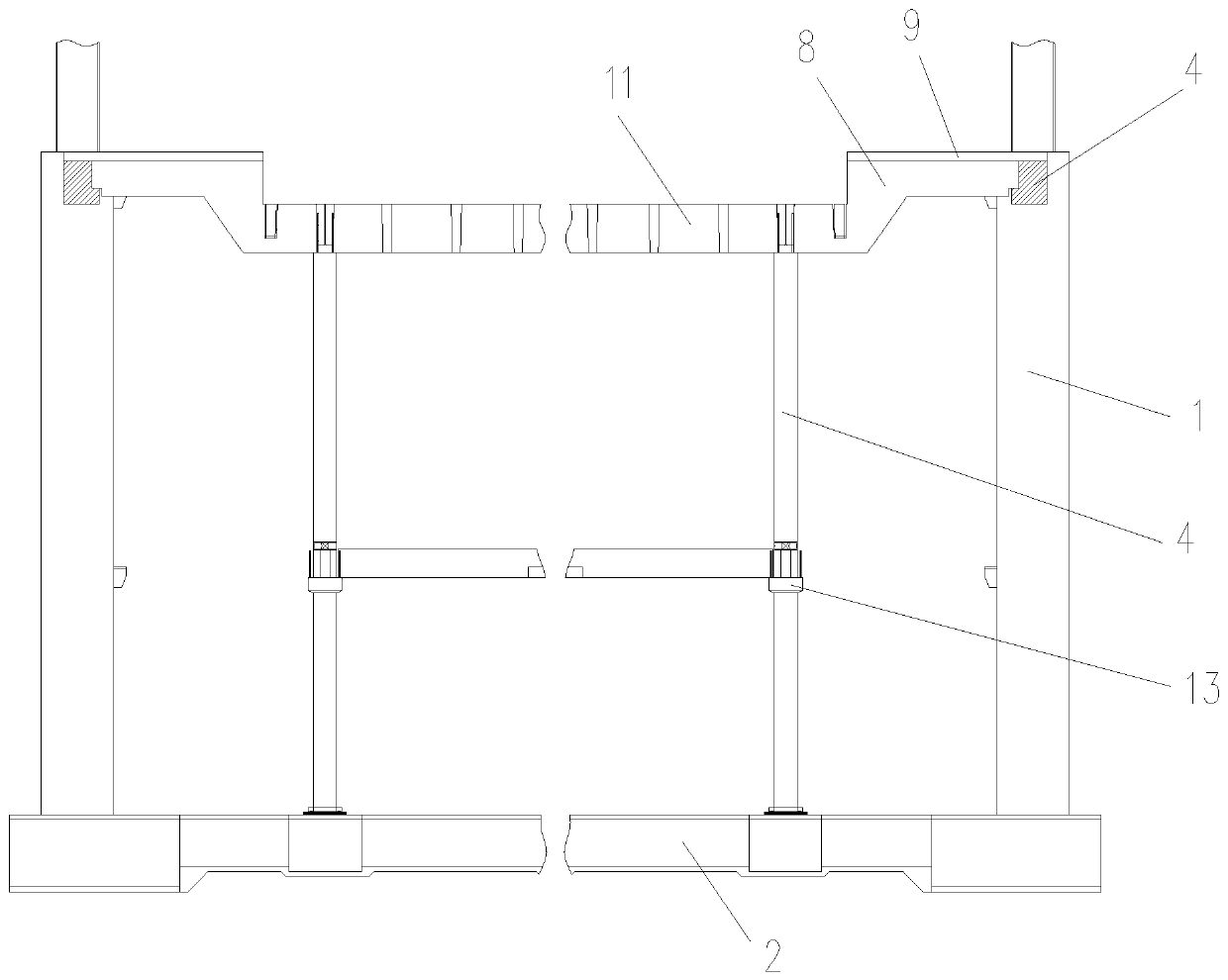

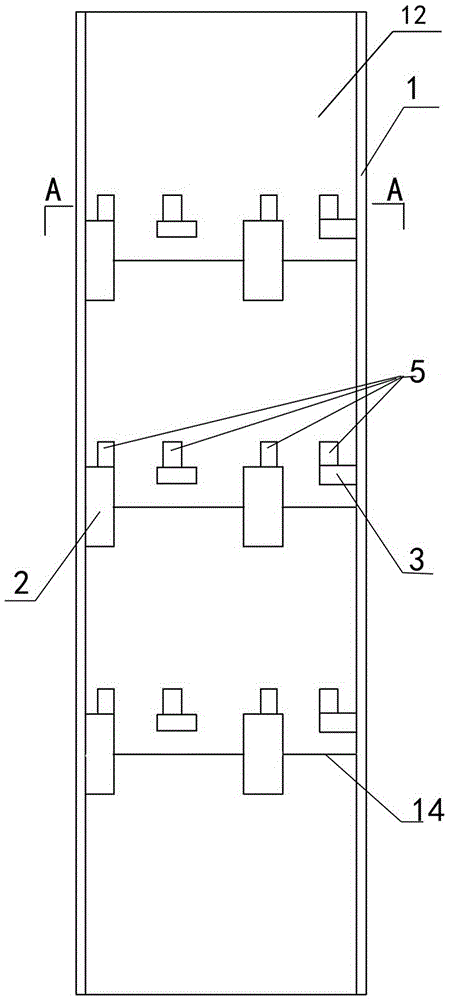

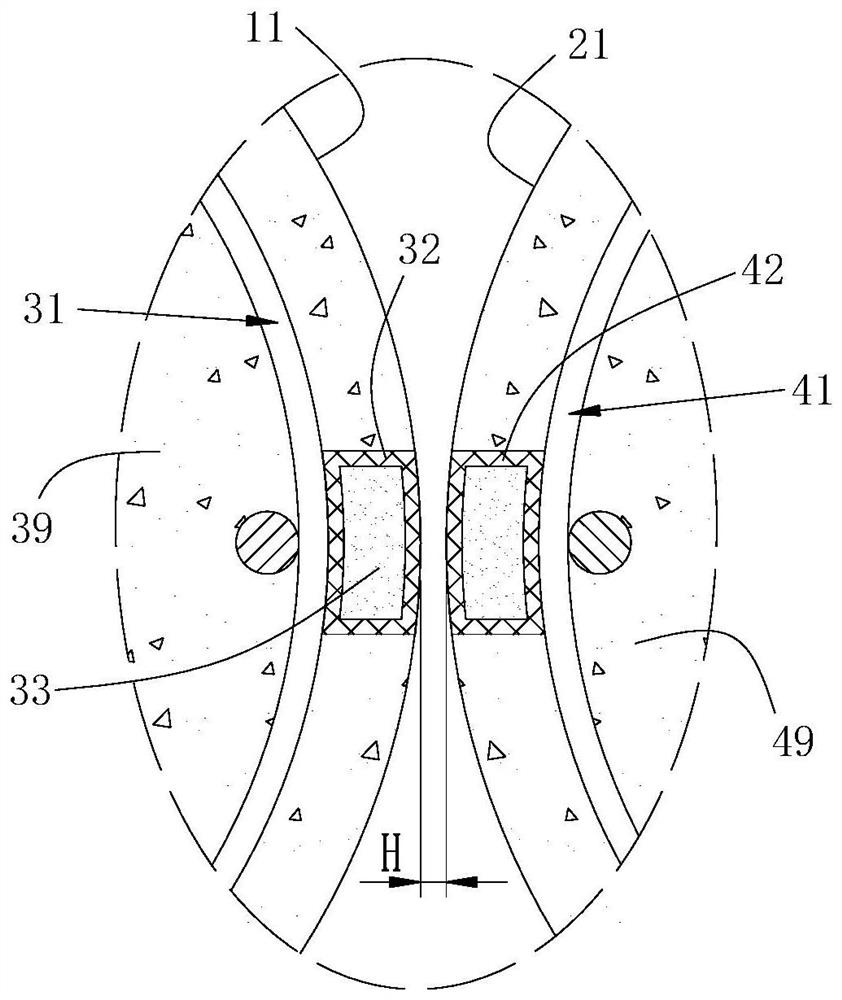

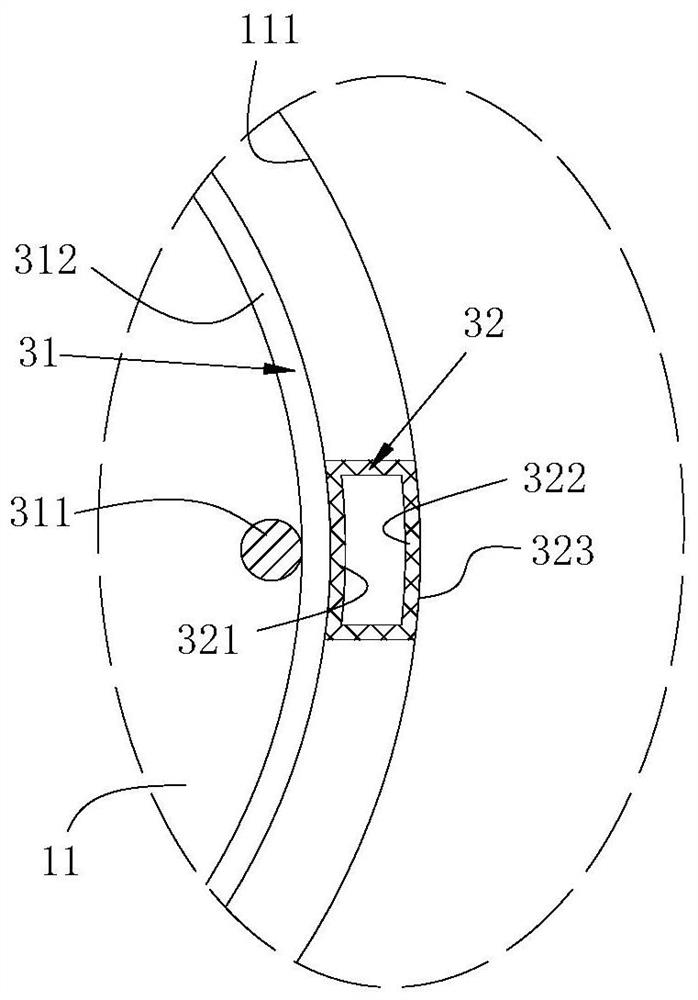

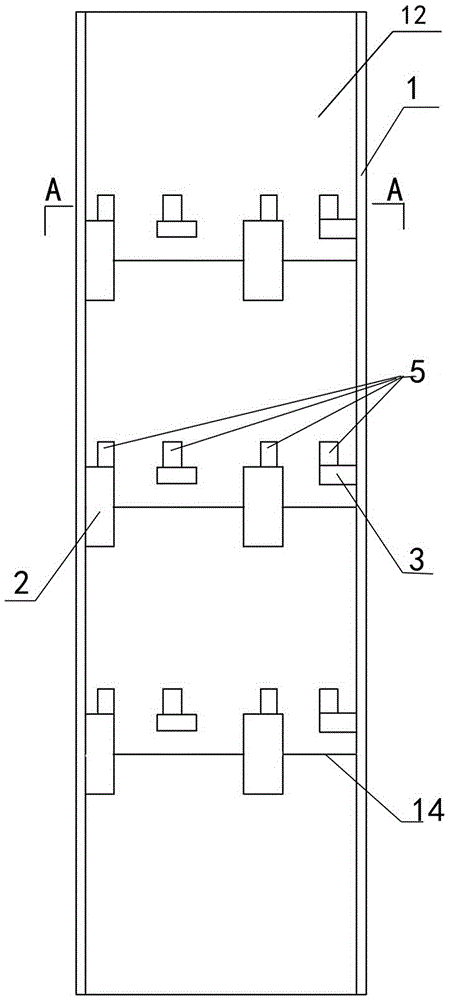

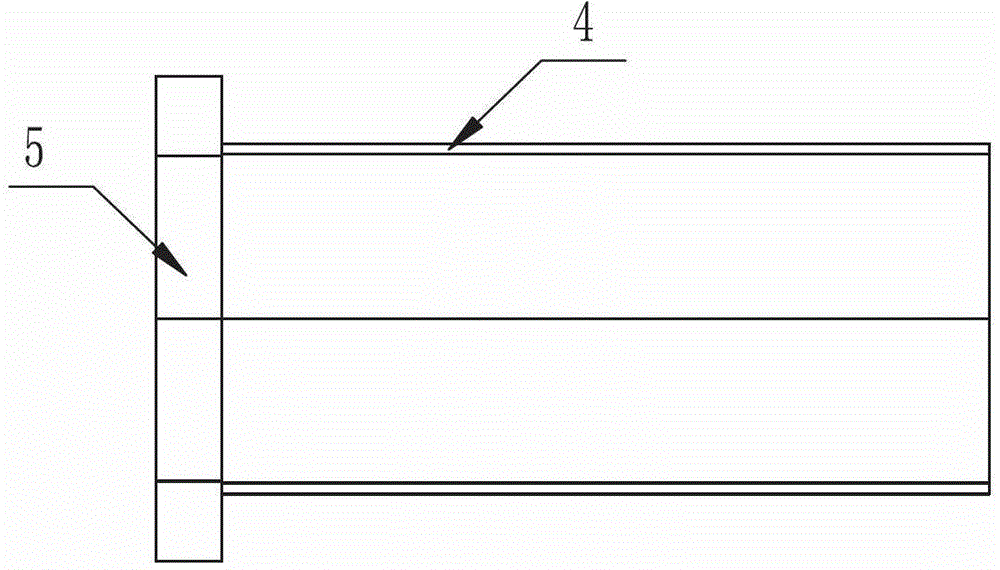

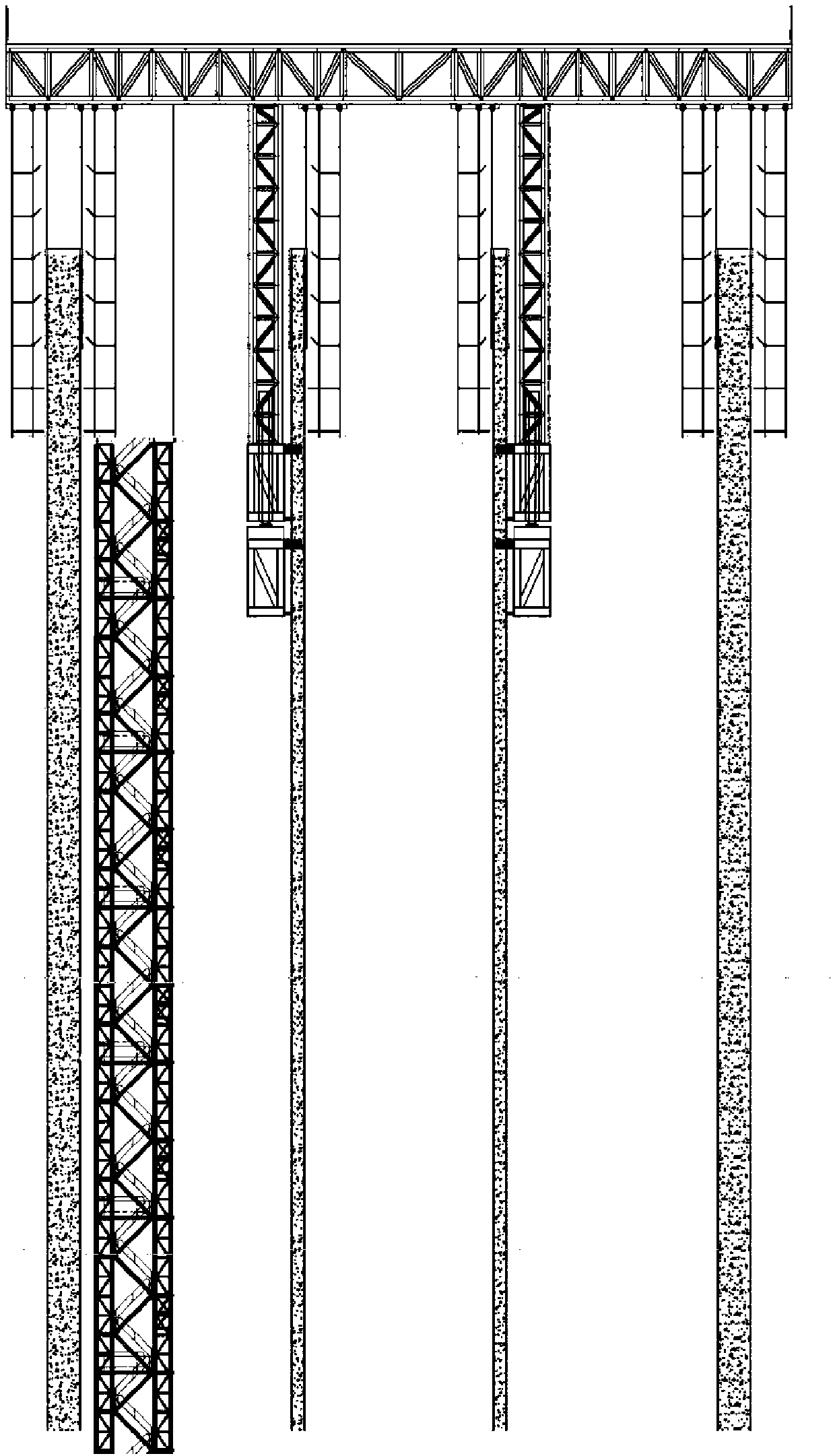

Inner roof external climbing type formwork construction platform for super high-rise building construction

InactiveCN106437130AReduce weightReduce the burden onBuilding support scaffoldsArchitectural engineeringEngineering

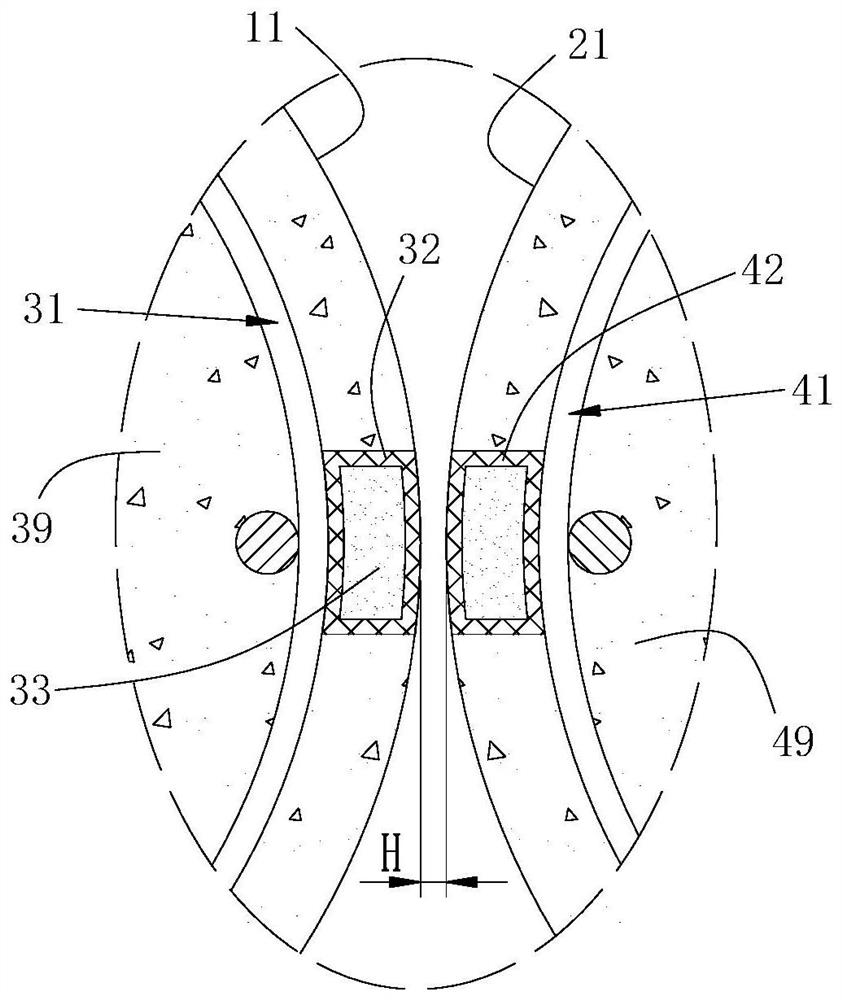

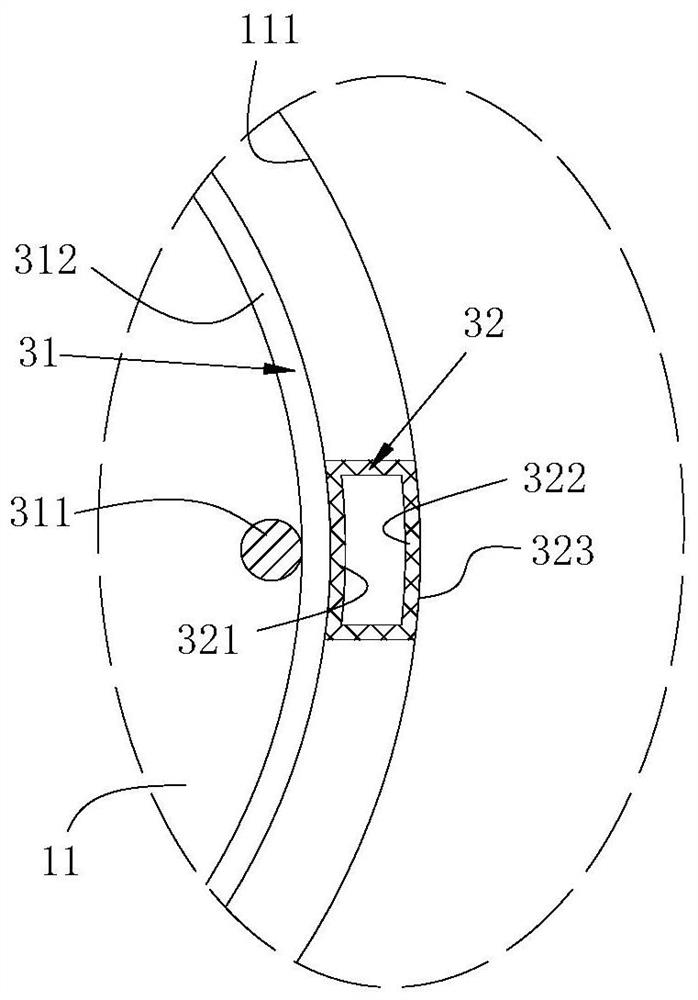

The invention discloses an inner roof external climbing type formwork construction platform for super high-rise building construction. The inner roof external climbing type formwork construction platform comprises a hydraulic creeping formwork system arranged on the outer side of a building and located on building walls and a jacking platform system arranged on the inner side of the building and located between adjacent building walls. The jacking platform system comprises a climbing device, an operating platform arranged on the climbing device and wall-attached embedder parts installed on the building walls and used for the climbing device to climb and attach. The hydraulic creeping formwork system adopted on a building external wall and the jacking platform system adopted on the inner side of the building and located between the building walls simultaneously operate to replace a traditional integral jacking type construction platform, horizontal supporting steel beams are not needed, oil cylinder climbing can be achieved only by installing the wall-attached embedder parts on the building walls, the total height of the construction platform and a supporting frame body of the platform is decreased, and a construction difference between a vertical structure and a horizontal structure is decreased, so that the hydraulic climbing system does not influence horizontal structure construction.

Owner:中国华西企业股份有限公司 +2

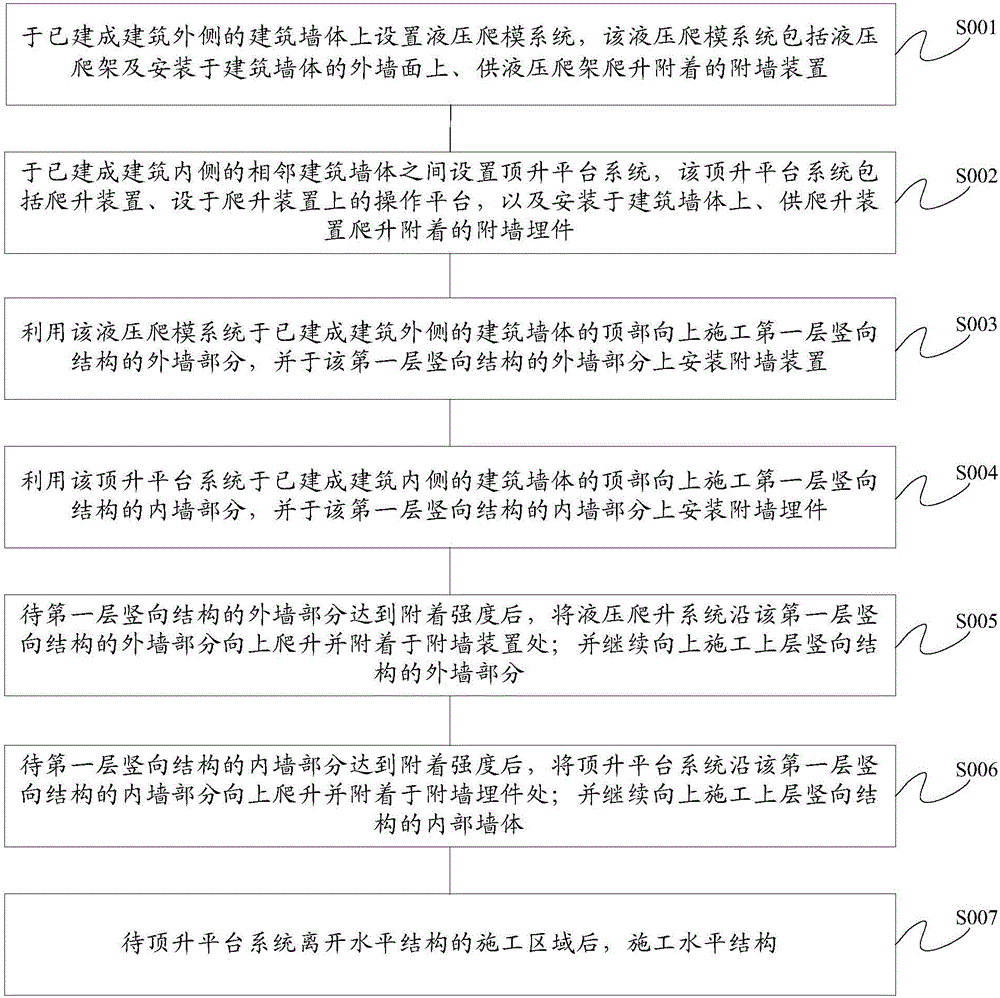

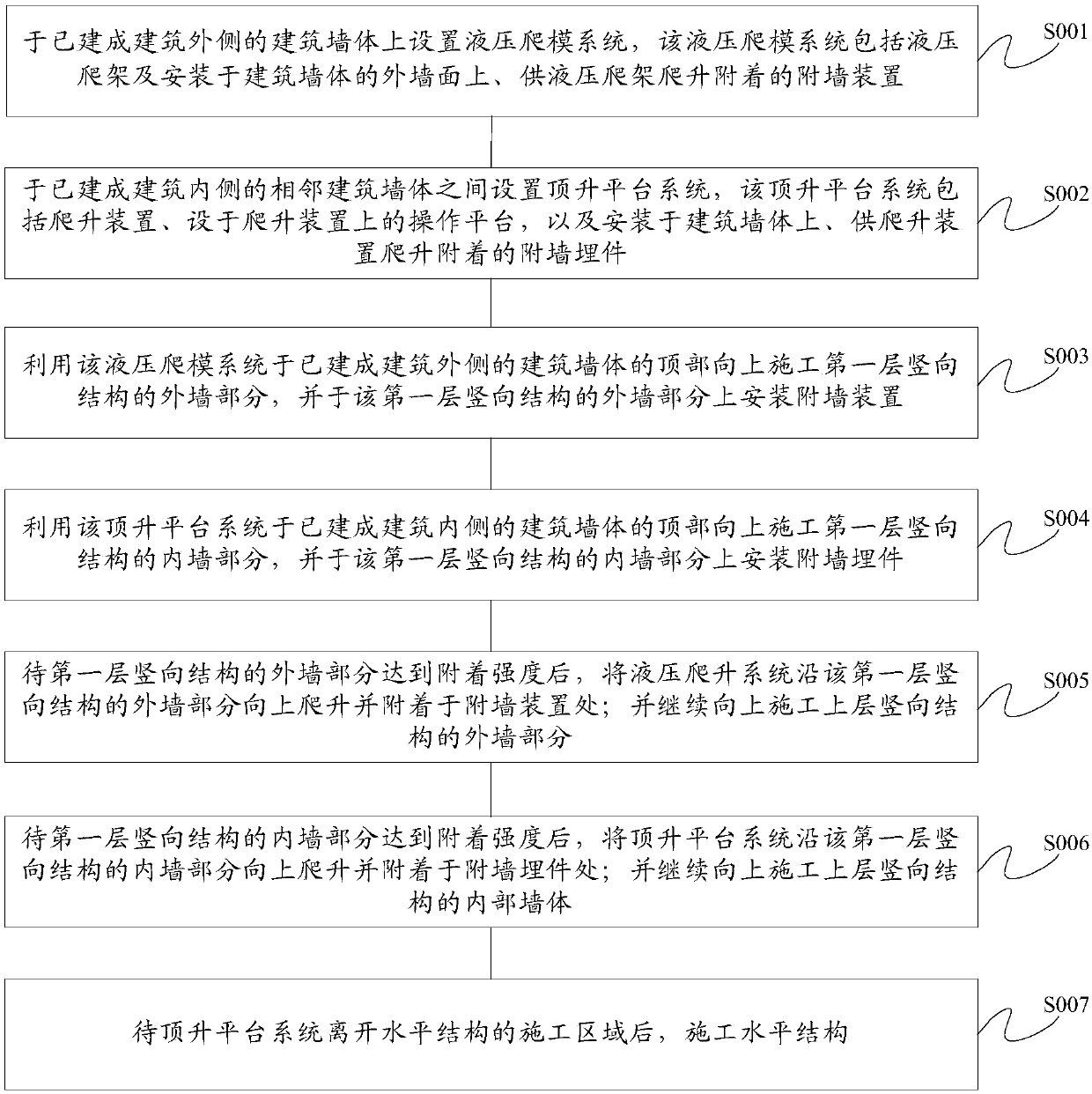

Synchronous construction method for horizontal and vertical structures of super high-rise building

ActiveCN106400951AReduce overall weightReduce the burden onForms/shuttering/falseworksRebarBuilding construction

The invention discloses a synchronous construction method for horizontal and vertical structures of a super high-rise building. According to the synchronous construction method, a hydraulic creeping formwork system is adopted on the outer wall of the super high-rise building, and a jacking platform system is adopted between two building walls on the inner side of the super high-rise building; when being operated at the same time, the two systems can replace a conventional overall jacking construction platform as a construction platform, thereby reducing the overall weight of a construction platform and the burden of a hydraulic jacking system, achieving higher flexibility, and improving the construction speed; as the light-weight jacking platform system is configured, a small-sized oil cylinder can be adopted; accordingly, no horizontal supporting steel beam is needed, oil cylinder climbing can be achieved as long as wall-attached embedded parts are mounted on the building walls, the total height of the construction platform and a supporting frame body can be reduced, the construction gap between the vertical and horizontal structures can be narrowed, and the construction of the horizontal structure can be prevented from being influenced by a hydraulic climbing system; and the jacking platform system adopted on the inner wall of the super high-rise building is prevented from penetrating through the building walls, and the gap between the construction platform and a reinforcing bar colligation operation surface is equal to the height of one floor, thereby achieving convenient reinforcing bar transfer and colligation.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +2

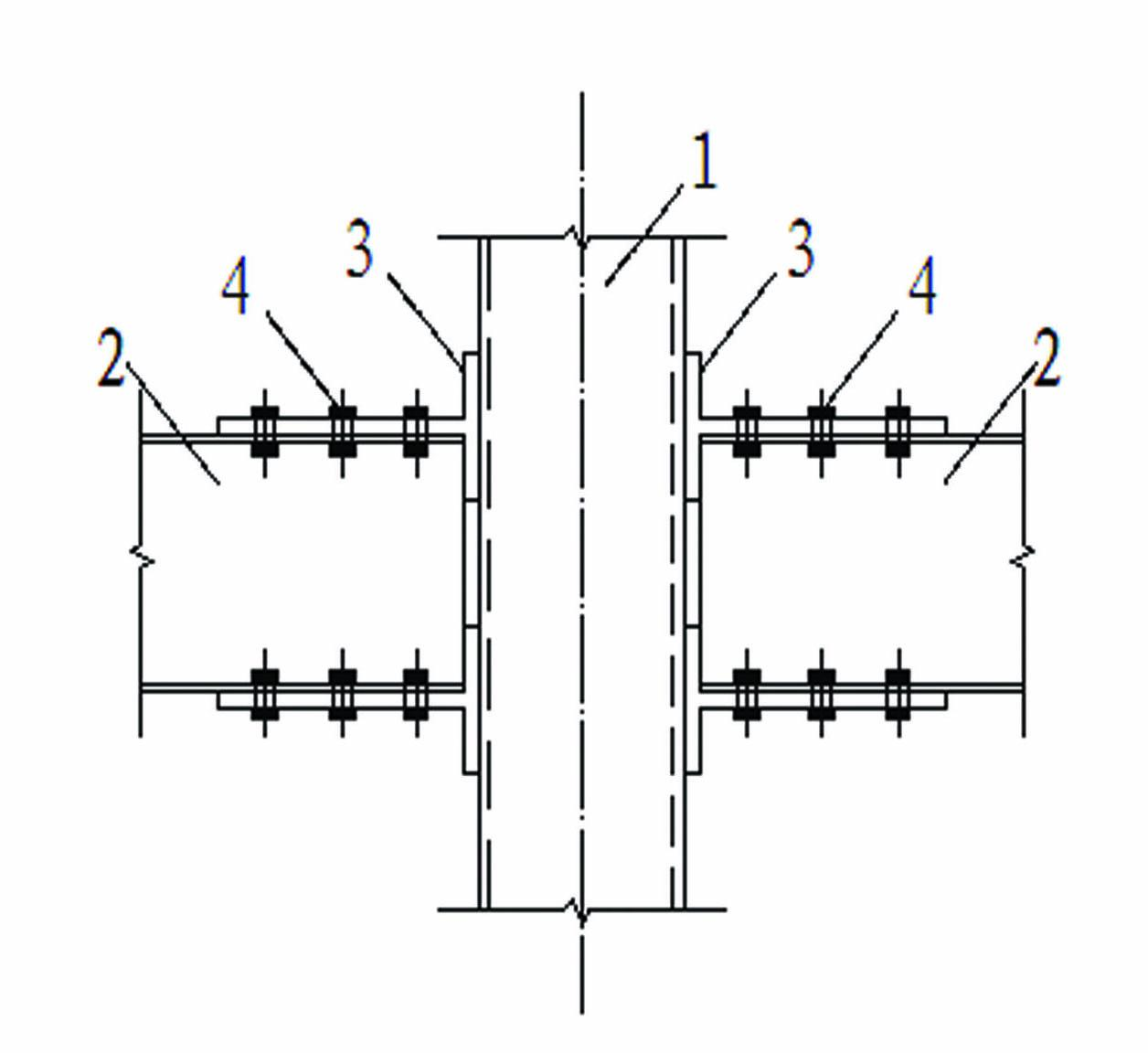

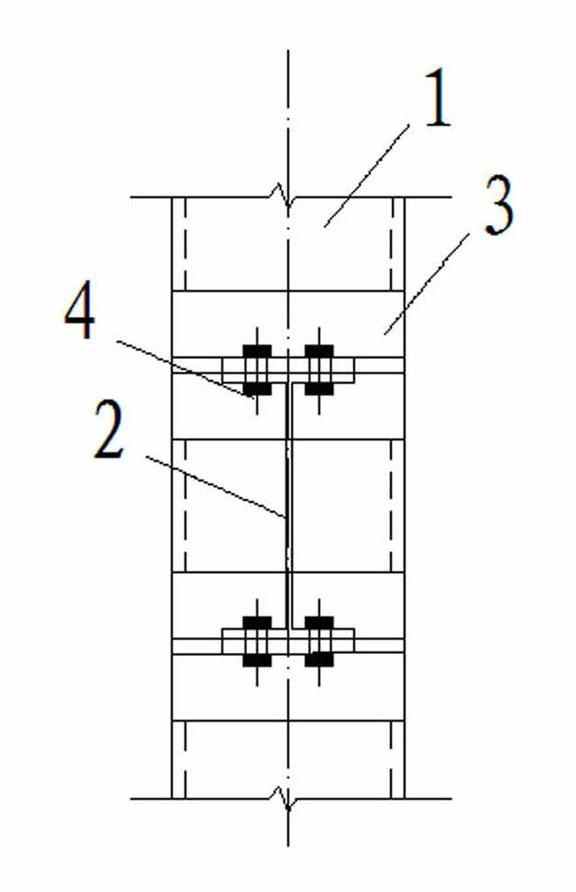

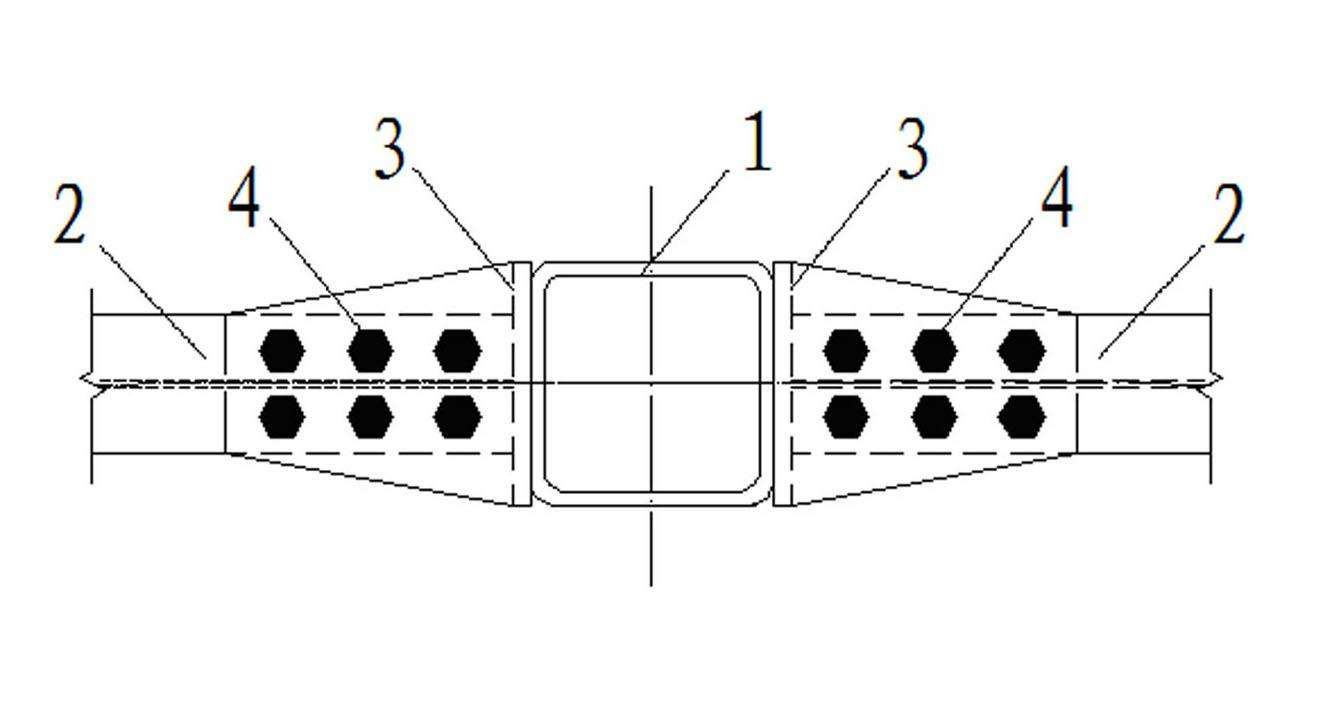

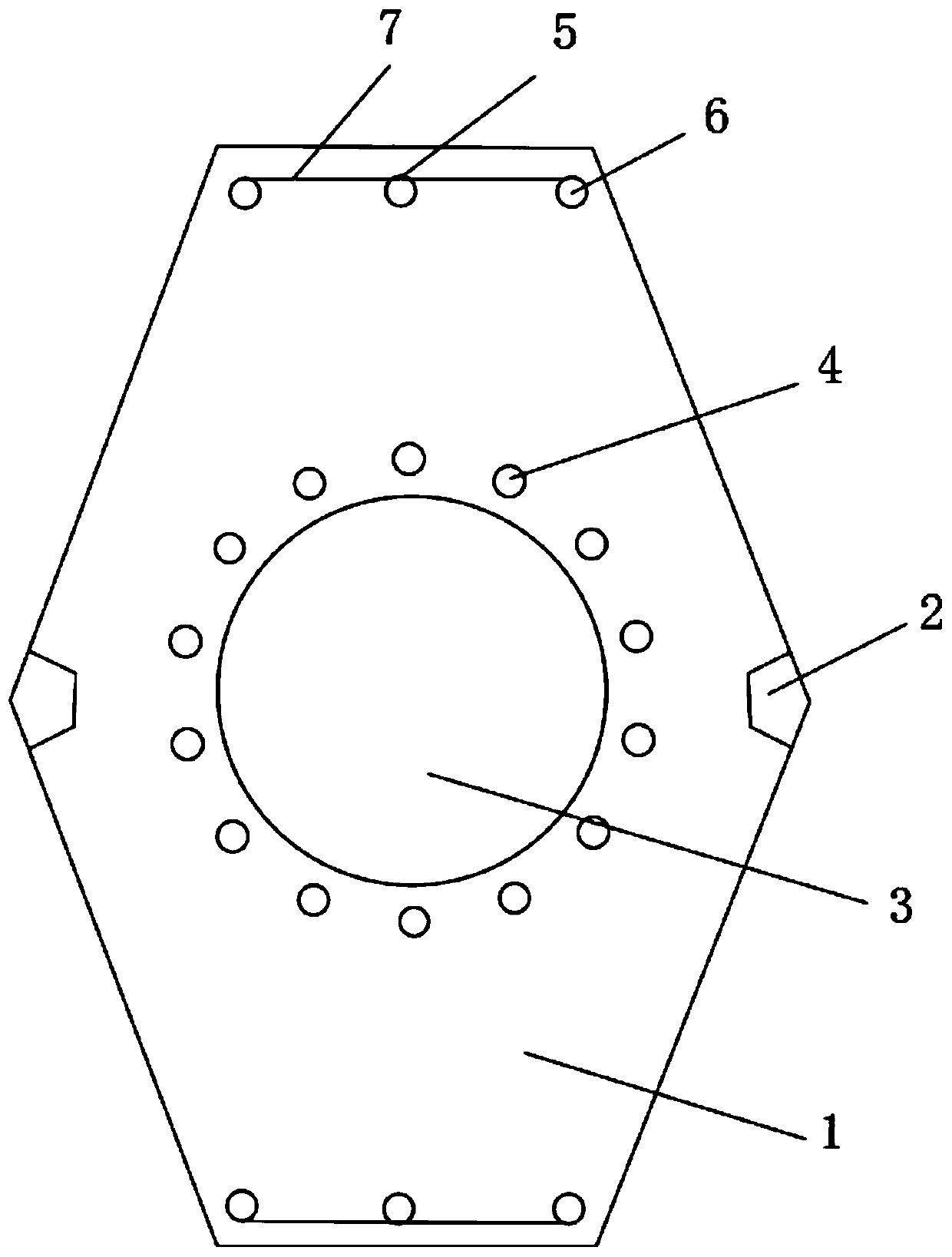

Connecting node of square steel pipe column and H-shaped steel beams

InactiveCN102635166APrevent local bucklingImprove the shortcomings of insufficient stiffnessBuilding constructionsFloor slabShock resistance

The invention relates to a connecting node of a beam and a column of building steel structures, in particular to a connecting node of a square steel pipe column and H-shaped steel beams for multi-layer and high-rise steel structures. The connecting node comprises a square steel pipe column, H-shaped steel beams and T-shaped steels; the T-shaped steels are arranged on the lateral wall of the square steel pipe column and the upper and lower wing edges of the H-shaped steels; webs of the T-shaped steels are connected with the wing edges of the H-shaped steel beams; and the wing edges of the T-shaped steels are fixedly connected with the lateral walls of the square steel pipe column. According to the connecting node of the square steel pipe column and the H-shaped steel beams, the connecting node is simple in structure, and the problem of construction difficulty in installing an internal separating plate is solved; a plastic hinge shifts outwards and better shock-absorbing property is achieved; the construction of an upper floor and the casting of concrete in the square steel pipe are not influenced; and the steel consumption is low. Therefore, the connecting node has high economic and social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

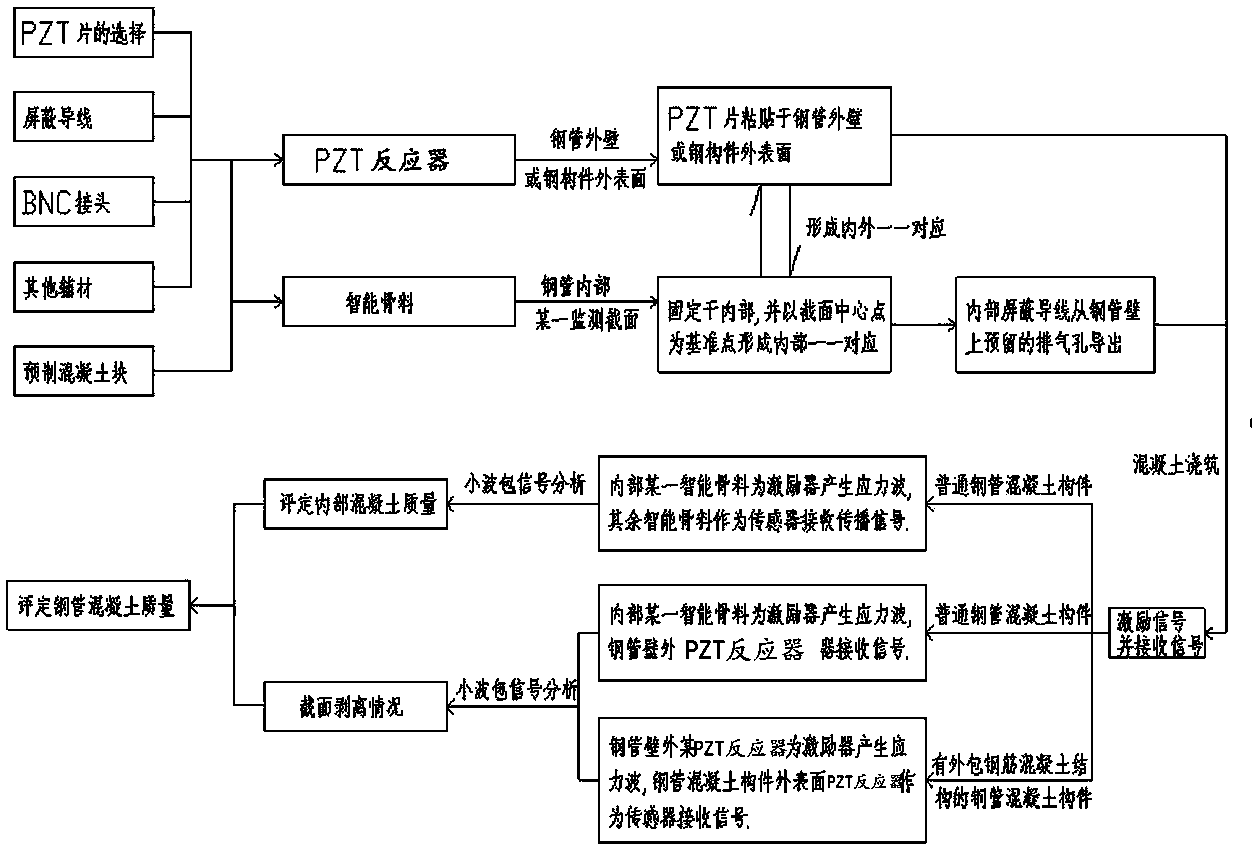

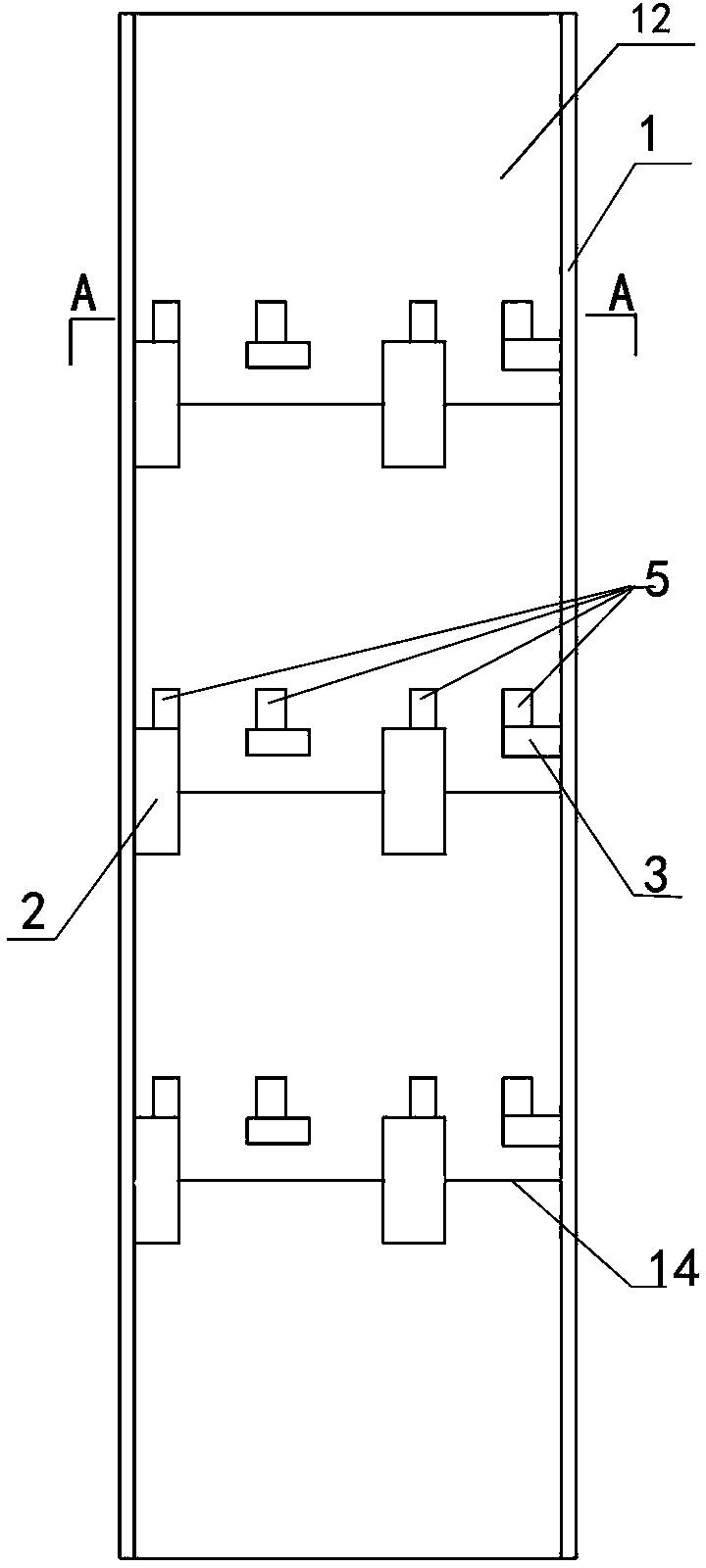

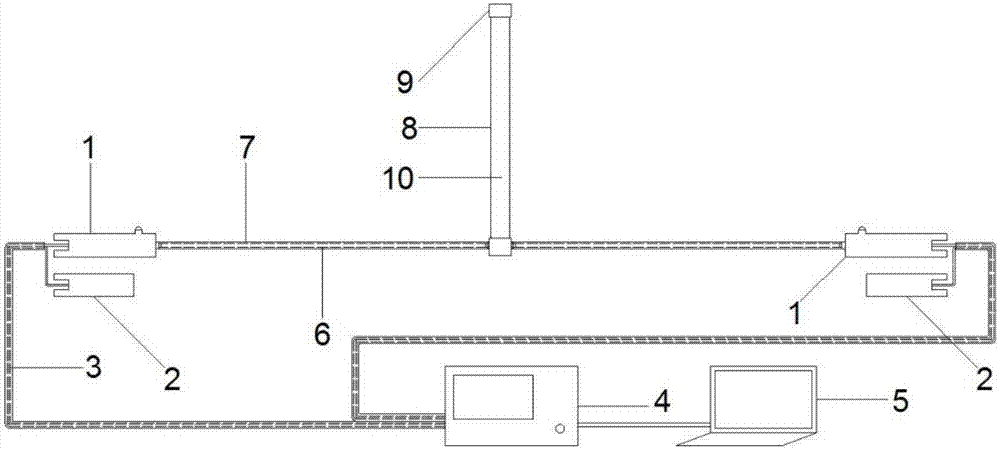

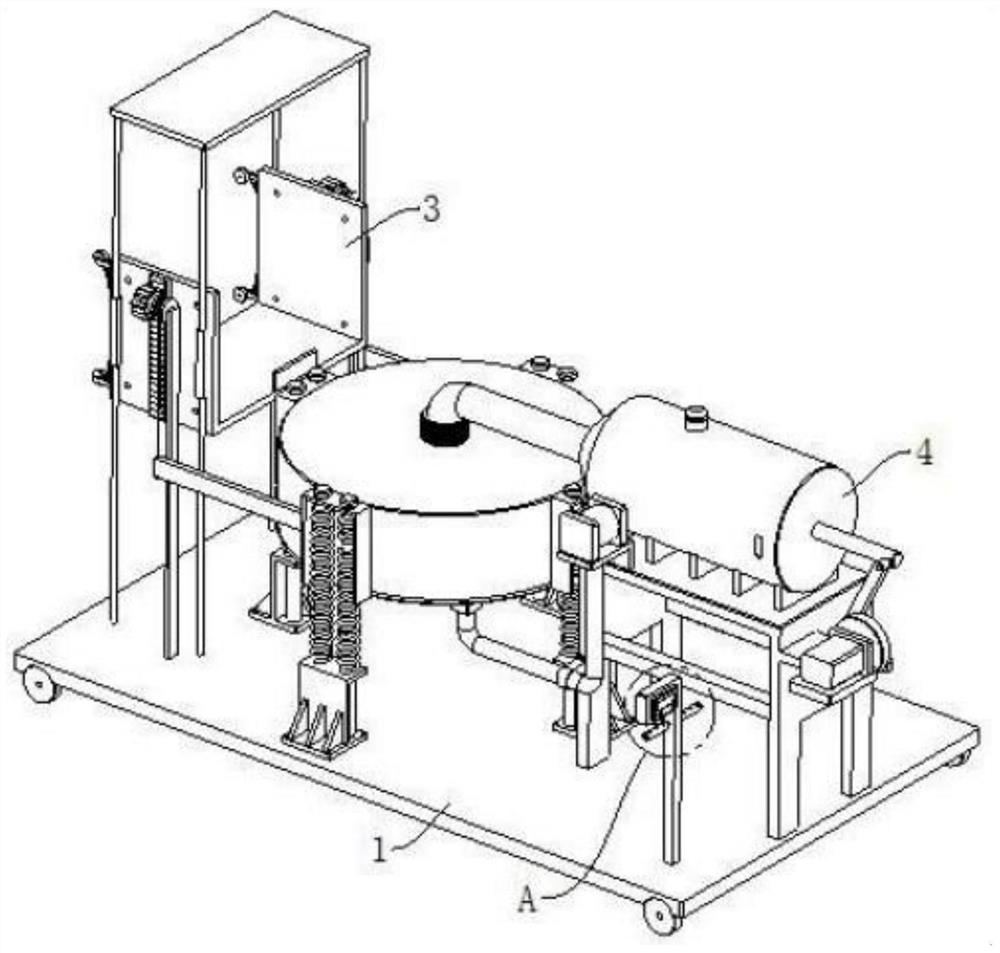

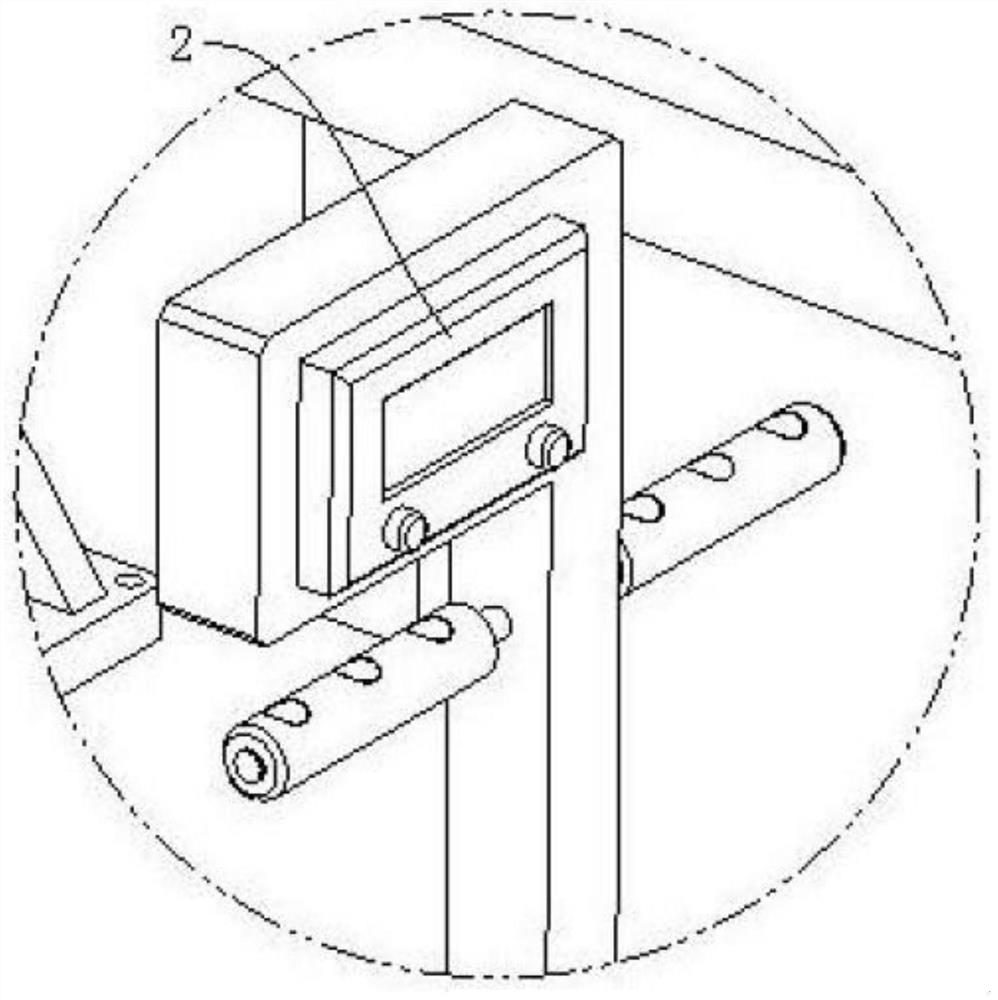

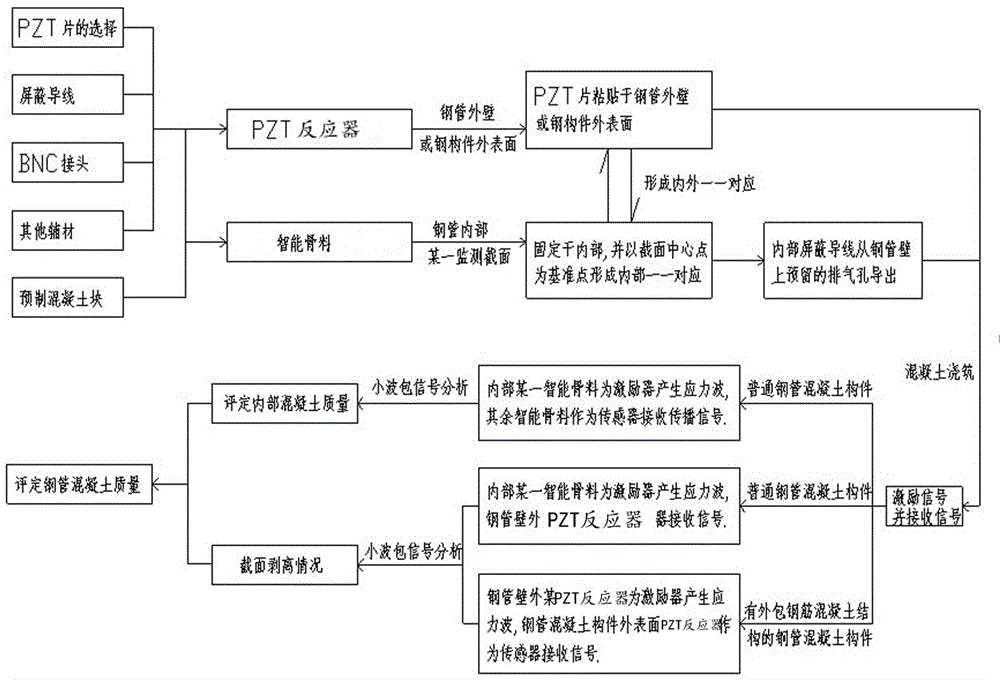

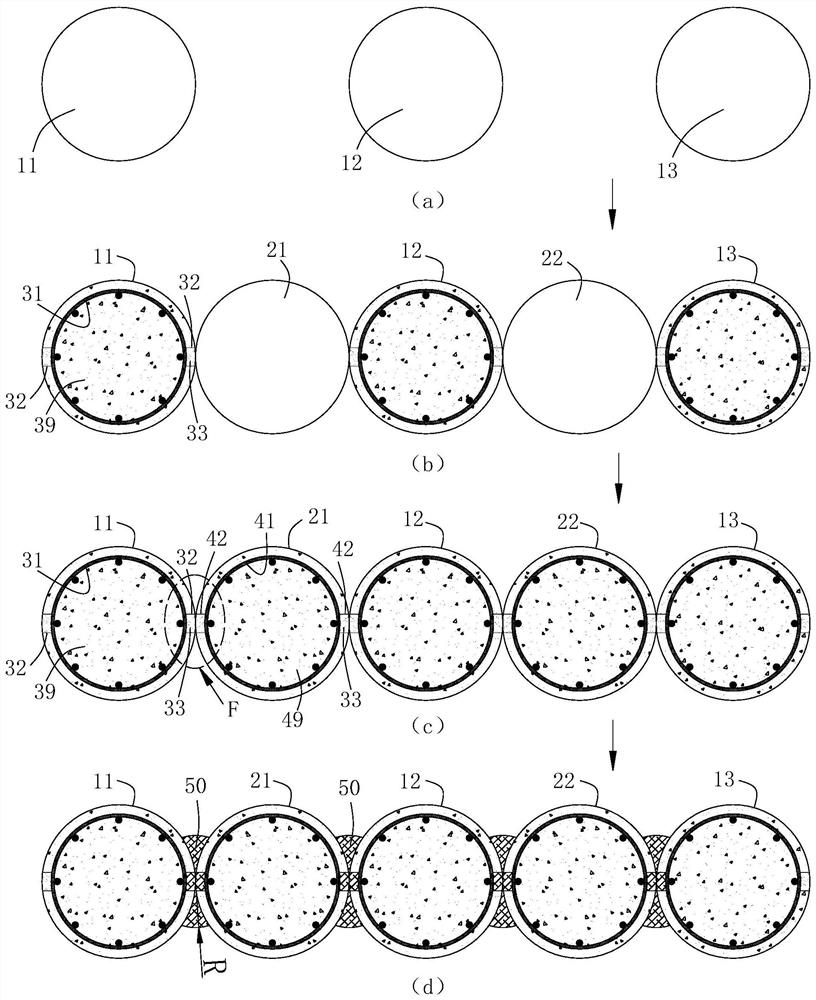

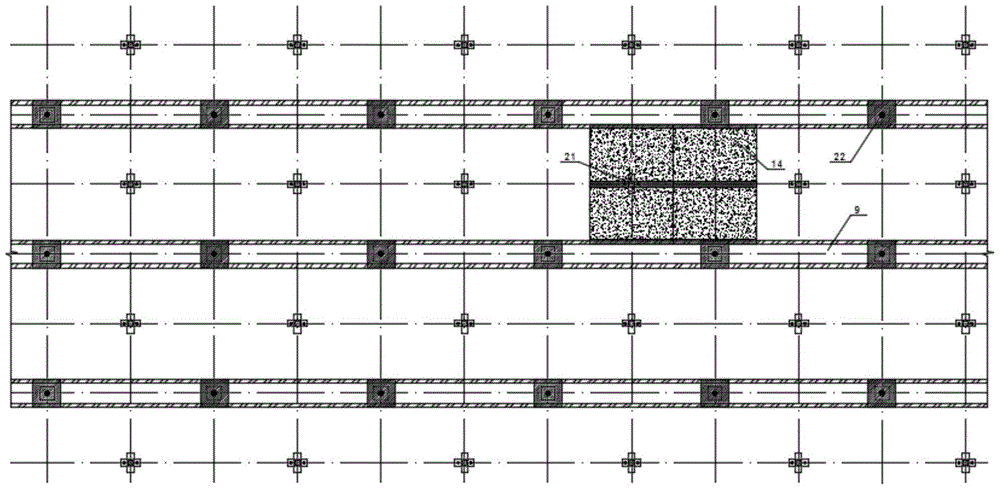

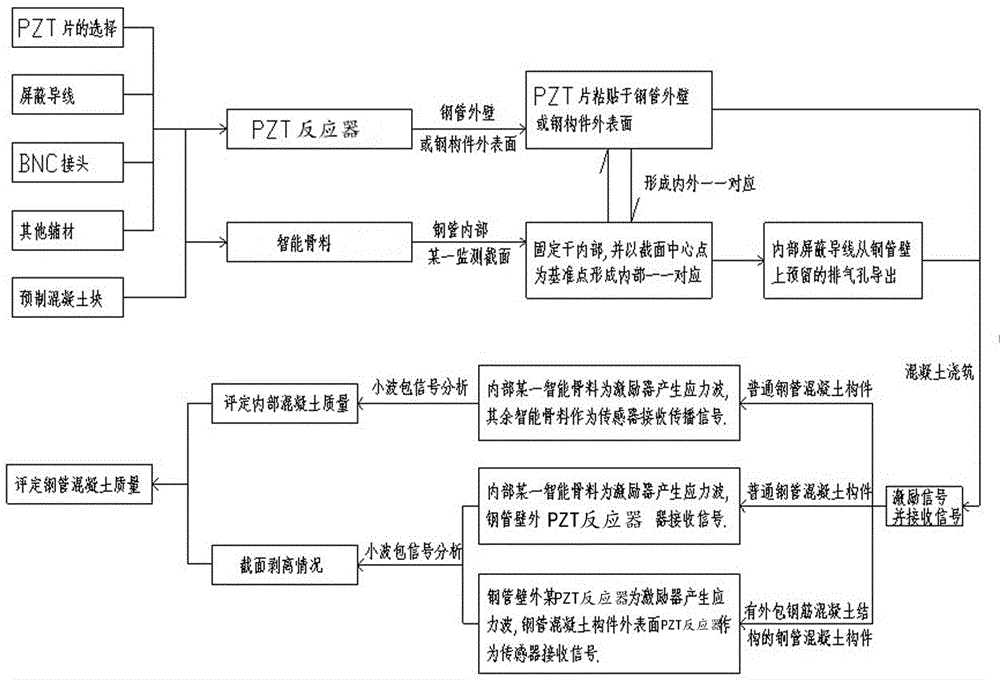

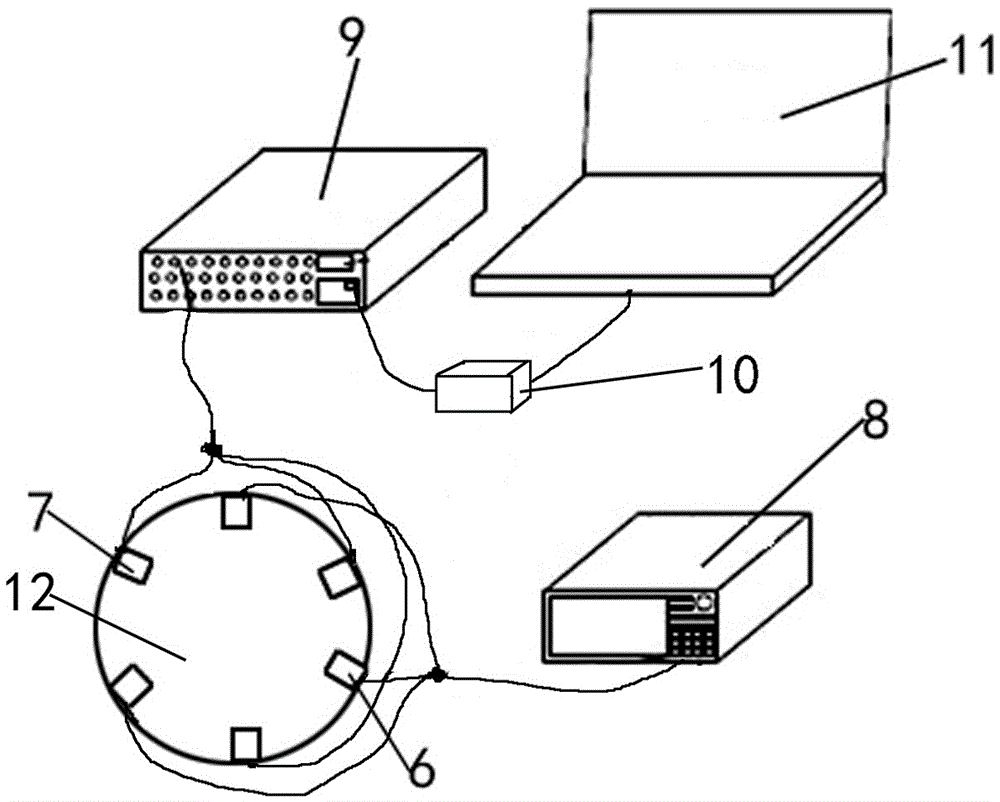

Piezoelectric-material-based construction method for monitoring concrete filled steel tubular member quality through impedance method

ActiveCN103675030AEasy to collectEasy to compare and analyzeMaterial impedanceElectricityData acquisition

The invention discloses a piezoelectric-material-based construction method for monitoring concrete filled steel tubular member quality through the impedance method. According to the working principle of a PZT substrate, multi-section and multi-layer arrangement is performed on intelligent aggregate and a PZT reactor. The construction method aims to solve the problems that the existing concrete filled steel tubular member quality monitoring method stays in the test period and is poor in practicability to facilitate data acquisition and contrastive analysis. Multiple concrete member quality indicators, such as concrete filling density and the interface bonding quality of concrete on a tube wall, can be detected through one-time construction; in addition, the impedance method is utilized to verify a result, the operation is simple and the detection accuracy is high; the material can be recycled and the utilization rate is high; the detection and the engineering can be carried out simultaneously, the construction of an upper major structure can not be affected, so that the investment in construction period cost is reduced, and the on-line monitoring can be carried out in real time; the method is particularly suitable for evaluating the concrete pouring quality and the interface bonding quality of concrete filled steel tubular members.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU +1

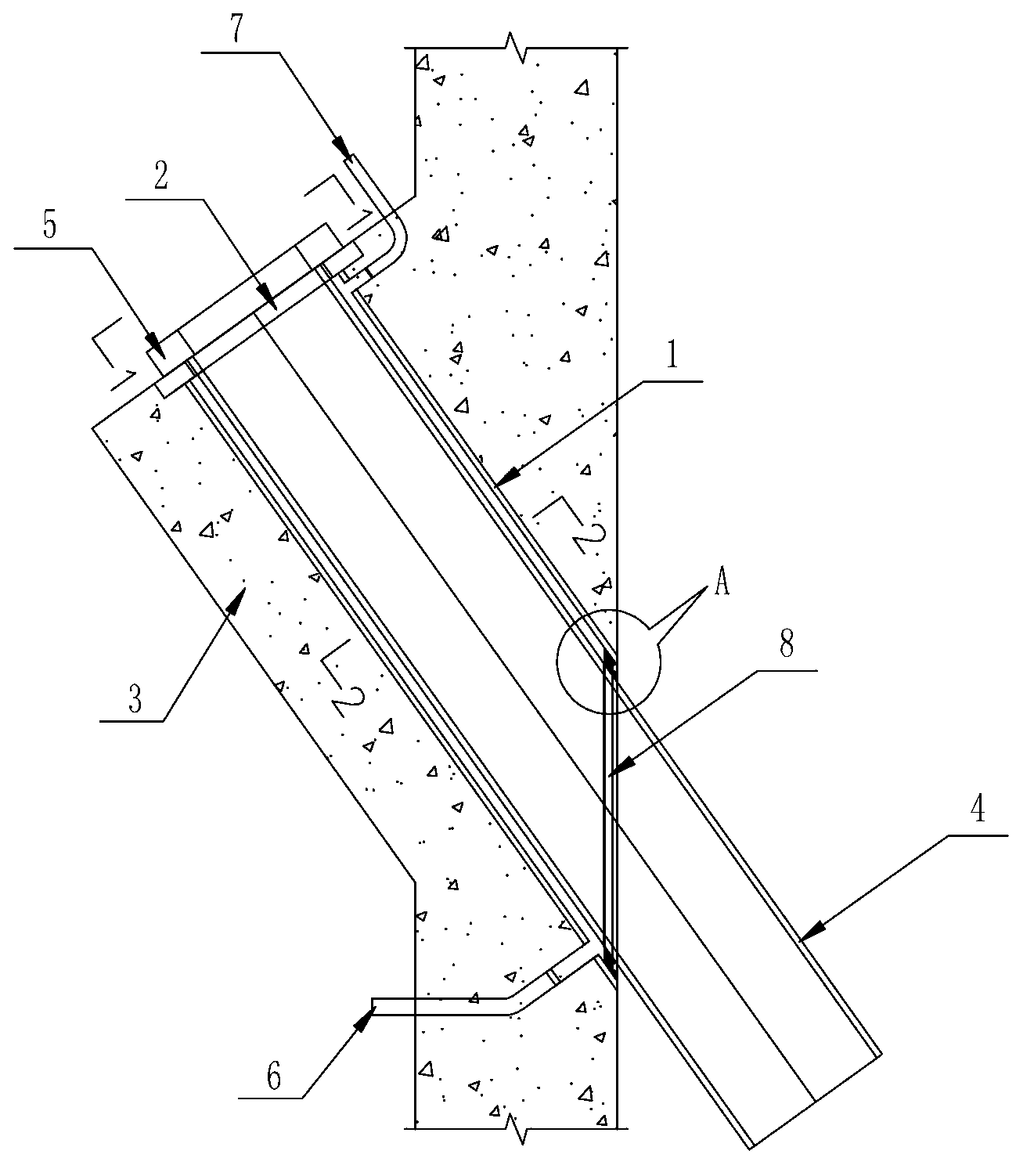

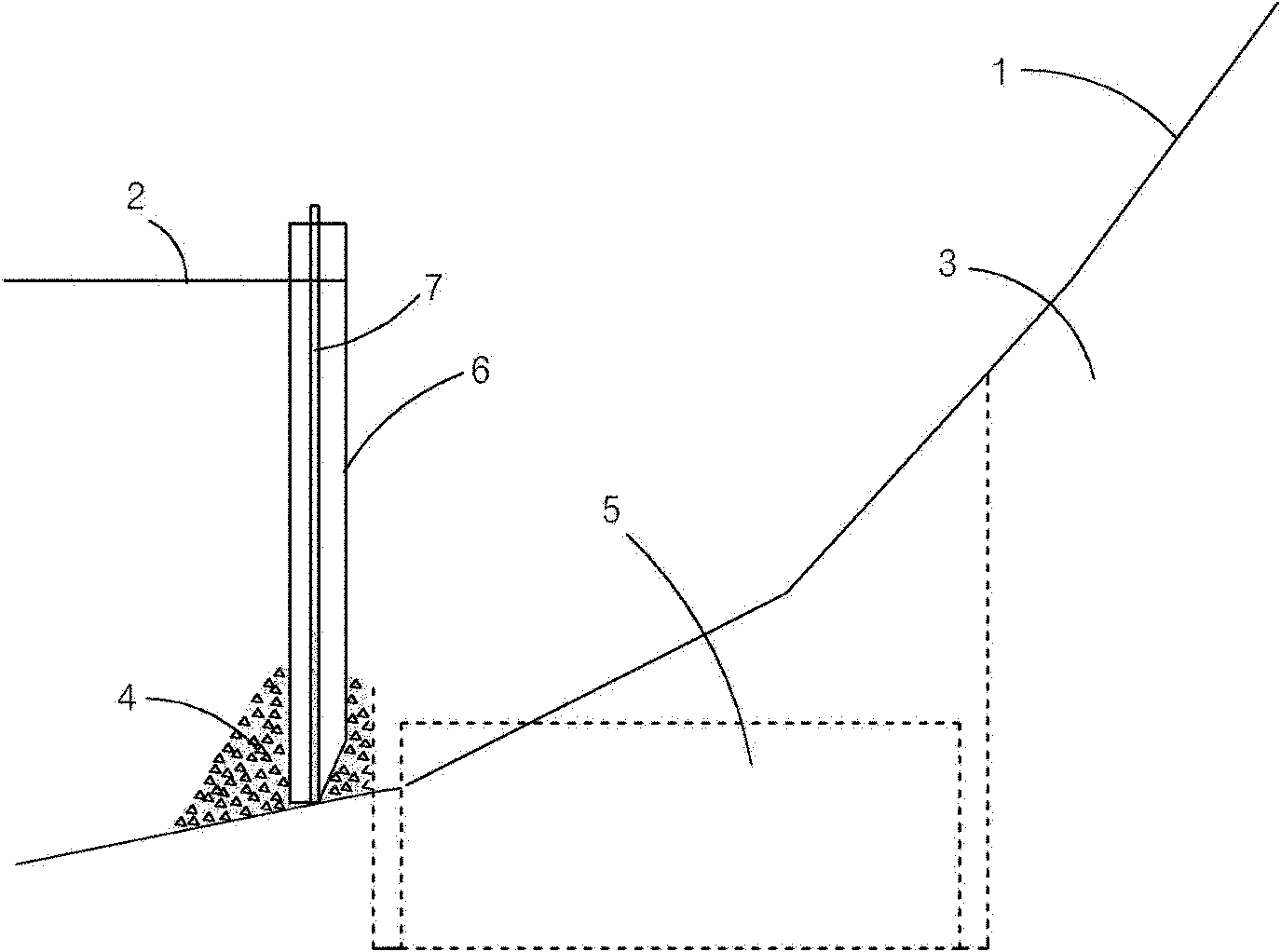

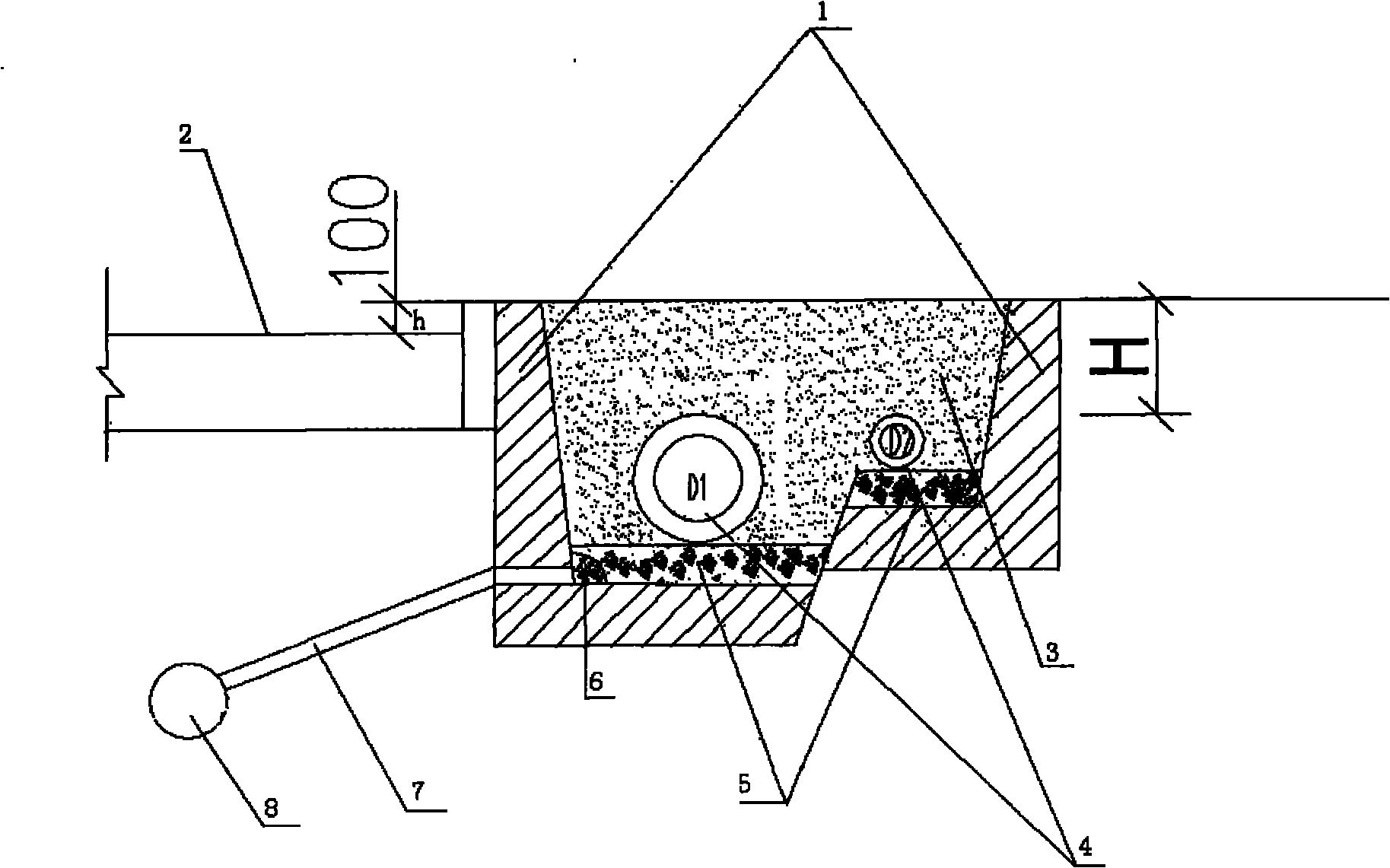

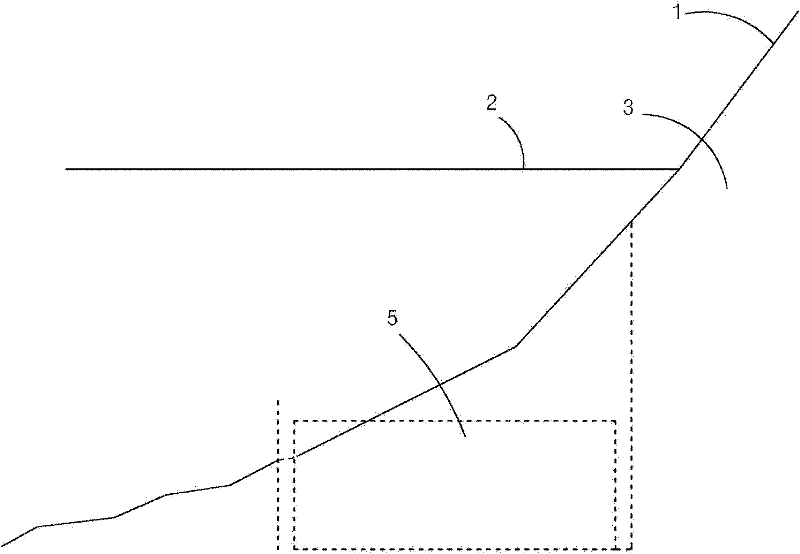

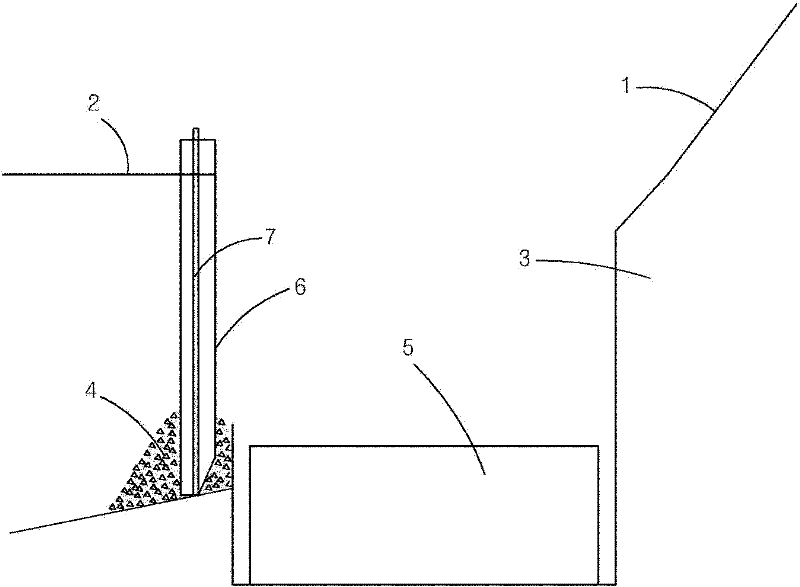

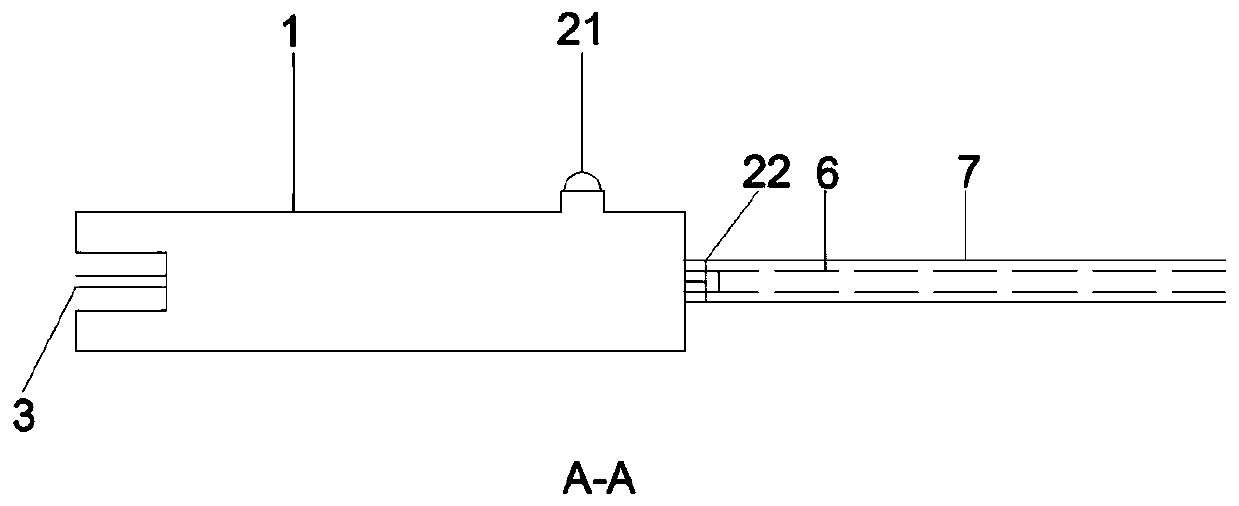

Embedded optical fiber roadbed settlement observing apparatus, and observation method thereof

The invention discloses an embedded optical fiber roadbed settlement observing apparatus, and an observation method thereof. The apparatus comprises fiber grating pressure sensing devices, fiber grating temperature sensing devices, a fiber grating demodulator, a terminal receiving device, a PVC tube, a nylon conduit and a PE protection tube. According to the observation method, the fiber grating pressure sensing devices and the nylon conduit are embedded in soil in advance, and thus, the apparatus overcomes the defect that traditional settlement observation instruments interfere in construction due to burying of the instruments in filling soil for a construction area. During construction and post-construction settlement monitoring of a roadbed, the settlement of one point in the roadbed is converted into changes in the reflection wavelengths of fiber gratings of the fiber grating pressure sensing devices along with soil settlement, so settlement observation means are improved; and the apparatus has the characteristics of simple measurement method, high measurement accuracy, capacity of measuring upheaval displacement and high efficiency.

Owner:中交投资南京有限公司

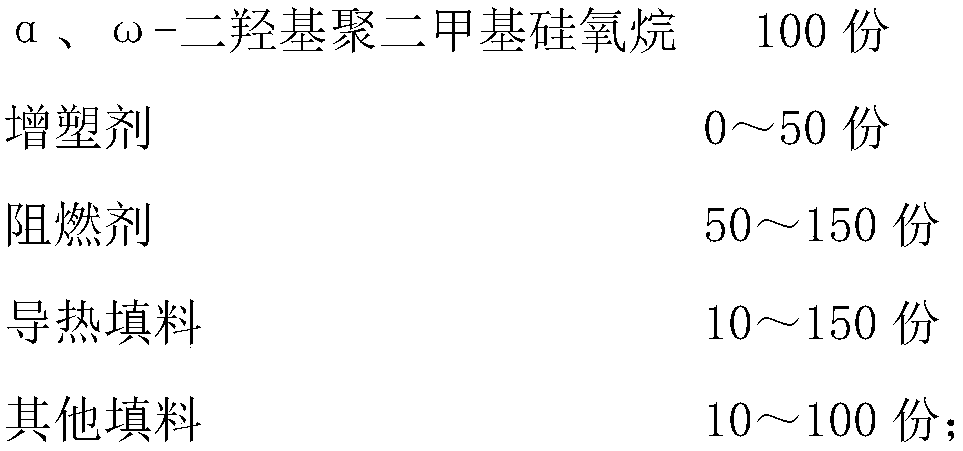

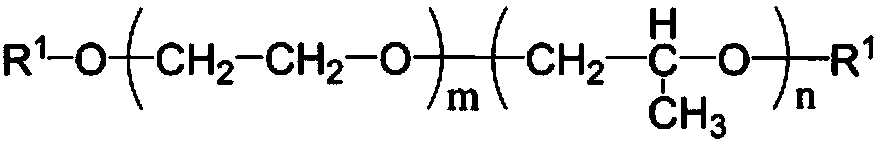

Double-component condensed type encapsulating material convenient for construction and preparation method thereof

ActiveCN111286299AIncrease forceImprove potting pass rateNon-macromolecular adhesive additivesPolyether adhesivesPolymer sciencePtru catalyst

The invention provides a double-component condensation type encapsulating material convenient for construction. The mixing ratio of a component A to a component B is (4-6): 1. The component A is prepared from the following main raw materials in parts by mass: 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 0-50 parts of a plasticizer, 50-150 parts of a flame retardant, 10-150 parts of aheat conduction filler and 10-100 parts of other fillers. The component B comprises the following main raw materials in parts by mass: 0.1-5 parts of a catalyst, 100 parts of polyether and 20-100 parts of a cross-linking agent composition, and the component B does not contain linear dimethyl silicone oil or branched chain type dimethyl silicone oil. The viscosity difference multiple of the component A and the component B can be controlled within the range of 5, so that the good matching performance of the pouring sealant and equipment is ensured, the proportional fluctuation of materials during gluing is reduced, and the pouring qualification rate of parts is increased.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

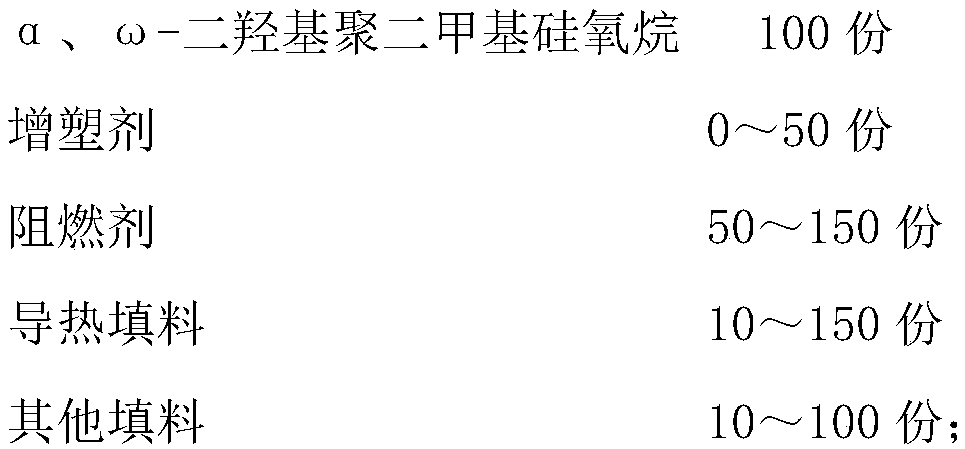

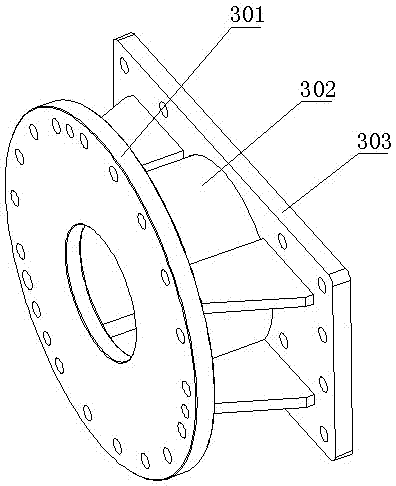

Inner sleeve-type inclined guy cable main tower cable guide pipe and construction method thereof

ActiveCN103015318APrevent spillageConstruction will not affectBridge structural detailsBridge erection/assemblyTowerGuide tube

The invention relates to an inner sleeve-type guy cable main tower cable guide pipe and a construction method thereof. A pre-buried pipe pre-buried in a main tower is the same as the cable guide pipe in mounting angle, and is flush with the outer side of the main tower; a pre-buried plate at the inner end of the pre-buried pipe is flush with a concrete surface of an inclined stay cable anchor block; the outer end of the cable guide pipe is exposed out of the main tower; the inner end of the cable guide pipe is connected with an anchor padding plate; the anchor padding plate is welded with the pre-buried plate; and a gap is reserved between the cable guide pipe and the pre-buried pipe. The construction method comprises the following steps: pre-burying the pre-buried pipe in a main tower section required to be poured with concrete; jacking a main tower mold plate after the pouring of concrete; mounting the cable guide pipe in the pre-buried pipe in such a manner that the gap is reserved between the cable guide pipe and the pre-buried pipe; mounting a circular plug between the outer end of the pre-buried pipe and the cable guide pipe; and grouting from a grouting port, so that the mounting of the inner sleeve-type cable guide pipe is fulfilled. As no hole for the cable guide pipe is formed in the main tower mold plate, the service life of the mold plate can be prolonged, and time for opening and lofting of a lower die plate is saved; and as obstruction caused by the exposing of the cable guide pipe is avoided, the construction speed as well as the operating efficiency is high. The cable guide pipe and the construction method are suitable for concrete main towers of which inclined stay cable guide pipes are exposed out of main tower walls.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Method for constructing special shaped deepwater cofferdams on steep rocky riverbeds

ActiveCN102021912ASuitable for constructionConstruction will not affectFoundation engineeringCrushed stoneEngineering

The invention discloses a method for constructing special shaped deepwater cofferdams on steep rocky riverbeds. The method is characterized by comprising the following steps: preferably selecting a prefabricated cofferdam wall, and arranging a grouting pipe which penetrates through the cofferdam wall up and down along the vertical direction in the cofferdam wall; then sinking the cofferdam wall on the riverbed, exposing the top end of the pipe above the water level, and using the grouting pipe to jet water to wash the riverbed; finally, filling the two sides of the cofferdam wall with broken stones, pouring cement mortar into the bottom of the cofferdam wall and the broken stones via the grouting pipe, draining the water in the cofferdam after the cement mortar and the broken stones are bonded and achieve the strength, and excavating a foundation pit in the absence of water, thus completing construction of bridge foundation. The method can be used for pretreating the riverbed without using equipment and is especially suitable for construction of deepwater cofferdams.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Method for installing outdoor process pipelines

InactiveCN101922586APrevent infiltrationExpel as soon as possiblePipe laying and repairCrushed stoneEngineering

The invention discloses a method for installing outdoor process pipelines, relates to a method for installing pipelines, in particular to a method for industrial and mining enterprises to install various process pipelines outdoors. In the method, a ditch is excavated and the pipeline is embedded outdoors. The method comprises the following steps of: a, excavating the ditch, wherein the distance from the edge of the ditch to the edge of an outdoor road is 1 to 1.5m; and the width of the ditch is 1.5 to 2m; b, tamping the bottom of the ditch, and then paving a gravel layer with gravel, wherein the thickness of the gravel layer is 20 to 40cm; c, placing the pipeline on the gravel layer, and covering grain-size fine stone or coarse sand with the thickness of 45 to 55cm on the pipeline; d, covering river sand with the covering thickness of 4 to 20cm on the top of the fine stone or coarse sand, and planting plants on the river sand; and e, arranging a drain pipe at a position, which is closest to a rainwater collecting pit of the road, on the gravel layer at the bottom. Due to the adoption of the method, various pipelines can be flexibly arranged according to the distances of different pipelines; and the fine sand is covered on the surface and the plants are planted, so that the embedding depth of the pipelines can be reduced, the excavating detection of the pipelines is facilitated, and the pipelines can be overhauled and replaced by excavating the coarse sand during the overhauling. By arranging the drain pipe, the rainwater can be effectively removed from the coarse sand, and the pipelines can be effectively protected.

Owner:YUNNAN BAIYAO GROUP

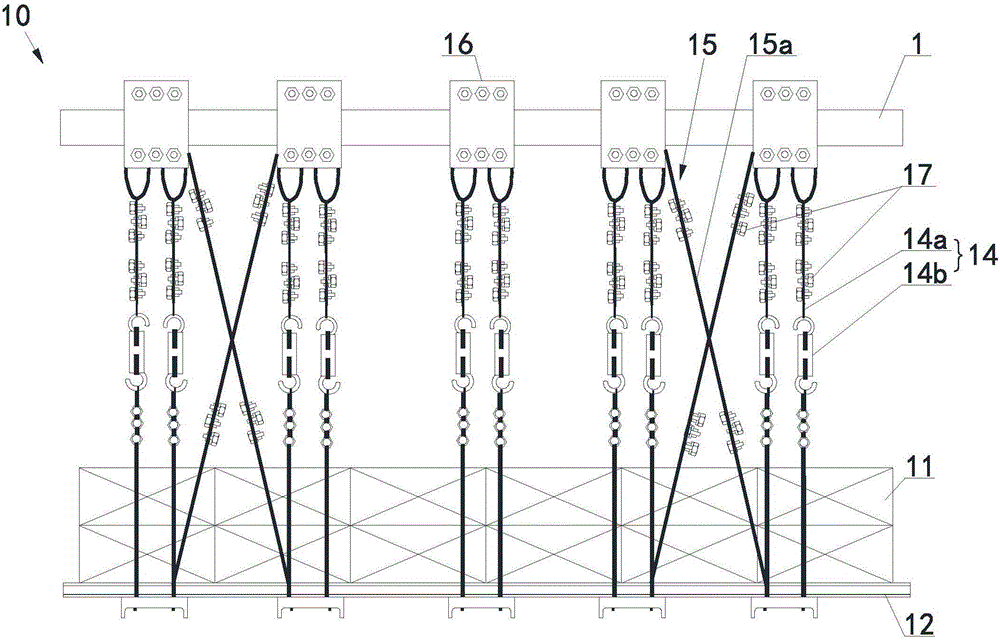

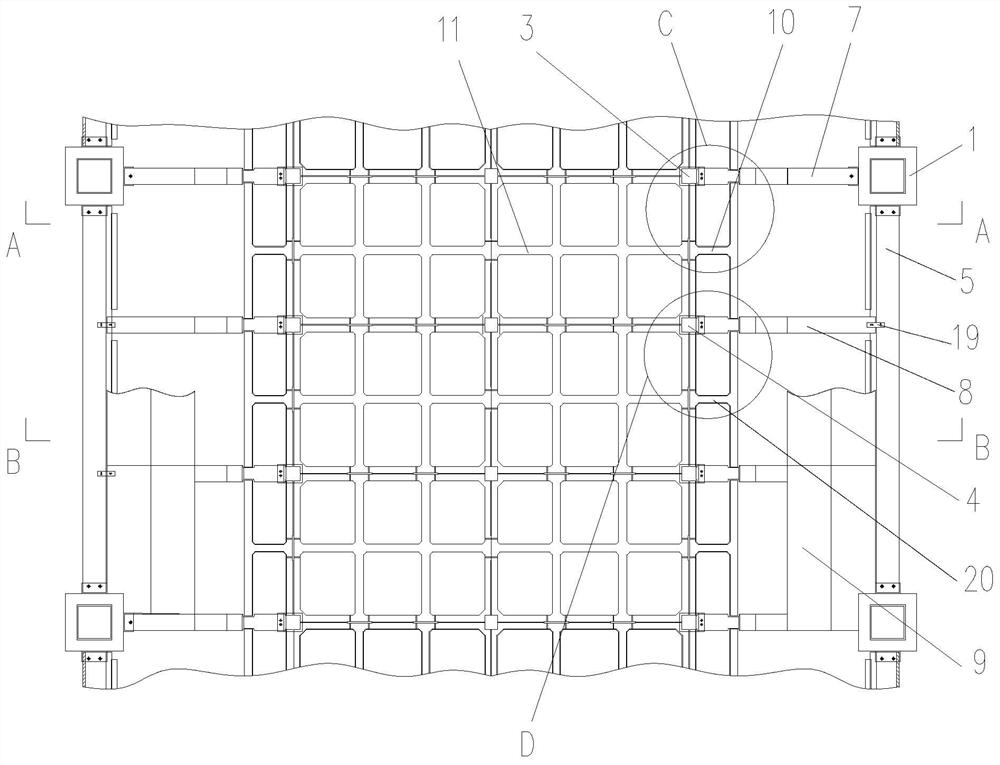

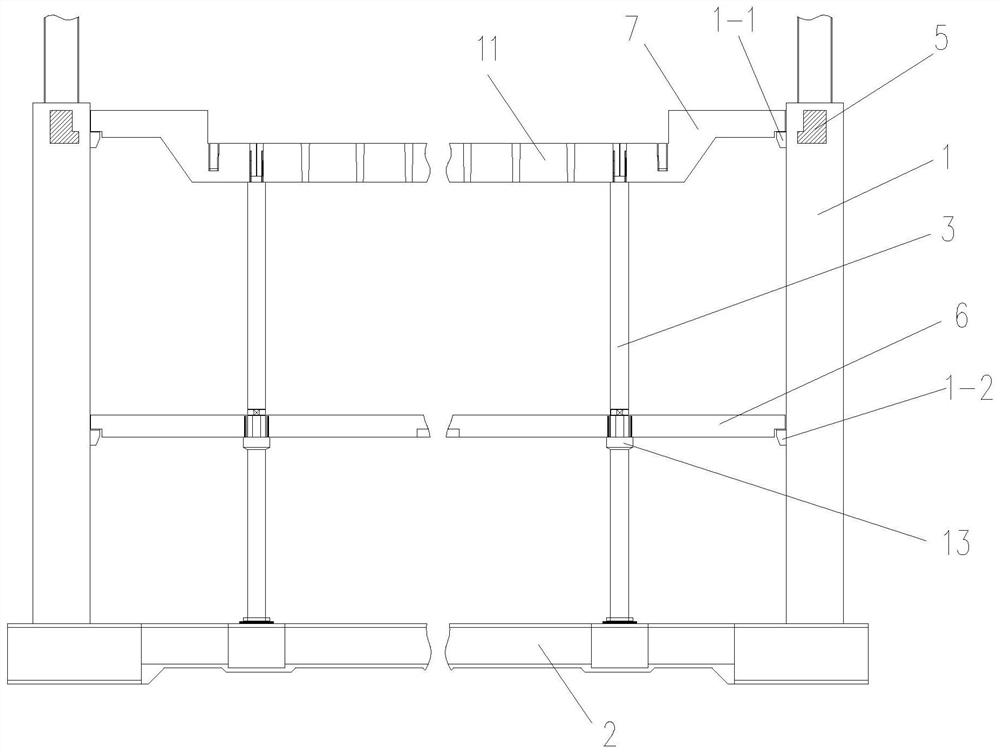

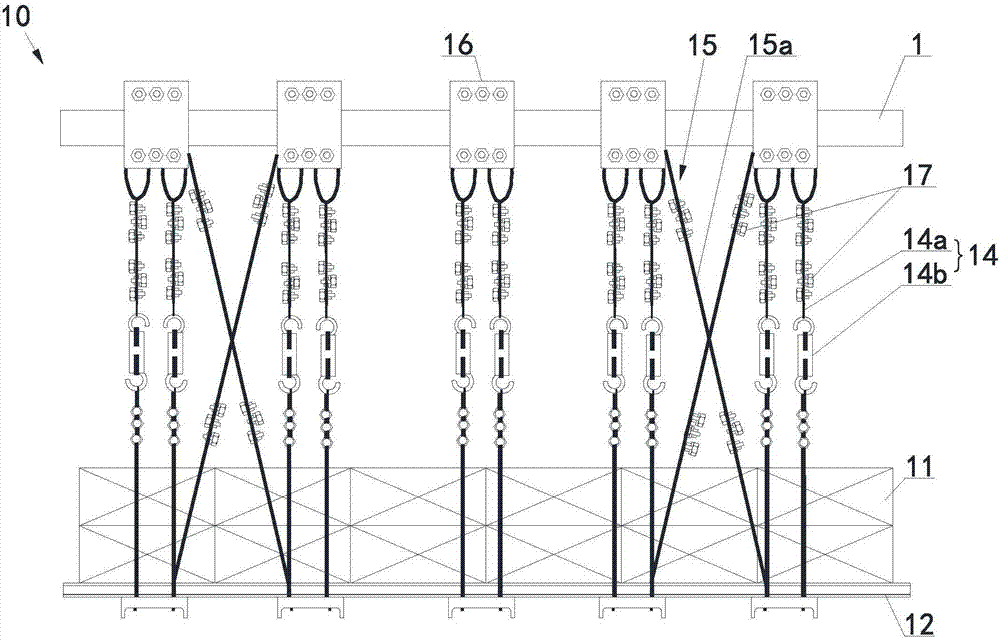

Hanging type anti-shaking construction platform and mounting method thereof

ActiveCN106049843AImprove bearing capacitySpeed up the overall progressScaffold accessoriesBuilding support scaffoldsWire ropeArchitectural engineering

The invention provides a hanging type anti-shaking construction platform and a mounting method thereof and relates to the technical field of building construction equipment. The hanging type anti-shaking construction platform and the mounting method thereof are invented in order to solve the problem that flexibility, safety and economical efficiency of existing construction equipment cannot be taken into consideration completely. The hanging type anti-shaking construction platform comprises a steel structure construction platform body, a supporting frame, vertical steel wire rope sets and anti-shaking steel wire rope sets located on the two sides of the construction platform body. Each vertical steel wire rope set comprises two pairs of first steel wire ropes located on the two sides of the construction platform body, wherein one ends of the first steel wire ropes are connected with the supporting frame, and the other ends of the first steel wire ropes are connected with a building structural beam. Each anti-shaking steel wire rope set comprises two slant intersecting second steel wire ropes, wherein the bottom ends of the second steel wire ropes are connected with the construction platform body, and the top ends of the second steel wire ropes are connected with the building structural beam. The mounting method includes the steps that ejecting parts are arranged on the building structural beam in a sleeving mode and fastened, the construction platform body and the supporting frame are hoisted to the positions below the building structural beam, the bottom ends of the vertical steel wire rope sets are connected with the supporting frame, and the top ends of the vertical steel wire rope sets are connected to the building structural beam through the ejecting parts; and the anti-shaking steel wire rope sets are arranged at the two ends of the construction platform body, the bottom ends of the anti-shaking steel wire rope sets are connected with the construction platform body, and the top ends of the anti-shaking steel wire rope sets are connected with the building structural beam.

Owner:SHANGHAI INSTALLATION ENG GRP

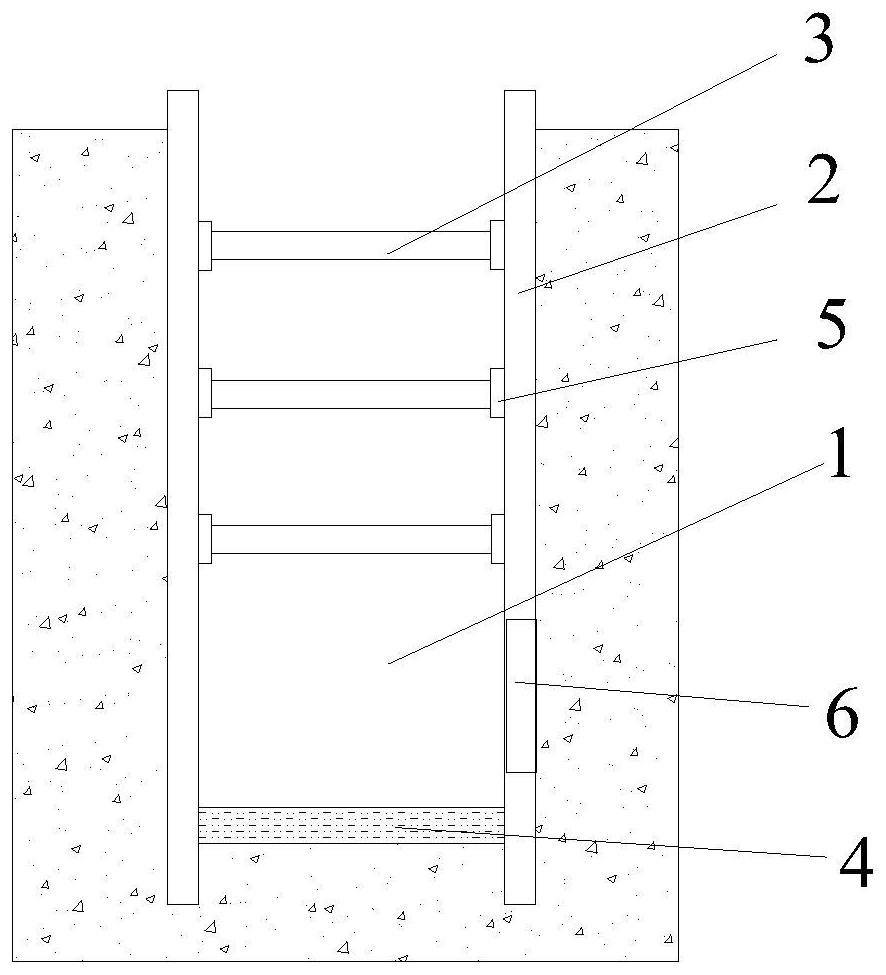

Recoverable assembly type composite soil nailing wall supporting structure system based on anchor cables and soil nails

The invention discloses a recoverable assembly type composite soil nailing wall supporting structure system based on anchor cables and soil nails. The recoverable assembly type composite soil nailing wall supporting structure system comprises a plurality of anchor cables arranged on a slope of a foundation pit in multiple rows and multiple columns, the recoverable soil nails are arranged between every two adjacent rows of anchor cables, each row of anchor cables are connected with the corresponding adjacent row of soil nails through panels, an anchorage section of each anchor cable is provided with a plurality of inner anchor heads with the width larger than that of the anchor cable so as to bear supporting force, and the anchor cables can be recovered. The recoverable assembly type composite soil nailing wall supporting structure system has the beneficial effects that all supporting structure components can be machined in a factorization manner, and assembling can be carried out for conducting construction; supporting materials are recoverable and can be recycled so that resources can be saved; and the construction cost is saved, the supporting materials cannot be left underground, and therefore construction of newly-built underground engineer on the periphery in the later period cannot be influenced.

Owner:SHANDONG UNIV

Complex stratum pipe jacking working well and construction technology thereof

PendingCN114809094AImprove ergonomicsSolve problems such as precipitation difficultiesArtificial islandsExcavationsPurlinArchitectural engineering

The invention discloses a complex stratum pipe-jacking working well and a construction technology thereof, and belongs to the technical field of pipe-jacking working well construction. The complex stratum pipe jacking working well construction technology comprises the following steps that the well position is determined; steel sheet pile construction; grouting reinforcement is conducted, specifically, grouting in the working well is conducted through drilling, and then cement or cement and water glass slurry are injected into the position 0-3 m below the pit bottom in a hole; working well outer grouting is conducted from 1.5 m below the ground to 3 m below the well bottom, and the lower portion of the working well outer grouting is connected with a well inner grouting soil body; after grouting is finished, purlin enclosing, supporting and excavation construction is carried out; after excavation is conducted to the bottom of the working well, reinforcing steel bars are bound at the bottom of the well, a concrete bottom plate is poured, equipment is installed in the working well, and after all the equipment is installed and debugged in place, portal steel sheet piles are cut, and pipelines are jacked. The complex stratum pipe jacking working well construction technology is an economical and safe technical measure for complex stratum construction working well construction, the problems of difficult precipitation and the like are solved, and the working efficiency of working well manufacturing is greatly improved.

Owner:西安市政道桥建设集团有限公司

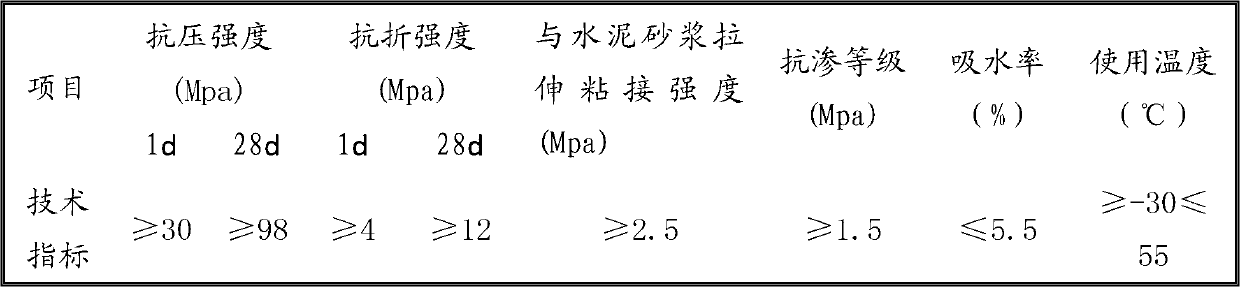

Low-temperature ultrahigh-strength inorganic multi-purpose mortar

The invention belongs to the field of chemical engineering, and provides low-temperature ultrahigh-strength inorganic multi-purpose mortar which solves the technical problems that the function of the mortar is single, and the viscosity of the mortar at low temperature is low in the prior art. The low-temperature ultrahigh-strength inorganic multi-purpose mortar comprises the following components by weight percent: 33%-56% of cement, 2%-6% of calcium oxide, 2%-3% of coal ash, 25%-35% of quartz sand, 0.3%-1% of activating agent, 0.2%-0.5% of early strength agent, 0.2%-0.5% of antifoaming agent, 0.8%-1.5% of water reducing agent, 0.8%-1.5% of consolidation agent and the balance of water. The low-temperature ultrahigh-strength inorganic multi-purpose mortar has the advantages of high strength, adhesion, crack resistance and waterproofness, and obvious extremely good low-temperature work performance.

Owner:SHANGHAI LANGZHAO HIGHWAY & RAILWAY MAINTENANCEENG TECH

Fabricated electronic plant side span structure and construction method thereof

ActiveCN110206347AReduce investmentHigh speedFloorsBuilding material handlingH shapedBuilding construction

The invention discloses a fabricated electronic plant side span structure and a construction method thereof. The fabricated electronic plant side span structure comprises a plurality of first prefabricated PC columns, a plurality of second prefabricated PC columns, longitudinal prefabricated rectangular PC beams, transverse prefabricated rectangular PC beams, first prefabricated Z-shaped PC beamsand second prefabricated Z-shaped PC beams. The construction method comprises the steps that first, the longitudinal prefabricated rectangular PC beams are hoisted; second, the first prefabricated PCcolumns and the second prefabricated PC columns are hoisted; third, the transverse prefabricated rectangular PC beams are hoisted; fourth, the first prefabricated Z-shaped PC beams and the second prefabricated Z-shaped PC beams are hoisted; fifth, prefabricated laminated boards are laid; sixth, first prefabricated H-shaped PC beams and second prefabricated H-shaped PC beams are hoisted; seventh, prefabricated lattice beams are hoisted; and eighth, first connection joints and second connection joints are constructed. According to the construction method, the stability of the fabricated electronic plant side span structure is improved, the construction quality of the fabricated electronic plant side span structure is ensured, and the plant construction speed of a fabricated electronic plantis increased.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

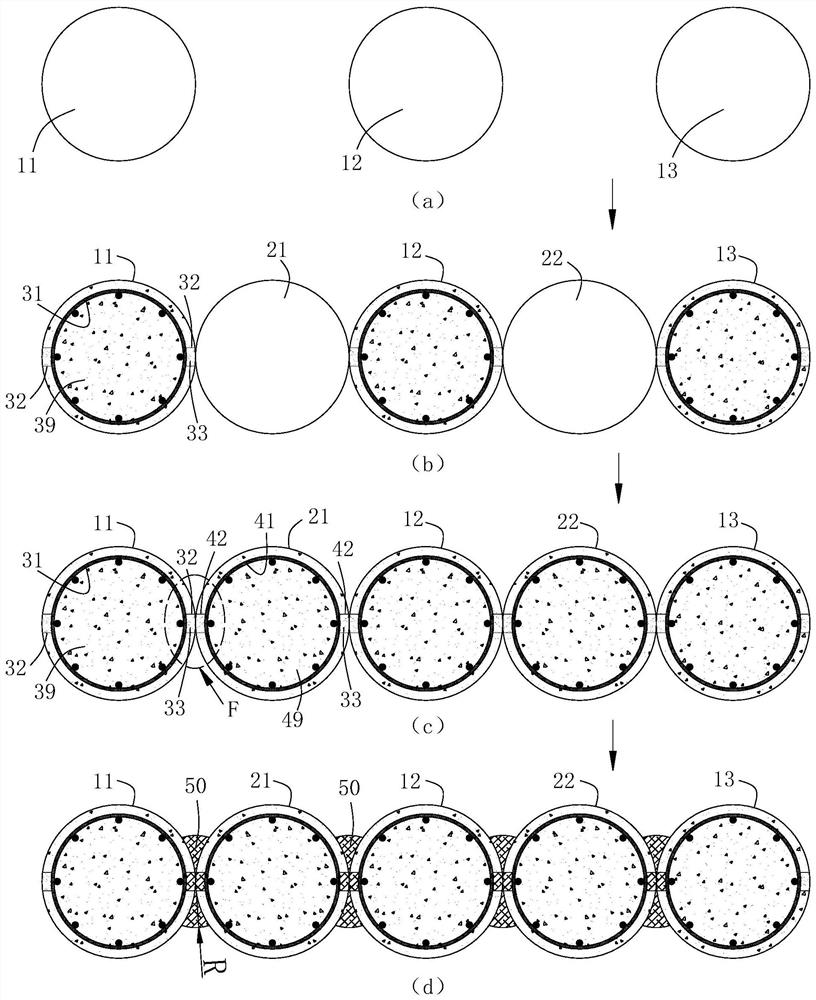

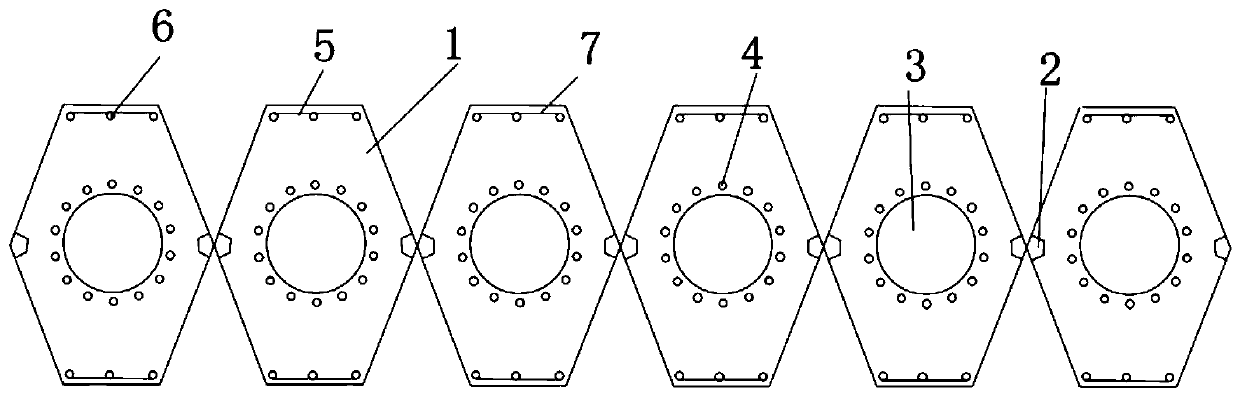

Construction method of plastic casing occlusal pile

ActiveCN112681336BConstruction will not affectLow construction requirementsExcavationsBulkheads/pilesCement slurryRebar

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD +1

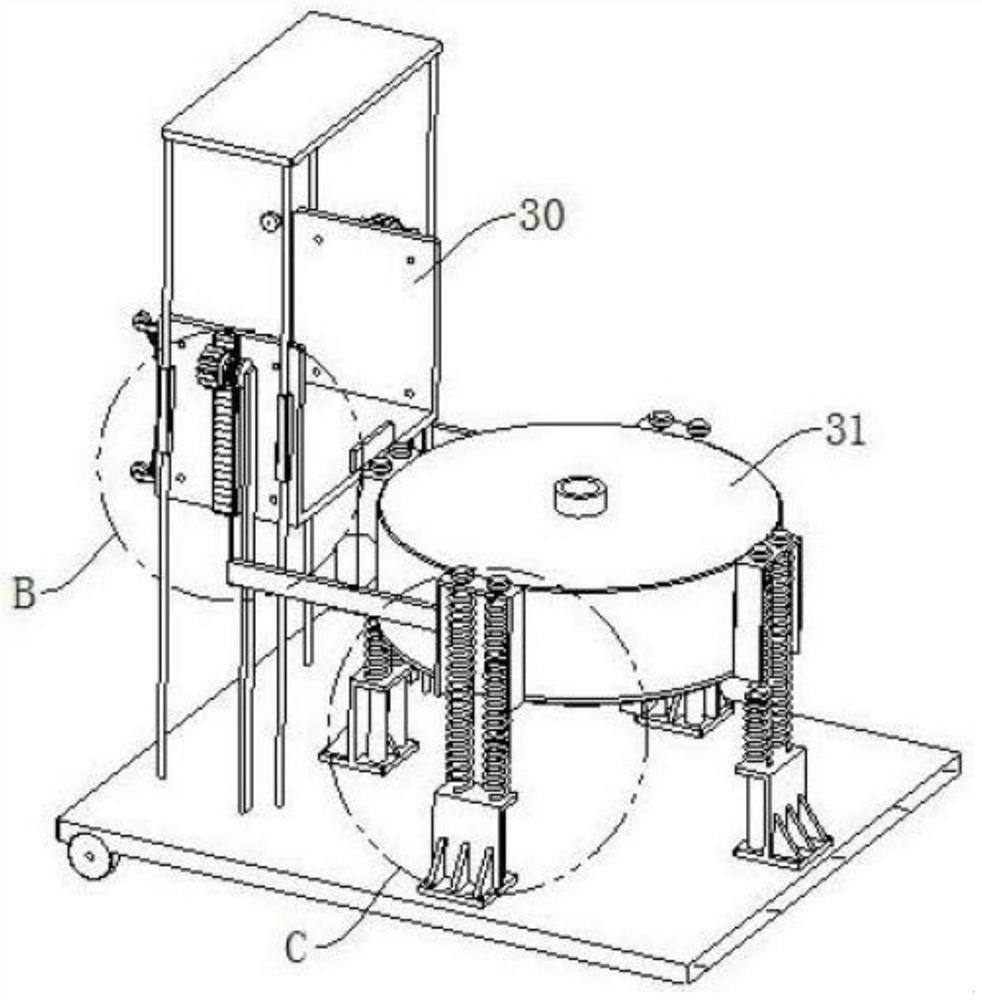

A method of using a safety protection device for a building exterior wall construction platform

ActiveCN111997334BStable supportEnsure safetyScaffold accessoriesArchitectural engineeringExternal cladding

The invention relates to the field of building construction auxiliary equipment, in particular to a method for using a safety protection device for a building exterior wall construction platform, which includes a chassis and a pole, and also includes a controller, a traction mechanism and a conveying mechanism. The top of the chassis is used to support the construction platform. The traction mechanism includes a support frame, a circular housing, two traction assemblies and four supporting assemblies. Assemblies, the support platform is fixed on the top of the chassis, the extruding assembly is arranged on the top of the supporting platform and plugged with the storage barrel, the extruding assembly is electrically connected to the controller, a building of the present invention The safety protection device and use method of the external wall construction platform can realize immediate support when workers are constructing, the support effect is better, and the height can be adjusted at the same time, and the shaking of the construction platform can be effectively reduced without affecting the construction, which is safe. Sex is higher.

Owner:成都建工第三建筑工程有限公司

Quality fluctuation method monitoring construction method of concrete filled steel pipe components based on piezoelectric materials

ActiveCN103645210BEasy to collectEasy to compare and analyzeMaterial analysis by electric/magnetic meansElectricityAnalysis data

The invention discloses a construction method for monitoring the quality fluctuation of steel pipe concrete members based on piezoelectric materials. According to the working principle of PZT substrates, intelligent aggregates and PZT reactors are arranged in multiple sections and layers. The construction method of the present invention solves the problem that the current steel pipe concrete member quality detection method stays in the test stage and has poor practicability, and is beneficial to data collection and comparative analysis; it realizes simultaneous detection of multiple concrete member quality indicators in one construction, such as concrete filling density and The bonding quality of the pipe wall concrete interface; and the results are verified by the impedance method, which is easy to operate and has high detection accuracy; the materials can be recycled again, and the utilization rate is high; the detection can be carried out simultaneously with the project, and will not affect the construction of the upper main structure. It can reduce the investment of construction period cost, and can carry out real-time online monitoring; it is especially suitable for evaluating the concrete pouring quality and interface bonding quality of steel pipe concrete members.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU +1

Self-waterproof support pile and self-waterproof support system

PendingCN110206044ALow costConstruction will not affectProtective foundationExcavationsSupporting systemSupport system

The invention provides a self-waterproof support pile. The self-waterproof support pile comprises a support pile body, vertical waterproof belts with materials being water swelling rubber are correspondingly arranged on the opposite two sides of the support pile body. According to the self-waterproof support pile, the vertical waterproof belts with the materials being the water swelling rubber arecorrespondingly arranged on the opposite two sides of the support pile body, the vertical waterproof belts are attached to the support pile body, before construction, the vertical waterproof belts are in the contraction state, construction of adjacent support piles cannot be influenced, after construction is completed, water swelling is conducted on the vertical waterproof belts, and gaps are sealed to achieve the effect of sealing up. Therefore, according to the self-waterproof support pile, construction of the adjacent support piles cannot be influenced, gap sealing and the sealing up effect can also be achieved after support pile construction is completed, waterproof curtains can be saved, and the engineering cost is lowered to a certain extent. The invention further provides a self-waterproof support system containing the self-waterproof support pile.

Owner:宁乡宁华新材料有限公司

A side-span structure of a prefabricated electronic factory building and its construction method

ActiveCN110206347BReduce investmentHigh speedFloorsBuilding material handlingStructural engineeringMechanical engineering

The invention discloses a fabricated electronic plant side span structure and a construction method thereof. The fabricated electronic plant side span structure comprises a plurality of first prefabricated PC columns, a plurality of second prefabricated PC columns, longitudinal prefabricated rectangular PC beams, transverse prefabricated rectangular PC beams, first prefabricated Z-shaped PC beamsand second prefabricated Z-shaped PC beams. The construction method comprises the steps that first, the longitudinal prefabricated rectangular PC beams are hoisted; second, the first prefabricated PCcolumns and the second prefabricated PC columns are hoisted; third, the transverse prefabricated rectangular PC beams are hoisted; fourth, the first prefabricated Z-shaped PC beams and the second prefabricated Z-shaped PC beams are hoisted; fifth, prefabricated laminated boards are laid; sixth, first prefabricated H-shaped PC beams and second prefabricated H-shaped PC beams are hoisted; seventh, prefabricated lattice beams are hoisted; and eighth, first connection joints and second connection joints are constructed. According to the construction method, the stability of the fabricated electronic plant side span structure is improved, the construction quality of the fabricated electronic plant side span structure is ensured, and the plant construction speed of a fabricated electronic plantis increased.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Construction method of plastic sleeve secant pile

ActiveCN112681336AConstruction will not affectLow construction requirementsExcavationsBulkheads/pilesCement pasteRebar

The invention discloses a construction method of a plastic sleeve secant pile. The construction method comprises the following steps of: (1) constructing first pile holes at intervals; (2) putting down first reinforcement cages carrying first plastic hollow pipes into the first pile holes, pouring sand into the first plastic hollow pipes, and pouring concrete into the first pile holes to form first pile bodies; (3) constructing second pile holes between the adjacent first pile holes; (4) putting down second reinforcement cages carrying second plastic hollow pipes into the second pile holes, pouring sand into the second plastic hollow pipes, and pouring concrete into the second pile holes to form second pile bodies; and (5) drilling holes between the adjacent first pile bodies and second pile bodies by adopting a high-pressure rotary jet drill, and spraying cement paste to form cement mortar, wherein the cement mortar connects the adjacent first pile bodies and second pile bodies into a whole. By utilizing the construction method, a supporting wall with good water stopping performance and soil retaining performance can be formed by adopting a single concrete pile body, and a water stopping curtain does not need to be additionally arranged.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD +1

Method for constructing special shaped deepwater cofferdams on steep rocky riverbeds

ActiveCN102021912BSuitable for constructionConstruction will not affectFoundation engineeringCrushed stoneCofferdam

The invention discloses a method for constructing special shaped deepwater cofferdams on steep rocky riverbeds. The method is characterized by comprising the following steps: preferably selecting a prefabricated cofferdam wall, and arranging a grouting pipe which penetrates through the cofferdam wall up and down along the vertical direction in the cofferdam wall; then sinking the cofferdam wall on the riverbed, exposing the top end of the pipe above the water level, and using the grouting pipe to jet water to wash the riverbed; finally, filling the two sides of the cofferdam wall with broken stones, pouring cement mortar into the bottom of the cofferdam wall and the broken stones via the grouting pipe, draining the water in the cofferdam after the cement mortar and the broken stones are bonded and achieve the strength, and excavating a foundation pit in the absence of water, thus completing construction of bridge foundation. The method can be used for pretreating the riverbed without using equipment and is especially suitable for construction of deepwater cofferdams.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

An Observation Method Based on Embedded Optical Fiber Subgrade Subsidence Observation Device

The invention discloses an embedded optical fiber roadbed settlement observing apparatus, and an observation method thereof. The apparatus comprises fiber grating pressure sensing devices, fiber grating temperature sensing devices, a fiber grating demodulator, a terminal receiving device, a PVC tube, a nylon conduit and a PE protection tube. According to the observation method, the fiber grating pressure sensing devices and the nylon conduit are embedded in soil in advance, and thus, the apparatus overcomes the defect that traditional settlement observation instruments interfere in construction due to burying of the instruments in filling soil for a construction area. During construction and post-construction settlement monitoring of a roadbed, the settlement of one point in the roadbed is converted into changes in the reflection wavelengths of fiber gratings of the fiber grating pressure sensing devices along with soil settlement, so settlement observation means are improved; and the apparatus has the characteristics of simple measurement method, high measurement accuracy, capacity of measuring upheaval displacement and high efficiency.

Owner:中交投资南京有限公司

A suspended anti-shake construction platform and its installation method

ActiveCN106049843BWill not affect construction workImprove bearing capacityScaffold accessoriesBuilding support scaffoldsBraced frameArchitectural engineering

The invention provides a hanging type anti-shaking construction platform and a mounting method thereof and relates to the technical field of building construction equipment. The hanging type anti-shaking construction platform and the mounting method thereof are invented in order to solve the problem that flexibility, safety and economical efficiency of existing construction equipment cannot be taken into consideration completely. The hanging type anti-shaking construction platform comprises a steel structure construction platform body, a supporting frame, vertical steel wire rope sets and anti-shaking steel wire rope sets located on the two sides of the construction platform body. Each vertical steel wire rope set comprises two pairs of first steel wire ropes located on the two sides of the construction platform body, wherein one ends of the first steel wire ropes are connected with the supporting frame, and the other ends of the first steel wire ropes are connected with a building structural beam. Each anti-shaking steel wire rope set comprises two slant intersecting second steel wire ropes, wherein the bottom ends of the second steel wire ropes are connected with the construction platform body, and the top ends of the second steel wire ropes are connected with the building structural beam. The mounting method includes the steps that ejecting parts are arranged on the building structural beam in a sleeving mode and fastened, the construction platform body and the supporting frame are hoisted to the positions below the building structural beam, the bottom ends of the vertical steel wire rope sets are connected with the supporting frame, and the top ends of the vertical steel wire rope sets are connected to the building structural beam through the ejecting parts; and the anti-shaking steel wire rope sets are arranged at the two ends of the construction platform body, the bottom ends of the anti-shaking steel wire rope sets are connected with the construction platform body, and the top ends of the anti-shaking steel wire rope sets are connected with the building structural beam.

Owner:SHANGHAI INSTALLATION ENG GRP

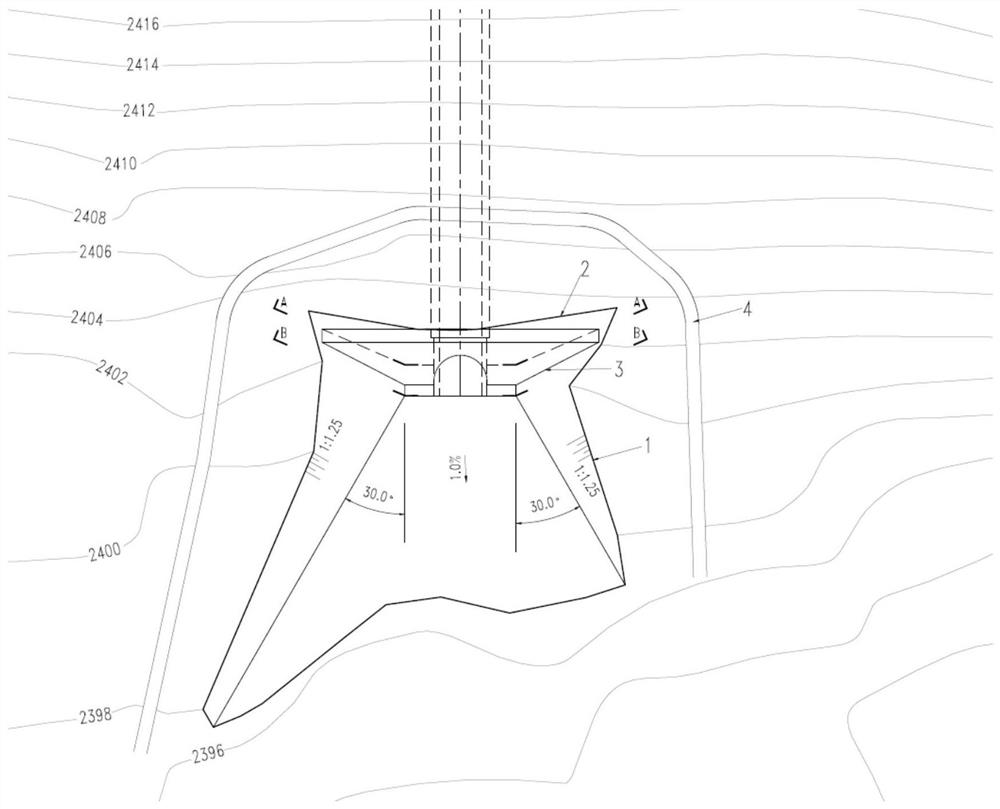

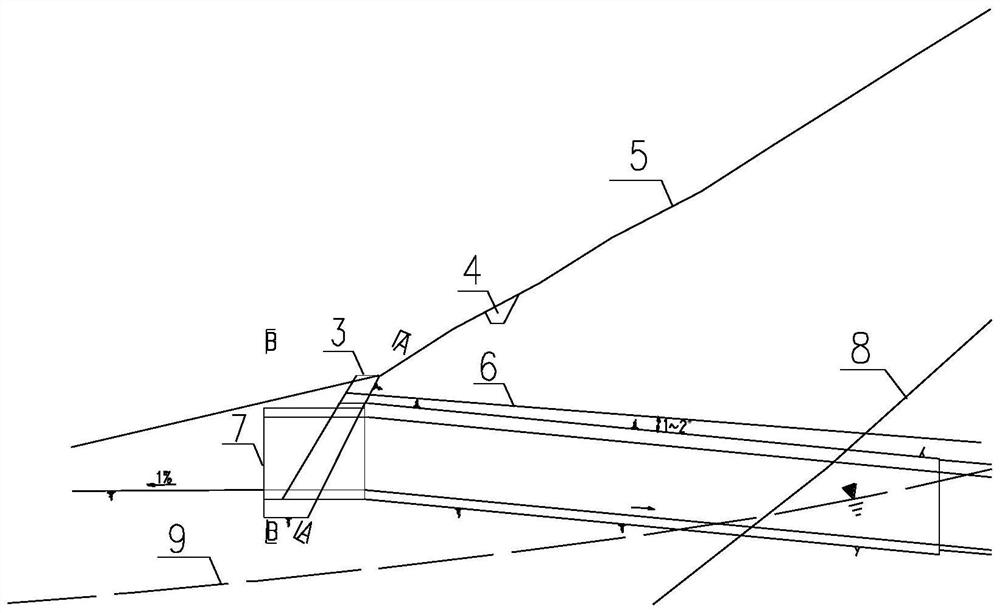

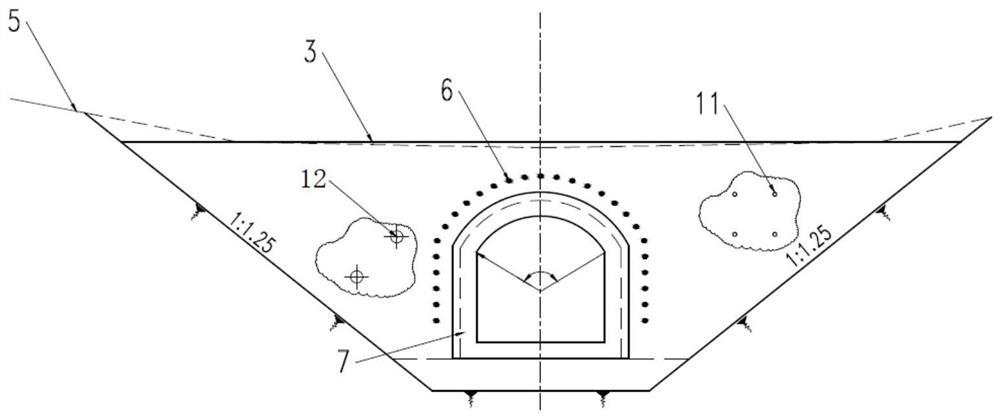

Construction method suitable for construction adit entrance area with relatively poor geological conditions

InactiveCN113106941AEnsure safetyReduce excavationWater-power plantsHydro energy generationAditArchitectural engineering

The invention provides a construction method suitable for a construction adit entrance area with relatively poor geological conditions, and relates to the technical field of various construction adit entrance constructions. The construction method comprises the steps that a construction adit entrance section area is excavated, and side slopes on the two sides and a front adit face side slope adopt different slope ratios; the excavated side slopes on the two sides are timely subjected to reinforcing mesh hanging and anchor-gunited supporting, and drainage holes are formed in the side slopes; after excavation of the front adit face side slope is completed, slope attaching concrete construction is conducted in time, so that the side slope stability of a front adit face is ensured; construction of an advanced grouting large pipe shed is performed; and construction of an open cut tunnel section of the entrance area is performed, wherein arrangement of a road surface from the open cut tunnel section to a downhill section of an outer side slope is performed, so that it is guaranteed that external rainwater cannot be collected into a construction adit. According to the method, the construction requirement is met, good safety guarantee is provided for subsequent excavation and supporting of an adit body section of the construction adit, the safety construction condition can be improved, and the engineering investment is effectively saved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

Construction method of recyclable prefabricated composite soil nail wall support based on anchor cable and soil nail

ActiveCN105672324BAchieve recyclabilityGood repeatabilityExcavationsBulkheads/pilesSoil nailingCement slurry

The invention discloses a construction method of a recyclable assembled composite soil-nailed wall support based on anchor cables and soil nails. The construction method comprises the following steps: manufacturing the recyclable anchor cables; arranging a foundation pit slope, determining waist beams, anchor cable hole locations and node locations, and drilling holes in the slope; arranging the waist beams, enabling the anchor cables to penetrate through the waist beams to be fixed and grouting by virtue of grouting holes; laying nodes, and inserting the recyclable soil nails in the slope; fixing panels between each row of anchor cables and each adjacent row of soil nails, and conducting tension and lockup on the anchor cables after cement slurry reaches the design strength; sealing the connection parts between the any two adjacent panels and between the panels and the waist beams with a sealant; and continuously excavating a foundation pit and supporting; and after the supporting is completed, dismounting supporting materials sequentially layer by layer to realize reutilization. The construction method has the beneficial effects that all supporting structural members can be processed in a factory, and can be assembled to be constructed; and the recycling and reuse of the supporting materials are realized, so that resources can be saved, and the construction cost is reduced.

Owner:SHANDONG UNIV

Construction method of mass impedance method monitoring of steel pipe concrete members based on piezoelectric materials

ActiveCN103675030BEasy to collectEasy to compare and analyzeMaterial impedanceElectricityData acquisition

The invention discloses a piezoelectric-material-based construction method for monitoring concrete filled steel tubular member quality through the impedance method. According to the working principle of a PZT substrate, multi-section and multi-layer arrangement is performed on intelligent aggregate and a PZT reactor. The construction method aims to solve the problems that the existing concrete filled steel tubular member quality monitoring method stays in the test period and is poor in practicability to facilitate data acquisition and contrastive analysis. Multiple concrete member quality indicators, such as concrete filling density and the interface bonding quality of concrete on a tube wall, can be detected through one-time construction; in addition, the impedance method is utilized to verify a result, the operation is simple and the detection accuracy is high; the material can be recycled and the utilization rate is high; the detection and the engineering can be carried out simultaneously, the construction of an upper major structure can not be affected, so that the investment in construction period cost is reduced, and the on-line monitoring can be carried out in real time; the method is particularly suitable for evaluating the concrete pouring quality and the interface bonding quality of concrete filled steel tubular members.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU +1

Inner sleeve-type inclined guy cable main tower cable guide pipe and construction method thereof

ActiveCN103015318BPrevent spillageConstruction will not affectBridge structural detailsBridge erection/assemblyTowerConductor pipe

The invention relates to an inner sleeve-type guy cable main tower cable guide pipe and a construction method thereof. A pre-buried pipe pre-buried in a main tower is the same as the cable guide pipe in mounting angle, and is flush with the outer side of the main tower; a pre-buried plate at the inner end of the pre-buried pipe is flush with a concrete surface of an inclined stay cable anchor block; the outer end of the cable guide pipe is exposed out of the main tower; the inner end of the cable guide pipe is connected with an anchor padding plate; the anchor padding plate is welded with the pre-buried plate; and a gap is reserved between the cable guide pipe and the pre-buried pipe. The construction method comprises the following steps: pre-burying the pre-buried pipe in a main tower section required to be poured with concrete; jacking a main tower mold plate after the pouring of concrete; mounting the cable guide pipe in the pre-buried pipe in such a manner that the gap is reserved between the cable guide pipe and the pre-buried pipe; mounting a circular plug between the outer end of the pre-buried pipe and the cable guide pipe; and grouting from a grouting port, so that the mounting of the inner sleeve-type cable guide pipe is fulfilled. As no hole for the cable guide pipe is formed in the main tower mold plate, the service life of the mold plate can be prolonged, and time for opening and lofting of a lower die plate is saved; and as obstruction caused by the exposing of the cable guide pipe is avoided, the construction speed as well as the operating efficiency is high. The cable guide pipe and the construction method are suitable for concrete main towers of which inclined stay cable guide pipes are exposed out of main tower walls.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

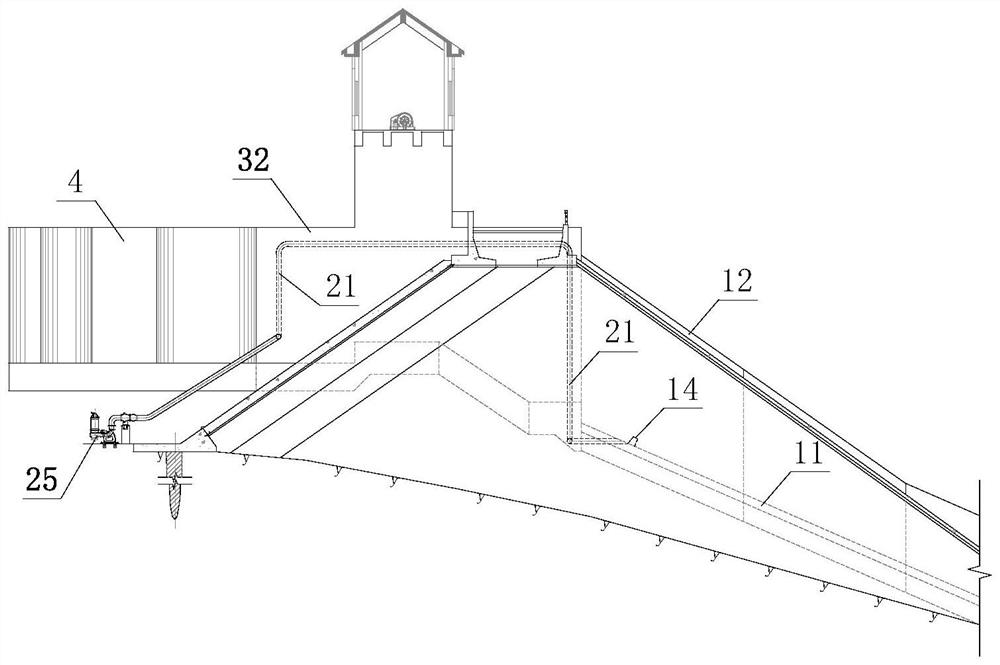

Water-stacked landscape discharge chute

PendingCN114687329AImprove landscapeImprove the landscape effectBarrages/weirsGeneral water supply conservationWater dischargeStream flow

The invention discloses a stacked water landscape discharge chute which comprises a stacked water discharge chute body and a water conveying system. The water stacking discharge chute comprises a bottom plate, a side wall, a drop sill and a water collecting sill; the side walls are located at the bottom and on the two sides of the stacked water discharge chute, and the drop sill is located on the upper portion of the bottom plate. The drop sill comprises an L-shaped plate, an anchor bolt and a rubber gasket, the L-shaped plate is fixed to the surface of the bottom plate through the anchor bolt, the rubber gasket is clamped between the L-shaped plate and the bottom plate, and water leakage is reduced. The water collecting ridge is located at the head end of the water stacking discharge chute and stores water stably on the initial water surface. The water delivery system comprises a water delivery pipe, a water intake, a vacuum pipe, a control valve and a submersible pump, and the water intake, the vacuum pipe, the control valve and the water delivery pipe form a siphon for self-flowing water diversion when the normal water level of the reservoir is higher than the water collecting ridge; the submersible pump is located at the front end of the water conveying pipe and used for pumping water to the sump when the reservoir normal water level is lower than the sump. The method has the advantages that the surface landscape of the discharge chute is improved, the landscape effect under the dam is improved, channels for discharging ecological flow are enriched, flood discharge is basically not affected, and construction is convenient.

Owner:浙江省水利水电勘测设计院有限责任公司

A simultaneous construction method for horizontal and vertical structures of super high-rise buildings

The invention discloses a synchronous construction method for horizontal and vertical structures of a super high-rise building. According to the synchronous construction method, a hydraulic creeping formwork system is adopted on the outer wall of the super high-rise building, and a jacking platform system is adopted between two building walls on the inner side of the super high-rise building; when being operated at the same time, the two systems can replace a conventional overall jacking construction platform as a construction platform, thereby reducing the overall weight of a construction platform and the burden of a hydraulic jacking system, achieving higher flexibility, and improving the construction speed; as the light-weight jacking platform system is configured, a small-sized oil cylinder can be adopted; accordingly, no horizontal supporting steel beam is needed, oil cylinder climbing can be achieved as long as wall-attached embedded parts are mounted on the building walls, the total height of the construction platform and a supporting frame body can be reduced, the construction gap between the vertical and horizontal structures can be narrowed, and the construction of the horizontal structure can be prevented from being influenced by a hydraulic climbing system; and the jacking platform system adopted on the inner wall of the super high-rise building is prevented from penetrating through the building walls, and the gap between the construction platform and a reinforcing bar colligation operation surface is equal to the height of one floor, thereby achieving convenient reinforcing bar transfer and colligation.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +2

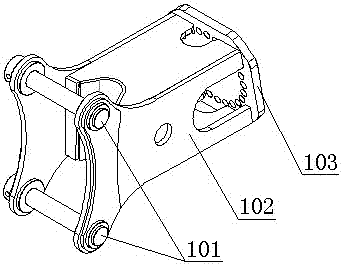

A new type of drilling rod grabber

ActiveCN104895134BReduce construction linksReduce labor costsDerricks/mastsSoil-shifting machines/dredgersEngineeringExcavator

The invention relates to a novel rod grabbing device for drilling, which includes a movable connection arm assembly, a rotary drive assembly, a connector assembly, a rod grab handle assembly, and an auger assembly. The movable connection arm assembly One end is connected with the digging arm of the excavator, and the other end is connected with the rod grabber gripper assembly through the rotary drive assembly and the connector assembly. The middle part of the connecting arm assembly is also equipped with an auger assembly. The invention can complete multiple construction procedures such as drilling, grabbing rods, inserting rods, etc., realizes one machine with multiple functions, can adapt to construction in special occasions such as fields and mountains, and has high construction efficiency.

Owner:湖南亚工智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com