Double-component condensed type encapsulating material convenient for construction and preparation method thereof

A condensation type, two-component technology, used in adhesive types, non-polymer adhesive additives, polyether adhesives, etc. Equipment matching stability is reduced, etc., to achieve good construction performance and improve the effect of potting qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

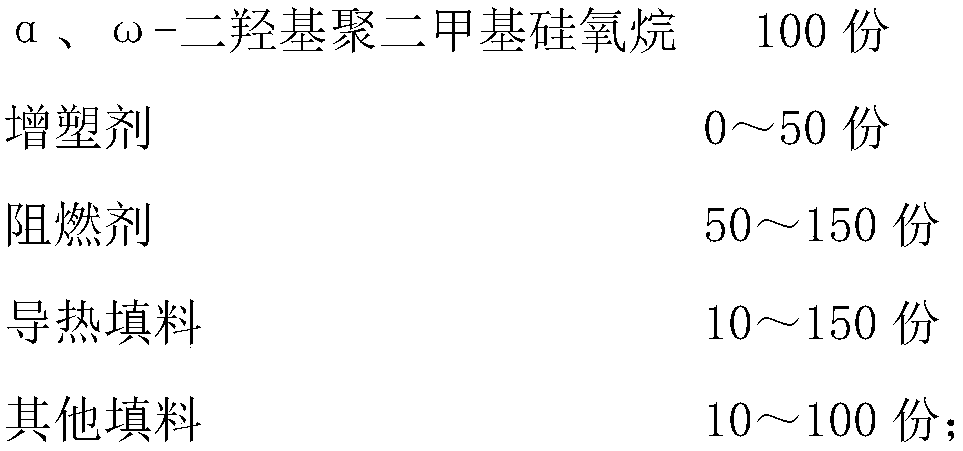

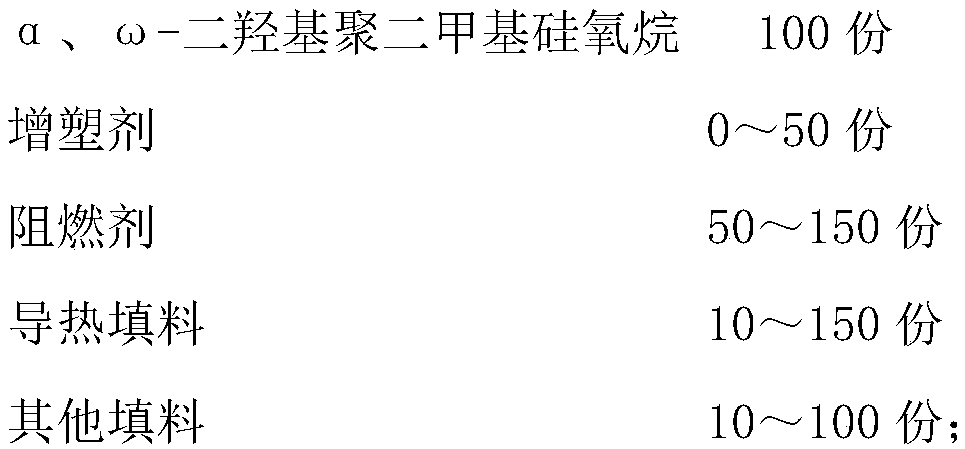

[0060] 100 parts of α, ω-dihydroxy polydimethylsiloxane (viscosity of 400mPa s), 30 parts of dimethyl silicone oil (viscosity of 50mPa s), 150 parts of flame retardant, 10 parts of thermally conductive filler and 10 parts Parts of heavy calcium carbonate were added in proportion to the planetary mixer, stirred for 20 minutes, and then vacuumed and stirred for 5 minutes to obtain component A of the two-component potting glue. Among them, the flame retardant is zinc borate and aluminum hydroxide, and the ratio is 1:3 in parts by mass; the heat-conducting filler is aluminum oxide and zinc oxide, and the ratio is 3:1 in parts by mass; the median of zinc borate and aluminum hydroxide is The particle size (D50) is 7 μm; the median particle size (D50) of aluminum oxide is 5 μm, and the median particle size (D50) of zinc oxide is 1 μm; the median particle size (D50) of the heavy calcium carbonate is 1 μm .

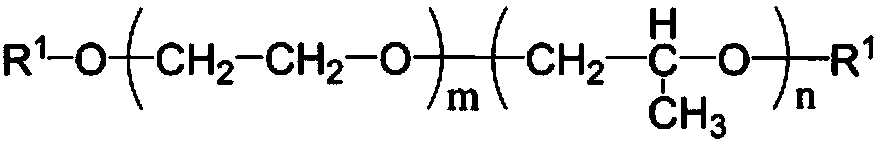

[0061] Add 1 part of dibutyltin dilaurate, 100 parts of polyether and 30 par...

Embodiment 2

[0065] Except that the mass ratio of component A and component B is 4:1, the others are the same as in Example 1.

Embodiment 3

[0067] Except that the mass ratio of component A and component B is 6:1, the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com