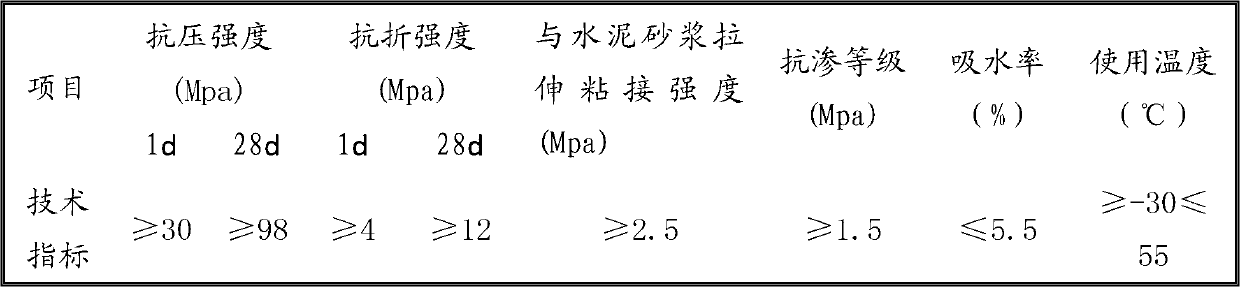

Low-temperature ultrahigh-strength inorganic multi-purpose mortar

An ultra-high-strength, mortar technology, applied in the chemical field, can solve the problems that waterproof mortar can only be used in waterproof engineering, thermal insulation mortar can only be used in construction, and a single application range, etc., and achieves strong durability, simple construction and good durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention is a kind of low-temperature ultra-high-strength inorganic universal mortar, which is composed of cement, calcium oxide, fly ash, quartz sand, activator, early strength agent, defoamer, water reducer, consolidation agent and water, wherein the The weight percentage of the cement in the mortar is 33% to 56%, the weight percentage of the calcium oxide in the mortar is 2% to 6%, and the fly ash is in the The percentage by weight in the mortar is 2% to 3%, the percentage by weight of the quartz sand in the mortar is 25% to 35%, and the percentage by weight of the activator in the mortar is 0.3% ~1%, the weight percentage of the said early strength agent and the said defoamer in the said mortar is 0.2%~0.5%, the said water reducer and the said consolidation agent in the said The weight percentage in the mortar is 0.8%-1.5%, and the balance is water.

[0032] Further, the activator is selected from fatty alcohol polyoxyethylene (7) ether, its molecular formula ...

Embodiment 2

[0041] Embodiment 2: using method of the present invention

[0042] 1) Low-temperature ultra-high-strength inorganic universal mortar can be used in concrete, masonry or steel structures.

[0043] 2) The ambient temperature of low-temperature ultra-high-strength inorganic universal mortar construction is likely to be minus 30°C to minus 55°C, and the materials must not be affected by moisture, rain, sun and sundries.

[0044] 3) Preparation of low-temperature ultra-high-strength inorganic universal mortar:

[0045]The low-temperature ultra-high-strength inorganic universal mortar is directly mixed with water, which can be mechanically or manually mixed. The water addition rate is 13-14%. According to the construction conditions, it is suitable for plastering or spraying. Plastering is used for construction, the amount of water added to the mortar is slightly smaller, and the mixed mortar is slightly thicker. For spraying construction, the amount of water added should be slig...

Embodiment 3

[0049] Embodiment 3 Scope of application of the present invention

[0050] 1) Concrete or cracked building surfaces, panels, load-bearing columns, beams and other external plastering repairs in industrial and civil facilities, rapid repair of thin and thick layers of roads, building plastering, large-volume pouring grouting, etc.;

[0051] 2) Repair of defects such as concrete honeycomb and holes;

[0052] 3) The plastering and thermal insulation treatment of industrial and civil buildings. Applicable to floor slabs, bridge decks and open-air thin slabs;

[0053] 4) Thin-layer repair of damaged concrete floor;

[0054] 5) Rapid repair of expressway and ordinary cement concrete pavement, railway sleeper;

[0055] 6) Rapid repair of airport runways;

[0056] 7) It can be sprayed and anchored on high slopes;

[0057] 8) The foundation can be reinforced by grouting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com