Inner sleeve-type inclined guy cable main tower cable guide pipe and construction method thereof

A cable guide and main tower technology, which is applied to the cable guide of the inner-sleeve cable main tower and its construction field, can solve the problems of formwork lifting obstruction, shorten the service life of formwork, etc. The effect of reducing the difficulty of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

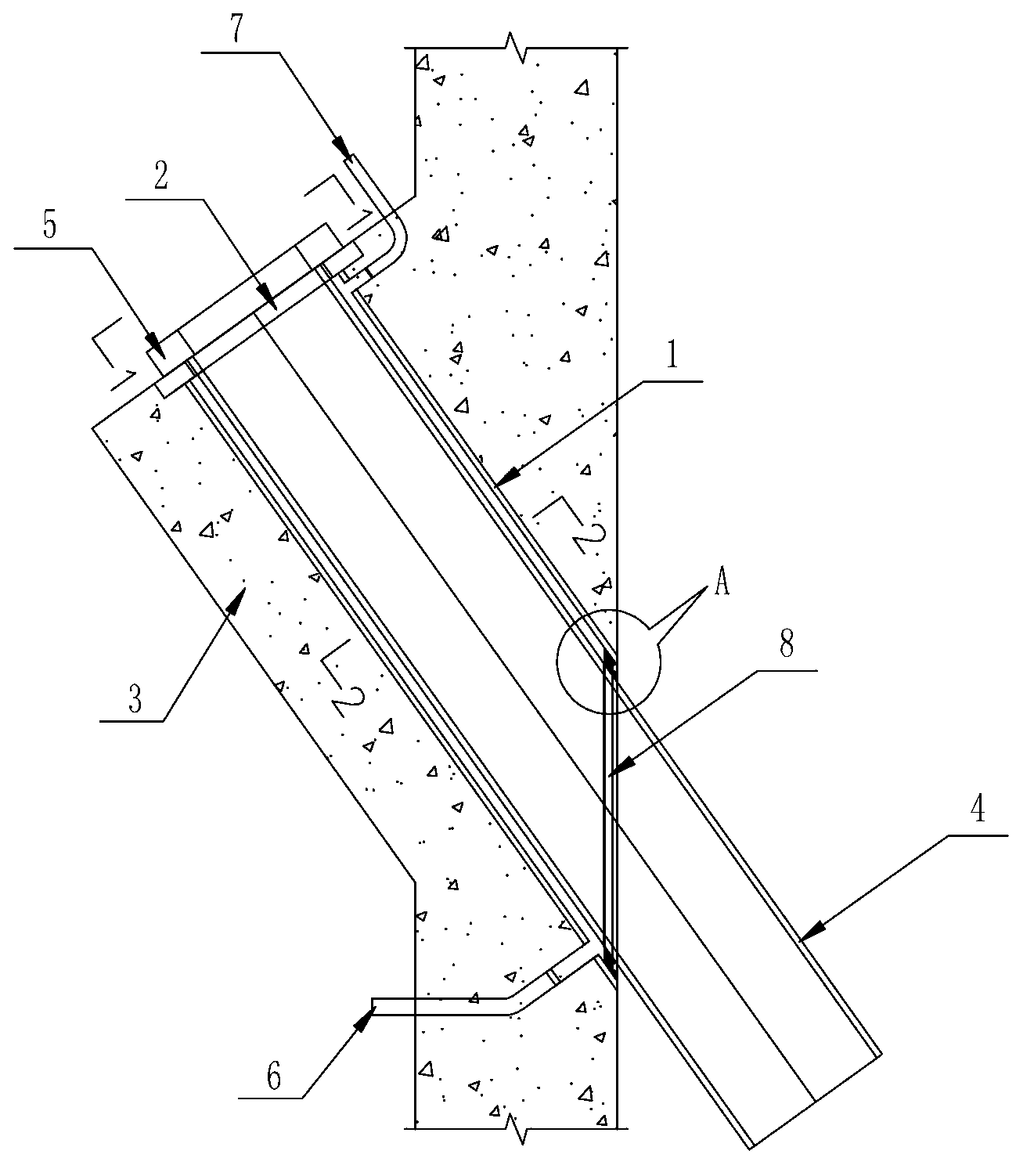

[0019] The present invention is a cable conduit of the main tower of the inner sleeve type cable. The installation angle of the pre-embedded pipe in the main tower is the same as that of the cable conduit. The buried plate 2 is flush with the concrete surface of the stay cable anchor block 3, the outer end of the cable conduit 4 is exposed outside the main tower, the inner end is connected to the anchor pad 5, the anchor pad and the pre-embedded plate 2 are welded, the cable conduit 4 and the pre-embedded Spaces are left between tubes 1.

[0020] There is a gap between the cable conduit and the pre-embedded pipe, the upper part is connected to the grout outlet 7, and the lower part is connected to the grouting port 6, so as to ensure that the grouting is dense. There should be an annular plug 8 between the outer end of the embedded pipe 1 and the cable conduit 4 to prevent the slurry from flowing out during grouting.

[0021] The present invention is a kind of construction me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com