Quality fluctuation method monitoring construction method of concrete filled steel pipe components based on piezoelectric materials

A steel pipe concrete, quality fluctuation technology, applied in the direction of material analysis, material analysis, and measuring devices through electromagnetic means, can solve the problems of inability to apply online monitoring, low utilization rate, low material recovery rate, etc., and achieve data-friendly Collection and comparative analysis, reduced construction period cost investment, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

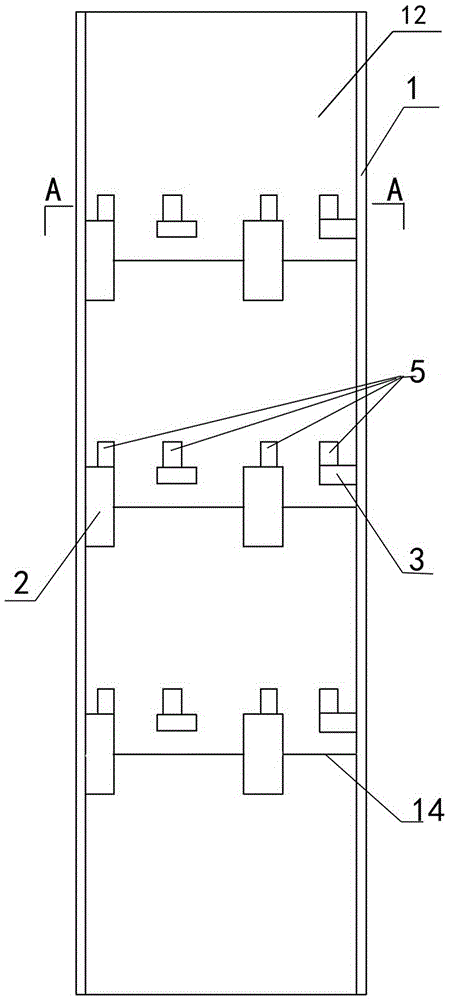

[0040] Such as Figure 3-6 , Example 1 selected two 18-meter-high concrete-filled steel pipe structural columns hoisted in three sections as test objects. The filling density of the concrete inside the steel pipe and the interface bonding quality of the inner wall of the steel pipe are respectively detected; three detection sections I, II, and III are selected on this column, and six PZT smart aggregates 5 are arranged in each section along the circumferential direction. Paste 6 PZT sheets on the corresponding positions outside the wall.

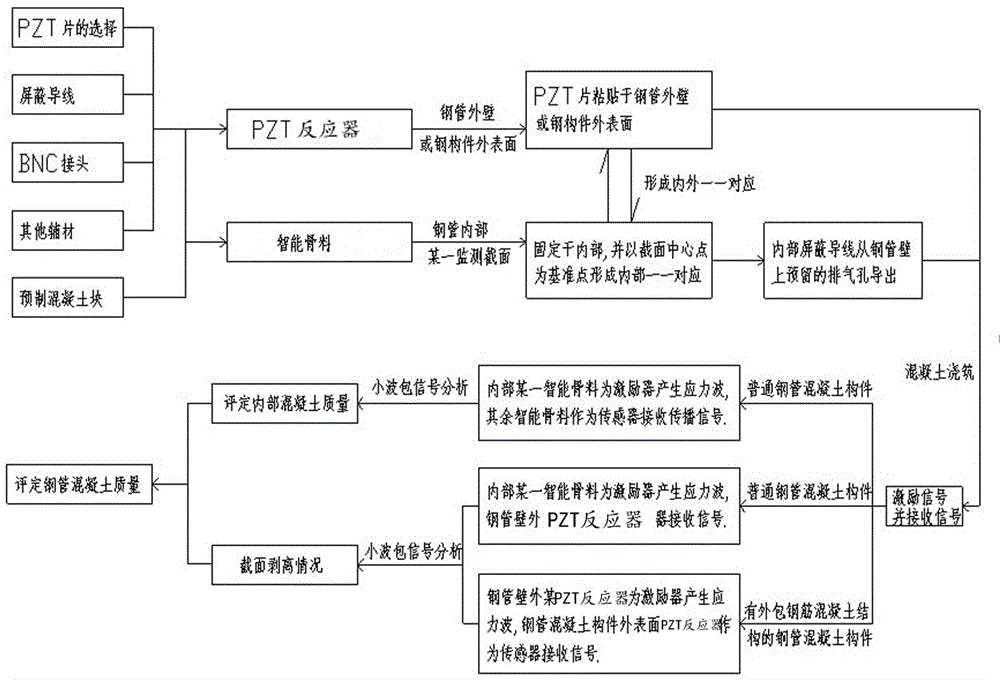

[0041] Such as figure 1 It is a process flow chart of the monitoring construction method of the steel pipe concrete member quality fluctuation method according to the present invention. As shown in the figure, a piezoelectric material-based steel pipe concrete member quality fluctuation method monitoring construction method includes the following steps:

[0042] Step 1. Develop a detection plan, and use the wave method to detect the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com