Method for installing outdoor process pipelines

An installation method and process pipeline technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of high cost, cumbersome, labor and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

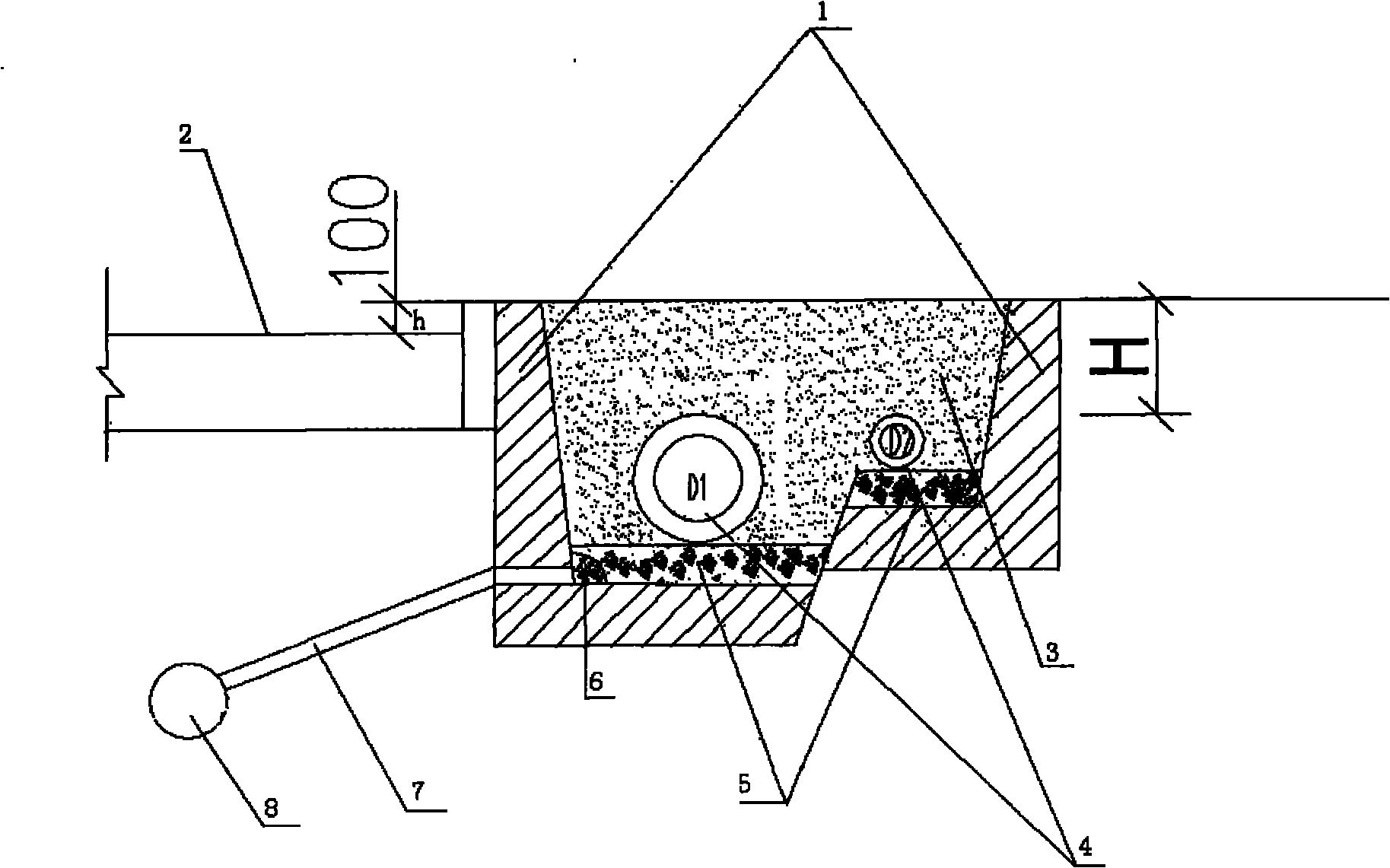

[0020] The outdoor process pipeline installation method of the present invention is to excavate ditches outdoors and bury pipelines, the steps of which are:

[0021] a. Dig a ditch, the distance between the ditch and the two sides of the outdoor road is 1 meter, the ditch is 1.5 meters wide, the ditch is backfilled, and the ditch is compacted with clay to form a clay layer 1;

[0022] After b, the bottom of the ditch is tamped with sticky upper layer 1, pave gravel layer 5 with the crushed stone of 2 centimeters particle diameter, the thickness of crushed stone layer 5 is 20 centimetres;

[0023] c, the pipeline 4 is placed on the gravel layer 5, and the pipeline 4 is covered with 45 centimeters of fine stone or coarse sand with a particle size of 0.4 centimeters;

[0024] D, the top of fine stone or coarse sand cover with river sand again, be covered with the river sand layer 3 that thickness is 4 centimetres, plant grass on river sand layer 3;

[0025] e. Set D100 drainpipe...

Embodiment 2

[0027] The outdoor process pipeline installation method of the present invention is to excavate ditches outdoors and bury pipelines, the steps of which are:

[0028] a. Digging a ditch, the distance between the ditch side and the two sides of the outdoor road is 1.5 meters, the ditch width is 2 meters, and the ditch side is the original soil, and if there is less disturbance during excavation, it is not necessary to compact;

[0029] B, after the ditch has been dug, pave the crushed stone layer 5 with crushed stones of 5 centimeters in particle size, the thickness of the crushed stone layer 5 is 40 centimetres;

[0030] c, the pipeline 4 is placed on the gravel layer, and the pipeline 4 is covered with 55 centimeters of fine stone or coarse sand with a particle size of 0.6 centimeters;

[0031] D, the top of fine stone or coarse sand is covered with river sand again, and covering becomes the river sand layer 3 that thickness is 20 centimetres, and flowers are planted on river ...

Embodiment 3

[0034] The outdoor process pipeline installation method of the present invention is to excavate ditches outdoors and bury pipelines, the steps of which are:

[0035] a, dig a ditch, the distance between the side of the ditch and the 2 sides of the outdoor road is 1.25 meters, the width of the ditch is 1.75 meters, and the surroundings of the ditch are compacted with clay to be clay layer 1;

[0036] B, the bottom of ditch is tamped with clay layer 1, paves gravel layer 5 with the crushed stone of 3.5 centimeter particle diameters then, and the thickness of crushed stone layer 5 is 25 centimetres;

[0037] c, the pipeline 4 is placed on the gravel layer, and the pipeline 4 is covered with 50 centimeters of fine stone or coarse sand with a particle size of 0.5 centimeters;

[0038] D, the top of fine stone or coarse sand is covered with river sand again, and covering becomes the river sand layer 3 that thickness is 5 centimeters, plant grass on river sand layer 3;

[0039] e. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com