Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Constant wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

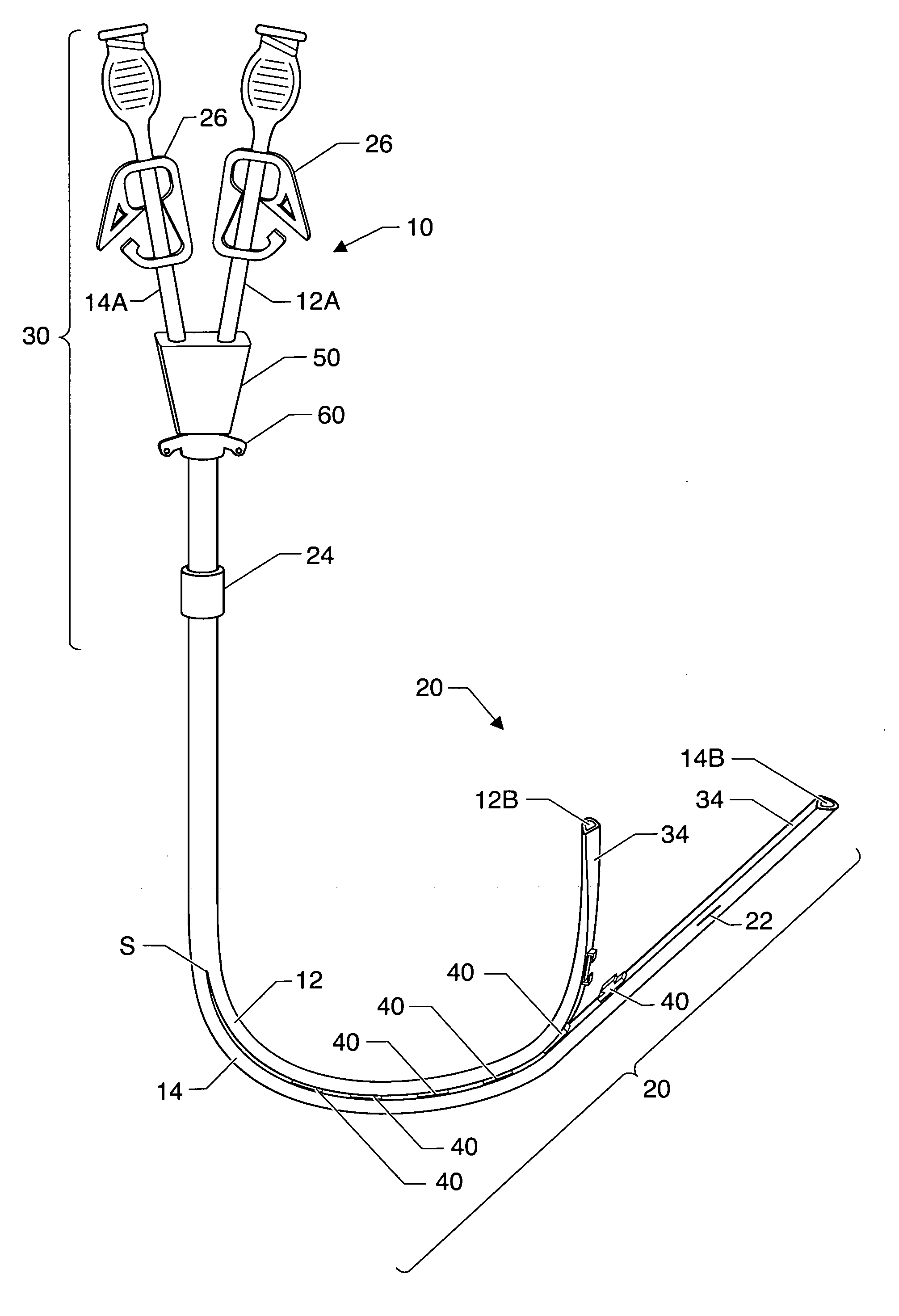

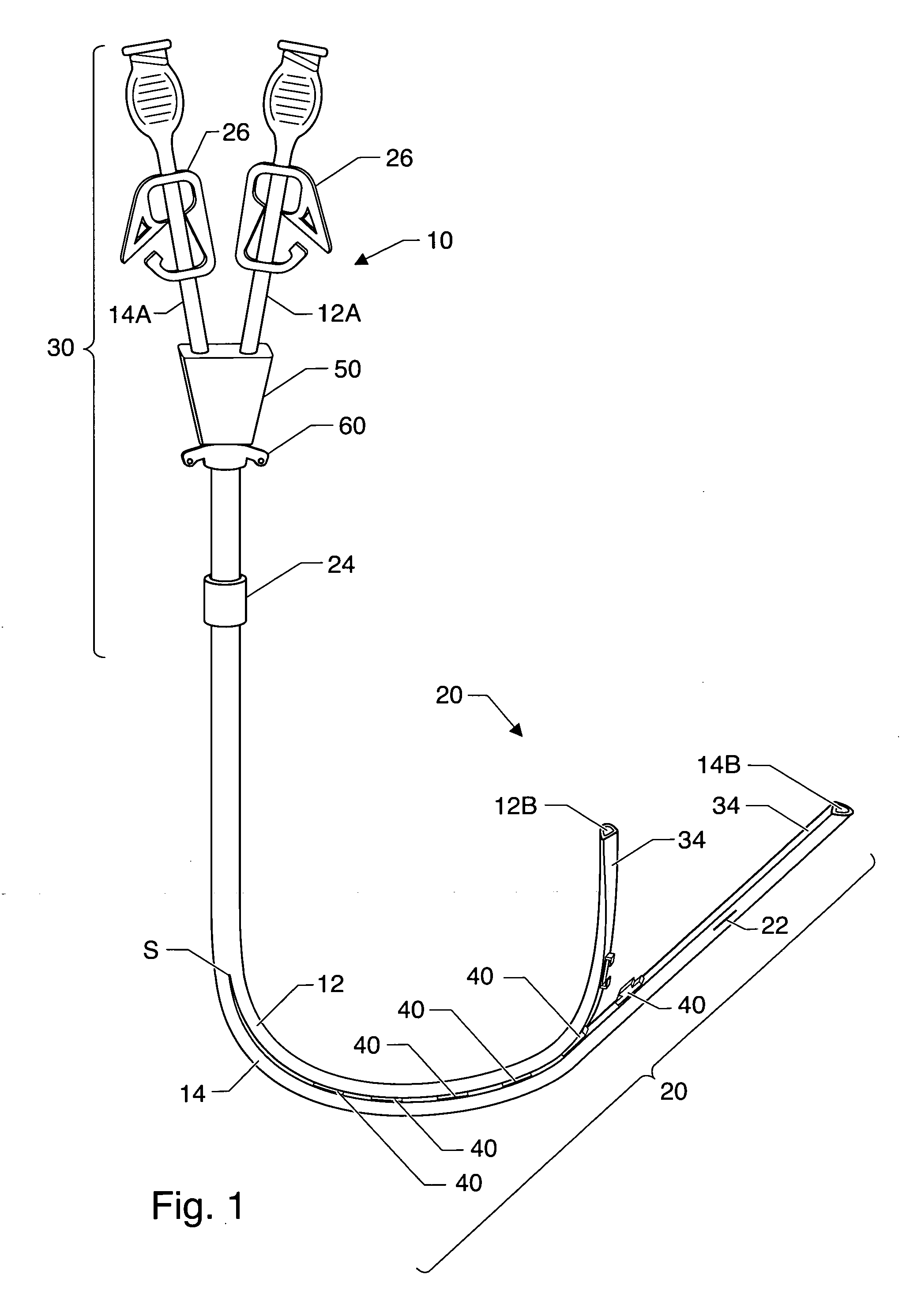

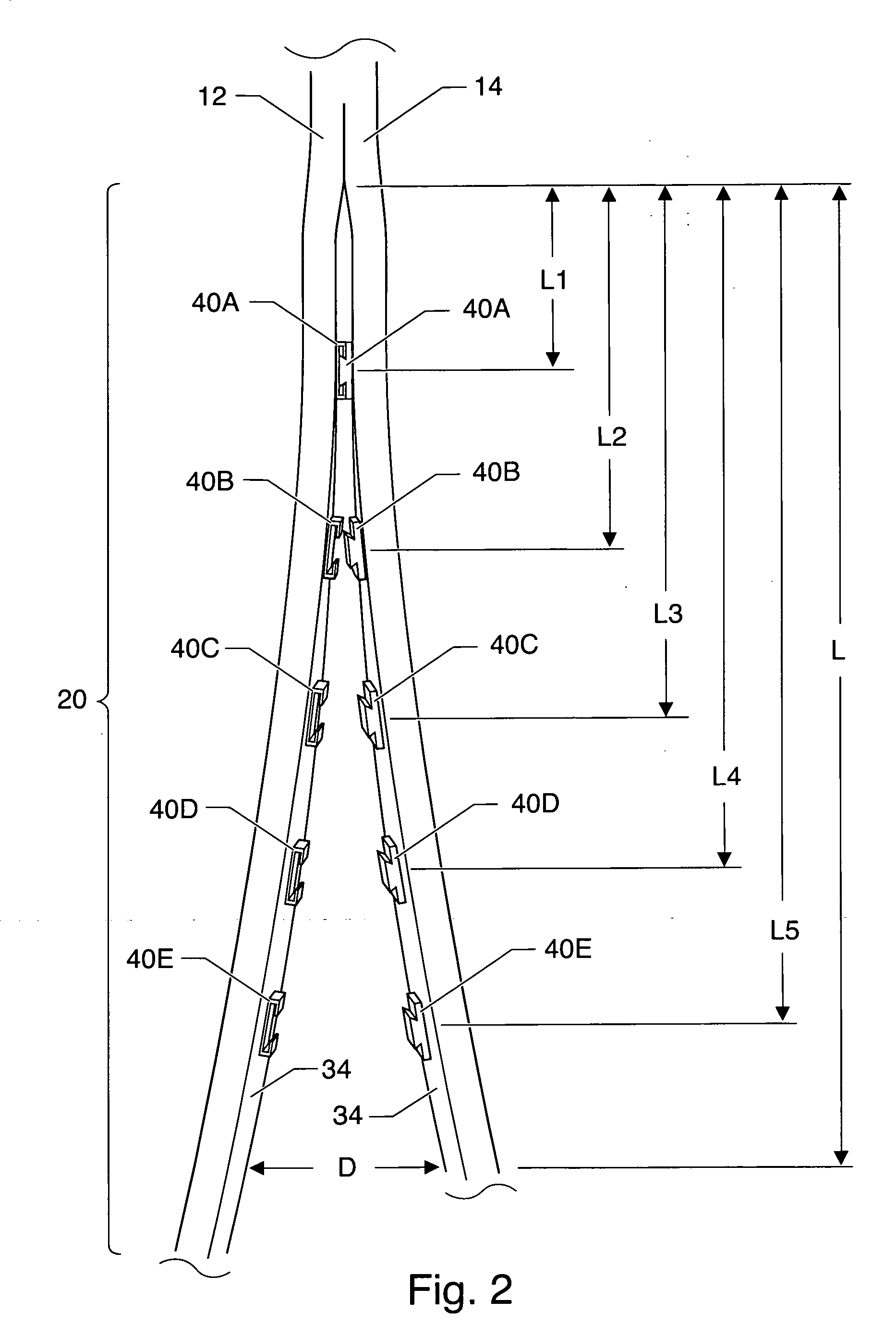

Catheter assembly with joinable catheters

InactiveUS20050171469A1Avoid discomfortAvoid traumaMulti-lumen catheterMedical syringesCatheter device

Owner:CUNNINGHAM JON

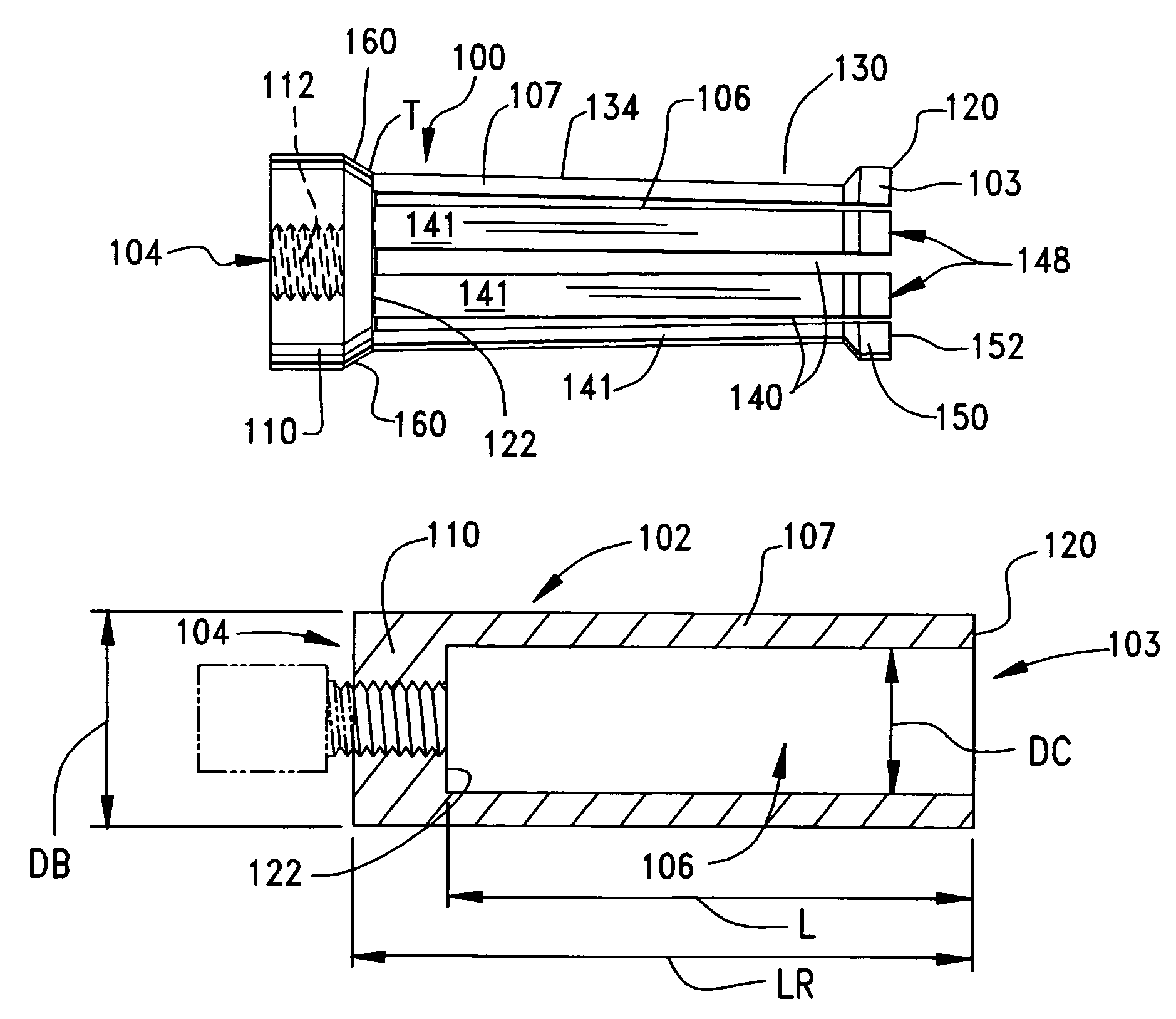

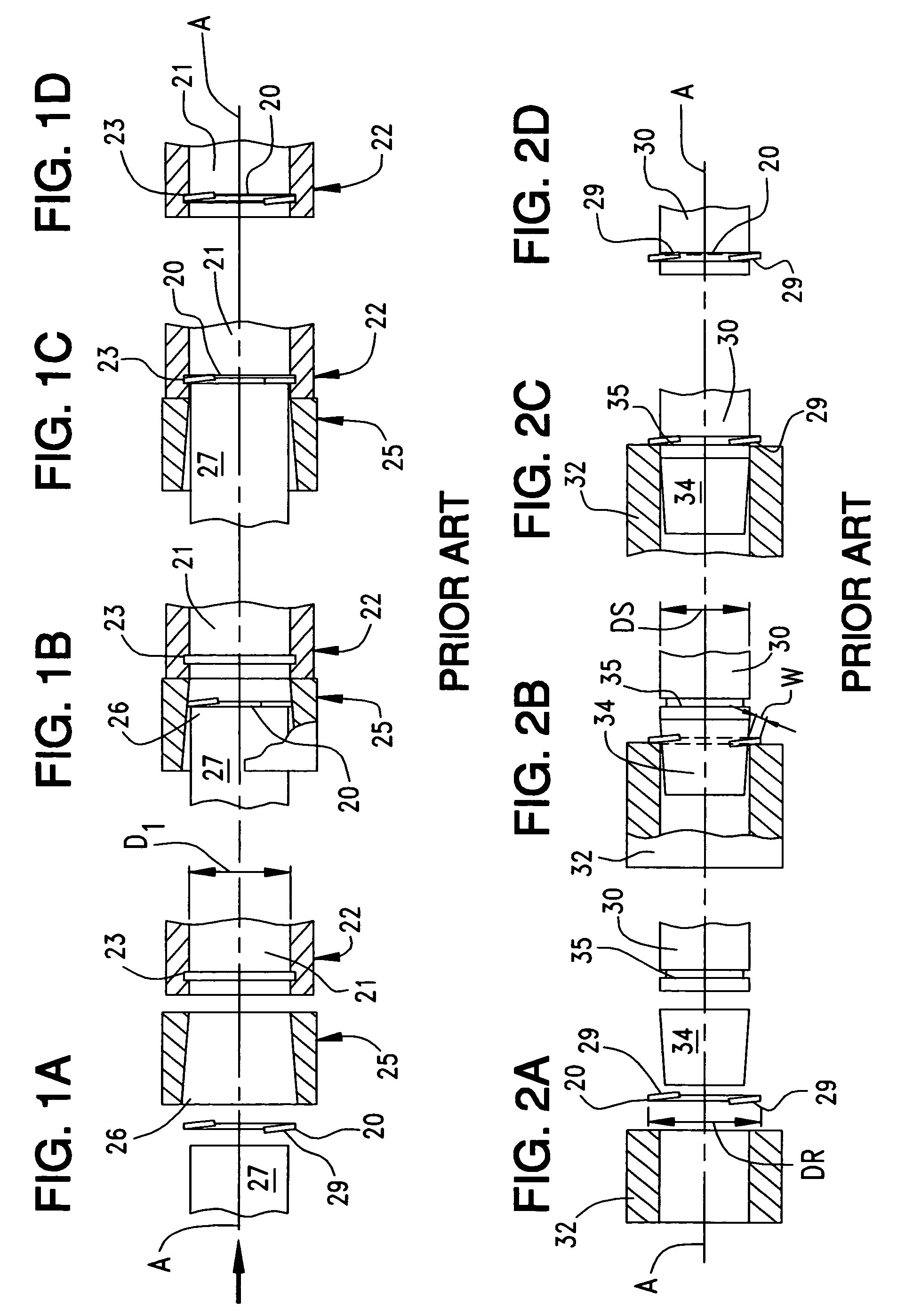

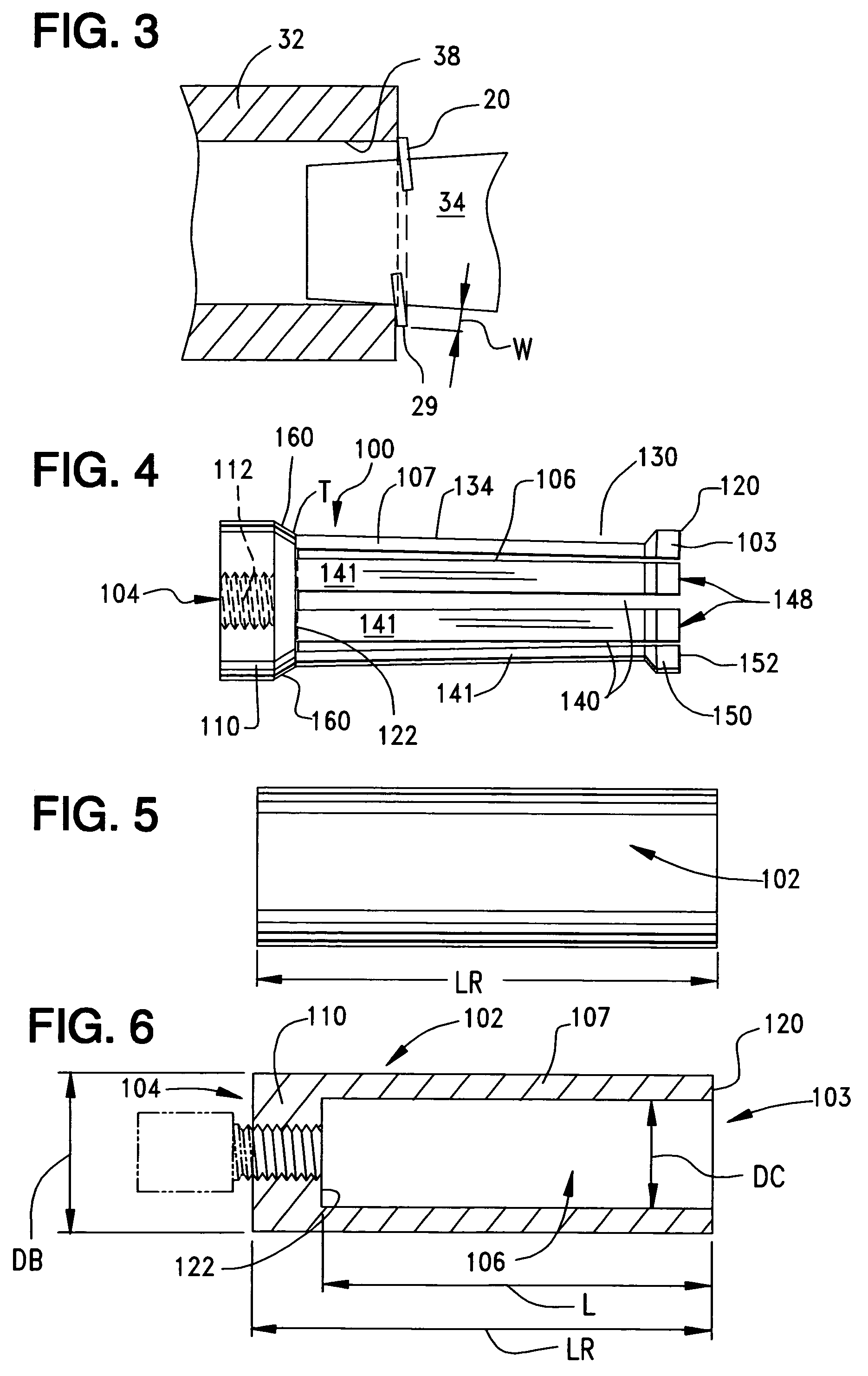

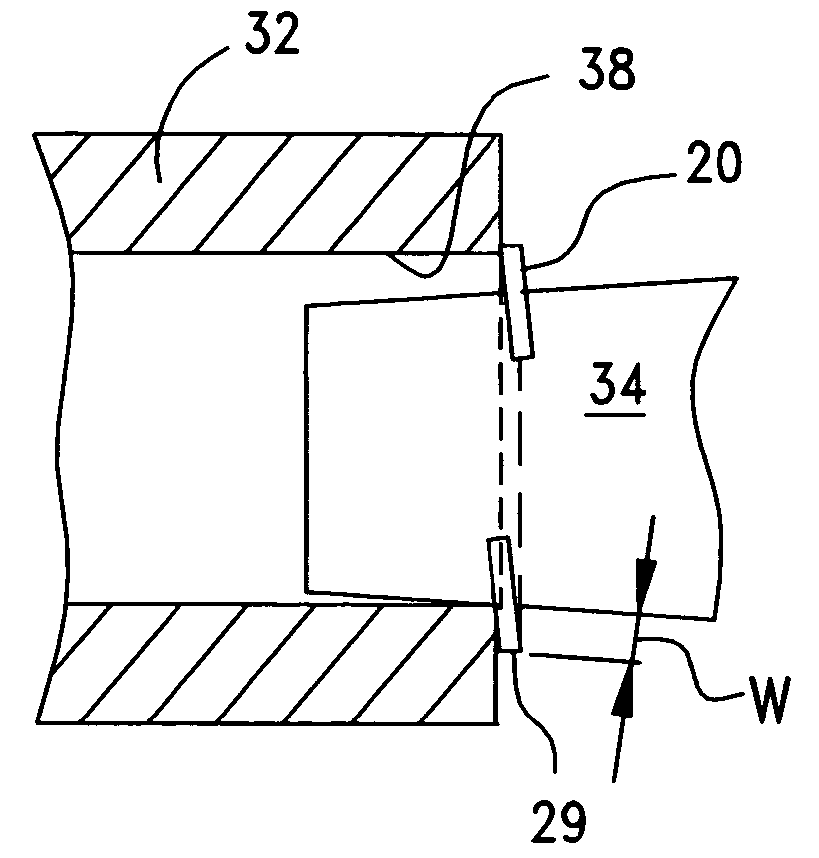

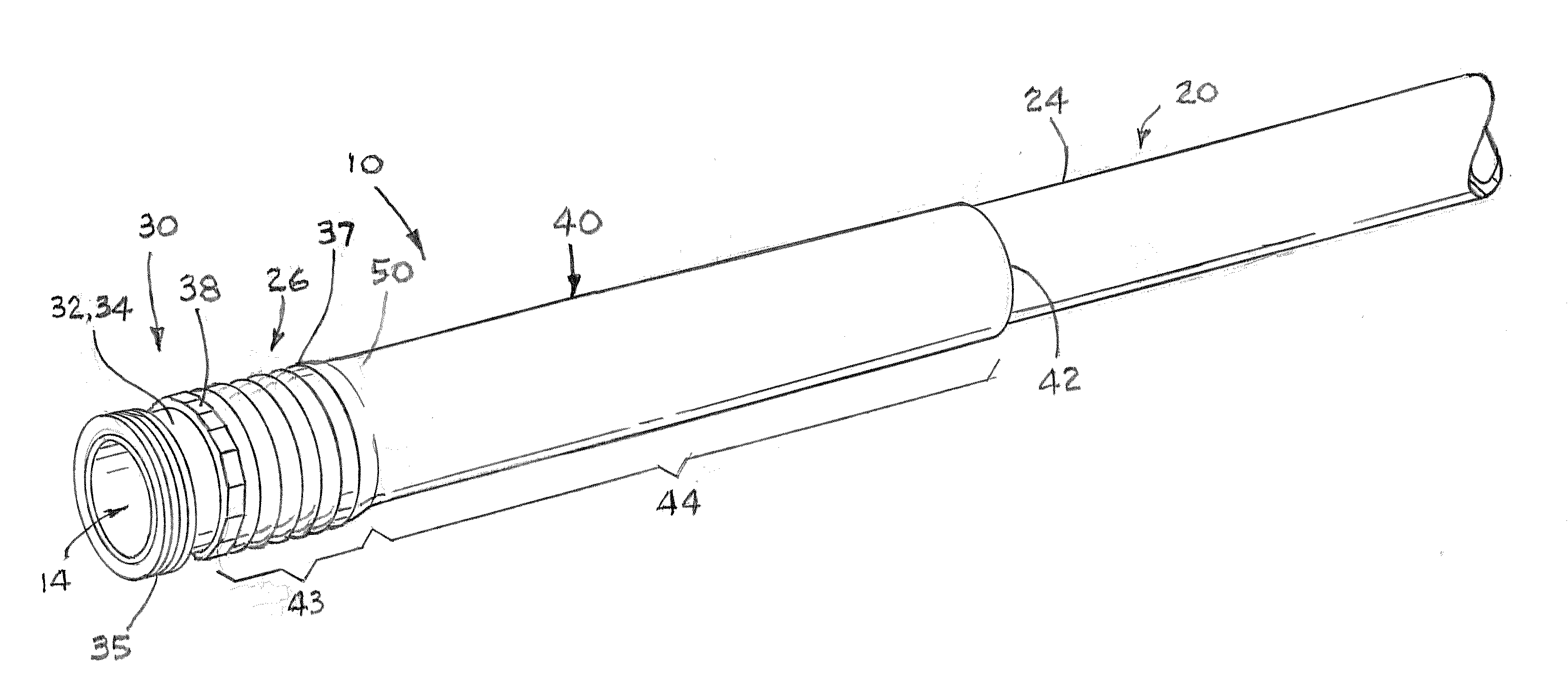

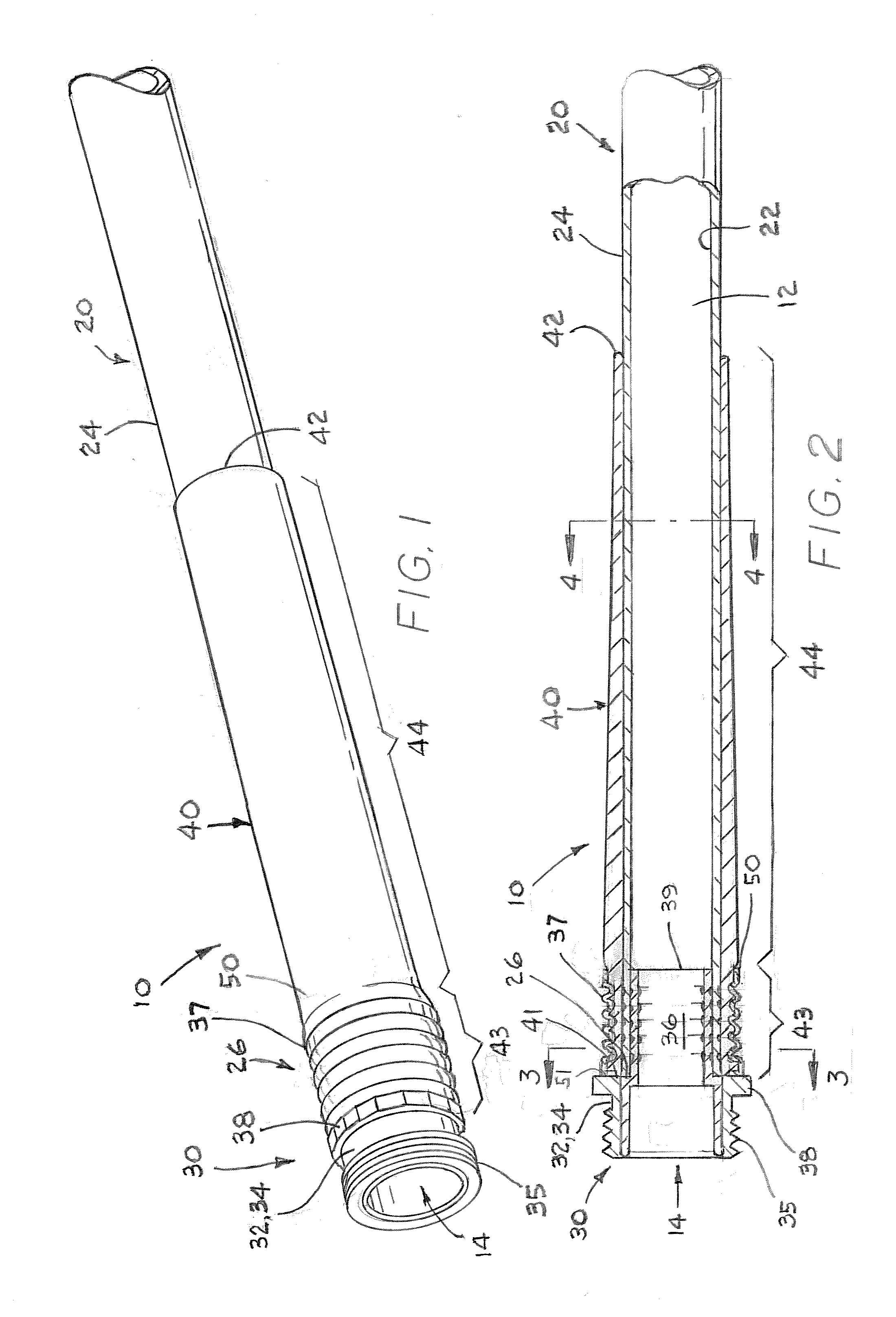

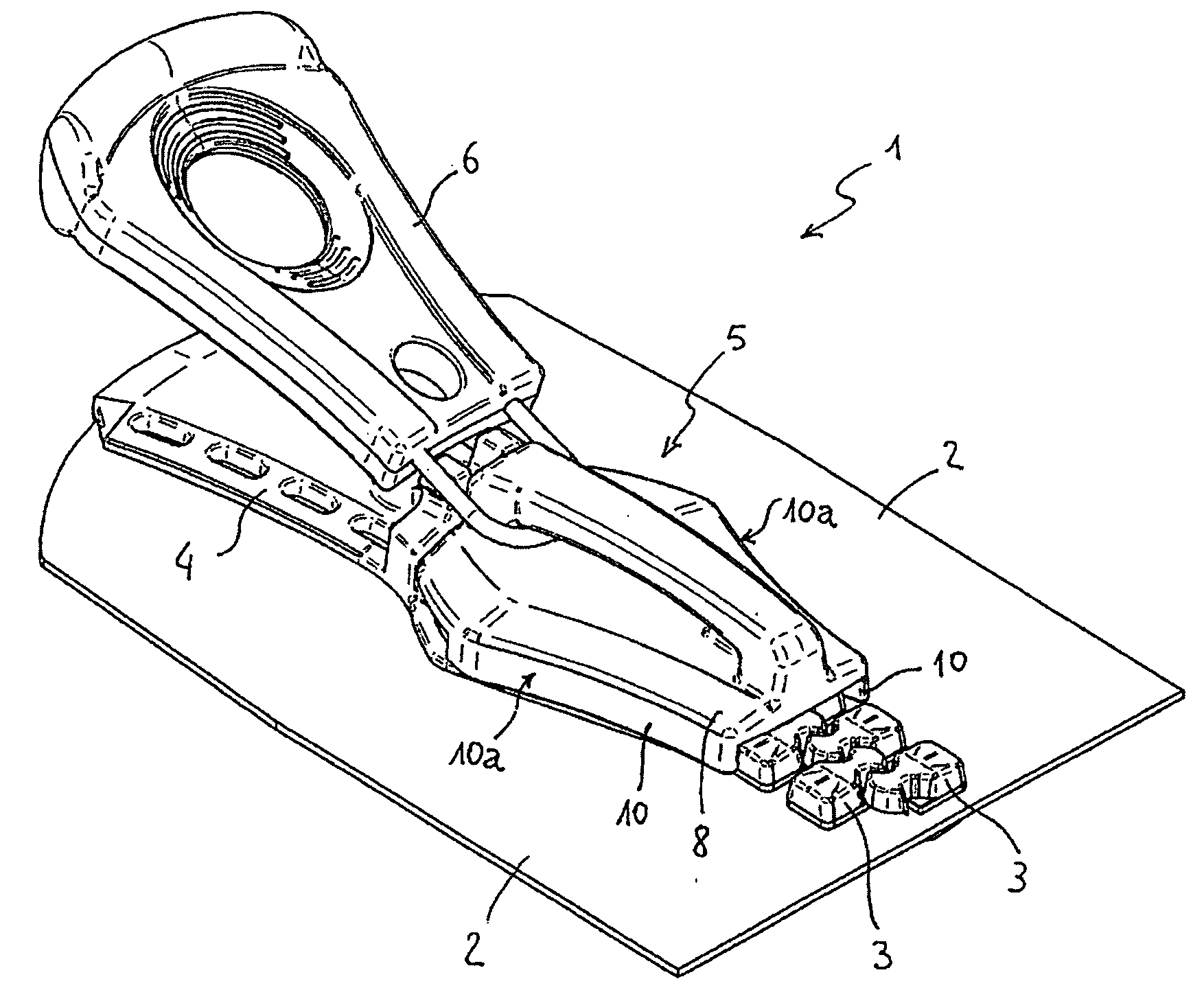

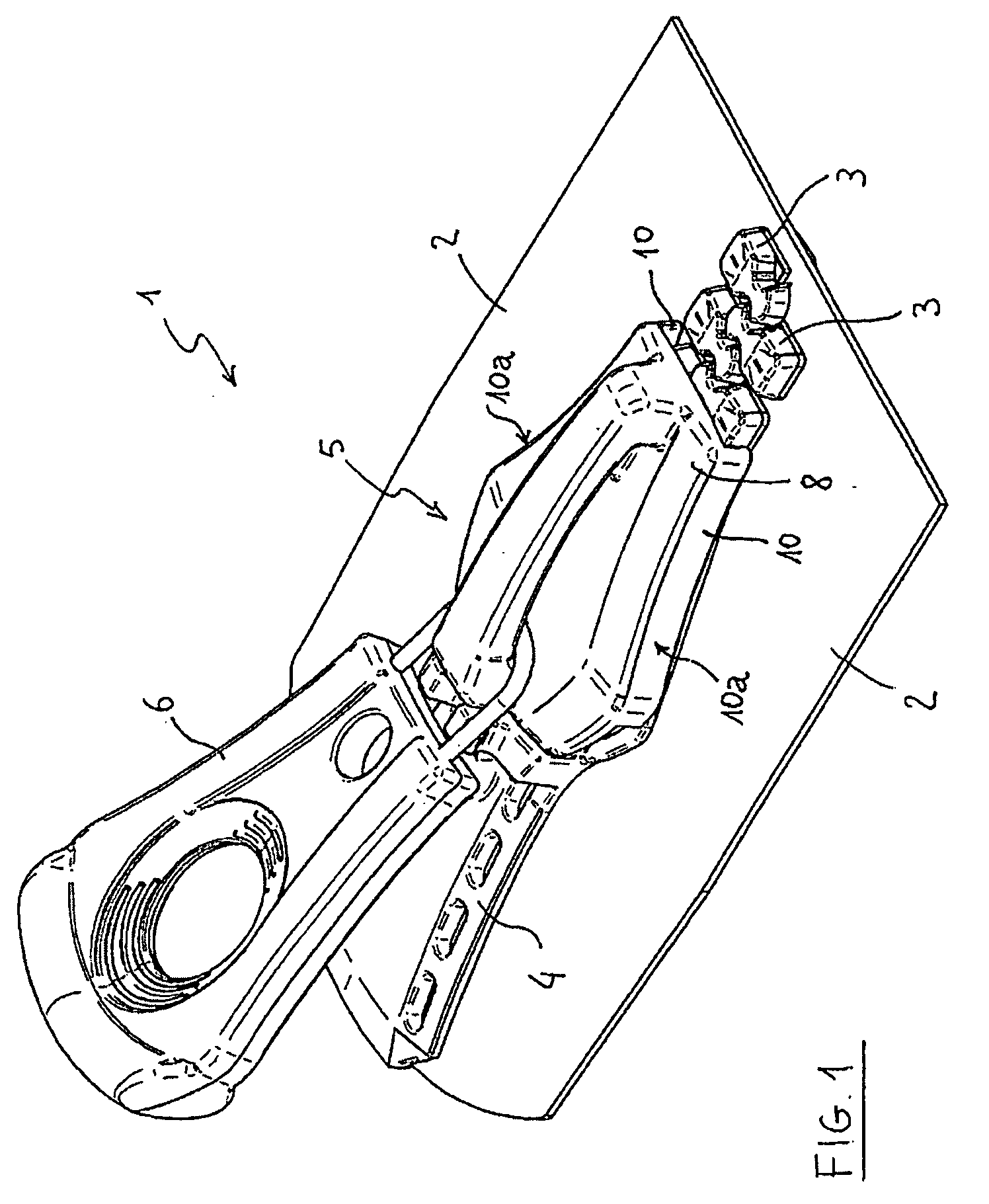

Retaining ring installation tool

ActiveUS6993816B2Necessary flexibilityNecessary strengthMetal working apparatusMetal-working hand toolsEngineeringMetal

A retaining ring installation tool for use in installing retaining rings onto shafts and into bores is formed from a single piece of metal to define a cylindrical, elongated body. A hollow cavity is formed in one end of the body and the wall of the body that defines the cavity is slotted to form a plurality of individual, flexible spring contact arms or fingers which extend forwardly from a rear body portion and which collectively define an insertion end of the tool. The ends of the fingers are enlarged to ensure contact occurs between the tool and the retaining ring during the installation of the ring onto a shaft or into a bore. The contact arms are bent either radially inwardly or outwardly so that they will contact the retaining ring at all times during installation of the ring.

Owner:SMALLEY STEEL RING CO

Retaining Ring Installation Tool

ActiveUS20050132552A1Necessary flexibilityNecessary strengthMetal working apparatusMetal-working hand toolsEngineeringRetaining ring

A retaining ring installation tool for use in installing retaining rings onto shafts and into bores is formed from a single piece of metal to define a cylindrical, elongated body. A hollow cavity is formed in one end of the body and the wall of the body that defines the cavity is slotted to form a plurality of individual, flexible spring contact arms or fingers which extend forwardly from a rear body portion and which collectively define an insertion end of the tool. The ends of the fingers are enlarged to ensure contact occurs between the tool and the retaining ring during the installation of the ring onto a shaft or into a bore. The contact arms are bent either radially inwardly or outwardly so that they will contact the retaining ring at all times during installation of the ring.

Owner:SMALLEY STEEL RING CO

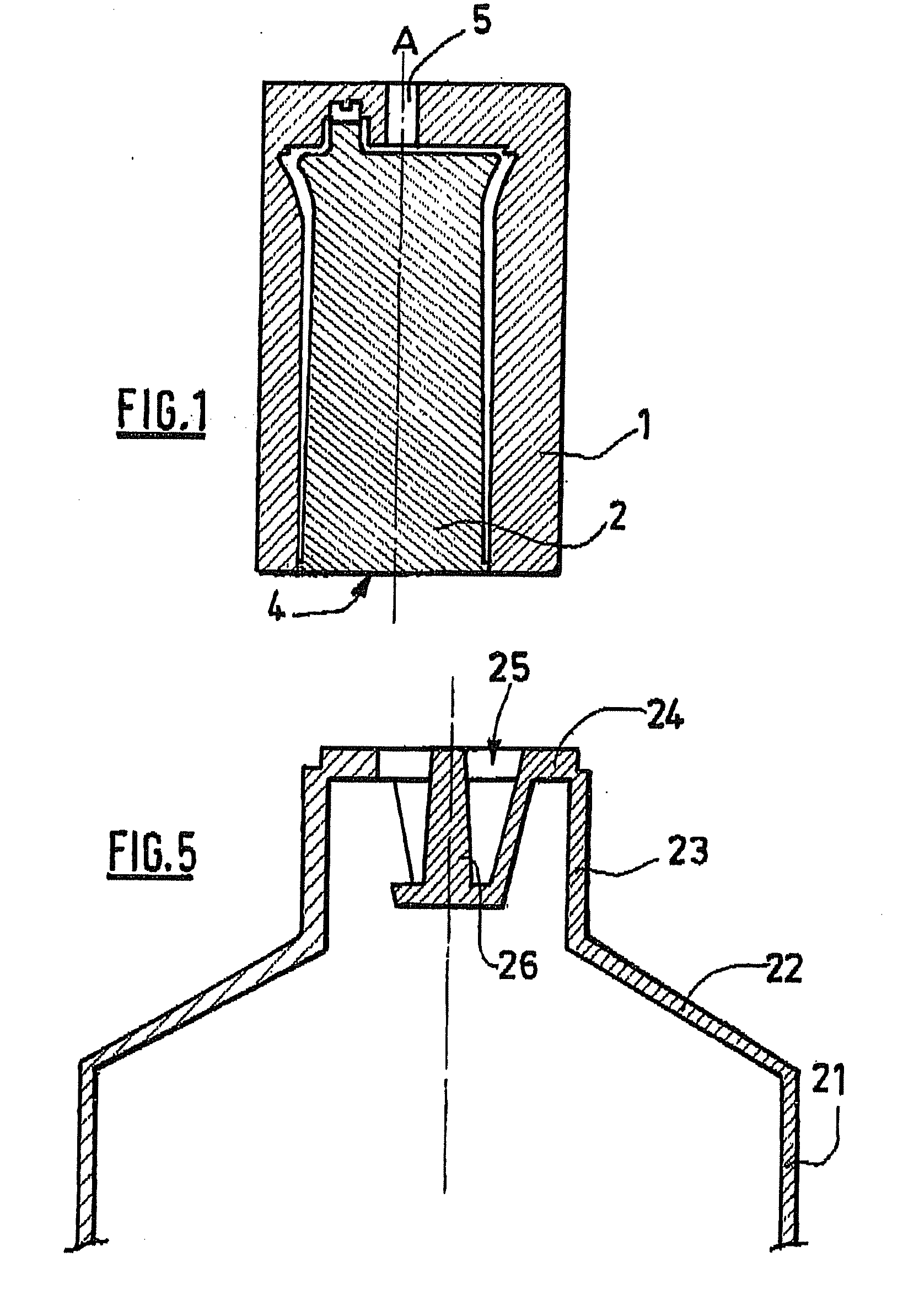

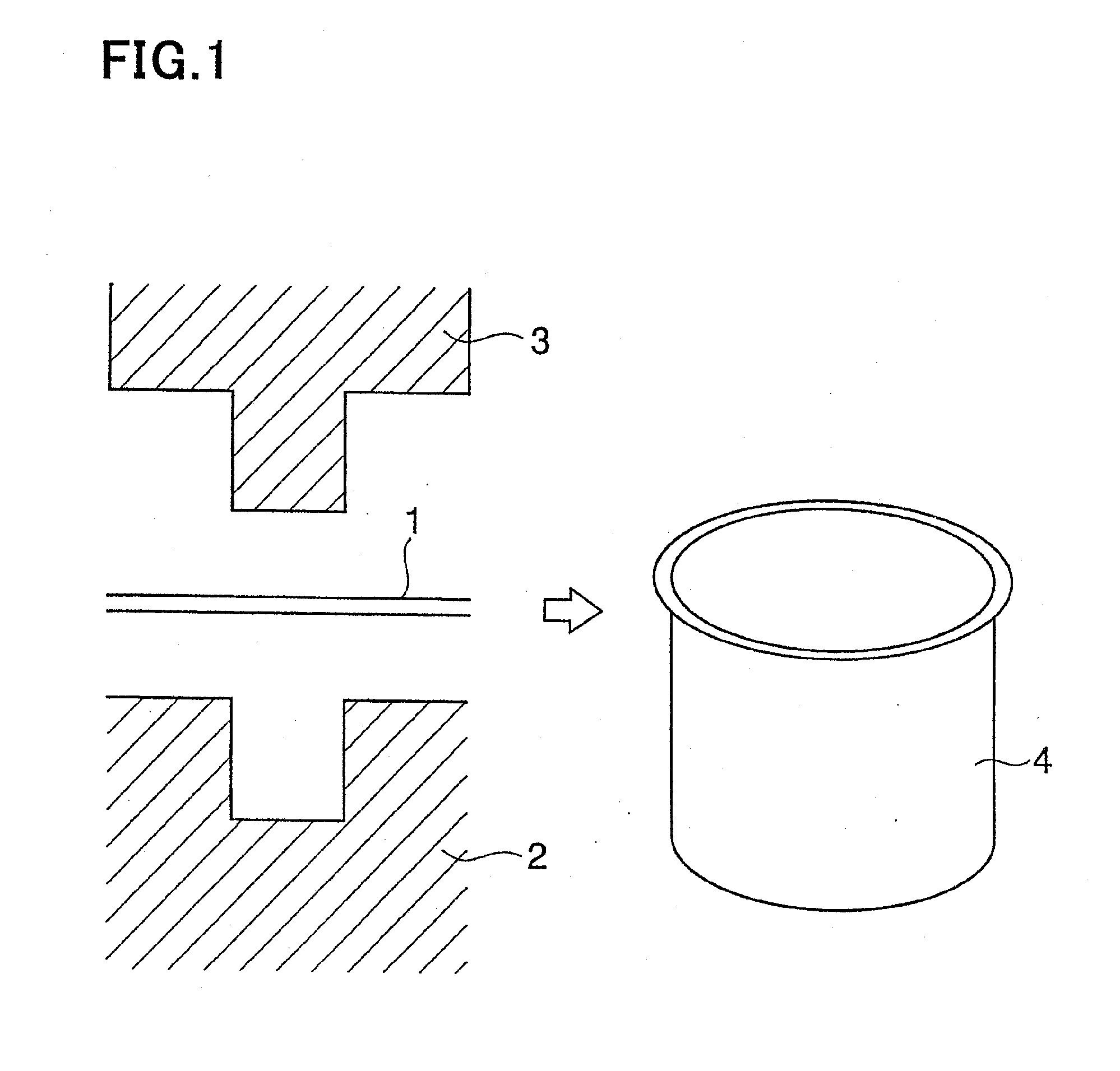

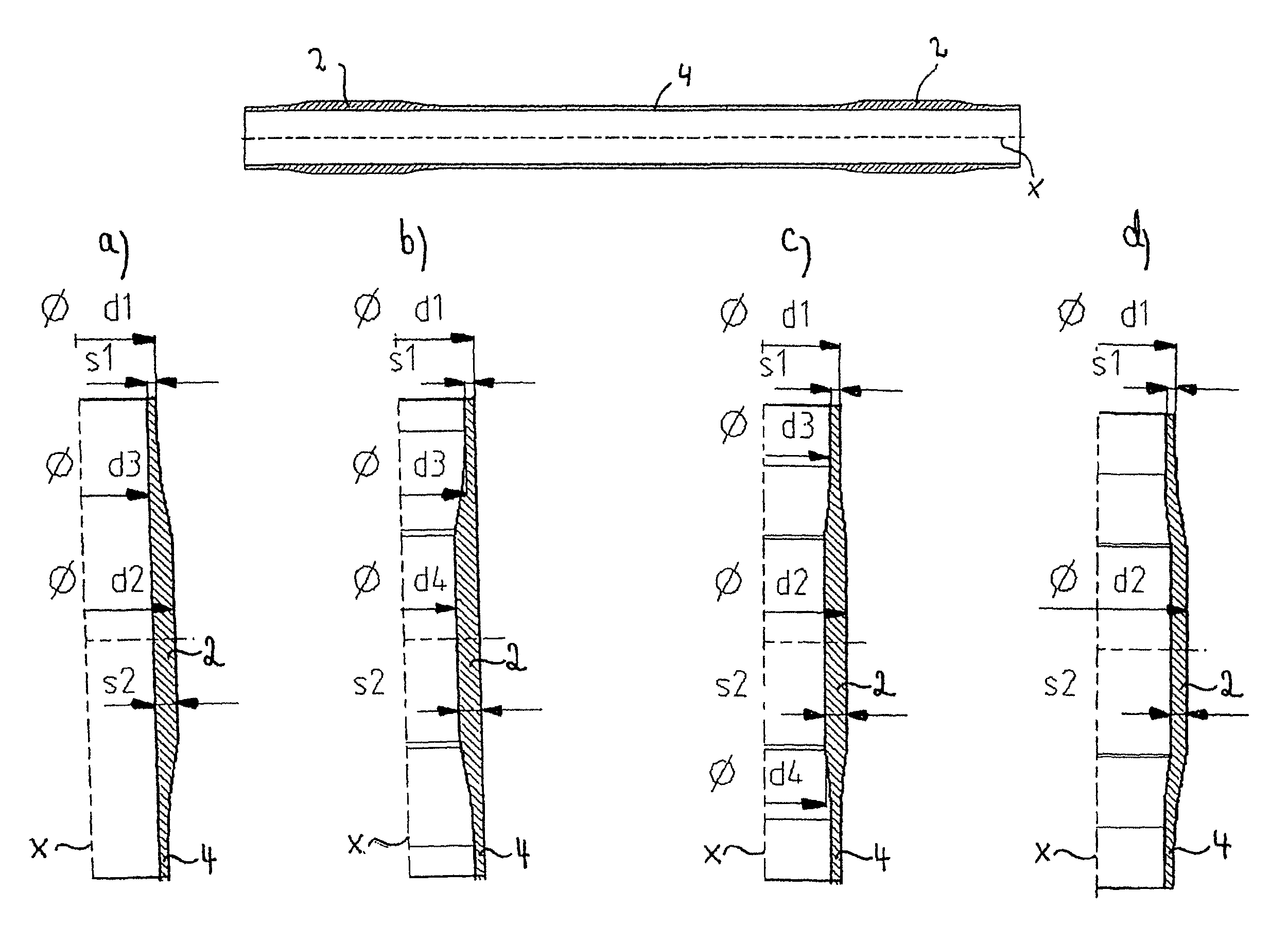

Device for injection molding a tubular element from synthetic material

InactiveUS20090004324A1Compensation for shrinkageConstant wall thicknessFood shapingTubular articlesSynthetic materialsBiomedical engineering

Owner:VIEL +1

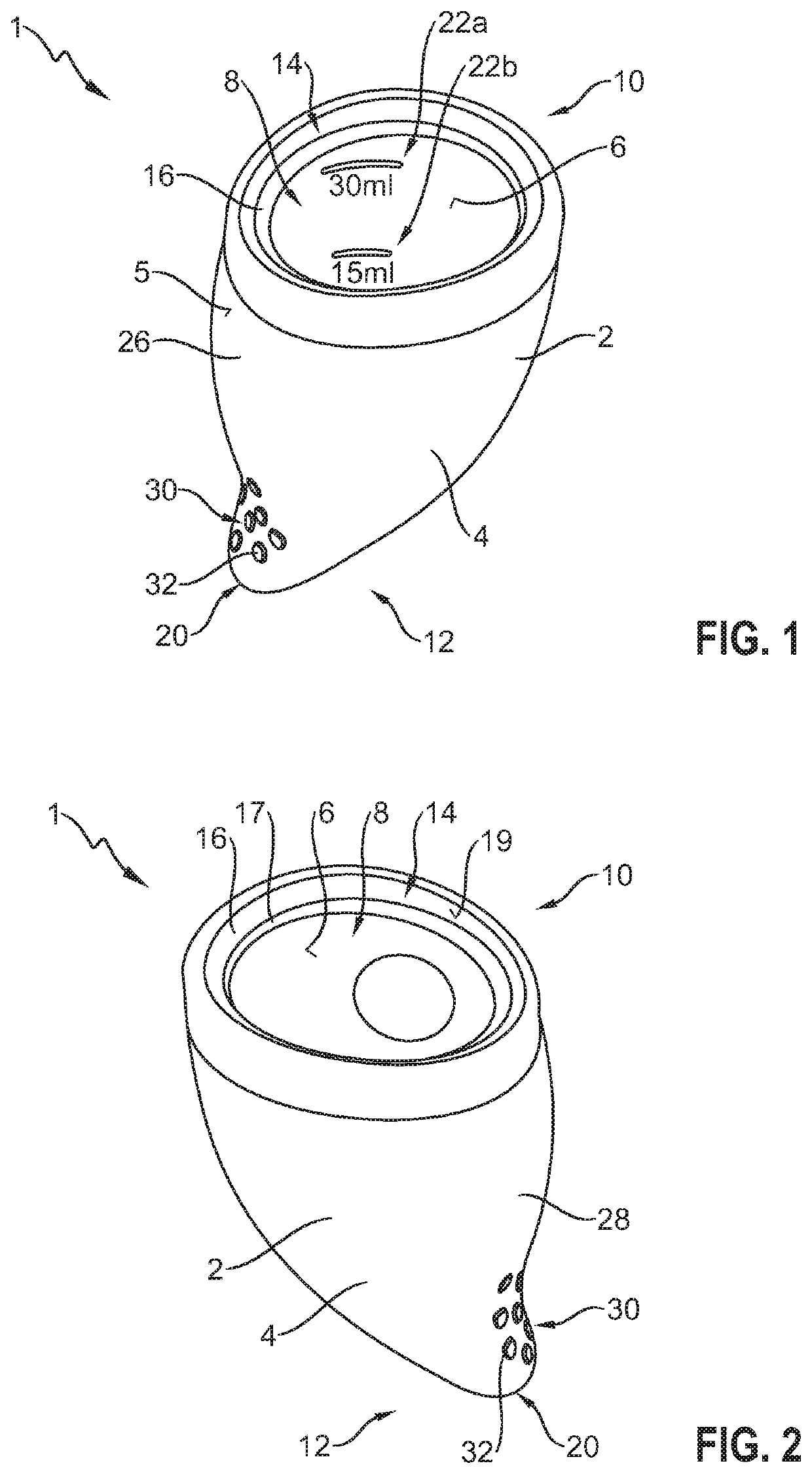

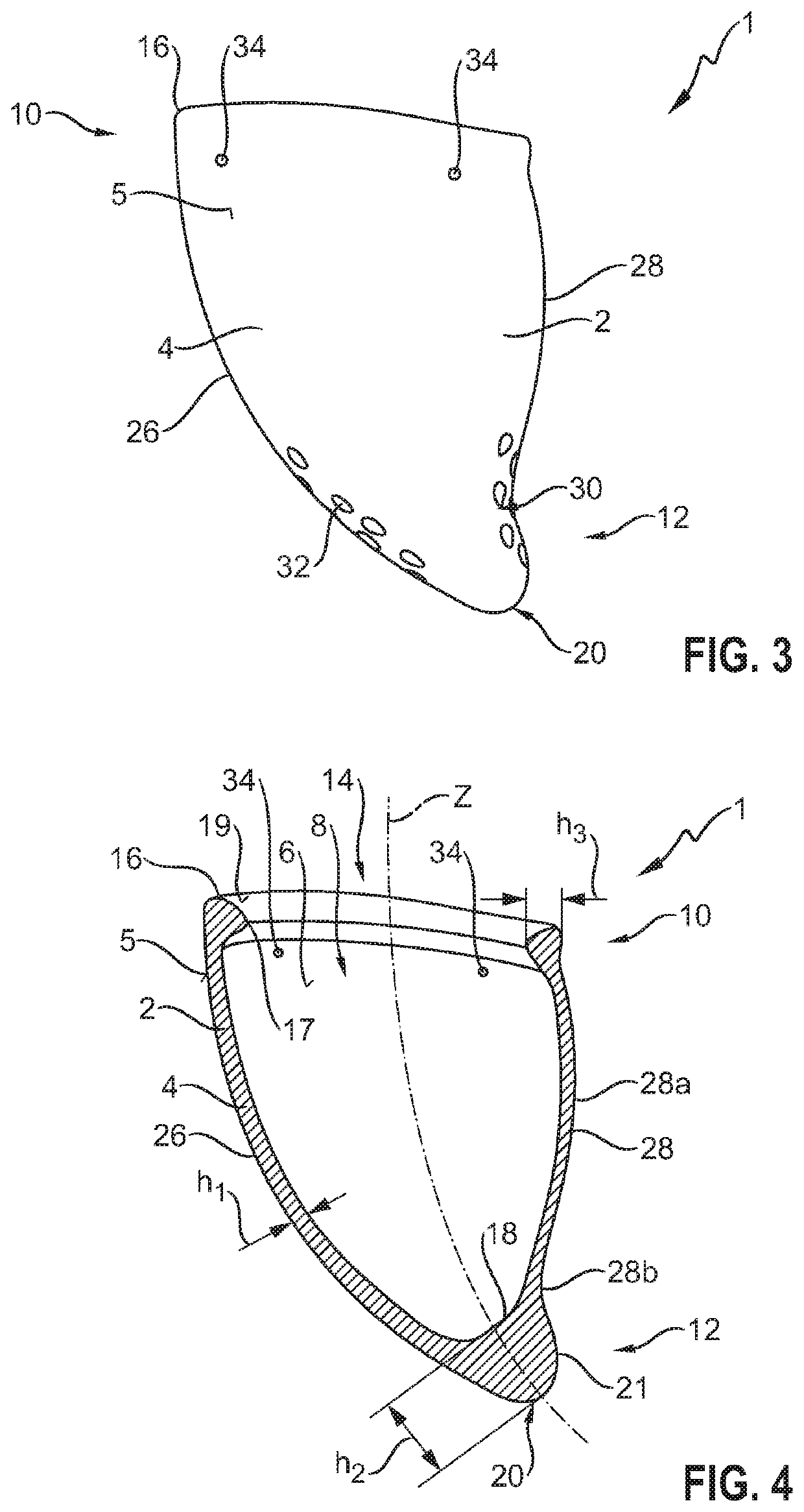

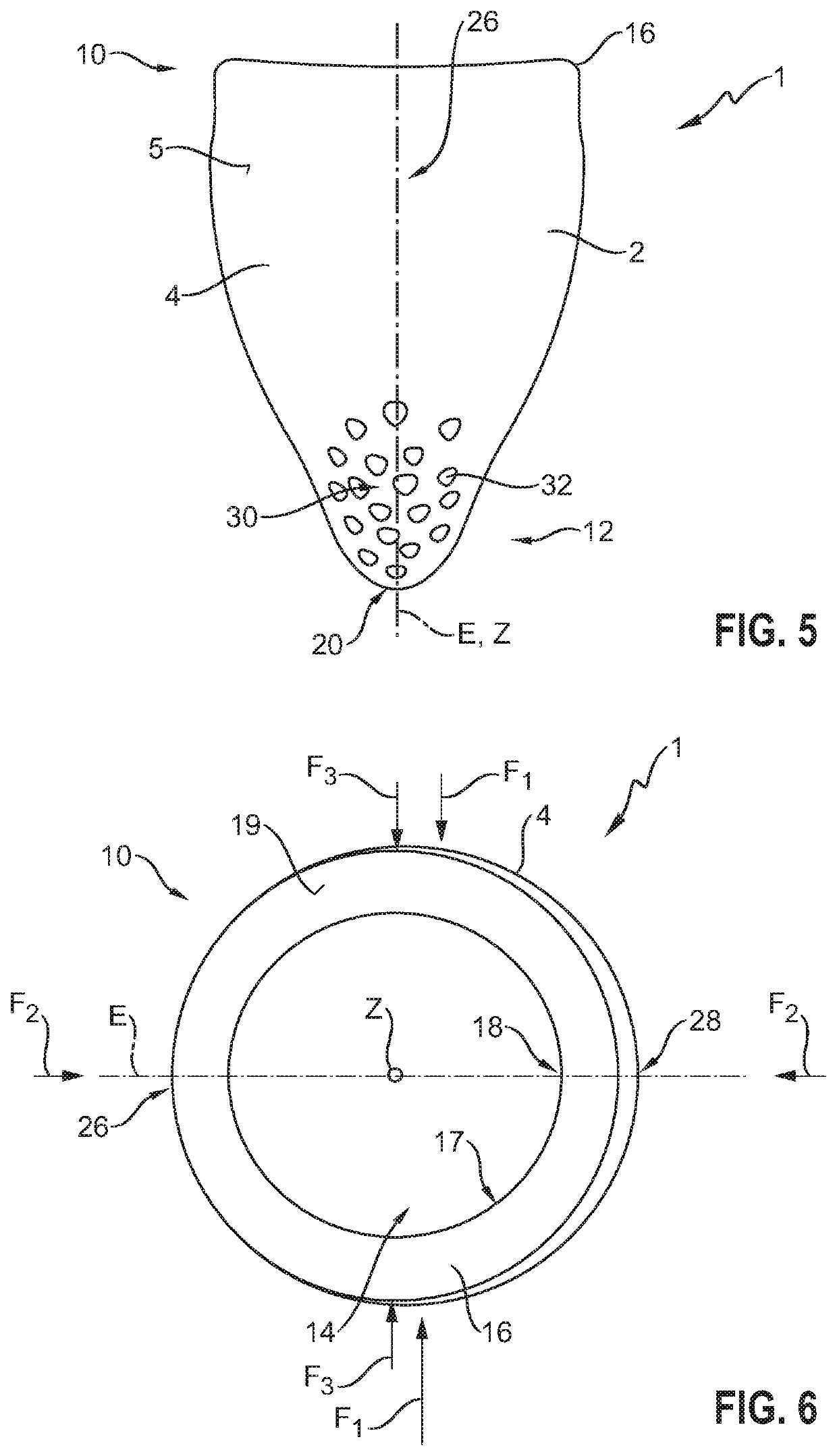

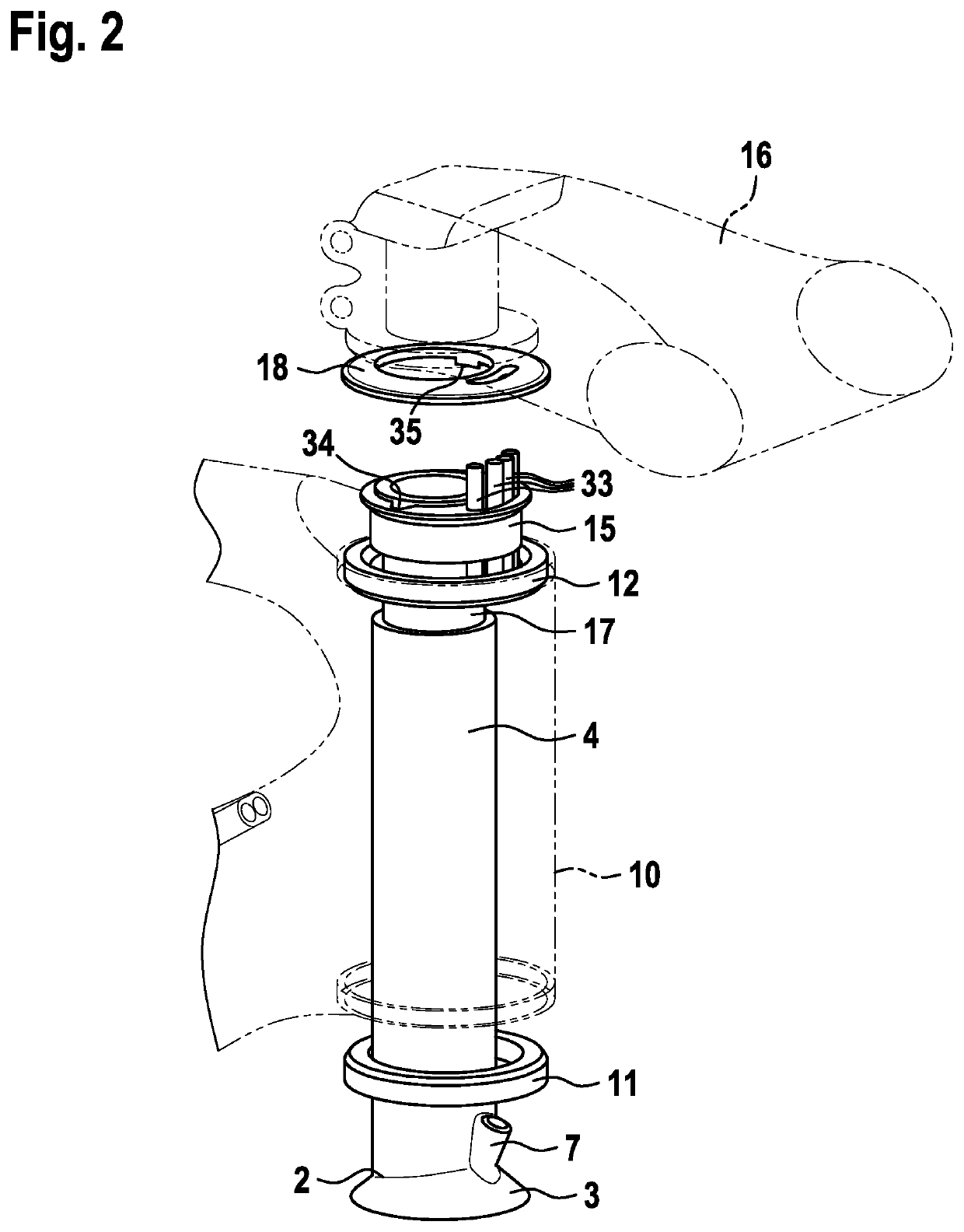

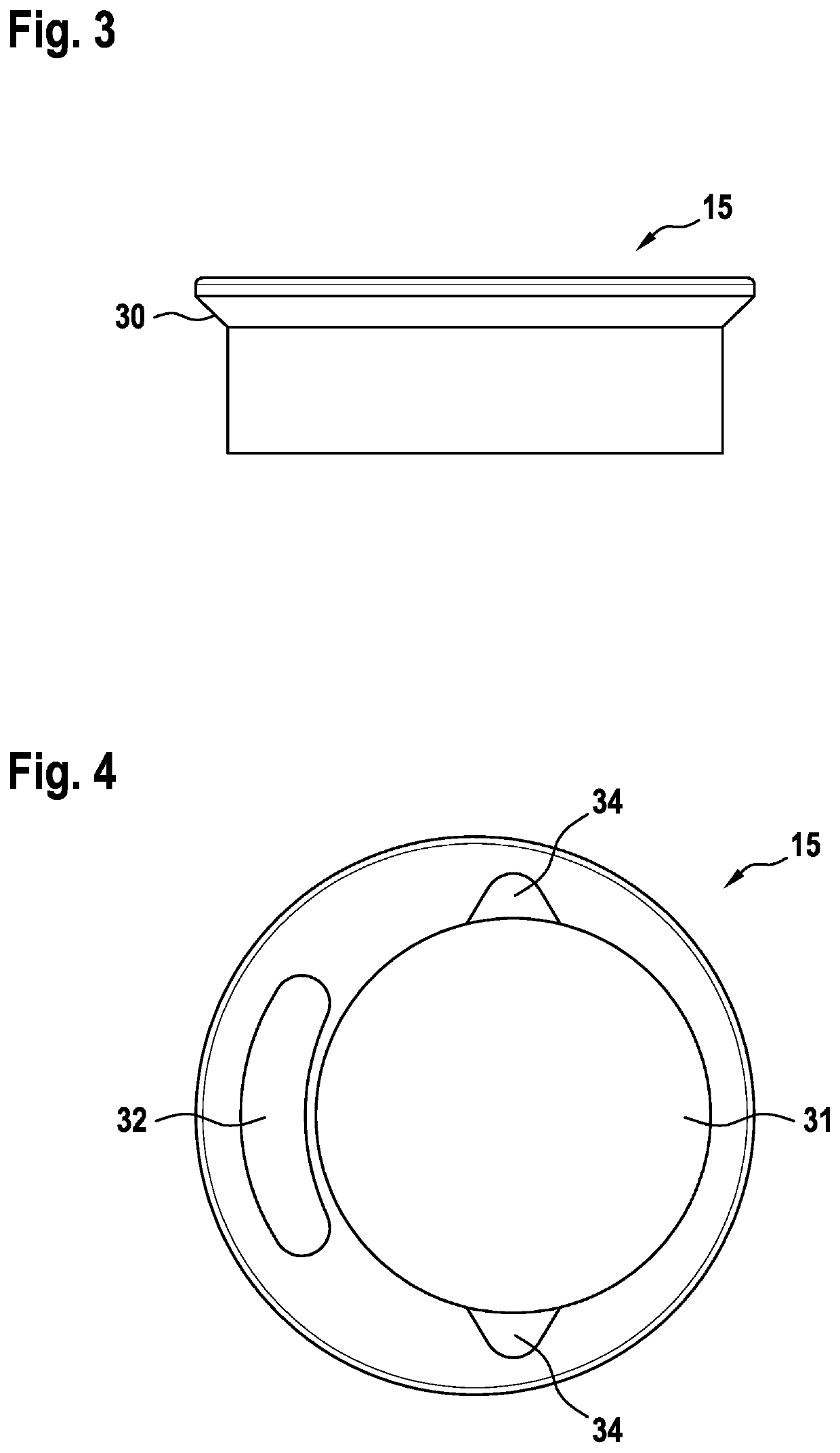

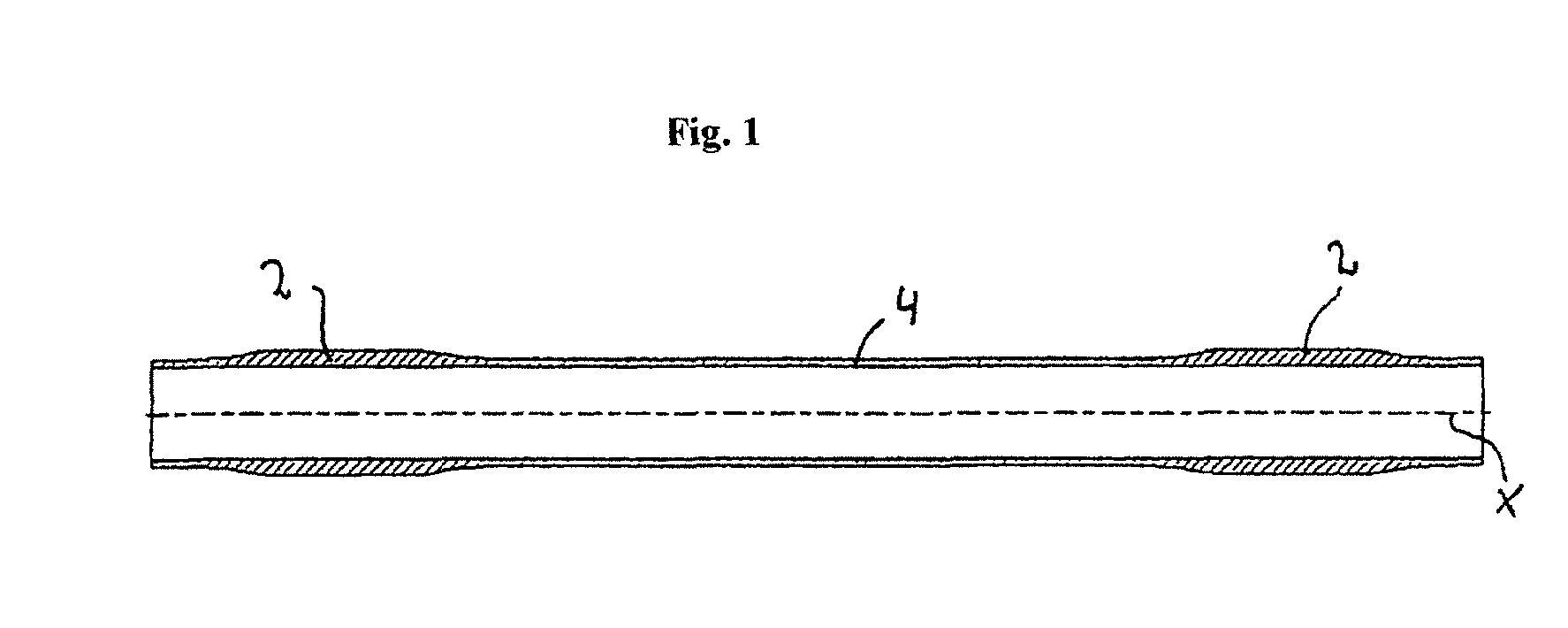

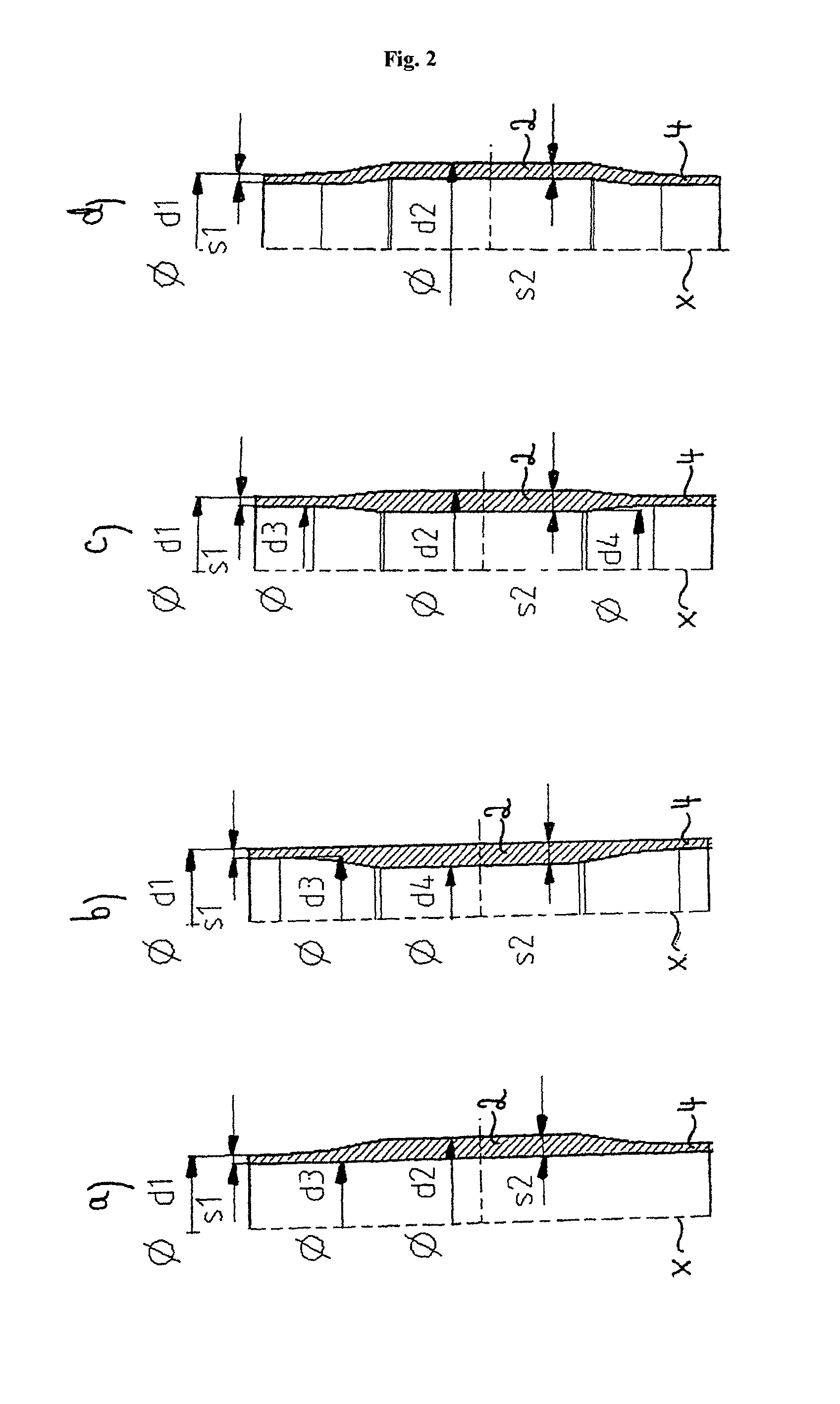

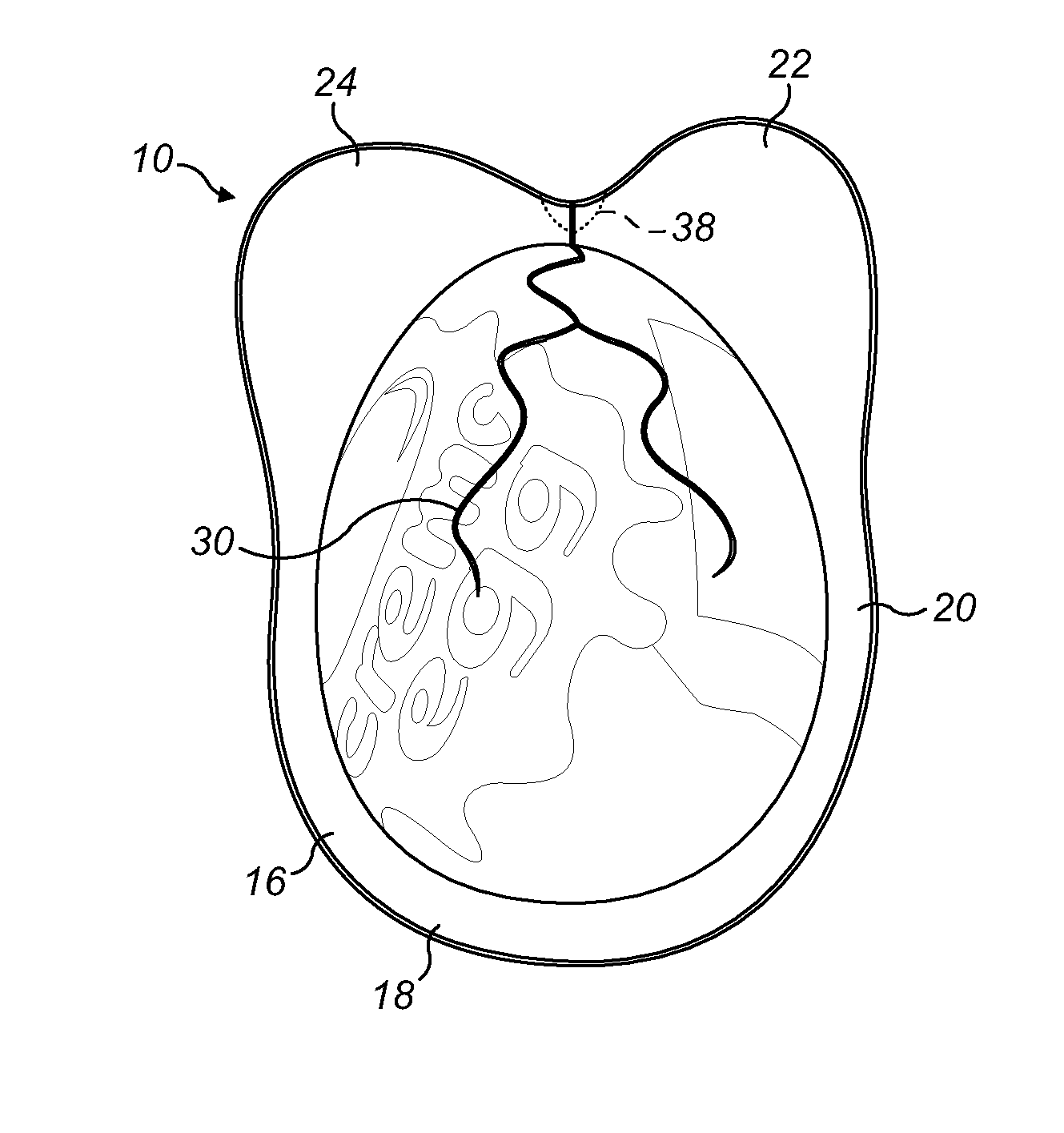

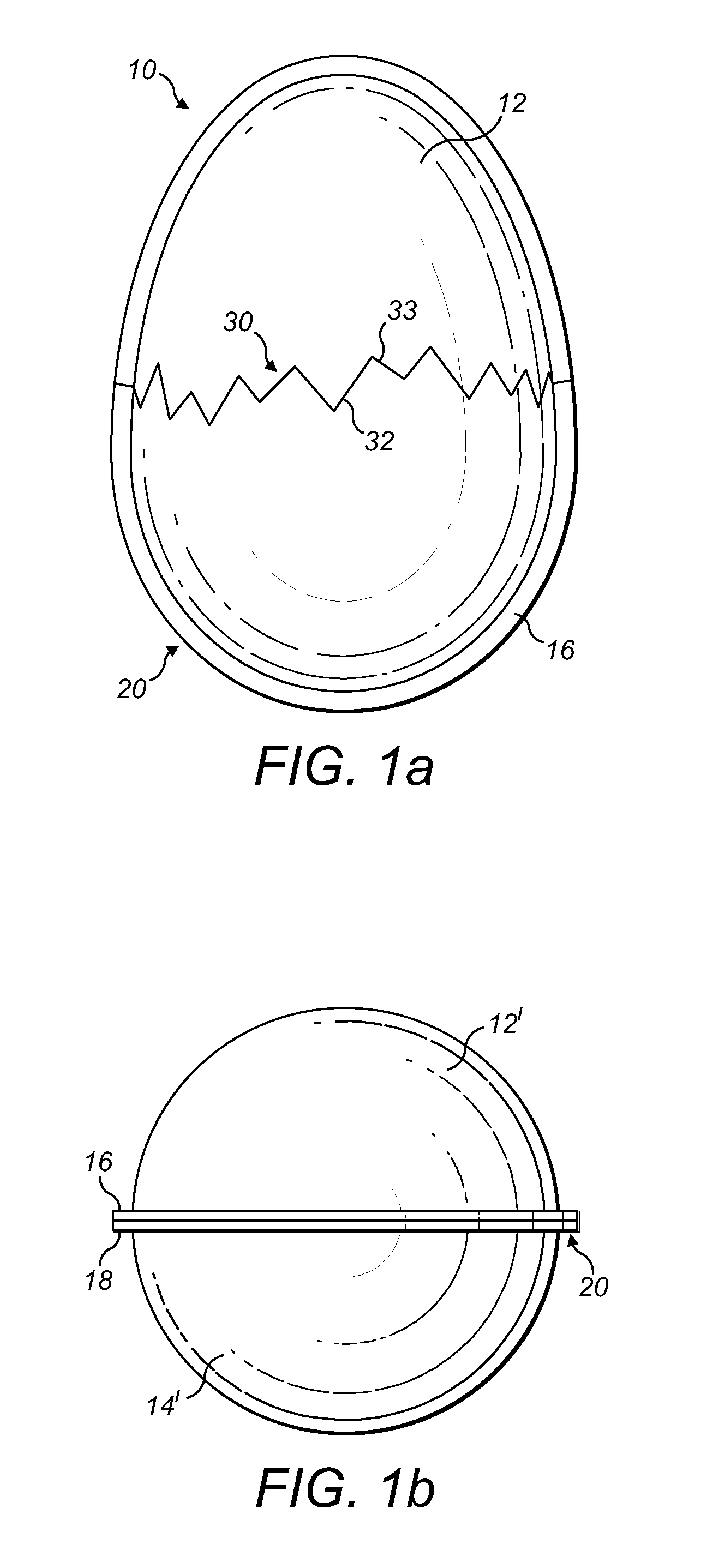

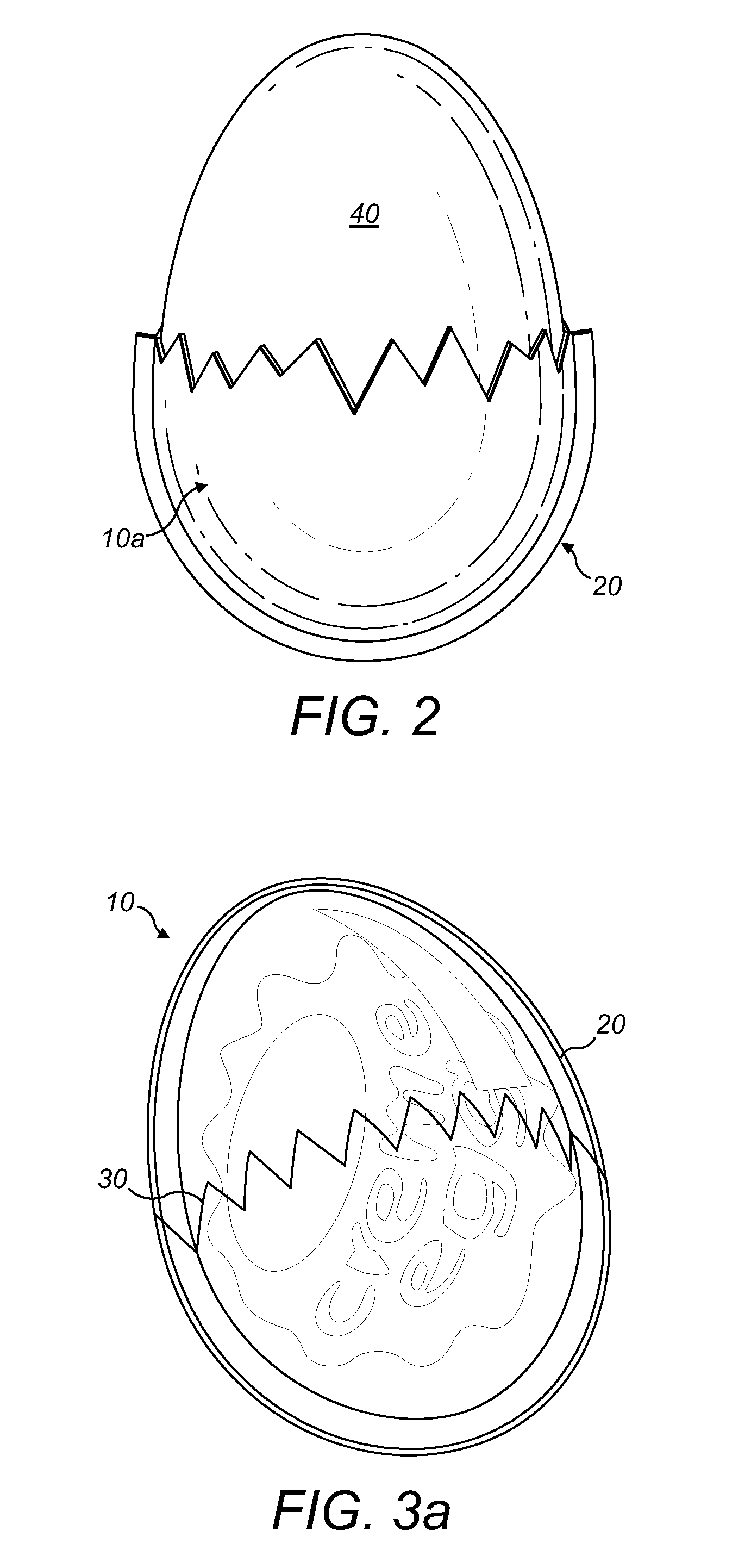

Hygiene product, in particular menstrual cup with an ergonomic shape

ActiveUS20190358077A1Improved fluid receptionImprove wearing comfortMedical devicesBodily discharge devicesBiomedical engineeringHygiene

The disclosure relates to a hygiene product, in particular a menstrual cup, having a cup body comprising a cup wall defining a receiving space using an inner surface, the cup body comprising on a first end an opening into the receiving space, the opening having an edge, and at a second end, a bottom opposite the opening, and the cup body comprising a generally conical shape, tapering towards the bottom and terminating in a tip. The hygiene product is characterized in that the cup body is rotationally asymmetric and a central axis of the cup body runs curved.

Owner:FUN FACTORY

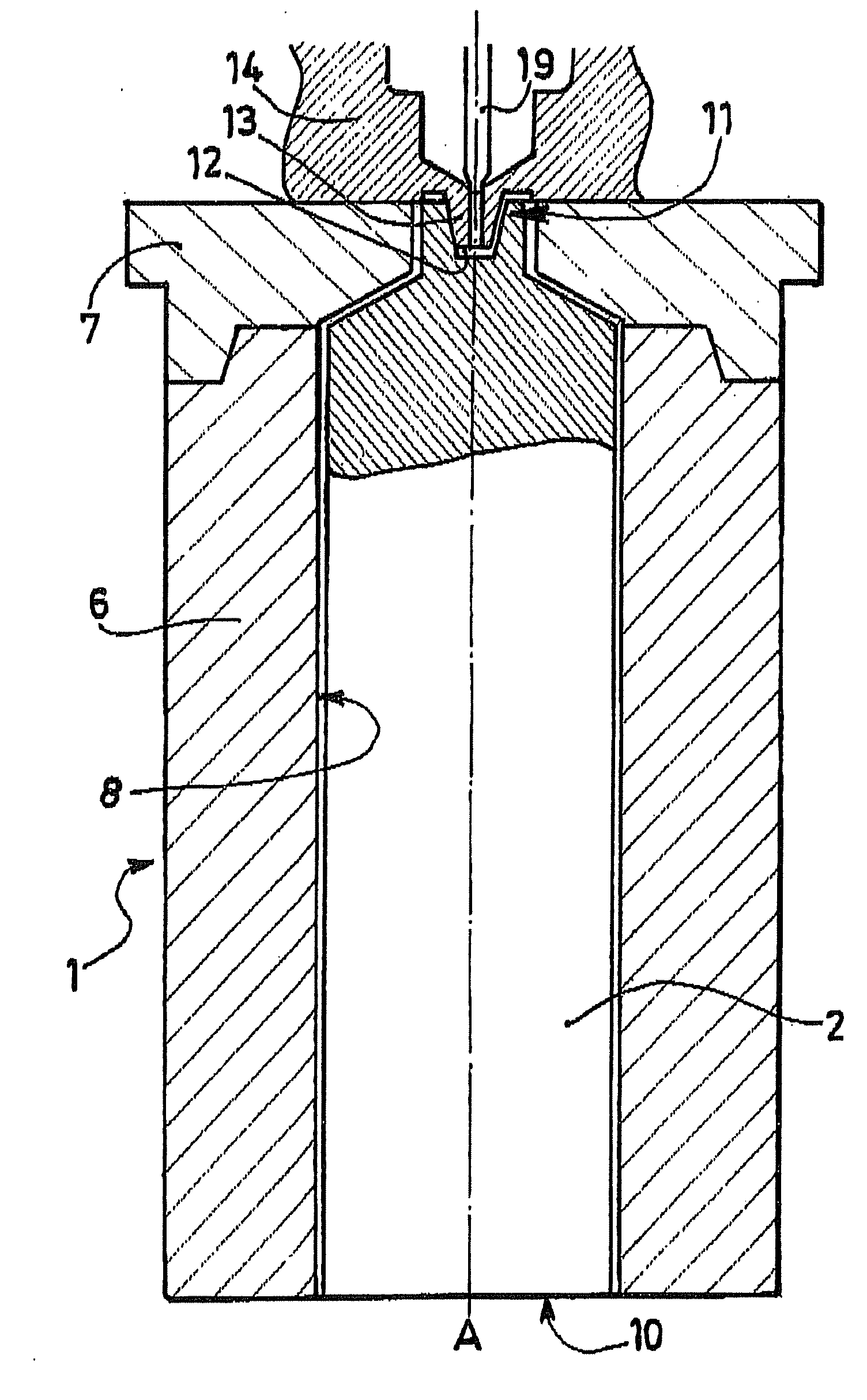

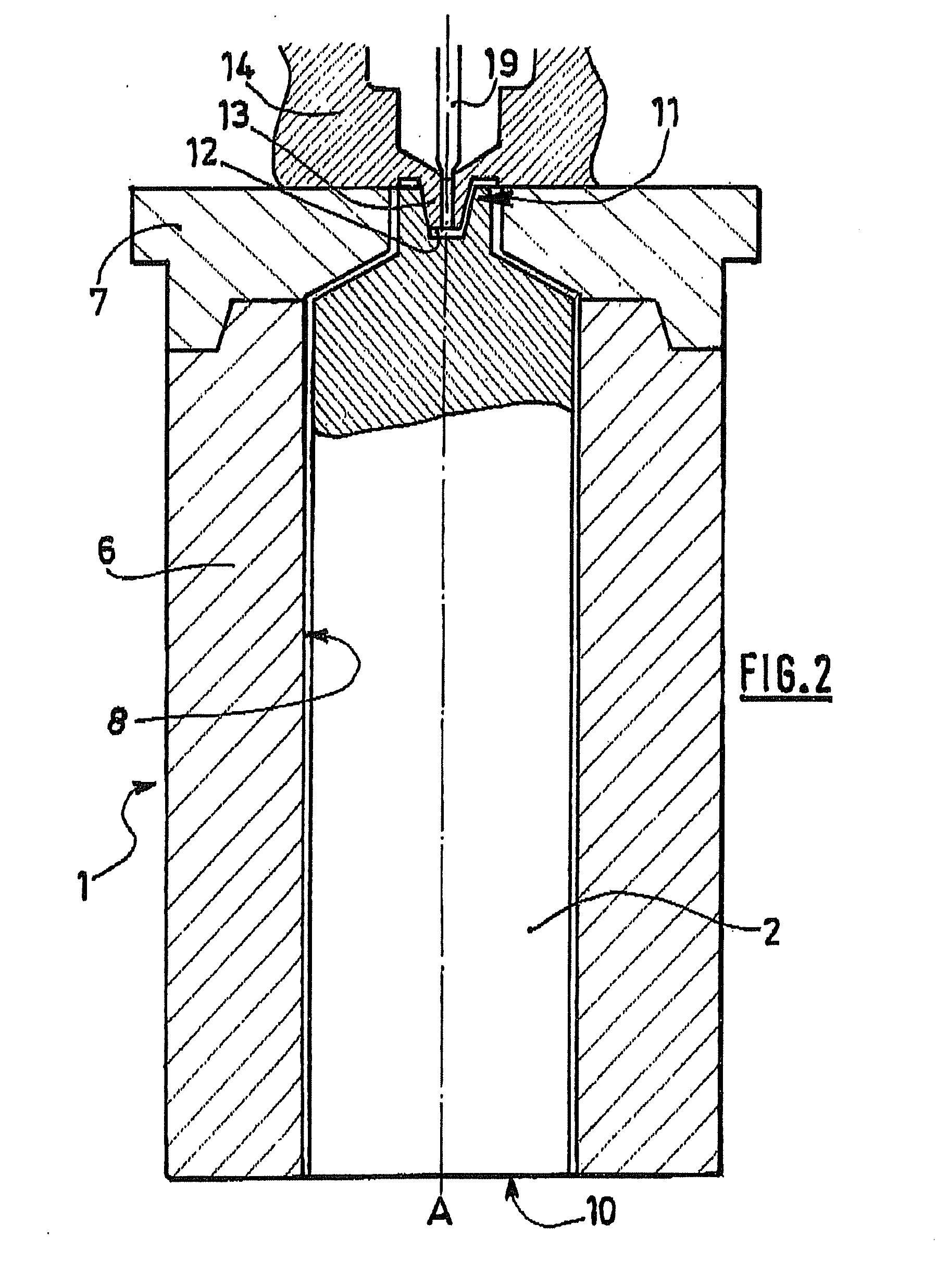

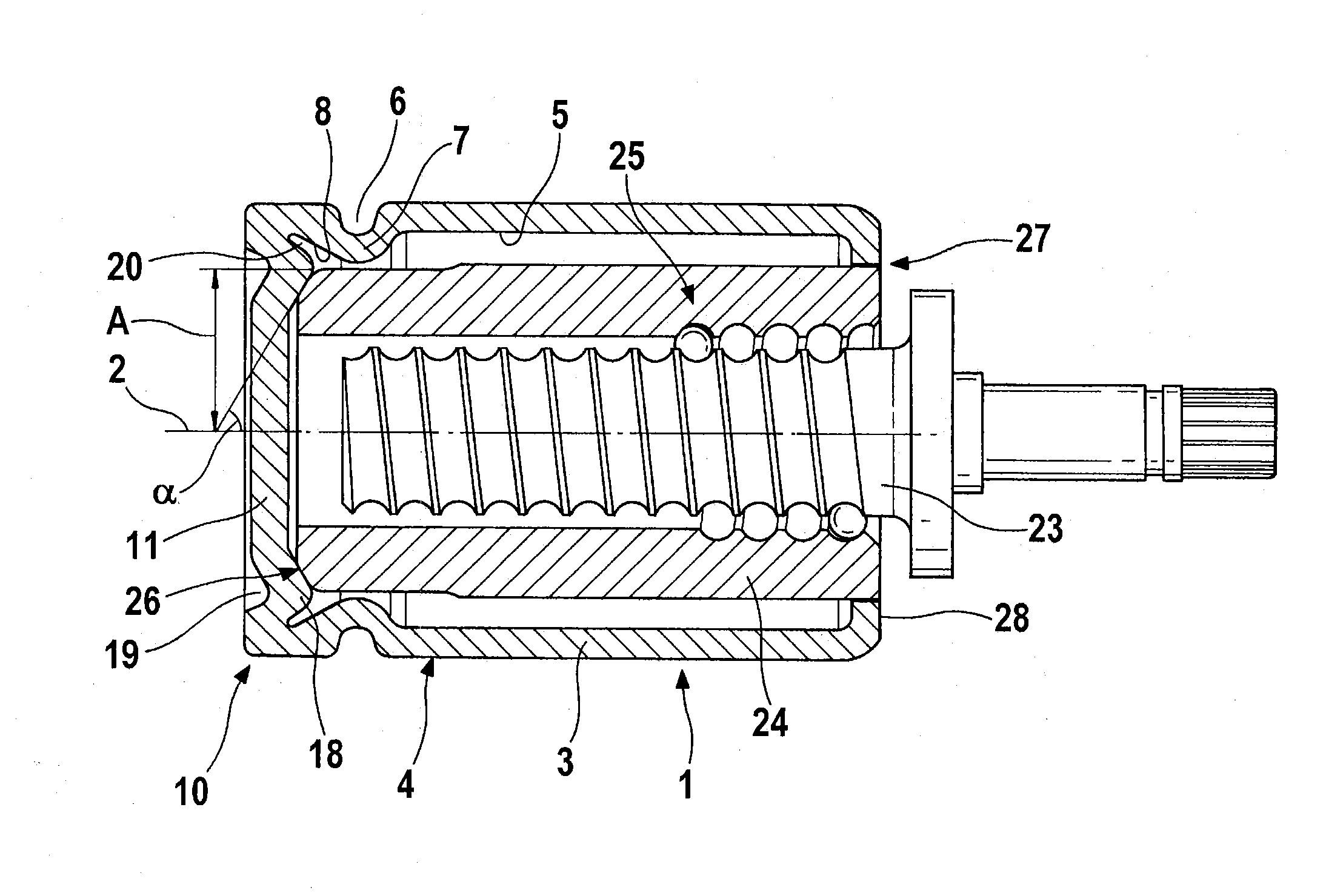

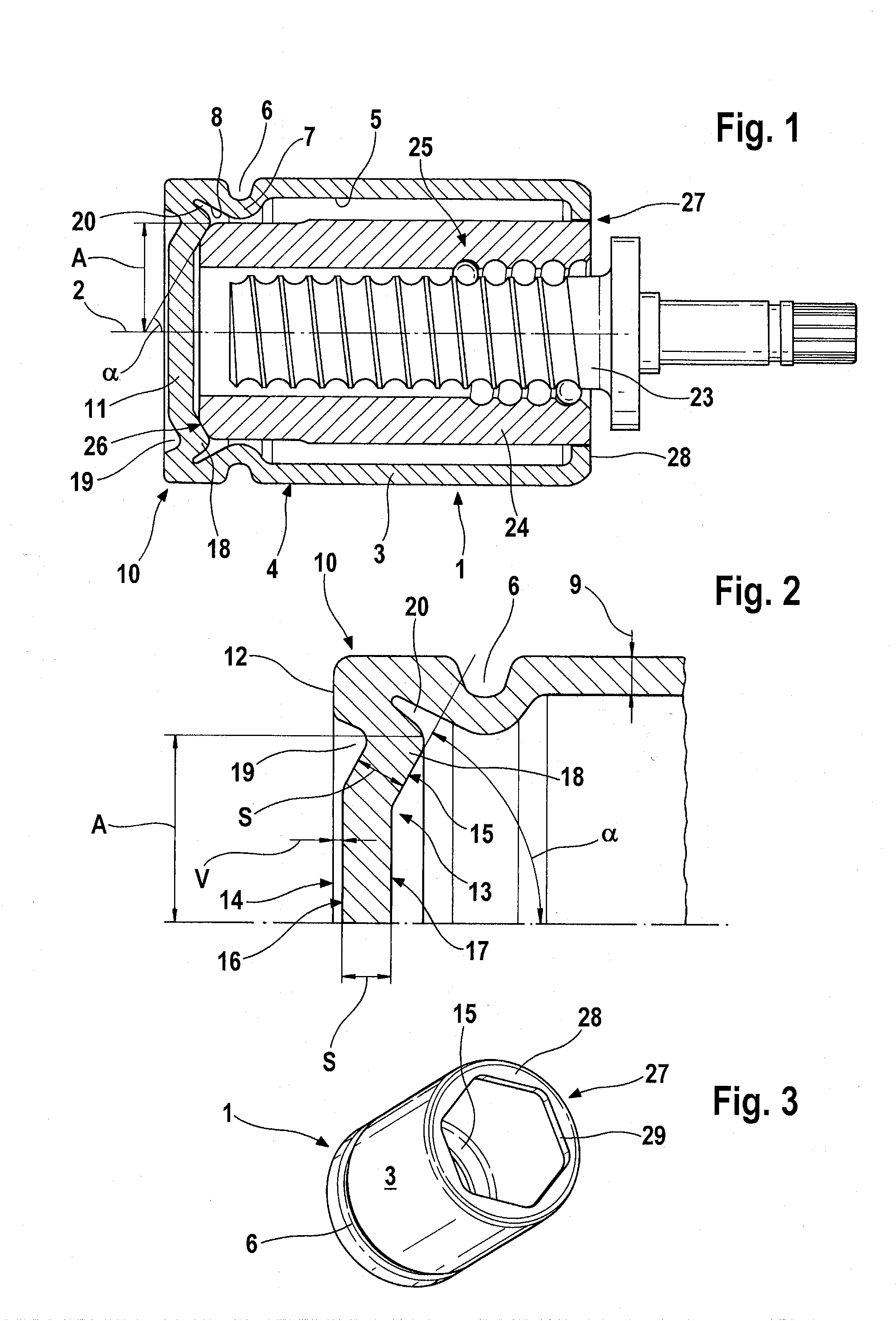

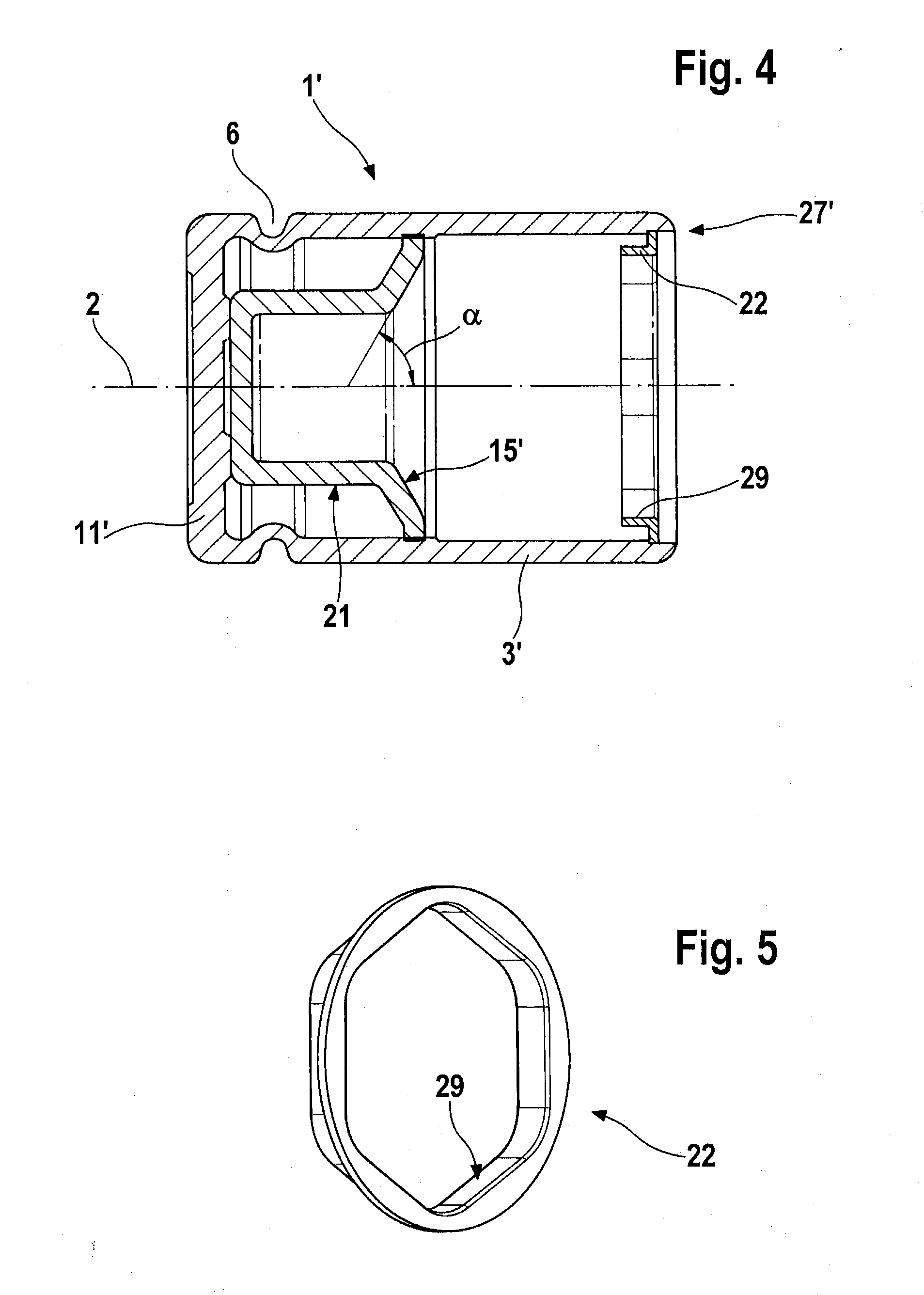

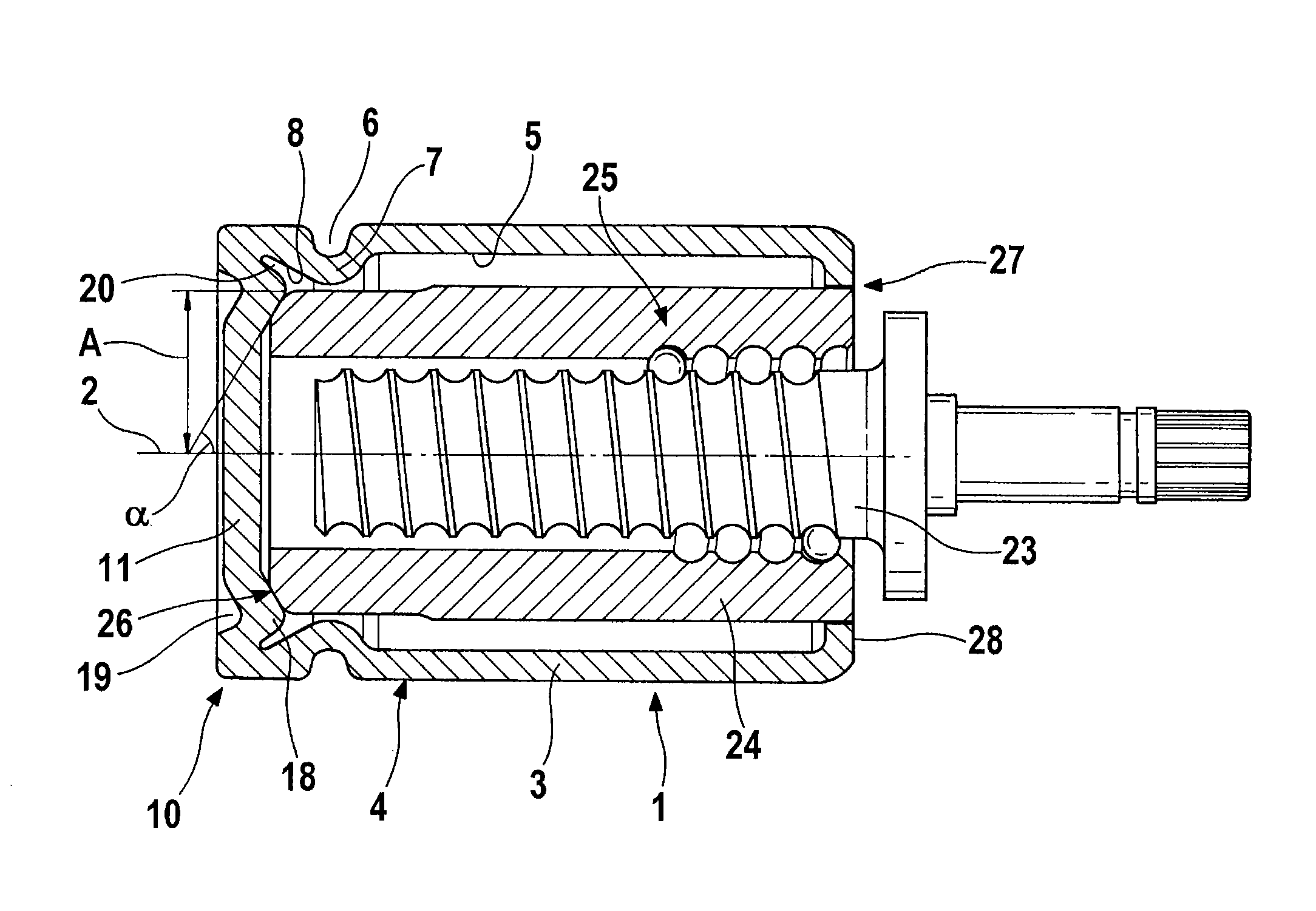

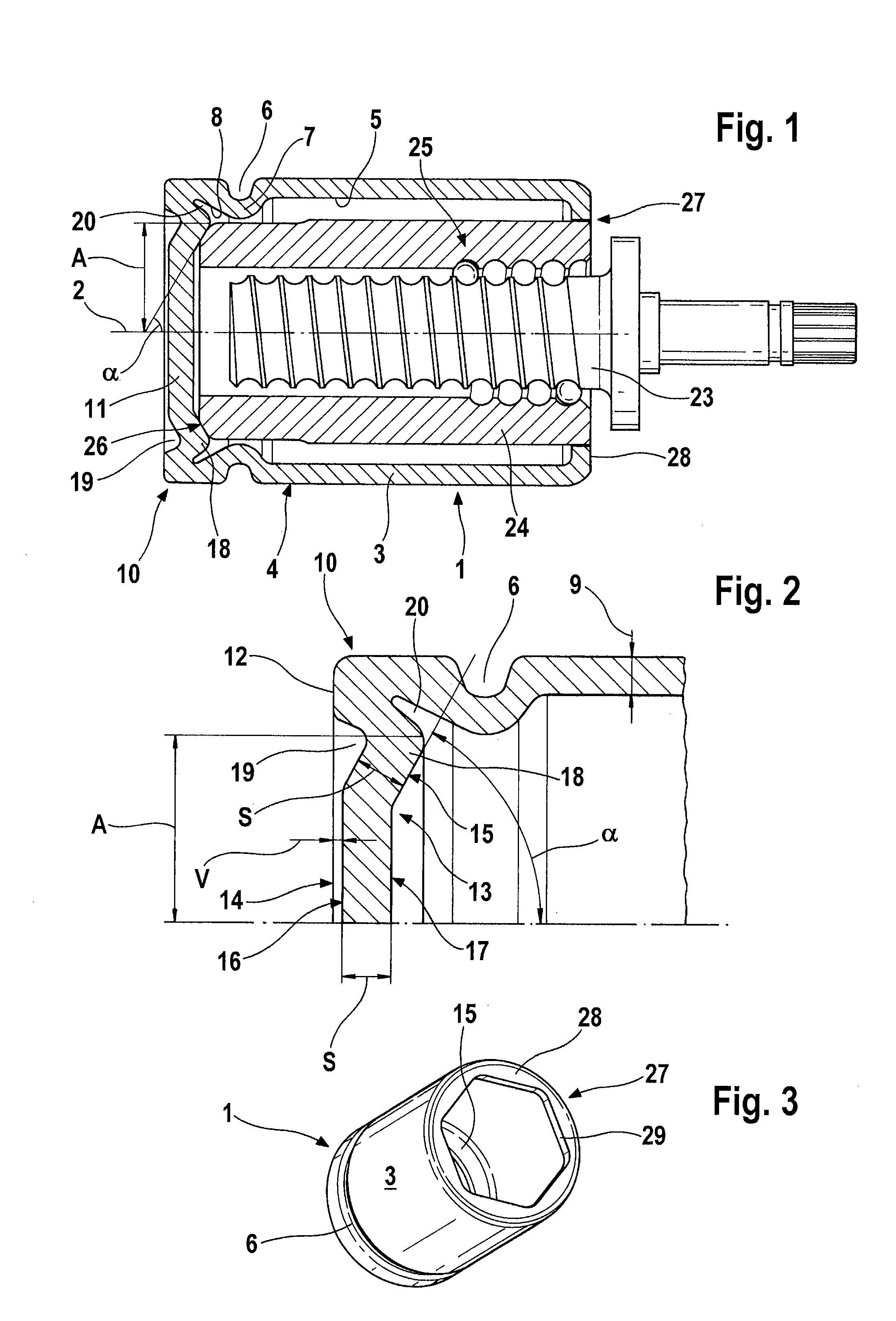

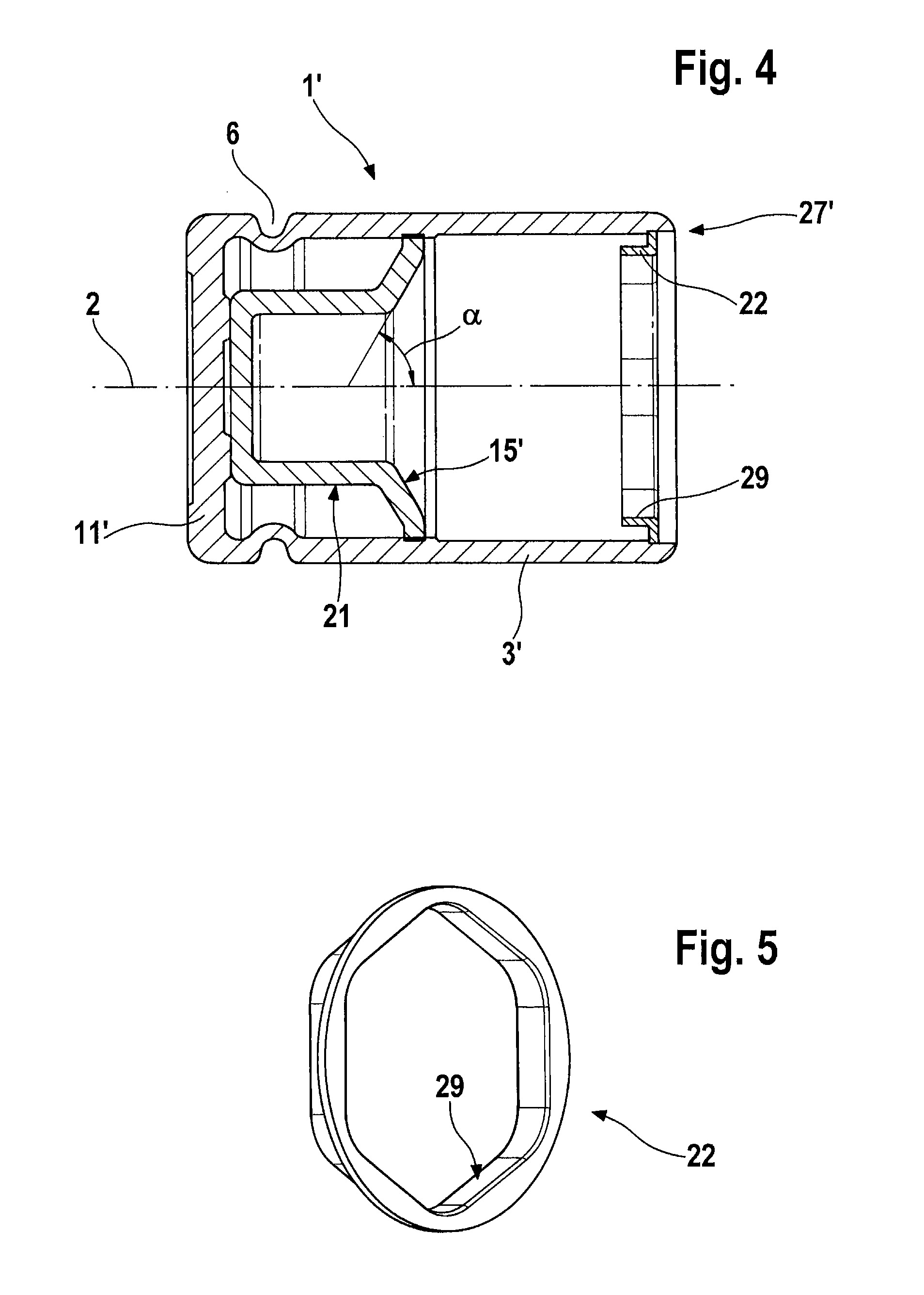

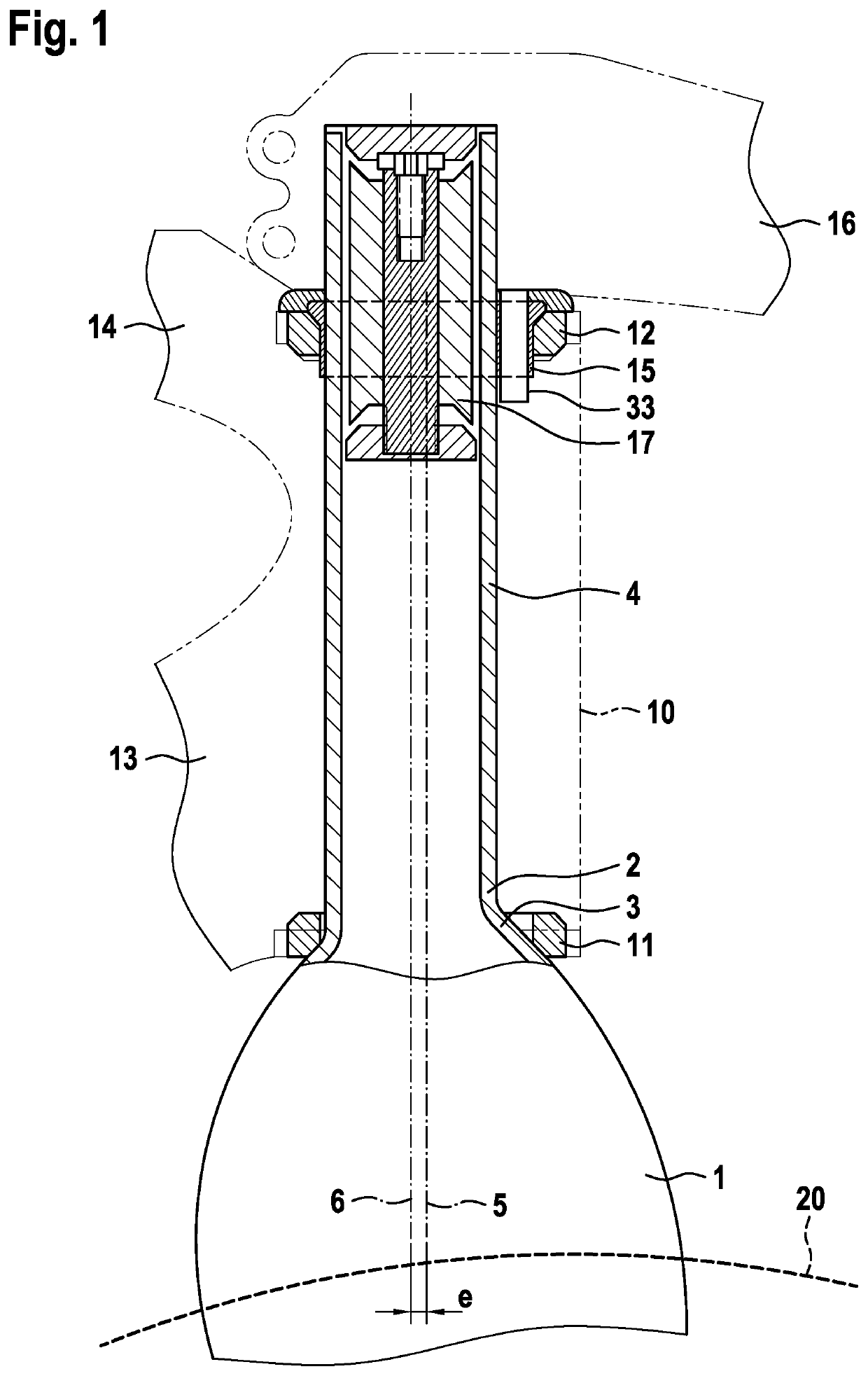

Piston for a brake caliper of a disc brake

ActiveUS20110315007A1Small dead volumeIncreasing hydraulic rigidityPlungersTrunk pistonsHydraulic fluidCalipers

A piston for a brake caliper of a disc brake constructed as a pot which is open at one end, having a longitudinal axis, a wall, and a piston head. The piston is supported in a cylinder of the brake caliper such that it can be moved along the longitudinal direction, and it can be placed against a brake pad in the region of the piston head by an axial contact surface. When the piston is subjected to pressure by a hydraulic fluid, the piston moves in the cylinder and presses the brake pad against a brake disc. A projection having a conical surface is provided on an inner surface of the piston head. A recess is provided, which is substantially at the same distance from the longitudinal axis as the projection on the inner surface of the piston head, on an outer surface of the piston head.

Owner:CONTINENTAL TEVES AG & CO OHG +1

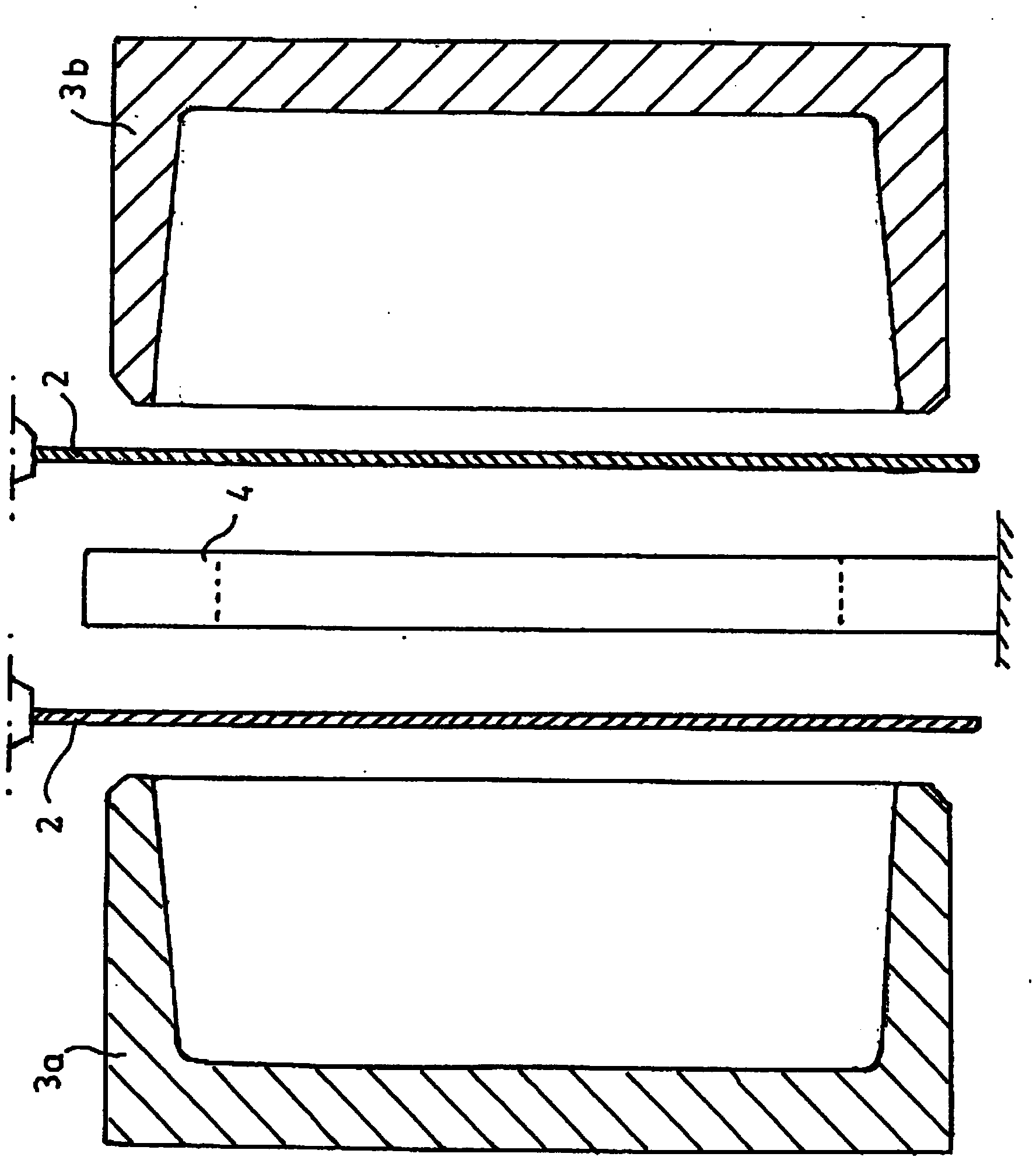

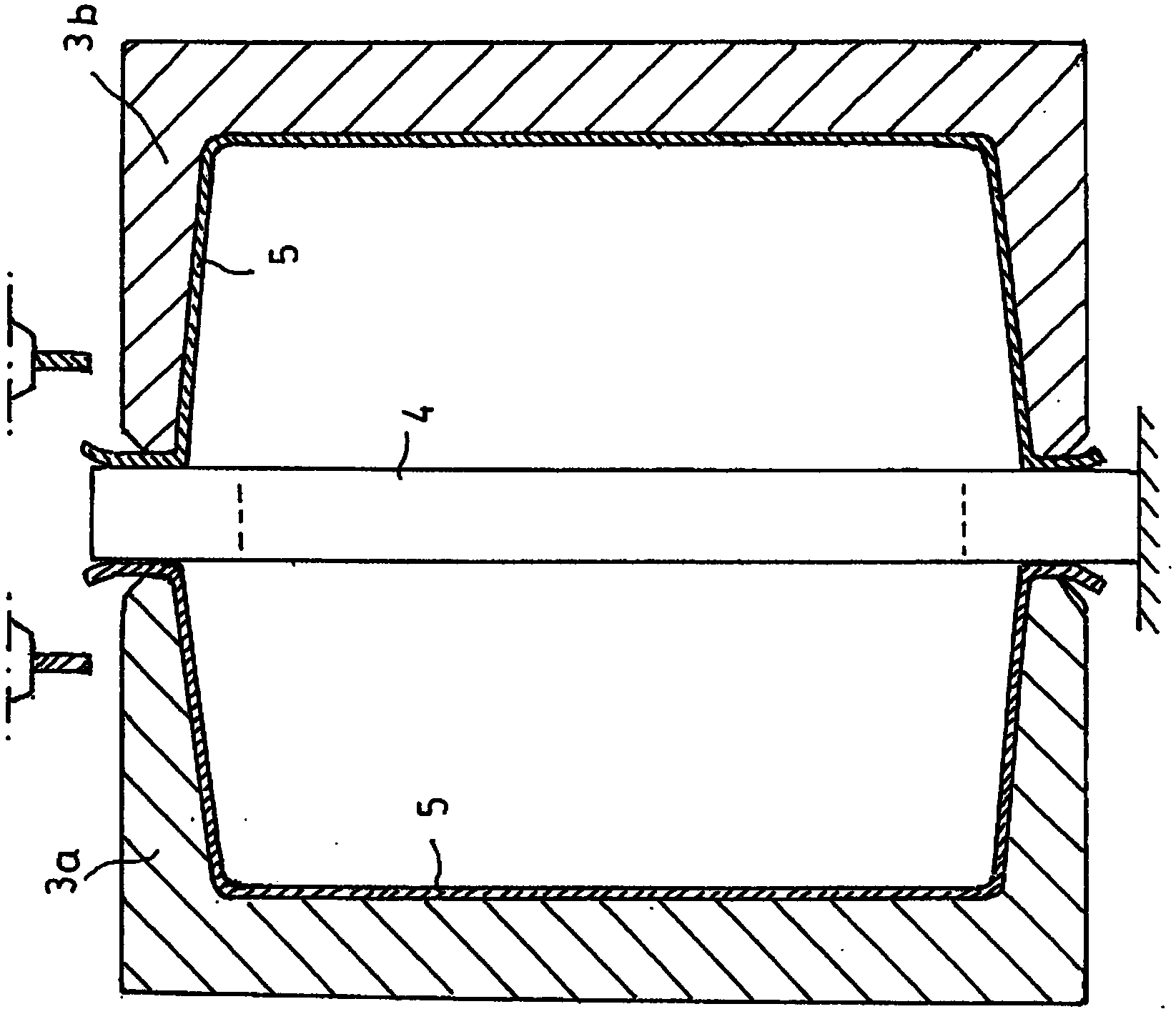

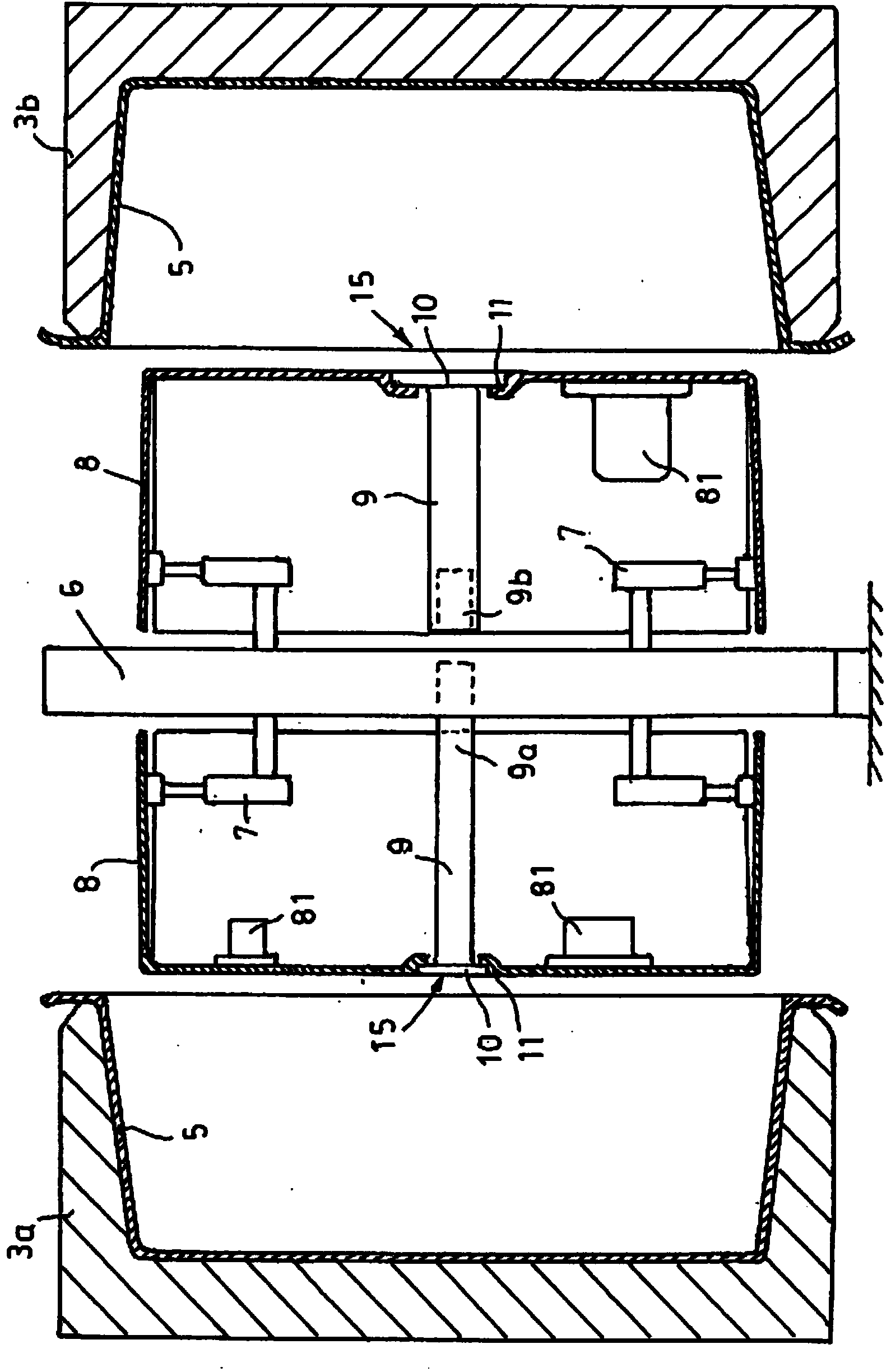

Extrusion-blow-molded fuel tank of thermoplastic material and method for the production thereof

InactiveCN104254437AContour exact matchEasy to joinLaminationLamination apparatusPolymer scienceFuel tank

The invention relates to an extrusion-blow-molded fuel tank (1) of thermoplastic material comprising a tank wall of a composite of various layers obtained in various production operations, at least one first layer comprising at least one shell-shaped supporting shell (8) and a second layer of a thermoplastic material forming an adhesive bond with the supporting shell (8), and the supporting shell (8) having a greater strength than the second layer. The supporting shell (8) forms an inner layer of the tank and the second layer forms an outer skin of the tank, two supporting shells within the tank forming a supporting cage or a supporting housing.

Owner:KAUTEX TEXTRON

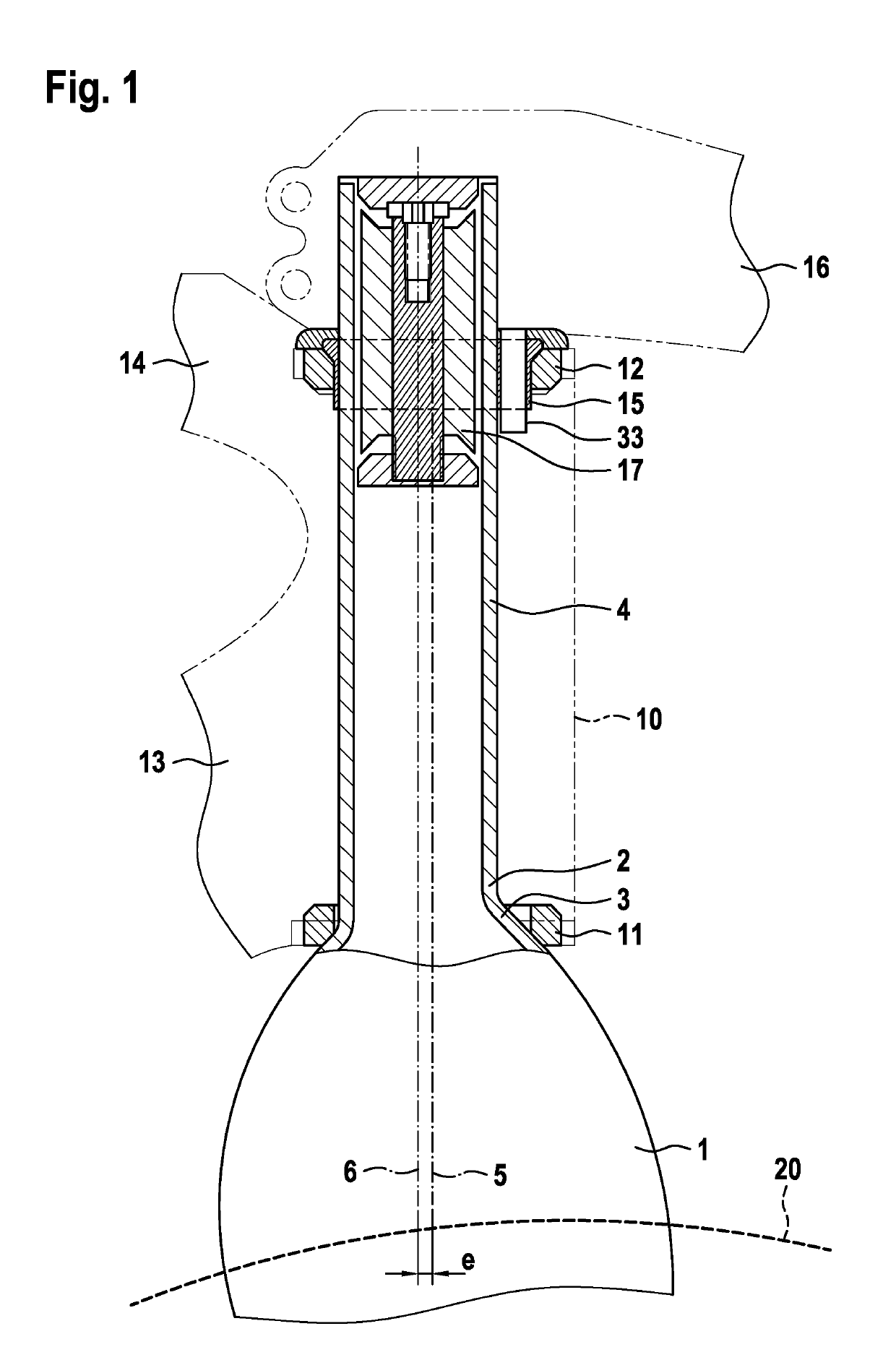

Eccentric bicycle fork shaft

ActiveUS20190092417A1Increased bending stiffnessIncrease flexibilitySteering deviceArticle supporting devicesMechanical engineering

A bicycle fork includes a fork shaft configured to be rotatably borne by headset bearings in a head tube of a bicycle frame so as to rotate about a steering axis. The fork shaft includes a cylindrical fork shaft segment that is disposed eccentrically with respect to the steering axis. The cylindrical fork shaft segment is a right circular cylinder having a hollow interior, a cylindrical inner surface and a central longitudinal axis that lies within a symmetry plane of the bicycle frame and extends parallel to the steering axis. The central longitudinal axis of the cylindrical fork shaft segment is spaced apart from the steering axis in a direction of eccentricity that points in an opposite direction with respect to a forward direction of travel of the bicycle.

Owner:SCOTT SPORTS

Garden hose coupling with protective, strain reducing sleeve

InactiveUS20160312940A1Provide strain reliefReduce wall thicknessSleeve/socket jointsHose connectionsWorking lifeEngineering

A flexible hose assembly, in particular a garden hose, having an end fitting including a protective, strain reducing sleeve fixedly secured at the male end segment of a fluid conveying tube. The sleeve is flexible and provides strain relief to the portion of the tube surrounded by the sleeve and reduces the ability of the tube to kink in the area adjacent to the end fitting. The prevention of kinks at the male end of the tube reduces stresses in this area of the tube and greatly extends the working life of the sleeve and tube assembly. The sleeve additionally serves as a gripping surface for one or more of facilitating the attachment of the hose assembly to another device such as a flow control device and holding the end of the hose during use.

Owner:TEKNOR APEX

Piston for a brake caliper of a disc brake

ActiveUS8869677B2Easy to operateWeight increaseAxially engaging brakesPlungersEngineeringHydraulic fluid

Owner:CONTINENTAL TEVES AG & CO OHG +1

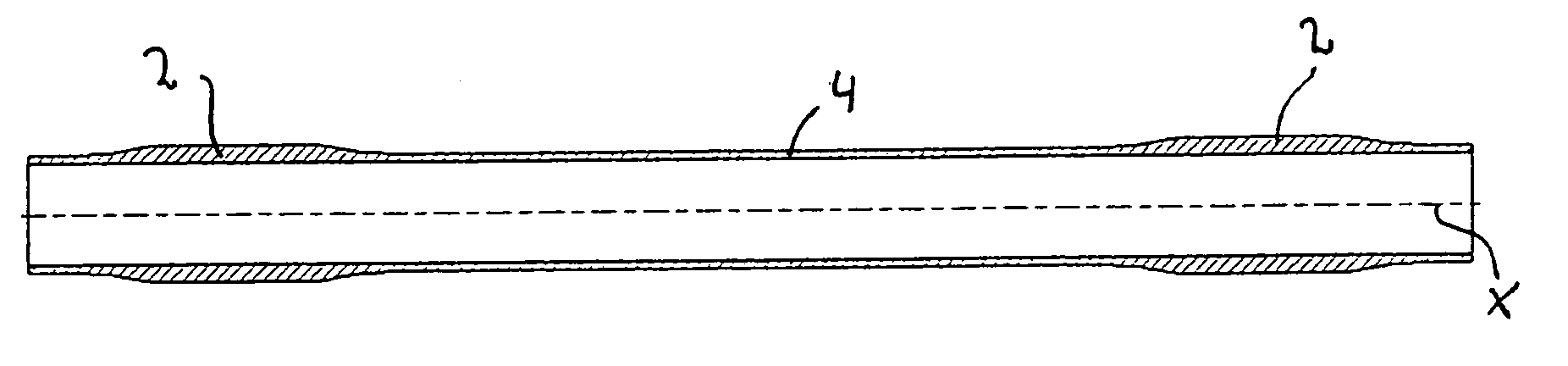

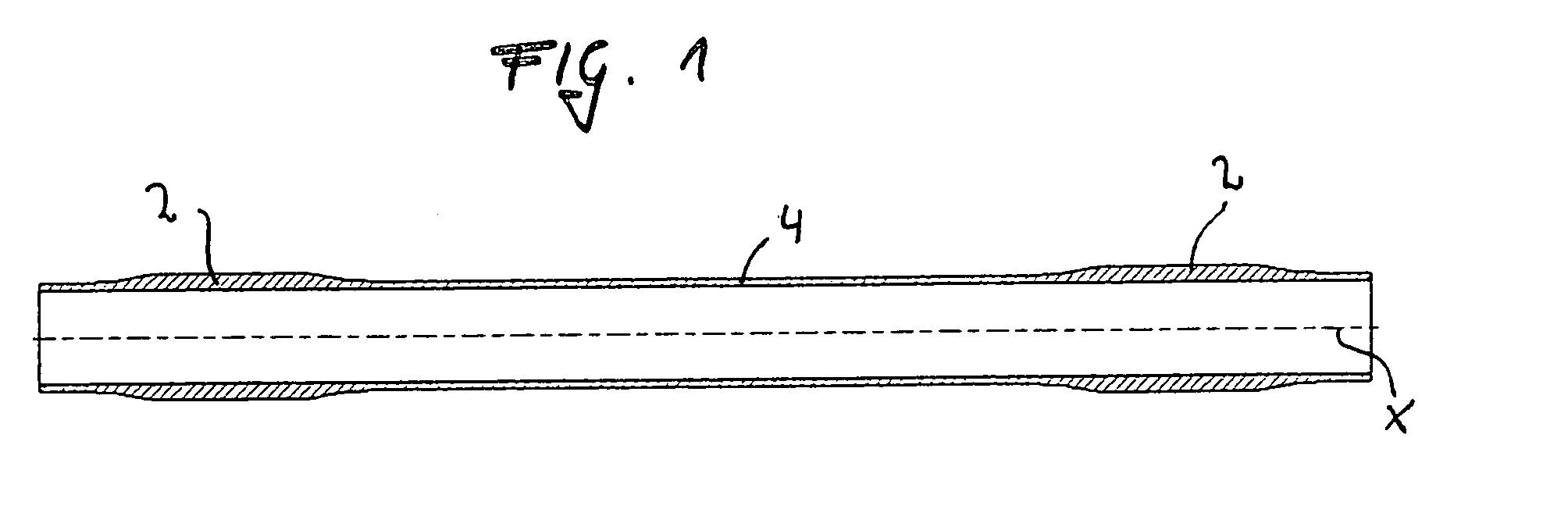

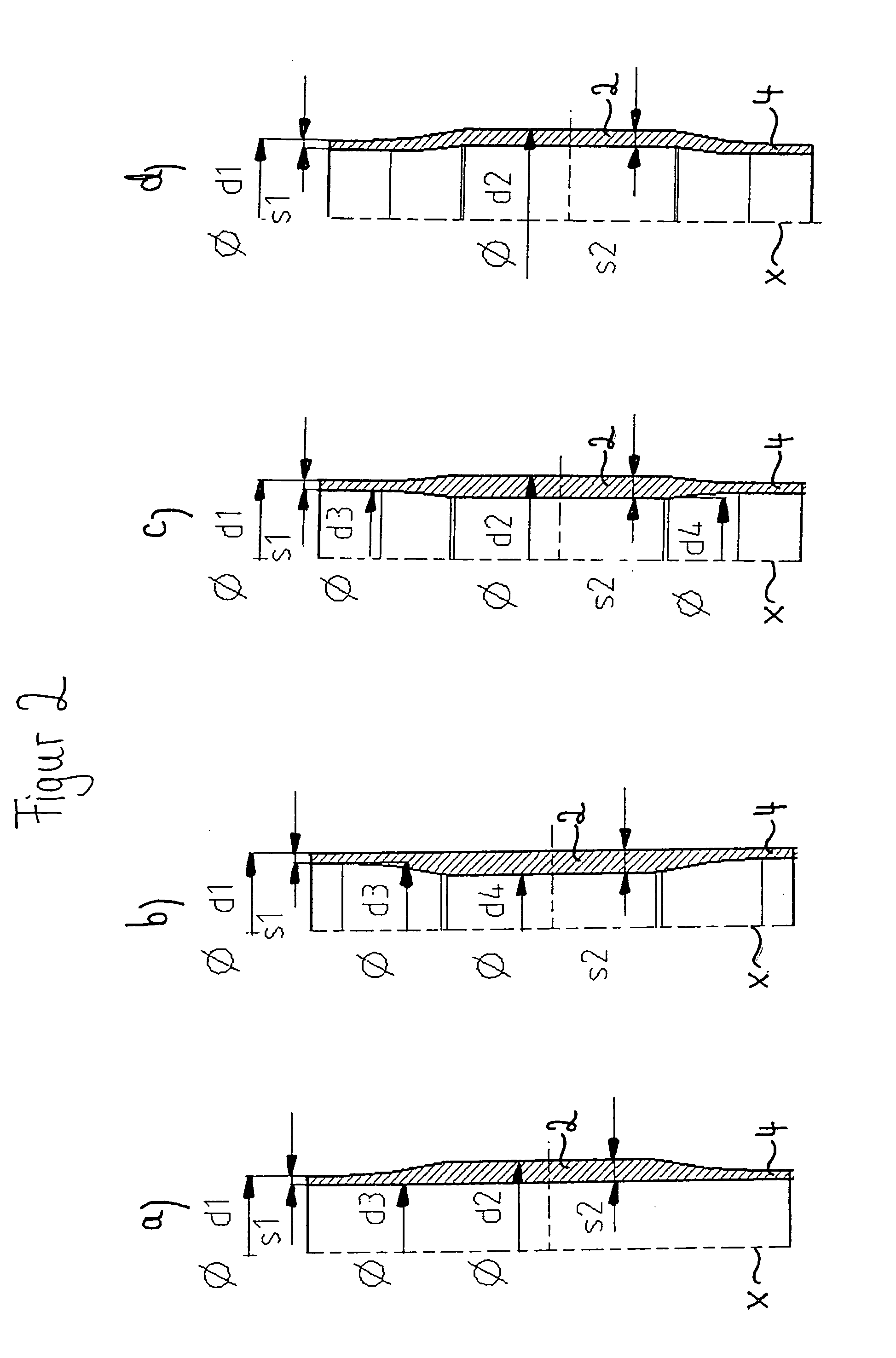

Axle body

ActiveUS20100013295A1Constant wall thicknessIncrease wall thicknessEngine componentsResilient suspensionsEngineeringCommercial vehicle

The invention relates to an axle body, particularly for a commercial vehicle, wherein the body is configured substantially as an axle pipe, which comprises a center section and at least one receiving section connected thereto for receiving an axle guide, wherein the axle body in the center section has a substantially constant wall thickness, and wherein the axle body in the receiving section, at least in some regions, has a wall thickness that is greater than the wall thickness of the center section.

Owner:SAF HOLLAND GMBH

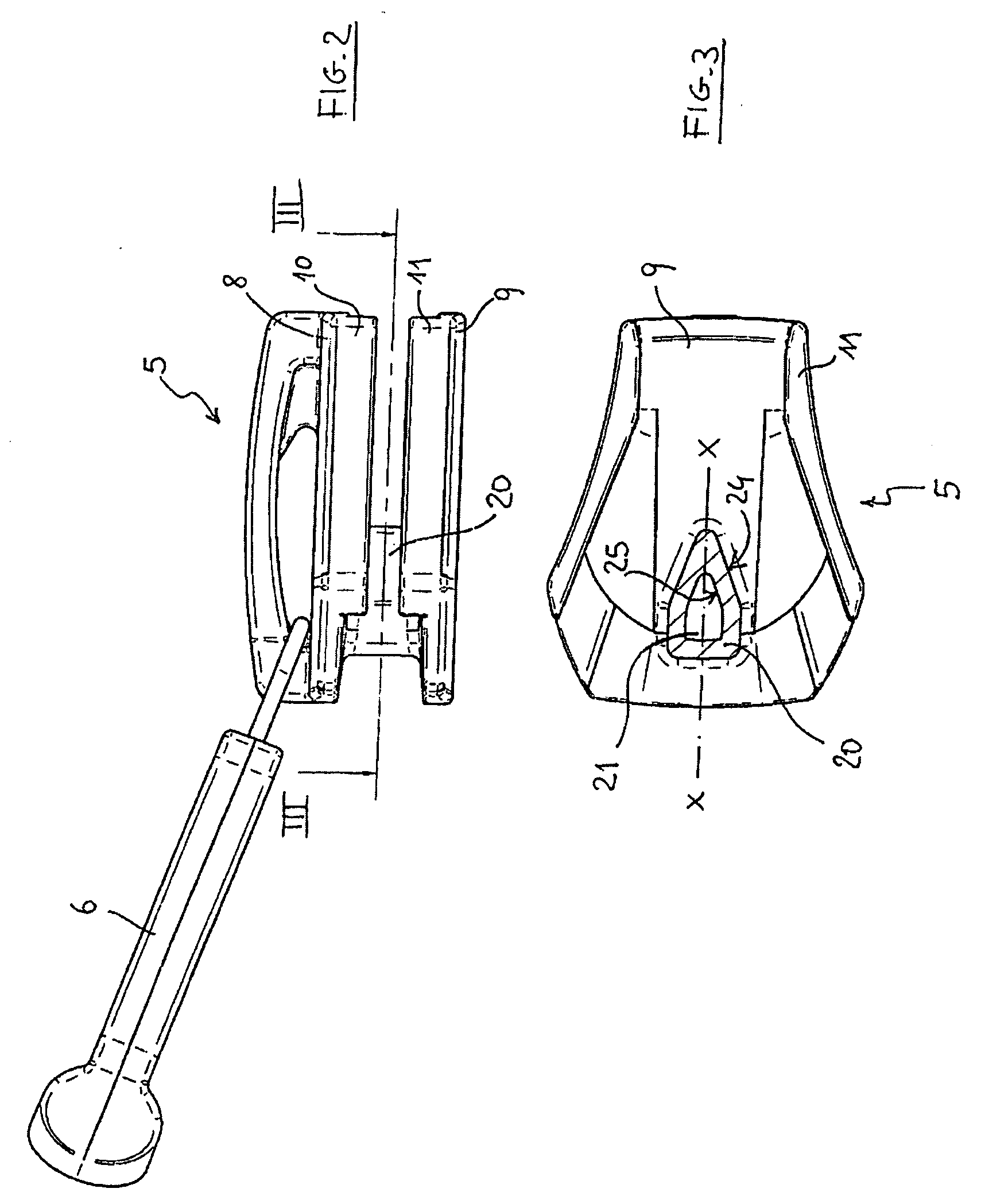

Slide Fastener and a Slider for a Slide Fastener

InactiveUS20090229091A1Constant wall thicknessReduce thicknessSnap fastenersWire articlesDie castingEngineering

A slide fastener (1) comprising a pair of tapes (2), carrying respective teeth (3), a top stop (4) and a die-cast or injection-molded slider (5), said slider (5) having a structure with an upper blade (8), a lower blade (9), lateral flanges (10, 11) and a diamond (20) connecting the upper and lower blades, wherein a cavity (21) is formed in said diamond (20).

Owner:RIRI

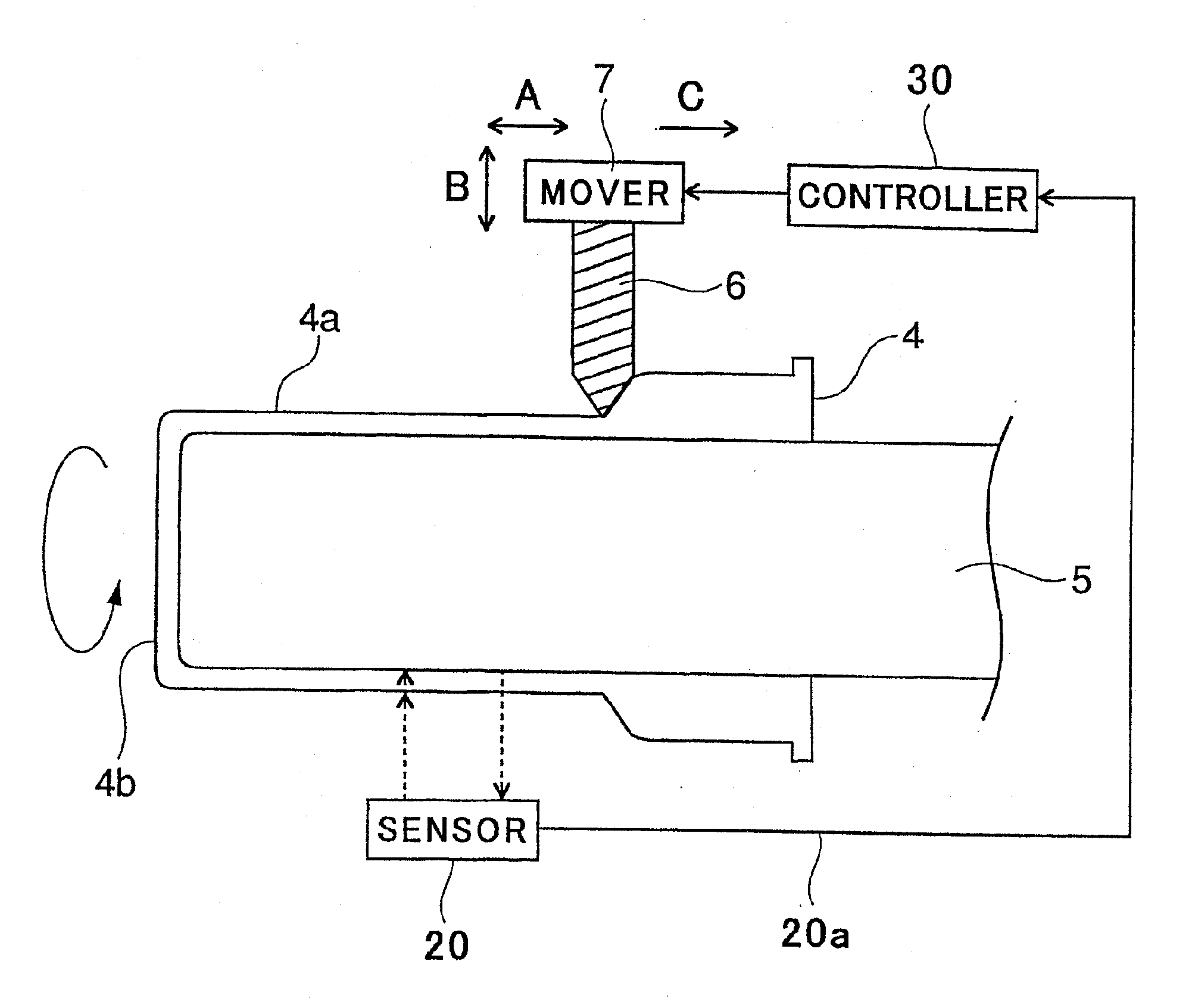

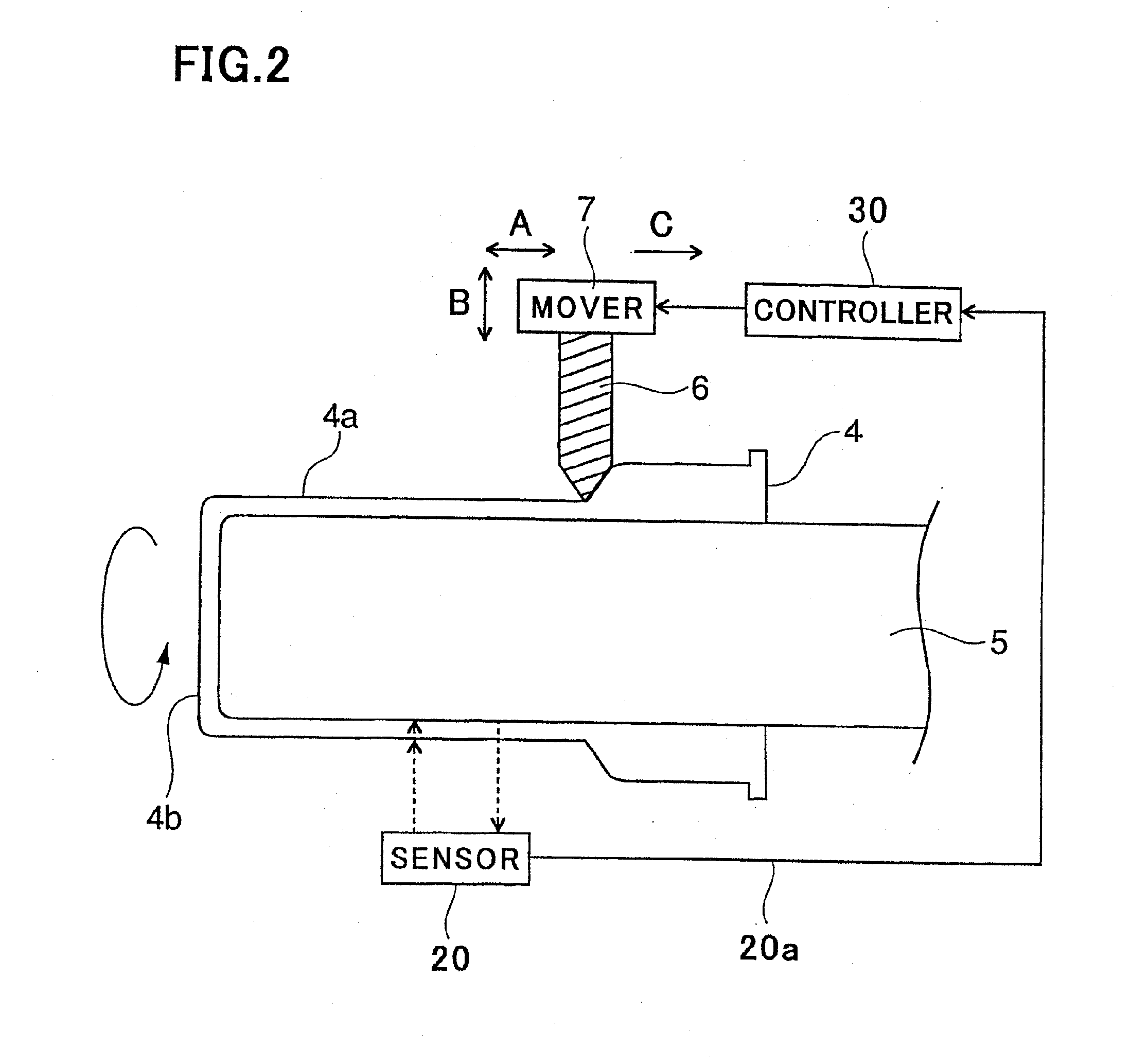

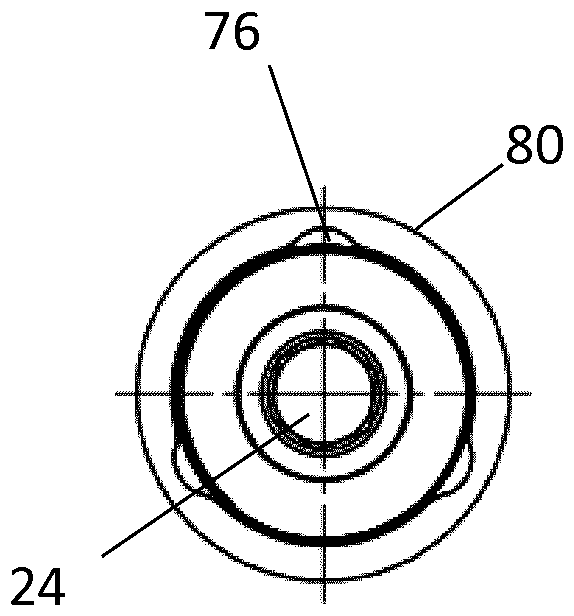

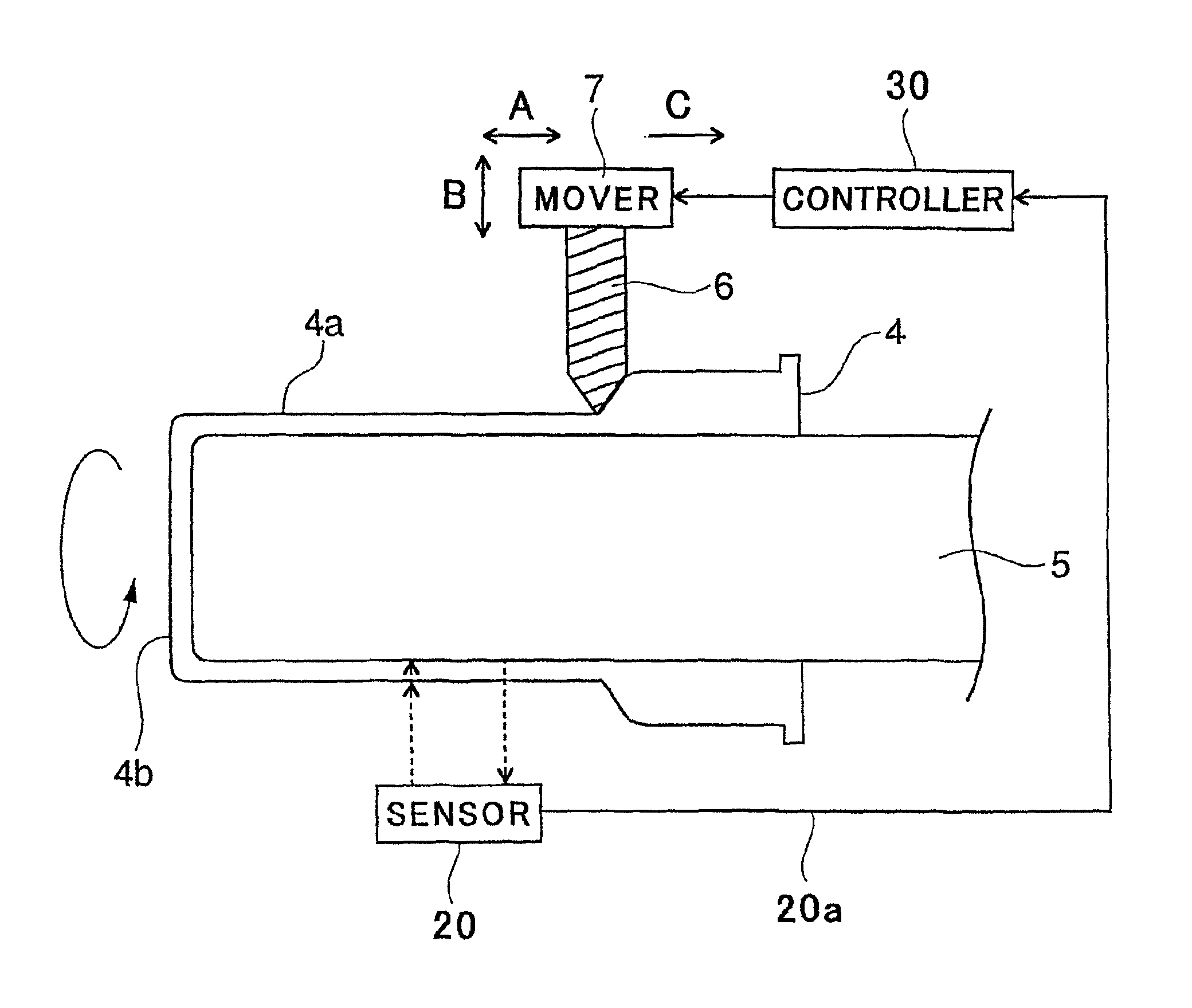

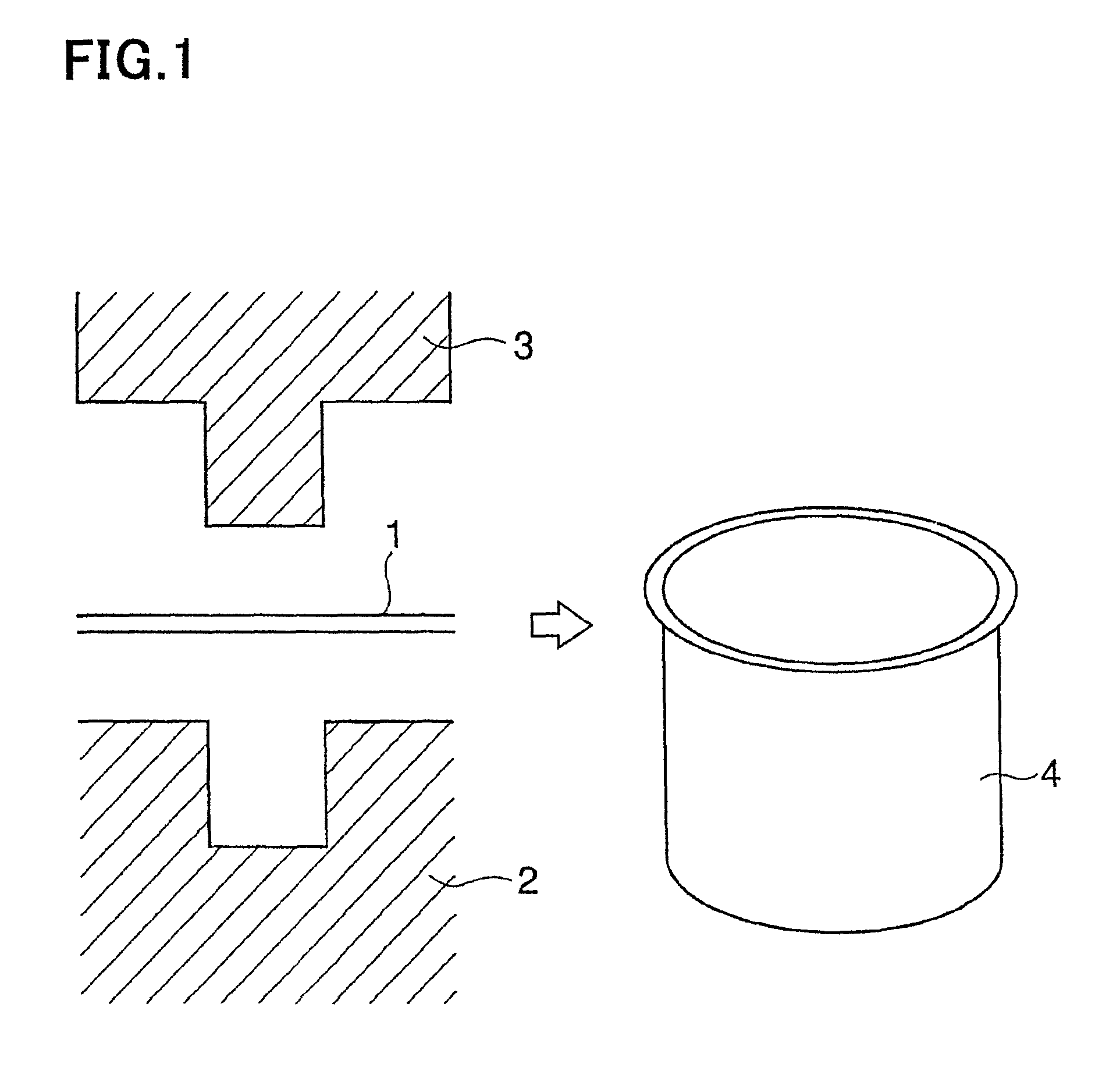

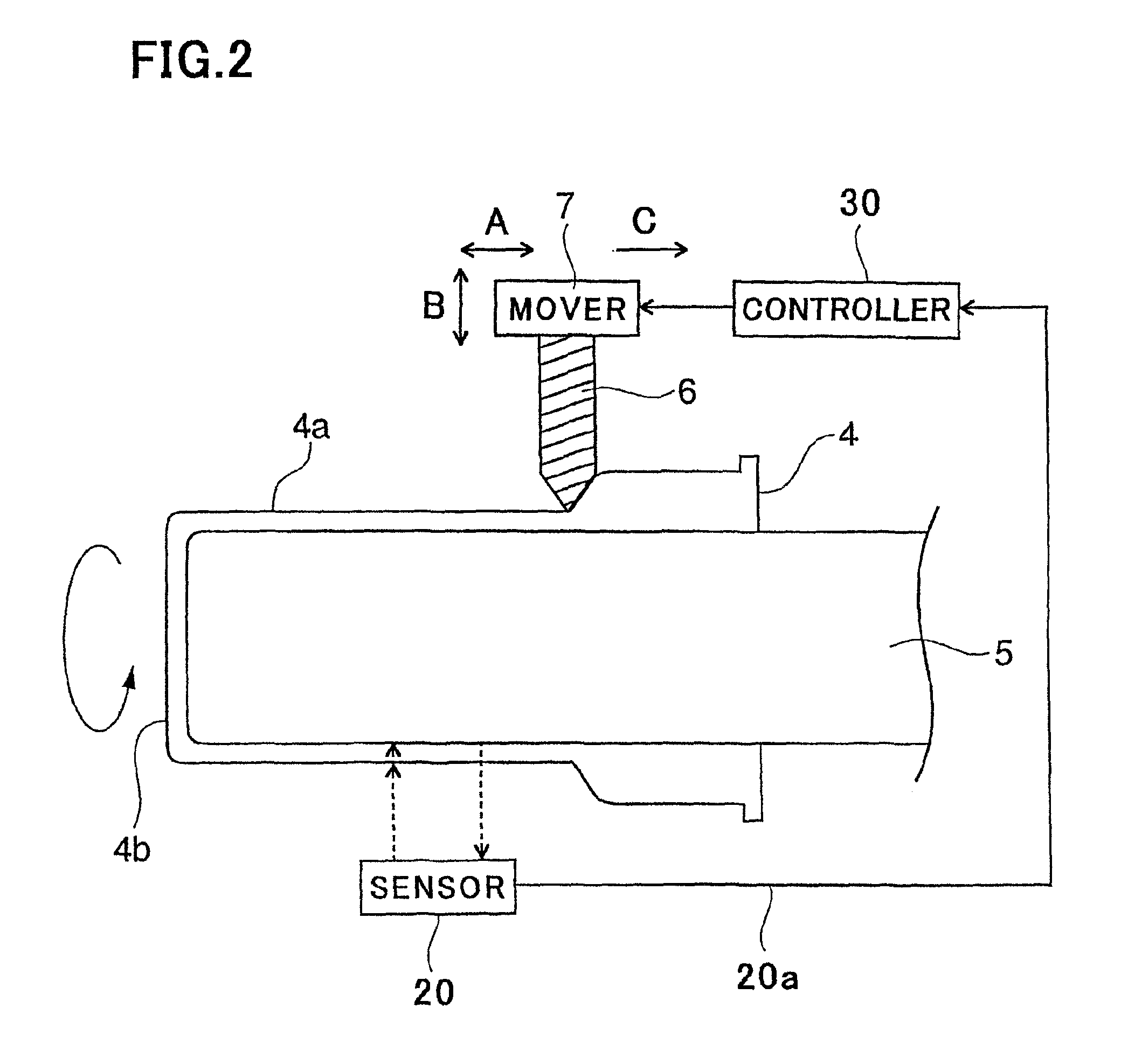

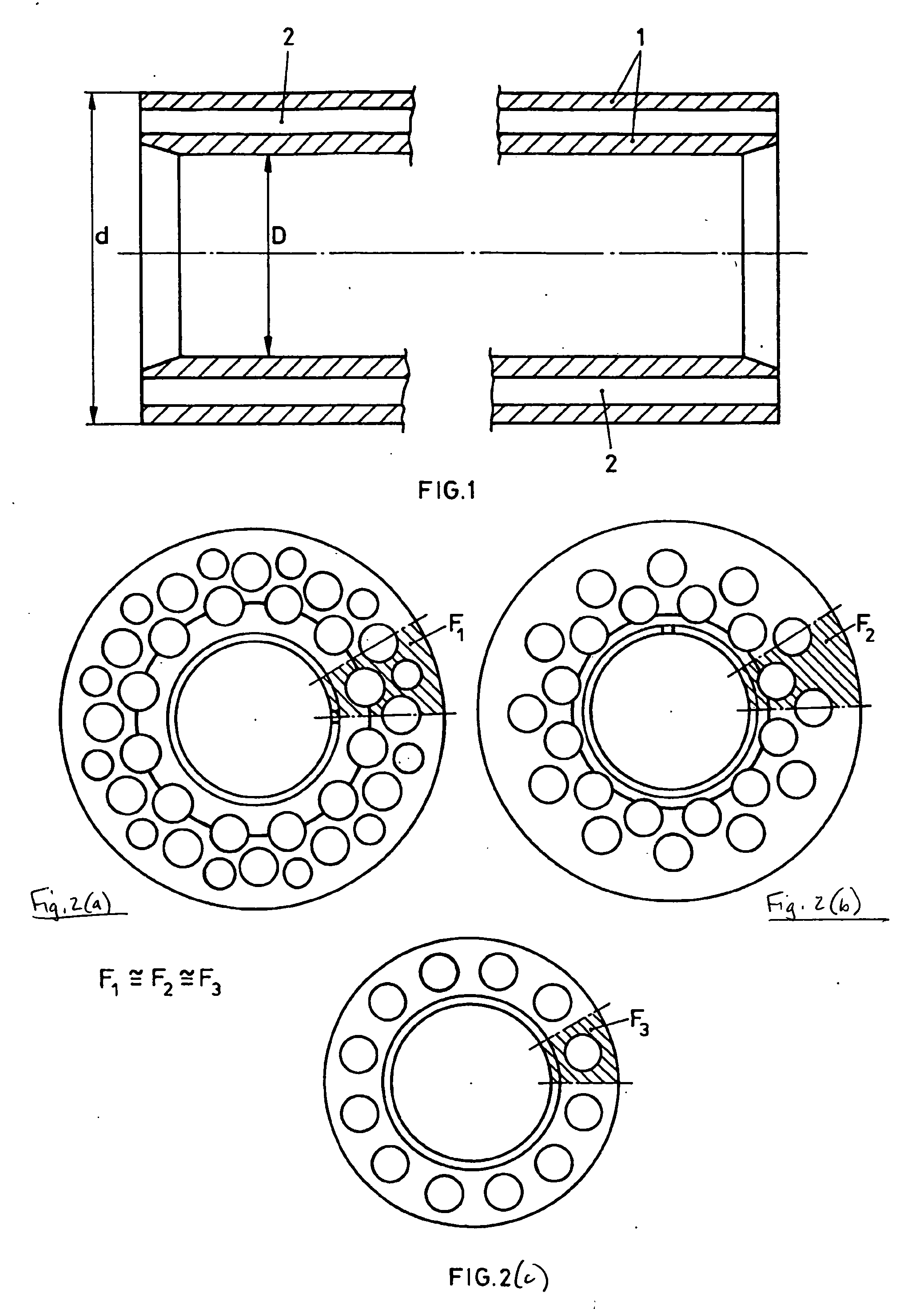

Circular-shaped metal structure, method of fabricating the same, and apparatus for fabricating the same

ActiveUS20070186402A1Improve thermal conductivityIncrease elasticityShaft and bearingsMeasurement/indication equipmentsMaterials scienceMetal

A method of fabricating a circular-shaped metal structure includes the steps of (a) rotating a pipe around an axis thereof, the pipe being composed of a plastic-workable metal, (b) moving a jig towards the pipe in a direction perpendicular to the axis until the jig makes contact with an outer surface of the pipe, and compressing the jig onto the pipe, (c) moving the jig in a direction in parallel with the axis with the jig being compressed onto the pipe while the pipe is kept rotated, (d) measuring a thickness of a wall of the pipe during the step (c), and (e) adjusting a pressure with which the jig is compressed onto the pipe, in accordance with the thickness measured in the step (d).

Owner:ENDO MFG COMPANY

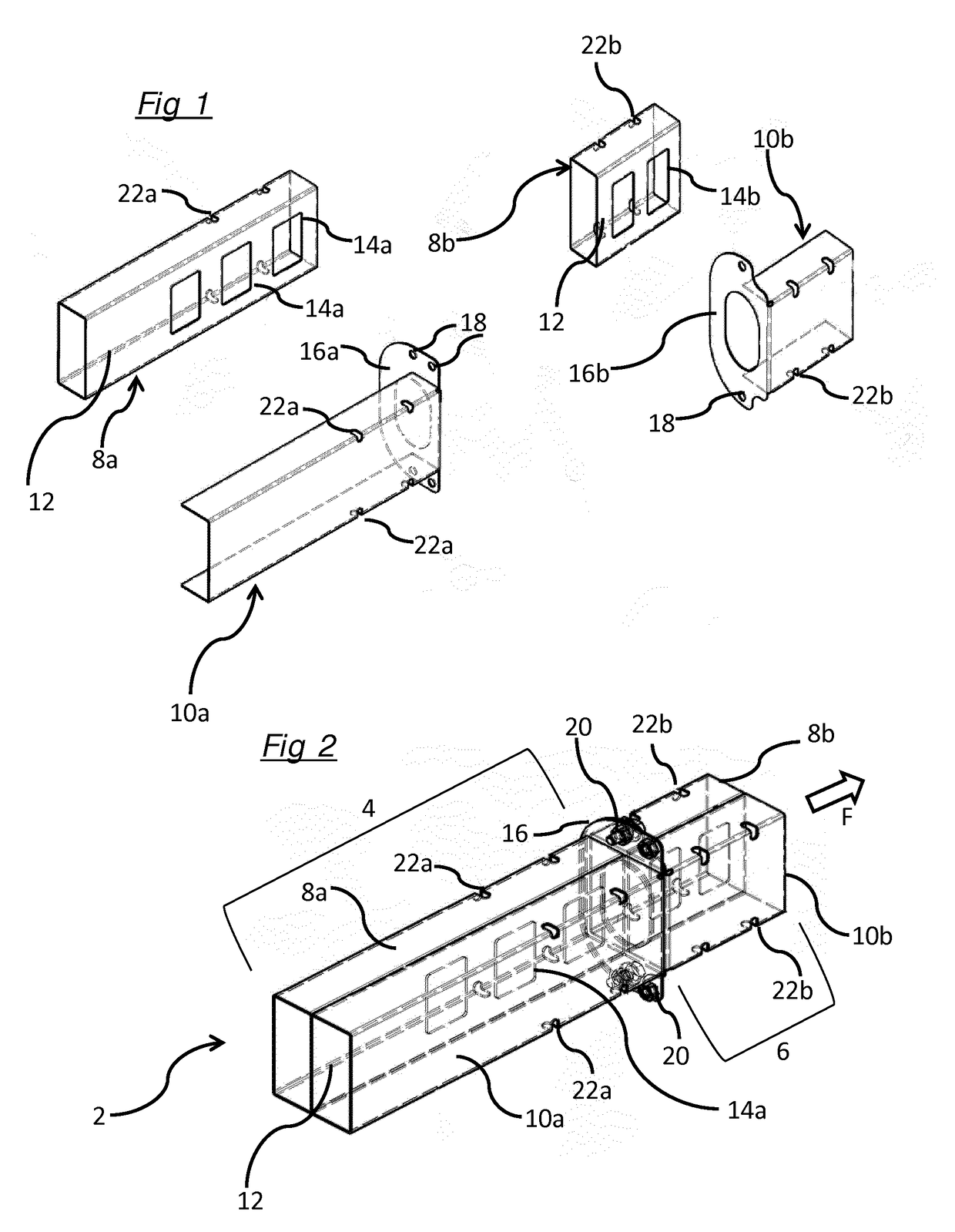

Impact Energy Absorbing Structure

An axially compressible energy absorbing member for a vehicle comprising a thin-walled tube having at least two adjacent, substantially parallel, axially-extending passageways defined by tube walls and separated where they are adjacent by a wall section, wherein the wall section includes one or more apertures of predetermined shape(s) and / or size(s), and wherein the thickness of the tube walls and of the wall section is substantially constant and the same.

Owner:GORDON MURRAY DESIGN

Eccentric bicycle fork shaft

ActiveUS10926827B2Increased bending stiffnessIncrease flexibilitySteering deviceArticle supporting devicesVehicle frameControl theory

A bicycle fork includes a fork shaft configured to be rotatably borne by headset bearings in a head tube of a bicycle frame so as to rotate about a steering axis. The fork shaft includes a cylindrical fork shaft segment that is disposed eccentrically with respect to the steering axis. The cylindrical fork shaft segment is a right circular cylinder having a hollow interior, a cylindrical inner surface and a central longitudinal axis that lies within a symmetry plane of the bicycle frame and extends parallel to the steering axis. The central longitudinal axis of the cylindrical fork shaft segment is spaced apart from the steering axis in a direction of eccentricity that points in an opposite direction with respect to a forward direction of travel of the bicycle.

Owner:SCOTT SPORTS

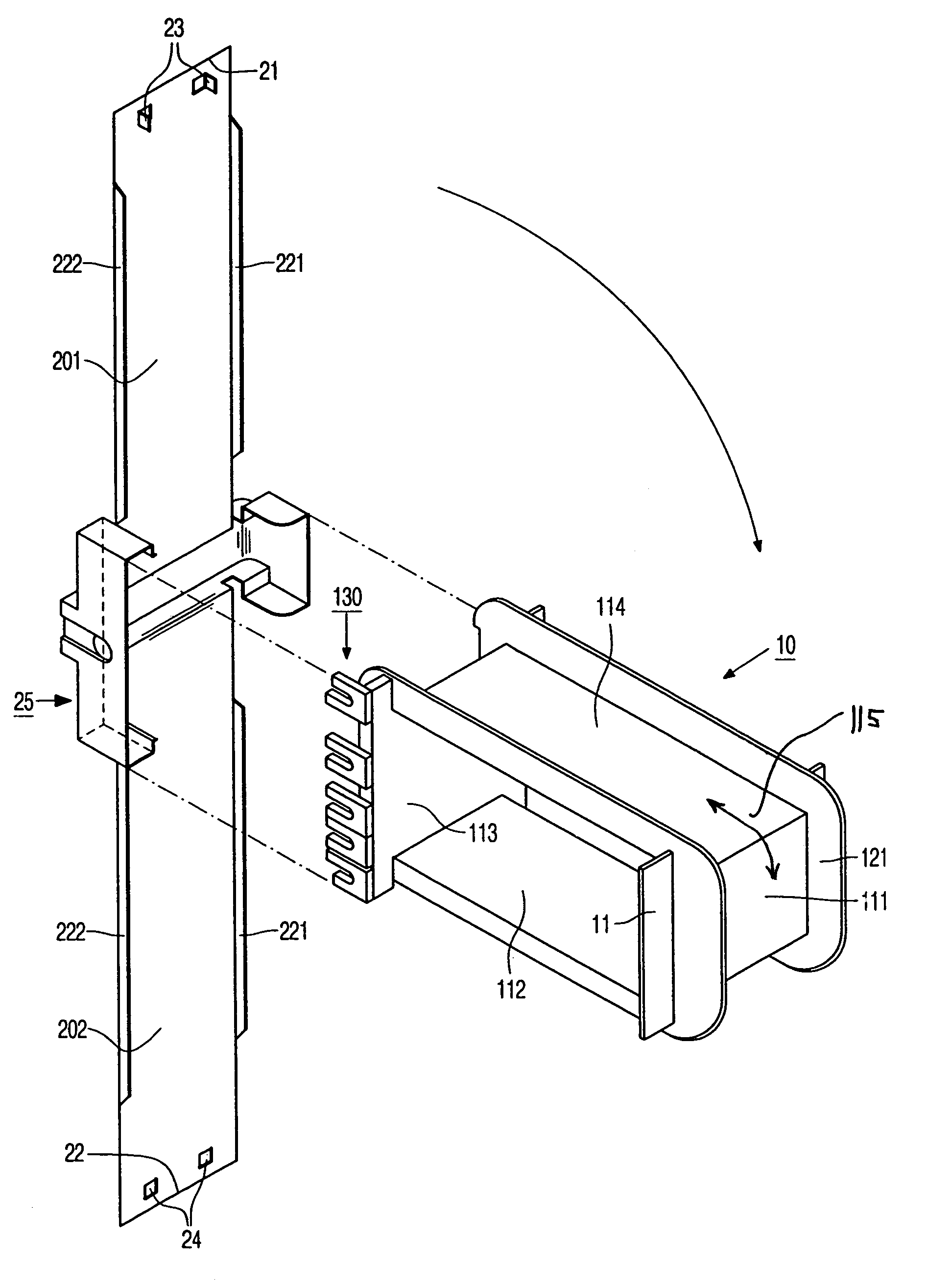

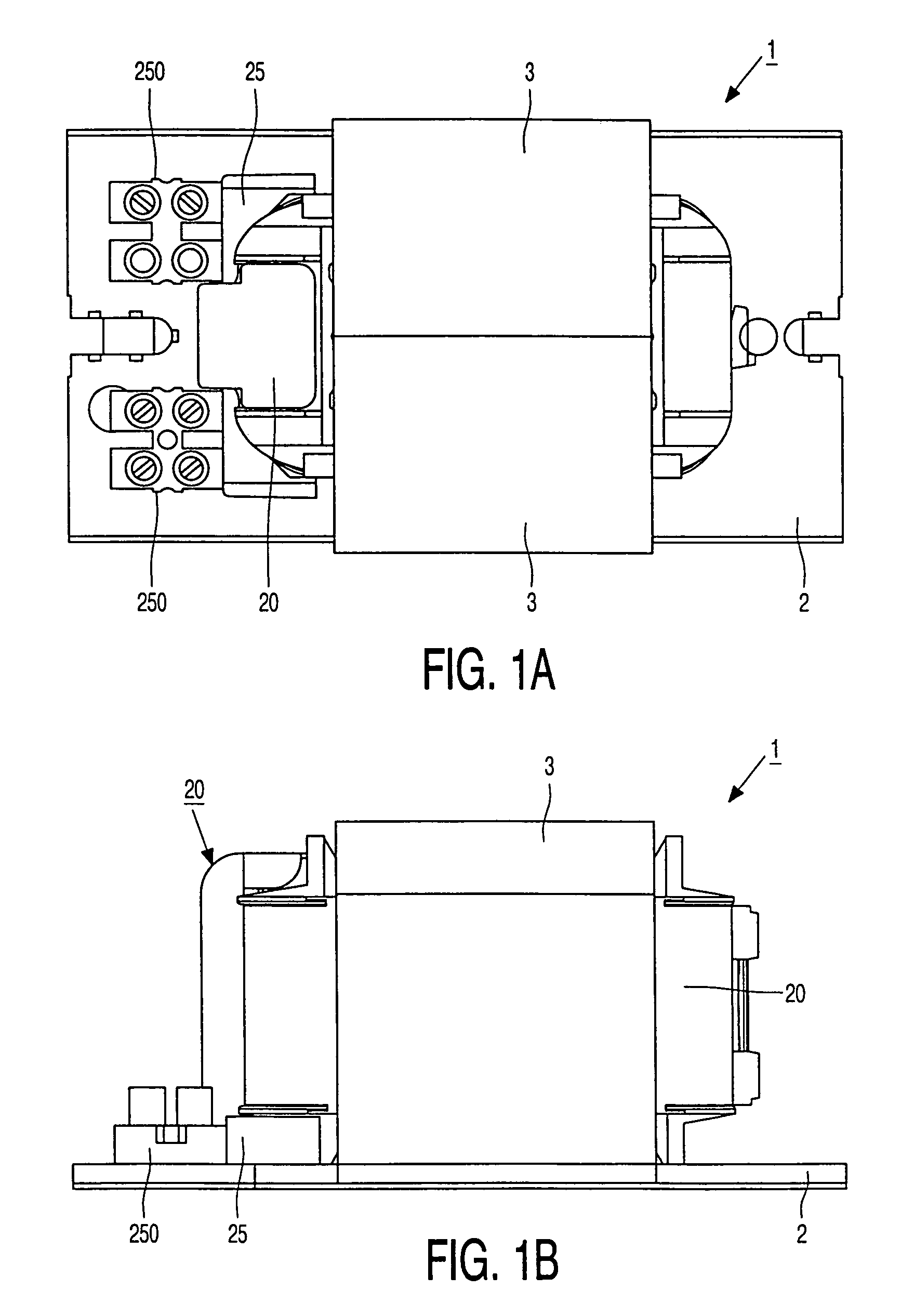

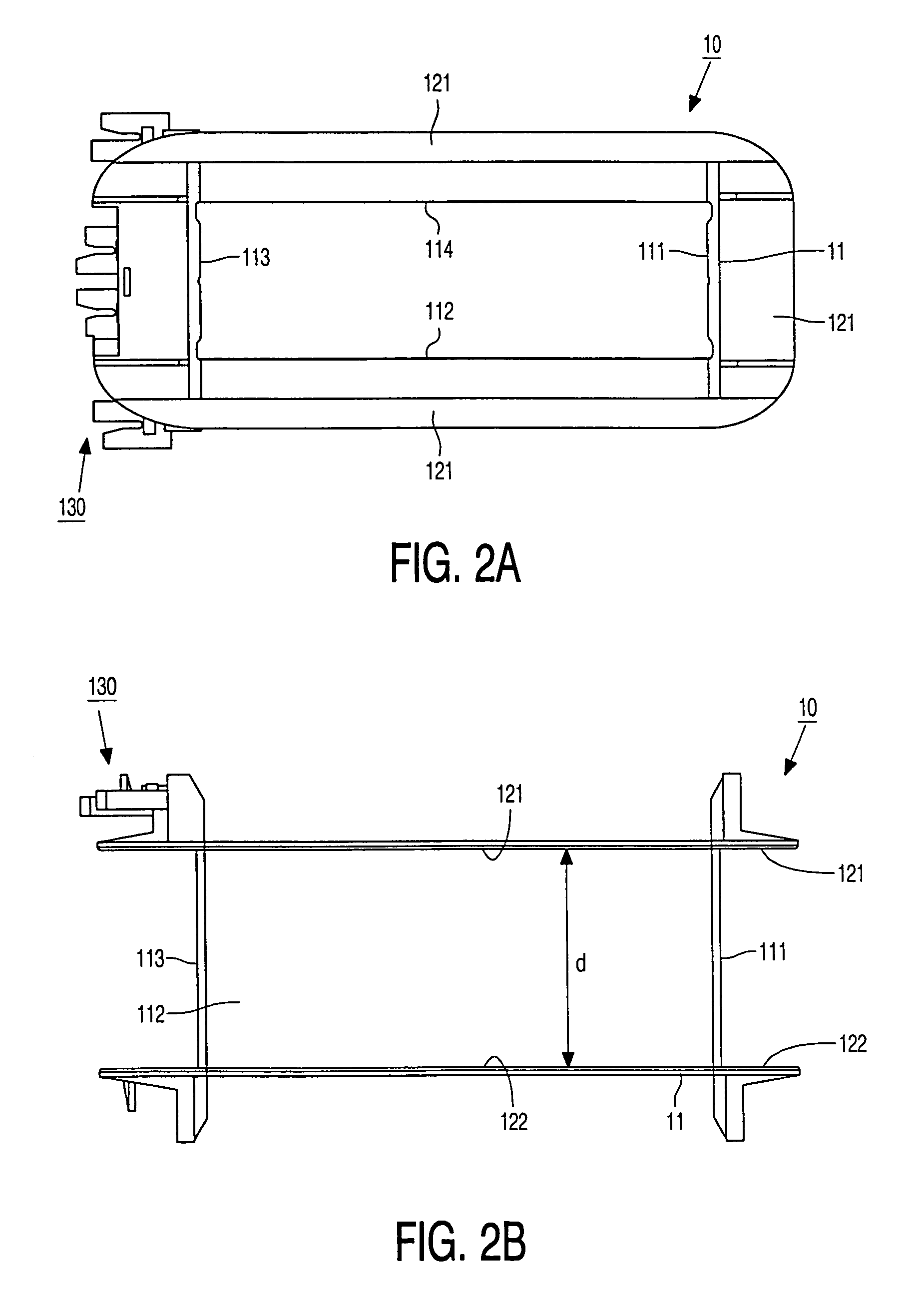

Electric ballast

InactiveUS6992558B1Efficient production cycleConstant wall thicknessTransformersTransformers/inductances casingsElectrical and Electronics engineeringConductor Coil

An electric ballast 1 is provided with an electric coil with windings having a width d which are wound on a synthetic resin coil base 10 comprising a box-like base part 11 of rectangular shape having four faces 111, 112, 113, 114. The base part is suited to accommodate an iron core of the coil. The base part is provided on either side with mutually parallel flanges 121, 122 which define the width d.The ballast is provided with a separate, insulating synthetic resin cover which is in one piece and which, when positioned in engagement with the coil base, cooperates therewith to substantially completely enclose the coil windings.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Axle body

ActiveUS8353562B2Constant wall thicknessUniform toleranceEngine componentsResilient suspensionsEngineeringCommercial vehicle

Owner:SAF HOLLAND GMBH

Antenna cover, use of an antenna cover, adapter for connecting two antenna covers and method for producing a lens-shaped antenna cover

ActiveUS20170331183A1Easy to joinConstant wall thicknessWaveguide hornsAntenna supports/mountingsAxis of symmetryEngineering

An antenna cover is provided, including a first base body and at least two first fins arranged on the first base body, the first base body having a curved surface, the two first fins being arranged symmetrically to a longitudinal axis of symmetry of the antenna cover and extending substantially parallel to the longitudinal axis of symmetry, the at least two first fins having a width that tapers as a distance from the first base body increases, and the at least two first fins being arranged with a spacing that corresponds substantially to the width of the at least two fins. A method for producing a lens-shaped antenna cover is also provided.

Owner:VEGA GRIESHABER GMBH & CO

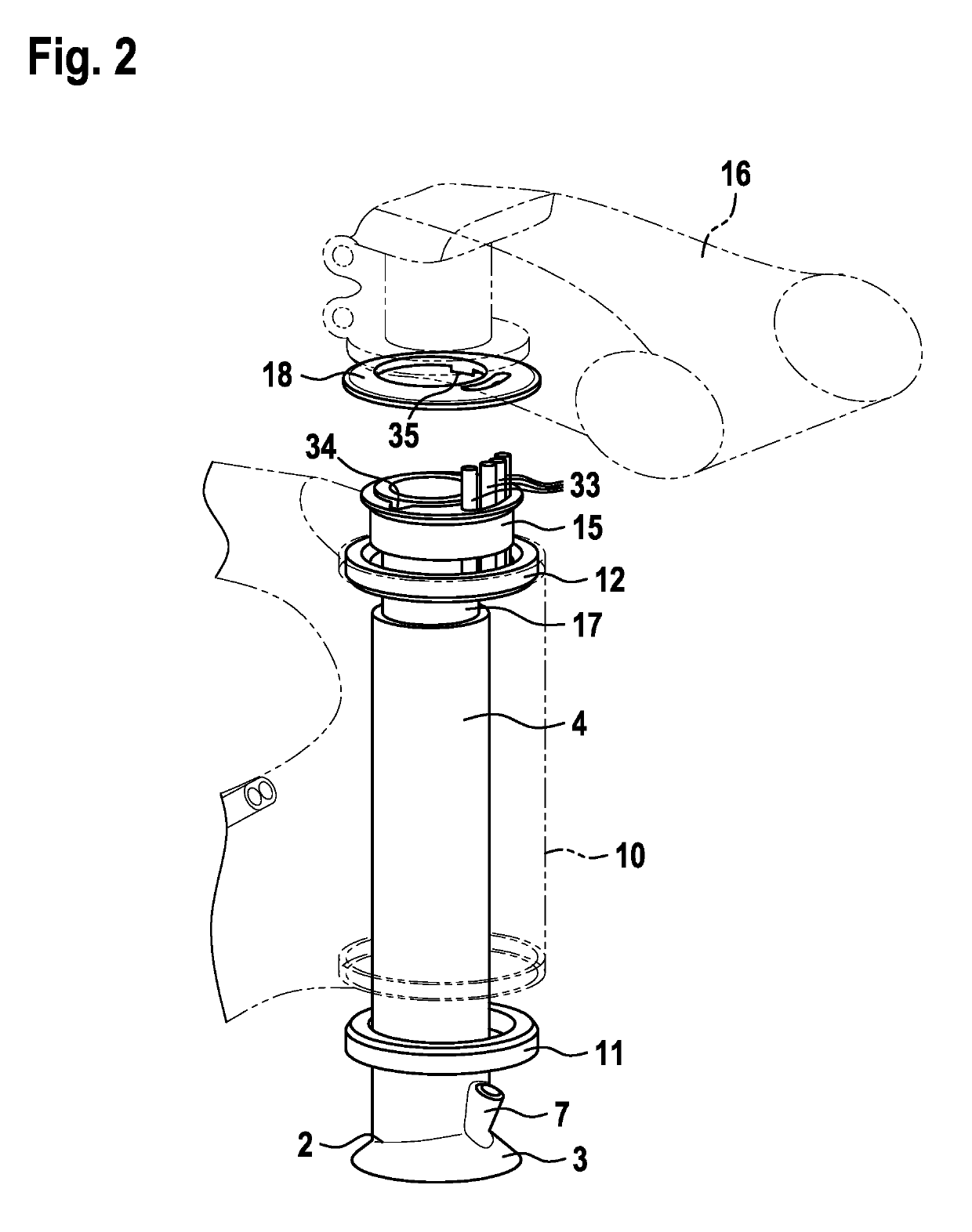

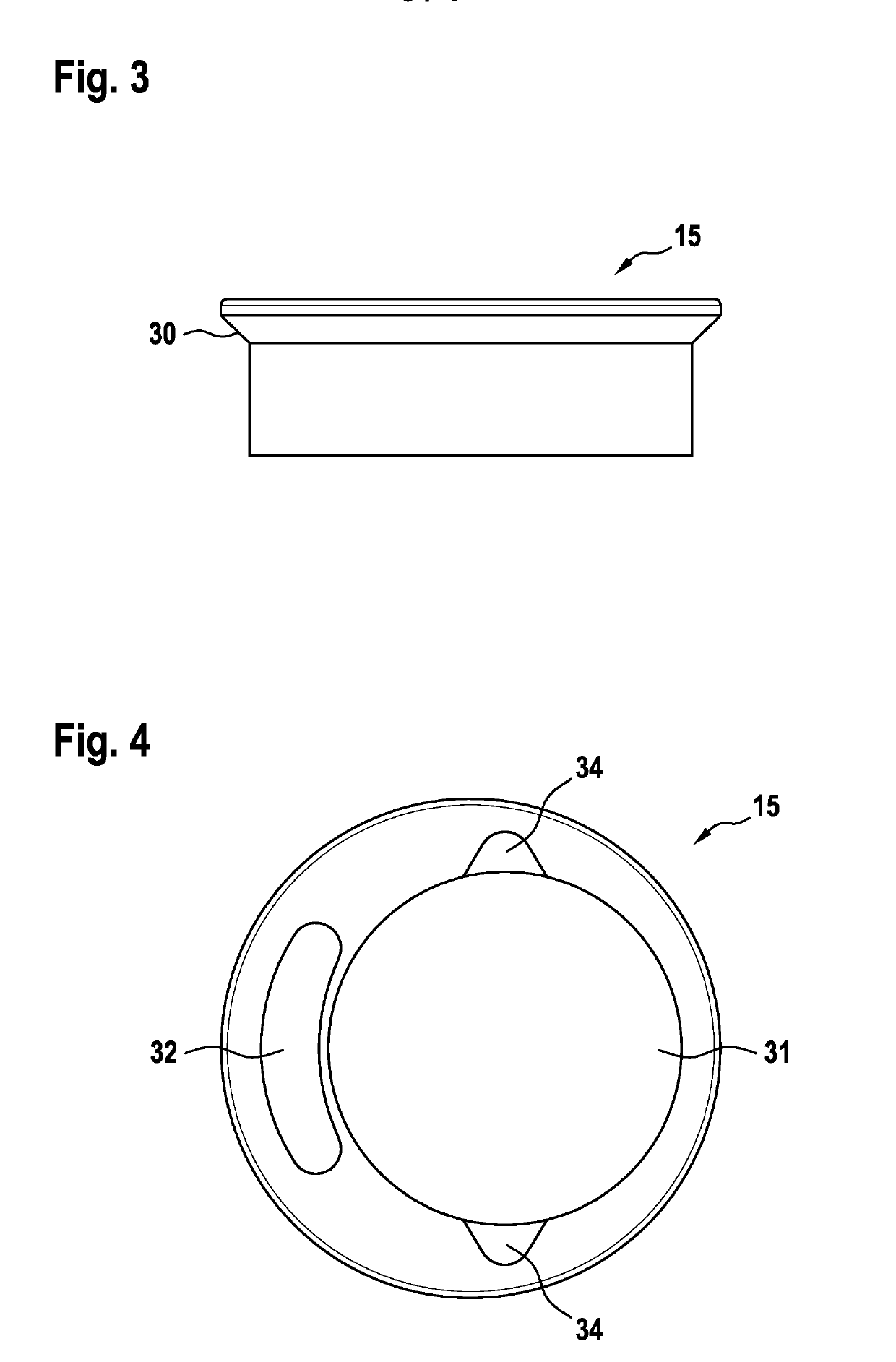

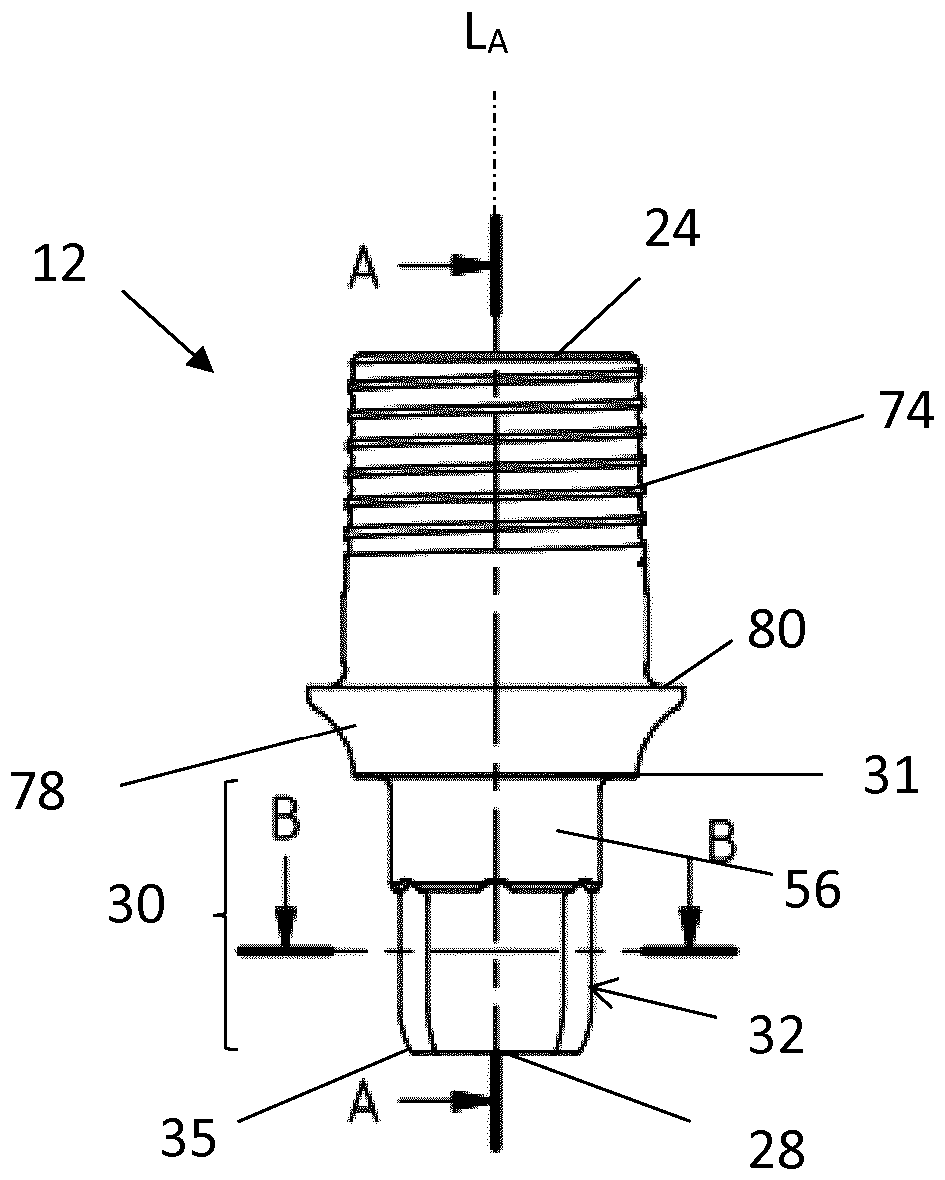

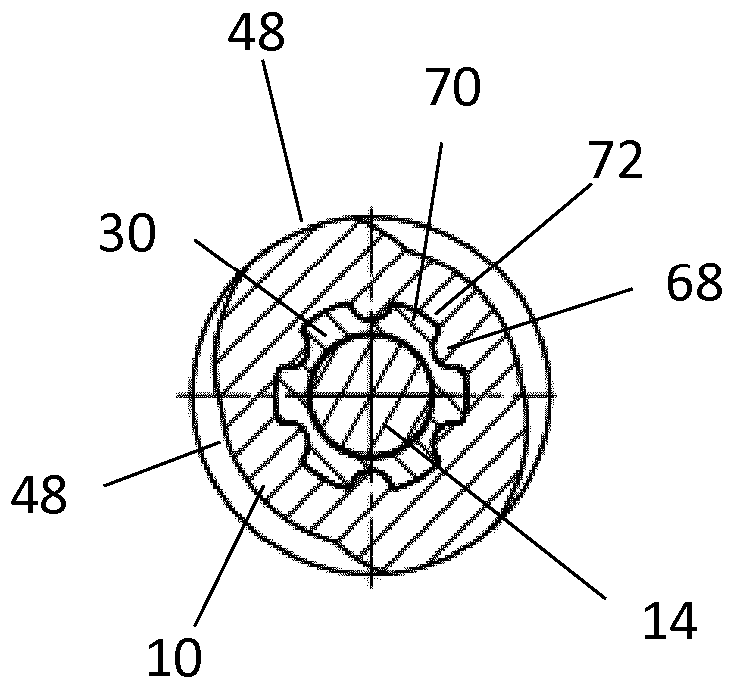

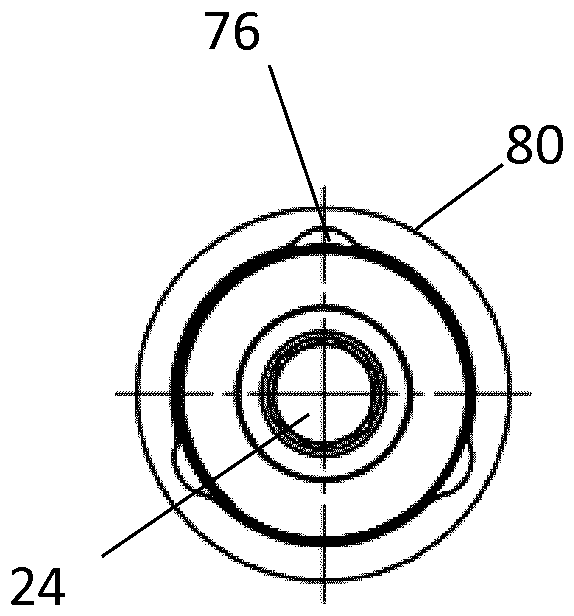

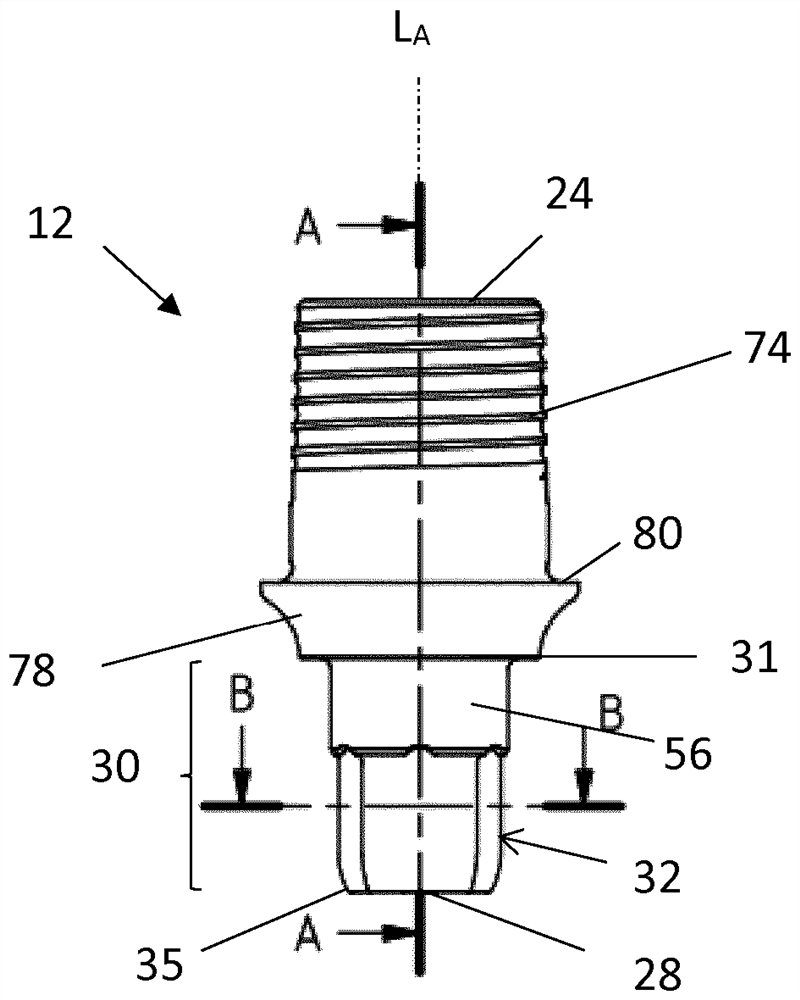

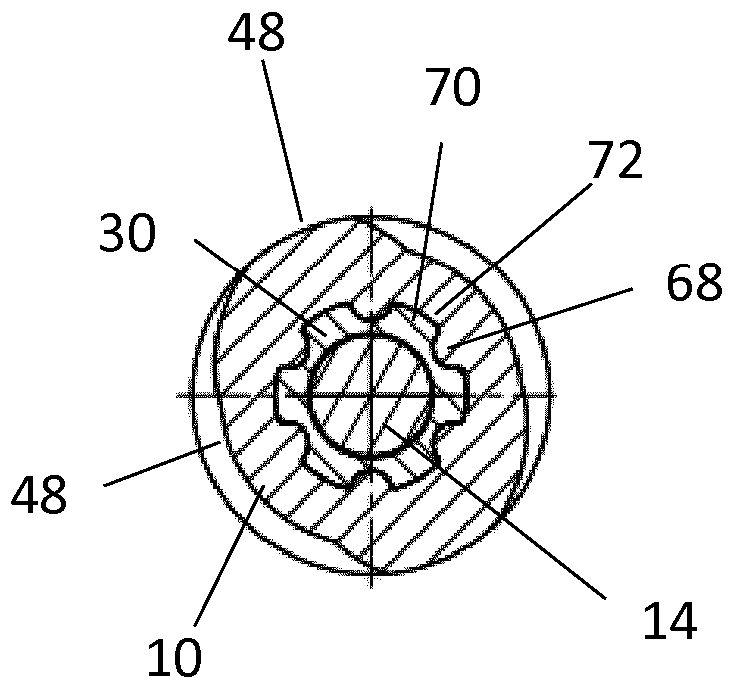

Implant system

ActiveCN110612068AAchieving a twist-proof connectionEnhanced transfer processDental implantsCeramic shaping apparatusEngineeringDentistry

The present invention relates to an implant system comprising a dental implant (10) and an abutment (12) which consists of a ceramic material. Said abutment (12) comprises a first anti-rotation element with a plurality of grooves and the dental implant (10) comprises a second anti-rotation element complementary thereto and having a plurality of ribs, the grooves being open towards a proximal end (28) of the abutment (12).

Owner:STRAUMANN HLDG AG +1

Packaging and method of opening

ActiveUS20150314949A1Improve consistencyOvercome disadvantagesOpening closed containersBottle/container closureMechanical engineeringEngineering

Owner:KRAFT FOODS SCHWEIZ HLDG AG

Circular-shaped metal structure, method of fabricating the same, and apparatus for fabricating the same

InactiveUS7963016B2Constant wall thicknessConstant diameterShaft and bearingsMeasurement/indication equipmentsMaterials scienceMetal

A method of fabricating a circular-shaped metal structure includes the steps of (a) rotating a pipe around an axis thereof, the pipe being composed of a plastic-workable metal, (b) moving a jig towards the pipe in a direction perpendicular to the axis until the jig makes contact with an outer surface of the pipe, and compressing the jig onto the pipe, (c) moving the jig in a direction in parallel with the axis with the jig being compressed onto the pipe while the pipe is kept rotated, (d) measuring a thickness of a wall of the pipe during the step (c), and (e) adjusting a pressure with which the jig is compressed onto the pipe, in accordance with the thickness measured in the step (d).

Owner:ENDO MFG COMPANY

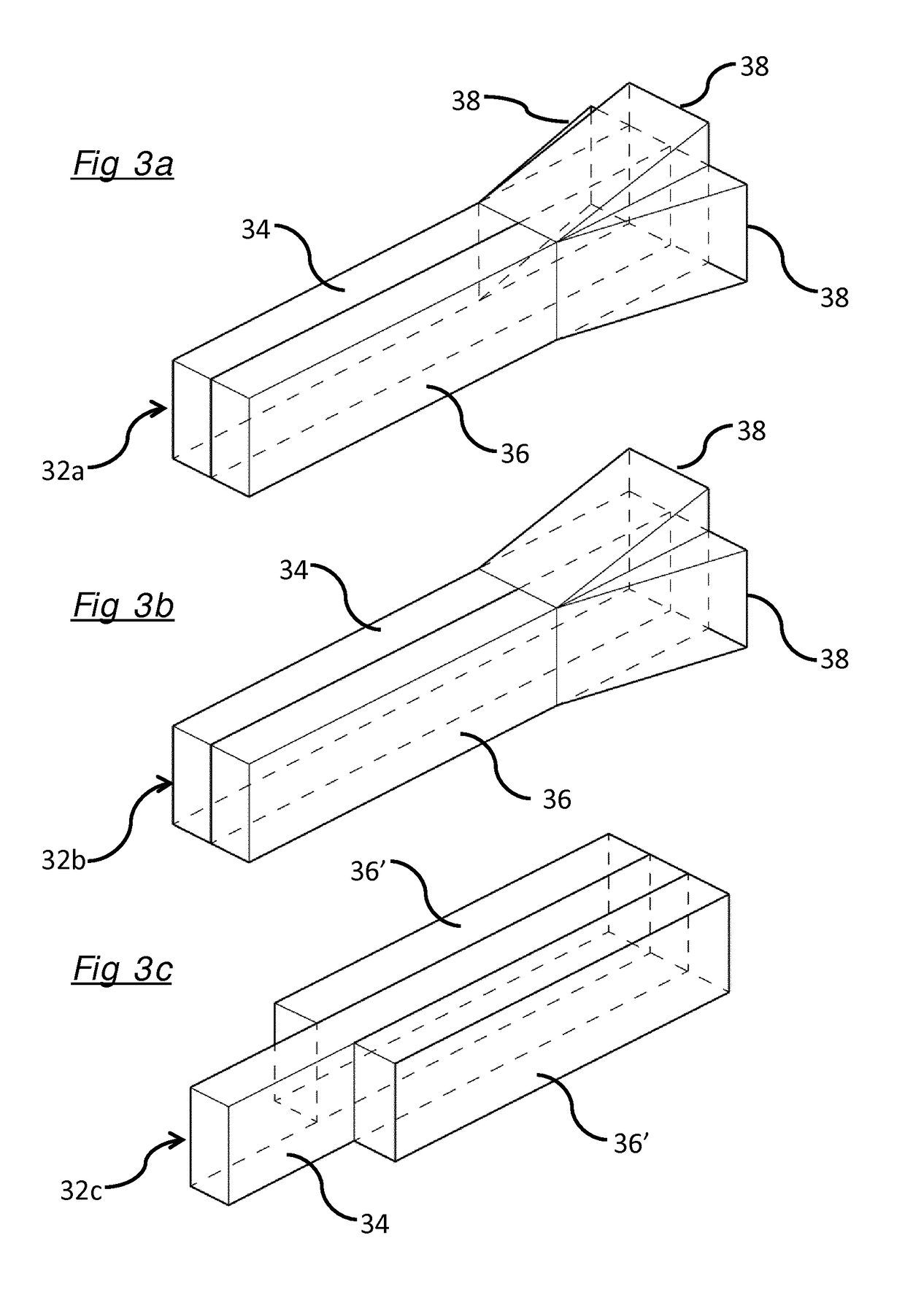

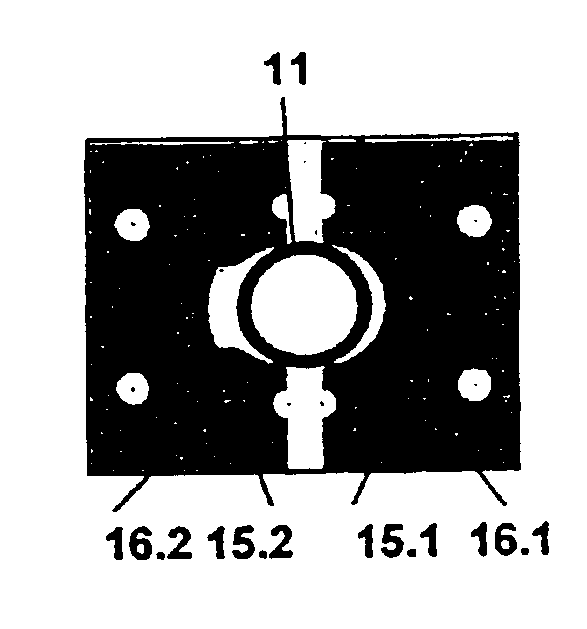

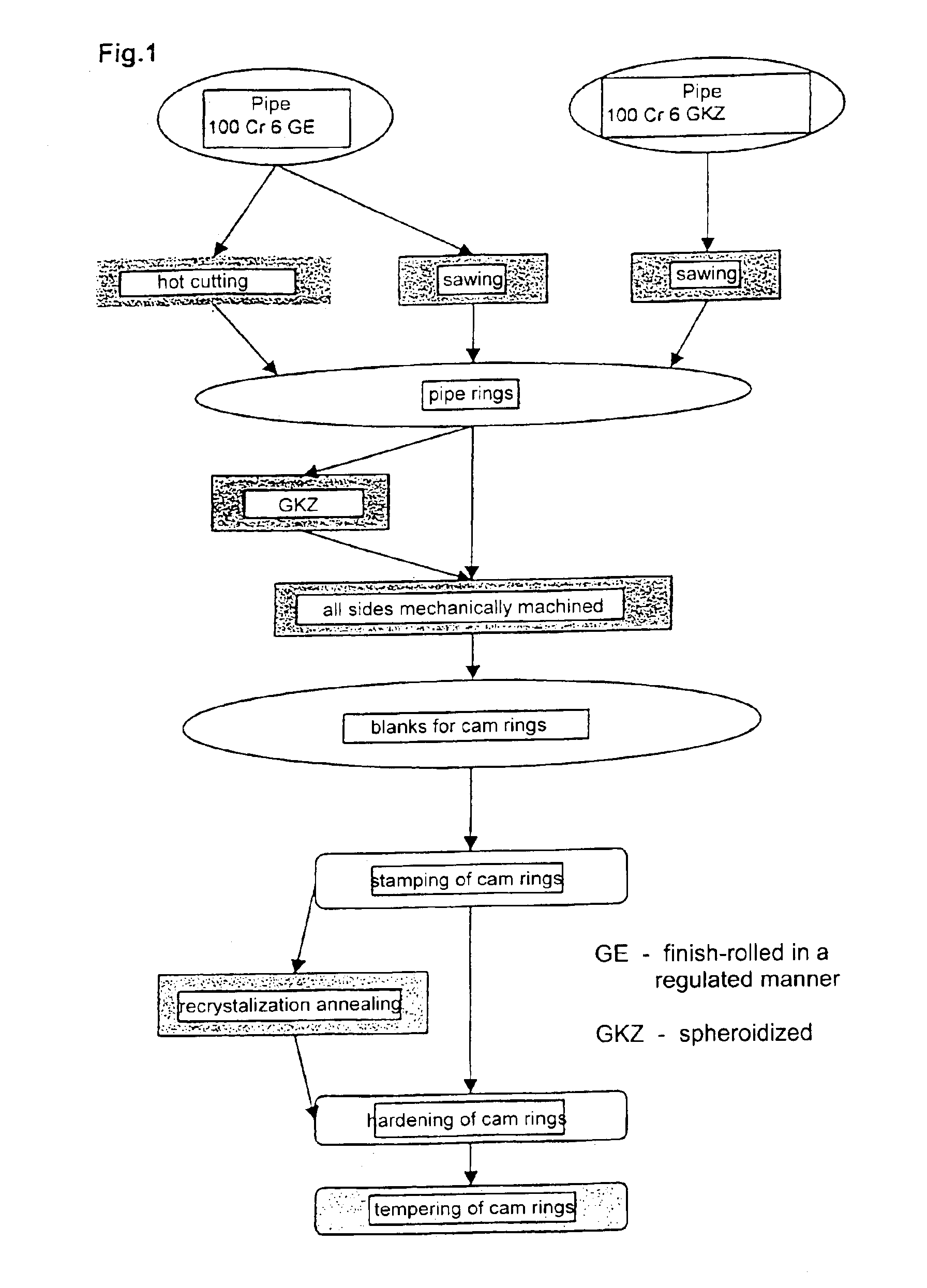

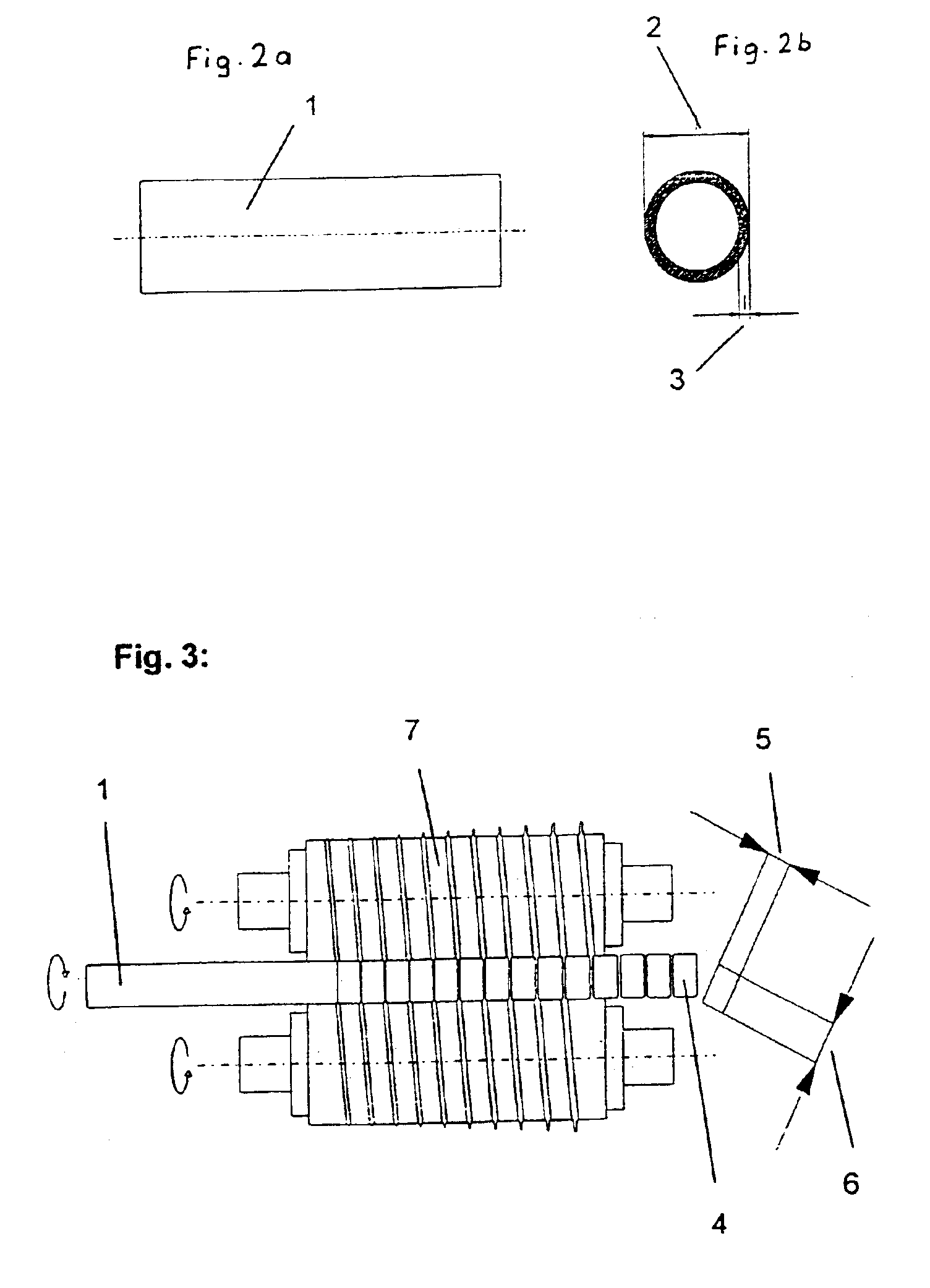

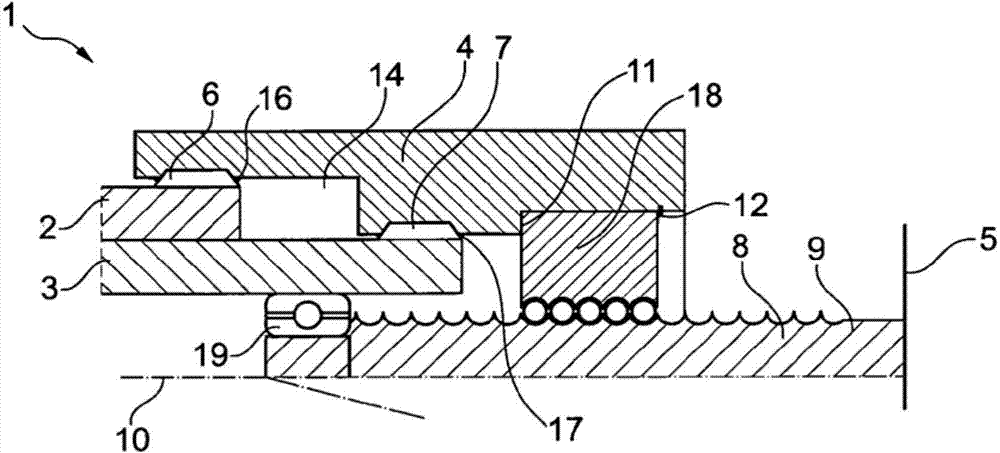

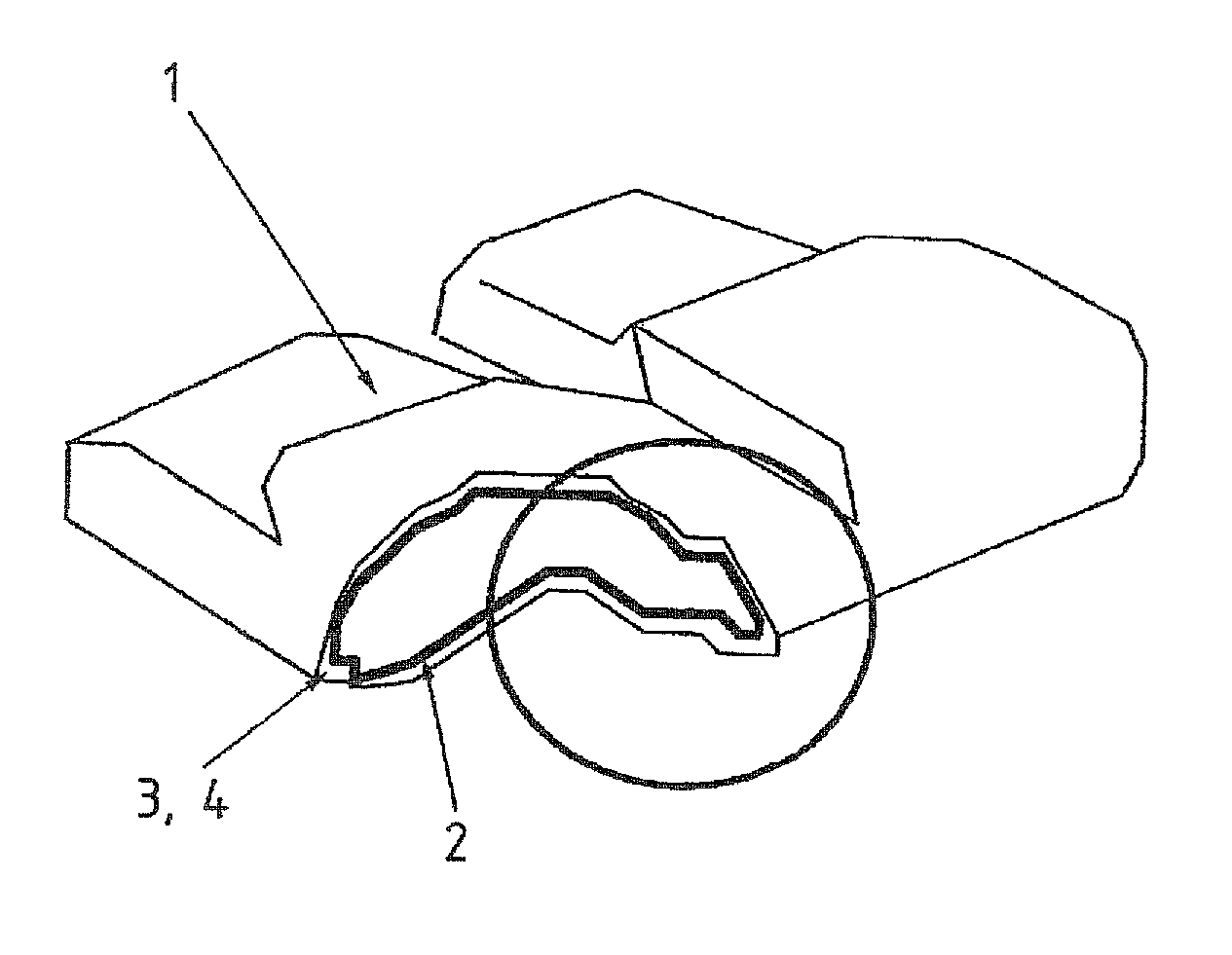

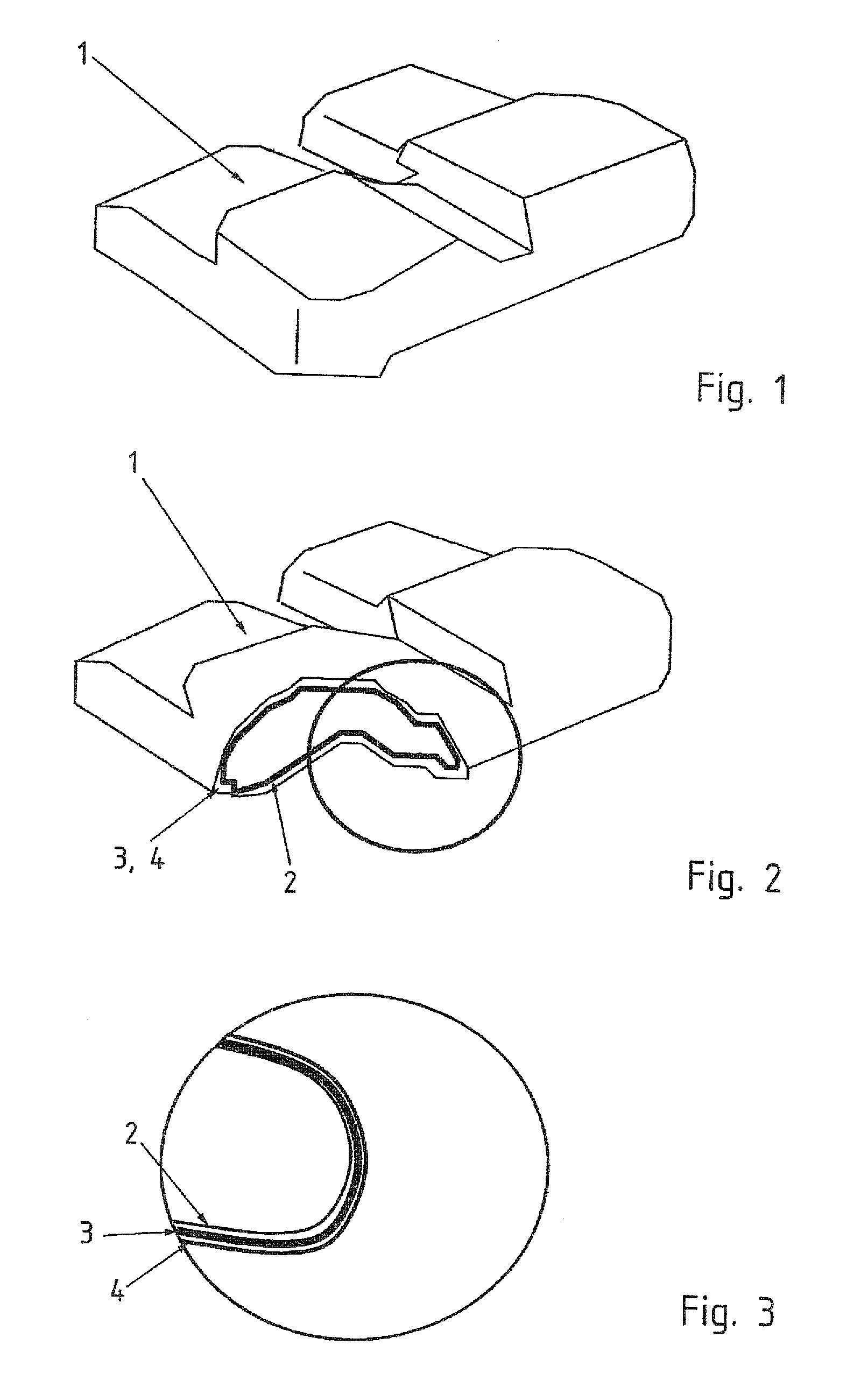

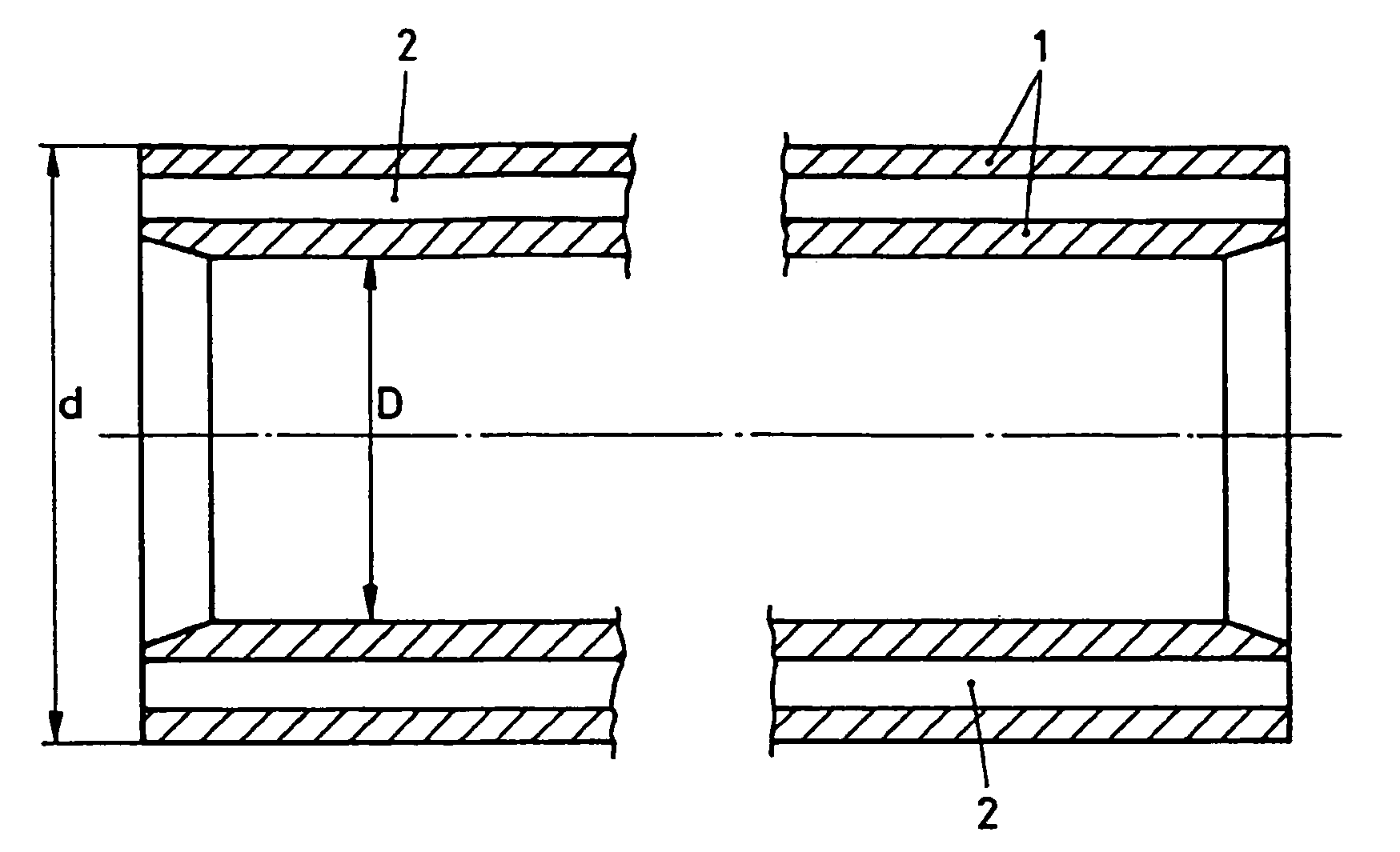

Method for producing metallic, non-rotationally symmetrical rings with a constant wall thickness over their circumference

The invention is directed to a method and a device for producing metal, non-rotationally symmetric rings with a constant wall thickness along their circumference, particularly cam rings, starting from a hot-rolled pipe from which individual portions are severed, mechanically machined and subsequently hardened and tempered. Ring blanks of equal width are severed from the pipe and are mechanically machined on all sides, and the non-rotationally symmetric shape is produced by cold forming, the pipe or the severed ring blank having a structure suitable for cold forming.

Owner:MANNESMANN ROHRENWERKE

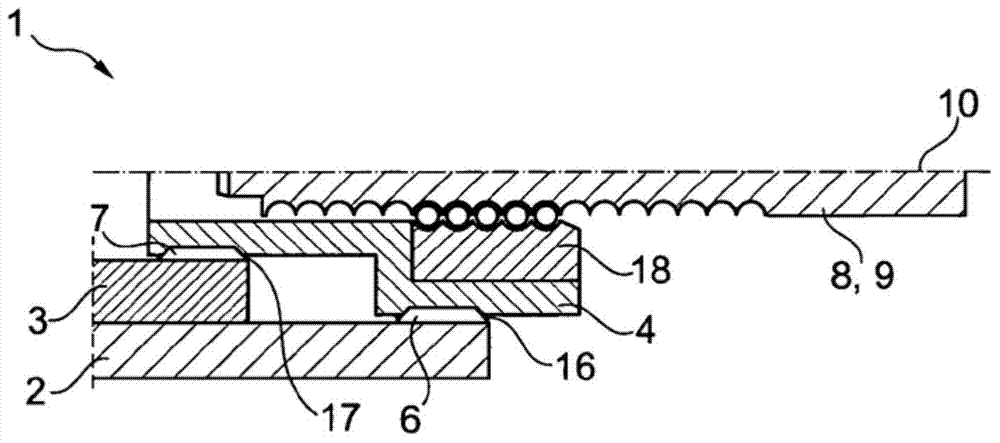

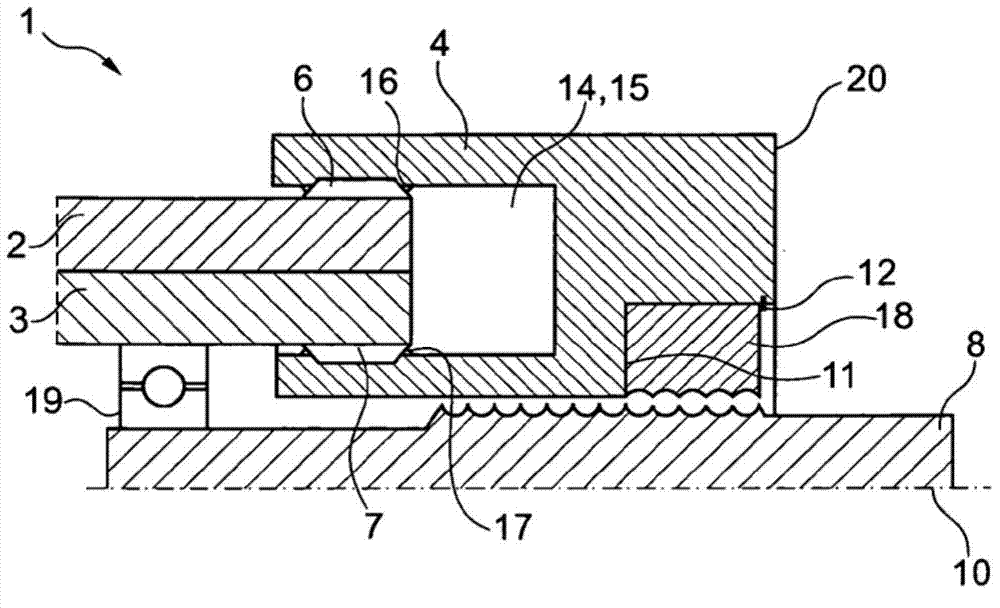

Camshaft unit

InactiveCN104246153ACompact structureConstant wall thicknessValve arrangementsMachines/enginesEngineeringCrankshaft

Camshaft unit (1) comprising a first camshaft (2), which is phase-settable with respect to a crankshaft, a second camshaft (3), which is disposed concentric to the first camshaft (2) and is always phase-true to the crankshaft, a camshaft adjuster (5) with which the first camshaft (2) is phase-settable with respect to the crankshaft, a connecting member (4), which is displaceable in the axial direction of the camshafts (2, 3) and has first toothing (16), wherein the first toothing (16) meshes with counter-toothing (6) on the first camshaft (2), and an adjusting drive (9) by means of which a connecting member (4) can be displaced axially, wherein by means of the axial advance, a relative rotation of the first camshaft (2) with respect to the connecting member (4) takes place.

Owner:SCHAEFFLER TECH AG & CO KG

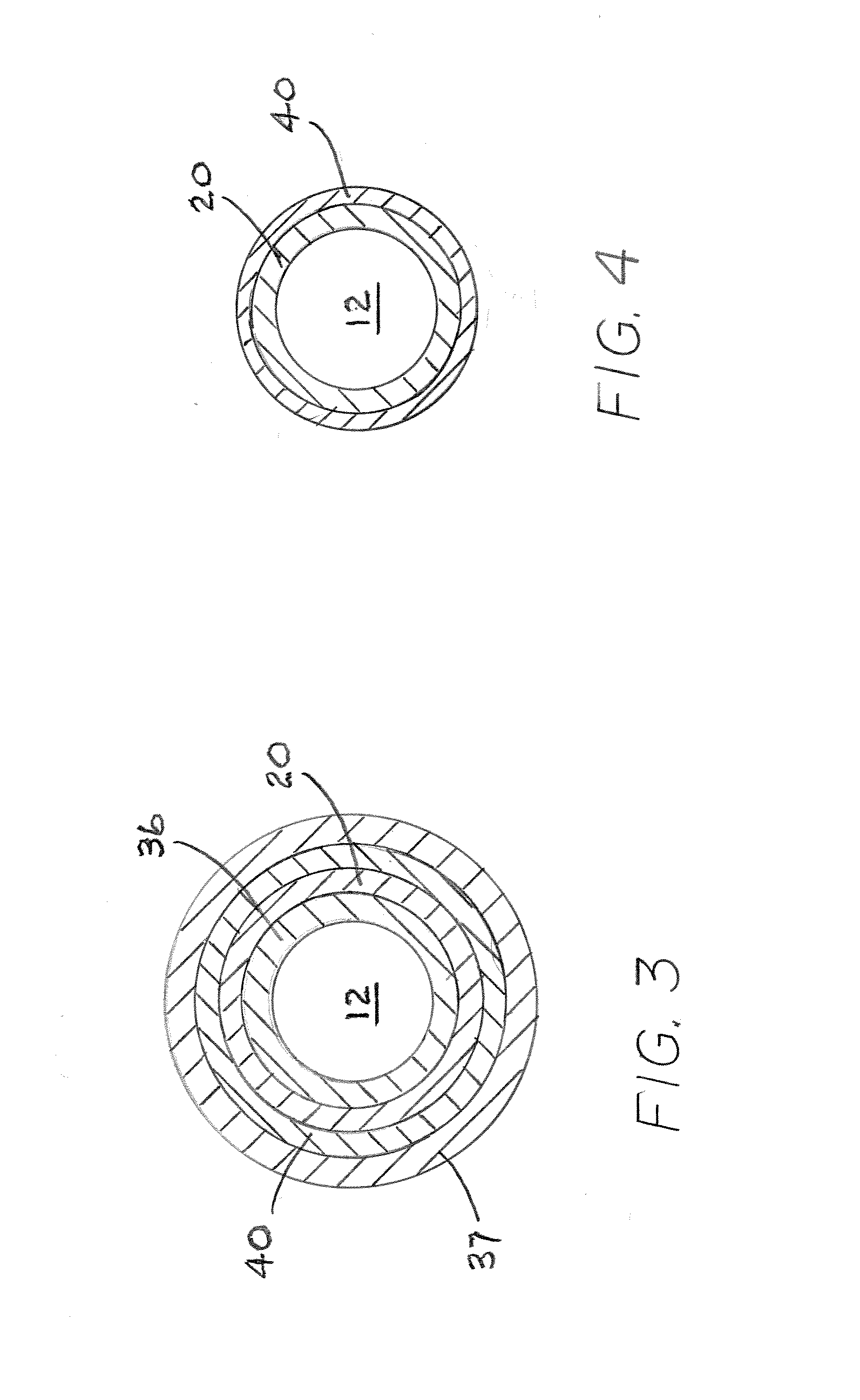

Method for producing a fuel tank

In a method for producing a fuel tank, an elastomer layer made of a rubber mixture is applied on an interior shell adapted to receive fuel, a fiber composite material forming a protective cover is introduced into a mold, inserting the fuel tank with the elastomer layer in the mold so as to surround the elastomer layer with the fiber composite material, the fiber composite material is adhesively bonded to the elastomer layer with a laminating resin, and the fuel tank with the protective cover is vulcanized at temperatures between 80° C. and 180° C. over a time of 2 hours to 36 hours. The fiber composite material includes a cover layer made of a gel coat having a higher flame point than the elastomer layer.

Owner:BENTELER DEFENSE

Particles

Manufactures particles comprising a chemical treatment agent which are useful in wells are provided. The particles have the advantage of being able to chemically treat a well, e.g. to remove filter cake. Embodiments of the invention improve well production by providing sand control and / or increasing permeability of a gravel pack. Methods of using the particles and a gravel pack comprising the particles are also provided.

Owner:ROBERTSON EWEN

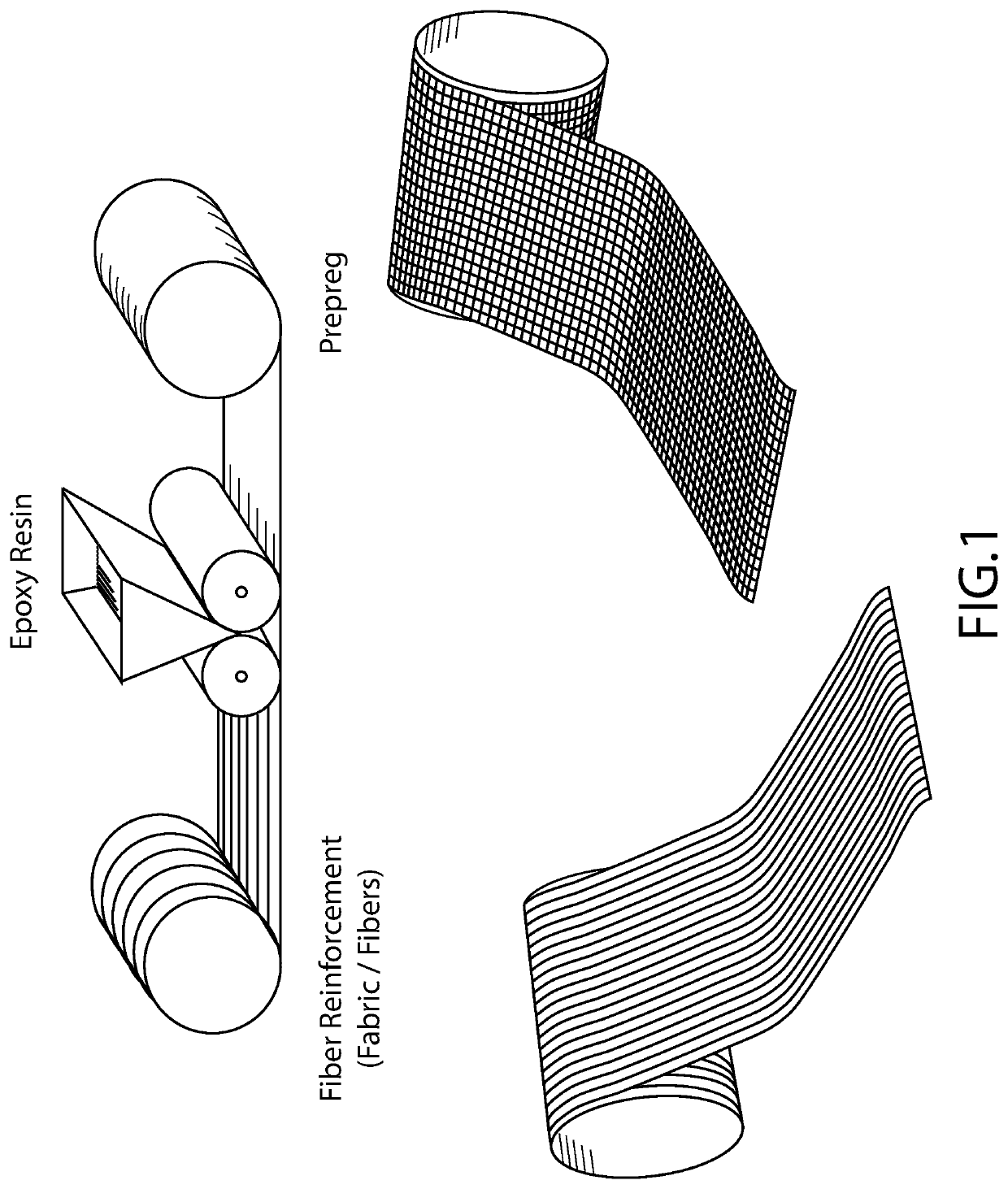

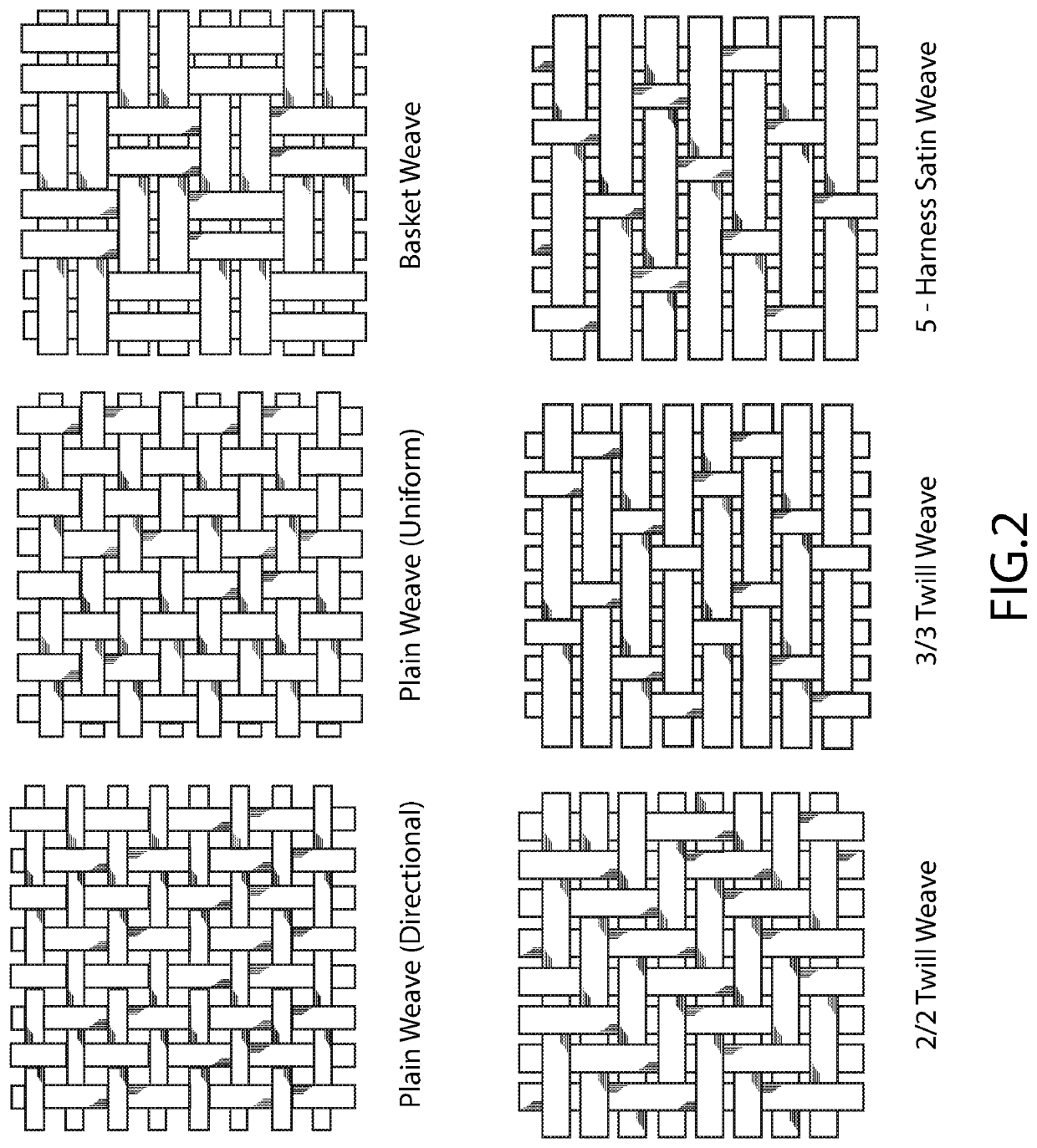

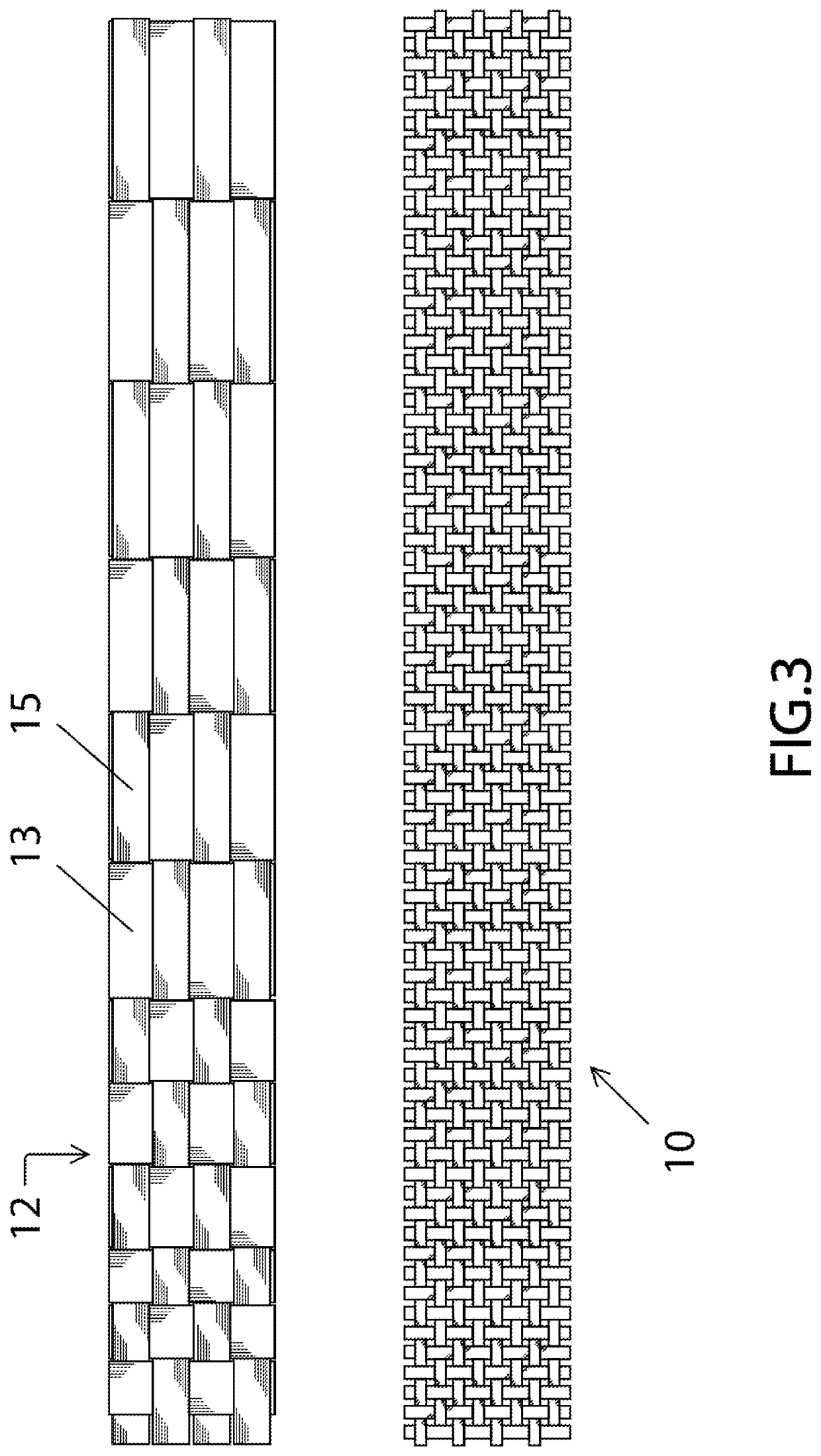

Methods of asymmetrically weaving raw fiber materials to create fiber reinforced products and products created thereby

PendingUS20210277547A1Easy to useConsistent weightLayered productsMulti-ply fabricsAramidFiber reinforcement

A fiber reinforced product includes a single ply composite weave made up of individual weaves interconnected together and then processed in a known manner. The individual weaves are made of one of a plurality of possible fiber reinforced materials such as carbon, Aramid or glass. Their fibers are angulated with respect to the axis of elongation of the composite weave in some cases and in other cases the respective lengths of the individual weaves are chosen to accomplish differences in stiffness and flexibility based upon the desired performance properties of the finished product in which the single ply composite weave is incorporated.

Owner:EPOCH SPORTS LLC

Pressure cylinder in the form of a hollow cylinder made of metal

InactiveUS20050166777A1Constant wall thicknessReduce wall thicknessLiquid surface applicatorsShaft and bearingsMechanical engineeringMetal

An impression cylinder in the form of a hollow cylinder made of metal, e.g., aluminum, for printing machines, having an essentially constant wall thickness over its length. The cylinder may have a predetermined inner diameter and may have various different outer diameters. The hollow cylinder includes a cylinder jacket. The cylinder jacket is provided with longitudinal openings, such as longitudinal bores. The employment of these longitudinal openings, e.g., bores, in various different numbers, sizes and shapes, enables impression cylinders having different external diameters and equal internal diameters to have substantially similar weights or mass per unit length.

Owner:GALLUS FERD RUESCH

planting system

ActiveCN110612068BEnhanced transfer processPrevent rotationDental implantsCeramic shaping apparatusDentistryDental implant

The invention relates to an implant system comprising a dental implant (10) made of ceramic material and a structural part (12), wherein the structural part (12) comprises a first anti-rotation element with a plurality of grooves and the dental implant (10) Comprising a second anti-rotation element with ribs complementary to the first anti-rotation element, wherein the groove is open towards the proximal end (28) of the structural part (12).

Owner:STRAUMANN HLDG AG +1

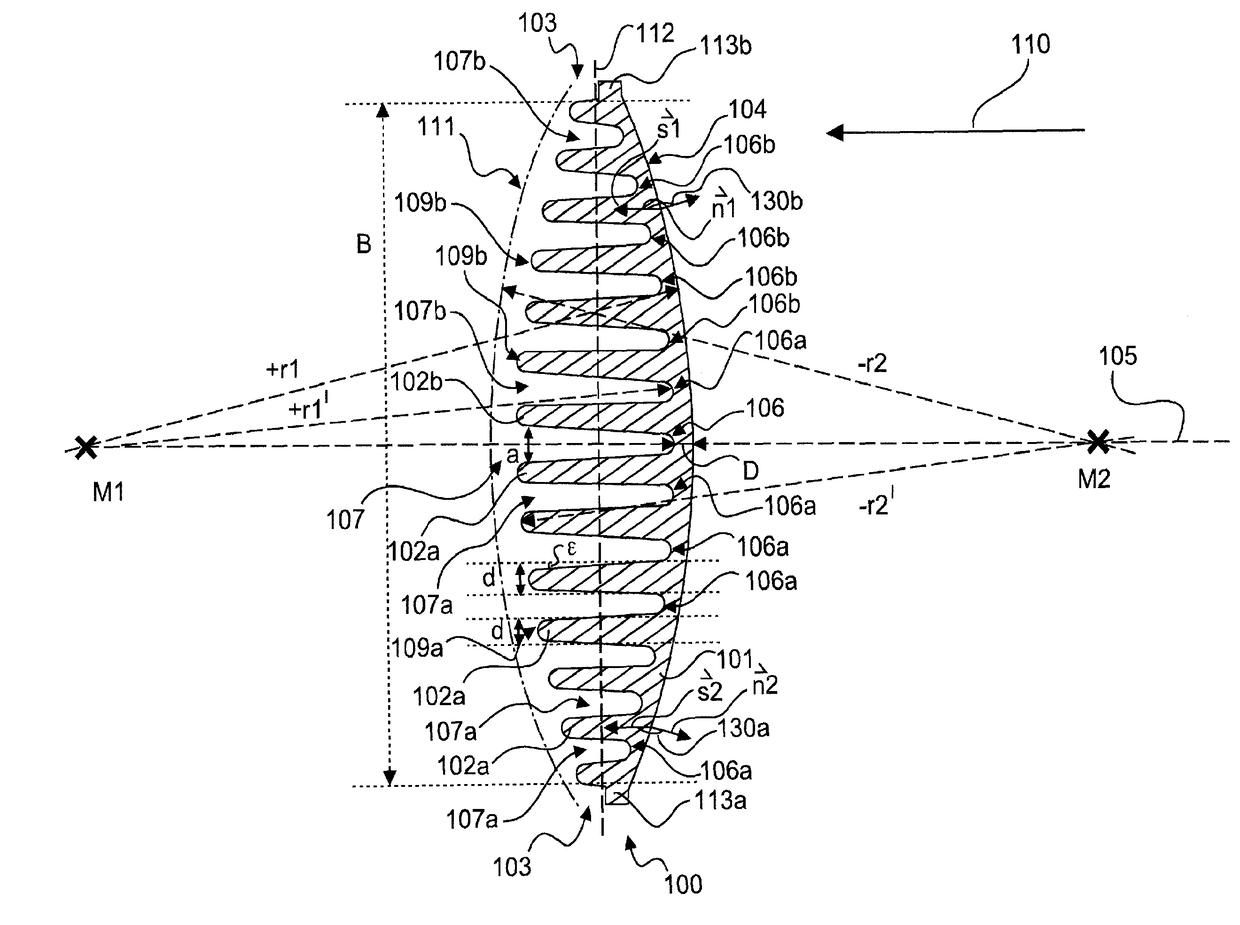

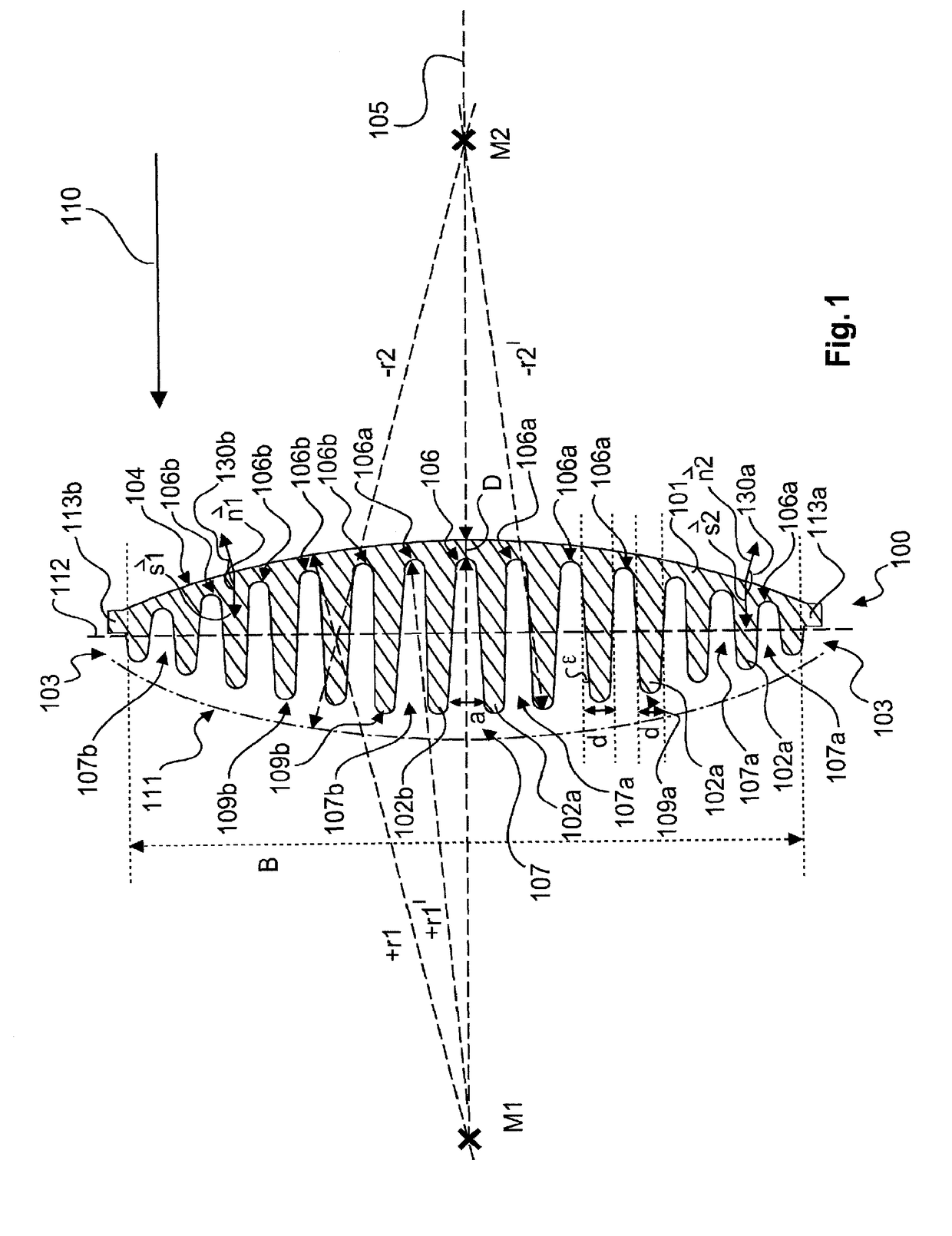

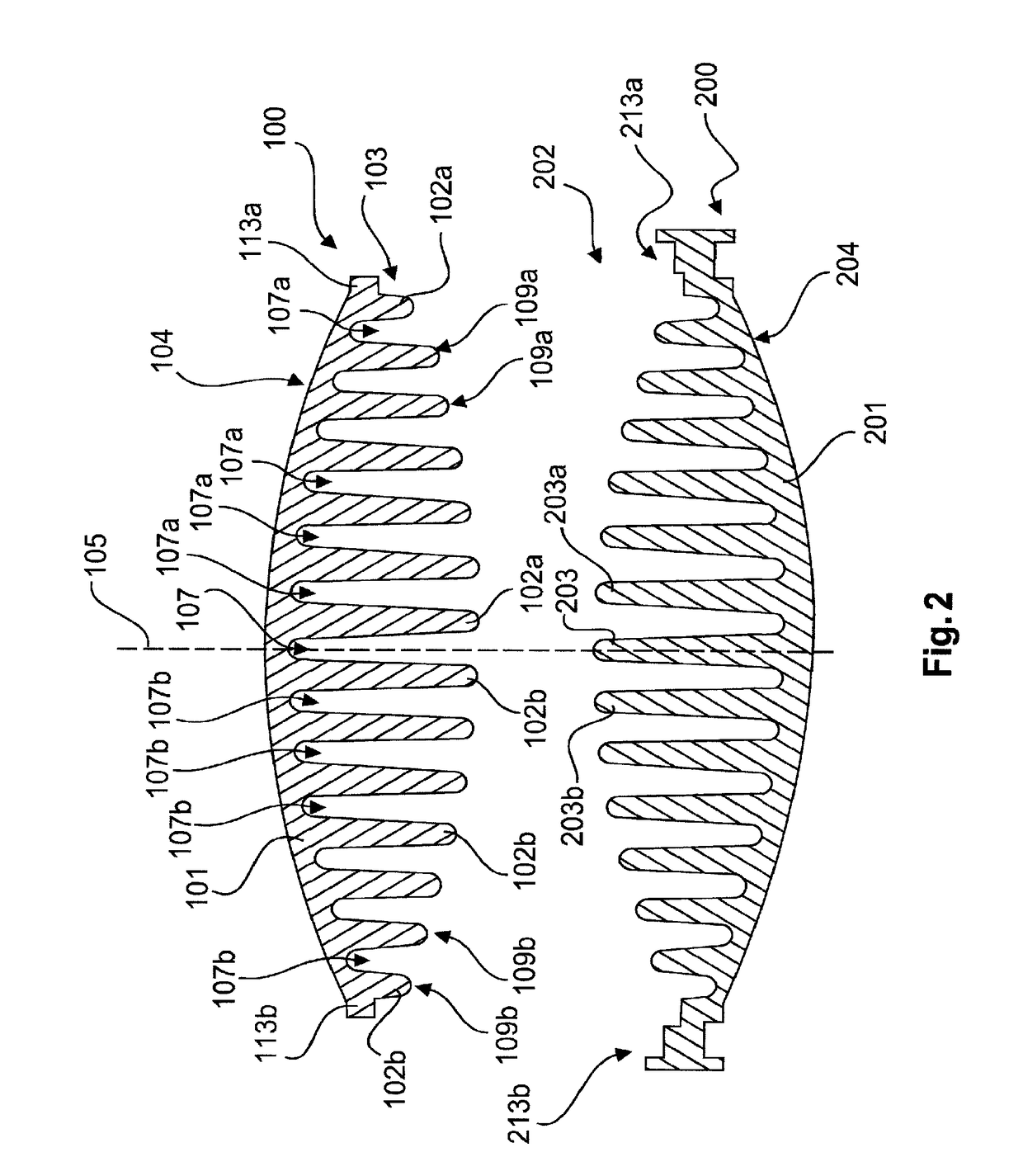

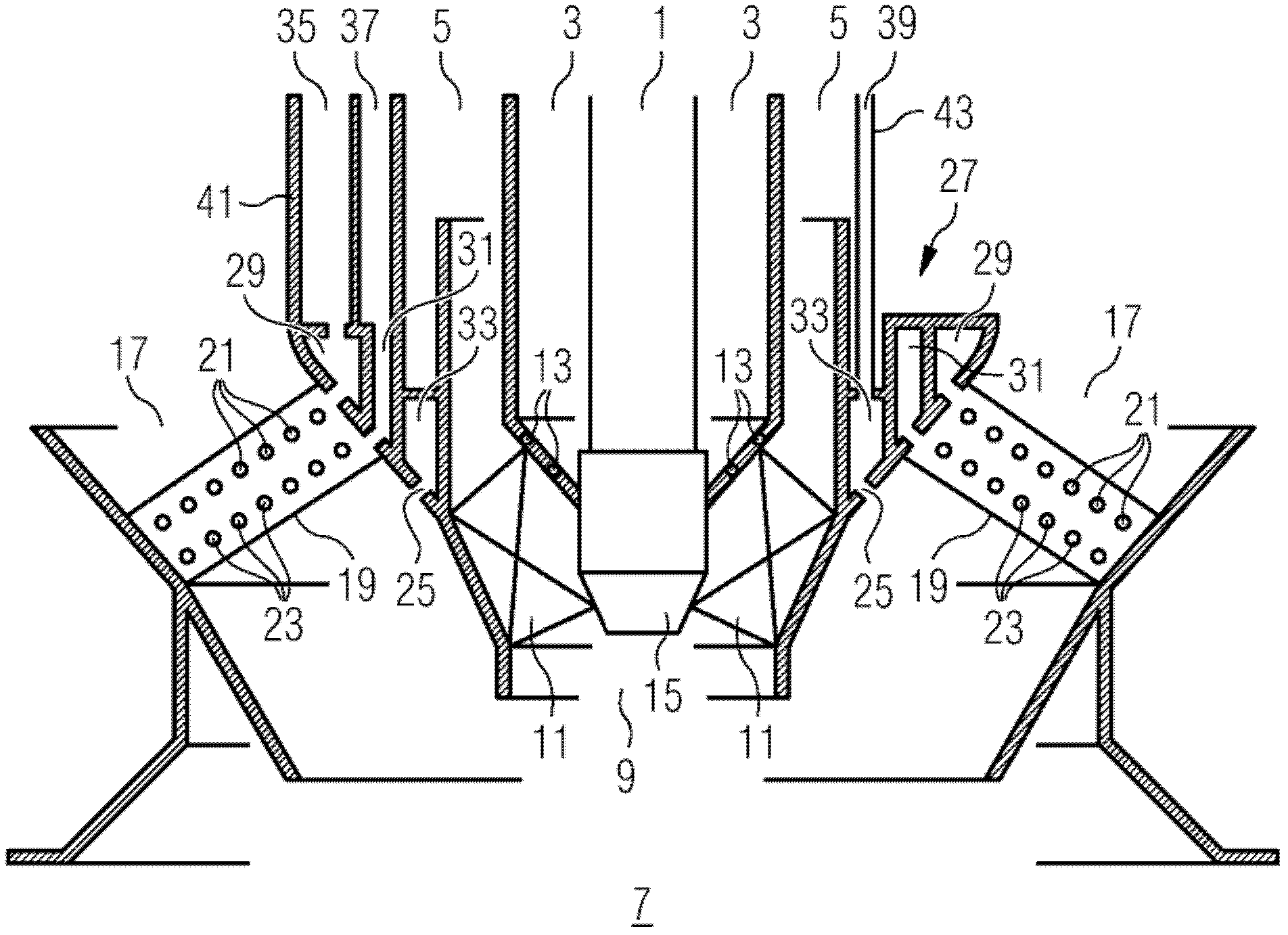

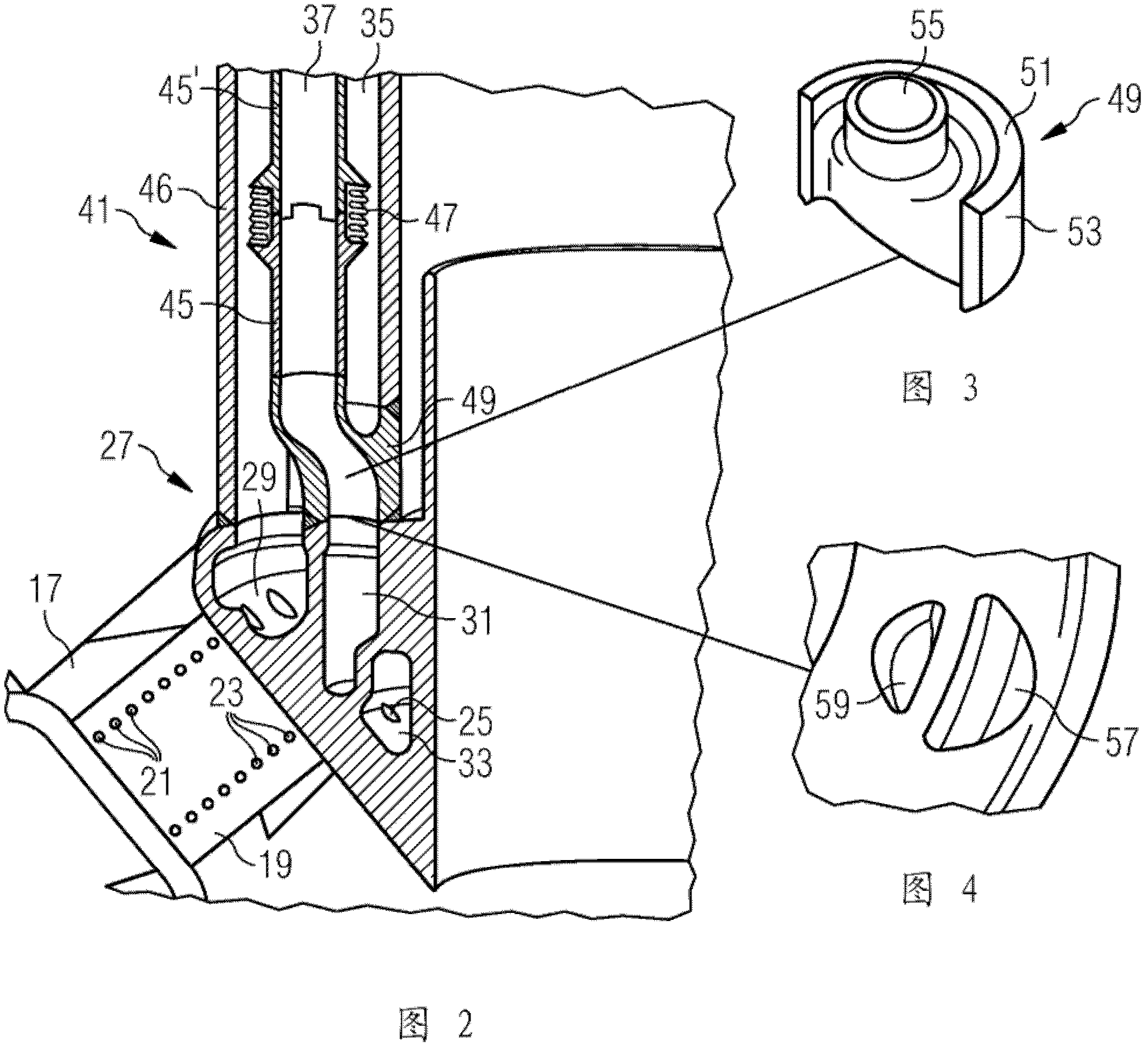

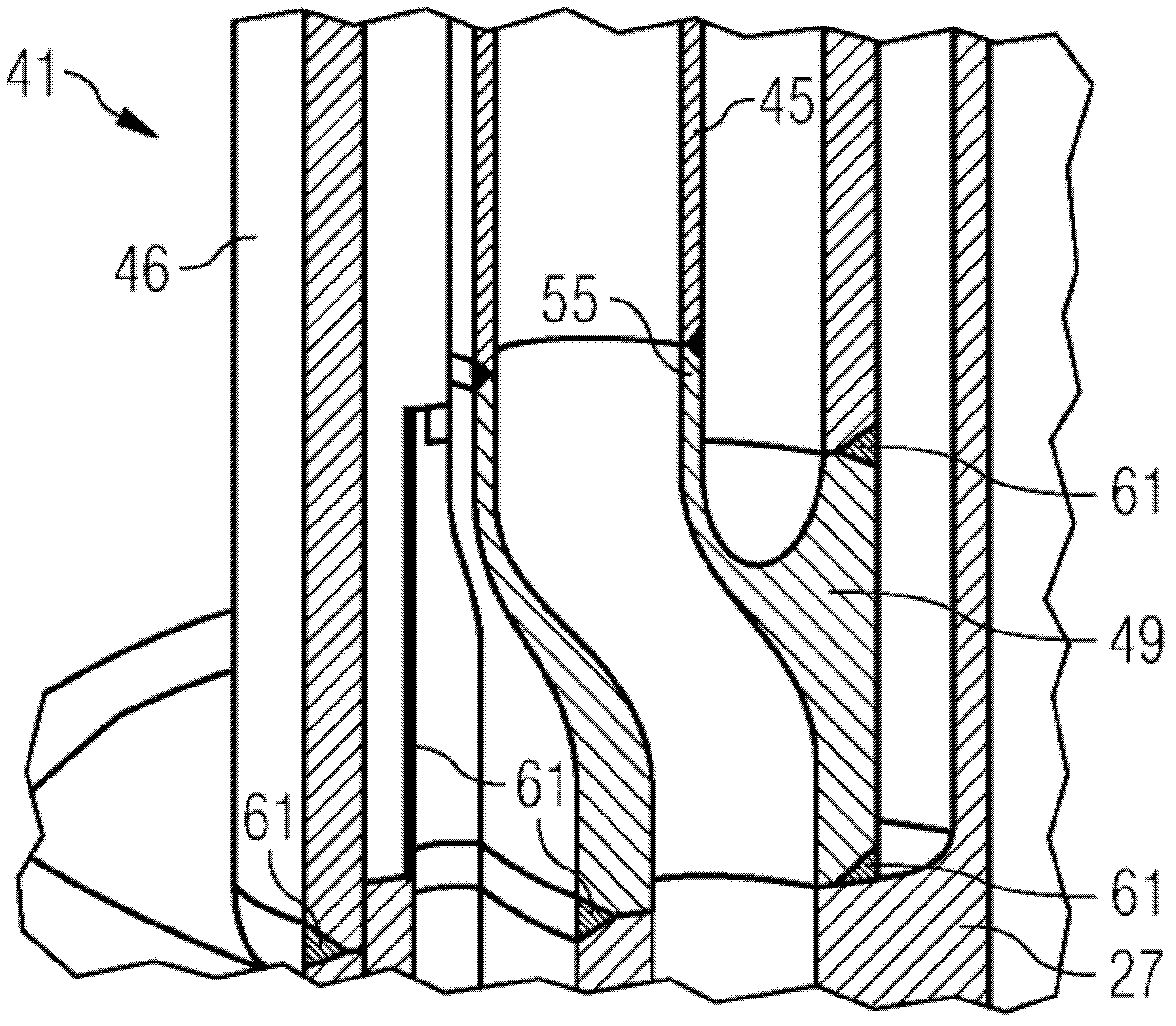

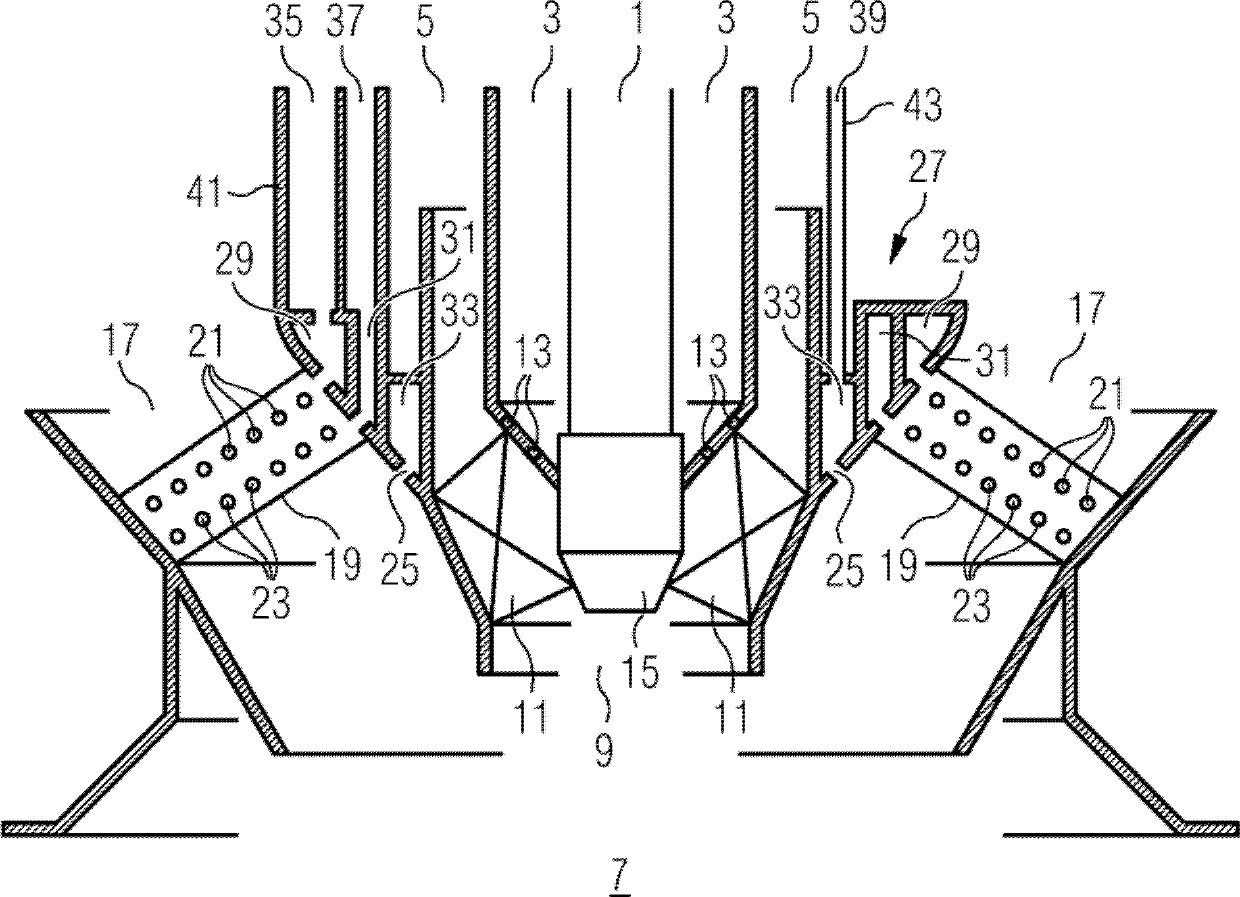

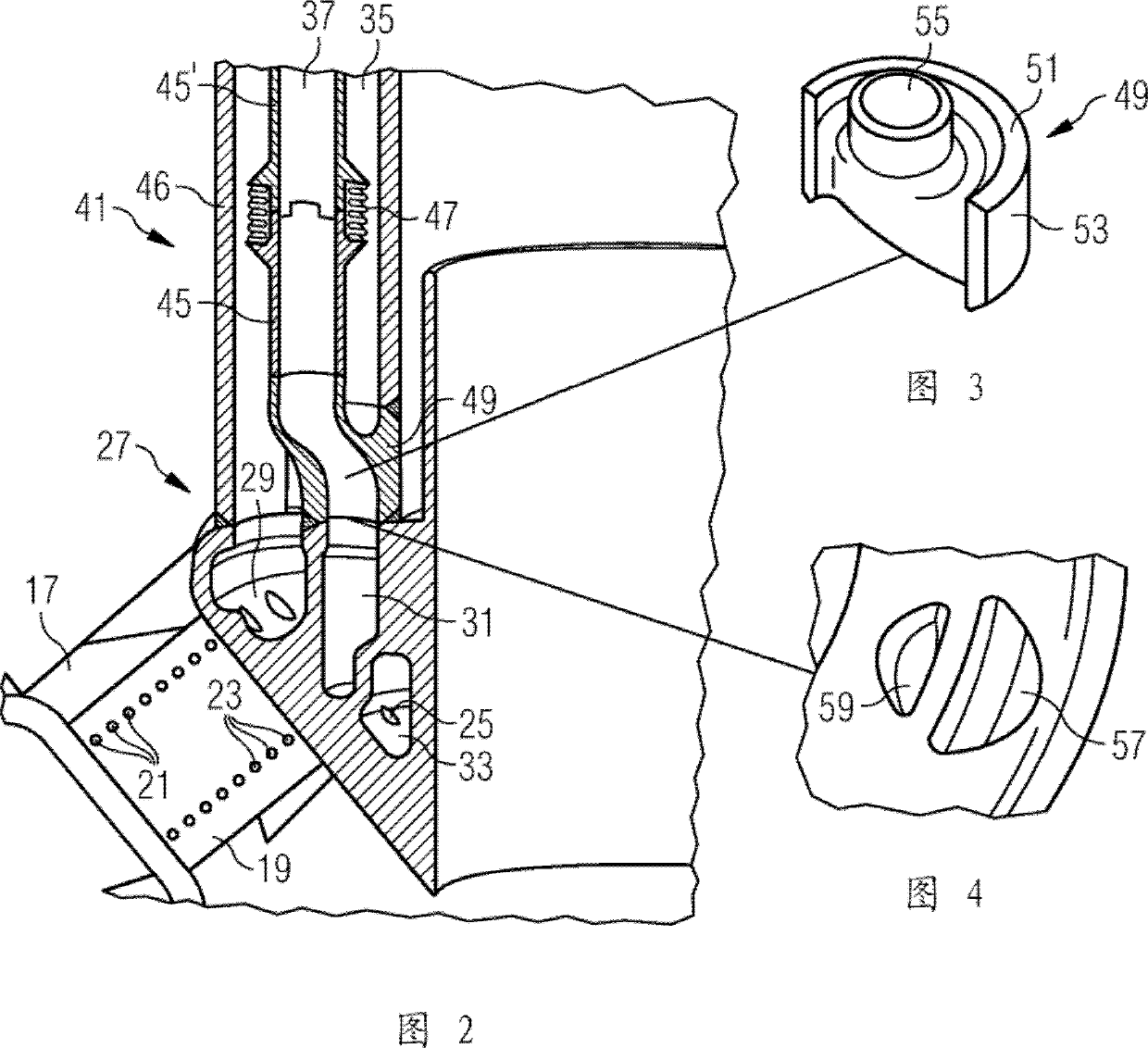

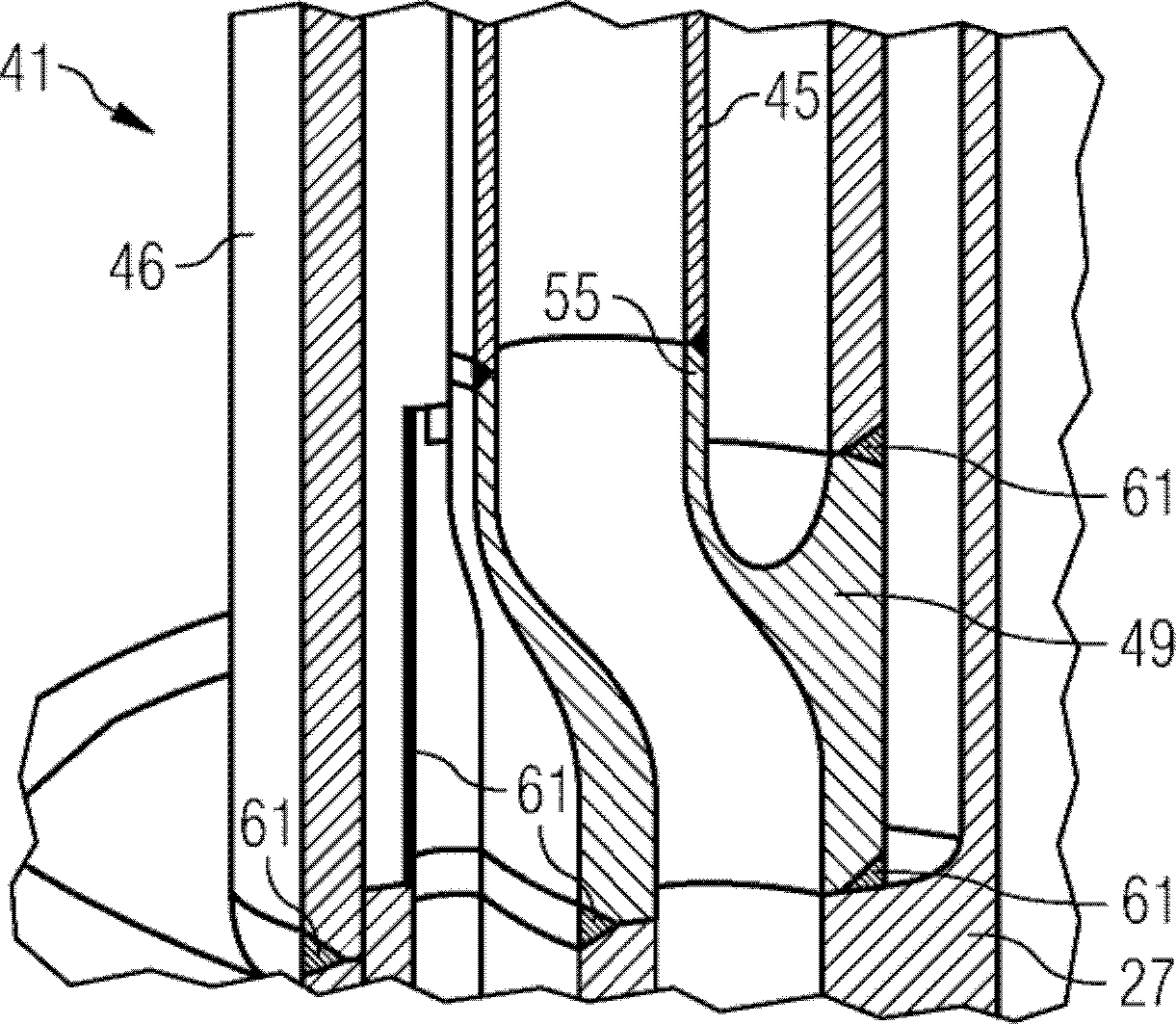

Burner, in particular for gas turbines

ActiveCN102472494ARealize the twistConstant wall thicknessBurnersContinuous combustion chamberCombustorGas supply

Provided is a burner with a central fuel supply arrangement (27), an annular air channel (17) surrounding the central fuel supply arrangement (27) for supplying combustion air, and swirl vanes (19) disposed in the annular air channel (17). The swirl vanes (19) have first gas nozzles (21) for injecting a gaseous fuel into the combustion air, and second gas nozzles (23) for injecting a gaseous fuel into the combustion air. The first gas nozzles (21) are fed from a first gas distribution channel (29) in the fuel supply arrangement (27), and the second gas nozzles (23) are fed from a second gas distribution channel (31) in the fuel supply arrangement (27). The first gas distribution channel (29) and the second gas distribution channel (31) are supplied with combustion gas from a gas supply pipe (41) which has a first gas supply channel (35) and a second gas supply channel (37), the first gas supply channel (35) being connected to the first gas distribution channel (29) and the second gas supply channel (37) being connected to the second gas distribution channel (31).

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

Burner, in particular for gas turbines

ActiveCN102472494BCompensation for thermal expansionGood inflowBurnersContinuous combustion chamberCombustorProcess engineering

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com