Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Complete nesting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

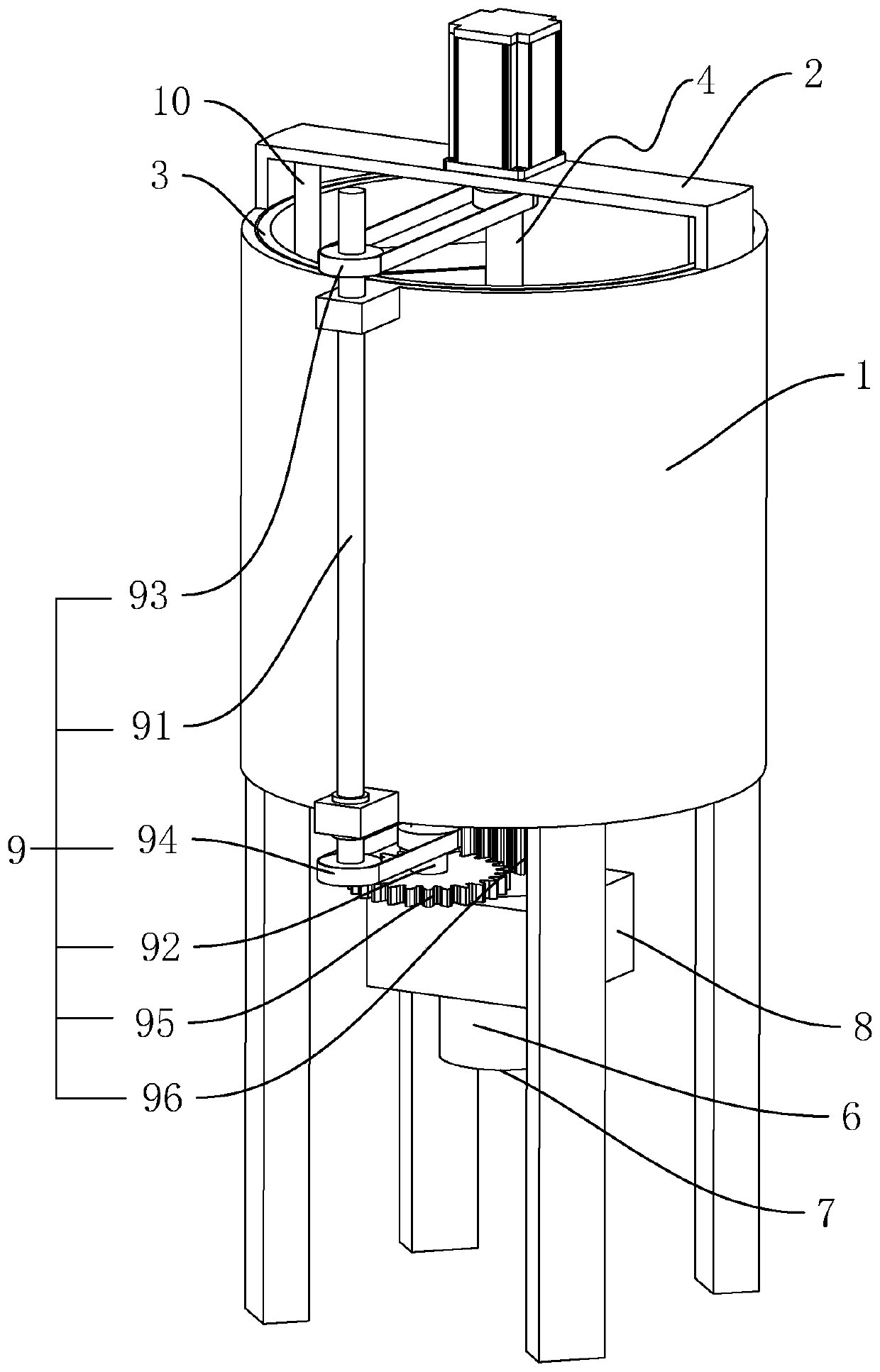

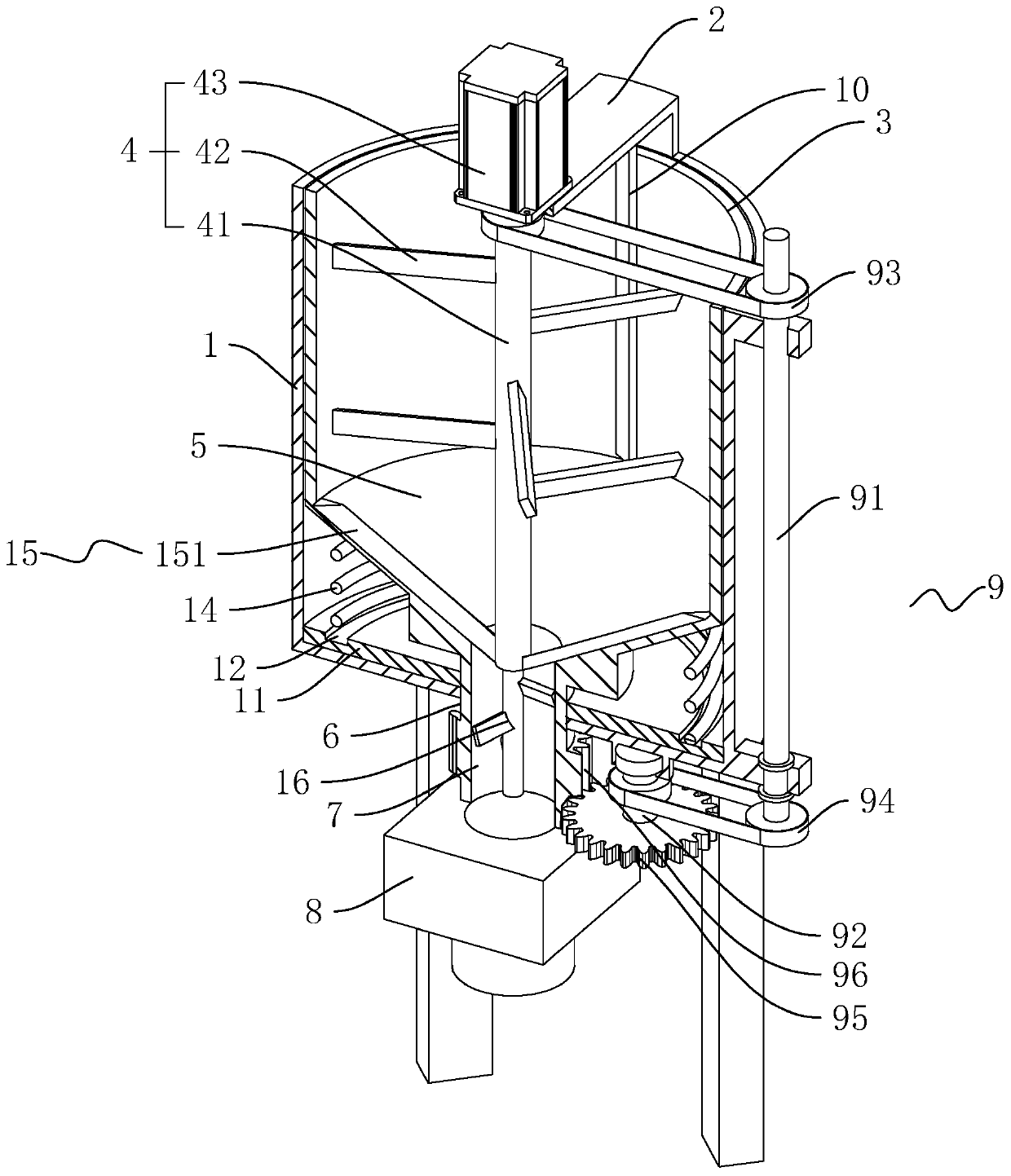

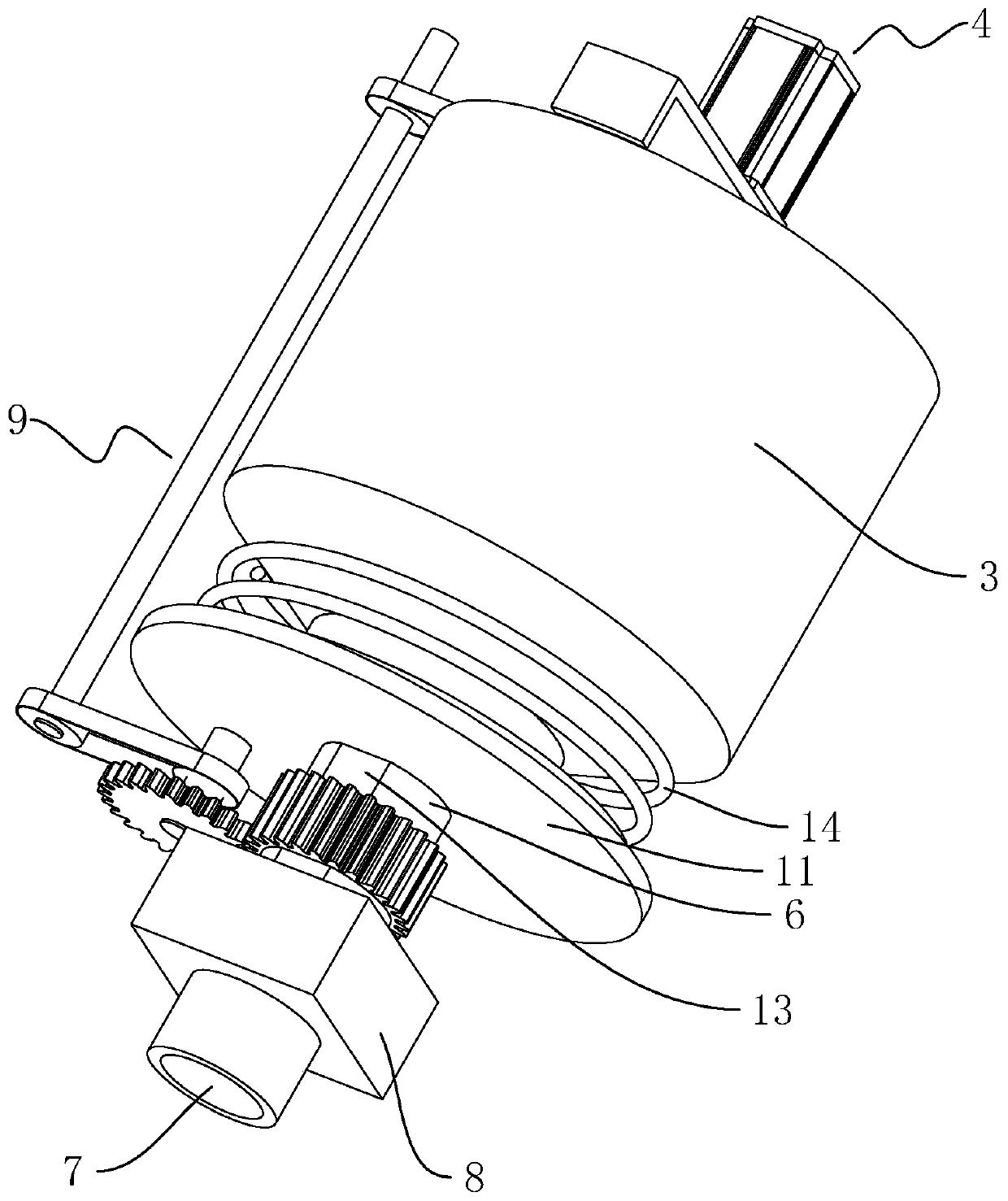

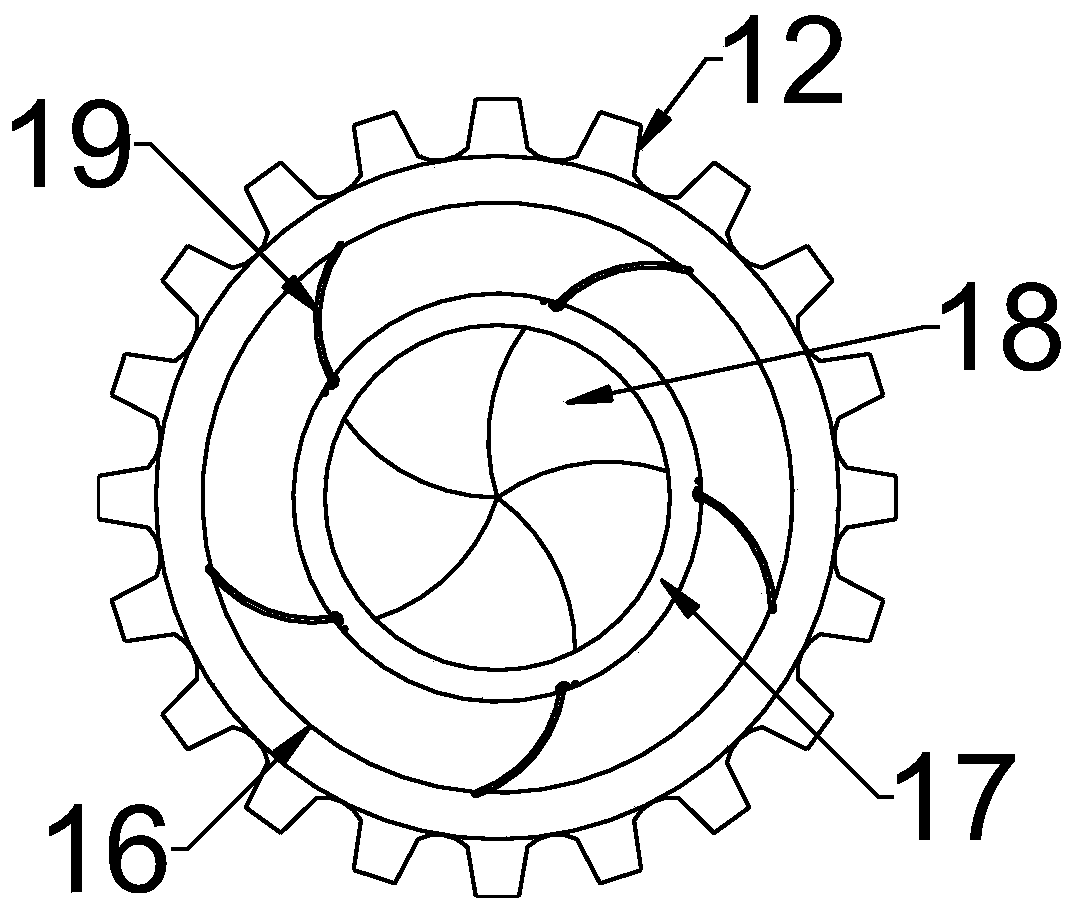

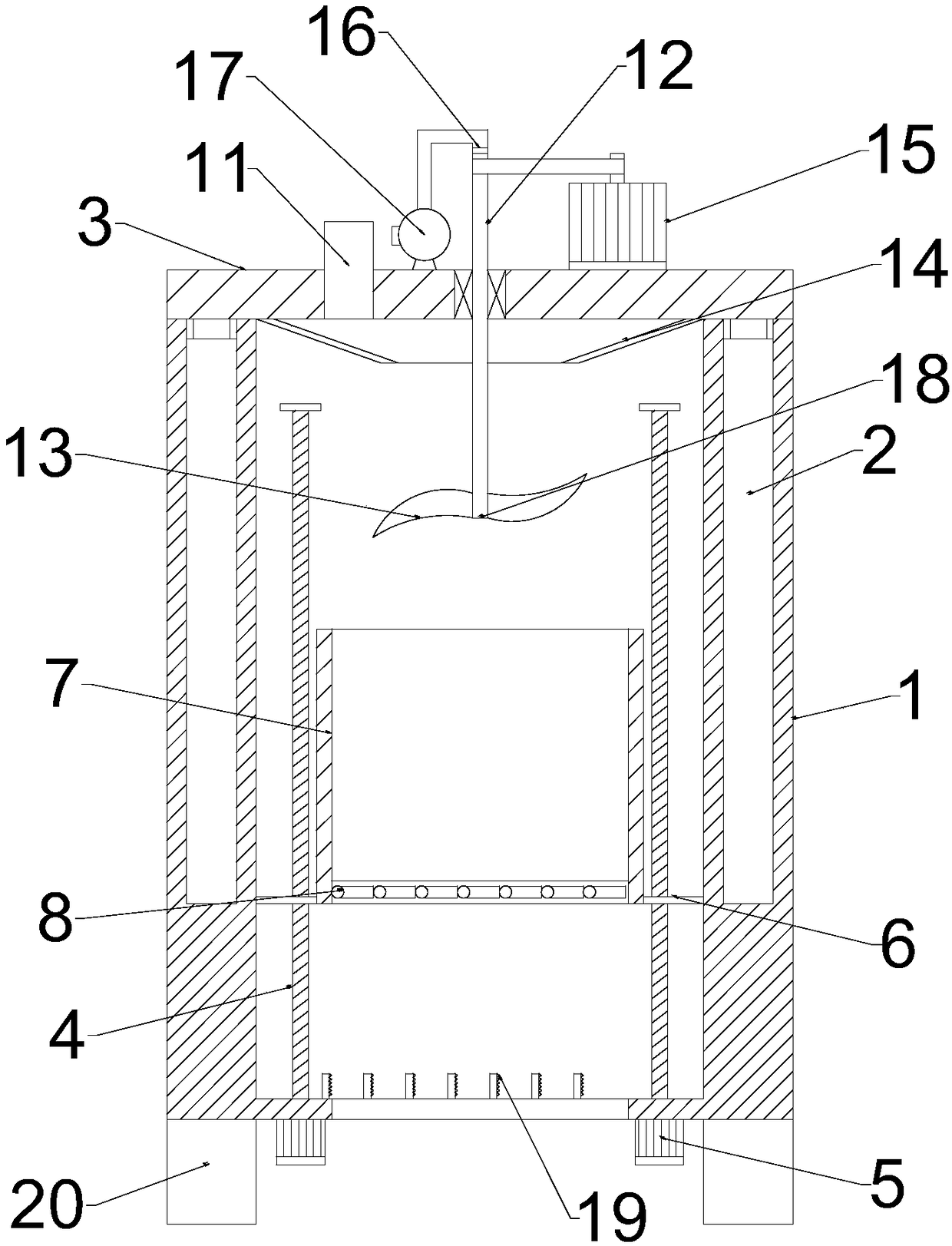

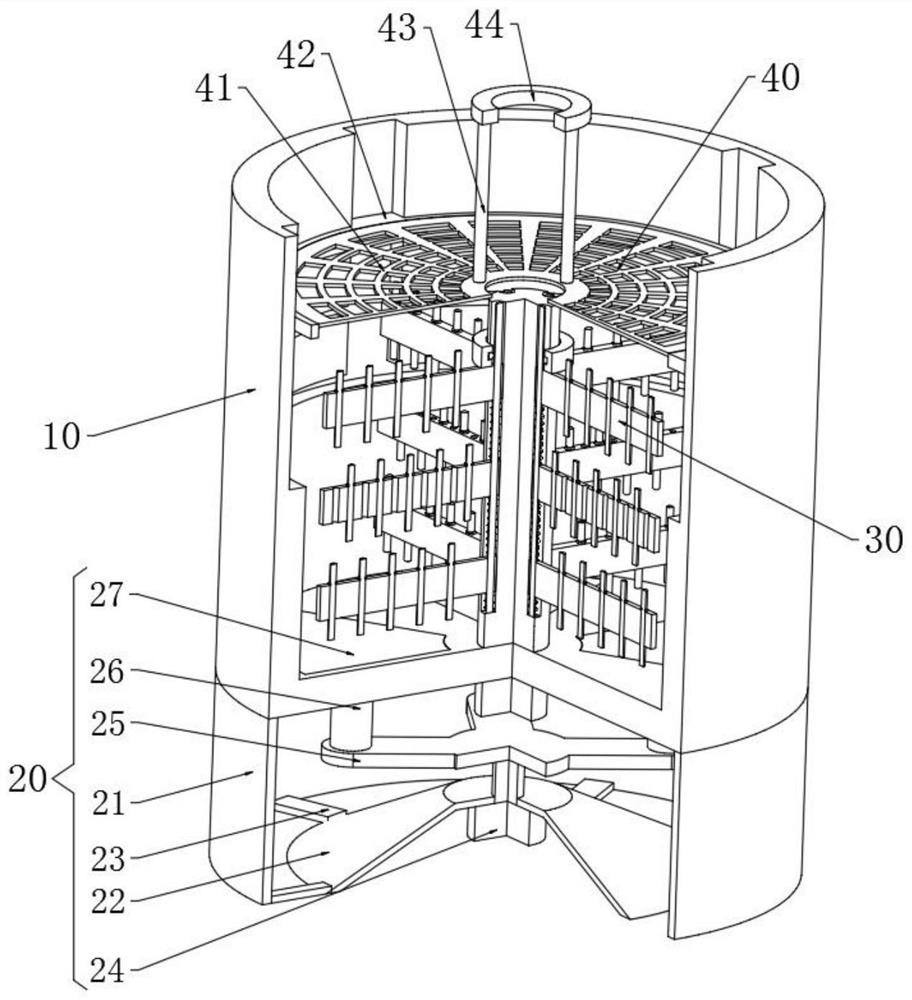

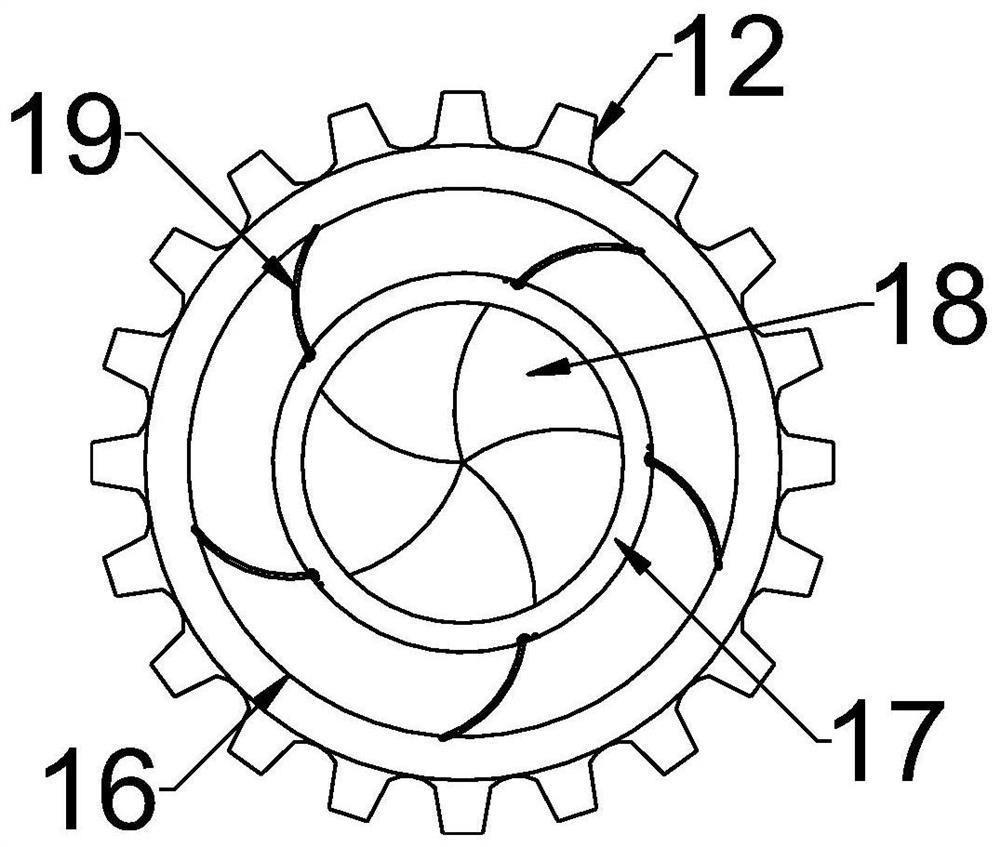

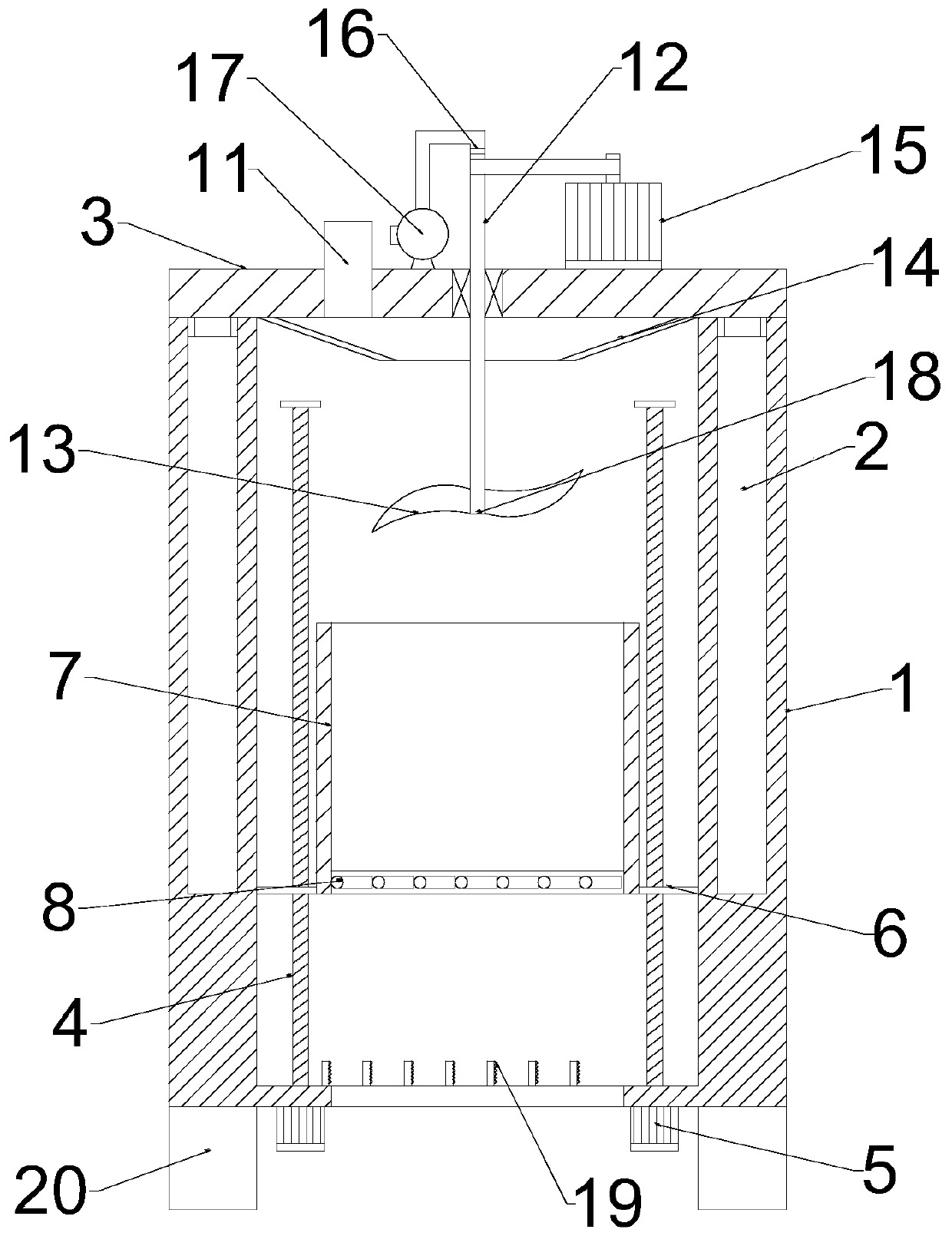

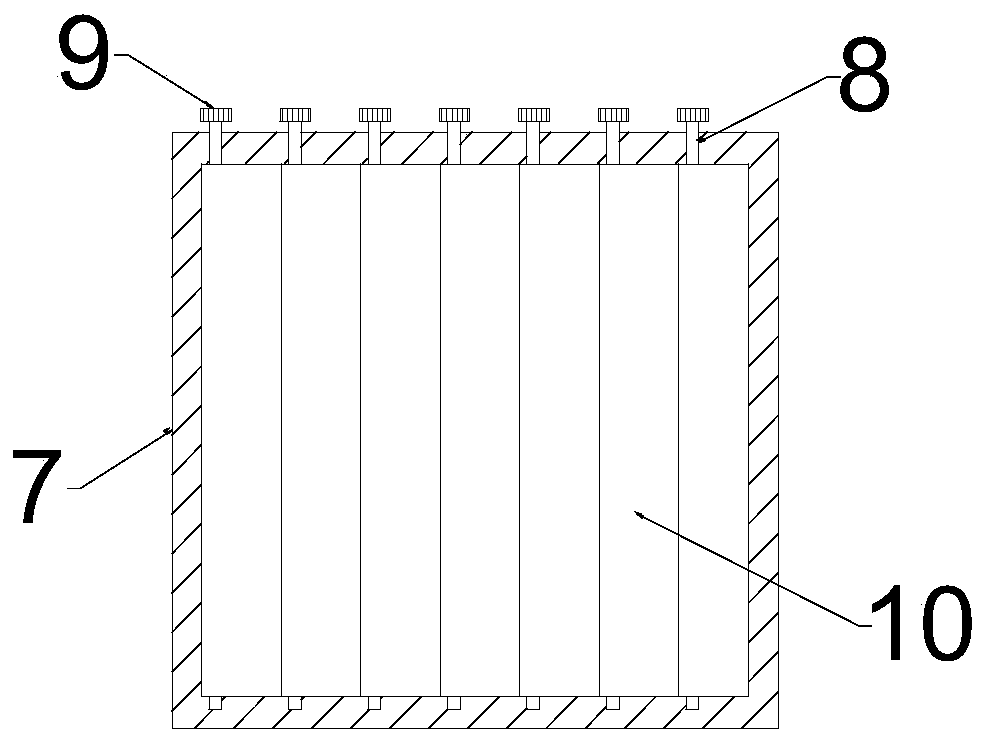

Agitator for concrete production system

InactiveCN111391133AImprove stirring efficiencyWell mixedCement mixing apparatusElectric machineryStructural engineering

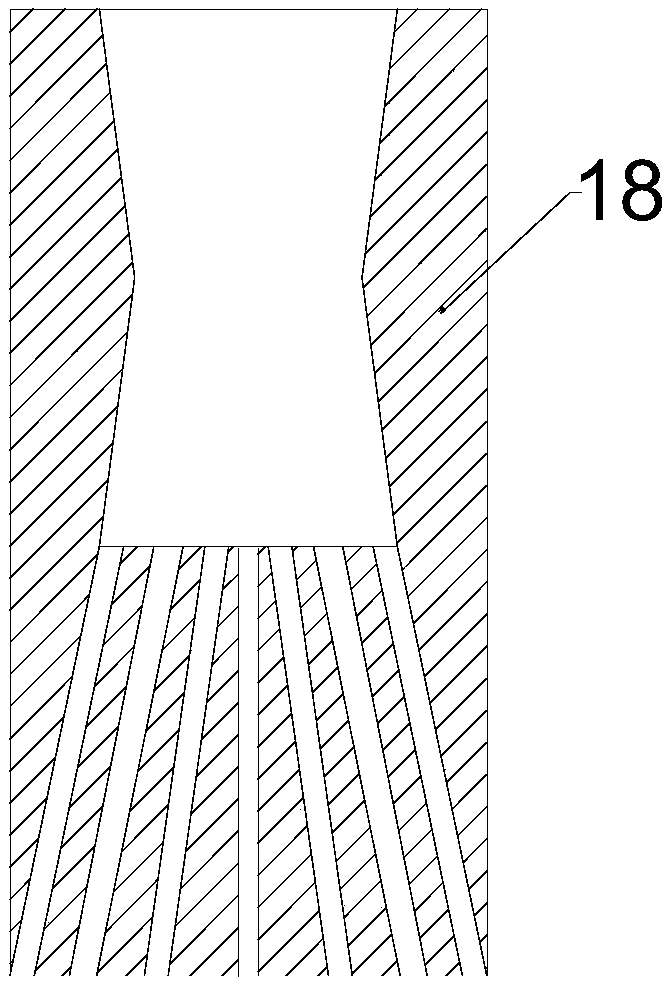

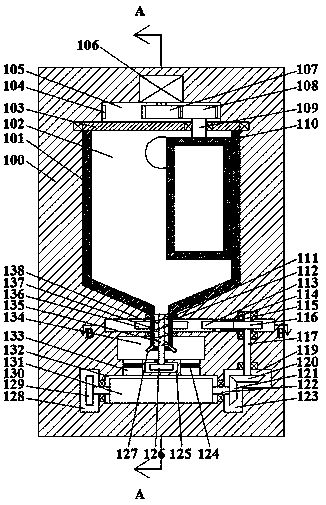

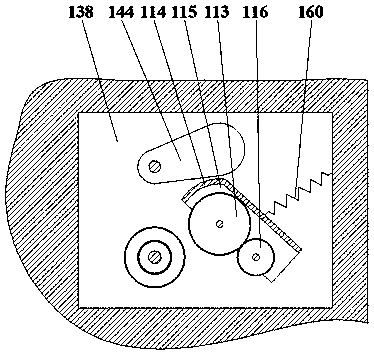

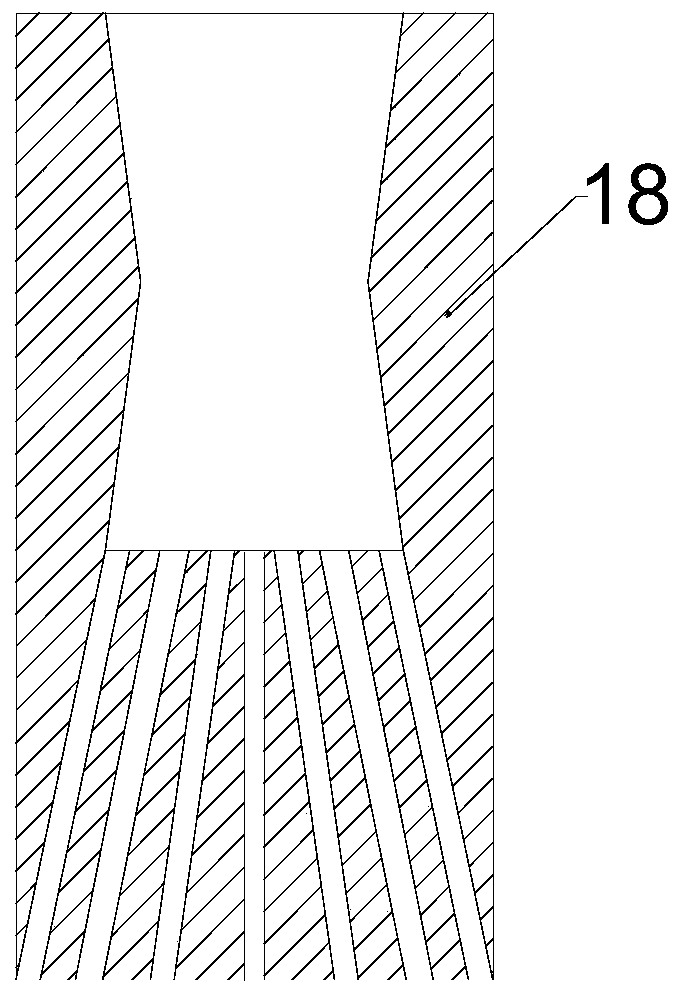

The invention discloses an agitator for a concrete production system and relates to the field of concrete production. The agitator for the concrete production system comprises a vertical barrel body and an agitation assembly arranged in the barrel body; an agitation barrel is arranged in the barrel body; a mounting frame is arranged at the upper end of the barrel body; the agitation assembly comprises an agitation rod, a plurality of agitation blades and a driving motor, the agitation rod is rotationally connected to the mounting frame and penetrates into the agitation barrel, the plurality ofagitation blades are arranged on the outer side wall of the agitation rod, and the driving motor is used for driving the agitation rod to rotate; the agitation barrel is coaxially and rotatably connected in the barrel, a rotating shaft is coaxially and fixedly arranged on the lower end face of the agitation barrel, the rotating shaft is coaxially and rotatably connected with the barrel and penetrates out of the barrel, a discharge hole communicating with the inside of the agitation barrel is coaxially formed in the lower end face of the rotating shaft, and a control valve is arranged on the discharge hole; and a transmission assembly is connected between the agitation rod and the rotating shaft and used for driving the agitation barrel and the agitation rod to rotate reversely. The agitation barrel and the agitation rod are driven to rotate reversely through the transmission assembly, so that the agitation efficiency is higher.

Owner:陕西百固建材有限公司

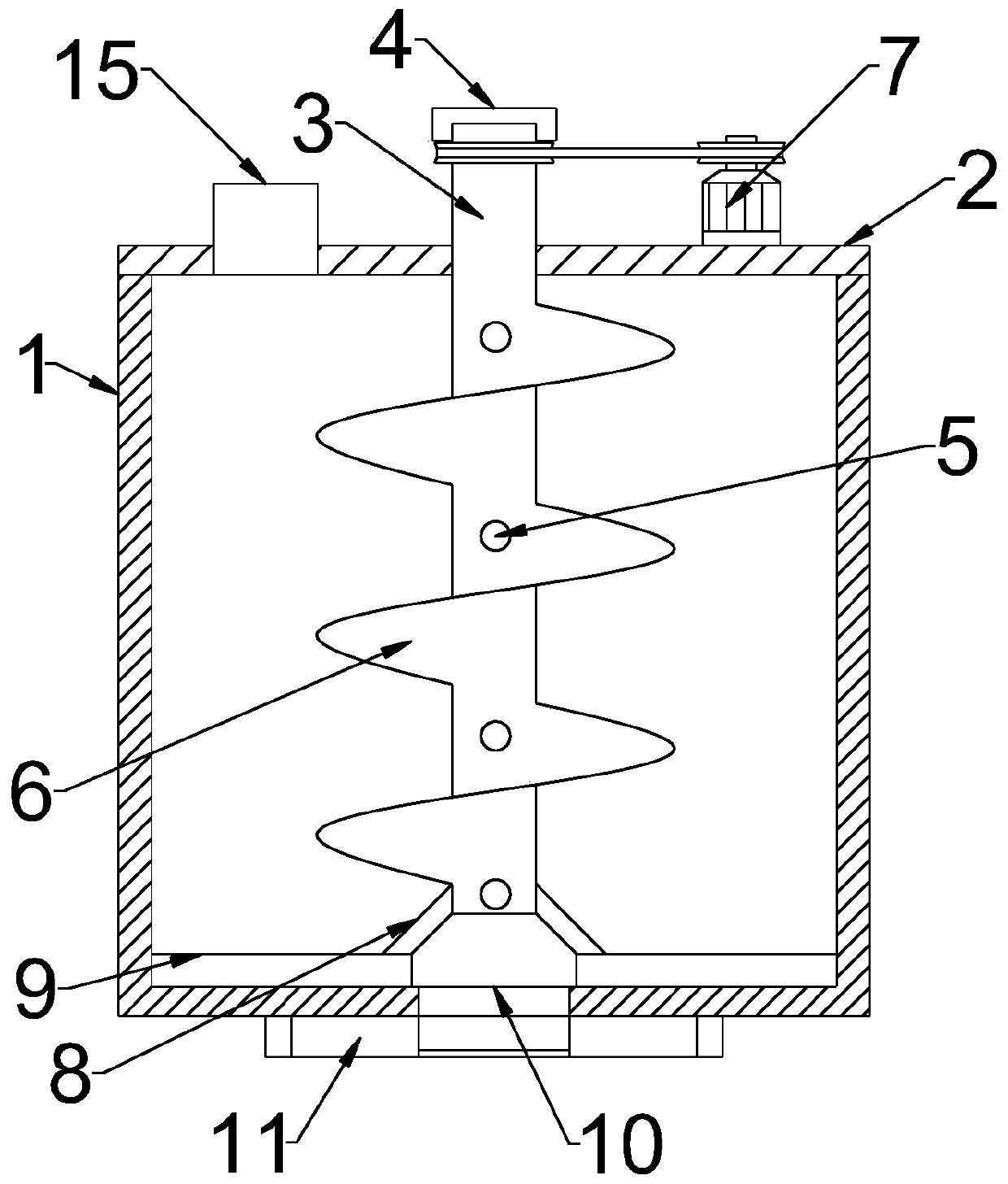

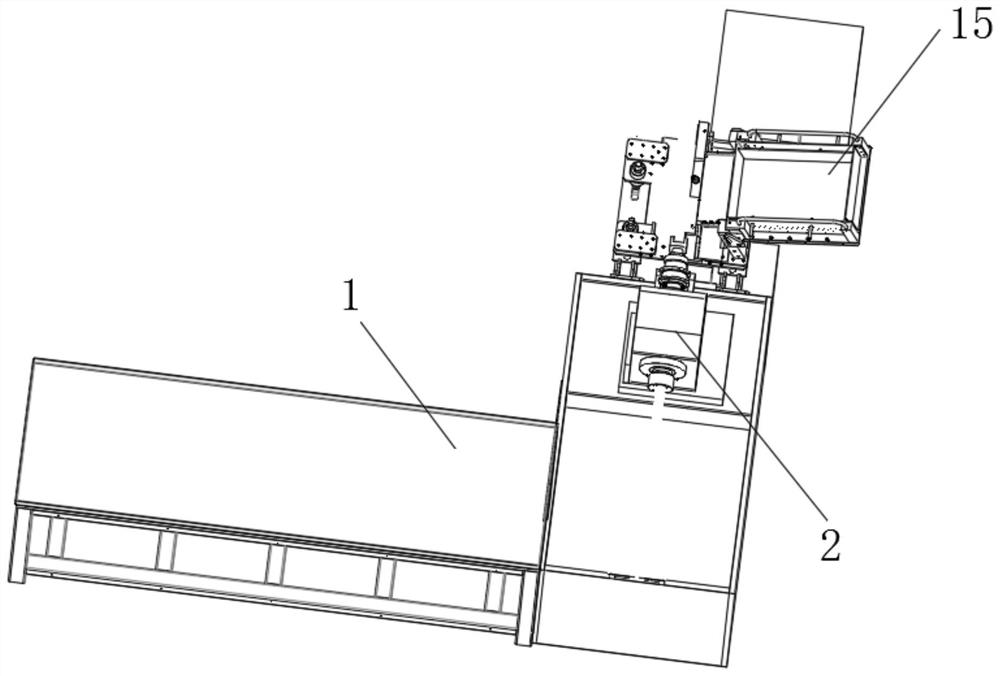

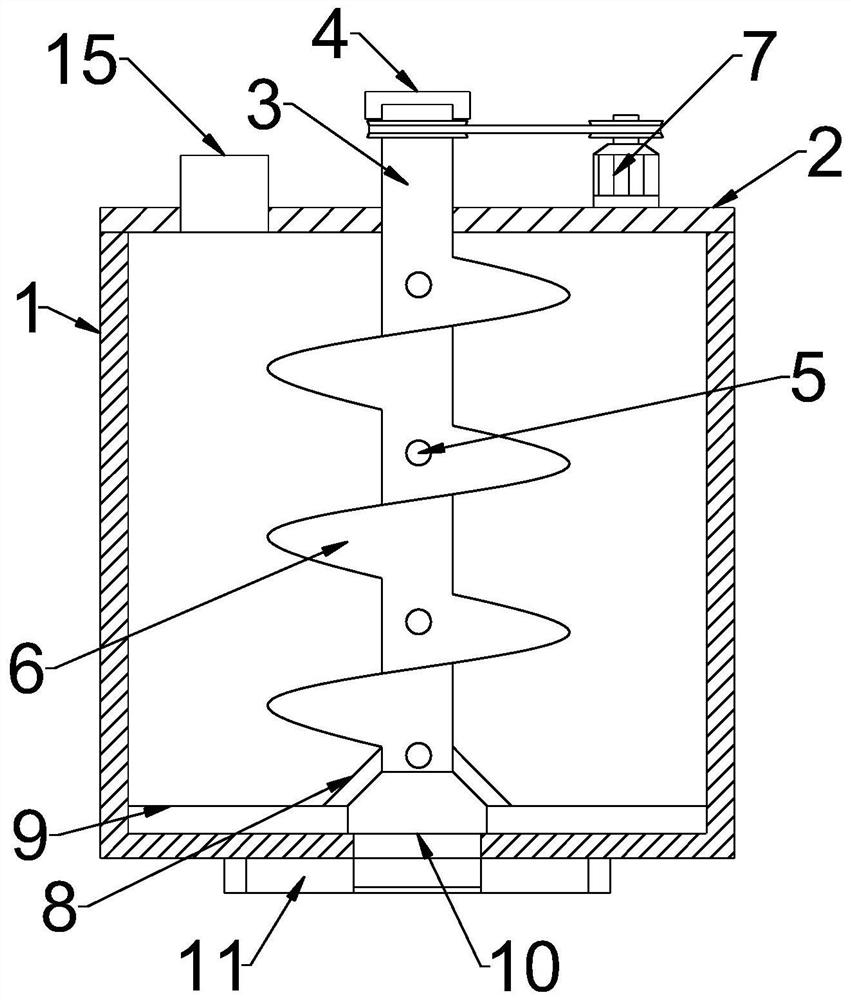

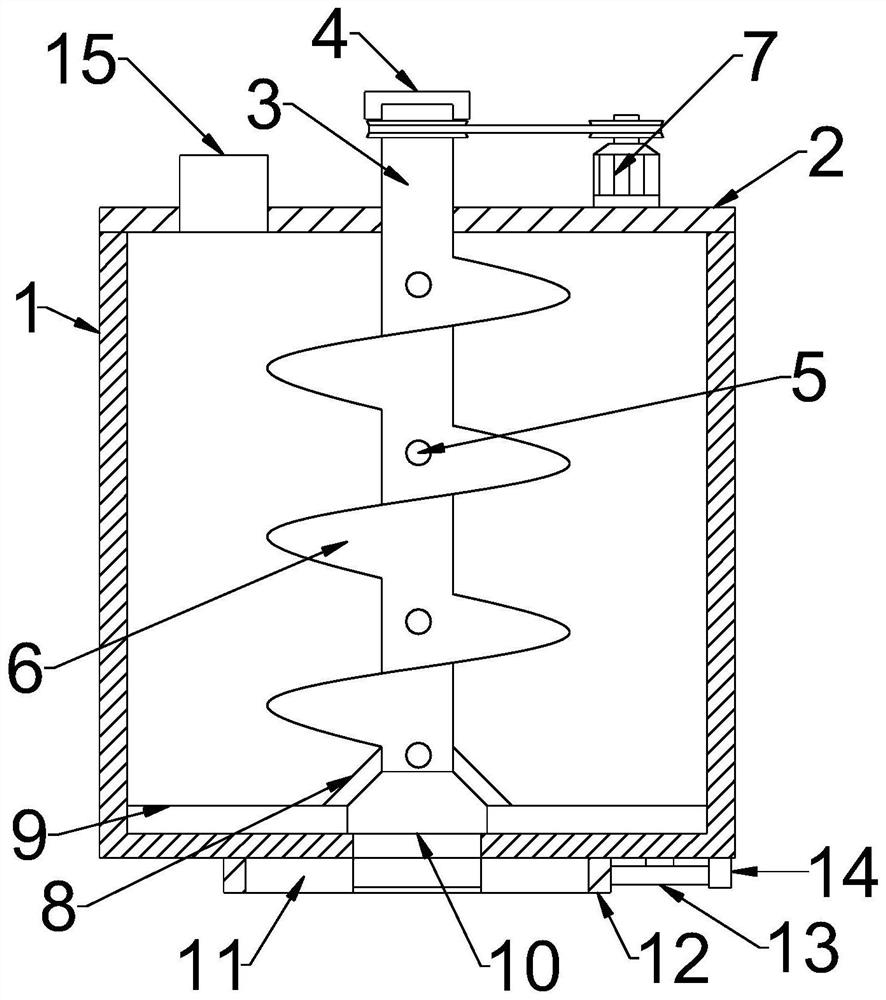

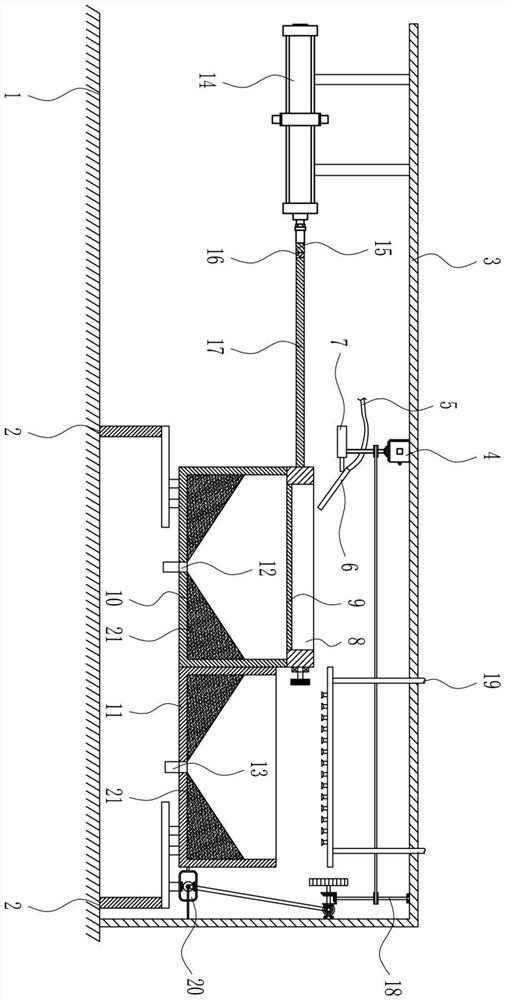

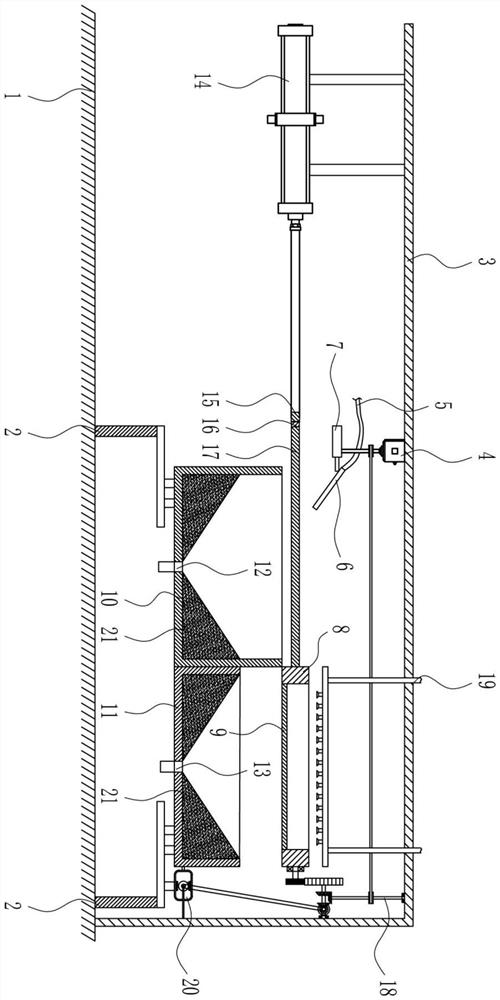

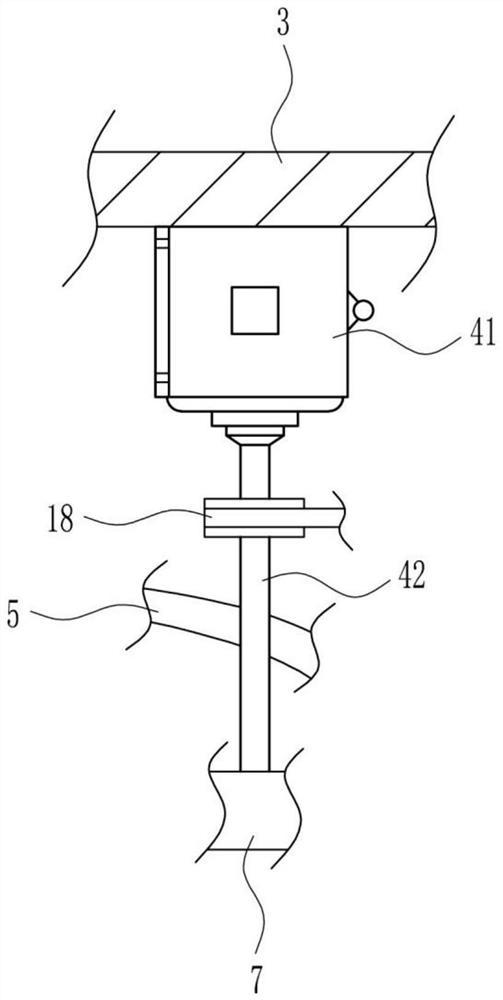

Batch-type uniform-speed discharging stirring device and construction method for self-leveling terrace

ActiveCN110453900ALift up movementEvenly mixedCement mixing apparatusFlooringElectric machineryEngineering

The invention discloses a batch-type uniform-speed discharging stirring device. The batch-type uniform-speed discharging stirring device comprises a kettle structure formed by assembling of a shell and an upper cover, the upper cover is provided with a stirring mechanism in a connected mode, a discharging hole is formed in the lower end of the shell in a penetrating mode, the stirring mechanism iscomposed of spiral fan blades connected to the periphery of a rotating shaft and used for introducing additives, the upper end of the rotating shaft is connected with a motor in a transmission mode,and a discharging mechanism opened in a mechanical and batch-type mode is further arranged at the lower end, of the periphery of the discharging hole, of the shell in a connected mode. A constructionmethod of a self-leveling terrace comprises the following steps that a base layer is checked, pulling-drawing detecting is conducted, and the base layer is cleaned; grinding, leveling by pushing and dust suction treatment are conducted; repairing treatment is conducted on gaps and hollowing parts; coating and painting of an interfacial agent are conducted, and line snapping and area division are conducted; mixed slurry is machined by using the device, and pumping construction is conducted after testing; and still standing and solidification, coating and painting of a protective agent, divisiondismantling and filling of joint mixture are conducted. The batch-type uniform-speed discharging stirring device can be matched with division-type construction to realize equal-amount batch-type material injection, and thus the structure problem of large-area construction is solved.

Owner:福建磊鑫(集团)有限公司

Medical waste crushing device with crushed materials easy to discharge

The invention discloses a medical waste crushing device with crushed materials easy to discharge. The medical waste crushing device comprises a shell; electric push rods are symmetrically arranged onthe two sides of the shell; threaded rods are arranged on the two sides in the shell; synchronous motors are arranged at the lower ends of the threaded rods; a lifting placement plate is arranged on the periphery of the threaded rods; a machining cavity is formed in the middle of the lifting placement plate; rotary shafts, transmission gears and rotary base plates are arranged on the lower parts of the front side wall and the rear side wall of the machining cavity; a rotary pipeline is arranged in the middle of an upper cover; crushing blades are arranged on the periphery of the rotary pipeline; a crushing motor is arranged on the upper right side of the upper cover; an air pump is connected to the upper end of the rotary pipeline through a rotary joint; a spray head is connected to the lower end of the rotary pipeline in an embedded mode; toothed plates are perpendicularly welded to the rear side of the bottom in the shell; and supporting bases are symmetrically welded to the two sides of the lower end of the shell. The medical waste crushing device has the advantages that the threaded rods can be driven to rotate through the synchronous motors, so that the machining cavity can becontrolled to ascend and descend, when the machining cavity ascends to the upper portion, crushing can be carried out, when the machining cavity descends to the bottom, the crushed materials can be discharged at the same time, and therefore the the crushed materials is convenient to collect, and the medical waste crushing device is convenient to use and efficient.

Owner:XUZHOU XINFA MACHINERY

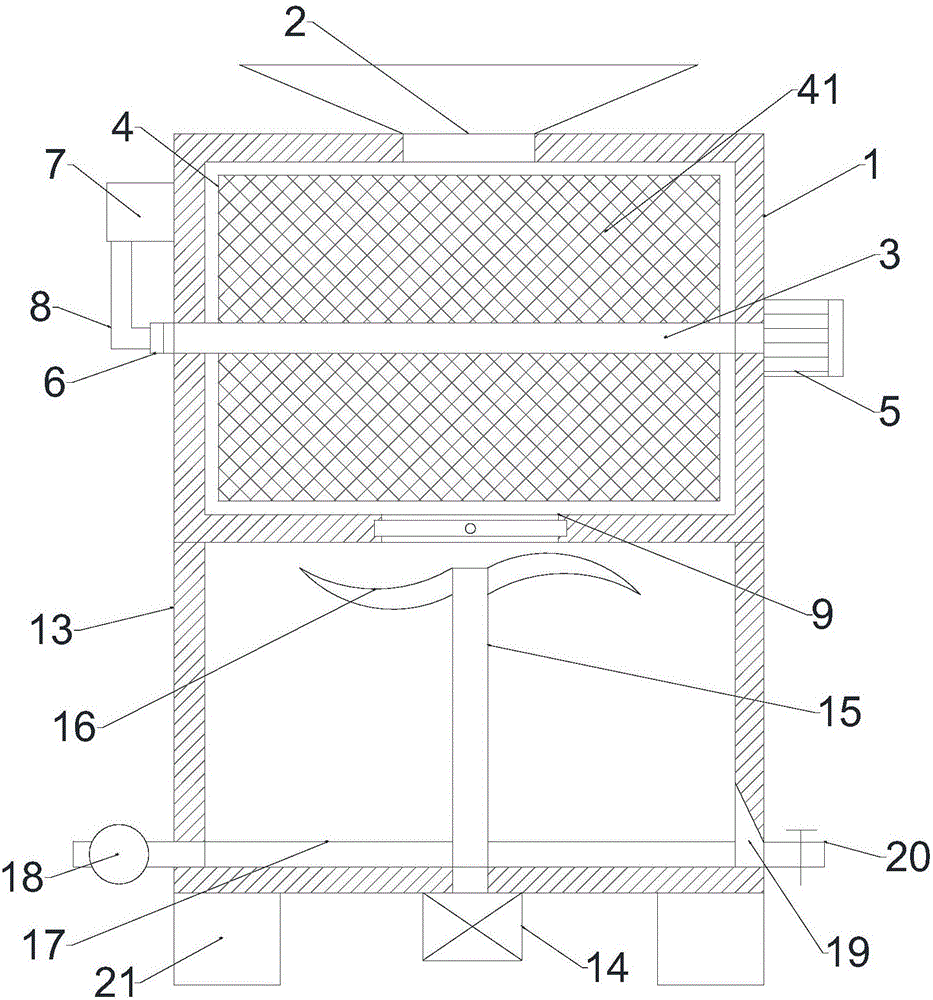

Low-temperature drying and crushing device for horseradish tree leaves

PendingCN107525379AEasy dischargeKeep dryDrying gas arrangementsDrying machines with non-progressive movementsCold airEngineering

The invention discloses a low-temperature drying and crushing device for horseradish tree leaves. The low-temperature drying and crushing device comprises a drying cavity and a crushing cavity; a first stirring shaft is arranged in the drying cavity; a first blade and a second blade are arranged in the first stirring shaft; ventilation holes are formed in the surface of the first stirring shaft; a rotary frame and a metal filter net are arranged on the periphery of the first stirring shaft; a sealing bearing is arranged on the left end of the first stirring shaft; a cold air fan is arranged on the left wall of the drying cavity; a material outlet, a slide chute, a slide baffle plate, a threaded rod and the crushing cavity are arranged on the lower end of the drying cavity; a second motor and a second stirring shaft are arranged on the lower end of the crushing cavity; a first crushing fan blade and a second crushing fan blade are arranged on the second stirring shaft; and an air blower is arranged on the left wall of the crushing cavity. According to the low-temperature drying and crushing device, horseradish tree leaves are driven to turn; cold air is injected into the first stirring shaft through the cold air fan, and exhausting is realized through the ventilation holes; low-temperature drying is efficiently finished; and materials are controlled to fall into the crushing cavity through the threaded rod and are subjected to multi-level crushing efficiently and thoroughly.

Owner:ZHENGZHOU UNIV

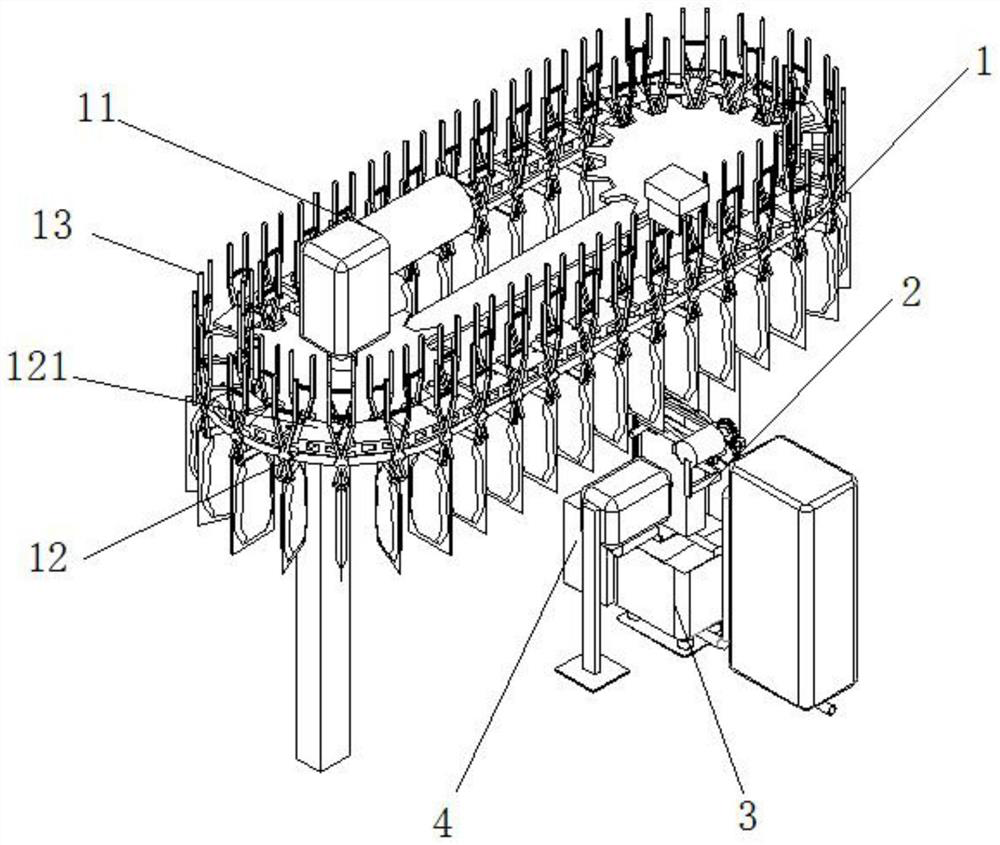

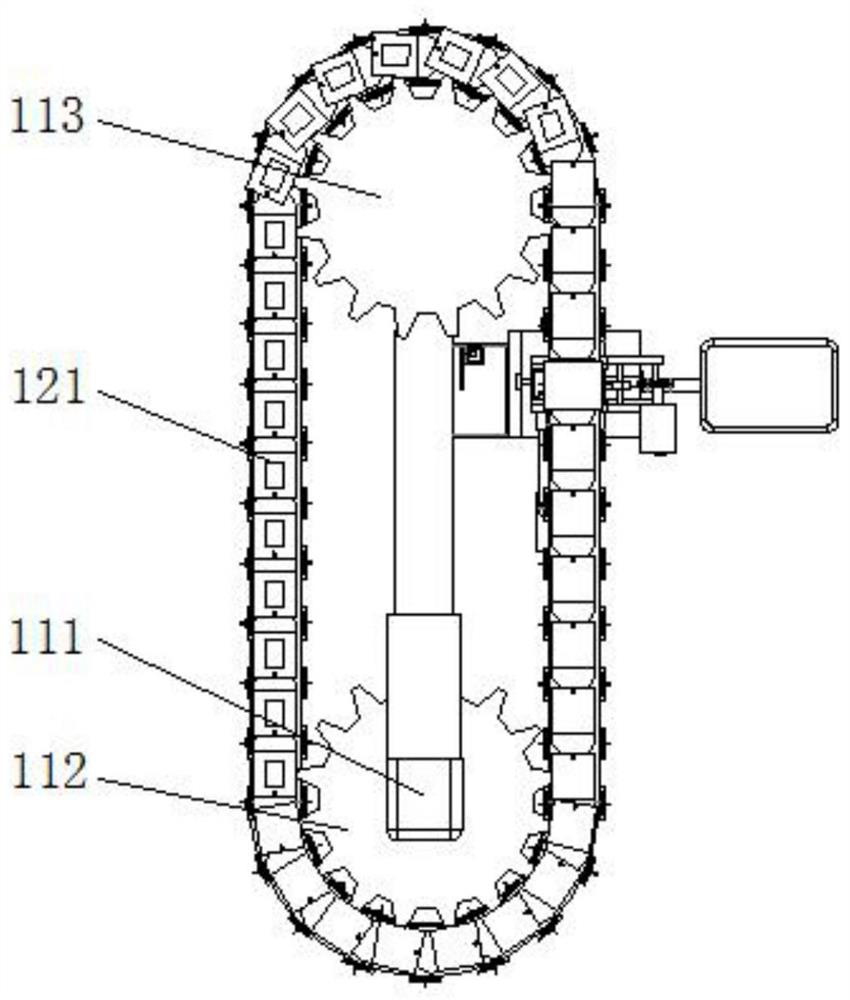

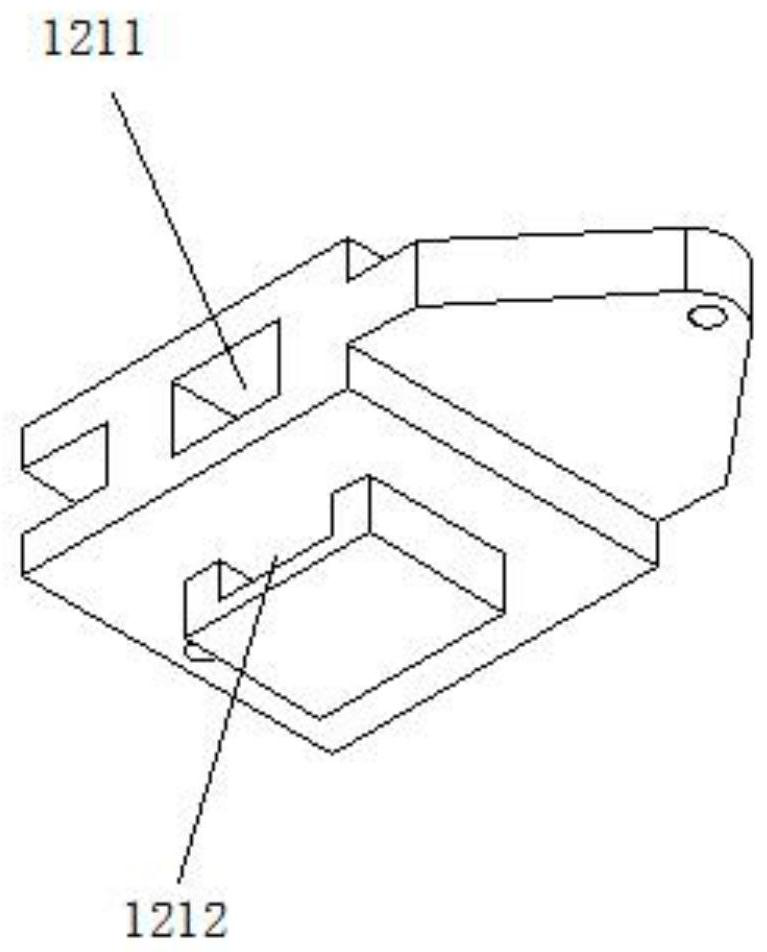

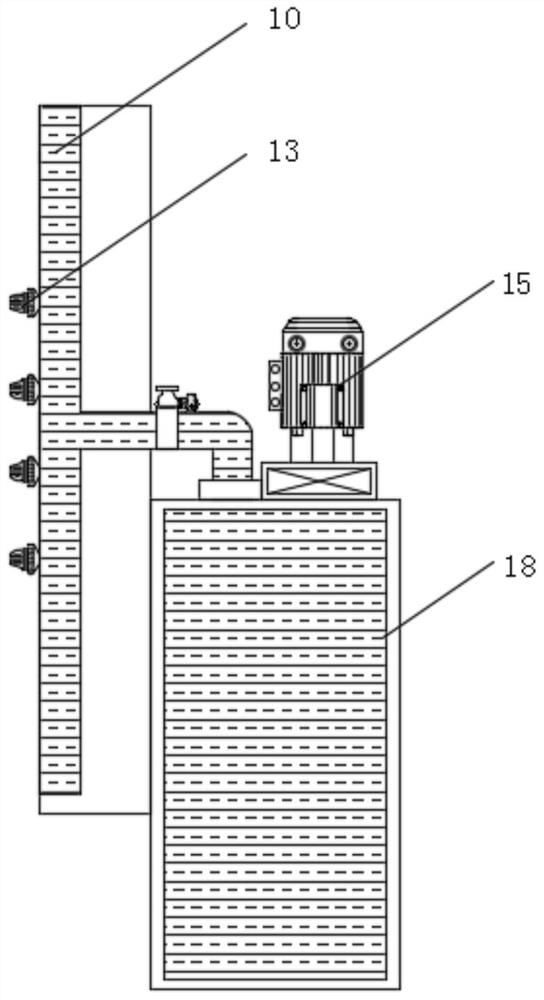

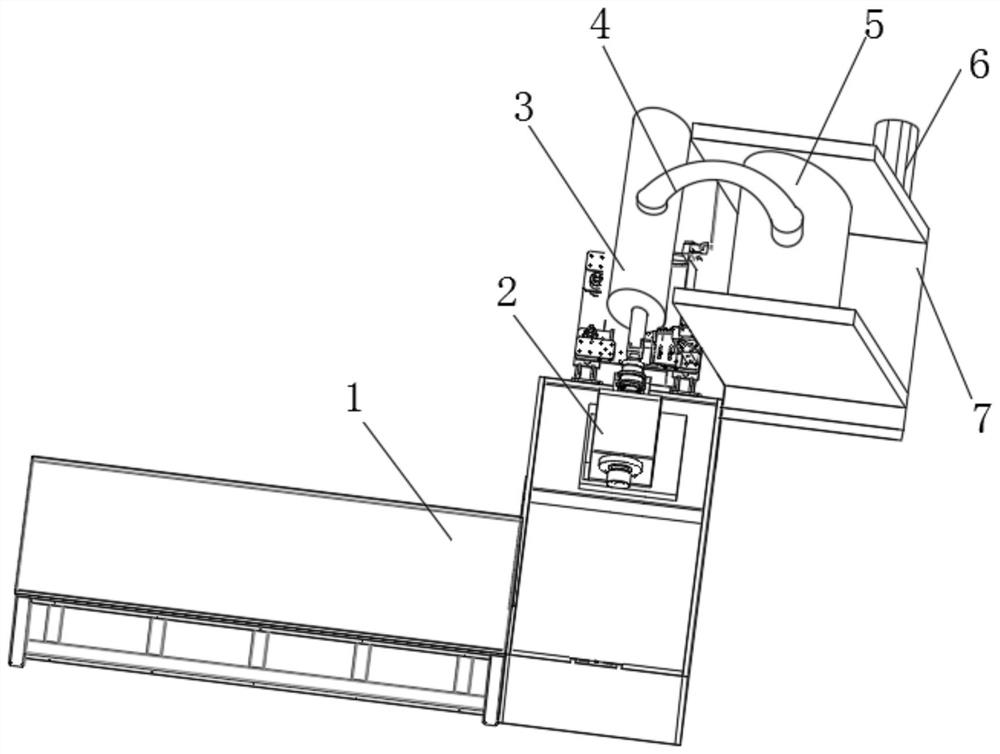

Automatic bag-opening, adding, dissolving and liquid-supplying system for bagged powder

The invention discloses an automatic bag-opening, adding, dissolving and liquid-supplying system for bagged powder. The automatic bag-opening, adding, dissolving and liquid-supplying system comprisesa temporary storage part, a discharging part and a liquid preparing barrel, wherein the temporary storage part comprises a driving mechanism, a hanging mechanism and a plurality of positioning clamp mechanisms; the hanging mechanism is formed by connecting a plurality of chain plates end to end and is in an oval track shape; and the discharging part comprises a rotary motor mounting bracket, a rotary motor, a loading box, a sealing clamp mechanism, a centering mechanism, a cutting mechanism, a bag locking push rod and a bag discharging push rod mechanism. The whole set of operation process ofpowder bag temporary storage, bag opening, feeding and empty bag recycling is completely automatic. Only manual participation is needed during bagging, so that the automation level of equipment is improved, and the dependence on personnel is reduced; meanwhile, discharging is thorough, material scattering is avoided, a bag opening is completely cut open in the bag opening process, elasticity is achieved in the discharging process, a powder bag is kept extruded, and thorough discharging is achieved; and after the bag is opened, the bag is sealed by the sealing clamp mechanism all the time, andthe liquid preparation barrel can ascend to be butted with the discharging part to avoid scattering.

Owner:SHANDONG WEIGAO HONGRUI MEDICAL TECH CO LTD

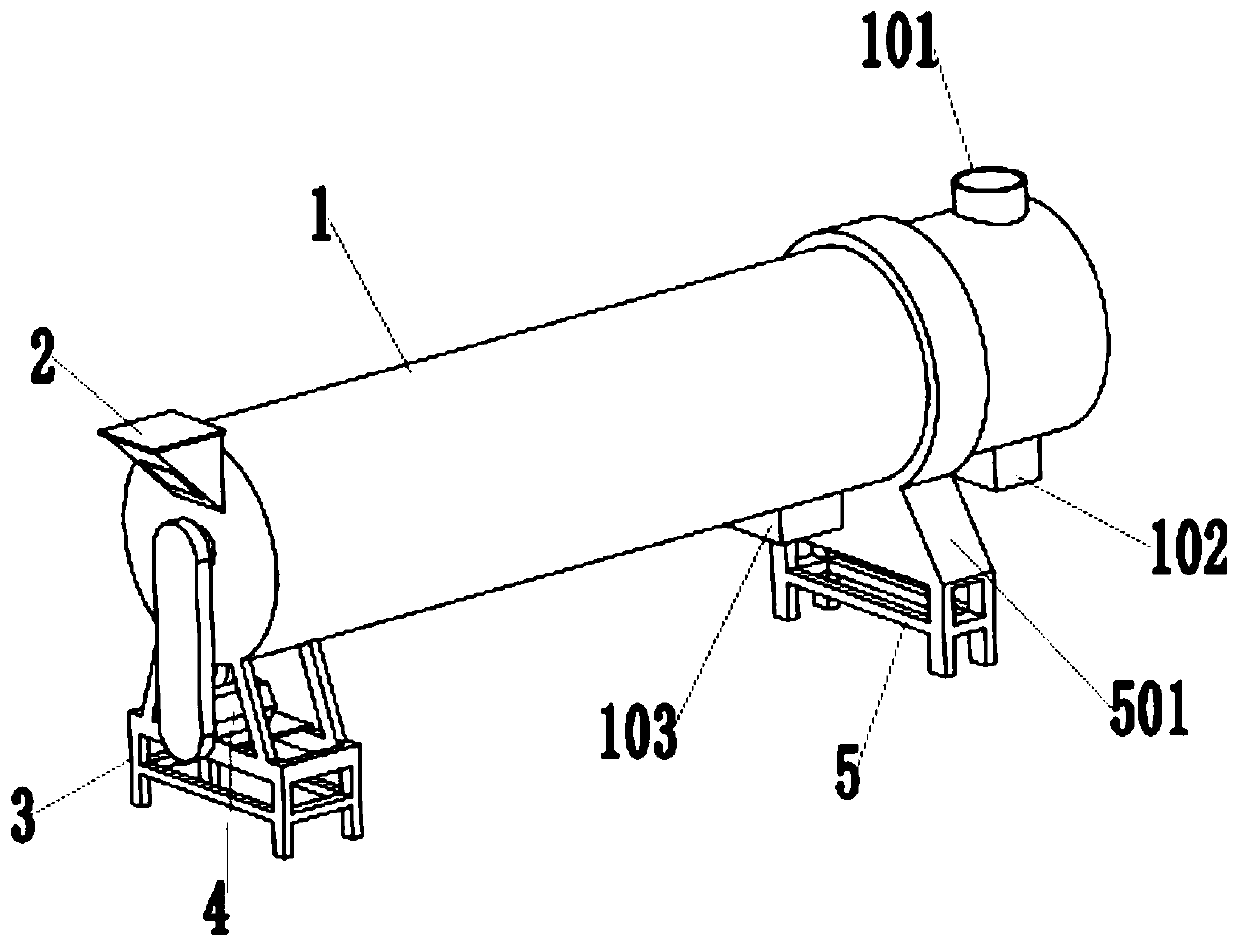

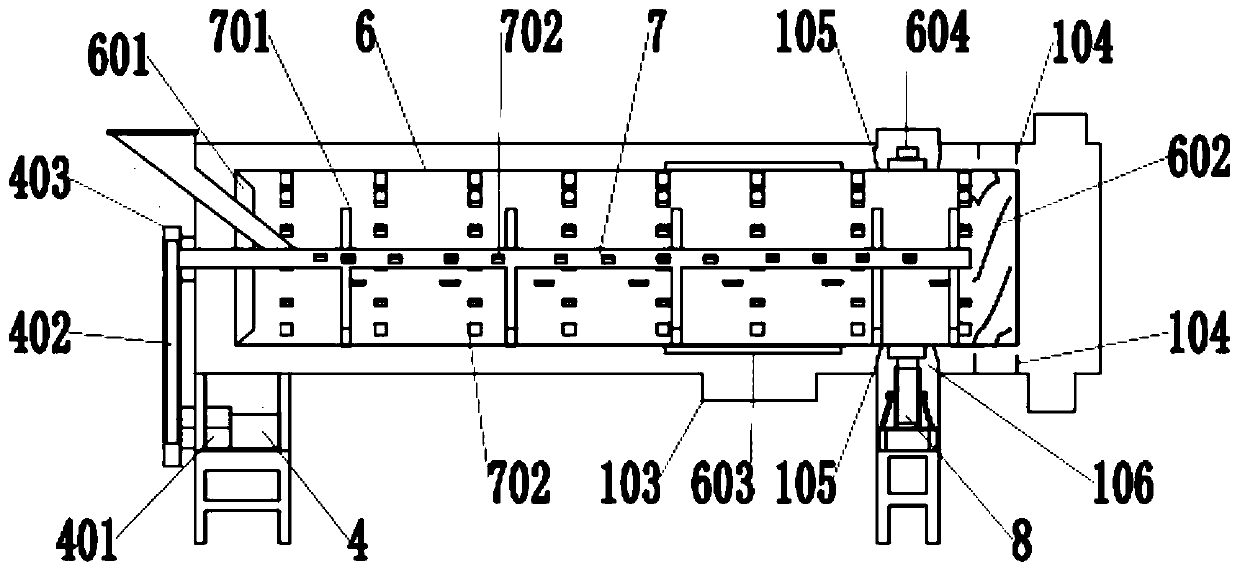

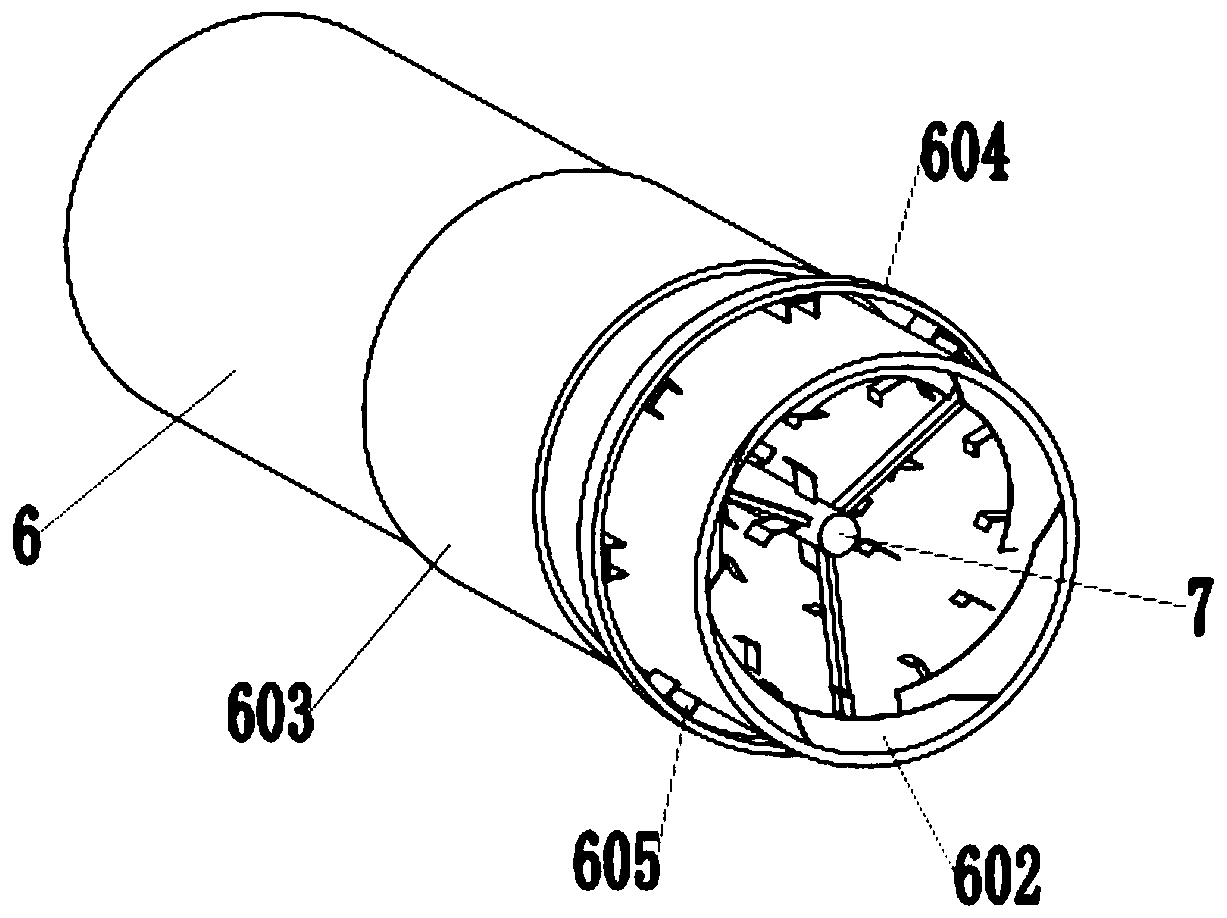

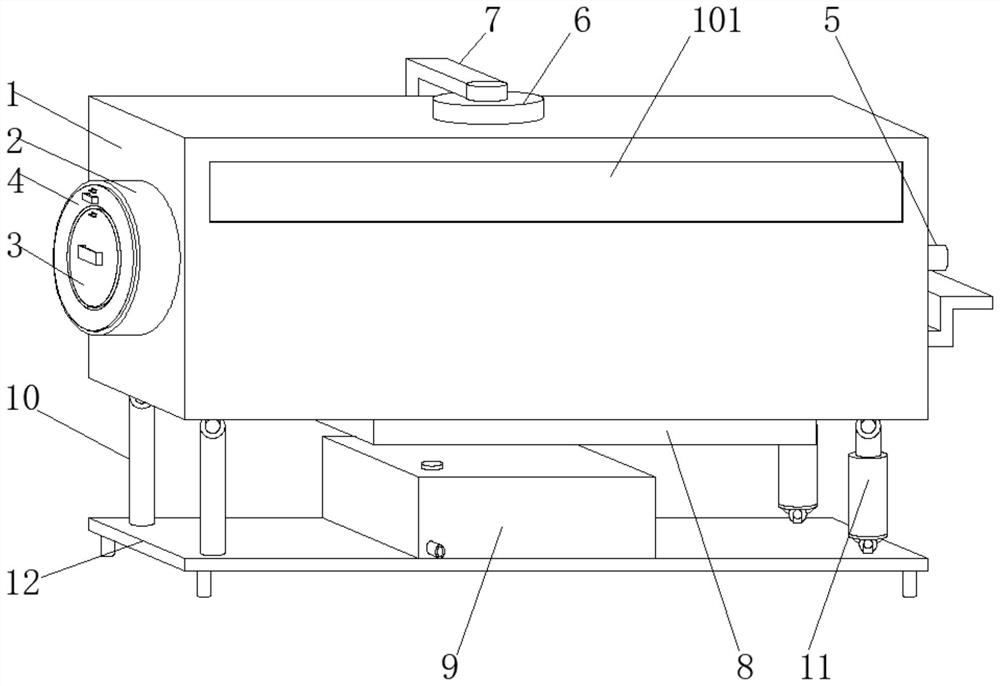

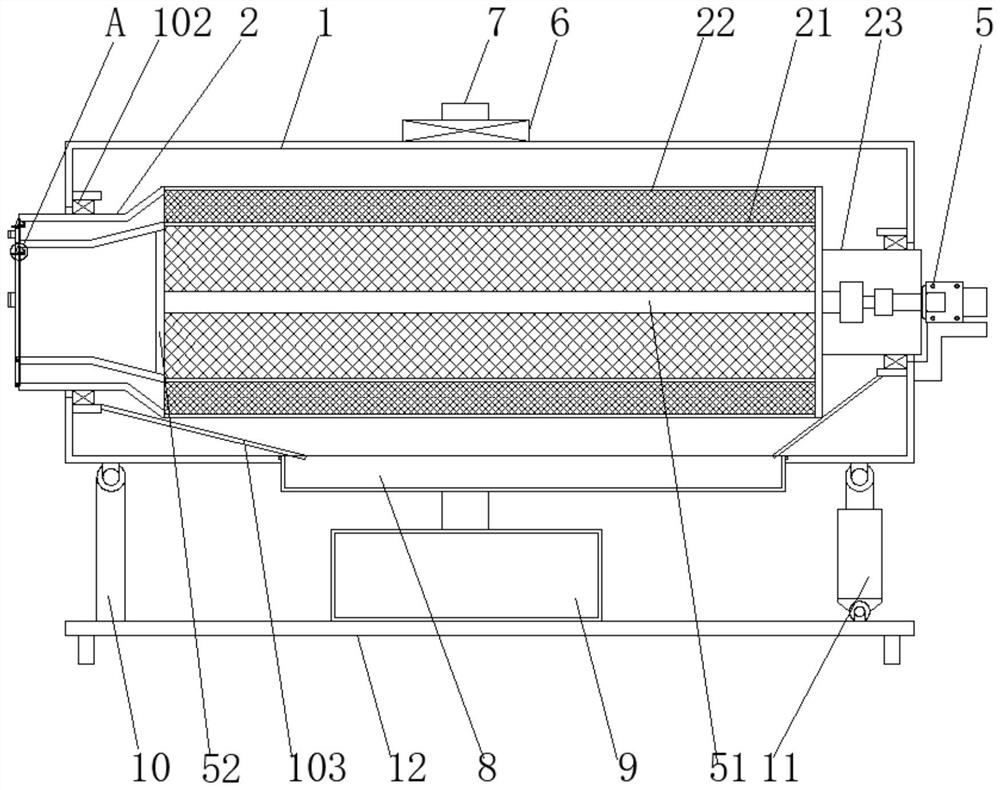

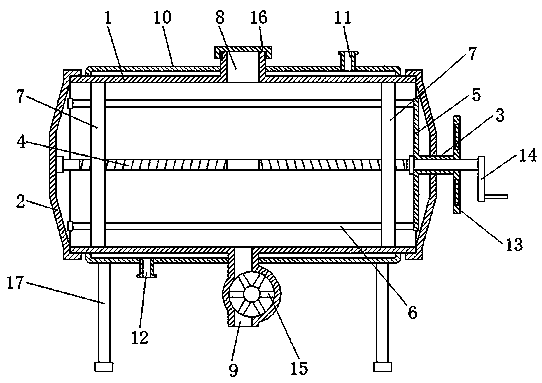

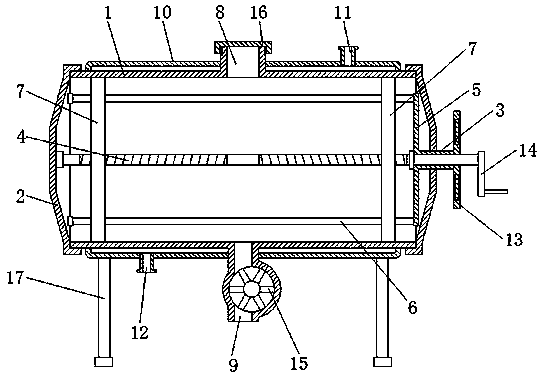

Energy-saving roller dryer

PendingCN110455051AIncrease profitImprove uniformityDrying gas arrangementsDrying chambers/containersEngineeringFire retardant

The invention discloses an energy-saving roller dryer which comprises an outer barrel, a motor, an inner barrel, a main shaft and a supporting barrel device. The inner barrel is arranged in the outerbarrel, a feeding box communicating with the inner barrel is arranged at one end of the outer barrel, a feeding baffle is arranged at the end, close to the feeding box, of the inner barrel, a discharging guide plate is arranged at the end, far away from the feeding box, of the inner barrel, a ventilation opening and a discharging opening are arranged at the other end of the outer barrel, a front support frame and a rear support frame are arranged at the lower end of the outer barrel, the motor is fixed on the front support frame, the main shaft is connected to the middle of the inner barrel, one end of the main shaft is arranged outside the outer barrel and connected with the motor through a chain, a sealing plate is arranged between the rear support frame and the outer barrel, the supporting barrel device is arranged at the upper end of the rear support frame, a supporting hole matched with the supporting barrel device is formed in the side wall of the outer barrel, a smooth ring matched with the supporting barrel device is formed in the outer wall of the inner barrel, the two ends of the smooth ring are provided with fire retardant plates connected with the inner wall of the outer barrel, and the side wall of the outer barrel is provided with a furnace opening.

Owner:济南宇川环保设备有限公司

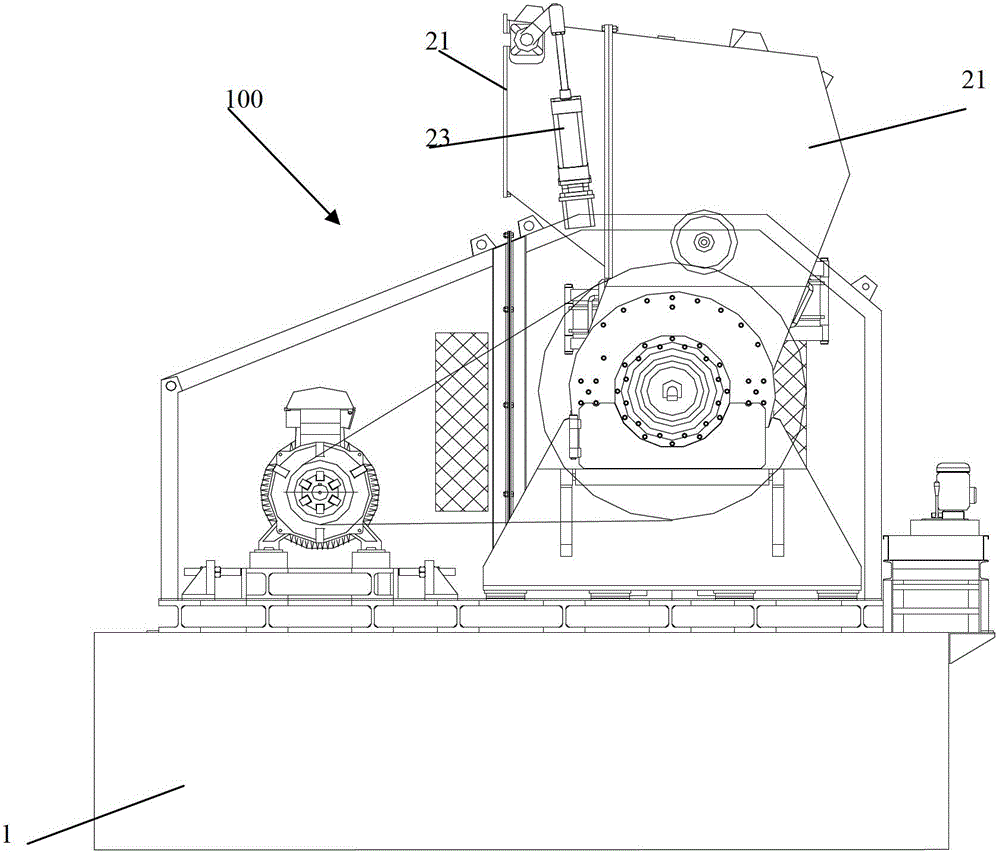

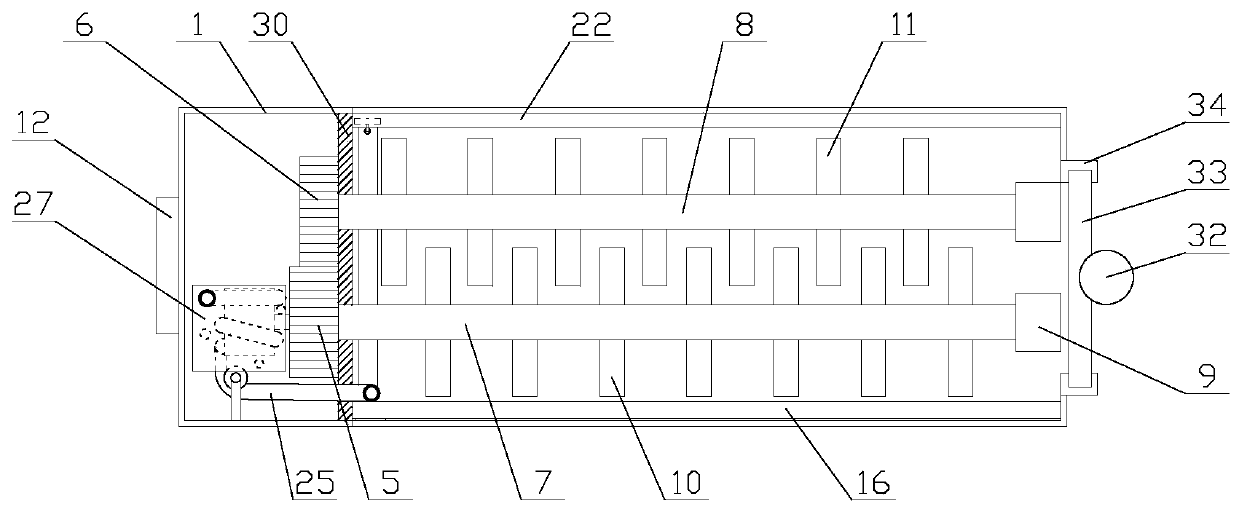

Rubber brick grinding production line

The invention discloses a rubber brick grinding production line which comprises a chopping machine, a mixing machine and a conveying belt arranged between the chopping machine and the mixing machine. The chopping machine comprises a feeding hopper, a chopping device, a discharging device and a parting agent spraying device capable of respectively spraying a parting agent into the feeding hopper and the discharging device. The mixing machine comprises a rack and two mixing tanks arranged on the rack and driven to rotate along a horizontal shaft. A two-way delivery belt is arranged at a feeding hopper position of the two mixing tanks, receives rubber particles conveyed from the conveying belt, and is controlled to feed one mixing tank feeding head. The chopping step of the rubber brick grinding production line is implemented by a fixed cutter and a movable cutter for cutting in cooperation with sieving of a sieve, the rubber brick grinding production line can effectively chop large rubber blocks and ensure that chopped rubber particles are even and uniformed in granularity. The two mixing tanks are arranged in parallel, the two-way delivery belt is adopted to feed materials in one of the mixing tanks, and the two mixing tanks run alternately, thereby guaranteeing stable running of the whole production line.

Owner:TIANJIN SAIXIANG TECH

Treatment process for regenerated rubber material preparation raw materials

InactiveCN111842316AEasy to cleanAvoid stickingPlastic recyclingCleaning using liquidsRubber materialPolymer science

The invention relates to a treatment process for regenerated rubber material preparation raw materials. A following pretreatment machine is adopted for the treatment process for the regenerated rubbermaterial preparation raw materials. The pretreatment machine comprises a shell and an unloading device arranged at the bottom of the shell. The shell is of a cylindrical structure with the closed bottom and the open top. A stirring device is arranged in the shell, and an anti-floating device is arranged above the stirring device. As the anti-floating device is arranged, an annular filter net is clamped in the middle of the shell, rubber fragments are pressed into water through the annular filter net, meanwhile, in cooperation with stirring blades, the rubber fragments and the water are stirred, and the rubber fragments are more efficiently washed. The unloading device is arranged at the bottom of the shell, the washed rubber fragments are discharged along with water currents, under the guide effect of a guide ring, the rubber fragments and the water are discharged from the gap between the guide ring and a circular ring, compared with the manner that the rubber fragments are dischargedafter the water is discharged, the rubber fragments are prevented from adhering into the shell, and discharging is safer.

Owner:赵虎

Round screen drum with dustproof effect for rice primary processing

InactiveCN114042619AAvoid scatterReduce environmental pollutionSievingScreeningAgricultural engineeringElectric machinery

The invention discloses a round screen drum with the dustproof effect for rice primary processing, which comprises a shell, wherein a drum screen is installed in the shell, a first-stage sealing cover is hinged to the middle position of a left end opening of the drum screen, and a second-stage sealing cover is hinged to the outer side of the first-stage sealing cover; a driving motor connected to the right end of the shell, wherein an exhaust fan is installed on the top of the shell, an air pipe is connected to the rear side of the exhaust fan, and a particle dust collecting box is slidably connected to the lower portion of the shell; and a dust collection water tank which is arranged below the particle dust collecting box, wherein vertical rods are hinged to the front end and the rear end of the left side of the shell, and a bottom frame is fixed to the lower ends of the vertical rods. According to the round screen drum for rice primary processing, the whole screening mechanism is arranged in the shell, meanwhile, the exhaust fan is arranged to collect dust generated by screening, the problem that dust is scattered all around due to direct exposure of the screen is avoided, unified collection and treatment are facilitated, and the problem that the dust pollutes the environment is effectively solved.

Owner:湖南米米梦工场科技股份有限公司

Material conveying device, kitchen storage tool and cooking appliance

The invention provides a material conveying device, a kitchen storage tool and a cooking appliance. The material conveying device comprises a transition cavity and a blower device, and the transition cavity is provided with a feeding opening for materials to enter, an air inlet for airflow to enter and a discharging opening for the materials to flow out of; the blower device is connected with the air inlet and used for blowing air into the transition cavity. According to the material conveying device, wind power is utilized to drive the materials in the transition cavity to be discharged to the discharging opening and further drive the materials to be conveyed to receiving devices such as cooking utensils of the cooking appliance. Compared with the usage of hydraulic conveying in the prior art, dry materials are conveyed, so that the problem of material residues caused when materials are attached to the inner wall of a pipeline through the adoption of water for conveying is solved; compared with the usage of gravity falling conveying in the prior art, during conveying by wind power, the gravity of the materials can be overcome, and the materials can be conveyed and lifted, so that the material conveying device can be applied to conveying occasions with different demands.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

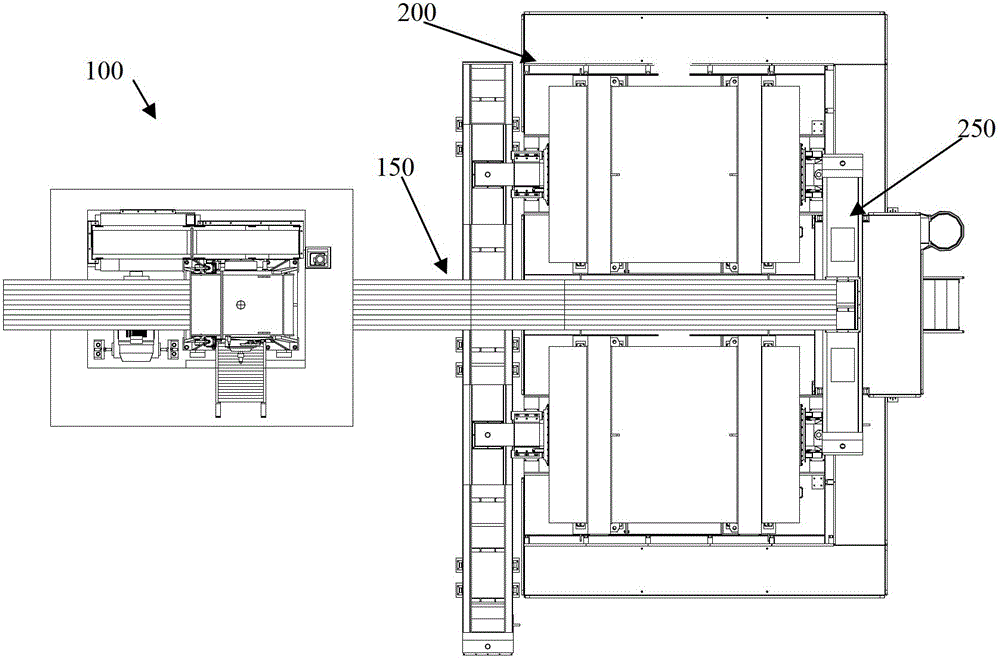

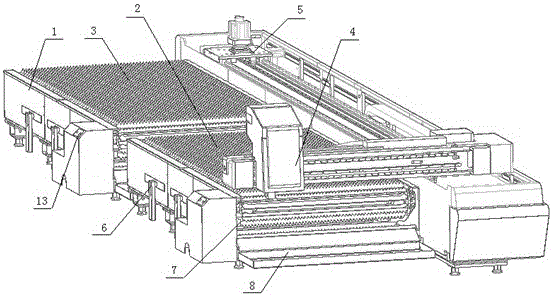

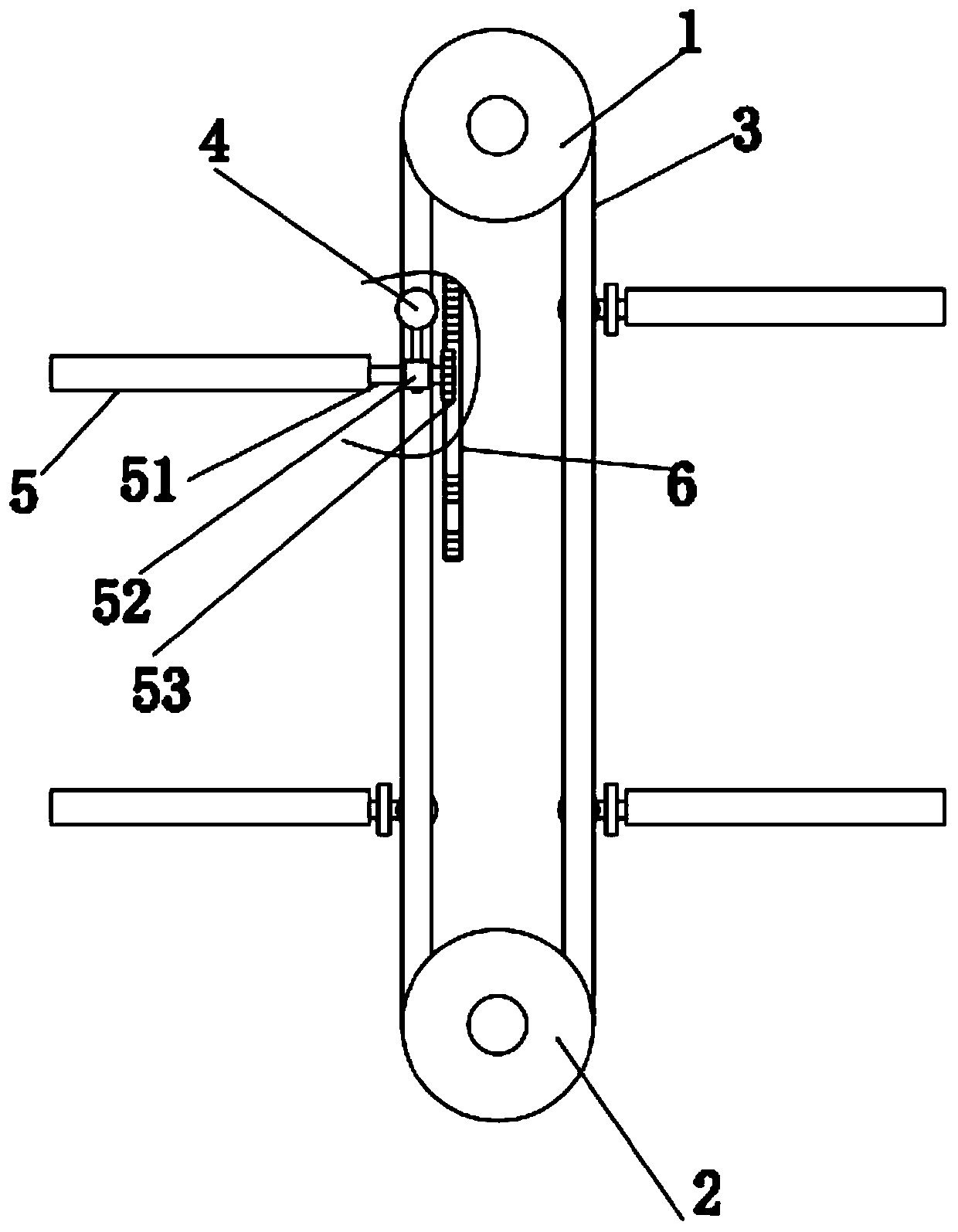

Rotary dual-workbench cantilever type laser cutting machine

InactiveCN105817772AImprove efficiencyFast switching speedLaser beam welding apparatusLaser cuttingEngineering

The invention provides a rotary double-table cantilever laser cutting machine, which includes a frame, a workbench 1, a workbench 2, a laser cutting assembly, a host for longitudinally moving the laser cutting assembly, and workbench 1 and workbench 2. The same and all adopt rotary workbenches. Workbench 1 includes motor, driving roller, driven roller and chain plate conveyor belt. The chain plate conveyor belt surrounds the driving roller and driven roller. The driving roller is connected to the rotating shaft of the motor. The limit switch is connected in series with the motor and power supply in sequence. Side storage boxes are respectively provided on the sides of workbench 1 and workbench 2, and end storage boxes are respectively provided at the ends of workbench 1 and workbench 2. Not only can materials be discharged to the side, It can also discharge to the end face, the discharge is fast and complete, saving time and effort, and flexible application.

Owner:SUZHOU TIANHONG LASER

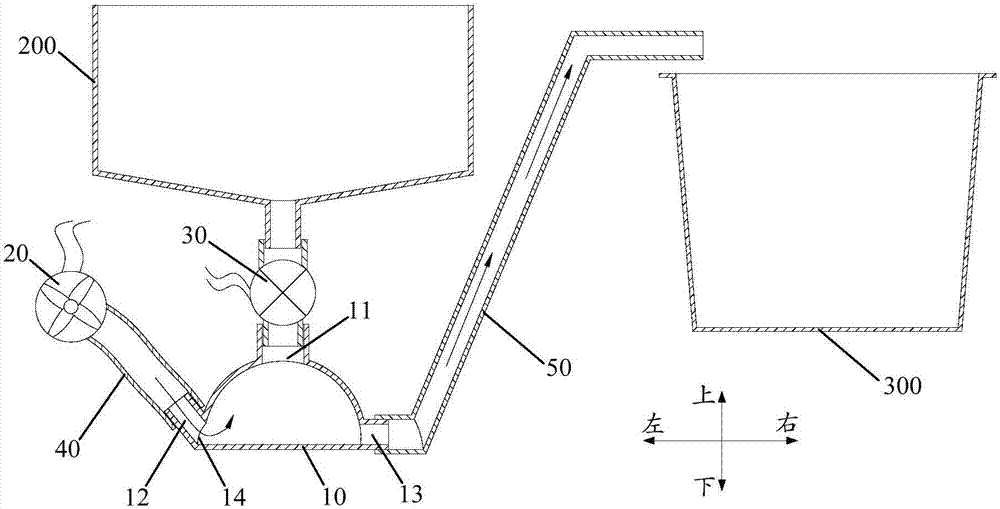

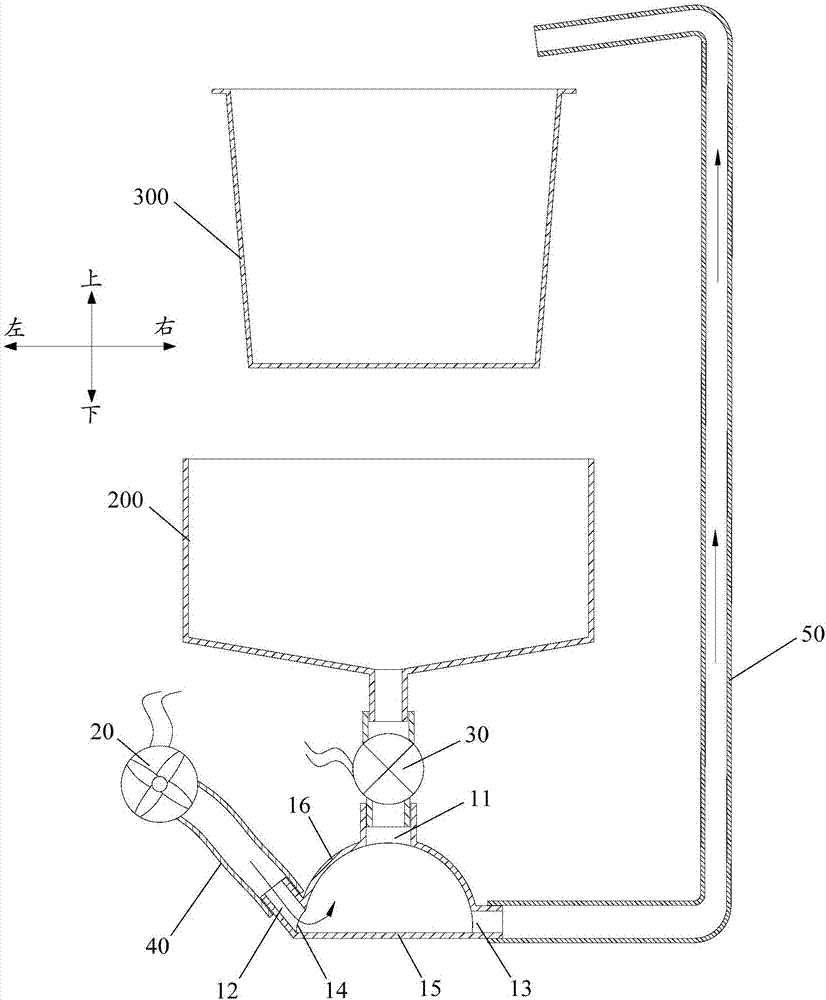

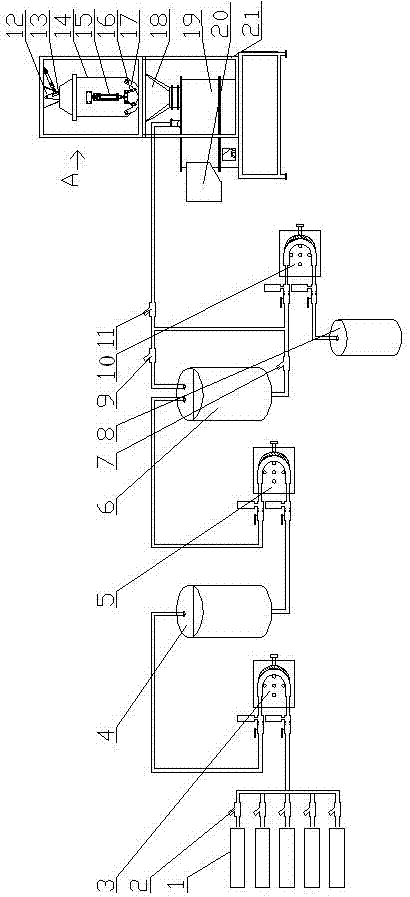

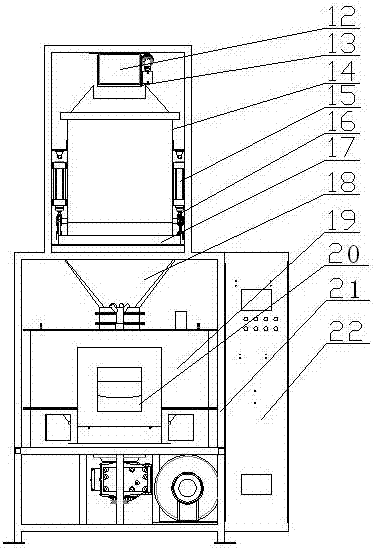

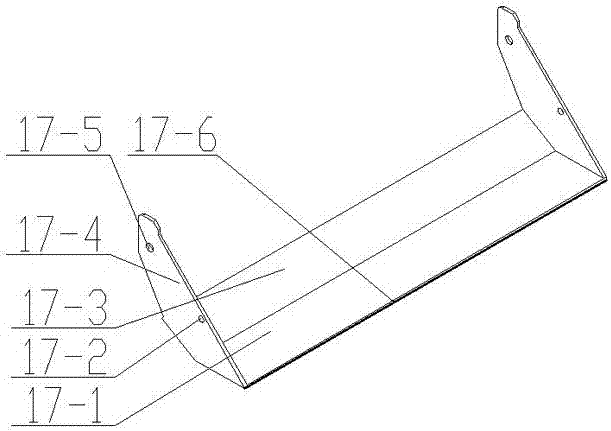

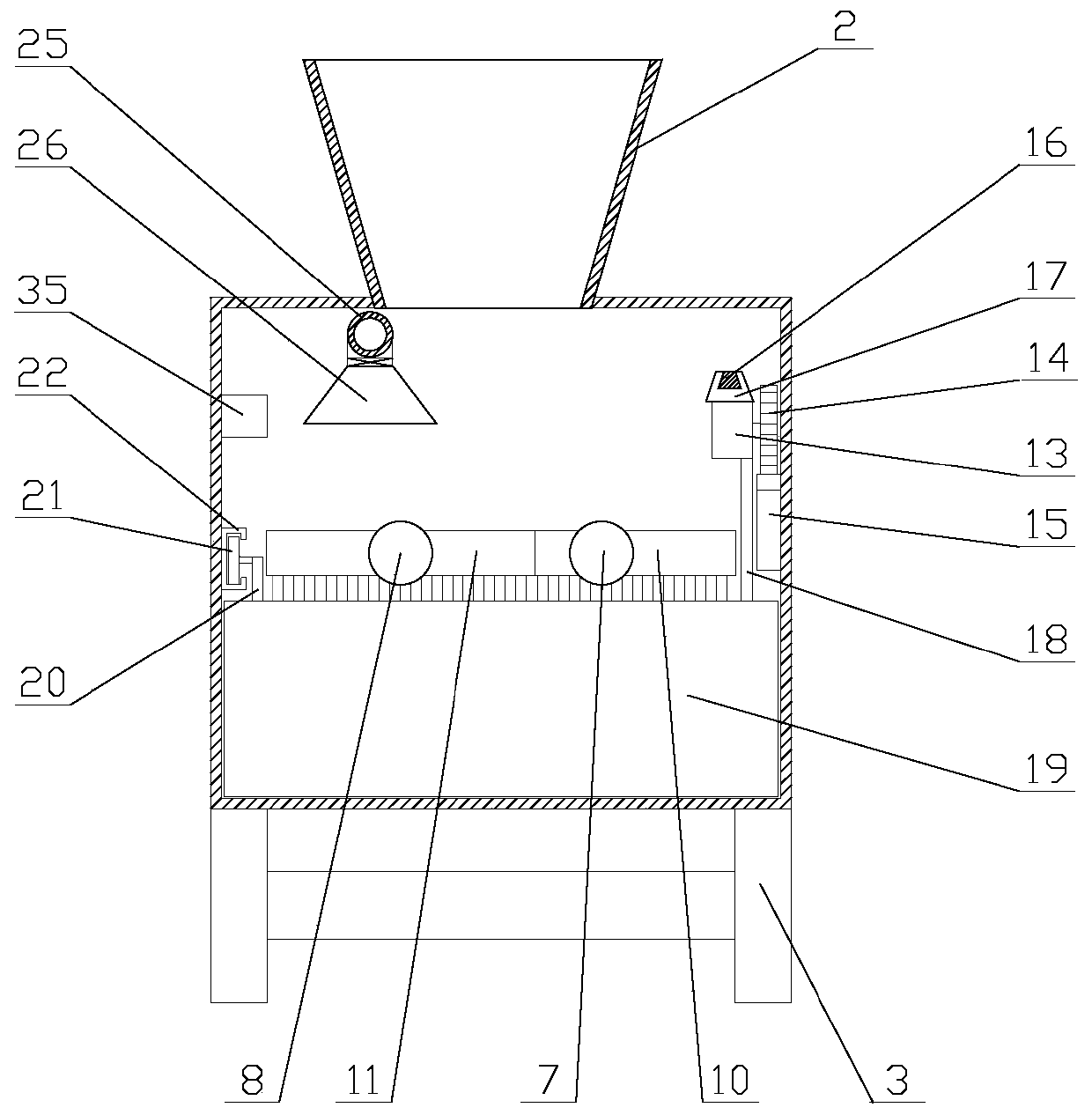

Batch continuous coating control method and coating machine with premixing function of seed coating agent

ActiveCN104855002BAvoid jammingAvoid breakingSeed coating/dressingAgricultural engineeringBatch method

The invention discloses a batch continuous seed coating machine with the function of seed coating agent premixing, comprising a seed coating agent premixing device, a metering hopper, a two-way feeding funnel, a coating chamber, a coating frame and a discharge port; The seed coating agent premixing device transports the formulated seed coating agent to the coating room through pipelines, and the coating room is fixed on the coating frame; a two-way feeding funnel is arranged above the coating room; A bidirectional feeding funnel is installed above the coating chamber; a metering hopper is installed above the bidirectional feeding funnel; a feeding hopper is arranged above the metering hopper; a discharge port is arranged on one side of the coating chamber. The invention also discloses a batch continuous coating control method with the premixing function of the seed coating agent. The present invention is a batch continuous seed coating machine with a seed coating agent premixing device, which is simple in structure, practical and convenient, realizes simultaneous delivery of seeds and agents, synchronous contact and full mixing, and precisely controls the uniformity of feeding and drug supply , The seed coating film is uniform.

Owner:HUNAN LIBEN SEED TECH

Pigment production device

InactiveCN109200930AFully grind and disperseImprove qualityTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention discloses a pigment production device, comprising a device body, a first cavity arranged in the device body, and a second cavity arranged in the device body, wherein the top wall of thefirst cavity is internally provided with a third cavity having a downward opening; an inner ring gear is fixedly mounted in the circumferential wall of the third cavity; a first motor is fixedly mounted in the top wall of the third cavity; the downwardly-extending tail end of the output shaft of the first motor is fixedly provided with a first gear; a rotating disk is rotatably mounted in the first cavity; and a first rotating shaft extending upward and downward is rotatably mounted in the rotating disk. The device of the invention is simple in structure and convenient to operate; the same power source is adopted to drive the feeding and discharging of pigment; cooperation between stirring and grinding functions is realized during switching, and equipment is simplified; a scraping plate isused for scraping off materials adhered onto a wall during stirring and discharging, so stirring and mixing are more sufficient, and discharging is more thorough; and various procedures work cooperate with each without influencing each other, so the practical performance of the device is improved.

Owner:绍兴初汇纺织有限公司

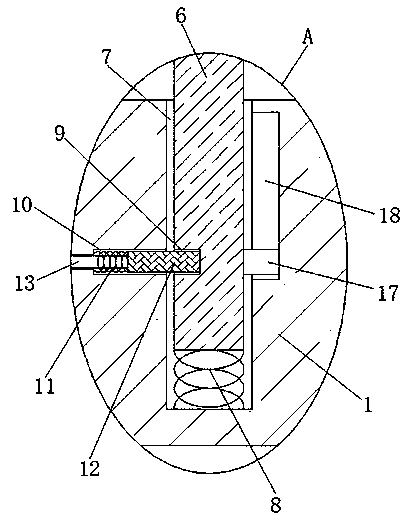

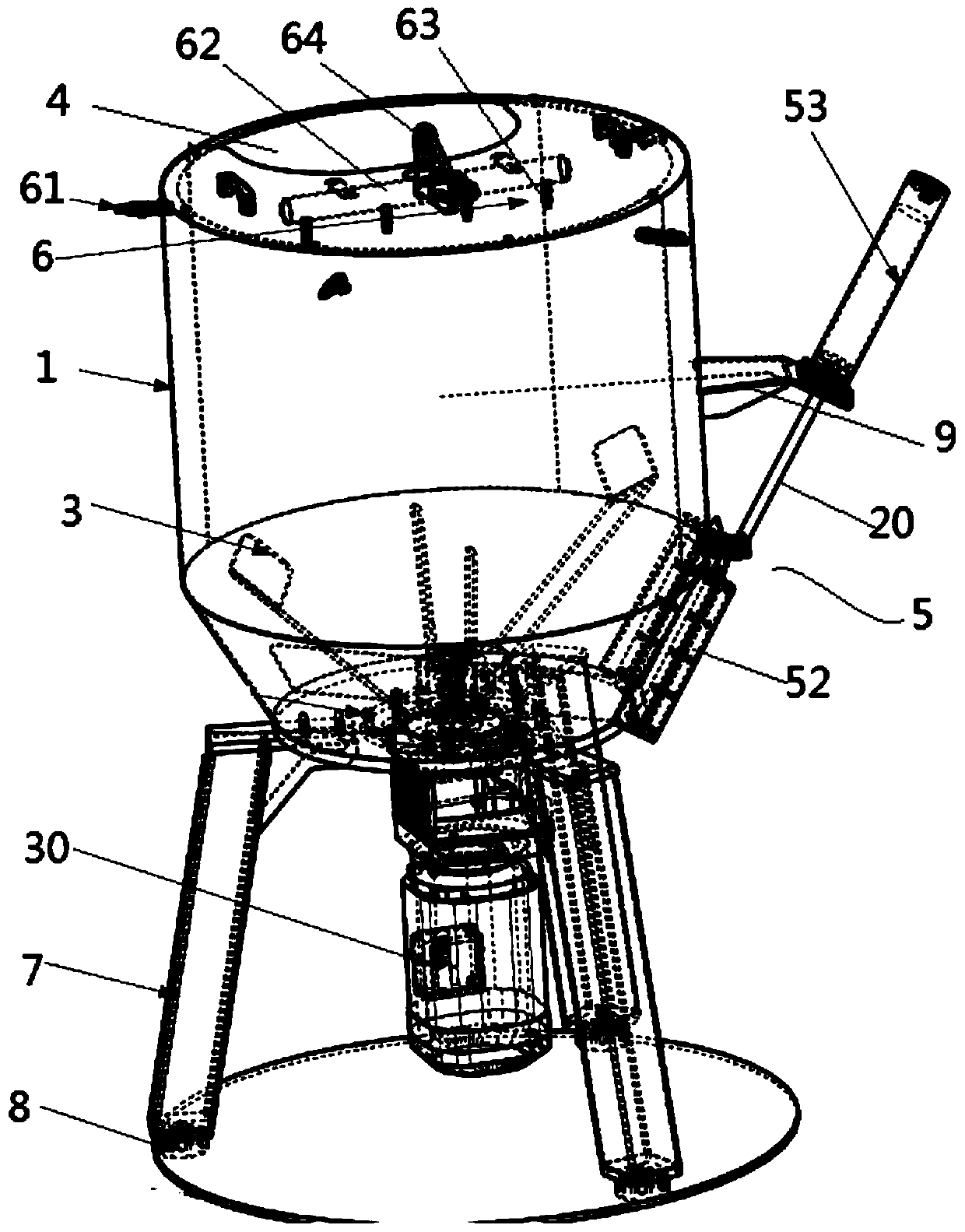

Food emulsifier storage device

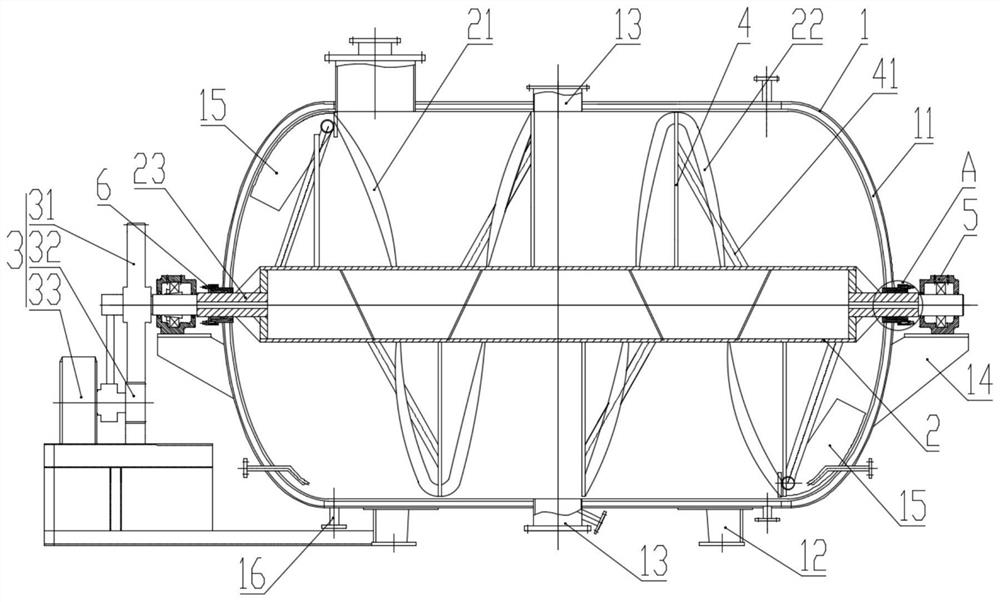

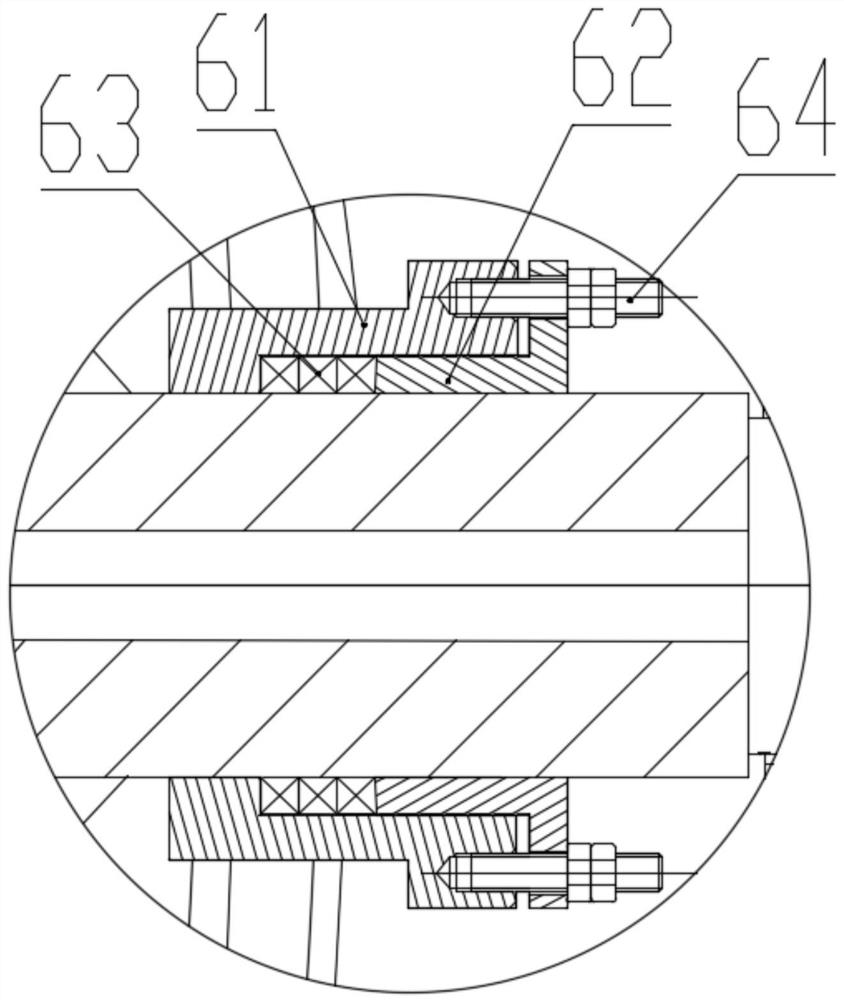

ActiveCN110758929AEfficient NestingComplete nestingRotary stirring mixersLarge containersFood safetyEngineering

The invention discloses a food emulsifier storage device, and relates to the technical field of food safety. The food emulsifier storage device comprises a tank body, wherein end covers are fixed at two ends of the tank body; a sleeve rotationally penetrates through the center of one end cover; a screw rod shaft is rotationally matched with the inner wall of the sleeve; a turntable is fixed at oneend, positioned inside the tank body, of the sleeve; a plurality of stirring rods are fixed on the end surface of the turntable; two piston plates are glidingly matched with the surface of each stirring rod; two sections of screw threads with opposite rotating directions are arranged on the surface of the screw rod shaft; the two piston plates are respectively matched with the two sections of screw thread sections of the screw rod shaft through screw threads. The emulsifier can be uniformly stirred and mixed through the sleeve, the turntable and the stirring rods; the solidification is prevented; the screw rod shaft in coaxial design can drive the piston plates to slide along the stirring rods for opposite extrusion discharging, so that the emulsifier can be efficiently and completely discharged; the problem that the complete discharging cannot be realized due to the lack of a stirring function or the arrangement of a stirrer of the conventional storage device is solved; and the sanitation safety of the device is improved.

Owner:烟台虹月电子商务有限公司

Floating objectfishing device for river regulation

The invention discloses a floating objectfishing device for river regulation. Thefloating objectfishing device comprises a vertically arranged first chain wheel, a vertically arranged second chain wheel and transmission chains connecting the two chain wheels in a transmission mode, and the transmission chains are connected and fixed through connecting columns; the connecting columnsare provided with material lifting parts for fishing floating objects in water; thematerial lifting partsinclude hanging rods disposed at the lower ends of the connecting columns, fixing sleeves and connecting rods rotatably connected with the fixing sleeves are arranged atthe lower ends of the hanging rods, and the inner walls of the fixing sleeves are connected and fixed to the connecting rods through reset torsion springs; and one ends of the connecting rodsare connected withmaterial collecting plates for carrying materials. According to thefloating objectfishing device, the disadvantages of an existing device is overcome, by designing an overturning unloading method for unloading, theoverturning-type collecting method is more thorough in discharging, preliminary solid-liquid separation can be performed, so that the disadvantages of incomplete discharge in the existing device is avoided, and practicability is high.

Owner:YIKANG TECH CO LTD

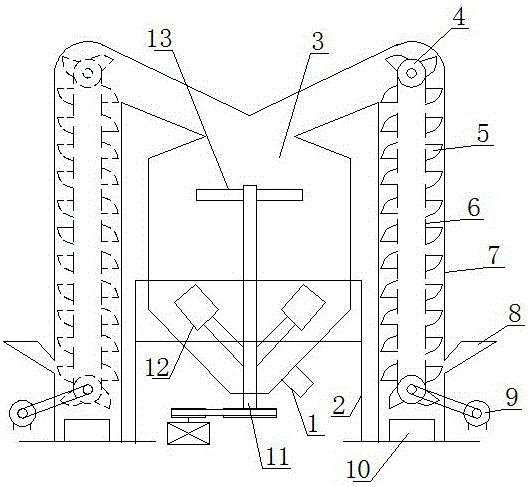

Efficient mixing machine

PendingCN106040051AWell mixedImprove qualityRotary stirring mixersTransportation and packagingRivetEngineering

The invention belongs to the field of mixing processing and particularly relates to an efficient mixing machine for mixing powdery particle materials. The efficient mixing machine is characterized by comprising a mixing barrel, a left elevating rack and a right elevating rack. The mixing barrel is of an inverted-cone-shaped circular barrel structure; a rotary shaft is arranged in the center of the mixing barrel, a dispersing wheel is mounted at the top of the rotary shaft, and the dispersing wheel is provided with arc-shaped grooves of an outward-diffusion structure; a left rivet-shaped shifting tooth inclining 45 degrees and a right rivet-shaped shifting tooth inclining 45 degrees are arranged below the rotary shaft; a discharge outlet is formed in the conical face of the mixing barrel; each elevating rack is of a vertical rectangular tube structure, and a vertical conveying belt is mounted in the elevating rack. The efficient mixing machine has the advantages that the mixing machine is fast in feeding, safe, sanitary, convenient to operate, simple, low in cost, thorough in discharge and capable of satisfying the requirements of large-scale automatic production; to-be-mixed substances are evenly mixed in air, and high mixing quality is achieved.

Owner:SHANDONG SHUANGHE MACHINERY MFG CO LTD

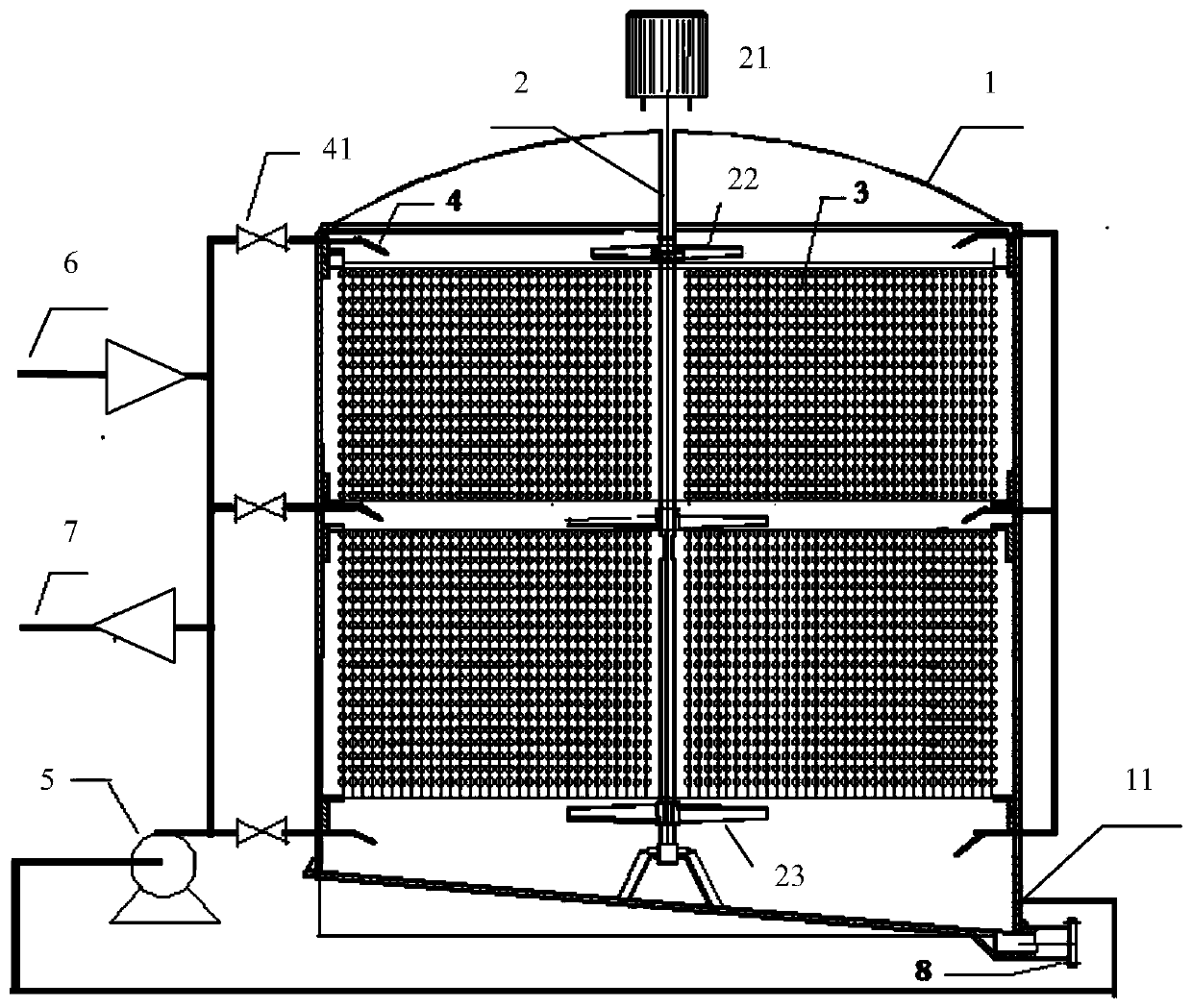

Novel fermentation device and application thereof for immobilized yeast fermentation preparation of ethyl alcohol

PendingCN110117526AEasy to makeLow costBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholEngineering

The invention discloses a novel fermentation device which comprises a fermentation tank body, a vertical stirring device, an immobilized carrier and a circulation pipeline for feeding and dischargingof the fermentation tank body; a plurality of feeding nozzles are annularly arranged at the side wall of the fermentation tank body for feeding of the fermentation tank body; a discharging outlet is formed in the bottom of the fermentation tank body for discharging of the fermentation tank body; a circulation pump is arranged between the discharging outlet and the feeding nozzles and connected through the circulation pipeline to form a circulation loop, materials inside the fermentation tank body enter the circulation pipeline through the discharging outlet, under the drive of the circulationpump, and the materials enter the fermentation tank body through the feeding nozzles for circulation fermentation; the circulation pipeline is further provided with a feeding pipe and a discharging pipe, and the feeding pipe and the discharging pipe are each provided with a one-way valve; a fermented culture medium is guided into the circulation pipeline through the feeding pipe and enters the fermentation tank body through the feeding nozzles; a fermented product passes through the circulation pipeline and is discharged through the discharging pipe. The invention further provides applicationof the fermentation device for immobilized yeast fermentation preparation of ethyl alcohol.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD +1

Feeding device for sludge treatment

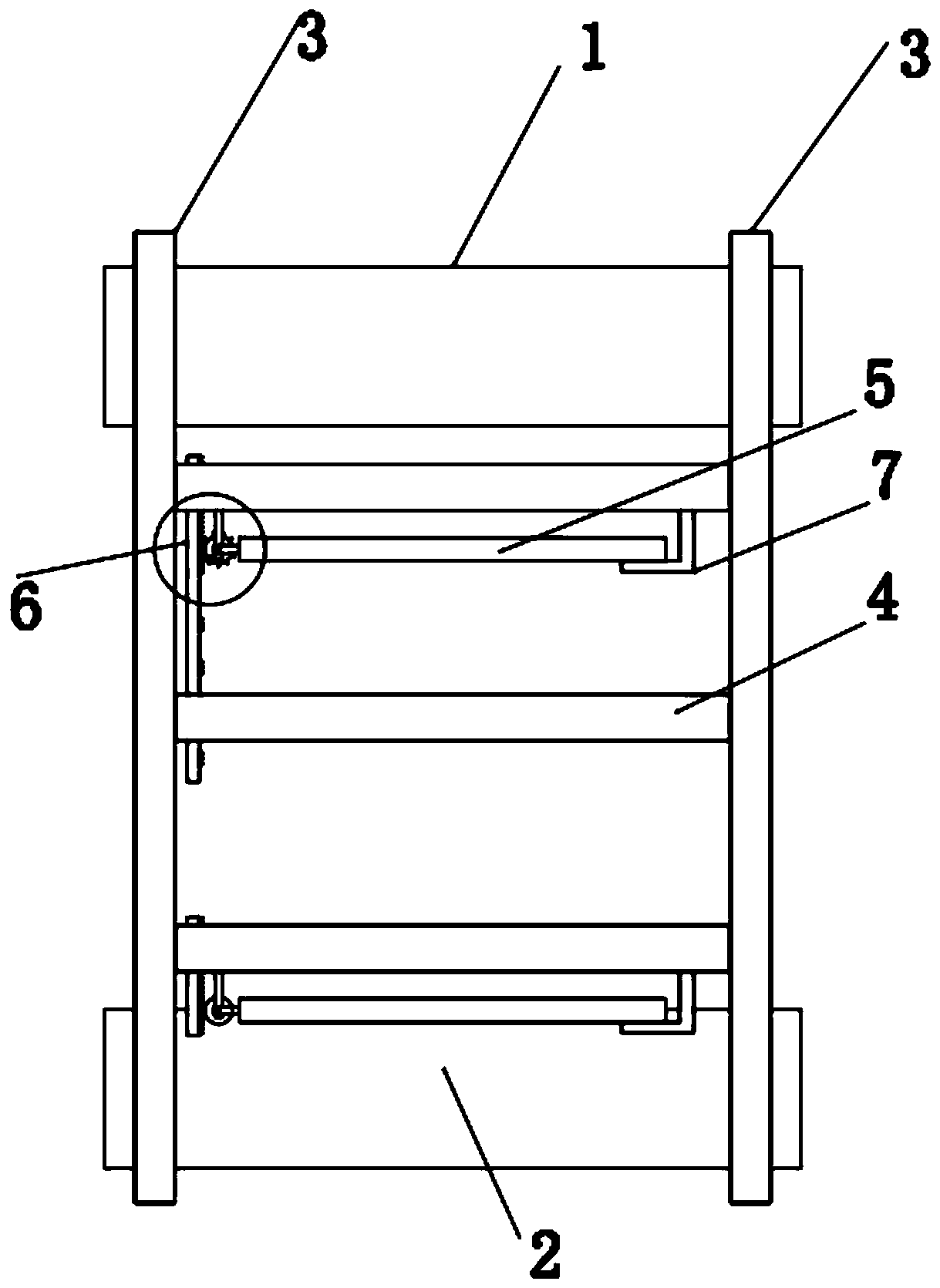

InactiveCN111098907AConvenience for centralized transportationExhausted completelySludge treatmentHand carts with multiple axesSludgeAgricultural engineering

The invention discloses a feeding device for sludge treatment. The device comprises a base and a feeding box, wherein universal wheels are fixedly mounted at four corners of the bottom of the base correspondingly, the feeding box is of a hollow structure with an opening in one side, a box door is connected with the opening through a hinge, the box door is connected with the feeding box through a hasp, the feeding box is located above the base, a lower surface, close to the box door, of the feeding box is rotationally connected with an upper surface of the base through a rotating shaft, a sliding rod is hinged to a lower surface, away from the box door, of the feeding box, an inserting groove matched with the sliding rod is formed in the position, corresponding to the sliding rod, of an upper surface of the base, first springs are fixedly connected with the groove bottom of the inserting groove, the other ends of the first springs abut against ends, away from the feeding box, of the sliding rod, clamping grooves are formed in a rod wall of the sliding rod, and sliding grooves matched with the clamping grooves are formed in the positions, corresponding to the clamping grooves, of theinserting grooves. The device is advantaged in that through a sludge conveying cart, discharging can be thorough, and discharging efficiency is higher.

Owner:扬州市国翔智慧机电设备有限公司

Bidirectional auger frying pan

InactiveCN114061286AImprove mixing uniformityAvoid stickingTransportation and packagingRotary stirring mixersAugerEngineering

The invention discloses a bidirectional auger frying pan, which comprises a cylinder body, a stirring shaft capable of rotating relative to the cylinder body, and stirring paddles arranged at the side part of the stirring shaft, and is characterized in that the side part of the cylinder body is provided with a material inlet / outlet, the stirring paddles comprise a stirring paddle I and a stirring paddle II which are respectively arranged at the two sides of the material inlet / outlet, and the spiral directions of the stirring paddle I and the stirring paddle II are opposite; two ends of the stirring shaft are hermetically connected with the cylinder body through a filler assembly, and one end of the stirring shaft is connected with a power system for driving the stirring shaft to rotate; the cylinder body is provided with a cylinder cavity, and the cylinder cavity is provided with at least two steam connecting ports. The uniform degree of material heating is improved through two modes, firstly, the materials are heated through the inner heating mode and the outer heating mode, and the heating effect is better; and secondly, the stirring uniformity of the internal materials is improved by the two-way auger, the materials are prevented from being adhered to the inner wall of the cylinder body by an end scraper, and the dried materials are more efficiently and thoroughly discharged by the design of the two-way auger.

Owner:镇江市普瑞兴机械制造有限公司

Automatic garbage compression device for electric garbage truck

The invention discloses an automatic garbage compression device for an electric garbage truck, which comprises a compression box body and a base. There is an electric door, the bottom surface of the electric door is provided with a rack matched with the first gear, and the inside of the electric door is provided with a first chute. In the present invention, the device is equipped with an electric door at the bottom of the compression box body, which can quickly discharge the compressed garbage after compression, and at the same time, the push plate is firmly attached to the bottom of the compression box body because of the push plate pulley, so that It can better and more conveniently discharge the solid, liquid and other garbage in the compression box body more thoroughly, preventing the garbage from being left inside the compression box body, or leaving garbage behind the push plate when the push plate is pushing and compressing due to gaps , resulting in a situation where garbage is difficult to clean up.

Owner:JIANGSU AOXIN NEW ENERGY AUTOMOBILE

A food emulsifier storage device

ActiveCN110758929BEfficient NestingComplete nestingRotary stirring mixersLarge containersFood safetyEngineering

The invention discloses a food emulsifier storage device and relates to the technical field of food safety. The invention comprises a tank body. End caps are fixed at both ends of the tank body. A casing runs through the center of one of the end caps. The inner wall of the casing rotates and fits with a screw shaft. There are a number of stirring rods, the surface of the stirring rod is slidably fitted with two piston plates, the surface of the screw shaft is provided with two sections of threads with opposite directions, and the two piston plates cooperate with the two sections of threads of the screw shaft respectively. The invention can stir and mix the emulsifier through the casing, the turntable and the stirring rod to prevent solidification, and the coaxially designed screw shaft can drive the piston plate to slide along the stirring rod to squeeze and discharge the material, so that the emulsifier can be efficiently and efficiently Complete discharge, which solves the problem that the traditional storage device lacks the stirring function or cannot completely discharge the material due to the installation of the agitator, and improves the sanitation and safety of the equipment.

Owner:烟台虹月电子商务有限公司

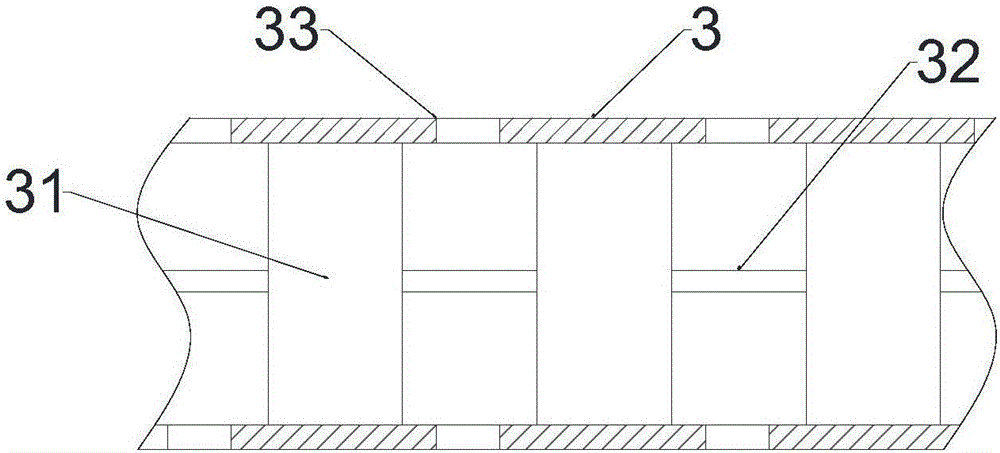

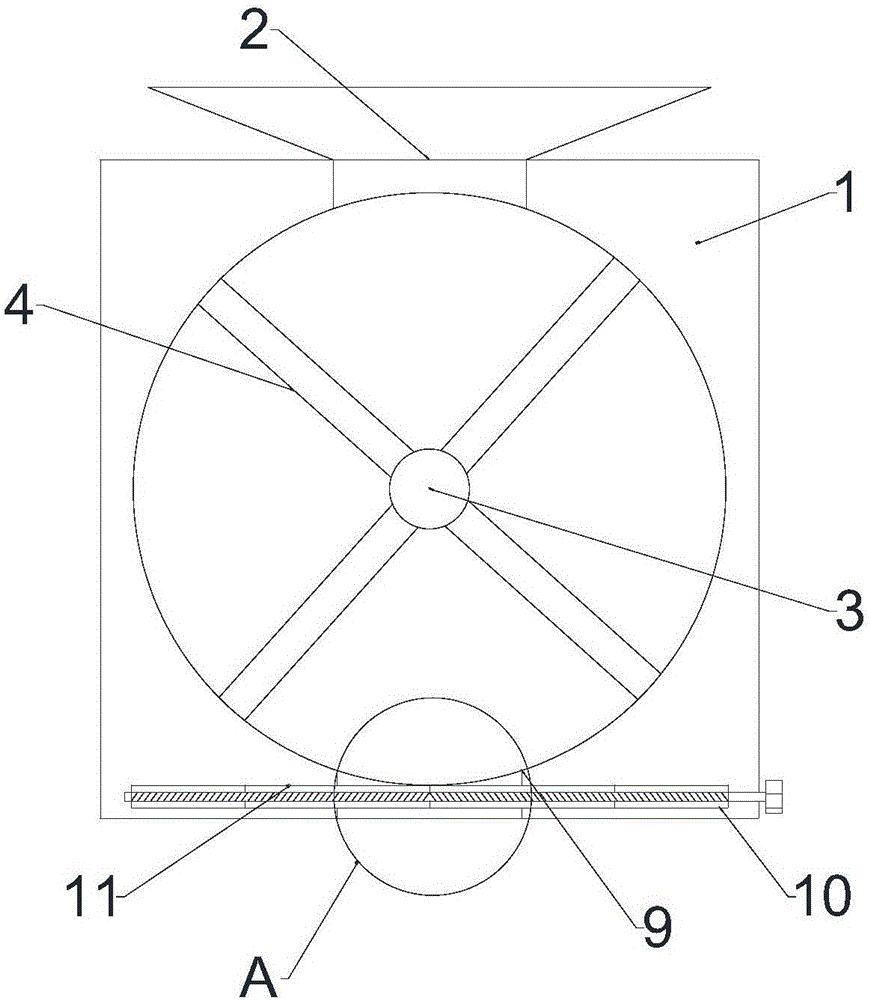

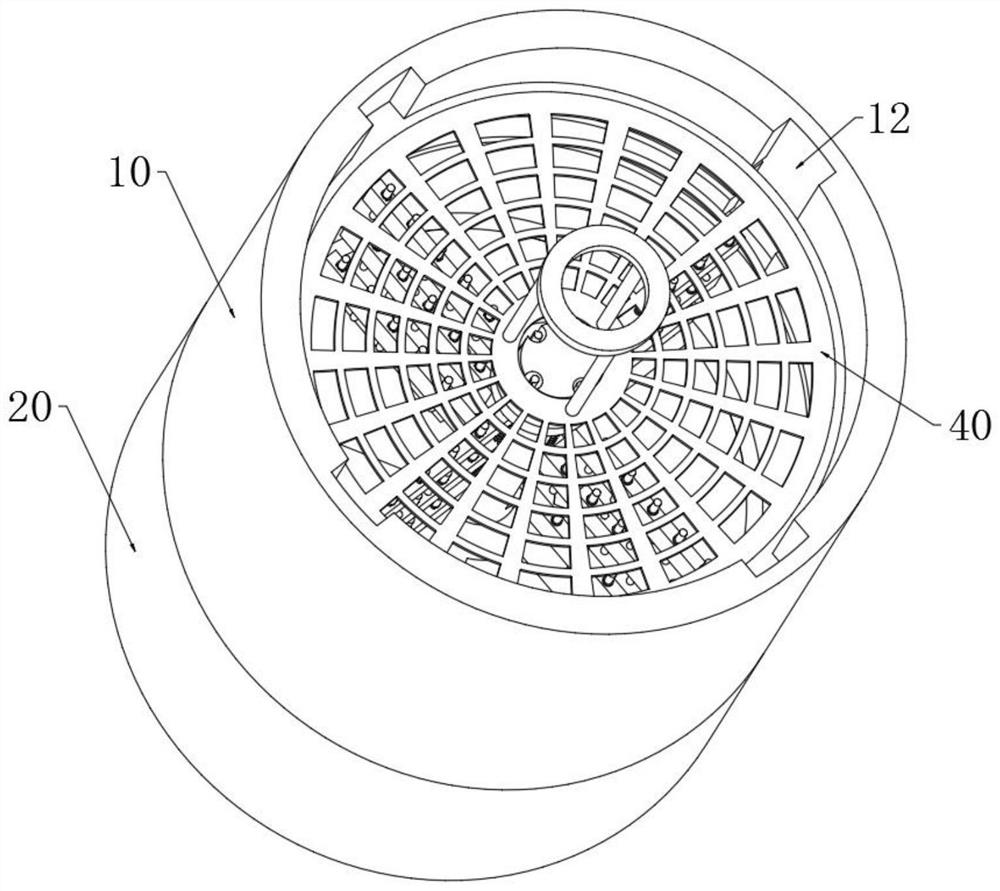

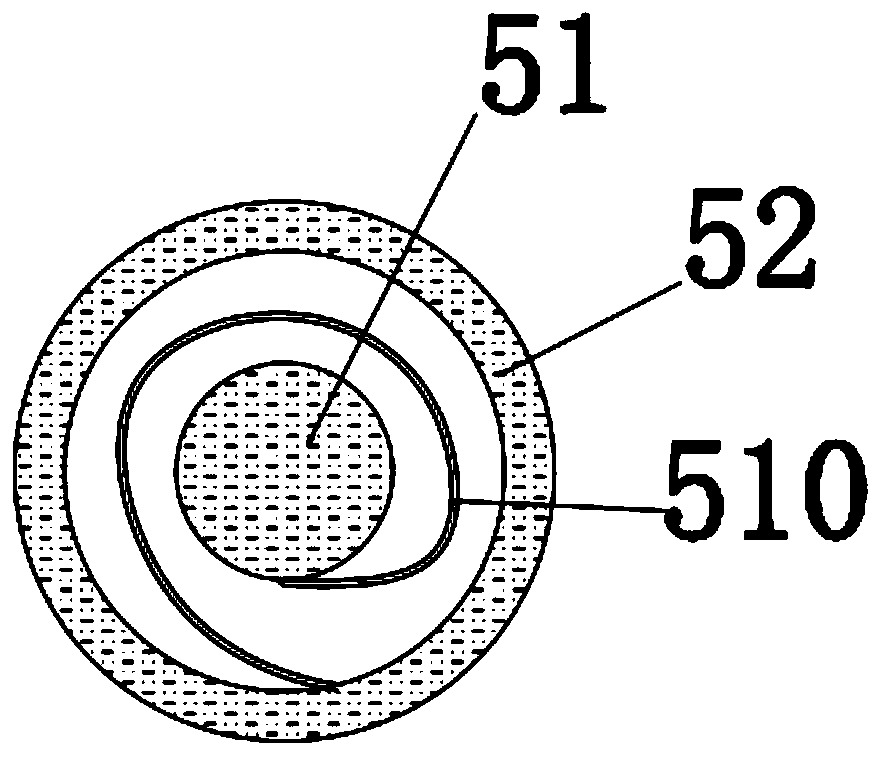

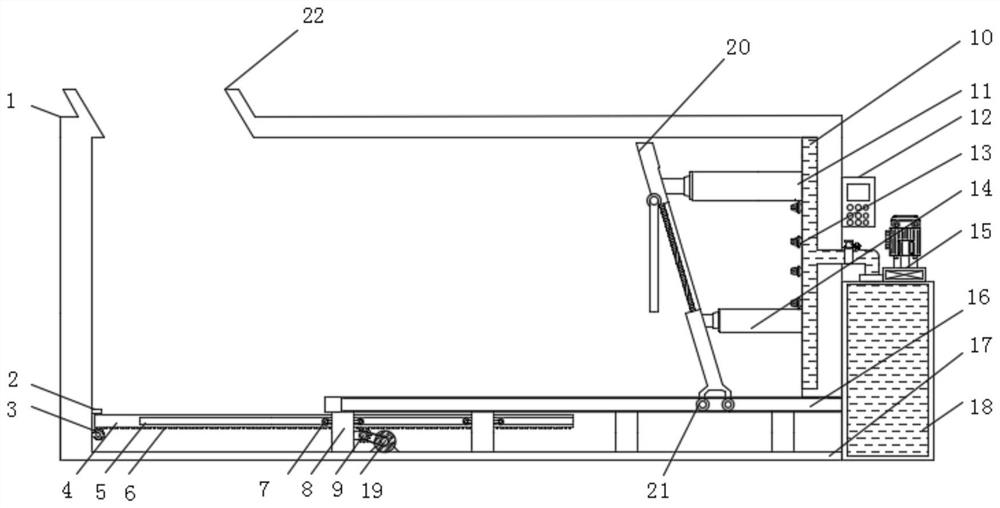

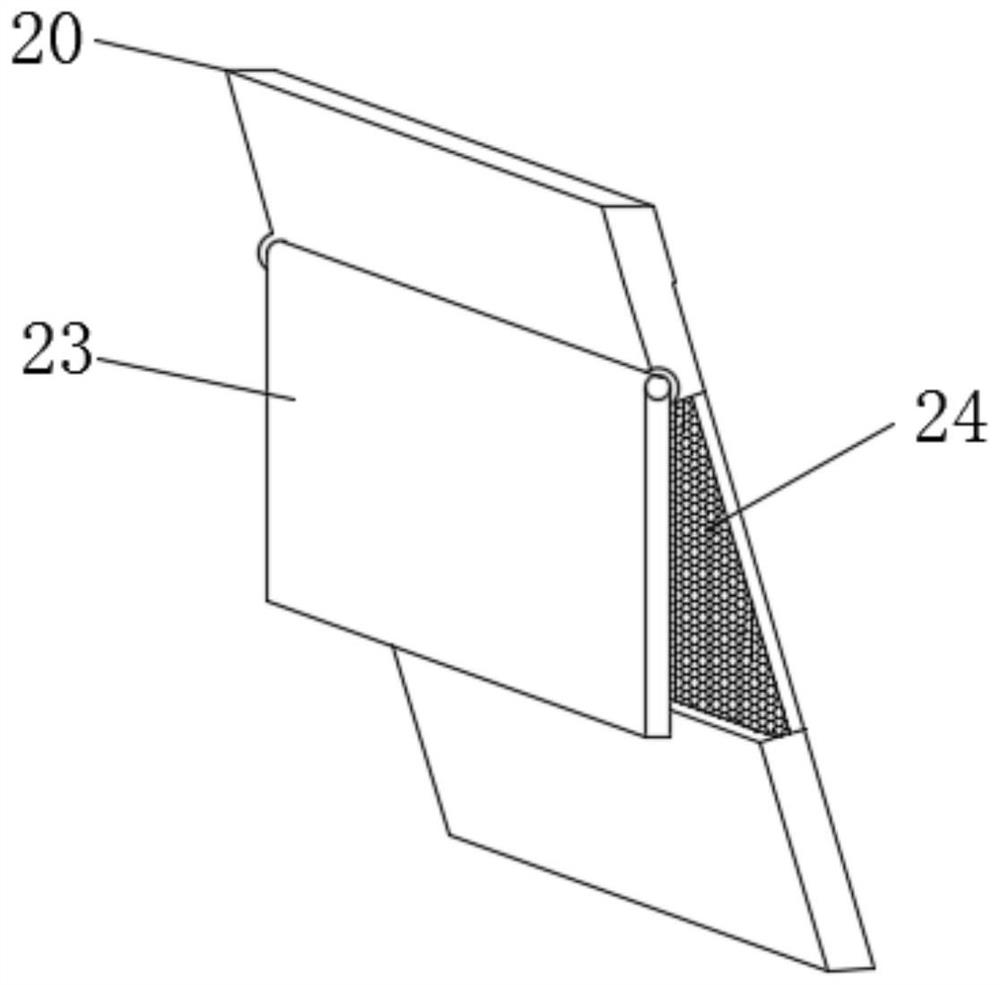

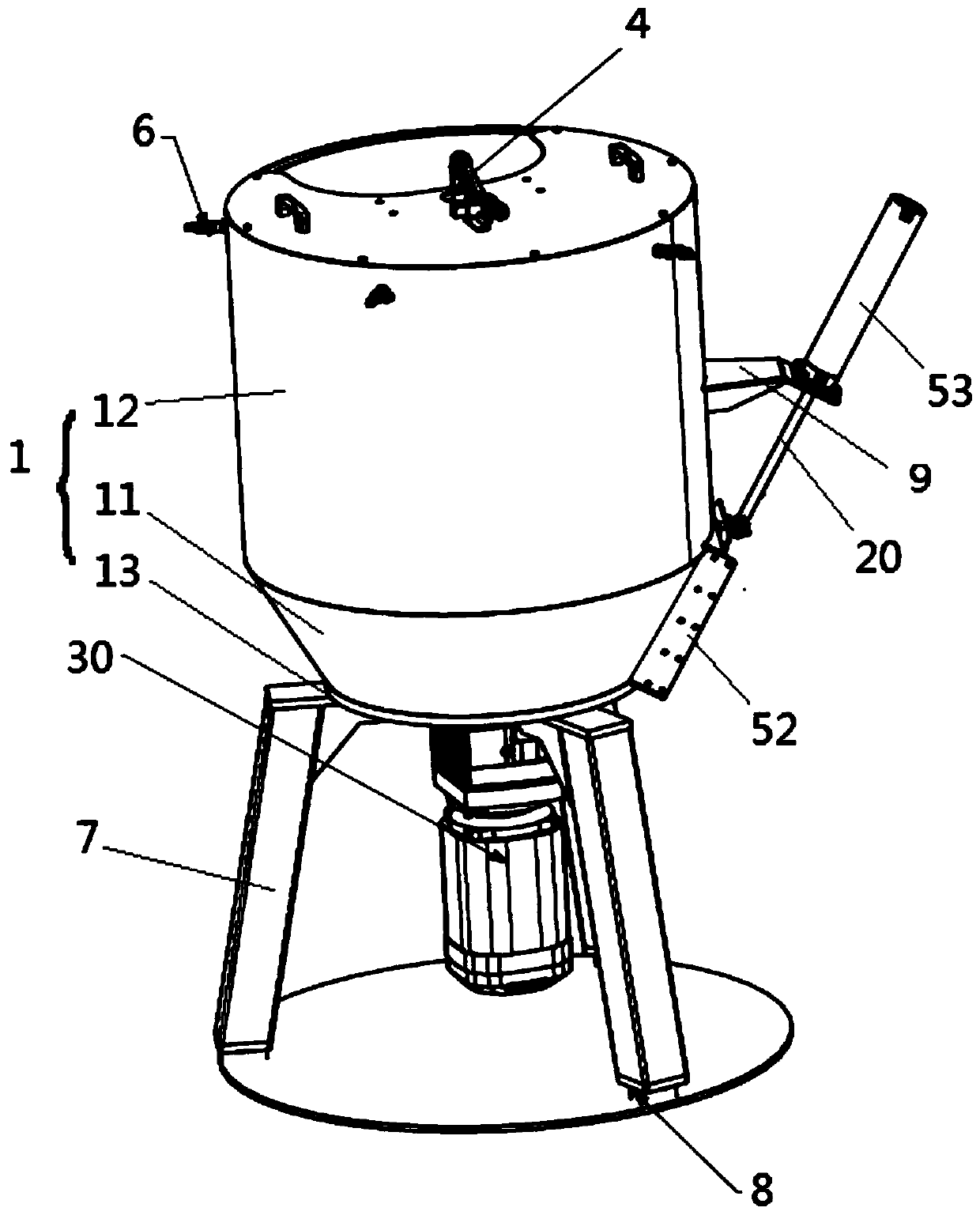

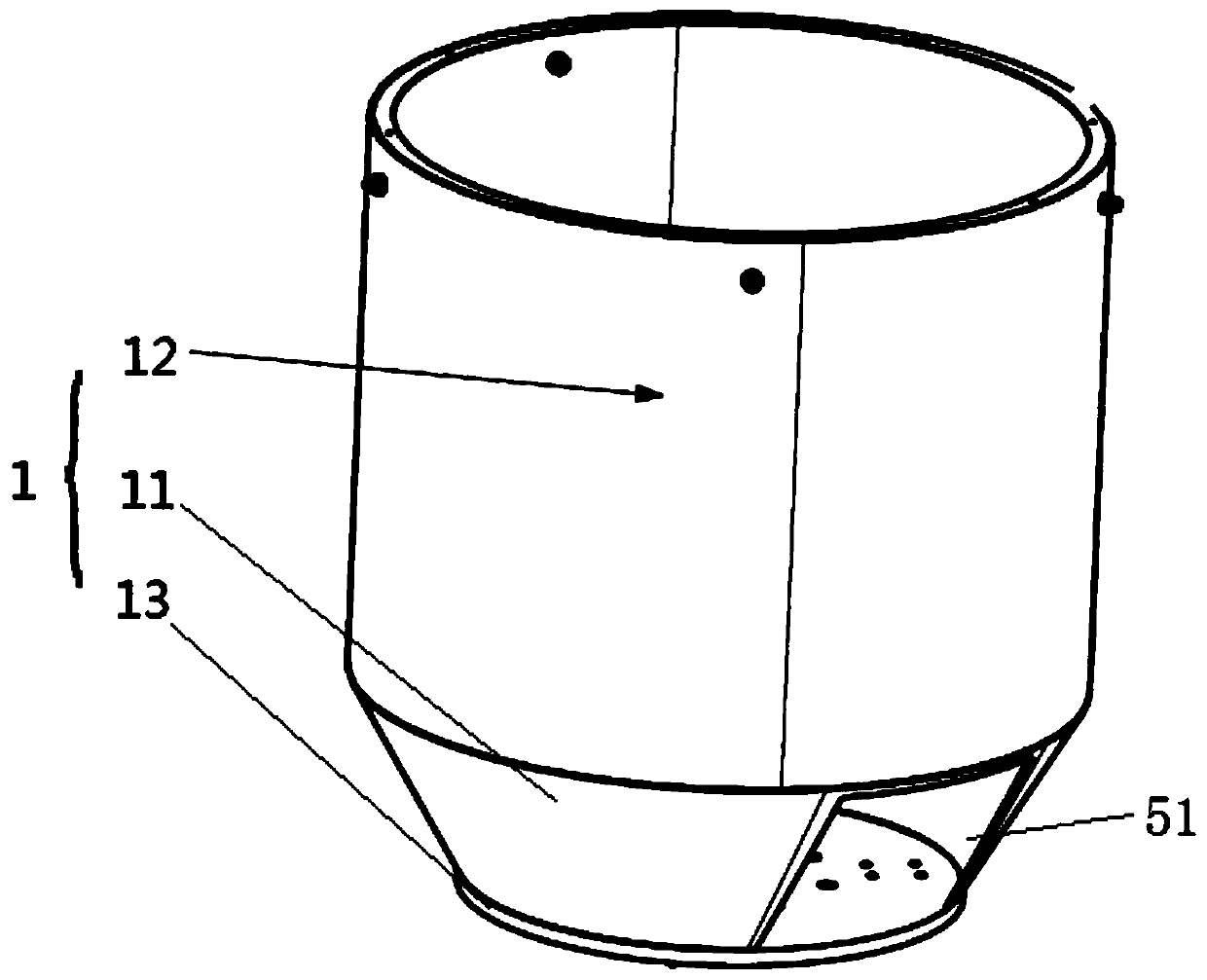

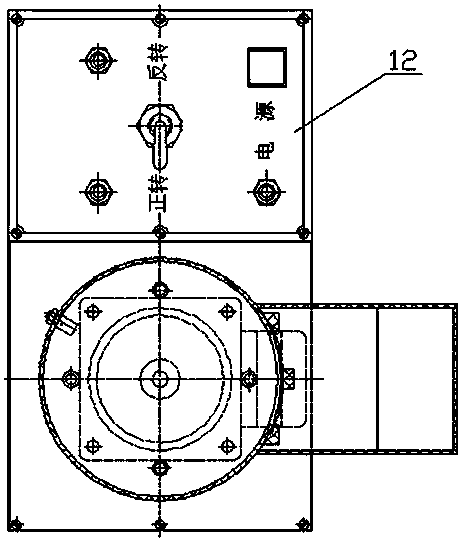

A tea rehydration mixer

ActiveCN106237887BLoose tea evenlyUniform rehydrationPre-extraction tea treatmentTransportation and packagingPulp and paper industryTea leaf

The invention discloses a tea rehydration stirrer, comprising a stirring cylinder (1), a stirring shaft (2) and multiple sets of stirring blades (3) fixedly connected to the stirring shaft (2), the stirring cylinder ( 1) is provided with a feeding port (4) at the top, and a discharge device (5) is provided at the bottom thereof, and a water channel control device (6) for sprinkling water is also provided in the mixing cylinder, and the multiple sets of mixing blades (3 ) includes a scraping blade (31), a middle stirring blade (32) and an external stirring blade (33), and the discharge device is arranged on the lower side wall of the mixing cylinder (1) outside the scraping blade (31). The stirring height and stirring radius of the middle stirring blades are both smaller than the stirring height and stirring radius of the outer stirring blades. Through the setting of different stirring radii and stirring heights of the stirring blades in the mixing cylinder, the purpose of uniform rehydration of loose tea can be achieved. Under the action of scraping blades, the rehydrated loose tea can be completely discharged from the discharge device without any It sticks to the stirring paddle and the wall of the barrel, resulting in unclean discharge and material jamming.

Owner:CHINA TEA CO LTD

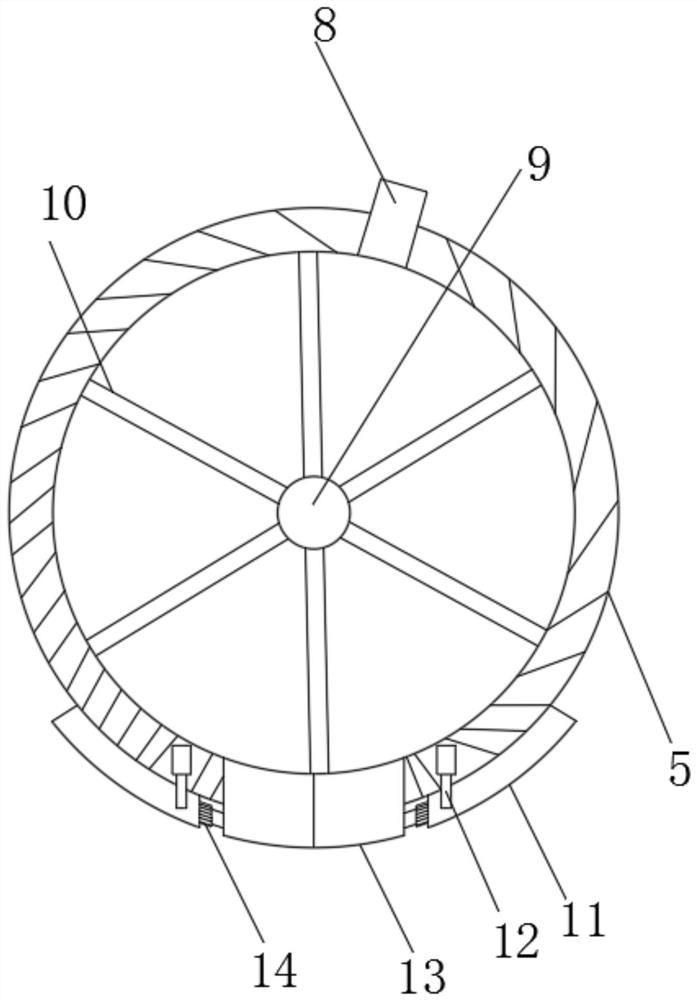

A compression spring automatic separation device

The invention discloses an automatic separation device for a compression spring. The automatic separation device comprises a material barrel (10), a motor (3) and a rotary disc (7). Stirring cones (9) are installed on the rotary disc (7). The rotary disc (7) is installed at the bottom of the material barrel (10) and connected with the motor. A stop pin (8) is arranged at the bottom of the side wall of the material barrel (10) and located above the rotary disc (7) and the gap between the stop pin (8) and the rotary disc (7) is smaller than 0.5 mm. Due to the fact that the stop pin is additionally arranged on the combination face of the barrel wall and the rotary disc, the bottom spring collides with the stop pin, ascend and separation are accelerated, and materials are completely discharged.

Owner:缪小忠

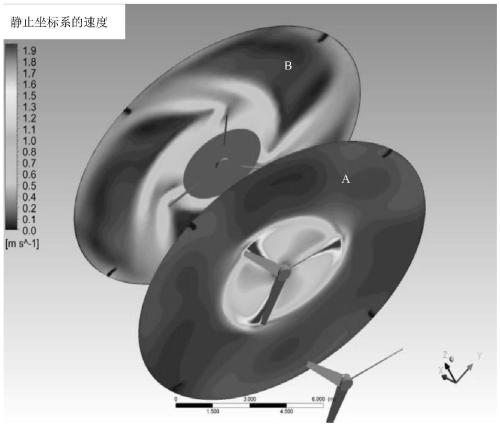

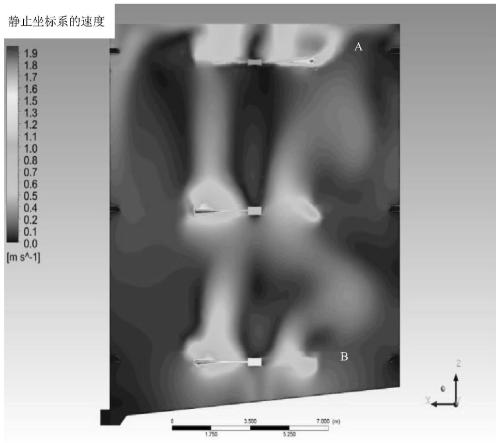

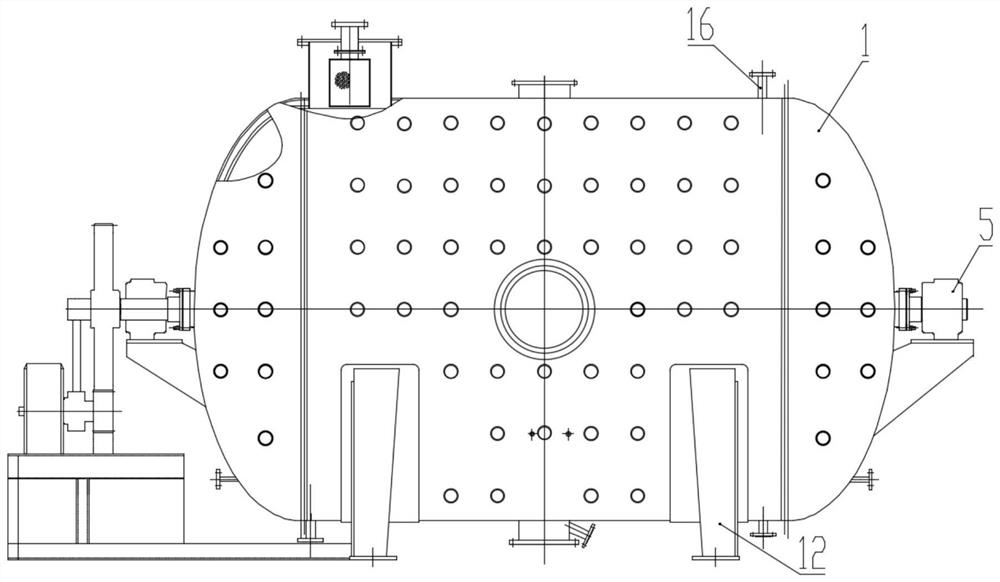

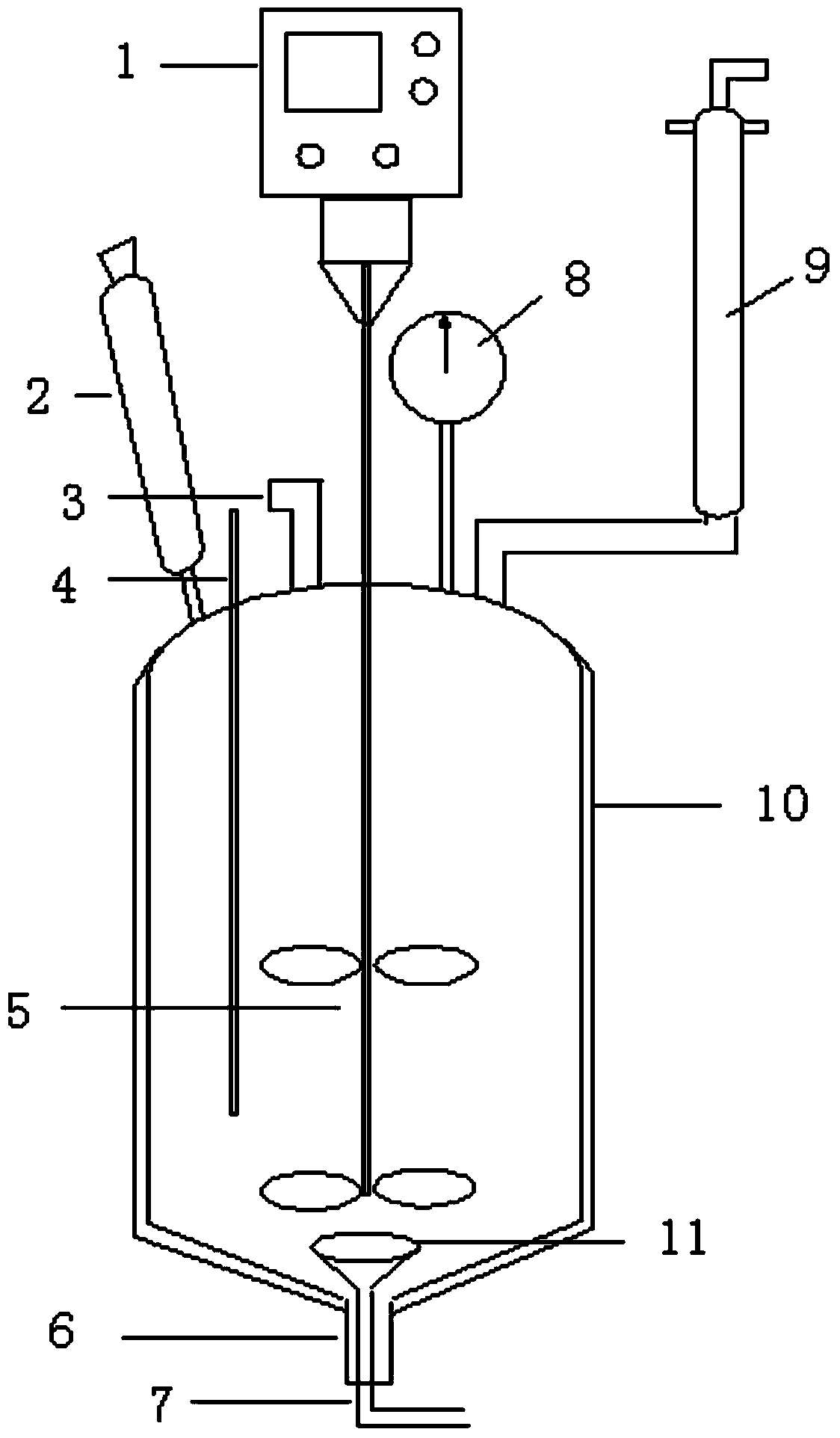

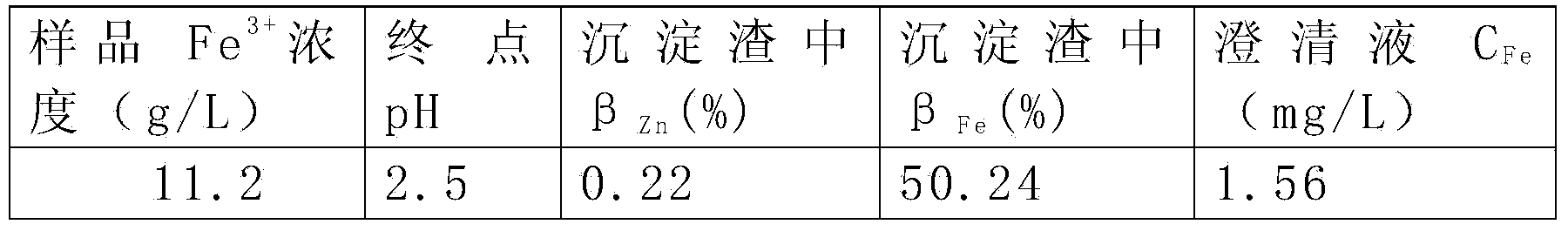

Uniform aerating double-layered glass reaction kettle

InactiveCN103506061AIncrease pressureImprove air tightnessChemical/physical/physico-chemical stationary reactorsBorosilicate glassHeating energy

The invention discloses a uniform aerating double-layered glass reaction kettle. The uniform aerating double-layered glass reaction kettle comprises a reaction kettle main body, a stirring paddle and a baiting valve, wherein the reaction kettle main body is an aerating double-layered glass reaction kettle (10) made of GG17 high borosilicate glass; an aerating plate is arranged at the bottom of the reaction kettle main body; and the stirring paddle is a double-layered stirring paddle (5). The technical method of the uniform aerating double-layered glass reaction kettle is simple and convenient to operate, can quickly and efficiently utilize the heating energy, and sufficiently utilizes the gas utilization rate.

Owner:CENT SOUTH UNIV

Preparation method for anthocyanin

The invention particularly relates to a preparation method for anthocyanin. The preparation method comprises the following steps of raw material collecting, stoving, smashing, anthocyanin extracting, concentrating, distilling, drying and superfine grinding. Propyl alcohol of 95wt% serves as an extracting solution. A concentrating and extracting machine of a TS-NS series is used for concentrating. A superfine grinder of the HMB-701 model is used for superfine grinding. The whole process works cooperatively, and finally powder with a high content of the anthocyanin is obtained. The preparation method is simple in process, easy to operate, short in extracting time, low in production cost and environmentally friendly.

Owner:宁夏天瑞产业集团现代农业有限公司

Safe and reliable double-shaft stirrer with thoroughly discharging function

InactiveCN110115947AComplete nestingIncrease productionRotary stirring mixersTransportation and packagingWind componentDrive motor

The invention relates to a safe and reliable double-shaft stirrer with a thoroughly discharging function. The double-shaft stirrer comprises a bracket, a hopper, a tank body, a driving motor, a stirring mechanism and a discharging device; a heat dissipation mechanism is arranged above the tank body; a discharging mechanism is arranged at the bottom of the tank body, and the discharging mechanism comprises a moving assembly, a connecting rod, a scraping plate and a sliding assembly; a movable assembly comprises a movable motor, a movable gear, a rack and a limiting unit; the heat dissipation mechanism comprises a water tank, a water pump, a water delivery pipe, a winding component and a sprayer; the winding component comprises a fixed pulley, two clamping plates and a plurality of springs.According to the safe and reliable double-shaft stirrer with the thoroughly discharging function, the discharging mechanism is used for discharging fertilizer left in the tank body and on the stirringmechanism, discharging is thorough, and the yield of the fertilizer is increased. Moreover, the heat dissipation mechanism is used for dissipating heat for the driving motor while the fertilizer is humidified, so that the practicability is improved.

Owner:广州贤智科技有限公司

A kind of production method of biomass environment-friendly fuel

The invention discloses a production method of biomass environment-friendly fuel. The production method comprises the following steps: material selection-crushing-mixing-press molding; step 1: material selection, the environmentally-friendly fuel mainly consists of straw, wood and fruit shells 48%-50% of straw, 36%-55% of wood, 6%-9% of husk; step 2: crushing, the raw materials in step 1, straw, The wood and husks are dried and crushed into 1-2.5cm granules; step 3: mixing, mixing the straw, wood and husks in step 2 through a mixing device; step 4: pressing and forming, Utilize the molding device to extrude and cut the mixed material into blocks with edges of 2-5 cm. The binder in the material helps the combustion of the fuel, and the flame is better in the biofuel. Using the oil extracted from animal carcasses or the oil extracted from waste food residues as oil for processing can not only utilize waste, but also reduce energy consumption.

Owner:梁文静

Stirring device for intermittent constant-velocity discharge and construction method for self-leveling floor

ActiveCN110453900BLift up movementEvenly mixedCement mixing apparatusFlooringBLENDER/MIXERElectric machine

Owner:福建磊鑫(集团)有限公司

An easy -going medical waste crushing device

ActiveCN108405100BEasy to cleanAvoid direct contactGrain treatmentsSynchronous motorElectric machine

The invention discloses a medical waste crushing device with crushed materials easy to discharge. The medical waste crushing device comprises a shell; electric push rods are symmetrically arranged onthe two sides of the shell; threaded rods are arranged on the two sides in the shell; synchronous motors are arranged at the lower ends of the threaded rods; a lifting placement plate is arranged on the periphery of the threaded rods; a machining cavity is formed in the middle of the lifting placement plate; rotary shafts, transmission gears and rotary base plates are arranged on the lower parts of the front side wall and the rear side wall of the machining cavity; a rotary pipeline is arranged in the middle of an upper cover; crushing blades are arranged on the periphery of the rotary pipeline; a crushing motor is arranged on the upper right side of the upper cover; an air pump is connected to the upper end of the rotary pipeline through a rotary joint; a spray head is connected to the lower end of the rotary pipeline in an embedded mode; toothed plates are perpendicularly welded to the rear side of the bottom in the shell; and supporting bases are symmetrically welded to the two sides of the lower end of the shell. The medical waste crushing device has the advantages that the threaded rods can be driven to rotate through the synchronous motors, so that the machining cavity can becontrolled to ascend and descend, when the machining cavity ascends to the upper portion, crushing can be carried out, when the machining cavity descends to the bottom, the crushed materials can be discharged at the same time, and therefore the the crushed materials is convenient to collect, and the medical waste crushing device is convenient to use and efficient.

Owner:XUZHOU XINFA MACHINERY

A kind of vegetable oil oil separation equipment

ActiveCN109758815BReduce wasteHigh purityFatty-oils/fats refiningStationary filtering element filtersVegetable oilOil separation

The invention relates to the technical field of vegetable oil, in particular to a vegetable oil separation device. The technical problem to be solved by the present invention is to provide a vegetable oil separation device with less waste of vegetable oil, high purity of the separated vegetable oil, less residue retention on the filter, and easy discharge of vegetable oil and secondary oil. A vegetable oil separation equipment, including a support platform, a frame, a first driving mechanism, a soft feeding pipe, a hard feeding pipe, and a uniform feeding mechanism; the support platform and the frame are fixed on the ground, and the supporting A moving mechanism is fixedly connected to the top of the platform. The invention achieves the effects of less waste of vegetable oil, high purity of separated vegetable oil, difficulty in retaining residues on the filter screen, easy discharge of vegetable oil and secondary oil, and more thorough discharge of vegetable oil collection frame and secondary oil collection frame.

Owner:山东创优生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com