Automatic garbage compression device for electric garbage truck

A compression device and garbage truck technology, applied in garbage collection, garbage cleaning, garbage storage, etc., can solve the problems of reducing the service life of machinery, unfavorable discharge, device corrosion, etc., to prolong service life, prevent dust accumulation, and improve cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the accompanying drawings in the embodiments of the present invention,

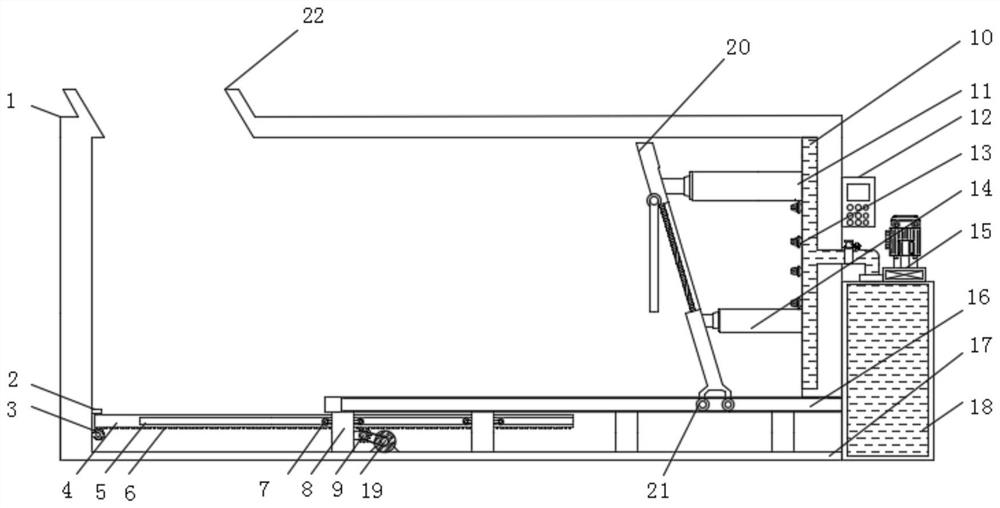

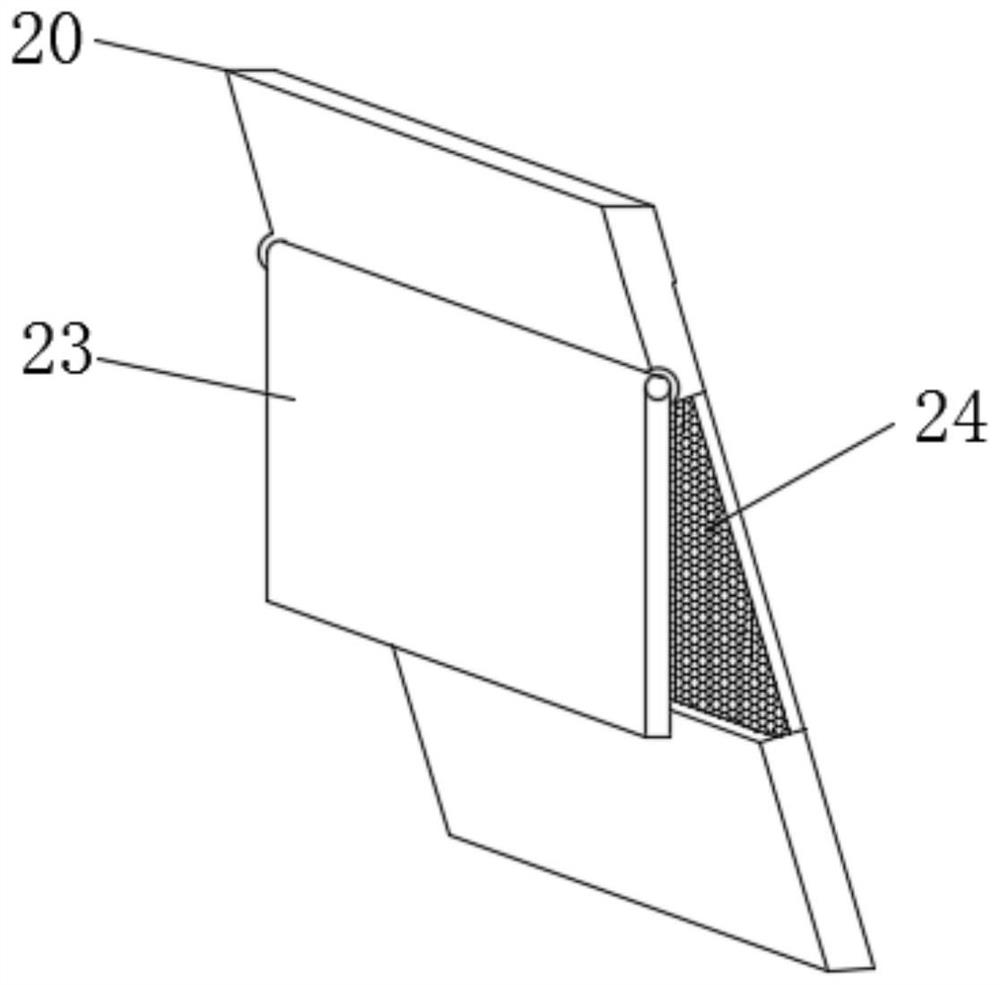

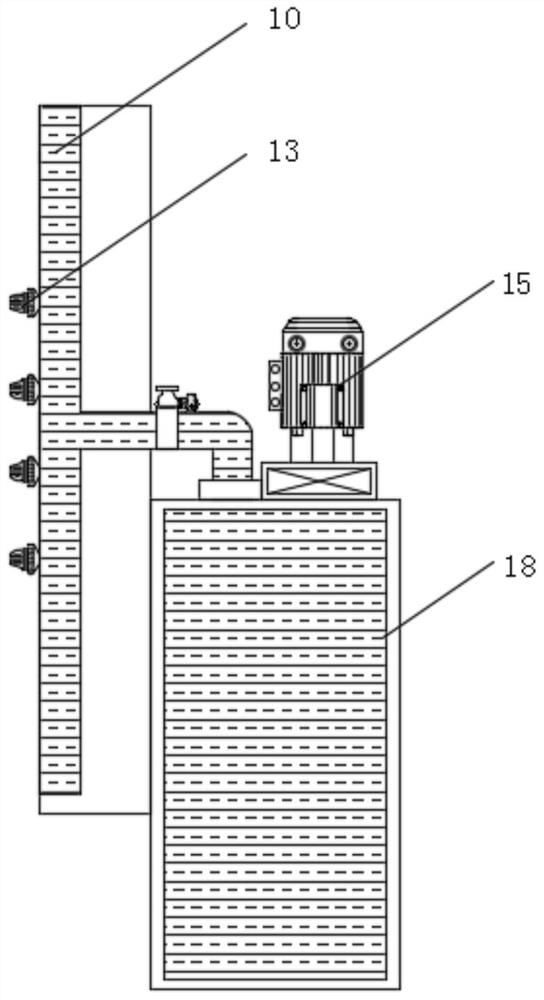

[0025] Please refer to Figure 1-4 , an automatic garbage compression device for an electric garbage truck, comprising a compression box body 1 and a base 17, characterized in that a fixed block 2 is provided on the bottom inner surface of the compression box body 1, and the bottom of the fixed block 2 is meshed by the first gear 3 Connected with an electric door 4, the bottom surface of the electric door 4 is provided with a rack 6 matched with the first gear 3, the inside of the electric door 4 is provided with a first chute 5, and the inside of the first chute 5 is slidingly connected Electric door pulley 7 is arranged, and electric door pulley 7 is connected with support bar 8, and one side surface of support bar 8 is provided with second gear 9 through fixed plate, and second gear 9 is connected with motor 19 by chain, and motor 19 is fixed in compression In the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com