Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid secondary attachment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

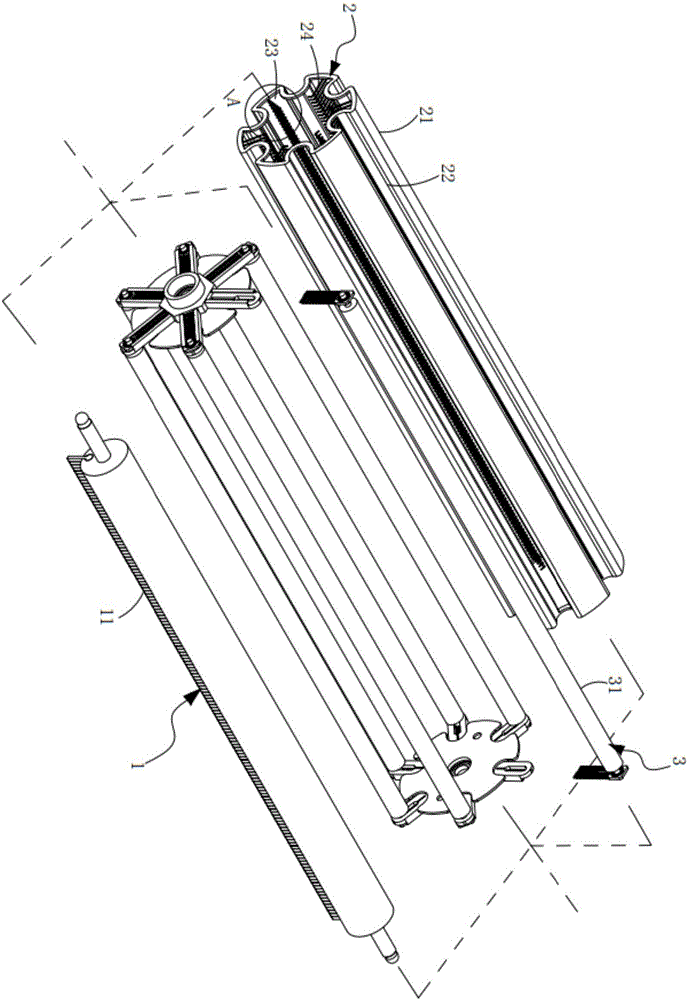

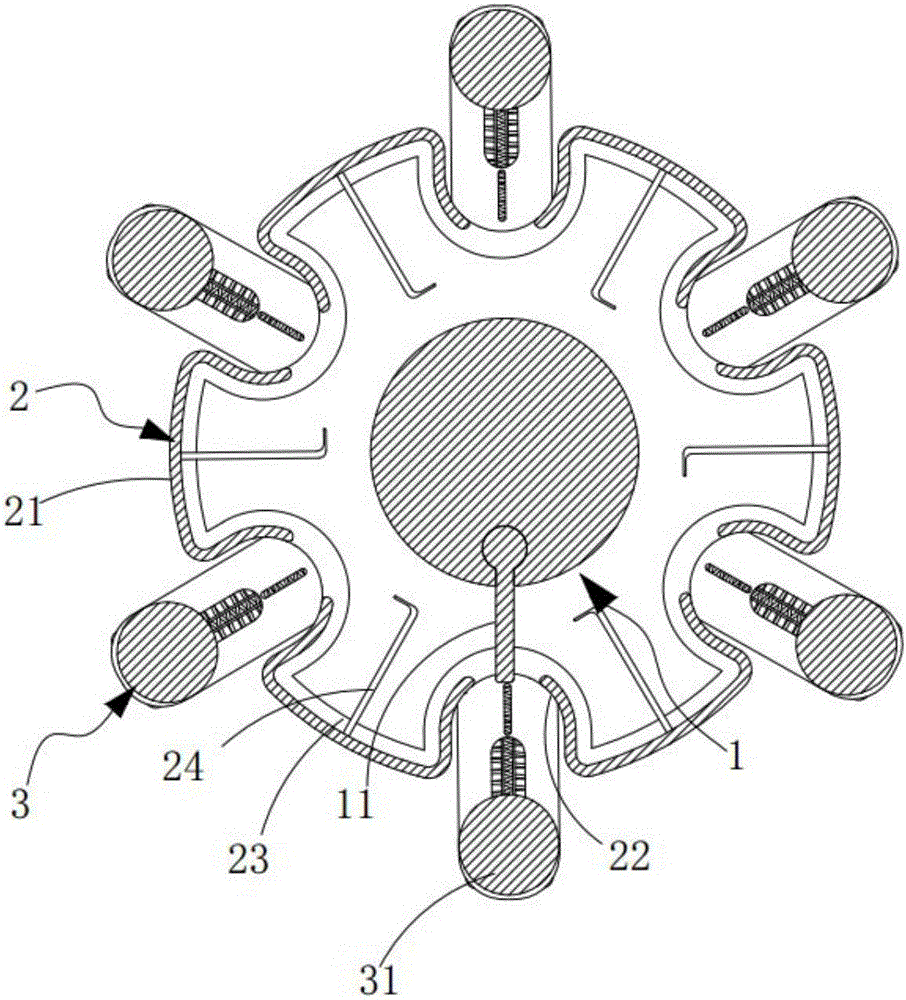

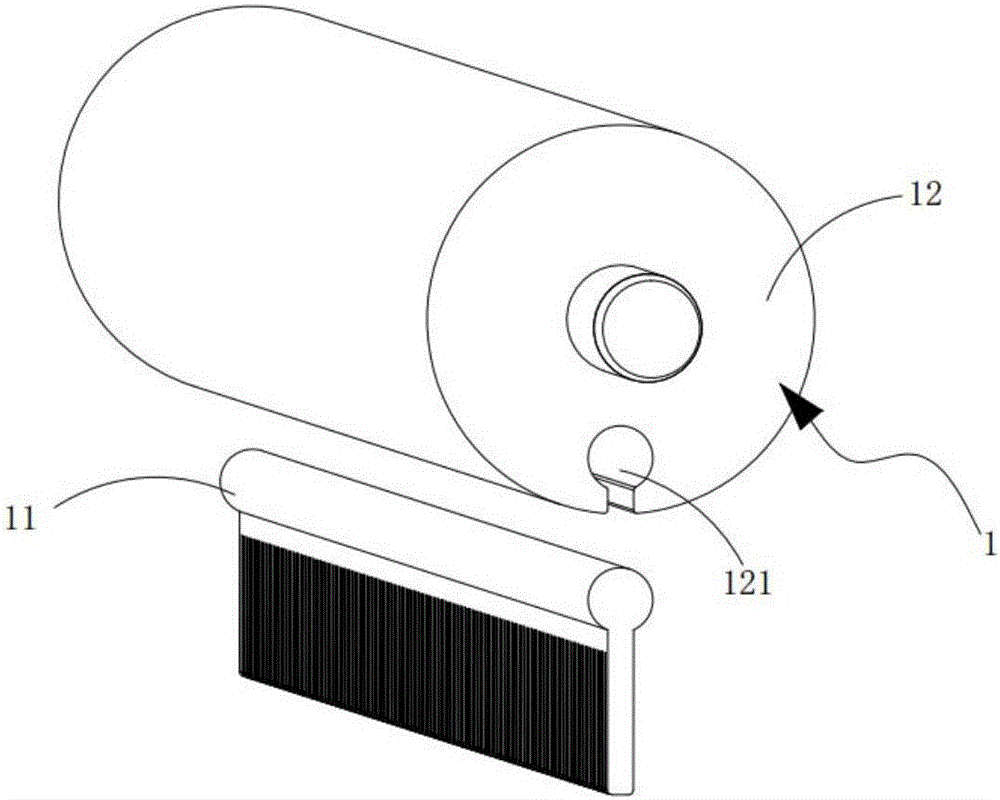

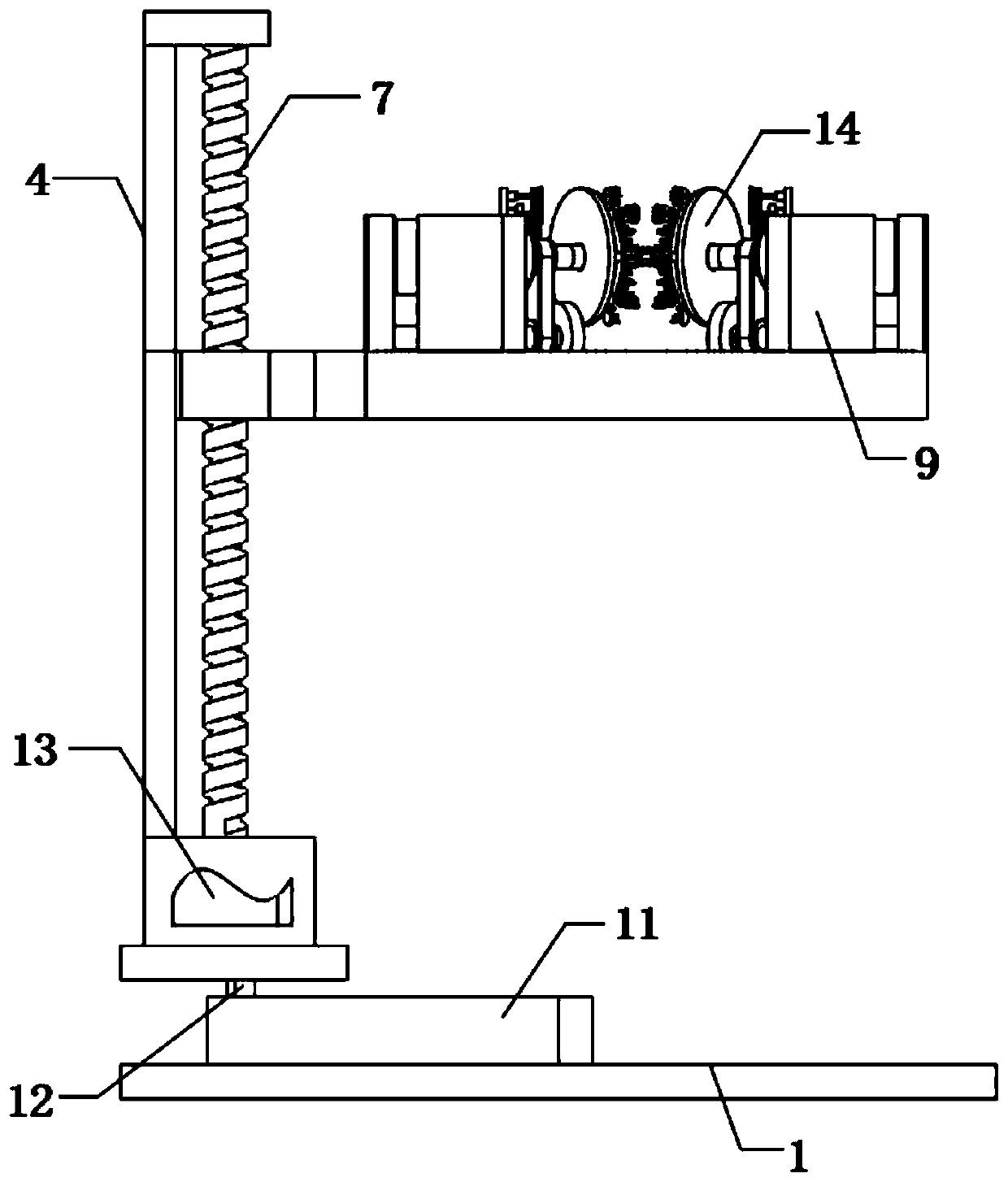

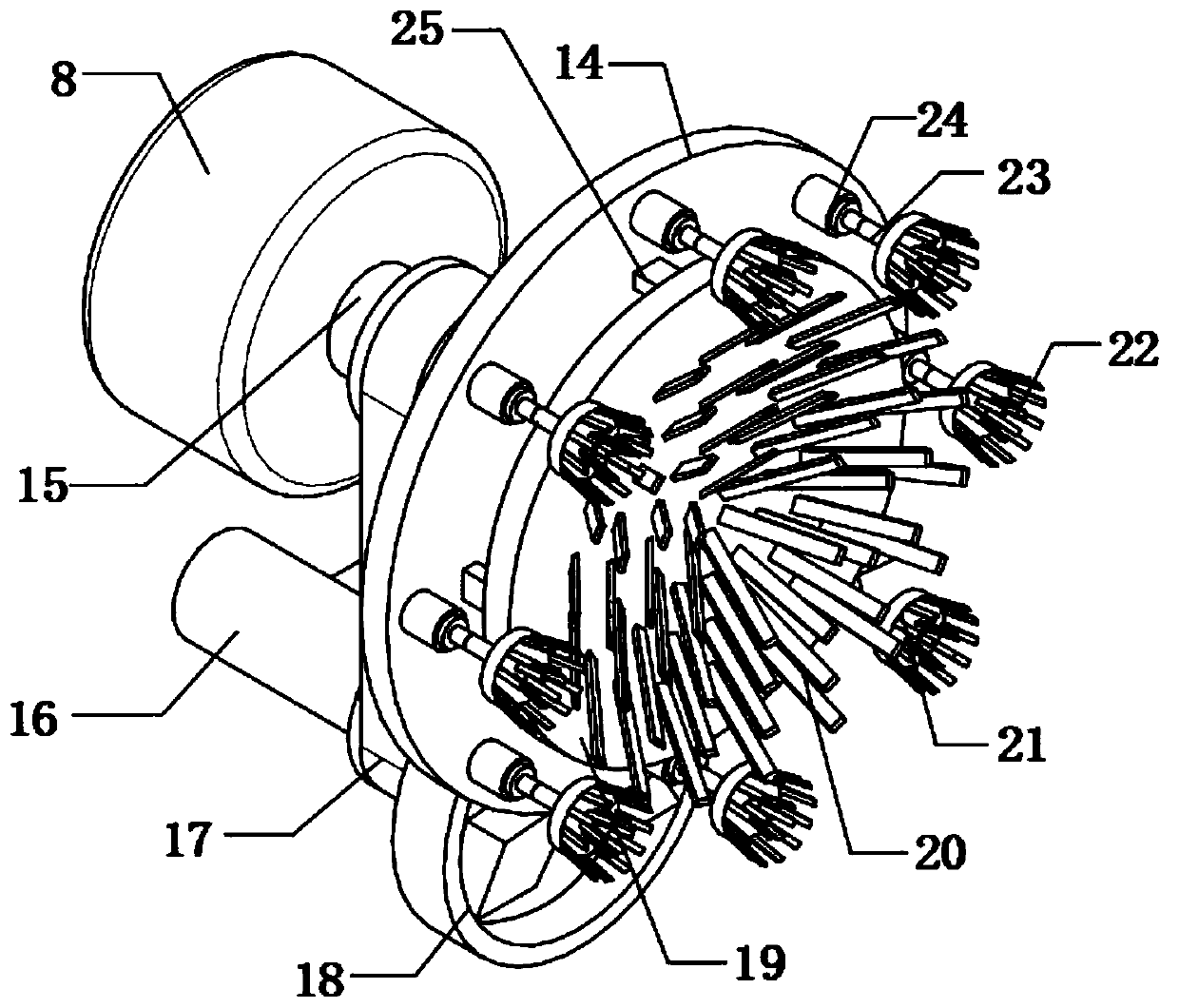

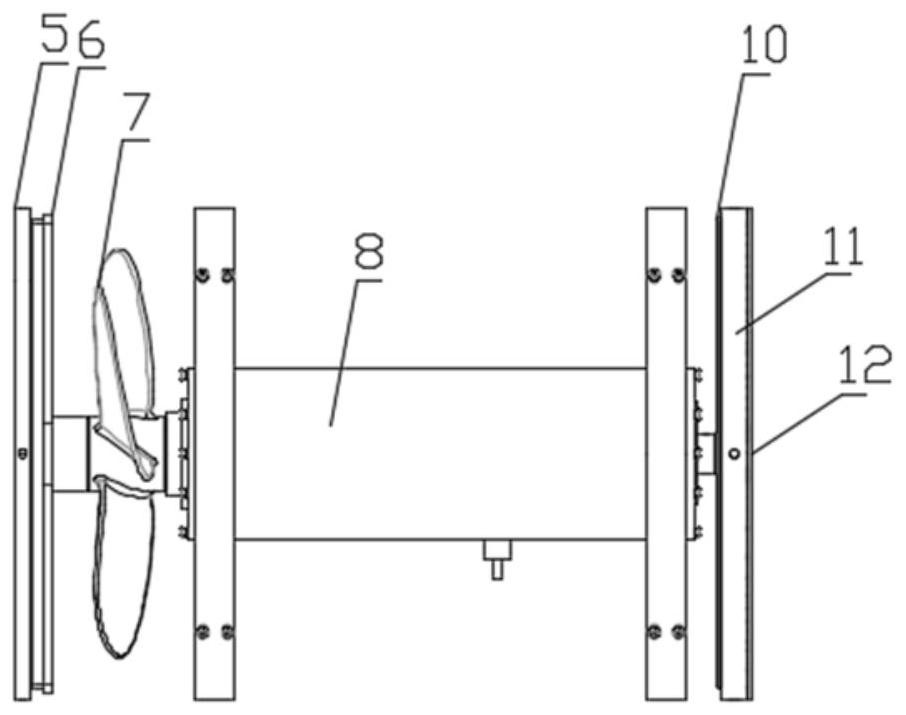

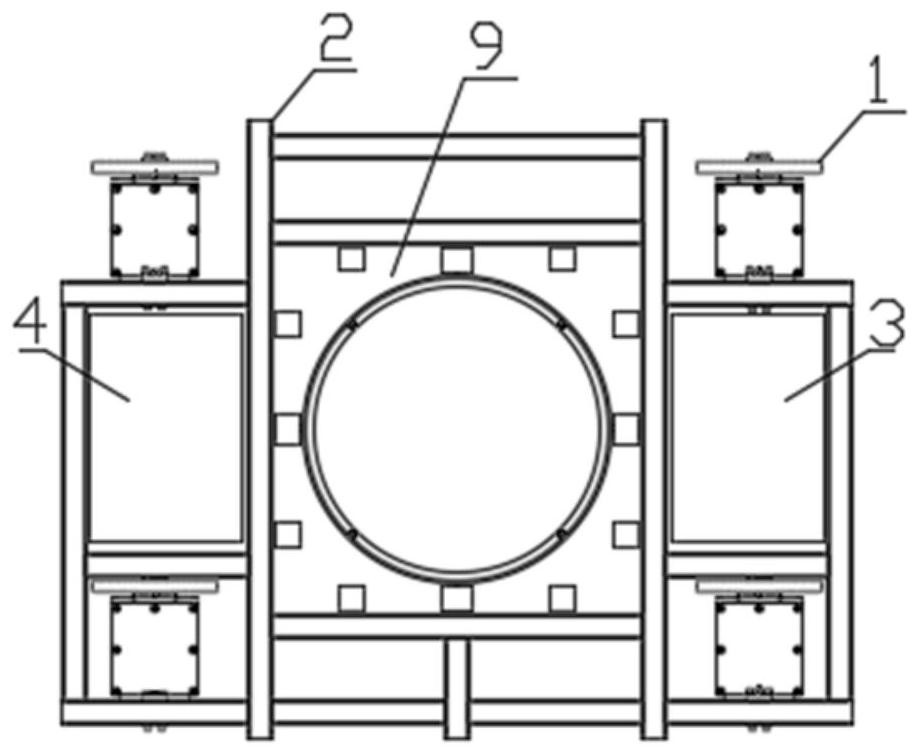

Dedusting composite cloth roller with self-cleaning function

InactiveCN106801327ASolve the removal problemAvoid secondary attachmentMechanical cleaningPressure cleaningEngineeringImpurity

The present invention relates to a dedusting composite cloth roller with a self-cleaning function. A brush roll mechanism and a fine cloth roller mechanism are additionally arranged on a coarse cloth roller mechanism, the combination of the three is utilized to form a composite cloth roller, the fine cloth roller mechanism is employed to generate static electricity through friction of the textile fabrics to absorb the dust impurity, the brush roll mechanism is employed to remove the dust impurity on the fine cloth roller mechanism, the dust impurity is stored in the coarse cloth roller mechanism, and the dust impurity can be rapidly extracted from the coarse cloth roller mechanism through a cleaner when cleaning. The problem is solved that the impurity on the textile fabrics cannot be removed through adoption of the cloth roller in the prior art so as to further solve the problem that the dust impurity is kicked up to be absorbed on the textile fabrics after the dust impurity is removed and solve the problem that the dust impurity is rapidly removed from the composite cloth roller.

Owner:南通滨海东泰纺织有限公司

Track cleaning equipment wide in application range and having deicing function

The invention relates to track cleaning equipment wide in application range and having a deicing function. The track cleaning equipment comprises a shell, a connecting bar, two moving blocks, two limiting plates and two deicing mechanisms. An adjusting mechanism is arranged in the shell. The adjusting mechanism comprises a drive assembly and two adjusting assemblies. The drive assembly comprises afirst motor, a first gear and two drive units. Each drive unit comprises a first rack, a limiting slot, a vertical bar and a link. Each adjusting assembly comprises a fixed bar, a slider and two drive bars. According to the track cleaning equipment wide in application range and having the deicing function, the distance between the two moving blocks is adjusted through the adjusting mechanism, sothat the track cleaning equipment is suitable for tracks of different gauge specifications, the application range of the track cleaning equipment is increased, the deicing mechanisms clean away obstacles on the track such as frost and ice that affect the track cleaning operation, thus the cleaning effect is strengthened, and the practicality of the track cleaning equipment is greatly improved.

Owner:MAANSHAN XINQIAO IND DESIGN CO LTD

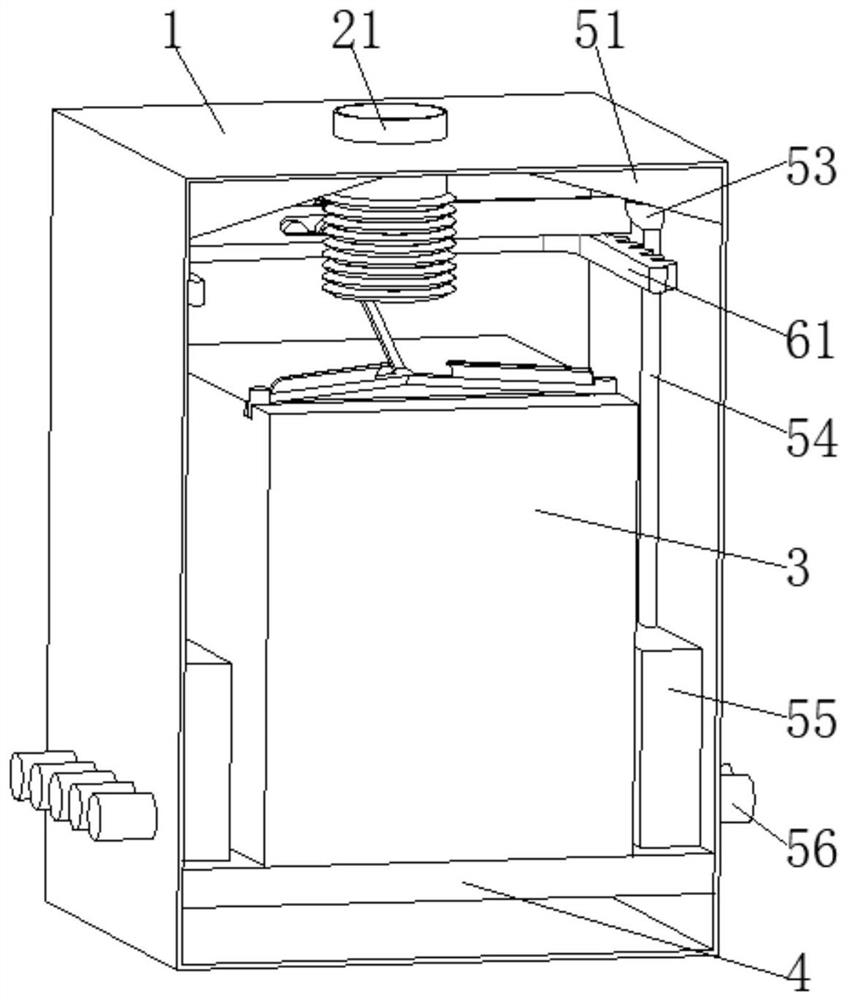

Power distribution cabinet with temperature adjusting function

InactiveCN113964678AExpand the cooling rangeAdequate heat dissipationSubstation/switching arrangement cooling/ventilationCircular discElectric power equipment

The invention discloses a power distribution cabinet with a temperature adjusting function, and relates to the technical field of power equipment. The cabinet comprises a power distribution cabinet, a heat dissipation device is arranged in the power distribution cabinet, the heat dissipation device comprises a heat dissipation pipe, the top of the heat dissipation pipe is fixedly installed at the top of the power distribution cabinet, the lower half portion of the heat dissipation pipe is in a plastic elastic shape, and a heat dissipation fan is rotatably installed on the inner wall of the heat dissipation pipe. A rotating shaft of the heat dissipation fan is in transmission connection with a rotating shaft of the disc through a belt, the disc is rotationally installed on the inner wall of the top of the power distribution cabinet, a cylinder is fixedly installed at the bottom of the disc, and the cylinder is installed at the fork-shaped end of the fork-shaped rod in a sliding mode. According to the power distribution cabinet with the temperature adjusting function, the heat dissipation device is arranged, and when heat dissipation operation is performed on the power distribution cabinet through a heat dissipation fan and a heat dissipation pipe, a fork-shaped rod can drive the lower half part of the heat dissipation pipe to swing, so that the heat dissipation range of the heat dissipation pipe is expanded, and the problem of insufficient heat dissipation is effectively solved.

Owner:郭一鸣

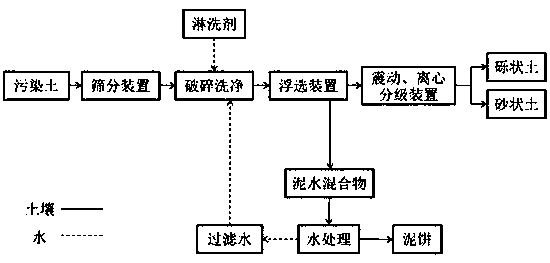

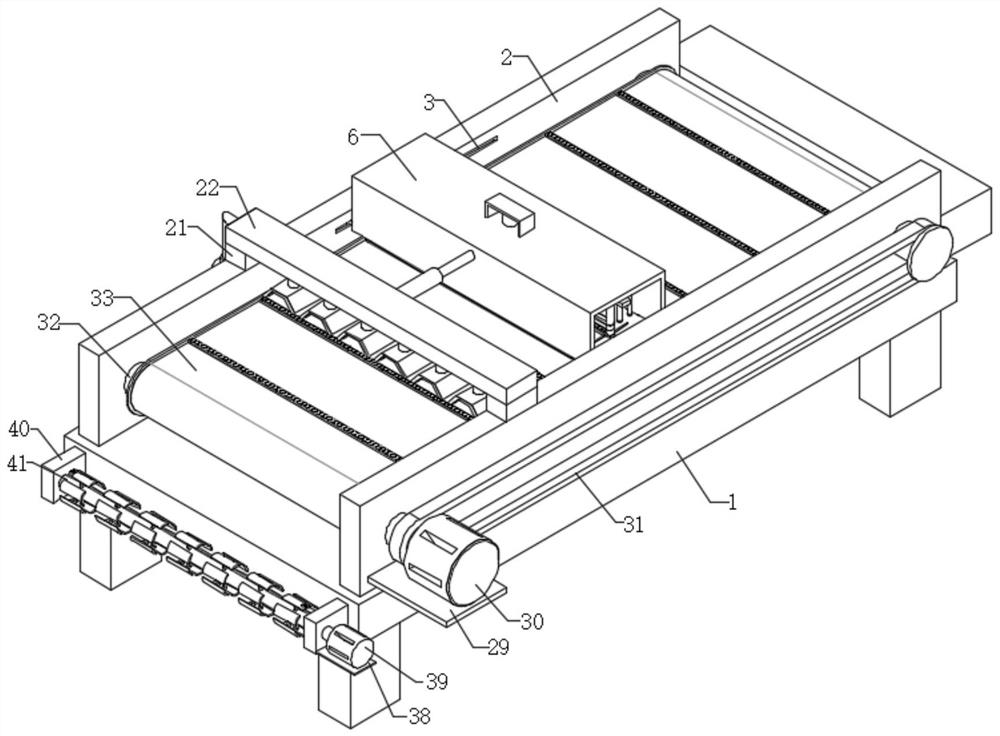

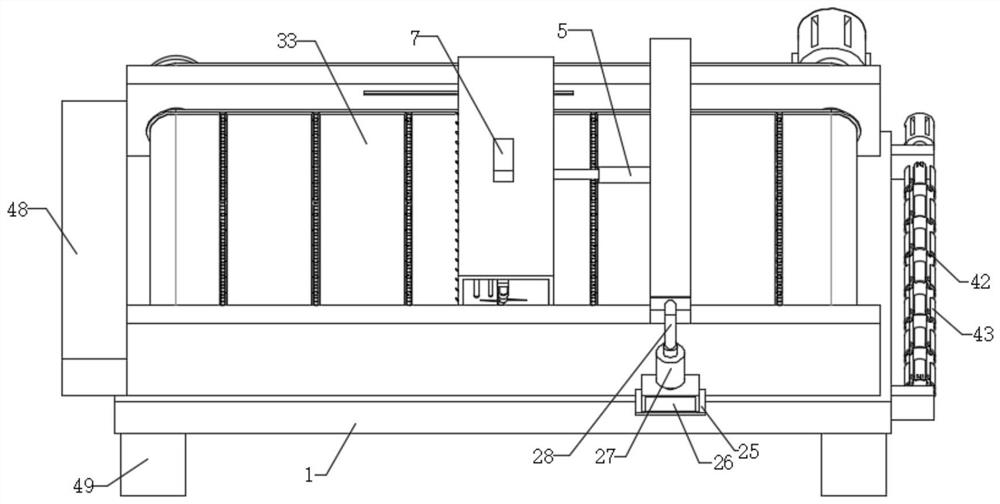

Modular soil leaching method and equipment

PendingCN108620427AHigh reuse rateAvoid secondary attachmentContaminated soil reclamationParticulatesSludge

The invention relates to the field of contaminated soil repair, in particular to a modular soil leaching method and equipment. The equipment is sequentially connected with the following devices including a soil sieving device, a cleaning device, a grading sieving system, a transfer groove and water treatment equipment through pipelines, wherein the soil sieving device is used for separating out particles being greater than 40mm; the cleaning device is used for leaching soil and crushing the soil particles; the grading sieving system is used for separating out psephitic cleaned soil with the particle size being 5 to 40mm and sandy cleaned soil with the particle size being 0.075 to 5mm; the transfer groove is used for storing a mud water mixture; the water treatment equipment is used for treating the mud water mixture and obtaining mud cake and filtered water through press filtering. The leaching and sieving functions are integrated; the space utilization rate is improved; during the soil leaching, particulate matters with different particle sizes can be separated as much as possible; the cleaned soil resource reutilization rate is improved; the production of sludge is reduced.

Owner:上海康恒环境修复有限公司

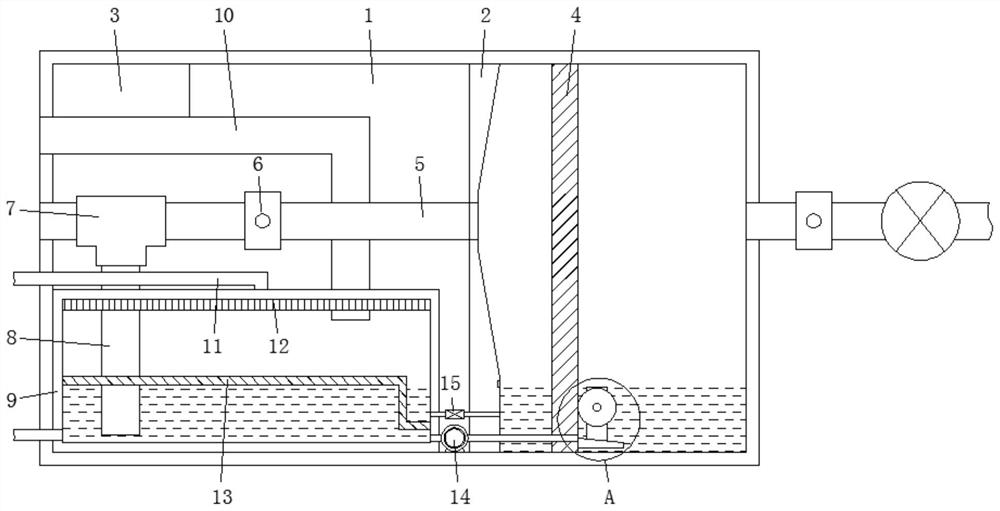

Intelligent electrical automatic dust removal device

ActiveCN111001253AAffect the dust removal effect of pretreatmentImprove the effect of secondary dust removalCombination devicesDust controlEnvironmental engineering

The invention belongs to the technical field of dust removal devices, and discloses an intelligent electric automatic dust removal device, which comprises a control device, a device shell and an air inlet assembly connected to the air inlet end of the device shell, wherein a partition plate is arranged in the device shell, and divides the interior of the device shell into two treatment cavities, the control device is installed in any one treatment cavity, a first filtering screen is mounted in one treatment cavity, a first air outlet pipe is mounted in the other treatment cavity, a water tankis mounted below the first air outlet pipe, and the first air outlet pipe and the air inlet assembly are each provided with a detection device. Based on the arrangement of the detection device, the air inlet dust content and the air outlet dust content of the dust removal device are effectively detected, it is judged that the first filtering screen is damaged if the air outlet dust content is higher than a preset value, and at the moment, the air outlet direction of the dust removal device is adjusted to enter the water tank so as to carry out secondary dust removal, so that the pretreatment dust removal effect of the dust removal device is guaranteed.

Owner:茂名市茂南奥邦涂料有限公司

Slag removing mechanism for PCB hole

ActiveCN107457207AEfficient removalAvoid secondary attachmentDirt cleaningCleaning using toolsTool bitSlag

The invention discloses a slag removing mechanism for a PCB hole. The slag removing mechanism for the PCB hole comprises a motor, a supporting plate, an air box, a clamping head, a hollow sleeve pipe, two limiting sleeves and two drilling tool mechanisms, wherein the limiting sleeves and the drilling tool mechanisms are symmetrically arranged along the hollow sleeve pipe, the hollow sleeve pipe is inserted into a hole needing to be subjected to slag removing, and then, the motor works so as to drive the hollow sleeve pipe to rotate, the drilling tool mechanisms slowly extend out due to the effect of bearing centrifugal force under the damping effect of an elastic column, tool bits arranged on the drilling tool mechanisms smash and remove the adhered slag in the hole, a brush cleans the hole wall which is subjected to machining by the tool bits, and thus slag is removed; and meanwhile, negative pressure is pumped out of the air box through an air pipe, the dissociative waste slag enters the air box successively passing through the hollow sleeve pipe, slag discharging holes arranged on the clamping head, and further is discharged out through the air pipe. The slag removing mechanism is simple in structure, can effectively remove the slag and the dust adhered to the inner wall of the PCB hole, not only is environmentally friendly, but also has a good removal effect, and meanwhile, the slag can be automatically absorbed and discharged, secondary adhesion of the slag can be prevented, and the production efficiency is improved.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

Gear-type driven rotor dust treatment device for feed stirring motor

InactiveCN108097666AGuaranteed Periodic MotionEasy to handleFeeding-stuffCleaning processes and apparatusTherapeutic effectMechanical engineering

The invention discloses a gear-type driven rotor dust treatment device for a feed stirring motor. The device comprises a device body, the device body comprises a base, an adjusting box and an adhesivetape, a power cabin is arranged above the base, a supporting table is arranged above the adjusting box, a support is arranged in the power cabin, a pushing rod is arranged on the support, and a driving mechanism is arranged at the other end of the pushing rod and mainly comprises a driving gear, a rack, a driven and an incomplete gear. The device is simple in structure, the device body is drivenby the aid of a gear structure, back and forth cyclic motion of the adhesive tape is ensured, dust on the surface of a rotor is effectively removed in a sticking manner, treatment effects are good ascompared with treatment effects of a blowing mode, secondary attachment of dust is avoided, and the device is convenient to use and high in practicability.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

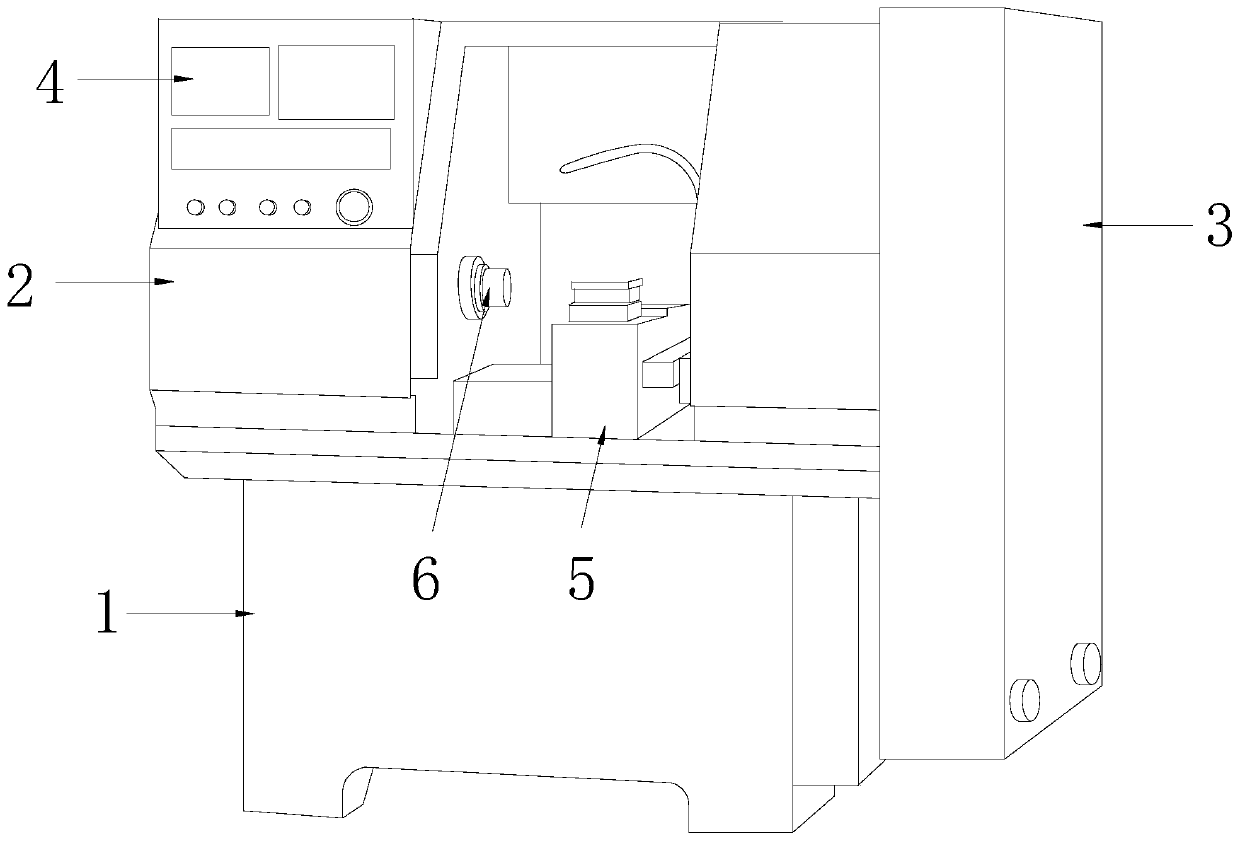

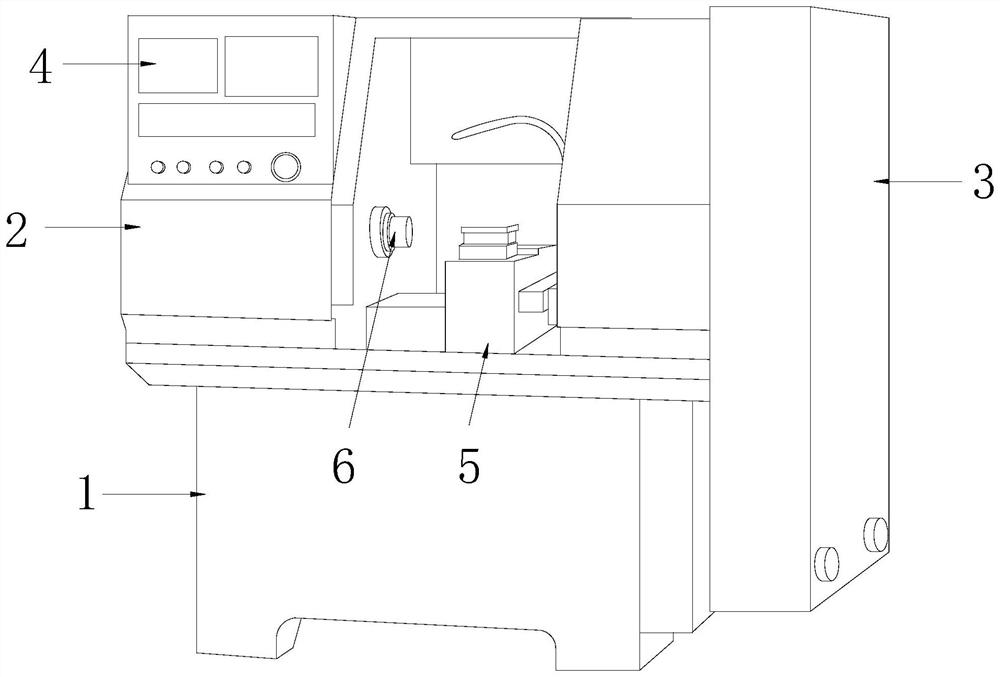

Numerical control lathe convenient for cleaning machine body

ActiveCN111515752AAchieving passive softeningAchieving a passive softening of the assuranceCleaning using toolsMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a numerical control lathe convenient for cleaning a machine body. The numerical control lathe convenient for cleaning the machine body structurally comprises a driving box, anequipment body, a smoothing device, a control panel, a working frame and a material buckle. The numerical control lathe convenient for cleaning the machine body has the beneficial effects that an arranged softening structure is used, under the cooperation of an internal air flow of a frame plate as a hot air flow and blowing outward and scraping plates installed in a symmetrical inclined shape, realizing the passive softening of oily stubborn impurities attached to the outer surface of the machine body is facilitated, then scraping is realized, and a large amount of thick accumulation on the outer surface of the machine body due to the characteristics of oily attachments is prevented from increasing the outer surface load of the machine body; and through the cooperation of a suction mechanism and a cleaning assembly, centralized adsorption treatment of attached metal chips is carried out to avoid secondary attachment, the magnetization of the metal chips on the machine body surface under the cooperation action of mechanical heat is prevented from enabling a machine body shell to appear a slight electrostatic phenomenon.

Owner:佛山市顺德区科创五金电器实业有限公司

Cleaning and maintaining device for construction equipment

InactiveCN111359939AReduce workloadEasy to cleanDrying gas arrangementsDirt cleaningWork taskSlide plate

The invention belongs to the technical field of construction, and particularly discloses a cleaning and maintaining device for construction equipment. In order to solve the problems that when the equipment is cleaned and maintained through an existing cleaning and maintaining device for construction equipment, due to single-spot sweeping, the working task load is high and omission spots easily occur during sweeping, paid energy is not proportional to harvest and the cleaning and maintaining effect is still poor, now the scheme is put forward. The cleaning and maintaining device comprises a bottom plate and a slide plate. A supporting ring is arranged and is of an elliptical annular structure, cleaning and maintaining apparatuses are installed on the supporting ring, when the equipment is cleaned and maintained, the equipment is cleaned through the cleaning and maintaining apparatuses at all spots on the supporting ring, workload is reduced, and the cleaning effect is improved; and meanwhile, all the apparatuses are slidingly connected to the inner wall of a slide groove through sliders, the position of the cleaning and maintaining device can be adjusted in the equipment cleaning and maintaining process, and therefore it is ensured that there are no dead corners in the cleaning process, and the cleaning and maintaining effect is further improved.

Owner:葛飞月

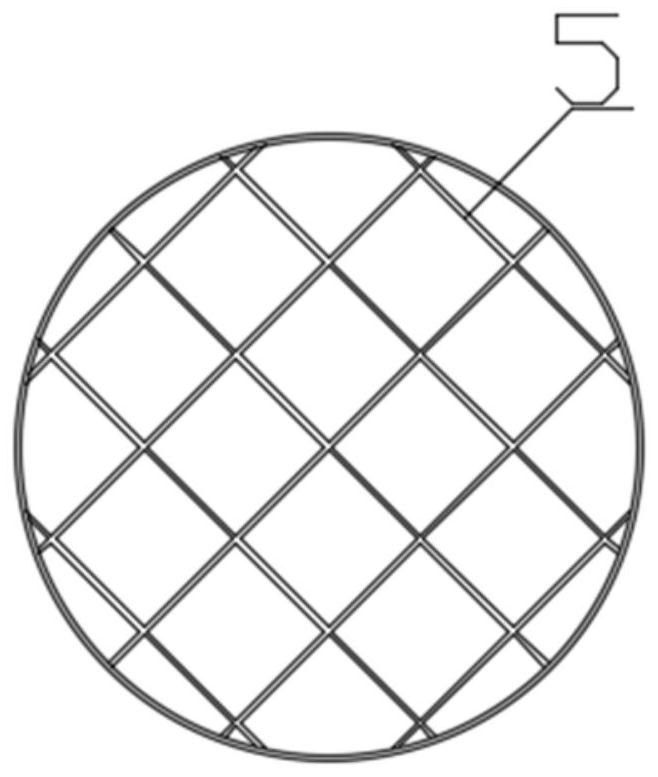

Self-suction underwater fishing net cleaning device capable of walking freely

InactiveCN112371607AImprove efficiencySimple structureCleaning using toolsCleaning using liquidsUnderwaterFishery

The invention discloses a self-suction underwater fishing net cleaning device capable of walking freely. The self-suction underwater fishing net cleaning device comprises a carrying frame, an idler wheel walking mechanism, a flow guide cover, a propeller and a main driving mechanism, wherein the propeller and the main driving mechanism are arranged in the flow guide cover. The idler wheel walkingmechanism is arranged at the four vertex corners of the carrying frame in the form of four idler wheels. The flow guide cover is fixedly arranged in the carrying frame, a suction inlet filter screen is arranged at a front end inlet, and an outlet filter screen is arranged at a rear end outlet; a steel wire brush is arranged at the suction inlet filter screen; and a rotary cutter and an outlet cutter edge plate are further arranged at the rear end of the flow guide cover. When the self-suction underwater fishing net cleaning device is started, a fishing net is adsorbed on the suction inlet filter screen, a propeller is started to generate negative pressure to suck water flow from the outside and fill the water flow, the fishing net makes full contact with the brush head of the steel wire brush at the moment, attachments flushed, ground and brushed off can be completely sucked into the flow guide cover in the water flow direction, and the attachments are cut by the rotary cutter and theoutlet cutter edge plate to meet the requirement for the mesh of the outlet filter screen and are then discharged to the external water environment along with water flow.

Owner:浙江维澜智能科技有限公司

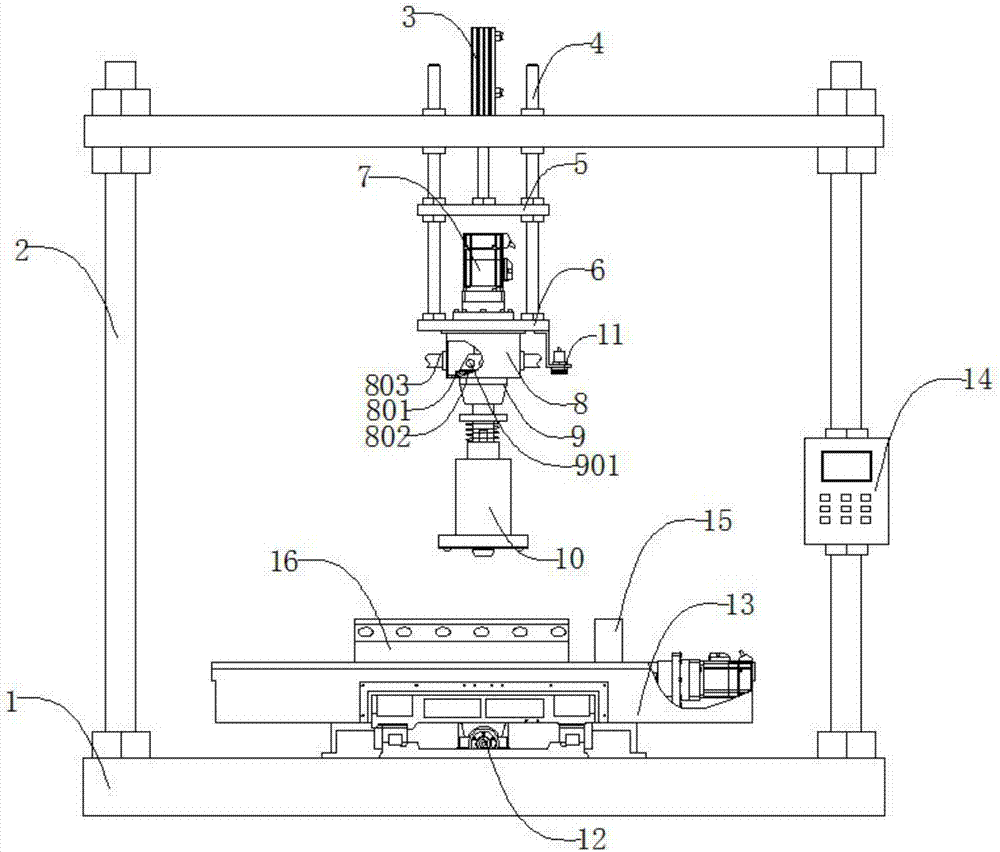

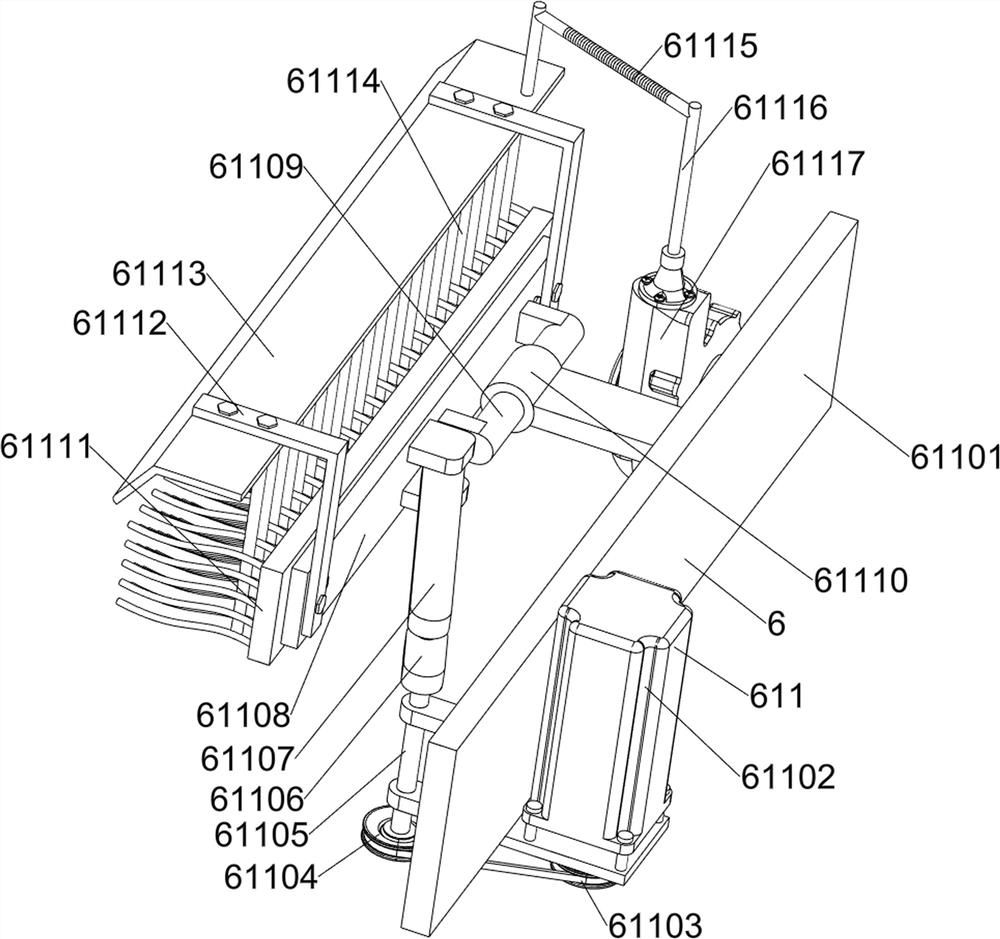

Slag removing machine for PCBhole

ActiveCN107457824ASimple device structureAvoid secondary attachmentMetal working apparatusElectronic waste recyclingElectric machinerySlag

The invention discloses a slag removing machine for a PCB hole. The slag removing machine for the PCB hole comprises a base, a door frame, an air cylinder, guide rods, an upper bearing plate, a lower bearing plate, a speed regulating motor, an air box, a clamping head, a pre-pressing drilling tool mechanism, a cross laser, a Y axis feeding mechanism, an X axis feeding mechanism, a controller, a marking block with a cross-shaped marking groove and a placing mold, wherein the guide rods are symmetrically arranged along the air cylinder; a PCB needing to be subjected to slag removing is placed in the placing mold, the controller controls the air cylinder to push the upper bearing plate to move down, thereby pushing the pre-pressing drilling tool mechanism to move down to compress the PCB tightly, the speed adjusting motor works to drive the drilling tool mechanism to extend out slowly, and a tool bit arranged on the drilling tool mechanism smashes and removes the slag adhered to the interior of the hole. The slag removing machine is simple in structure, and can effectively remove the slag and dust adhered to the inner wall of the PCB hole, environmental protection is achieved, the dissociative waste slag can be collected to prevent secondary adhesion of the waste slag, and simultaneously pre-pressing can automatically carried out, so that the hole wall is prevented from being damaged due to deformation of the PCB, and the yield of the PCB is improved.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

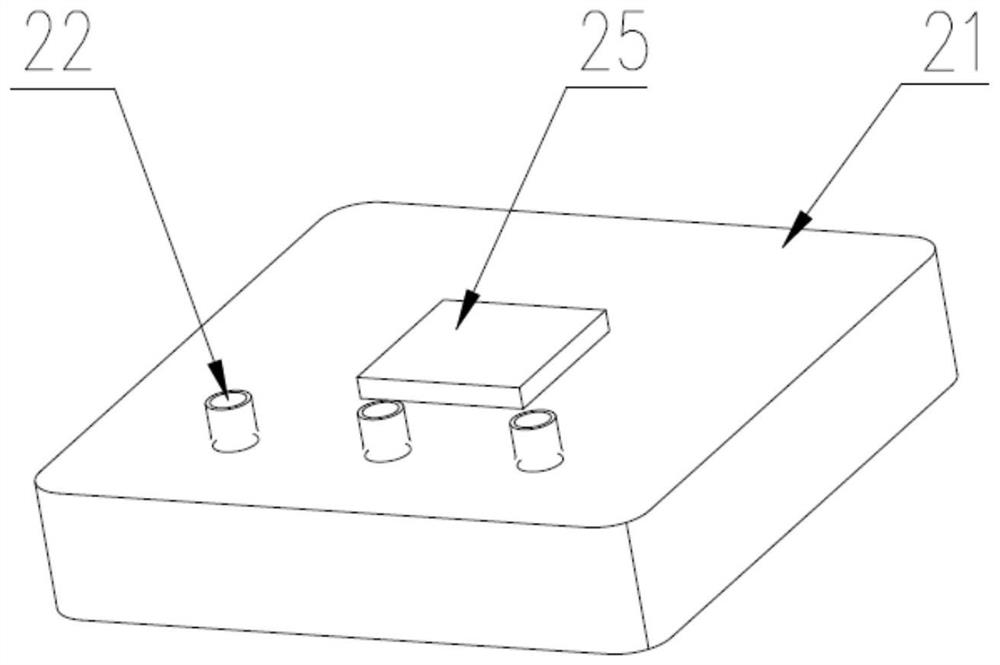

Integrated electroplating cleaning device

InactiveCN112481668AWell mixedGuaranteed cleanlinessDrying gas arrangementsCleaning using toolsAcid washingEngineering

The invention provides an integrated electroplating cleaning device. The integrated electroplating cleaning device comprises an electric mechanical arm (1), a pressure-resistant storage container (2),a spray head (4), a cleaning brush (5), a movable platform (7) and a controller (8), wherein the pressure-resistant storage container (2) comprises a container body (21), filling joints (22), discharge holes (23) and a mounting boss (25); the spray head (4) comprises a spray head shell (41), a sealing boss (42), a spraying channel (43), a brush mounting part (44) and a spraying hole (45); and thecleaning brush (5) comprises a cleaning brush disc (51), an arc-shaped guide plate (52) and brush heads (53). According to the device, acid pickling, cleaning, brushing, drying and combined compositewashing processes are effectively achieved; moreover, in the cleaning or drying process of the device, the brush heads always sweep the surface of a workpiece, so that dust is effectively prevented from being attached to the surface of the workpiece, the cleaning efficiency is high, and the effect is good; and the integrated electroplating cleaning device is widely suitable for cleaning treatmentof large-plane workpieces before electroplating.

Owner:龚兵

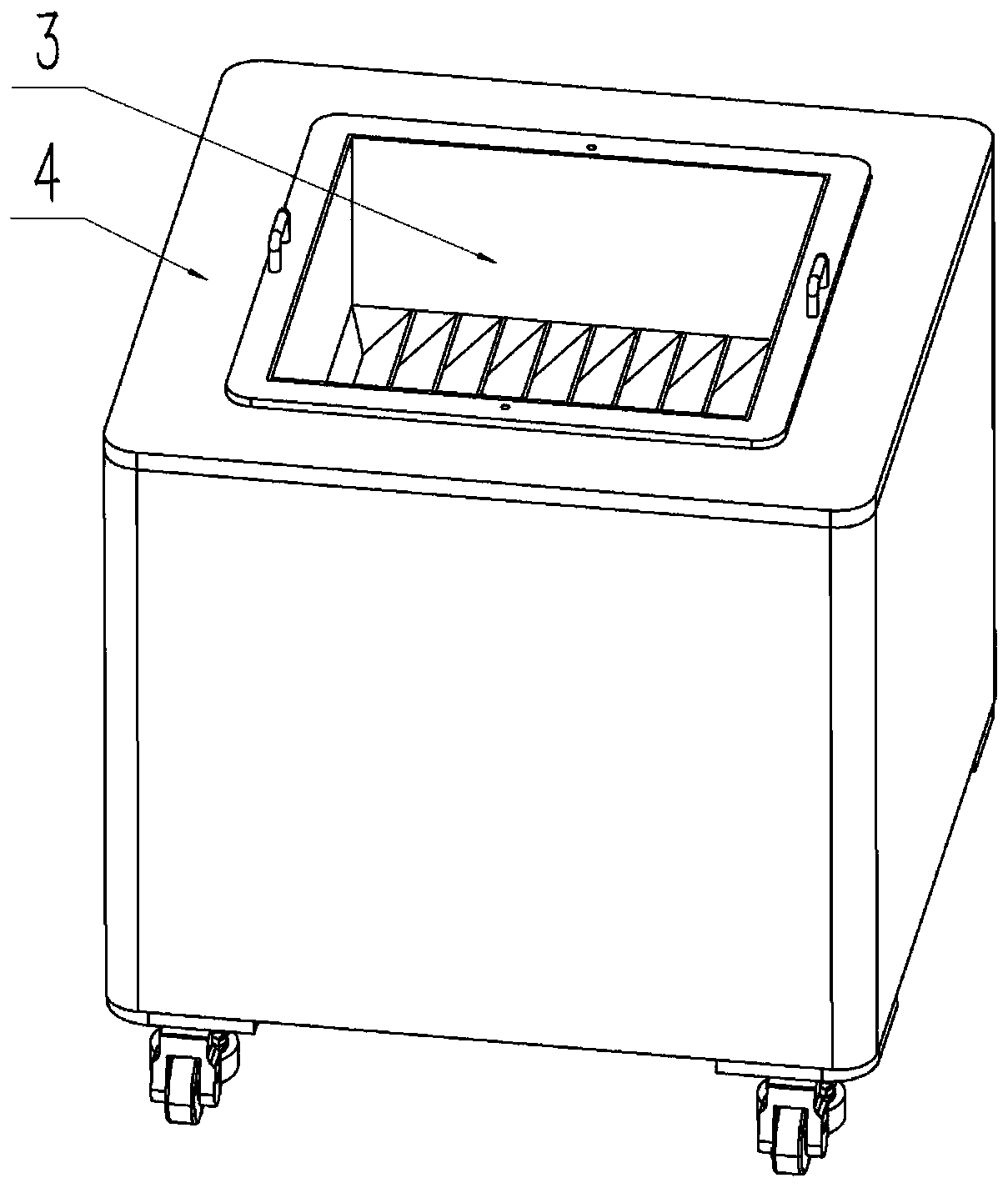

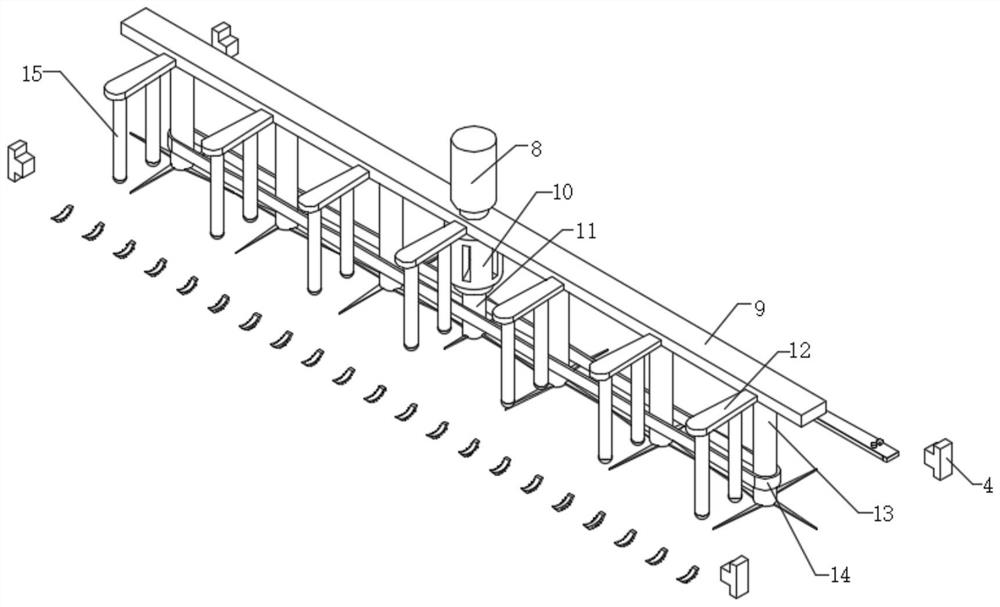

Workpiece production line, workpiece cleaning machine and workpiece cleaning groove

PendingCN110369366AAvoid secondary attachmentReduce the frequency of water changesCleaning using liquidsMaintainance and safety accessoriesProduction lineEngineering

The invention discloses a workpiece cleaning groove. A plurality of chip guide plates are arranged between opposite first groove wall and second groove wall of the workpiece cleaning groove; the chipguide plates are arranged slantwise; the upper space of each chip guide plate is a workpiece cleaning area; the lower space of each chip guide plate is a chip storage area; and each chip storage areais used for storing chips sliding off via the plurality of chip guide plates. The chip guide plates arranged slantwise are capable of effectively preventing the chips from continuing to move upwards,secondary attachment of the chips is avoided, and the water change frequency is reduced, so that thorough cleaning, high efficiency and low cost are achieved. The invention further discloses a workpiece cleaning machine. The workpiece cleaning machine comprises the workpiece cleaning groove. The invention further discloses a workpiece production line. The workpiece production line comprises the workpiece cleaning groove or the workpiece cleaning machine.

Owner:SUZHOU INST OF INDAL TECH

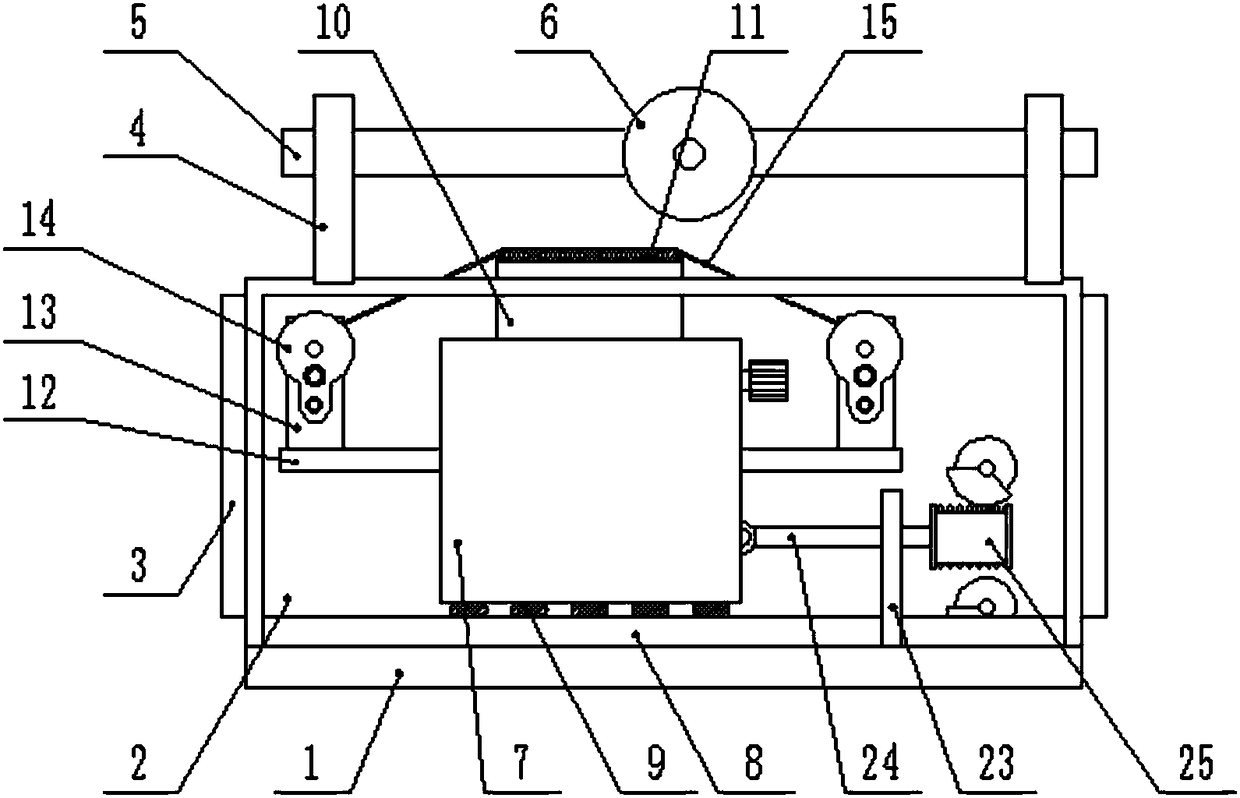

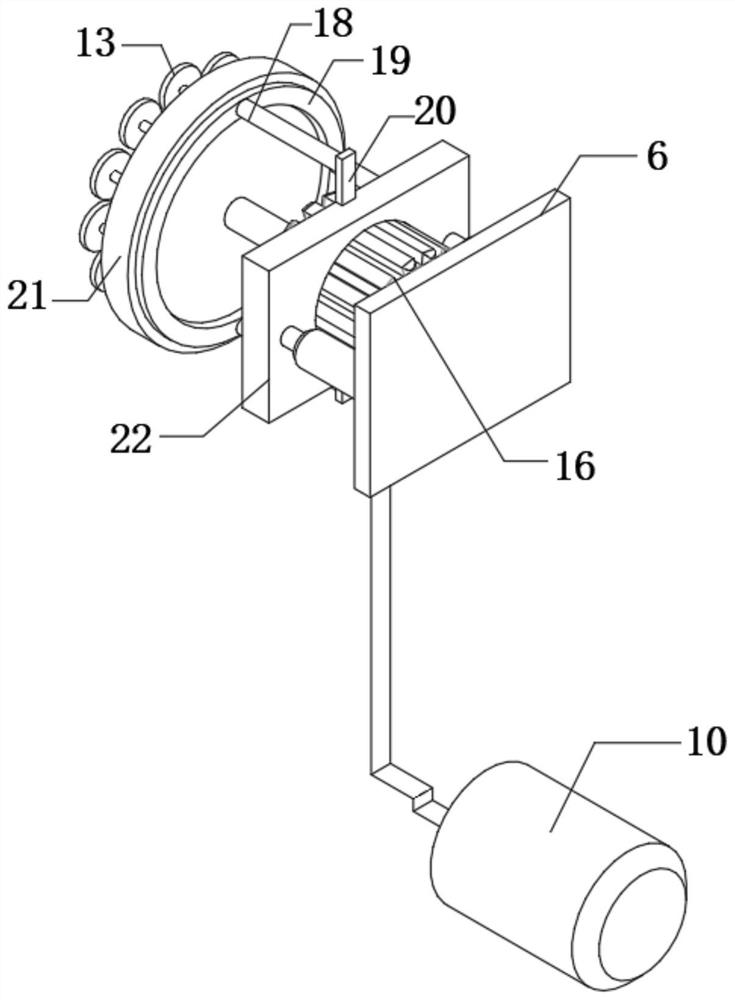

Swing type scrap iron removal device for grinding machining of cast iron materials

ActiveCN110153890AEasy to handleAvoid secondary attachmentGrinding/polishing safety devicesScrapCast iron

The invention discloses a swing type scrap iron removal device for grinding machining of cast iron materials. The scrap iron removal device comprises a device body, wherein the device body is providedwith a base, a treatment chamber is arranged above the base, a rolling screen is arranged inside the treatment chamber, the treatment chamber is internally provided with a sliding framework, an electromagnet is arranged inside the sliding framework, the device body is provided with an air pipe, a fan is arranged above the air pipe, a rotating shaft is arranged in the middle of the rolling screen,a gear is arranged on the rotating shaft, and the device body is provided with a power device. The swing type scrap iron removal device has the advantages that the structure is simple, scraps in thecast iron materials can be effectively treated in rotating and air blowing cooperated mode, moreover, the troublesome that due to the fact that the materials rotate in the same direction, the materials and the scraps synchronously rotate and then the scraps cannot be removed is avoided in a forward and reverse driving mode, after the scraps are collected, the scraps are attracted through the action of the electromagnet, the situation that the scraps are adhered to the materials again due to air blowing is avoided, the whole use is convenient, the process is simple, and the practicability is high.

Owner:东台震坤机械科技有限公司

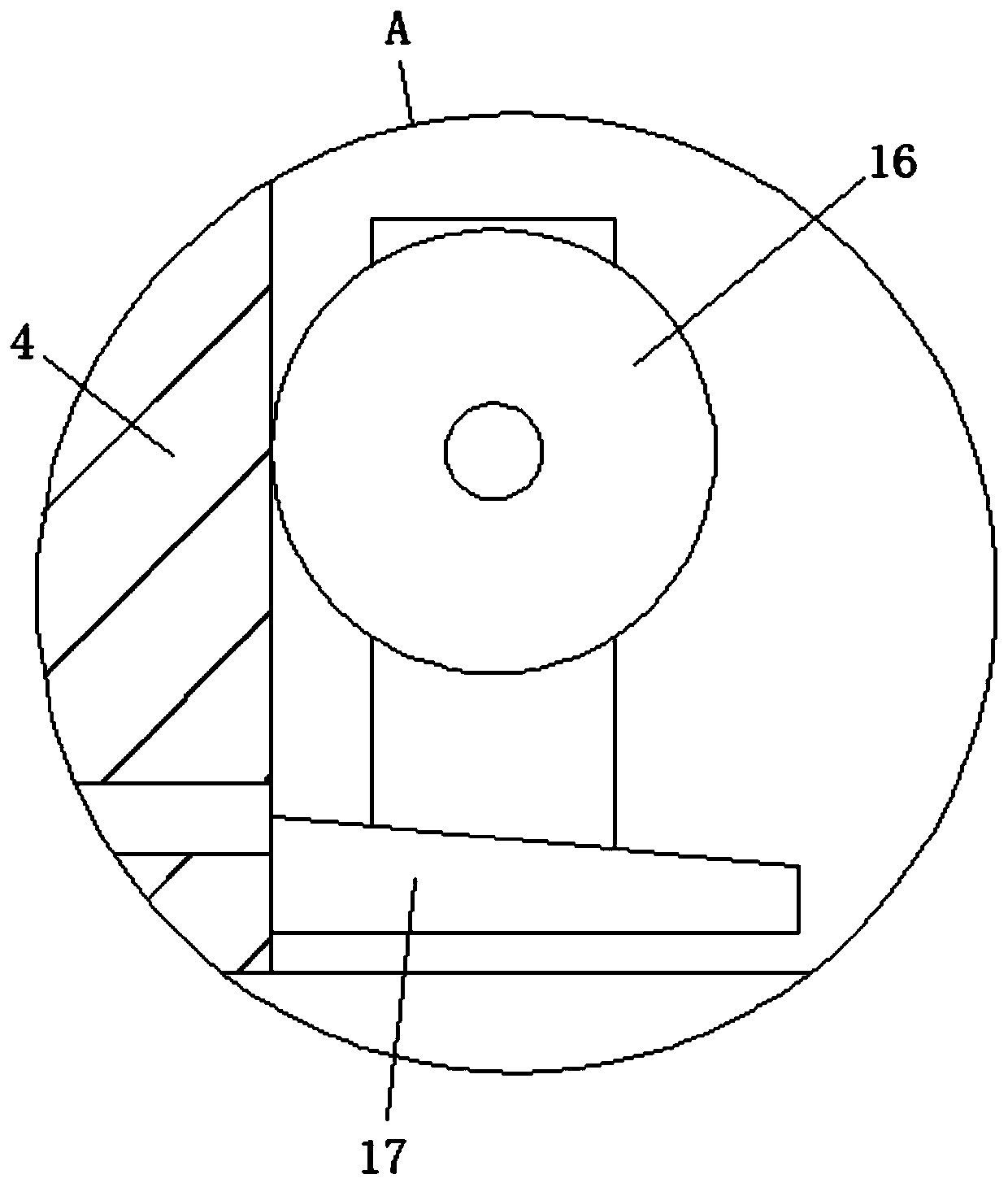

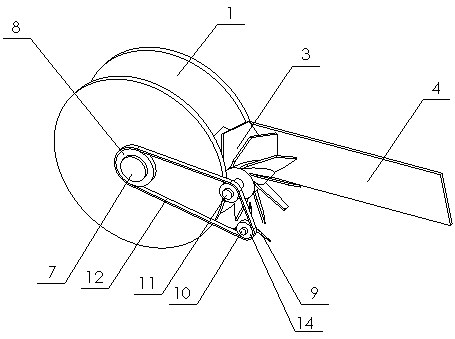

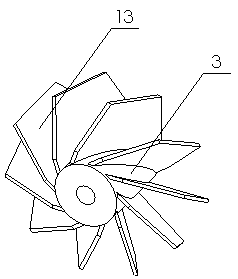

Soil removing device for belt pulley of agricultural machine

PendingCN110999582AAvoid secondary attachmentInhibit sheddingAgricultural machinesBlade plateImpeller

The invention discloses a soil removing device for a belt pulley of an agricultural machine. According to the soil removing device disclosed by the invention, the soil removing device is mounted on the existing belt grooved pulley and is driven by using power of the belt grooved pulley, scraped mud soil is pushed to one side of a belt in a manner that a tilted scraping blade is matched with blowing of fan blades, and thus, secondary attachment is avoided. The soil removing device is characterized in that a primary fixing frame and an auxiliary fixing frame are connected through an impeller shaft, a supporting bearing is arranged at a joint between the primary fixing frame and the auxiliary fixing frame, the primary fixing frame and the auxiliary fixing frame are in parallel, a scraping impeller sleeves the impeller shaft and is located between the primary fixing frame and the auxiliary fixing frame, a plurality of scraping blade plates are arranged on the impeller shaft in an equiangular manner, are trapezoidal plates and are of oblique stretching distribution, a connecting lug is arranged at the bottom of the primary fixing frame, one end of a fan shaft is arranged on the connecting lug at the bottom of the primary fixing frame through a bearing, and the fan blades are arranged at the other end of the fan shaft.

Owner:徐州蔬客达农业科技有限公司

A dust-removing composite cloth roller with self-cleaning function

InactiveCN106801327BSolve the removal problemAvoid secondary attachmentMechanical cleaningPressure cleaningEngineeringStatic electricity

Owner:南通滨海东泰纺织有限公司

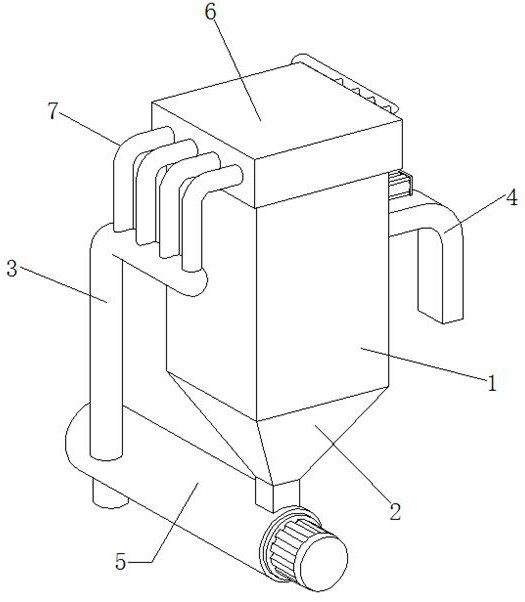

Dust removal device for electrical automation equipment

InactiveCN110813849AAvoid secondary attachmentGuaranteed cleaning effectDispersed particle filtrationTransportation and packagingElectric machineryDrive motor

The invention discloses a dust removal device for electrical automation equipment. The dust removal device comprises a base, wherein the top of the base is fixedly connected with a dust collection box; the top of the dust collection box fixedly communicates with a dust suction fan; one side of the dust collection box is symmetrically and fixedly connected with handle frames; anti-slip sleeves sleeve the handle frames; the other side of the dust collection box is fixedly connected with a connecting plate; the top of the connecting plate is fixedly connected with an electric push rod; the top ofthe electric push rod is fixedly connected with a clamp; the top of the dust suction fan is fixedly connected with a conveying leather hose; one end of the conveying leather hose is fixedly connectedwith a dust suction cover on the clamp; and the inside of the dust suction cover is symmetrically and rotationally connected with dust removal rollers. The dust removal device has the advantages thatthe dust suction fan is matched with the dust removal rollers arranged in the dust suction cover for dust removal on electrical parts; and meanwhile, the dust can be collected; the secondary attachment is avoided; the cleaning effect is ensured; a dismountable component is put on a filter screen frame; a driving motor can drive cleaning brush hair arranged on a rotating rod to be singly cleaned;and the use effect is good.

Owner:苏州吉玛自动化科技有限公司

Cement foaming plate dust removal system

InactiveCN106827275ARemove completelyRealize programming controlWorking accessoriesEngineeringDust fall

The invention discloses a cement foaming plate dust removal system. The cement foaming plate dust removal system is provided with a machine cover; an S-shaped positioning strip is arranged in the machine cover, a plurality of eccentric vibration wheels and a plurality of transmission wheels are arranged below the S-shaped positioning strip, the eccentric vibration wheels and two transmission wheels are connected together through a metal mesh belt, and a dust fall collection conveying belt is arranged below the metal mesh belt. The S-shaped positioning strip can ensure the floating dust removal effect on the two sides of a cement foaming plate, and non-thorough removing of floating dust can be avoided; through combination of the metal mesh belt and the eccentric vibration wheels, it can be ensured that after floating dust on the cement foaming plate is separated from the cement foaming plate, the floating dust falls on a dust fall collecting belt of the lower layer to be thoroughly separated from the cement foaming plate; the dust fall collecting belt continuously and synchronously conveys the floating dust separated from the cement foaming plate out of the machine body; stacking and choking of the dust fall in the machine body are avoided; a dust suction machine and a dust removing machine are combined, and secondary attaching of the dust fall on the cement foaming plate can be avoided.

Owner:张晓武

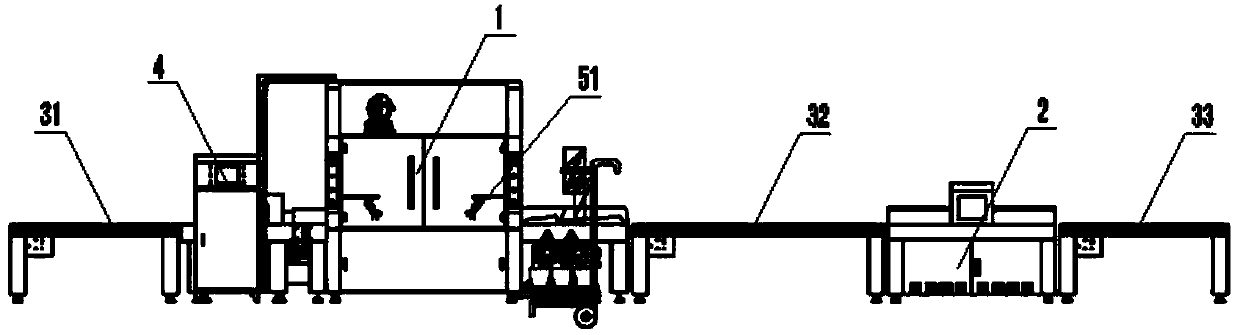

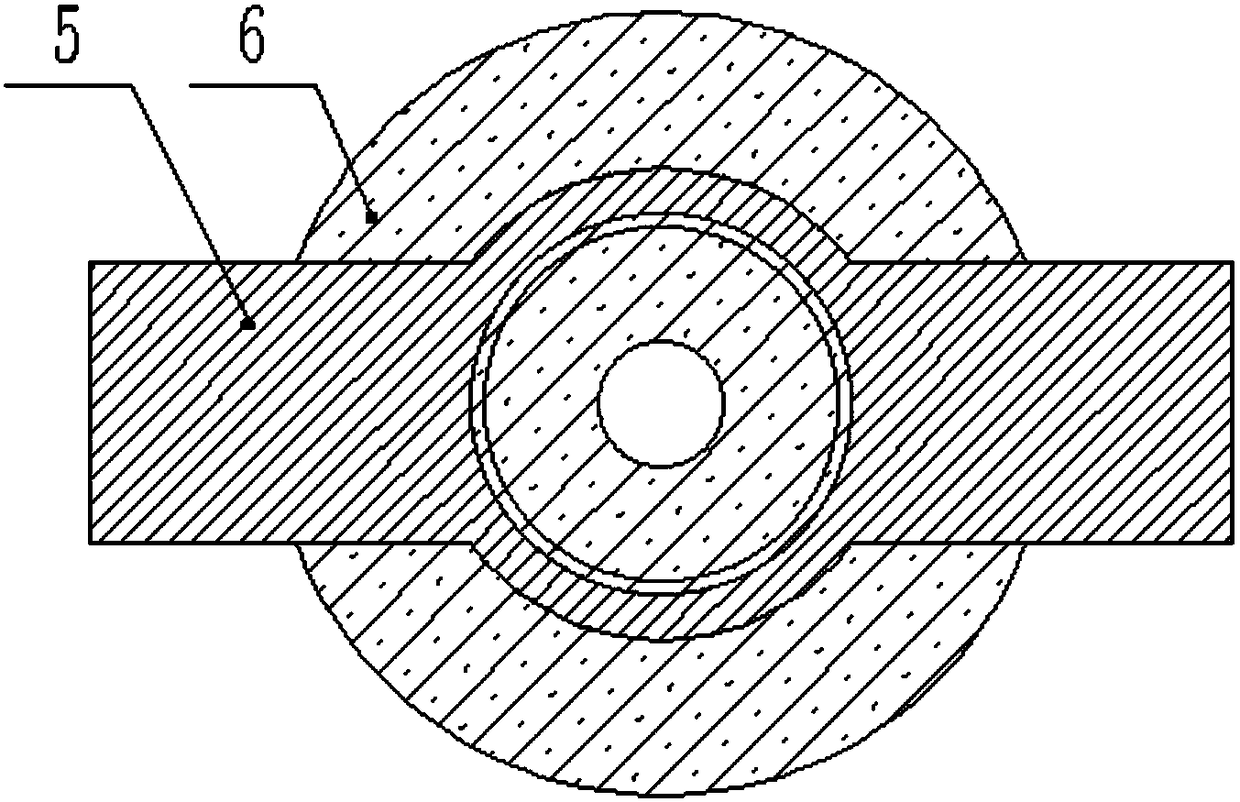

LED (light emitting diode) quick drying coating line

PendingCN109092596AImprove spraying effectAvoid secondary attachmentSpray boothsSpray coatingEngineering

The invention relates to an LED quick drying coating line. The LED quick drying coating line comprises a first feeding machine, a reciprocating coating machine, a second feeding machine, a curing machine and a third feeding machine, wherein the reciprocating coating machine comprises a spray coating chamber, a spray coating mechanism arranged inside the coating chamber, a conveying mechanism arranged inside the coating chamber, and a cleaning mechanism for cleaning the conveying mechanism, wherein the conveying mechanism comprises a conveying rack extending in a conveying direction inside thespray coating chamber, and conveying rollers arranged on the conveying rack; the cleaning mechanism comprises a scraper for cleaning the conveying rollers, and the scraper is arranged under the conveying roller and in contact with the outer circumferential surfaces of the conveying rollers. According to the LED quick drying coating line, the scraper in contact with the outer circumferential surfaces of the conveying rollers is applied to cleaning the conveying rollers; when conveying materials, the conveying rollers can rotate relative to the scraper, so that the scraper can timely clean oil attached to the conveying rollers, spray oil residues on the conveying rollers can avoid being attached to materials again, and further the material spray coating effects can be enhanced.

Owner:苏州首开环保科技有限公司

Injection mold cleaning equipment

The invention discloses injection mold cleaning equipment. The equipment comprises a shell, a laser, an air dryer, a cooling device and an air blowing device, wherein symmetrically-arranged laser moving rails are welded to the inner wall of the shell, the two ends of the laser are inserted into the laser moving rails correspondingly and do up-down translational motion along the laser moving rails through a motor driver, the laser is used for emitting laser to the surface of an injection mold to enable smudginess particles attached to the surface of the injection mold to generate expansion displacement of different degrees, and the air dryer is located on the inner wall of the shell and used for dehumidifying the shell; the cooling device is located on the inner wall of the shell and corresponds to the air dryer relative to the laser moving rails, the cooling device is used for enabling the dirty particles to generate a low-temperature cold brittleness phenomenon so as to prevent the dirty particles from deforming, and the blowing device is installed on the bottom face of the shell and located between the cooling device and the air dryer. The problem that the drying degree of air in equipment is low is solved, and secondary attachment of dirty particles caused by airflow backflow is avoided.

Owner:武汉兴天乐机电技术有限公司

Treatment device for bed board paint spraying

InactiveCN112372403AAvoid secondary attachmentImprove grinding effectGrinding carriagesGrinding drivesPolishingAir pump

The invention belongs to the technical field of furniture machining, and particularly relates to a treatment device for bed board paint spraying. Aiming at solving the problems that after a bed boardis subjected to paint spraying operation, the paint spraying thickness on the bed board is different, the paint thickness needs to be treated through a treatment device, the existing device usually adopts polishing plates for polishing, the polishing plate and paint contact points are in a tight connection state, consequently, excessive paint at the polished position is located between the polishing plate and paint, the polished paint is likely to be secondarily attached to the surface of the bed board, and the paint spraying treatment effect is reduced, the following scheme is now put forwards. According to the scheme, the device comprises a bottom plate and an adjusting plate. According to the treatment device, by arranging a hollow plates, polishing plates and an air sucking pump, during paint polishing, second hydraulic cylinders are adjusted to enable the polishing plates to make contact with paint on the bed board, gaps exist between the polishing plates in the polishing process,and therefore the air sucking pump can guide the ground paint into a collecting box through air holes, the situation that in the polishing process, the polished paint is secondarily attached to the bed board is avoided, and the polishing treatment effect is improved.

Owner:李家臣

Equipment for producing dustproof glass fiber composite felt

PendingCN114438694AAvoid wrinklesReduce contaminationMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention belongs to the technical field of glass fiber composite felts, in particular to equipment for producing dustproof glass fiber composite felts, and provides the following scheme that the equipment comprises a conveying table and a communicating plate, two fixed connecting plates are fixedly connected to the outer wall of the top of the conveying table, and sliding grooves are formed in the outer walls of one sides of the two fixed connecting plates; and the inner walls of the two sliding grooves are each slidably connected with two sliding blocks, the outer wall of one side of each sliding block is fixedly connected with the same first connecting frame, and the outer wall of the top of each first connecting frame is fixedly connected with a fixing base. Through the arrangement of the dust collection pump, the communicating plate, the flow dividing pipe and the dust collection plate, the dust collection pump is started after a blade cuts off thread residues on the glass fiber composite felt, and the dust collection pump collects the cut-off thread residues into the collection box through the dust collection plate on the flow dividing pipe on the communicating plate; therefore, the cut thread residues are prevented from being secondarily attached to the surface of the glass fiber composite felt, and the treatment effect on the glass fiber composite felt is improved.

Owner:JIANGSU JIACHENG SPECIAL FIBER

Crank-driven rotor dust treatment device for feed stirring motor

InactiveCN108176684AGuaranteed Periodic MotionEasy to handleCleaning processes and apparatusCircular discEngineering

The invention discloses a crank-driven rotor dust treatment device for a feed stirring motor. The crank-driven rotor dust treatment device for the feed stirring motor comprises a device body, whereinthe device body is provided with a base; a power cabin is arranged above the base; the device body is provided with an adjusting tank; a support table is arranged above the adjusting tank; the devicebody is provided with an adhesive tape; a support is arranged in the power cabin; a push rod is arranged on the support; one end of the push rod is hinged with an outer wall of the adjusting tank; a connecting rod is arranged on the other end of the push rod; a circular disc is arranged on the other end part of the connecting rod; and a fixing plate is arranged on the other side of the adjusting tank. The crank-driven rotor dust treatment device for the feed stirring motor provided by the invention is simple in structure; and the device body is driven through a crank structure, so that the back-and-forth periodic motion of the adhesive tape is ensured, dust on a surface of a rotor is effectively removed in an adhesion way, a treatment effect is better compared with an air blowing manner, secondary adhesion of the dust is avoided, and the crank-driven rotor dust treatment device for the feed stirring motor is convenient to use and high in practicability.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Efficient zinc oxide filtering and collecting device

InactiveCN113621830ASolve filterabilitySolve problems such as easy to cause blockageGas treatmentDispersed particle filtrationPhysical chemistryOxide zinc

The invention relates to the technical field of zinc oxide production equipment, and particularly discloses an efficient zinc oxide filtering and collecting device. The efficient zinc oxide filtering and collecting device comprises a collecting box, a collecting hopper, a feeding system and a negative pressure air inducing pipe, a partition plate is arranged at the upper end of the collecting box, a plurality of filter bag assemblies extending into the lower end of the collecting box are installed on the partition plate, a dust striking plate is arranged under the partition plate, through holes corresponding to the filter bag assemblies are formed in the dust striking plate, and a power assembly used for driving the dust striking plate to rise and fall instantly is further arranged on the partition plate; through the arrangement of the dust striking plate and a compressed air cleaning system, when the dust striking plate falls down and excites dust attached to a filter cloth bag, the excited dust is blown into the collecting hopper by blowing compressed air, so that the excited dust can be effectively prevented from being attached to the filter cloth bag for the second time, the filter cloth bag can be quickly and effectively cleaned and dredged, the whole efficient zinc oxide filtering and collecting device is novel in structural arrangement, excellent in anti-blocking effect and high in practicability.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

A self-cleaning anti-secondary pollution LED screen dust removal device

ActiveCN113198752BSelf-cleaningAvoid damageCleaning using toolsCleaning using gasesDust controlSelf adaptive

The invention relates to LED screen maintenance equipment, in particular to a self-cleaning LED screen dust removal device for preventing secondary pollution. The technical problem of the present invention is to provide a self-cleaning anti-secondary pollution LED screen dust removal device. Technical solution: A self-cleaning anti-secondary pollution LED screen dust removal device, including a connecting frame, a control screen, a first connecting ring, a second connecting ring, a clamping system and a dust removal system; the connecting frame is connected to the control screen The connecting frame is fixedly connected with the first connecting ring and the second connecting ring in turn; the connecting frame is connected with the clamping system; the connecting frame is connected with the dust removal system. The invention can adapt to the size of the frame of the LED screen, fix the frame of the LED screen, prevent the LED screen from being damaged during cleaning, and remove the dust on the LED screen from top to bottom, avoiding secondary adhesion of dust, and at the same time can Realize self-cleaning of dust removal parts, good cleaning effect and easy operation.

Owner:广东瀛凯视讯科技有限公司

A wide range of track cleaning equipment with deicing function

The invention relates to track cleaning equipment wide in application range and having a deicing function. The track cleaning equipment comprises a shell, a connecting bar, two moving blocks, two limiting plates and two deicing mechanisms. An adjusting mechanism is arranged in the shell. The adjusting mechanism comprises a drive assembly and two adjusting assemblies. The drive assembly comprises afirst motor, a first gear and two drive units. Each drive unit comprises a first rack, a limiting slot, a vertical bar and a link. Each adjusting assembly comprises a fixed bar, a slider and two drive bars. According to the track cleaning equipment wide in application range and having the deicing function, the distance between the two moving blocks is adjusted through the adjusting mechanism, sothat the track cleaning equipment is suitable for tracks of different gauge specifications, the application range of the track cleaning equipment is increased, the deicing mechanisms clean away obstacles on the track such as frost and ice that affect the track cleaning operation, thus the cleaning effect is strengthened, and the practicality of the track cleaning equipment is greatly improved.

Owner:MAANSHAN XINQIAO IND DESIGN CO LTD

An intelligent electric automatic dust removal device

ActiveCN111001253BAffect the dust removal effect of pretreatmentImprove the effect of secondary dust removalCombination devicesDust controlEnvironmental engineering

The invention belongs to the technical field of dust removal devices, and discloses an intelligent electric automatic dust removal device, which includes a control device, a device housing, and an air intake assembly connected to the air inlet end of the device housing, and a partition is arranged inside the device housing , and thus separate the inside of the device housing to form two processing chambers, and the control device is installed in any of the processing chambers; one of the processing chambers is equipped with a first filter screen; the other processing chamber is installed with a first air outlet Pipe, and a water tank is installed under the first air outlet pipe; detection devices are installed on the first air outlet pipe and the air inlet assembly; the above-mentioned settings based on the detection device can effectively detect the dust content of the air intake of the dust removal device Once the dust content of the air outlet is higher than the preset value, it is determined that the first filter is damaged; at this time, adjust the direction of the air outlet of the dust removal device to enter the water tank for secondary dust removal, thus ensuring The pretreatment dust removal effect of the dust removal device.

Owner:茂名市茂南奥邦涂料有限公司

A kind of CNC lathe which is easy to clean the machine body

ActiveCN111515752BAchieving passive softeningAchieving a passive softening of the assuranceCleaning using toolsMaintainance and safety accessoriesNumerical controlStructural engineering

The invention discloses a numerically controlled lathe which is convenient for cleaning the machine body. The structure comprises a drive box, a device main body, a smoothing device, a control panel, a working frame and a material buckle. Beneficial effects: the present invention utilizes the softening structure provided, and with the cooperation of the airflow inside the frame plate being a hot airflow blowing outward and the scraper being installed in a symmetrical and inclined shape, it is beneficial to ensure the oiliness of the outer surface of the fuselage. Stubborn impurities are passively softened, and then scraped off to avoid a large amount of thick accumulation on the outer surface of the fuselage due to the characteristics of oily deposits, which will increase the load on the outer surface of the fuselage. The cooperation of the components, the concentrated adsorption treatment of the attached metal shavings to avoid secondary attachment, and then help to prevent the metal shavings from being magnetized on the surface of the fuselage under the cooperation of mechanical heat, resulting in slight static electricity on the fuselage shell Phenomenon.

Owner:佛山市顺德区科创五金电器实业有限公司

Computer memory bank cleaning device based on new-generation information technology

InactiveCN112337837AAvoid scratchesTo achieve the effect of wiping the memory stickCleaning using toolsCleaning using gasesMemory bankEngineering

The invention relates to the technical field of computer auxiliary equipment, and discloses a computer memory bank cleaning device based on a new-generation information technology. The computer memorybank cleaning device comprises a base, the top of the base is fixedly connected with a fixed plate, the inner bottom wall of the fixed plate is fixedly connected with a reset spring, and the top of the reset spring is fixedly connected with a movable block; and a sliding block is movably connected to the right side of the fixed plate, a movable rod is inserted into the left side of the sliding block, a movable plate is fixedly connected to the right side of the movable rod, and two rubber blocks are fixedly connected to the right side of the movable plate. When the sliding block and the movable block move downwards, the movable rod always abuts against the movable block to enable the rubber blocks to extend rightwards to wipe a memory bank, when the sliding block reaches the lowest position, the movable block rapidly ascends and resets under the action of the reset spring to be separated from the movable rod, and the movable rod drives the rubber blocks to shrink leftwards under the action of an extrusion spring, so that the memory bank is not wiped when the sliding block moves upwards, and the memory bank is prevented from being repeatedly wiped and scratched by the rubber blockson the memory bank.

Owner:南京希远侃商贸有限公司

A device for removing iron scraps for grinding and processing of swing type cast iron materials

ActiveCN110153890BEasy to handleAvoid secondary attachmentGrinding/polishing safety devicesGear wheelEngineering

The invention discloses a device for removing iron scraps for grinding and processing swing-type cast iron materials. A sliding frame is arranged, an electromagnet is arranged inside the sliding frame, an air duct is arranged on the device body, a fan is arranged above the air pipe, a rotating shaft is arranged in the middle of the rolling screen, a gear is arranged on the rotating shaft, and a power device is arranged on the device body. The invention has a simple structure, can effectively process debris in the cast iron material by means of rotation and air blowing, and avoids the synchronous rotation of the material and debris caused by the rotation of the material in the same direction and cannot be removed by means of forward and reverse driving. After the debris is collected, it is adsorbed by the electromagnet to avoid the secondary attachment of debris caused by blowing to the material. The overall use is convenient, the process is simple, and the practicability is strong.

Owner:东台震坤机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com