Dedusting composite cloth roller with self-cleaning function

A self-cleaning, composite cloth technology, used in mechanical cleaning, high-pressure cleaning, textiles and papermaking, etc., can solve the problems of not removing dust and impurities from textiles, inconvenient to remove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

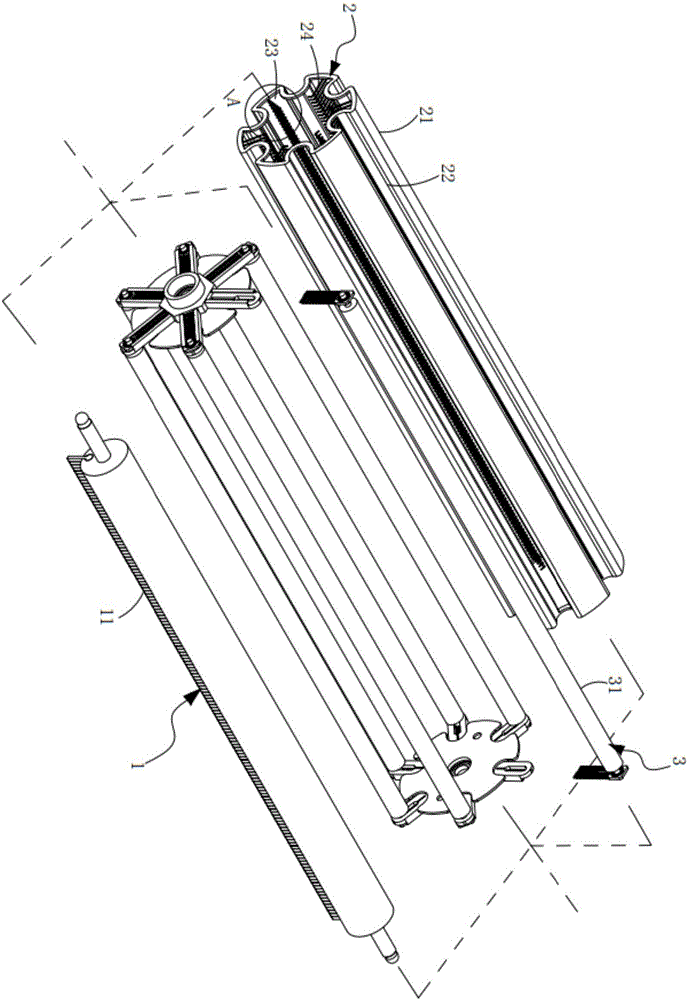

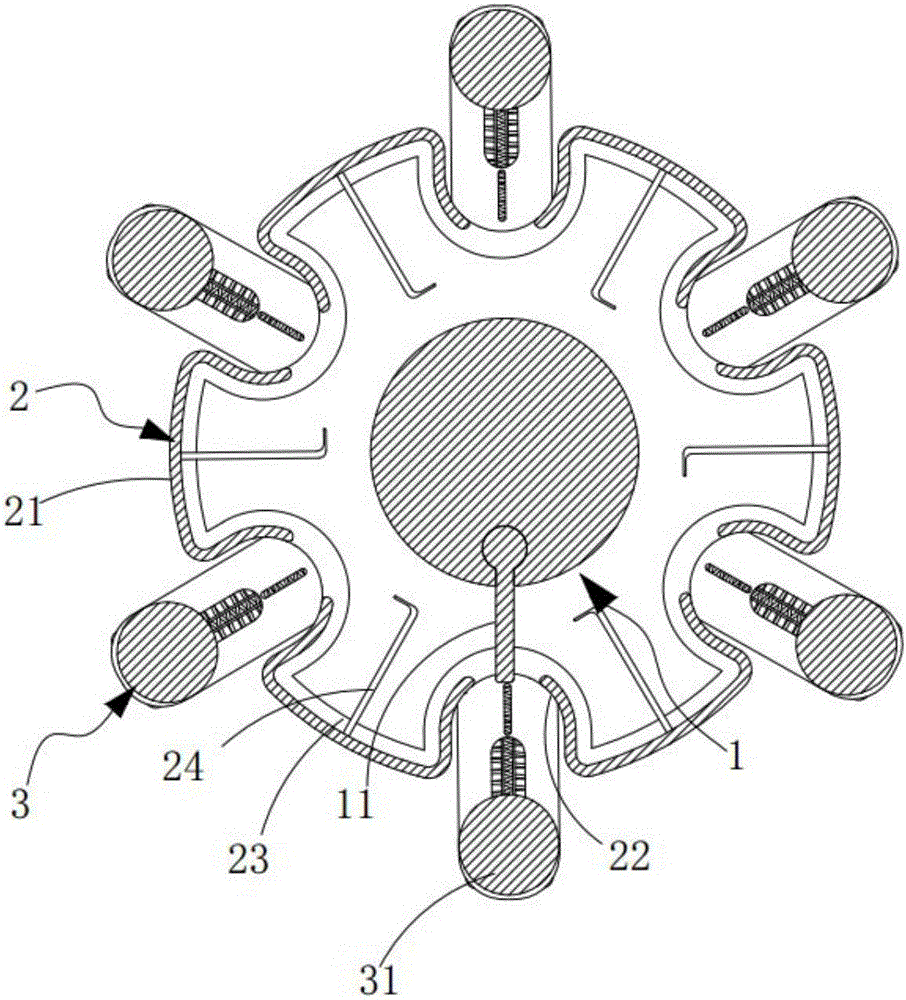

[0051] Such as figure 1 and figure 2 As shown, a dust-removing composite cloth roller with self-cleaning function includes:

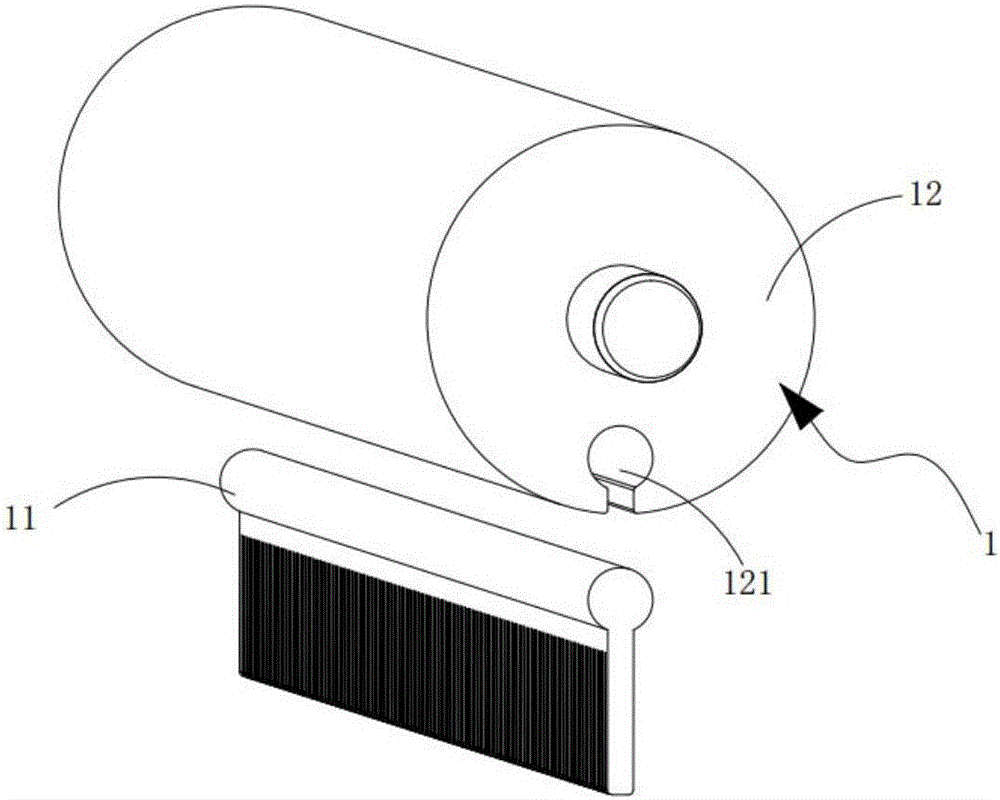

[0052] A brush roller mechanism 1, a coarse cloth roller mechanism 2 and a fine cloth roller mechanism 3, the brush roller mechanism 1 is concentrically arranged inside the coarse cloth roller mechanism 2, and its two ends are fixedly arranged, and the coarse cloth roller mechanism 2 can be opposite to the brush The roller mechanism 1 rotates; the fine cloth roller mechanism 3 is sleeved on the outside of the coarse cloth roller mechanism 2, and it rotates synchronously with the coarse cloth roller mechanism 2; one end of the brush roller mechanism 1 is provided with a brush 11. The coarse cloth roller mechanism 2 includes a coarse cloth roller 21 which is hollow inside, and a number of arc-shaped storage grooves 22 are arranged in an array on its circumference, and the arc-shaped storage grooves 22 penetrate from one end of the coarse cloth roller 21...

Embodiment 2

[0072] Figure 9 , Figure 10 and Figure 11 It is a schematic structural view of Embodiment 2 of a dust-removing composite cloth roller with self-cleaning function of the present invention; as Figure 9 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0073] Such as Figure 9 As shown, a sealing assembly 27 is provided at the bottom of the arc-shaped storage slot 22 , and the sealing assembly 27 slides along the arc-shaped storage slot 22 to control the opening and closing of the bottom opening of the arc-shaped storage slot 22 .

[0074] Further, as an improved technical solution, the sealing assembly 27 includes:

[0075] The fan-shaped sealing plate 271 symmetrically arranged at the bottom of the arc-shaped storage groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com