A kind of CNC lathe which is easy to clean the machine body

A technology of CNC lathes and fuselages, which is applied in the field of CNC lathes, and can solve problems such as inability to remove stubborn objects, static electricity on the surface of the fuselage, and thermal magnetization of metal shavings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

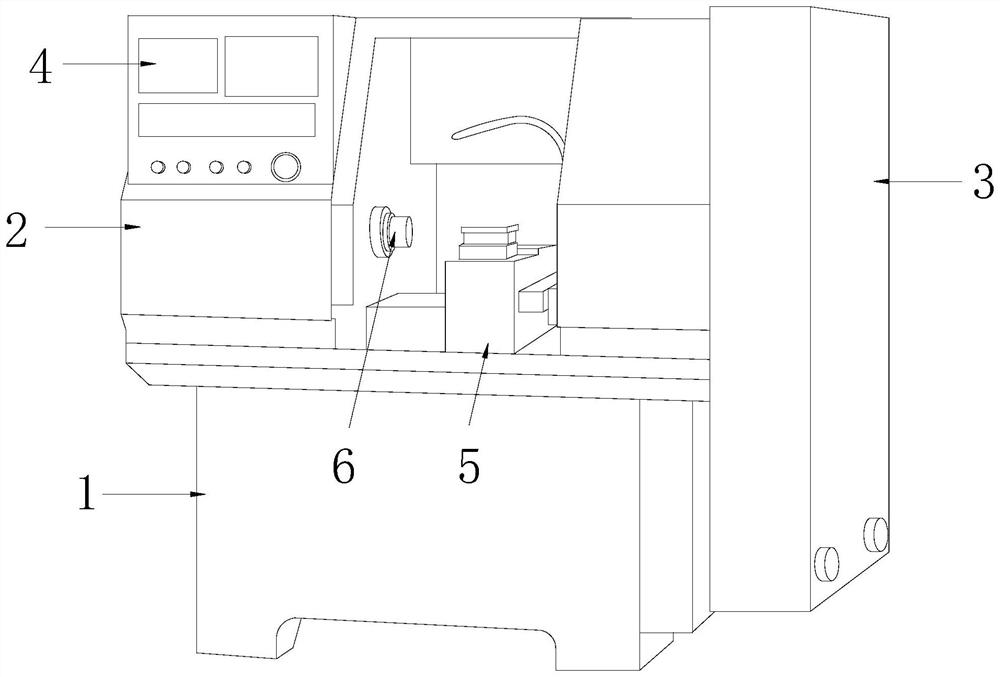

[0027] like Figure 1-Figure 3 As shown, the present invention provides a kind of technical scheme that is convenient to clean the numerical control lathe of fuselage:

[0028] like Figure 1-Figure 2 As shown, a kind of numerical control lathe that is easy to clean the fuselage, its structure includes driving box 1, equipment main body 2, smoothing device 3, control panel 4, working frame 5, material buckle 6, and described equipment main body 2 is arranged on driving box The upper surface of 1 is connected by electric welding, the smoothing device 3 is arranged on the outer surface of the equipment main body 2 and connected by screw fastening, the control panel 4 is arranged on the front surface of the equipment main body 2 and connected by electric welding, the The working frame 5 is arranged in the middle of the equipment main body 2 and connected by electric welding. The material buckle 6 is arranged on the left side of the middle of the equipment main body 2 and connect...

no. 2 example

[0037] like figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the present invention provides a kind of technical scheme that is convenient to clean the numerical control lathe of fuselage:

[0038] like Figure 1-Figure 2 As shown, a kind of numerical control lathe that is easy to clean the fuselage, its structure includes driving box 1, equipment main body 2, smoothing device 3, control panel 4, working frame 5, material buckle 6, and described equipment main body 2 is arranged on driving box The upper surface of 1 is connected by electric welding, the smoothing device 3 is arranged on the outer surface of the equipment main body 2 and connected by screw fastening, the control panel 4 is arranged on the front surface of the equipment main body 2 and connected by electric welding, the The working frame 5 is arranged in the middle of the equipment main body 2 and connected by electric welding. The material buckle 6 is arranged on the left side of the middle of the equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com