Cleaning and maintaining device for construction equipment

A technology for construction and equipment, applied in the field of cleaning and maintenance devices for construction equipment, can solve the problems of disproportion between effort and harvest, easy to miss points in cleaning, poor cleaning and maintenance effect, etc., so as to improve cleaning and maintenance effect and reduce work amount, the effect of accelerating the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

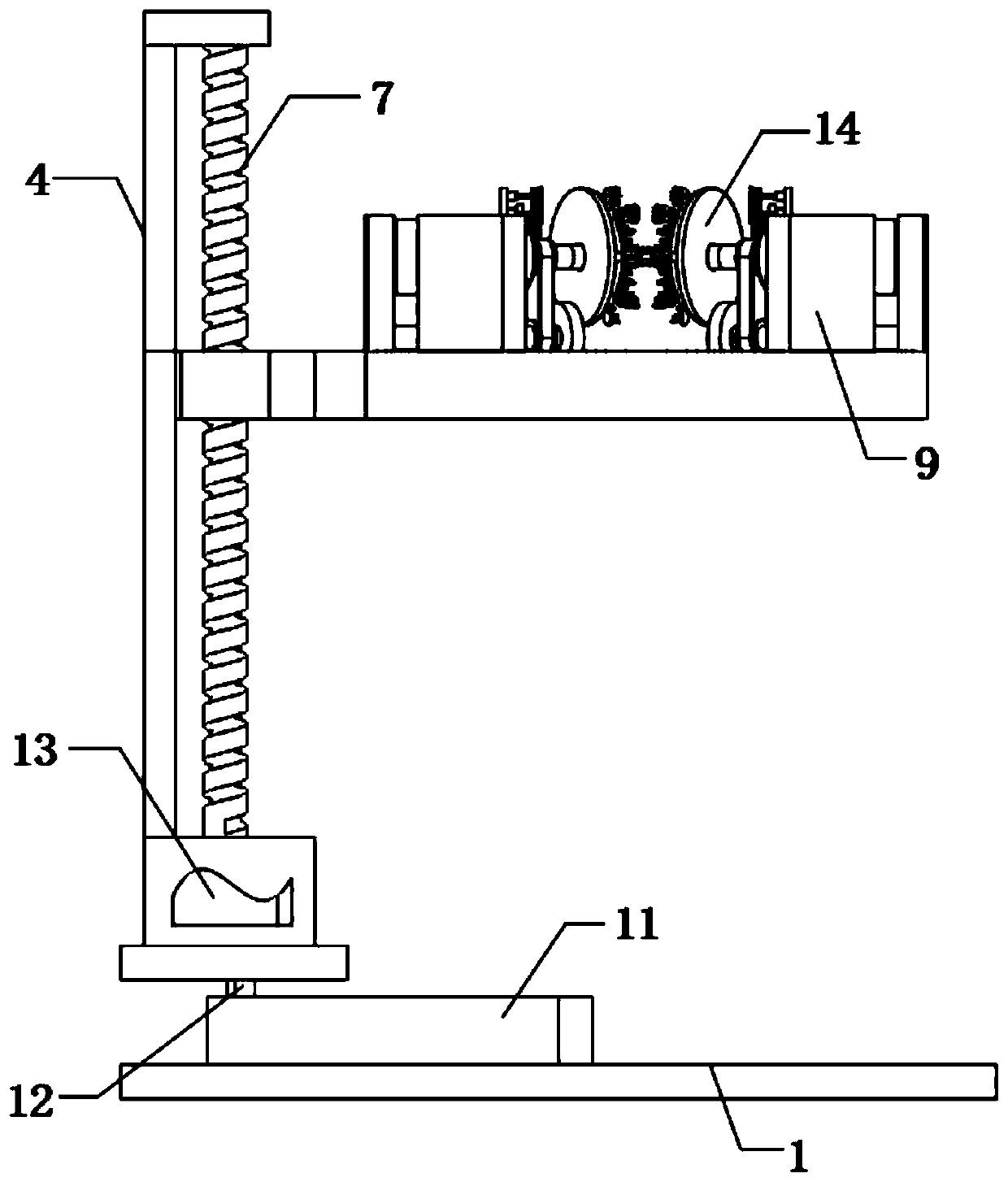

[0028] refer to Figure 1-3 , a cleaning and maintenance device for building construction equipment, comprising a base plate 1 and a slide plate 2, the top outer wall of the slide plate 2 is fixedly connected with a motor box 3, and the inner wall of the motor box 3 is fixedly connected with a No. 2 motor 13, and the output shaft of the No. 2 motor 13 The lead screw 7 is fixed through the coupling, and the top outer wall of the motor box 3 is fixedly connected with the limit groove 4, the top outer wall of the limit groove 4 is fixedly connected with the top plate 6, and the other end of the lead screw 7 is connected to the top plate 6 through a bearing The outer wall of the bottom of the lead screw 7 is threadedly connected with a threaded block 5, the threaded block 5 is slidably connected to the inner wall of the limit groove 4, and the other side outer wall of the threaded block 5 is fixedly connected with a support ring 10, and the support ring 10 is fixedly connected with...

Embodiment 2

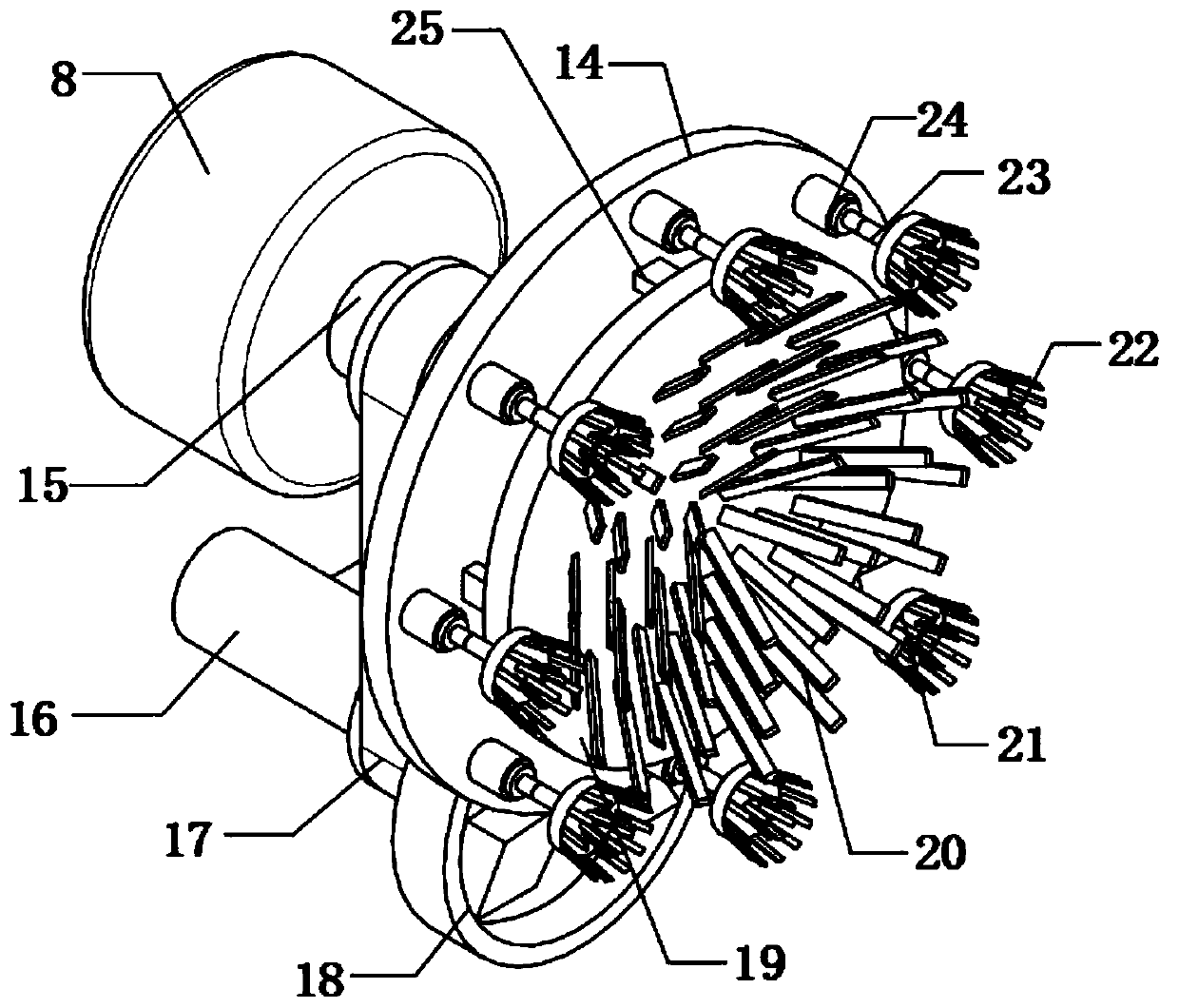

[0038] refer to Figure 3-5, a cleaning and maintenance device for building construction equipment, comprising a base plate 1 and a slide plate 2, the top outer wall of the slide plate 2 is fixedly connected with a motor box 3, and the inner wall of the motor box 3 is fixedly connected with a No. 2 motor 13, and the output shaft of the No. 2 motor 13 The lead screw 7 is fixed through the coupling, and the top outer wall of the motor box 3 is fixedly connected with the limit groove 4, the top outer wall of the limit groove 4 is fixedly connected with the top plate 6, and the other end of the lead screw 7 is connected to the top plate 6 through a bearing The outer wall of the bottom of the lead screw 7 is threadedly connected with a threaded block 5, the threaded block 5 is slidably connected to the inner wall of the limit groove 4, and the other side outer wall of the threaded block 5 is fixedly connected with a support ring 10, and the support ring 10 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com