Integrated electroplating cleaning device

A cleaning device and integrated technology, which is applied in the directions of dry gas arrangement, cleaning method and tools, cleaning method using tools, etc., can solve the problems of granular impurities on the surface of the workpiece, affecting the smooth progress of electroplating, dust or floating ash residue, etc. , to achieve the effect of avoiding two or more cleanings, saving manpower and material resources, production costs, and prolonging the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

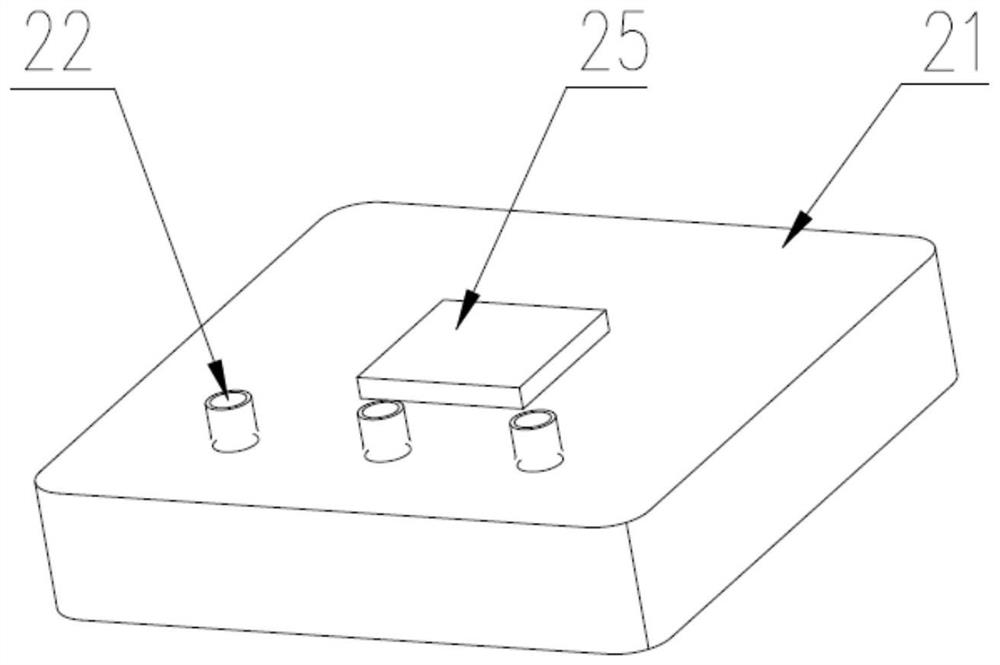

[0035] As shown in Figures 1 to 9, an integrated electroplating cleaning device is characterized in that the cleaning device includes an electric mechanical arm 1, a pressure-resistant storage container 2, a nozzle 4, a cleaning brush 5, a movable platform 7 and a controller 8; The electric mechanical arm 1 is a multi-axis mechanical arm, which is fixedly installed on the movable platform 7; the electric mechanical arm 1 is a three-axis or four-axis mechanical arm, and the multi-axis mechanical arm can be selected according to the workpiece to be sprayed. The central axes of joint connection points are parallel to each other (such as figure 1shown). The pressure-resistant storage container 2 includes a container body 21, a filling joint 22, a discharge hole 23, and an installation boss 25. The container body 21 is a square structure, and the installation boss 25 is arranged on the center position of the upper end surface of the container body 21. The end of the mechanical arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com