Slag removing machine for PCBhole

A technology of PCB board and slag remover, applied in metal processing and other directions, can solve the problems of long reaction time and low efficiency, and achieve the effect of preventing secondary adhesion, preventing hole wall damage, and improving PCB board yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

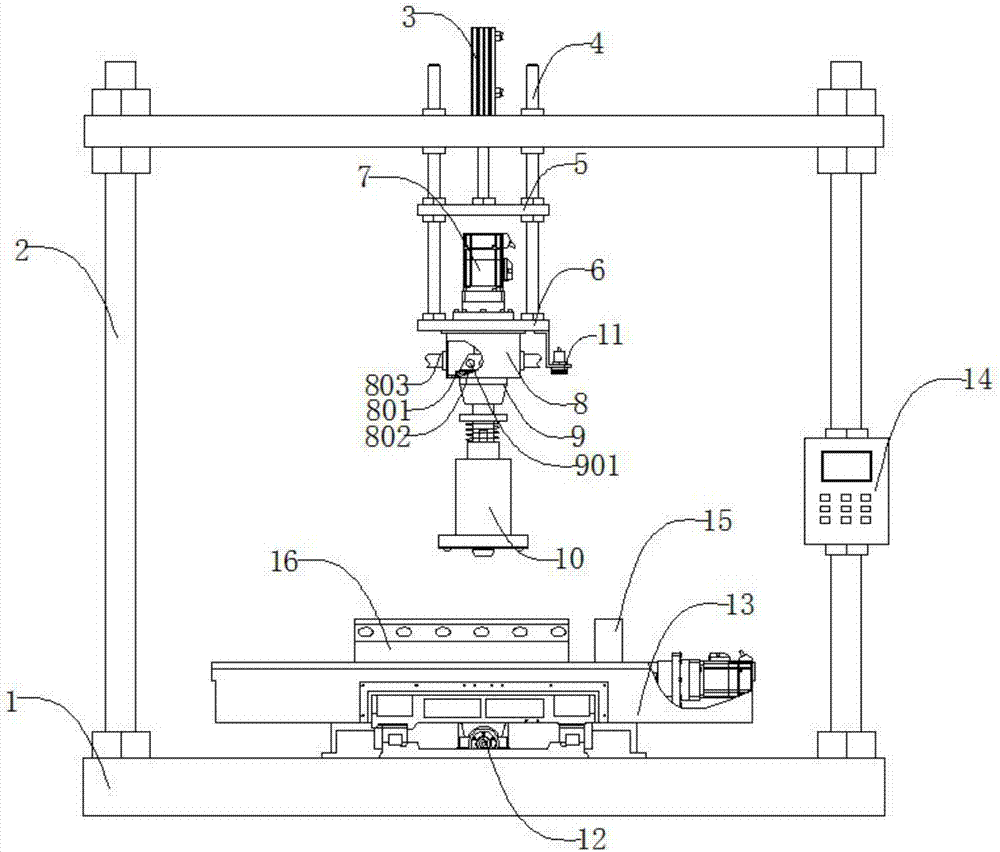

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a PCB board hole slag remover includes a base 1, a door frame 2, a cylinder 3, a guide rod 4 arranged symmetrically along the cylinder 3, an upper pallet 5, a lower pallet 6, a speed regulating motor 7, Bellows 8, collet 9, pre-pressing drill mechanism 10, cross laser 11, Y-axis feed mechanism 12, X-axis feed mechanism 13, controller 14, marking block 15 with cross mark groove 1501, placement mold 16 , the door frame 2 is located at the upper end of the base 1, the door frame 2 is threaded adjacent to the base 1, the cylinder 3 is located at the upper end of the door frame 2, and the cylinder 3 is connected with the door frame 2 with threads, the The guide rod 4 runs through the door frame 2, the guide rod 4 is connected with the door frame 2 in a gap, the upper supporting plate 5 is located at the lower end of the cylinder 3 and is penetrated by the guide rod 4, the upper supporting plate 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com