Workpiece production line, workpiece cleaning machine and workpiece cleaning groove

A cleaning tank and cleaning machine technology, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of high water change frequency, unclean workpiece cleaning, low cleaning efficiency, etc., and achieve low water change frequency, Avoid secondary attachment and clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

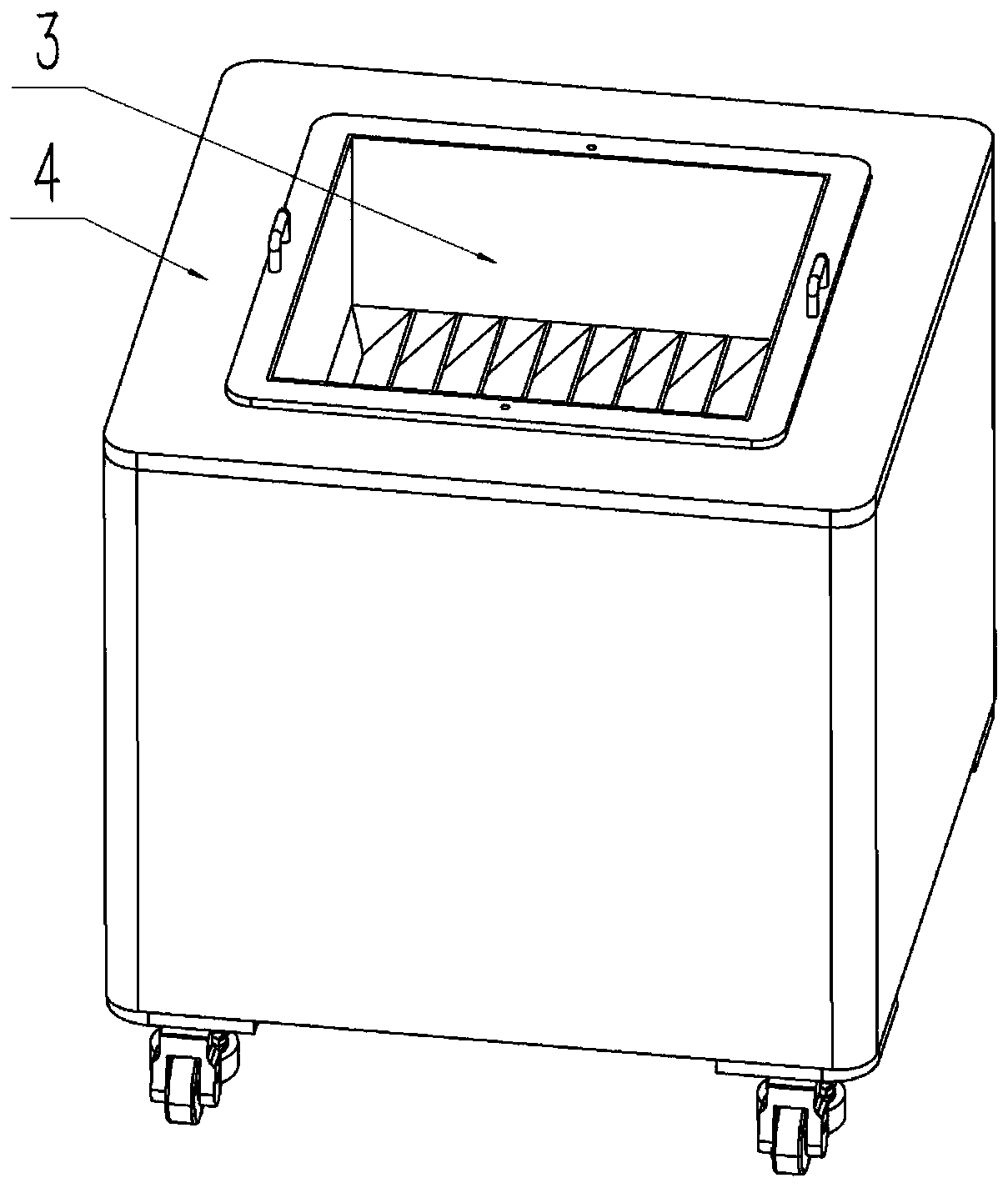

[0028] see figure 1 , figure 2 , image 3 , this embodiment provides a workpiece cleaning tank 3, a plurality of chip guide plates 1 arranged in the same direction are arranged between the first tank wall and the second tank wall opposite to the workpiece cleaning tank 3, and the chip guide plates 1 There is a certain distance between them, the chip guide plate 1 is arranged obliquely, the inclination direction of the chip guide plate 1 can be the same or different, preferably the same, the horizontal distance between the upper ends of the chip guide plate 1 is smaller than the size of the workpiece, so that the workpiece Will not fall, swarf can fall. The upper space of the chip guide plate 1 is a workpiece cleaning area, and the lower space of the chip guide plate 1 is a chip storage area. The chip storage area is used to store chips that slide down through the plurality of chip guide plates 1, and the chips are removed from the workpiece. The surface falls into the chip...

Embodiment 2

[0033] The present invention also provides a workpiece cleaning machine 4, which includes the workpiece cleaning tank 3 in Embodiment 1. The workpiece cleaning machine 4 can also be equipped with a water pump instead of manually changing the water. An angle is set between the chip barrier 2 in the workpiece cleaning tank 3 and the upper surface of the chip guide 1, that is to say, a chip blocking space 5 is provided between the chip barrier 2 and the chip guide 1, The chip barrier 2 can be a straight plate obliquely downward, or a downward curved arc plate. There is a small gap between the second end of the chip barrier 2 and the adjacent chip guide plate 1, which can make the chips Through this, a channel with a large top and a small bottom is formed so that the chips can fall, but they cannot move upward again into the cleaning area. The cleaning machine is clean and the water change frequency is low.

Embodiment 3

[0035] The present invention also provides a workpiece production line, including the workpiece cleaning tank 3 in Embodiment 1 or the workpiece cleaning machine 4 in Embodiment 2. The workpiece cleaning tank 3 in the production line can isolate the cleaned chips, avoid the secondary attachment of the chips, and improve the overall production efficiency and yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com