Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid major failures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

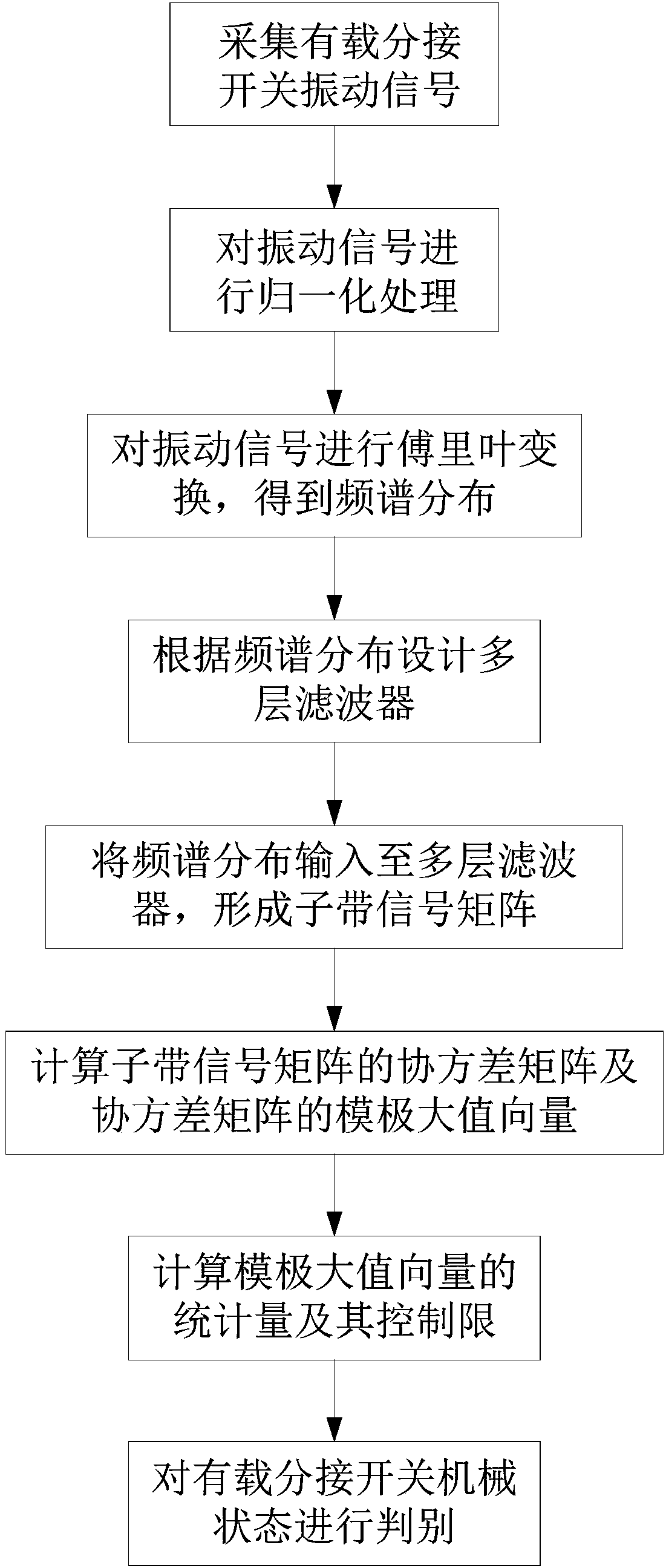

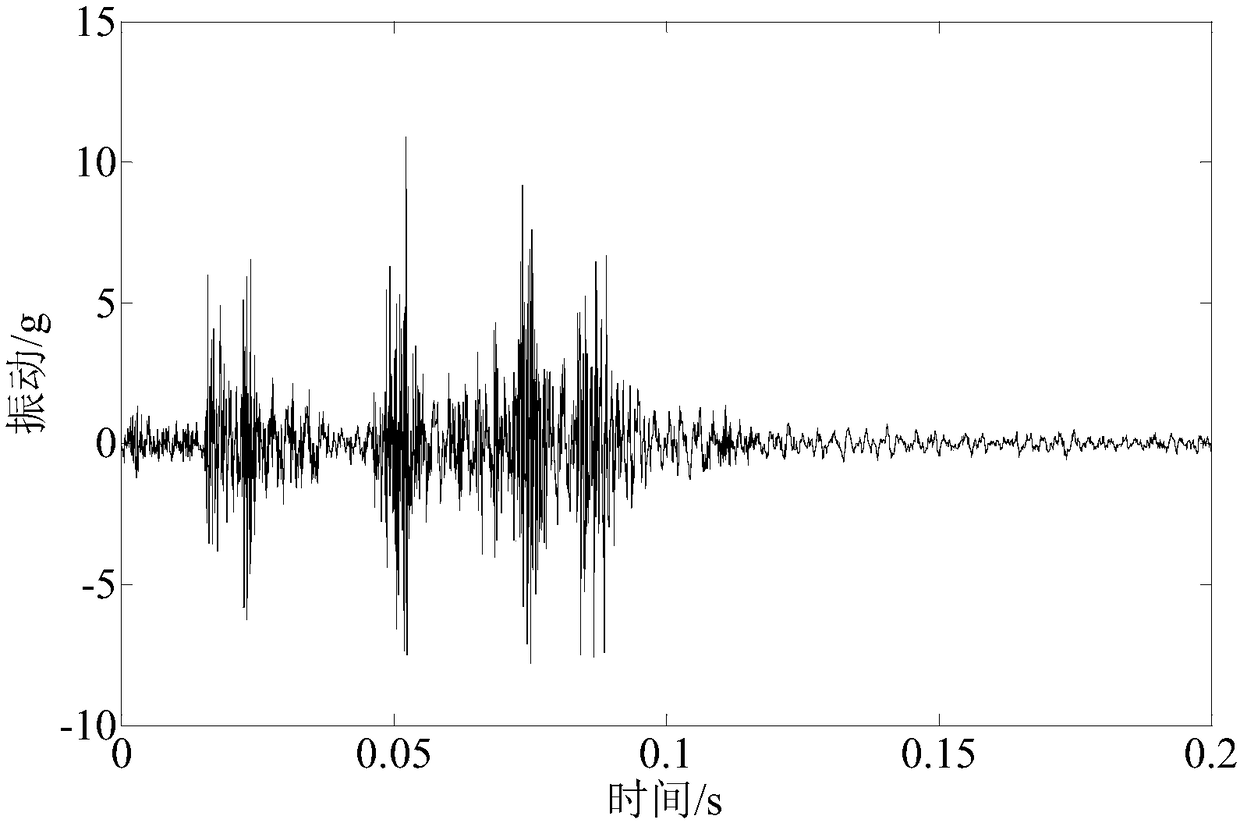

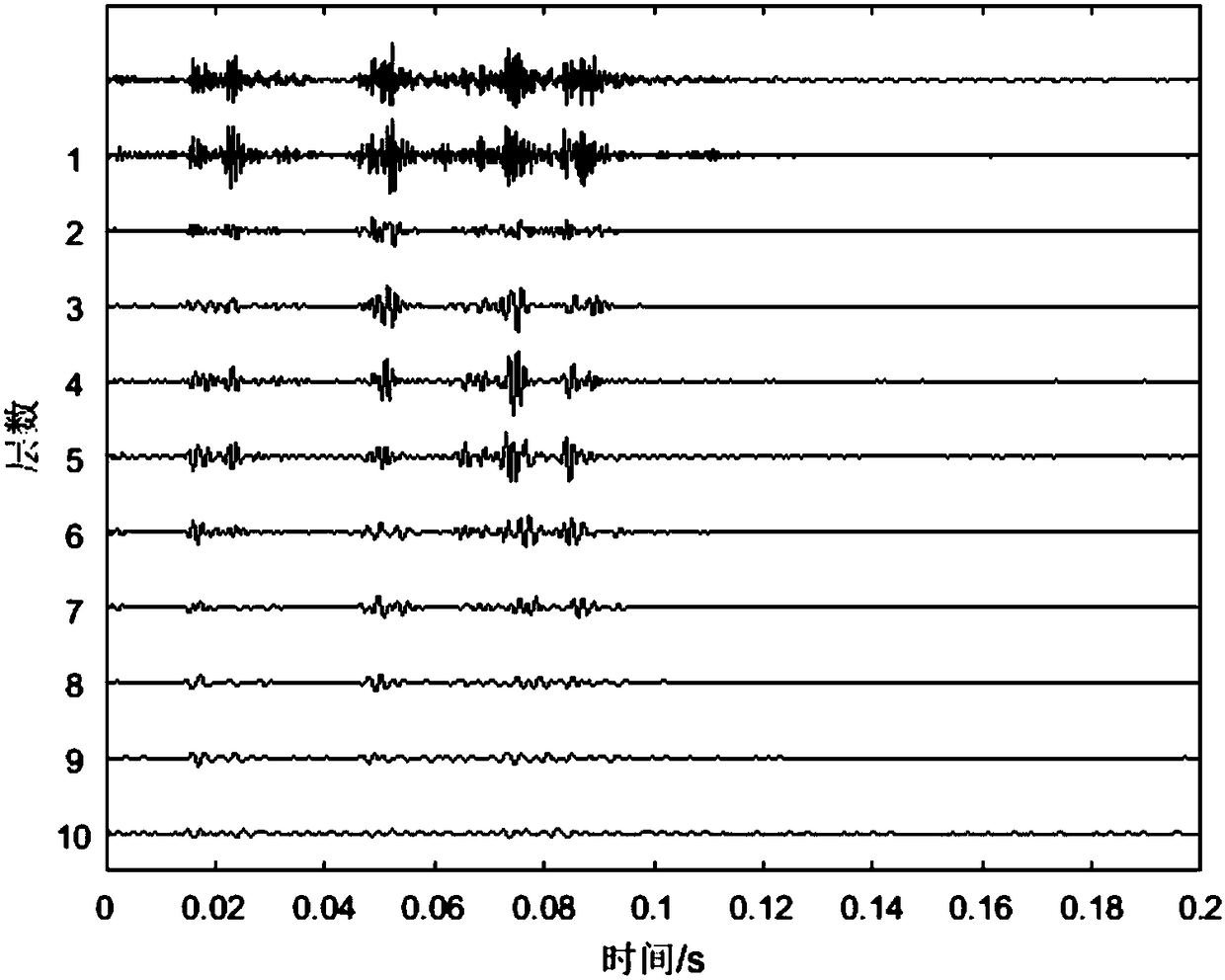

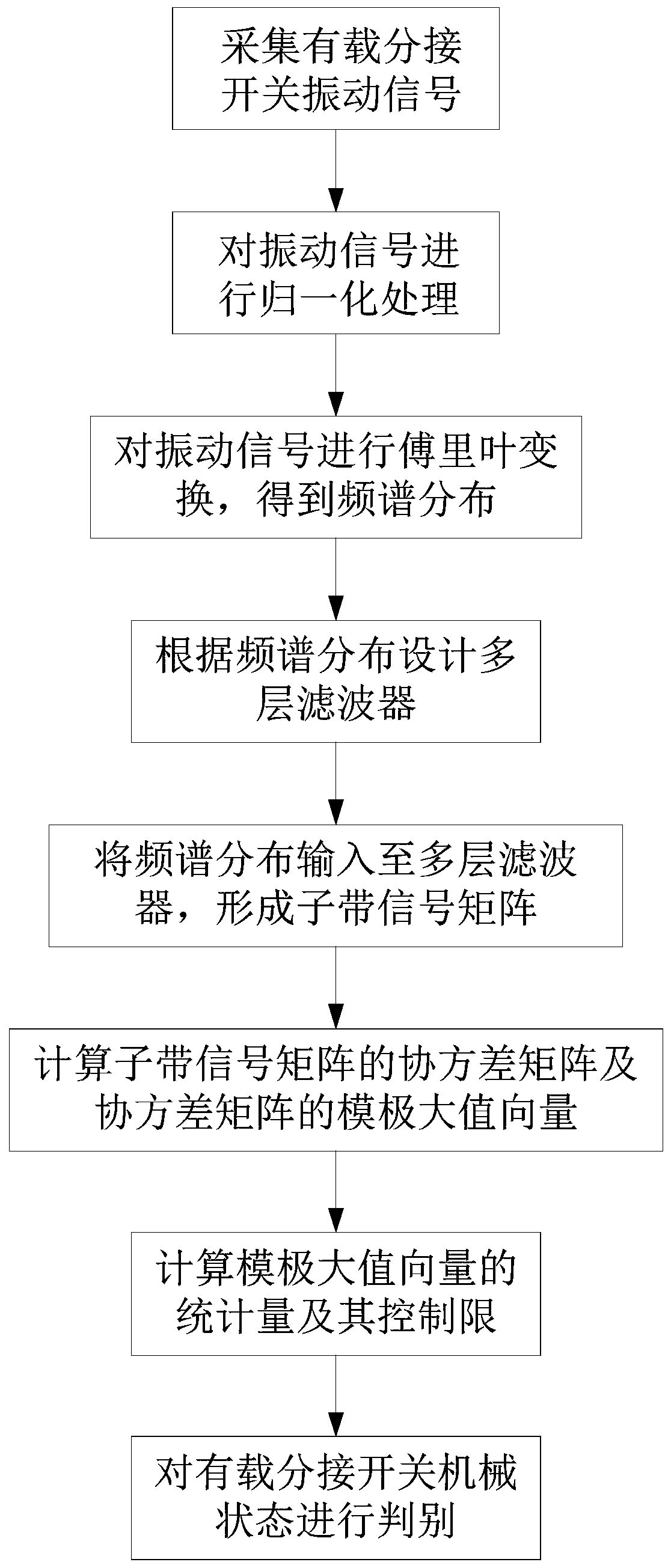

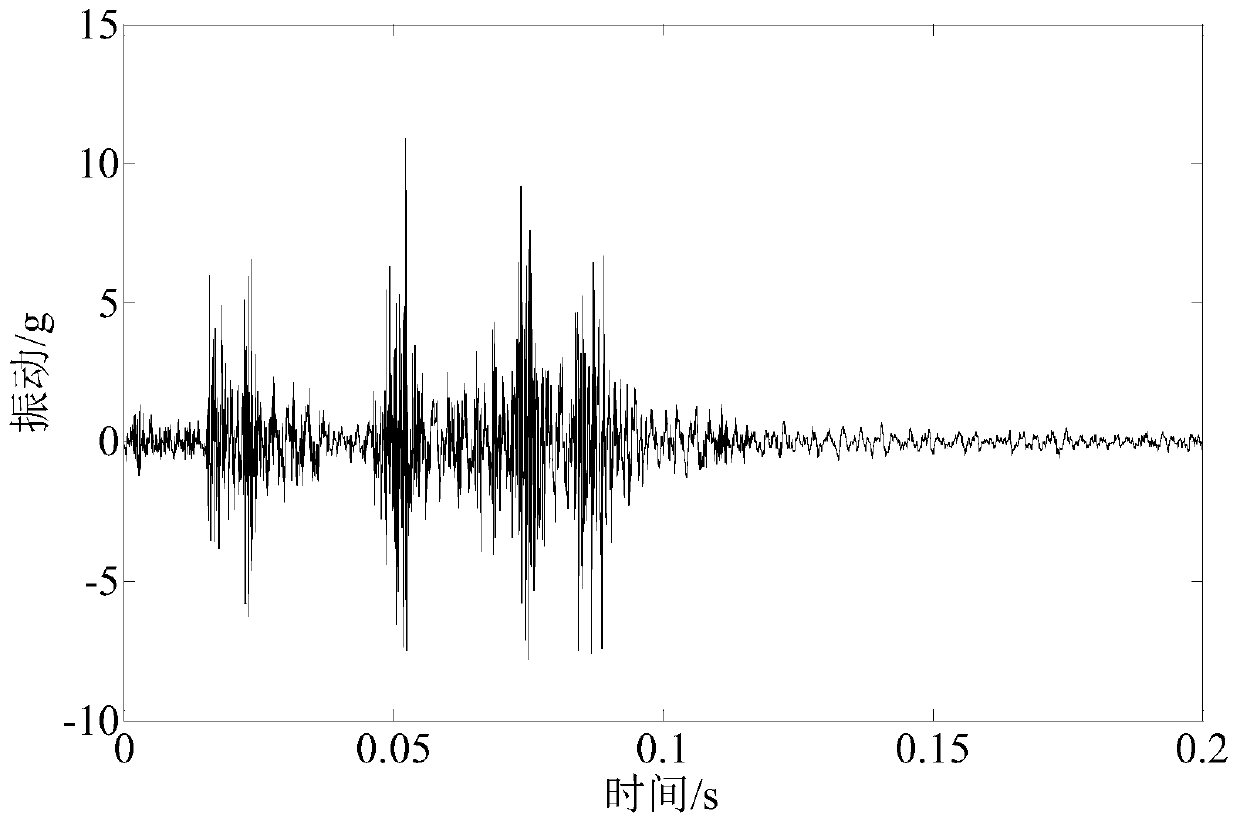

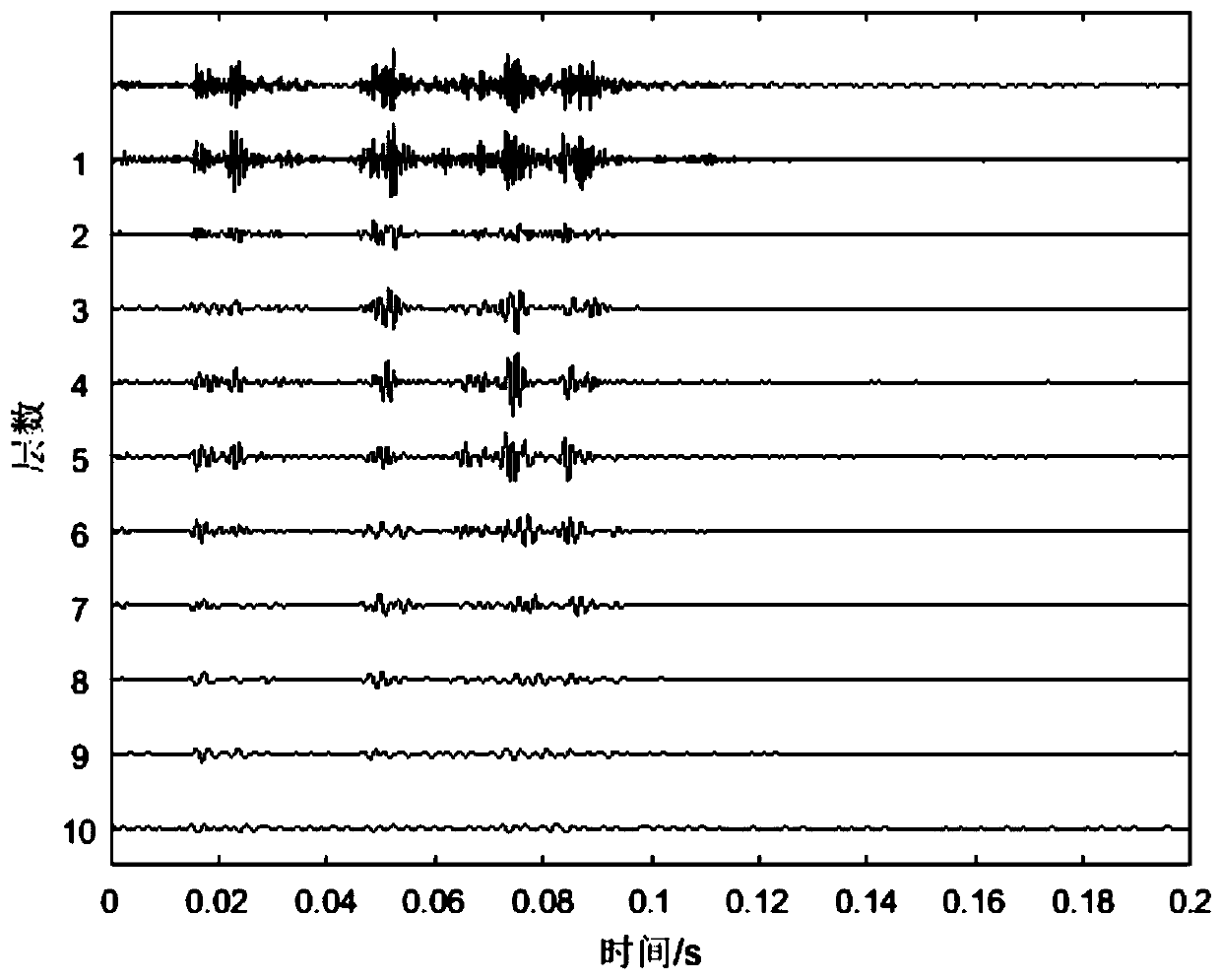

An on-load tap-changer mechanical state monitoring method and system based on a multi-layer filter

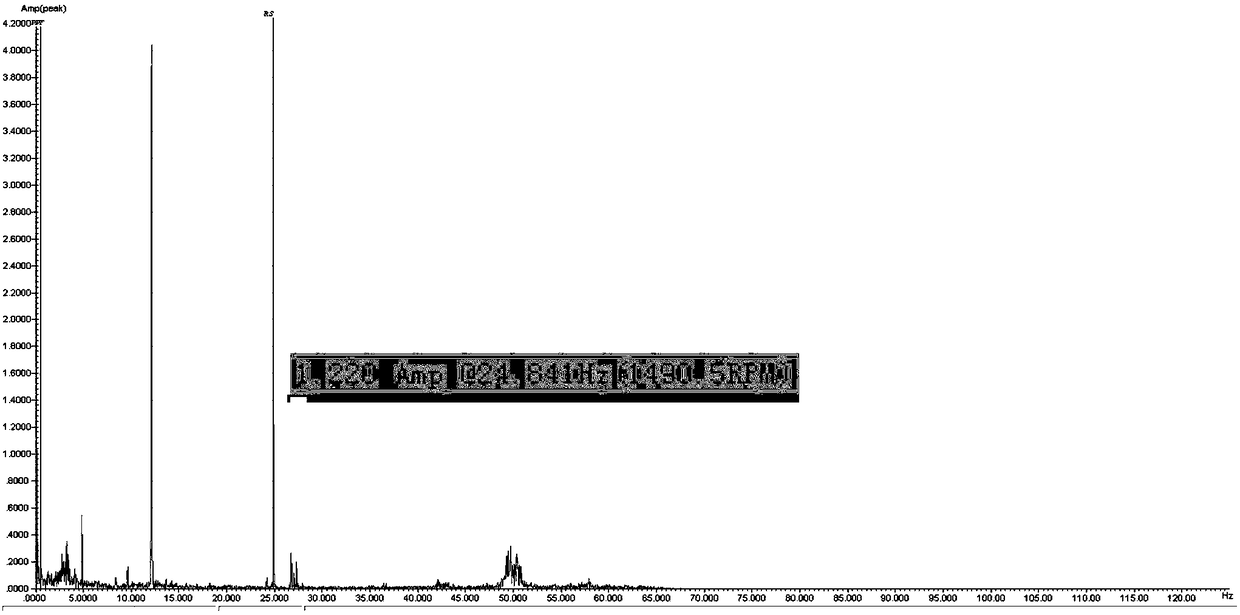

ActiveCN108535638AEfficient identificationEffective Operation and Maintenance StrategyMachine part testingCircuit interrupters testingFrequency spectrumTap changer

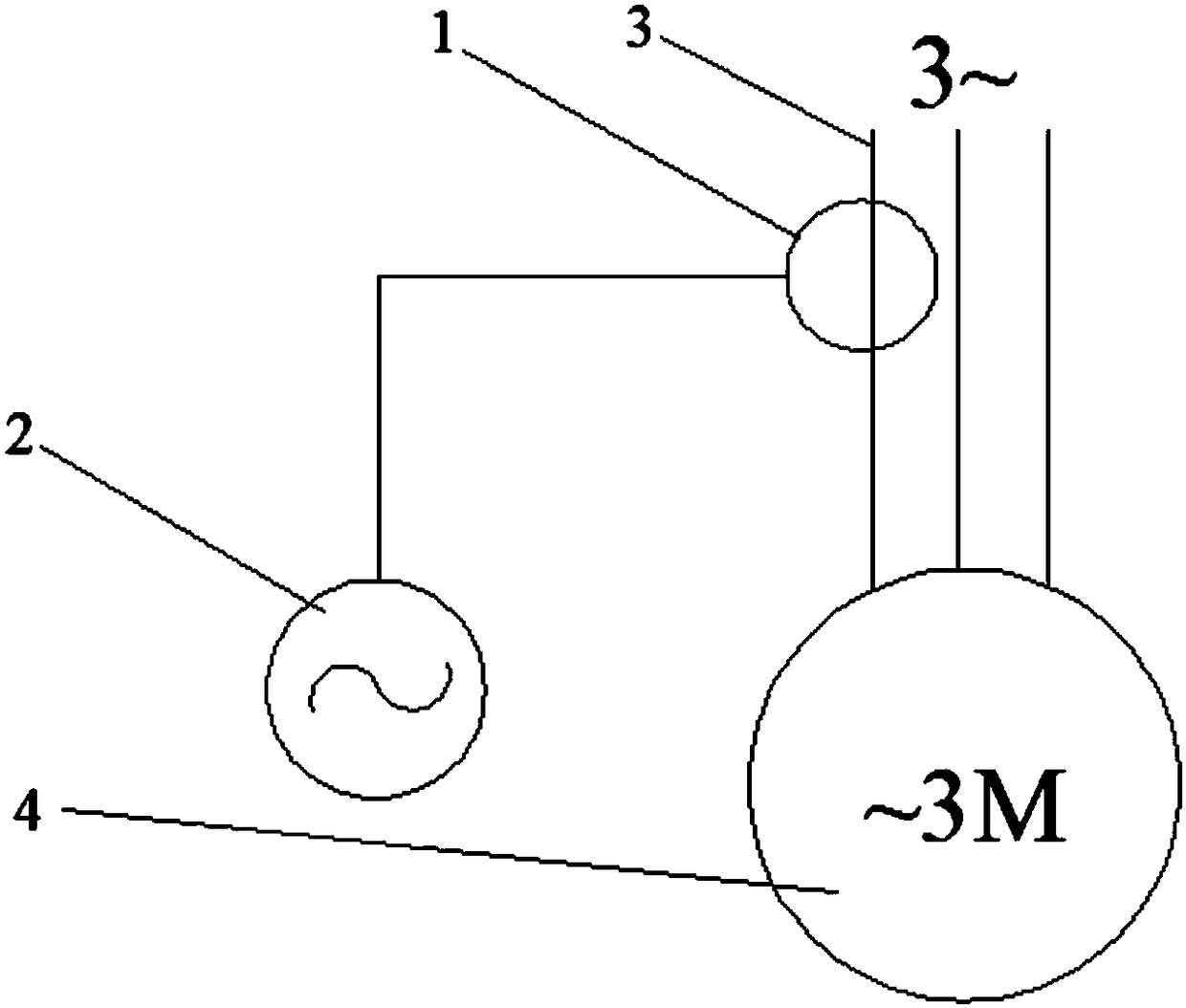

The invention provides an on-load tap-changer mechanical state monitoring method and system based on a multi-layer filter. The method comprises the steps of: acquiring vibration signals in a switchingprocess of an on-load tap-changer; performing normalization processing on the vibration signals; performing discrete Fourier transform on the vibration signals subjected to normalization to obtain frequency spectrum distribution of the vibration signals; determining a quality factor according to the frequency spectrum distribution and designing a multi-layer filter; inputting the frequency spectrum distribution to the multi-layer filter to obtain a plurality of sub-band signals to form a sub-band signal matrix; calculating a covariance matrix of the sub-band signal matrix according to columnsand the modulus maximum of the covariance matrix; calculating the statistical magnitude of the modulus maximum and the control limit of the statistical magnitude; judging the mechanical state of theon-load tap-changer according to the statistical magnitude. The method and the system can diagnose the mechanical work state of a tap-changer of a transformer and can detect whether the mechanical state of a tap-changer of a transformer changes effectively and accurately, so that effective measures can be adopted for a tap-changer timely.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

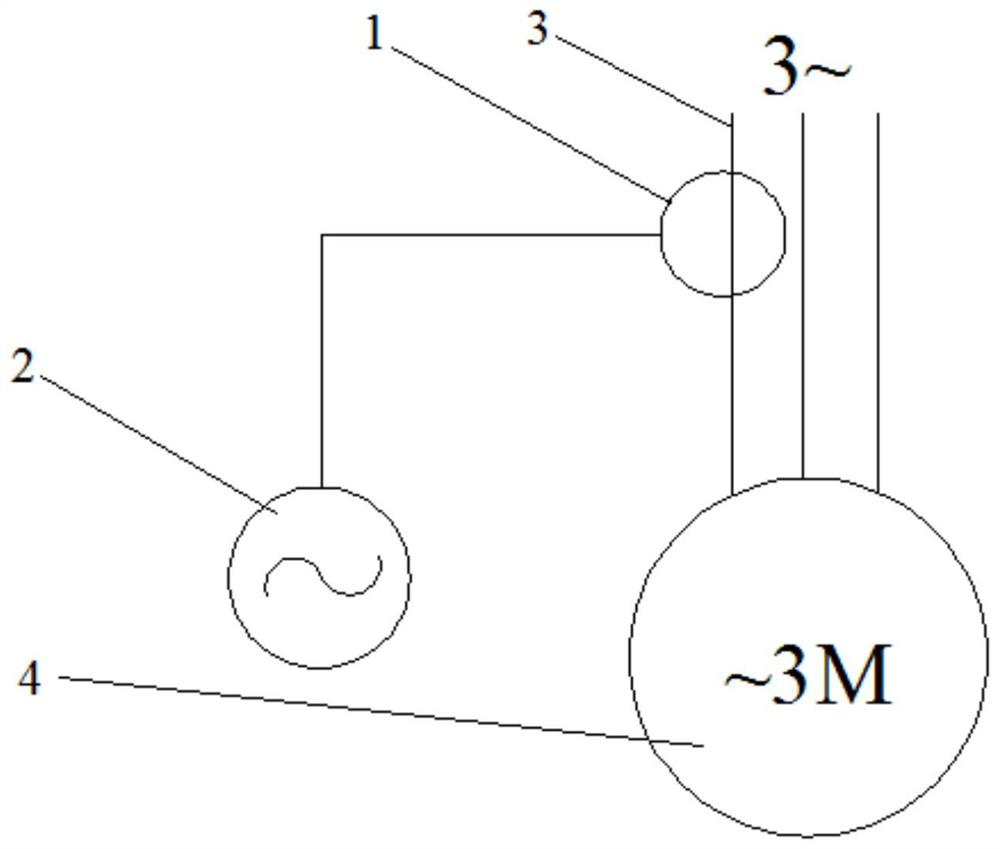

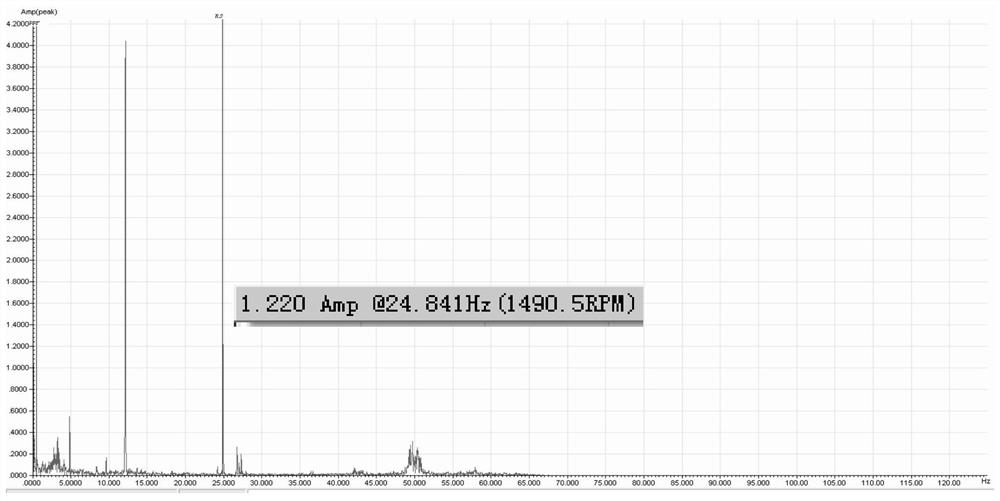

Motor stator current spectrum analysis equipment abnormity determination method

ActiveCN108169559APrevent catastrophic failuresAccurate analysisSpectral/fourier analysisDynamo-electric machine testingPhysicsElectricity

The invention discloses a motor stator current spectrum analysis equipment abnormity determination method. The method comprises steps of motor current signal acquisition, abnormity existence monitoring, abnormity type analysis and abnormity severe degree determination. Firstly, a motor current signal is acquired, whether a signal acquisition point is accurate is confirmed, abnormity existence is confirmed and analyzed, acquired signals are filtered, through continuous practice, the magnitude of the motor abnormity passing frequency is found to be relevant to the motor abnormality severe degree. The method is advantaged in that the abnormality severe degree of motor equipment can be rapidly and accurately analyzed online, whether emergent shutdown maintenance is needed can be determined, and the great equipment fault can be prevented in advance.

Owner:HAINAN JINHAI PULP & PAPER

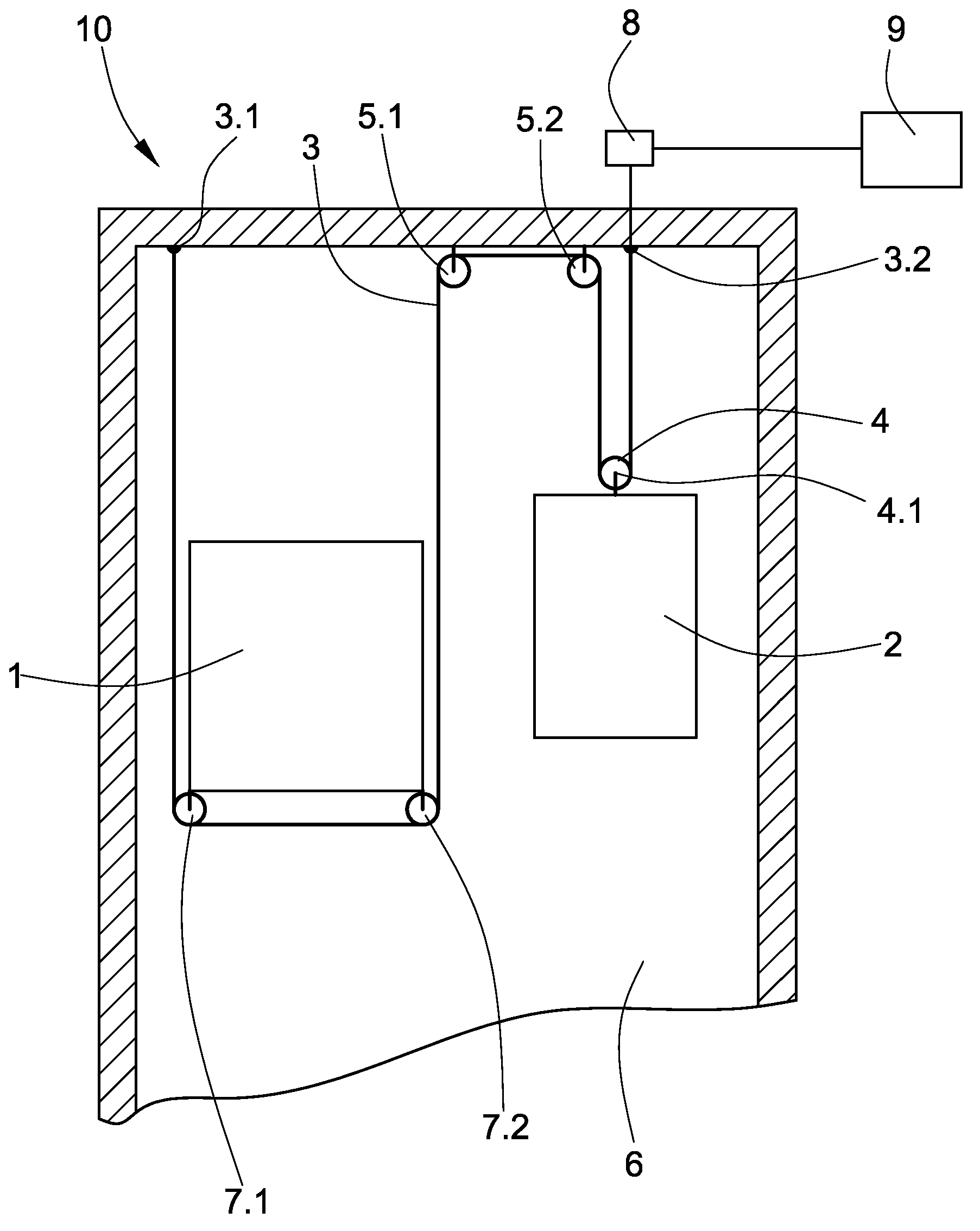

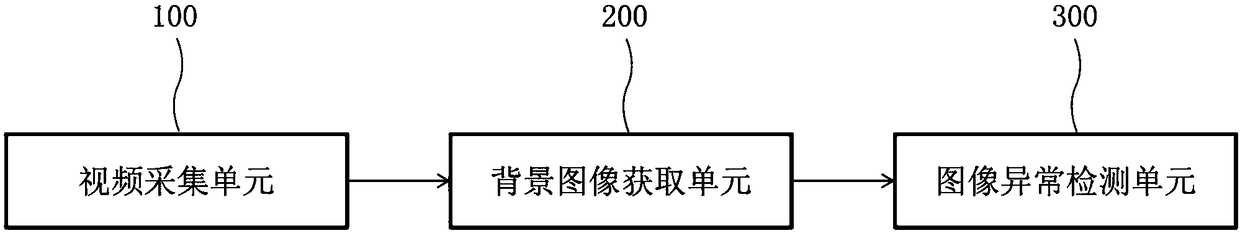

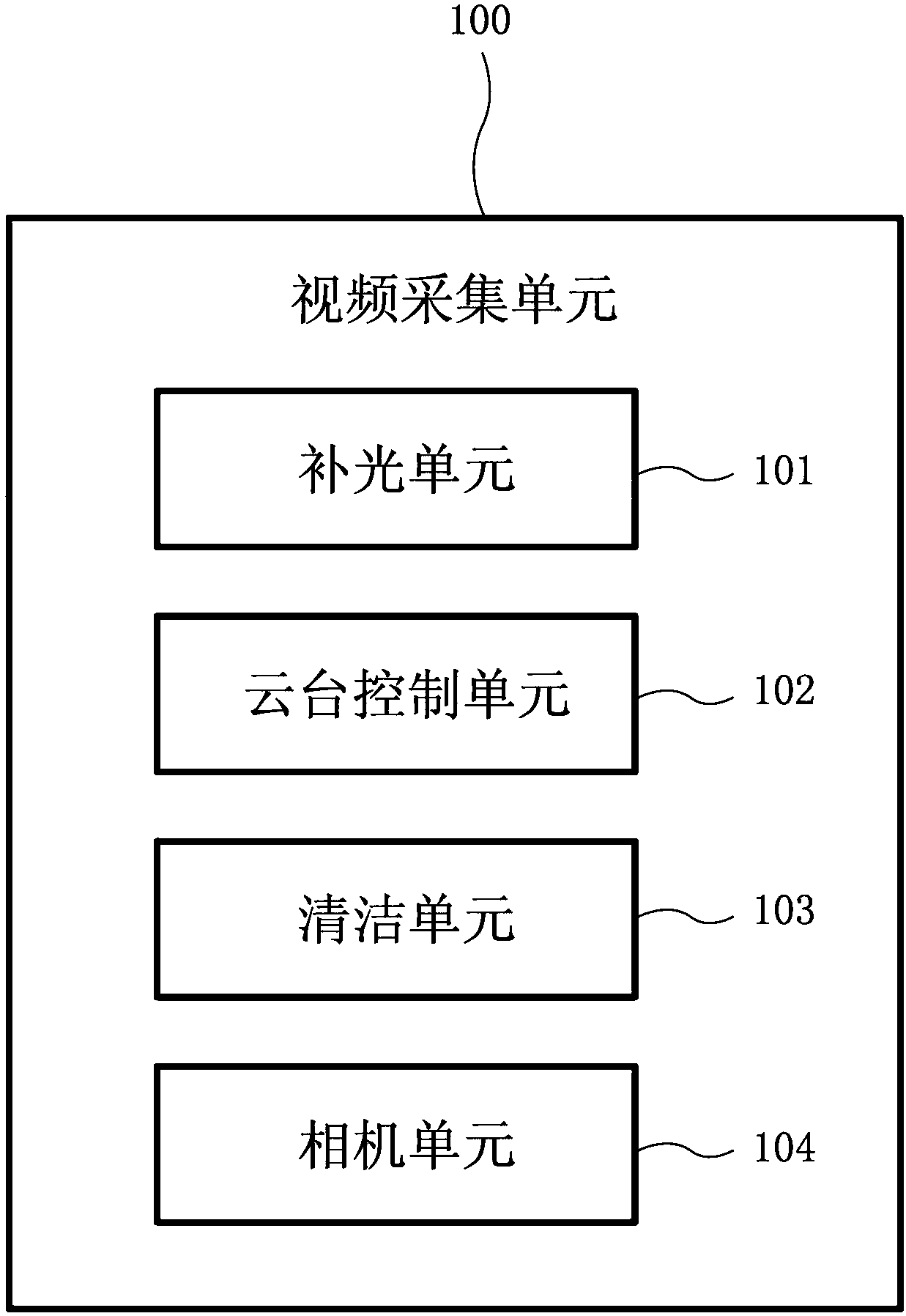

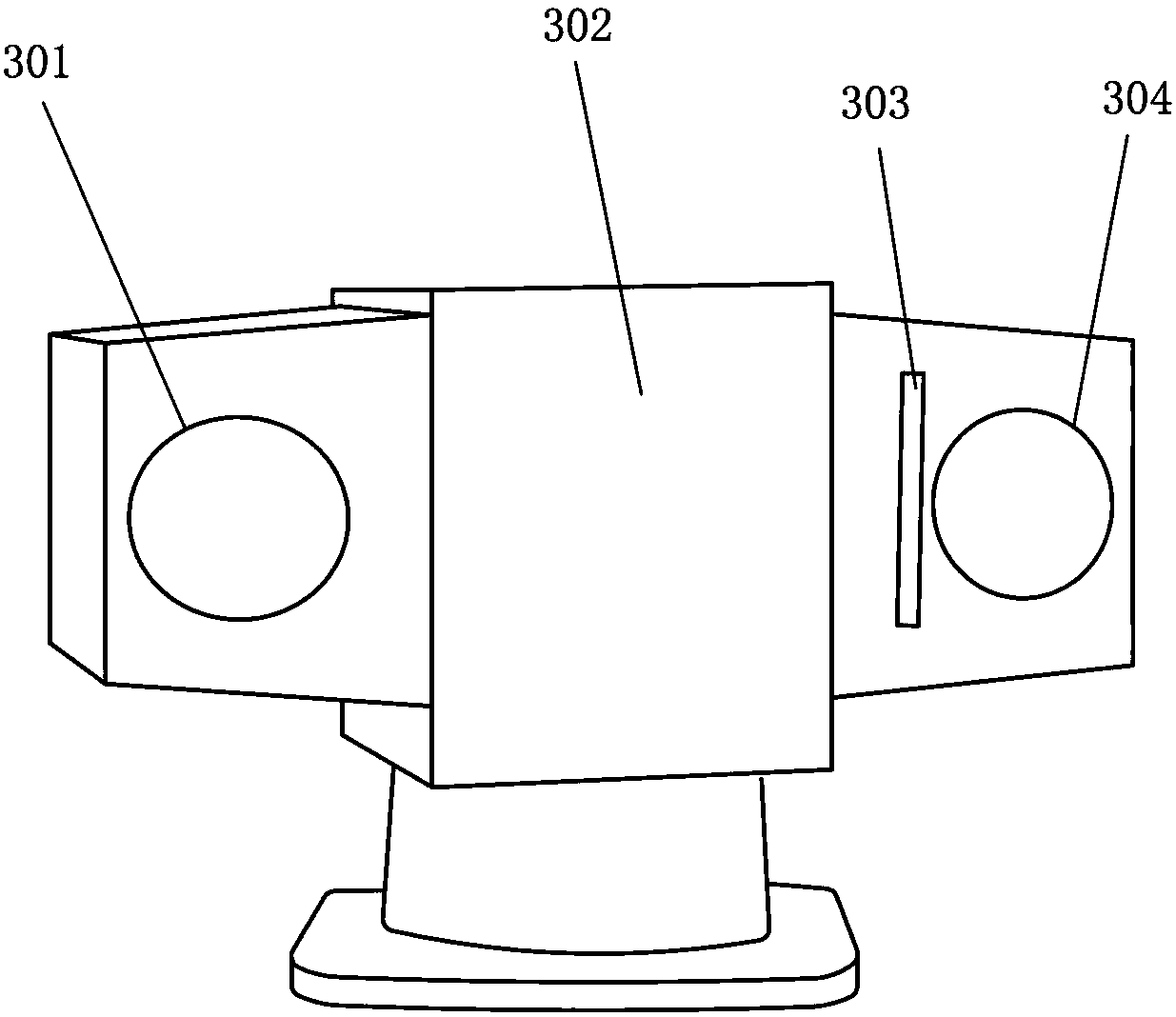

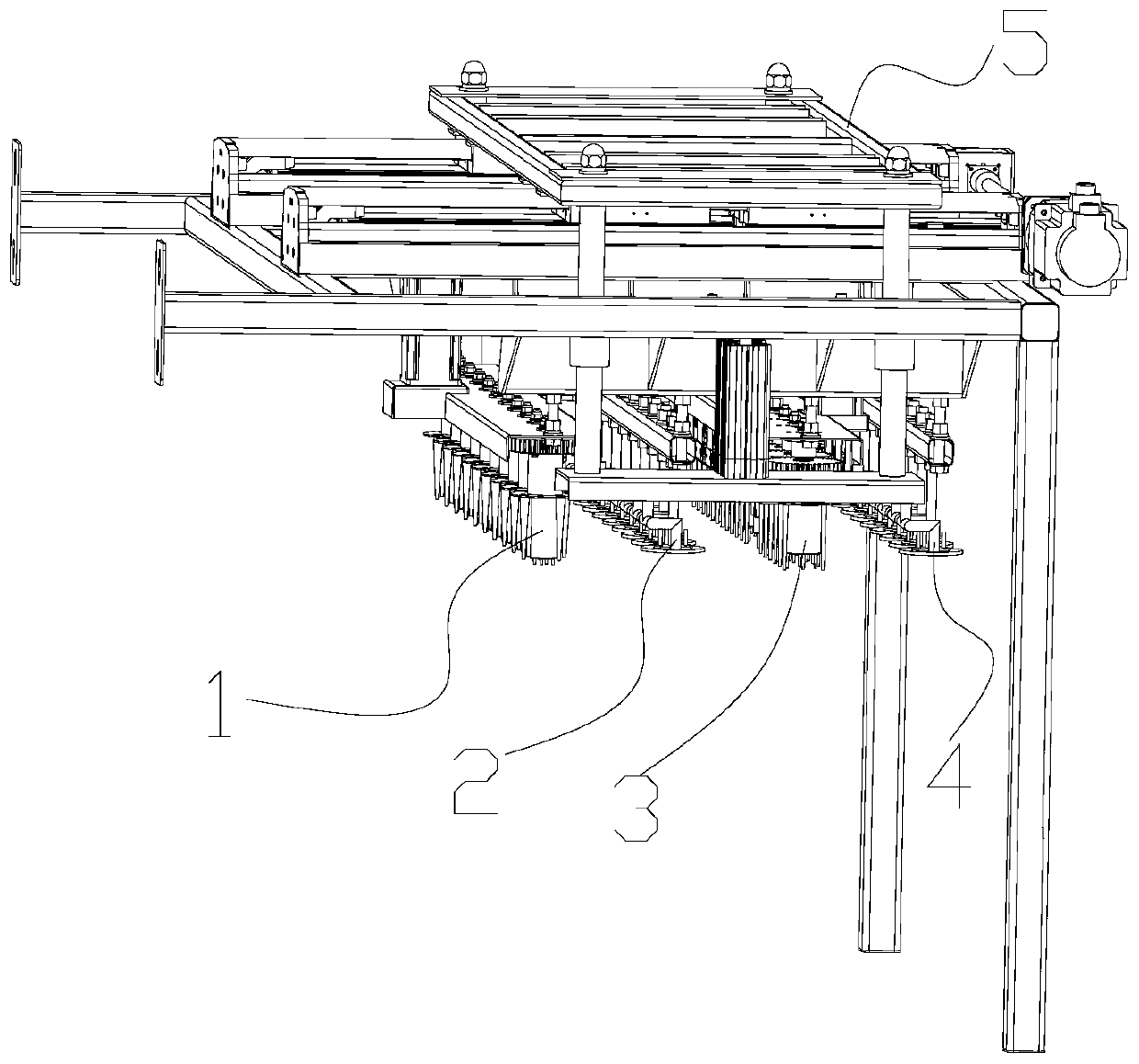

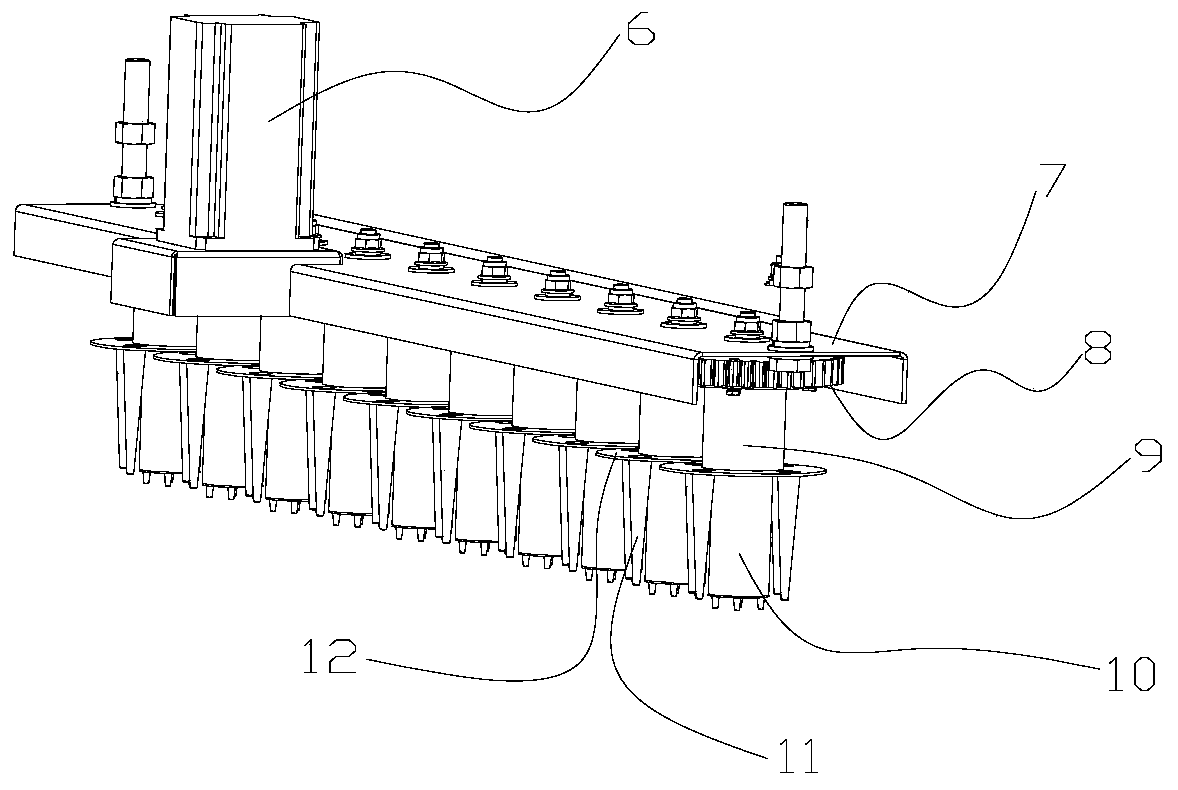

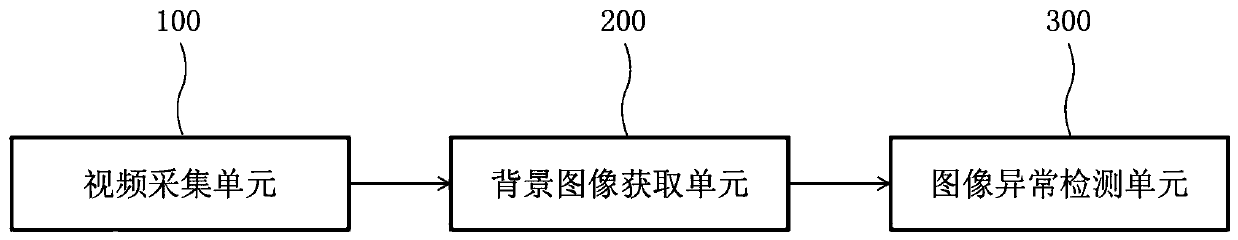

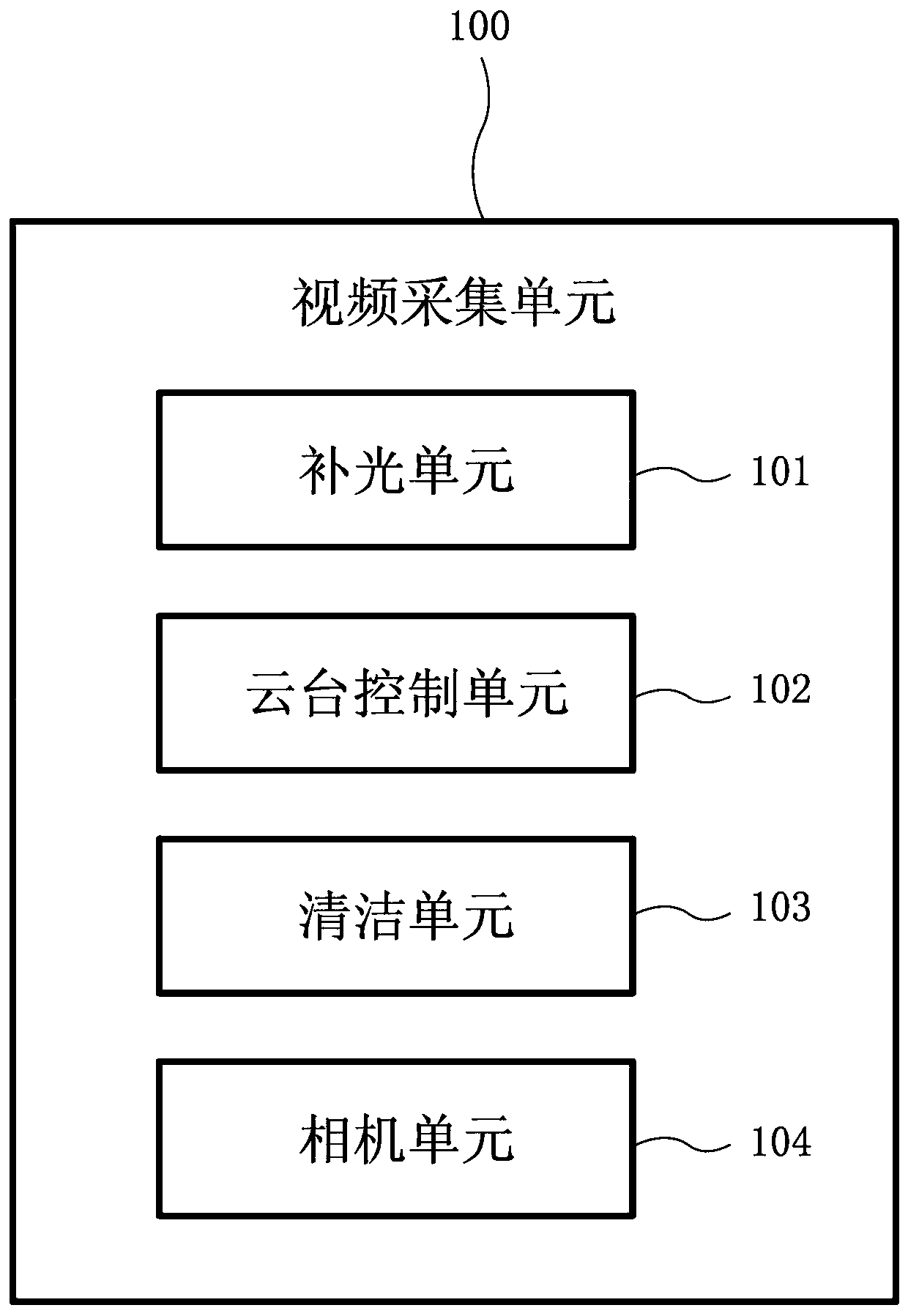

Equipment and method for monitoring blades of wind turbine generator set

ActiveCN108799011ARealize analysisRealize evaluationEngine fuctionsMachines/enginesElectricityBackground image

The invention provides equipment and a method for monitoring blades of a wind turbine generator set. The equipment comprises a video collecting unit, a background image acquiring unit and an image abnormality detection unit, wherein the video collecting unit collects videos of the blades of the wind turbine generator set to acquire a video image sequence; the background image acquiring unit extracts background images from the acquired video image sequence; and the image abnormality detection unit detects whether the blades in the images in the video image sequence have abnormal image characteristics or not based on the extracted background images.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

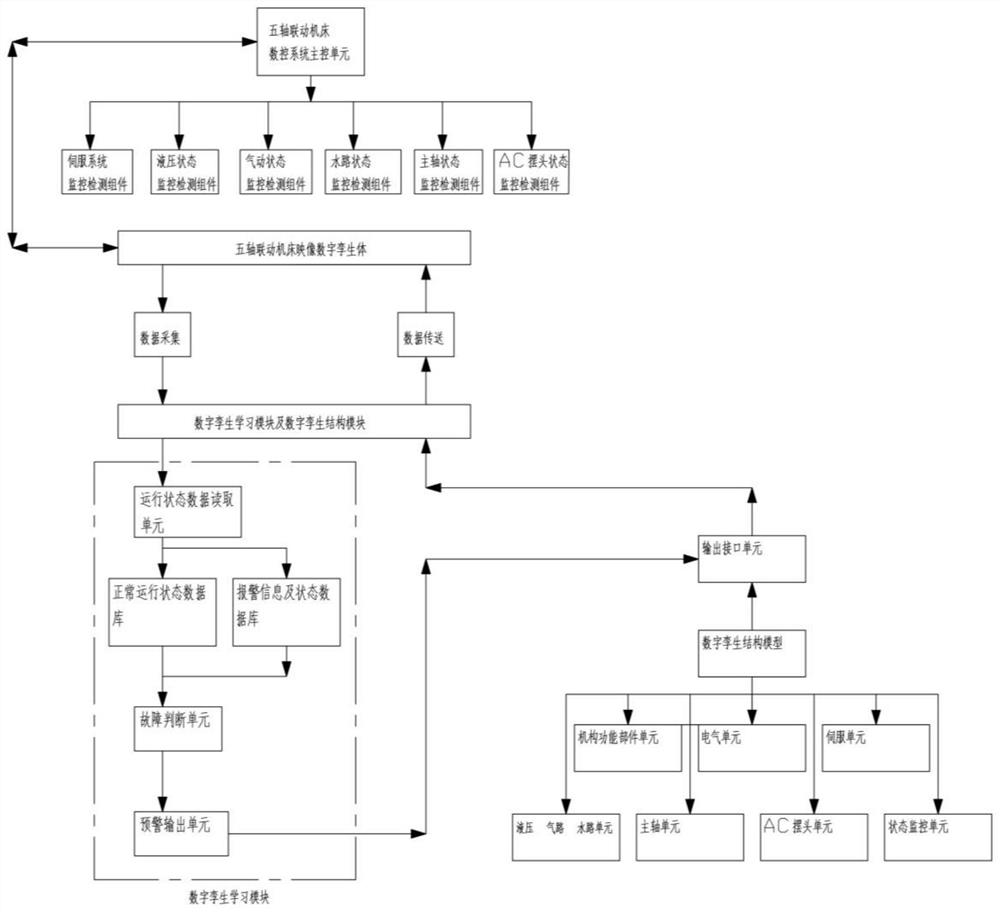

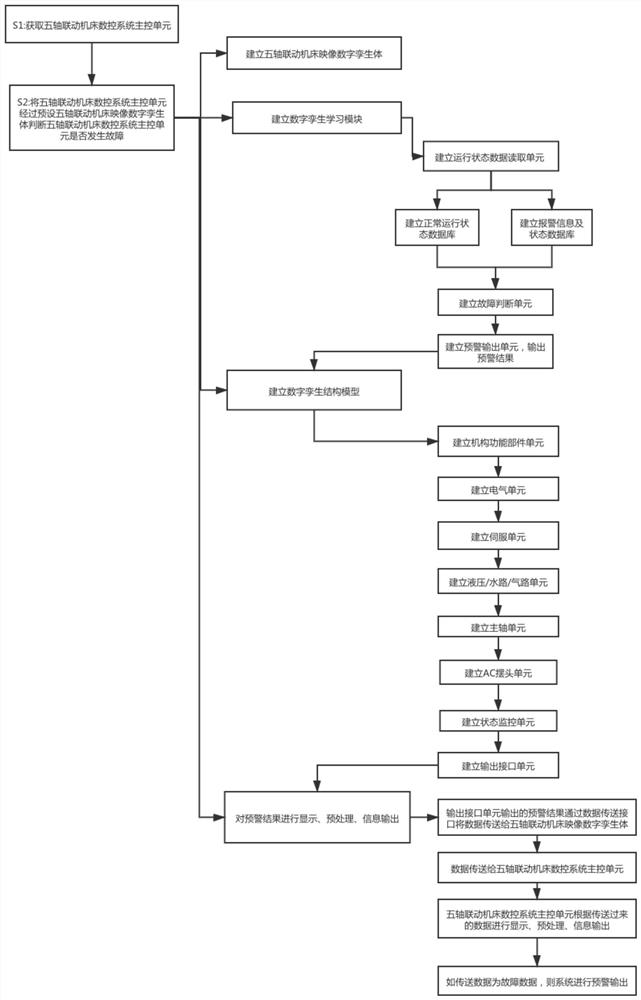

Five-axis linkage machine tool online diagnosis early warning system and method based on digital twinning

InactiveCN113538865AAvoid major failuresImprove performanceAlarmsMaintainance and safety accessoriesMachine toolReliability engineering

The invention discloses a five-axis linkage machine tool online diagnosis early warning system and method based on digital twinning. The system comprises a five-axis linkage machine tool numerical control system main control unit, a five-axis linkage machine tool image digital twinning body, a digital twinning learning module and a digital twinning structure module. The method comprises the following steps: S1, acquiring a five-axis linkage machine tool numerical control system main control unit; and S2, judging whether the master control unit of the five-axis linkage machine tool numerical control system breaks down or not through a preset five-axis linkage machine tool image digital twin, and if yes, pushing the early warning information. By introducing a digital twinning technology, fault early warning output is carried out on a five-axis linkage machine tool which possibly breaks down, and early-stage early warning output is achieved according to whether the machine tool breaks down or not according to the current state of the machine tool. According to the scheme, major faults of the machine tool can be avoided, and the overall operation performance of the machine tool is improved.

Owner:YITELI SHANGHAI SCI TECH CO LTD

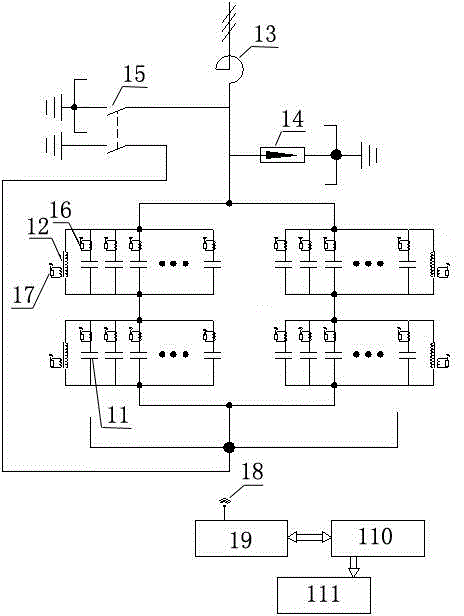

Reactive power compensation protective device in power transmission and transformation system

InactiveCN104092189AAchieving Sensitive ProtectionImprove reuseEmergency protective circuit arrangementsReactive power adjustment/elimination/compensationElectric power transmissionPower compensation

The invention relates to a reactive power compensation protective device in a power transmission and transformation system, and belongs to the technical field of reactive power compensation in the power transmission and transformation system. The technical scheme is that a plurality of single capacitors (11) are connected in parallel to form string sections of high-voltage parallel capacitor groups; each string section is connected with a discharging coil (12) in parallel; a current unit (16) which contains a current sensor is arranged on each capacitor branch of each single capacitor; a background host processes received current signals of all the current units and received voltage signals of all the discharging coils, and transmits data to a protective module. According to the reactive power compensation protective device in the power transmission and transformation system, the sensitive protection on discharging coil failures and each capacitor can be realized; the most sensitive protection and failure warning on the high-voltage parallel capacitor groups can also be realized earliest; the reuse rate of reaction equipment is improved; the operation reliability of a reactive compensation device is improved; major failures are avoided as far as possible; the protection sensitivity is improved; failure equipment is cut in time; serious failures are avoided.

Owner:STATE GRID CORP OF CHINA +2

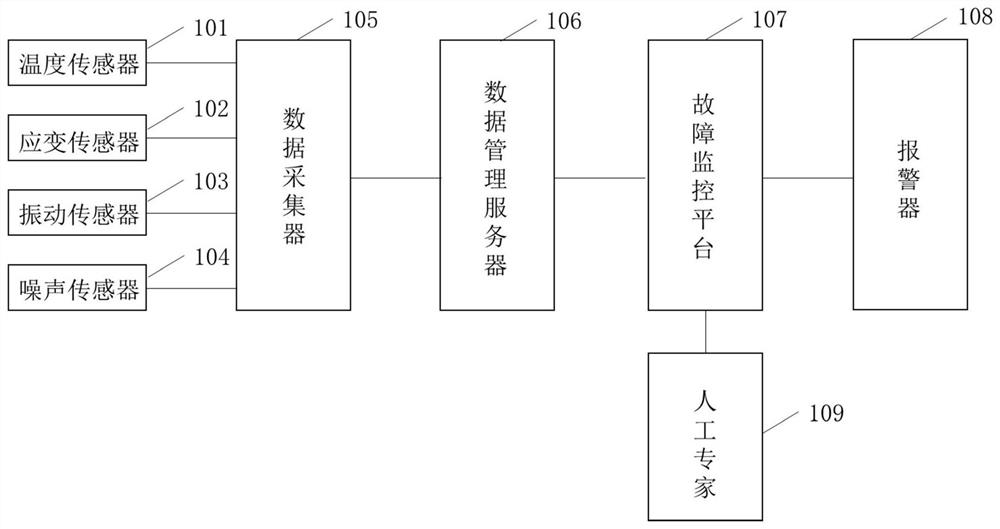

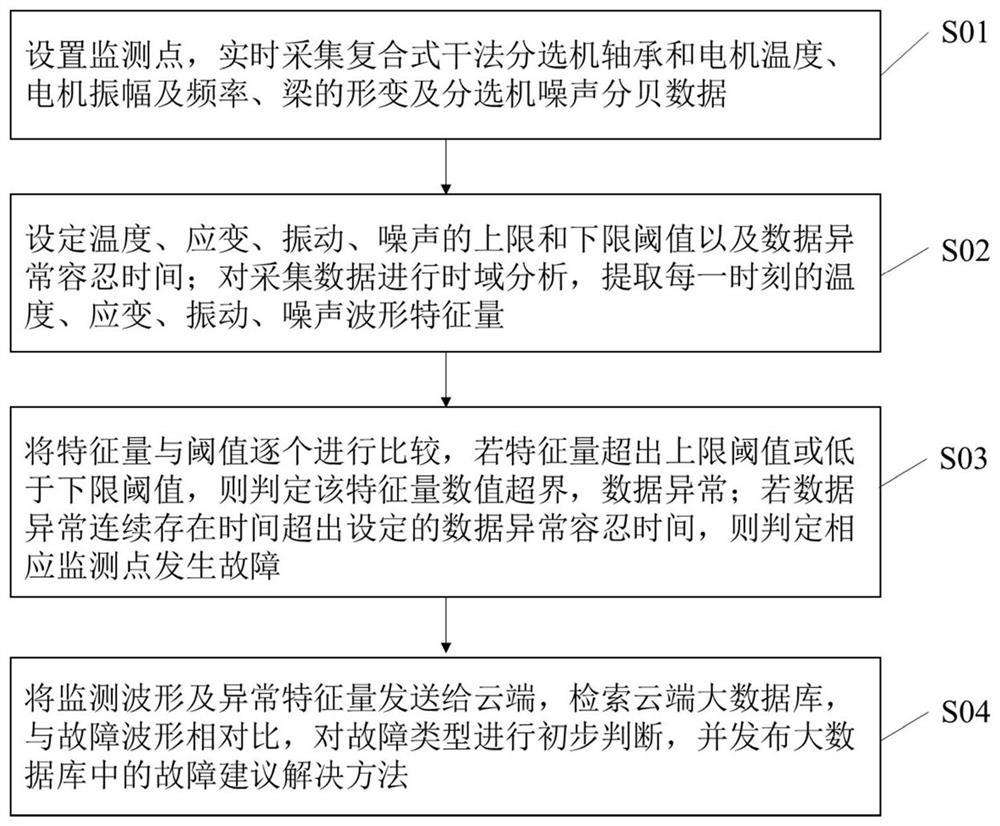

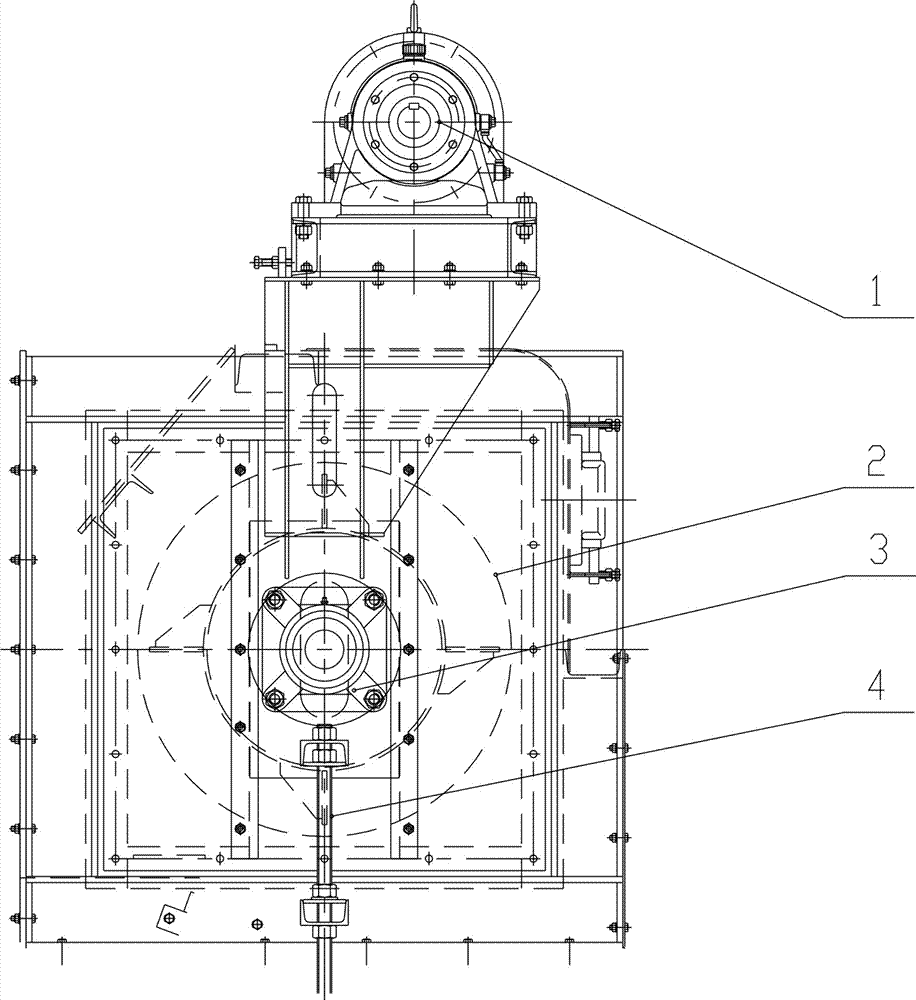

Intelligent fault diagnosis system and method for large composite dry separator

PendingCN111609882AQuick responseImprove reliabilityMeasurement devicesData miningAlarm messageControl engineering

The invention discloses an intelligent fault diagnosis system and method for a large composite dry separator, and relates to the field of ore dressing machineries. The system comprises a detection module and an analysis and diagnosis module, wherein the detection module is used for detecting the temperatures of a bearing and a motor of the composite dry separator, the amplitude and frequency of the motor, the deformation of a beam and the noise decibel of the separator, and transmitting detection data to the analysis and diagnosis module; and the analysis and diagnosis module is used for analyzing the detection data, judging whether the composite dry separator has a mechanical fault or not, storing a fault waveform, predicting and judging a fault type, issuing a fault suggestion solution and sending alarm information. According to the intelligent fault diagnosis system and method for the composite dry separator, the safe operation of equipment can be guaranteed, accidents are preventedand reduced, the production efficiency is improved, and the economic loss of a coal preparation plant is reduced.

Owner:CHINA UNIV OF MINING & TECH

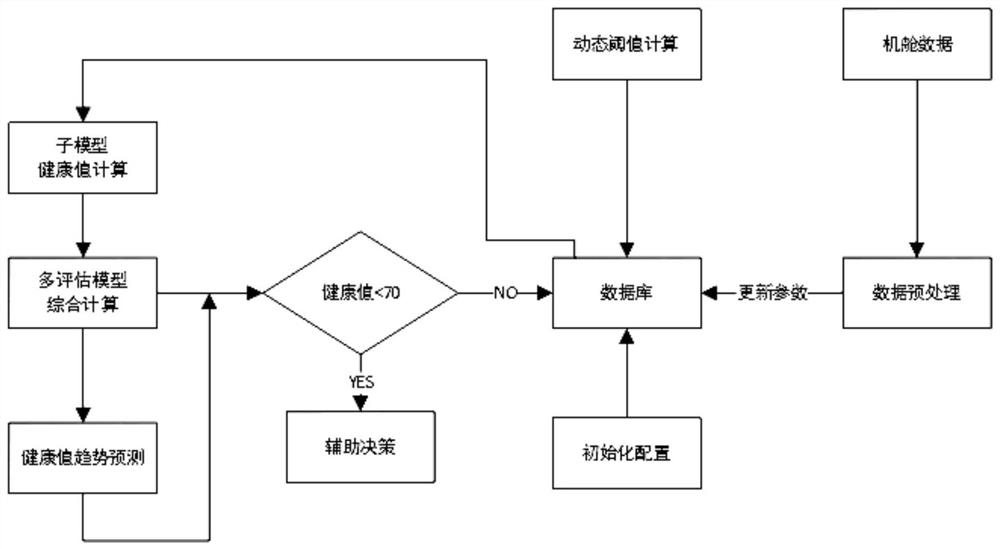

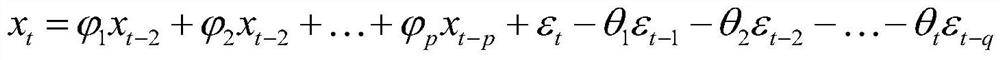

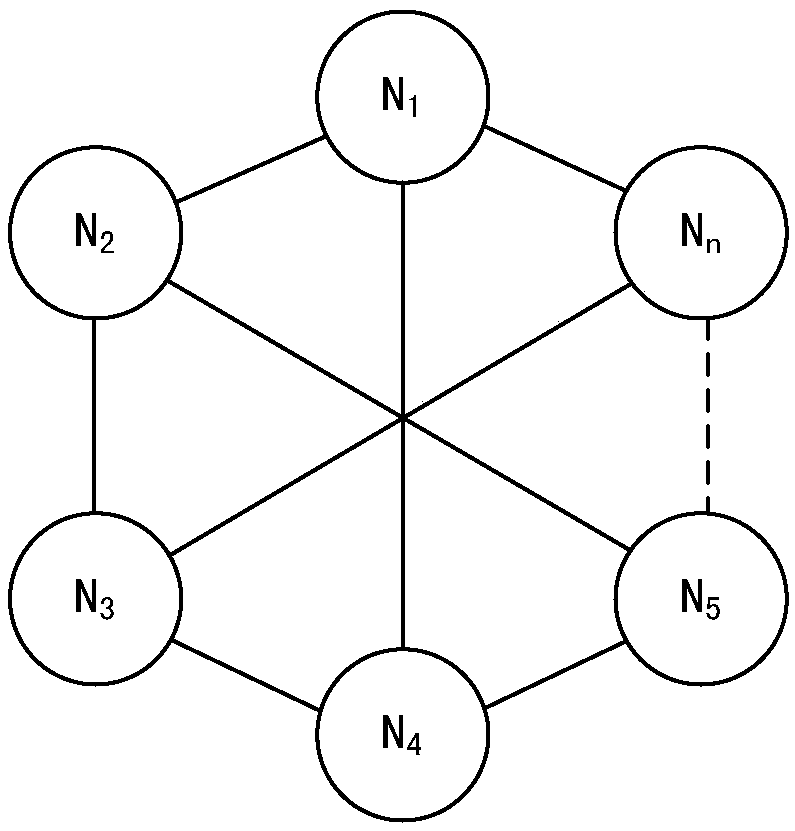

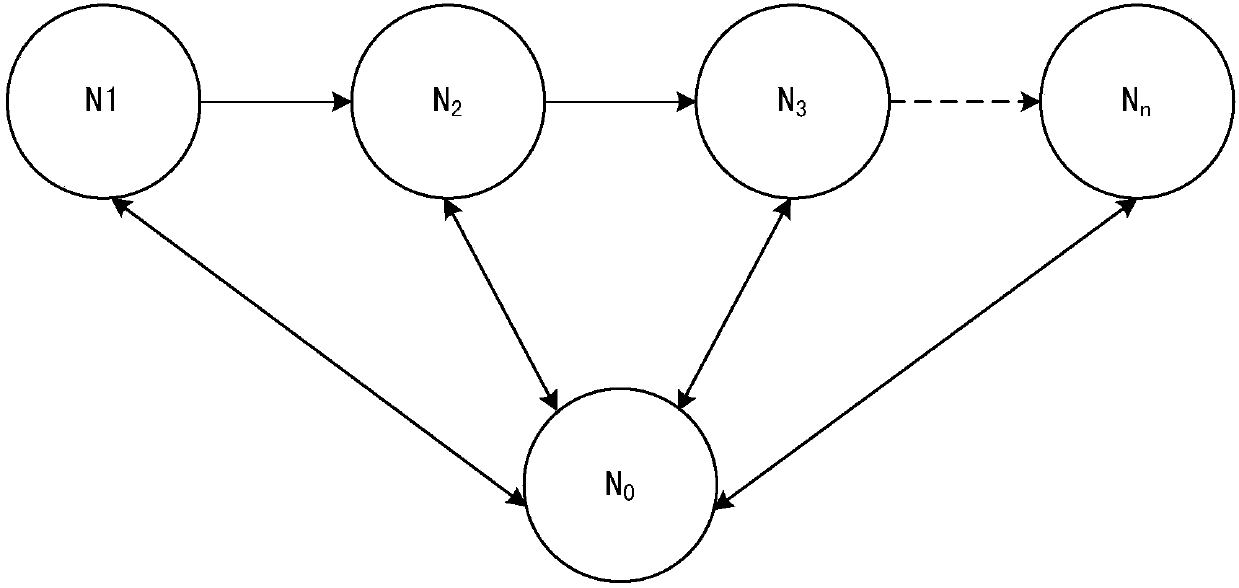

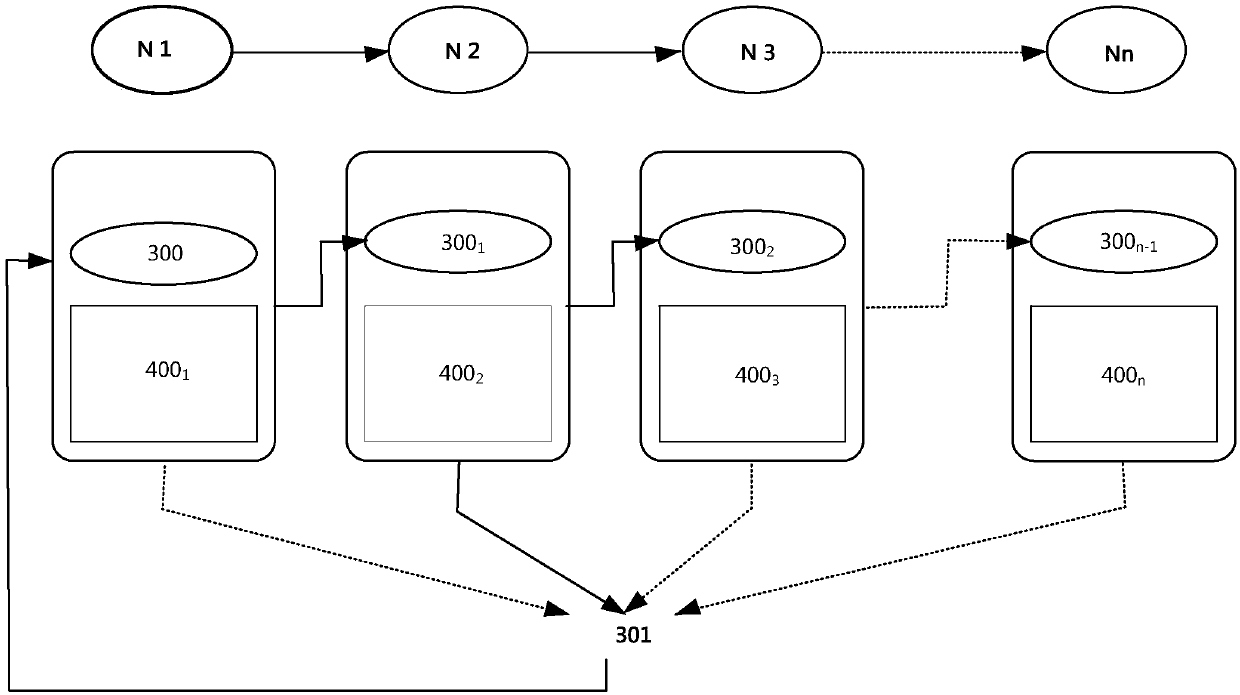

Ship machinery health state assessment method and system

PendingCN113033011AAvoid major failuresClear structureRelational databasesDesign optimisation/simulationReal time acquisitionData mining

The invention provides a ship machinery health state assessment method and system. The system comprises an initialization information configuration module, a data preprocessing module, a sub-model health value calculation module, a node comprehensive health value calculation module, a health value prediction module, an auxiliary decision-making module, a database module, an initialization information configuration module and a dynamic threshold calculation module. Initialized information configuration, including configuration of channel value signals of data, configuration of each module and the like, is performed before real ship application; ship cabin data is collected in real time, and the ship cabin data is preprocessed and stored; relevant data are extracted to calculate and store sub-model health values; a corresponding sub-model calculation result is extracted, and a node comprehensive health value is calculated; and the future development trend is predicted according to the historical health value of the node, and if the fault is predicted to occur, the auxiliary decision module is automatically triggered to give warning and maintenance suggestions to marine engineers, so that the occurrence of major faults is avoided.

Owner:DALIAN MARITIME UNIVERSITY

Control method of heat exchange system

InactiveCN112032939AReduce failure rateAvoid failureMechanical apparatusSpace heating and ventilation safety systemsThermal techniquesServer

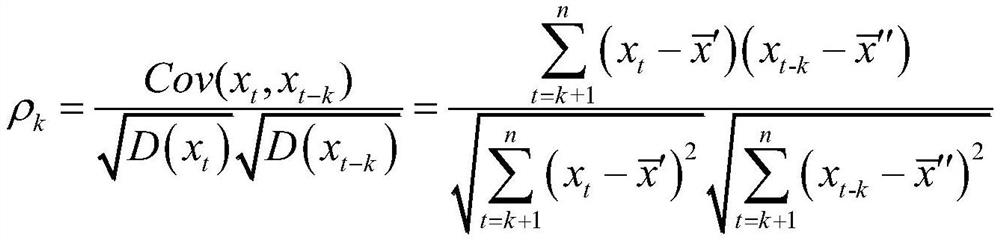

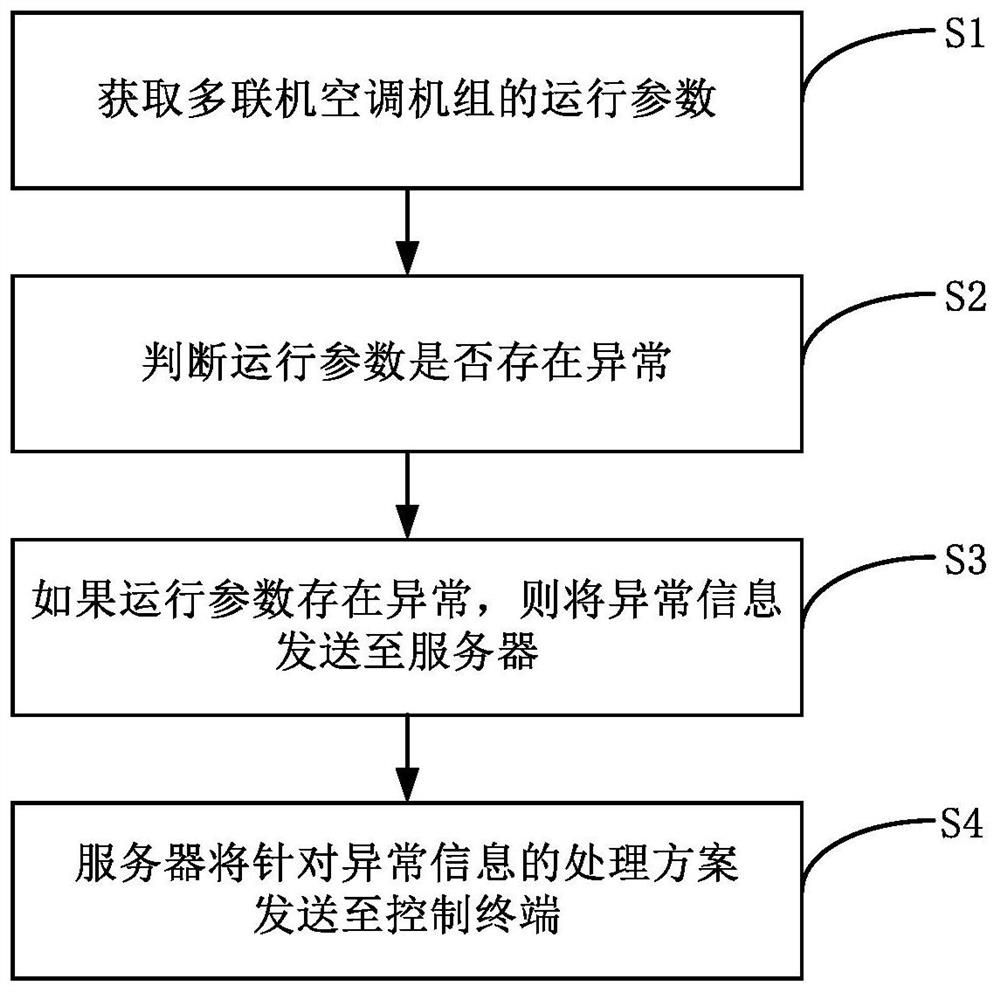

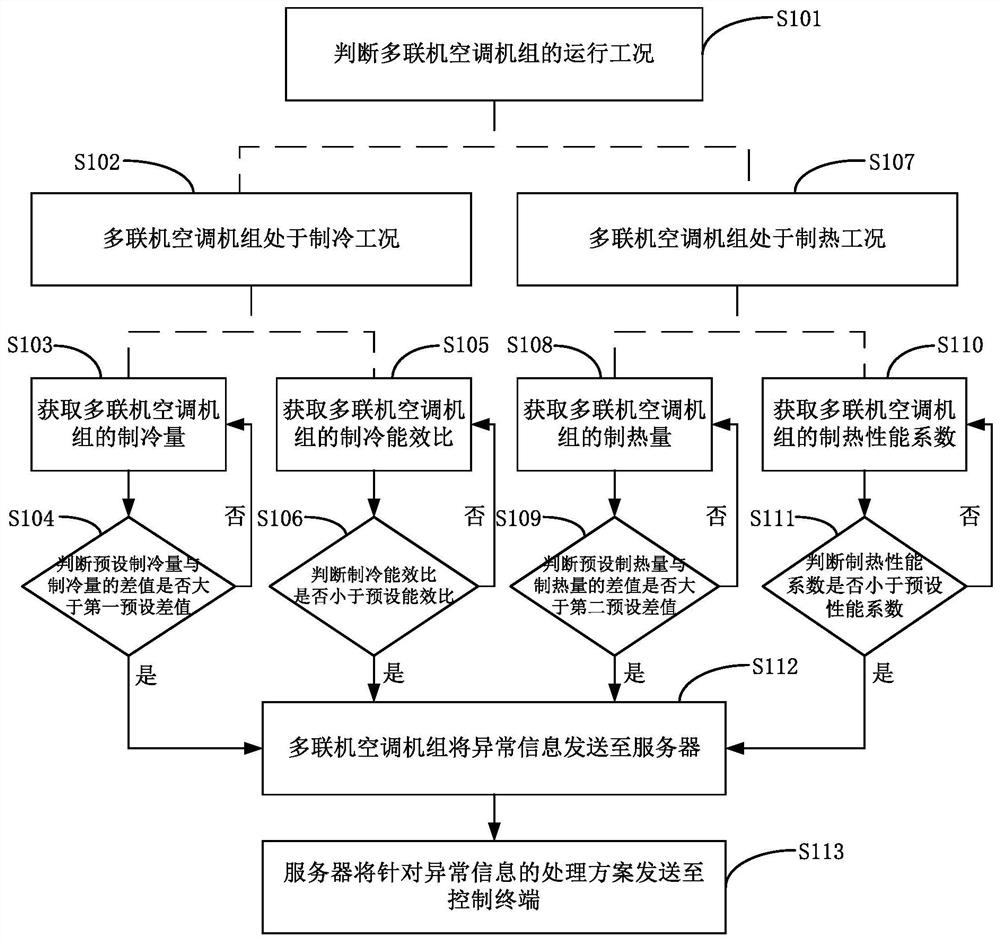

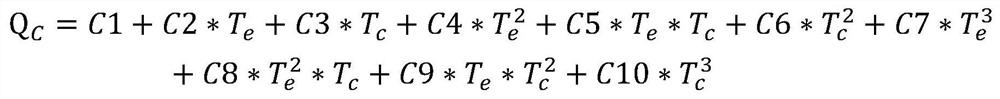

The invention belongs to the technical field of heat exchange, and particularly relates to a control method of a heat exchange system. The control method solves the problem that an existing multi-split air conditioning unit does not inform a user of abnormal information and a processing scheme in time, so that the multi-split air conditioning unit is prone to generating major faults. The heat exchange system comprises a multi-split air conditioning unit, a server and a control terminal. The control method comprises the following steps that operation parameters of the multi-split air conditioning unit are obtained; whether the operation parameters are abnormal or not is judged; if the operation parameters are abnormal, abnormal information is sent to the server; and the server sends the processing scheme for the abnormal information to the control terminal, so that a user can know the abnormal condition of the multi-split air conditioning unit and the processing scheme for the abnormalcondition in time through the control terminal, and the user has the capability of reducing the fault occurrence rate, so that the probability of major faults of the multi-split air conditioning unitis effectively reduced.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Preventive detection and maintenance method for elevator

PendingCN112061926AAvoid problematic detentionAvoid major failuresElevatorsBuilding liftsFloor levelAutomotive engineering

The invention provides a preventive maintenance method for an elevator. The preventive maintenance method for the elevator comprises the following steps of firstly, aiming at the load capacity detection of the elevator, installing a bottom plate with a pressure sensor on an inner bottom plate of the elevator, and enabling persons to slowly stand on the bottom plate; displaying the load capacity bythe pressure sensor every time when one person stands on the bottom plate, and until the elevator gives an alarm, recording pressure reading; and carrying an acceleration sensor onto the elevator, testing the acceleration between ascending and floor stopping as well as descending and floor stopping, and completing the acceleration detection. According to the preventive maintenance method for theelevator provided by the invention, load capacity detection, acceleration detection, levelness detection and steel wire rope detection of the elevator can be completed by using a simple method, so that the internal condition of the elevator can be known easily; if an abnormality occurs, the abnormality can be handled quickly, so that major faults in the elevator are avoided; and meanwhile, some common faults of an elevator door are effectively detected and processed through different methods, so that the comprehensive preventive detection is conducted on the elevator.

Owner:杭州本系机电工程有限公司

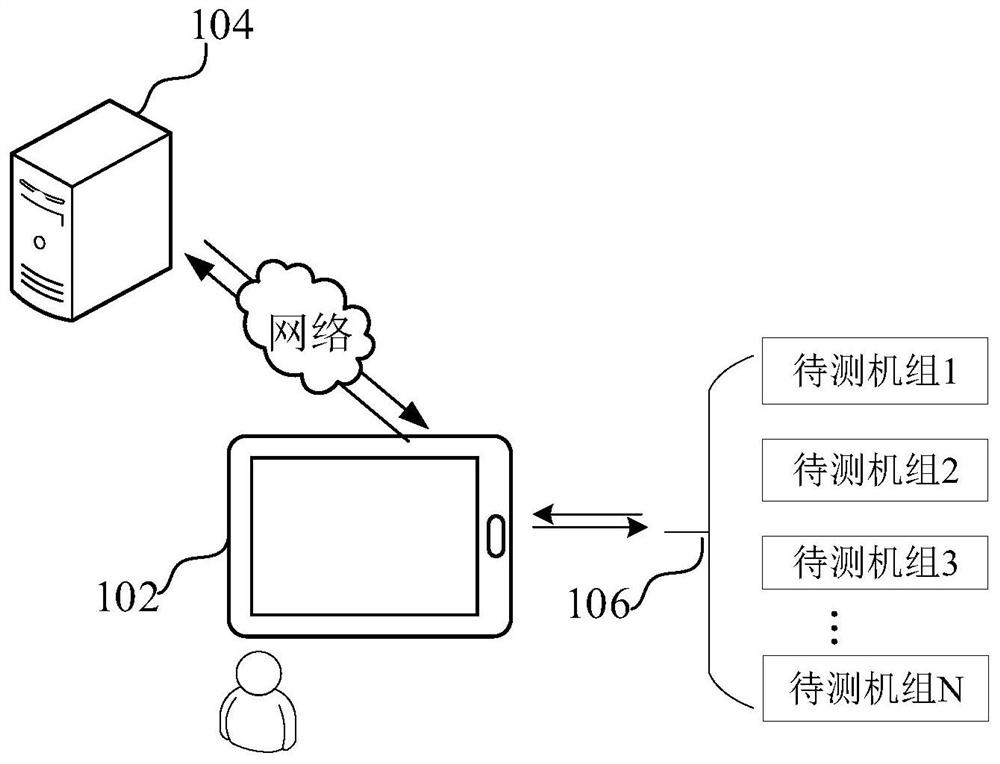

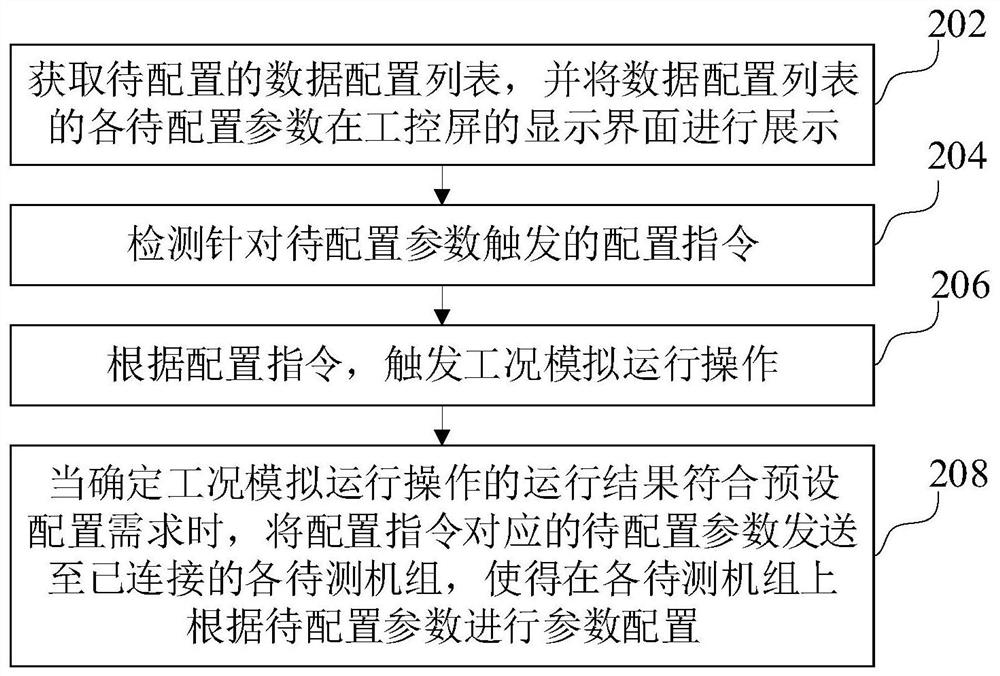

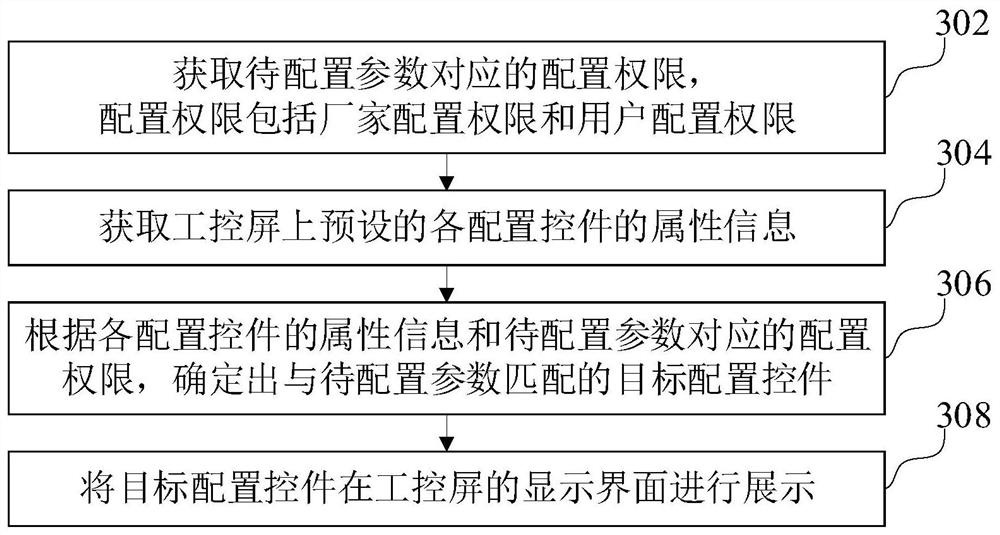

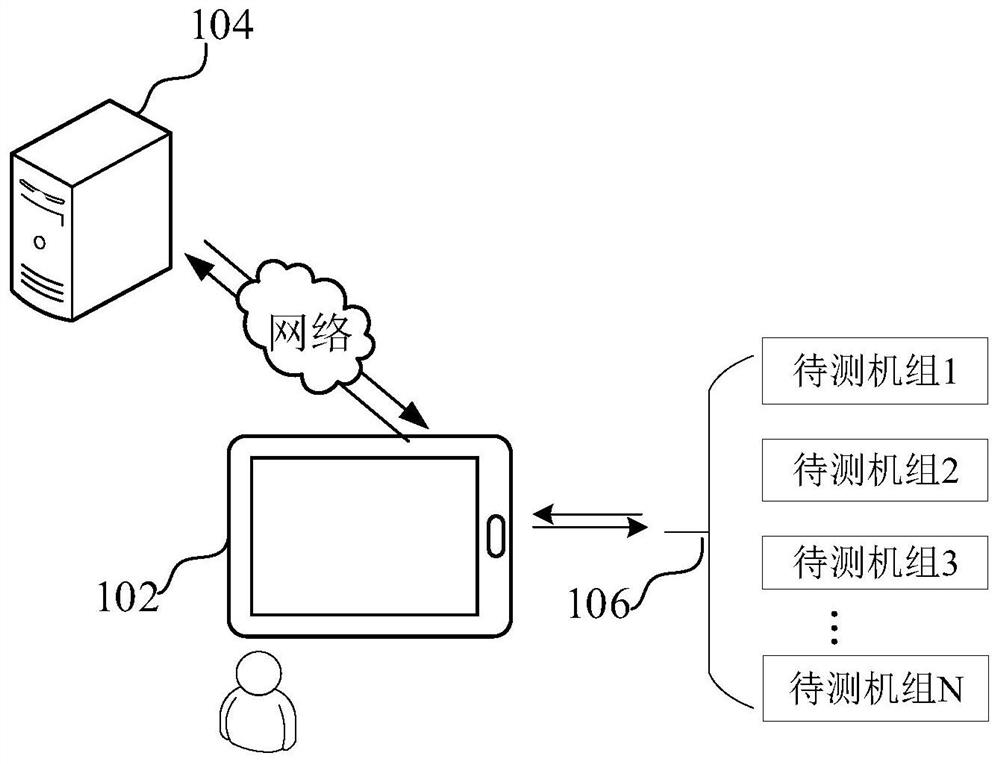

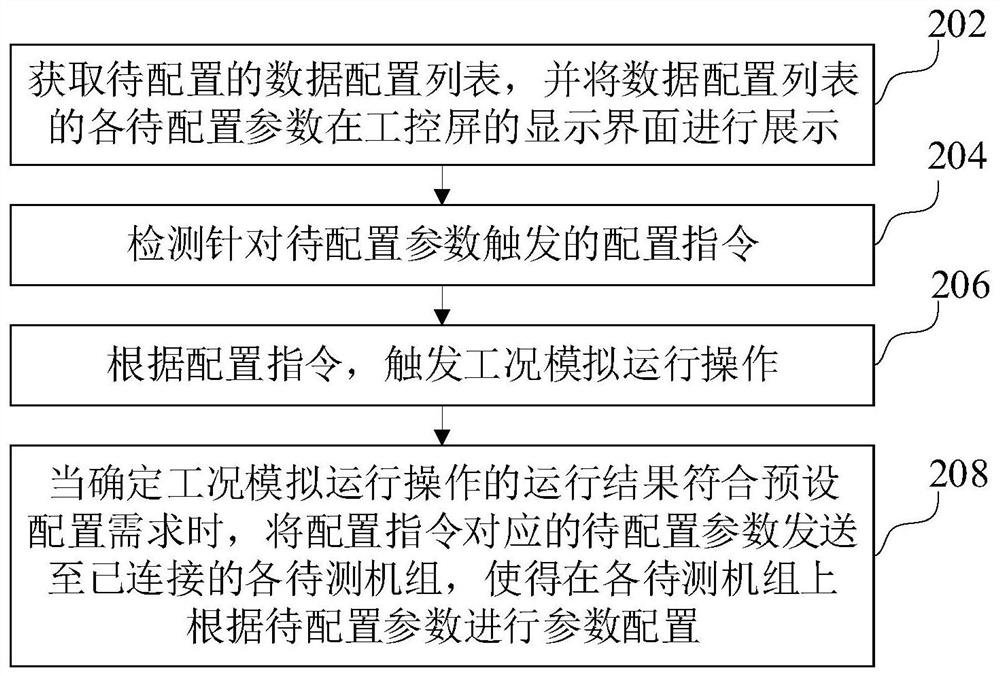

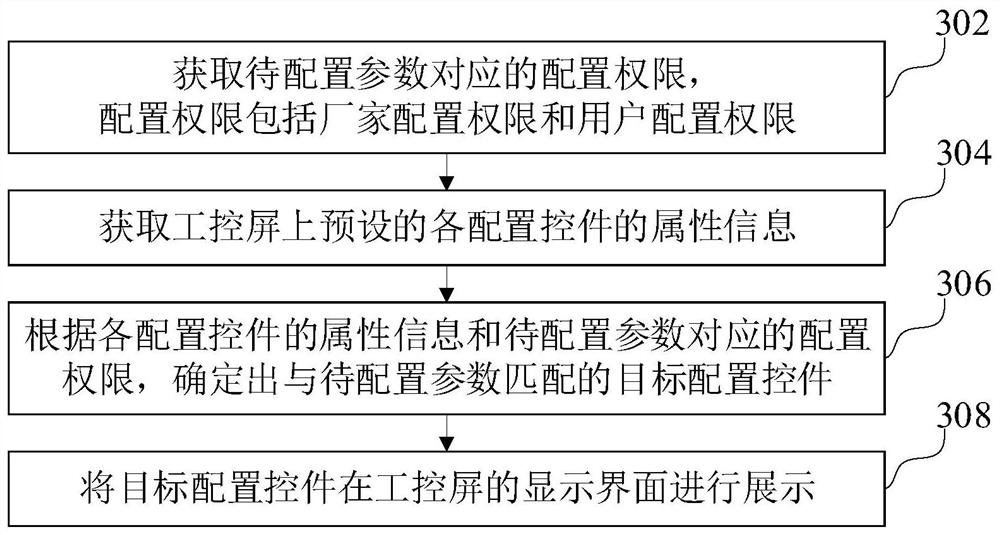

Parameter configuration method and device based on industrial control screen and computer equipment

ActiveCN112114897AGuarantee internal securityReduce mismatches and missesDigital data protectionProgram loading/initiatingComputer equipmentMaterial resources

The invention relates to a parameter configuration method and device based on an industrial control screen and computer equipment. The method comprises the steps of obtaining a to-be-configured data configuration list, and displaying all to-be-configured parameters of the data configuration list on a display interface of an industrial control screen; detecting a configuration instruction triggeredfor the to-be-configured parameter; triggering a working condition simulation running operation according to the configuration instruction; and when it is determined that the operation result of theworking condition simulation operation meets a preset configuration requirement, sending the to-be-configured parameters corresponding to the configuration instruction to each connected to-be-tested unit, so that parameter configuration is performed on each to-be-tested unit according to the to-be-configured parameters. By the adoption of the method, one-key parameter configuration of the to-be-tested unit is achieved, workers do not need to conduct manual configuration on site, the mismatching and mismatching situations caused by errors of manual operation are reduced, manpower and material resources consumed by repeated configuration or modification are reduced, and the parameter configuration efficiency for the large to-be-tested unit is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

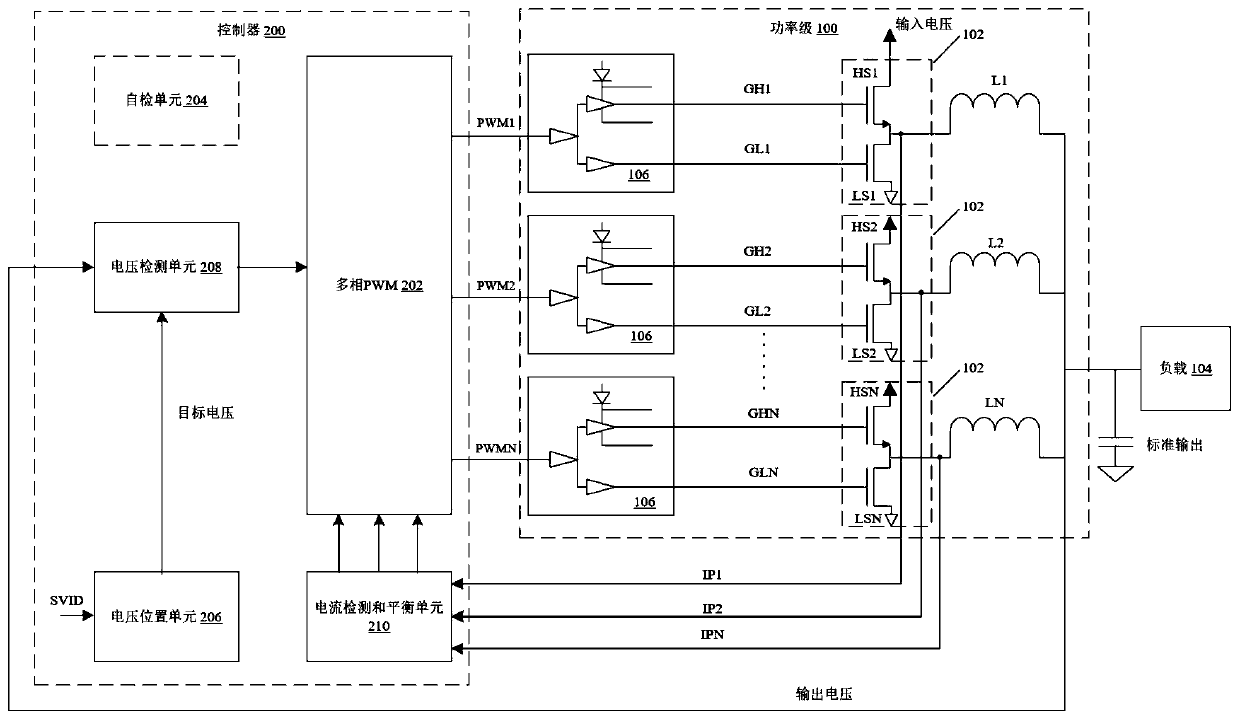

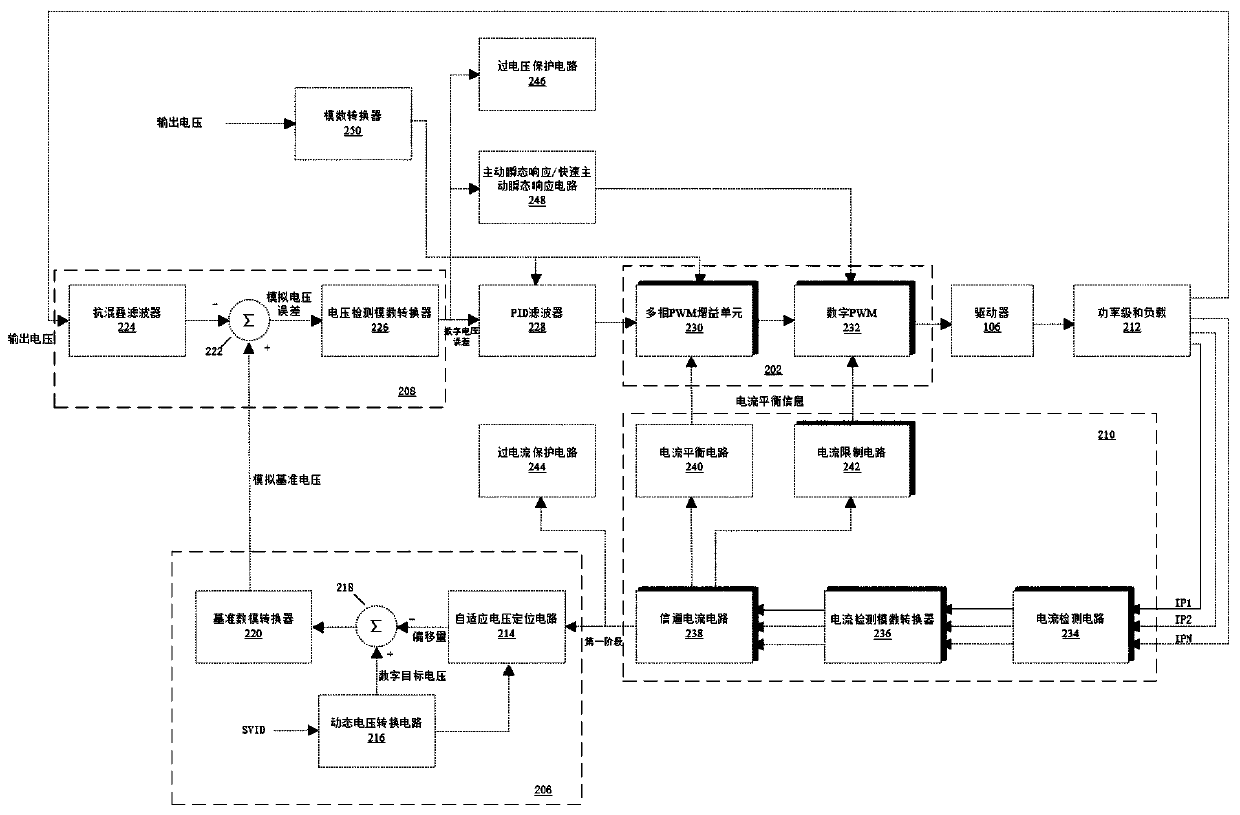

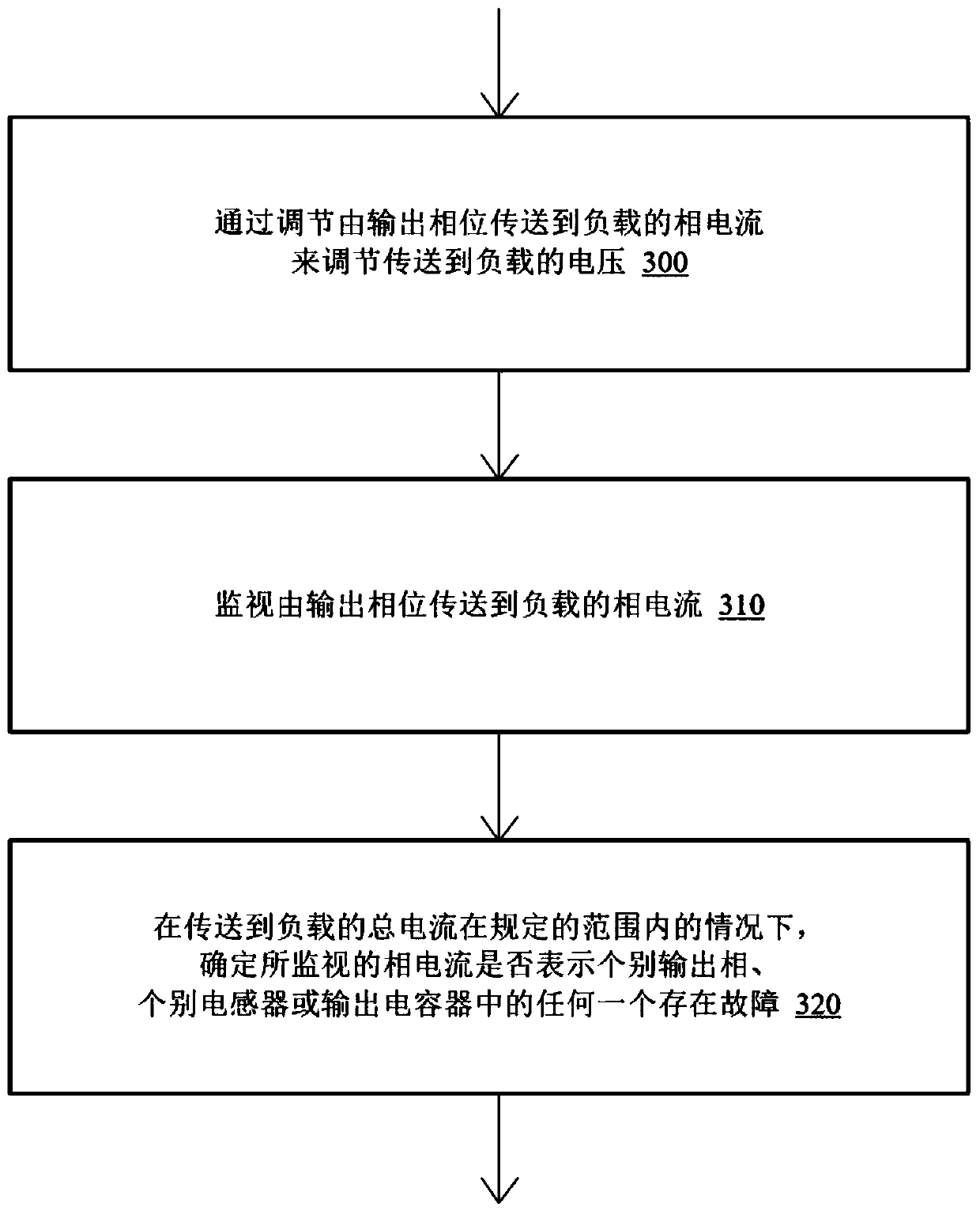

Multi-phase voltage stabilizer for phase current testing in slope current mode

InactiveCN111580589AAvoid major failuresAvoid failureElectric variable regulationPhase currentsControl engineering

The invention discloses a multiphase voltage stabilizer for carrying out phase current testing in a slope current mode and belongs to the technical field of multiphase voltage stabilizers. The multiphase voltage stabilizer comprises a multiphase regulator, wherein the multiphase regulator comprises a power stage 100, wherein the power stage 100 comprises a plurality of output phases 102 and a controller 200 used for controlling the power stage 100, and the controller 200 is provided with a self-test unit. The stabilizer is used for identifying the condition that the multiphase regulator cannotwork normally, therefore, the regulator is prevented from suffering from major faults during working, a controller of the multiphase regulator uses a complex method to execute self-checking of the regulator; the abnormal operation condition is detected by checking the available information in the controller, alternatively, the controller may detect a number of fault conditions in which the multiphase regulator may still provide regulation in some cases, but may fail when operating conditions change, or operate the system using a particular operating mode to detect abnormal operating conditions in which the controller may detect many fault conditions.

Owner:XI'AN PETROLEUM UNIVERSITY

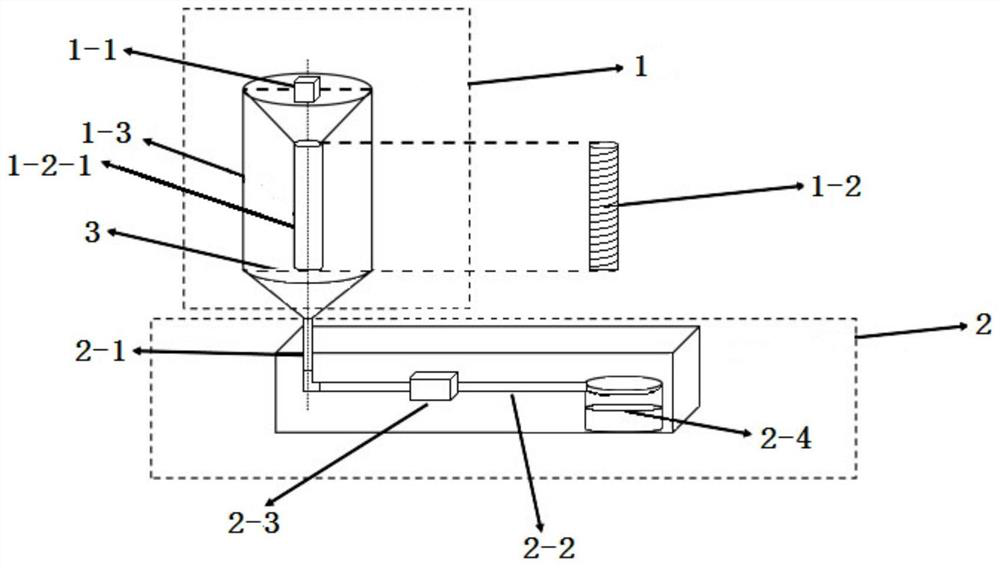

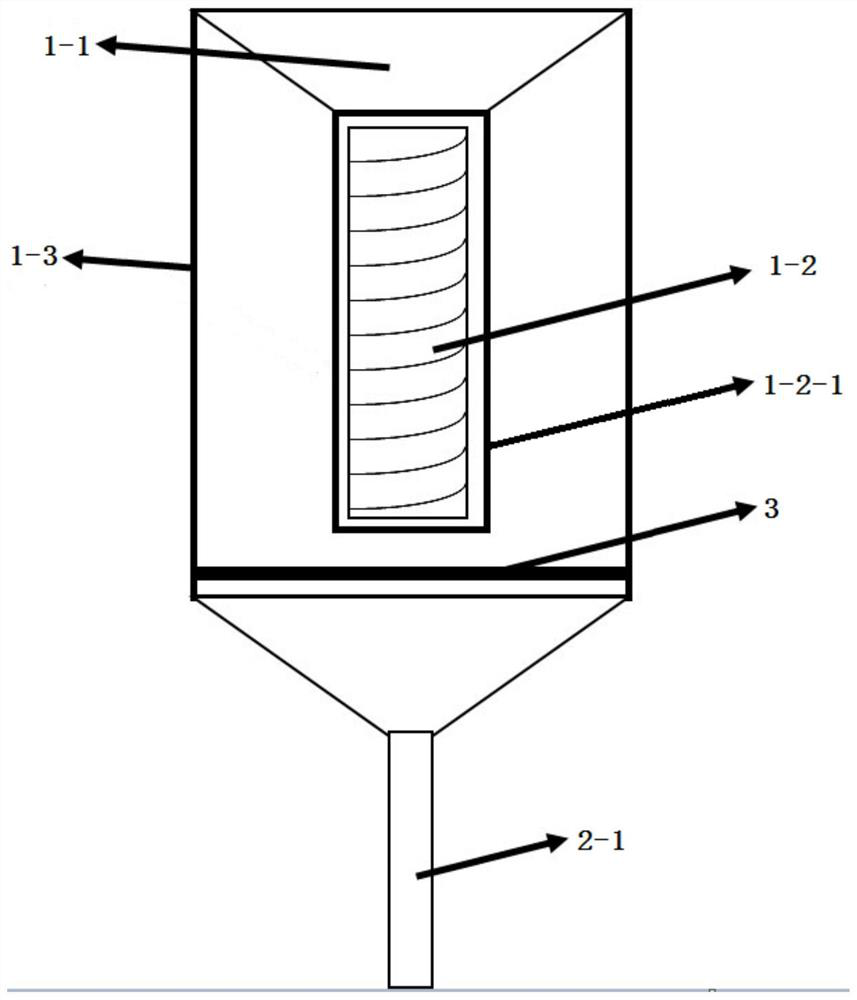

Lubricating grease pollutant detection device and detection method thereof

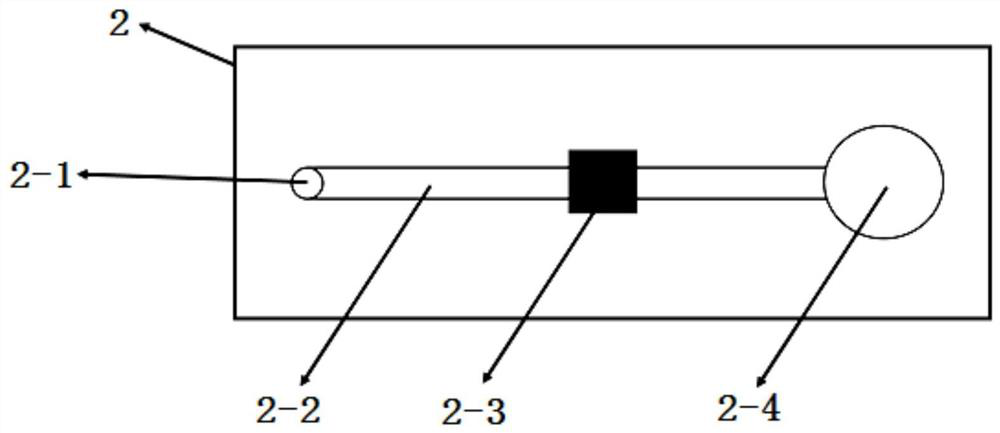

The invention provides a lubricating grease pollutant detection device and method. The device comprises a lubricating grease heating and liquefying module and an oil liquid detection chip, the lubricating grease heating and liquefying module comprises a lubricating grease inlet, a resistance wire heating device and a first metal pipe; the lubricating grease inlet is connected with the resistance wire heating device, and the lubricating grease inlet and the resistance wire heating device are both arranged in the first metal pipe and wrapped by the first metal pipe; lubricating grease is heated by the resistance wire heating device through the lubricating grease inlet, so that solid lubricating grease is liquefied; the oil detection chip comprises an oil inlet, a micro-channel, a detection unit and an oil storage tank; the oil inlet is formed below the resistance wire heating device, the detection unit is connected with the oil inlet through a micro-channel, the oil storage tank is connected to the tail end of the micro-channel, a liquefied lubricating grease sample is conveyed to the detection unit through the oil inlet, and the detection unit detects metal particles and moisture in the oil sample; and the detected oil sample flows into the oil storage tank through the micro-channel.

Owner:DALIAN MARITIME UNIVERSITY

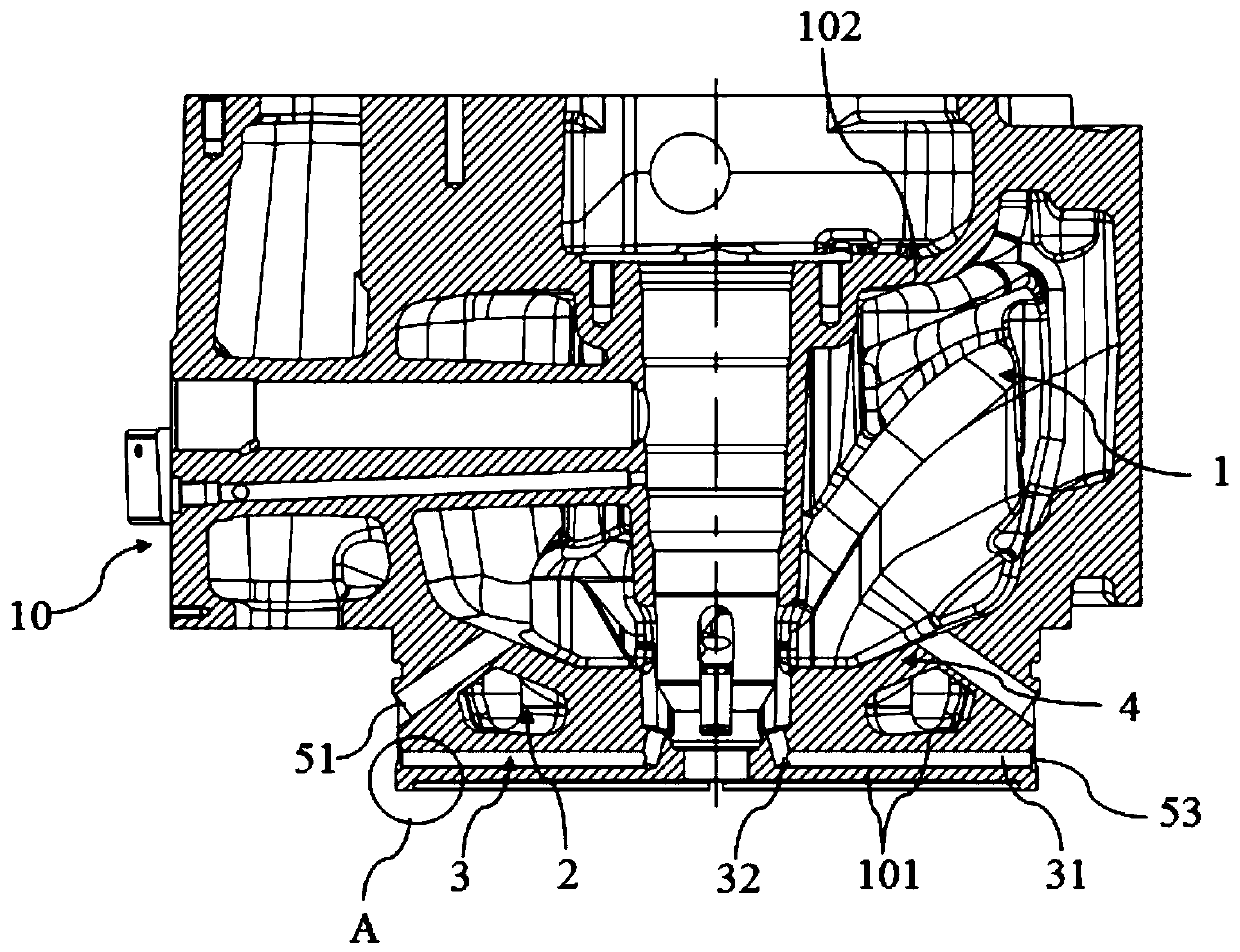

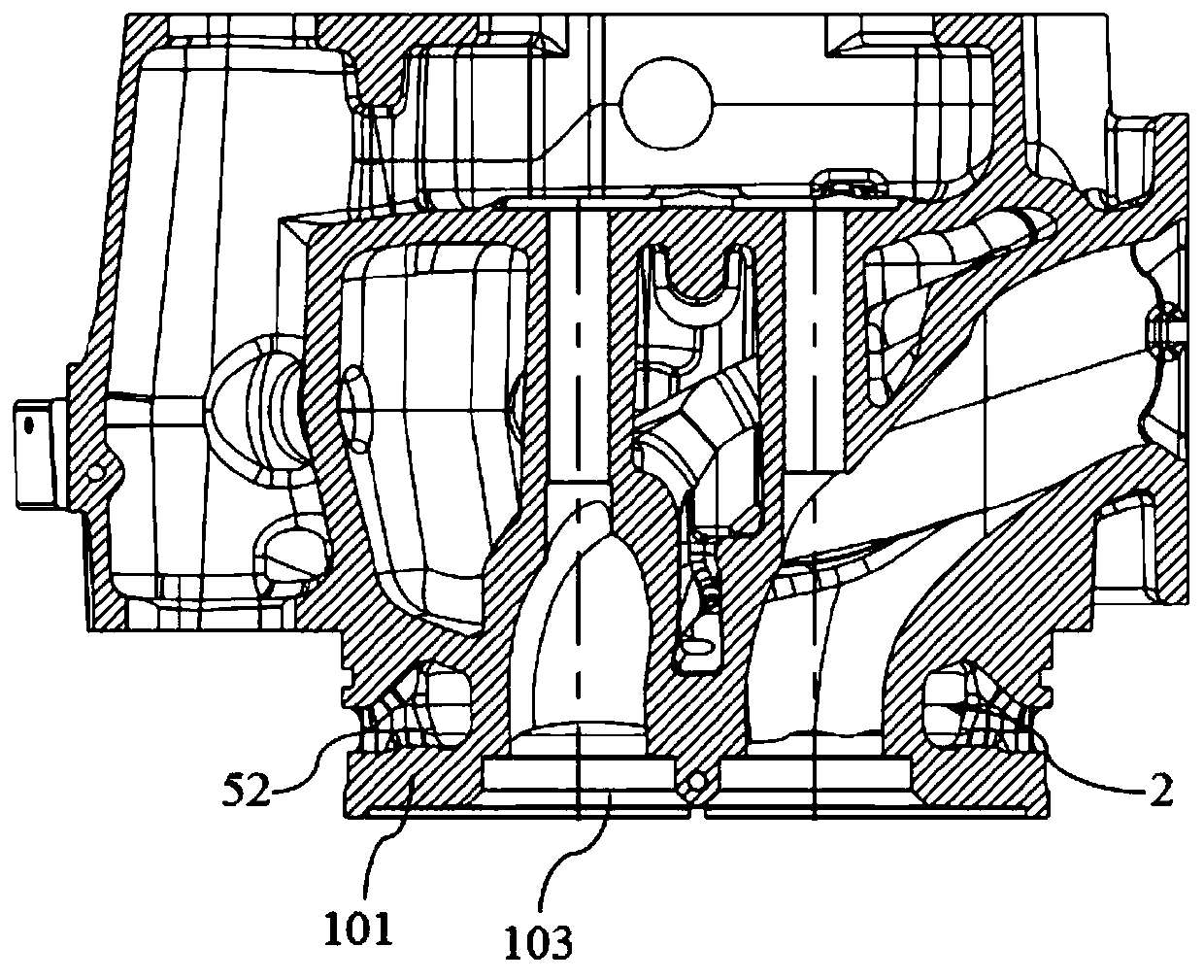

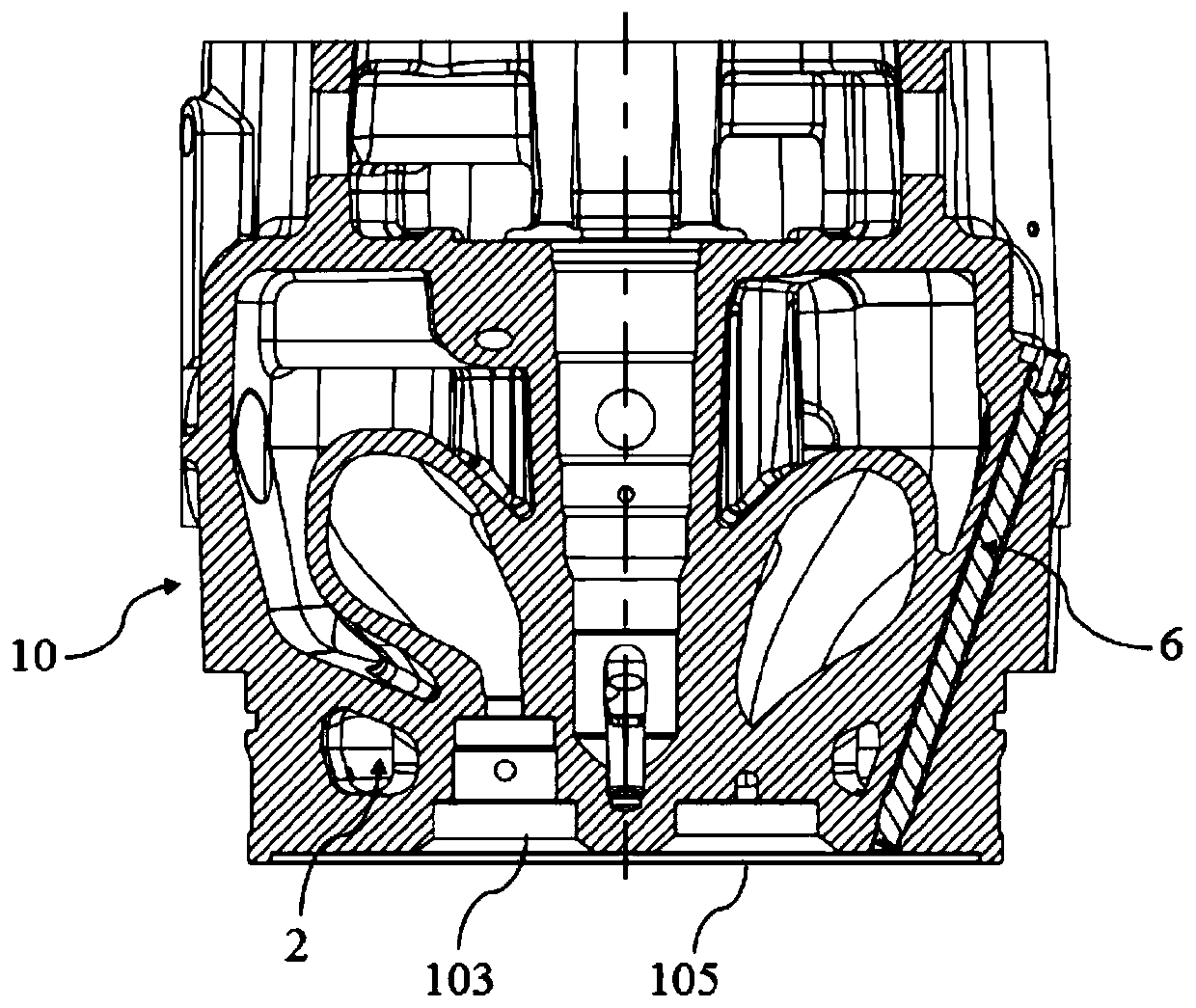

Cylinder head and engine with same

ActiveCN109854403BRaise the intensity levelImprove cooling effectCylinder headsCylindersCylinder headEngineering

The invention provides a cylinder cover and an engine. A cooling water jacket is arranged in the cylinder cover, and comprises an upper layer water jacket body, a middle layer water jacket body and alower layer water jacket body which are sequentially arranged from top to bottom; the side wall of the cylinder cover is provides with different water inflow holes communicating with the upper layer water jacket body, the middle layer water jacket body and the lower layer water jacket body; and cooling liquid can enter the upper layer water jacket body, the middle layer water jacket body and the lower layer water jacket body through the different water inflow holes to cool different areas of the cylinder cover. According to the cylinder cover and the engine, by arranging a thick fire power plate to meet the high detonation pressure and high load requirement of the cylinder cover, the strength level of the cylinder cover is substantially improved; due to the fact that the side face of the fire power plate is provided with cooling through holes, the three-layer cooling water jacket structure is formed; the bottom plate can be cooled through the middle layer water jacket body and the lower layer water jacket body at the same time, and the cooling capacity of the cylinder cover is enhanced; and the side face of the cylinder cover is provided with an installing hole for installing a detonation pressure sensor, through the detonation pressure sensor, detonation pressure of the engine can be monitored in real time, and a huge fault is prevented from happening.

Owner:WEICHAI POWER CO LTD

A Judgment Method for Abnormality of Motor Stator Current Spectrum Analysis Equipment

ActiveCN108169559BAccurate analysisAvoid major failuresSpectral/fourier analysisDynamo-electric machine testingElectric machineCurrent spectrum

The invention discloses a method for judging the abnormality of a motor stator current spectrum analysis device, comprising the following steps: collecting motor current signals, monitoring whether there is abnormality, analyzing the abnormality type, and judging the abnormality severity. First, collect the motor current signal, confirm that the collected signal points are correct, analyze and confirm whether there is a motor abnormality, and filter the collected signal. Through continuous practice, it is found that the frequency amplitude of the motor abnormality is related to the severity of the motor abnormality. The above judgment method can quickly and accurately analyze the abnormal severity of the electrical equipment online, so as to judge whether an emergency shutdown is required for maintenance, so as to prevent major equipment failures in advance.

Owner:HAINAN JINHAI PULP & PAPER

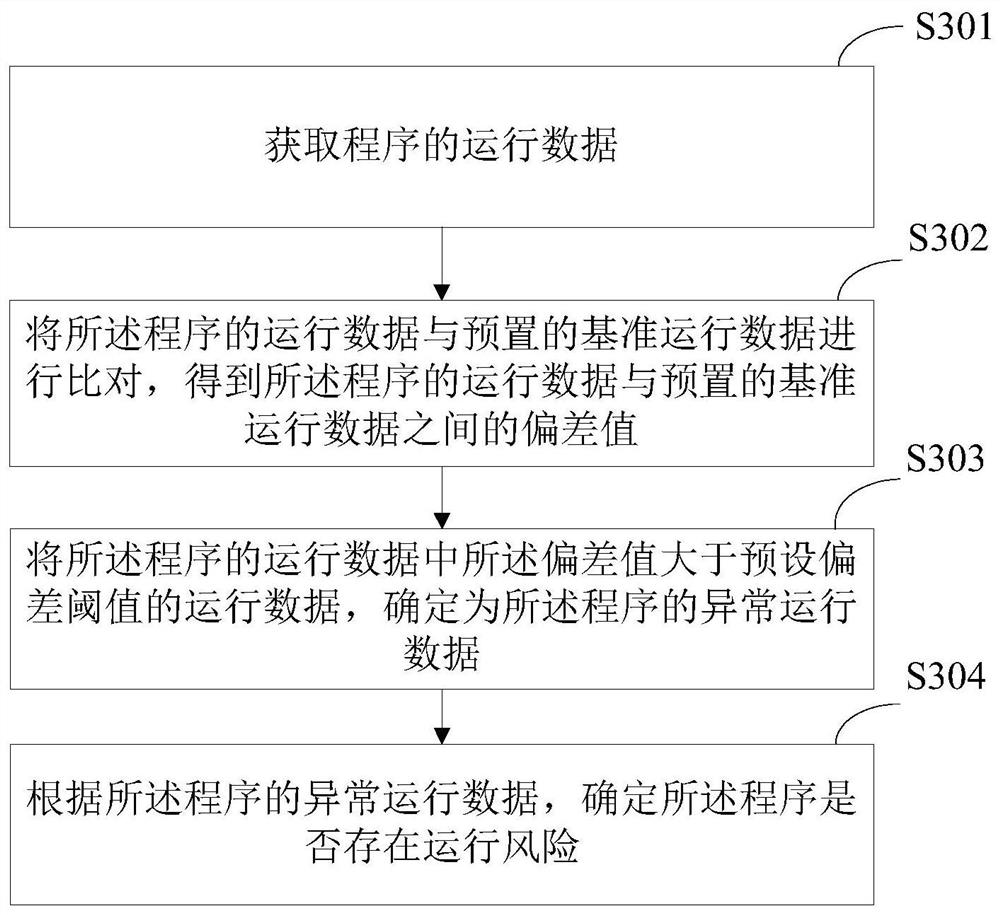

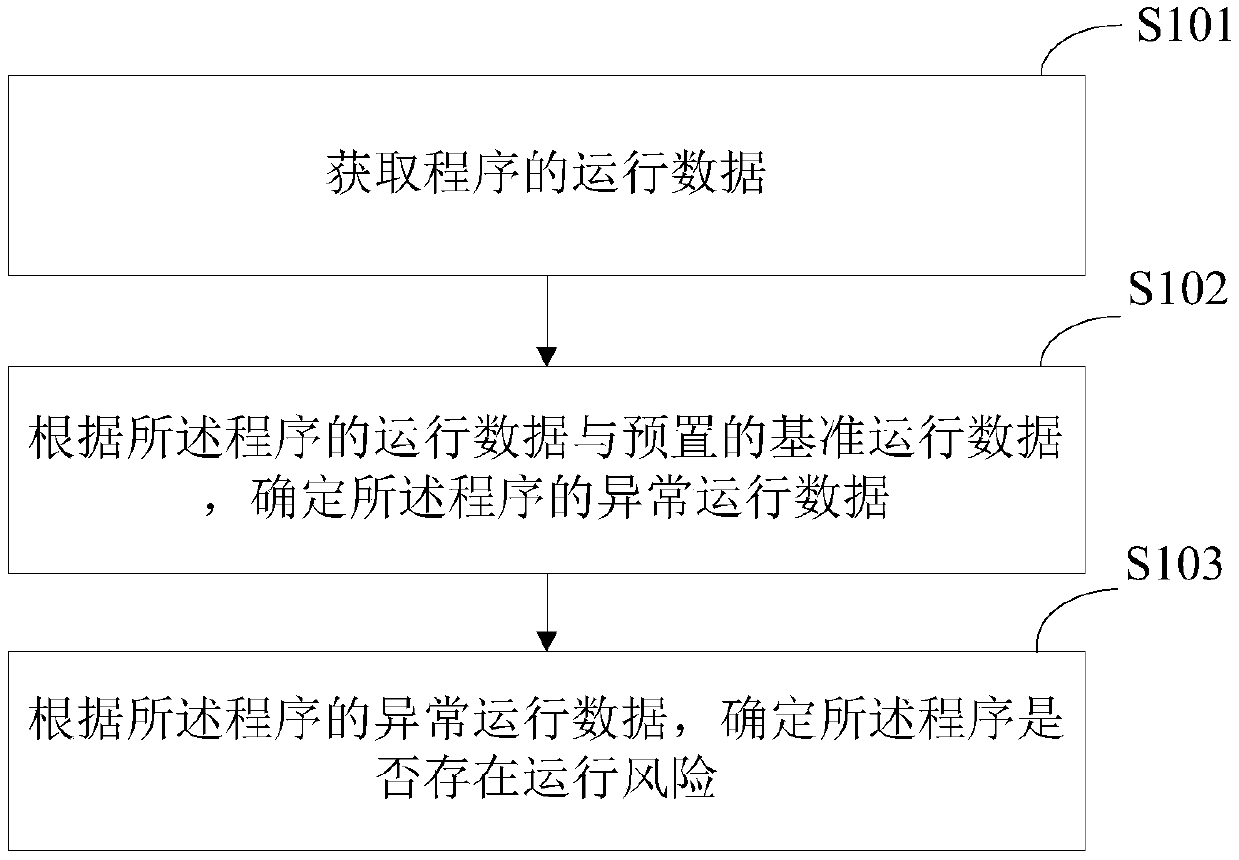

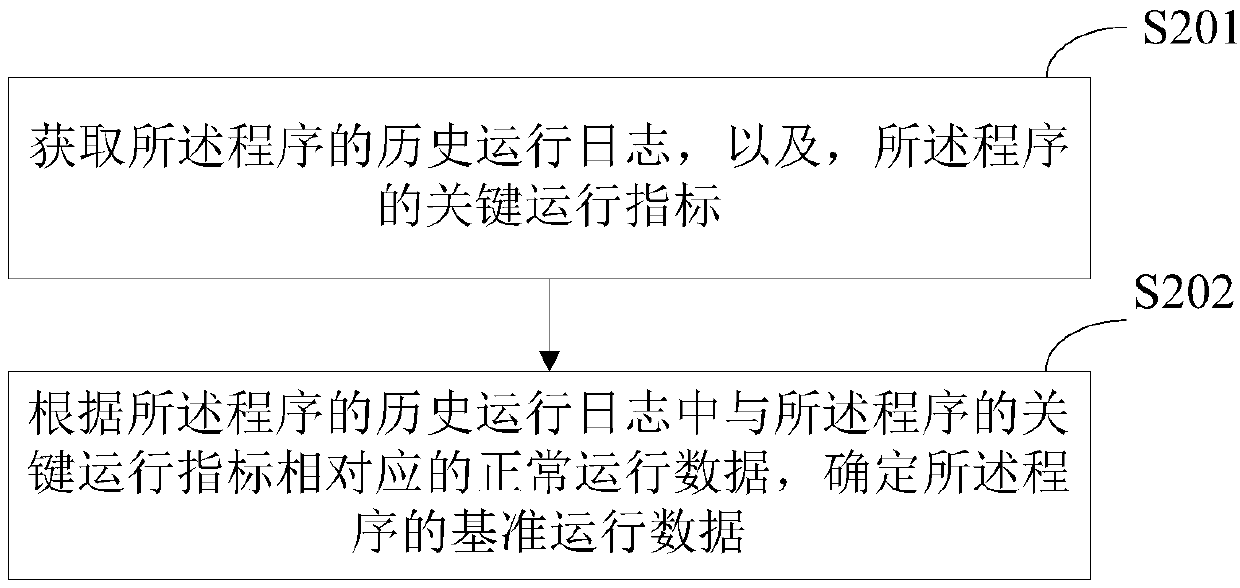

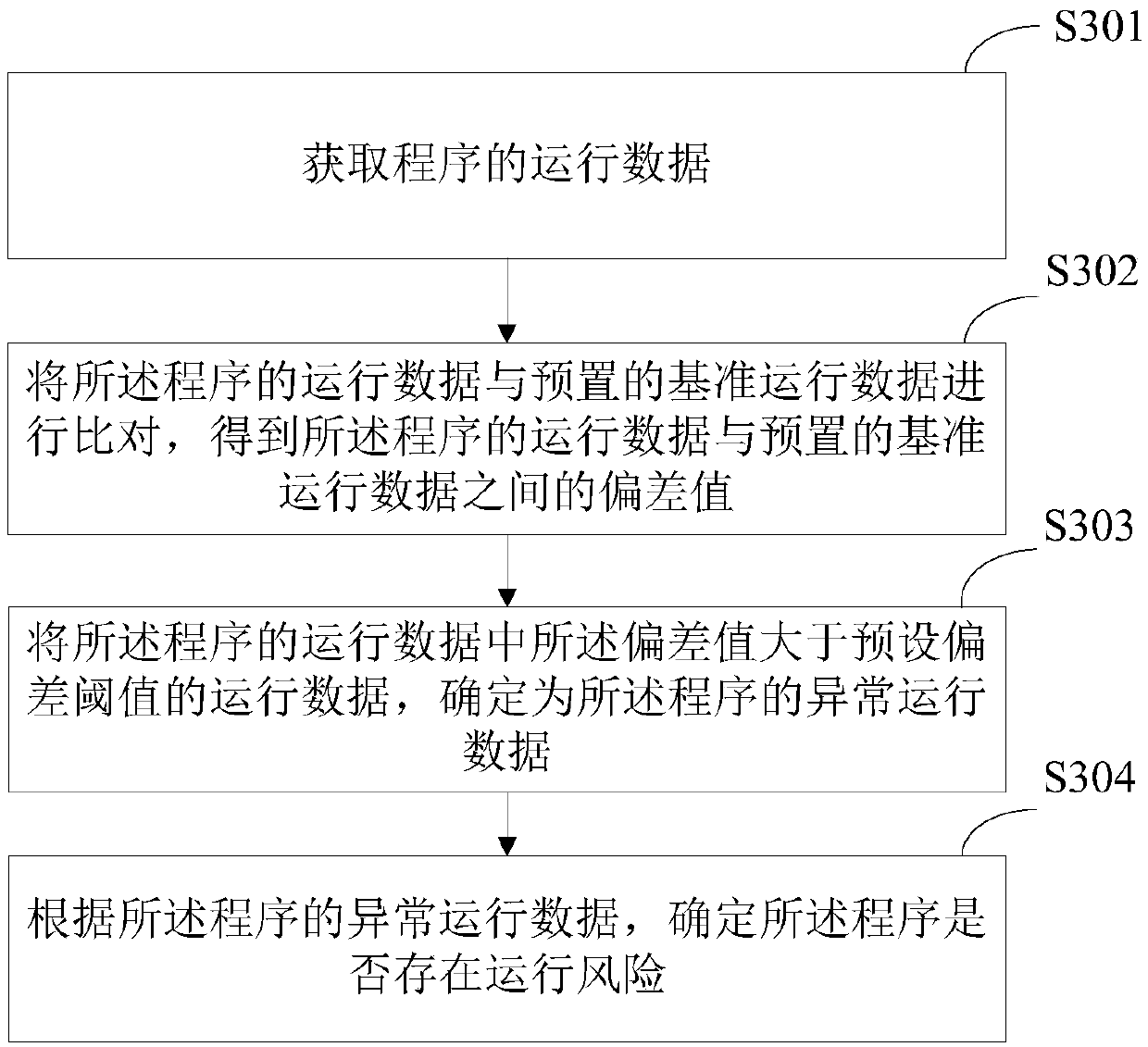

Analysis method and device for program operation risk

ActiveCN110489967BAvoid major failuresImprove robustnessPlatform integrity maintainanceReliability engineeringComputer engineering

Owner:BEIJING GRIDSUM TECH CO LTD

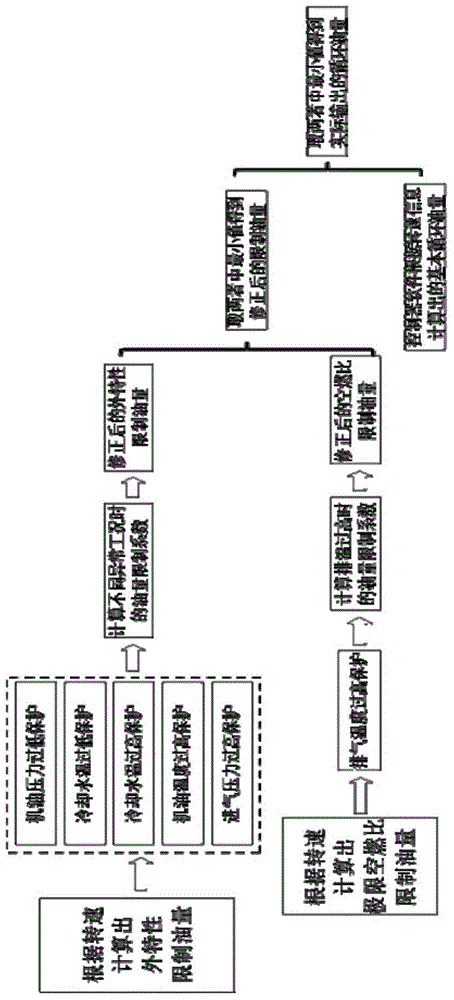

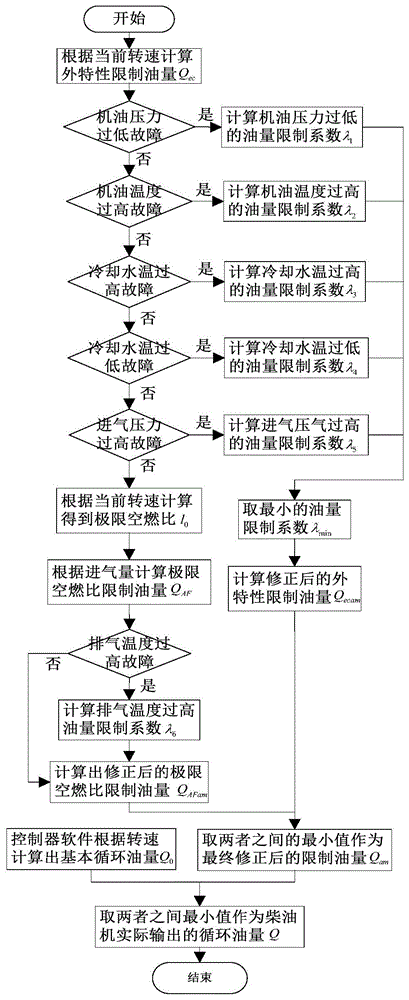

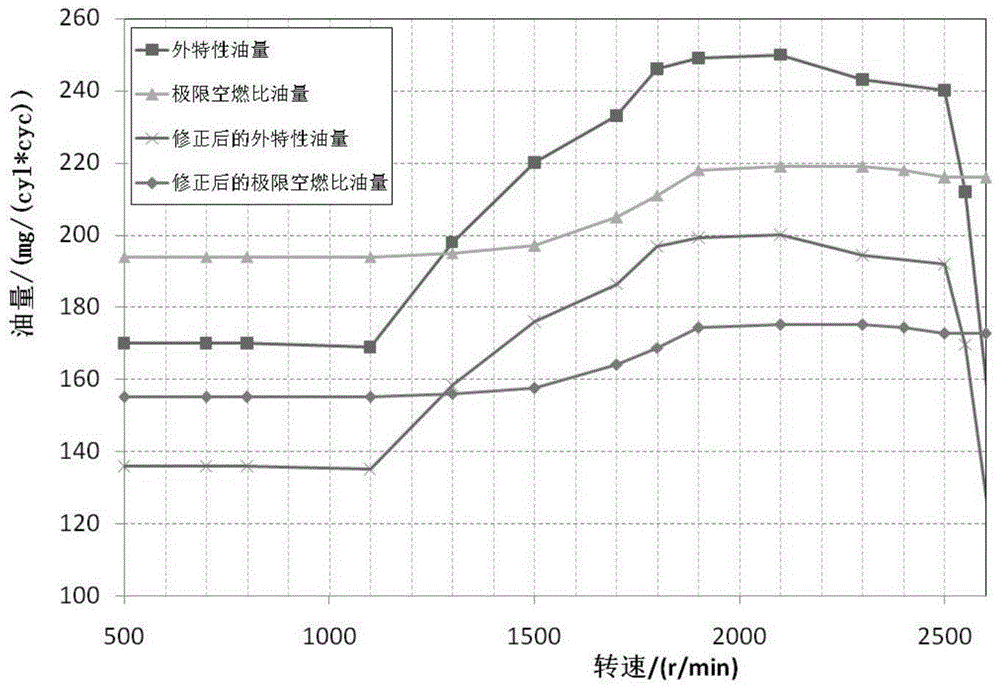

A Method for Determining the Output Oil Quantity of Electronically Controlled Diesel Engine under Abnormal Condition

InactiveCN104153899BImprove powerImprove economyElectrical controlMachines/enginesEngineeringDiesel engine

The invention discloses a method for determining the output oil volume of an electronically controlled diesel engine under abnormal conditions. The method includes: obtaining the corrected limited oil volume, which includes the following steps: calculating the external characteristic limited oil volume and the limit air-fuel ratio limited oil volume; Calculating a first fuel quantity limiting coefficient according to one or more abnormal conditions; calculating a modified external characteristic limiting fuel quantity; calculating a second fuel quantity limiting coefficient; calculating a corrected limit air-fuel ratio limiting fuel quantity; The smaller value of the limited oil quantity of external characteristics and the modified limit air-fuel ratio limited oil quantity is used as the revised limited oil quantity; the basic cycle oil quantity is calculated; the comparison between the corrected limited oil quantity and the basic cycle oil quantity is obtained The small value is used as the actual output circulating oil volume; and the actual output circulating oil volume is used to adjust the fuel injection of the electronically controlled diesel engine. This method enables automatic repair of the diesel engine, avoiding major failures.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

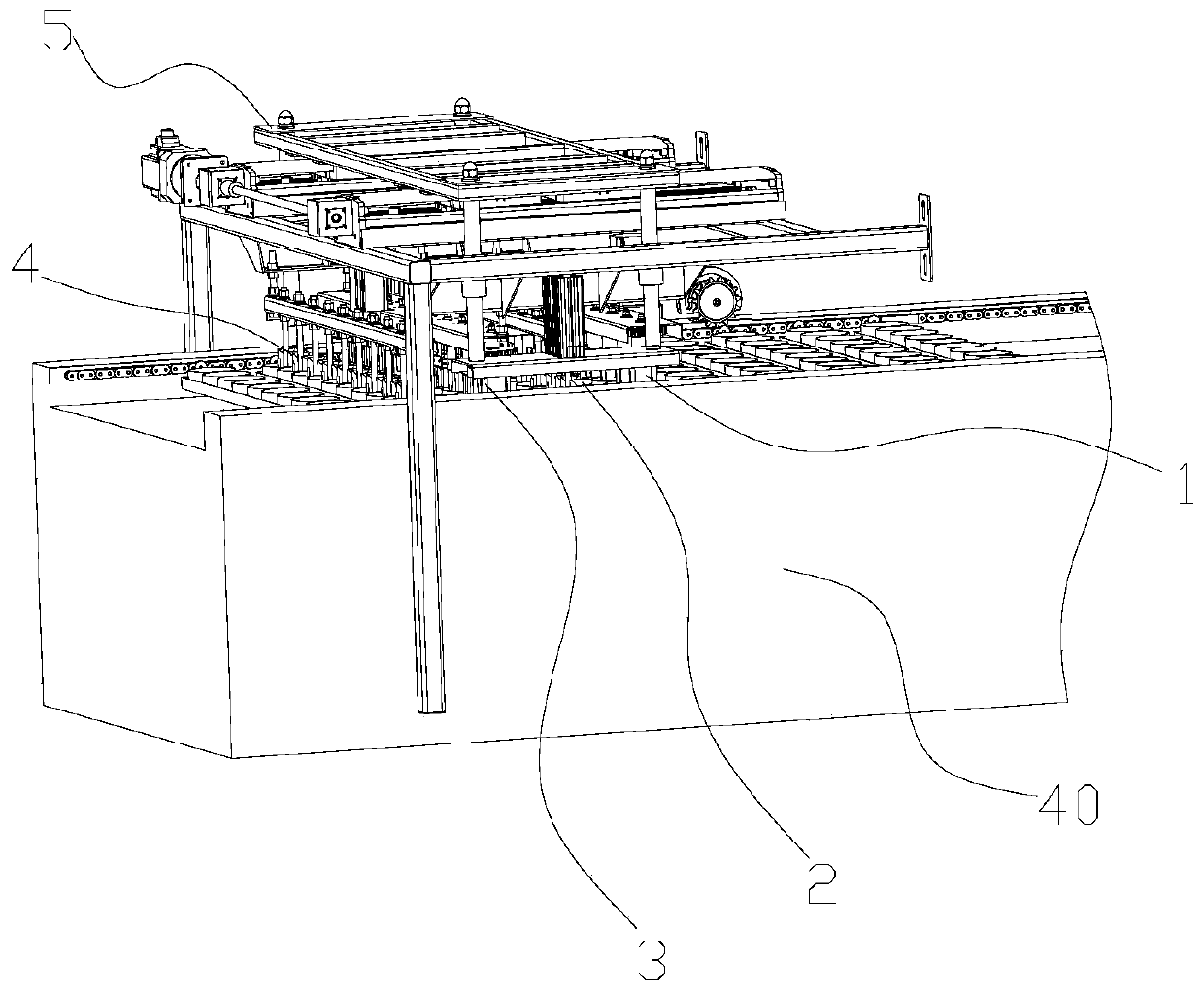

Adjustable material shifting device

InactiveCN107161673AEasy to adjust manuallyAvoid cloggingConveyorsConveyor partsMechanical engineeringPower consumption

An adjustable material shifting device, including a drive unit, a roller, a bearing seat, and a screw rod. The drive unit is connected to the roller, and the roller is installed on the bearing seat. The up and down movement of the rod drives the bearing seat and the roller to move up and down. The adjustable feeding device of the invention can not only prevent blockage, but also reduce deformation and reduce power consumption; it can reduce feeding pressure and reduce equipment operating power.

Owner:宜都中起重工机械有限公司

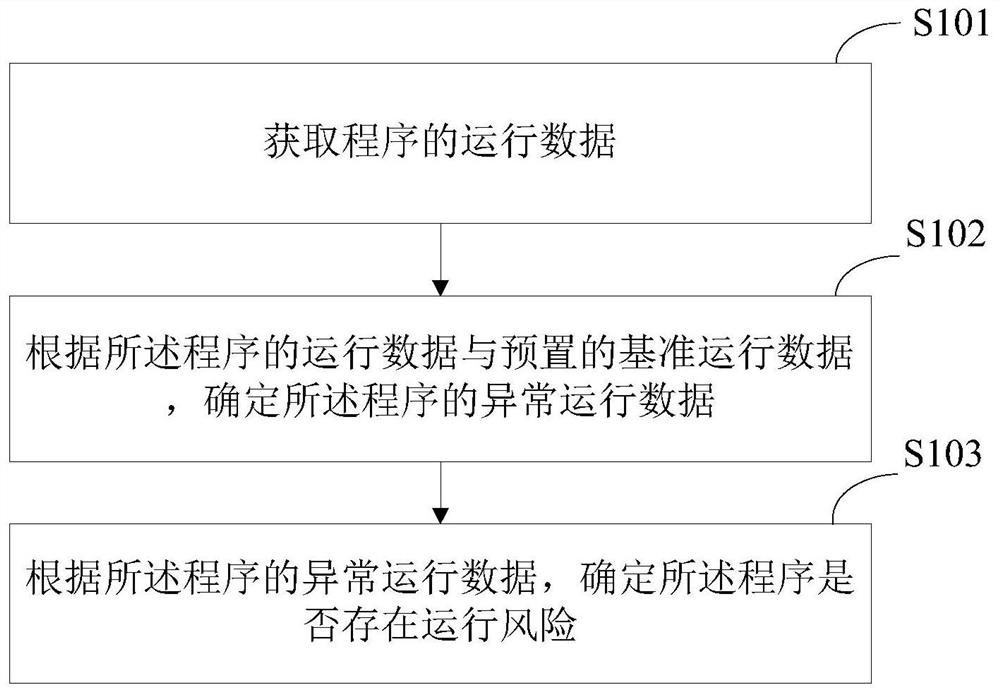

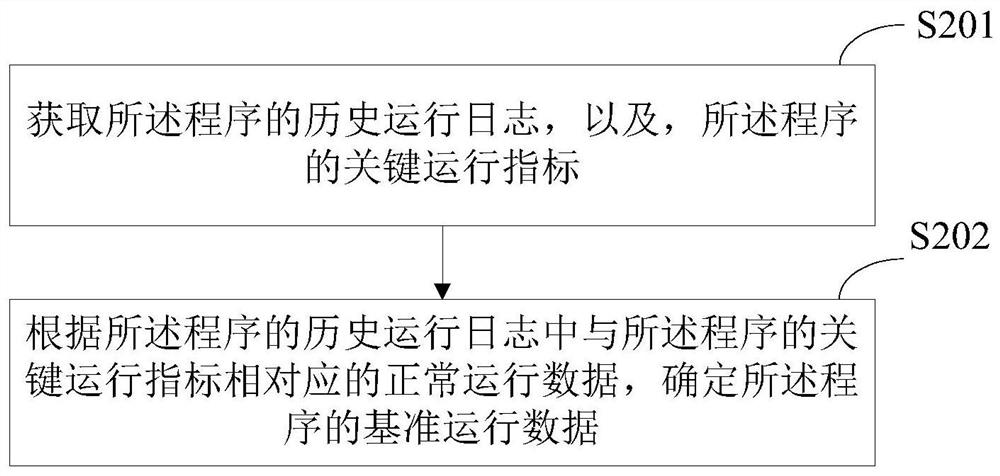

Program running risk analysis method and device

ActiveCN110489967AAvoid major failuresImprove robustnessPlatform integrity maintainanceProcess MeasuresAnalysis method

The invention provides a program running risk analysis method and device. The program running risk analysis method comprises the steps: obtaining running data of a program; determining abnormal operation data of the program according to the operation data of the program and preset reference operation data, wherein the reference operation data is determined according to normal operation data in a historical operation log of the program; and according to the abnormal operation data of the program, determining whether the program has an operation risk or not. Therefore, potential risks in the program running process can be found in time before major faults happen to the program, and operation and maintenance personnel can take processing measures in time according to the running risks existing in the program, and the major faults of the program are avoided, and the robustness of the program running process is improved, and normal running of services is guaranteed.

Owner:BEIJING GRIDSUM TECH CO LTD

Method and system for monitoring mechanical state of on-load tap-changer based on multi-layer filter

ActiveCN108535638BEfficient identificationEffective Operation and Maintenance StrategyMachine part testingCircuit interrupters testingFrequency spectrumTransformer

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

Flour tidying device for noodles, bean vermicelli and rice noodles

InactiveCN109775013AEasy to storeEffective aggregationRod-shaped articlesDISC assemblyFood processing

Owner:ACCUBAL INTELLIGENT MACHINERY CO LTD

Device and method for monitoring blades of wind turbines

ActiveCN108799011BRealize analysisRealize evaluationEngine fuctionsMachines/enginesEngineeringBackground image

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

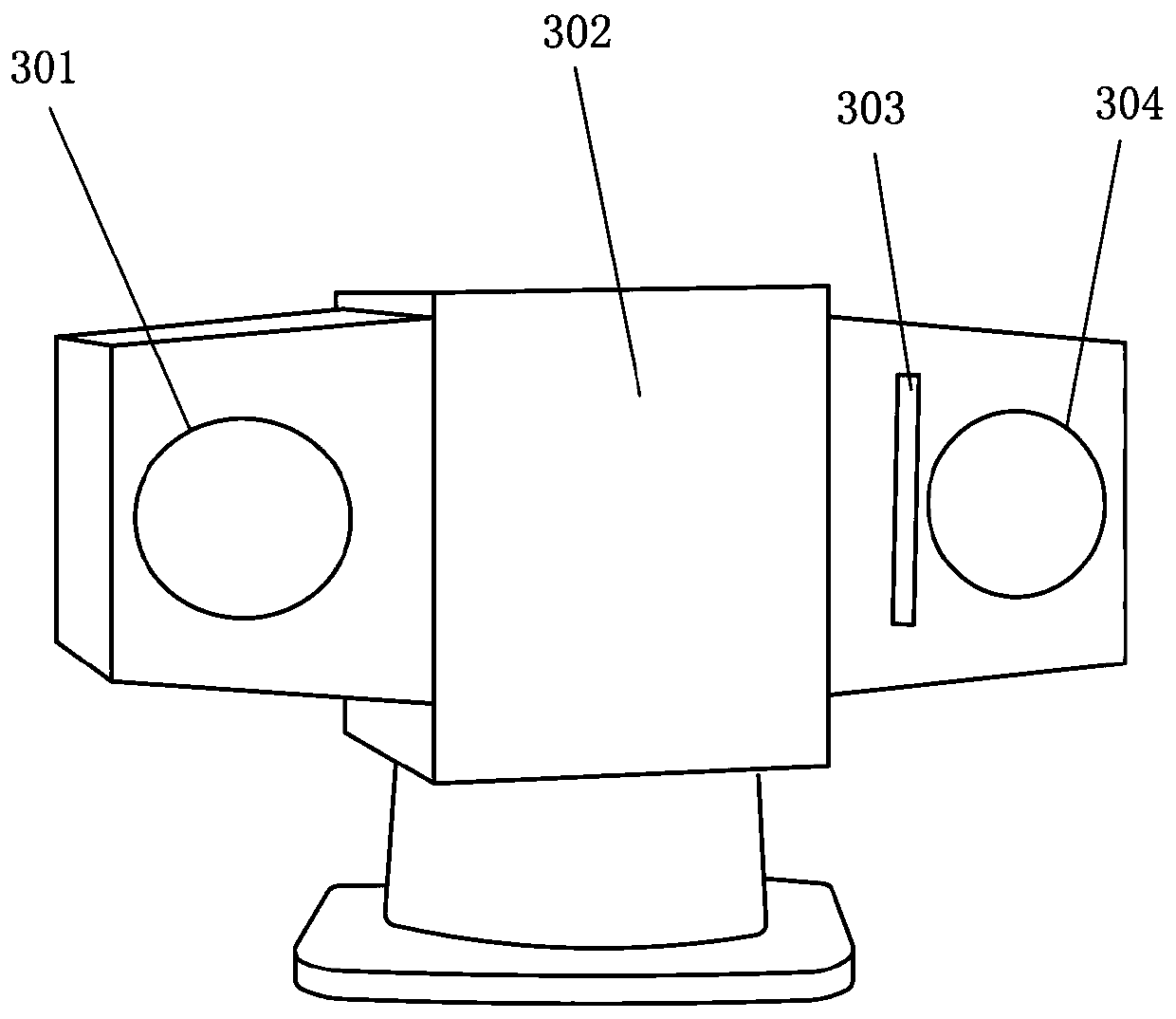

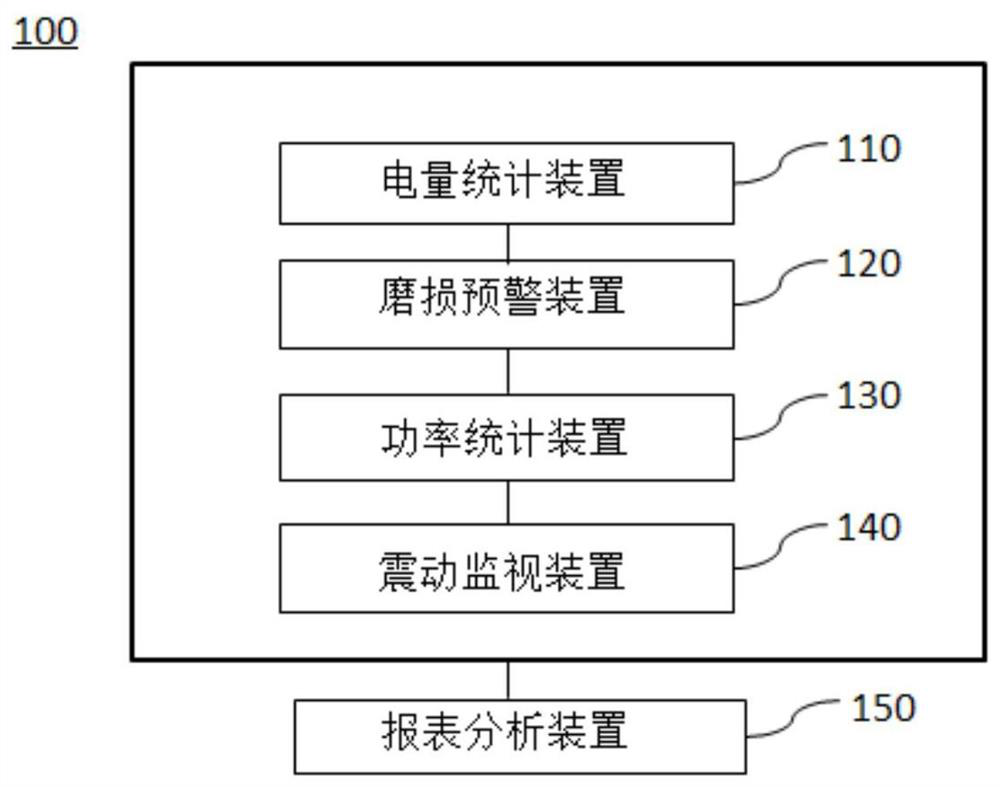

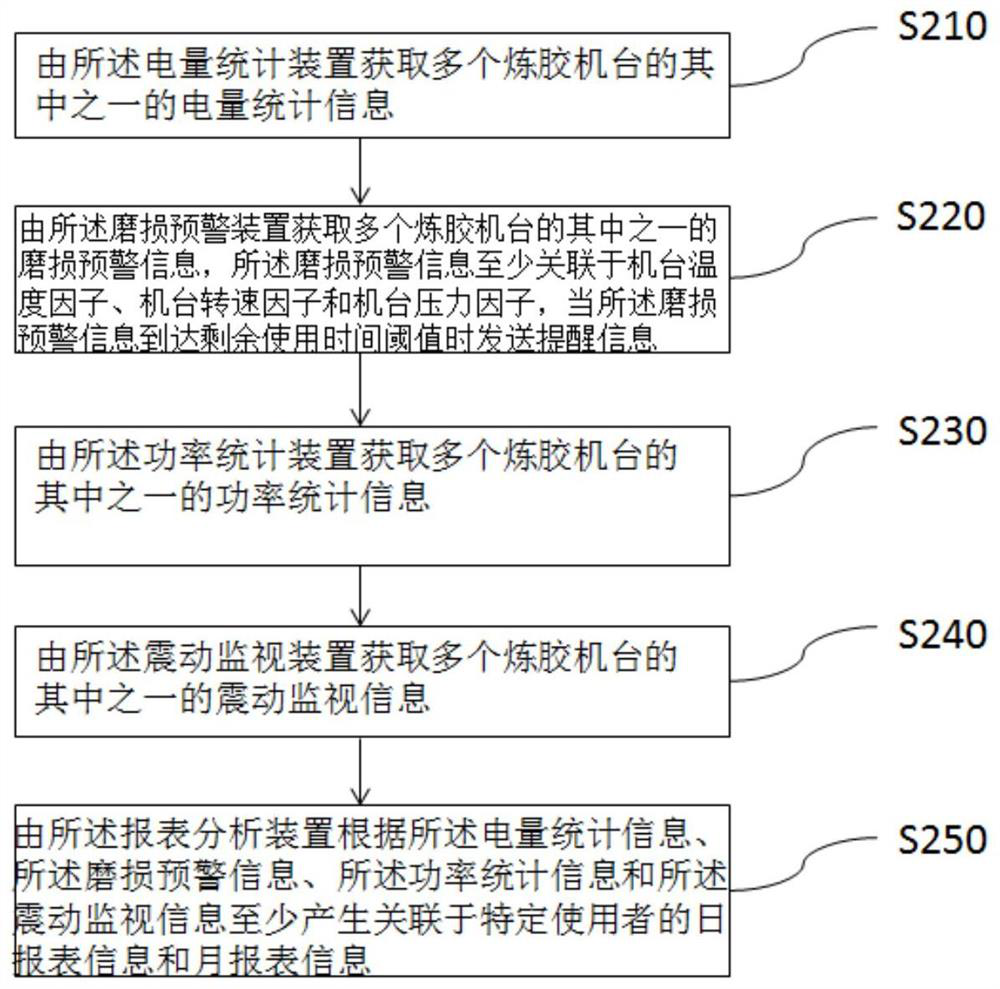

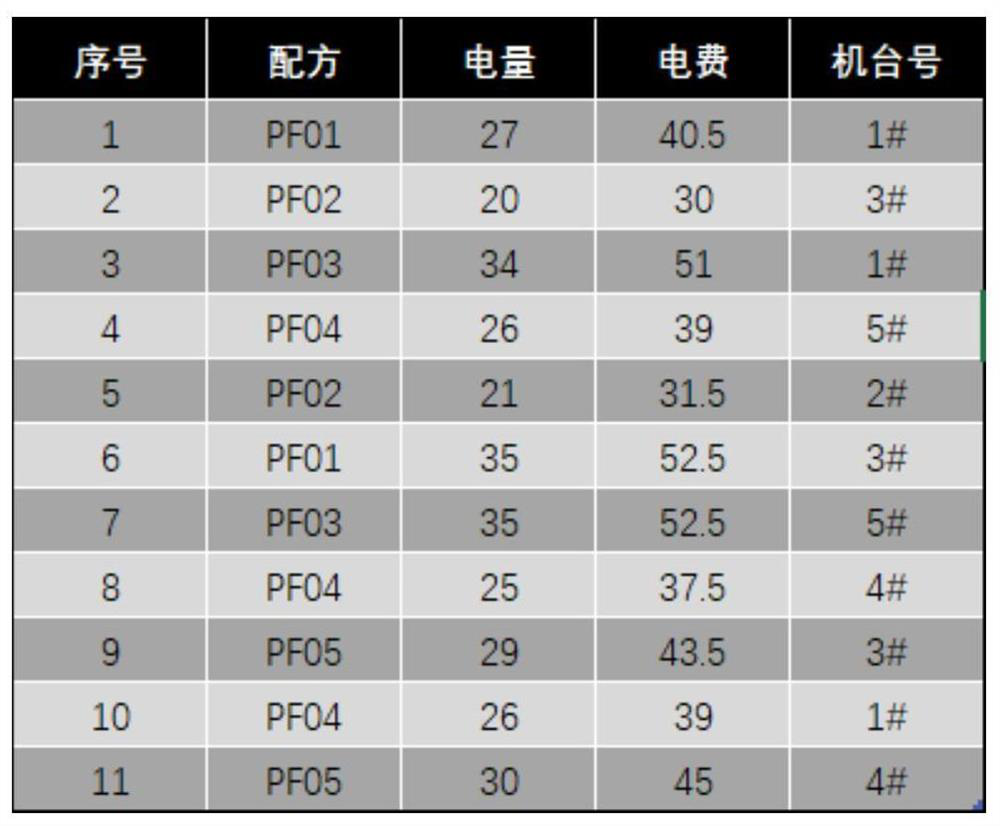

Intelligent rubber mixing system and method

PendingCN111832978AImprove monitoring accuracyReduce damage rateText processingAlarmsIndustrial engineeringReliability engineering

The invention provides an intelligent rubber mixing system. The intelligent rubber mixing system comprises an electric quantity statistics device, a wear early warning device, a power statistics device, a vibration monitoring device and a report analysis device. The electric quantity statistics device is used for acquiring electric quantity statistics information of the rubber mixing machine. Thewear early warning device is used for acquiring wear early warning information of the rubber mixing machine table and sending reminding information when the wear early warning information reaches a residual use time threshold value. The power statistics device is used for acquiring power statistics information of the rubber mixing machine table. The vibration monitoring device is used for acquiring vibration monitoring information of the rubber mixing machine table. The report analysis device generates daily report information and monthly report information associated with the specific user according to the electric quantity statistical information, the wear early warning information, the power statistical information and the vibration monitoring information. According to the invention, abnormal condition early warning in operation of the rubber mixing machine table equipment can be monitored in real time through each device of the intelligent rubber mixing system, major faults of theequipment are prevented, the monitoring accuracy of the rubber mixing machine table equipment is effectively improved, and the yield is increased.

Owner:上海弘奕电气有限公司

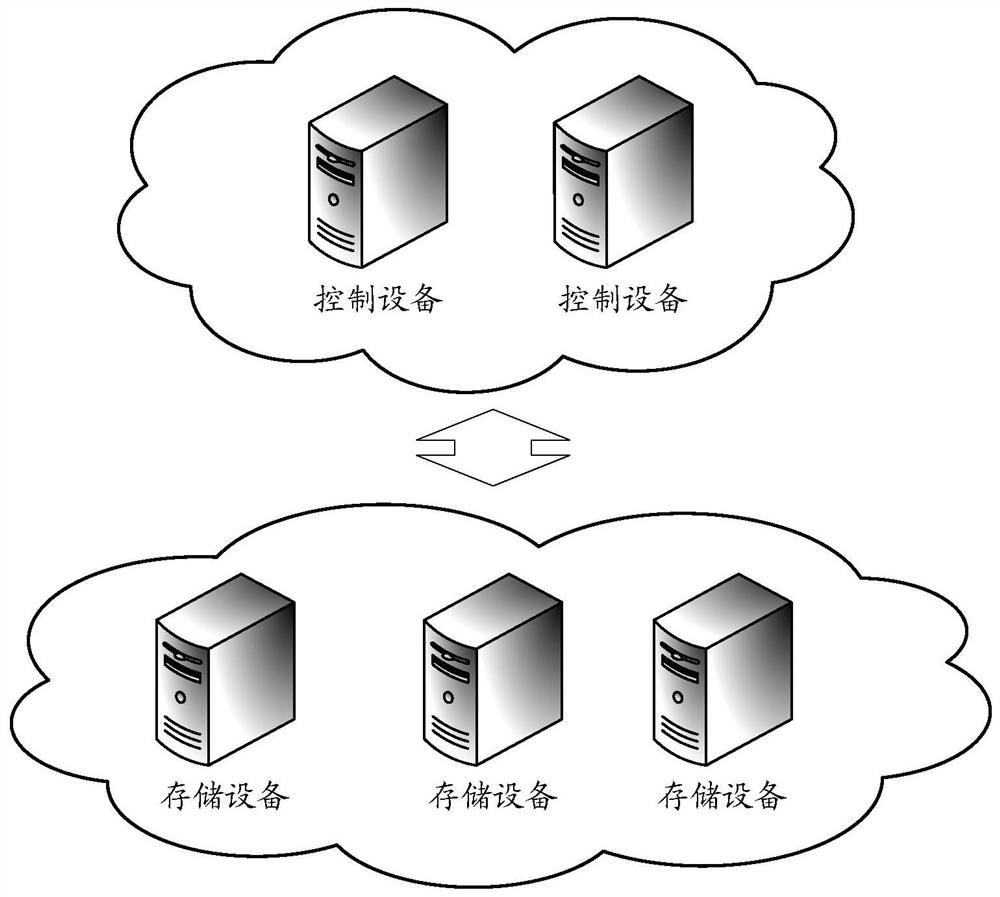

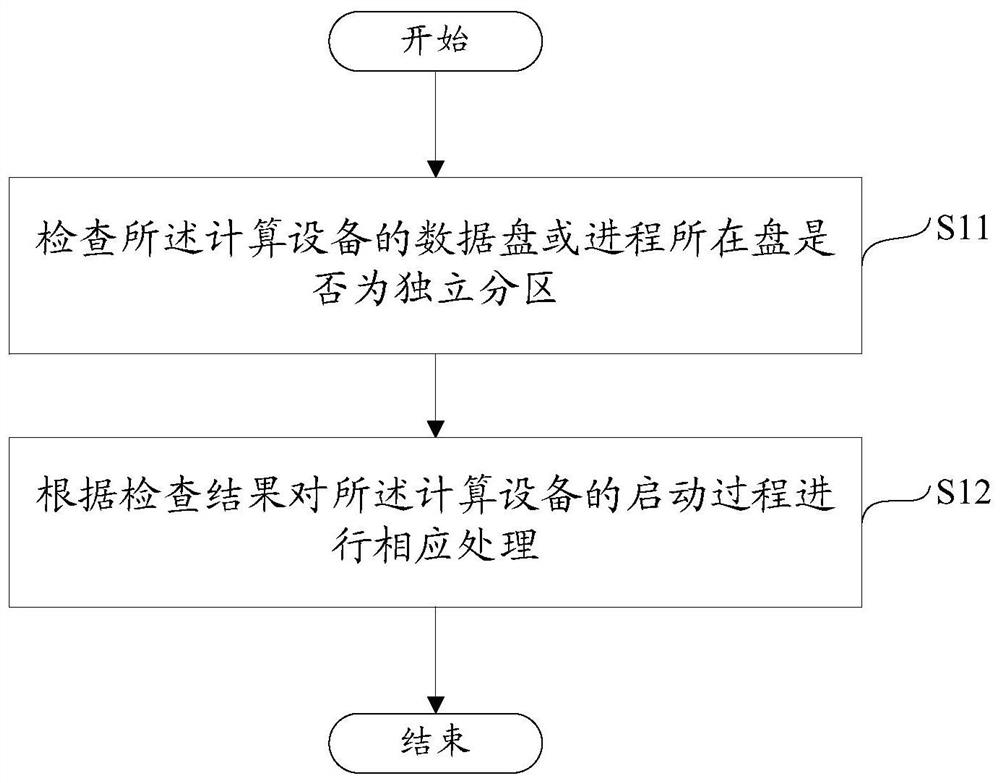

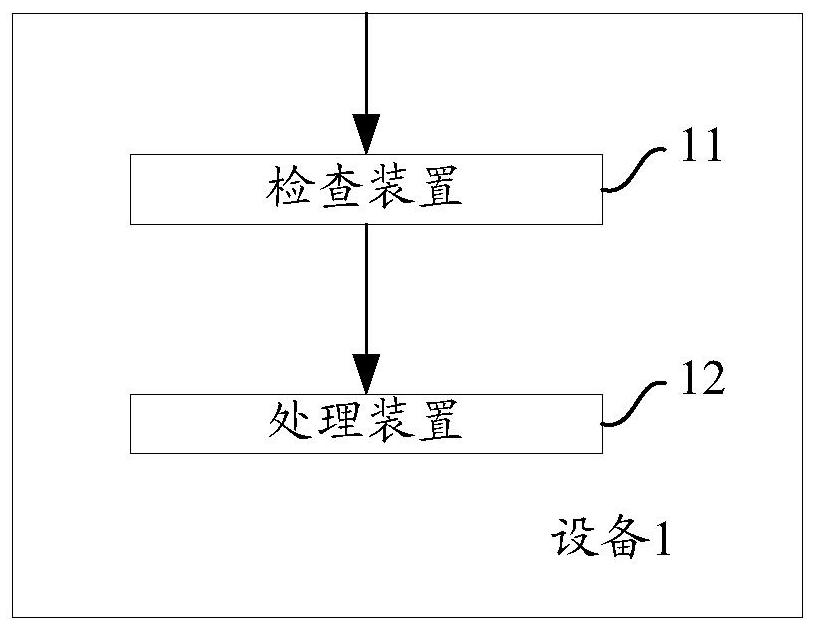

Method and device for performing a boot check on a computing device

ActiveCN107766196BAvoid major failuresImprove stabilityHardware monitoringReliability engineeringDistributed memory systems

The purpose of this application is to provide a method and device for checking the startup of computing devices in a distributed storage system. Compared with the prior art, this application checks the startup of the computing device during the startup process of the computing device in the distributed storage system, and performs corresponding processing on the startup process of the computing device according to the corresponding inspection results; the present application Carry out a start-up check before the distributed storage system starts, standardize the software and hardware requirements of the distributed storage system, avoid major failures after the distributed storage system starts, and improve the stability and performance of the distributed storage system . Further, the application handles the startup process of the computing device according to the corresponding inspection result and the security level information of the startup inspection, and if the inspection result with serious impact is found, the startup is not allowed, and if the inspection result with secondary impact is found, the alarm will be called. deal with.

Owner:ALIBABA GRP HLDG LTD

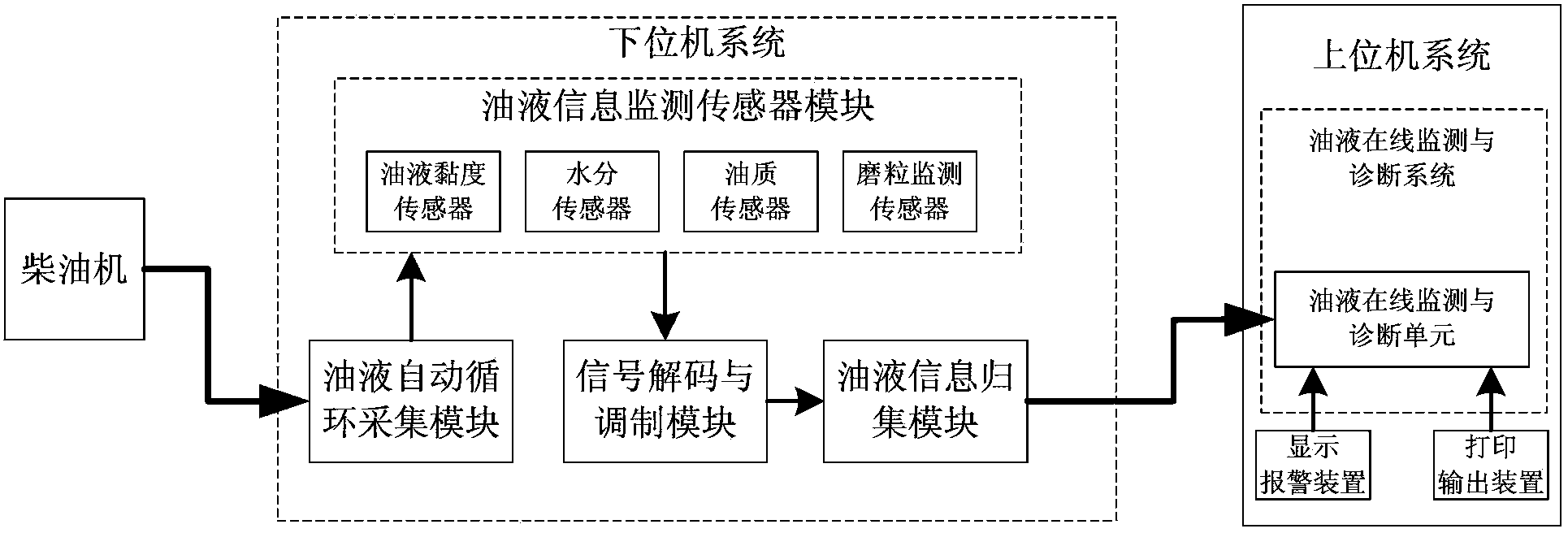

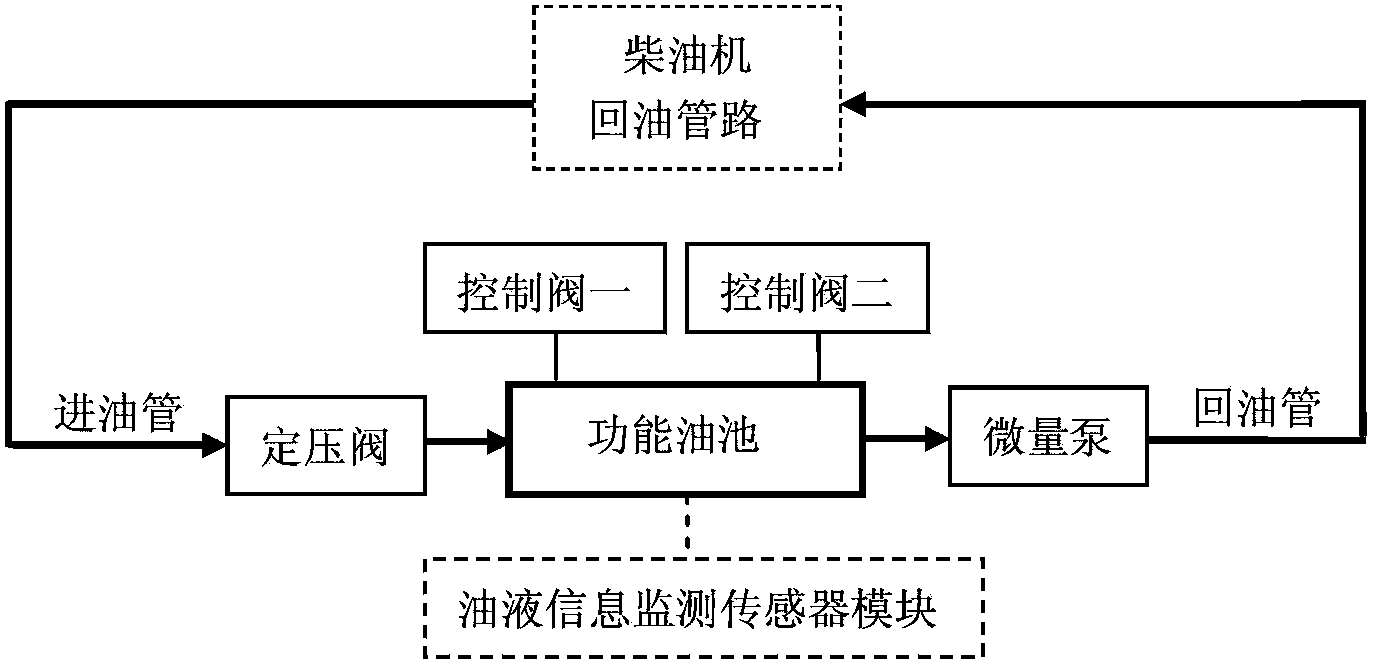

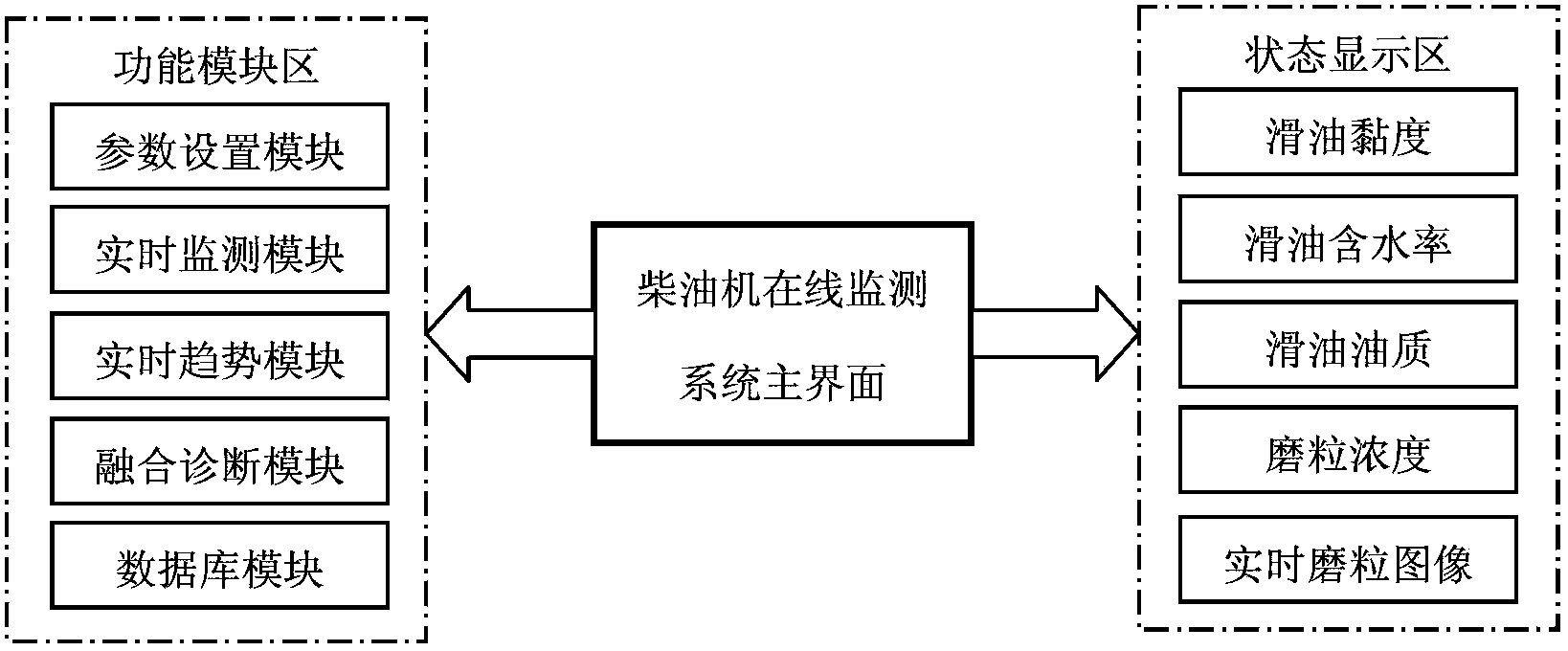

On-line monitoring system for diesel engine lubricating oil

ActiveCN102707037BReal-time monitoringEliminate the lack of quality evaluationMaterial testing goodsContinuous glucose monitoringMonitoring system

Owner:GUANGZHOU MECHANICAL ENG RES INST

Parameter configuration method, device and computer equipment based on industrial control screen

ActiveCN112114897BImprove configuration efficiencyGuarantee internal securityDigital data protectionProgram loading/initiatingControl engineeringComputer science

The present application relates to a parameter configuration method, device and computer equipment based on an industrial control panel. The method includes: obtaining a data configuration list to be configured, and displaying each parameter to be configured in the data configuration list on the display interface of the industrial control screen; detecting a configuration command triggered by the parameter to be configured; triggering a working condition simulation according to the configuration command Running operation; when it is determined that the operating result of the working condition simulation operation meets the preset configuration requirements, the parameters to be configured corresponding to the configuration command are sent to each connected unit to be tested, so that each unit to be tested can be configured according to the parameters to be configured. parameter configuration. This method realizes one-key parameter configuration of the unit to be tested, without the need for staff to manually configure on-site, reduces the mismatch and omission caused by manual operation errors, and reduces the consumption of human and material resources due to repeated configuration or modification. , to improve the efficiency of parameter configuration for large units to be tested.

Owner:GREE ELECTRIC APPLIANCES INC

Data integrity protection method and device

PendingCN109993002AReduce the burden onEasy centralized maintenanceProgramme controlTesting/monitoring control systemsData integrityIndustrial control system

The invention provides a data integrity protection method and data integrity protection equipment, which are used for protecting key data in control components in an industrial control system, and themethod comprises the following steps of: establishing correlation among a plurality of control components in the industrial control system; based on identity characteristics and data characteristicsof other control components related to a first control component in the plurality of control components, determining an abstract indicating the integrity of to-be-protected data in the first control component, the data feature being used to identify the to-be-protected data in a control component, and the first control component being any one of the plurality of control components. Due to the factthat the safety of the data in any control assembly is set up on other related control assemblies, the key data in the control assemblies can be effectively protected.

Owner:SIEMENS AG

Robot work state intelligent judgment system under high-temperature environment

The invention relates to improvement of a robot work state intelligent judgment system under high-temperature environment, in particular to the robot work state intelligent judgment system under high-temperature environment. The safe and reliable robot work state intelligent judgment system under the high-temperature environment comprises a robot information receiving and feedback module, a digital screen display module, a PLC processing system module, an automatic alarm module, a manual data input module, a video data collecting module and a temperature data collecting module and is characterized in that the robot information receiving and feedback module is in dual-way communication with the PLC processing system module, and the signal output end of the manual data input module is connected with the input end of the PLC processing system module; the output end of the PLC processing system module is connected with the digital screen display module.

Owner:沈阳元生鑫达科技有限公司

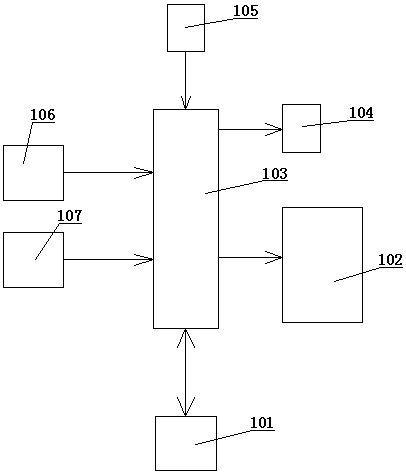

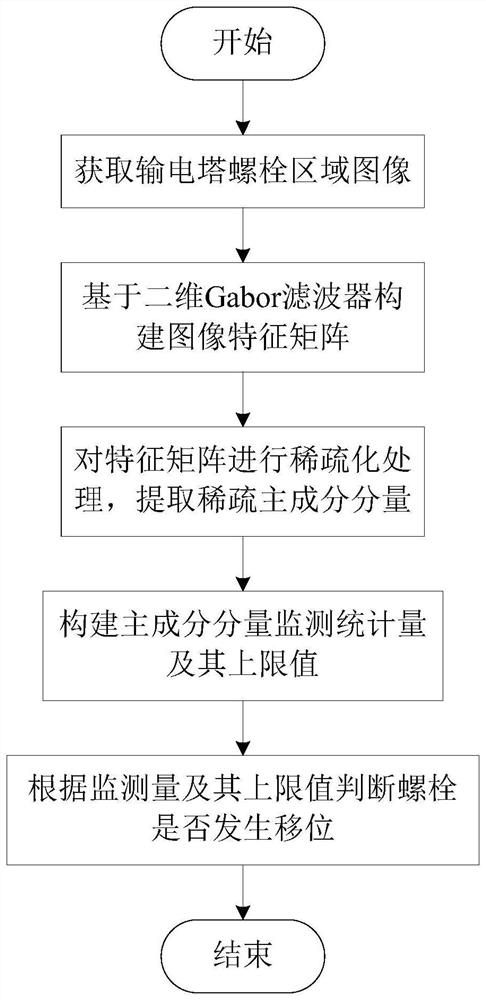

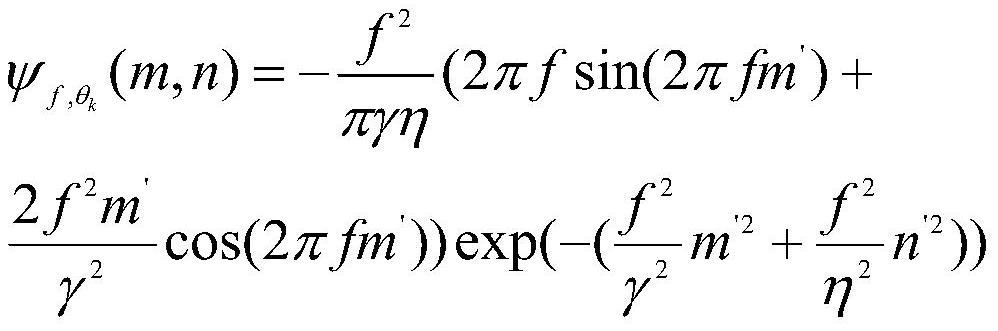

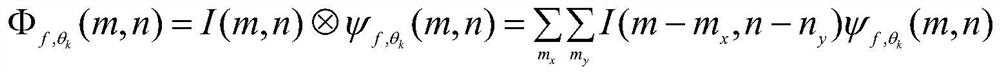

Power transmission tower bolt displacement monitoring method based on image features

PendingCN114241418AEffective identification of sliding hazardsEffective Operation and Maintenance StrategyCharacter and pattern recognitionTransmission towerImaging Feature

The invention discloses a power transmission tower bolt displacement monitoring method based on image features, and the method comprises the steps: starting a camera terminal, and obtaining a power transmission tower bolt region image; constructing a bolt area image feature matrix based on a two-dimensional Gabor filter; sparse processing is carried out on the bolt area image feature matrix, and sparse principal components of the image feature matrix are extracted; constructing a monitoring statistic of the sparse principal component and an upper limit value of the monitoring statistic; and judging the bolt slippage state of the power transmission tower according to the monitoring statistical magnitude of the sparse principal component of the bolt area image feature matrix and the upper limit value thereof: when the statistical magnitude exceeds the upper limit value thereof, judging that the bolt of the power transmission tower slips, and at the moment, carrying out maintenance processing in time to avoid major faults. According to the method, the bolt displacement state of the power transmission tower can be diagnosed, and whether the bolt of the power transmission tower is displaced or not can be effectively and accurately detected, so that effective measures can be taken in time for the power transmission tower, and the operation reliability of the power transmission tower is improved.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

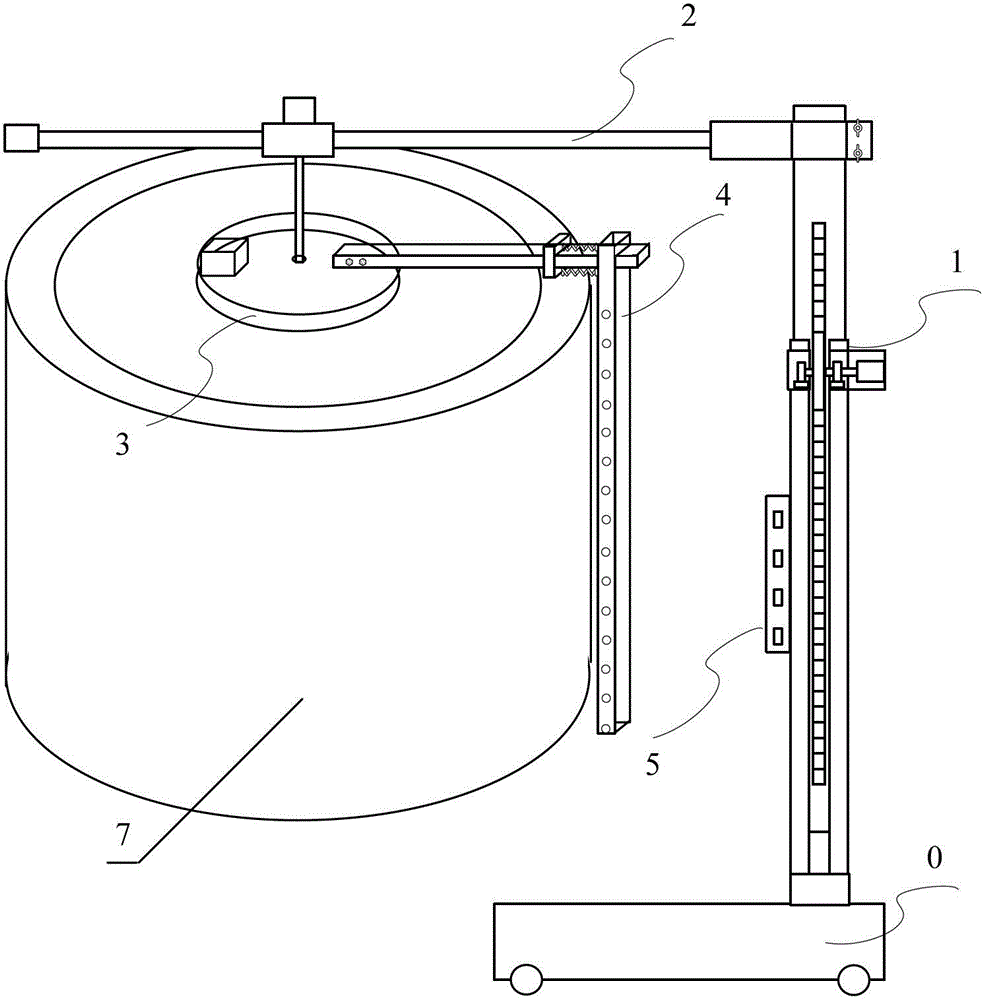

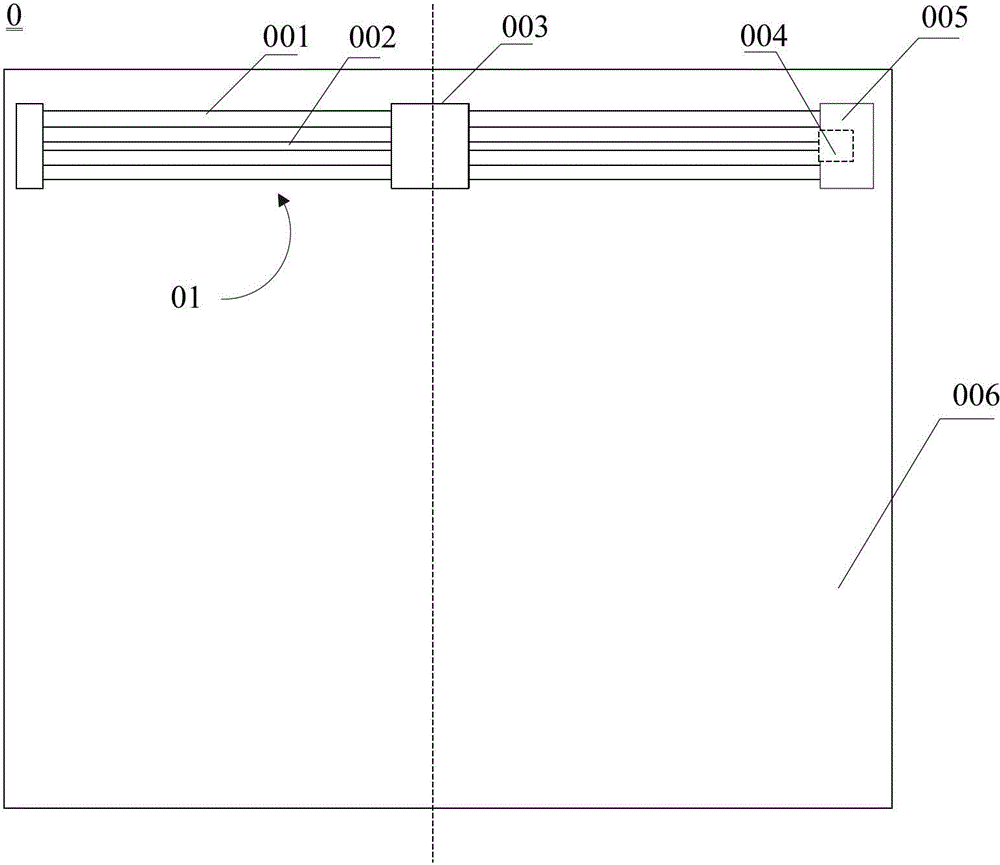

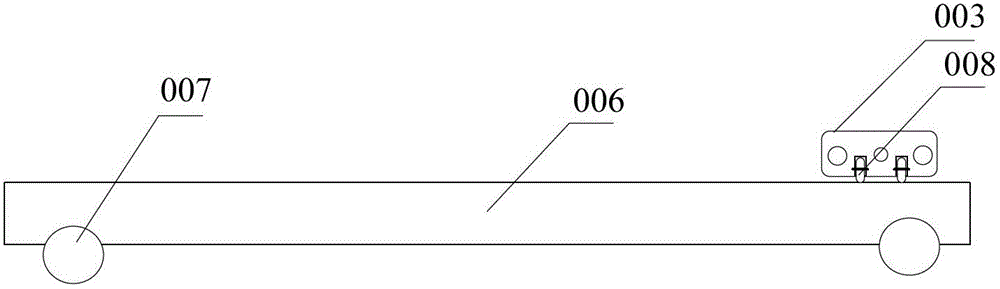

Magnetic memory scanning detection device for cylindrical ferromagnetic components

ActiveCN103196990BAvoid major failuresAvoid safety accidentsMaterial magnetic variablesMagnetic memoryEngineering

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com