Intelligent fault diagnosis system and method for large composite dry separator

A compound dry method and intelligent diagnosis technology, which is applied in the field of fault intelligent diagnosis system of large compound dry method sorting machine, can solve problems such as fatigue of mechanical structure, fracture of main parts such as beams, and destruction of the whole machine, so as to achieve reliability Good, reduce production loss, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

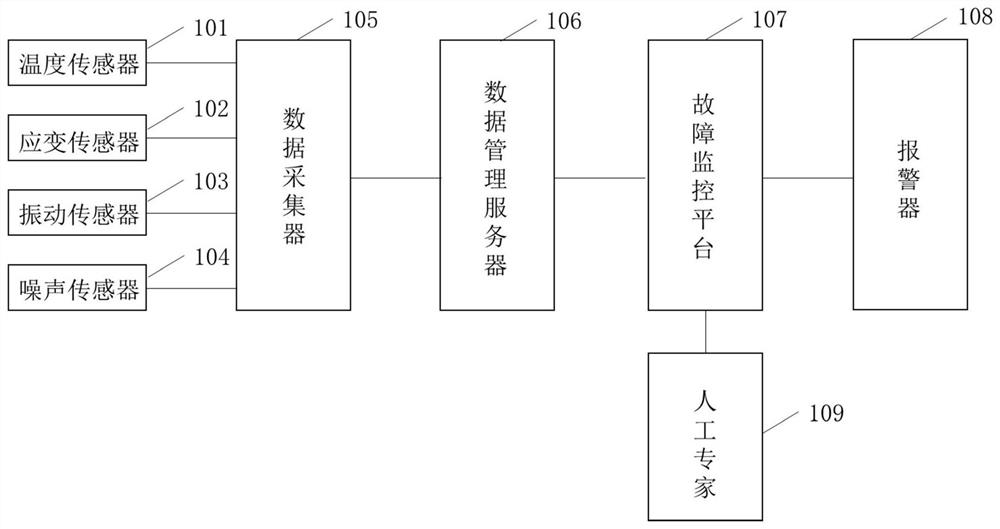

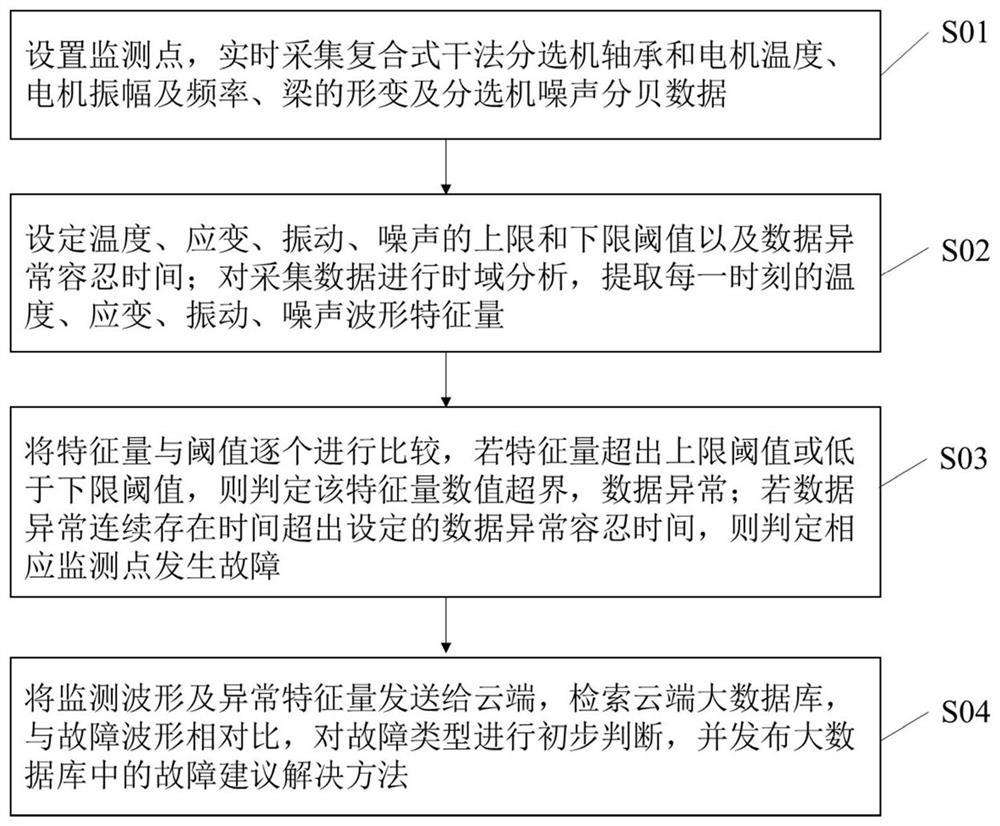

[0020] A large-scale composite dry-process sorting machine failure intelligent diagnosis system according to the present invention includes a detection module and an analysis and diagnosis module; the detection module is used for the composite dry-process sorting machine bearing and motor temperature, motor amplitude and frequency , the deformation of the beam and the noise decibel of the sorting machine, and transmit the detection information to the analysis and diagnosis module; the analysis and diagnosis module is used to analyze the detection information and judge whether there is a mechanical failure in the compound dry separation machine and store the fault waveform , to predict and judge the type of fault, give a suggested solution to the fault and send an alarm messa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com