On-line monitoring system for diesel engine lubricating oil

A monitoring system and lubricating oil technology, applied in the direction of material inspection products, etc., can solve problems such as the inability to complete the multi-information collection and data of lubricating oil, the failure to realize the cause and type of failure, and the low accuracy of diesel engine failure oil to achieve continuous Monitoring and fault early warning, avoiding major faults, eliminating the effect of offline sampling detection and analysis time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

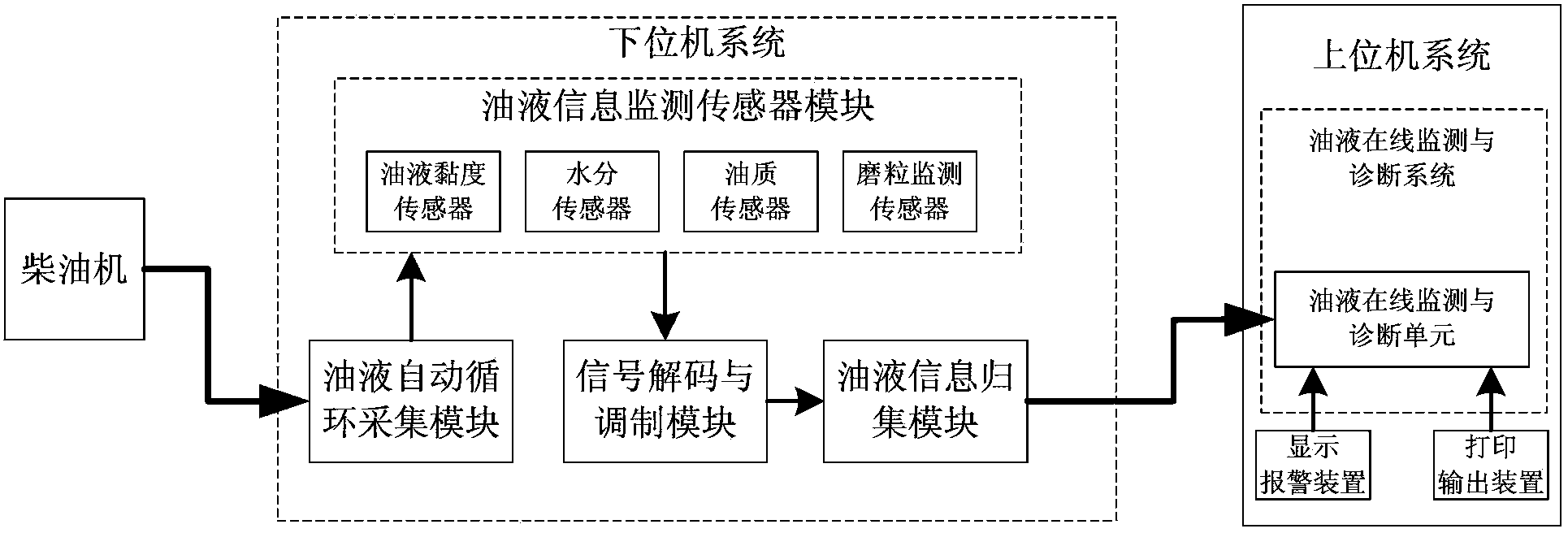

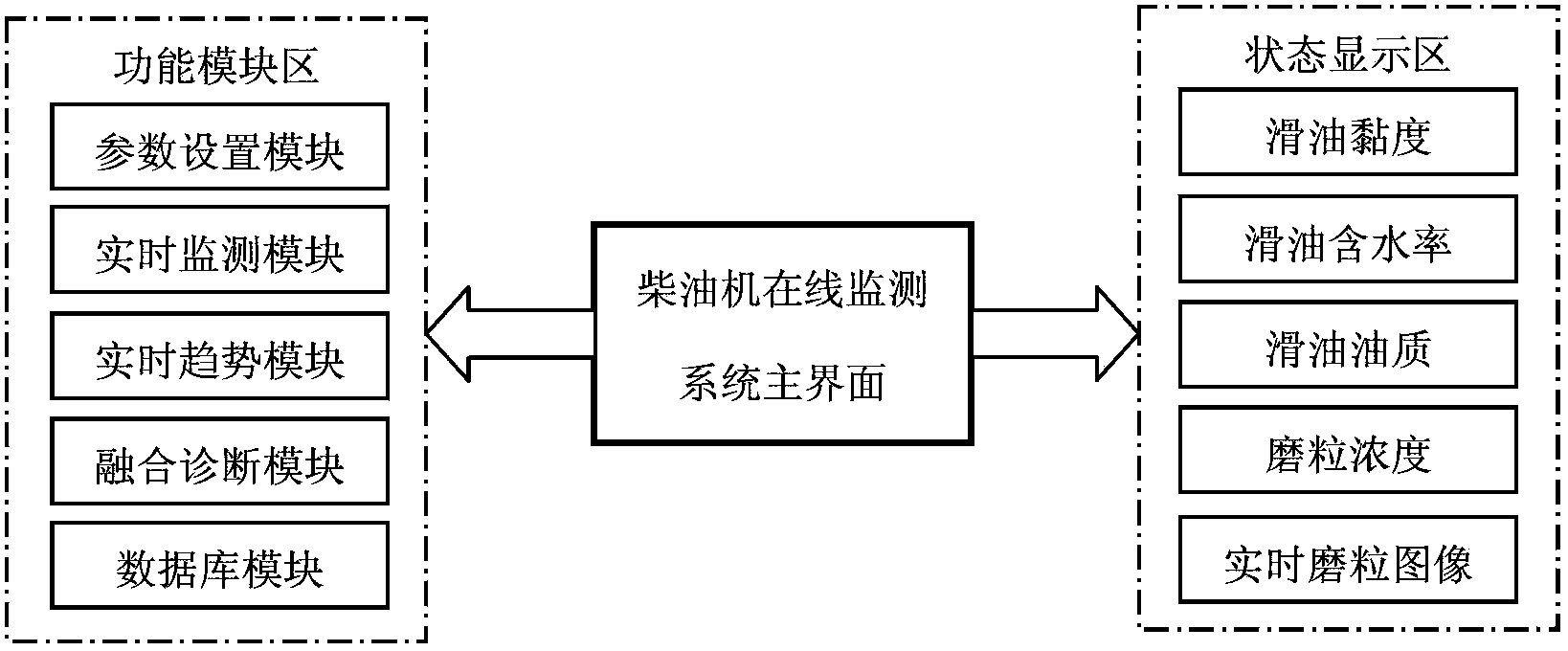

[0035] Such as figure 1 As shown, an online monitoring system for lubricating oil of a diesel engine in this embodiment includes an upper computer system and a lower computer system. With the modulation module and the oil information collection module, the oil information monitoring sensor module is respectively connected with the oil automatic circulation acquisition module and the signal decoding and modulation module, and the signal decoding and modulation module is connected with the oil information collection module ;

[0036] The oil information monitoring sensor module is used to collect the physical and chemical characteristic parameters of the lubricating oil and the wear characteristic information of each friction pair carried by it according to the characteristics and working conditions of the diesel engine oil;

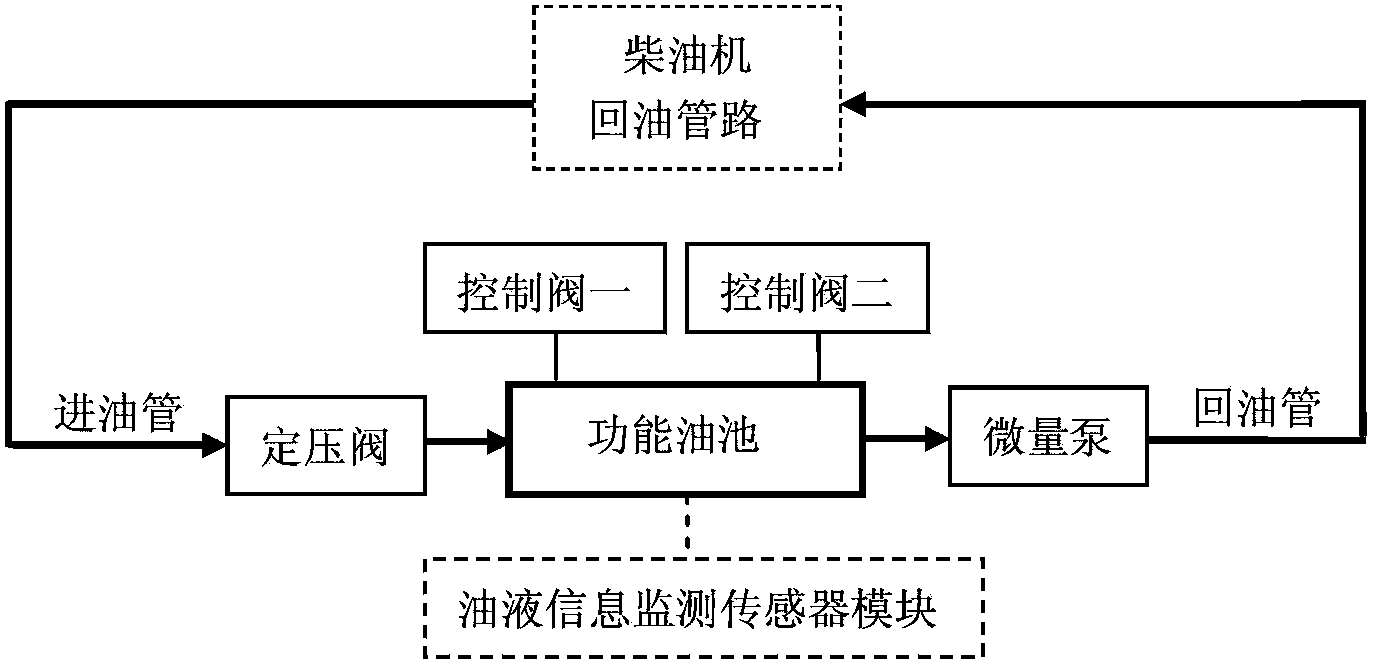

[0037] The oil automatic circulation acquisition module is used to collect lubricating oil in the oil return pipeline of diesel engines in real time, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com