Droplet control detector and working method thereof

A technology for controlling detection and working methods, applied in the field of microfluidics, can solve the problems of high production cost, need to improve droplet control accuracy, complex structure, etc., and achieve the effect of efficient and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

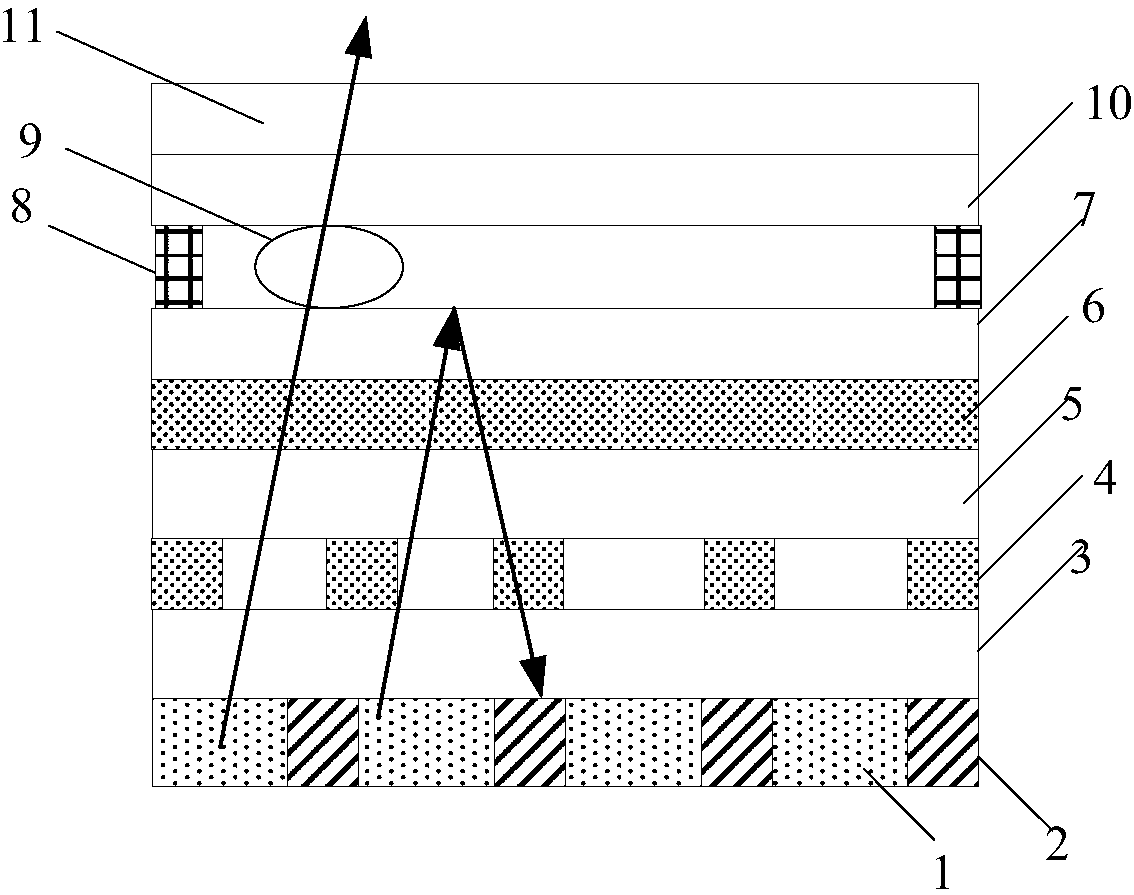

[0059] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0060] The embodiments of the present invention aim at the problems that the structure of the microfluidic device in the prior art is relatively complex, the production cost is high, and the accuracy of droplet control needs to be improved, and a droplet control detection device and its working method are provided, which can Achieve efficient and precise droplet control.

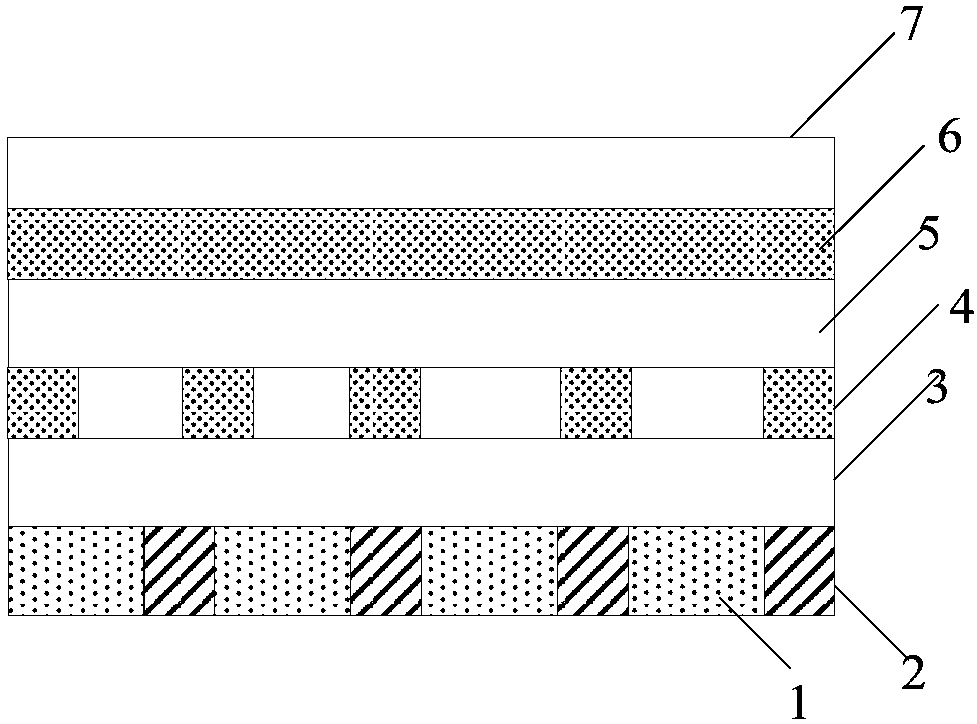

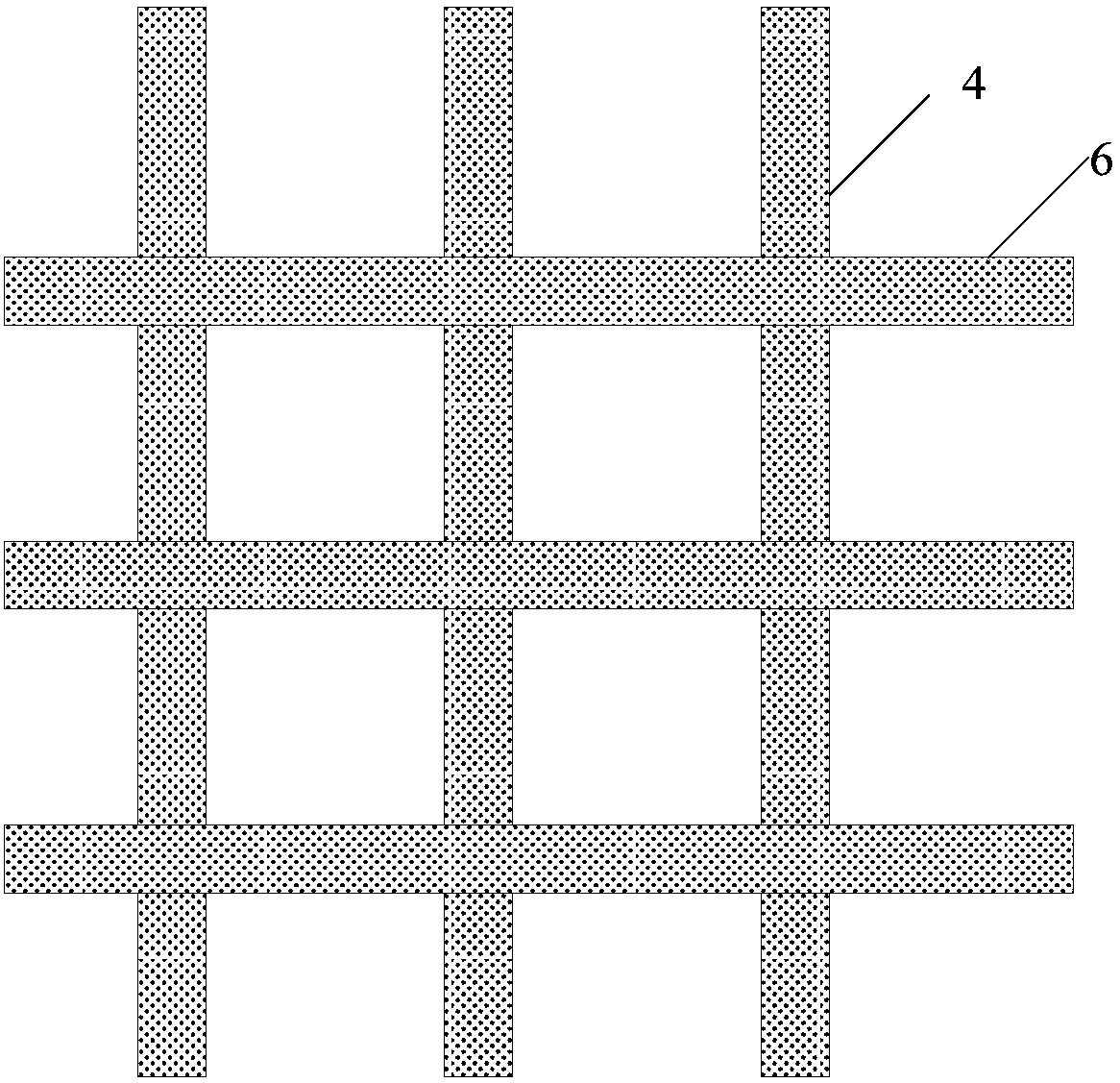

[0061] An embodiment of the present invention provides a droplet control detection device, including:

[0062] light source;

[0063] a first electrode and a second electrode, an electric field capable of driving droplet movement can be formed between the first electrode and the second electrode;

[0064] The liquid droplet located on the light emitting side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com