Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Avoid assembly gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

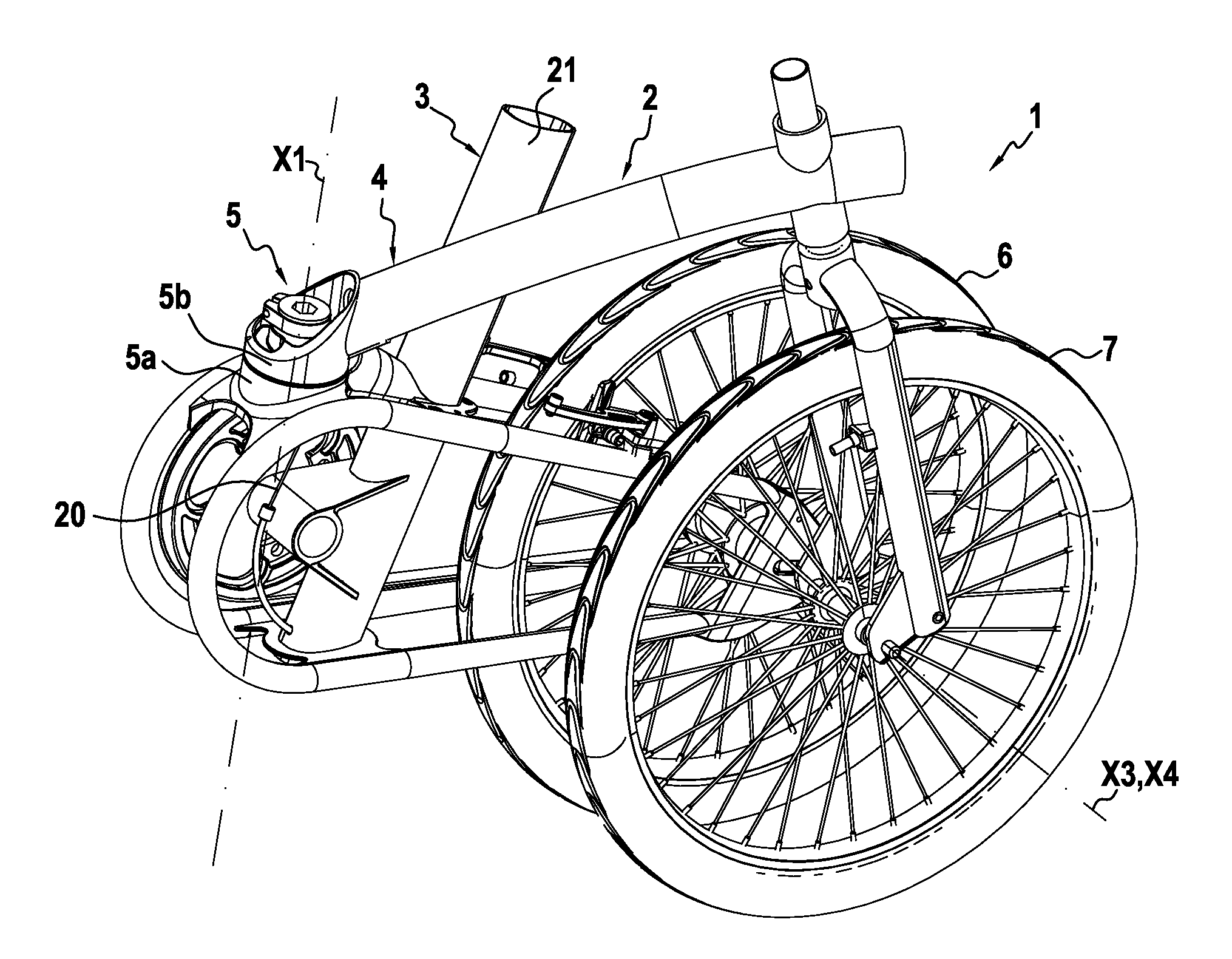

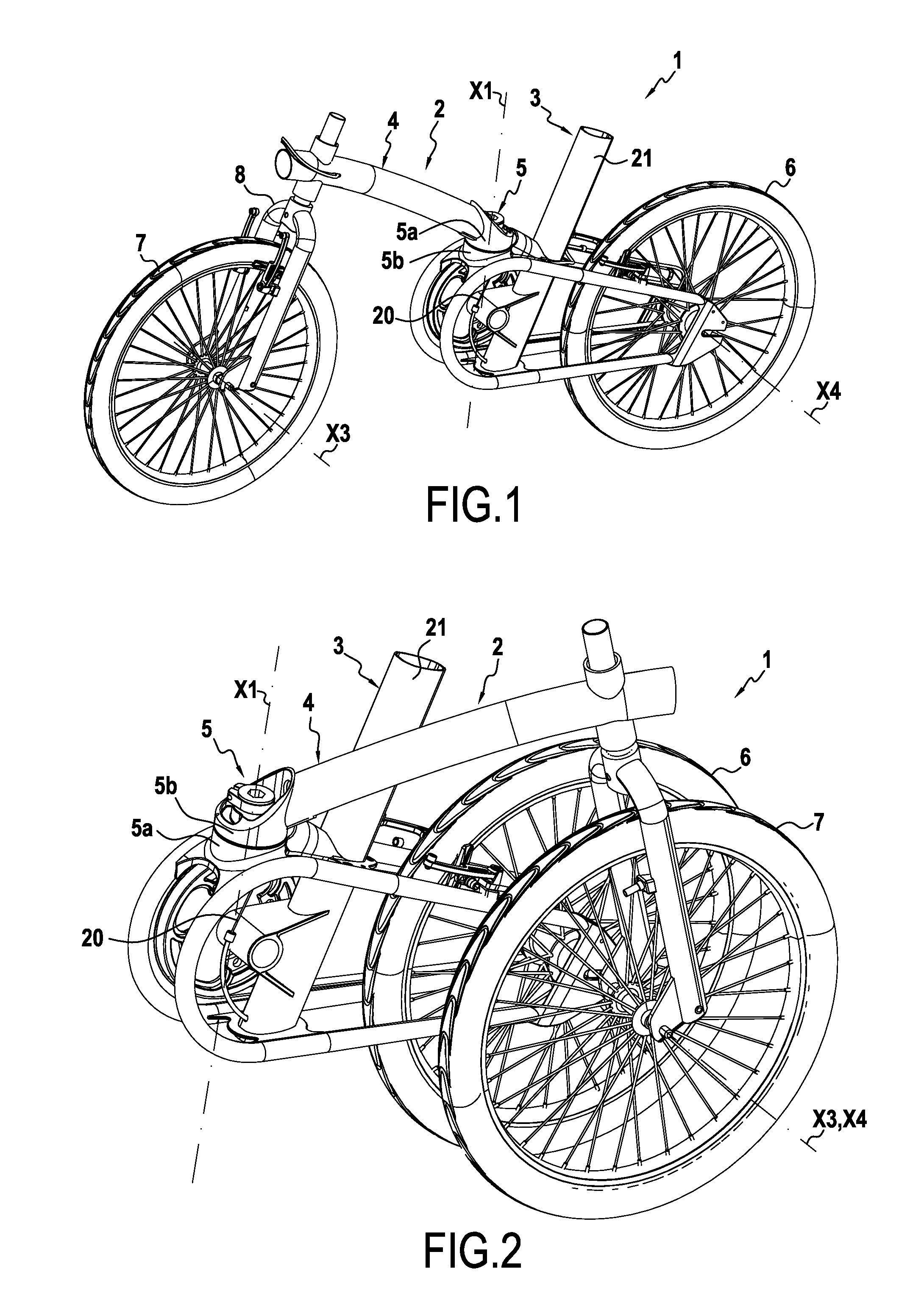

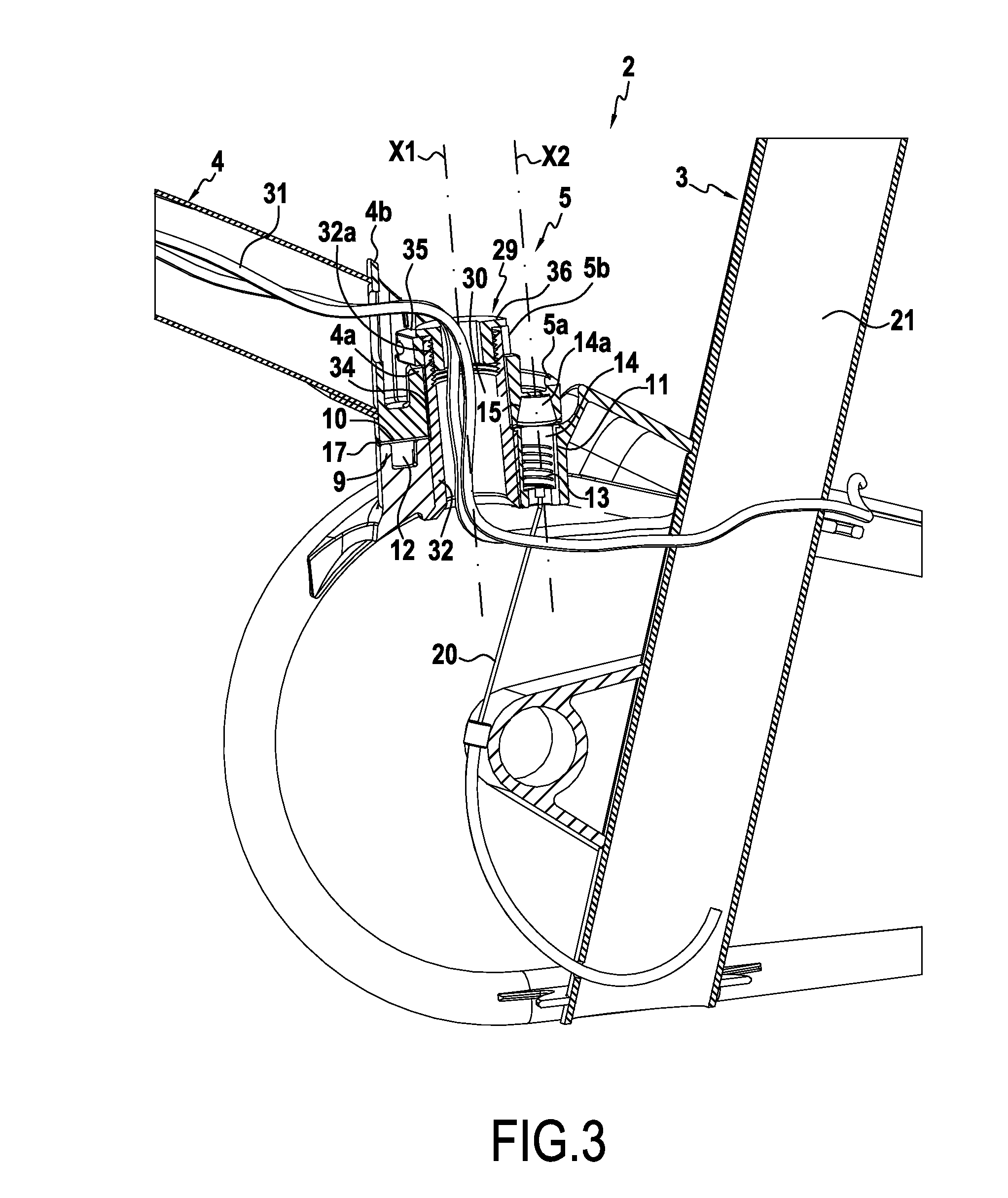

Foldable bicycle

ActiveUS20120169029A1Avoid assembly gapsEasy to unlockPassenger cyclesChildren cyclesActuatorEngineering

Owner:DECATHLON SA

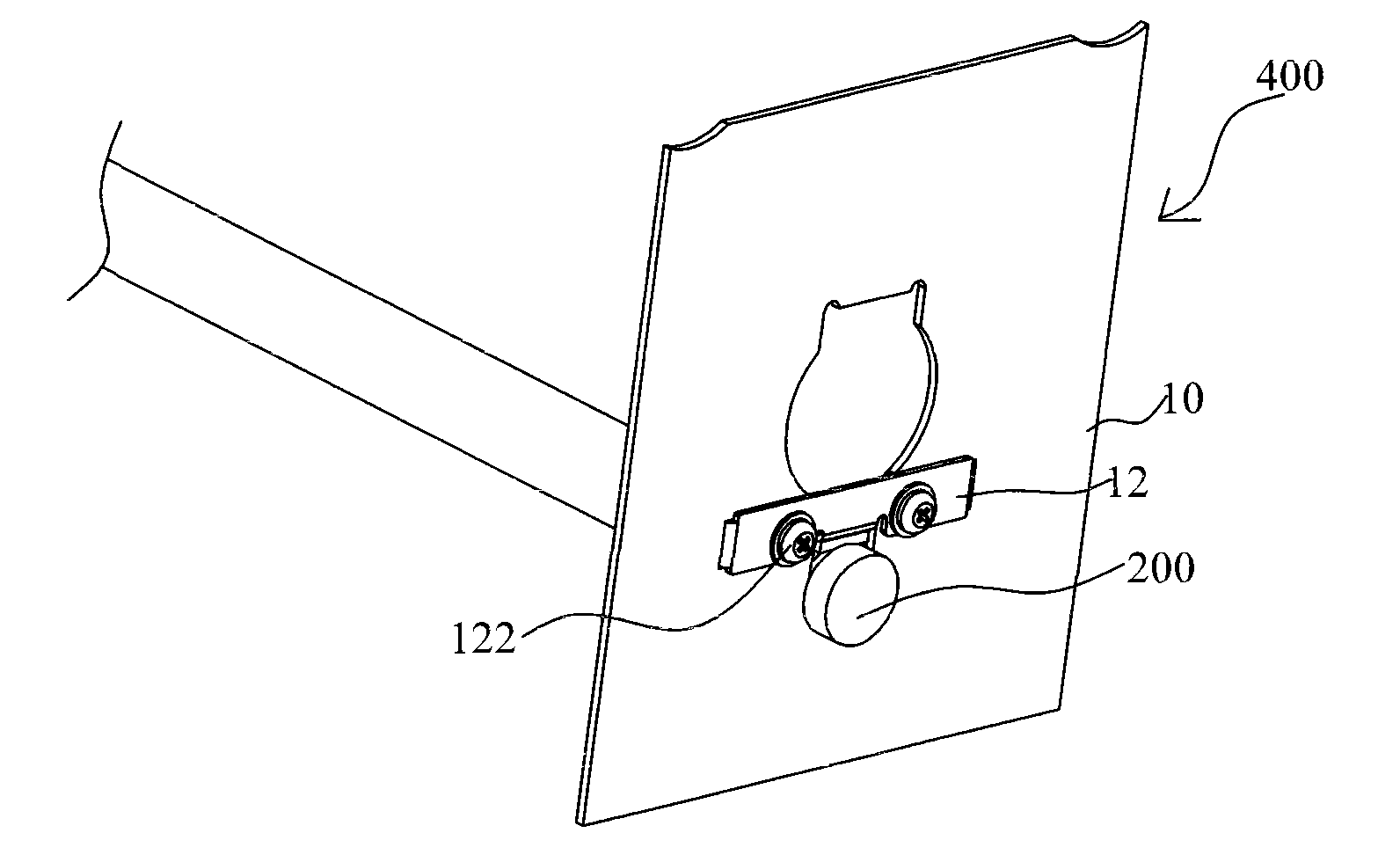

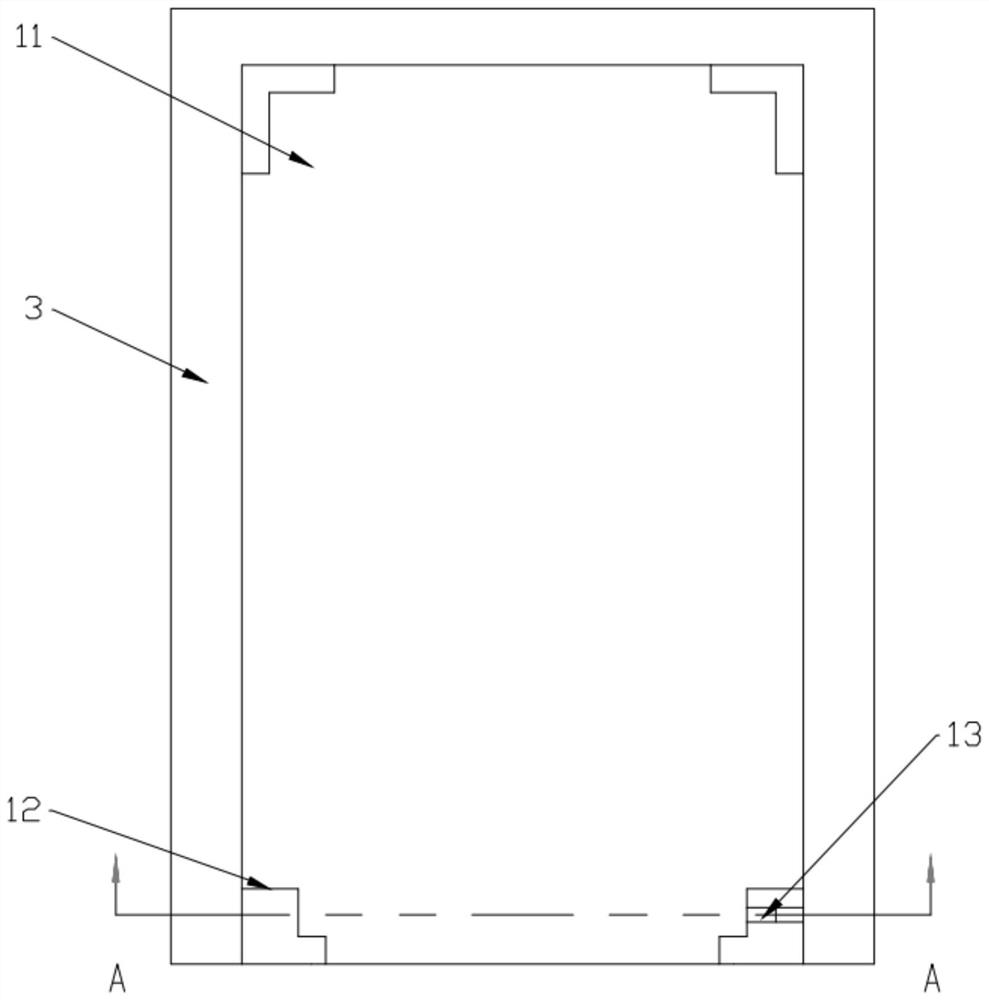

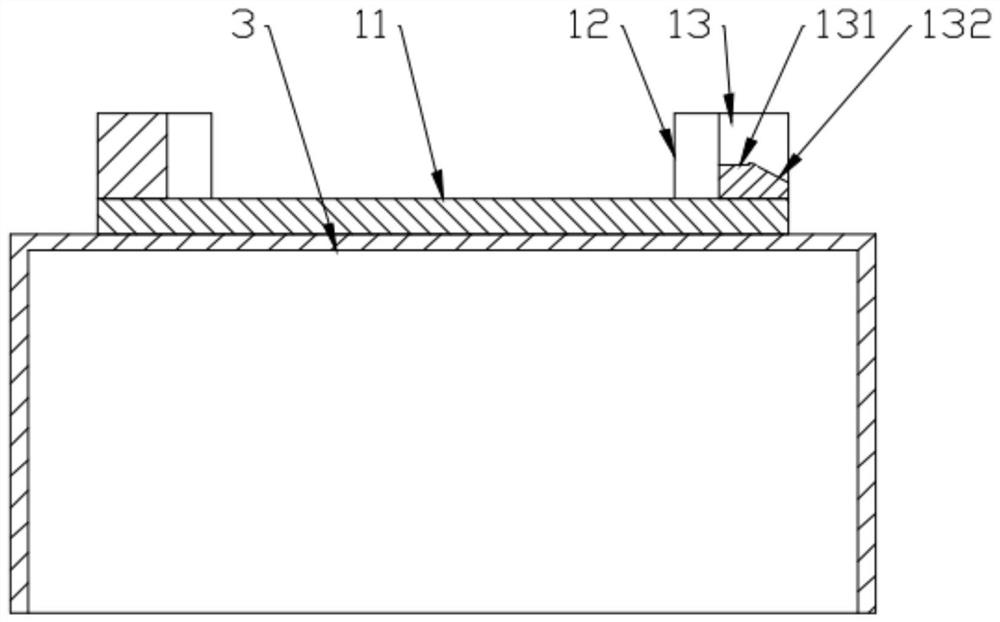

Large-size display and splicing method thereof

InactiveCN111128051AAvoid Assembly GapsReduce seamsNon-linear opticsIdentification meansDisplay deviceEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

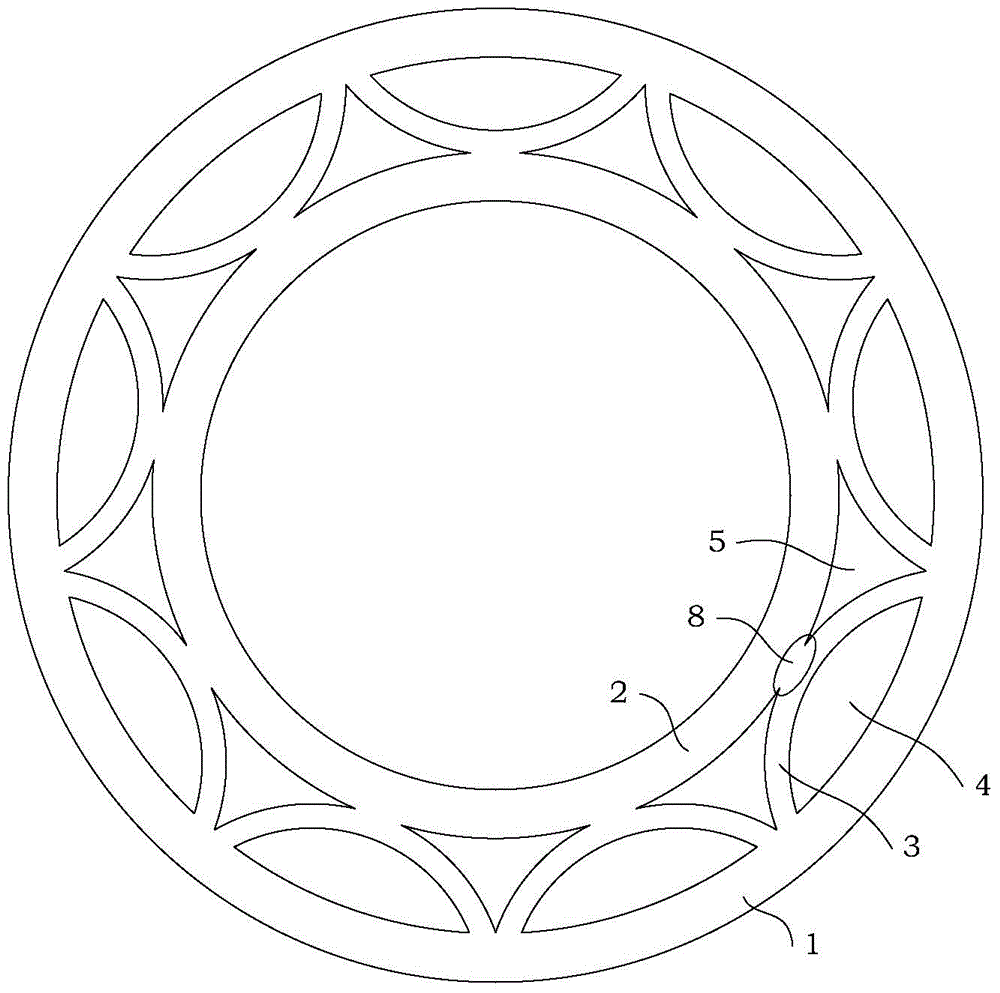

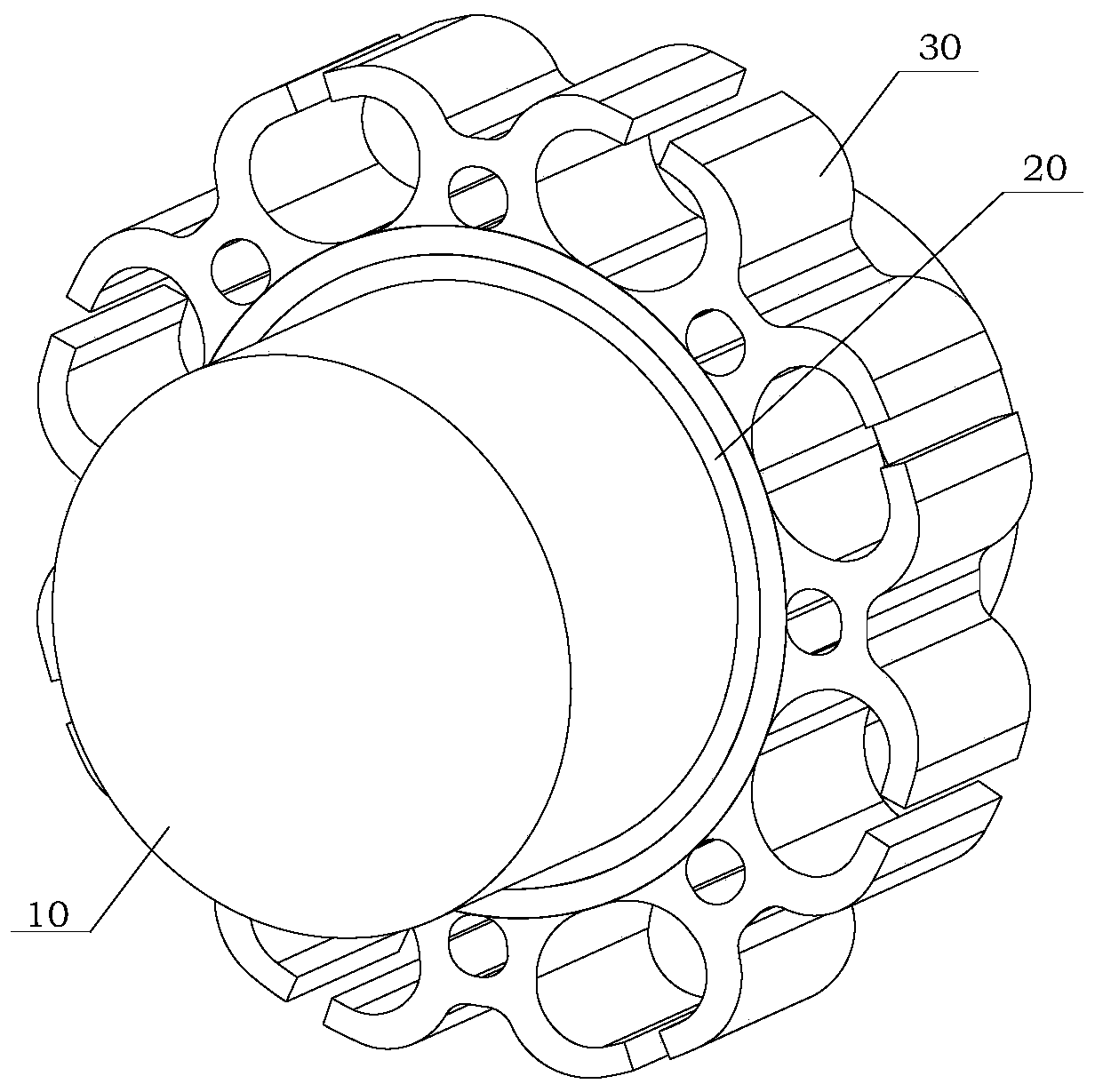

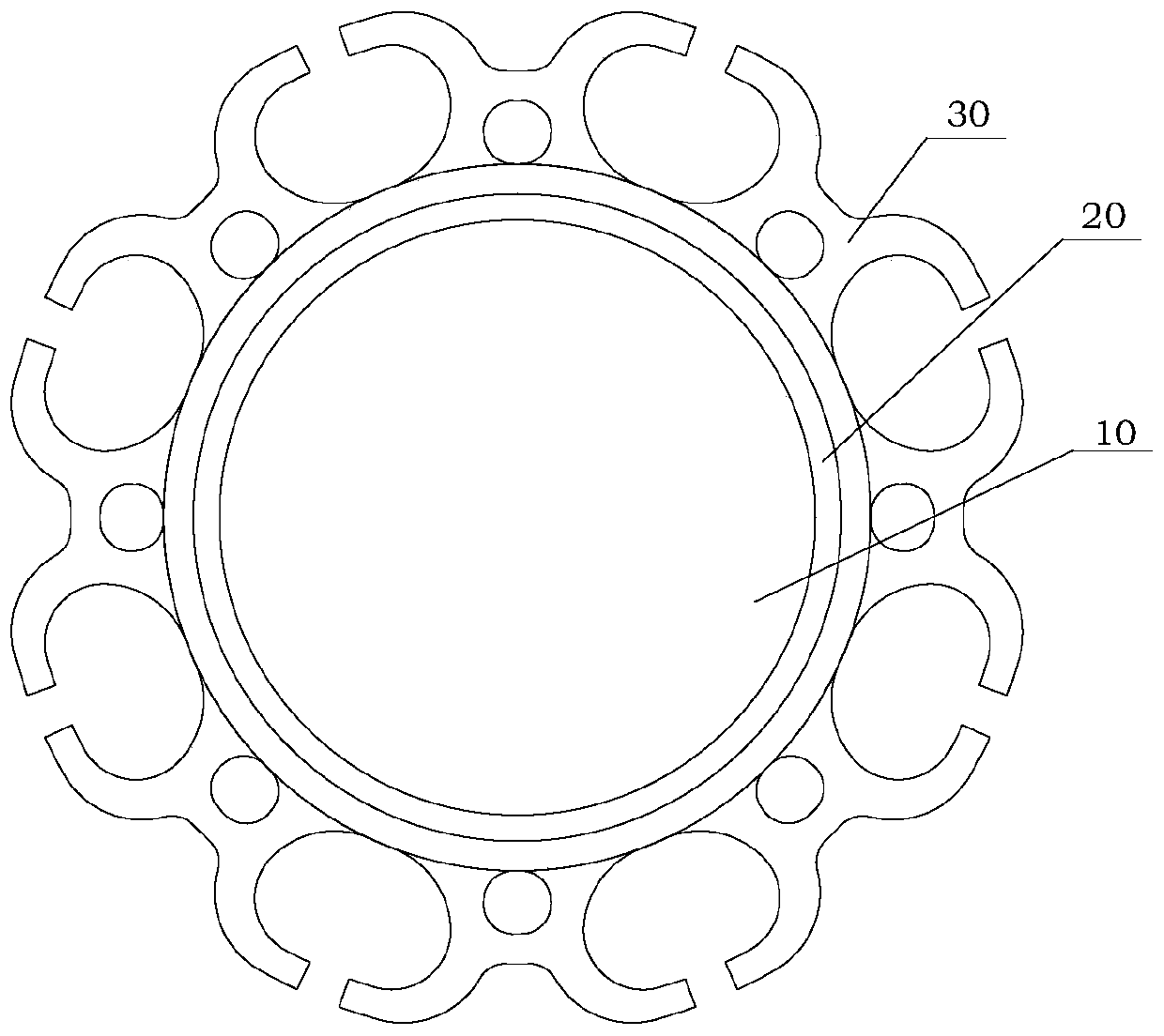

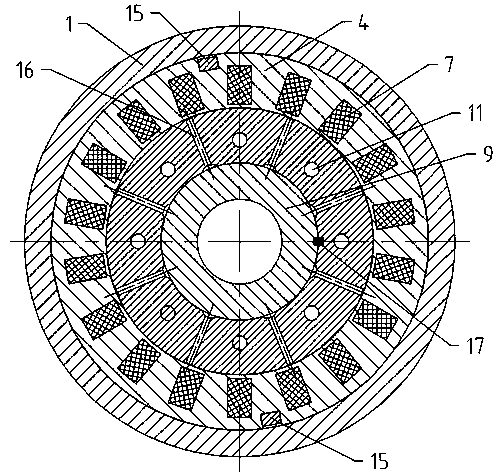

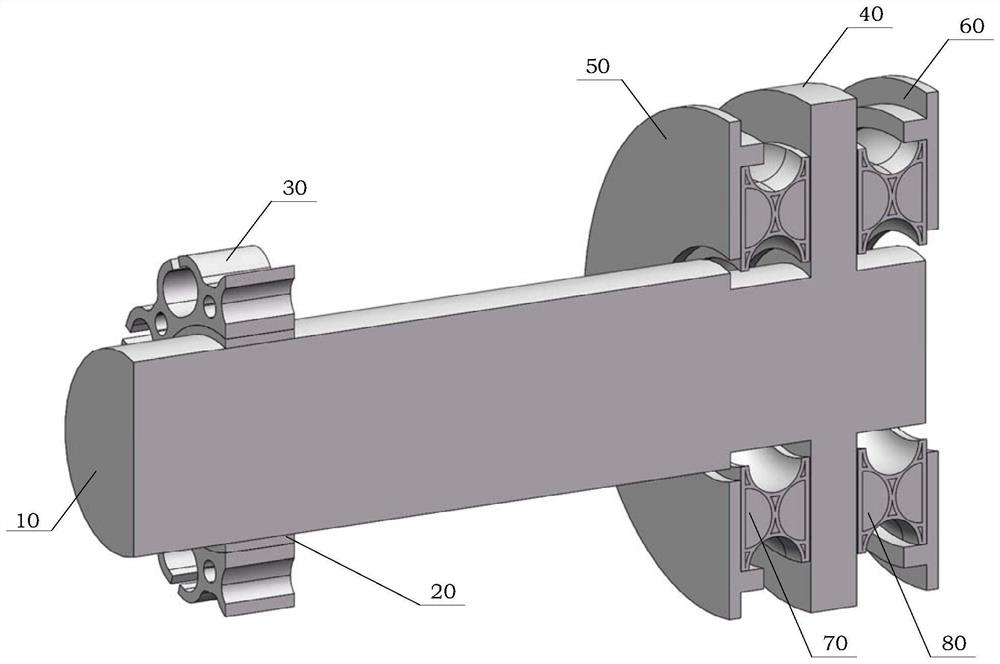

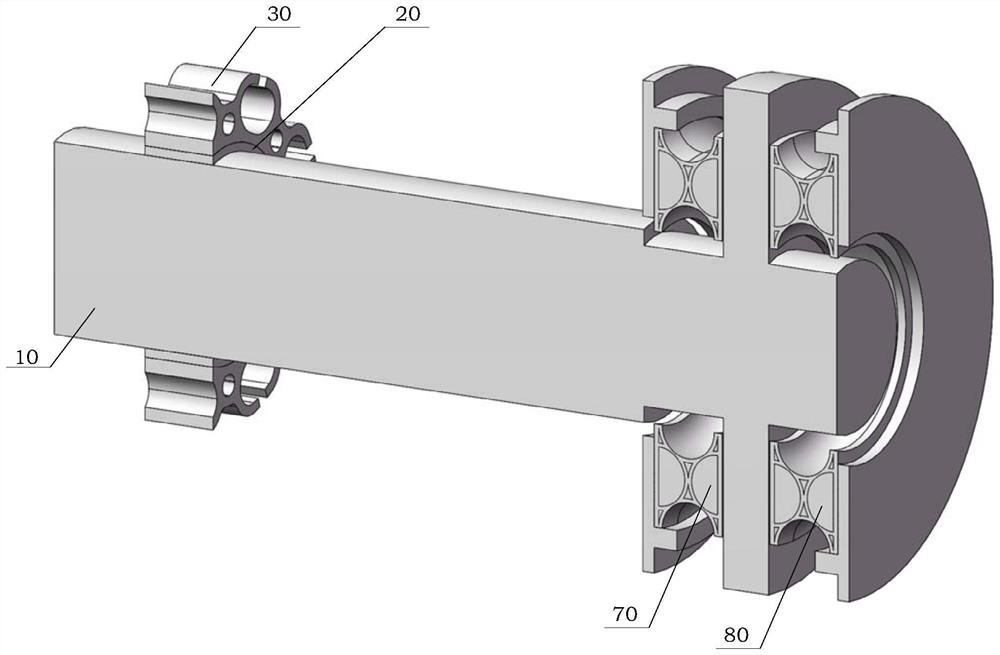

Radial-bearing flexible protecting bearing for magnetic suspension high-speed rotating equipment

InactiveCN104632884AAvoid damageExtended service lifeElastic bearingsBearing unit rigid supportEngineeringMechanical engineering

The invention discloses a radial-bearing flexible protecting bearing for magnetic suspension high-speed rotating equipment. The radial-bearing flexible protecting bearing is an integrally machined structural component and is characterized in that a bearing outer ring, a bearing inner ring and flexible reeds are designed on the protecting bearing, wherein the flexible reeds are arranged between the bearing outer ring and the bearing inner ring, external gaps are formed between the flexible reeds and the bearing outer ring, and internal gaps are formed between the flexible reeds and the bearing inner. According to the radial-bearing flexible protecting bearing, a flexible reed structure is designed between the bearing inner ring and the bearing outer ring, and the joints between the flexile reeds and the bearing inner ring are flexible formation point, so that when great impact is caused because a rotor is unstable, lots of kinetic energy of the rotor can be absorbed by virtue of the elastic deformation of the flexible reeds, without damaging other parts in the equipment.

Owner:BEIHANG UNIV

Quick dismounting and filling-sealing apparatus for electric connector

InactiveCN106207711AImprove potting efficiencyEasy to operateContact member cases/bases manufactureElectricityMachine parts

Owner:BEIJING MECHANICAL EQUIP INST

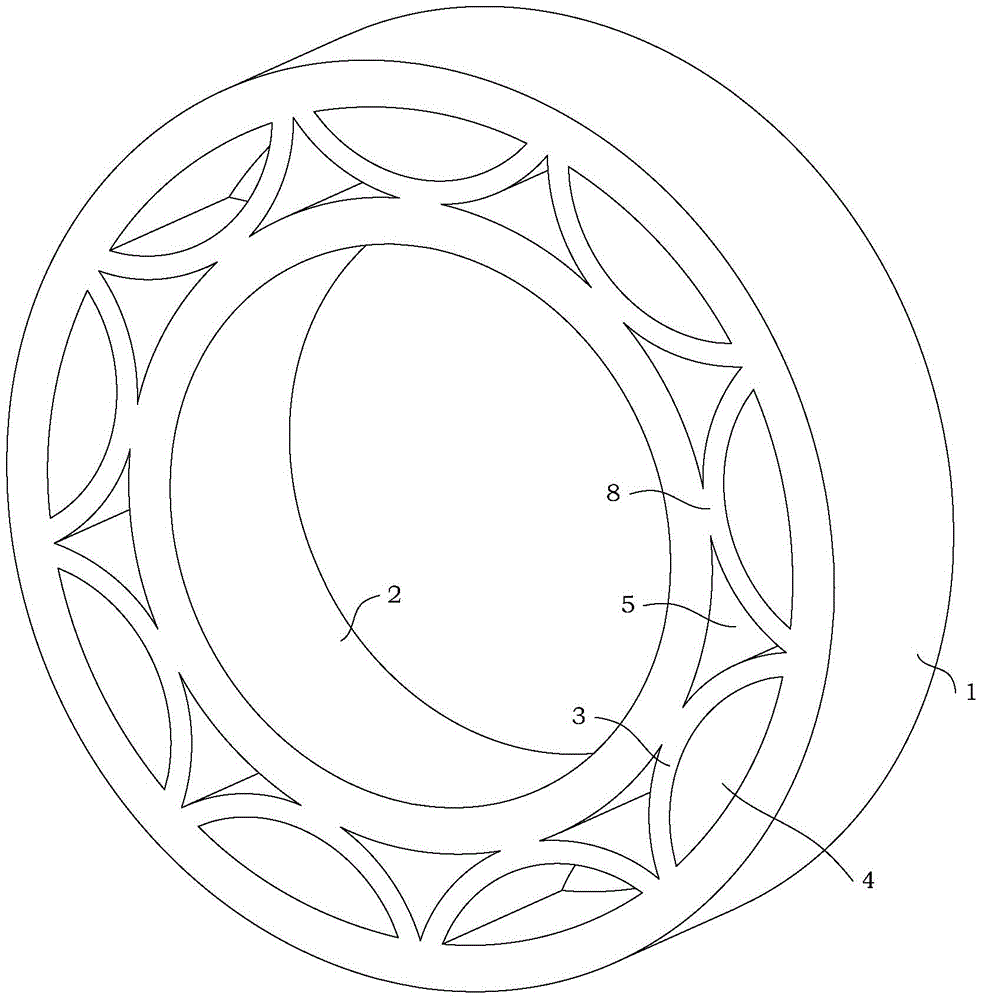

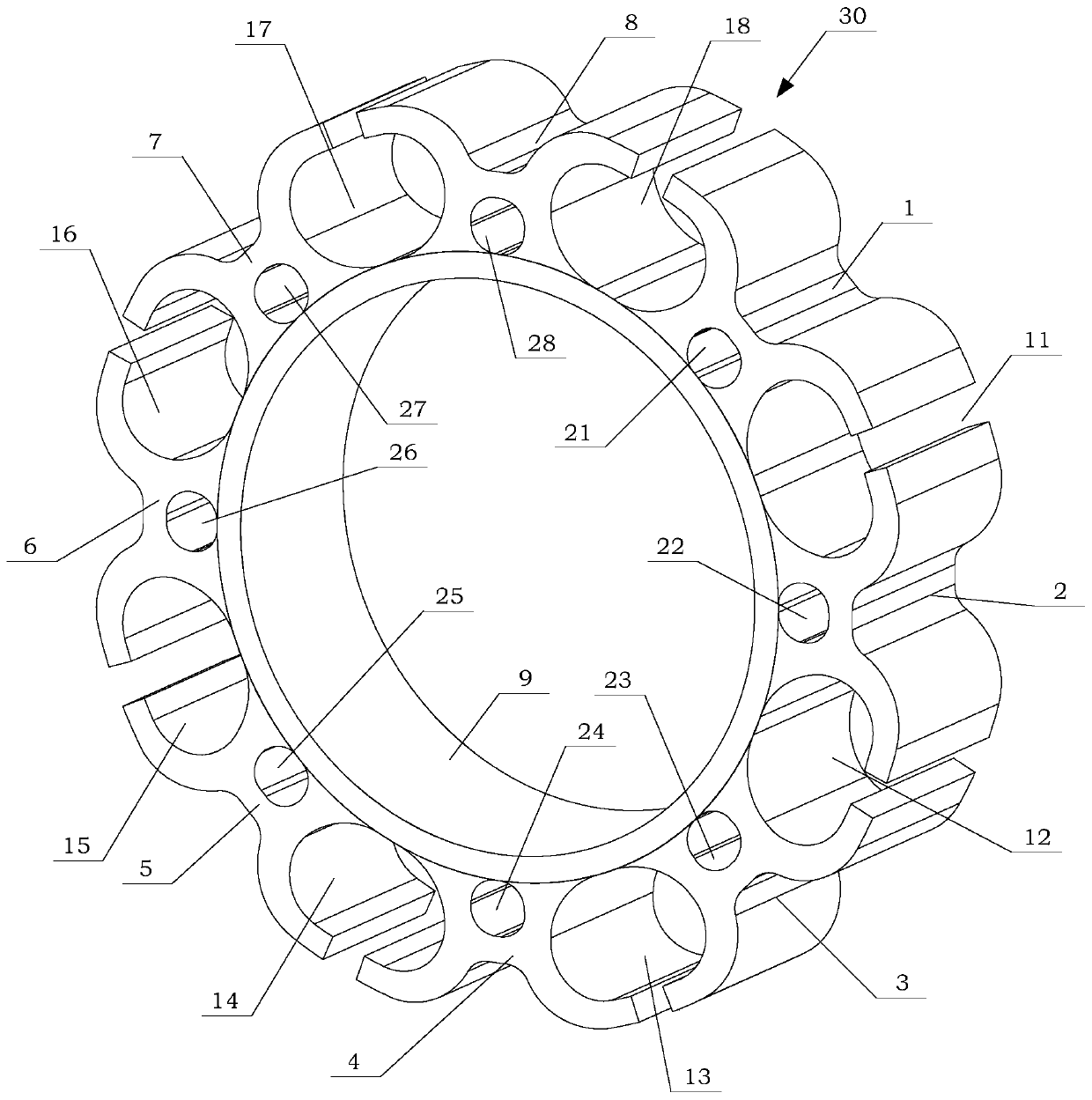

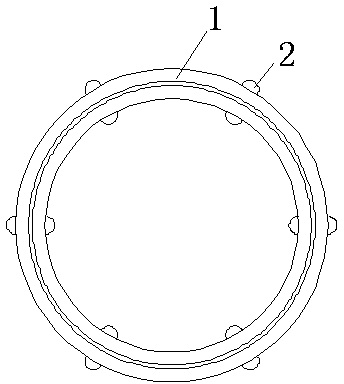

Segmented open flexible segment radial protection bearing for magnetic bearing

ActiveCN110725858AAvoid stuck and stalled situationsAvoid Rigid ImpactElastic bearingsBearing unit rigid supportMagnetic bearingEngineering

The invention discloses a segmented open flexible segment radial protection bearing for a magnetic bearing. The radial protection bearing is an integrated machined forming structural member. The radial protection bearing is composed of eight open flexible bodies of the same structure and an inner ring, an open arc-shaped hole is formed between every two adjacent open flexible bodies, and elliptical through holes are formed in the open flexible bodies and the outer ring surface of the inner ring. The radial protection bearing utilizes a segmented open flexible segment structure and is matched with flexible deformation of the open arc-shaped holes and the elliptical through holes. When a rotor is unstable and generates huge impact, the radial protection bearing can use elastic deformation ofa segmented open flexible segment to absorb a large amount of kinetic energy of the rotor, and other parts in a high-speed rotary magnetic suspension mechanism cannot be damaged.

Owner:BEIHANG UNIV

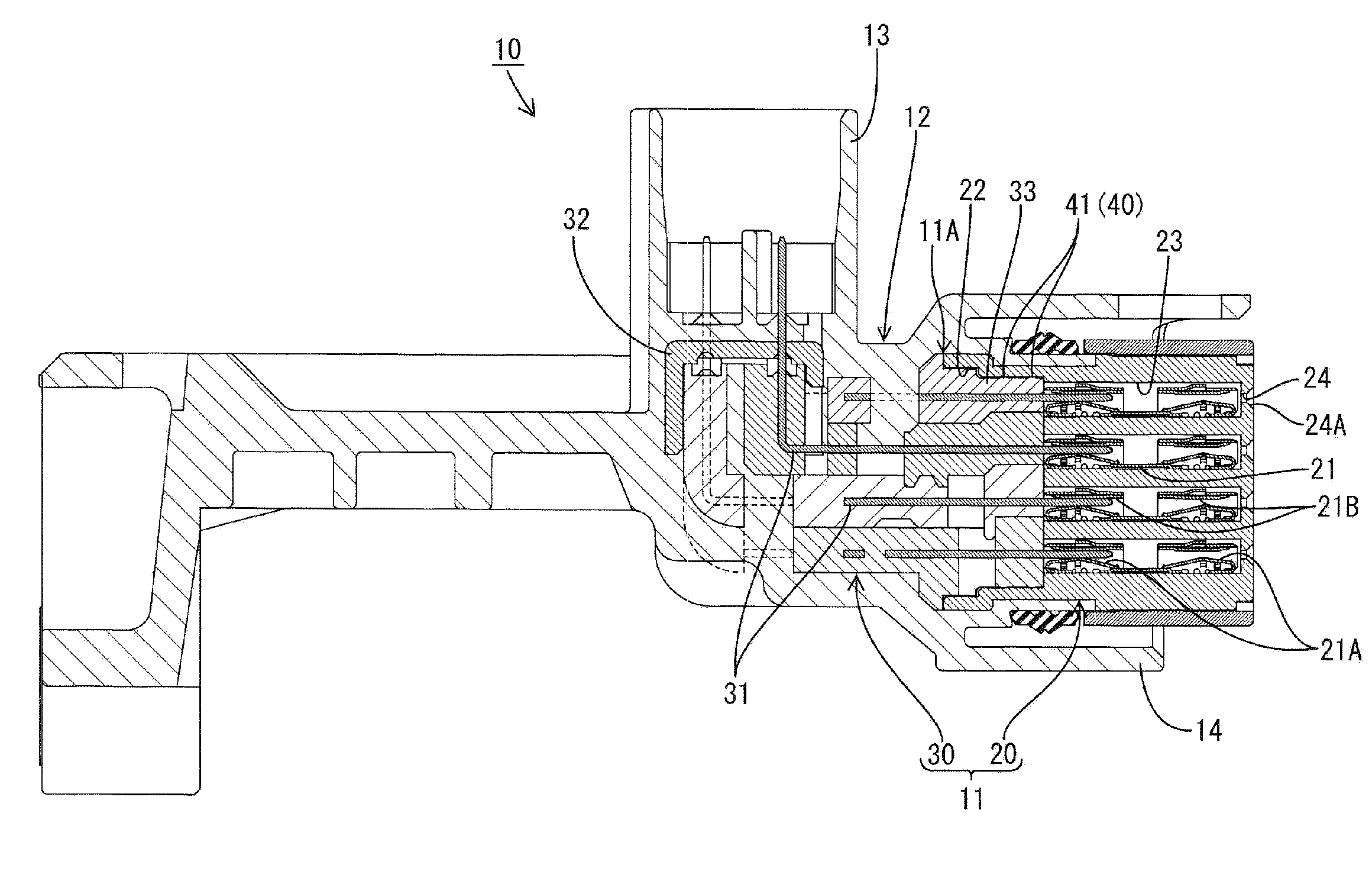

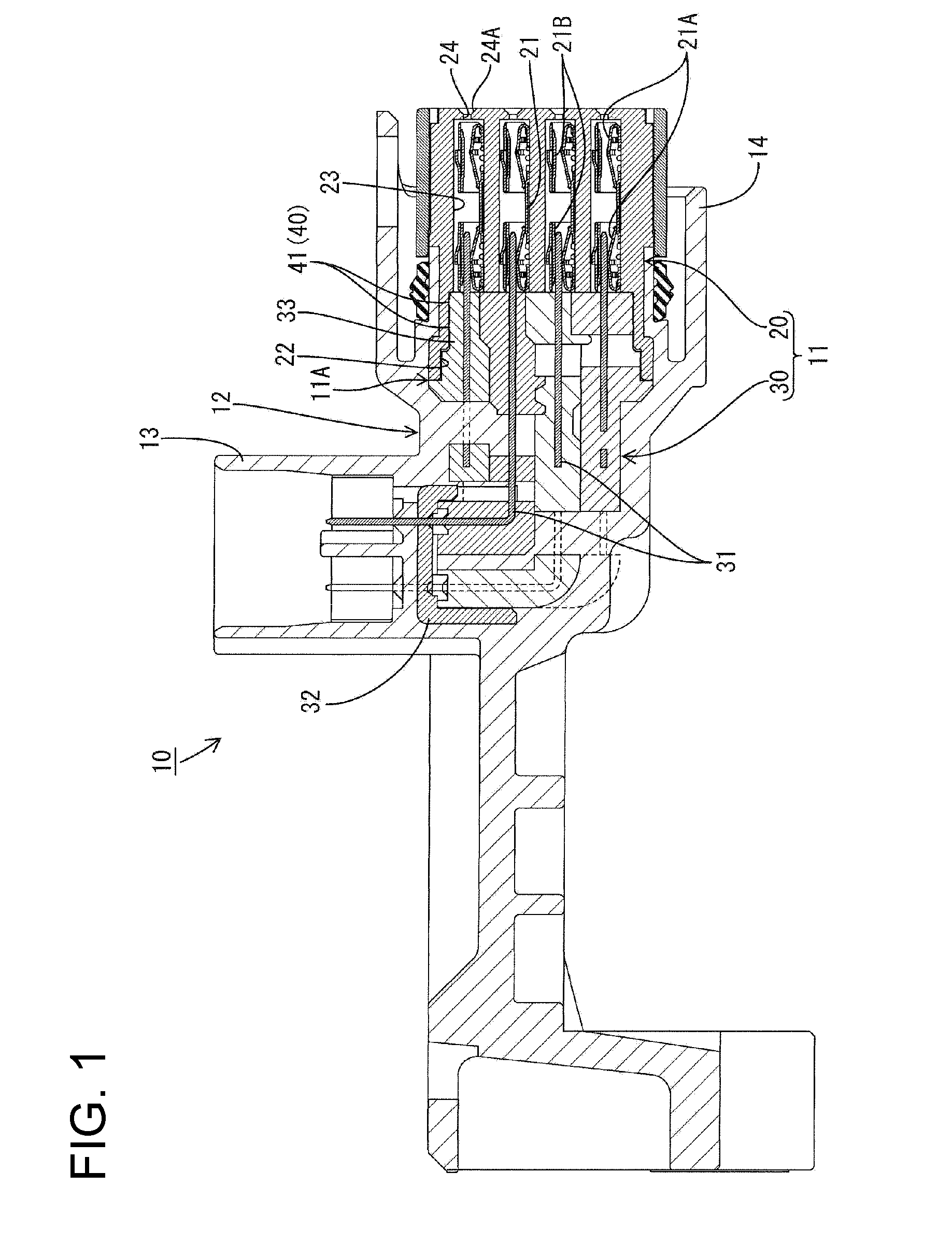

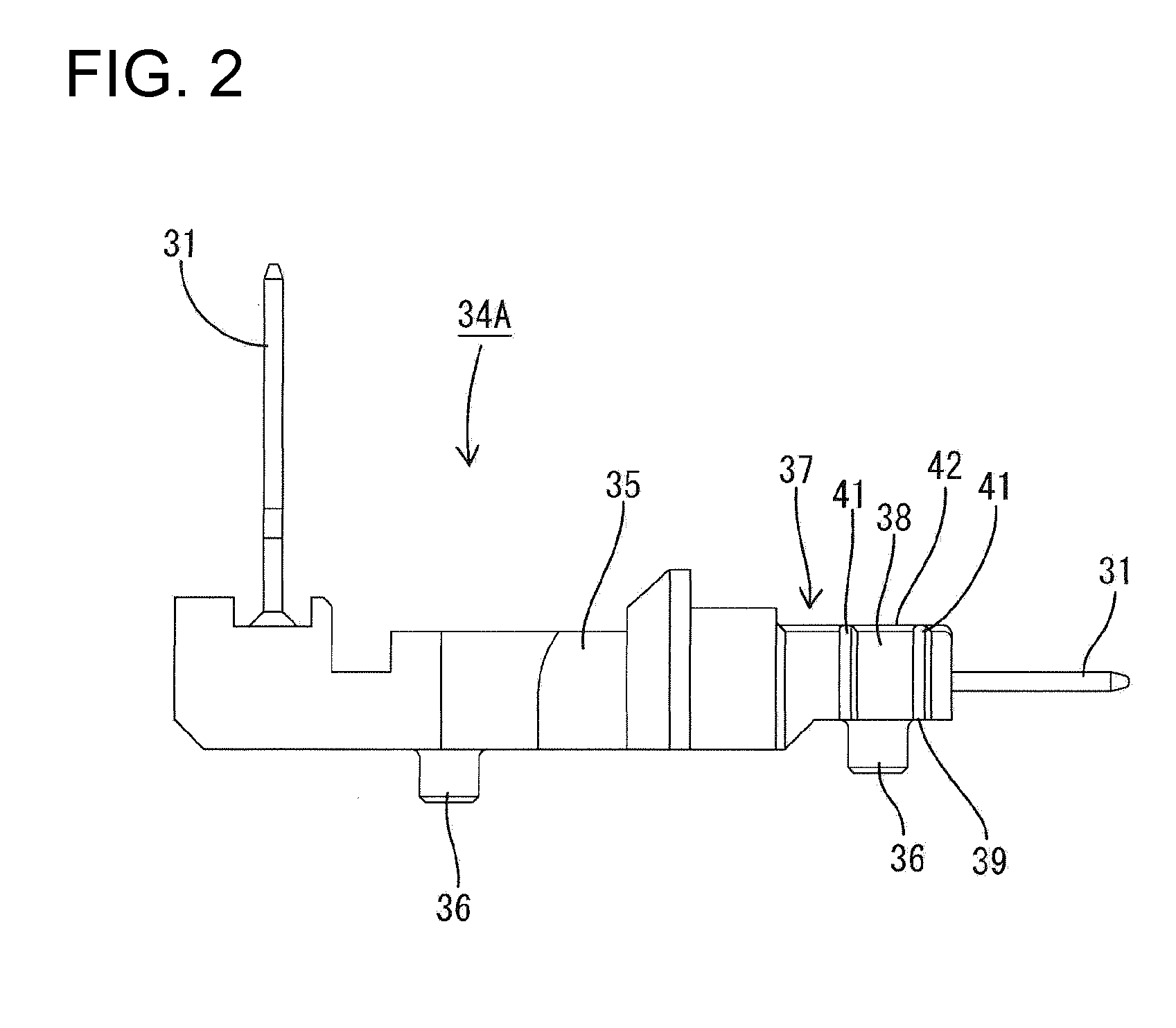

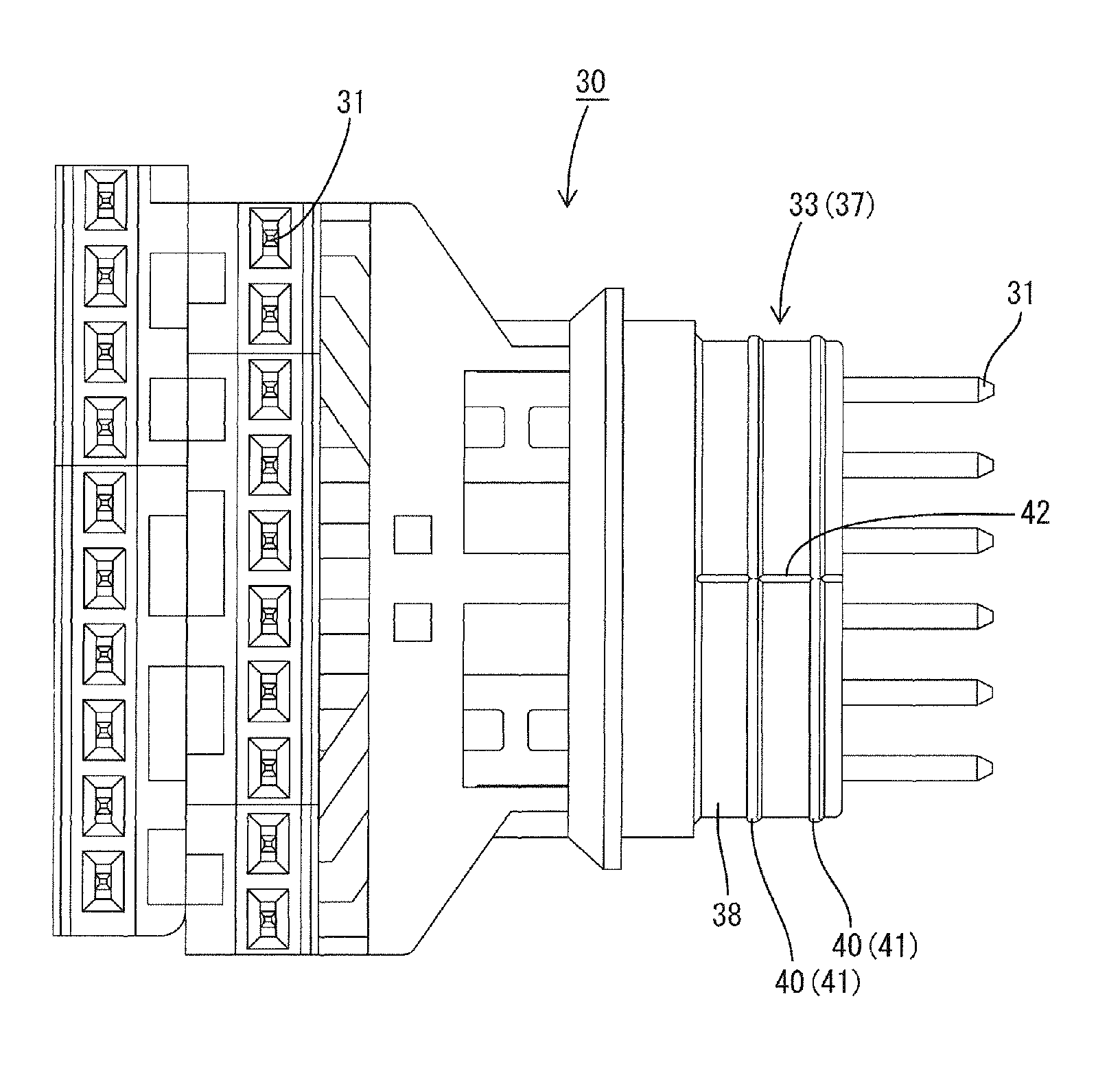

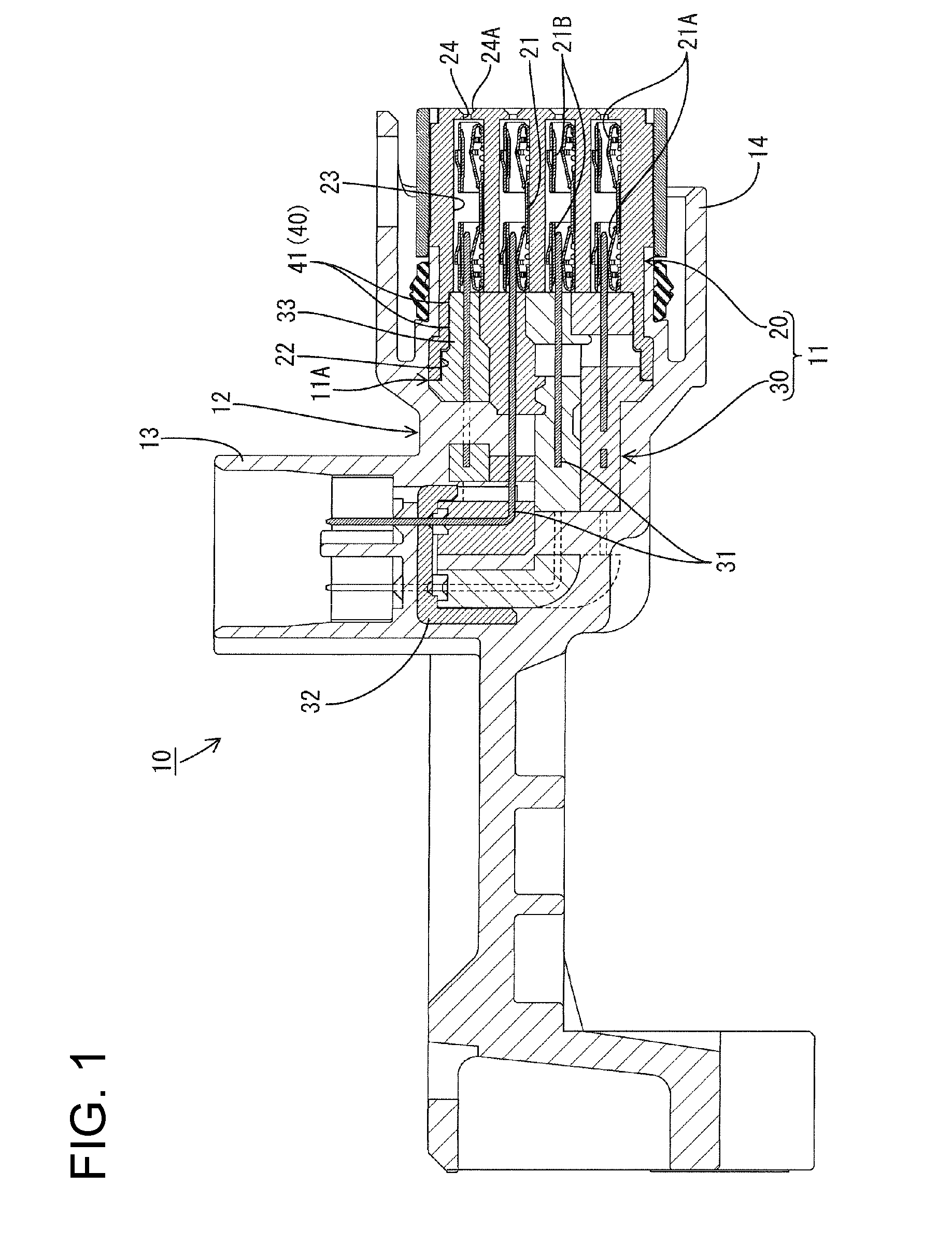

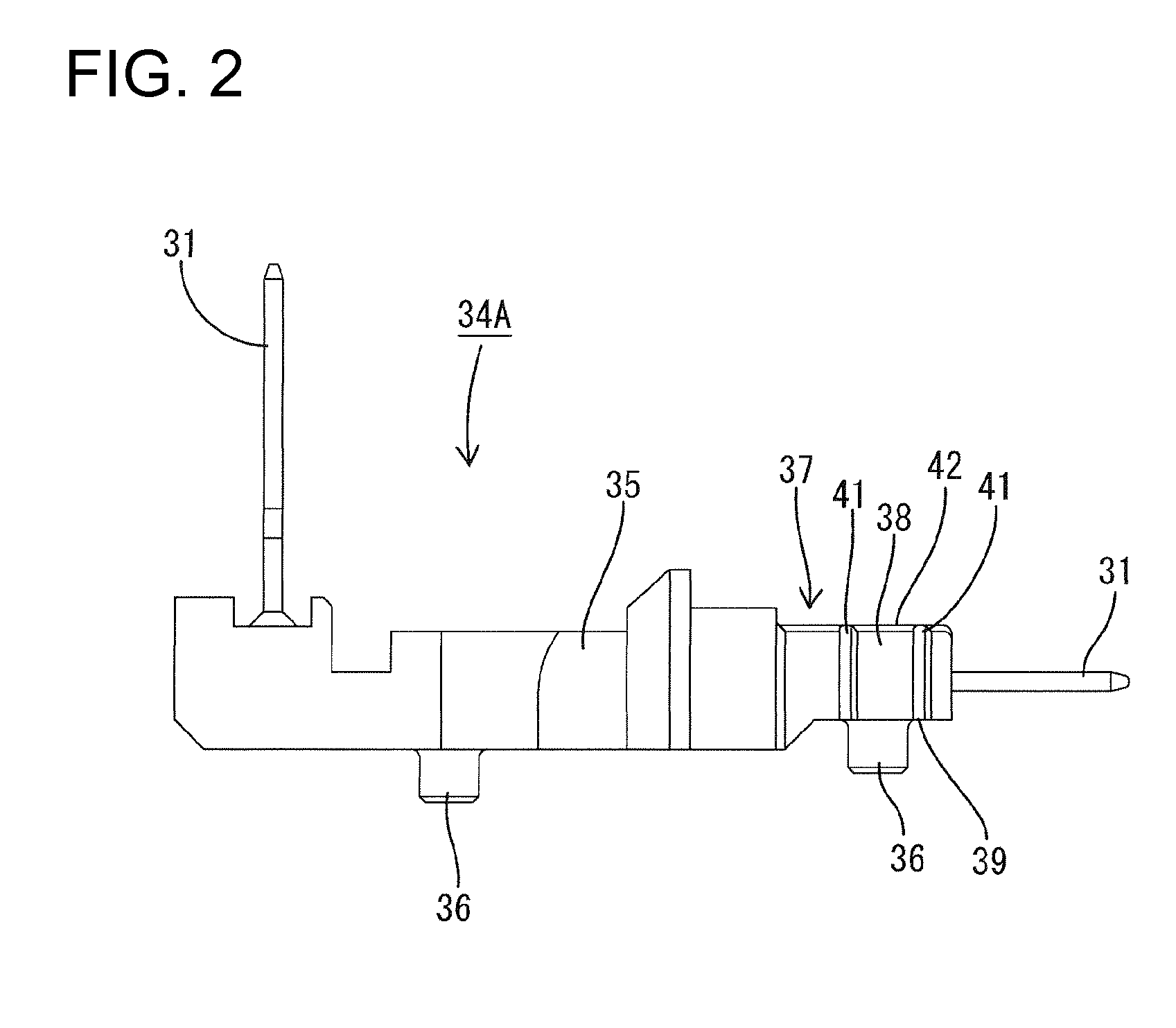

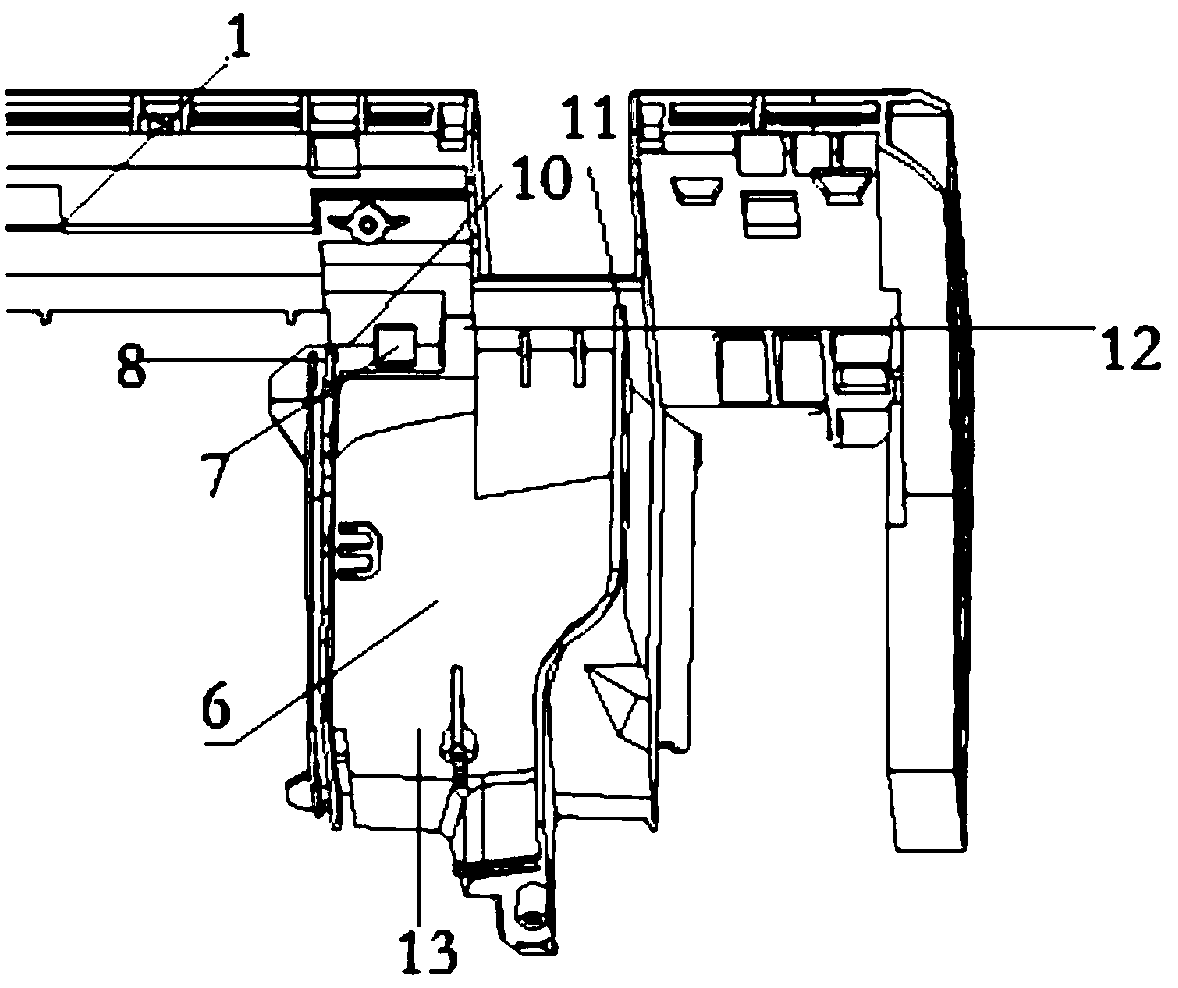

Case-integrated connector

ActiveUS20120094547A1Avoid assembly gapsAvoid flowContact member assembly/disassemblyCoupling device detailsStructural engineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

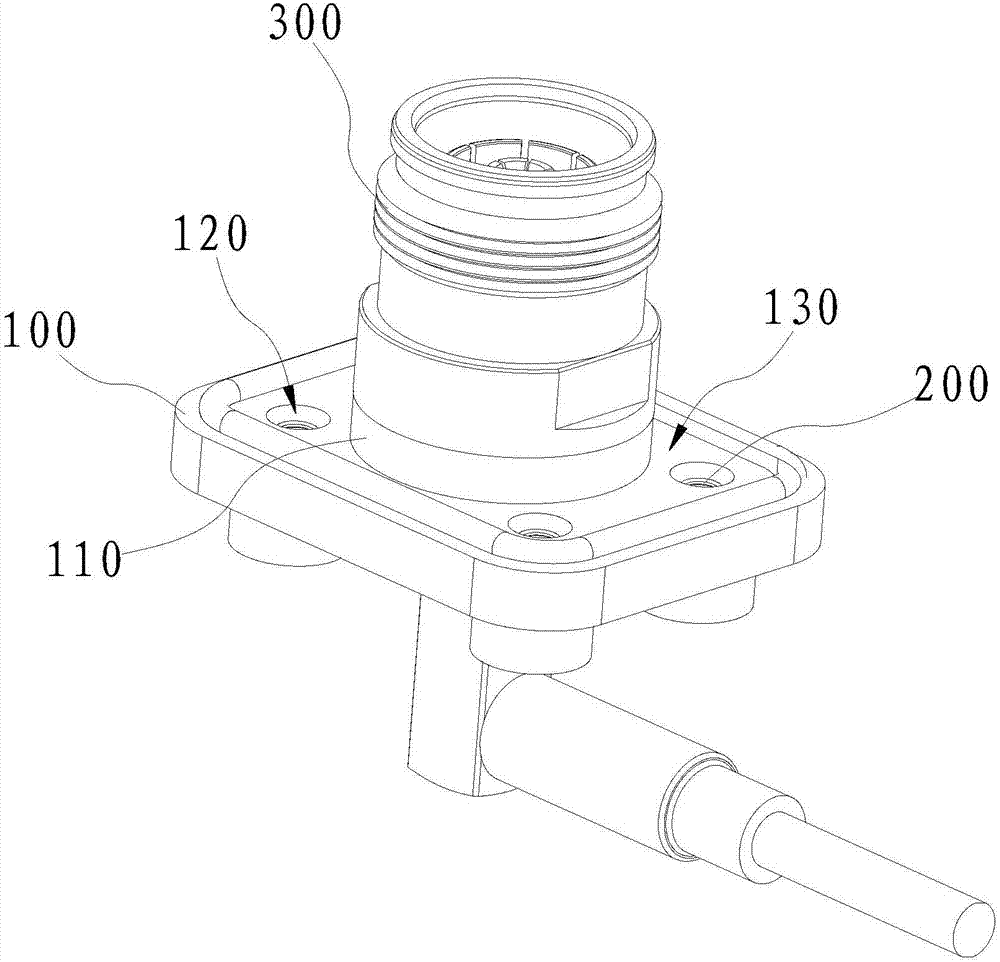

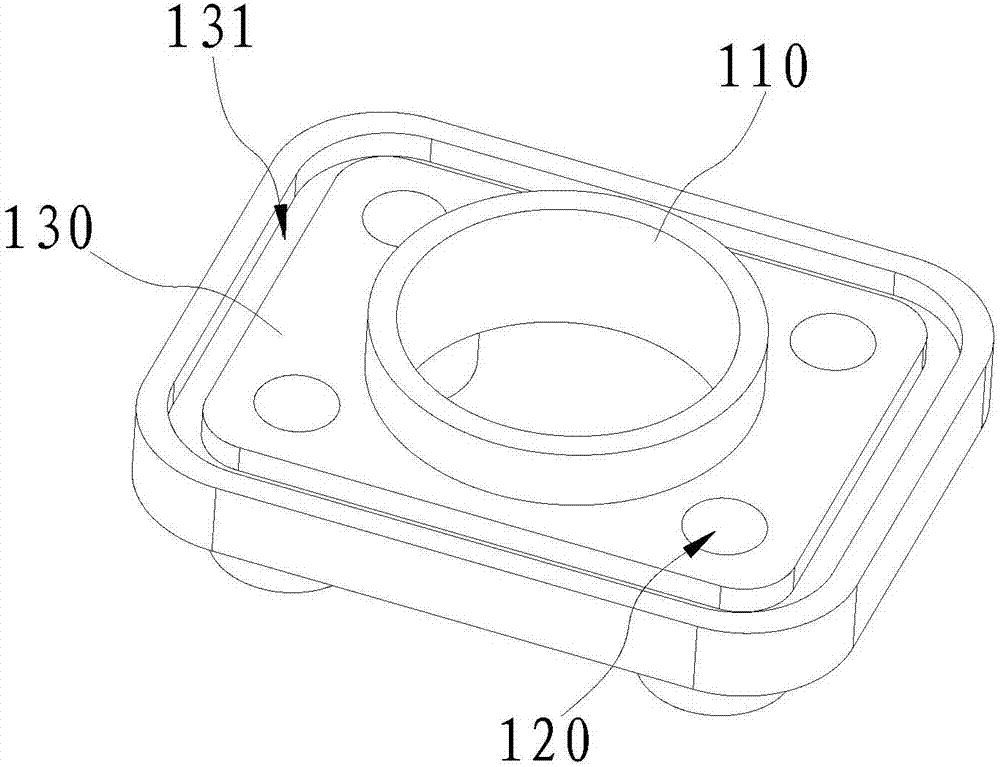

Radio-frequency connector and communication system

PendingCN106953198AImprove insulation performanceEliminate potential problems with intermodulation anomaliesTwo pole connectionsCouplings bases/casesCommunications systemEngineering

The invention discloses a radio-frequency connector and a communication system. The radio-frequency connector comprises a flange and a radio-frequency connector body, the flange is provided with a first assembling part capable of being insulated from external equipment, the radio-frequency connector body is provided with a second assembling part, and the second assembling part and the first assembling part are fixedly connected into one body. When the radio-frequency connector is manufactured, the flange is made of an insulation material, or the first assembling part insulated from the external equipment is manufactured on the flange, and then the radio-frequency connector body and the first assembling part are fixedly connected into one body through the second assembling part. In this way, when the radio-frequency connector is in assembling connection with the external equipment, the radio-frequency connector has good insulation performance due to the insulation property of the flange, metal conduction of a direct contact with the external equipment can be avoided, a potential problem that an abnormity occurs due to antenna intermodulation is eliminated, existence of an assembling gap can also be prevented at the same time. And the radio-frequency connector has excellent waterproof and dustproof performance.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

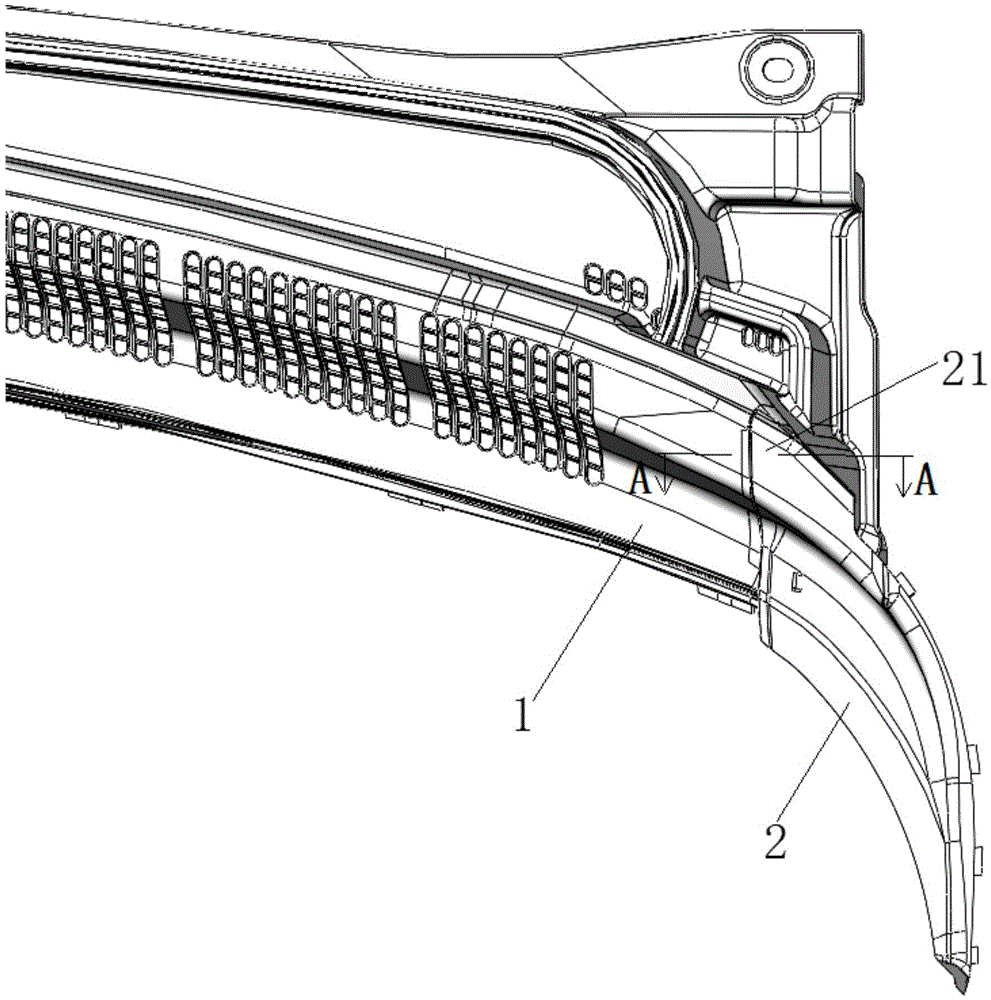

Ventilation cover plate assembly for vehicle

InactiveCN105480306AEasy to installAchieve connectionSuperstructure subunitsAgricultural engineeringEngineering

The invention discloses a ventilation cover plate assembly for a vehicle, comprising a ventilation cover plate body and end covers connected at two sides of the ventilation cover plate body, wherein the ventilation cover plate body is connected with the end covers in a clamping mode, a plurality of slots are symmetrically arranged at two sides of the ventilation cover plate body, a plurality of buckles are correspondingly arranged on the end covers, and the buckles are respectively clamped in the slots in a matching mode. The ventilation cover plate body is connected with the end covers in the clamping mode, limiting plates for limiting the positions of the buckles as well as guide plates are arranged on the slots, and the buckles are stably installed in the slots, thereby realizing the connection between the ventilation cover plate body and the end covers; and meanwhile, limiting ribs are arranged on the ventilation cover plate body and are used for limiting the positions of the top ends of the end covers so as to effectively avoid the problem of assembly clearance between the end covers and the ventilation cover plate body due to assembly deformation of the end covers, thereby improving the assembly quality and appearance quality of the ventilation cover plate assembly.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

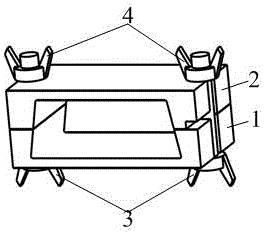

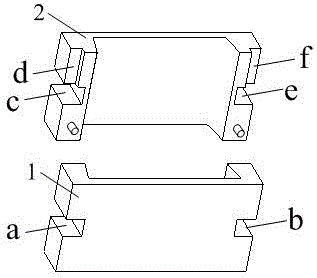

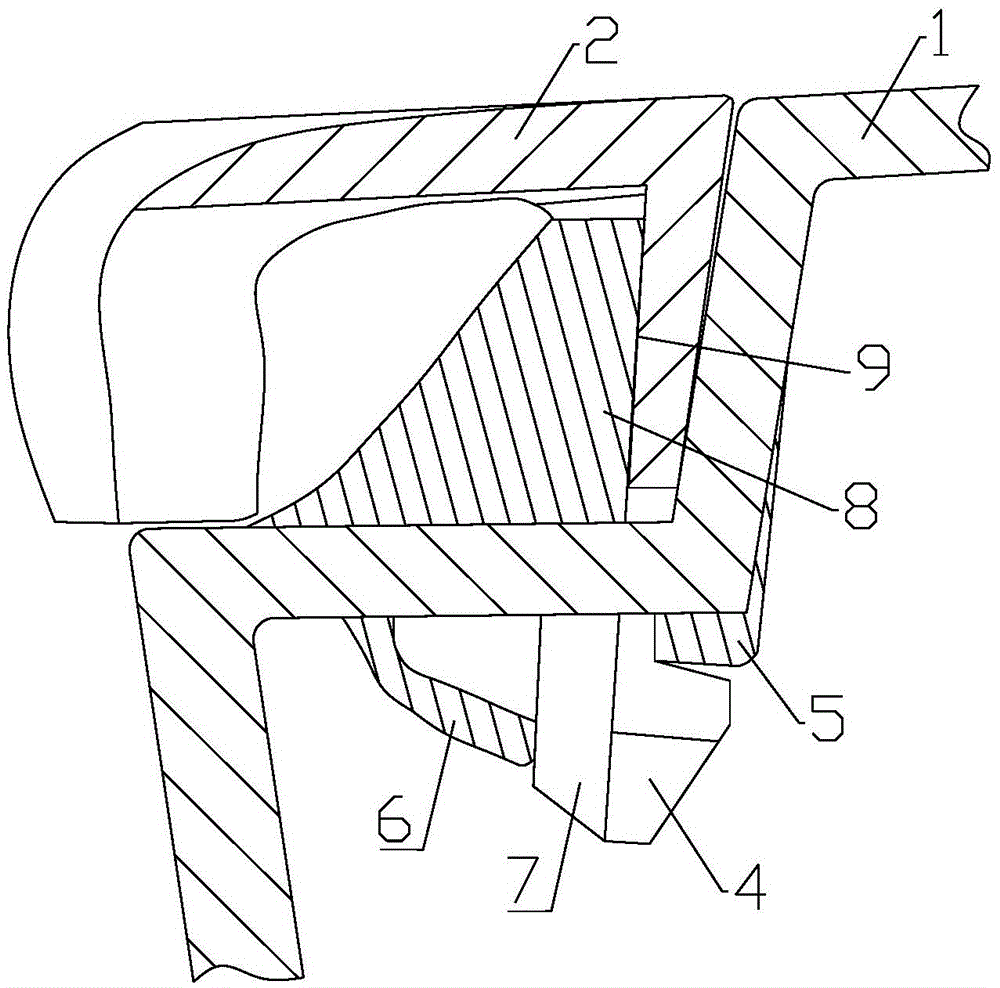

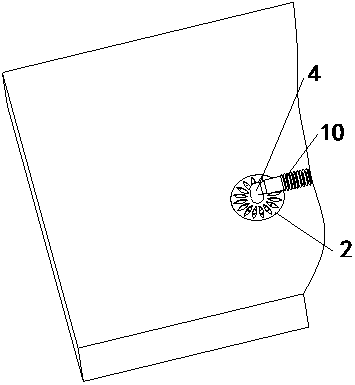

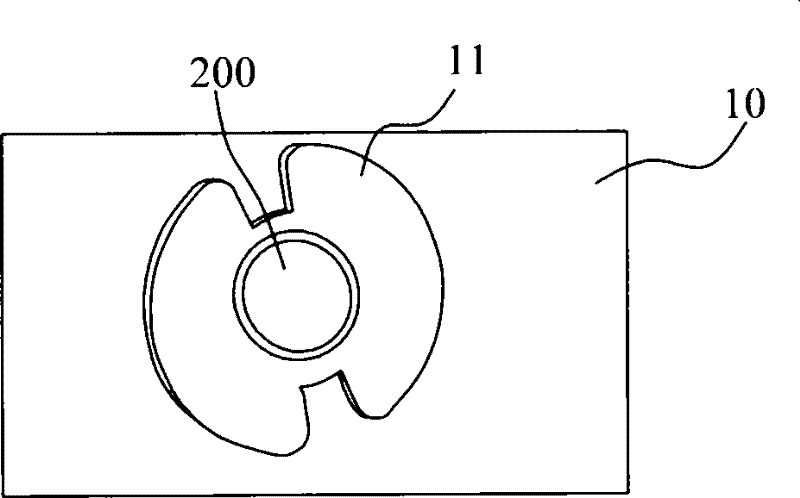

Case-integrated connector

ActiveUS8382530B2Avoid assembly gapsAvoid flowContact member assembly/disassemblyCoupling device detailsEngineeringMechanical engineering

A case-integrated connector (10) is such that a connector (11) is integrally assembled into a resin-made case body (12) by insert molding using the connector (11) as an insert. The connector (11) is provided with a first housing (20) including a receptacle (22) at one end and a second housing (30) including a connecting portion (33) to be fit into the receptacle (22). The case body (12) covers the outer peripheral surface of a fitting portion (11A) in which the receptacle (22) of the first housing (20) and the connecting portion (33) of the second housing (30) face each other. One of facing surfaces of the receptacle (22) and the connecting portion (33) is formed with annular projections (40) that project outward over the entire periphery to be held in contact with the other facing surface.

Owner:SUMITOMO WIRING SYST LTD

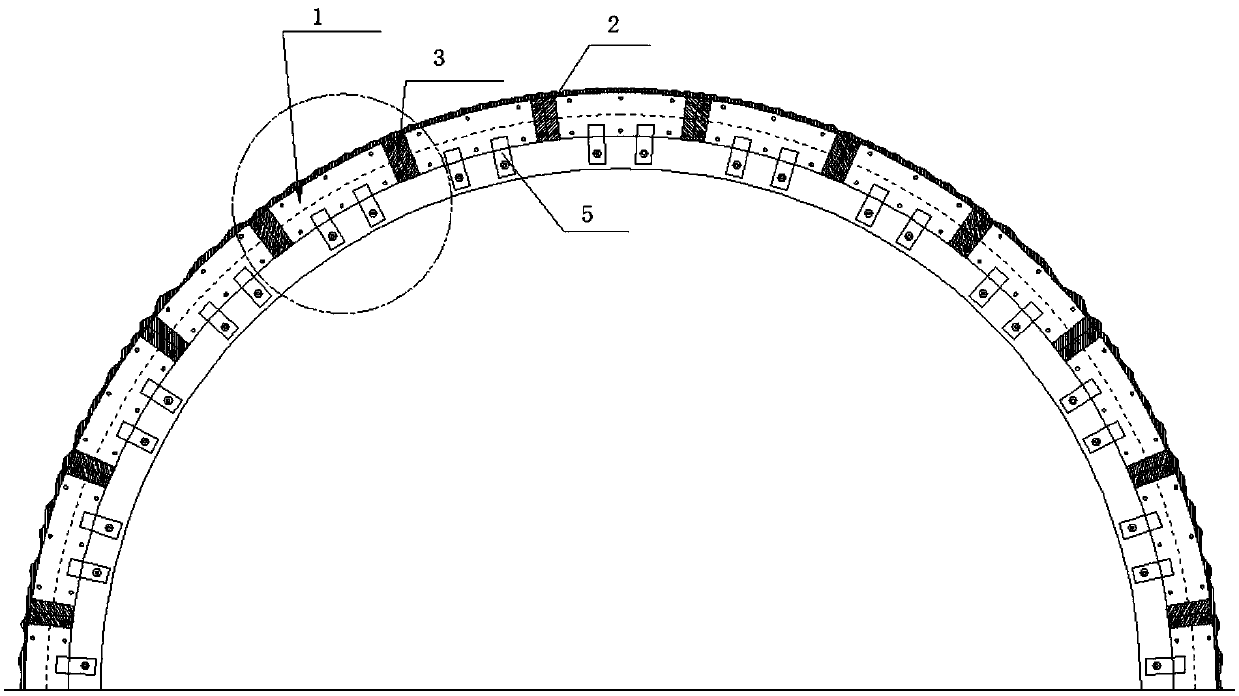

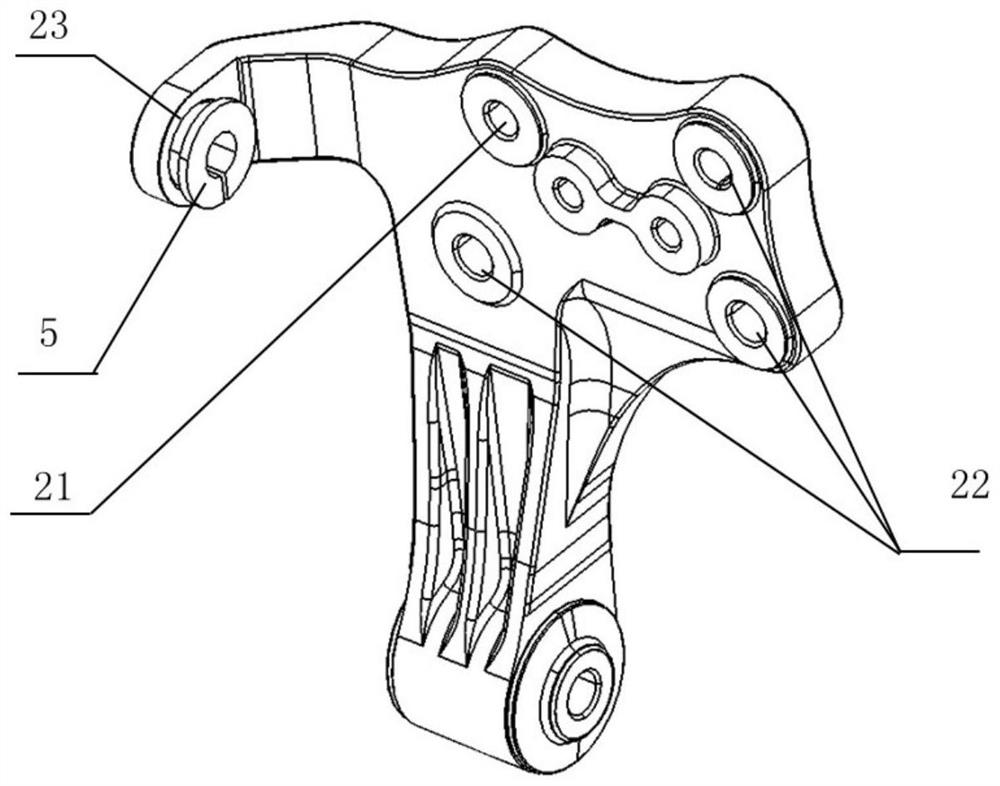

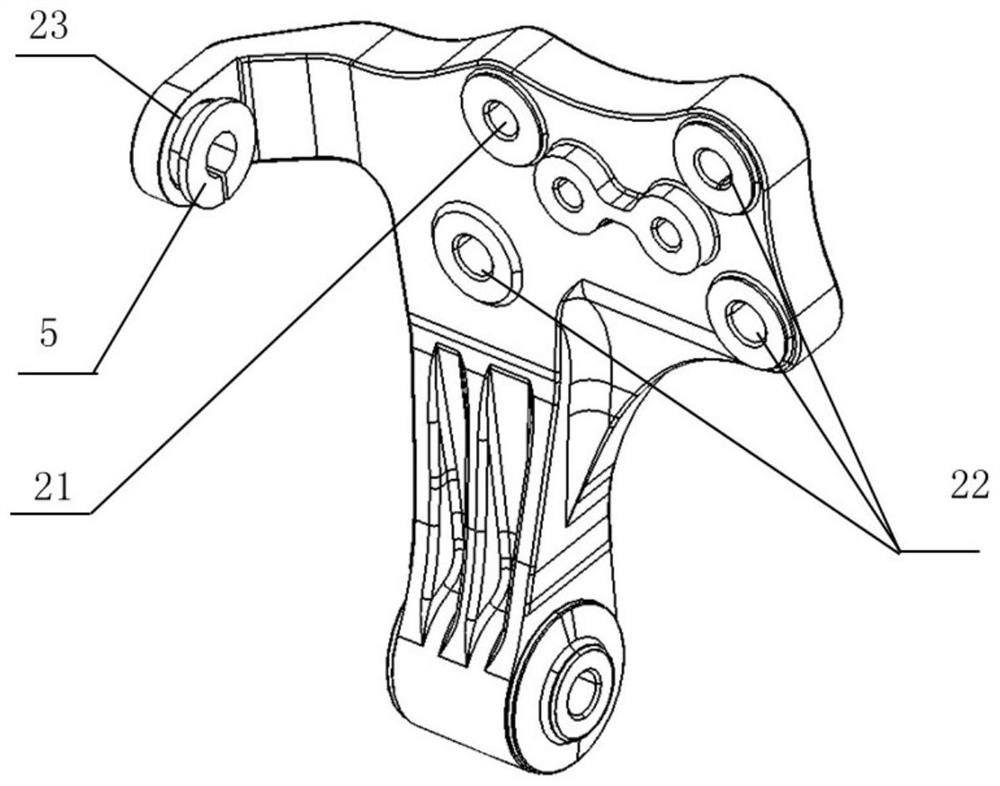

Joint structure of second-lining end mold having sealing devices

PendingCN108678783AAvoid Assembly GapsPrevent slurry leakageUnderground chambersTunnel liningElectrical and Electronics engineeringMultiple layer

The invention discloses a joint structure of a second-lining end mold having sealing devices. The structure comprises multiple arc end molds (1) and L-shaped fixing devices (5). One sides of the L-shaped fixing devices (5) are fixed on the arc end molds (1) and the other sides thereof are fixed onto a second-lining trolley. Adjacent arc end molds (1) are spliced to form the second-lining end mold.End-mold clamping groove joints, detachably connected, are arranged between adjacent arc end molds (1). One ends of the end-mold clamping groove joints are arranged on one arc end mold (1) and the other ends thereof are arranged on the other arc end mold (1) adjacent to the above. One sides, close to a preliminary bracing, of the arc end molds (1) are equipped with the multiple layers of sealingdevices (1) which are arranged at staggered joints. Each layer of sealing devices (2) comprises multiple sealing brushes which are arranged at intervals. The joint structure of the second-lining end mold having the sealing devices helps prevent mortar leakage in spliced gaps and resolves the problem of an irregular concrete-spraying surface of the primary bracing.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

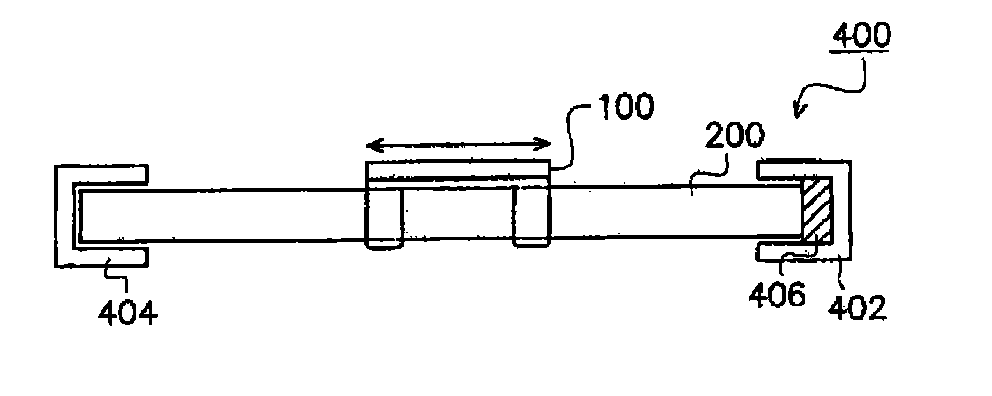

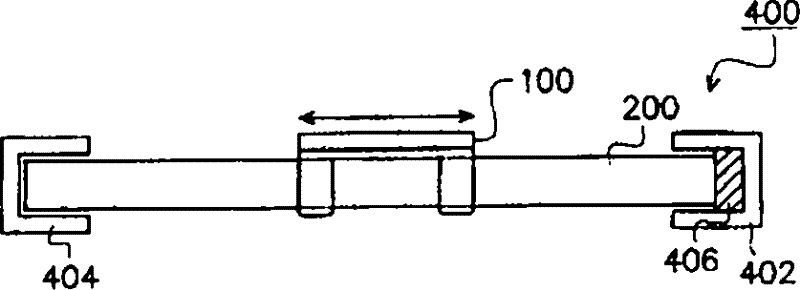

Mandrel rod damping structure

InactiveCN101552859AControl Position AccuracyAvoid assembly gapsPictoral communicationEngineeringReciprocating motion

The invention provides a mandrel rod damping structure for reducing the shake of a mandrel rod. The mandrel rod is sleeved with a scanner and a scanning module, and the scanning module can reciprocate along the mandrel rod which is arranged in a shaft hole. The mandrel rod damping structure is characterized in that a part of the shaft hole, which bears the mandrel rod, is in a V-shaped structure and provided with a fastening component for fixing the mandrel rod, and the mandrel rod is supported by the V-shaped structure which is in point contact with the mandrel rod so as to better control the position precision of the mandrel rod; the mandrel rod is contacted with an elastic component made of rubber materials and pressed by a rigid fastening component so as to keep in a gapless state all the time, thus the problem of the assembly gap of the mandrel rod can be effectively solved, and the elastic component made of the rubber materials can damp the shake. The mandrel rod damping structure can solve a plurality of image problems due to great shakes along a circumferential direction of the mandrel rod and no scanning module deviation in the scanning process.

Owner:LITE ON OPTO TECH (CHANGZHOU) CO LTD +2

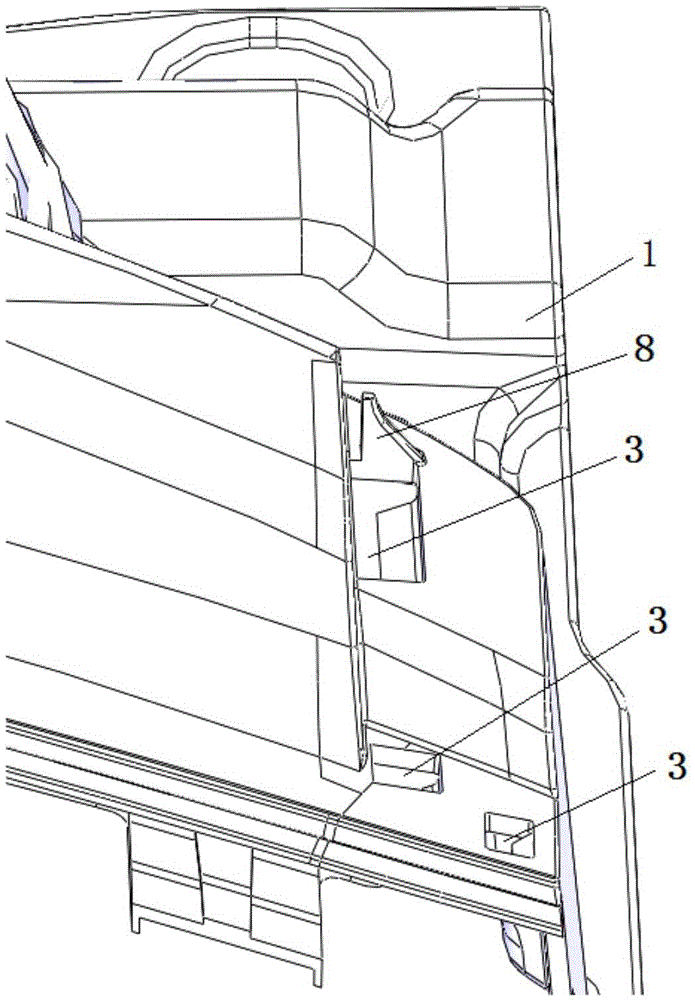

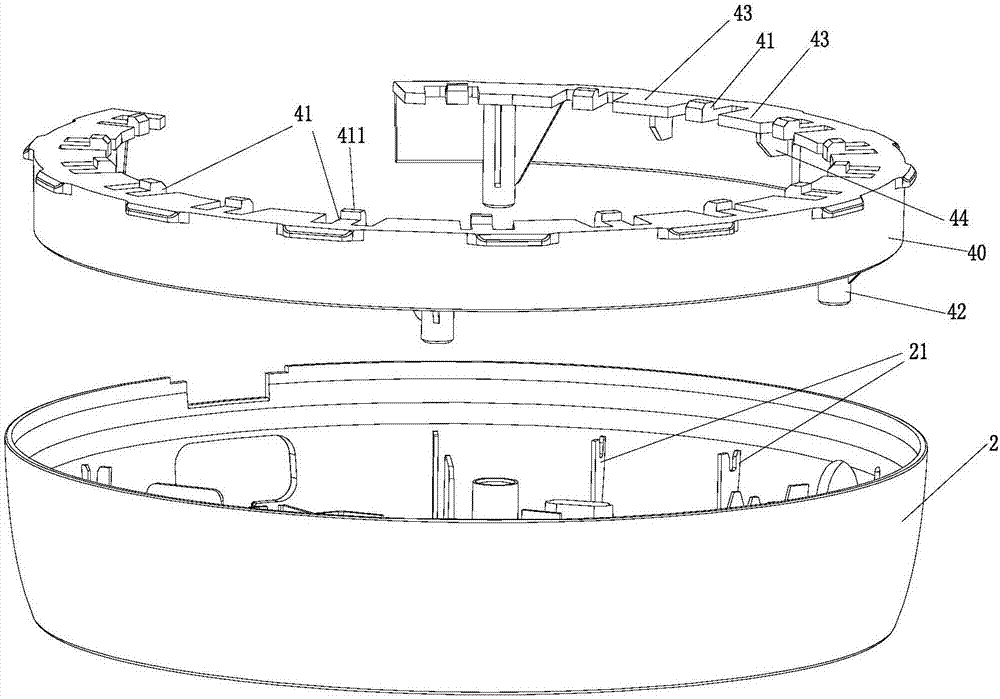

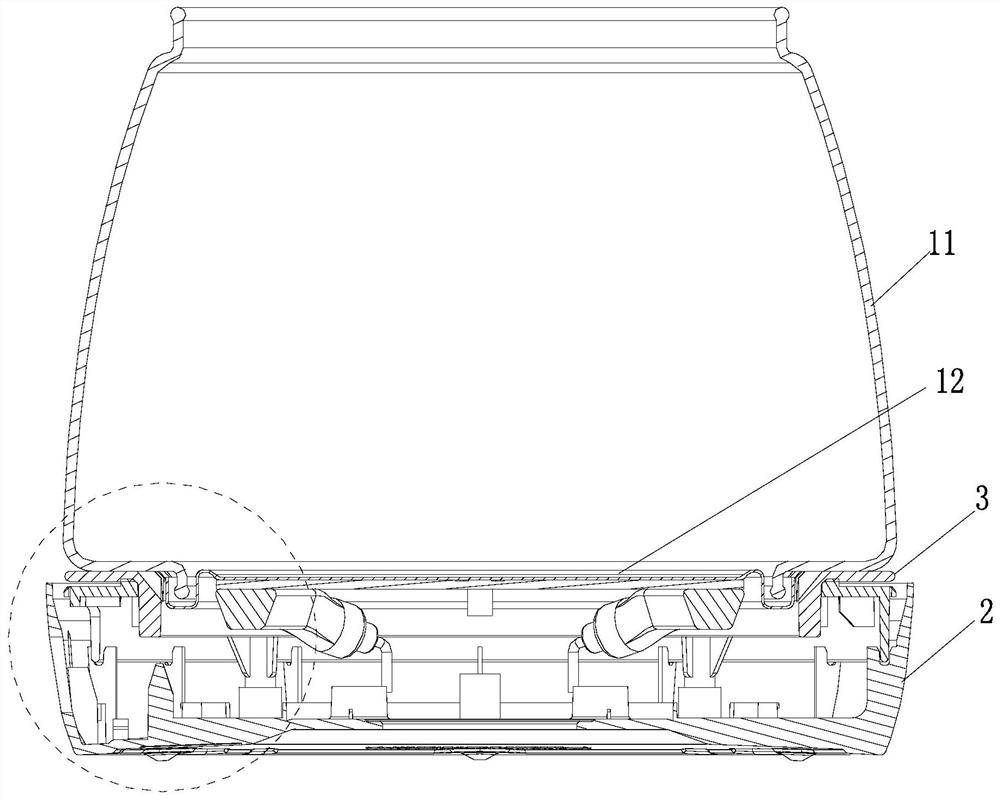

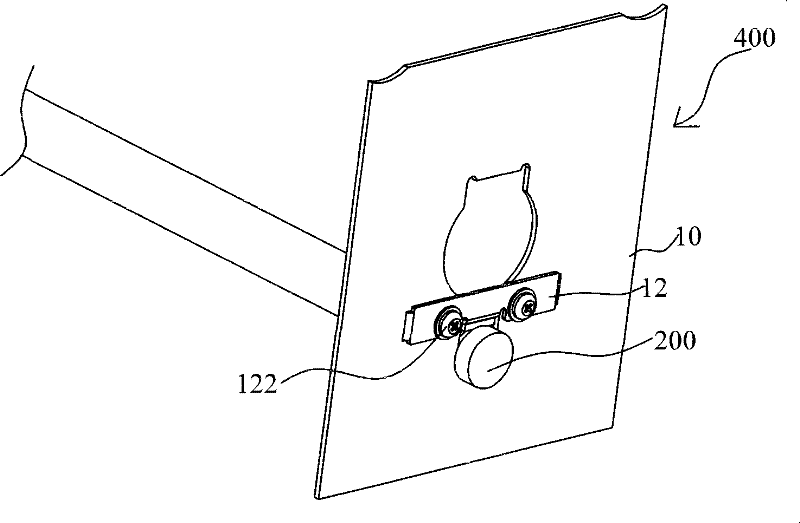

Motor installation assembly, indoor unit, air conditioner and motor installation method

PendingCN109539522AAvoid assembly gapsAvoid enteringCondensate preventionLighting and heating apparatusWater leakageWater channel

The invention provides a motor installation assembly, an indoor unit, an air conditioner and a motor installation method. The motor mounting assembly comprises a first base, a second base and a motorfixing cover, wherein a water retaining cover and the first base are integrally formed, the water retaining cover comprises a water leakage hole and a guide groove which are formed in the outer surface of the water retaining cover, and the guide groove is in fluid communication with the water leakage hole and a second water channel, so that condensed water from the water leakage hole is led into the second water channel through the guide groove; and the motor fixing cover is detachably connected with a first cavity so as to fix the motor in the first cavity. According to the motor installationassembly, the fixing of the motor fixing cover and the water retaining and blocking function are separated, the complexity of parts is remarkably reduced, the implementation difficulty of a mold is remarkably reduced, the assembling precision requirement is reduced, the complexity of components is reduced, the assembling process is not increased, the installation efficiency is remarkably improved, and the installation cost is reduced.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

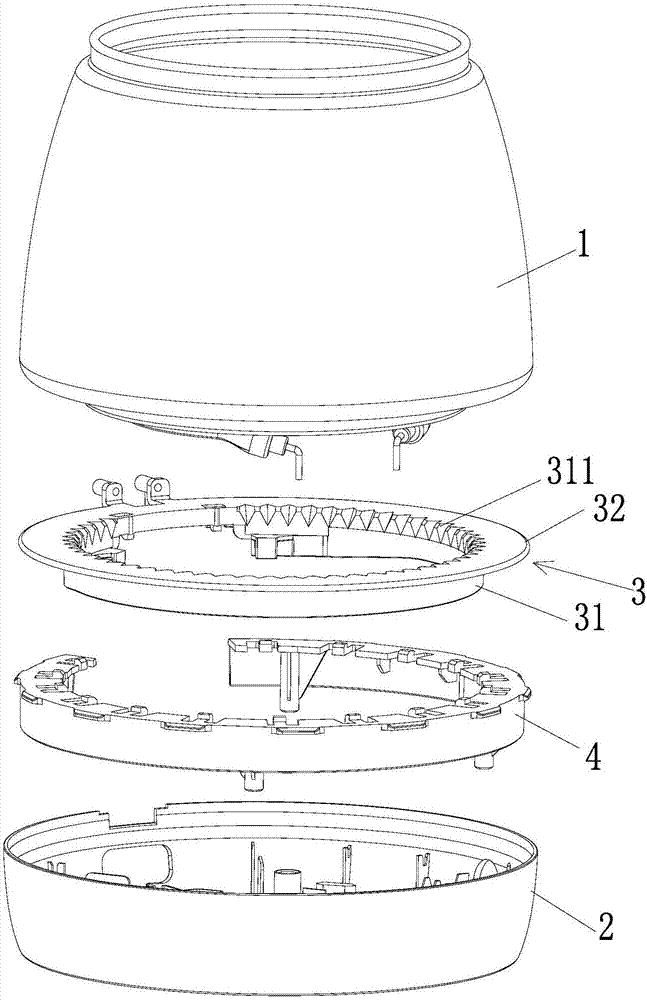

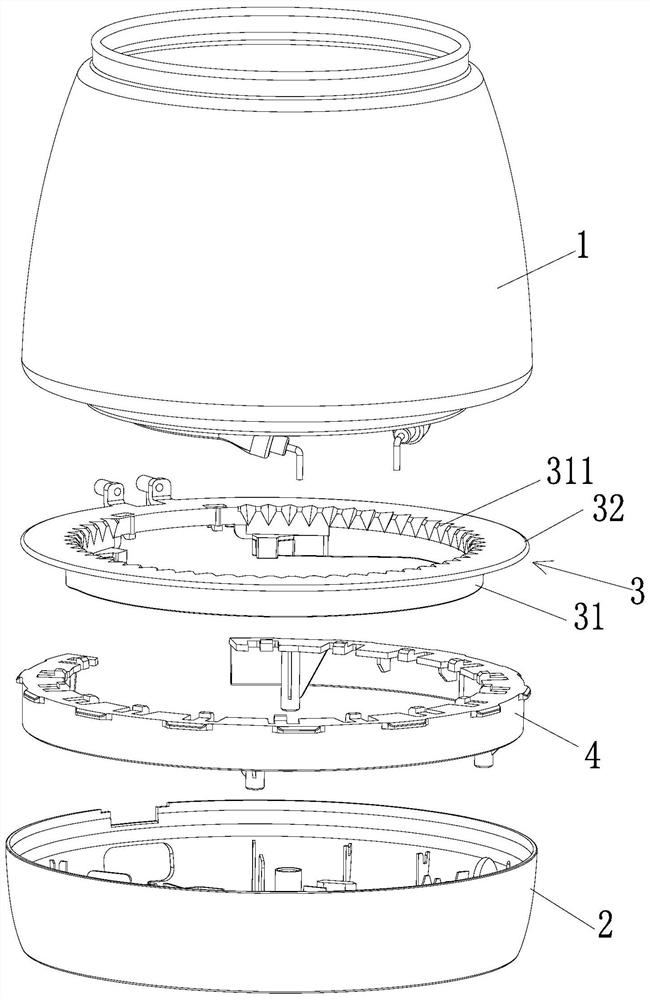

Glass electric kettle and lampshade fixing structure thereof

The invention discloses a glass electric kettle and a lampshade fixing structure thereof. The lampshade fixing structure comprises a base and an elastic support fixed in the base, the elastic support comprises an annular body and a plurality of elastic support pieces which are arranged in the manner that the tail ends extend horizontally inward on the annular body, a lug which protrudes upwards is arranged on each elastic support piece, and all the lugs abut against different positions close to the lower surface of the lampshade so as to attach the lampshade to the lower bottom surface of a glass kettle body. According to the glass electric kettle and the lampshade fixing structure thereof, the technical problem that bad appearance is easily caused due to the fact that a larger assembly gap exists when the lampshade is mounted on the bottom surface of the glass kettle body is solved substantially, so that a smaller assembly gap can exist between the lampshade and the glass kettle body, the product yield can be improved, and the glass electric kettle and the lampshade fixing structure thereof have the advantages that the structure is simple, the reliability is high, processing and manufacturing are convenient and the like.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

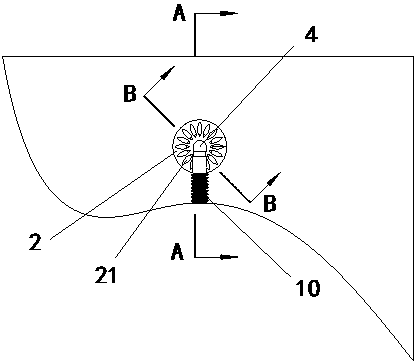

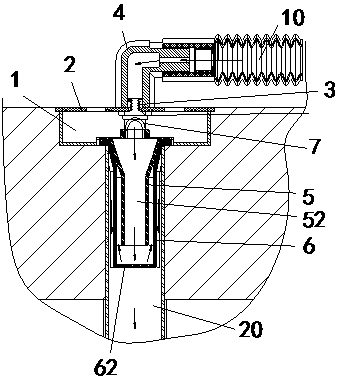

Floor drain assembly for washing machine

PendingCN109868886AAvoid assembly gapsImprove sealingSewerage structuresPulp and paper industryDrainage flow

The invention provides a floor drain assembly for a washing machine. The floor drain assembly comprises a floor drain base groove and a face cover arranged at the top of the floor drain base groove. The floor drain assembly is characterized in that the face cover is provided with filtering holes and a through opening communicating with a drainage pipe of the washing machine, the floor drain assembly further comprises a first connecting pipe matched with the through opening, and the first connecting pipe is fixed to the through opening in a sealed mode. According to the floor drain assembly forthe washing machine, the first connecting pipe is fixed to the through opening in the sealed mode, and the drainage pipe of the washing machine communicates with the through opening; in this way, thedrainage pipe can be not inserted into the face cover and communicates with the first connecting pipe in a sealed mode, an assembly gap of a drainage flowing way of the washing machine is avoided, the sealing property of the drainage flowing way of the washing machine is improved advantageously, and the situation of odor returning or water returning from the gap is avoided; and the filtering holes are formed in the face cover, thus water on the ground can flow into the floor drain assembly through the filtering holes, that is, the floor drain assembly can conduct washing machine drainage andground drainage simultaneously.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

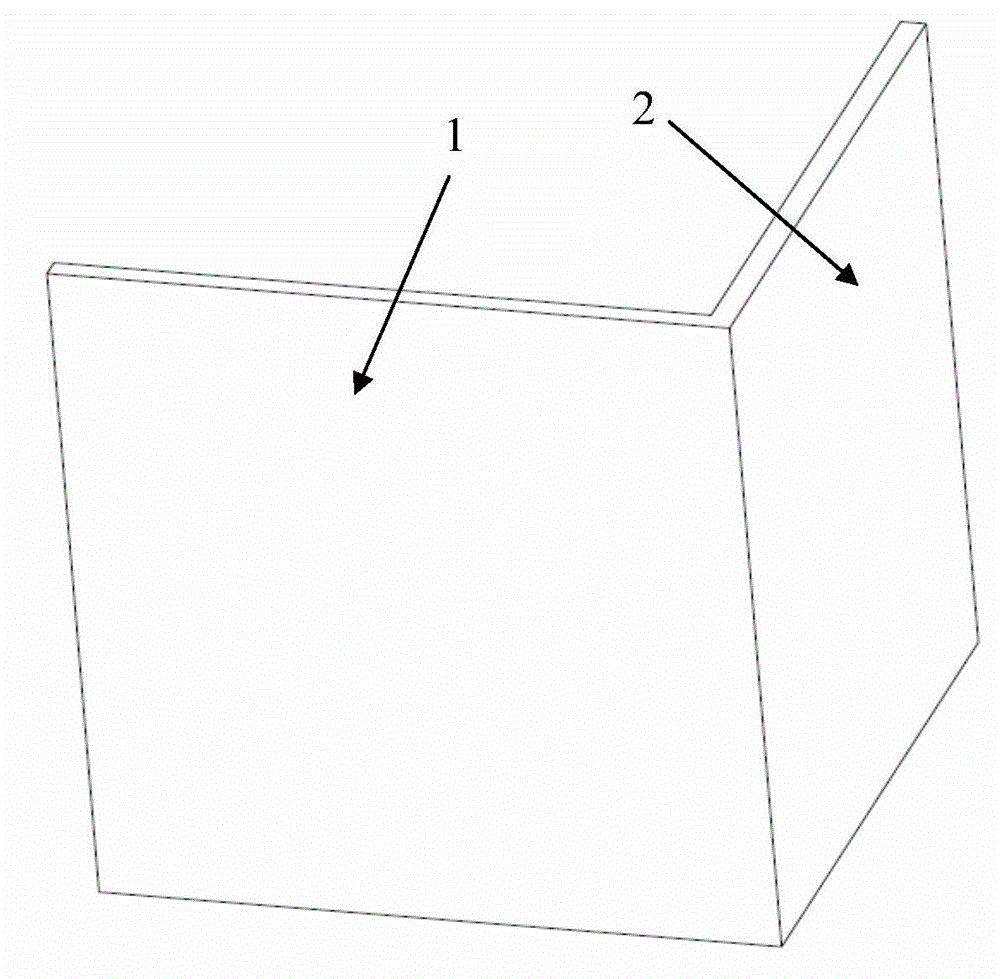

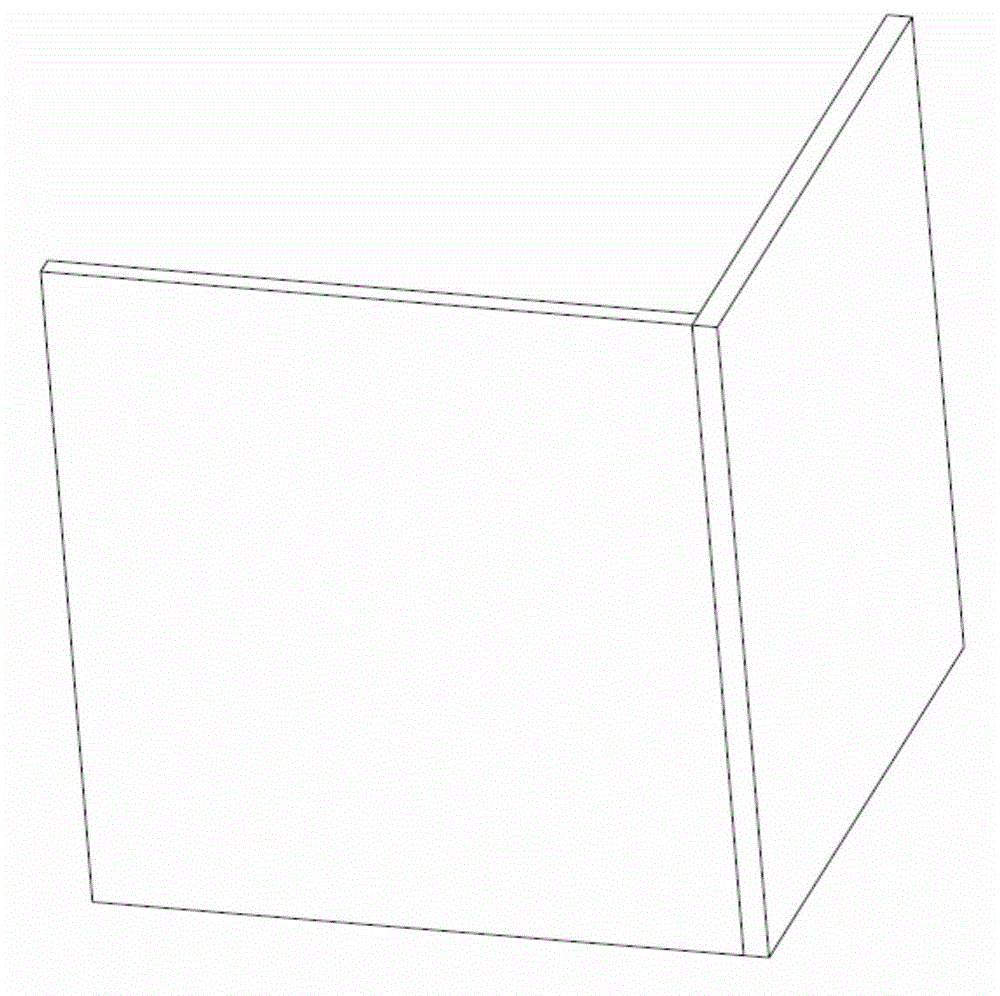

Wall corner and method for manufacturing same

The invention relates to the technical field of housing construction, and particularly discloses a wall corner and a method for manufacturing the same. The wall corner is used for being arranged at a corner between two walls, is of an integral structure and comprises a first wallboard and a second wallboard. An included angle between the first wallboard and the second wallboard corresponds to an included angle between the two walls. The method for manufacturing the wall corner includes manufacturing the wall corner by the aid of a jet forming process and a steel frame embedding process by an integral form. The wall corner and the method have the advantages that the wall corner is of the integral structure, so that the problem of assembly gaps at corners of houses in the prior art can be solved, the wall corner is good in integrity, reliable in seismic performance, good in firmness and durability, simple in structure and convenient to construct, and is environmental friendly, and energy can be saved; a house with the wall corner is good in integrity, low in construction cost, short in construction period and good in anesthetics.

Owner:北京市飞翔建筑艺术雕刻有限责任公司

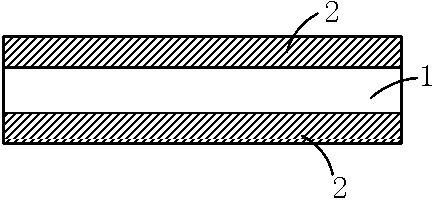

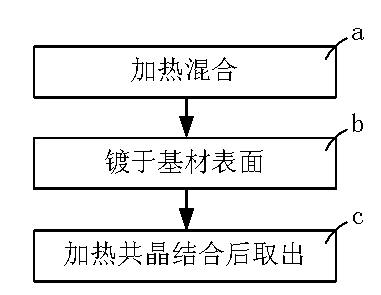

Copper-based composite heat conduction material and manufacturing method thereof

InactiveCN103855108AAvoid assembly gapsNot easy to liquefyHot-dipping/immersion processesSemiconductor/solid-state device detailsElectron flowThermal expansion

The invention relates to a heat conduction material and a manufacturing method thereof, in particular a copper-based composite heat conduction material and a manufacturing method thereof. The heat conduction material includes a copper base material; the surface of one side or two sides of the copper base material is provided with a mixed metal material; and the mixed metal material is a eutectic mixed metal material composed of 6 to 12% silver, 8 to 3% gallium and 80 to 91% tin. The method includes the following steps that: the 6 to 12% silver, the 8 to 3% gallium and the 80 to 91% tin are heated and mixed so as to form a mixed metal liquid; the mixed metal liquid is plated on the surface of the sheet-shaped copper base material; and the copper base material of the surface is plated with the mixed metal liquid is heated and is subjected to eutectic combination, and is cooled. With the copper-based composite heat conduction material of the invention adopted, large assembly clearance, thermal resistance increase, and interfacial contact thermal resistance reduction of an electronic device, which are caused by frequent thermal expansion and cold contraction when common composite materials are used, can be avoided; an electron flow transfer path in a metal material heat conduction process can be shortened, and heat transfer rate can be increased, and possibility of liquidation or deformation is low, and the stability of heat transfer can be ensured.

Owner:JIAWEI RENEWABLE ENERGY CO LTD

A powertrain mounting arrangement structure and its assembly method, and vehicle

ActiveCN112373284BAlleviate NVH issuesAvoid assembly gapsJet propulsion mountingInternal combustion mountingSuspension (vehicle)Control theory

The present application relates to the technical field of vehicles, in particular to a powertrain suspension arrangement structure and an assembly method thereof, and a vehicle. The suspension arrangement structure of the power assembly includes a power assembly, a suspension bracket, a steel sleeve and connecting bolts, the suspension bracket includes a first positioning hole, a first assembly hole and a second assembly hole, and the location where the second assembly hole is located Part of the first assembly hole and the first positioning hole are in a bent structure. The power assembly includes the second positioning hole, the third assembly hole and the fourth assembly hole. The connecting bolts pass through the corresponding holes to connect the power assembly. Forming and suspending the bracket, the steel sleeve is located between the first positioning hole and the second positioning hole, a part of which is embedded in the first positioning hole, and the other part is embedded in the second positioning hole. The power assembly suspension arrangement structure provided by the present application can effectively improve the positioning accuracy, avoid the situation that the assembly gap is too large or cannot be assembled, and improve the assembly stability.

Owner:CHERY AUTOMOBILE CO LTD

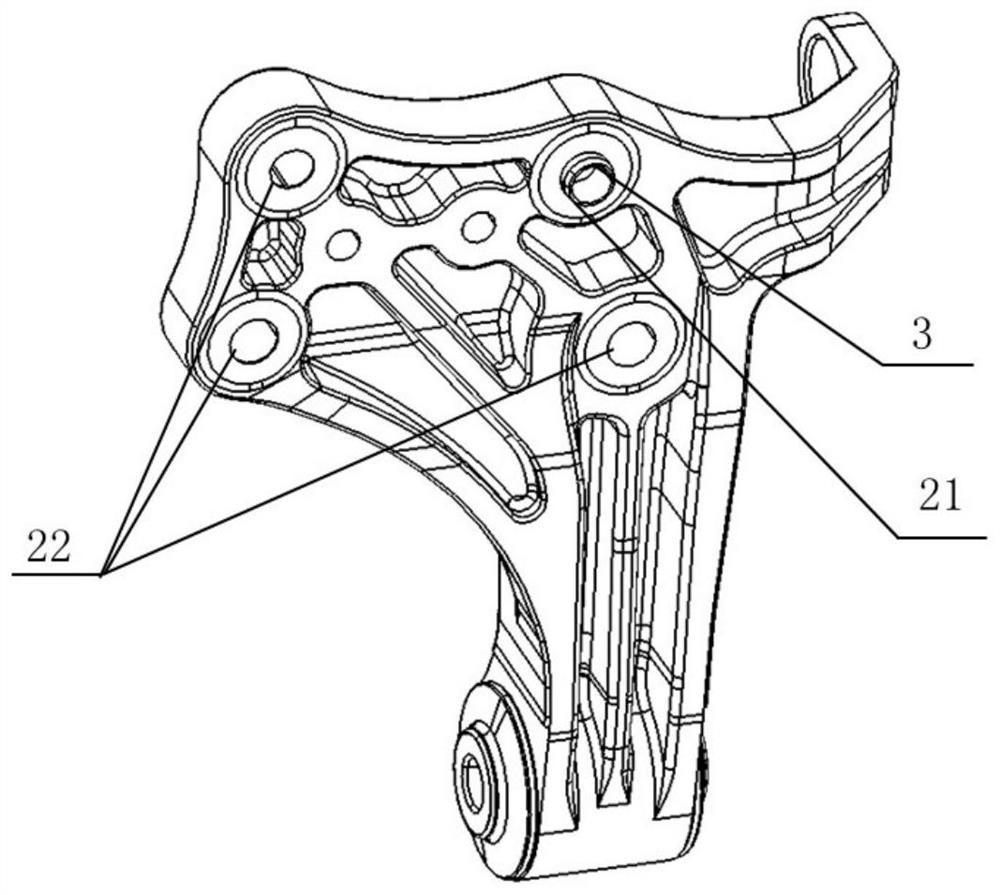

Power assembly suspension arrangement structure, assembling method thereof and vehicle

ActiveCN112373284AAlleviate NVH issuesAvoid assembly gapsJet propulsion mountingInternal combustion mountingEngineeringStructural engineering

The invention relates to the technical field of vehicles, and especially relates to to a power assembly suspension arrangement structure, an assembling method thereof and a vehicle. The power assemblysuspension arrangement structure comprises a power assembly, a suspension support, a steel sleeve and a connecting bolt, the suspension support comprises a first positioning hole, a first assemblinghole and a second assembling hole, and the portion where the second assembling hole is located, the first assembling hole and the portion where the first positioning hole is located form a bent structure. The power assembly comprises a second positioning hole, a third assembling hole and a fourth assembling hole, the connecting bolts penetrate through the corresponding holes to be connected with the power assembly and the suspension support, the steel sleeve is located between the first positioning hole and the second positioning hole, one part of the steel sleeve is embedded into the first positioning hole, and the other part of the steel sleeve is embedded into the second positioning hole. According to the power assembly suspension arrangement structure, the positioning precision can beeffectively improved, the situation that the assembling gap is too large or assembling cannot be conducted is avoided, and the assembling stability is improved.

Owner:CHERY AUTOMOBILE CO LTD

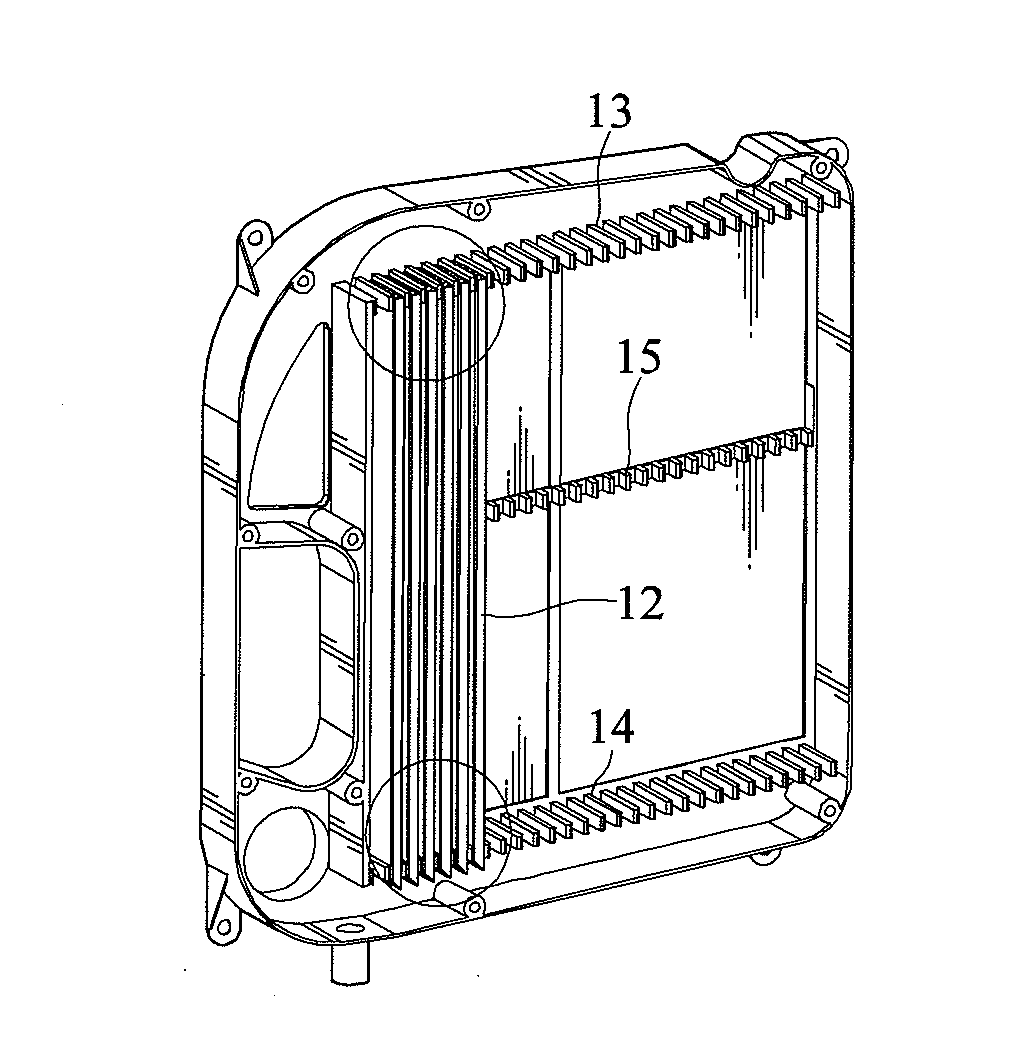

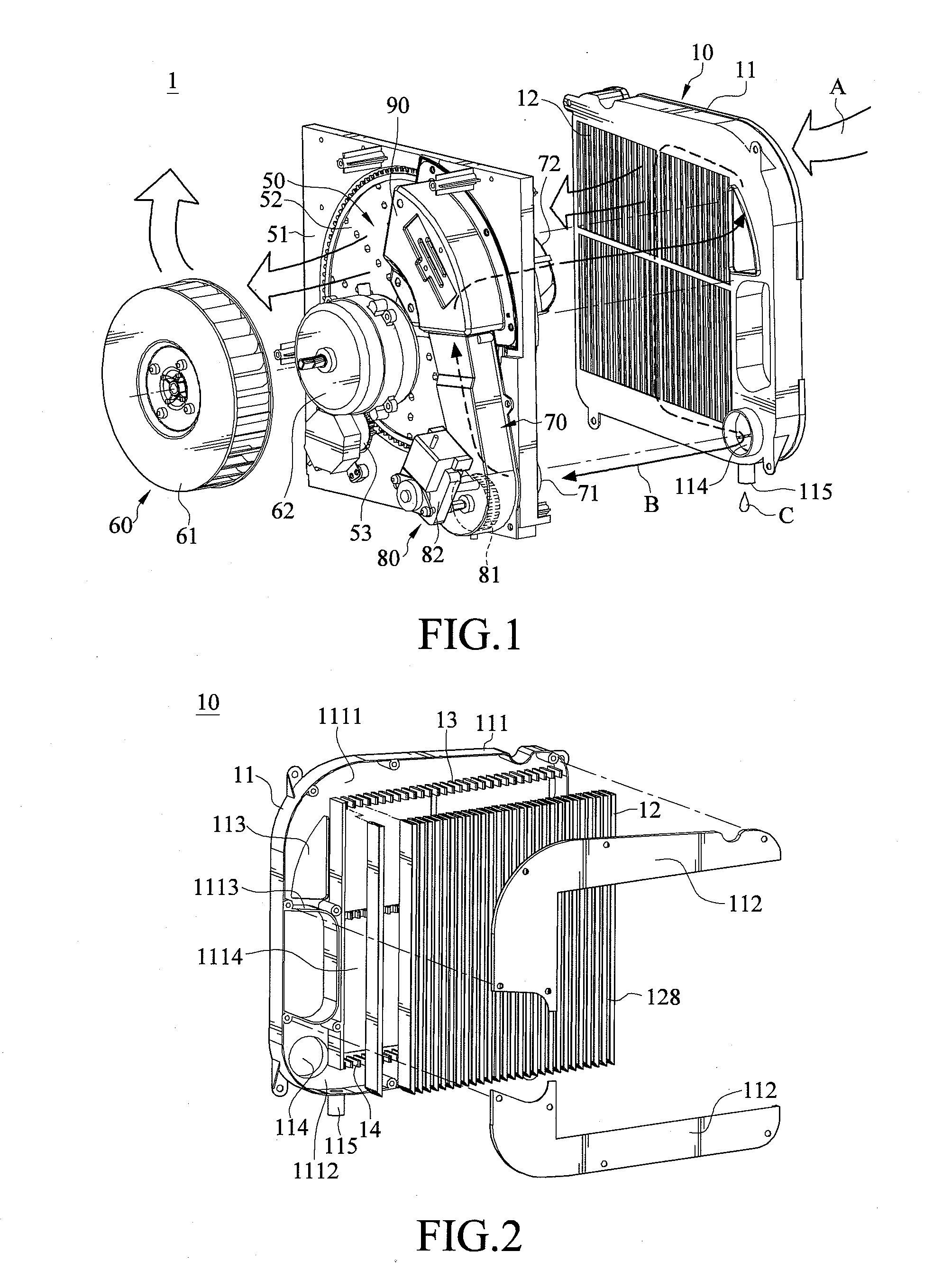

Desiccant wheel dehumidifier and heat exchanger thereof

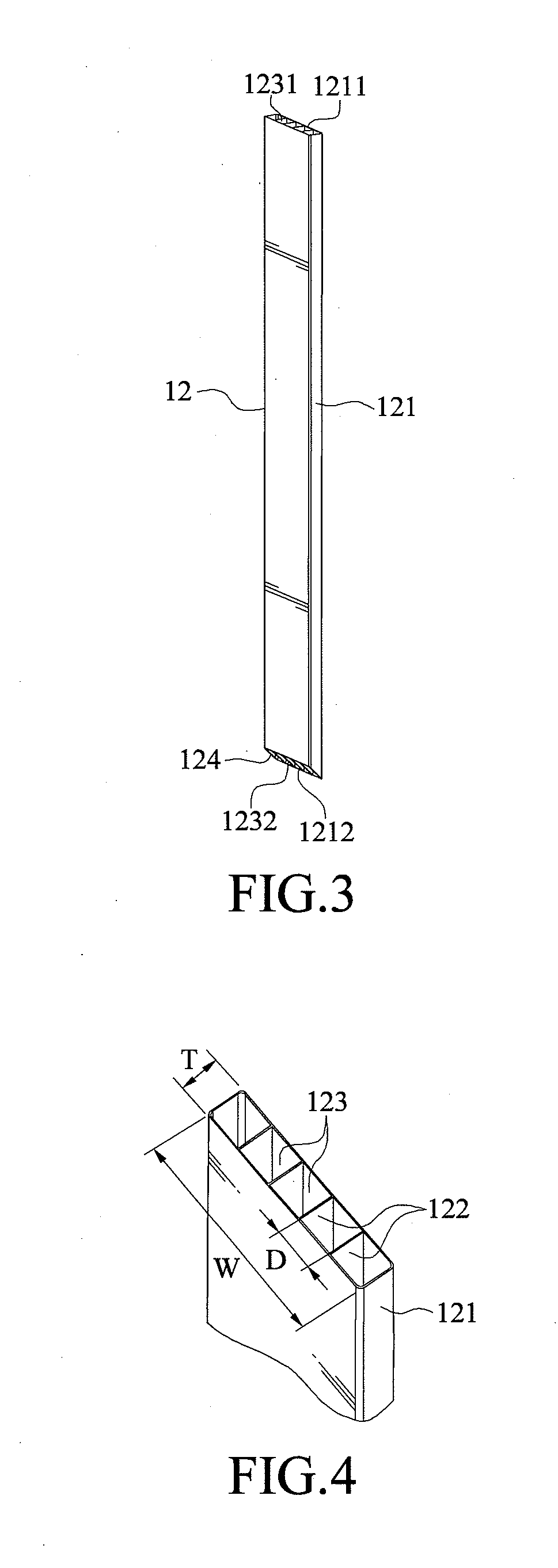

ActiveUS20140196606A1Increase productivityCondensing performance can be improvedIsotope separationStationary conduit assembliesDesiccantEngineering

A heat exchanger of a desiccant wheel dehumidifier, disclosed in the disclosure, includes a frame and multiple heat exchange platy tubes. The frame has an air inlet and an air outlet. The multiple heat exchange platy tubes are fixed on the frame and are substantially arranged side by side with each other. Every two of the multiple heat exchange platy tubes adjacent to each other are separated at an interval from each other to form a first flow channel. Each of the multiple heat exchange platy tubes includes a main body and at least one spacing wall. The main body has multiple second flow channels therein. The at least one spacing wall is located between two of the multiple second flow channels adjacent to each other. The air inlet and the air outlet communicate with the multiple second flow channels.

Owner:NORM PACIFIC AUTOMATION

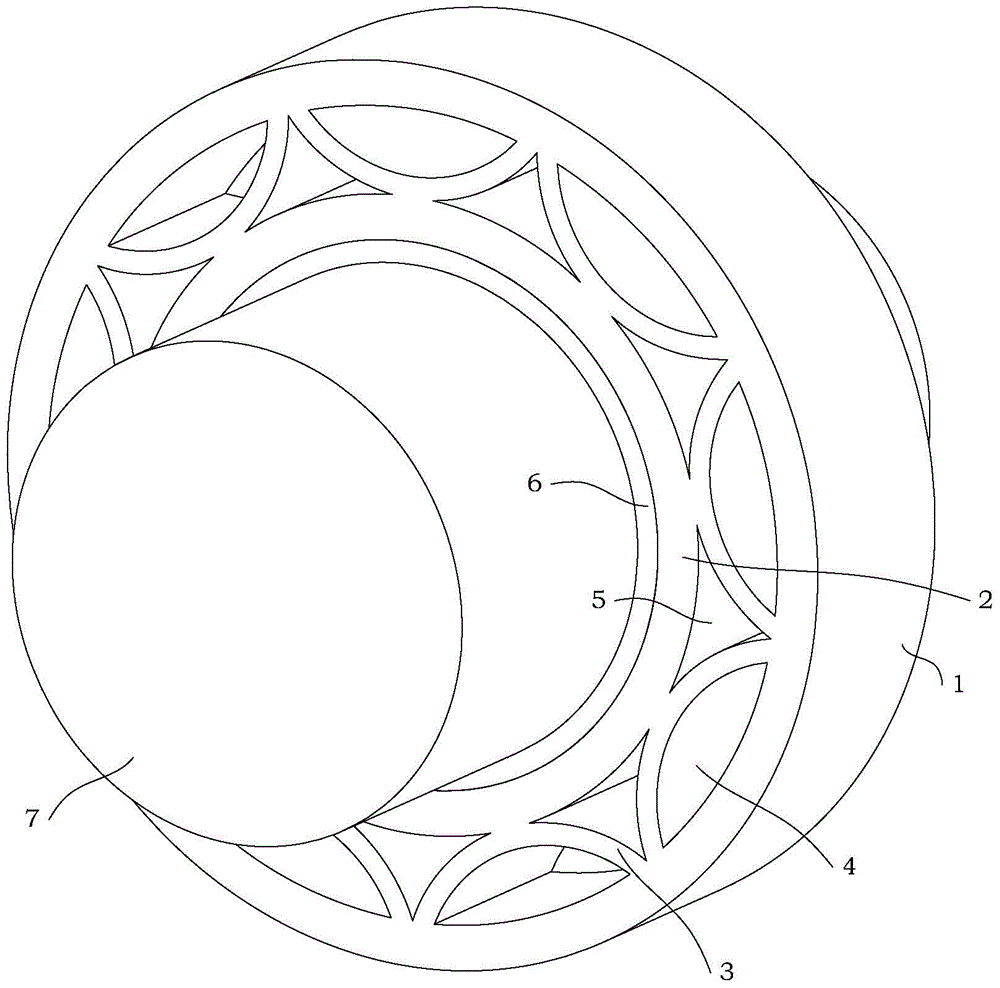

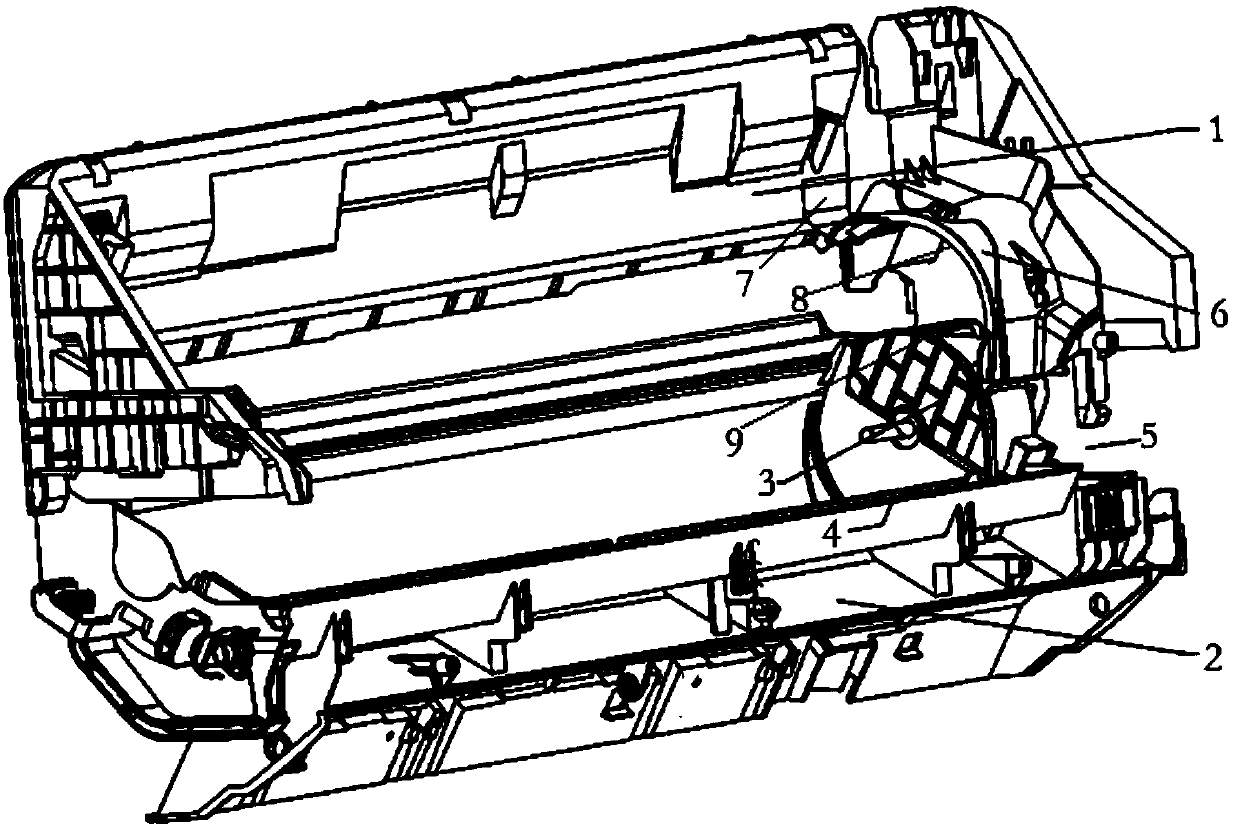

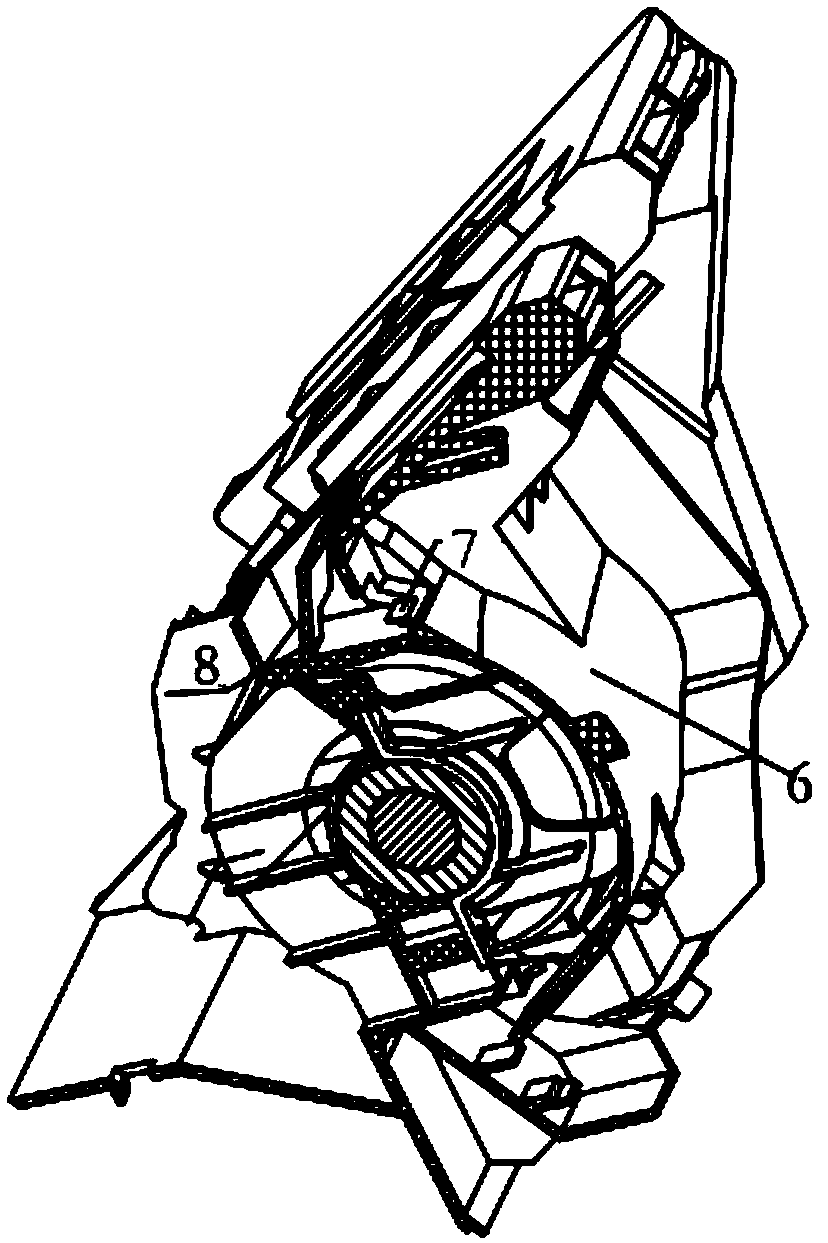

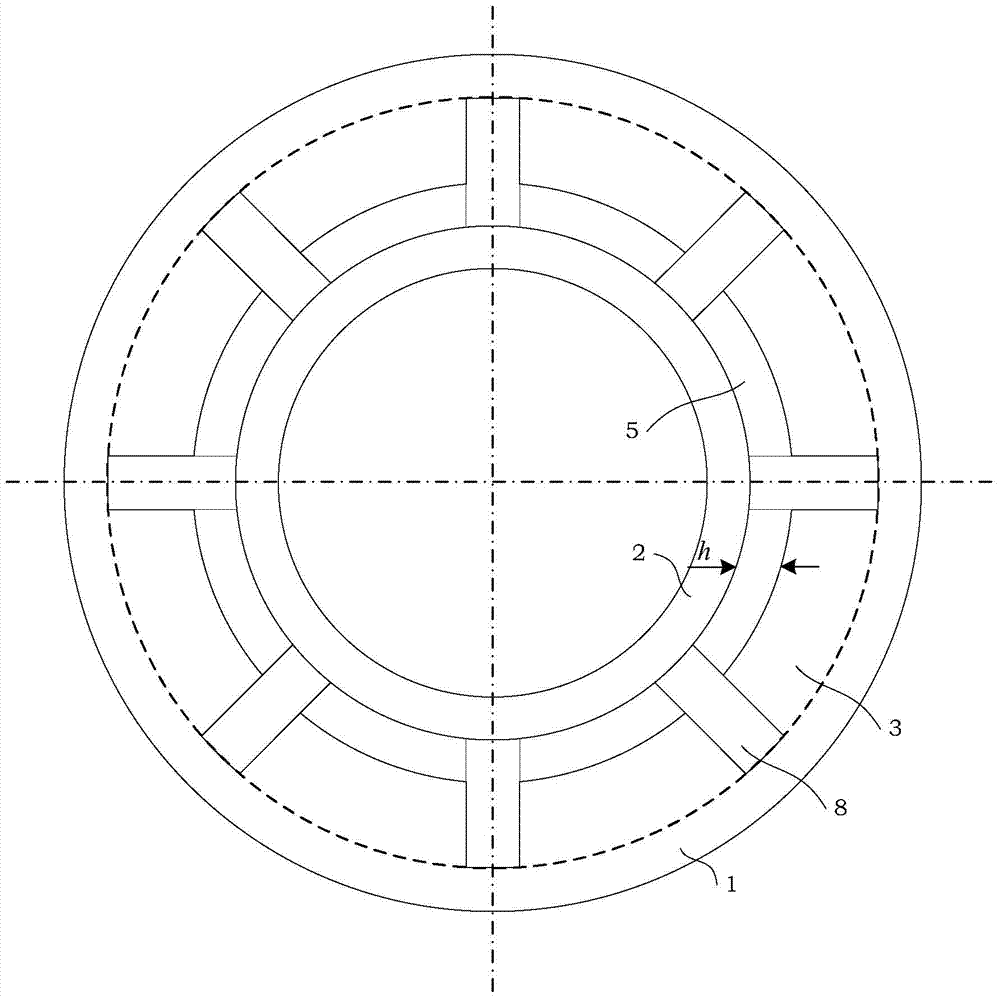

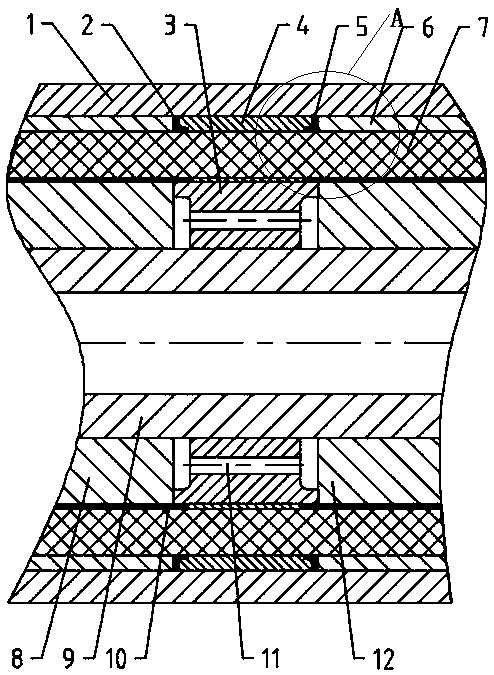

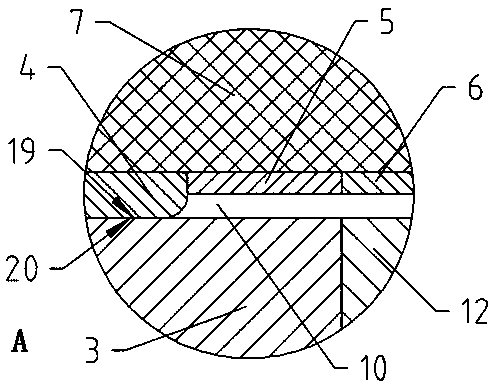

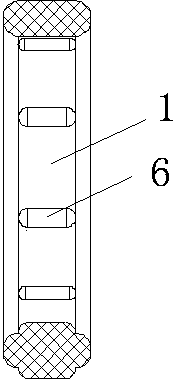

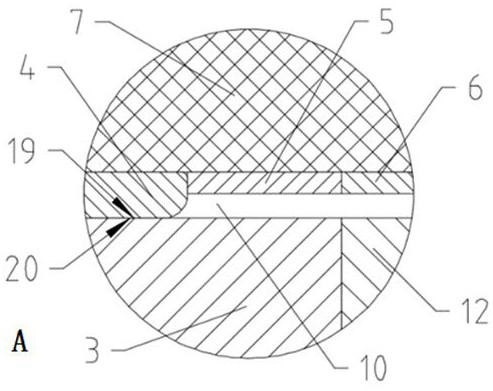

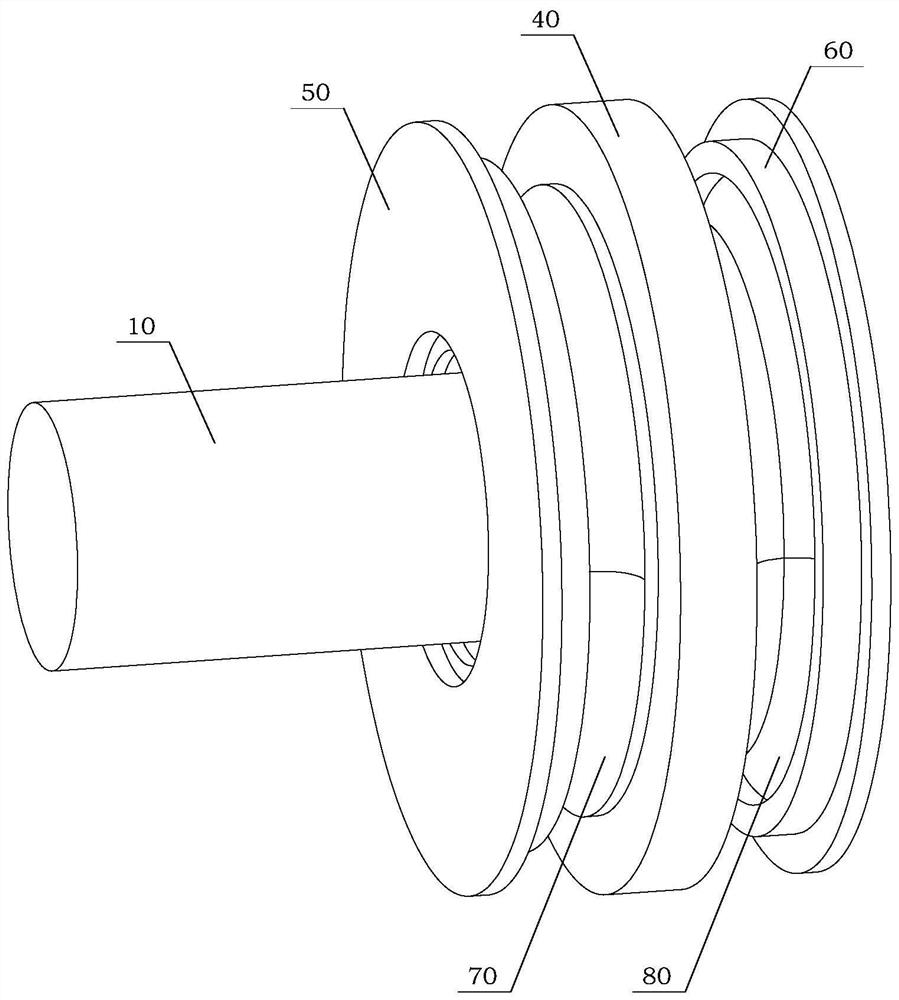

A radial shaft integrated flexible protective bearing for magnetic levitation high-speed rotating equipment

InactiveCN104806631BAvoid damageExtended service lifeSliding contact bearingsInstabilityMechanical engineering

The invention discloses a radial-shaft integrated flexible protective bearing for magnetic levitation high-speed rotating equipment. The protective bearing is integrally processed into a structural member; the protective bearing is designed with a bearing outer ring (1) and a bearing inner ring (2). ), a Z-shaped structure (3) and a hollow groove (8); the Z-shaped structure (3) is placed between the bearing outer ring (1) and the bearing inner ring (2), and the Z-shaped structure (3 ) and the bearing outer ring (1) have an outer annular groove (4), and the Z-shaped structure (3) and the bearing inner ring (2) have an inner annular groove (5); the hollow groove (8) is spaced Place it between the bearing outer ring (1) and the bearing inner ring (2). The protective bearing designed in the present invention can absorb a large amount of kinetic energy of the rotor by using the elastic deformation of the Z-shaped structure itself when the rotor is unstable and produces a huge impact, so as not to damage other parts inside the equipment.

Owner:BEIHANG UNIV

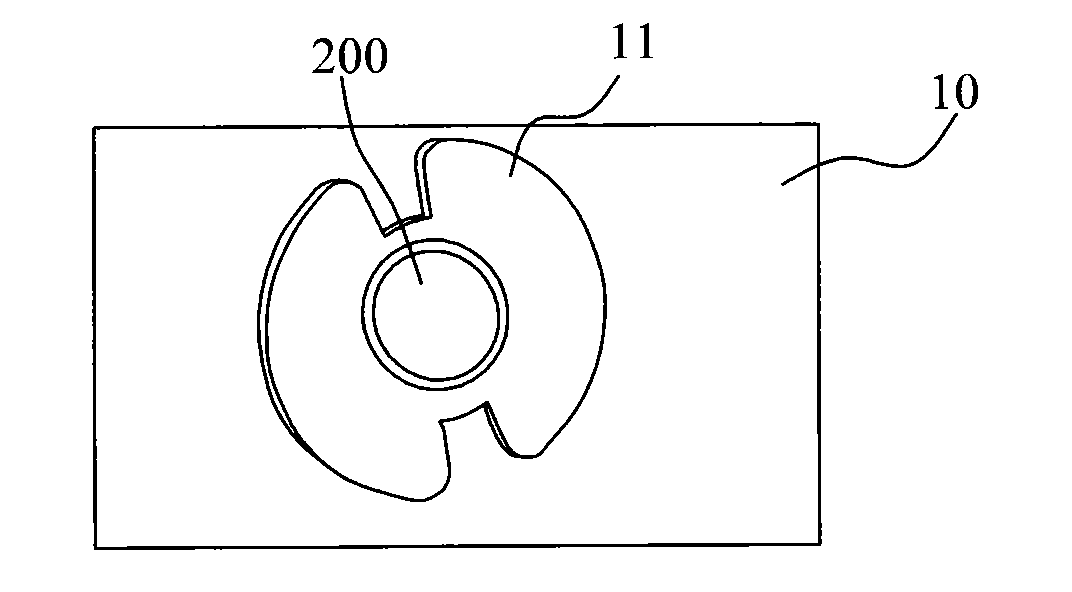

Glass electric kettle and its lampshade fixing structure

ActiveCN107212741BAvoid assembly gapsImprove yieldWater-boiling vesselsEngineeringStructural engineering

The invention discloses a glass electric kettle and a lampshade fixing structure thereof. The lampshade fixing structure includes a base and an elastic support fixed in the base. The elastic support includes an annular body, a plurality of elastic support pieces extending horizontally inward from the upper end of the annular body, and each elastic support piece has a convex block protruding upward. , each bump is pressed against different positions on the lower side of the lampshade, so that the lampshade is attached to the lower bottom surface of the glass pot body. The invention substantially solves the technical problem of "large assembly gaps on the bottom surface of the glass pot body can easily lead to poor appearance", so that there is a small assembly gap between the lampshade and the glass pot body, which can improve the yield of products, and has the advantages of It has the advantages of simple structure, high reliability and easy processing and manufacturing.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

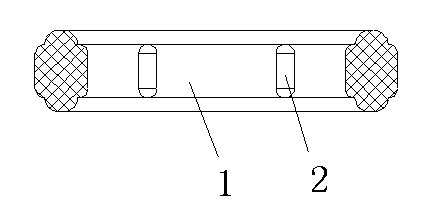

EGR tube seal ring

InactiveCN103850823AReasonable designImprove sealingSealing arrangements for enginesMachines/enginesExhaust gas emissionsEngineering

The invention discloses an EGR tube seal ring comprising a seal ring body which is circular. The cross section of the seal ring body is rectangular; four corners of a rectangle are all chamfered; the inner and outer sidewalls of the seal ring body are evenly provided with a plurality of paired projections; each projection is semi-cylindrical; two ends of every projection are transitionally connected with the sidewall of the seal ring body through semispherical shapes. The EGR tube seal ring is reasonable in design and good in sealing performance, and exhaust gas emission efficiency can be effectively improved so that pollution is reduced.

Owner:JIANGSU DONGFANG AUTOMOTIVE ORNAMENTS GENERAL FACTORY

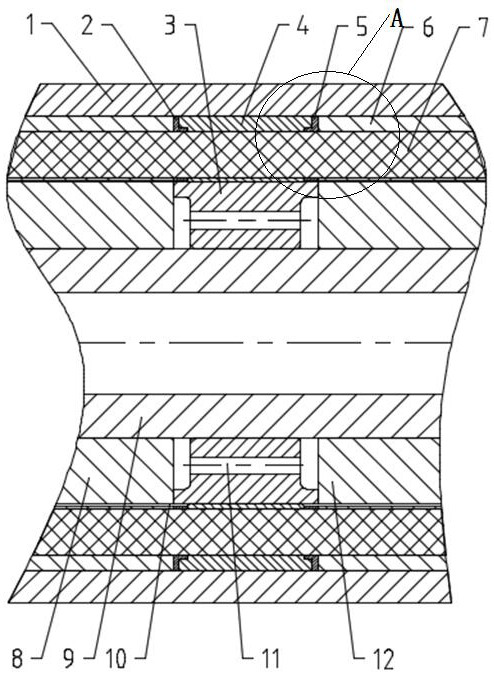

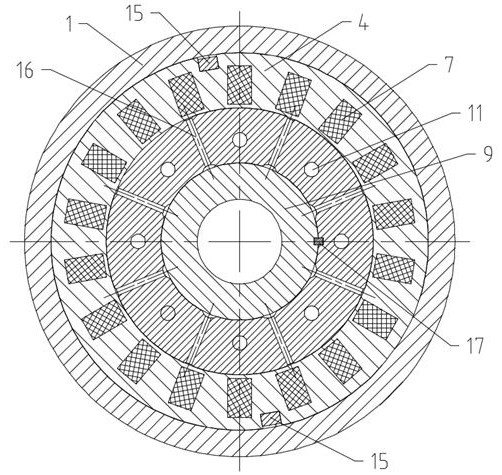

Alignment bearing for underground drilling tool motor

ActiveCN111293816AImprove carrying capacitySave radial spaceBorehole drivesSupports/enclosures/casingsElectric machineClassical mechanics

The invention discloses an alignment bearing for an underground drilling tool motor, and relates to the technical field of underground motors. The alignment bearing comprises a bearing static ring anda bearing movable ring. A plurality of static ring notches allowing stator coils to penetrate through are formed in the alignment bearing static ring, the inner surface of the bearing static ring isof a closed structure, and a static ring friction surface is formed; a bearing moving ring friction surface is formed on the outer surface of the bearing moving ring; and the diameter of the bearing moving ring friction surface and the diameter of the static ring friction surface are the same as the outer diameter of the rotor core. The plurality of static ring notches are formed in the static ring in the axial direction, the stator coils can directly penetrate through the static ring notches, so that the radial space of the motor is utilized to the maximum extent, the diameter of the frictionsurface is increased, the bearing capacity of the bearing is improved, the axial space of the whole motor is further saved, and the length of the motor is reduced.

Owner:DONGFANG ELECTRIC MACHINERY

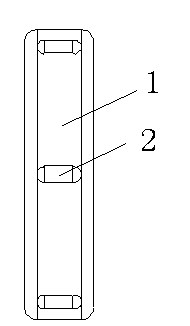

Throttle valve gasket

The invention discloses a throttle valve gasket comprising a gasket body. The gasket body is an enclosed ring, the enclosed ring is formed by connecting two ends of a great semicircle segment and an irregular arc segment through tangent straight flanges, a connecting boss is further arranged on the outer side of the great semicircle segment, multiple pairs of bosses are arranged on the inner and outer side walls of the gasket body, each boss is integrally semi-cylindrical, and two ends of each boss are in transition connection with the side walls of the gasket body through hemispheres. The throttle valve gasket fits with a throttle valve in shape and is good in assembly effect and small in clearance, so that sealing effect is improved.

Owner:JIANGSU DONGFANG AUTOMOTIVE ORNAMENTS GENERAL FACTORY

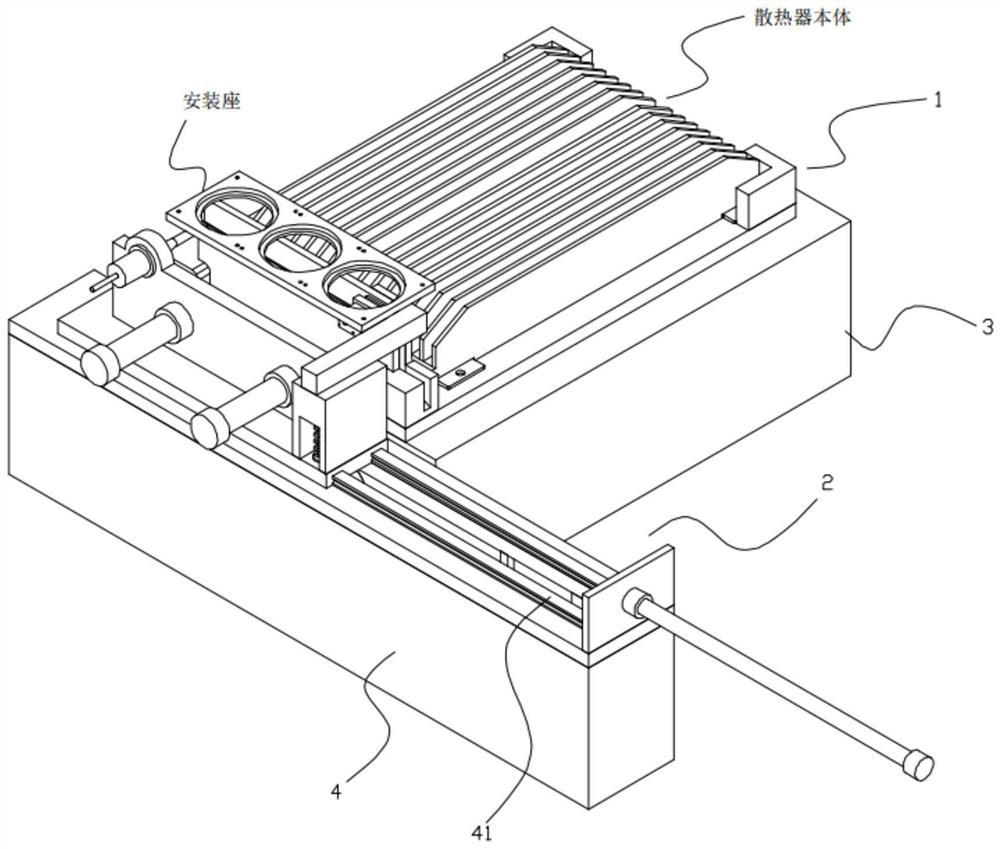

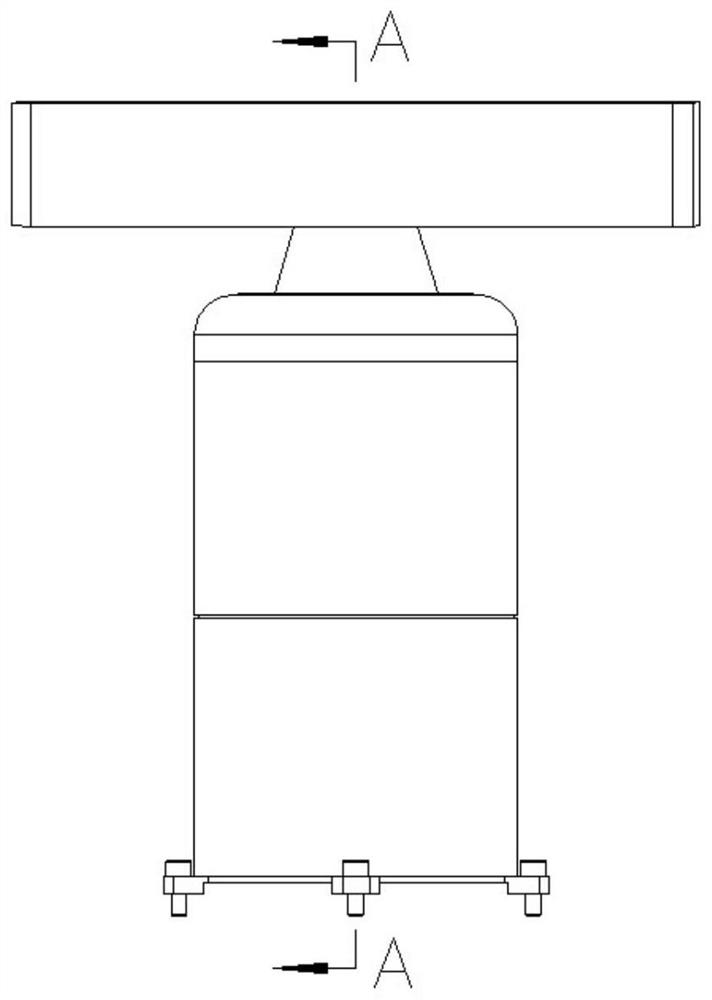

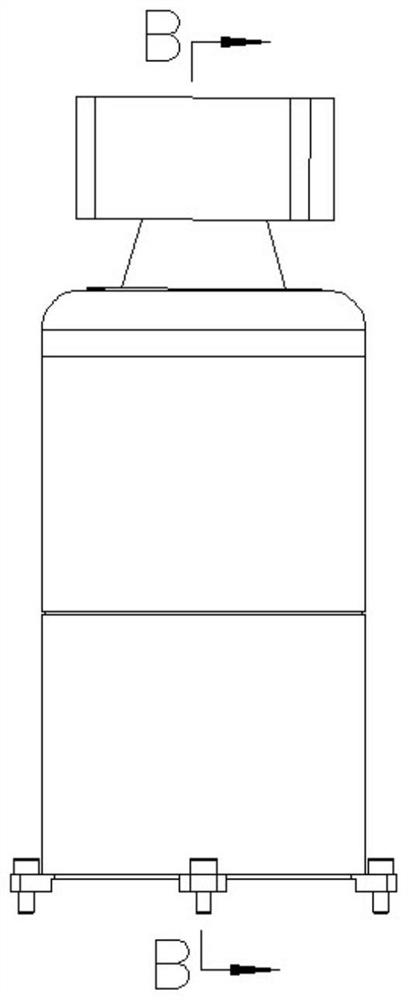

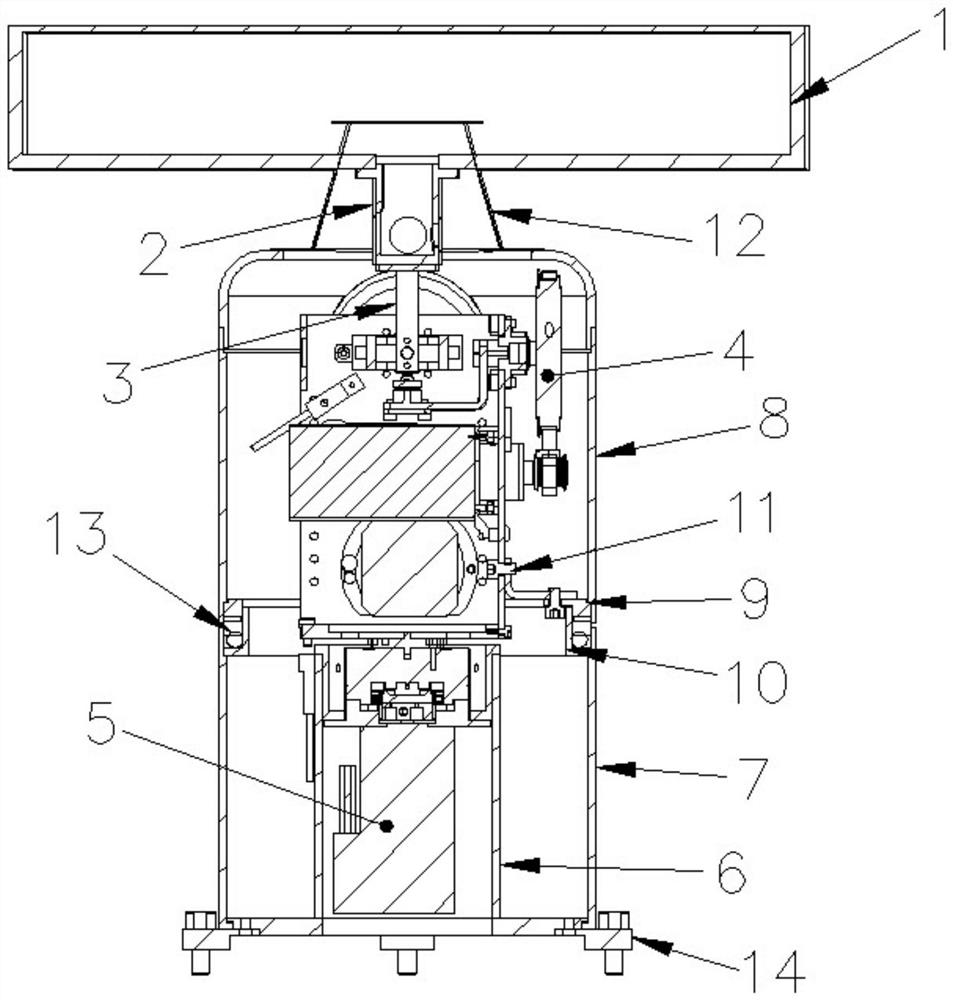

A small assembly equipment for a radiator

ActiveCN112008282BSimplify the assembly processImprove assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkbench

The invention discloses a small assembly equipment for a radiator, which relates to the field of automation equipment and includes a fixing tool and an assembling mechanism. The second is used to assemble the mounting seat in the radiator to the radiator body. The second table is located on one side of the first table. The assembly mechanism includes a sliding seat, a sliding rail, a flexible clamping mechanism, and a pre-positioning mechanism. , welding torch, pushing mechanism and reset mechanism, the present invention realizes the positioning of the radiator body by means of the fixing tool, and at the same time realizes a series of processing such as feeding, pre-positioning and welding of the mounting seat by using the assembly mechanism, which simplifies the assembly process. Improved assembly efficiency.

Owner:重庆上方汽车配件有限责任公司

Wall corner and method for manufacturing the same

The invention relates to the technical field of housing construction, and particularly discloses a wall corner and a method for manufacturing the same. The wall corner is used for being arranged at a corner between two walls, is of an integral structure and comprises a first wallboard and a second wallboard. An included angle between the first wallboard and the second wallboard corresponds to an included angle between the two walls. The method for manufacturing the wall corner includes manufacturing the wall corner by the aid of a jet forming process and a steel frame embedding process by an integral form. The wall corner and the method have the advantages that the wall corner is of the integral structure, so that the problem of assembly gaps at corners of houses in the prior art can be solved, the wall corner is good in integrity, reliable in seismic performance, good in firmness and durability, simple in structure and convenient to construct, and is environmental friendly, and energy can be saved; a house with the wall corner is good in integrity, low in construction cost, short in construction period and good in anesthetics.

Owner:北京市飞翔建筑艺术雕刻有限责任公司

Uprighting bearings for downhole drilling motors

ActiveCN111293816BImprove carrying capacitySave radial spaceBorehole drivesSupports/enclosures/casingsElectric machineClassical mechanics

The invention discloses a centralizing bearing for a downhole drilling tool motor, and relates to the technical field of downhole motors. The present invention includes a bearing static ring and a bearing moving ring. The static ring of the righting bearing is provided with a plurality of static ring slots for the stator coil to pass through. The inner surface of the bearing static ring is a closed structure to form a friction surface of the static ring; the bearing The outer surface of the moving ring forms the friction surface of the moving ring of the bearing, and the diameters of the friction surface of the moving ring of the bearing and the friction surface of the static ring are the same as the outer diameter of the rotor iron core. In this application, several slots of the static ring are set in the axial direction of the static ring, and the stator coil can pass directly through the slots of the static ring. The radial space of the motor is used to the maximum, and the diameter of the friction surface is increased, so that the bearing capacity of the bearing is increased, thereby saving the entire The axial space of the motor reduces the length of the motor.

Owner:DONGFANG ELECTRIC MACHINERY

Intelligent robot camera holder

PendingCN112013214AHigh repeat positioning accuracyAvoid assembly gapsEngine sealsStands/trestlesControl engineering3d camera

The invention discloses an intelligent robot camera holder in the technical field of autonomous mobile robot application. The intelligent robot camera holder comprises a 3D camera, a camera fixing flange, a center rotating shaft, a pitching transverse rolling mechanism, a yawing mechanism, a holder support, a holder fixing shell, a holder upper shell, a bottom fixing base and a controller. The yawing mechanism is arranged in the holder support and connected with holder support ribs, the pitching transverse rolling mechanism is arranged in the holder upper shell, and the yawing mechanism and the pitching transverse rolling mechanism are connected through an upper connecting plate. The 3D camera is arranged at the upper part of the holder upper shell and is connected with the top of the center rotating shaft through the camera fixing flange; and the middle lower part of the center rotating shaft is arranged in the holder upper shell and is connected with the pitching transverse rolling mechanism. According to the intelligent robot camera holder, the camera can perform pitching, transverse rolling and yawing motions at the same time, the axes are decoupled from one another through robot dynamics calculation, the motion of the holder is accurately controlled, and therefore a larger visual field and a clearer image are obtained.

Owner:佳奕筱安(上海)机器人科技有限公司

Mandrel rod damping structure

InactiveCN101552859BControl Position AccuracyAvoid assembly gapsPictoral communicationRubber materialElastic component

The invention provides a mandrel rod damping structure for reducing the shake of a mandrel rod. The mandrel rod is sleeved with a scanner and a scanning module, and the scanning module can reciprocatealong the mandrel rod which is arranged in a shaft hole. The mandrel rod damping structure is characterized in that a part of the shaft hole, which bears the mandrel rod, is in a V-shaped structure and provided with a fastening component for fixing the mandrel rod, and the mandrel rod is supported by the V-shaped structure which is in point contact with the mandrel rod so as to better control theposition precision of the mandrel rod; the mandrel rod is contacted with an elastic component made of rubber materials and pressed by a rigid fastening component so as to keep in a gapless state allthe time, thus the problem of the assembly gap of the mandrel rod can be effectively solved, and the elastic component made of the rubber materials can damp the shake. The mandrel rod damping structure can solve a plurality of image problems due to great shakes along a circumferential direction of the mandrel rod and no scanning module deviation in the scanning process.

Owner:LITE ON OPTO TECH (CHANGZHOU) CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com