A flexible reed axial protection bearing for magnetic bearings

A technology for protecting bearings and magnetic bearings, applied to bearings, shafts and bearings, shafts, etc., can solve the problems of mechanical damage to bearing cages, protection of bearings stuck and stopped, and bearing expansion, so as to improve precision, improve service life, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

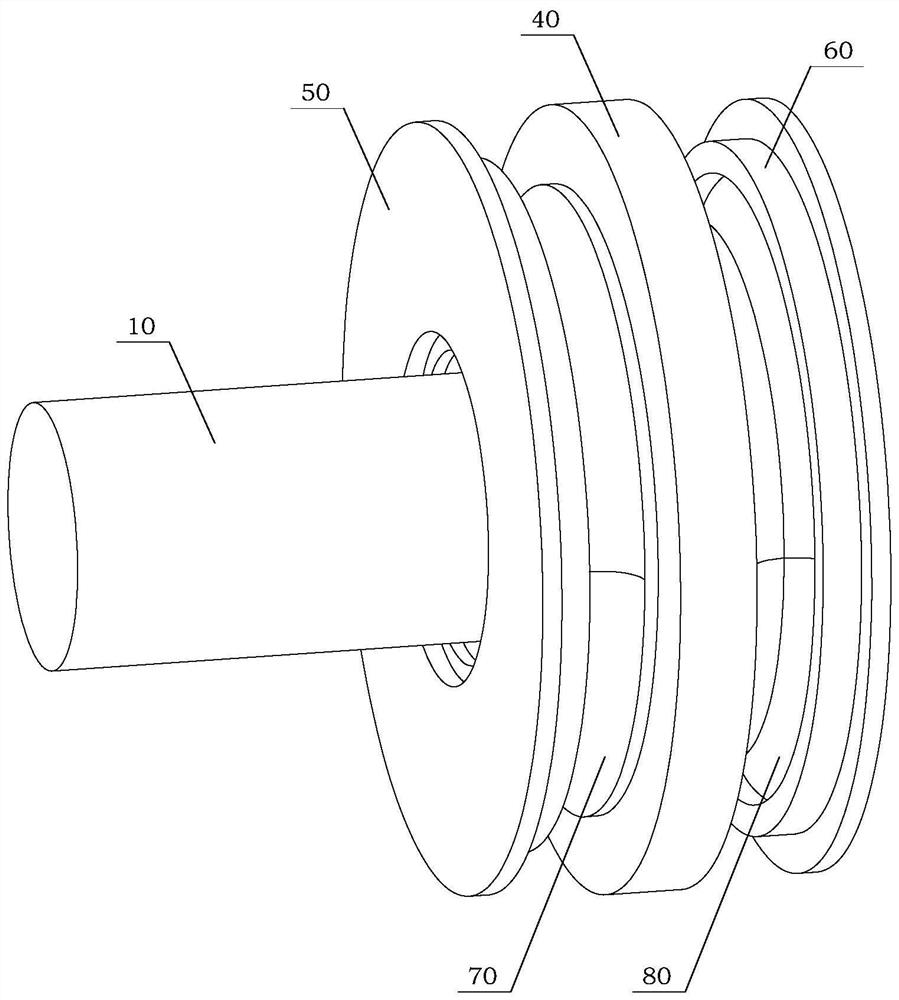

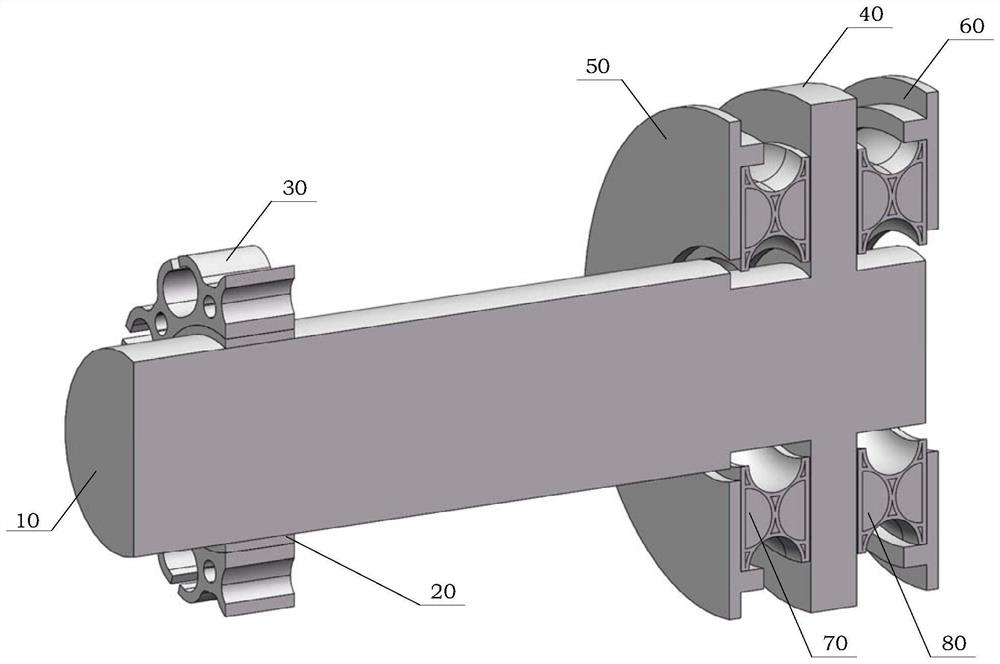

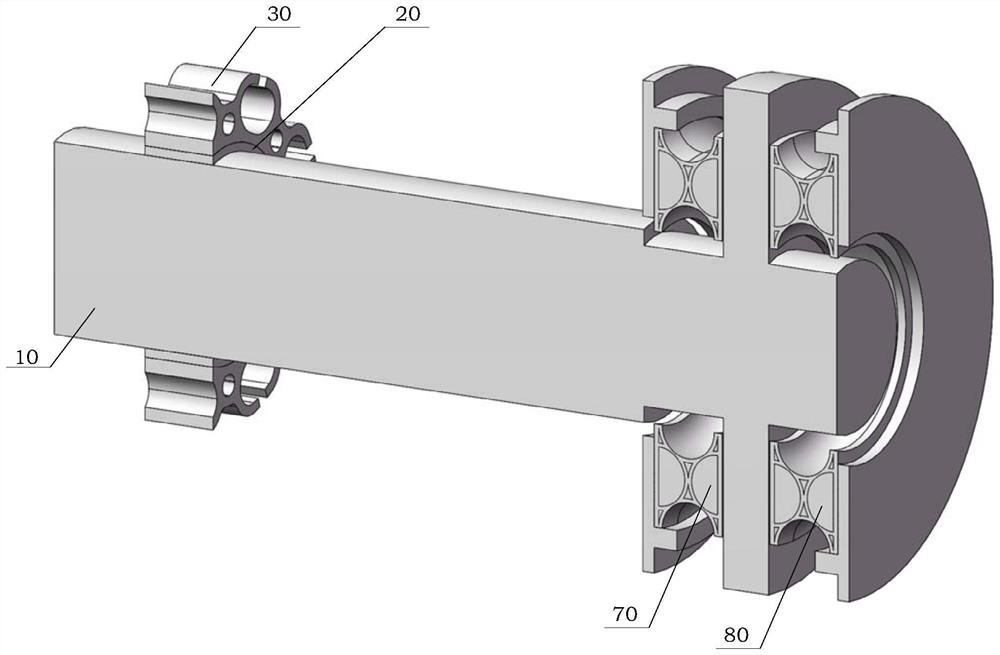

[0058] In order to illustrate the force analysis of the segmented open flexible segment radial protection bearing designed by the present invention, a high-speed magnetic levitation permanent magnet motor (March 2017, the 3rd issue of volume 25, "Optical Precision Engineering", high-speed magnetic levitation permanent magnet motor Magneto Multiphysics Analysis and Rotor Loss Optimization.) The way to protect the bearing installation. In the overall structure of the motor, it is introduced that the radial protection bearing is installed on the left side of the rotor, and the axial protection bearing is on the right side. In order to reflect the application of the radial protection bearing 30 of the present invention, please refer to Figure 1A with Figure 1B shown. A radial protective bearing 30 is installed on the left end of the rotor 10, and an A axial protective bearing 70 and a B axial protective bearing 80 are installed on the right end of the rotor 10, and the A axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com