Joint structure of second-lining end mold having sealing devices

A technology of joint structure and sealing device, applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problems of difficult cleaning, loose concrete at circumferential construction joints, and leakage of slurry, etc., to facilitate maintenance and replacement, and eliminate assembly. Error, avoid the effect of assembly gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

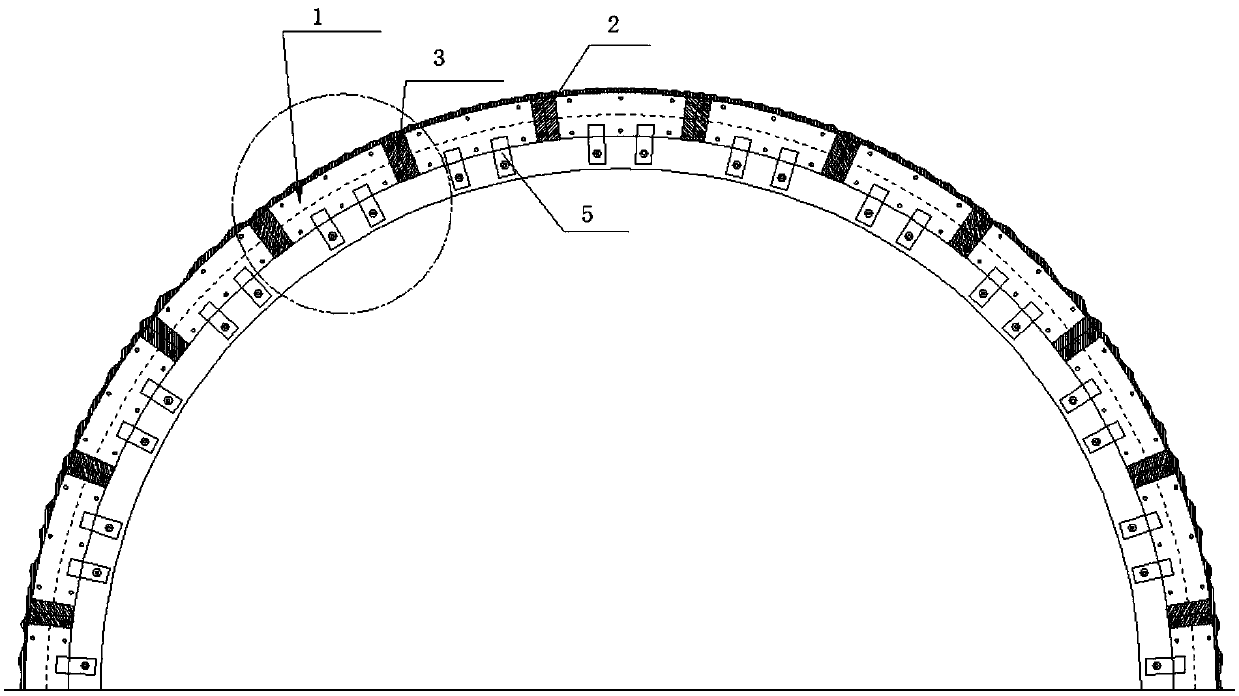

[0035] figure 1 It is a structural schematic diagram of a tunnel two-lined end die joint structure with a sealing device according to the first embodiment of the present invention. figure 2 for figure 1 A partial enlargement of the . image 3 It is a schematic structural diagram of the joint of the liner end die in the second embodiment of the present invention. Such as figure 1 , figure 2 and image 3 As shown, the joint structure of the second lining end mold of the tunnel includes an arc-shaped end mold 1, a first end mold slot joint 3 and an L-shaped fixing device. One side of the arc-shaped end mold 1 is fixed on the second lining platform by the L-shaped fixing device. On the car, wherein, the arc-shaped end molds 1 are several pieces, and the adjacent arc-shaped end molds 1 are assembled to form a combined and assembled two-liner structure; there are gaps in the assembly between the adjacent arc-shaped end molds, and the adjacent arc-shaped end molds 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com