Radial-bearing flexible protecting bearing for magnetic suspension high-speed rotating equipment

A technology for flexible protection of bearings and high-speed rotation. It is applied in the direction of rotating bearings, flexible bearings, and bearings. It can solve the problems of mechanical damage to bearing cages, protection of bearings stuck and stalled, and bearing expansion to reduce damage to parts. Probability, compact and reasonable structure of the whole machine, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

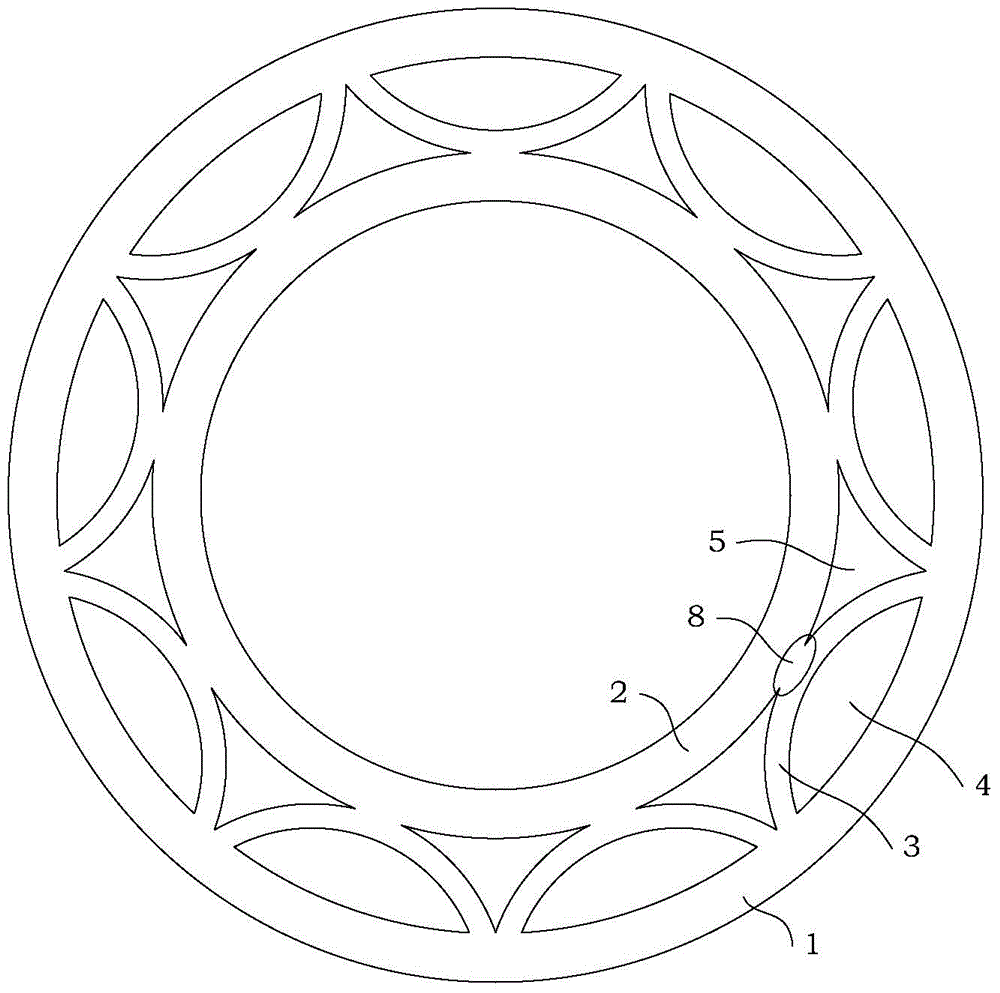

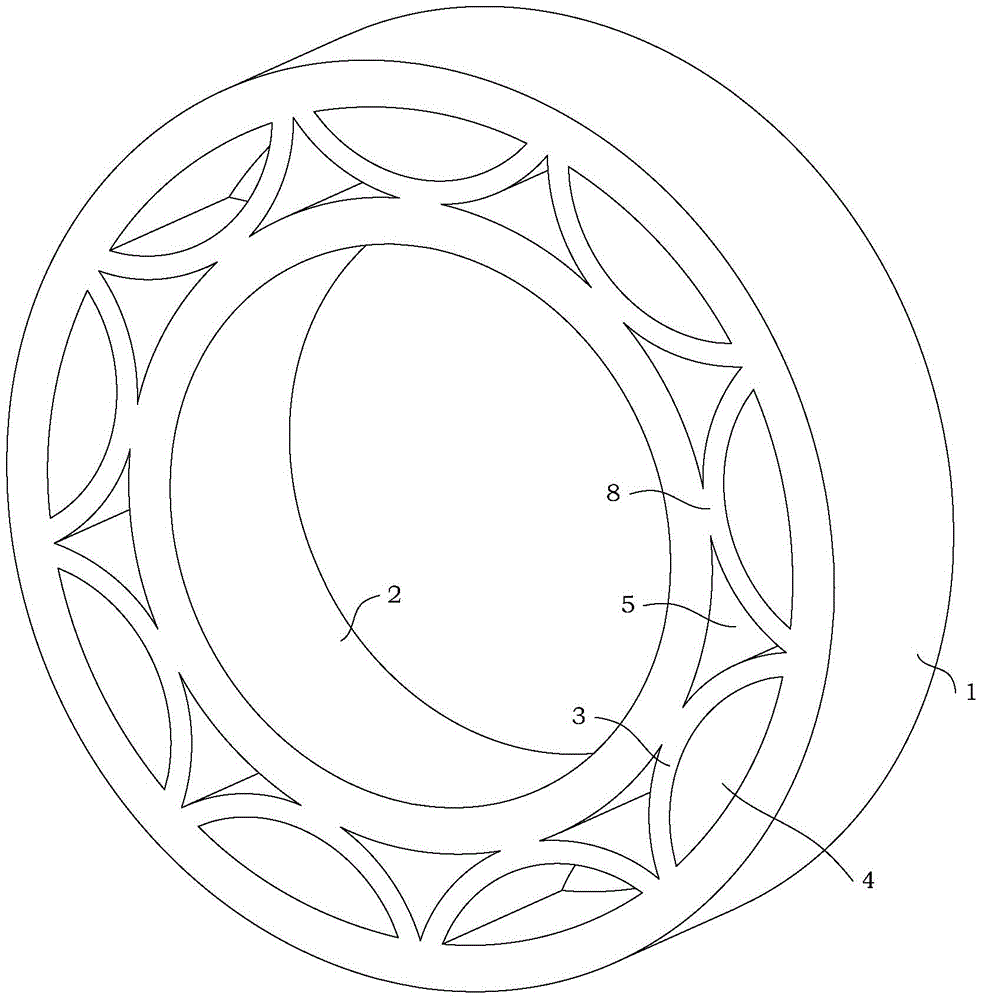

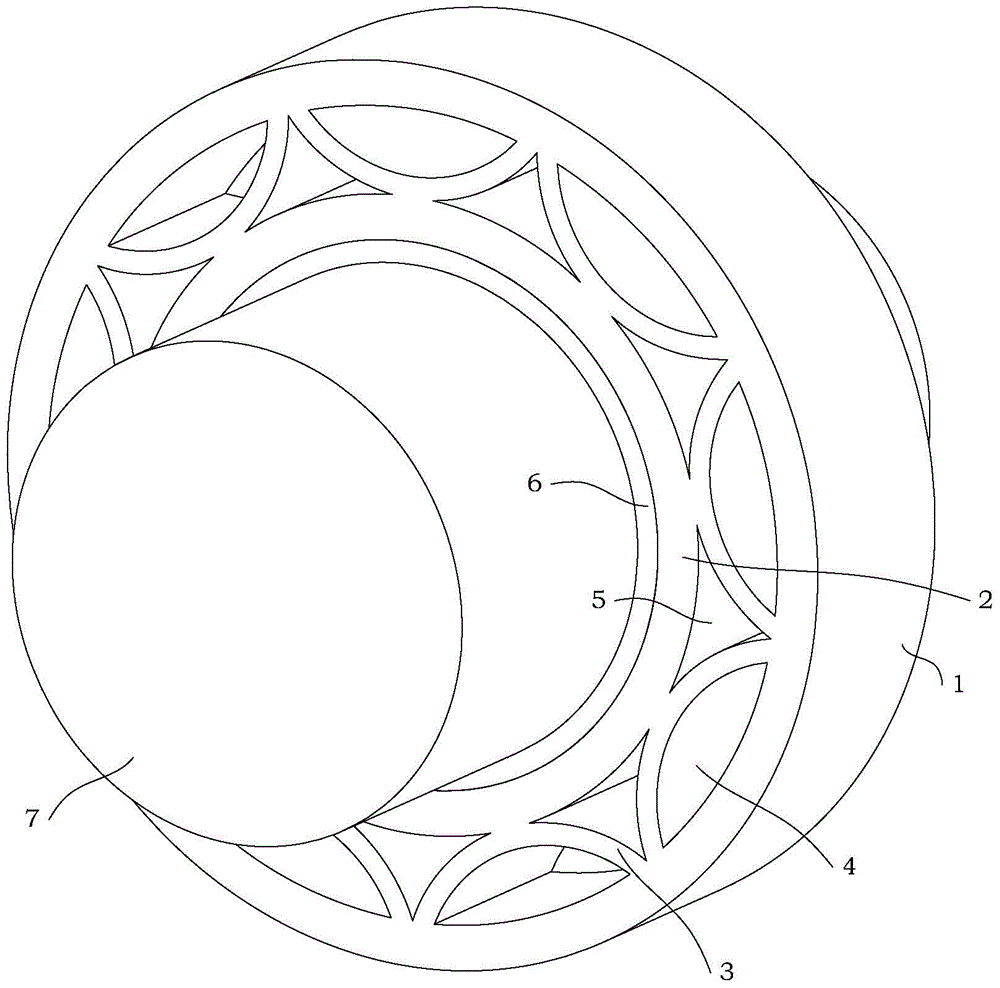

[0024] see figure 1 , figure 2 As shown, a radially loaded flexible protective bearing for magnetic levitation high-speed rotating equipment designed by the present invention, the protective bearing is integrally processed into a structural part; the protective bearing is designed with a bearing outer ring 1 and a bearing inner ring 2 and the flexible reed 3; the flexible reed 3 is placed between the bearing outer ring 1 and the bearing inner ring 2, and there is an outer gap 4 between the flexible reed 3 and the bearing outer ring 1, the flexible reed 3 and the bearing There is an inner gap 5 between the inner rings 2 .

[0025] The protective bearing designed in the present invention has a flexible reed 3 structure between the bearing inner ring and the outer ring, and the junction of the flexible reed 3 and the bearing inner ring 2 is a flexible deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com