Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Avoid aspiration of fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

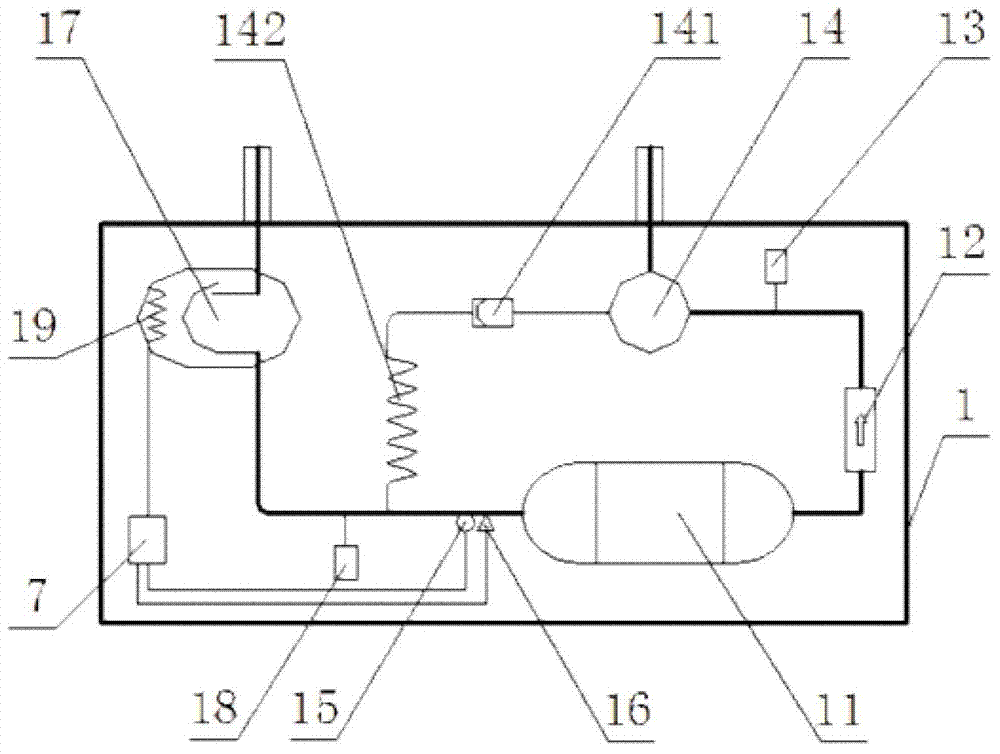

Frost-less air-source heat pump hot water unit and proportional-integral-differential control method for same

InactiveCN103245151AWell mixedImprove performanceFluid heatersCorrosion preventionProportional integral differentialEngineering

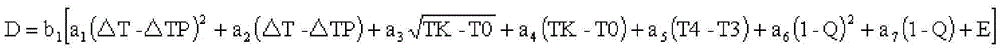

The invention discloses a frost-less air-source heat pump hot water unit and a proportional-integral-differential control method for the same. The proportional-integral-differential control method includes performing computation according to received air temperature and humidity parameters, received air pressure parameters and received surface temperature parameters of an evaporator when outdoor temperature parameters which are transmitted by a temperature and humidity sensor and are received by a computation controller are lower than 0 DEG C, controlling the opening of an electronic expansion valve according to a computation result and regulating the surface temperature of the evaporator by means of increasing or reducing the opening of the electronic expansion valve so that the surface temperature of the evaporator is constantly higher than a frost formation point; and enabling a silicon-controlled power regulator to judge a suction superheat degree of a compressor according to received suction temperature and suction pressure of the compressor, increasing or reducing the power of an electric heater and maintaining that the suction superheat degree of the compressor only varies within a set value range. The frost-less air-source heat pump hot water unit and the proportional-integral-differential control method have the advantage that adjustment for the opening of the electronic expansion valve is matched with adjustment for the power of the electronic heater, so that the purpose of maintaining safe and efficient running of a system is achieved.

Owner:NANJING NORMAL UNIVERSITY +1

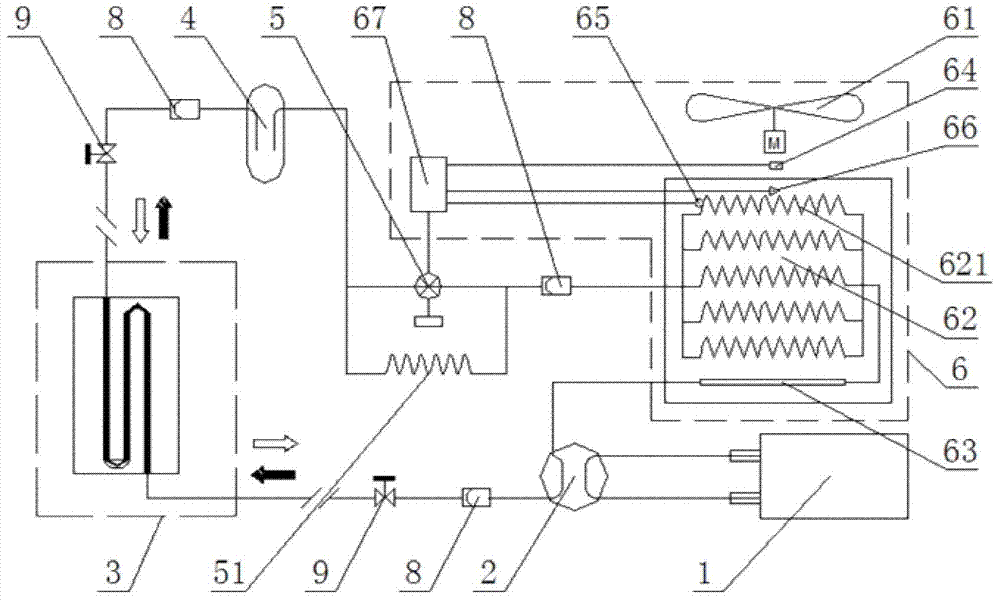

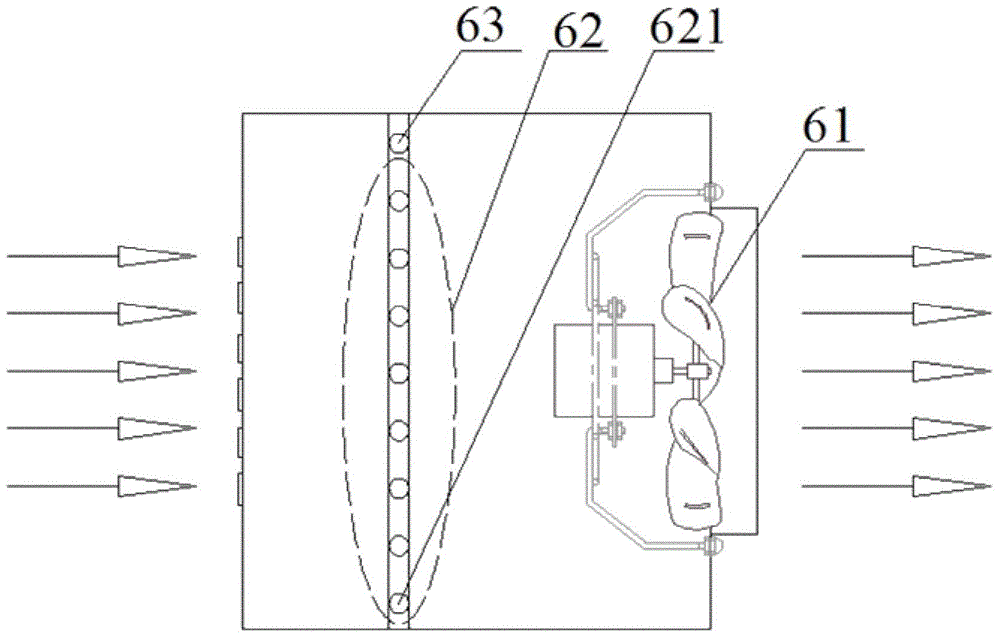

Frostless air handling unit and proportion-integration-differential control method thereof

InactiveCN103216981AWell mixedImprove performanceCorrosion preventionRefrigeration safety arrangementElectricityEngineering

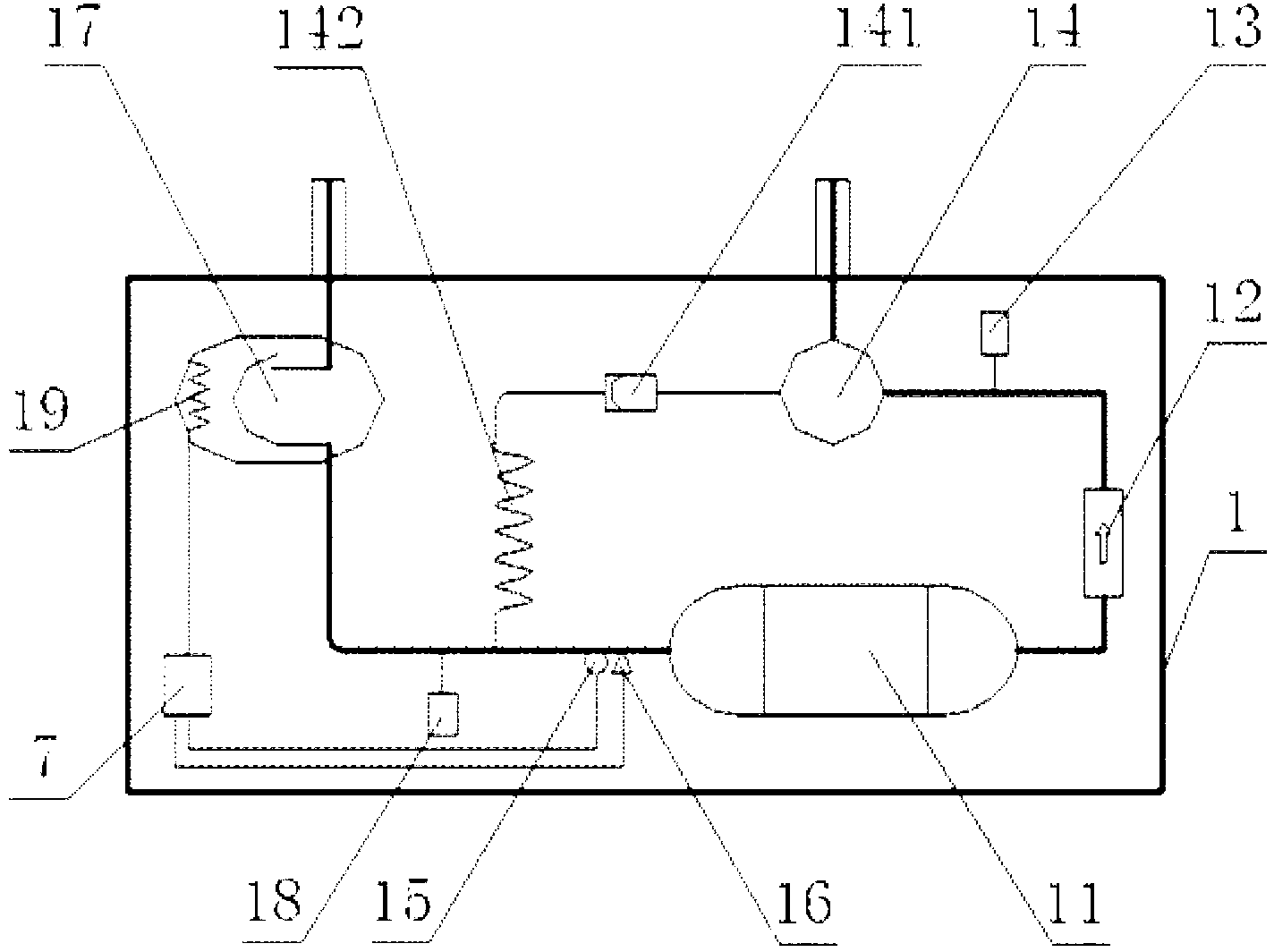

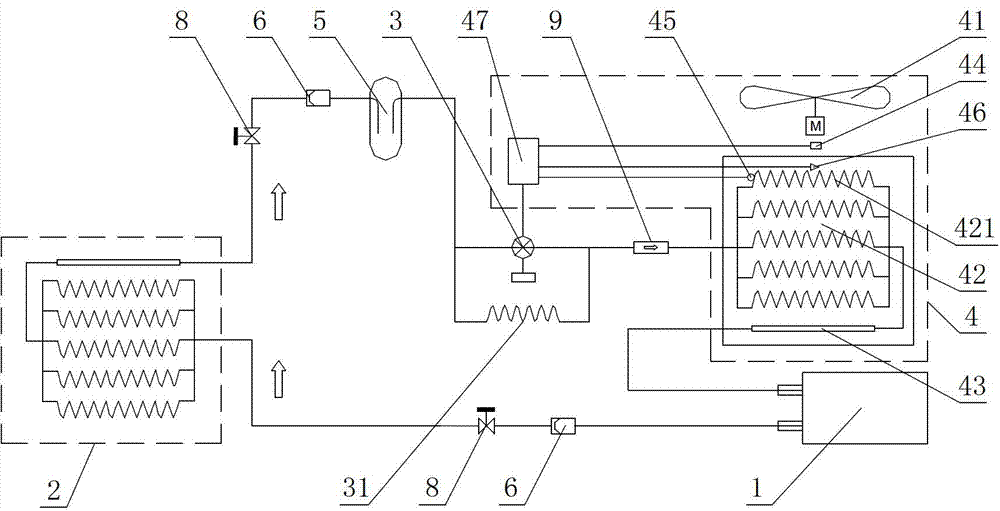

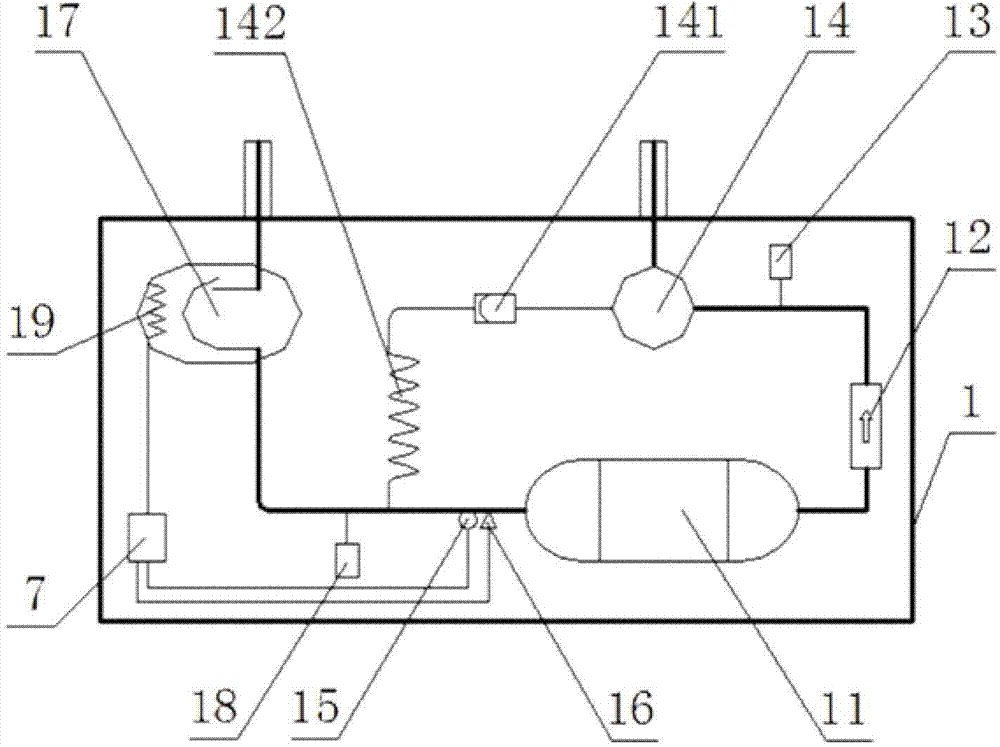

The invention discloses a frostless air handling unit and a proportion-integration-differential control method of the frostless air handling unit. The frostless air handling unit comprises a circulating working return circuit and a controllable silicon power adjuster, wherein the circulating working return circuit is composed of a compressor assembly, a condenser, an electronic expansion valve and an evaporator assembly, the compressor assembly, the condenser, the electronic expansion valve and the evaporator assembly are sequentially connected along the refrigerating fluid flowing direction. When a calculation controller receives an outdoor temperature parameter transmitted by a temperature-humidity sensor and the temperature parameter is lower than 0 DEG C, the calculation controller carries out calculation according to received air temperature and humidity parameters, an air pressure parameter and an evaporator surface temperature parameter, controls the opening degree of the electronic expansion valve according to the calculation results, and adjusts evaporator surface temperature through increase or reduction of the opening degree of the electronic expansion valve. Meanwhile, the controllable silicon power adjuster judges an air suction superheat degree of a compressor through received compressor air suction temperature and air suction pressure, adjusts increase or reduction of electric heater power, and maintains the air suction superheat degree of the compressor to be kept in a preset value range. According to the frostless air handling unit and the proportion-integration- differential control method of the frostless air handling unit, the aim of maintaining safe and high-efficiency operation of the system is achieved.

Owner:宁波沃弗圣龙环境技术有限公司 +1

Control method of air-conditioning system and air-conditioning system

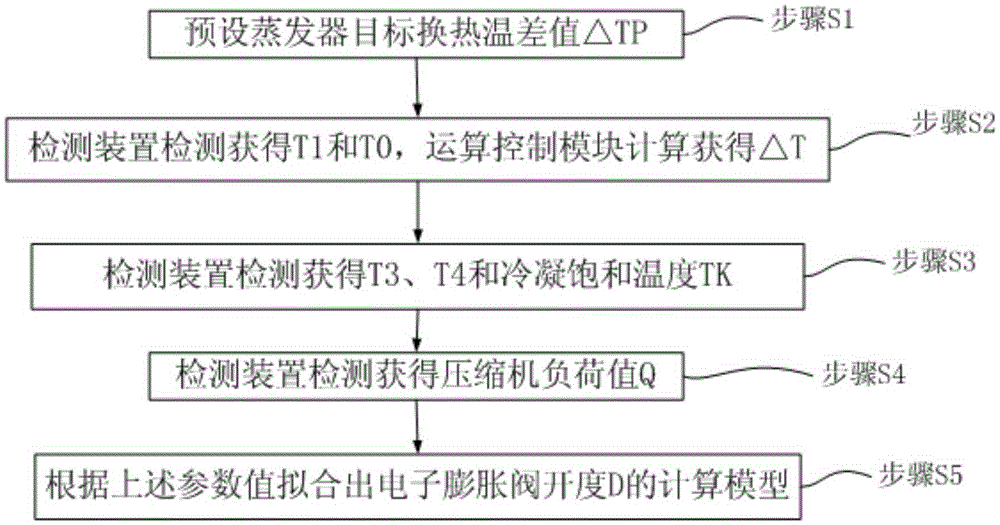

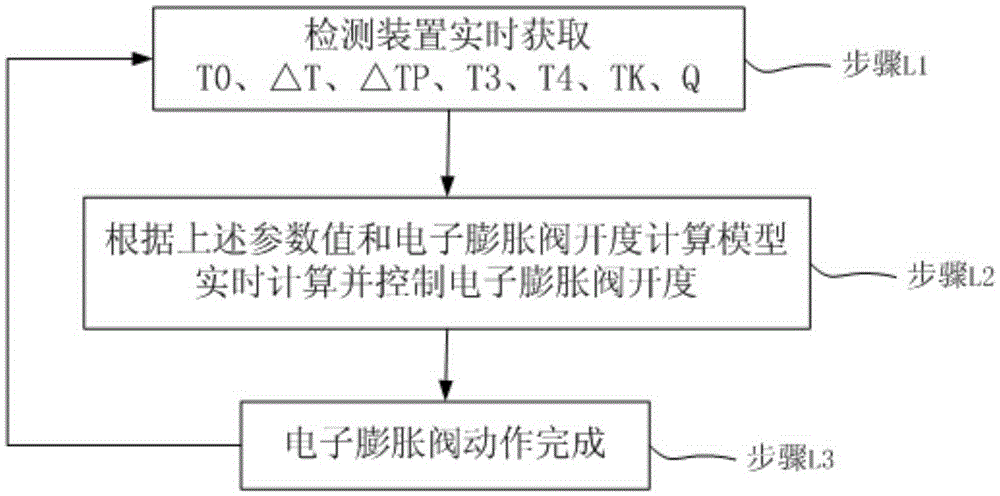

ActiveCN105423498AHigh control precisionBalance loadMechanical apparatusSpace heating and ventilation safety systemsCondenser (heat transfer)Control valves

The invention discloses a control method of an air-conditioning system and the air-conditioning system, belonging to the field of a temperature adjusting device and a control method thereof. The air-conditioning system is designed for solving the problem that an electronic expansion valve of a conventional air-conditioning system is low in control accuracy. The control method of the air-conditioning system comprises the steps of: detecting temperature parameter values of an evaporator and a condenser, a loading value of a compressor and a preset target heat transfer temperature difference value of the evaporator by using a detection device to obtain a calculation model of the opening of the electronic expansion valve; and computing and controlling the opening of the electronic expansion valve in real time by using a computing control module according to the calculation model of the opening of the electronic expansion valve. The air-conditioning system comprises the detection device and the computing control module. The control method of the air-conditioning system can improve the control accuracy of the electronic control valve and ensure the balance between the liquid supplying volume of the electronic control valve and the actual load. The air-conditioning system is reliable in operation, low in operation cost and good in user experience.

Owner:GREE ELECTRIC APPLIANCES INC

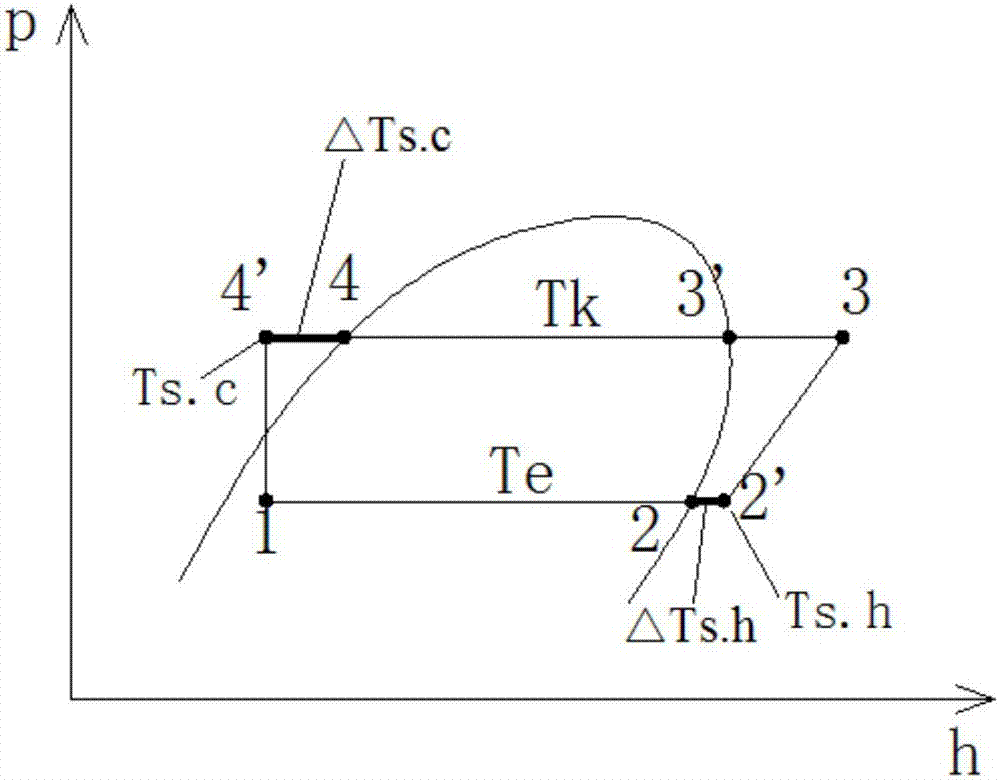

Electronic expansion valve control method and refrigerant circulation system

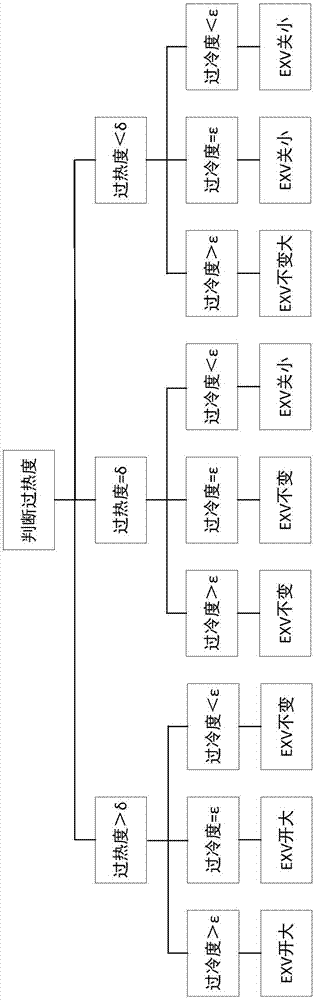

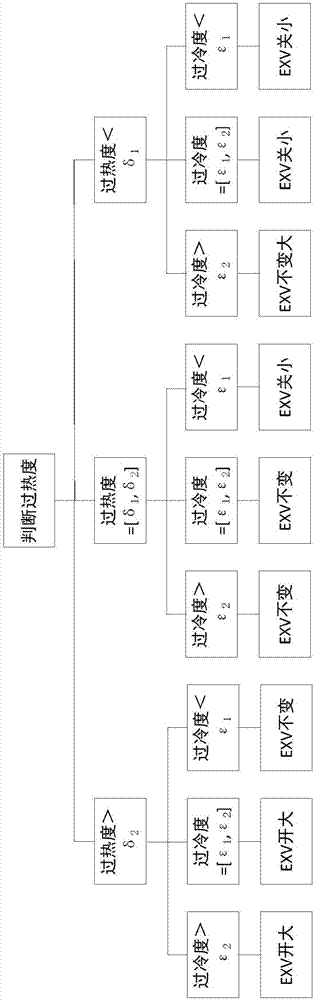

ActiveCN107990609AAvoid aspiration of fluidImprove heat transfer effectMechanical apparatusEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides an electronic expansion valve control method and a refrigerant circulation system. The control method comprises the steps of acquiring a current actual degree of superheat delta' and a current actual degree of supercooling epsilon' of the refrigerant circulation system; obtaining a first comparing result by comparing the actual degree of superheat delta' with a preset degree of superheat threshold value delta or a preset degree of superheat range [delta 1, delta 2], wherein the delta 1 is a first degree of superheat threshold value, and the delta 2 is a second degree ofsuperheat threshold value; obtaining a second comparing result by comparing the actual degree of supercooling epsilon' and a preset degree of supercooling threshold value epsilon or a preset degree of supercooling range [epsilon 1, epsilon 2], wherein the epsilon 1 is a first degree of supercooling threshold value, and the epsilon 2 is a second degree of supercooling threshold value; and adjusting the opening degree of an electronic expansion valve by comprehensively comparing the first comparing result and the second comparing result. According to the control method of the electronic expansion valve, heat exchange capacity and energy efficiency of the system can be improved while gas suction with liquid is avoided, the structure of system is not changed, and the production cost of the system is not increased.

Owner:GREE ELECTRIC APPLIANCES INC

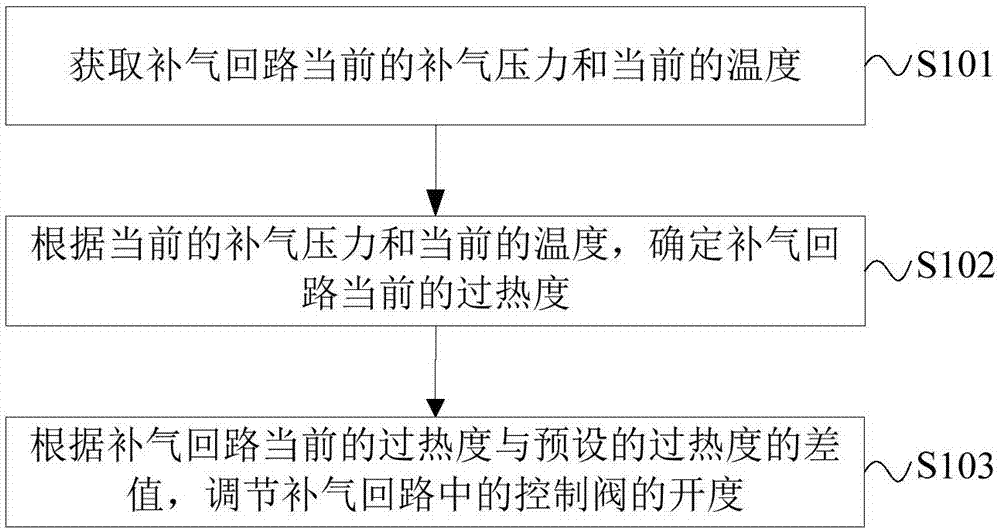

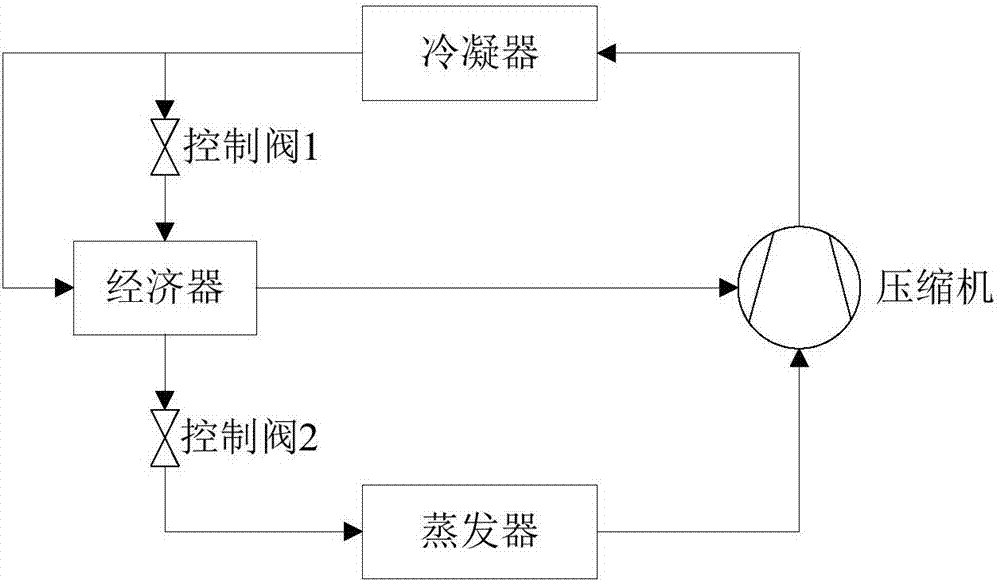

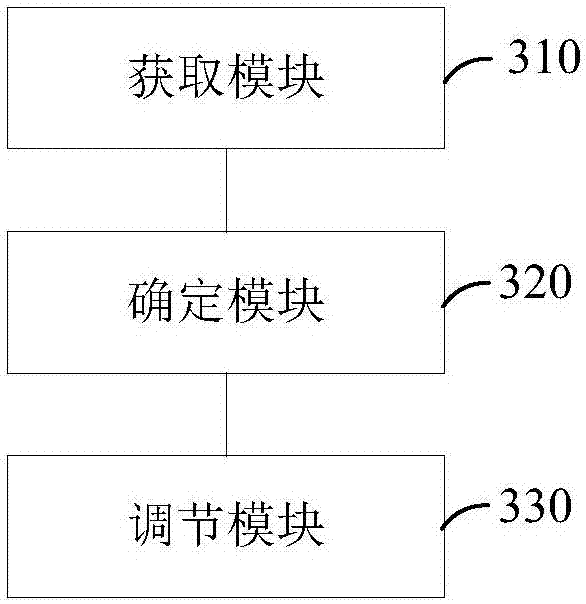

Control method and device for air-replenishing enthalpy increasing

InactiveCN106969565AImprove performanceGood energy saving effectRefrigeration safety arrangementEngineeringControl valves

The invention provides a control method and device for air-replenishing enthalpy increasing. The method comprises the following steps that the current air-replenishing pressure and temperature of an air-replenishing loop are obtained; and according to the current air-replenishing pressure and temperature, the current superheat degree of the air-replenishing loop is determined. Through the method, according to the difference value of the current superheat degree and a preset superheat degree of the air-replenishing loop, the opening of an electronic control valve is adjusted, the purpose that air suction has an enough superheat degree can be ensured, liquid is prevented from being carried in air suction, and performance of a compressor is improved; and the air-replenishing quantity can be quickly adjusted, it is ensured that a unit can efficiently operate under different working condition loads, and energy saving performance of the unit is greatly improved.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

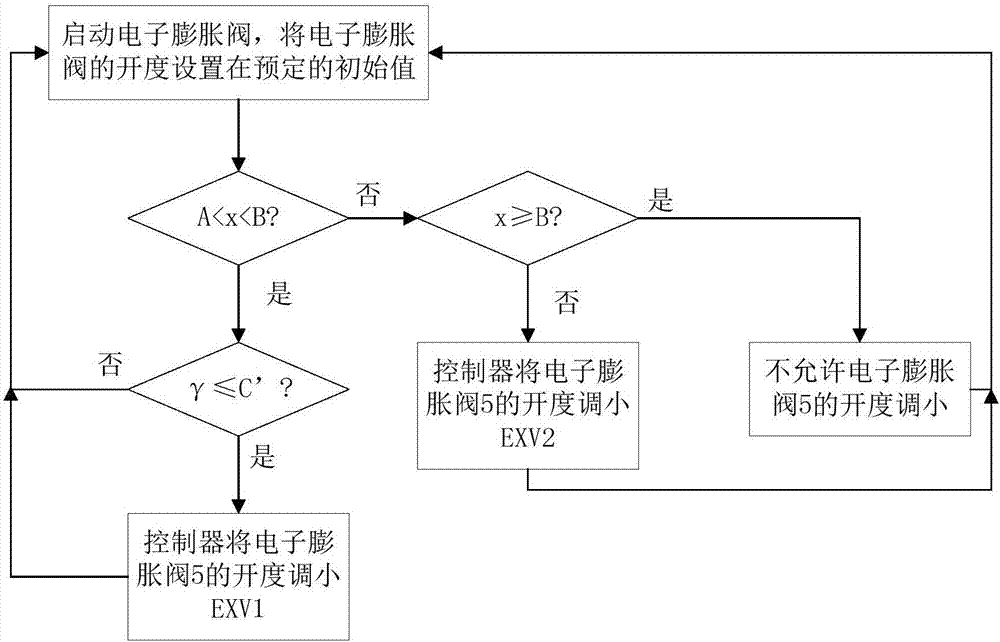

Control method of electronic expansion valve and heat pump system

ActiveCN107421176AIncrease production costImprove heat transfer effectMechanical apparatusEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides a control method of an electronic expansion valve and a heat pump system. The control method comprises the following step: when the current actual air suction superheat degree x of the heat pump system is within a preset range, adjusting the opening degree of the electronic expansion valve according to the current actual supercooling degree gamma of the heat pump system and the current load of a compressor. In the control method provided by the invention, the opening degree of the electronic expansion valve is adjusted according to the actual supercooling degree and the current load when the actual air suction overheat degree is within the preset range, so that the supercooling degree of the heat pump system can be matched with the actual load of the compressor. Accordingly, the heat exchange capacity and the energy efficiency of the heat pump system can be improved when the entrainment of a liquid in air suction is avoided, the own structure of the heat pump system cannot be changed, and the production cost of the heat pump system cannot be increased.

Owner:GREE ELECTRIC APPLIANCES INC

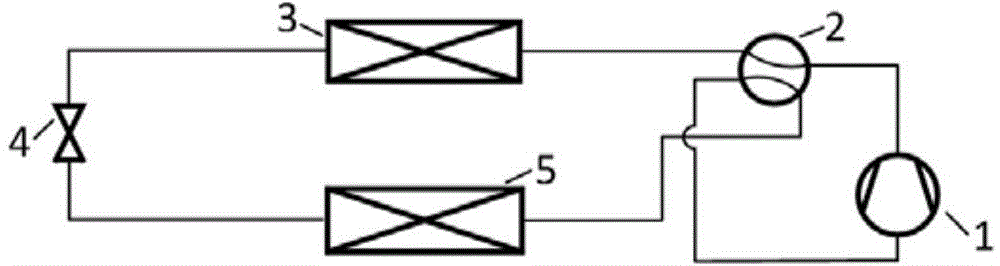

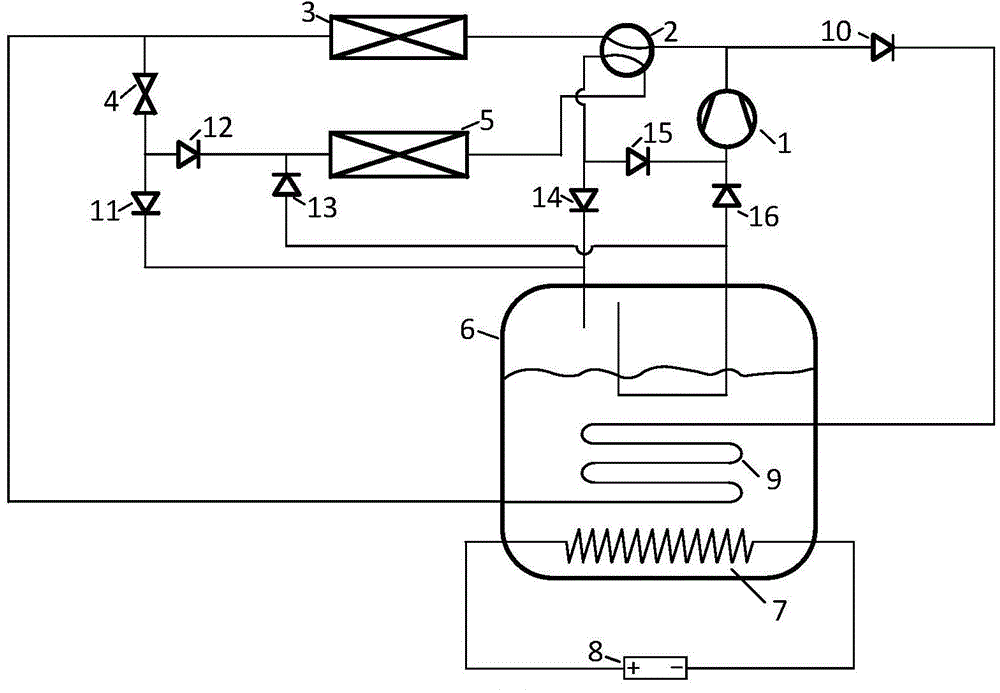

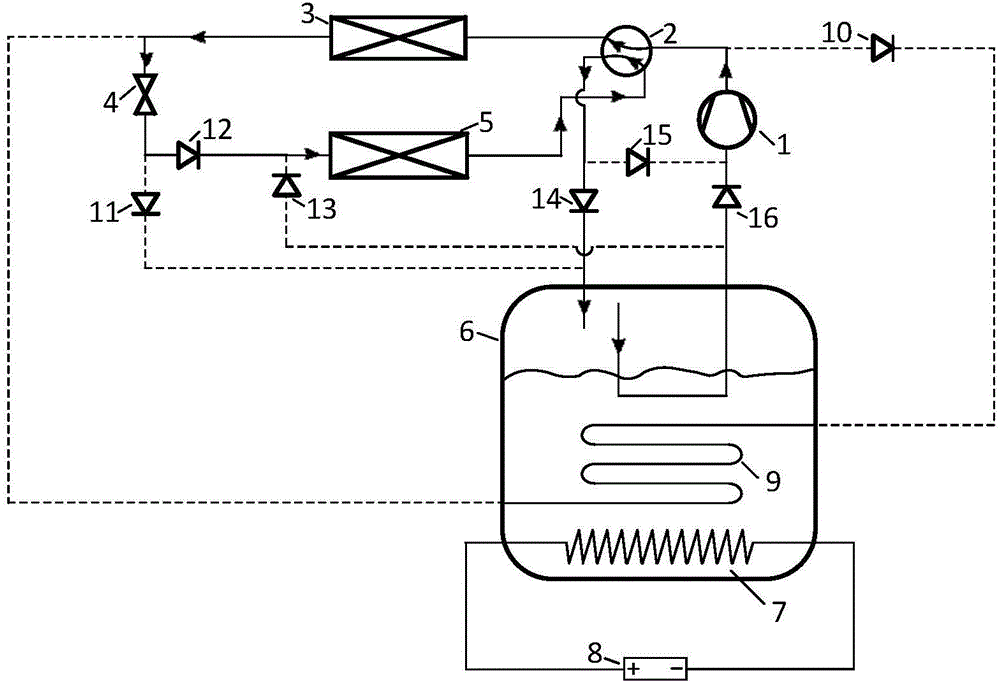

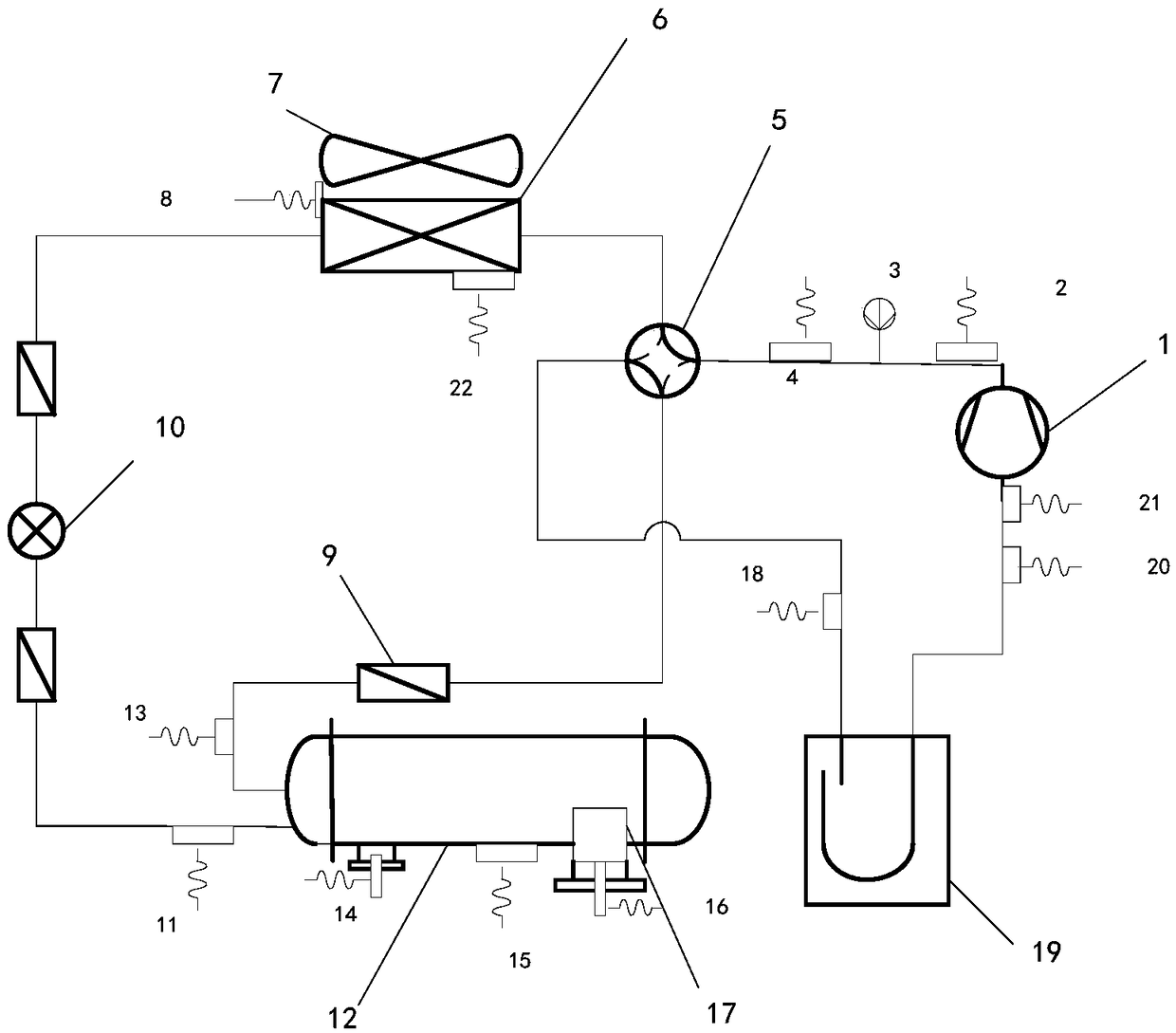

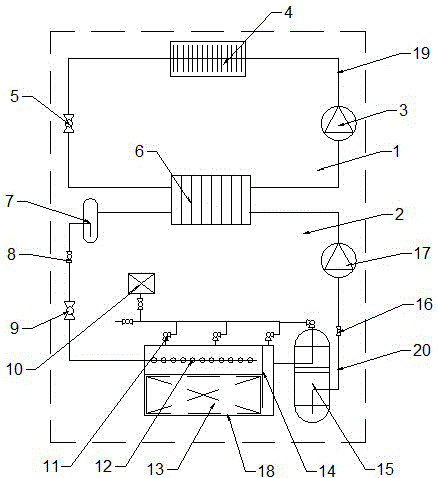

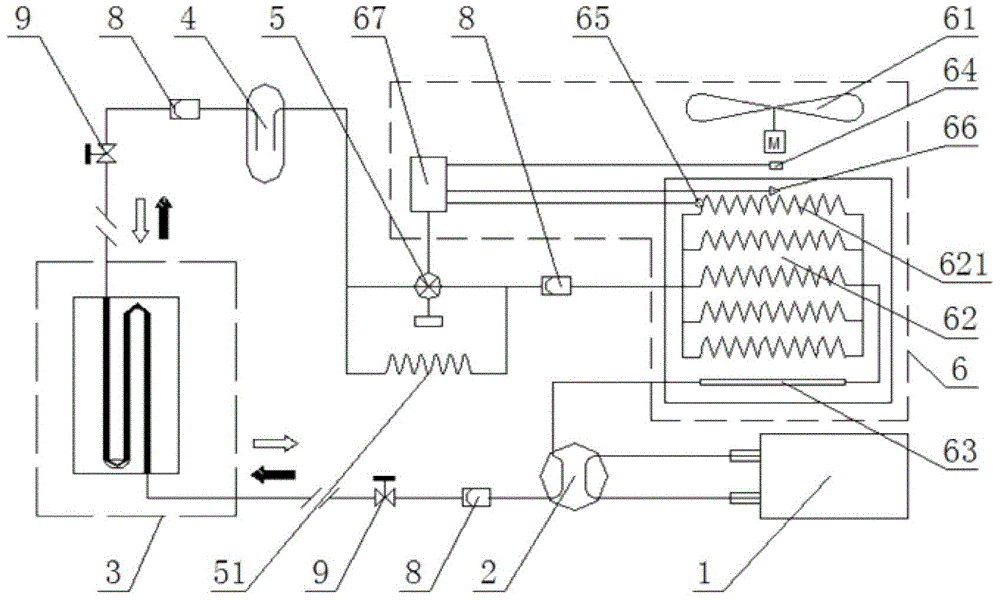

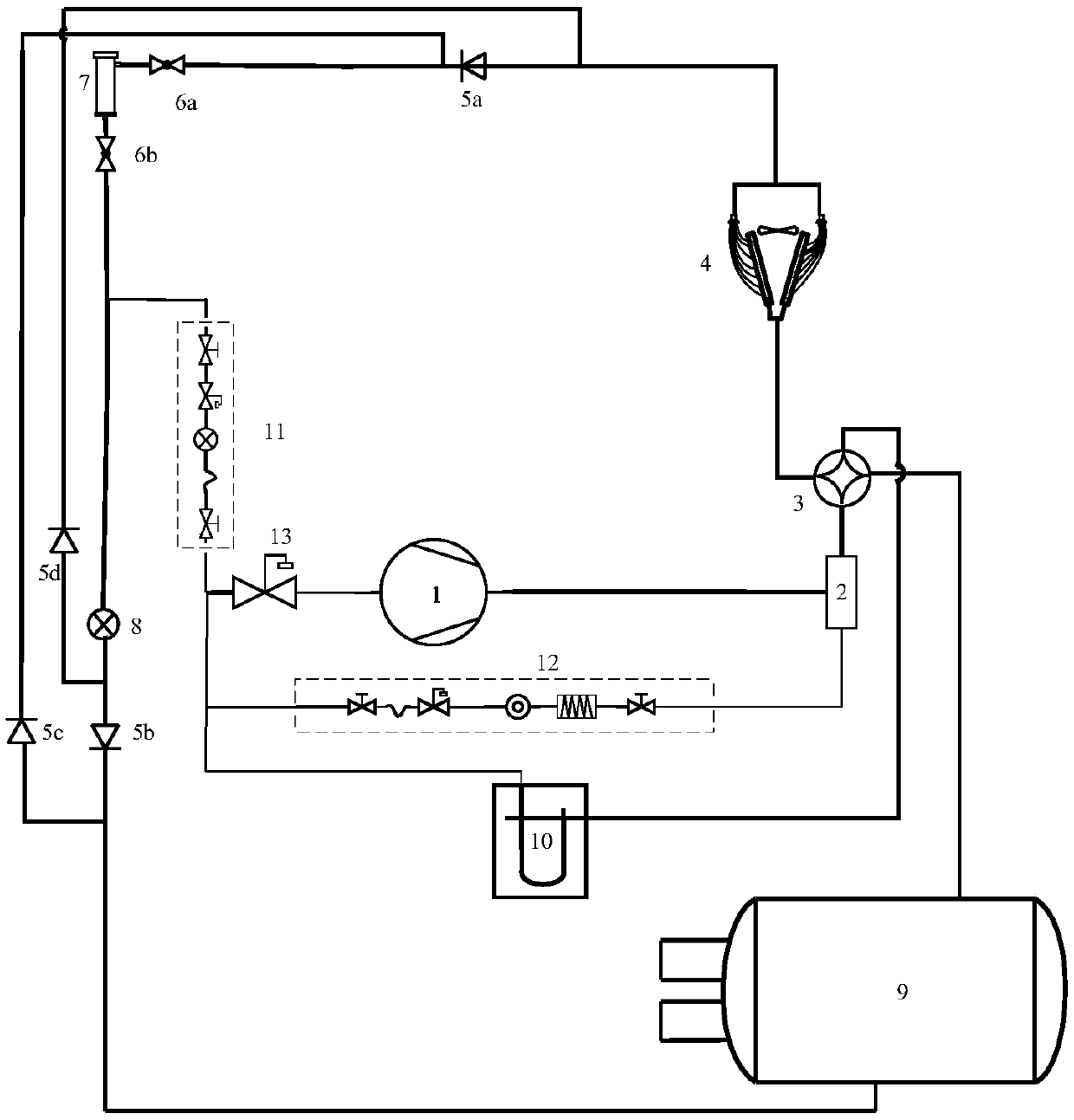

Liquid impact preventing air conditioner defrosting system

ActiveCN104833152ASolve the liquid hammer problemPrevent liquid shockCorrosion preventionRefrigeration componentsLiquid storage tankEngineering

The invention discloses a liquid impact preventing air conditioner defrosting system. The liquid impact preventing air conditioner defrosting system comprises a compressor (1), a four-way reversing valve (2), an indoor unit heat exchanger (3), a throttling device (4) and an outdoor unit heat exchanger (5). Four ports of the four-way reversing valve (2) are connected with an outlet of the compressor (1), one end of the indoor unit heat exchanger (3), one end of the outdoor unit heat exchanger (5) and an inlet of the compressor (1) respectively. The two ends of the throttling device (4) are connected with the other end of the indoor unit heat exchanger (3) and the other end of the outdoor unit heat exchanger (5). A liquid storage tank (6) capable of separating gas-liquid two-phase refrigerating fluid is arranged between the four-way reversing valve (2) and the inlet of the compressor (1) and is capable of preventing liquid impact. A heating coil (9) and an electric heater (7) are arranged in the liquid storage tank (6), high-temperature and high-pressure refrigerating fluid gas can be provided for the outdoor unit heat exchanger (5) for defrosting, and it can be guaranteed that the indoor unit heat exchanger (3) can continuously provide heat for a room in the defrosting process.

Owner:SHANGHAI JIAO TONG UNIV

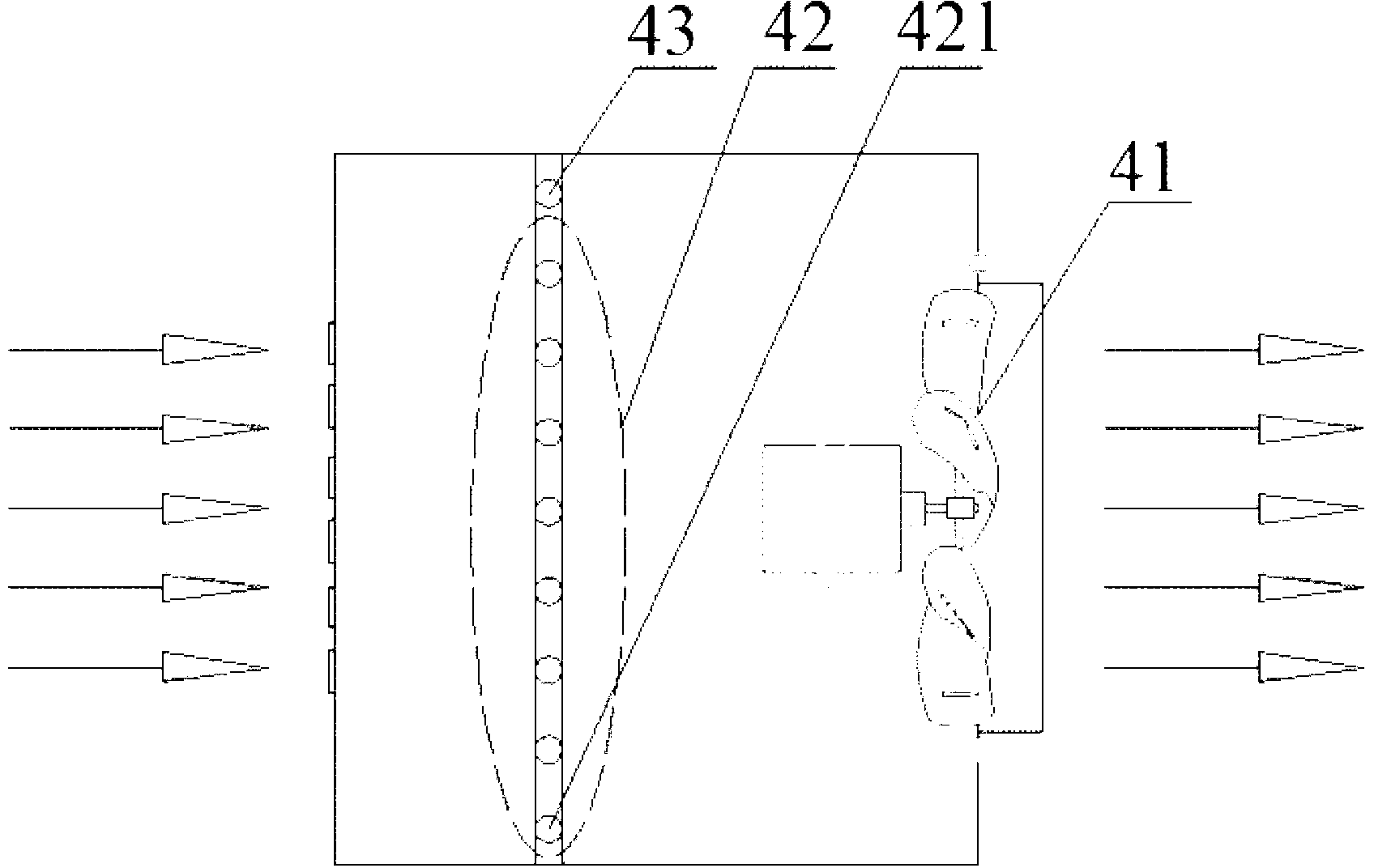

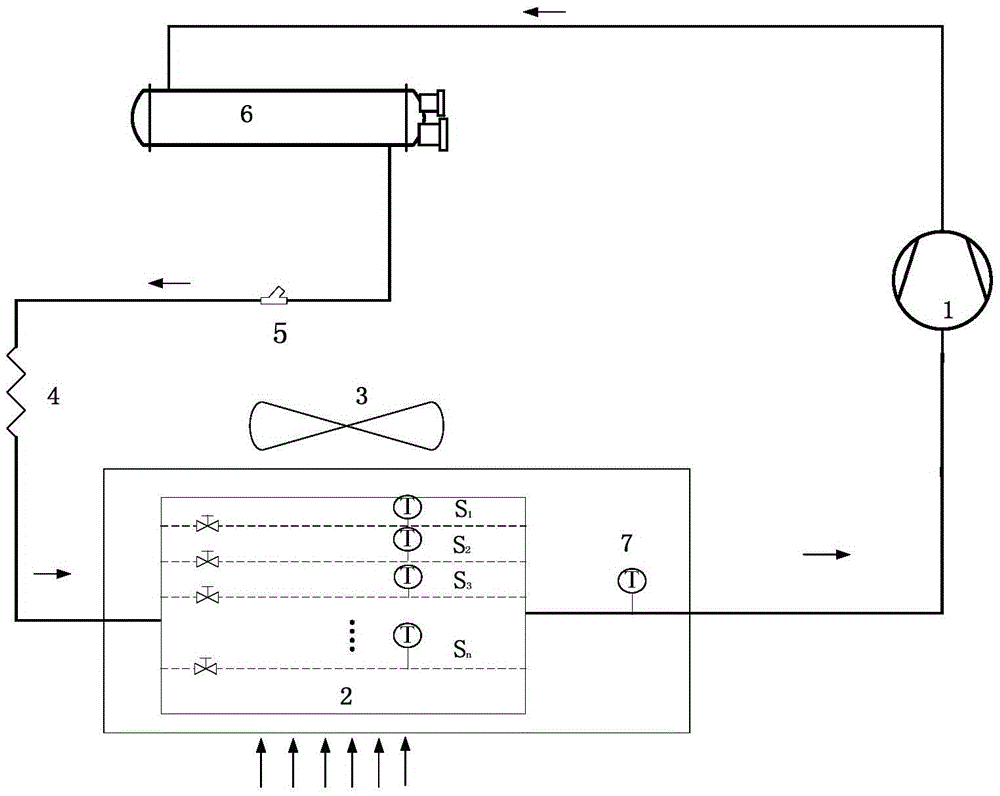

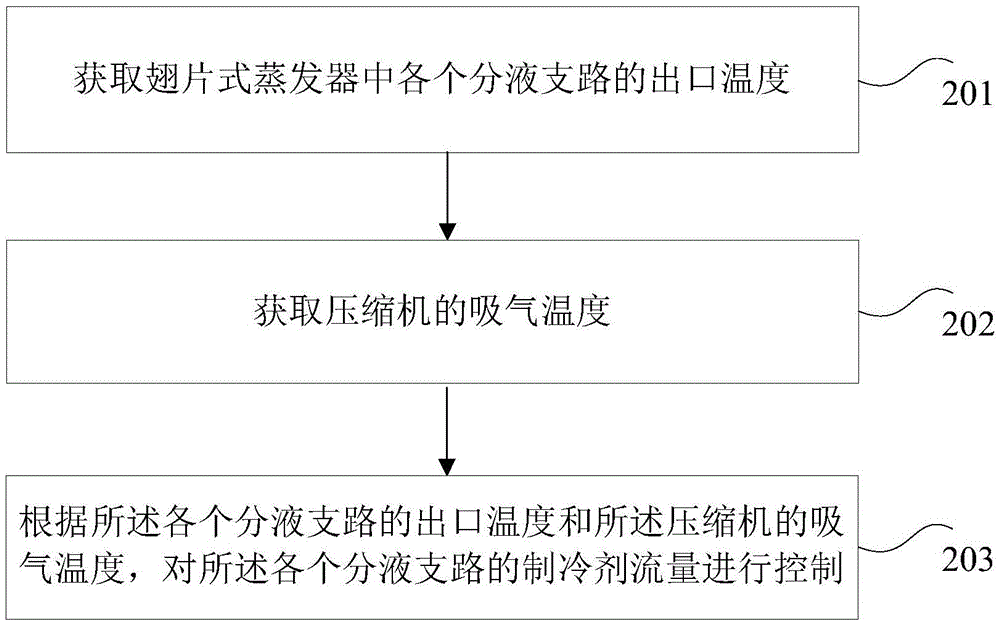

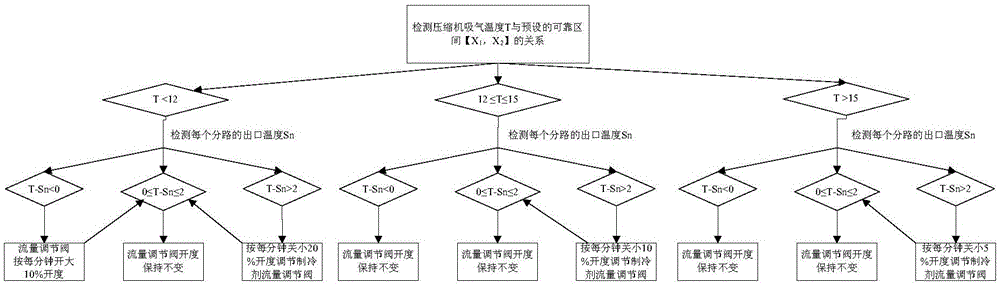

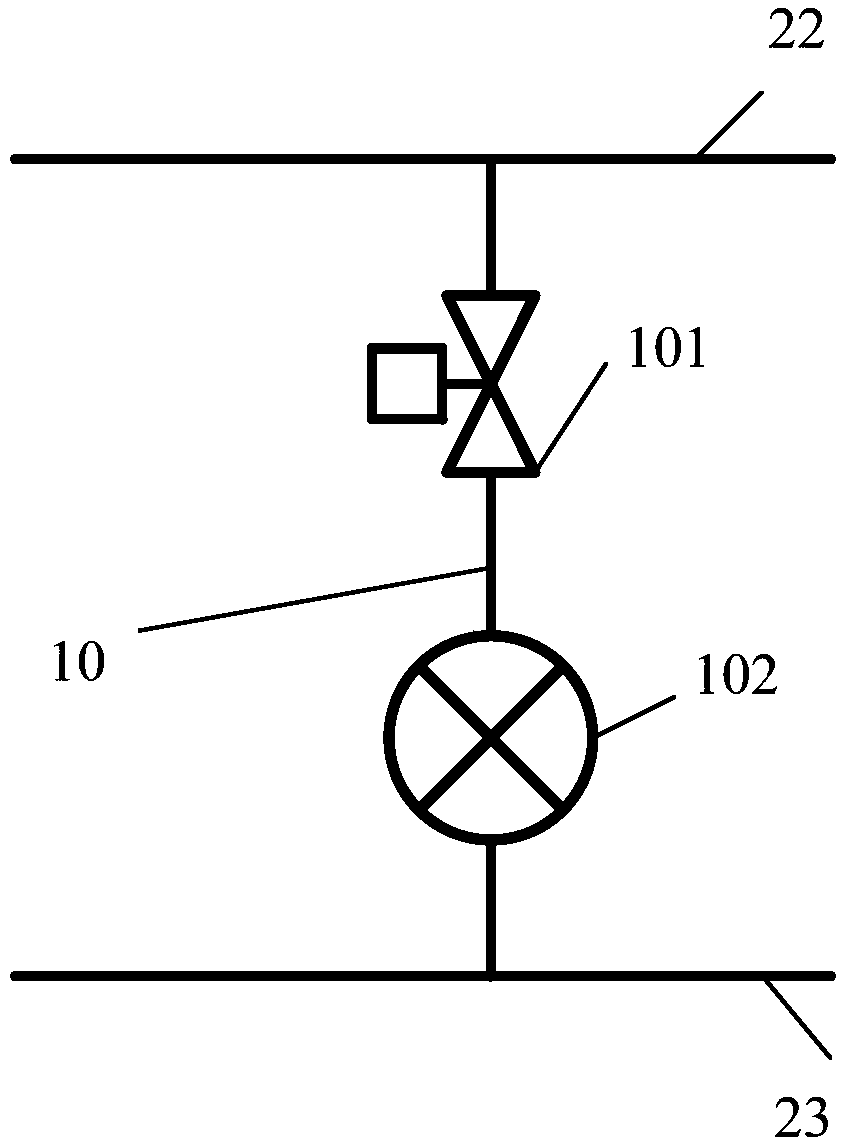

Finned evaporator and liquid distribution control method and device thereof

InactiveCN105674650AAvoid aspiration of fluidSolve the technical problem of uneven liquid separationMechanical apparatusFluid circulation arrangementDistribution controlLow load

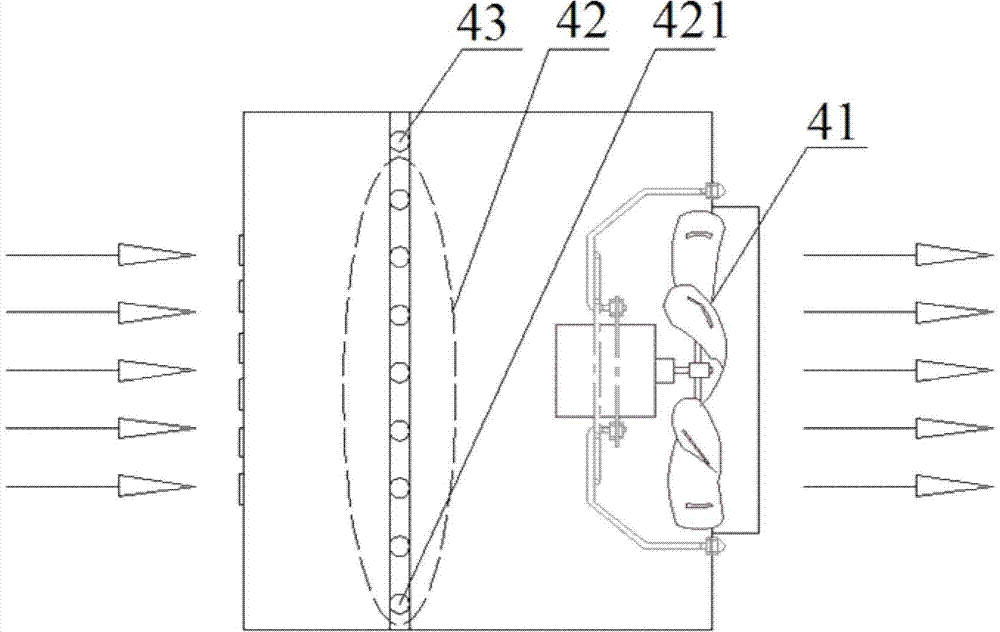

The invention provides a finned evaporator and a liquid distribution control method and device thereof. The finned evaporator comprises a plurality of liquid distribution branches, and a refrigerant flow adjusting valve and a temperature sensor are arranged on each liquid distribution branch; and a temperature sensor is arranged on a connecting pipeline of the finned evaporator and a compressor. The technical problem that liquid distribution of an existing finned evaporation heat exchanger is uneven is solved, the heat exchange performance loss of the heat exchanger due to uneven liquid distribution is avoided, and air suction with liquid of the compressor can be avoided under the rated load or the low load.

Owner:GREE ELECTRIC APPLIANCES INC

Liquid impact preventing system and method

ActiveCN109373636AAvoid aspiration of fluidImprove utilization efficiencyCompressorMechanical apparatusVapor–liquid separatorElectronic expansion valve

The invention discloses a liquid impact preventing system and method. The liquid impact preventing system comprises a bypass pipeline, an adjustable switch and an electronic expansion valve, wherein the bypass pipeline is connected with an exhaust gas pipeline and a suction gas pipeline of a compressor and is provided with the adjustable switch and the electronic expansion valve; the bypass pipeline is used for extracting exhaust gas of the compressor so that the exhaust gas can sequentially pass through the adjustable switch and the electronic expansion valve to be mixed with suction gas of the compressor, the superheat degree of the suction gas is controlled to meet a preset condition, and liquid impact is prevented; the adjustable switch is used for adjusting the suction volume of the exhaust gas in the bypass pipeline; and the electronic expansion valve is used for carrying out cooling and pressure reducing treatment on the exhaust gas. In this way, the situation that the suction gas of the compressor contains liquid can be avoided, it does not need to arrange a gas-liquid separator, return oil can directly flow into the compressor, and therefore the normal oil returning of thesystem is guaranteed while the liquid impact phenomenon is avoided. The utilization efficiency of lubricating oil is improved, the charge volume of lubricating oil is reduced, and energy sources aresaved.

Owner:GREE ELECTRIC APPLIANCES INC

Improved self-cascade refrigeration cycle system and control method thereof

ActiveCN108895694AIncrease speedReduce speedMechanical apparatusCompression machines with cascade operationVapor–liquid separatorEngineering

The invention discloses an improved self-cascading refrigeration cycle system and a control method thereof, which are applied to low-temperature systems such as low-temperature freezers, low-temperature refrigerators, medical low-temperature refrigeration instruments, etc. Compared with the traditional self-cascade system, the regenerator and throttle device are added between the condenser and thegas-liquid separator. The system can not only make the two fluids exchange heat more fully in the evaporative condenser, but also prevent the compressor from sucking in the liquid, raise the evaporative pressure of the whole system, reduce the pressure ratio of the compressor, and improve the efficiency of the compressor, so as to increase the refrigeration capacity of the system and improve theperformance of the circulating system. As such, that present invention has significant advantage over conventional self-cascade cycle using regenerator and throttle valves in front of the gas-liquid separator.

Owner:XI AN JIAOTONG UNIV

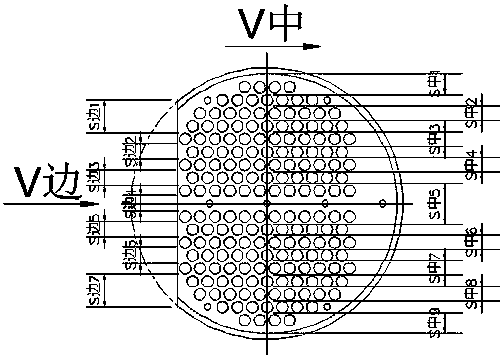

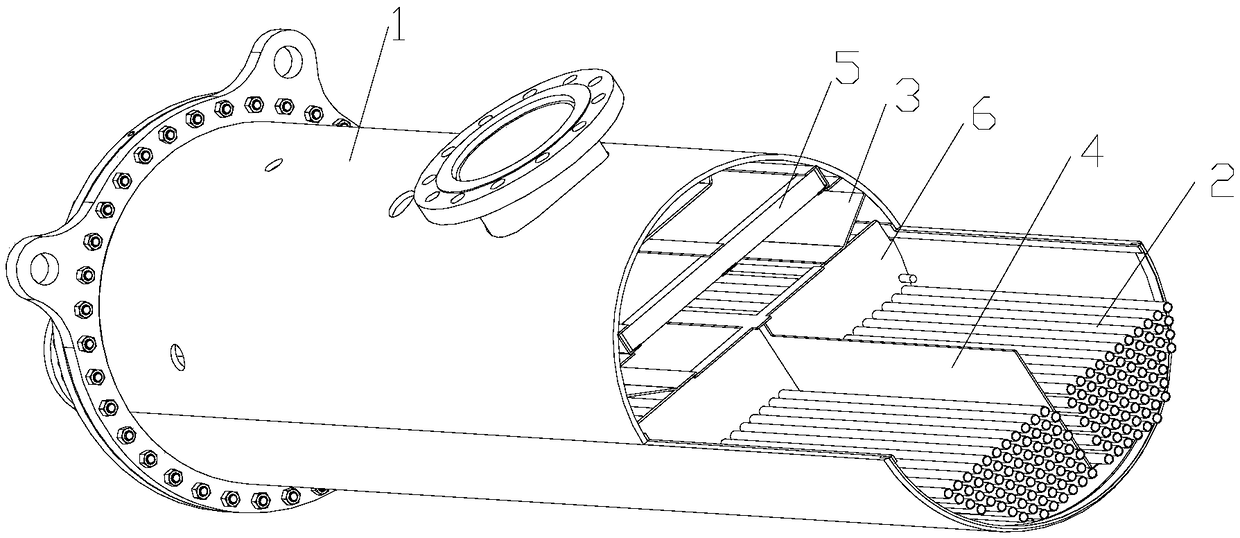

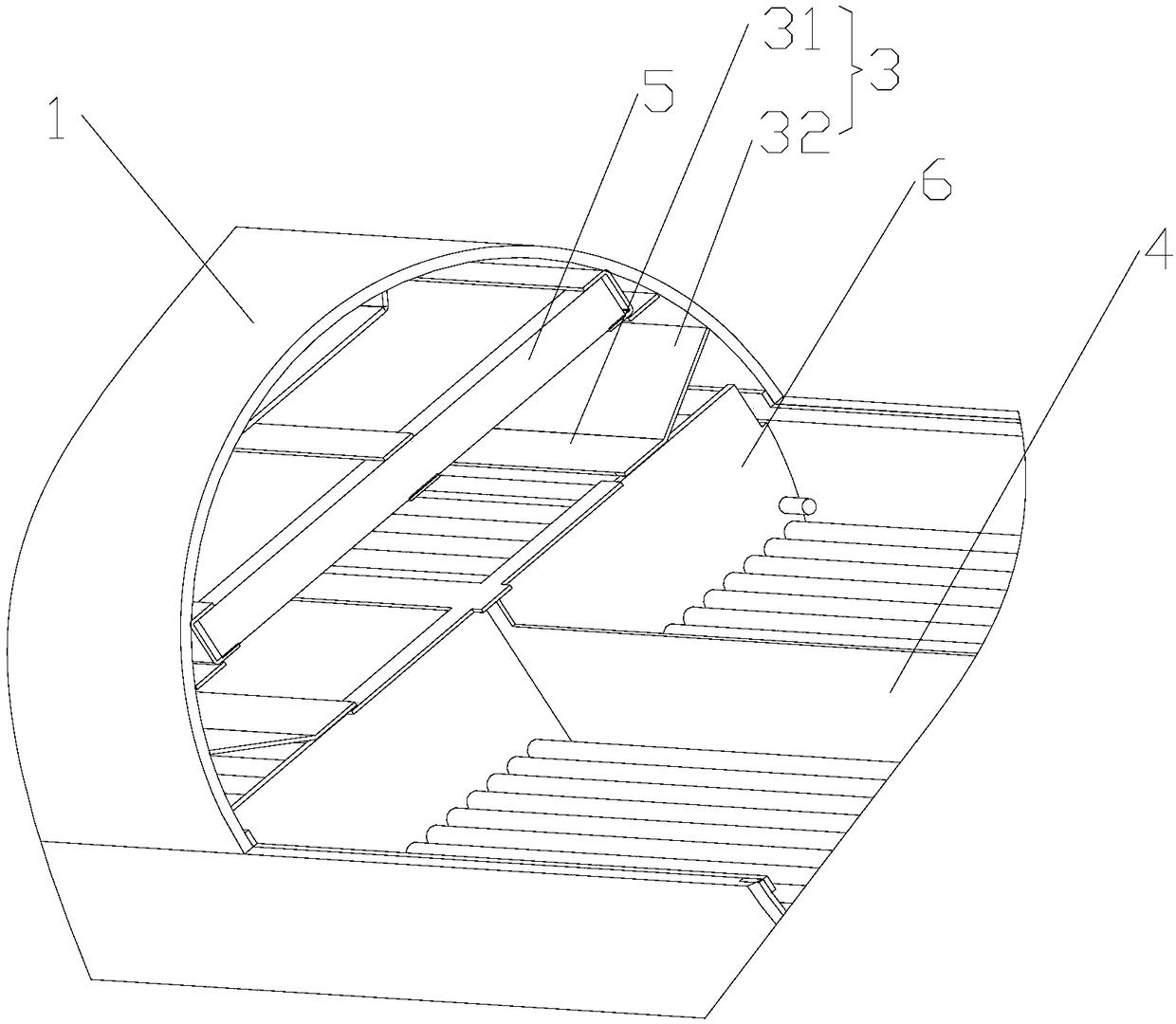

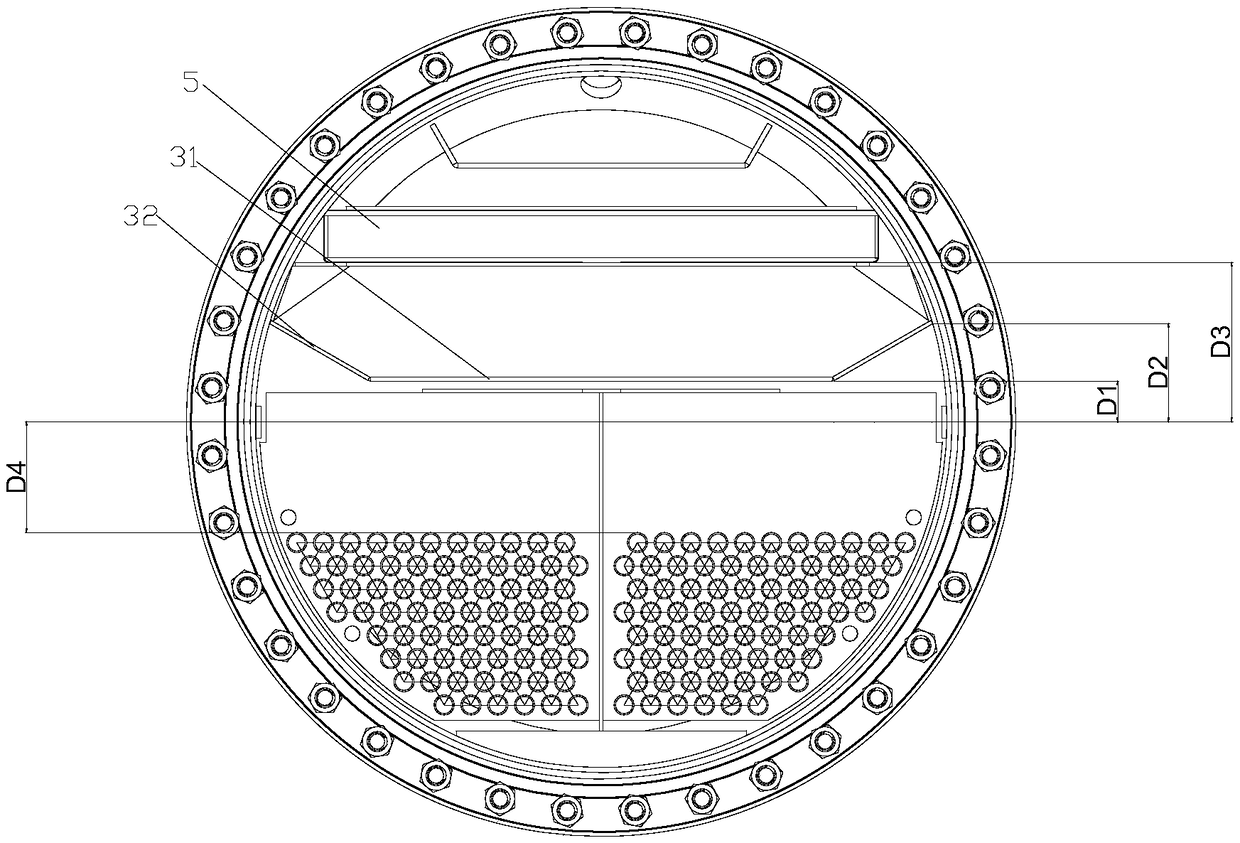

Rectangular dry type shell-and-tube heat exchanger

PendingCN107631521AConsistent heat transfer capabilityReduce the static pressure difference of the liquid columnEvaporators/condensersHeat exchanger casingsEngineeringPlate heat exchanger

The invention relates to a rectangular dry type shell-and-tube heat exchanger. The rectangular dry type shell-and-tube heat exchanger comprises a tube pass and a broken-line-shaped shell pass, whereinthe tube pass is composed of a channel and U-shaped heat exchange tubes, and the broken-line-shaped shell pass is composed of a shell, a tube sheet and spoilers; a tube pass inlet and a tube pass outlet are formed in the channel; and a shell pass inlet and a shell pass outlet are formed in the shell. The rectangular dry type shell-and-tube heat exchanger is characterized in that the shell is a rectangular shell; one end of the shell is closed; the tube sheet is arranged at the other end surface of the shell; the multiple U-shaped heat exchange tubes are arranged in the shell in a rectangularmode; the end parts of the U-shaped heat exchange tubes are supported by the tube sheet; the channel is arranged on the outer side of the tube sheet and is used for performing shunting on the U-shapedheat exchange tubes; and a rectangular sealing gasket is arranged between the channel and the tube sheet.

Owner:江苏世林博尔制冷设备有限公司

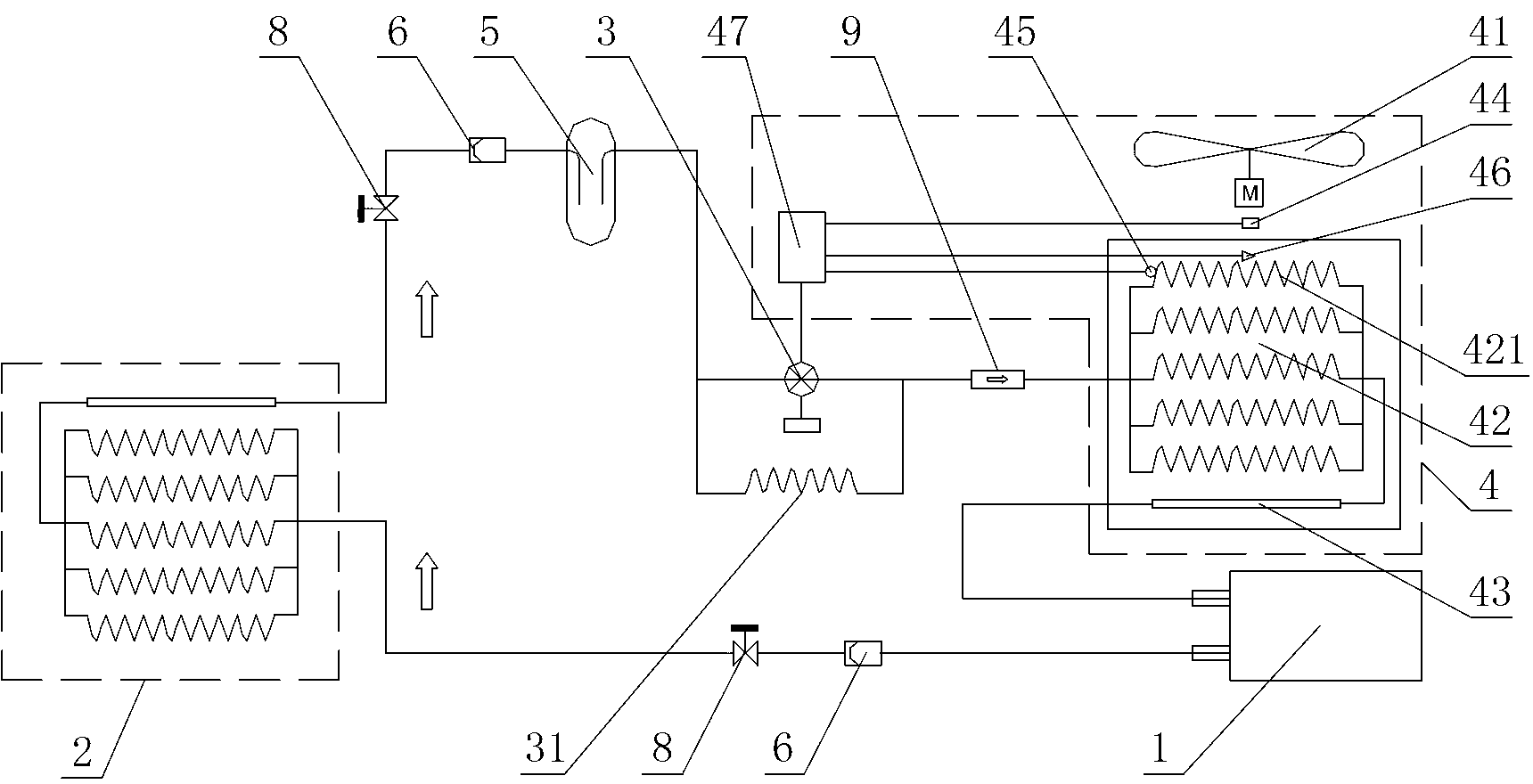

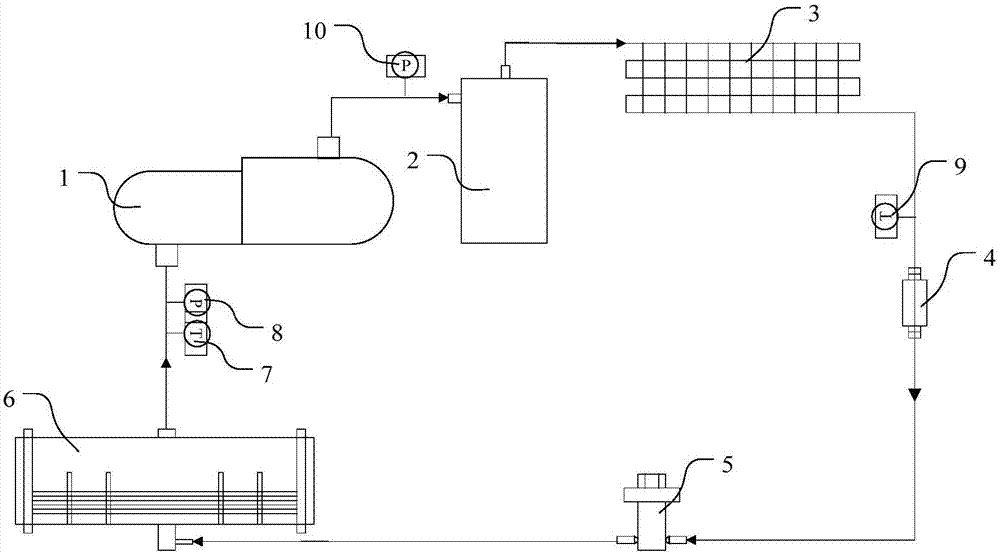

Heat pump system and control method thereof

ActiveCN109751795ARaise the suction temperatureAvoid aspiration of fluidMechanical apparatusHeat pumpsProcess engineeringHeat pump

The invention provides a heat pump system and a control method thereof. The heat pump system comprises a compressor (1), a first heat exchanger (3), a first gas supplementing pipeline and a first heatregenerator (6); the first end of the first gas supplementing pipeline is connected to a gas supplementing port of the compressor (1); a pipeline between the first heat exchanger (3) and the compressor (1) is a first heat exchanging pipeline; and heat exchanging is performed between the first heat exchanging pipeline and the first gas supplementing pipeline through the first heat regenerator (6).The heat pump system can effectively raise the gas sucking temperature of the compressor, it is avoided that liquid is taken during gas sucking of the compressor, the gas sucking superheat degree isimproved, and the unit heating capacity is increased.

Owner:GREE ELECTRIC APPLIANCES INC

Heat exchanger and air-conditioner with same

PendingCN109341147AAvoid dischargeAvoid aspiration of fluidEvaporators/condensersHeat exchanger casingsEngineeringMicro heat exchanger

The invention provides a heat exchanger and an air-conditioner with the same. The heat exchanger comprises a heat exchanger shell and a heat exchange pipe; a hydraulic filling heat exchange space is disposed in the heat exchanger shell; an air outlet which is connected with the hydraulic filling heat exchange space is disposed on the heat exchanger shell; the heat exchange pipe is disposed in thehydraulic filling heat exchange space; a liquid blocking structure which blocks liquid in the hydraulic filling heat exchange space from passing through is further disposed in the heat exchanger shell; and the liquid blocking structure is disposed between the hydraulic filling heat exchange space and the air outlet. The heat exchanger can block liquid refrigerant, and thus liquid carrying of sucked air of a compressor is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

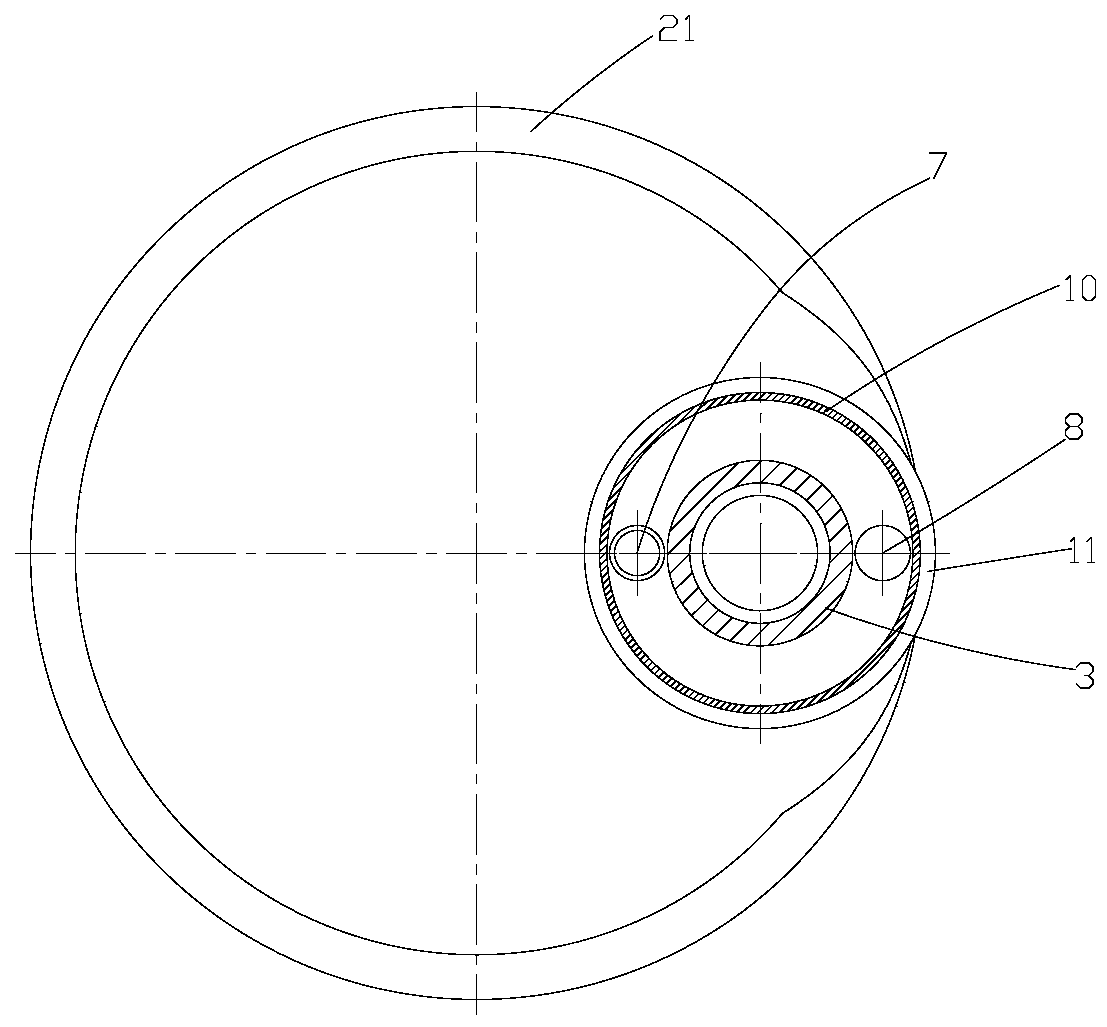

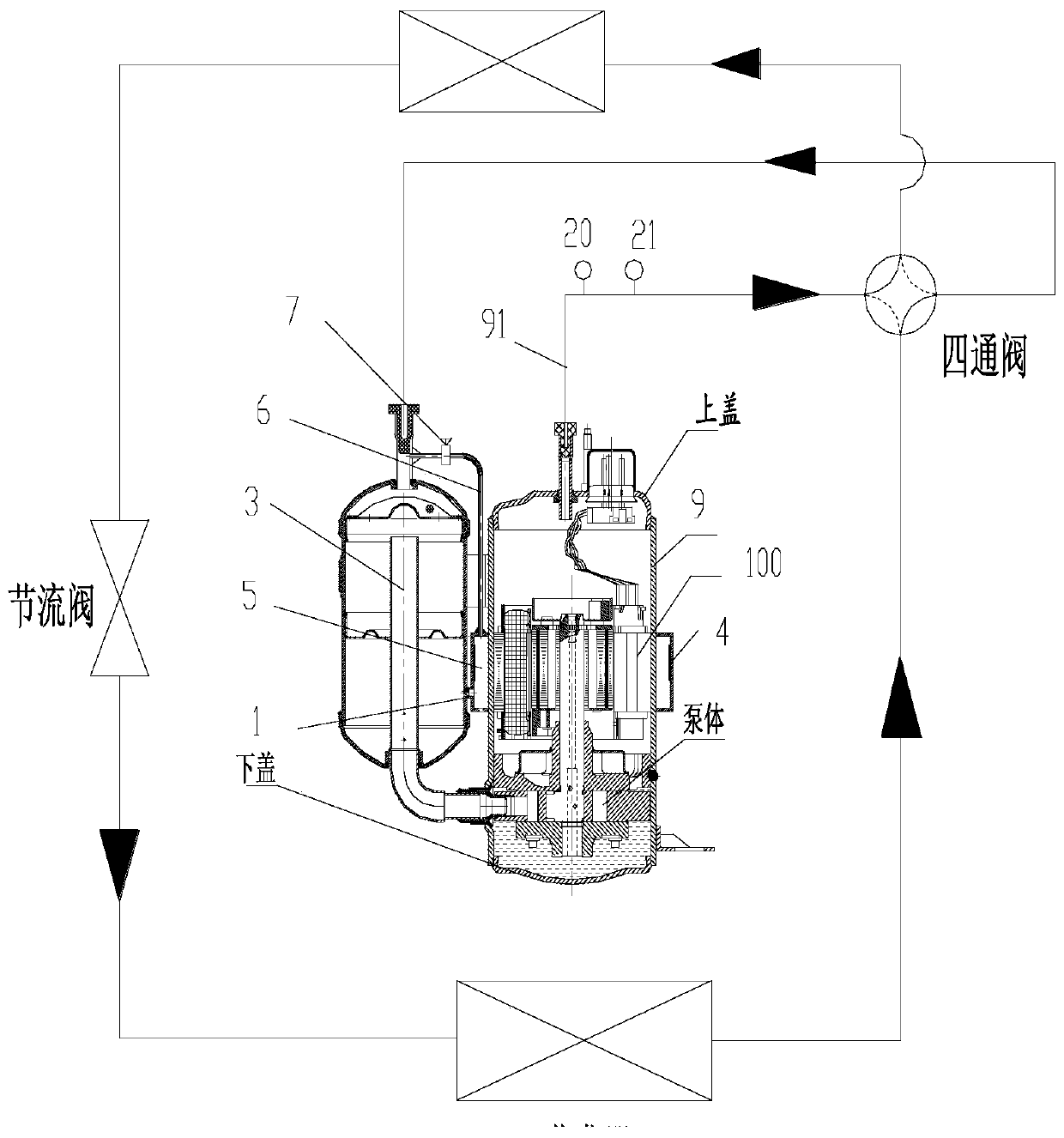

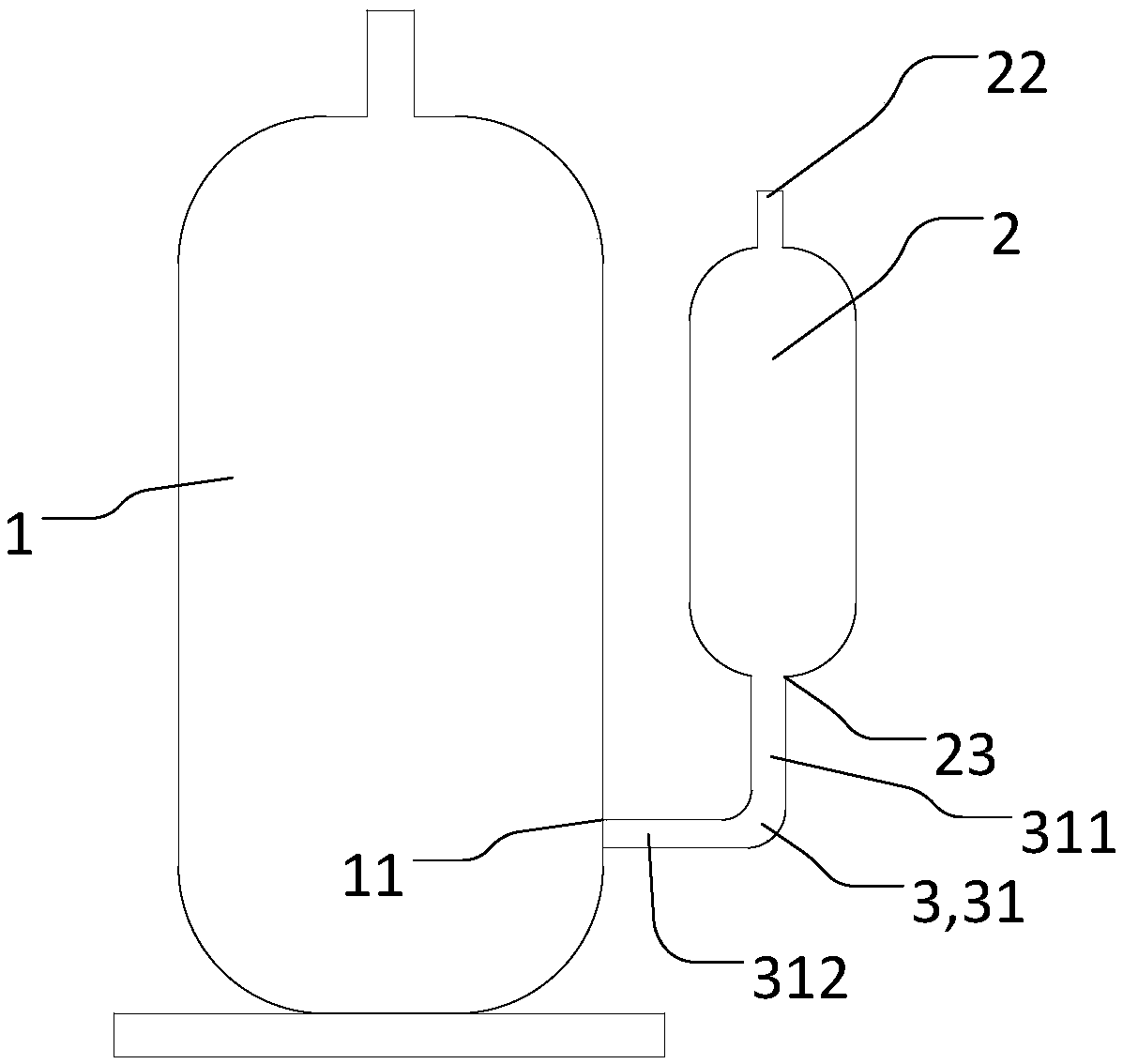

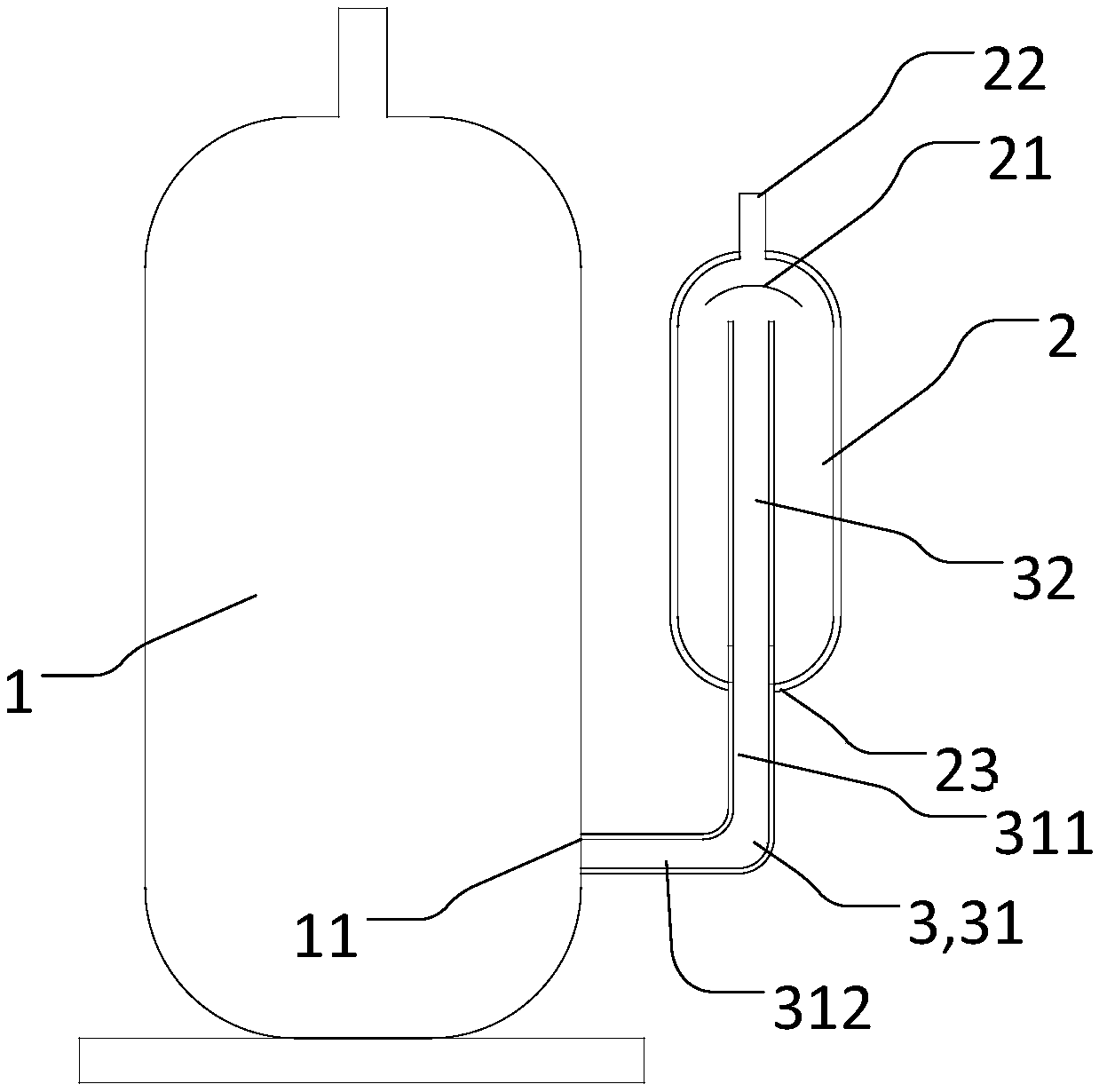

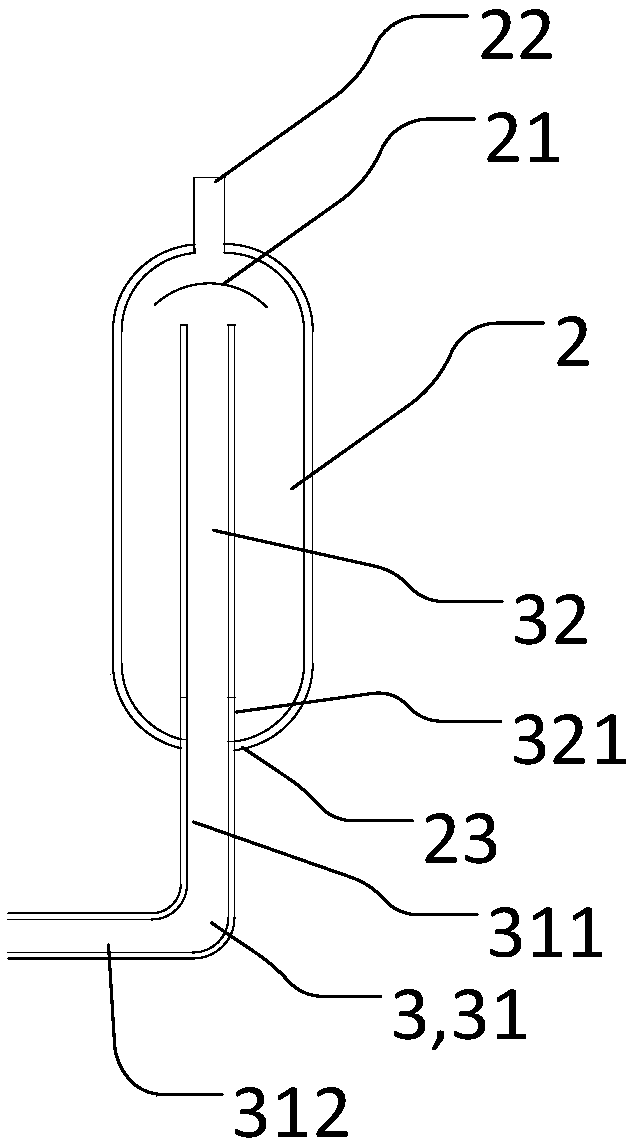

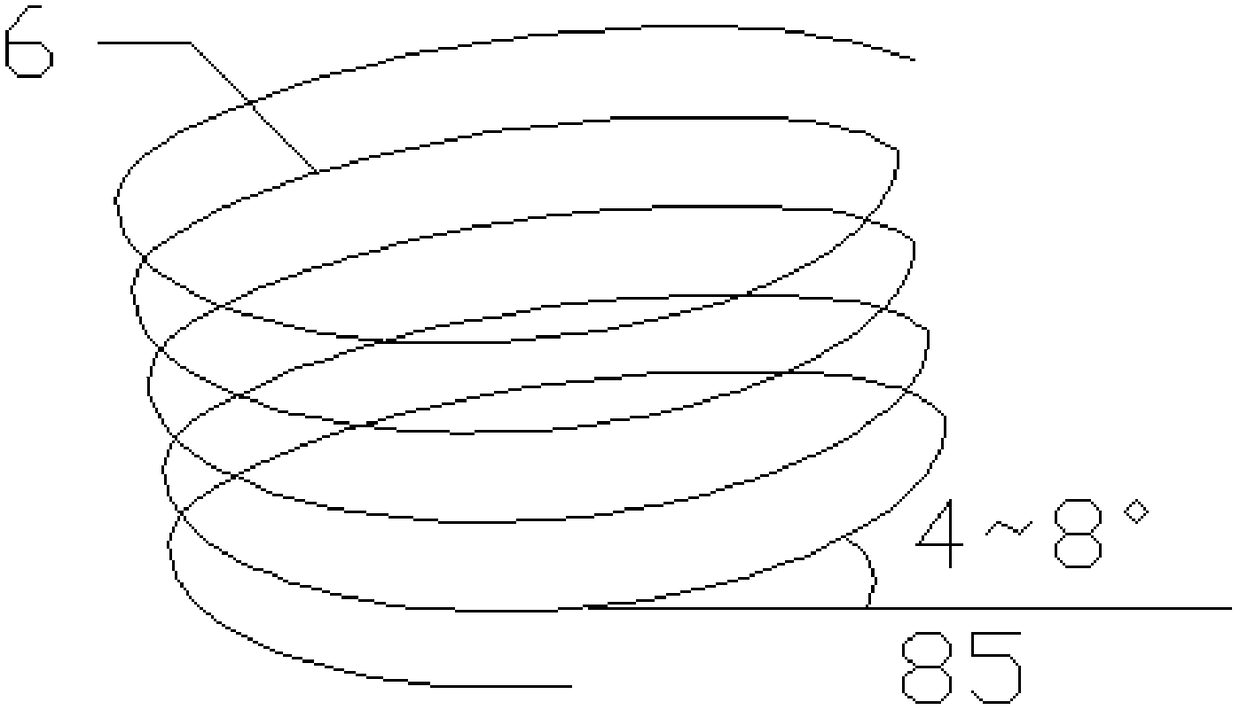

Scroll compressor and heat pump system

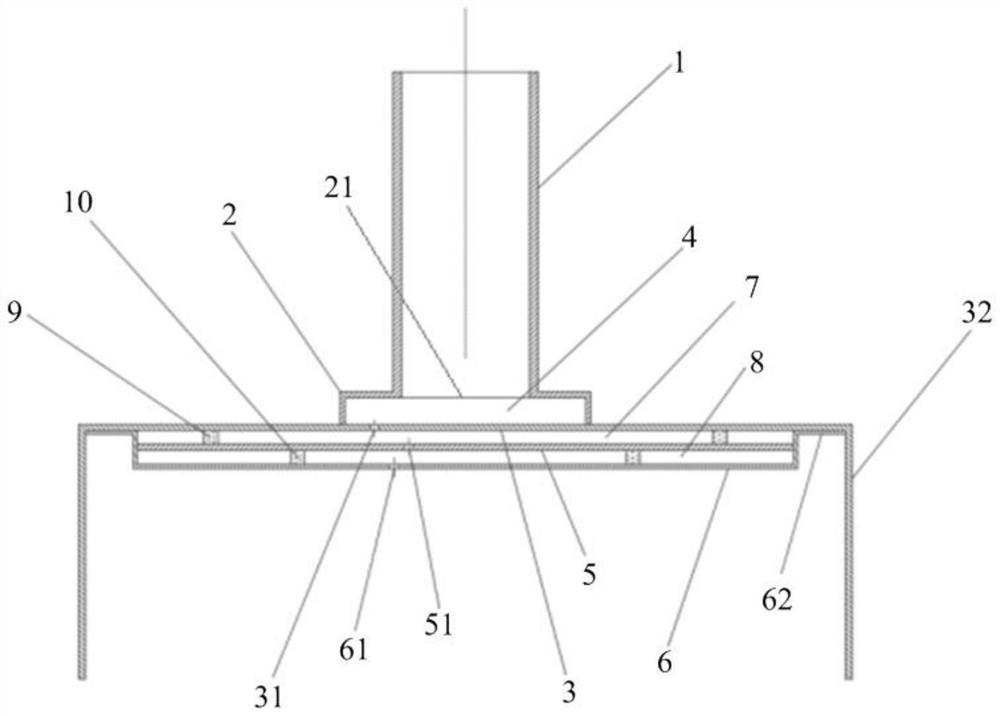

ActiveCN110345075AGuaranteed uptimeImprove operational reliabilityHeat pumpsRotary piston pumpsHeat pumpWaste management

The invention provides a scroll compressor and a heat pump system. The scroll compressor comprises a casing (1), a fixed scroll plate (2) and an air suction pipe (3); the air suction pipe (3) is arranged on the casing (1); the fixed scroll plate (2) is provided with an exhaust port (4); the scroll compressor further comprises an air suction reheating assembly; the air suction reheating assembly isin heat exchange contact with the air suction pipe (3); an air inlet of the air suction reheating assembly communicates with the exhaust port (4); an air outlet of the air suction reheating assemblycommunicates with an exhaust cavity (5) of the casing (1); and at least part of a refrigerant discharged from the exhaust port (4) flows through the air suction reheating assembly and flows to the exhaust cavity (5) after being subjected to heat exchange with a refrigerant flowing through the air suction pipe (3). According to the scroll compressor, the phenomenon that liquid is carried due to airsuction can be effectively avoided, and the operation reliability of the scroll compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Direct freezing device for liquid carbon dioxide

InactiveCN105091390AImprove economyImprove securityCompression machinesRefrigeration componentsEngineeringLiquid carbon

The invention relates to a direct freezing device for liquid carbon dioxide. The direct freezing device comprises a high-temperature section refrigerating system and a low-temperature section refrigerating system which are formed through overlapping of overlapped condensers. The high-temperature section refrigerating system comprises a high-temperature section compressor, a high-temperature section condenser, a high-temperature section throttle valve and the overlapped condenser, all of which are connected through a pipeline A. The low-temperature section refrigerating system comprises a low-temperature section compressor, the overlapped condenser, a low-temperature section storage tank, a cut-off valve A, a low-temperature section throttle valve, a freezing device and a cut-off valve B which are connected through a pipeline B. A carbon dioxide direct freezing evaporator is arranged in the freezing device, and emptying valves and a vacuum pump are connected to the exterior of the freezing chamber. The direct freezing device has the beneficial effects that a hole plate is arranged at the upper end of the carbon dioxide direct freezing evaporator, liquid supplying of the carbon dioxide direct freezing evaporator is mainly achieved through the hole plate, and the liquid carbon dioxide in the whole direct freezing area is even; and the quick freezing speed is high, the quick freezing time is shortened, and the quick freezing period is accelerated. A flow guiding partition plate is arranged at the tail end of the hole plate, the utilization rate of carbon dioxide is effectively increased, and the gas-liquid separation effect is improved.

Owner:NANTONG WORLDBASE REFRIGERATION EQUIP CO LTD

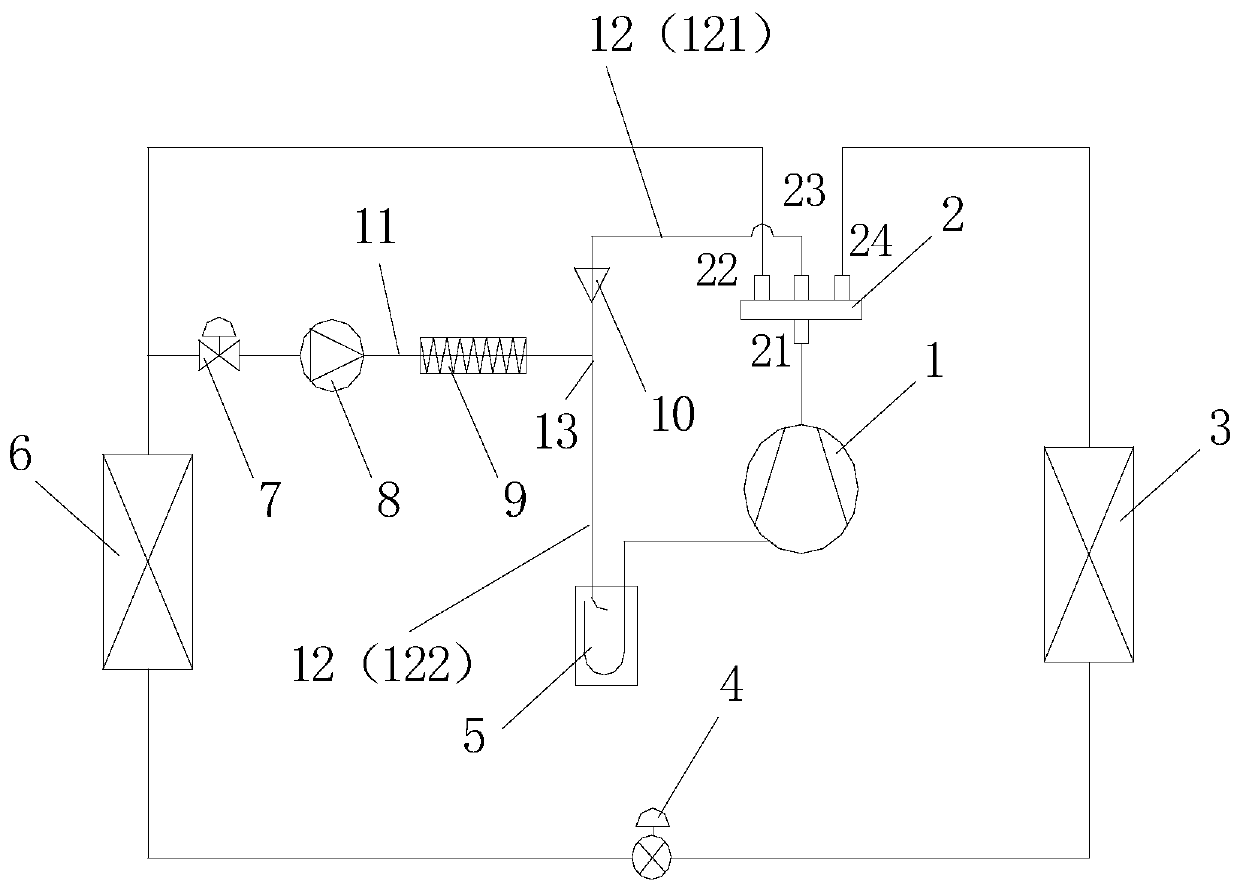

Compressor assembly, air conditioner and control method

InactiveCN110966197AIncrease suction superheatTo prevent the situation of aspirating with liquidRefrigeration componentsRotary/oscillating piston pump componentsVapor–liquid separatorEngineering

The invention provides a compressor assembly, an air conditioner and a control method. The compressor assembly comprises a compressor shell (9) and a gas-liquid separator (3), wherein the gas-liquid separator (3) communicates with external inlet gas and communicates with the interior of the compressor shell (9) through a first outlet pipe (32), a hybrid heat exchange cavity (5) is arranged outsidethe compressor shell (9) and can exchange heat with the compressor shell (9), and the hybrid heat exchange cavity (5) can be communicated with a first inlet pipe (31) through a second inlet pipe (6)and can be communicated with the gas-liquid separator (3) or a first outlet pipe (32) through a second outlet pipe (1). The invention discloses a compressor assembly. The compressor is advantaged in that refrigerant before entering the gas-liquid separator enters the hybrid heat exchange cavity to be heated and then is guided into the compressor shell to be compressed, the air suction superheat degree of the compressor is effectively increased, the situation that liquid is carried in air suction of the compressor is prevented, liquid impact is prevented, and running reliability and safety of the compressor are guaranteed.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Frostless air handling unit and proportion-integration-differential control method thereof

InactiveCN103216981BExtended service lifeGuaranteed uptimeCorrosion preventionRefrigeration safety arrangementElectricityEngineering

The invention discloses a frostless air handling unit and a proportion-integration-differential control method of the frostless air handling unit. The frostless air handling unit comprises a circulating working return circuit and a controllable silicon power adjuster, wherein the circulating working return circuit is composed of a compressor assembly, a condenser, an electronic expansion valve and an evaporator assembly, the compressor assembly, the condenser, the electronic expansion valve and the evaporator assembly are sequentially connected along the refrigerating fluid flowing direction. When a calculation controller receives an outdoor temperature parameter transmitted by a temperature-humidity sensor and the temperature parameter is lower than 0 DEG C, the calculation controller carries out calculation according to received air temperature and humidity parameters, an air pressure parameter and an evaporator surface temperature parameter, controls the opening degree of the electronic expansion valve according to the calculation results, and adjusts evaporator surface temperature through increase or reduction of the opening degree of the electronic expansion valve. Meanwhile, the controllable silicon power adjuster judges an air suction superheat degree of a compressor through received compressor air suction temperature and air suction pressure, adjusts increase or reduction of electric heater power, and maintains the air suction superheat degree of the compressor to be kept in a preset value range. According to the frostless air handling unit and the proportion-integration- differential control method of the frostless air handling unit, the aim of maintaining safe and high-efficiency operation of the system is achieved.

Owner:宁波沃弗圣龙环境技术有限公司 +1

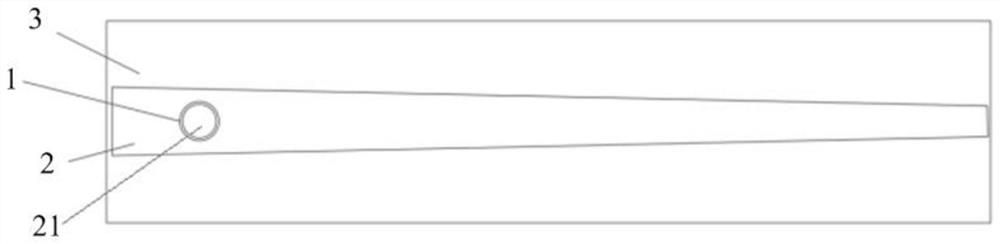

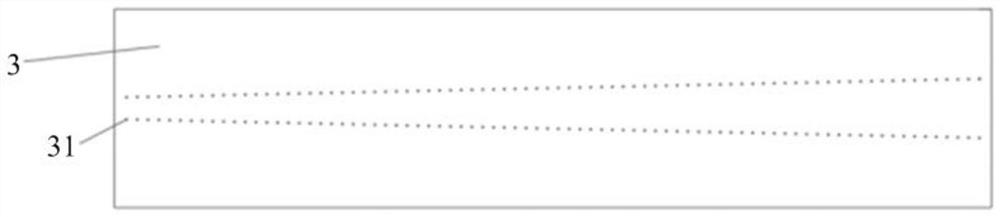

Liquid distributor, evaporator and air conditioning system

PendingCN114278994AKinetic energy unchangedEvenly dispersedHeating and ventilation casings/coversEvaporators/condensersEngineeringAir conditioning

The invention relates to the technical field of air conditioners, in particular to a liquid distributor, an evaporator and an air conditioning system. The liquid distributor aims at solving the problem that an existing liquid distributor is not uniform in liquid distribution. In order to achieve the purpose, the liquid distributor comprises an upper cover and an upper shell, a first liquid distribution cavity is defined between the upper cover and the upper surface of the upper shell, a plurality of first liquid distribution holes are formed in the position, located in the first liquid distribution cavity, of the upper shell, and a liquid inlet is formed in the upper cover; the upper cover is arranged in the length direction of the upper shell, the projection of the upper cover on the upper shell is in a trapezoid shape, and the liquid inlet is formed in the side, close to the lower bottom of the trapezoid, of the upper cover. The projection of the upper cover on the upper shell is arranged to be trapezoid, and the liquid inlet is formed in the side, close to the lower bottom of the trapezoid, of the upper cover, so that when a refrigerant flows, the kinetic energy of the refrigerant can be basically kept unchanged, and a better liquid homogenizing effect is achieved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

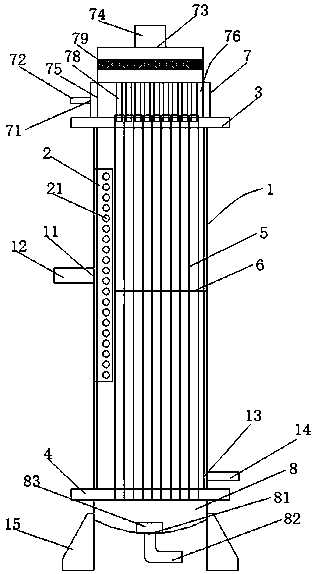

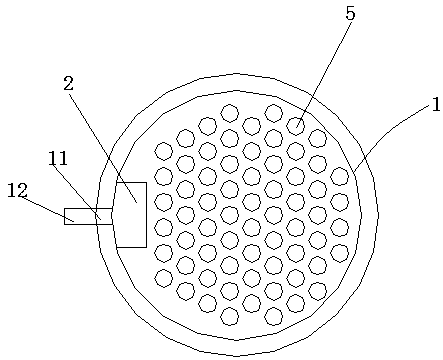

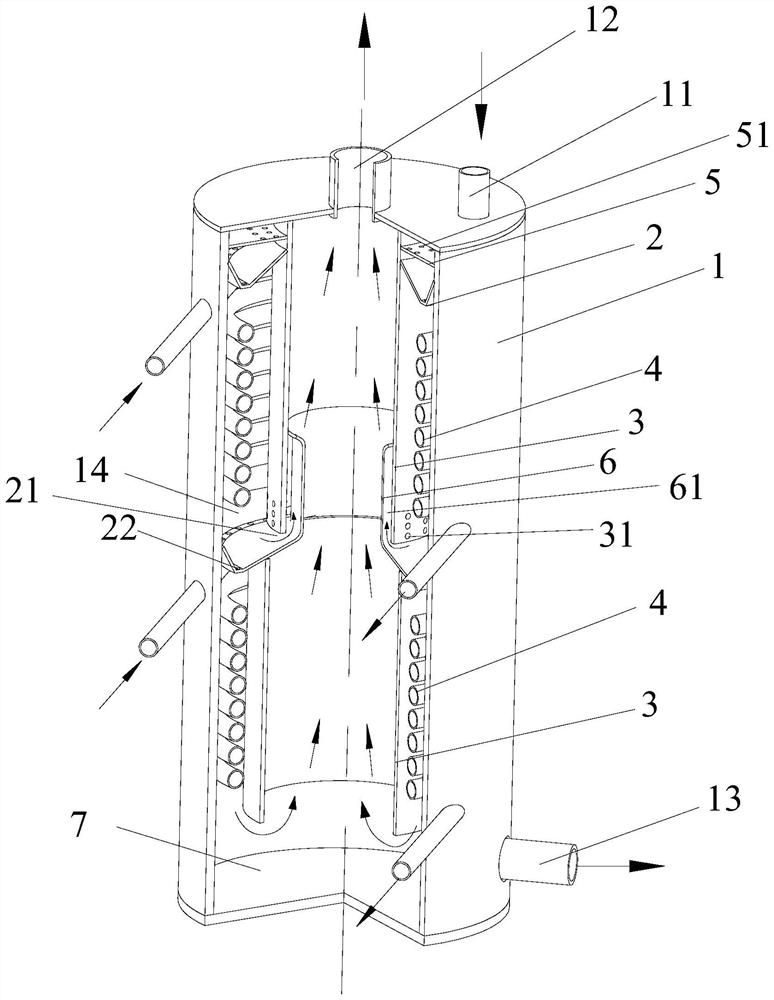

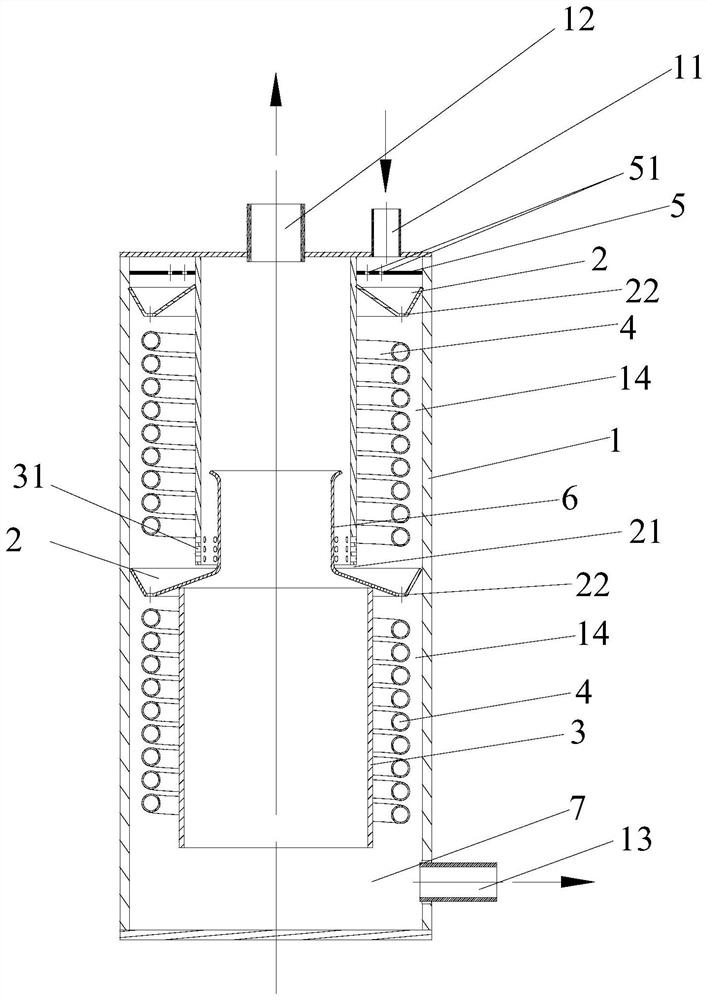

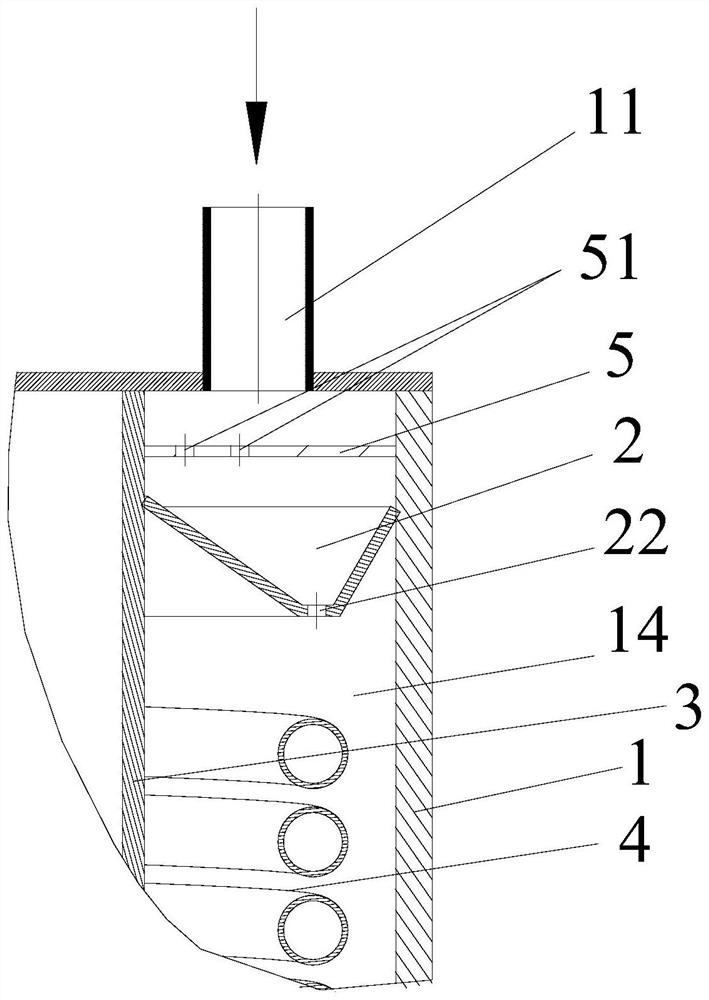

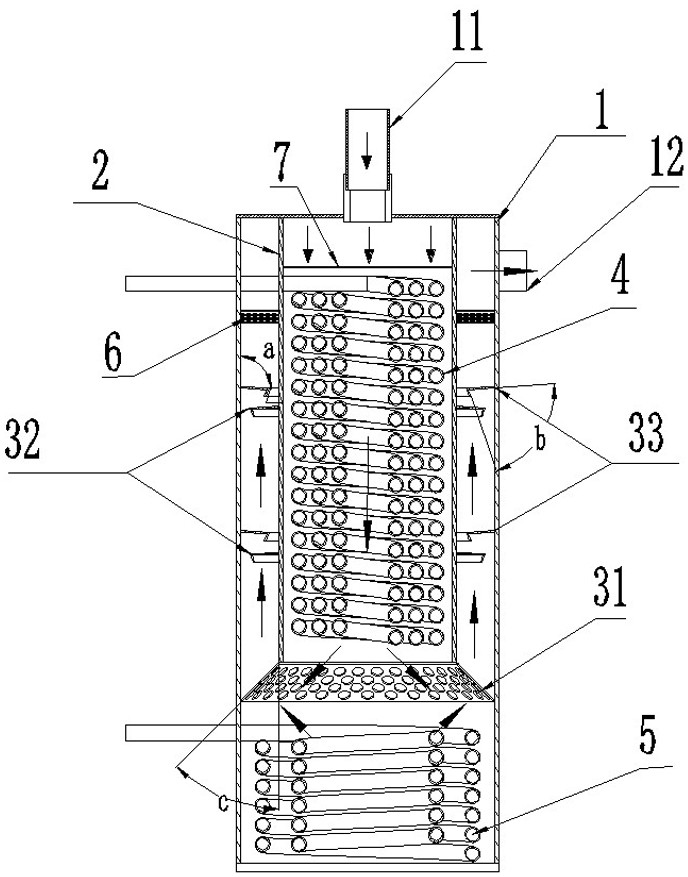

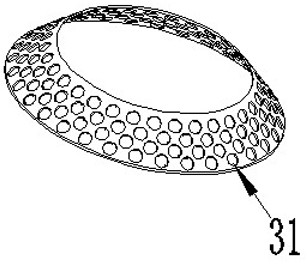

Vertical falling film heat exchanger

PendingCN107551580AEvenly distributedReduce thicknessEvaporator accessoriesWater/sewage treatment by heatingPorosityPlate heat exchanger

The invention provides a vertical falling film heat exchanger, comprising: a cylinder vertically arranged and provided with openings at both ends, an air inlet at the upper part of one side for insertion of an intake pipe, and a liquid outlet at the lower part of the other side; an exhaust distribution plate disposed on the inner wall of one side of the cylinder and provided with distribution holes in both sides; upper and lower tube plates respectively disposed on the upper and lower opening ends of the cylinder; a plurality of heat exchange pipes disposed at the inner part of the cylinder, and two ends of which are respectively inserted into the upper and lower tube plates; at least one liquid collecting plate provided with liquid collecting holes in the surface, sleeving the heat exchange pipe and provided with a notch on the outer edge; a water inlet chamber, of which an open end cover is arranged on the upper tube plate, the side wall is provided with a water inlet for insertion of a water inlet pipe, and the closed end is provided with an exhaust port for insertion of an exhaust pipe; a drainage chamber, of which an open end cover is arranged on the lower tube plate and the closed end is provided with a drainage port for insertion of a drainage pipe. The falling film heat exchanger improves the heat exchange performance on both sides of the shell side and pipe side, greatly improves the heat exchange performance, reduces the cost, is simple in structure, avoids aspirating liquid, and improves system reliability.

Owner:江苏必领能源科技有限公司

Frost-less air-source heat pump hot water unit and proportional-integral-differential control method for same

InactiveCN103245151BExtended service lifeSmooth and continuous adjustmentFluid heatersCorrosion preventionProportional integral differentialEngineering

The invention discloses a frost-less air-source heat pump hot water unit and a proportional-integral-differential control method for the same. The proportional-integral-differential control method includes performing computation according to received air temperature and humidity parameters, received air pressure parameters and received surface temperature parameters of an evaporator when outdoor temperature parameters which are transmitted by a temperature and humidity sensor and are received by a computation controller are lower than 0 DEG C, controlling the opening of an electronic expansion valve according to a computation result and regulating the surface temperature of the evaporator by means of increasing or reducing the opening of the electronic expansion valve so that the surface temperature of the evaporator is constantly higher than a frost formation point; and enabling a silicon-controlled power regulator to judge a suction superheat degree of a compressor according to received suction temperature and suction pressure of the compressor, increasing or reducing the power of an electric heater and maintaining that the suction superheat degree of the compressor only varies within a set value range. The frost-less air-source heat pump hot water unit and the proportional-integral-differential control method have the advantage that adjustment for the opening of the electronic expansion valve is matched with adjustment for the power of the electronic heater, so that the purpose of maintaining safe and efficient running of a system is achieved.

Owner:NANJING NORMAL UNIVERSITY +1

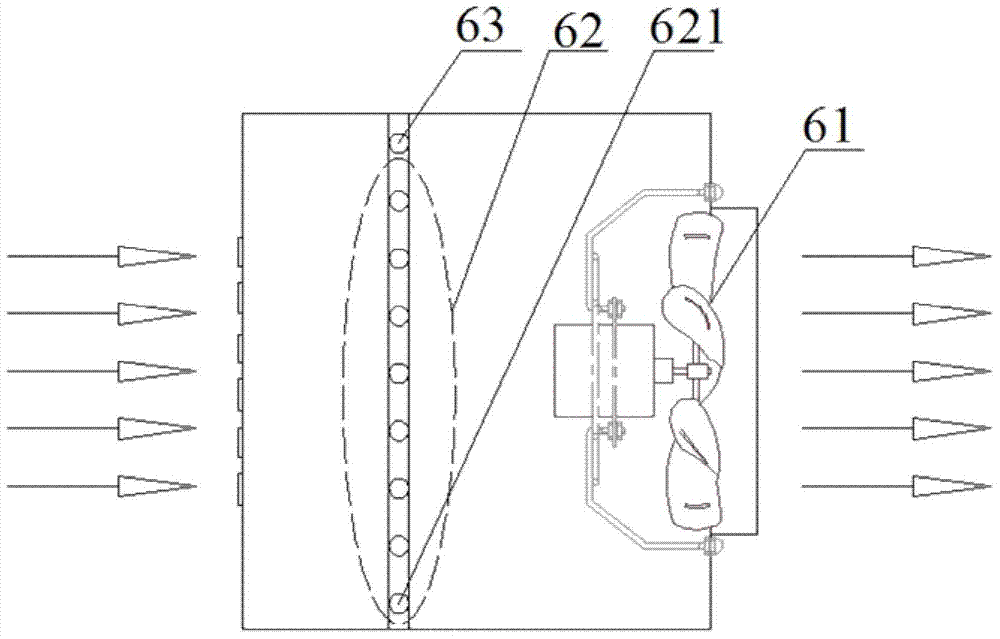

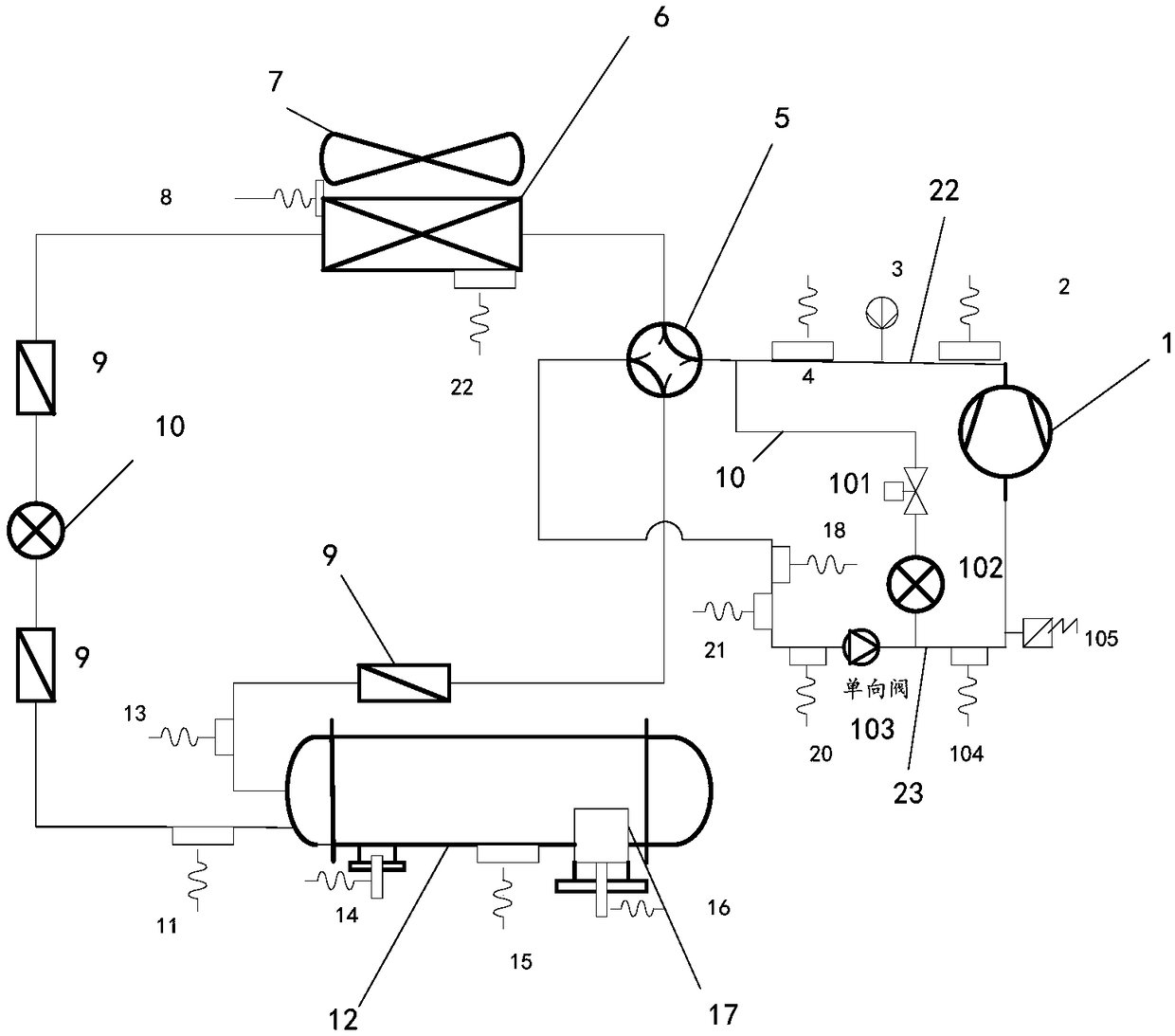

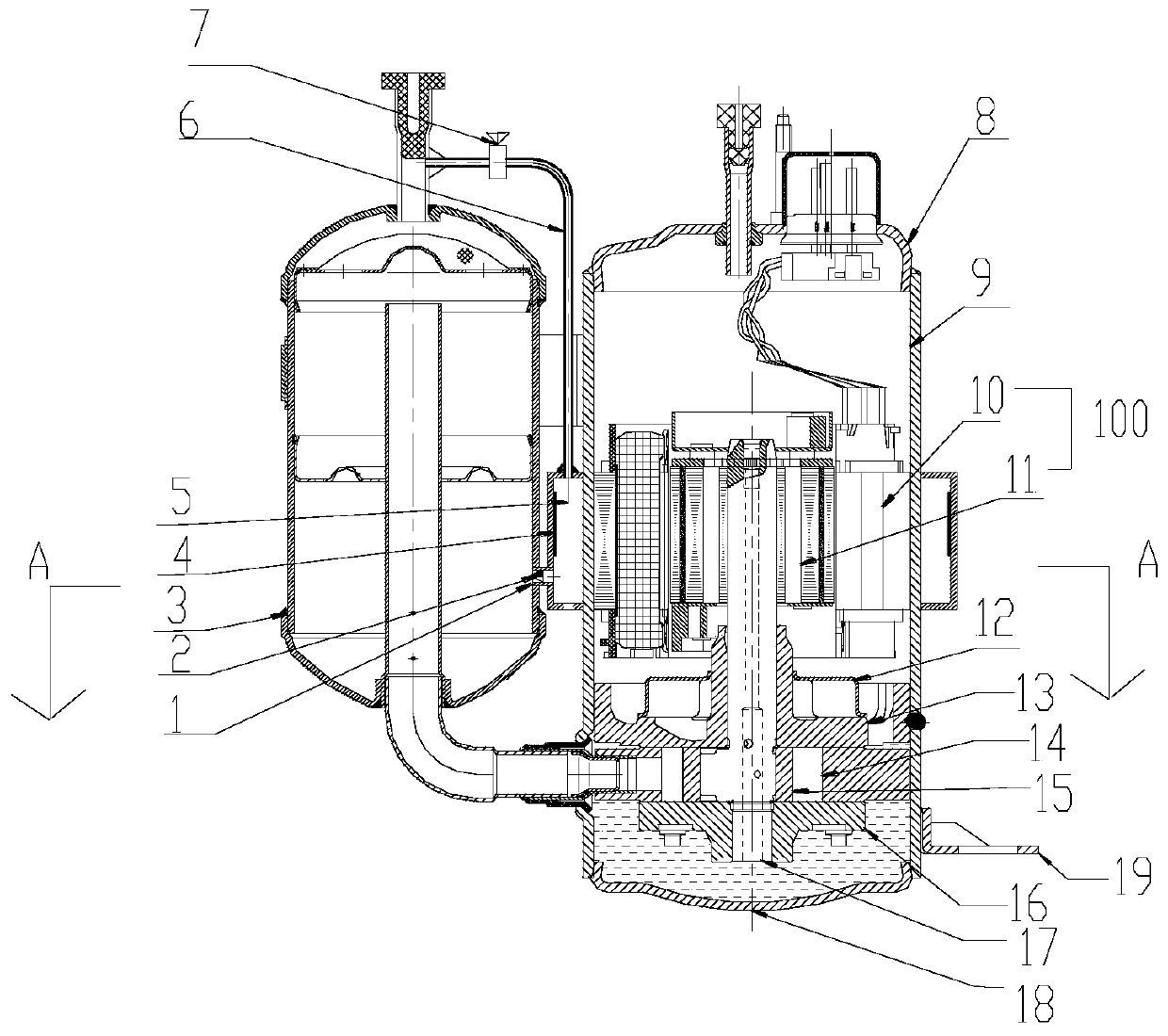

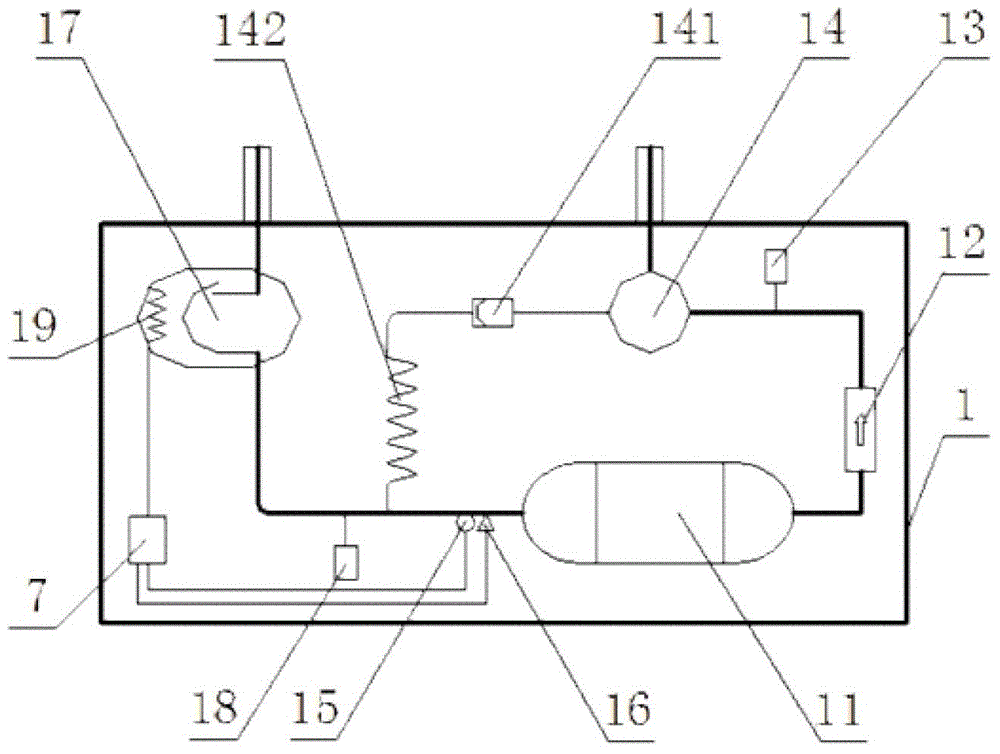

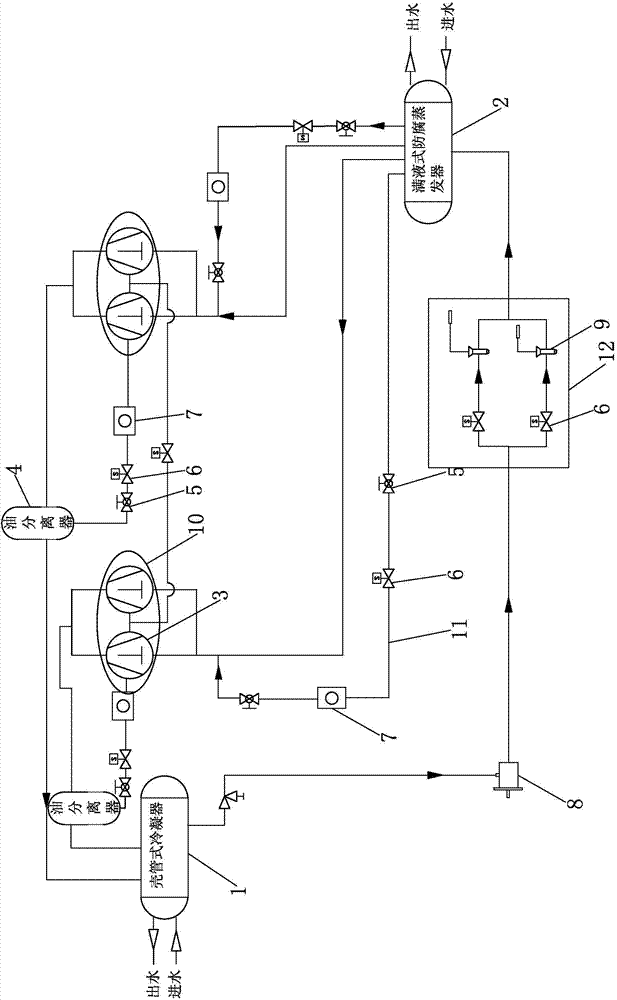

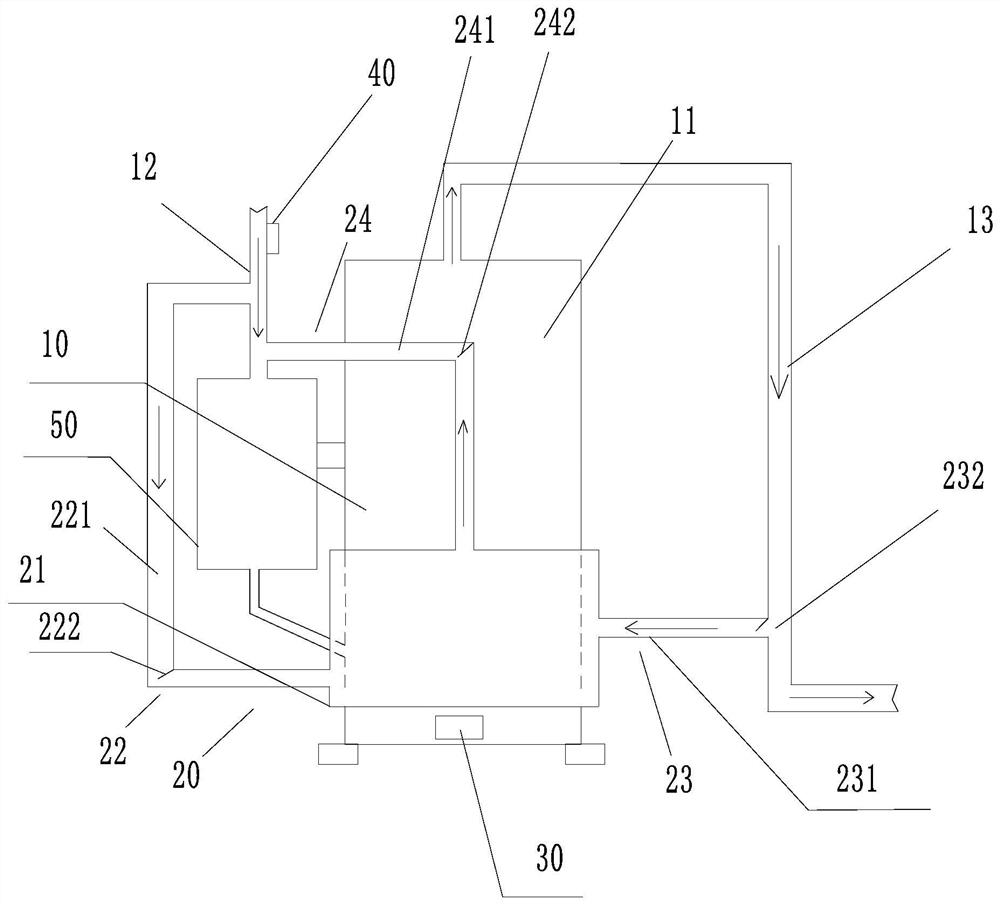

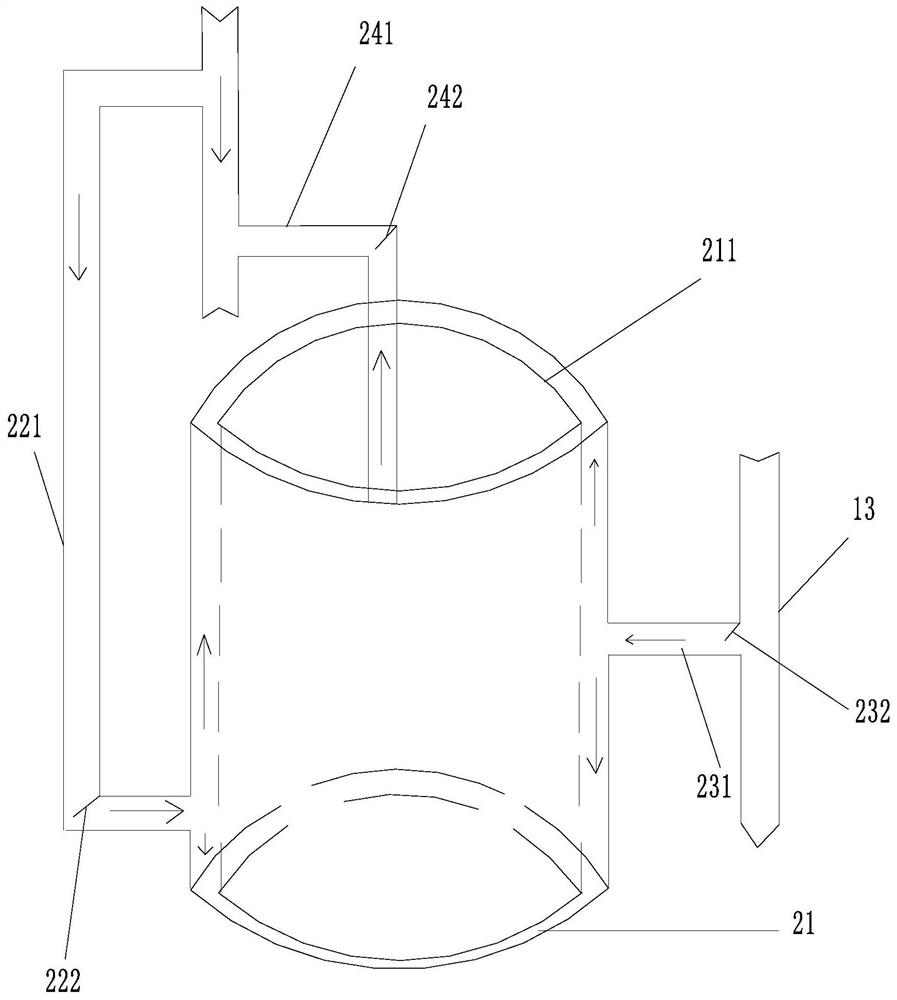

Parallel sharing system vortex hydraulic filling type direct cooling unit special for surface treatment industry

ActiveCN104121715ARealize the function of energy regulationSolve the difficulty of oil returnCompressorMechanical apparatusRefrigeration compressorEnergy regulation

The invention relates to a parallel sharing system vortex hydraulic filling type direct cooling unit special for the surface treatment industry. The parallel sharing system vortex hydraulic filling type direct cooling unit comprises a shell and tube type condenser, a hydraulic filling type corrosion prevention evaporator, a first pipeline system and a second pipeline system, wherein the first pipeline system and the second pipeline system are connected between the shell and tube type condenser and the hydraulic filling type corrosion prevention evaporator. The first pipeline system and the second pipeline system form a closed loop. The first pipeline system comprises two vortex compressor units which are connected in parallel, and each vortex compressor unit comprises multiple refrigeration compressors which are connected in parallel through pipelines, and an oil separator. The refrigeration compressors are connected with the hydraulic filling type corrosion prevention evaporator, the oil separators are connected with the shell and tube type condenser, and oil return pipelines are further connected between the oil separators and the refrigeration compressors. The second pipeline system comprises a drying filter and control valve sets which are connected in parallel and correspondingly control the different vortex compressor units. The parallel sharing system vortex hydraulic filling type direct cooling unit is reasonable and compact in structure, vortex compressors are connected in parallel to form a large-cooling capacity compressor module, and the function of small unit energy adjustment is achieved.

Owner:ZHEJIANG QINGFENG REFRIGERATION EQUIP MFG

Heat exchanger and air conditioning unit

PendingCN113932490ACompact structureIncrease the lengthEvaporators/condensersHeat exchanger casingsEngineeringAir conditioning

The invention provides a heat exchanger and an air conditioning unit. The heat exchanger comprises a shell, liquid homogenizing structures and an air return pipe, the air return pipe is arranged in the shell, one end of the air return pipe is communicated with an exhaust port, the other end of the air return pipe is communicated with the interior of the shell, and the periphery of the air return pipe is sleeved with the liquid homogenizing structures. According to the heat exchanger and the air conditioning unit, the multiple liquid homogenizing structures and multiple heat exchange mechanisms are arranged, coil pipe structures are adopted, the length of heat exchange pipes is effectively increased, and therefore the falling film evaporation effect is improved, and the gravity potential difference is greatly increased through the vertical shell. Meanwhile, air return channels are arranged in the middles of the heat exchange mechanisms, so that the heat exchanger is compact in structure, liquid blocking pipes can effectively prevent liquid drops from flowing, the problem of air suction with liquid of the heat exchanger is further avoided, and the falling film heat exchange effect of the heat exchanger is effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC

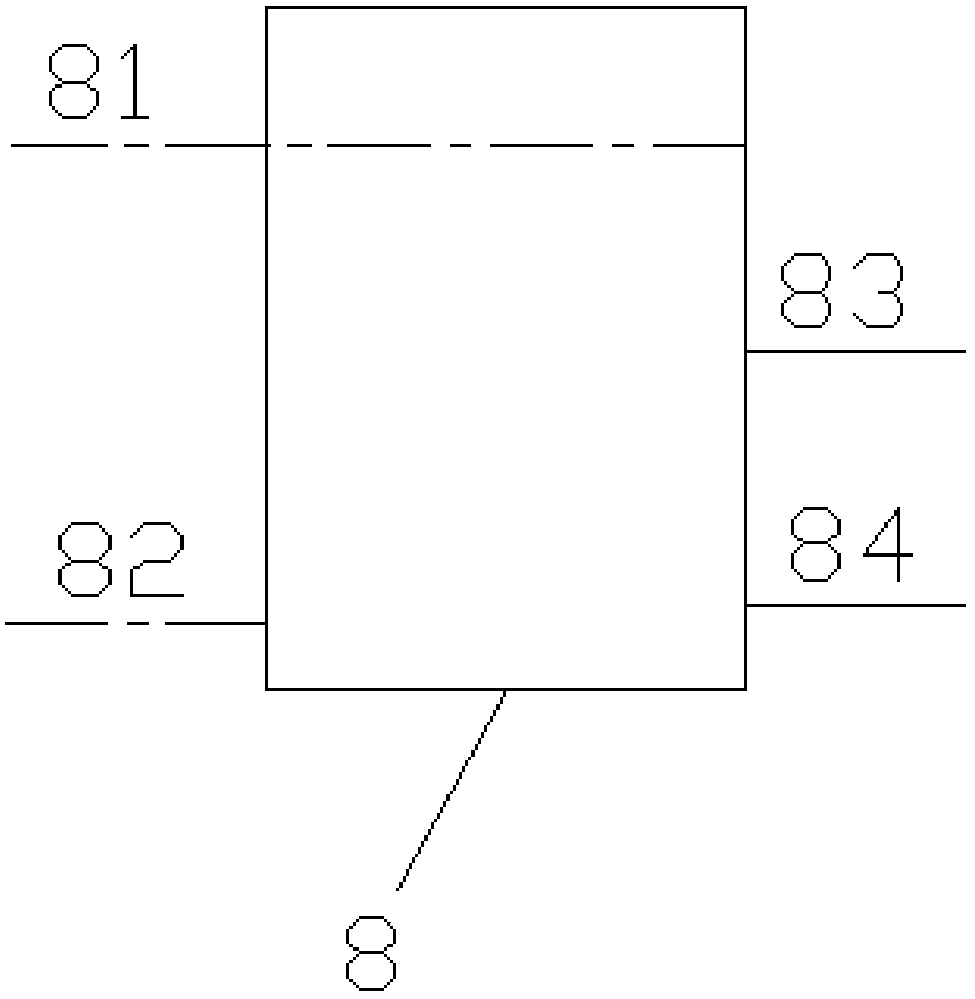

Liquid accumulator assembly, control method thereof and air conditioner system

PendingCN108375252AAvoid aspiration of fluidGuaranteed reliabilityRefrigeration componentsLiquid stateEngineering

The invention provides a liquid accumulator assembly, a control method of the liquid accumulator assembly and an air conditioner system. The liquid accumulator assembly comprises a liquid accumulatorand a connection pipe, the liquid accumulator is connected with an air suction port of a compressor through the connection pipe, and the liquid accumulator and / or the connection pipe are / is provided with a heat preservation structure; and / or, the liquid accumulator and / or the connection pipe are / is provided with a heating structure. The liquid accumulator assembly has a heat preservation layer andthe heating structure, refrigerants in the liquid accumulator can be effectively prevented from being changed into the liquid state from the gas state, so that all the refrigerants entering the compressor are gaseous refrigerants, the problem that the compressor brings liquid when performing air suction is avoided, the reliability and safety of the compressor in the use process are guaranteed, and the service life of the compressor is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

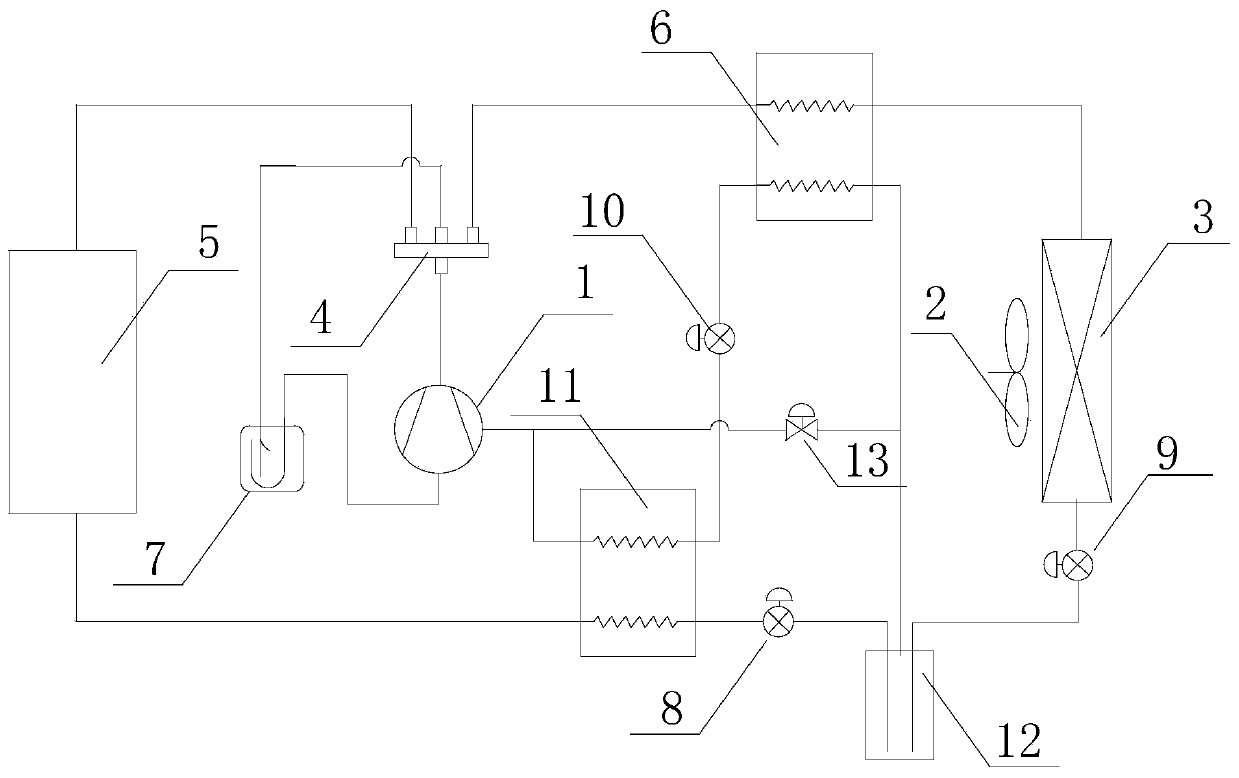

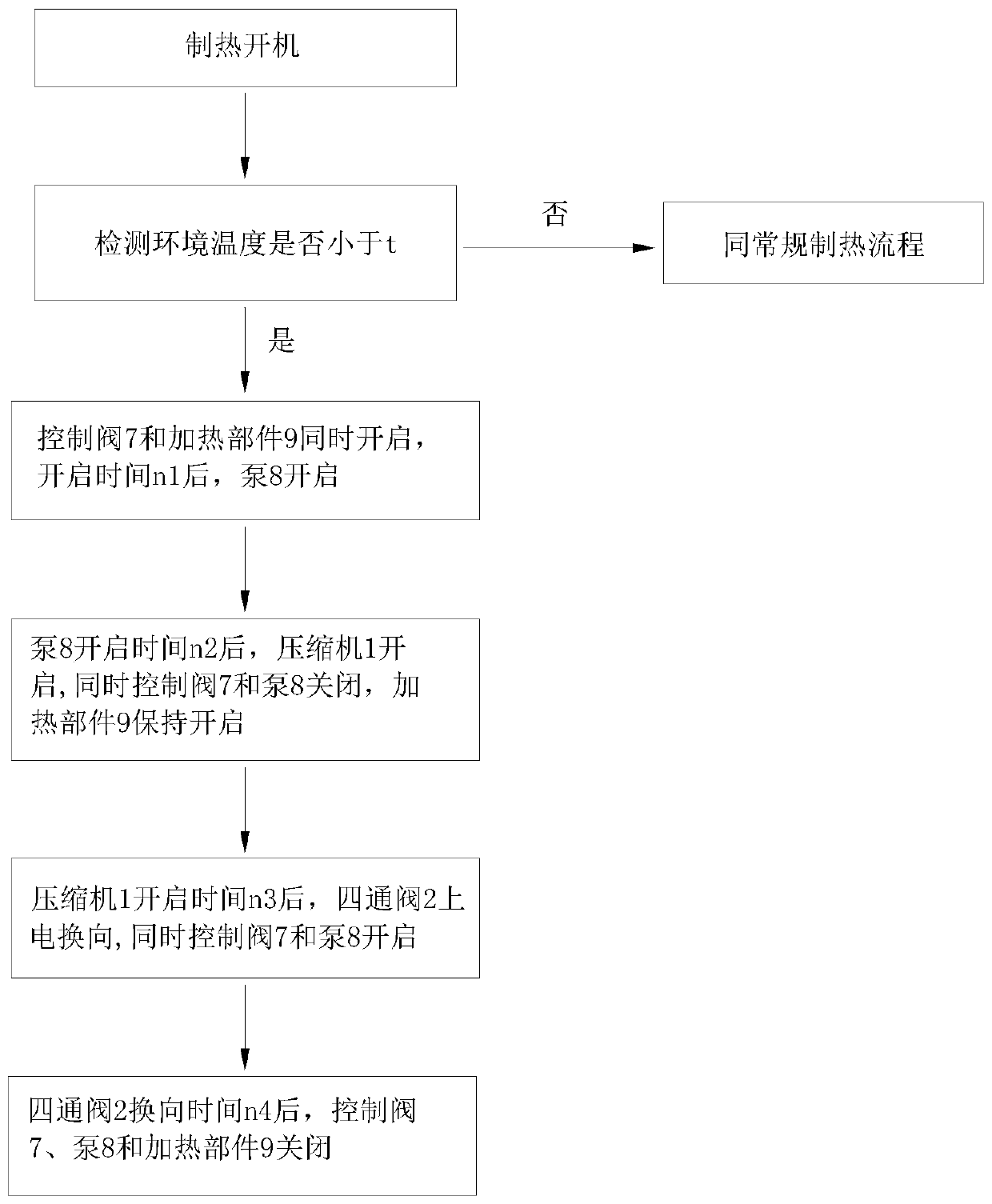

A heat pump system and its control method

ActiveCN109751723BFast heatingIncrease flow pressureMechanical apparatusHeat pumpsVapor–liquid separatorEngineering

The invention provides a heat pump system and a control method thereof. The heat pump system comprises a compressor (1), an outdoor heat exchanger (6) and a gas-liquid separator (5); and a bypass branch circuit (11) is connected between the outdoor heat exchanger (6) and the gas-liquid separator (5), a fluoride pump (8), a heating part (9) and a control valve (7) are arranged on the bypass branchcircuit (11), and a refrigerating agent in the outdoor heat exchanger (6) can be introduced into an air suction port of the compressor (1) after passing through the bypass branch circuit (11) and being heated. According to the heat pump system and the control method thereof, when a heat pump is started and the compressor is started, the refrigerating agent can be pumped out from the outdoor heat exchanger, heated and delivered to the air suction port of the compressor through the fluoride pump, the control valve and the heating part, therefore, a refrigerant entering the air suction port of the compressor is a gaseous refrigerant, and the technical problems that when the compressor is started to run under the low-temperature heating work condition, the refrigerant flow is small, and the air suction pressure of the compressor is low are solved.

Owner:GREE ELECTRIC APPLIANCES INC

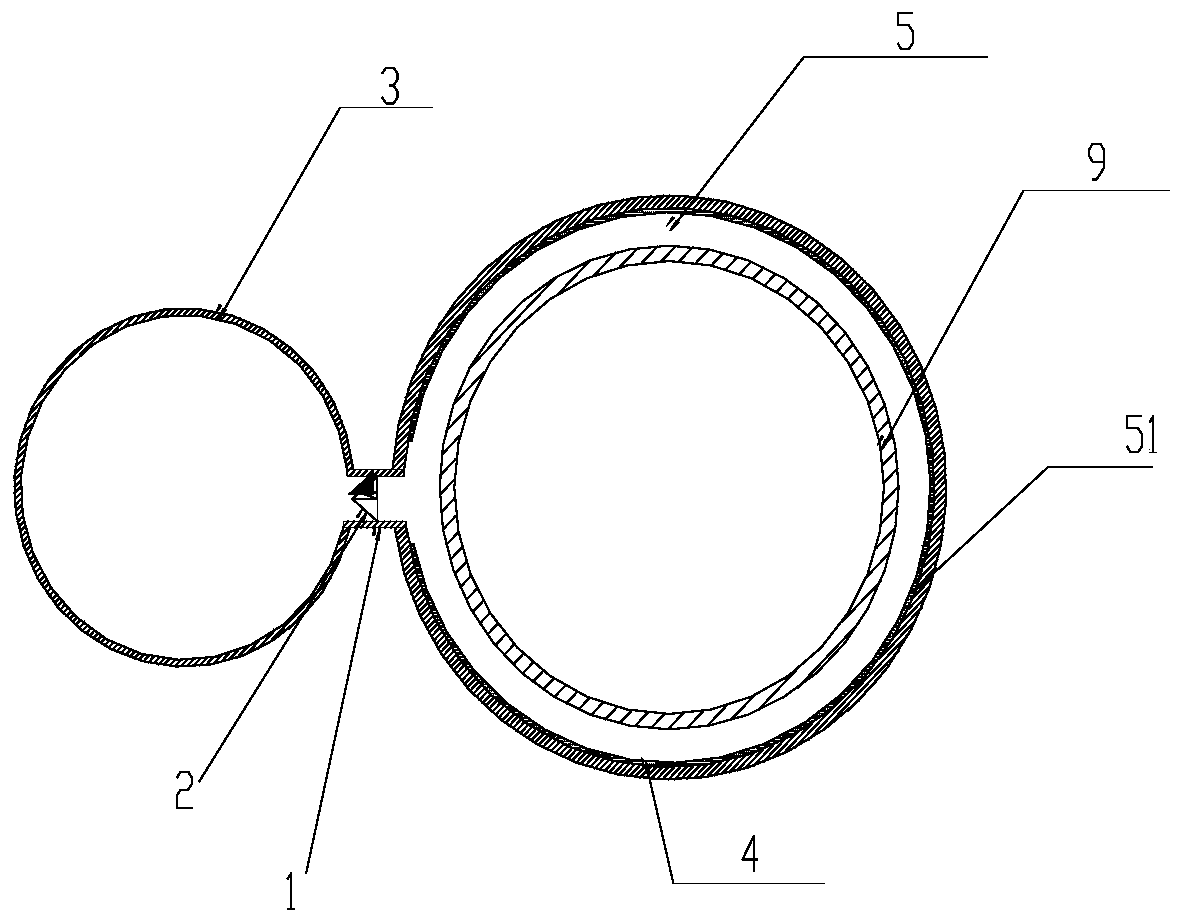

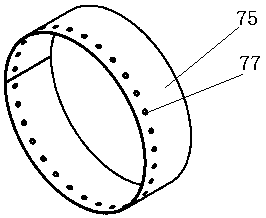

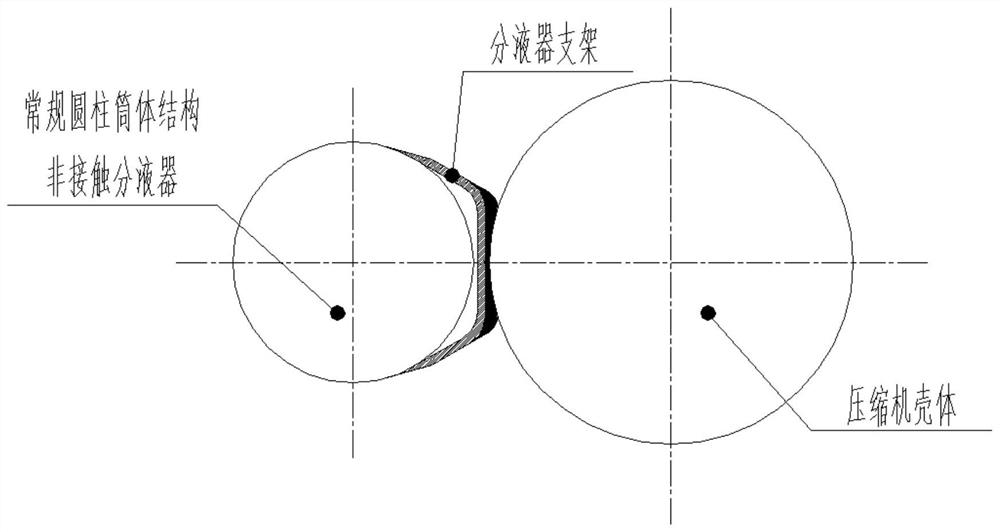

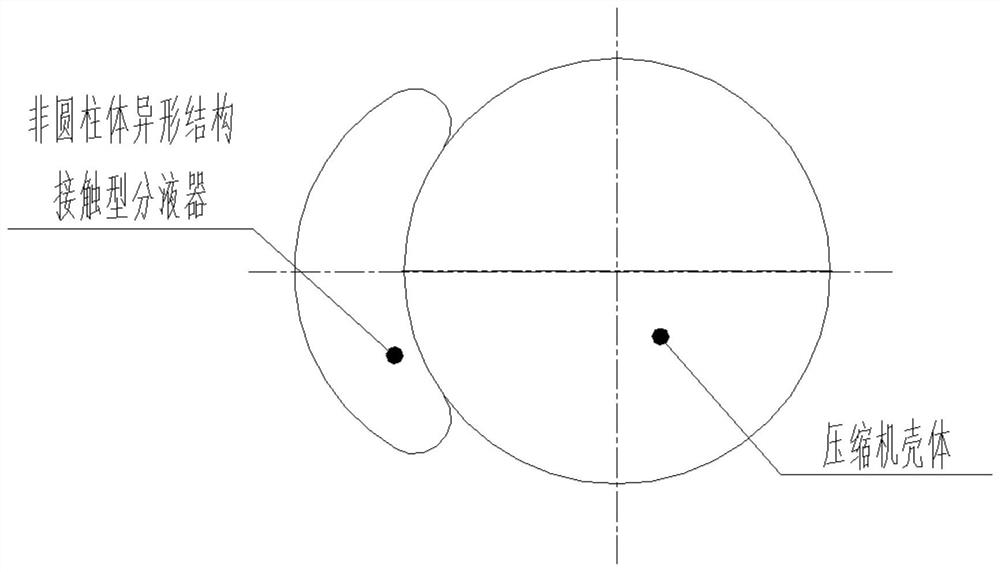

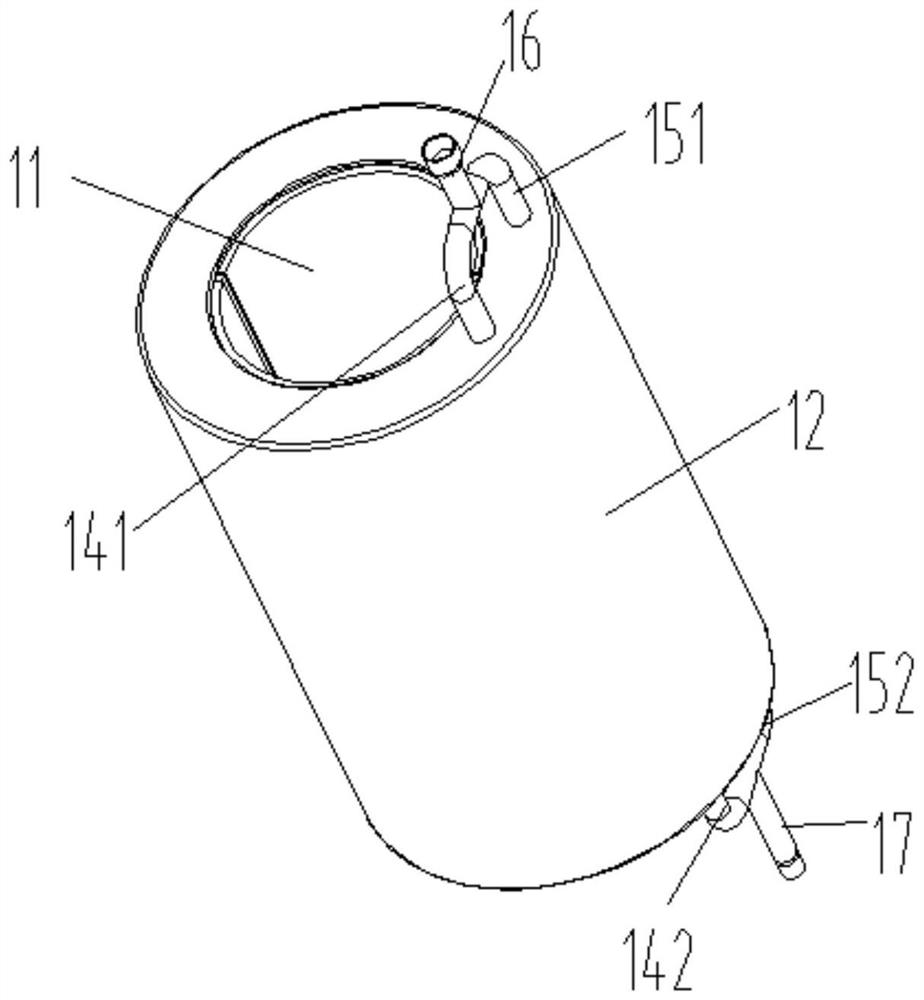

Liquid separator, compressor, air conditioner

ActiveCN112797679BImprove heating effectHigh working reliabilityRefrigeration componentsThermal insulationEngineering

The invention provides a liquid separator, a compressor, and an air conditioner, wherein the liquid separator includes a first ring wall and a second ring wall located radially outside the first ring wall, the first ring wall and the second ring wall A liquid separation space is formed between the walls, and a separator is provided in the liquid separation space to separate the liquid separation space into a first liquid separation chamber and a second liquid separation chamber, wherein the first liquid separation chamber corresponds to the first ring wall The first wall area, the first wall area can conduct heat exchange with the shell of the compressor, the second liquid separation chamber corresponds to the second wall area of the first ring wall, the distance between the second wall area and the shell of the compressor insulated. According to the present invention, by reasonably dividing the liquid separation space into mutually independent liquid separation chambers, and conducting heat conduction or heat insulation treatment between the liquid separation chamber and the shell of the compressor according to the difference between the cooling and heating modes of the air conditioner, it can satisfy The refrigerant in different states in the liquid separator has different requirements for heat transfer between the compressor body and the external environment.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Liquid blocking structure, heat exchanger and air conditioner

PendingCN114001498AIncrease heat transfer contact areaReduce perfusionEvaporators/condensersEngineeringRefrigerant

The invention discloses a liquid blocking structure, a heat exchanger and an air conditioner. The structure comprises a shell and an inner shell which is arranged in the shell and used for covering a heat exchange coil pipe, an air channel area is formed in a gap between the shell and the inner shell, a refrigerant outlet is formed in the upper portion, corresponding to the air channel area, of the shell, and a liquid blocking assembly is arranged in the air channel area. The multi-layer inner coil pipe type heat exchange pipe is adopted, the falling film area heat exchange pipe is covered with the barrel, an annular space is formed between the barrel and the shell, a gaseous refrigerant is discharged upwards from the peripheral annular area, the liquid blocking structure and the filter screen device are arranged between the inner shell and the shell, when gas flows upwards, the liquid blocking device is impacted through inertia, splashing liquid drops are separated out, and the liquid drops flow into the flooded area under the action of gravity, so that the compressor is prevented from sucking air and carrying liquid, the heat exchange performance of the unit is enhanced, and the refrigerant filling amount can be saved.

Owner:GREE ELECTRIC APPLIANCES INC

Compressor, air conditioner and control method of compressor

PendingCN111692653AAvoid aspiration of fluidAvoid reliabilityCompressorMechanical apparatusEngineeringMechanical engineering

The invention provides a compressor, an air conditioner and a control method of the compressor. The compressor comprises a compressor body, the compressor body comprises a compressor shell, an air suction pipe and an exhaust pipe, the compressor further comprises a refrigerant circulating device, the refrigerant circulating device comprises an air storage box arranged on the compressor shell, a first pipeline, a second pipeline and an exhaust pipeline, one end of the first pipeline is connected with the air storage box, the other end of the first pipeline is connected with the air suction pipe, and the first pipeline is connected with the air suction pipe in an on-off manner; one end of the second pipeline is connected with the air storage box, the other end of the second pipeline is connected with the exhaust pipe, and the second pipeline is connected with the exhaust pipe in an on-off manner; and one end of the exhaust pipeline is connected with the air storage box, the other end ofthe exhaust pipeline is connected with the air suction pipe, and the exhaust pipeline is connected with the air suction pipe in an on-off manner. The compressor solves the problem that the temperatureof a compressor cannot be adjusted in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

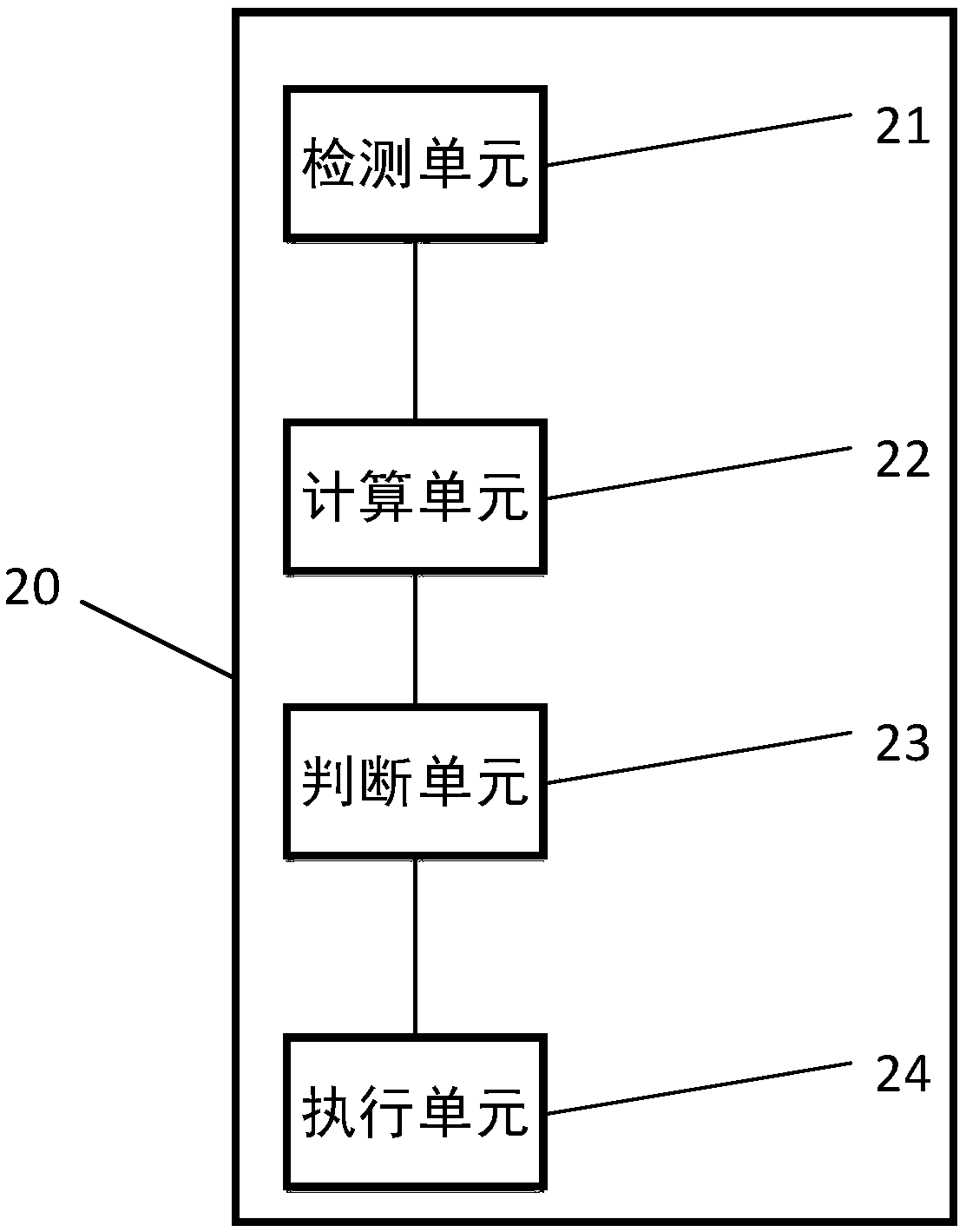

Control system, control method and air-conditioning system for preventing air-conditioning compressor liquid shock

ActiveCN106524612BPrevent liquid hammerAvoid aspiration of fluidRefrigeration safety arrangementControl systemExecution unit

The invention provides a control system and method for preventing liquid impacts of an air conditioner compressor and an air conditioner system. The air conditioner system comprises a flow adjusting valve (13) arranged at the position of the air suction end of the compressor (1) and used for adjusting the flow of refrigerants at the position. The control system comprises a detection unit, a calculation unit, a judgment unit and an execution unit, wherein the detection unit is used for detecting the refrigerant parameter value of an air conditioner and the parameter value of the compressor, the calculation unit is used for calculating the exhaust superheat degree fitted value of the air conditioner according to a detection result of the detection unit, the judgment unit is used for judging the relationship between the exhaust superheat degree fitted value and the preset value according to the calculation result of the calculation unit, and the execution unit is used for executing the flow adjusting valve adjustment on aperture increasing through opening or aperture reducing through closing according to the judgment result of the judgment unit. By means of the control system and method for preventing liquid impacts of the air conditioner compressor and the air conditioner system, the aperture of the flow adjusting valve can be adjusted according to the fact that whether the number of the refrigerants entering the compressor is too small or too large, the liquid impact phenomenon of the compressor is effectively prevented, and air suction liquid entrainment of the compressor is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

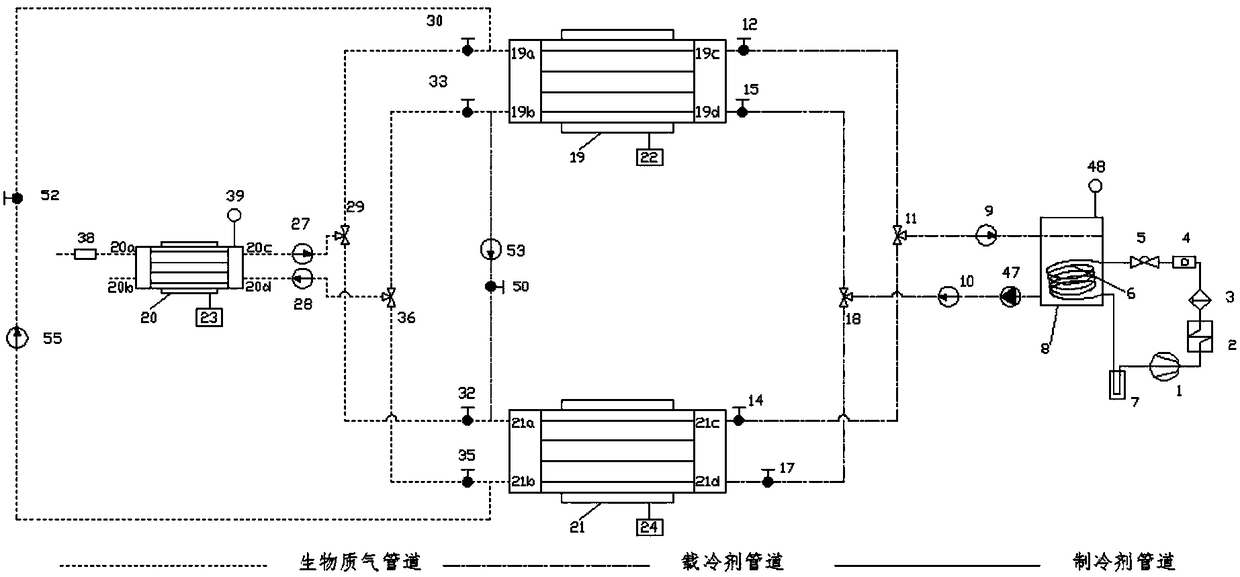

A device for removing siloxane from biomass gas

ActiveCN105910389BAvoid shockAvoid aspiration of fluidSolidificationLiquefactionProcess engineeringEnvironmental engineering

The invention discloses a device for removing siloxane in biomass gas, which includes a refrigeration cycle unit, a refrigerant cycle unit and a biomass gas siloxane removal unit; a cold storage tank is provided for cold storage of the refrigerant, and two The heat exchanger for removing siloxane works alternately, and the incoming biomass gas is precooled by the refrigerant after heat exchange with the biomass gas and the biomass gas after removing siloxane. The invention can adapt to different working conditions, and is suitable for removing siloxane gases in biomass gas in actual operation, so as to ensure efficient application of biomass gas.

Owner:CHANGZHOU TONGYI DRYING EQUIP

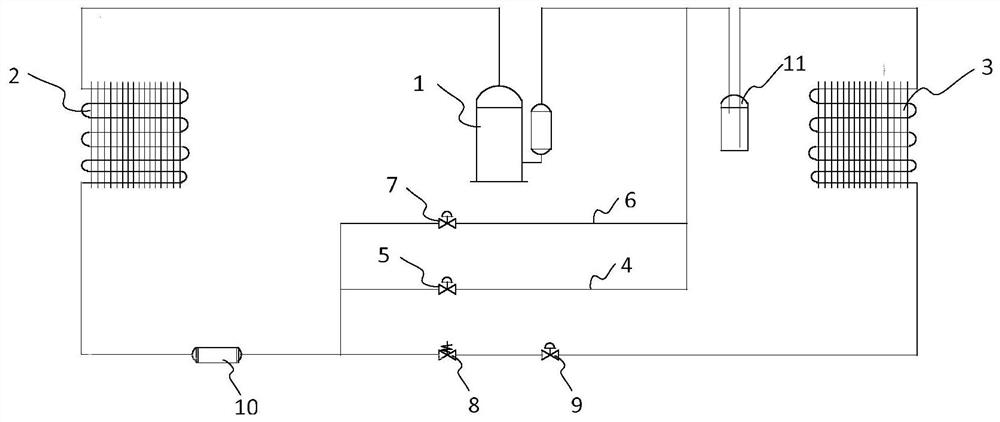

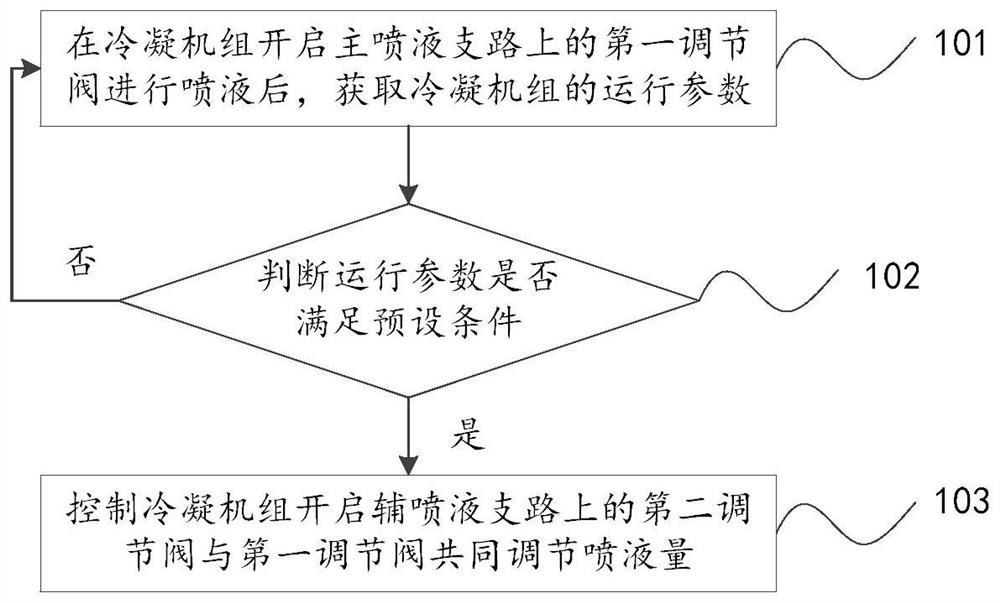

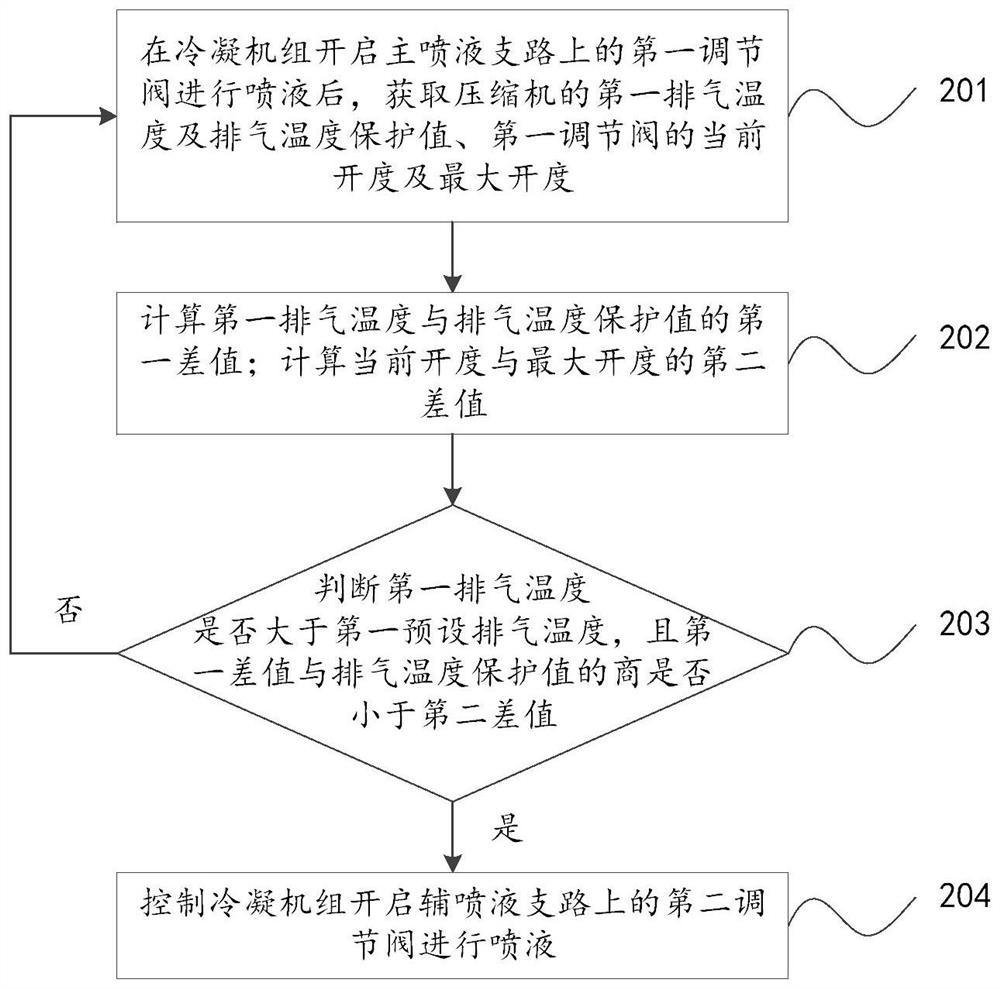

Condensing unit, liquid spraying control method and control device thereof and air conditioner

PendingCN114857793AAvoid aspiration of fluidExtend your lifeMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringMechanical engineering

The invention provides a condensing unit, a liquid spraying control method and device of the condensing unit and an air conditioner. The liquid spraying control method comprises the steps that after the condensing unit starts a first adjusting valve on a main liquid spraying branch to spray liquid, operation parameters of the condensing unit are obtained; judging whether the operation parameters meet preset conditions or not; and when the judgment result is yes, the condensing unit is controlled to open a second adjusting valve on the auxiliary liquid spraying branch to adjust the liquid spraying amount together with the first adjusting valve. According to the liquid spraying control method, the two adjusting valves are used for jointly coordinating to spray liquid, accurate control over the liquid spraying amount of the condensing unit is achieved, compressor shutdown caused by insufficient liquid spraying amount is prevented, and suction liquid carrying caused by excessive liquid spraying amount is prevented; the refrigerating capacity loss caused by too large liquid spraying amount is reduced; and moreover, the liquid spraying amount range is controlled more widely, the adaptability of the unit is improved, and comfortable operation can be maintained under the high-pressure-ratio working condition.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com