A heat pump system and its control method

A technology of a heat pump system and control method, which is applied to heat pumps, refrigerators, refrigeration components, etc., can solve the problems of low suction pressure of compressors and small refrigerant flow, and achieve increased refrigerant flow, suction pressure, and heating speed. Fast, smooth press start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

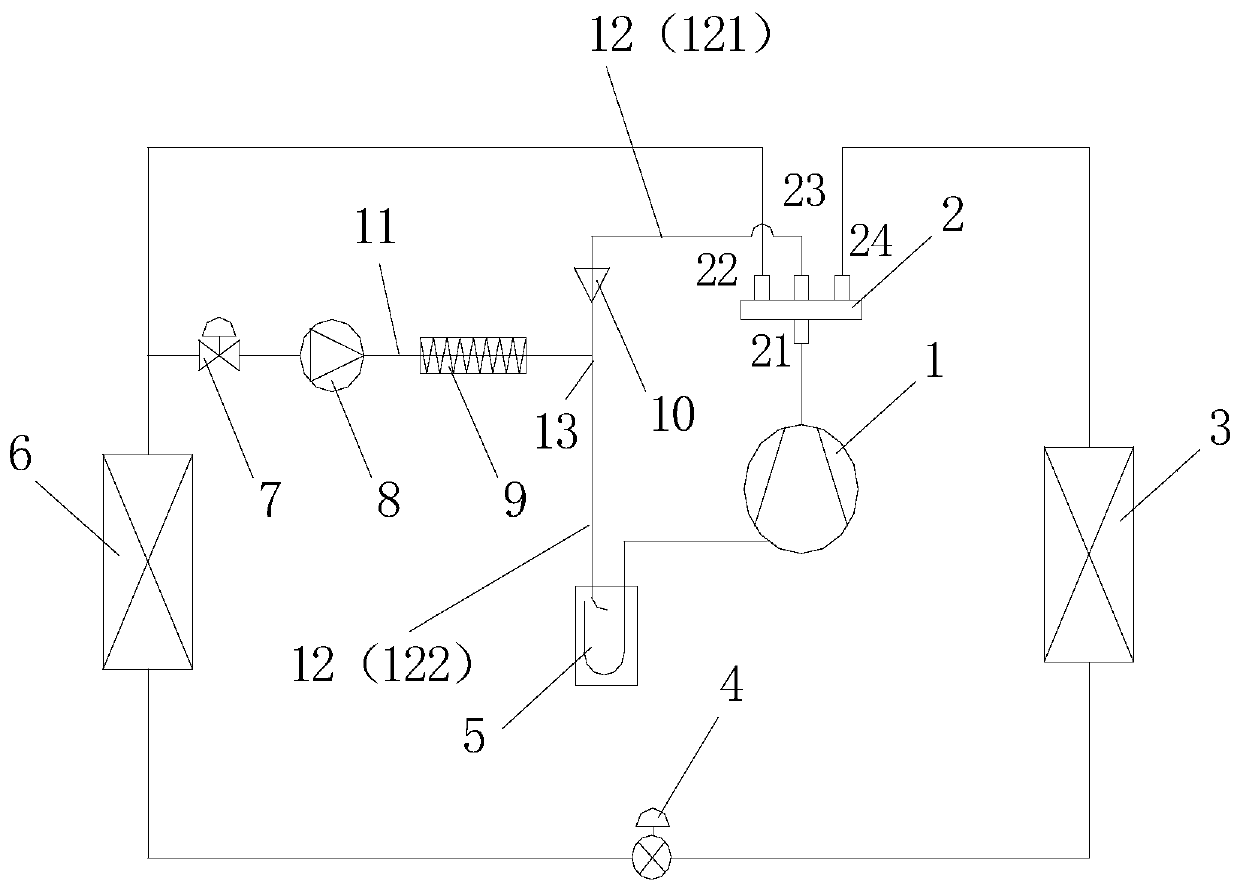

[0039] Such as Figure 1-2 As shown, the present invention provides a heat pump system, which includes:

[0040] Compressor 1, outdoor heat exchanger 6, gas-liquid separator 5;

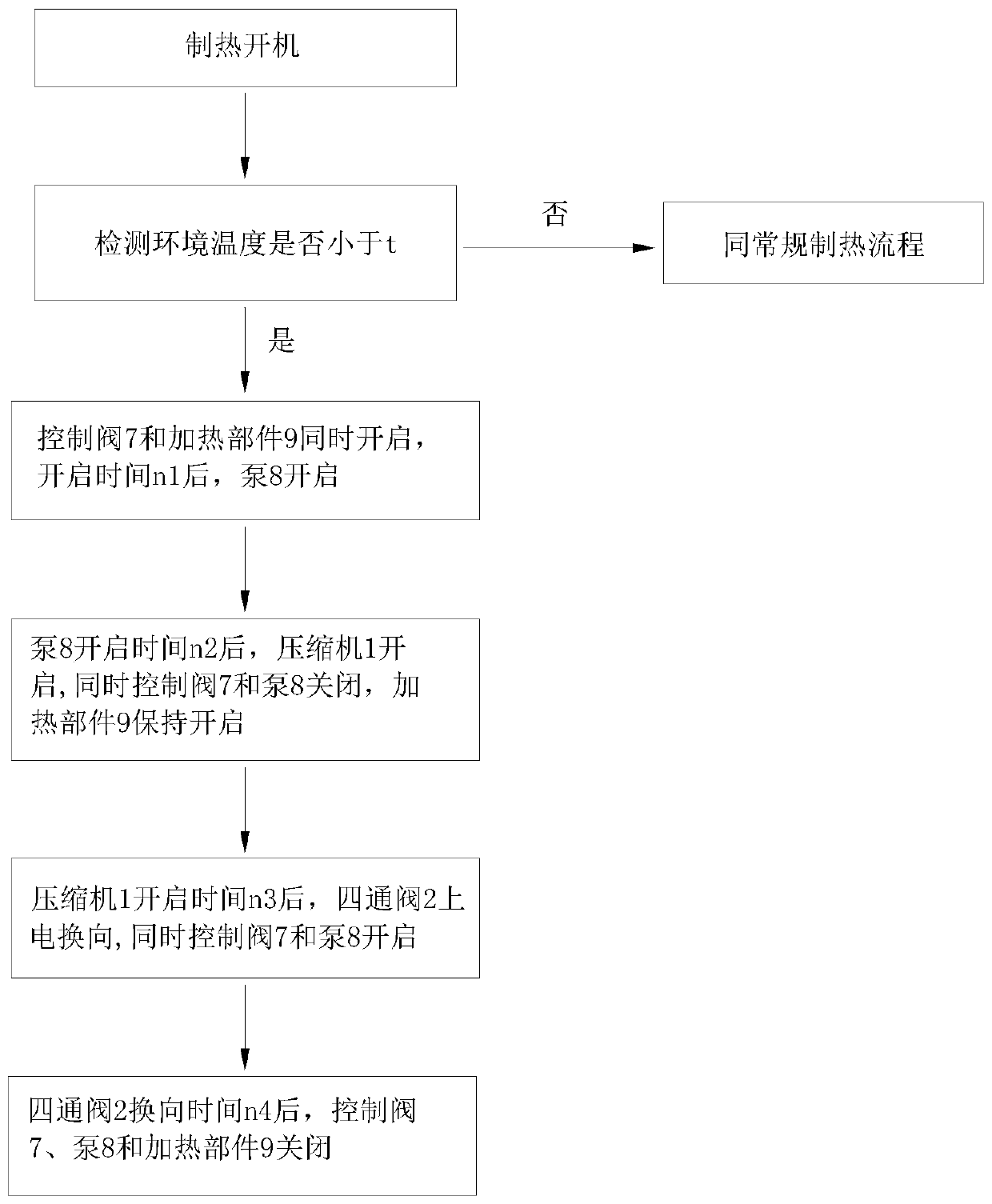

[0041] Furthermore, a bypass branch 11 is connected between the outdoor heat exchanger 6 and the gas-liquid separator 5, and a fluorine pump 8 and heating components 9 and 9 are also provided on the bypass branch 11. The control valve 7 can introduce the refrigerant in the outdoor heat exchanger 6 through the bypass branch 11 and be heated to the suction port of the compressor 1.

[0042] In the present invention, a bypass branch is added between the outdoor heat exchanger and the gas-liquid separator in the heat pump system, and the bypass branch is also provided with a fluorine pump, heating components and a control valve, which can compress when the heat pump is turned on. When the machine is started, the refrigerant is pumped from the outdoor heat exchanger to the suction port of the compressor through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com