Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Anti-reverse loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

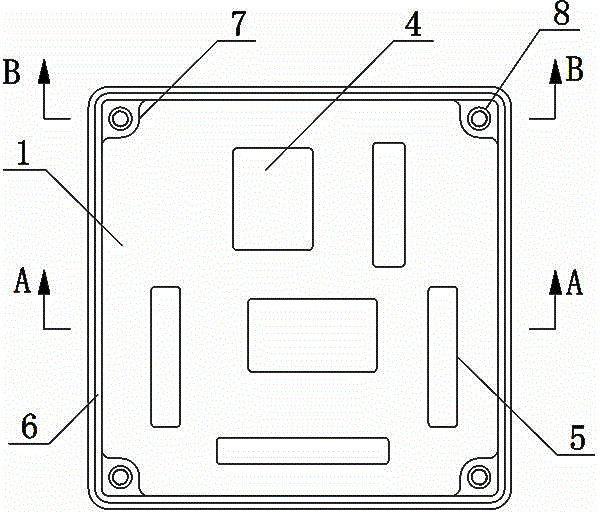

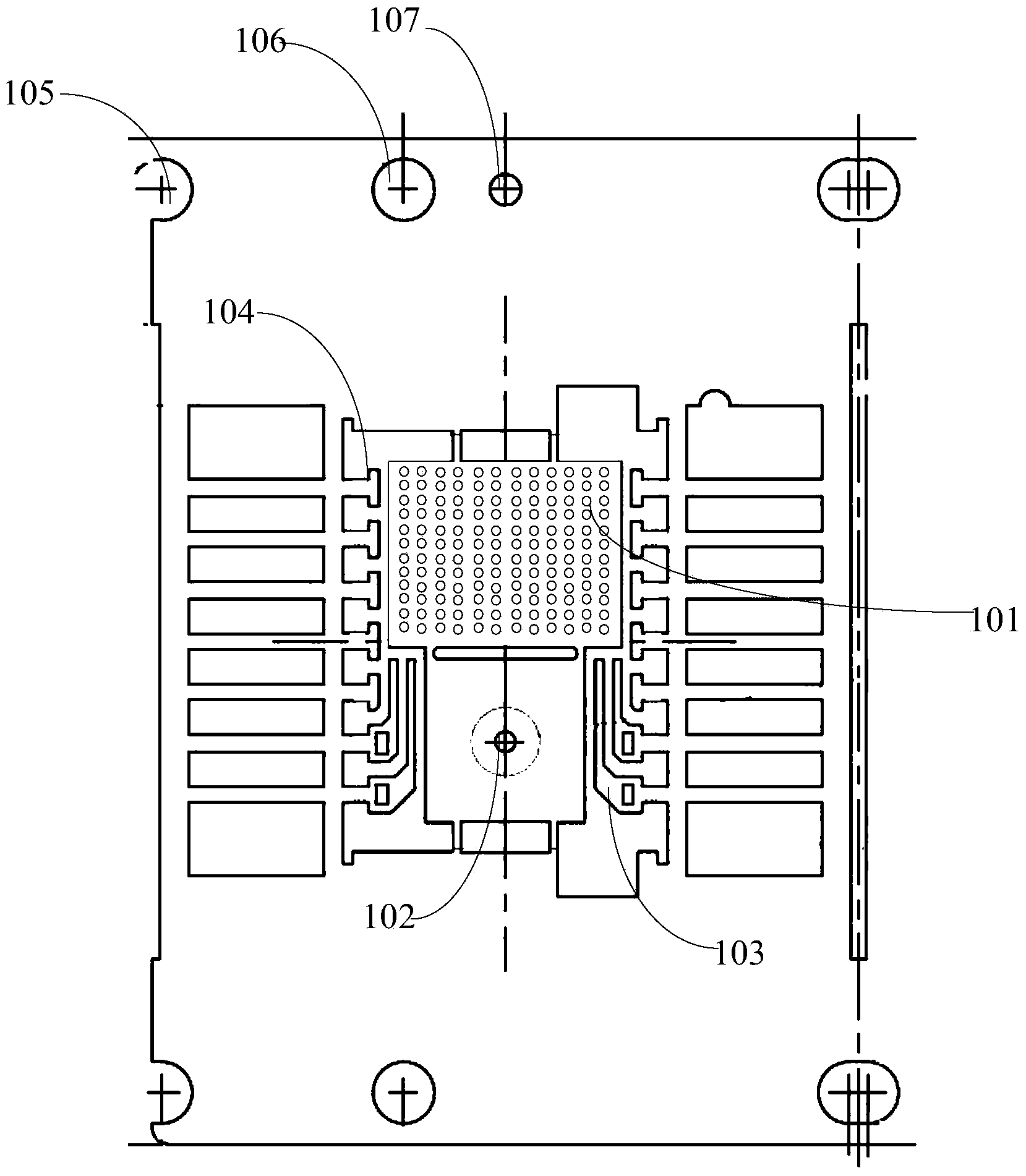

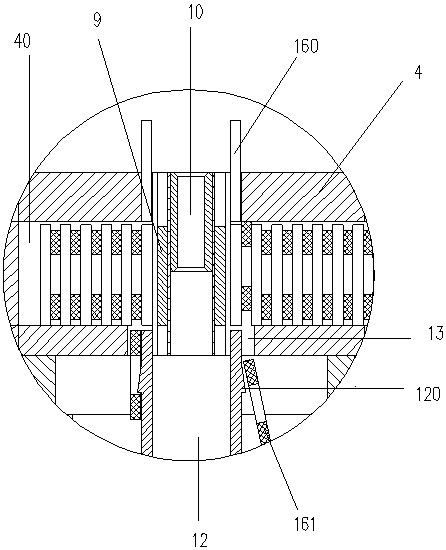

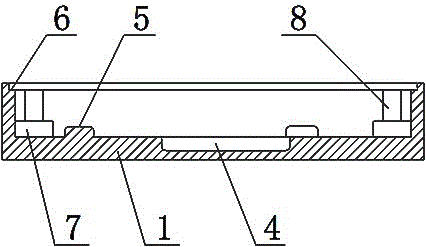

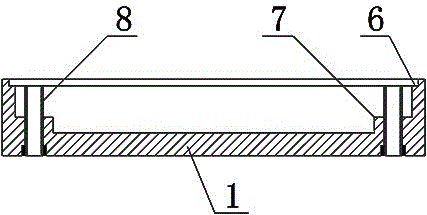

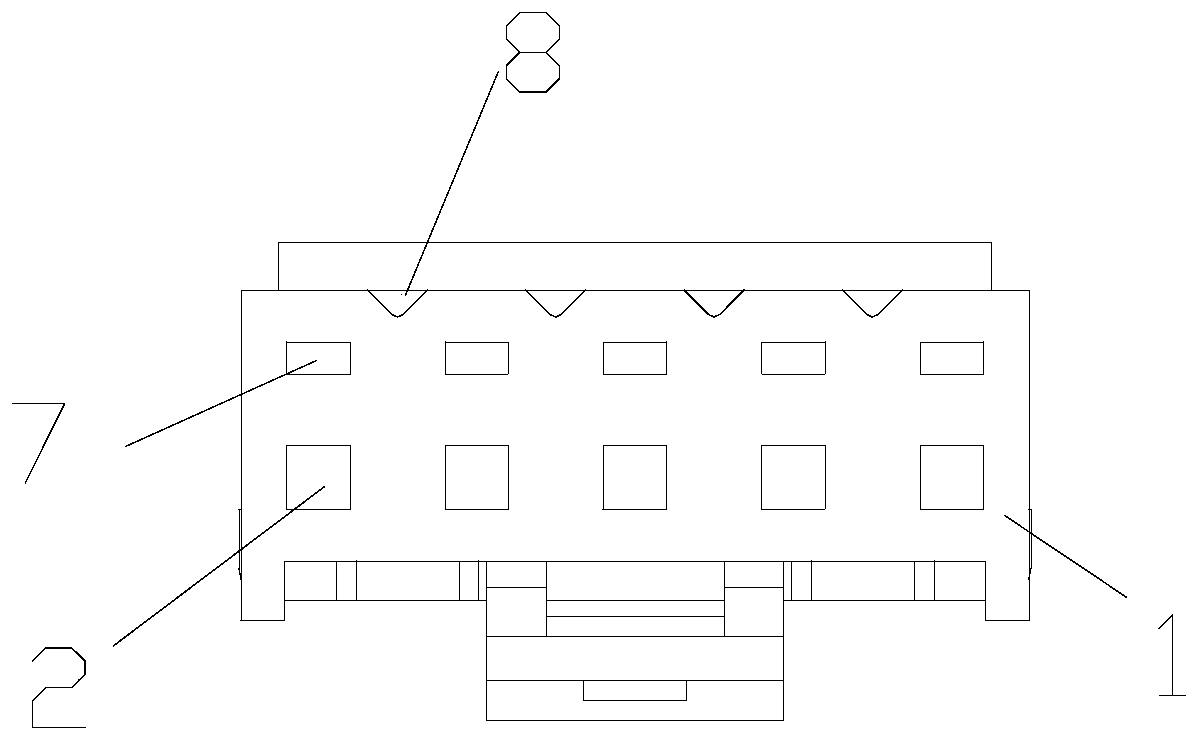

Well-radiating module power supply

ActiveCN104377940AIncrease contact areaImprove cooling effectCasings/cabinets/drawers detailsModifications for power electronicsEngineeringHeating element

Owner:SICHUAN SHENGHUA POWER TECH CO LTD

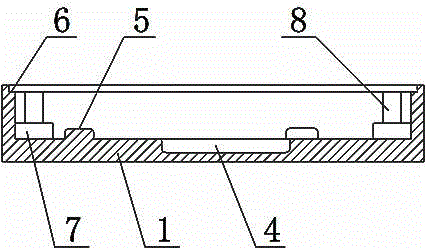

Puncture navigation system

PendingCN108577942APrecise and stable penetrationVersatileSurgical needlesX-ray/gamma-ray/particle-irradiation therapyEngineeringNavigation system

The invention belongs to the technical field of particle puncture, and provides a puncture navigation system. The puncture navigation system comprises an adjusting arm for achieving movement in the three-dimensional direction; a fine-adjusting device is arranged on the adjusting arm and comprises a first shaft sleeve arranged on the adjusting arm; a vertical rotating rod is rotatably arranged in the first shaft sleeve; a second shaft sleeve is arranged on the vertical rotating rod; a transverse rotating rod is arranged in the second shaft sleeve; a pin shaft is arranged at the end of the transverse rotating rod; a puncture needle clamping device is arranged on the pin shaft and comprises a rotating piece rotatably arranged on the pin shaft, the rotating piece is in a semicircular shape ora fan shape, and a vertical needle holding hole is formed in the rotating piece; and angular scale lines are arranged on the rotating piece, and pointers for indicating the rotating piece to rotate byangles are arranged on the transverse rotating rod. The technical problem that in the prior art, precision and regularity of puncture operation of a puncture needle are difficult to achieve is solved.

Owner:河北海思开尔医院管理股份有限公司

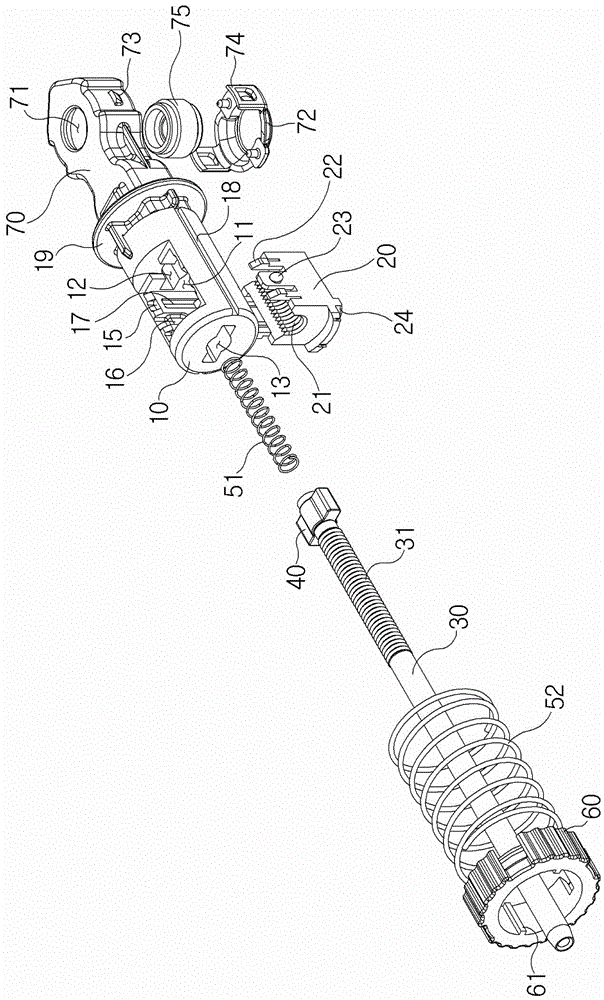

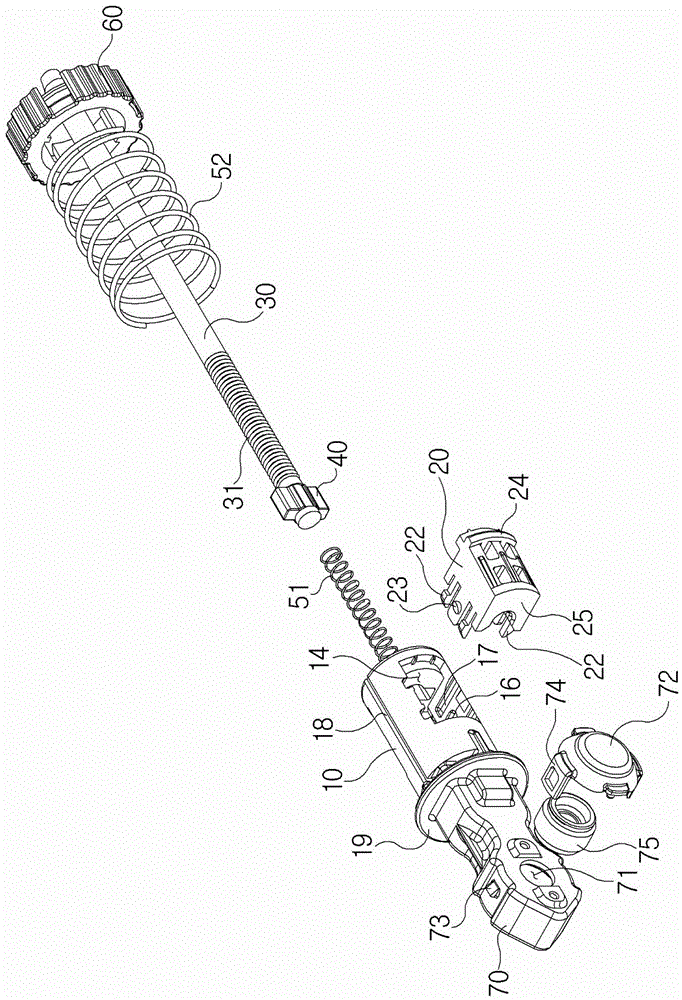

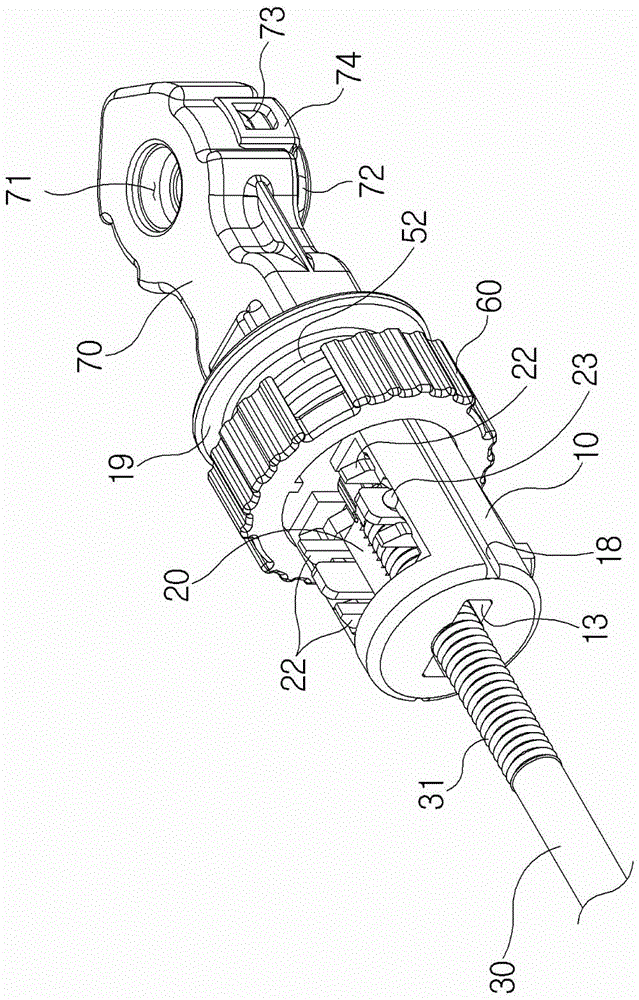

Vehicle cable connecting device

InactiveCN105593048AFirmly connectedImprove fastening forceGearing controlShaft for rotary movementElectric cablesEngineering

Owner:株式会社因派克

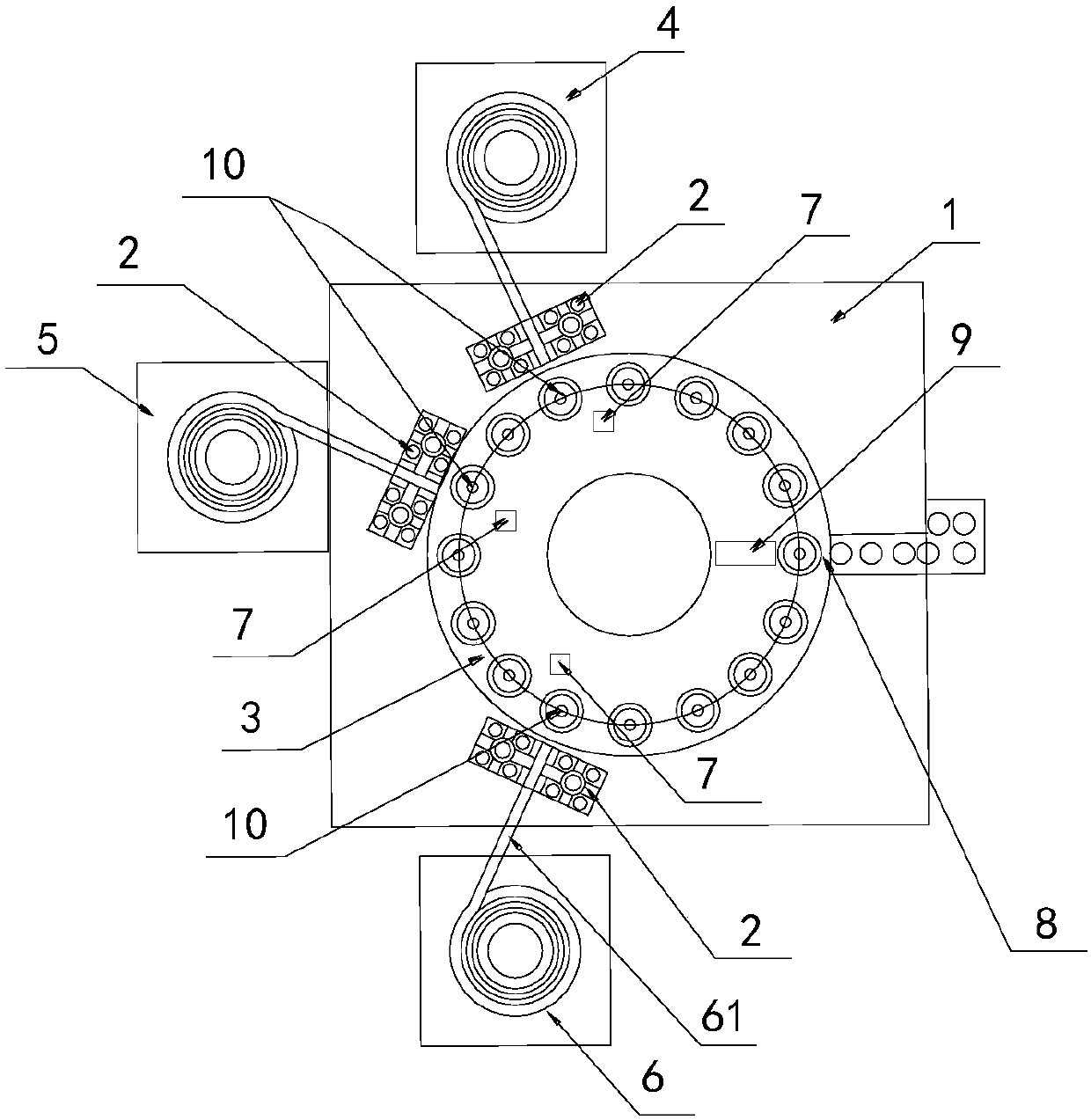

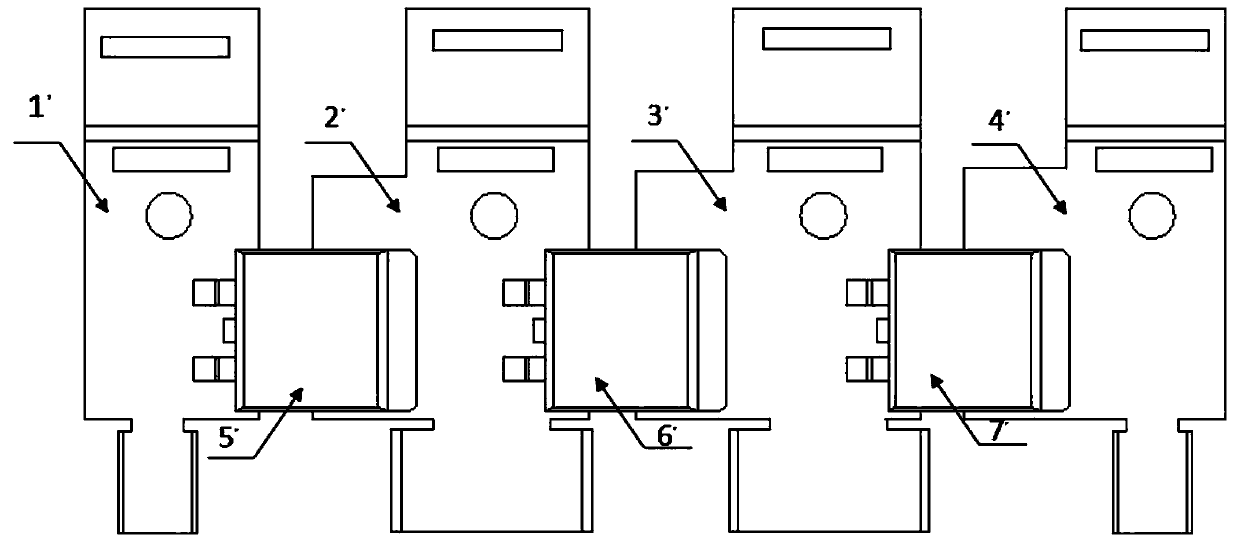

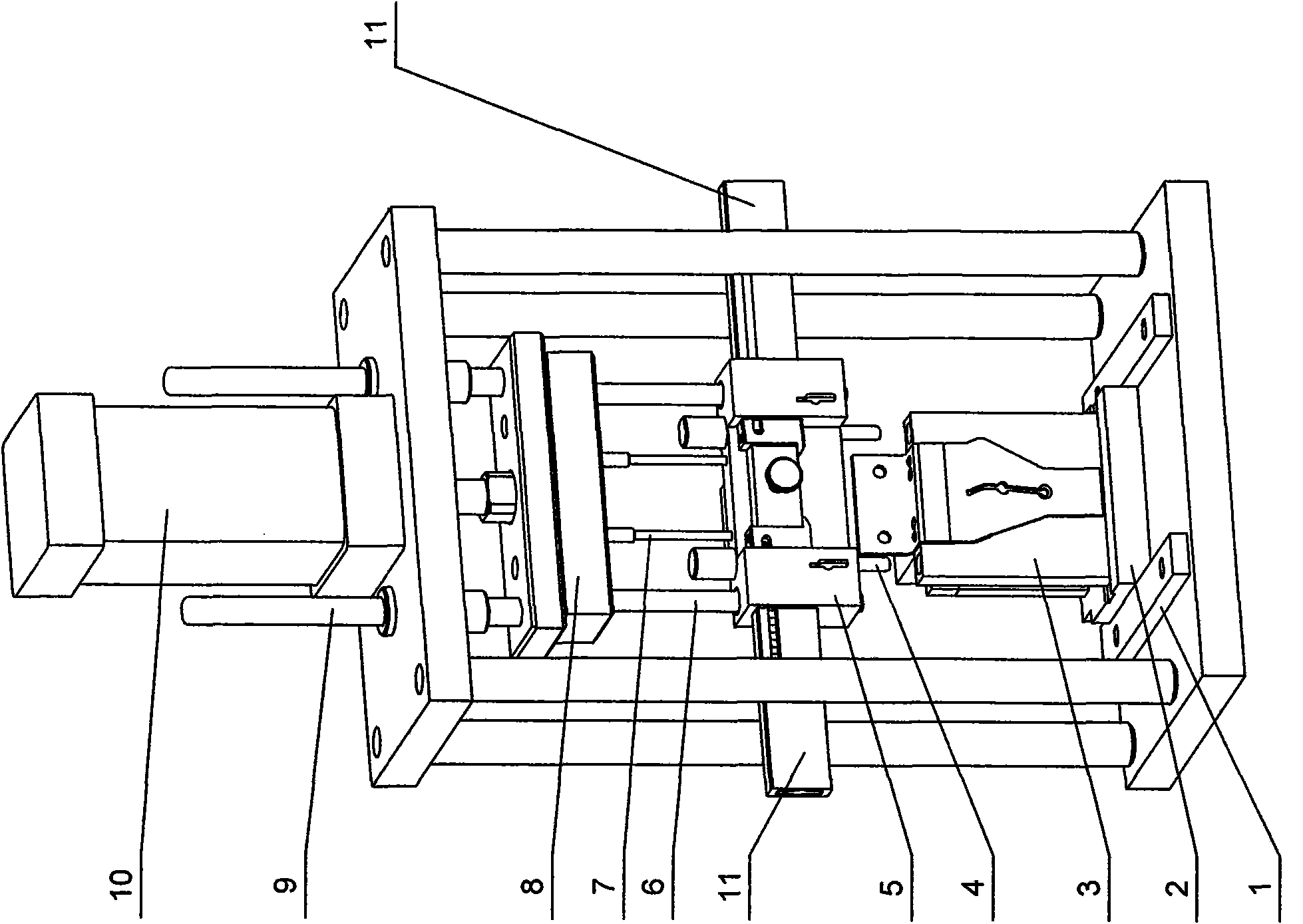

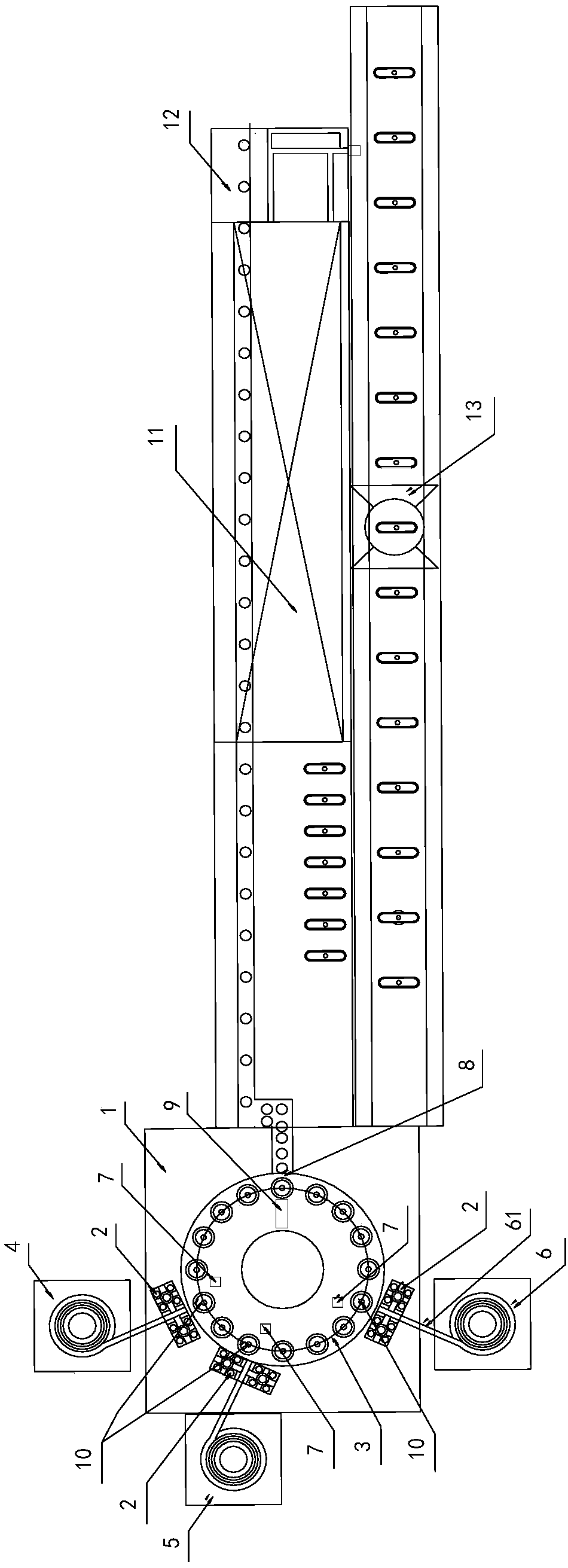

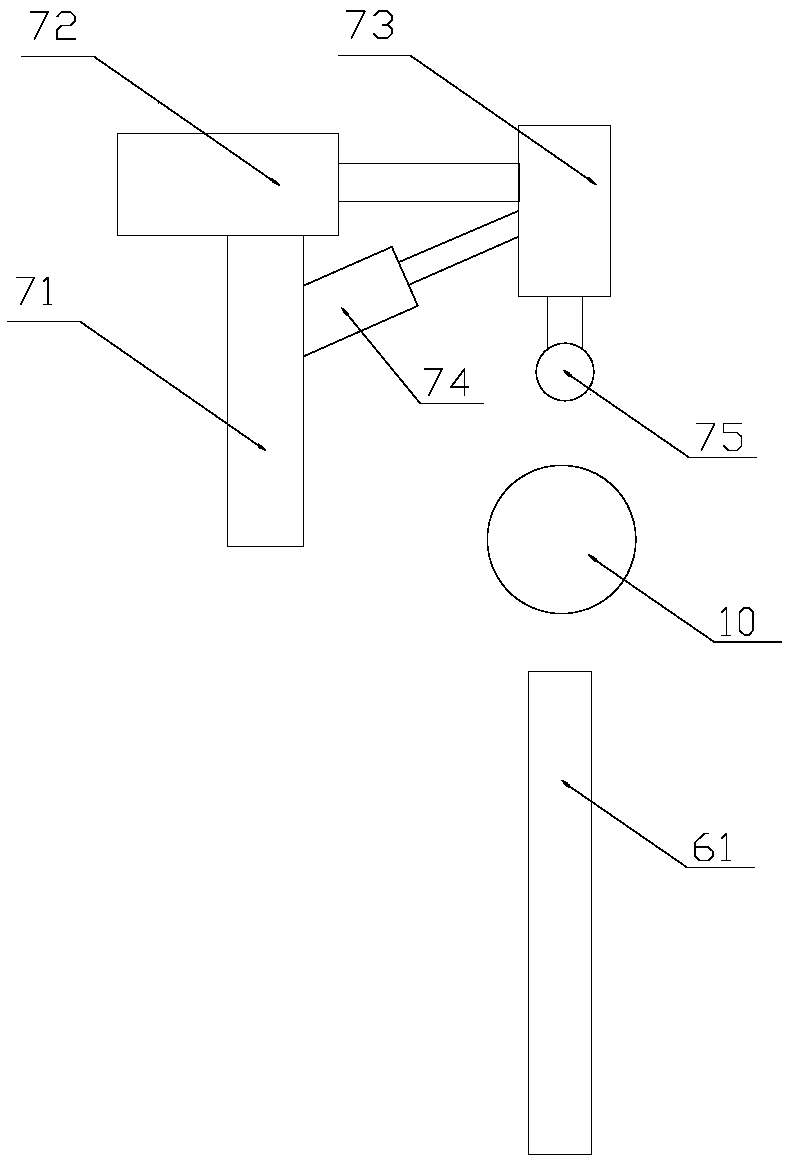

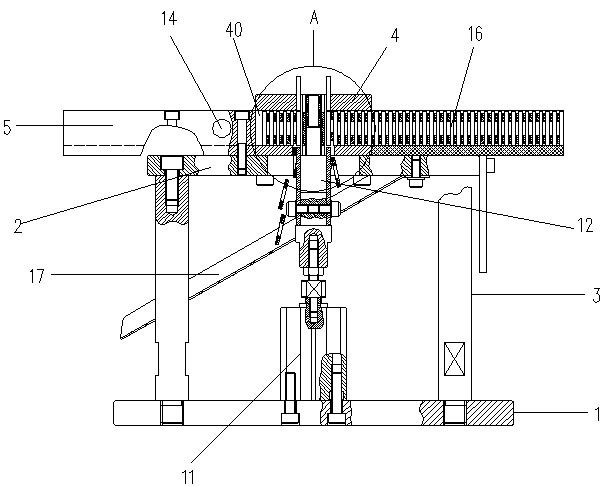

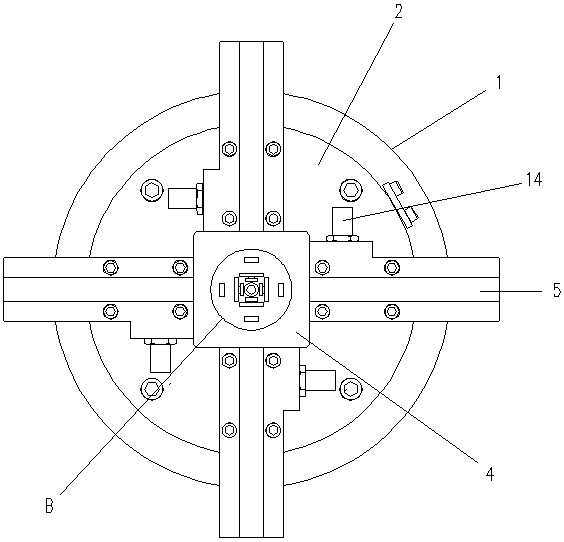

Loudspeaker internal magnetic circuit assembling machine with reverse installation prevention function

InactiveCN107708057AGuaranteed concentricityGuaranteed forward transferElectrical transducersConveyor beltLoudspeaker

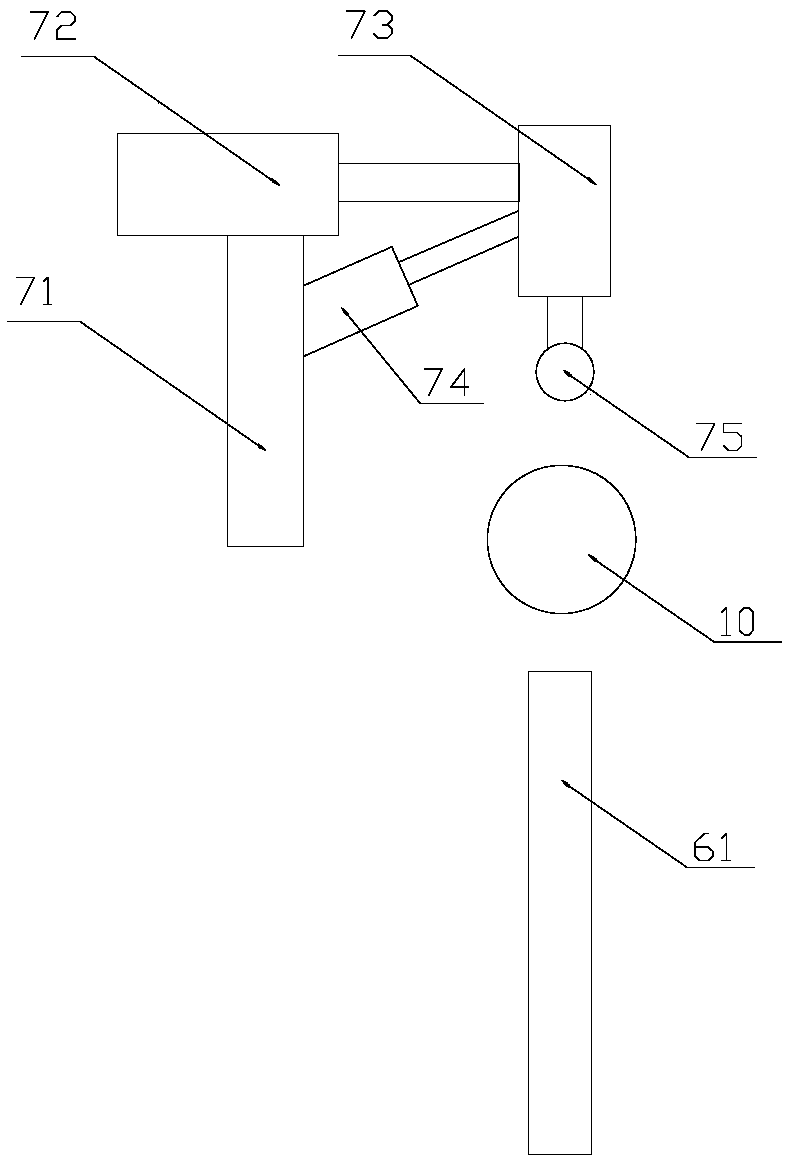

The invention discloses a loudspeaker internal magnetic circuit assembling machine with a reverse installation prevention function. The assembling machine includes a bracket automatic feeding platform, a magnet automatic feeding platform, a washer automatic feeding platform, dispensers, an indexing plate, dragging devices, and a discharge channel. Operation areas are set on the circumference of the indexing plate. One dispenser and one dragging device are arranged beside each operation area. The bracket automatic feeding platform, the magnet automatic feeding platform and the washer automaticfeeding platform are respectively connected to the peripheries of the corresponding operation areas. The discharge channel is connected to the periphery of the indexing plate. The bracket automatic feeding platform, the magnet automatic feeding platform and the washer automatic feeding platform are of the same structure. Each platform includes a connecting track, a vibration plate and a conveyor belt, wherein the vibration plate has an opening, the connecting track passes through the opening, the connecting track is at least partially disposed in the vibration plate, and the connecting track inclines. By using the loudspeaker internal magnetic circuit assembling machine, full-automatic loudspeaker internal magnetic circuit assembling is realized, the labor cost is greatly saved, and the labor intensity is reduced. The loudspeaker internal magnetic circuit assembling machine can ensure that the automatic feeding platforms carry out feeding forwardly and prevent reverse installation.

Owner:PENGMEI ELECTRIC AUDIO APPLIANCES DONGTAI CITY

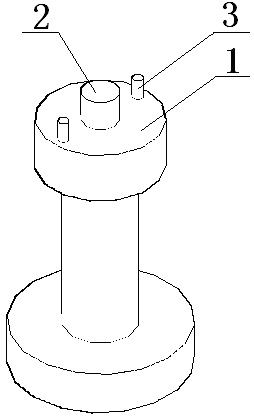

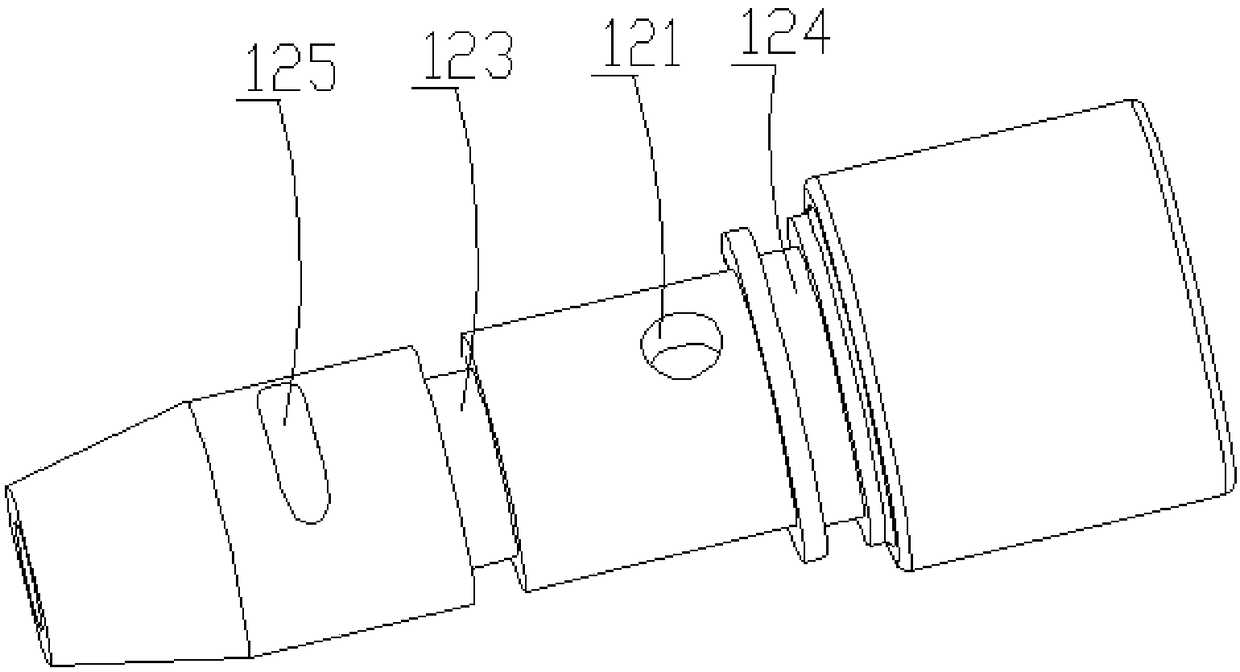

Oil-seal fool-proofing mounting tool

InactiveCN102672452AAnti-reverse loadingSimple structureMetal working apparatusPetroleum engineering

Owner:苏州金牛精密机械有限公司

Photovoltaic bypass diode in field of thin-film solar energy, and production process and installation method of photovoltaic bypass diode

PendingCN110931579ASimplify the installation processImprove cooling effectFinal product manufactureSemiconductor/solid-state device detailsHeat sinkSemiconductor

The invention discloses a photovoltaic bypass diode in the field of thin-film solar energy, production process thereof and an installation method thereof. The invention belongs to the technical fieldof semiconductor electrical components. The diode comprises a diode cathode lead end and a diode anode lead end. A diode chip is arranged between the diode cathode lead end and the diode anode lead end, a bonding jumper wire is connected above the diode chip, the diode chip is placed on the diode cathode lead end, the diode cathode lead end is connected with the diode anode lead end through the diode chip and the bonding jumper wire, a frame chip mounting surface is arranged below the diode chip, a diode plastic package body is arranged outside the diode chip, and a back plate cooling fin is arranged at the position, corresponding to the frame chip mounting surface, of the back surface of the diode body. A photovoltaic diode and an extension lead which are separated in an original productare integrated together, and a client element welding procedure is replaced. And the heat dissipation capability of the element is remarkably enhanced in an integrated packaging mode of the element.

Owner:山东芯诺电子科技股份有限公司

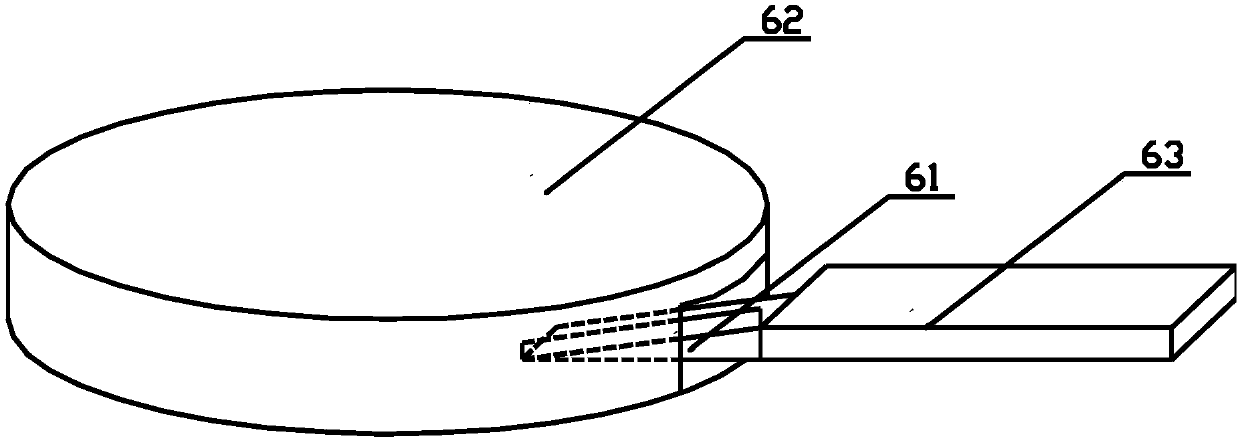

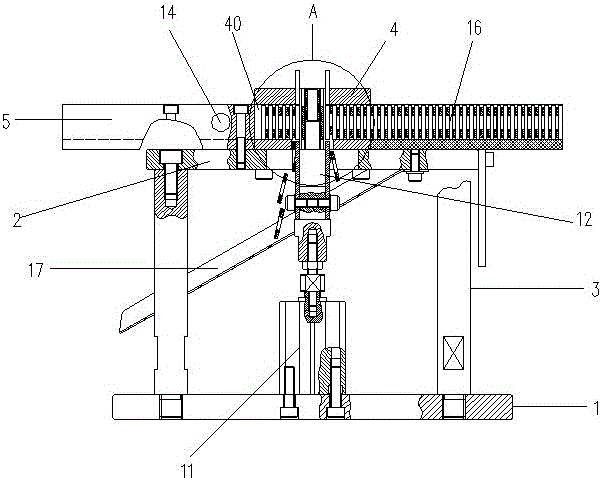

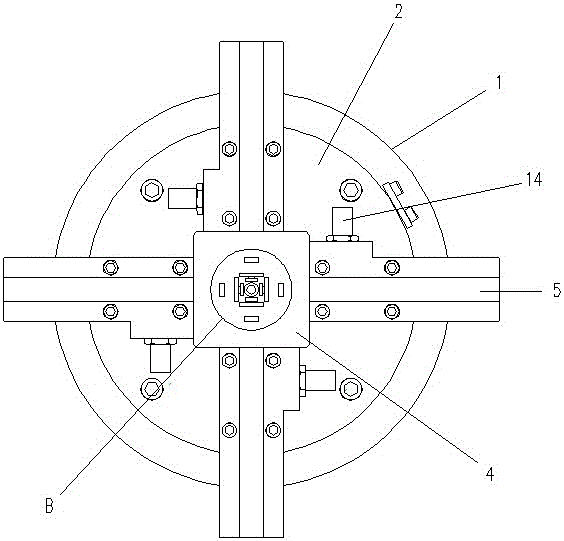

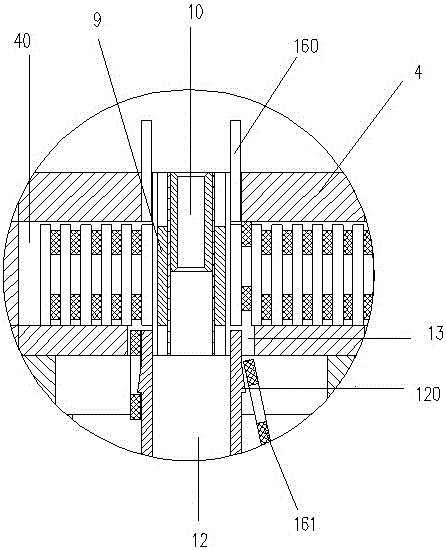

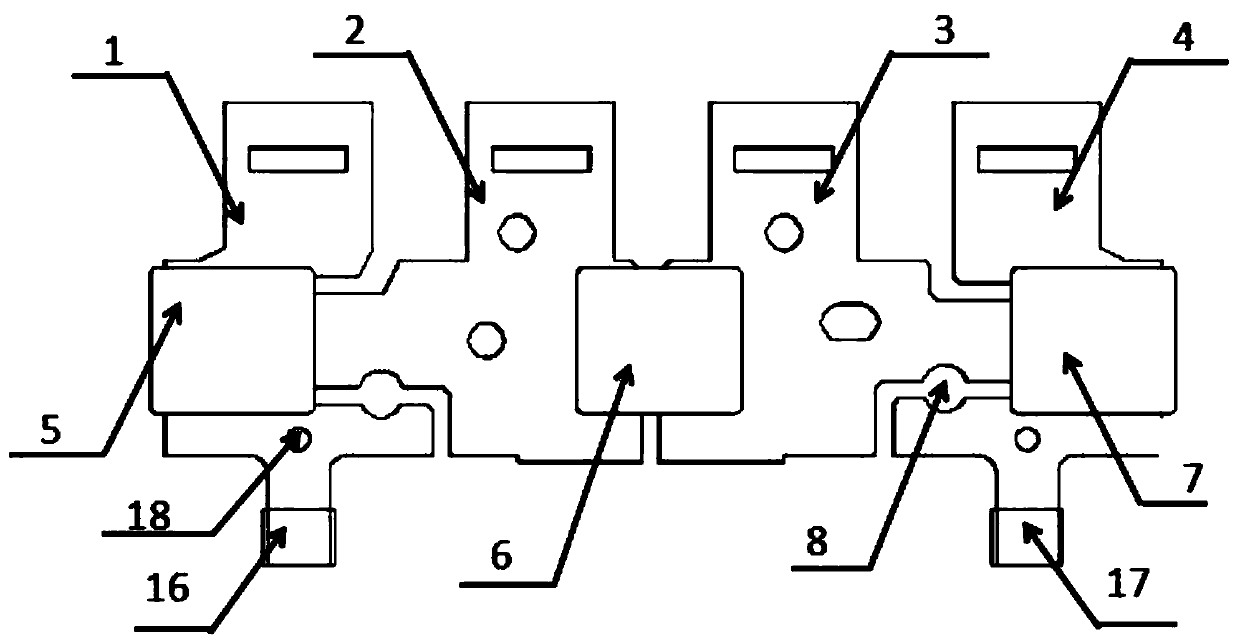

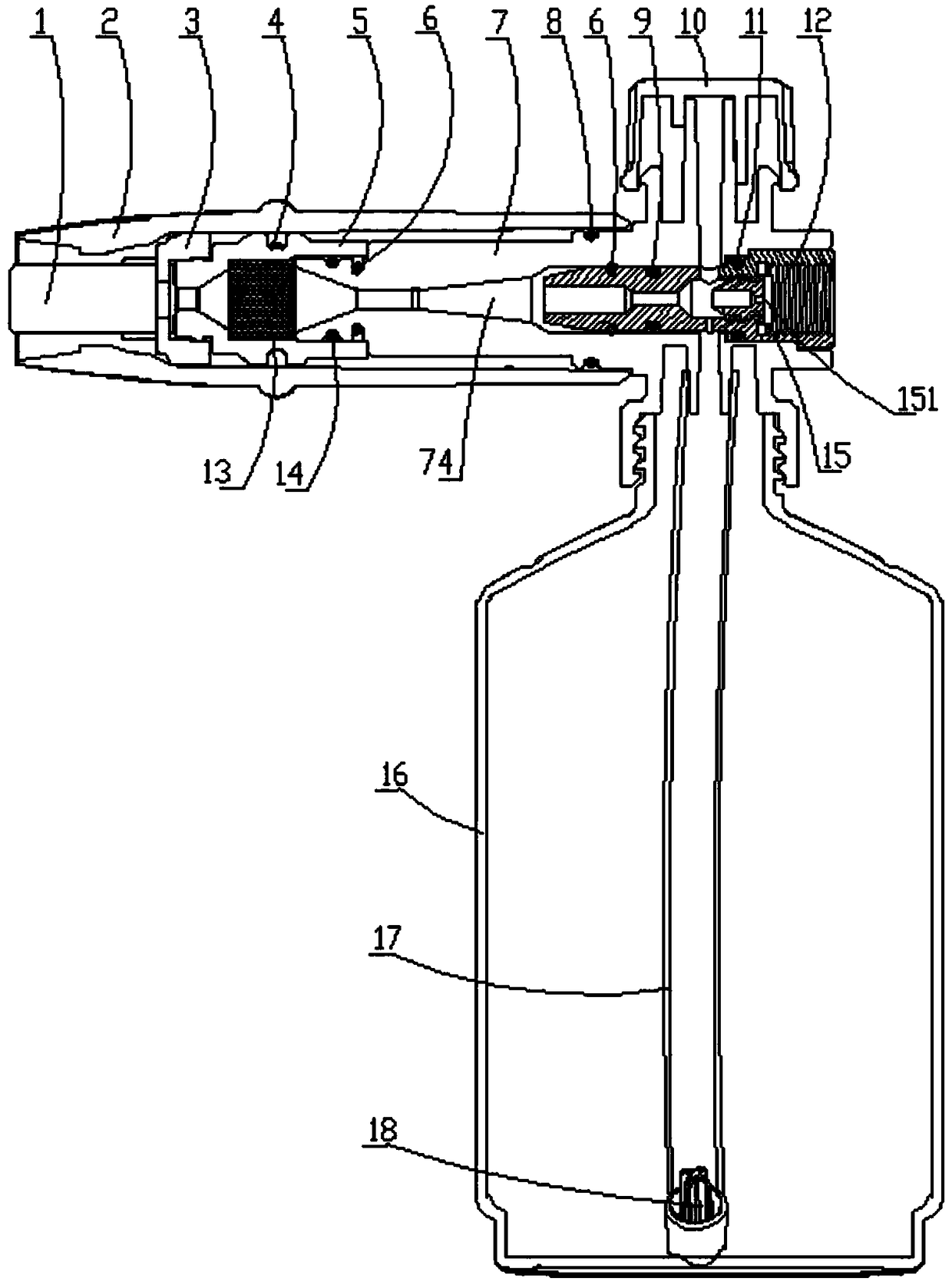

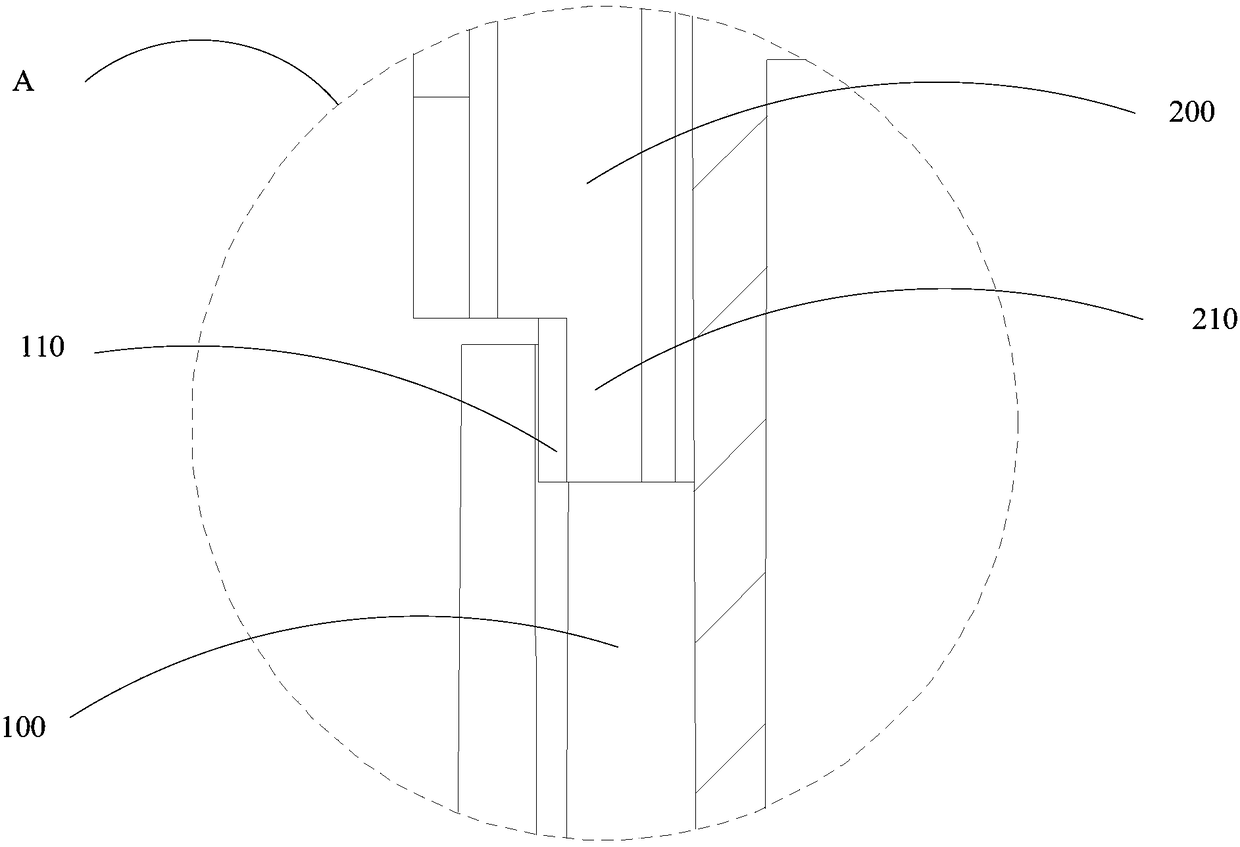

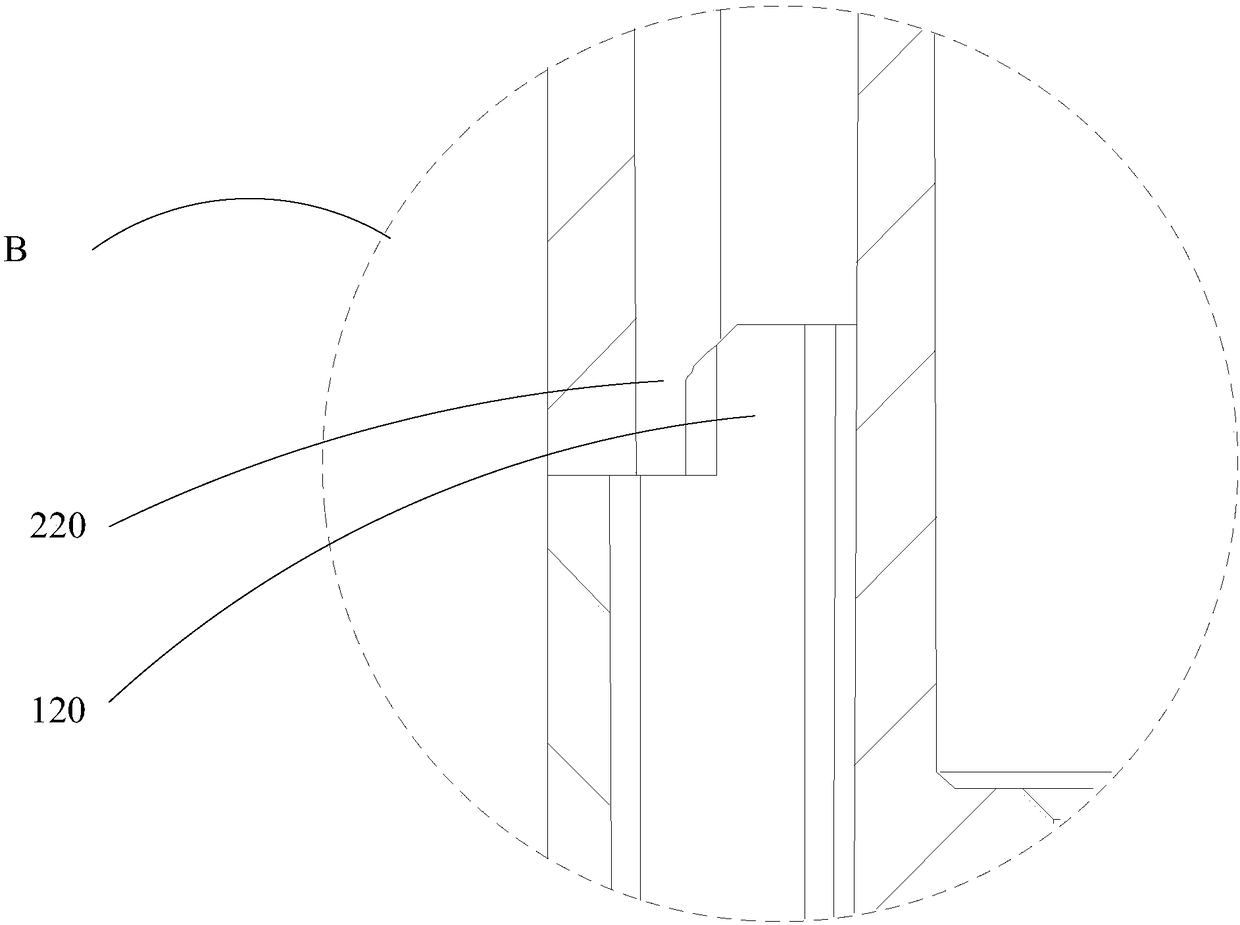

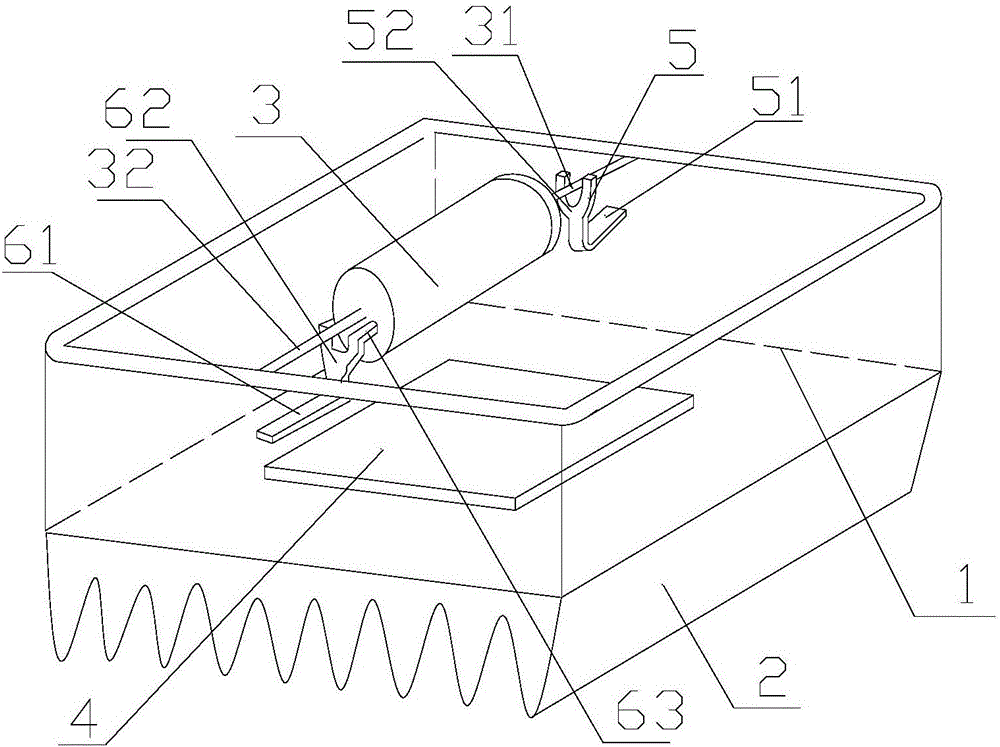

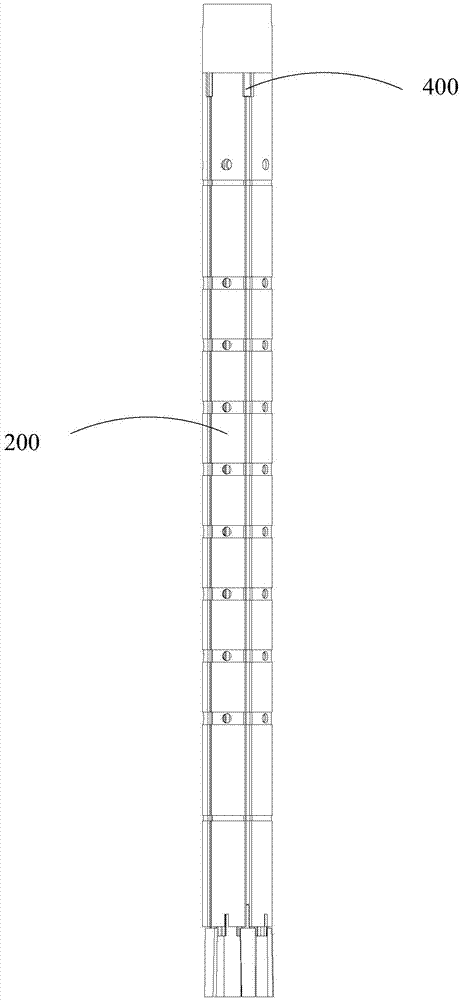

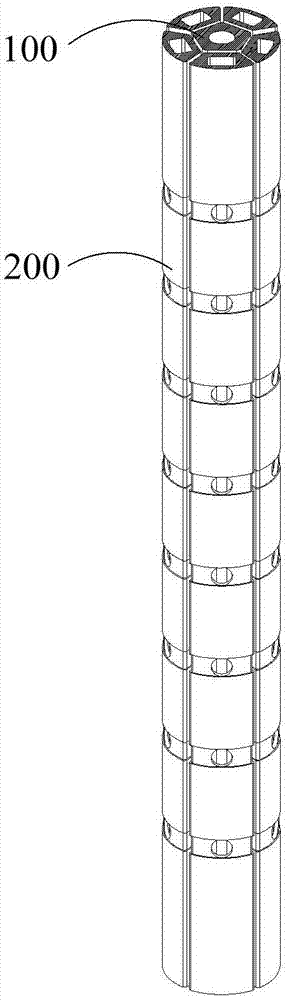

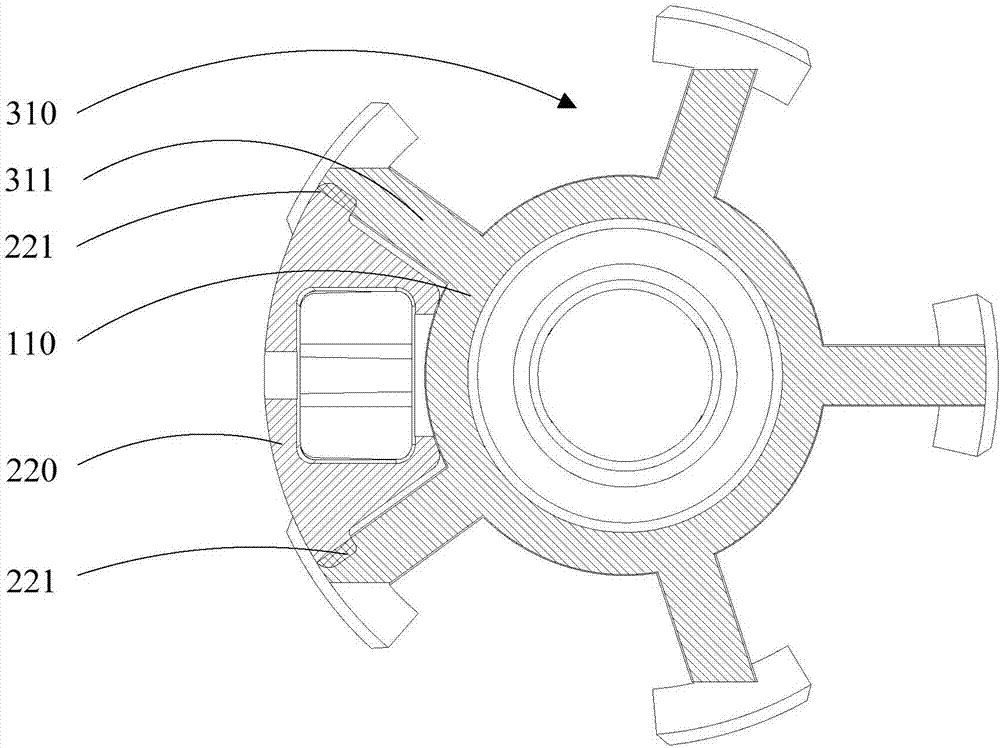

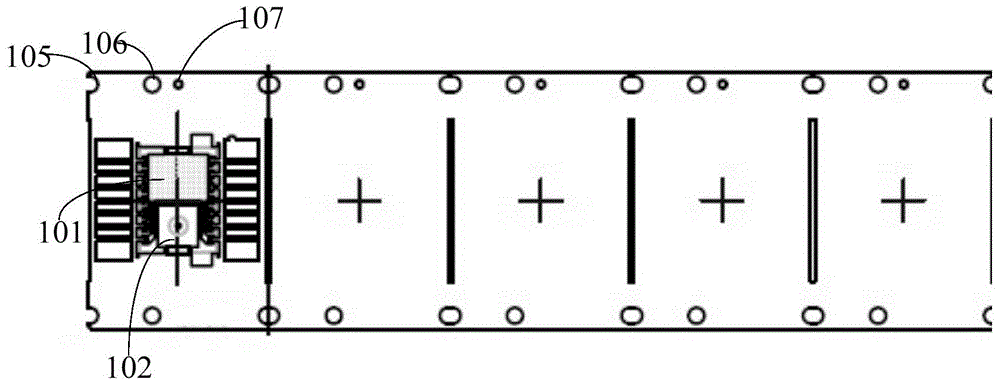

Multi-directional automatic magnetic steel guiding device

ActiveCN106558953AAvoid missingAnti-reverse loadingManufacturing stator/rotor bodiesEngineeringMulti directional

The invention, which relates to the technical field of motor rotor assembling, discloses a multi-directional automatic magnetic steel guiding device comprising a pedestal and a substrate. A magnetic steel guiding positioning seat is arranged at the center of the top surface of the substrate; feeding channels are formed in four side surfaces of the magnetic steel guiding positioning seat; four feeding tracks are formed in the top surface of the substrate; and four magnetic steel guiding positioning slots that correspond to and are communicated with the inner ends of the feeding channels one by one are formed in the top surface of the magnetic steel guiding positioning seat. In addition, permanent magnet pieces are arranged inside the inner end surfaces of the feeding channels. A motor rotating shaft positioning sleeve is arranged at the center of the top surface of the magnetic steel guiding positioning seat. A cylinder with a shaft end upward is arranged at the center of the pedestal; a magnetic steel push-out sleeve is arranged at the shaft end of the cylinder; and the cross section of the magnetic steel push-out sleeve has a square annular shape. Besides, a rectangular avoidance hole is formed in the center of the bottom of the magnetic steel guiding positioning seat. The magnetic steel piece assembling efficiency is high; and neglected mounting or reverse mounting of a magnetic steel piece can be prevented effectively.

Owner:ZHEJIANG ROSHOW ELECTROMECHANICAL

Integrated bypass protection device for field of solar energy and process method thereof

PendingCN111510064AAvoid influenceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesPhotovoltaic solar energyHemt circuits

The invention discloses an integrated bypass protection device used in the field of solar energy and a process method thereof. The invention belongs to the technical field of electronic component manufacturing. The device includes multiple frames which are horizontally connected in sequence. Protection device plastic package bodies are arranged at the connection parts between the frames; the protection device plastic package bodies are integrated on the frames and form an integral structure with the frames. Photovoltaic chips are arranged in the protection device plastic package bodies. Chip bonding pads and jumper bonding pads are arranged above the frames, the photovoltaic chips, the chip bonding pads and the jumper bonding pads are arranged in the protection device plastic package bodies, the photovoltaic chips are connected with the jumper bonding pads through jumpers, an anode pin and a cathode pin are connected to the exterior of the frames, and the frames bear and communicate the photovoltaic chips with an internal circuit and an external circuit to form an integrated bypass protection device. Therefore, the bypass protection device forms an integral structure, the reliability of the product is improved, and the production cost of the product can be greatly reduced. The stable development of the photovoltaic solar energy industry can be guaranteed.

Owner:山东芯诺电子科技股份有限公司

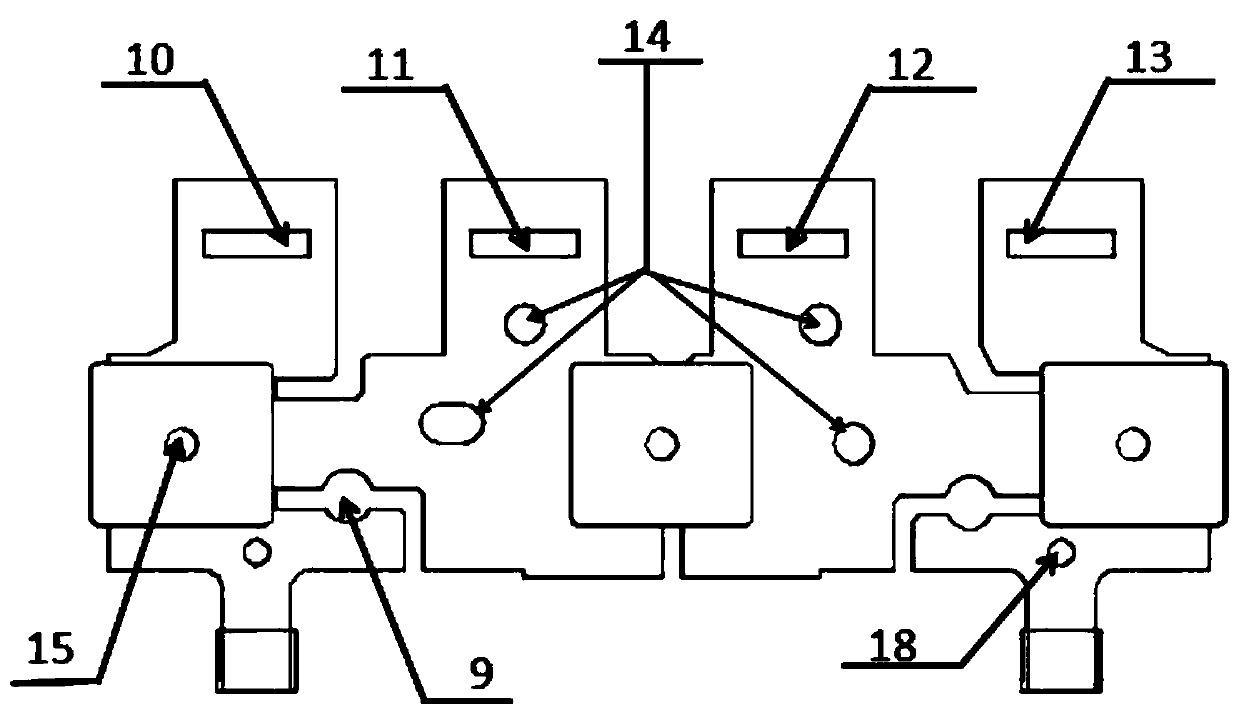

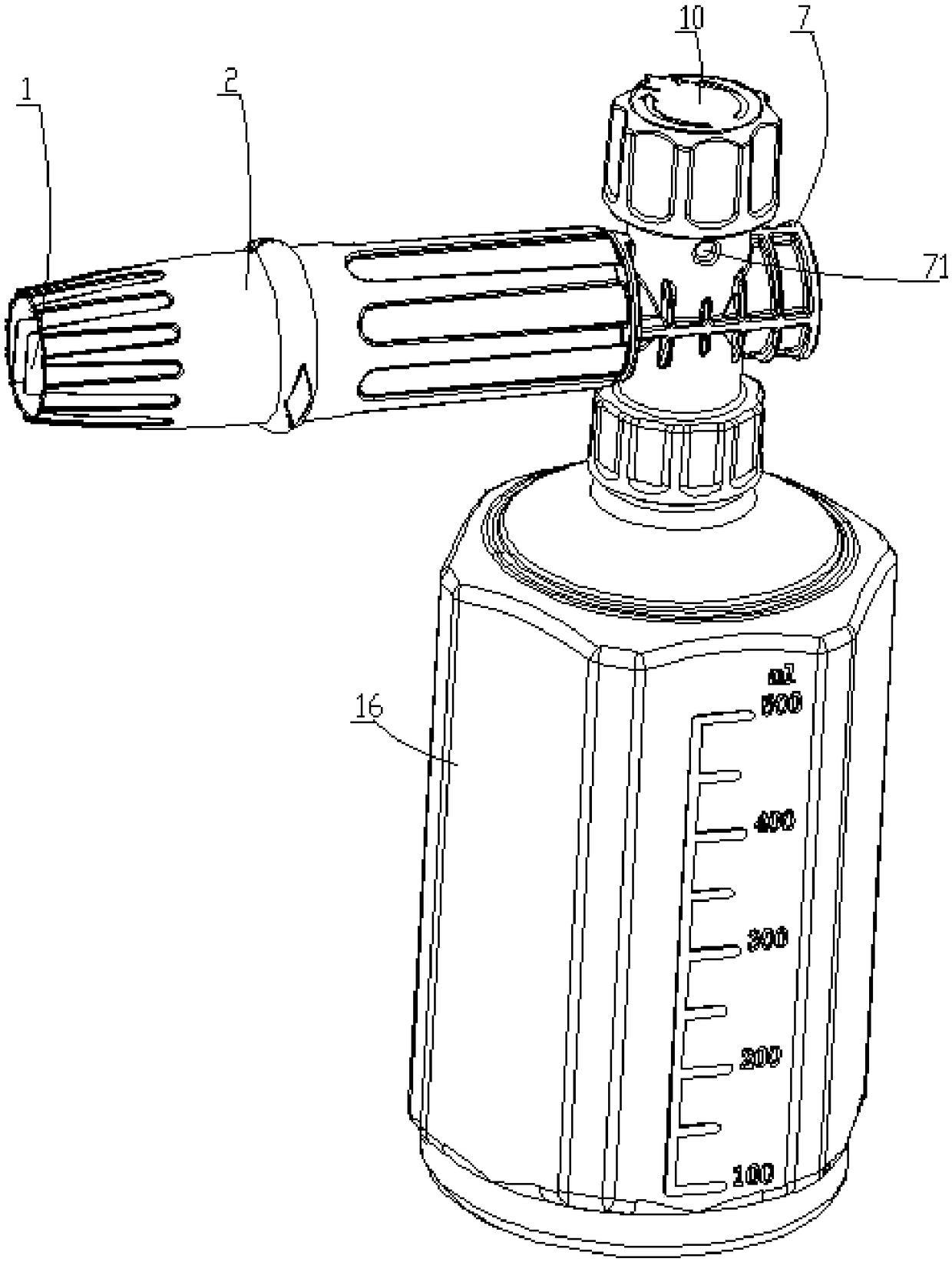

Foam sprinkling can for high-pressure cleaning machine

The invention provides a foam sprinkling can for a high-pressure cleaning machine. By adoption of the foam sprinkling can for the high-pressure cleaning machine, the technical problems that an existing foam sprinkling can is not provided with a water inlet connector or a negative-pressure cavity structure, consequentially, whether or not high-pressure liquid can be sprayed out cannot be determined, the negative pressure and the foam concentration cannot be adjusted freely, the cleaning effect is poor, and cleaning is inconvenient are solved. The foam sprinkling can for the high-pressure cleaning machine comprises a liquid storage bottle used for containing a foam cleaning agent, a spray head used for spraying the foam cleaning agent and a spray head base. An opening is formed in the upperend of the liquid storage bottle. A soap liquid filter head is fixed to the bottom of the inner side of the liquid storage bottle. A suction pipe used for sucking the foam cleaning agent is arranged in the liquid storage bottle. The foam sprinkling can for the high-pressure cleaning machine has the advantage of good cleaning effect.

Owner:安徽熊威机电有限公司

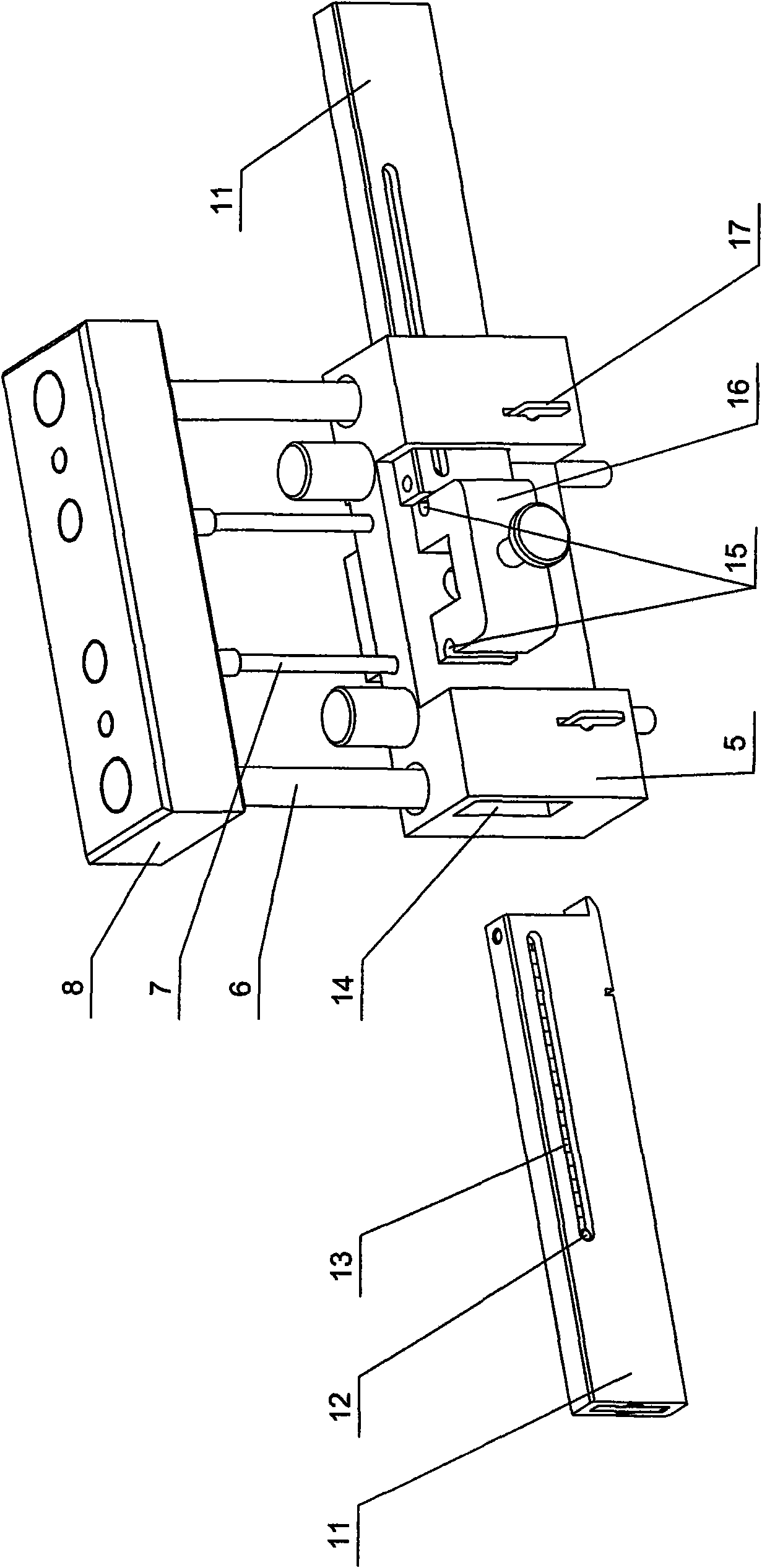

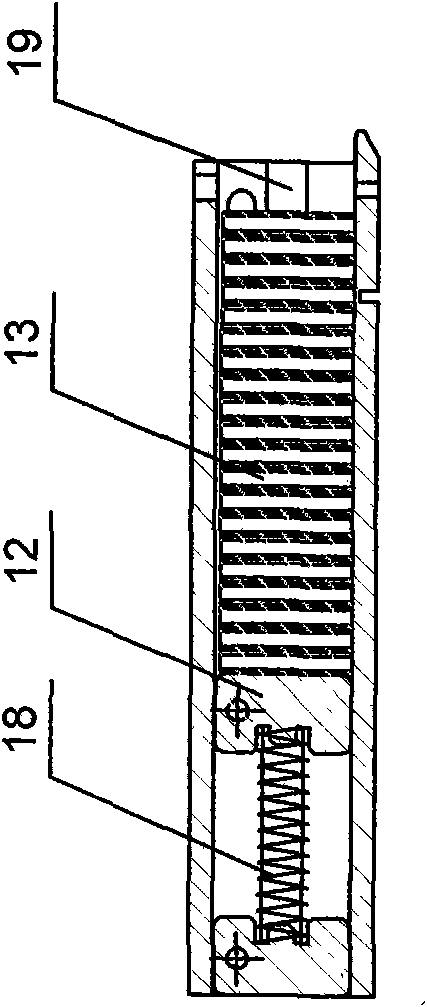

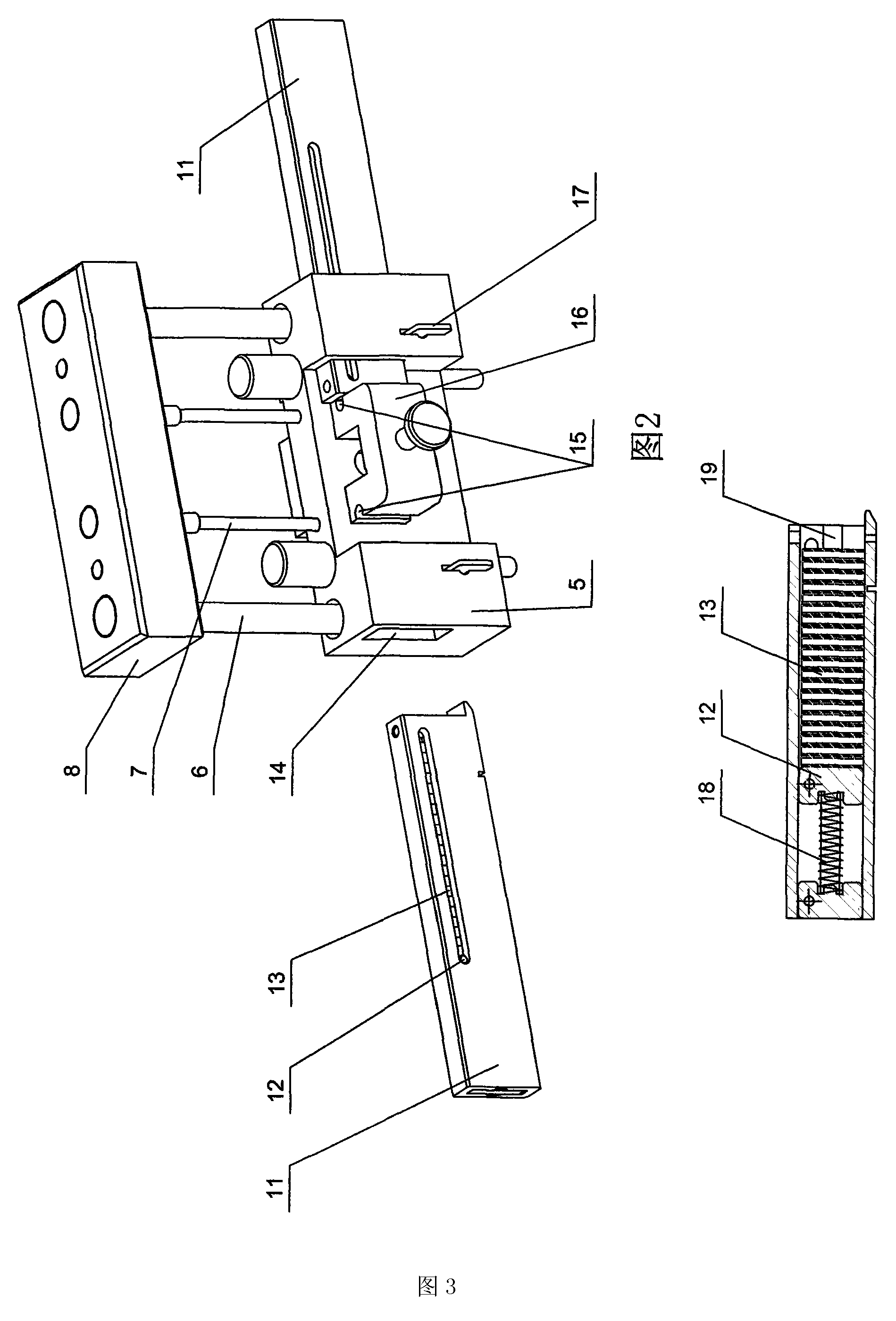

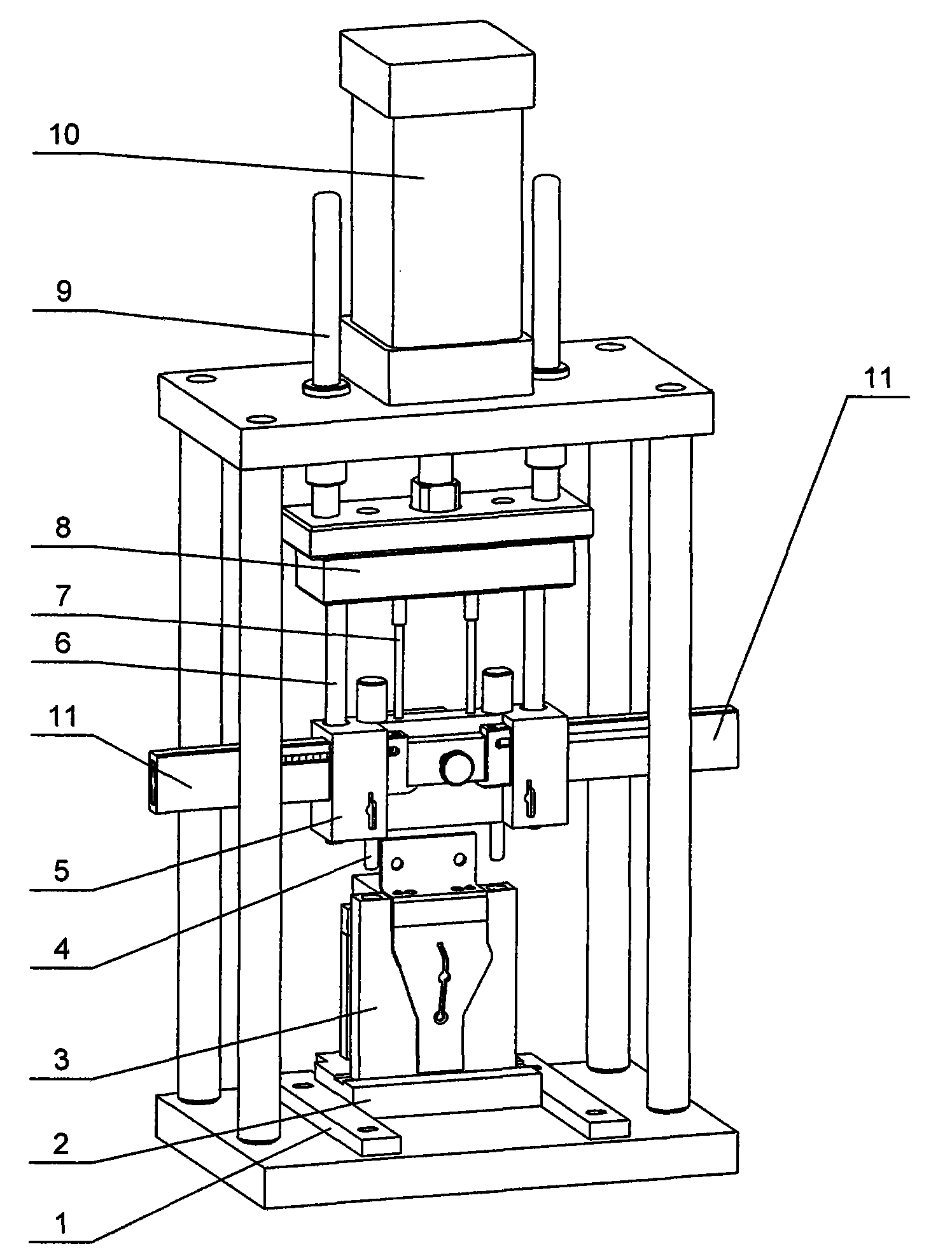

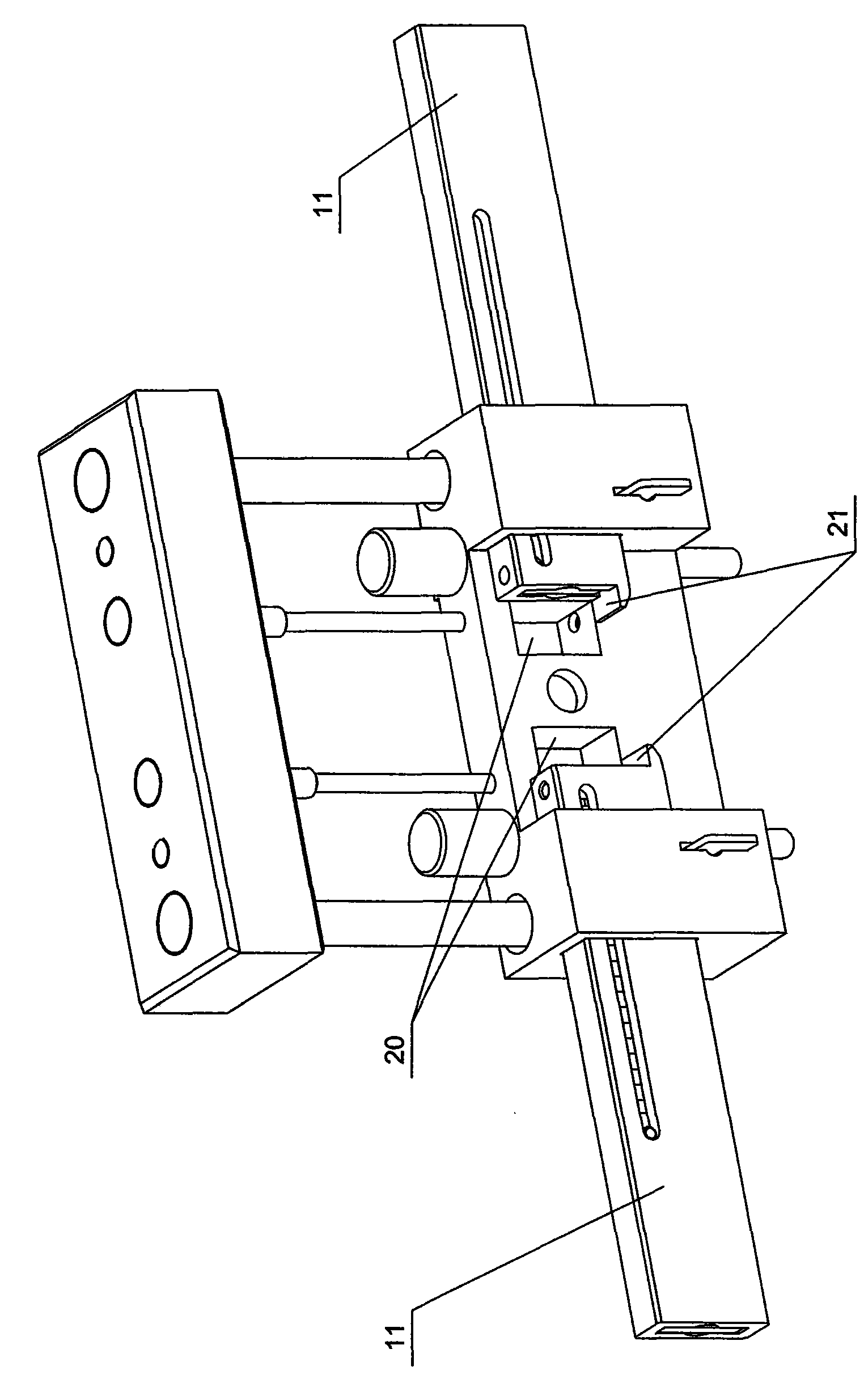

Elastic straight pin feeding device used for producing low-voltage circuit breakers

ActiveCN101630609AAvoid underpackingAnti-reverse loadingElectric switchesEmergency protective device manufactureLow voltage circuitsSemi automatic

The invention discloses an elastic straight pin feeding device used for producing low-voltage circuit breakers, which is characterized in that: a fixed plate is connected under an air cylinder, a slide rod is arranged under the fixed plate, two guide poles are arranged on the fixed plate, two lower guide poles are arranged between the fixed plate and the slide rod, two ejector pins are connected below the fixed plate, a corner plate, a static contact bus bar and an arc sheet are arranged on a locating block which is arranged below the slide rod, both ends of the slide rod are provided with square holes, a feeding block is fixed at the front end of the slide rod, both sides of the feeding block, which correspond to the square holes, are provided with U-shaped grooves, two popping-boxes are clamped in the square holes of the slide rod, a plurality of elastic straight pins are arranged in the popping-boxes, one side of each popping-box is provided with a spring, both ends of each spring are respectively provided with a slide rod provided with a spacer pin in a contacted way, and one end of each popping-box is provided with a notch. The invention adopts the popping-box type structure, realizes semi-automatic feeding operation, enhances the production efficiency, avoids the problem that the elastic straight pins are not loaded enough and are arranged in reverse and prevents the danger caused when human hands contact the elastic straight pins.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

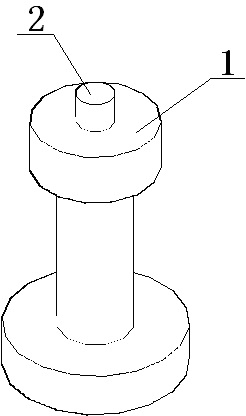

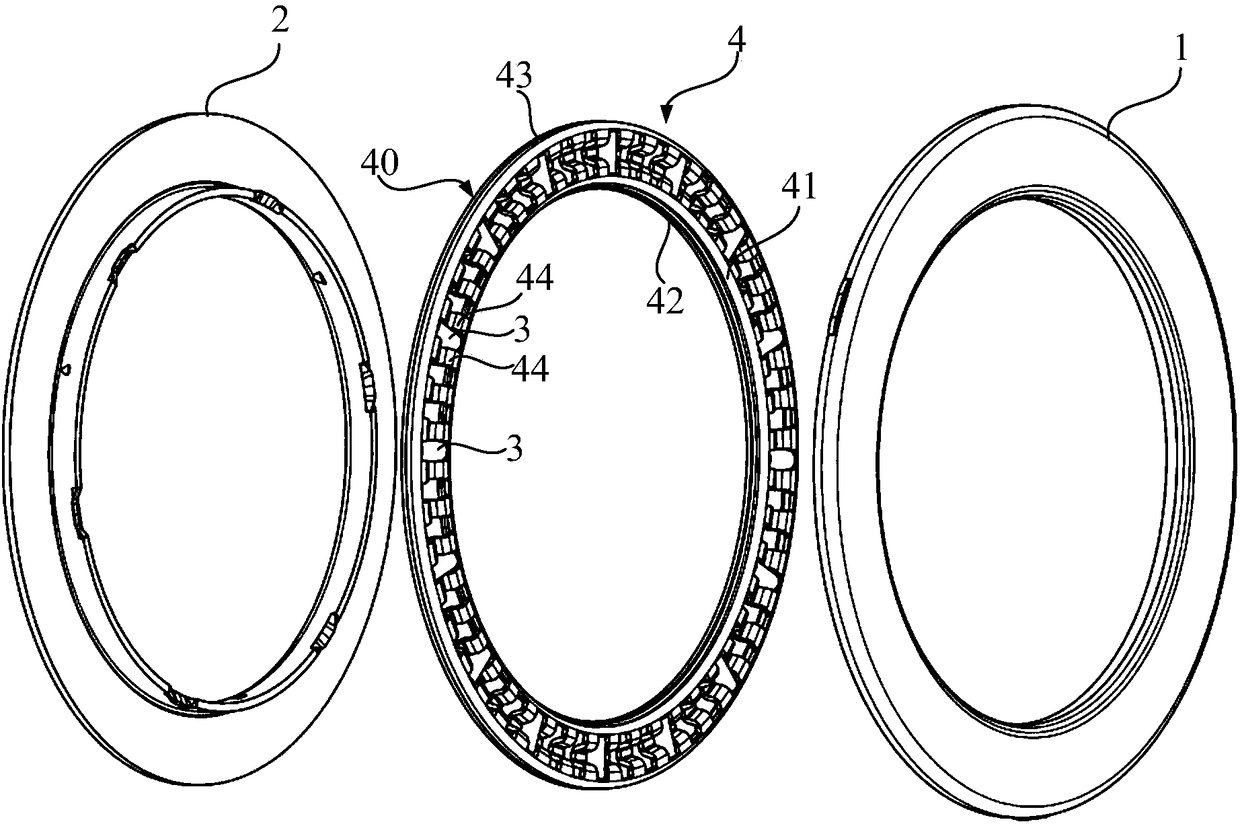

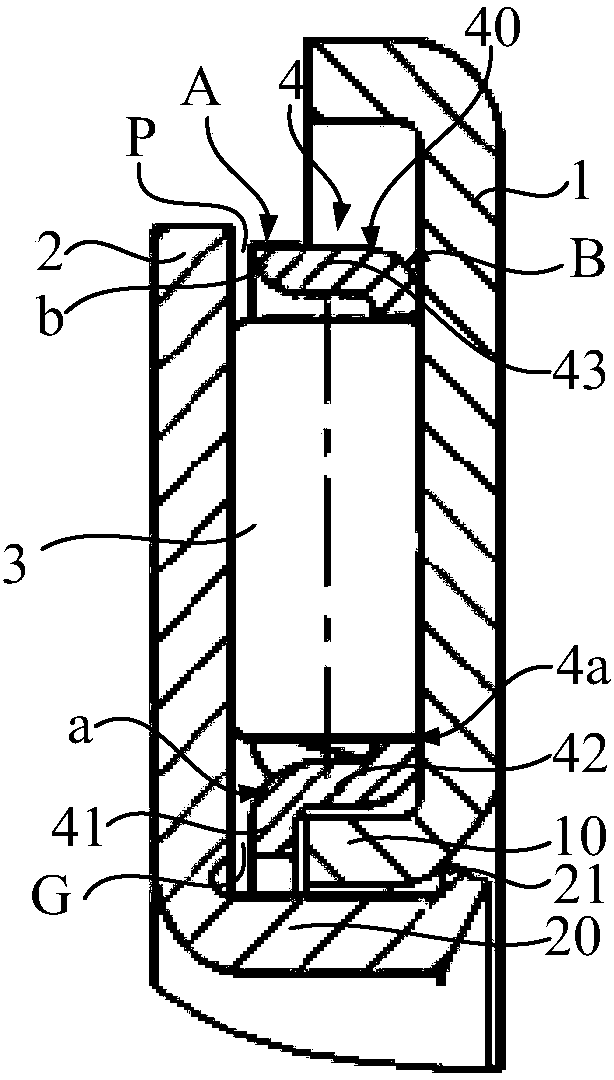

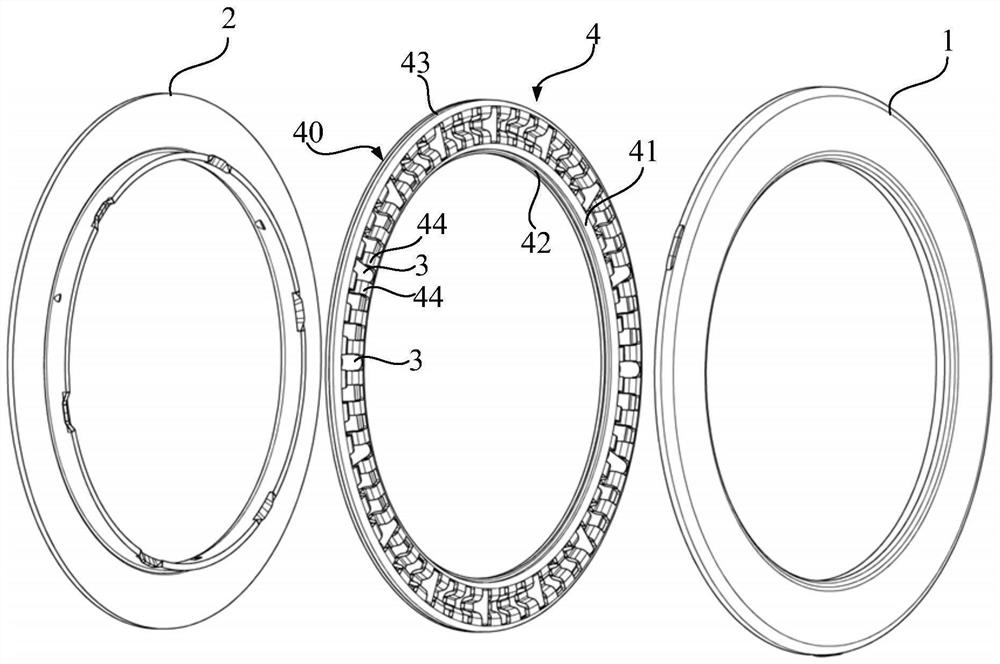

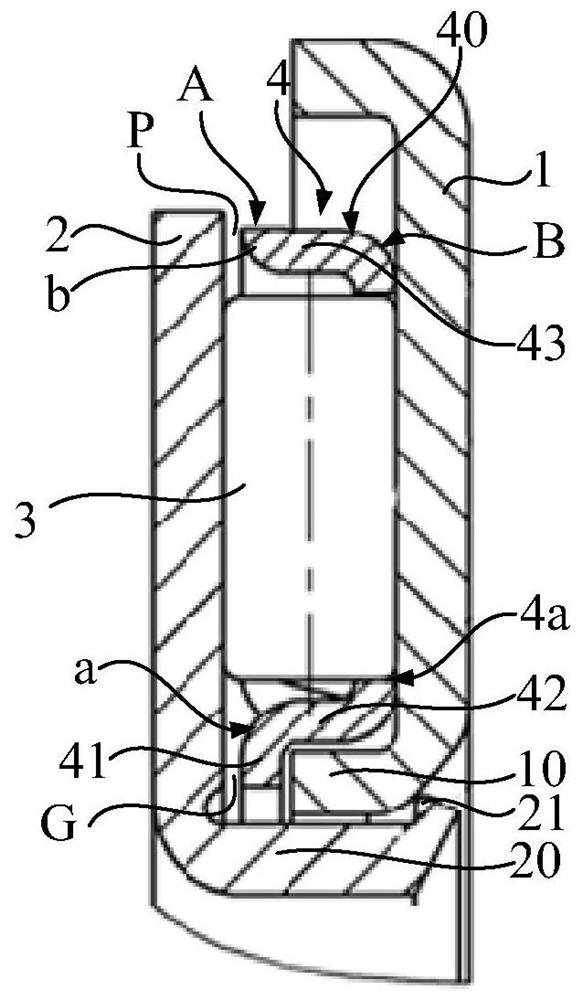

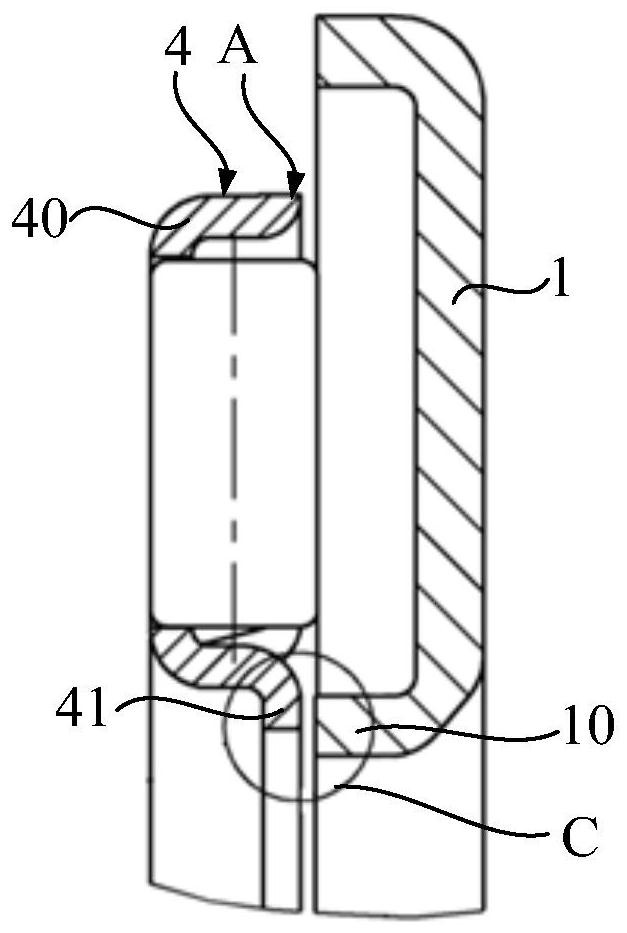

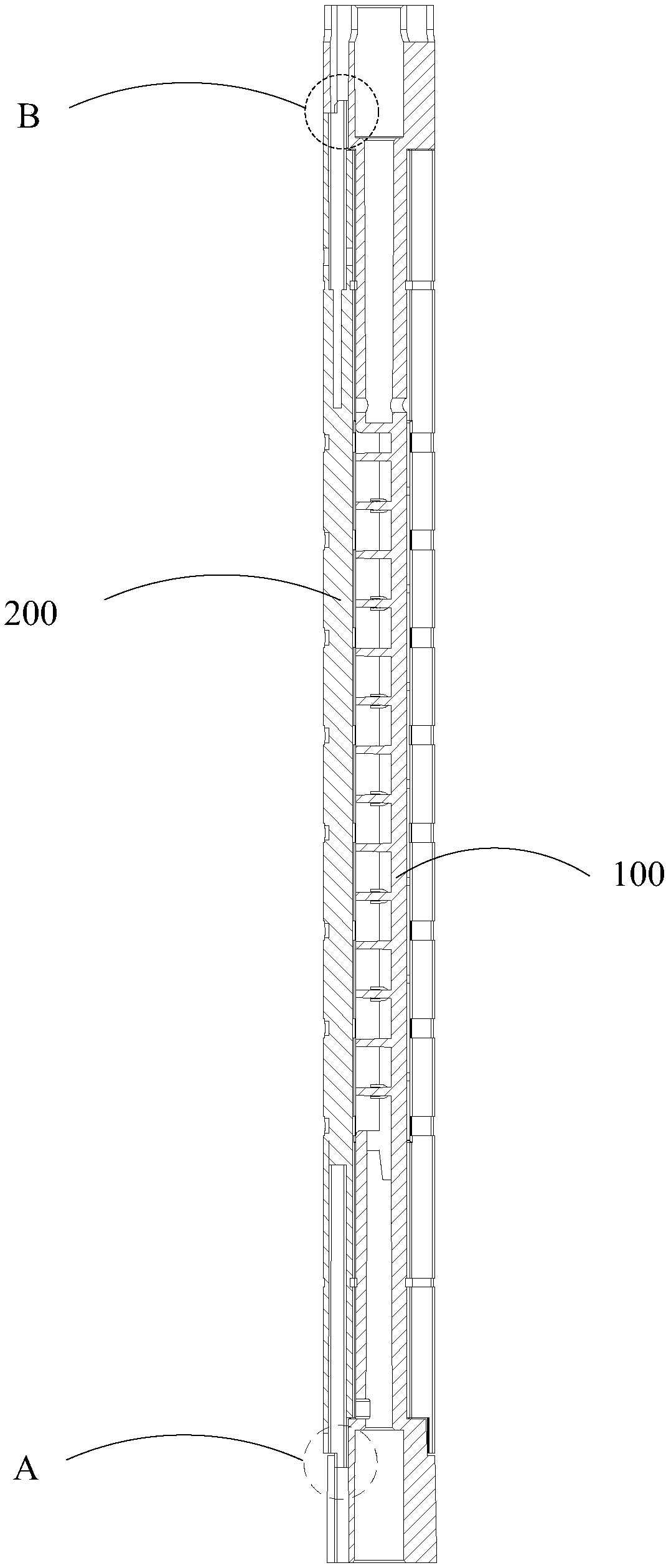

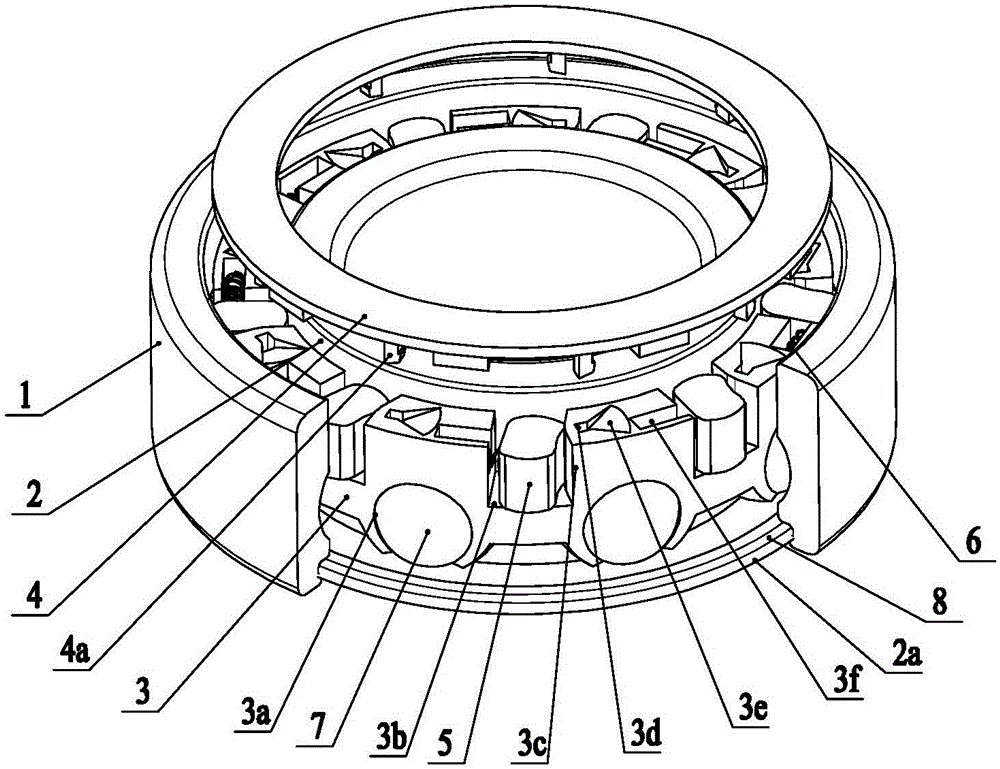

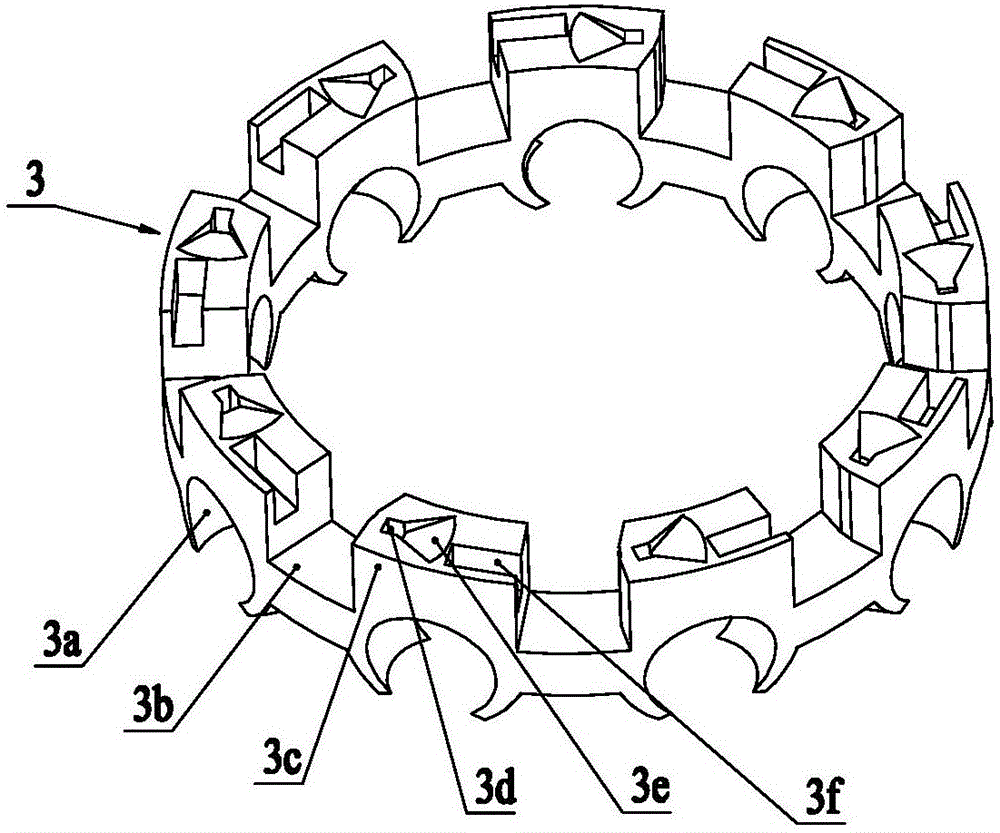

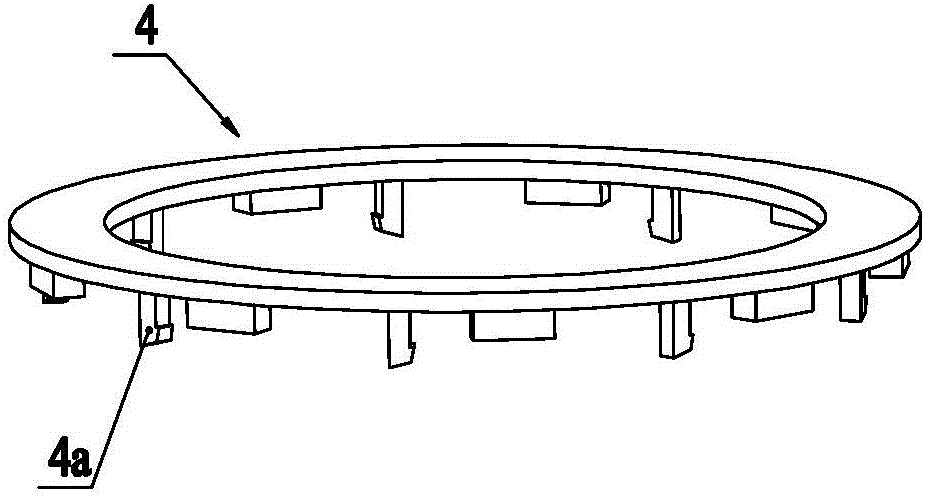

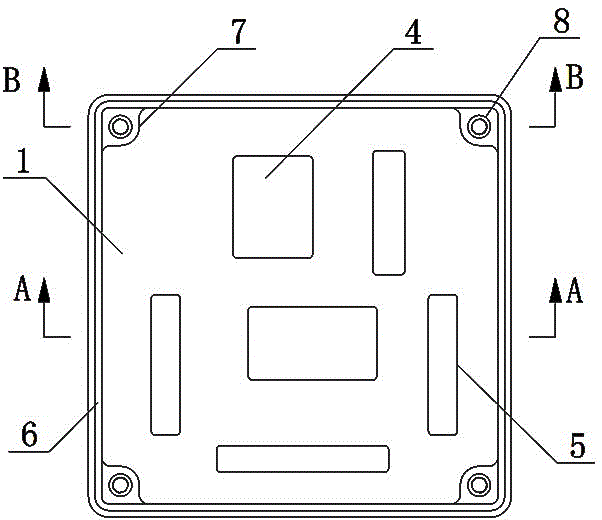

Thrust bearing and holder used for thrust bearing

ActiveCN108150524ASolve the problem of anti-installationEasy to installRoller bearingsBall bearingsThrust bearingEngineering

Disclosed are a thrust bearing and a holder used for the thrust bearing. The holder comprises a body frame, the body frame is provided with an inner circumferential surface and an outer circumferential surface, and one of the two axial ends of the body frame is a first end; the holder further comprises a radial inner protruding part and / or a radial outer protruding part, wherein the radial inner protruding part is connected to the first end and higher than the inner circumferential surface inwards in the radial direction of the body frame; and the radial outer protruding part is connected to the first end and higher than the outer circumferential surface outwards in the radial direction of the body frame. According to the technical scheme, the holder can be used for solving the problem that a holder is mounted reversely in the prior art, accurate assembling of the holder is achieved, it is ensured that the thrust bearing is effectively lubricated, and the risk of rotating clamping stagnation of the bearing is reduced.

Owner:SCHAEFFLER TECH AG & CO KG

Full-automatic horn internal magnetic circuit assembly molding device

InactiveCN107896360AGuaranteed concentricityGuaranteed forward transferElectrical transducersAutonomationAutomation

The invention discloses an automatic horn internal magnetic circuit assembly molding device. The device comprises a support automatic loading table, a magnetic automatic loading table, a washer automatic loading table, glue dispensers, an indexing plate, dragging devices, an oven, an automatic turnover line and a magnetizer. Operating areas are arranged at the circumference of the indexing plate,the sides of the operating areas are provided with the glue dispensers and the dragging devices, the support automatic loading table, the magnetic automatic loading table and the washer automatic loading table are connected with the peripheries of respective operating areas, the automatic turnover line is connected with the periphery of the indexing plate, the automatic turnover line is provided with the oven and the magnetizer, and the oven is disposed at the upstream end of the magnetizer. By use of the device provided by the invention, full-automation of the assembling of a horn internal magnetic circuit can be realized, the labor cost is greatly saved, and the labor intensity is reduced.

Owner:PENGMEI ELECTRIC AUDIO APPLIANCES DONGTAI CITY

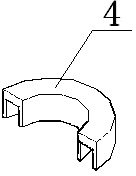

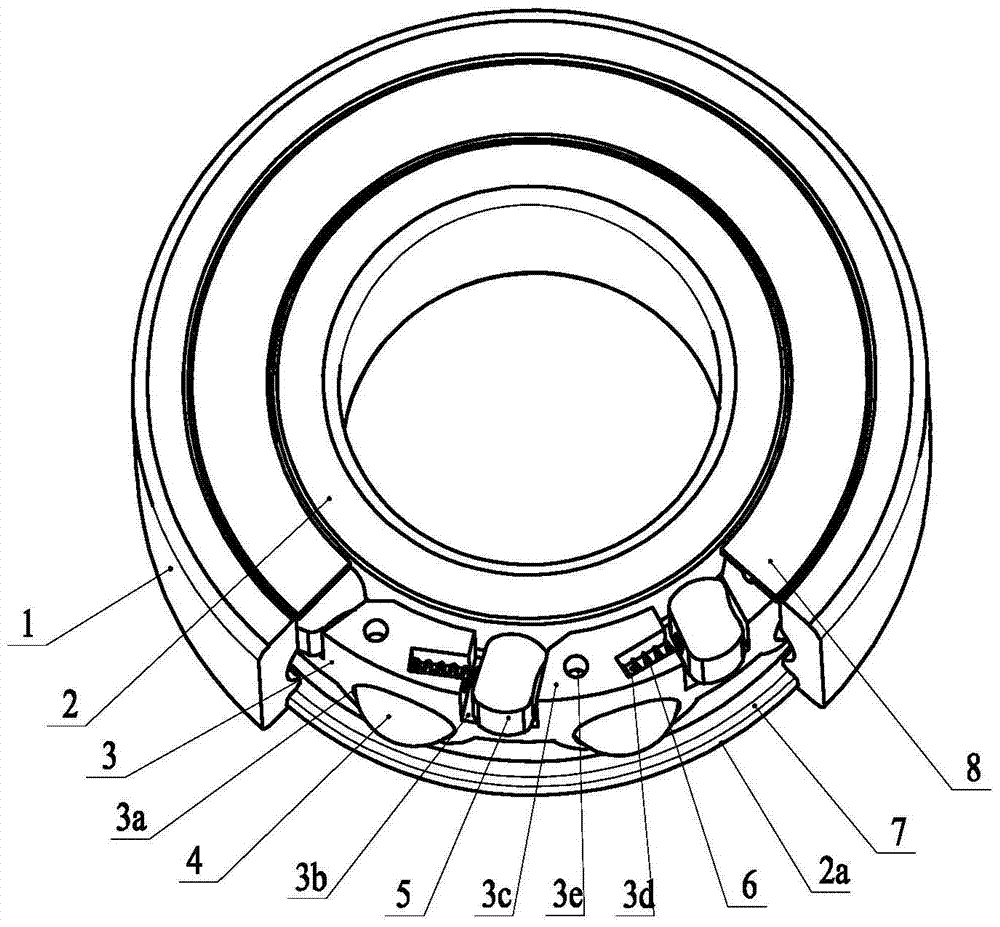

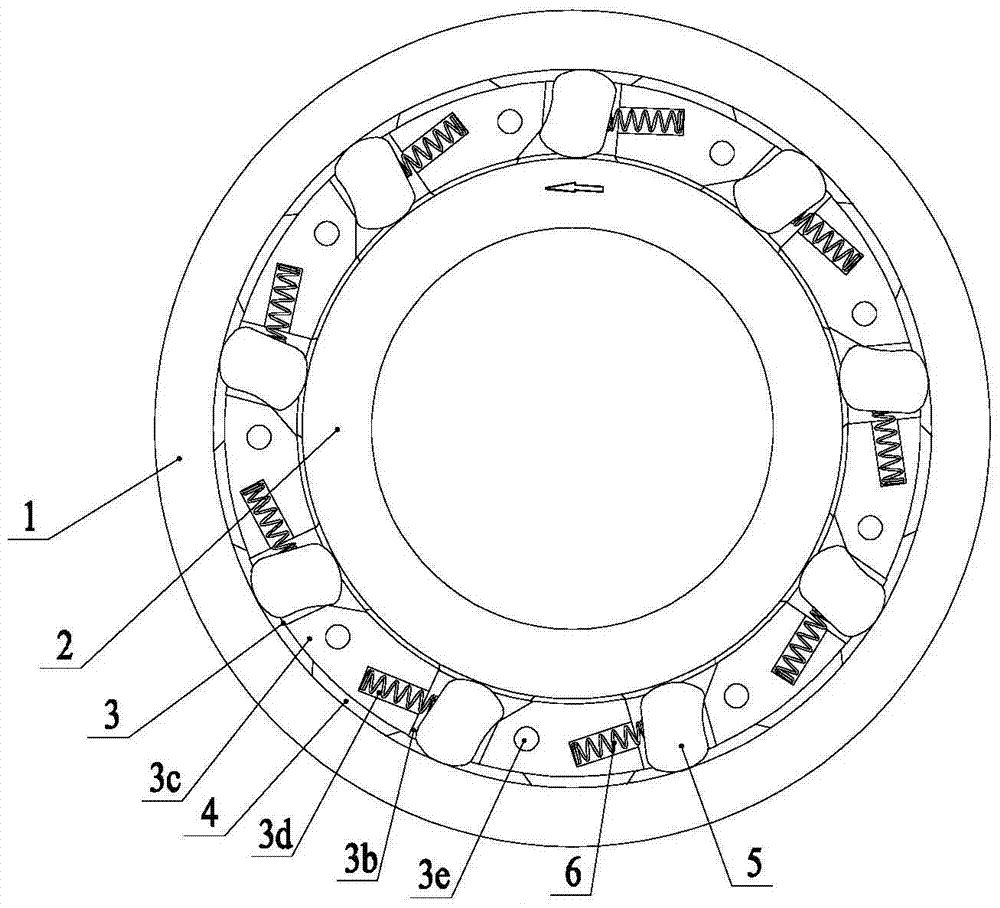

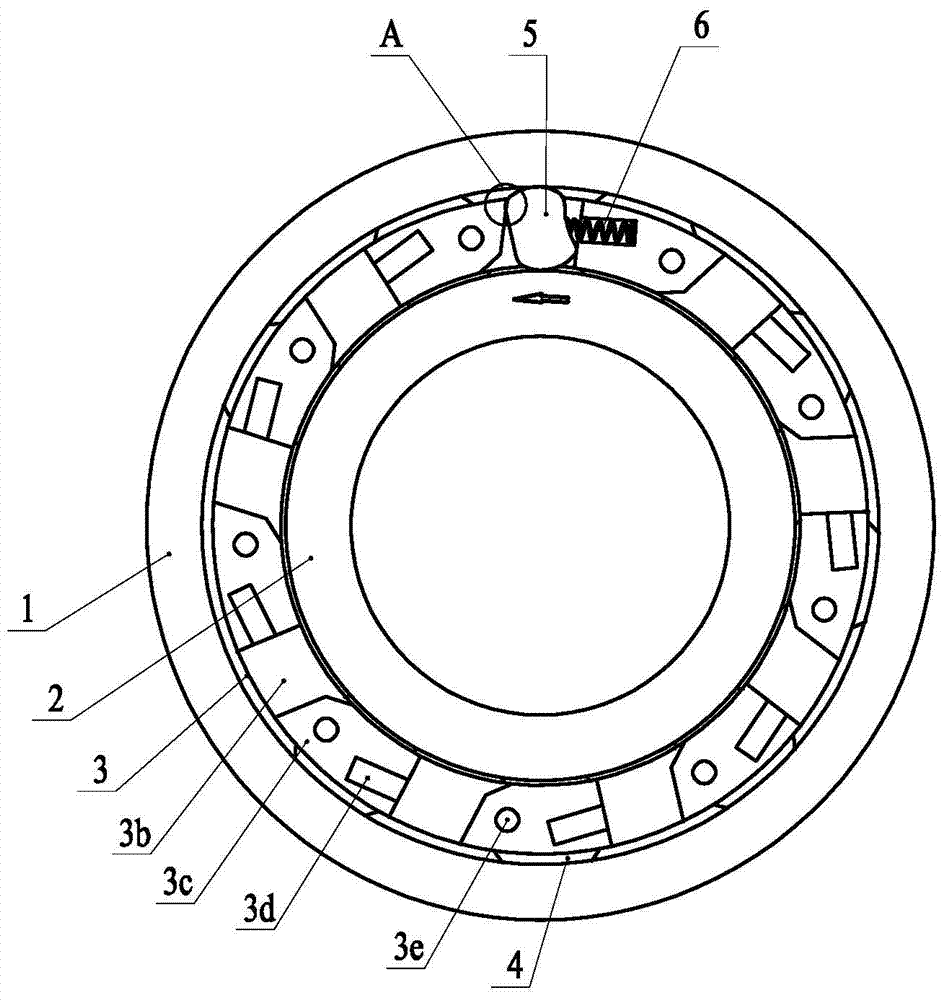

Reverse stop bearing with wedge reverse-mounting preventing bearing retainer

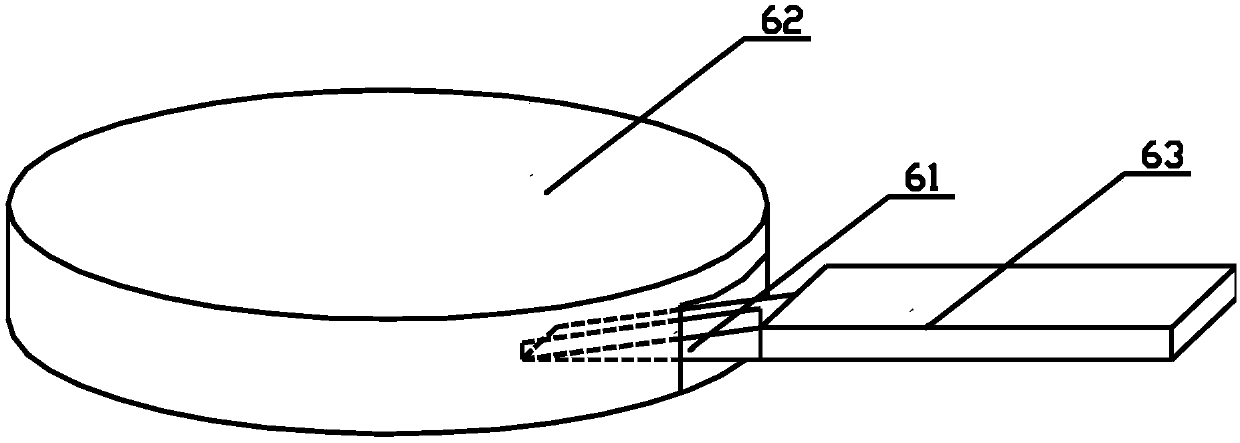

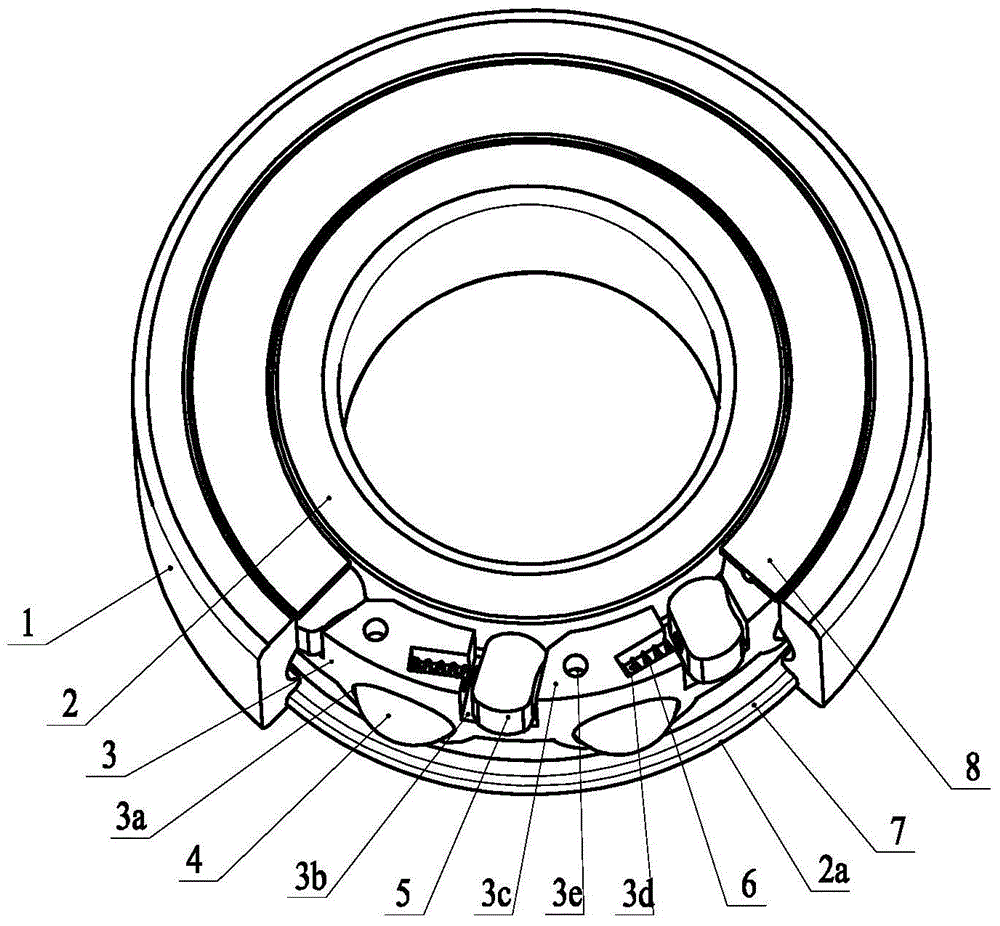

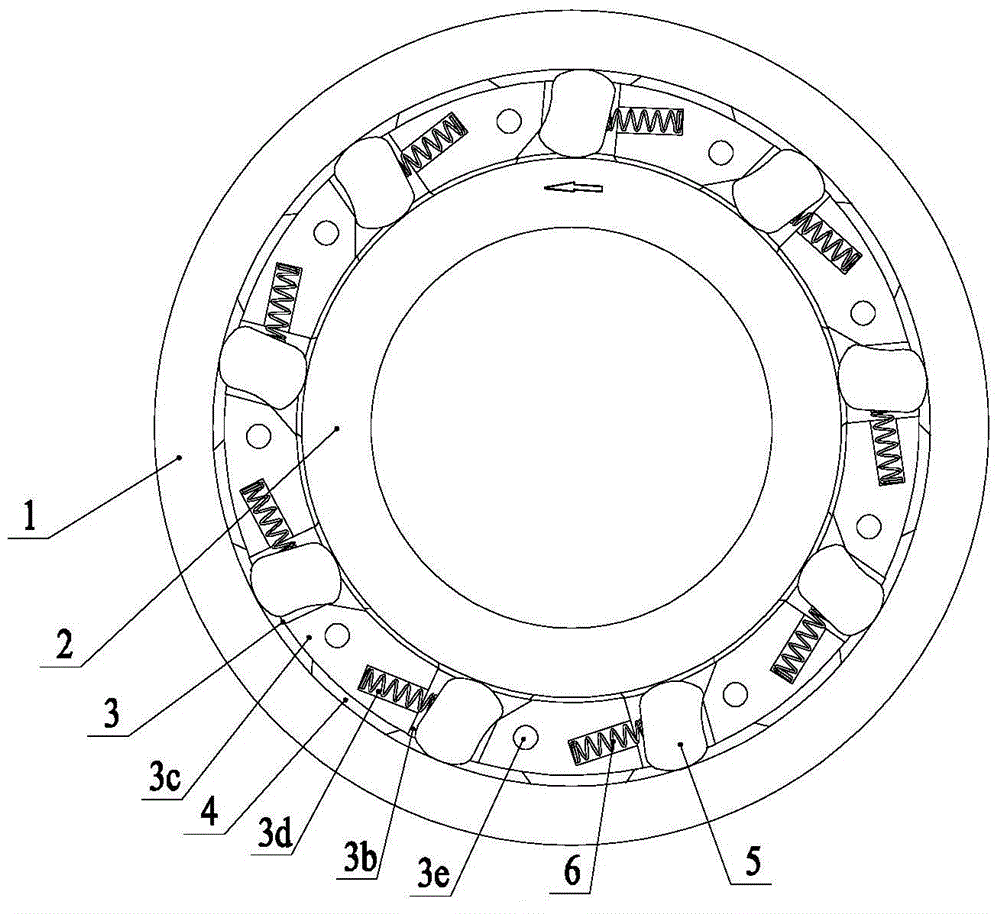

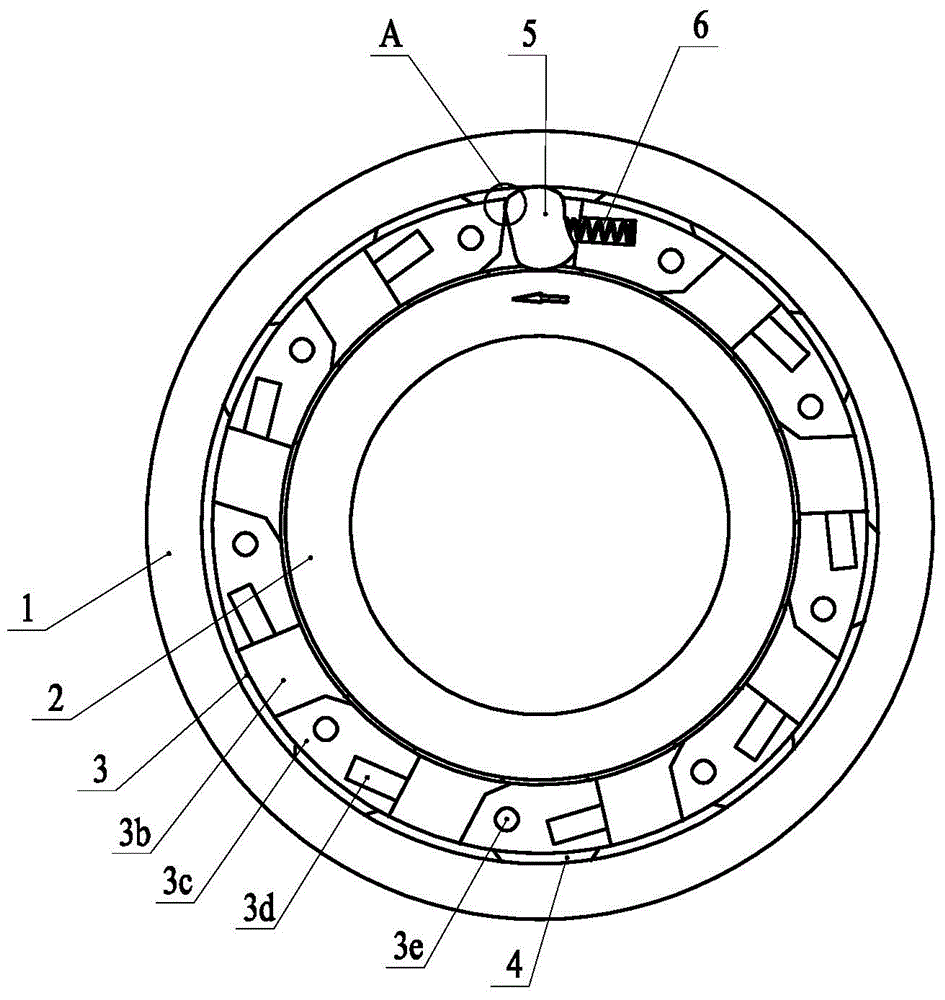

ActiveCN104482050AAnti-reverse loadingDoes not affect normal workBearing componentsFreewheel clutchesStructural engineeringSteel ball

The invention relates to a reverse stop bearing with a wedge reverse-mounting preventing bearing retainer. A retainer body is arranged between an inner ring and an outer ring; a steel ball is arranged in each ball pocket on the circumferential surface of the retainer body; a wedge is arranged in each wedge notch formed in the first end surface of the retainer body; a wedge spaced boss is arranged between the adjacent wedge notches; a fixed cover is connected with the first end of the retainer body. The reverse stop bearing is characterized in that a spring groove, of which one end is opened, is formed in each wedge spaced boss; the opening ends of the spring slots are communicated with the wedge notches in front of the inner ring of the bearing in the one-way rotation direction; compressed springs are arranged in the spring grooves; the inner ends of the compressed springs are connected with the retainer body; the outer ends of the compressed springs are exposed from the opening ends of the spring grooves and jack against the wedges, so that the wedges are still adhered to the outer ring and the inner ring. According to the reverse stop bearing, the normal operation of the wedges cannot be influenced, the capability of preventing reverse-mounting of the wedges is improved, the machining efficiency of the product is improved, the product quality is guaranteed, and the production cost is reduced.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

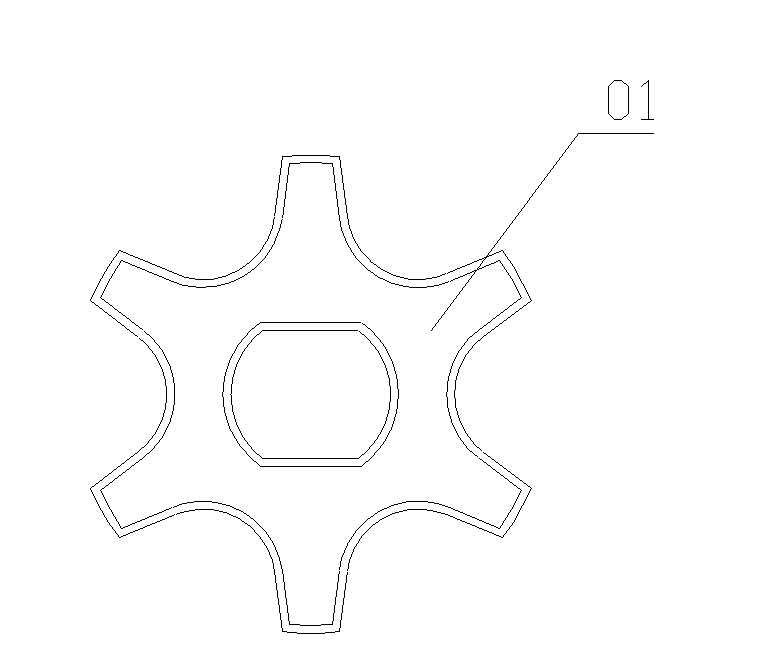

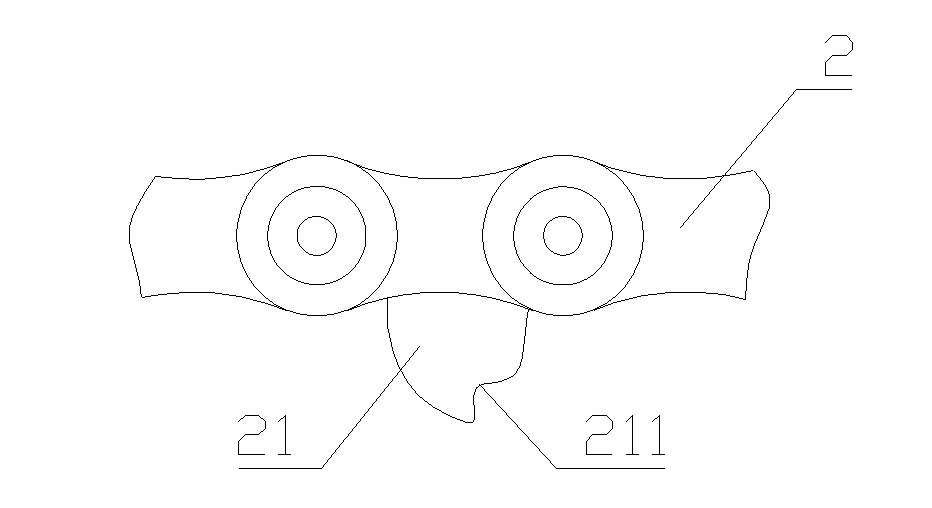

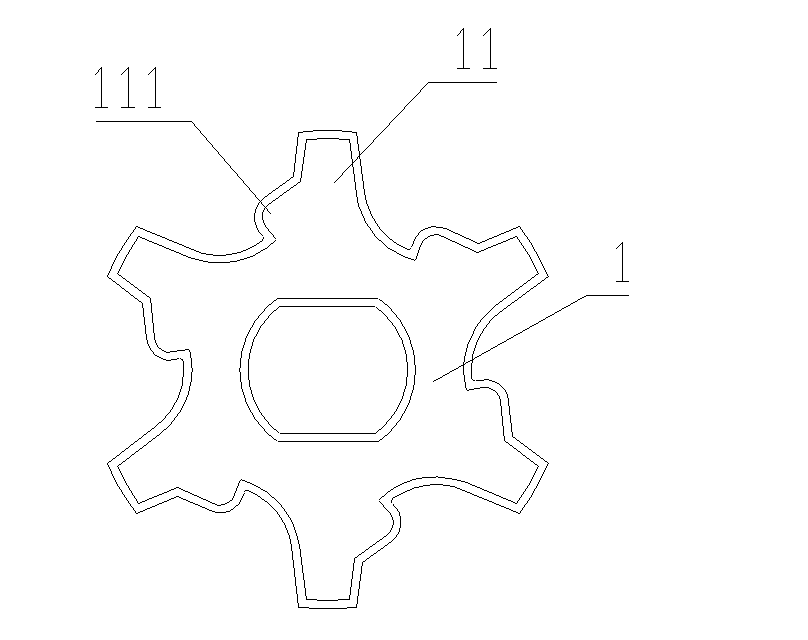

Reversed installation prevention structure for chain of chain saw

InactiveCN102151901AAvoid installationInstalled on the sprocket, if the user reverses to avoidMetal sawing devicesPortable liftingSprocketEngineering

The invention discloses a reversed installation prevention structure for a chain of a chain saw. The reversed installation prevention structure for the chain of the chain saw comprises a chain wheel on which chain wheel teeth are arranged; and a clamping structure is arranged on the chain wheel teeth so that the chain wheel teeth are matched with gaps on the right sides of chain teeth of the chain. The reversed installation prevention structure is simple and is convenient to manufacture, and the clamping structure matched with the gaps on the chain teeth is added on the chain wheel teeth; only by positively installing the chain, the clamping structure can be well matched with the gaps, and the chain can be installed on the chain wheel; if a user installs the chain reversely, the installation is difficult and the chain is difficult to install; therefore, by the reversed installation prevention structure, the easy reversed installation by the user can be avoided, and safety work of the chain saw can be realized.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

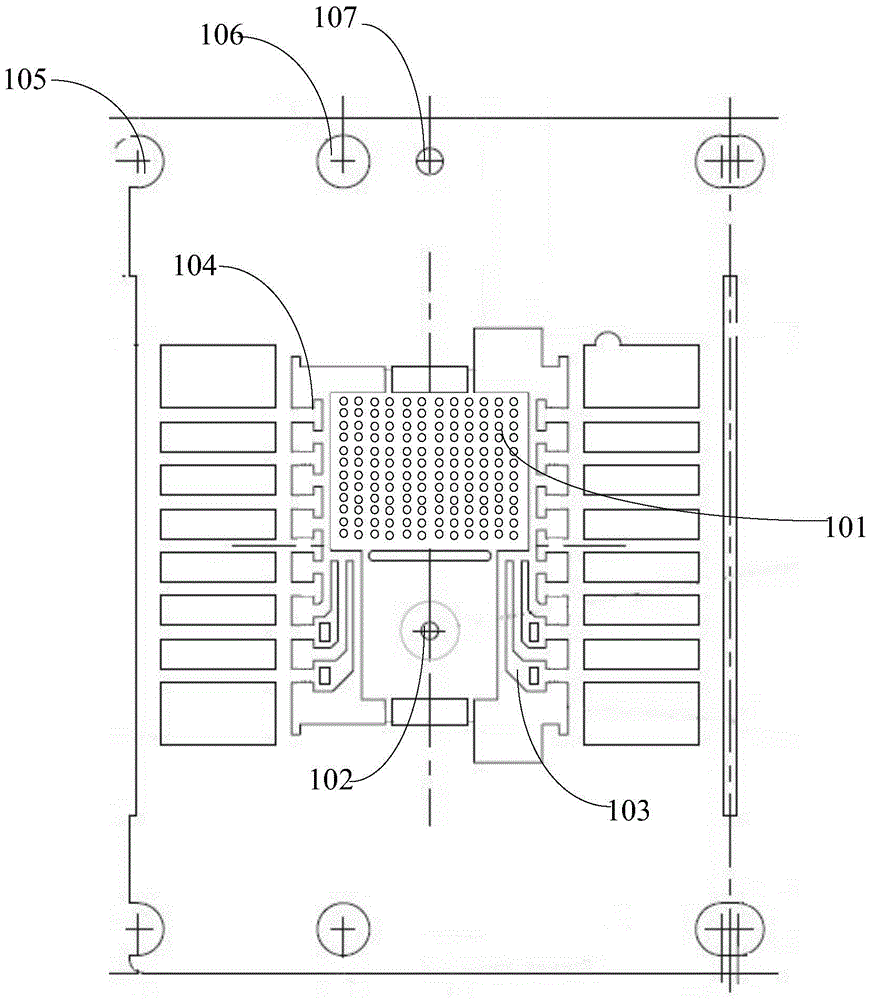

Tire pressure sensor packaging lead frame

ActiveCN104319270AImprove conductivityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringAtmospheric pressure

The invention provides a tire pressure sensor packaging lead frame which is used for being fixedly connected with a tire pressure sensor chip, a main control chip and a transmitting chip. The lead frame comprises a frame body which is made of nickel porpezite materials. The frame body comprises a first substrate, a second substrate, first pin wires and second pin wires. The first substrate and the second substrate are arranged in the center of the frame body. The first substrate is used for mounting the main control chip and the transmitting chip. A through hole is formed in the center of the second substrate and used for sensing the outside air pressure. The second substrate is used for fixing the tire pressure sensor. The first pin wires are in a T shape and are arranged on the opposite two sides of the first substrate. The second pin wires stretch and are distributed in the length direction of the side edge of the second substrate. The first pin wires and the second pin wires are used for transmitting signals of the main control chip, the transmitting chip and the tire pressure sensor to an external device respectively. The frame body is made of the nickel porpezite materials, and a later electroplating technology is omitted. Meanwhile, the lead frame has good electrical conductivity and thermal conductivity after the nickel porpezite materials are adopted.

Owner:GUANGDONG YUEJING HIGH TECH CO LTD +1

Thrust bearing and cage for thrust bearing

ActiveCN108150524BEasy to installAnti-reverse loadingRoller bearingsBall bearingsClassical mechanicsThrust bearing

A thrust bearing and a cage used for the thrust bearing, wherein the cage includes: a body frame having an inner peripheral surface and an outer peripheral surface, and one of the two ends in the axial direction is a first end; it also includes: a radially inner protrusion part, connected to the first end, and radially inwardly higher than the inner peripheral surface along the body frame; and / or, a radially outward protrusion, connected to the first end, and along the radial direction of the body frame Outwardly higher than the outer peripheral surface. The cage of the technical solution can solve the problem of reverse mounting of the cage in the prior art, realize accurate assembly of the cage, ensure effective lubrication of the thrust bearing, and reduce the risk of bearing rotation jamming.

Owner:SCHAEFFLER TECH AG & CO KG

Reverse stop bearing with anti-wedge reverse bearing retainer

ActiveCN104482050BAnti-reverse loadingDoes not affect normal workBearing componentsFreewheel clutchesEngineeringMechanical engineering

The present invention relates to reverse stop bearings with anti-wedge reverse mount bearing retainers. The retainer body is arranged between the outer ring and the inner ring, a steel ball is installed in each ball pocket on the circumferential surface of the retainer body, and a wedge is installed in each wedge notch on the first end face of the retainer body, correspondingly Between the notches of adjacent wedges is a wedge spacer boss; the fixed cover is connected to the first end of the retainer body; it is characterized in that: each of the wedge spacer bosses is provided with a spring slot with an open end, so The opening end of the spring groove communicates with the wedge notch in front of the inner ring of the bearing in the direction of one-way rotation. The spring groove is equipped with a compression spring. The inner end of the compression spring is connected to the retainer body. The outer end of the compression spring is exposed from the opening end of the spring groove and pushed Hold the wedges so that they remain snug against the outer and inner rings at all times. The invention does not affect the normal operation of the wedge and has the ability to prevent the reverse assembly of the wedge, improves the processing efficiency of the product, ensures the quality of the product, and reduces the production cost.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

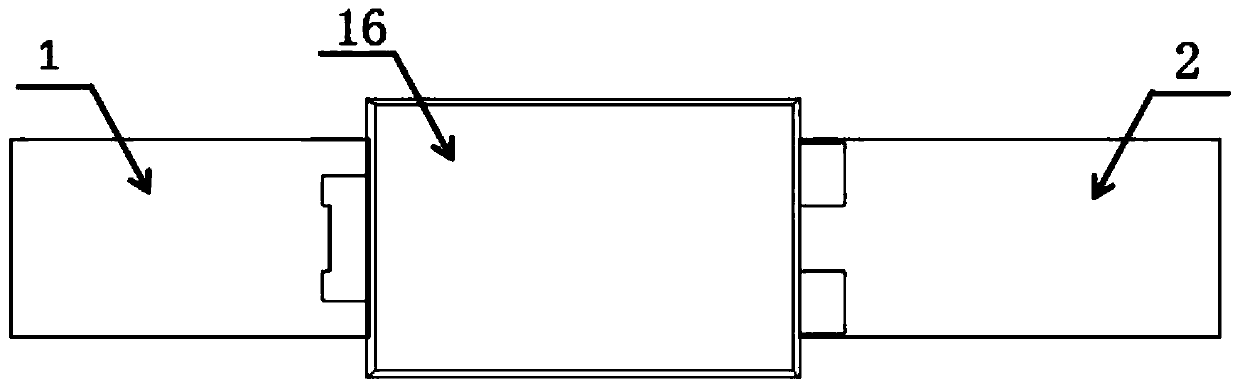

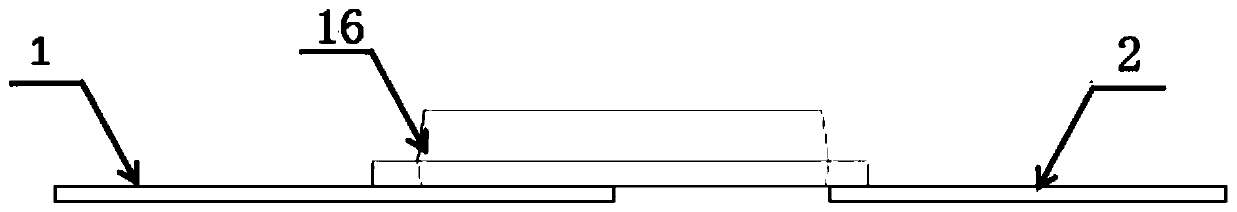

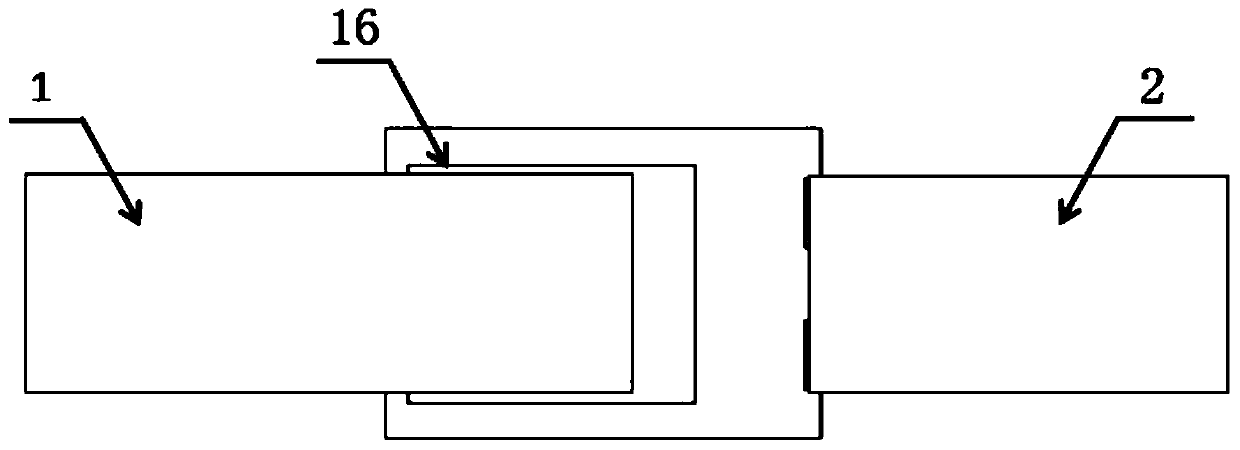

Membrane element pipe fitting, tool thereof, spiral wound water-saving membrane element, and water purifier

ActiveCN108295663AImprove assembly reliabilityFirmly connectedMembranesSemi-permeable membranesWater savingPipe fitting

The invention discloses a membrane element pipe fitting, a tool thereof, a spiral wound water-saving membrane element, and a water purifier. The tool of the membrane element pipe fitting comprises connecting pieces, insert parts, first fasteners and second fasteners, the connecting pieces are arranged at the first ends of pure water tubes, and the connecting pieces are provided with insert slots;the insert parts are adapted to the insert slots and are arranged at the first ends of wastewater tubes, and the wastewater tubes are arranged on the side surfaces of the pure water tubes side by sidealong the extending longitudinal direction of the pure water tubes; the first fasteners are arranged at the second ends of the pure water tubes; and the second fasteners are in close fit with the first fasteners and are arranged at the second ends of the wastewater tubes, and the size of the second fasteners is more than the size of the insert slots to prevent the second fasteners from being inserted into the insert slots. The assembling reliability of the membrane element pipe fitting is improved.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

An automatic exporting device for multi-directional magnetic steel sheets

ActiveCN106558953BAvoid missingAnti-reverse loadingManufacturing stator/rotor bodiesEngineeringMulti directional

The invention, which relates to the technical field of motor rotor assembling, discloses a multi-directional automatic magnetic steel guiding device comprising a pedestal and a substrate. A magnetic steel guiding positioning seat is arranged at the center of the top surface of the substrate; feeding channels are formed in four side surfaces of the magnetic steel guiding positioning seat; four feeding tracks are formed in the top surface of the substrate; and four magnetic steel guiding positioning slots that correspond to and are communicated with the inner ends of the feeding channels one by one are formed in the top surface of the magnetic steel guiding positioning seat. In addition, permanent magnet pieces are arranged inside the inner end surfaces of the feeding channels. A motor rotating shaft positioning sleeve is arranged at the center of the top surface of the magnetic steel guiding positioning seat. A cylinder with a shaft end upward is arranged at the center of the pedestal; a magnetic steel push-out sleeve is arranged at the shaft end of the cylinder; and the cross section of the magnetic steel push-out sleeve has a square annular shape. Besides, a rectangular avoidance hole is formed in the center of the bottom of the magnetic steel guiding positioning seat. The magnetic steel piece assembling efficiency is high; and neglected mounting or reverse mounting of a magnetic steel piece can be prevented effectively.

Owner:ZHEJIANG ROSHOW ELECTROMECHANICAL

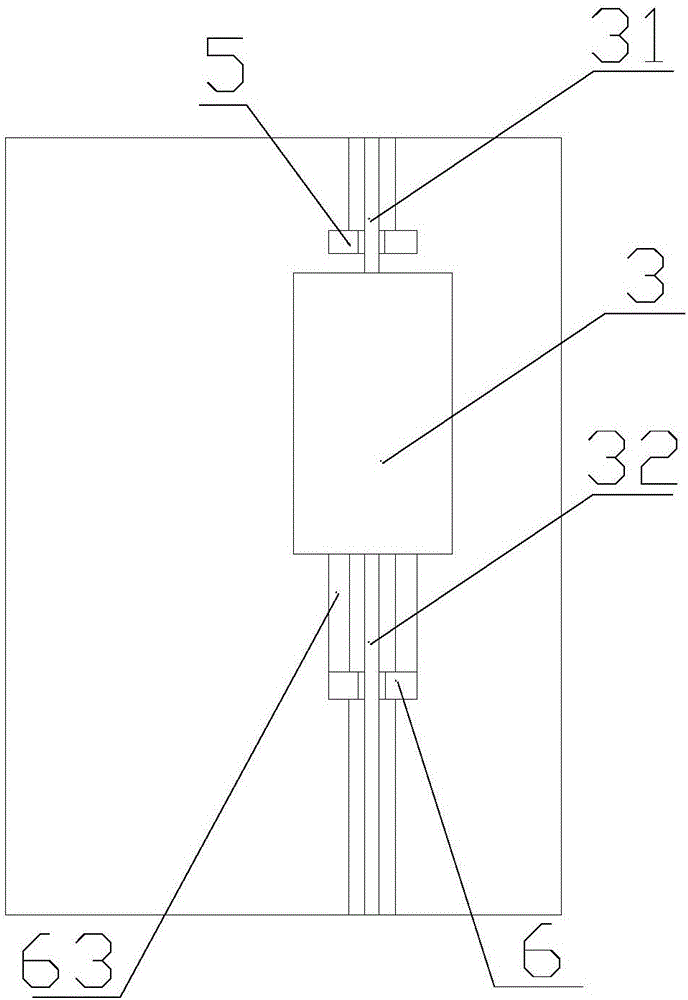

Fool-proof structure installed in regulator diode in automobile generator

PendingCN107528510AGuaranteed stabilityAnti-reverse loadingGenerator control detailsEngineeringDiode

The invention discloses a fool-proof structure installed in a regulator diode in an automobile generator. The structure comprises a box body and a diode. An inner wall in the box body, which corresponds to one side of a cathode of the diode, is installed with a first copper embedding sheet. An inner wall in the box body, which corresponds to one side of an anode of the diode, is installed with a second copper embedding sheet. The first and second copper embedding sheets comprise connection sheets and U-shaped fork hands. A length of the connection sheet of the first copper embedding sheet is greater than that of the connection sheet of the second copper embedding sheet. A gap is formed between the first copper embedding sheet and the second copper embedding sheet. The diode is installed in the gap. An anode lead wire of the diode is supported in a fork port of the U-shaped fork hand of the second copper embedding sheet. A cathode lead wire of the diode is supported in the fork port of the U-shaped fork hand of the first copper embedding sheet. In the invention, a condition that the diode is installed reversely because of misoperation can be avoided and work stability of a regulator is guaranteed. A jelly glue is filled in the box body so that connection of the diode is firm and the diode is not easy to shed.

Owner:江苏新凯晟机械设备有限公司

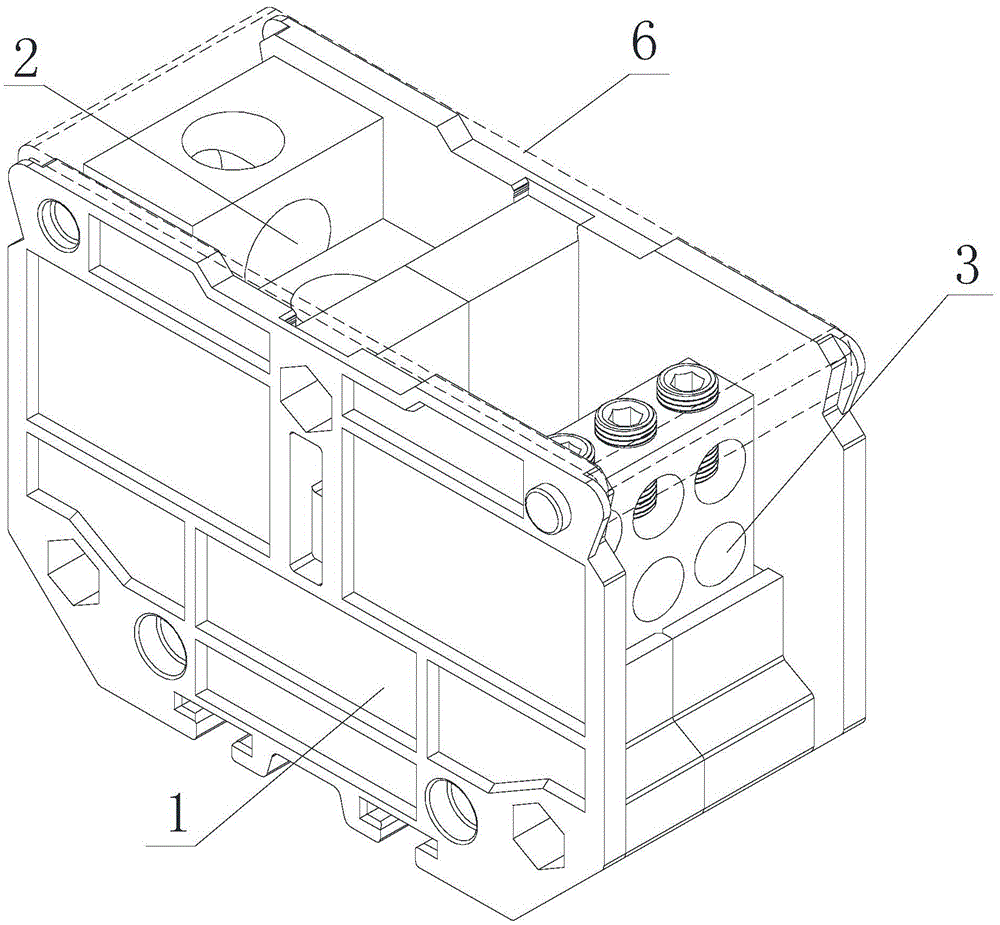

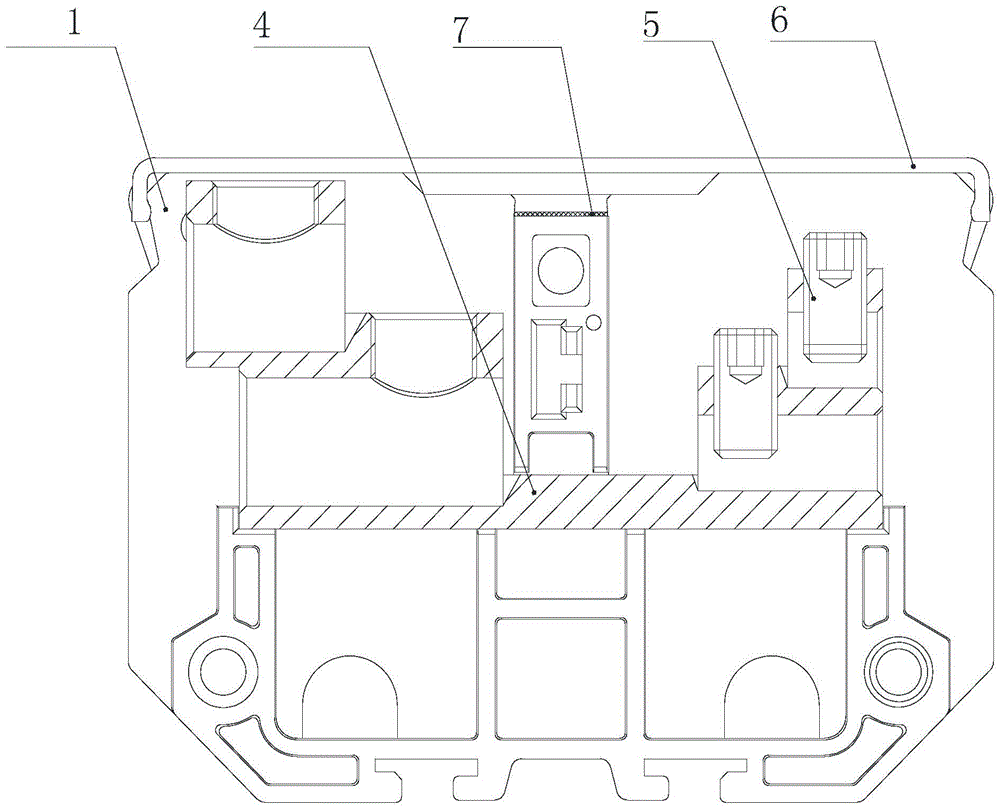

Two-in six-out branching terminal

InactiveCN105470667AAnti-reverse loadingSafe and reliable wiringClamped/spring connectionsInternal standardEngineering

The invention discloses a two-in six-out branching terminal. The two-in six-out branching terminal comprises a shell, an electric conductor, a dustproof cover, a marker bar and a screw, wherein wire inlet holes and wire outlet holes are formed in the two ends of the shell separately; the electric conductor is arranged in the shell; a circular hole is formed in the electric conductor; the dustproof cover is arranged at the top end of the shell; the marker bar is arranged in the shell; and the screw is arranged in the shell; the top end of the screw is in contact with the circular hole to form an arc surface; mould-pressed letters are arranged in the dustproof cover; and the shell is made of an insulating material. The wire inlets of the two-in six-out branching terminal adopt two American system threaded holes; the wire outlets adopt six internal standard fine thread screw holes; the marker bar adopts a PC environment-friendly material; the mould-pressed letters are designed to be in the inner surface of the dustproof cover, so that reverse installation is avoided; the head part of the fine thread screw is a flat end, and an arc surface is formed by the flat end and the circular hole of the electric conductor, so that wires can be collected and compressed tightly; and a wiring process is safer and more reliable.

Owner:SHANGHAI UPUN ELECTRIC GRP

Membrane element pipe fitting, tool thereof, spiral-wound water-saving membrane element, and water purifier

ActiveCN107998891AImprove assembly reliabilityAnti-reverse loadingMembranesSemi-permeable membranesWater savingPipe fitting

The invention discloses a membrane element pipe fitting, a tool thereof, a spiral-wound water-saving membrane element, and a water purifier. The tool of the membrane element pipe fitting comprises inserting grooves, inserting parts, and spacing convex parts; the inserting grooves are arranged on a first end of a pure water pipe; the inserting parts are designed to match the inserting grooves, andare arranged on first ends of waste water pipes; the waste water pipes are arranged along the extension longitudinal direction of the pure water on the side surface of the pure water pipe in parallel;the spacing convex parts are arranged on second ends of the waste water pipes so as to prevent inserting of the second ends of the waste water pipes into the inserting grooves. The above design is capable of improving the assembling reliability of the membrane element pip fitting.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

Reverse stop bearings with self-aligning snap-fit bearing retainers

ActiveCN104455002BAnti-reverse loadingSimple structureBearing componentsFreewheel clutchesClassical mechanicsRetainer

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

A modular power supply with good heat dissipation

ActiveCN104377940BIncrease contact areaImprove cooling effectCasings/cabinets/drawers detailsModifications for power electronicsEngineeringHeat power

Owner:SICHUAN SHENGHUA POWER TECH CO LTD

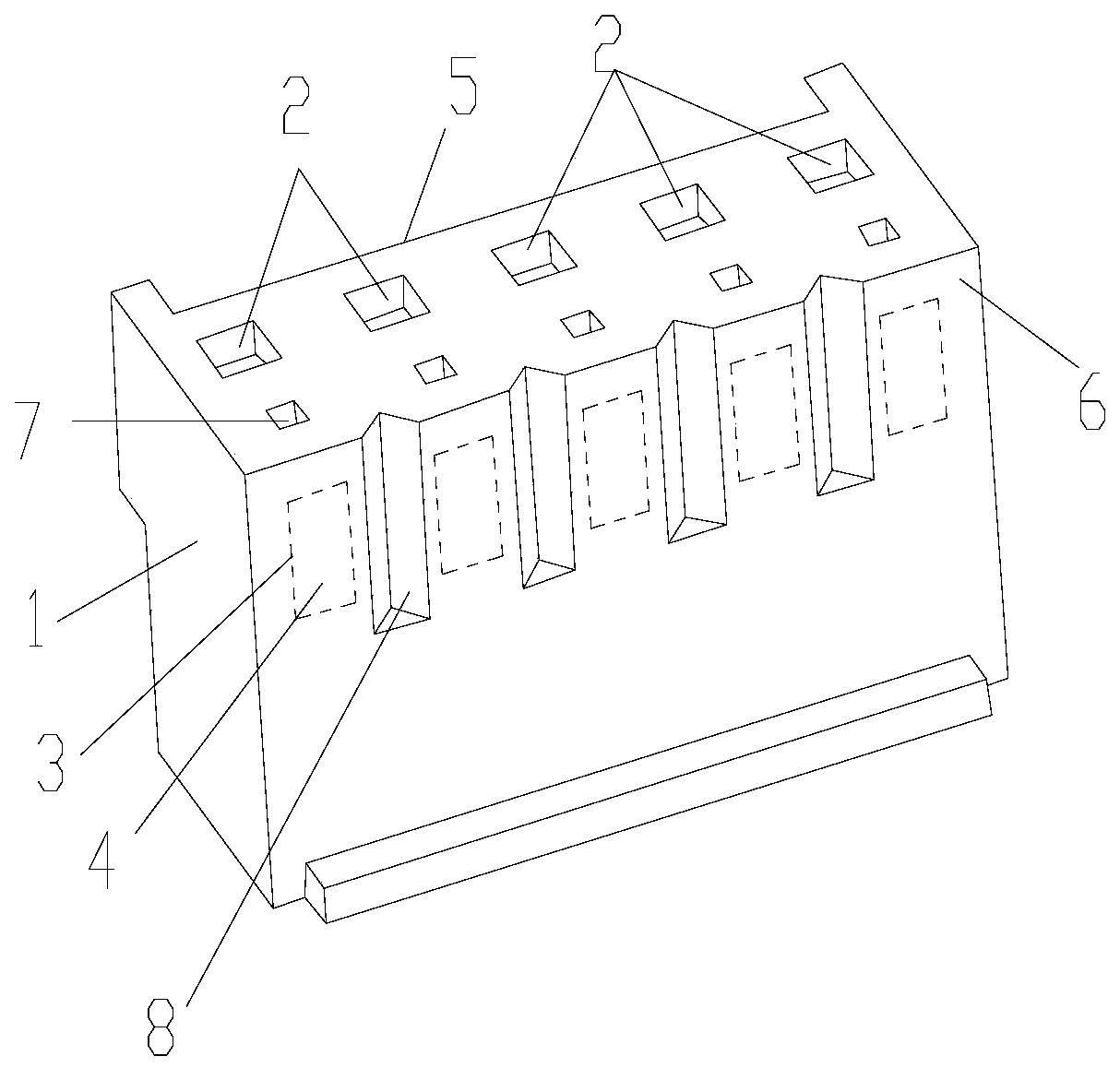

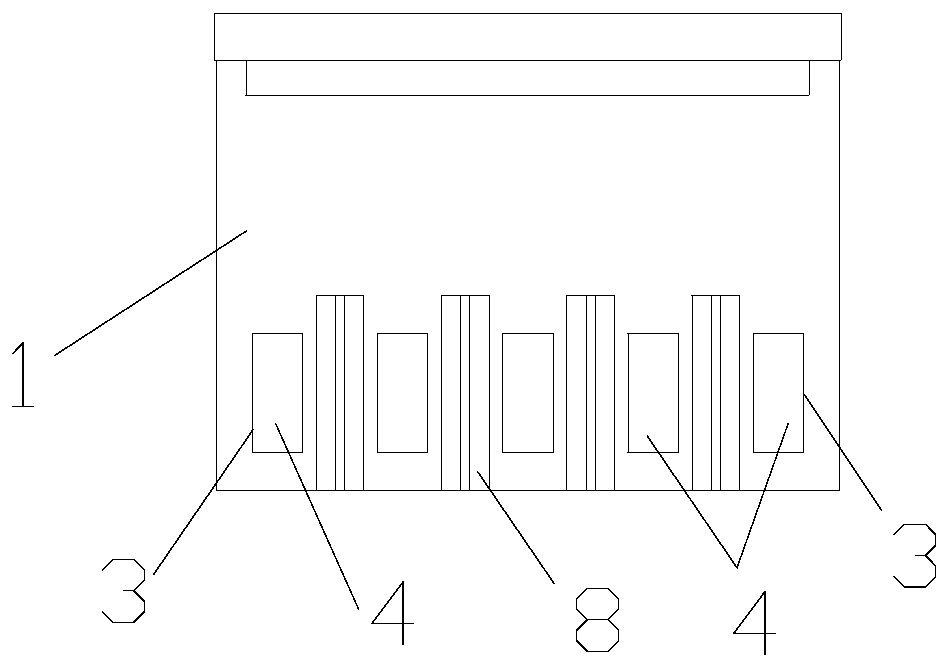

a terminal

ActiveCN106505362BReduce electrostatic hazardsImprove running stabilityCouplings bases/casesLive contact access preventionWindow openingElectronic component

The invention provides a connection terminal, which comprises a casing (1) and a pointer, the casing (1) is provided with a slot (2) for accommodating the pointer, and on the casing (1), the socket and the plug The position corresponding to the slot (2) is also provided with a window (3) for observation and / or maintenance, and the position of the window (3) on the casing (1) is also provided with a window for sealing the Open the window (3) to prevent the anti-static structure (4) from the channeling at the window. The invention can effectively isolate the terminal from the outside at the window opening position, preventing external static electricity from entering the terminal through the window opening position, thereby causing the terminal and the electronic components connected to the terminal to be damaged by static electricity, effectively reducing the wiring Electrostatic hidden dangers of the terminal, improve the operation stability and reliability of the terminal.

Owner:GREE ELECTRICHEFEI +1

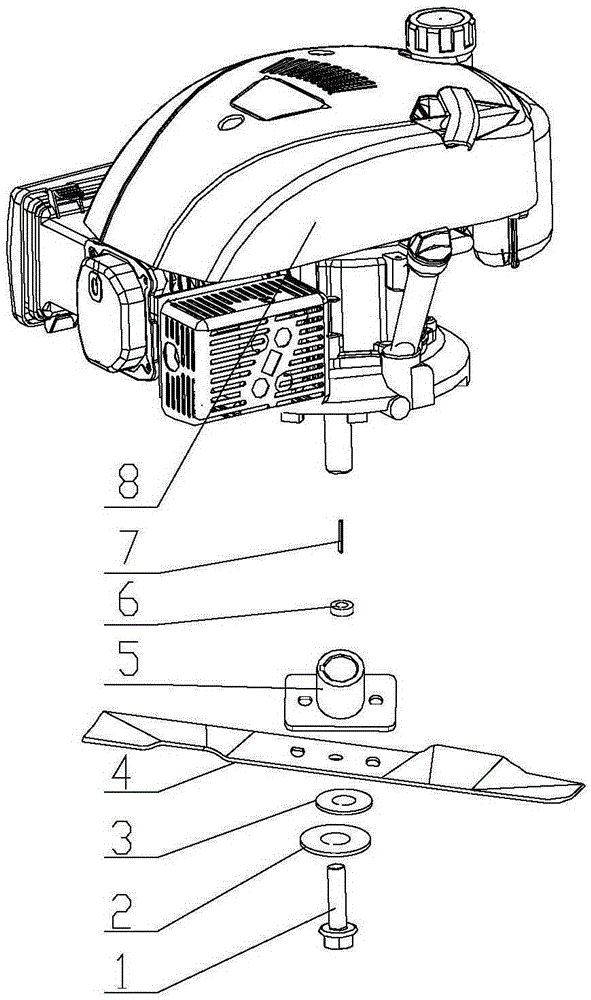

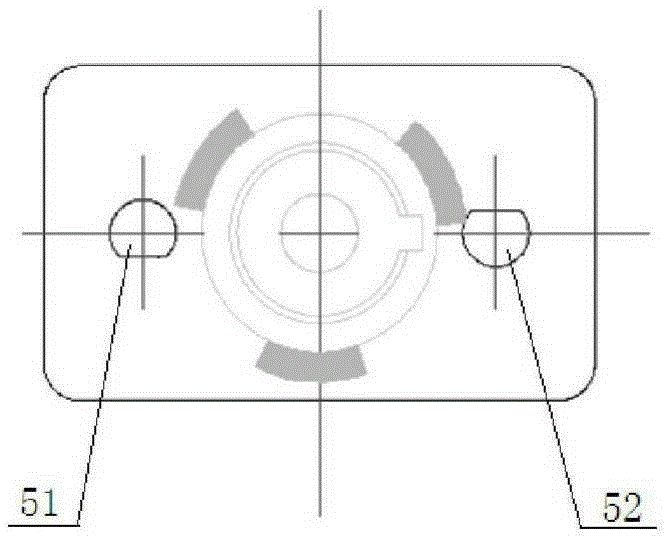

Reverse-assembling-prevention composite tool apron used for lawn pruning trolley

The invention discloses a reverse-assembling-prevention composite tool apron used for a lawn pruning trolley. The reverse-assembling-prevention composite tool apron comprises a blade and a tool apron body, the tool apron body comprises a pedestal and a mounting base being perpendicular to the pedestal, and the surface, of the pedestal, being attached to the blade is provided with several bosses; the blade is fixedly arranged under the tool apron body, and the position, of the blade, being attached to the pedestal of the tool apron body is provided with several grooves corresponding to the bosses. During the mounting process, once the blade is placed reversely, the bosses on the tool apron body and the grooves in the blade cannot be buckled to complete the assembly, and the effect that the blade is prevented from being assembled reversely is effectively achieved. Especially when the several bosses are in central symmetry, the blade is prevented from being assembled reversely, the mounting angle is fixed, the weight can be further balanced, and the high-speed rotation stability can be improved. The whole reverse-assembling-prevention composite tool apron used for the lawn pruning trolley is simple in structure, high in reliability and convenient to maintain, and is stable and practical.

Owner:镇江华龙煤质制样设备有限公司

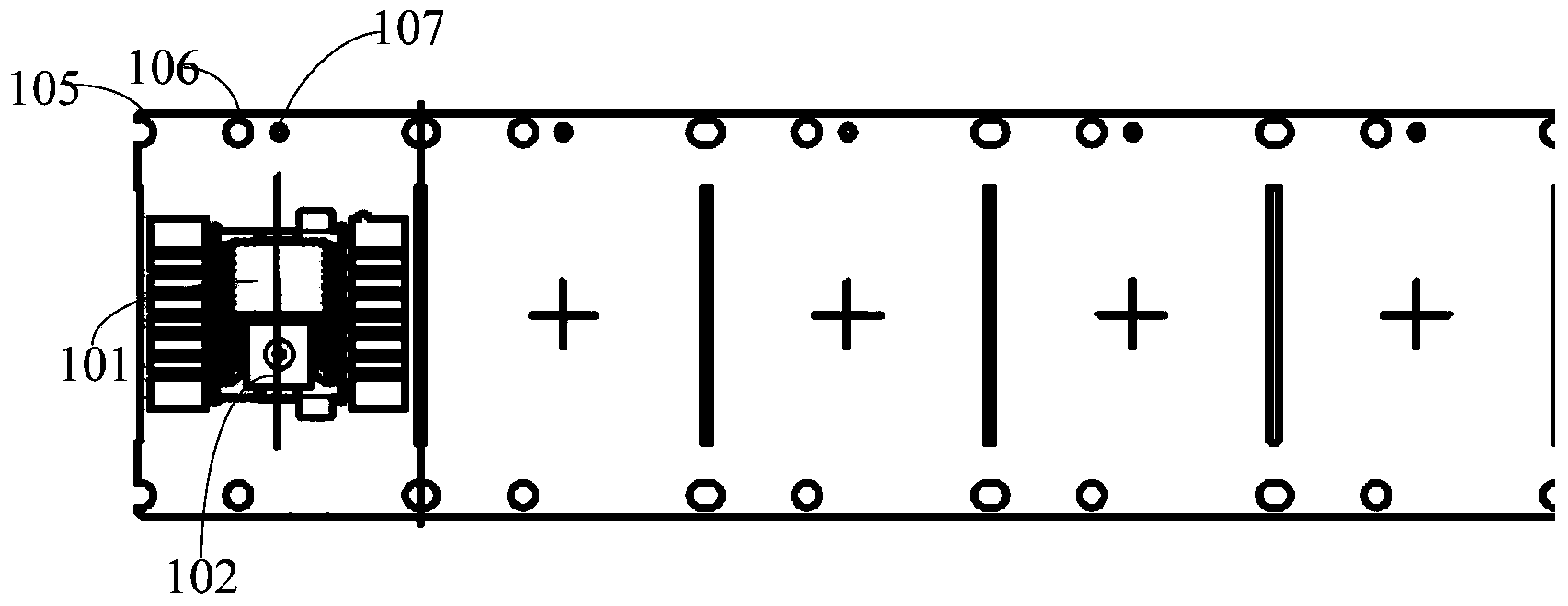

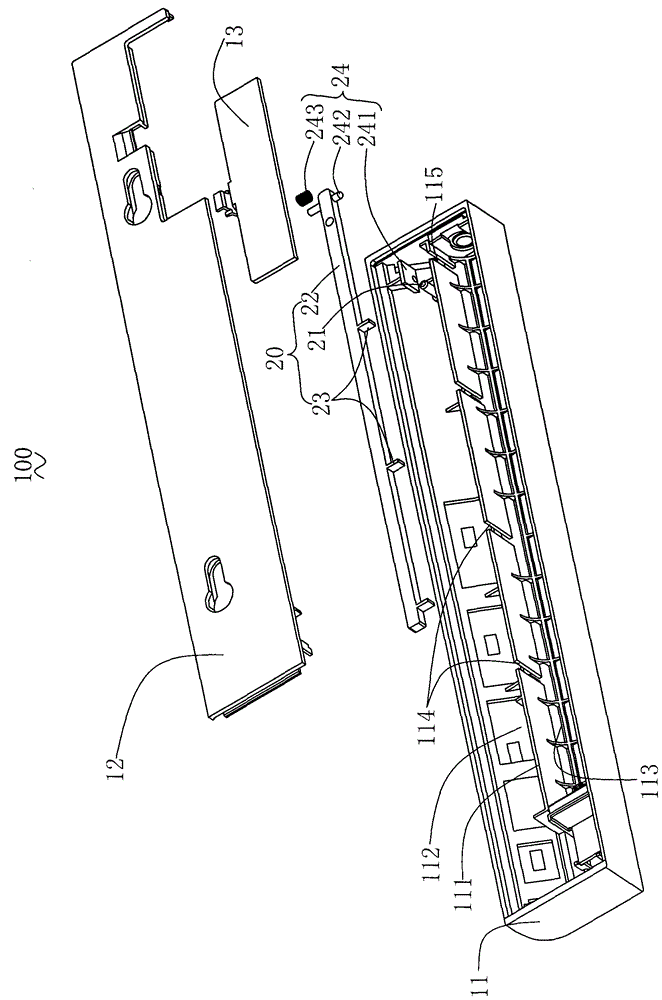

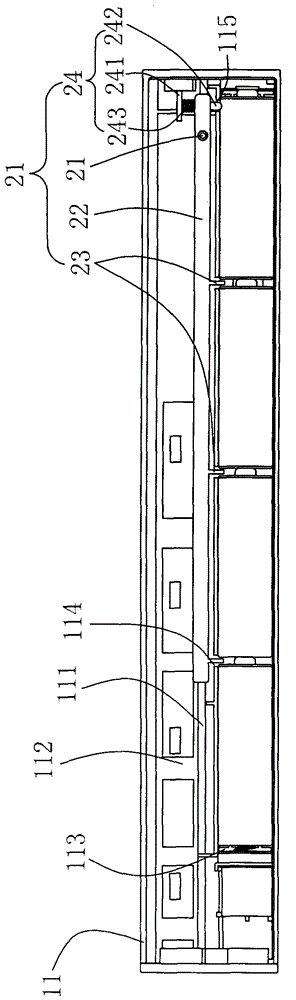

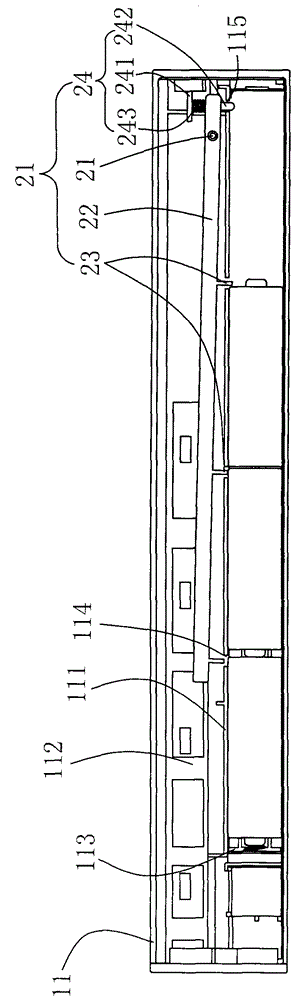

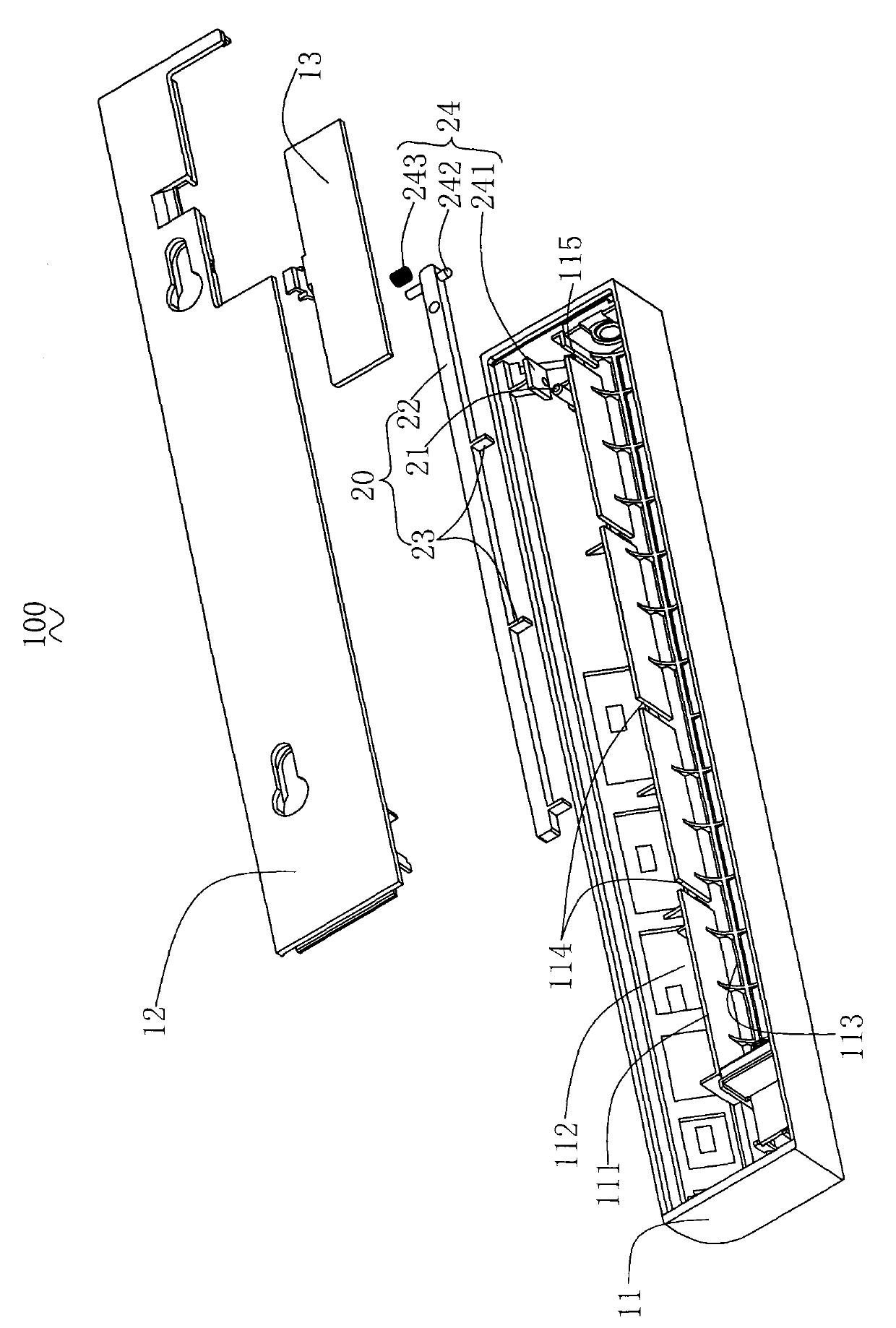

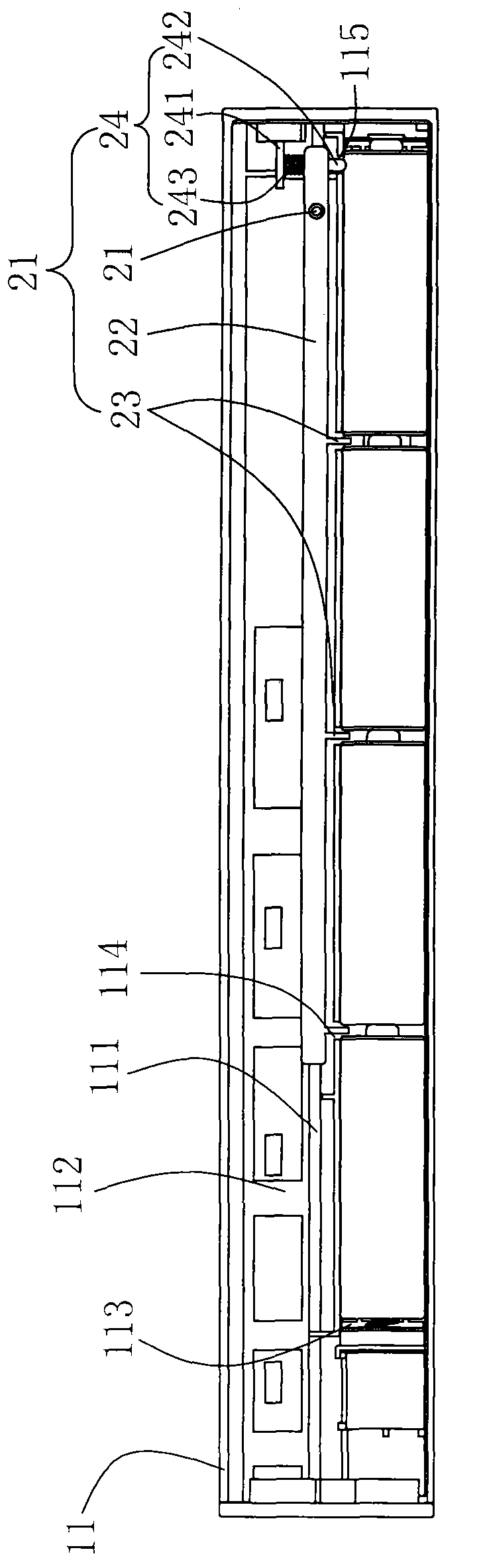

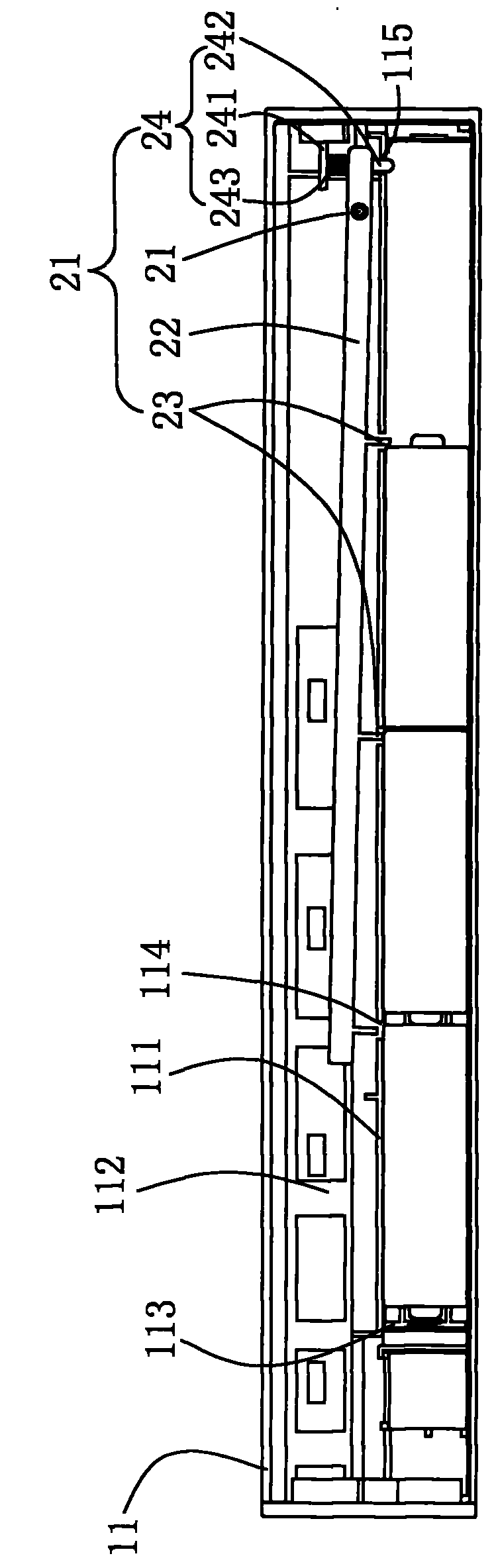

battery box for lamp

ActiveCN104183800BAnti-reverse loadingCell component detailsWith built-in powerEngineeringLight fixture

A lamp battery box comprises a frame body and a battery reverse-installation preventing device. The battery reverse-installation preventing device comprises a fixed shaft which is arranged on the frame body, a lever which is arranged on the fixed shaft in a penetrating manner, at least one positioning needle which is arranged on one side of the fixed shaft and a telescopic contact which is arranged on the lever; the positioning needle is inserted into a gap between two adjacent batteries; and the telescopic contact pushes against the side wall of the battery at a compression state. When a positive electrode and a negative electrode are reversely installed and a last battery is installed to facilitate the movement of a contact of the telescopic contact towards a clamping part, the positioning needle cannot be inserted into the gap between two adjacent batteries but pushes against the side wall of one battery, the contact of the telescopic contact cannot be ejected, and the installation of the last battery is stopped by the contact, so that the user can be reminded of the reverse installation of the batteries, and a purpose for preventing the reverse installation of the battery can be realized.

Owner:SELF ELECTRONICS CO LTD

Lamp battery box

ActiveCN104183800AAnti-reverse device, when one of the positive and negative poles of the battery is reversed to preventAnti-reverse loadingCell component detailsWith built-in powerEngineeringElectrical and Electronics engineering

A lamp battery box comprises a frame body and a battery reverse-installation preventing device. The battery reverse-installation preventing device comprises a fixed shaft which is arranged on the frame body, a lever which is arranged on the fixed shaft in a penetrating manner, at least one positioning needle which is arranged on one side of the fixed shaft and a telescopic contact which is arranged on the lever; the positioning needle is inserted into a gap between two adjacent batteries; and the telescopic contact pushes against the side wall of the battery at a compression state. When a positive electrode and a negative electrode are reversely installed and a last battery is installed to facilitate the movement of a contact of the telescopic contact towards a clamping part, the positioning needle cannot be inserted into the gap between two adjacent batteries but pushes against the side wall of one battery, the contact of the telescopic contact cannot be ejected, and the installation of the last battery is stopped by the contact, so that the user can be reminded of the reverse installation of the batteries, and a purpose for preventing the reverse installation of the battery can be realized.

Owner:SELF ELECTRONICS CO LTD

Tire pressure sensor package lead frame

ActiveCN104319270BImprove conductivityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

Owner:GUANGDONG YUEJING HIGH TECH CO LTD

Elastic straight pin feeding device used for producing low-voltage circuit breakers

ActiveCN101630609BAvoid underpackingAnti-reverse loadingElectric switchesEmergency protective device manufactureLow voltage circuitsSemi automatic

The invention discloses an elastic straight pin feeding device used for producing low-voltage circuit breakers, which is characterized in that: a fixed plate is connected under an air cylinder, a slide rod is arranged under the fixed plate, two guide poles are arranged on the fixed plate, two lower guide poles are arranged between the fixed plate and the slide rod, two ejector pins are connected below the fixed plate, a corner plate, a static contact bus bar and an arc sheet are arranged on a locating block which is arranged below the slide rod, both ends of the slide rod are provided with square holes, a feeding block is fixed at the front end of the slide rod, both sides of the feeding block, which correspond to the square holes, are provided with U-shaped grooves, two popping-boxes areclamped in the square holes of the slide rod, a plurality of elastic straight pins are arranged in the popping-boxes, one side of each popping-box is provided with a spring, both ends of each spring are respectively provided with a slide rod provided with a spacer pin in a contacted way, and one end of each popping-box is provided with a notch. The invention adopts the popping-box type structure,realizes semi-automatic feeding operation, enhances the production efficiency, avoids the problem that the elastic straight pins are not loaded enough and are arranged in reverse and prevents the danger caused when human hands contact the elastic straight pins.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com