Reversed installation prevention structure for chain of chain saw

An anti-reverse installation and chain technology, applied in the direction of sawing machine, belt/chain/gear, hoisting device, etc., can solve the problems of off-chain, chain vibration, poor installation, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

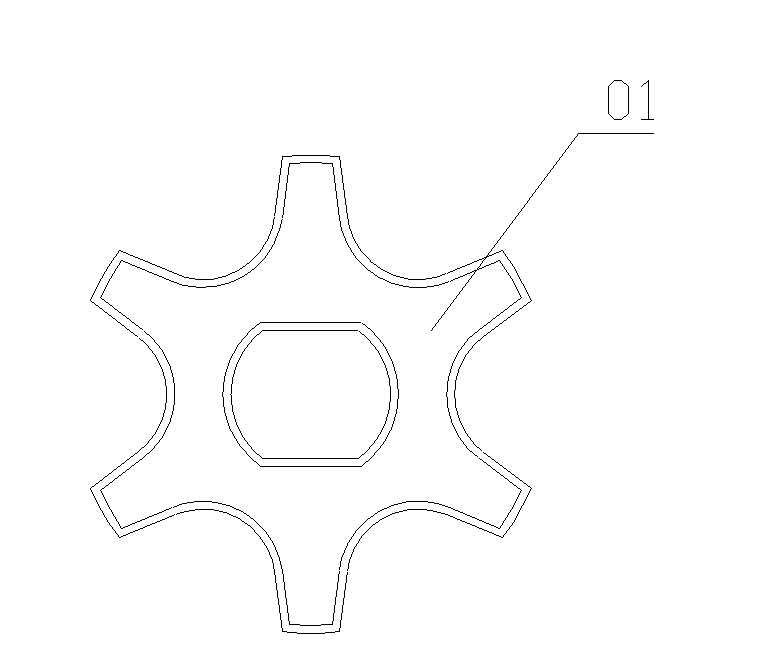

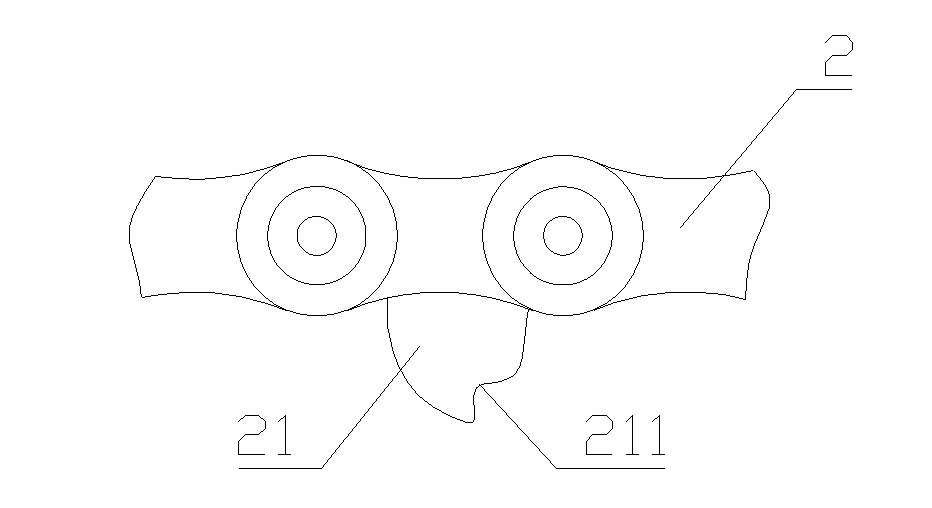

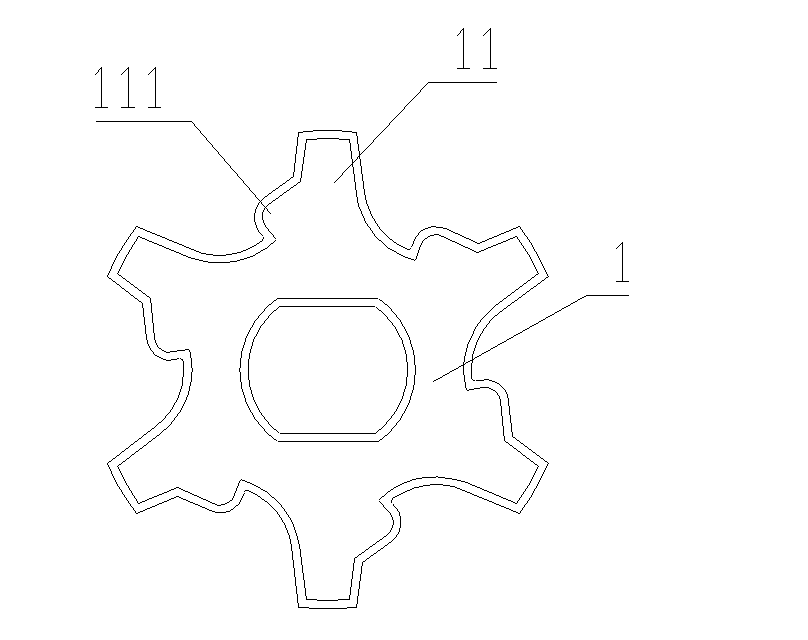

[0011] Such as figure 2 and 3 As shown, a chain saw chain anti-reverse assembly structure includes a sprocket 1, on which a sprocket tooth 11 is provided, and the sprocket tooth is provided with a snap-fit structure and the right side of the chain tooth 21 of the chain 2. The gap 211 fits. The engaging structure is a protrusion 111 arranged on the left side of the sprocket teeth, and the shape and size of the protrusion correspond to the notch.

[0012] In the above-mentioned embodiment, a snap-fit structure is added on the sprocket teeth to match the gaps on the chain teeth. The chain can only be installed on the sprocket when the chain is properly installed so that the protrusions fit well with the gaps. If the user reverses the chain, he will find that The installation is difficult, and it is difficult to install the chain well, so it is easy to prevent the user from reversely installing the chain and realize the safe operation of the chain saw.

[0013] The inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com