Photovoltaic bypass diode in field of thin-film solar energy, and production process and installation method of photovoltaic bypass diode

A technology of bypass diodes and thin-film solar energy, which is applied in photovoltaic power generation, circuits, and final product manufacturing. Product reliability, firm and reliable structure, and high electrical yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

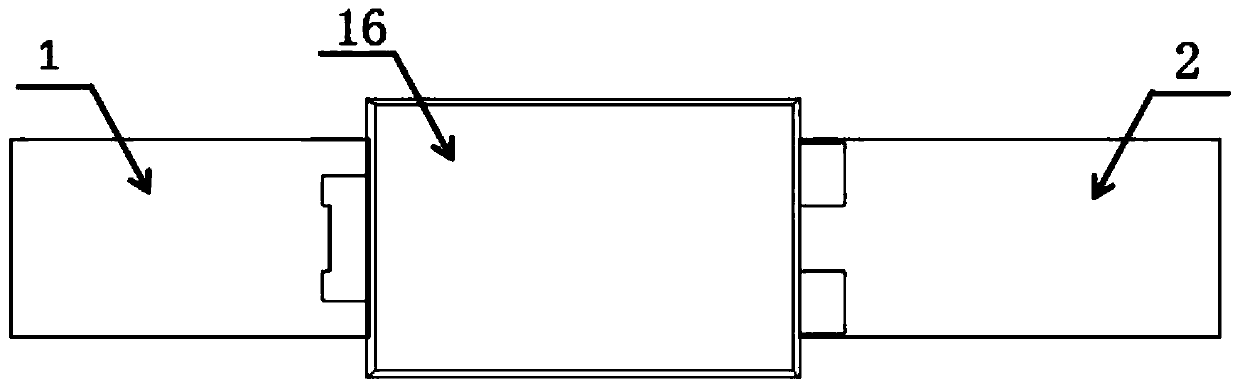

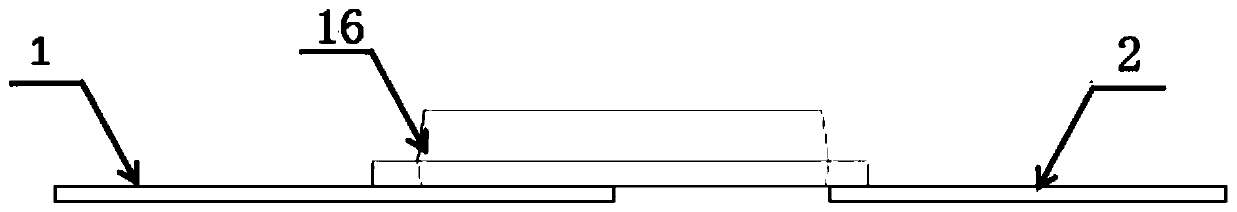

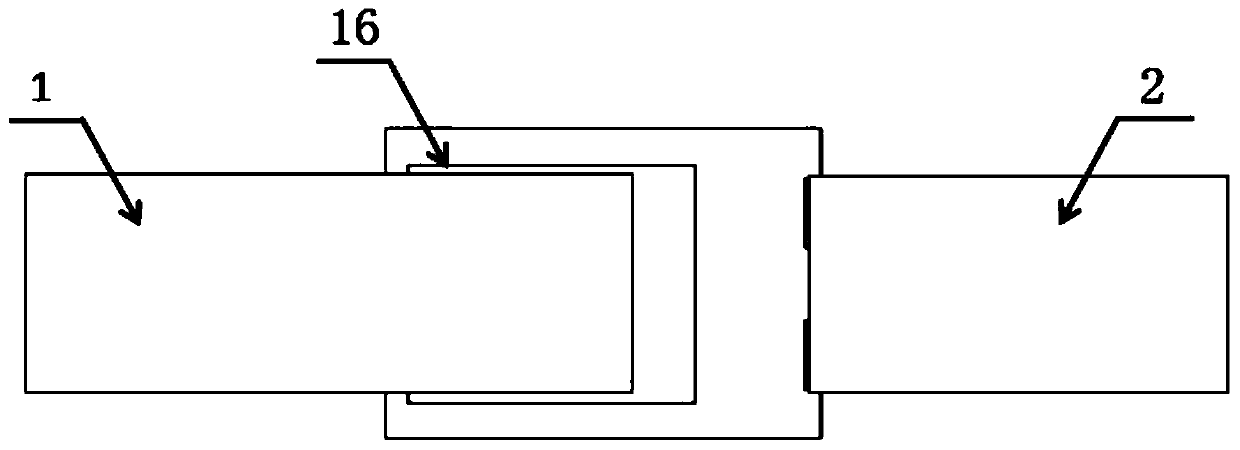

[0058] Such as Figure 5-10 As shown, the photovoltaic bypass diode in the field of thin film solar energy according to the present invention includes a diode body, and the diode body includes a diode negative lead terminal 1 and a diode positive lead terminal 2, and a diode negative lead terminal 1 and a diode positive lead terminal 2 are provided with Diode chip 9, a bonding jumper 11 is connected above the diode chip 9, one end of the bonding jumper 11 is connected to the top of the diode chip 9, and the other end is connected to the diode anode lead 2, wherein the diode chip 9 is placed on the diode cathode On the lead end 1, the diode cathode lead end 1 is connected to the diode anode lead end 2 through the diode chip 9 and the bonding jumper 11, and a chip mounting surface 8 is provided below the diode chip 9, and the diode chip 9 is placed above the chip mounting surface 8 , the bottom surface of the diode chip 9 is combined with the chip mounting surface 8, the diode c...

Embodiment 2

[0075] On the basis of Embodiment 1, the photovoltaic bypass diode also includes a frame, and several photovoltaic bypass diodes are arranged on the frame, and frames 17 are arranged on the upper and lower sides of the frame, and the upper and lower sides of the photovoltaic bypass diode are all connected with the frame set up and down. 17 connections, the photovoltaic bypass diodes are evenly arranged in a matrix on the frame, and support ribs 18 are arranged between multiple photovoltaic bypass diodes, and the support ribs 18 are connected to the positive and negative leads on the photovoltaic bypass diodes, so that the current passes through the surface of the frame .

[0076] The manufacturing process of the present invention adopts a matrix copper frame, and a single chip can accommodate 48 diode units, which improves the utilization rate of the frame and saves copper consumption. At the same time, due to the use of ultra-thin plastic packaging, the use of plastic packagin...

Embodiment 3

[0079] Such as Figure 11 As shown, the production process of the photovoltaic bypass diode in the field of thin film solar energy of the present invention comprises the following steps:

[0080] Step 1: Raw material preparation:

[0081] Prepare frame, diode chip, solder paste and molding material;

[0082] Step 2 Mounting and welding:

[0083] The assembly adopts automatic assembly of welding wires, distributing solder such as solder paste on the frame, then sucking and placing the diode chip 9 to the designated position of the frame, distributing solder paste on the surface of the diode chip 9, and then placing the bonding jumper 11 on the designated position position, let the diode chip 9 and the chip mounting surface 8 form a special connection circuit, and finally, solder, so that the above components form an integral circuit;

[0084] Step 3: Ultrasonic Cleaning:

[0085] Ultrasonic vibration cleaning is used to remove various residues and contamination after weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com