Aero-engine air rotational flow plasma igniter

An aero-engine and plasma technology, which is used in engine ignition, engine components, machines/engines, etc., can solve the problems of low working environment pressure, short life, and high electrode temperature, achieve strong electron emission capability, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

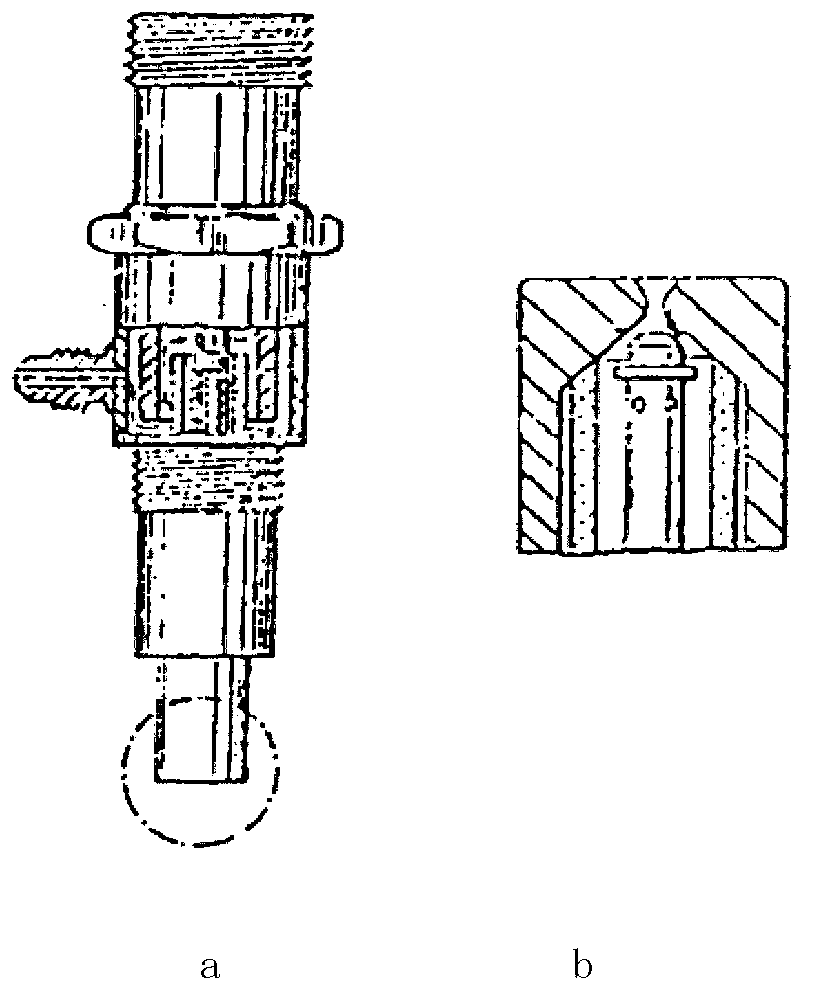

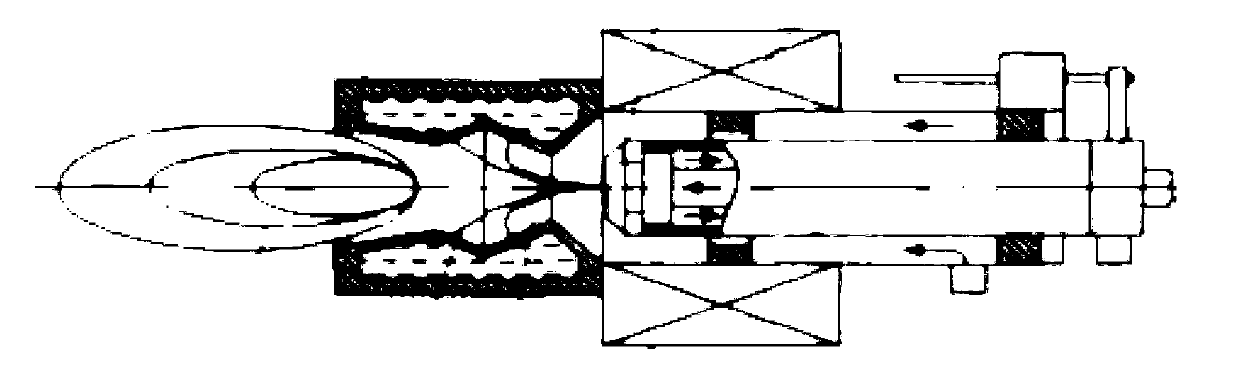

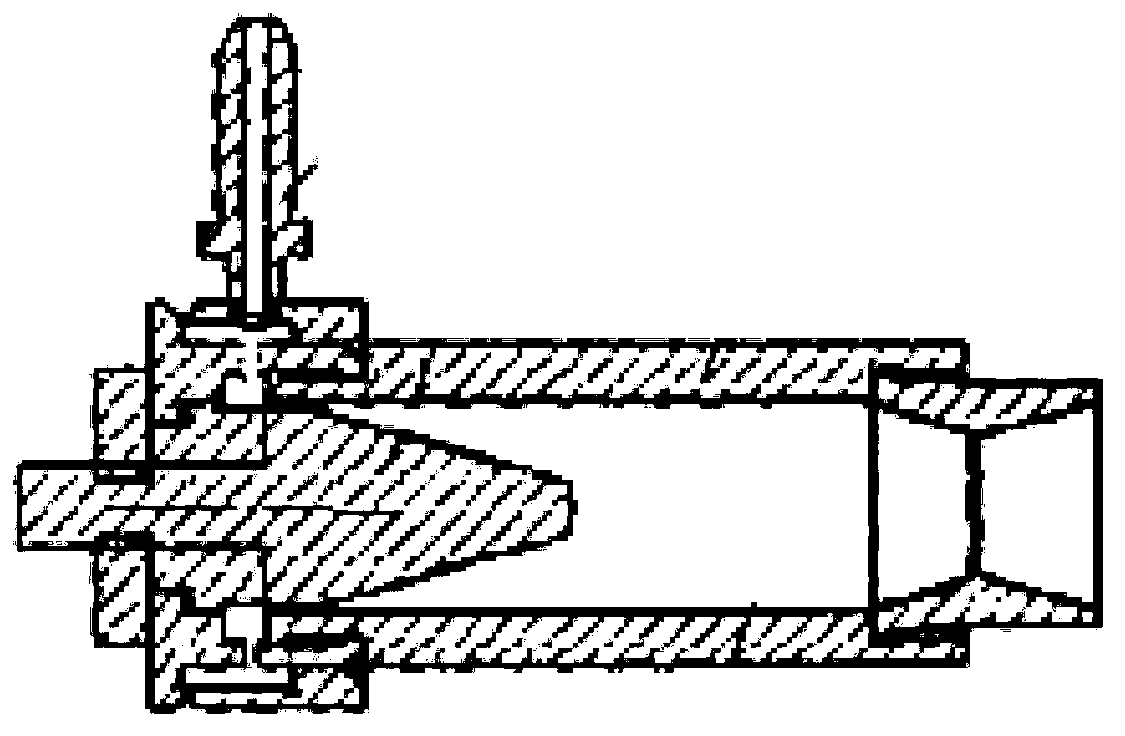

[0035] This embodiment is an air swirling plasma jet igniter for an aeroengine combustion chamber, comprising a housing 1, an air intake pipe 2, an anode sleeve 3, an insulating sleeve 4, a cathode mounting seat 5, a support sleeve 6, a cathode 7 and a rotary Streamer 8. Wherein, both the insulating sleeve 4 and the supporting sleeve 6 are installed in the casing 1 . The insulating sleeve 4 is located on one side of the inner partition of the housing, and the insulating sleeve 4 is in interference fit with the housing 1; the supporting sleeve 6 is located on the other side of the inner partition of the housing, and the supporting An air chamber is formed between the outer surface of the sleeve 6 and the inner surface of the casing 1 . One end of the supporting sleeve 6 passes through the central hole of the inner partition and is embedded in the groove on the end face of the insulating sleeve 4 . The anode sleeve 3 is fitted on the casing at the end of the housing 1 with the...

Embodiment 2

[0046] This embodiment is an air swirling plasma jet igniter for an aeroengine combustion chamber, comprising a housing 1, an air intake pipe 2, an anode sleeve 3, an insulating sleeve 4, a cathode mounting seat 5, a support sleeve 6, a cathode 7 and a rotary Streamer 8. Wherein, both the insulating sleeve 4 and the supporting sleeve 6 are installed in the casing 1 . The insulating sleeve 4 is located on one side of the inner partition of the housing, and the insulating sleeve 4 is in interference fit with the housing 1; the supporting sleeve 6 is located on the other side of the inner partition of the housing, and the supporting An air chamber is formed between the outer surface of the sleeve 6 and the inner surface of the casing 1 . One end of the supporting sleeve 6 passes through the central hole of the inner partition and is embedded in the groove on the end face of the insulating sleeve 4 . The anode sleeve 3 is fitted on the casing at the end of the housing 1 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com