Reverse-assembling-prevention composite tool apron used for lawn pruning trolley

A technology of anti-reverse installation and compound knives, applied in the field of lawn mowers, can solve the problem of easy reverse installation of the blade on the knife seat, etc., and achieve the effect of preventing the reverse installation of the blade, high reliability and balancing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

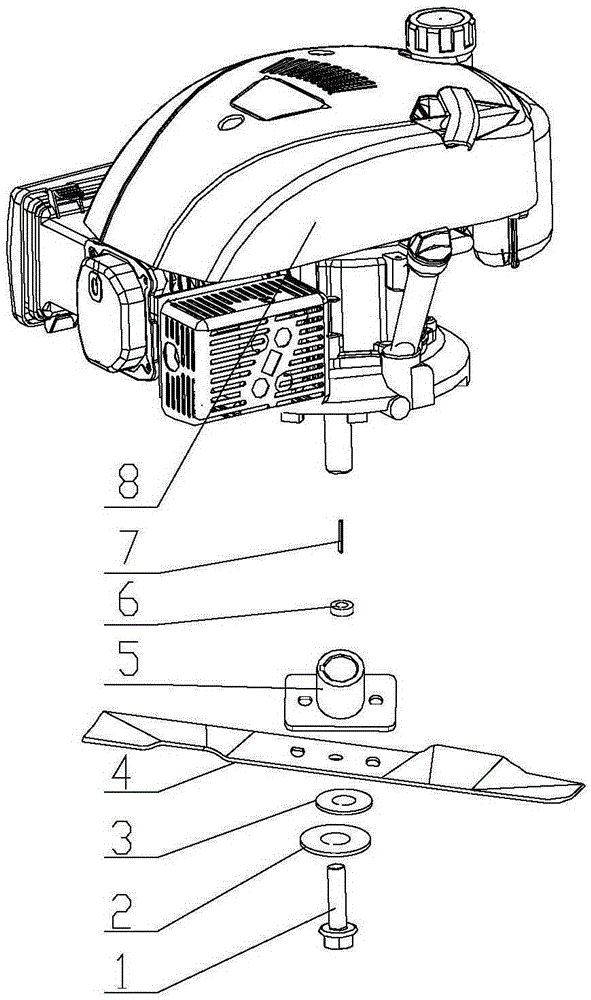

[0018] Example 1: as figure 1 As shown in the figure, the anti-reverse-installation composite tool holder for the lawn mowing vehicle provided in the present embodiment 1 includes a blade 4 and a tool holder 5. The tool holder 5 includes a base and a mounting seat perpendicular to the base. The base is connected to the blade. 4. Two bosses are arranged on the abutting surface; the blade 4 is fixedly arranged under the knife seat 5, and two grooves corresponding to the bosses are provided on the part that is fitted with the base of the knife seat 5.

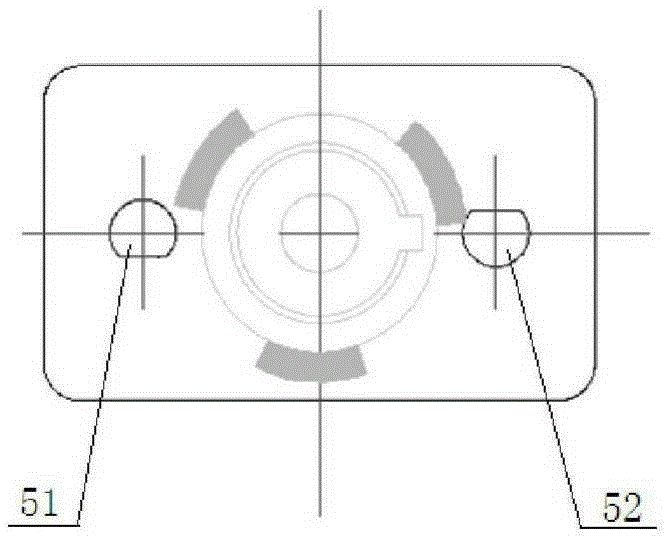

[0019] The mounting seat on the knife seat 5 is cylindrical, and the two bosses are evenly distributed in the circumferential direction with the center of the butting part of the base and the mounting seat as the center, and are symmetrical with the center of the butting part of the base and the mounting seat. The sections of the bosses are all arcuates with an area larger than a semicircle.

[0020] The inner wall of the mountin...

Embodiment 2

[0022] Embodiment 2: The structure is basically the same as that of Embodiment 1, and the similarities are not repeated, but the differences are:

[0023] The blade holder 5 is provided with two semicircular bosses which are axially symmetric with the diameter of the circular cross-section of the butting portion of the base and the mounting base, and the blade 4 is correspondingly provided with two semicircular grooves.

Embodiment 3

[0024] Embodiment 3: The structure is basically the same as that of Embodiment 1, and the similarities are not repeated, but the differences are:

[0025] The blade seat 5 is provided with four triangular bosses that are symmetrical with the center of the bottom of the mounting seat and evenly distributed in the circumferential direction, and the blade 4 is correspondingly provided with four triangular grooves.

[0026] Taking Embodiment 1 as an example, the working principle of the anti-reverse-installation composite tool holder for grass trimmers provided by the present invention is as follows: two bosses are arranged on the grass trimmer tool holder 5, and two bosses are also arranged on the blade 4. In this way, once the blade is reversed during the assembly process, the two bosses on the blade holder 5 cannot be placed in the corresponding grooves on the blade 4, so that they cannot be clamped and the installation can be completed. Prevent the blade from being reversed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com