Loudspeaker internal magnetic circuit assembling machine with reverse installation prevention function

An internal magnetic circuit, anti-reverse installation technology, applied in electrical components, sensors, etc., can solve the problems of product quality impact, low assembly efficiency, and high product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

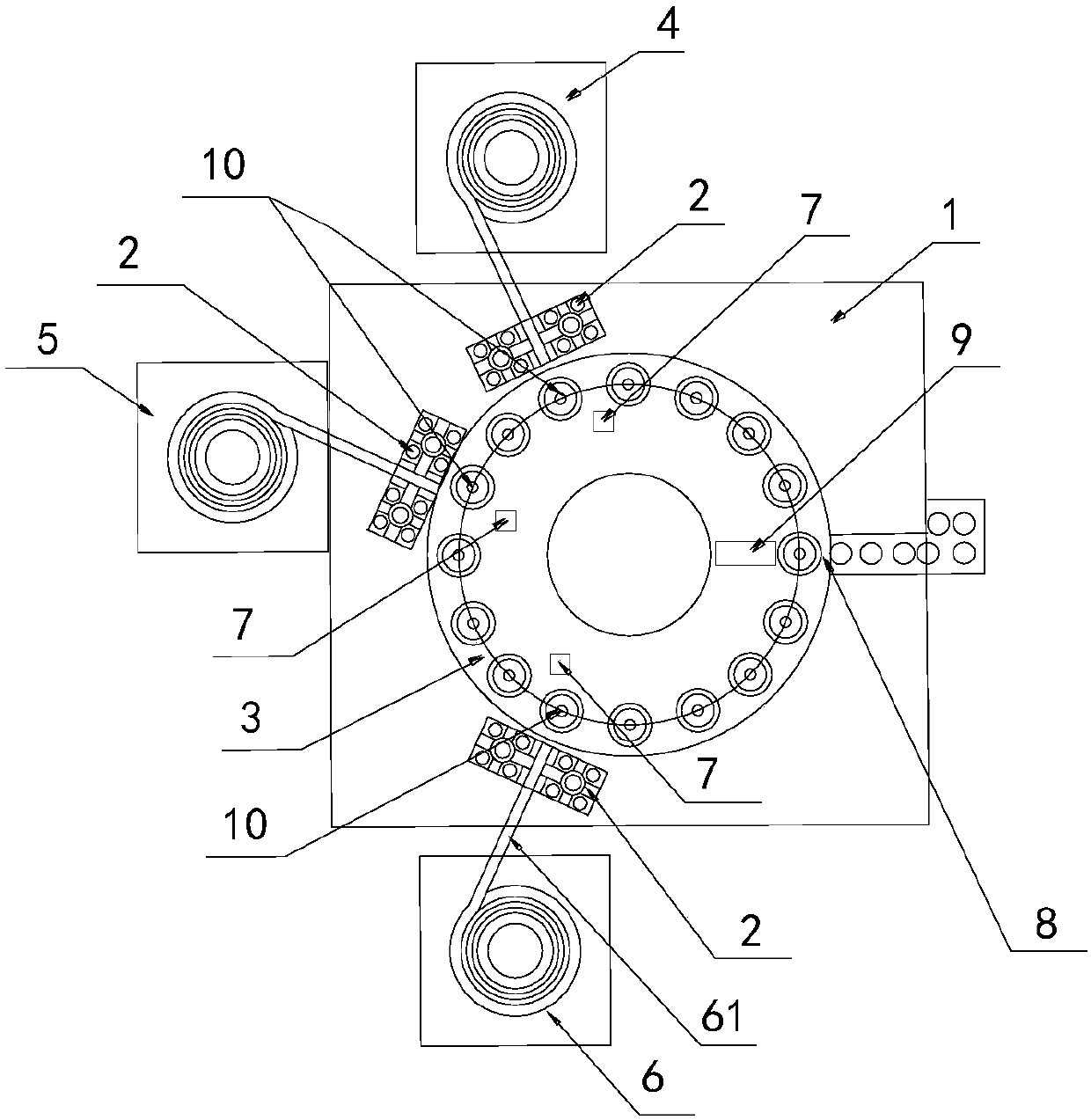

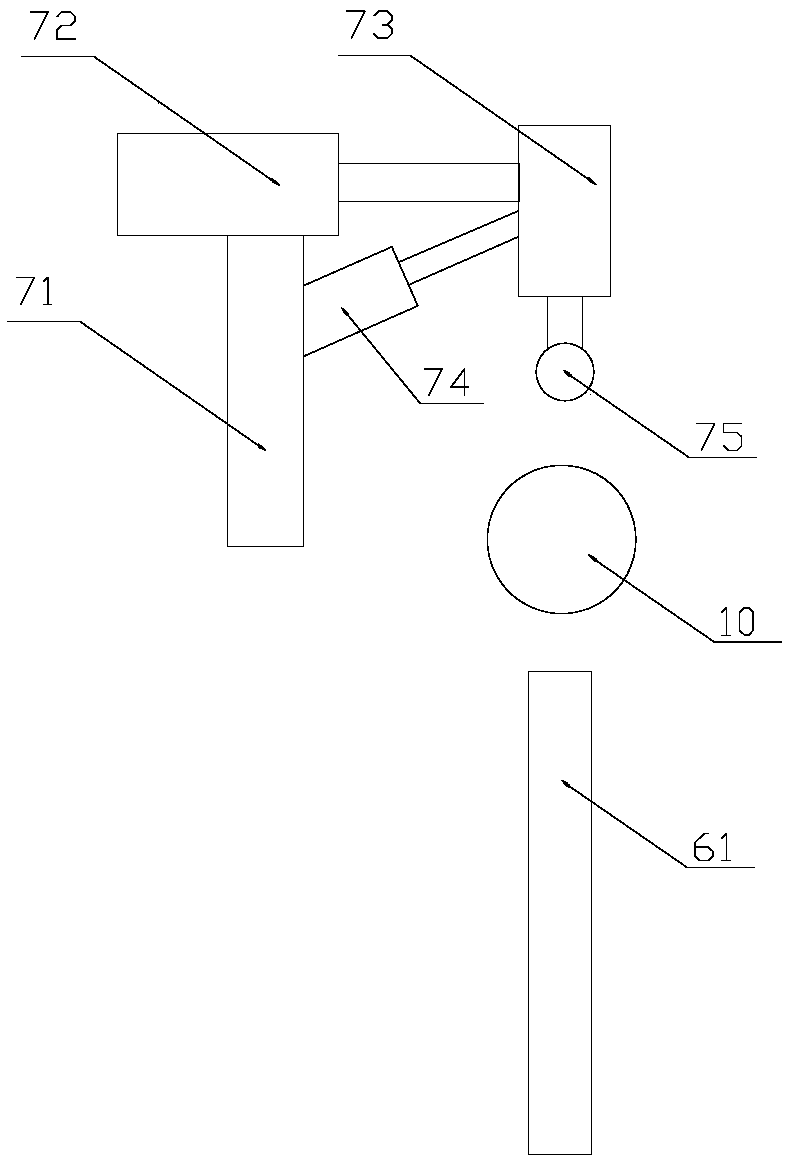

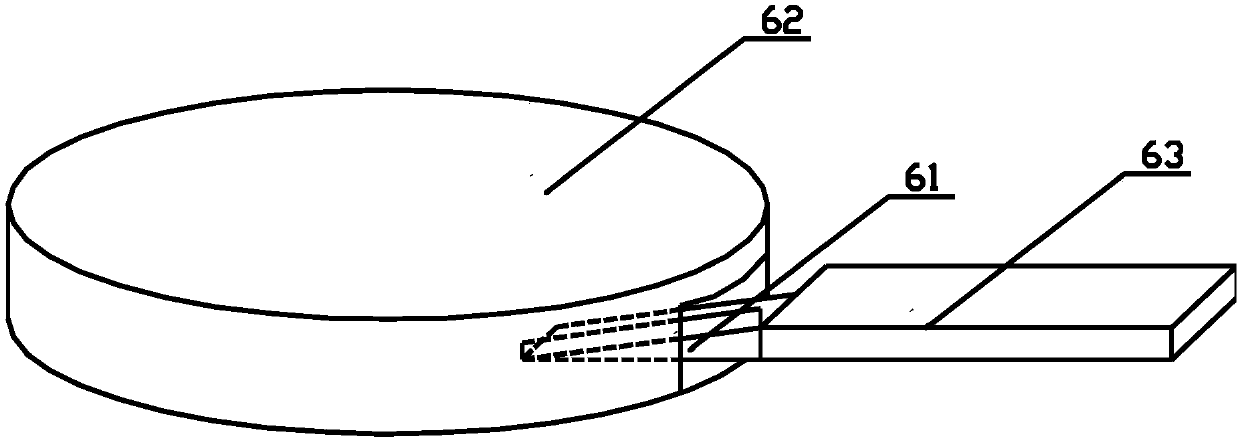

[0018] Such as figure 1 As shown, the speaker internal magnetic circuit assembly machine with anti-reversal function of the present invention includes a base 1, a bracket automatic feeding table 4, a magnet automatic feeding table 5, a washer automatic feeding table 6, a glue dispenser 2, and an indexing machine. Disc 3, drag device 7 and discharge channel, glue dispenser 2 and index plate 3 are all installed on the base 1, and three operating areas 10 are arranged on the circumference of index plate 3, correspondingly, glue dispenser 2 and drag device 7 are all provided with three, glue dispenser 2 and drag device 7 correspond to three operating areas 10 respectively, each operating area is provided with sensor, and each operating area 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com