Concave-convex annular spacing sealing structure with flanges

A sealing structure and flange technology, which is applied in the field of limiting and sealing pipeline structures, can solve the problems of reducing the service life of the pipeline, difficult to ensure the concentricity of the pipeline connection, and increasing the resistance of the pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

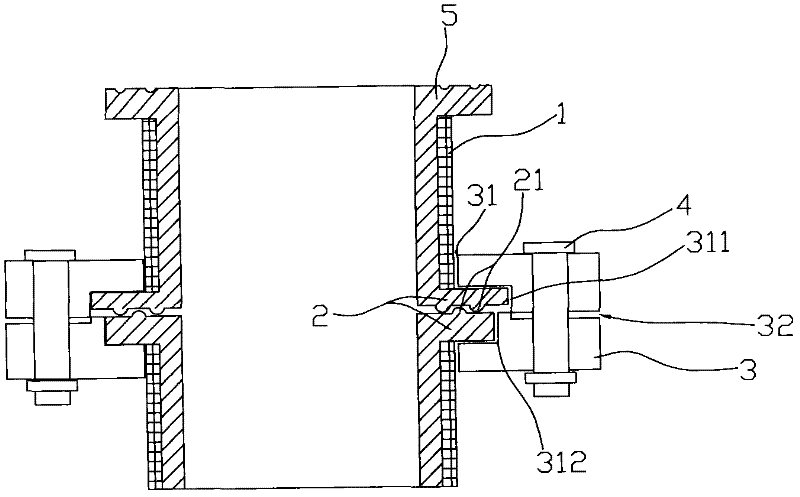

[0020] Embodiment 1: as figure 1 , figure 2 As shown, it consists of two pipe ends 1, two flanges 3 sleeved on the pipe ends 1, a seal 2 and a fastener 4. The flange has an inner end surface 31 and a through hole, and the seal 2 consists of two It is composed of a composite liner 5 set in the inner recesses 311, 312 and sleeved on the inner side of the pipe. The seal 2 can be in close contact after the flange 3 is fastened by fasteners, and the contact surface of the seal 2 can be tightly contacted. One of the surfaces is provided with at least one convex sealing ring 21, in order to improve the sealing performance, the number of convex sealing rings 21 can also be increased to 3 to 5 to achieve a better sealing effect, when When the number of convex sealing rings 21 is increased to 3 to 5, they can also be respectively arranged on two surfaces of the contact surface of the sealing member 2, so that the convex sealing rings 21 are alternated in pairs and facing each other. ...

Embodiment 2

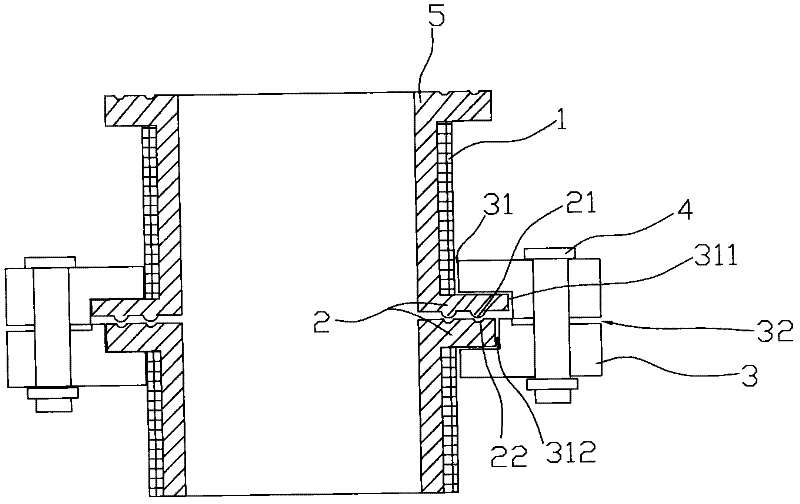

[0021] Embodiment 2: The implementation as described in Example 1: the convex sealing ring 21 on the contact surface of the seal 2 is replaced with a convex sealing ring 21 and a concave sealing ring 22 (such as image 3 ). The convex sealing ring 21 and the concave sealing ring 22 are respectively installed on both sides of the contact surface of the seal, and the convex sealing ring 21 is installed on one surface, and the convex sealing ring 21 is installed on the other surface opposite to it. Matching concave sealing rings 22 , of course, in order to improve the sealing performance, can also be increased to 3 to 5 pairs of convex sealing rings 21 and concave sealing rings 21 that are opposite and match each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com