Reverse stop bearings with self-aligning snap-fit bearing retainers

A technology for bearing retainers and stop bearings, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of affecting processing efficiency and fastening accuracy, one-way failure of bearing rings, and high alignment accuracy. It achieves the effects of simple structure, no reverse wedge installation, and guaranteed product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

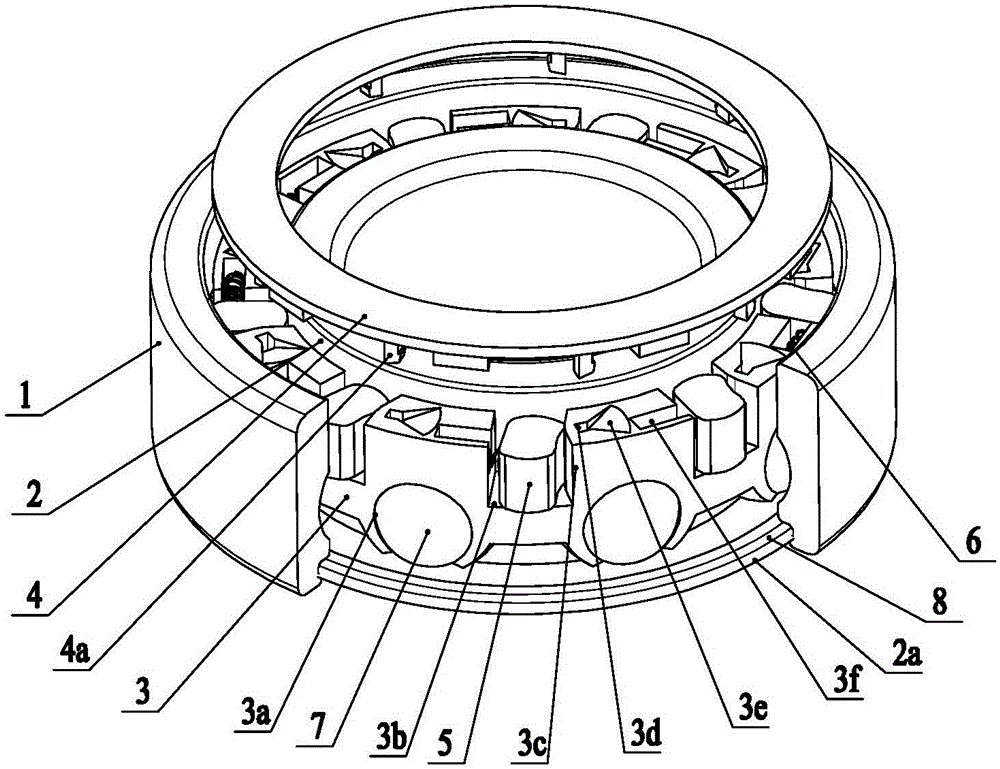

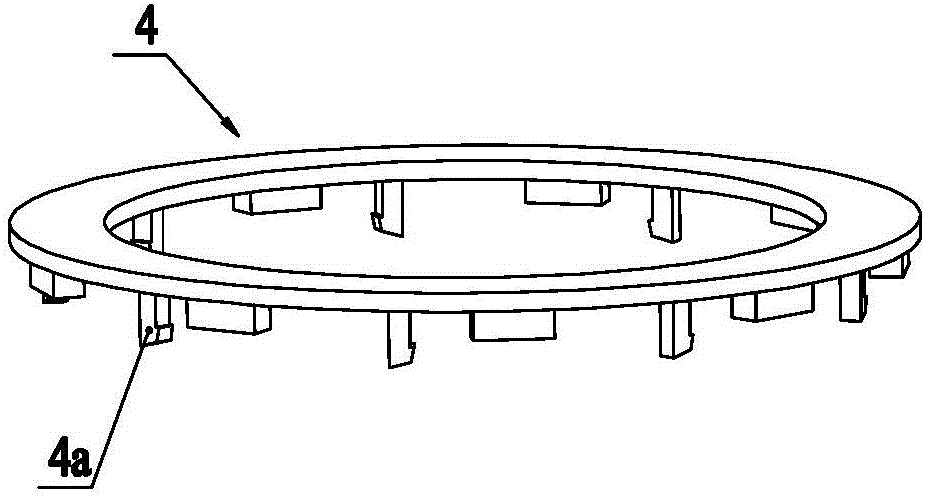

[0020] As shown in the figure, the reverse stop bearing with a self-locating fastening bearing retainer in the embodiment is mainly composed of an outer ring 1, an inner ring 2, a retainer body 3, a fixed cover 4, a wedge 5, a compression spring 6, Steel ball 7 and sealing ring 8 and composition.

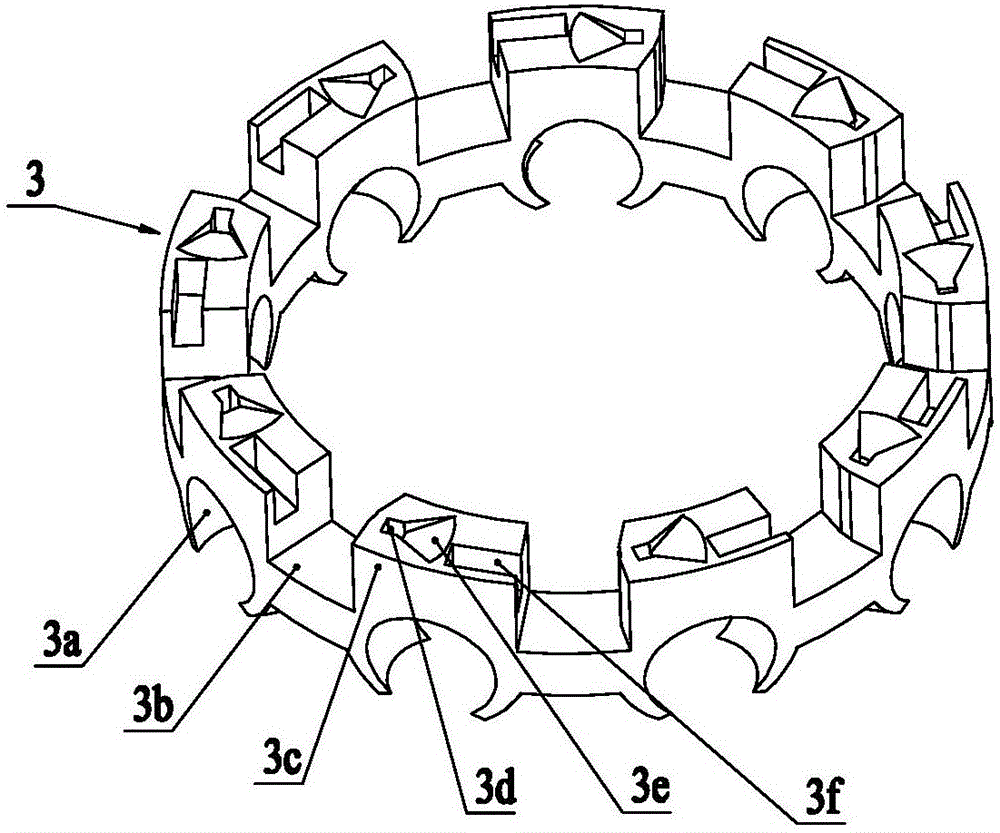

[0021] like Figure 1~Figure 4 As shown, the retainer body 3 is arranged between the outer ring 1 and the inner ring 2, and nine ball pockets 3a uniformly distributed in the circumferential direction are arranged on the circumferential surface of the retainer body 3, and each ball pocket 3a is equipped with a steel ball 7 ; The first end face of the retainer body 3 is provided with nine circumferentially evenly distributed wedge notches 3b, each wedge notch 3b is equipped with a wedge 5, and between adjacent wedge notches 3b is The wedge spacer boss 3c; the fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com