Oil-seal fool-proofing mounting tool

An oil seal and anti-fooling technology, which is applied in the field of oil seal anti-fooling installation tooling, can solve the problems of not detecting the bottom surface of the oil seal and the failure of the oil seal, and achieve the effects of preventing reverse installation of the oil seal, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

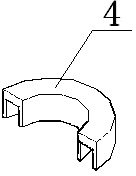

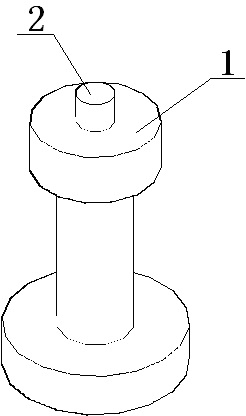

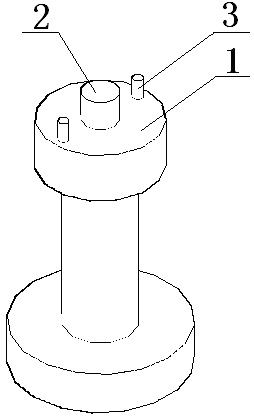

[0015] Such as image 3 Shown is an oil seal fool-proof installation tool, including an annular plane 1 supporting the bottom surface of the oil seal 4. The middle of the annular plane 1 is a cylindrical protrusion 2, and two protruding pins 3 are arranged on the annular plane 1. The height of the pin 3 is smaller than the depth of the groove of the oil seal 4; when the oil seal 4 is correctly installed, the pin 3 is located in the groove of the oil seal.

[0016] Such as Figure 4 As shown, it is a schematic diagram of the structure of the oil seal 4 reversely installed on the structure of the case. It can be seen from the figure that the oil seal 4 cannot be installed to the bottom, and the operator can easily find that the height of the oil seal 4 after installation is wrong, or even tilted; Figure 5 As shown, it is a structural schematic diagram of the oil seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com