Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about "Weighing temperature-compensating arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

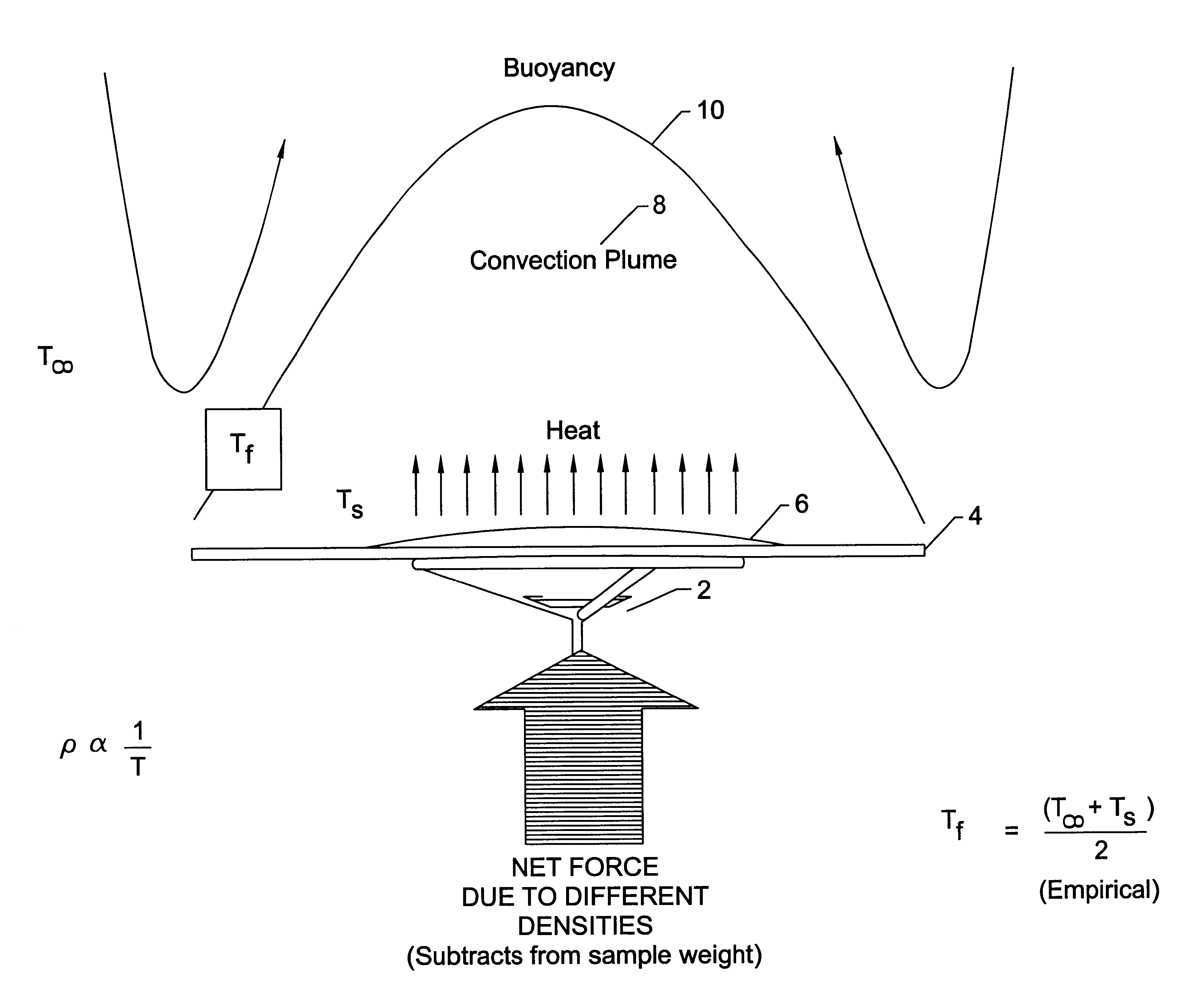

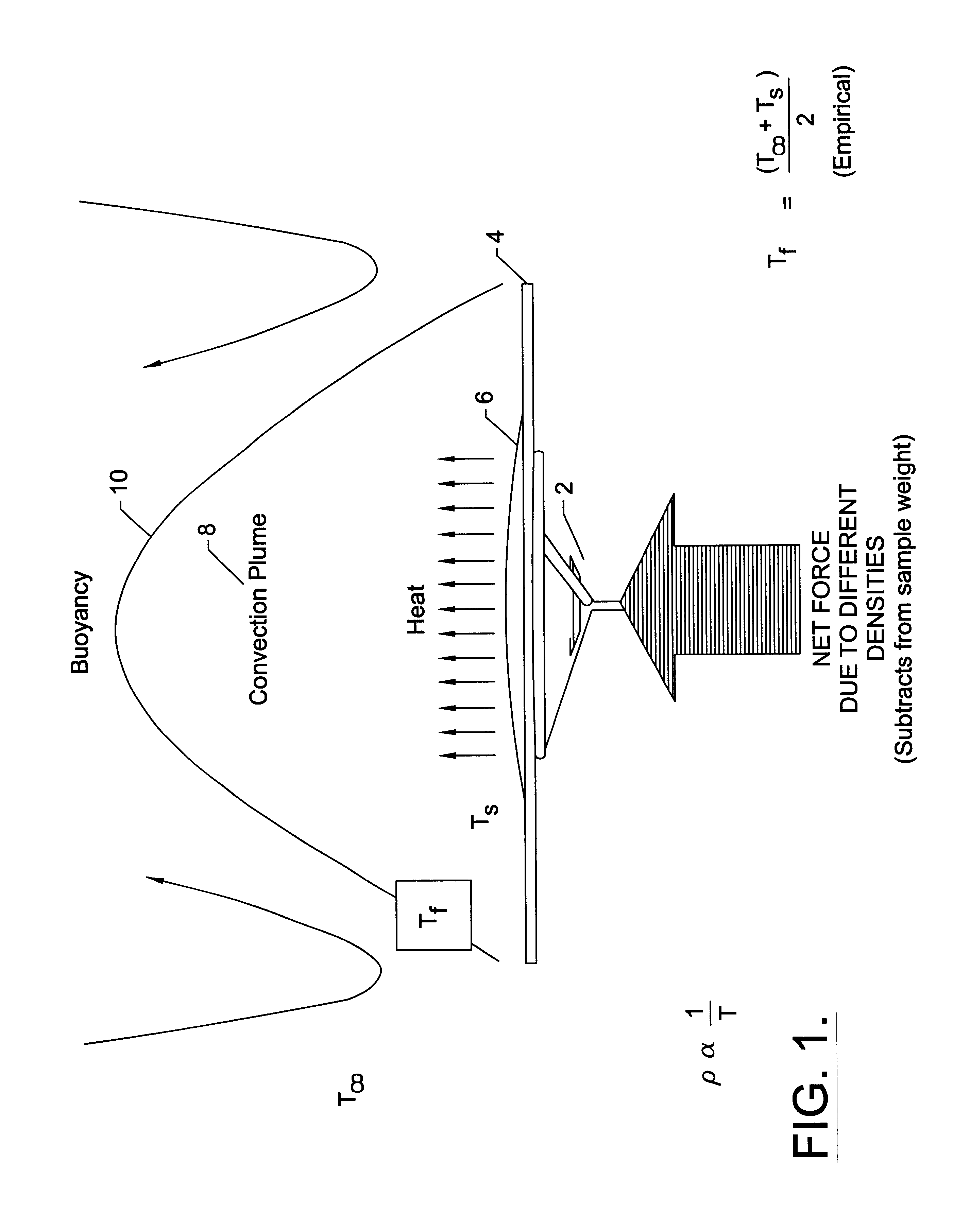

Method for correcting weight measurement errors during microwave heating

InactiveUS6268570B1Accurate sample weight measurementAccurate weighingWeighing apparatus testing/calibrationMaterial moisture contentObservational errorMicrowave

The invention is a method of measuring an apparent weight of a substance, while concurrently measuring a surface temperature of the substance and an ambient air temperature surrounding the substance, then predicting buoyancy forces acting upon the substance based on these temperature measurements. Thereafter, the true weight of the substance can be determined by correcting the apparent weight by the predicted buoyancy forces acting upon the substance.

Owner:CEM CORP

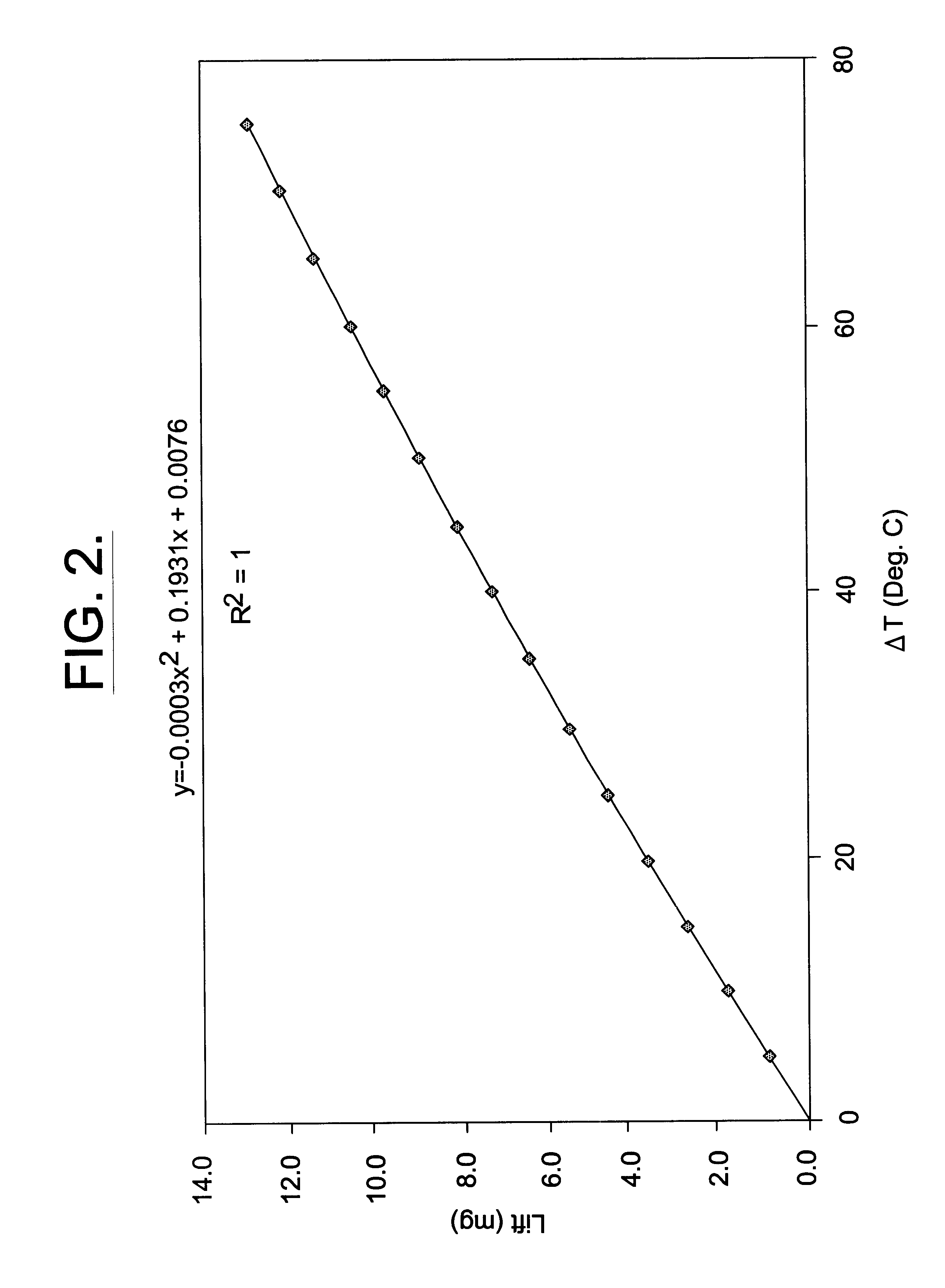

Gravimetric moisture measurement instrument

ActiveUS7851712B2Lower Level RequirementsPromote escapeWeighing apparatus testing/calibrationMaterial moisture contentMeasuring instrumentEngineering

Owner:METTLER TOLEDO GMBH

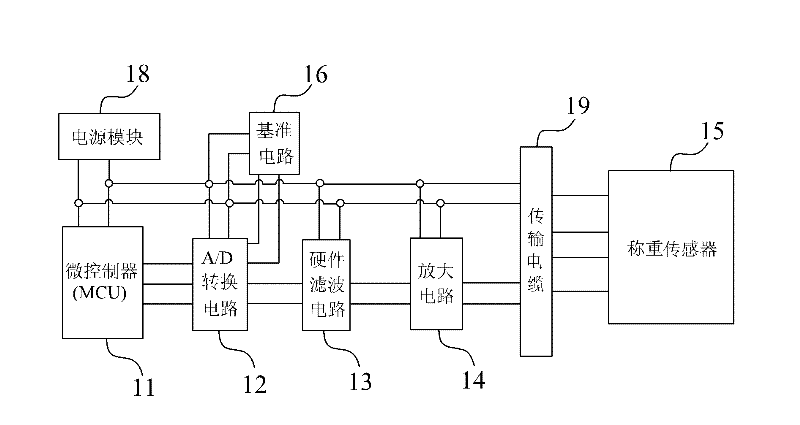

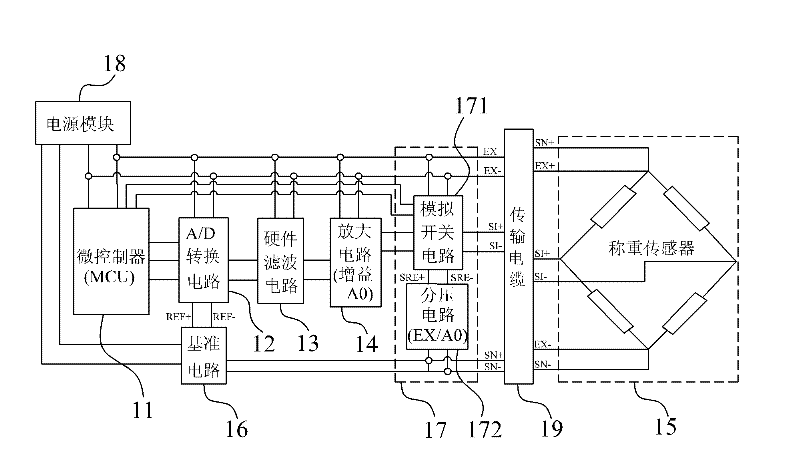

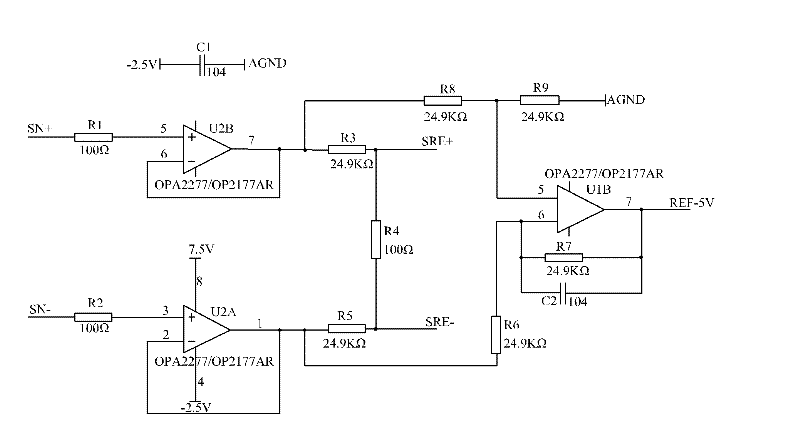

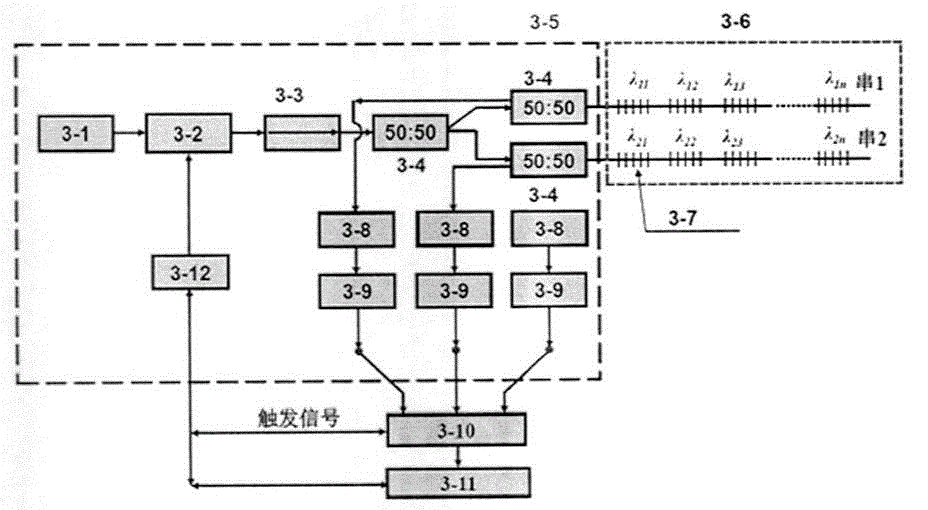

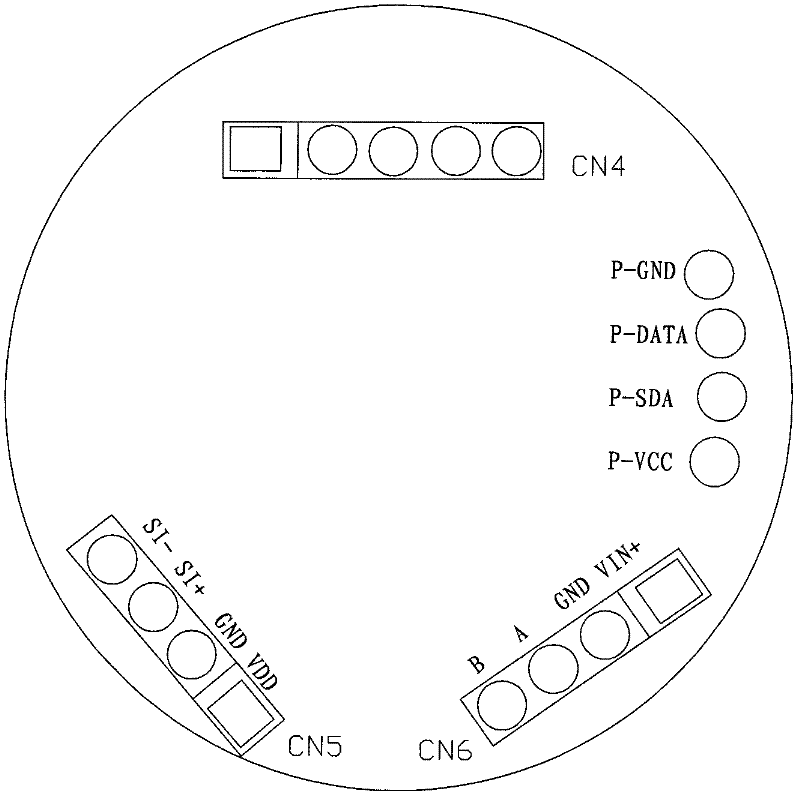

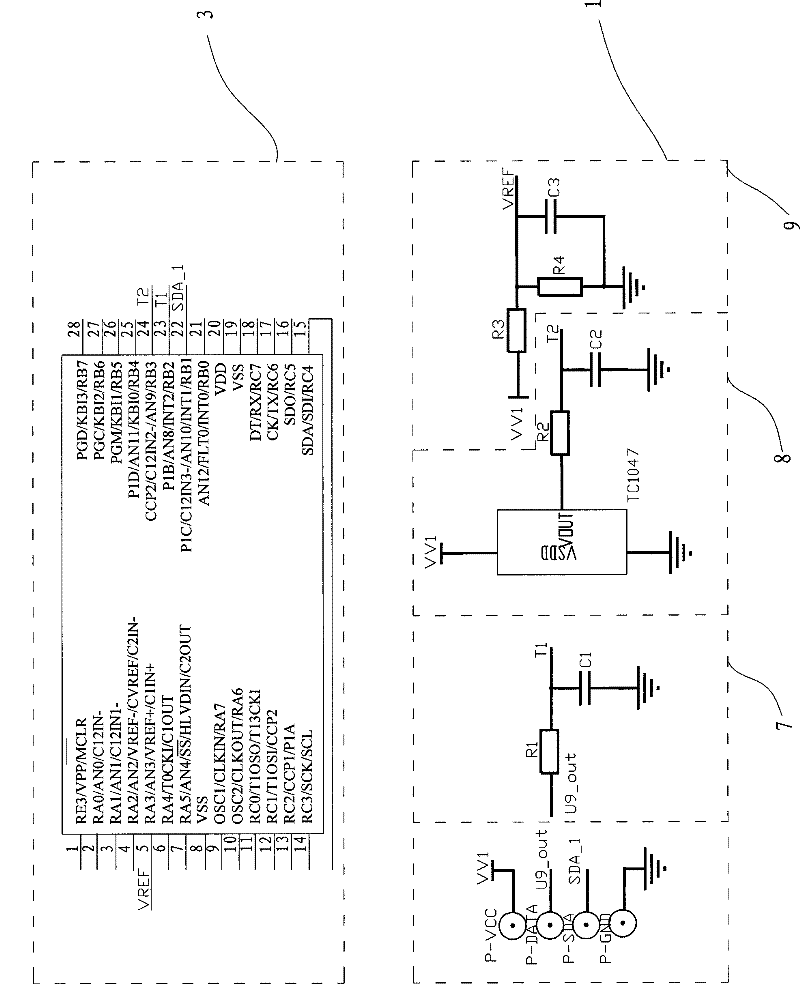

Automatic compensating signal acquiring system

ActiveCN102506982ARealize long line compensationHigh precisionWeighing temperature-compensating arrangementsMicrocontrollerComputer module

The invention discloses an automatic compensating signal acquiring system, which comprises a power module, a microcontroller, a reference circuit, an A / D switching circuit, a hardware filtering circuit, an amplifying circuit, a weighing sensor and a compensating module, wherein the compensating module comprises an analog switching circuit and a divider circuit, the weighing sensor outputs a pair of feedback signals to the divider circuit and the reference circuit, the reference circuit is used for adjusting an input impedance and outputting a reference voltage to the A / D switching circuit according to the feedback signals, the divider circuit is used for carrying out voltage division on the feedback signals to generate a reference signal, and the analog switching circuit is used for alternatively collecting an output signal of the weighing sensor and the reference signal of the divider circuit to determine a circuit deviation for realizing circuit compensation. According to the automatic compensating signal acquiring system, the pair of feedback signals is added through a six-wire connection, and the divider circuit and the analog switching circuit are matched for acquiring and processing the signals of the system for realizing the circuit compensation, thus precision and accuracy of the automatic compensating signal acquiring system are greatly improved.

Owner:SHENZHEN GENERAL MEASURE TECH

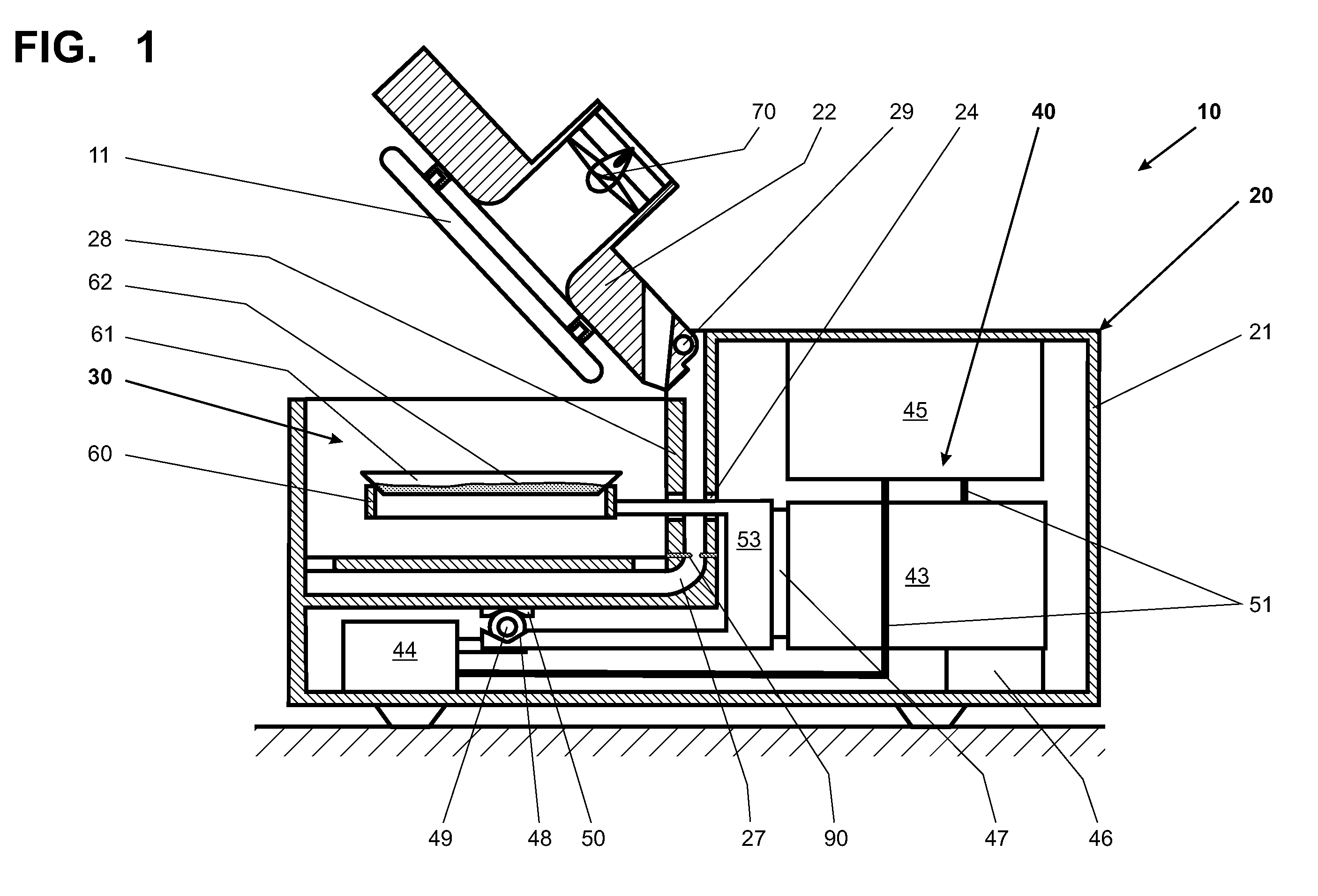

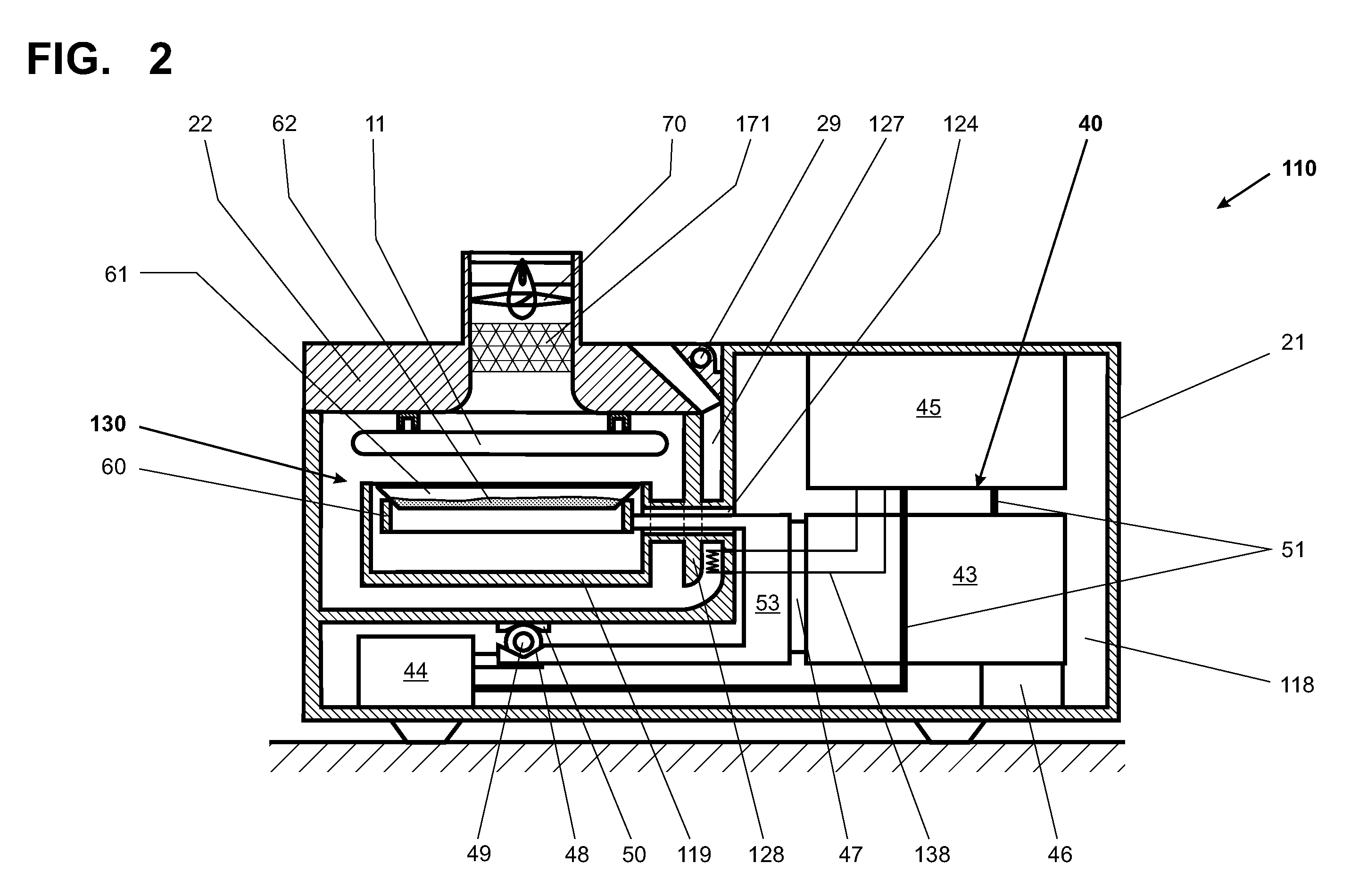

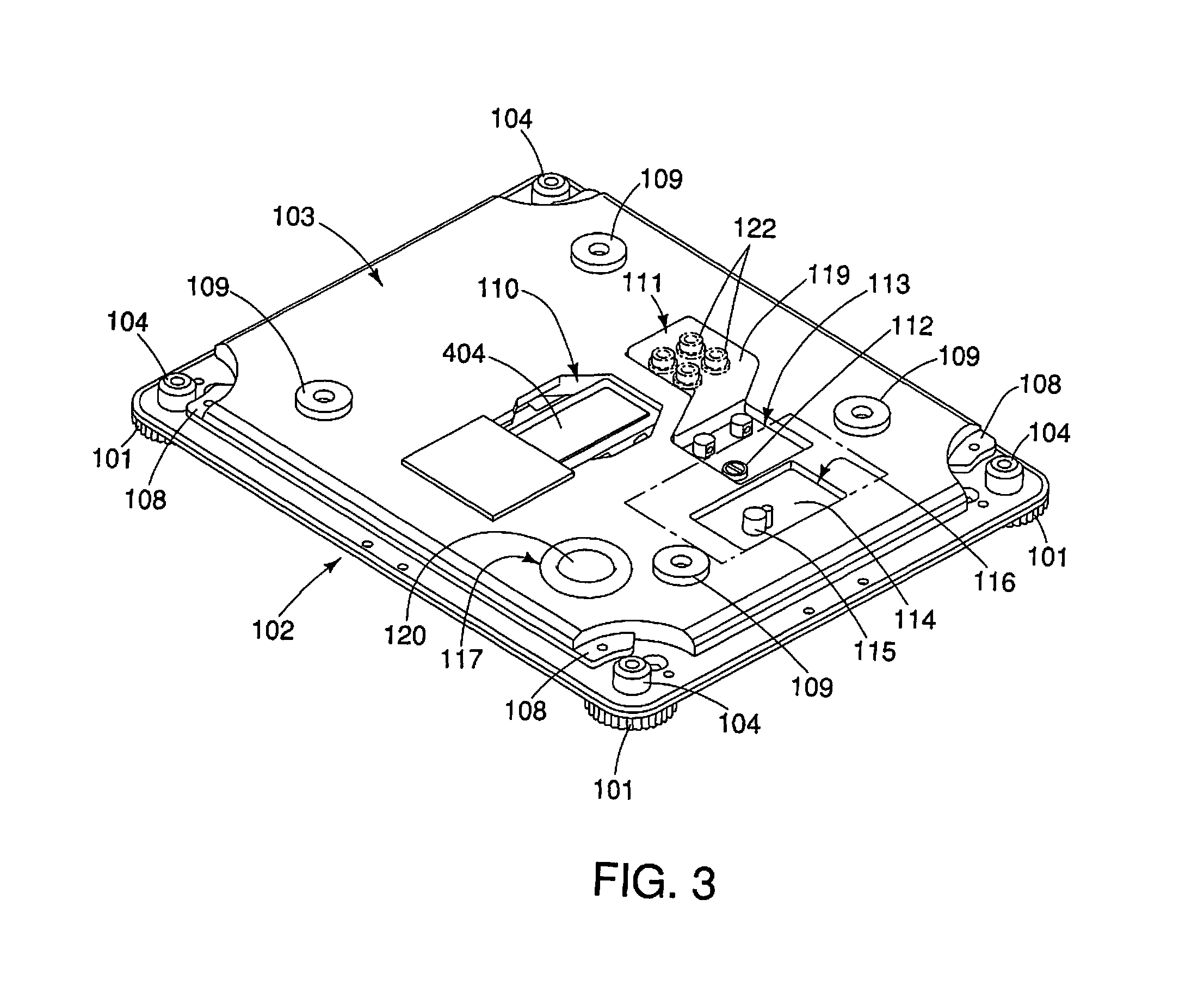

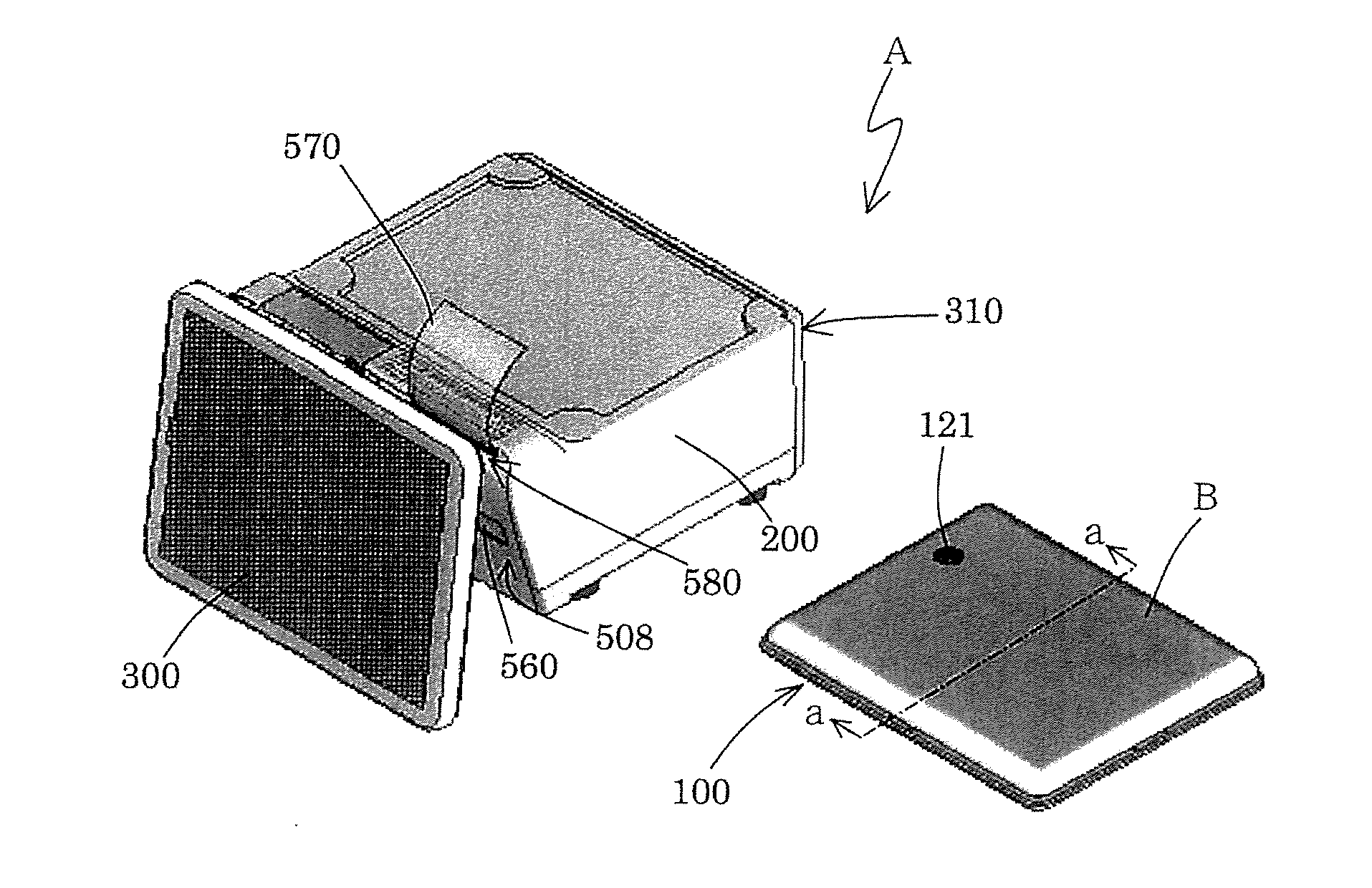

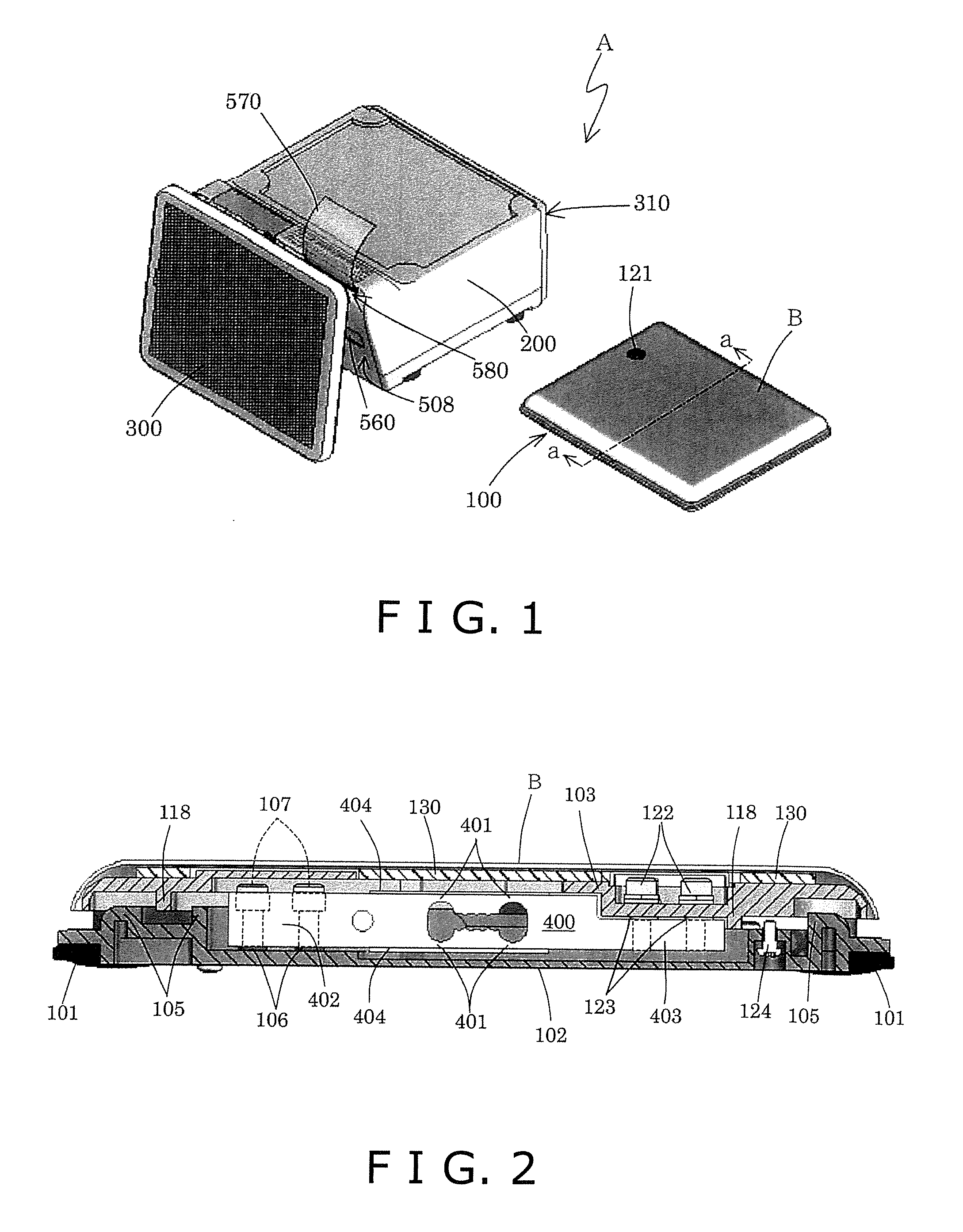

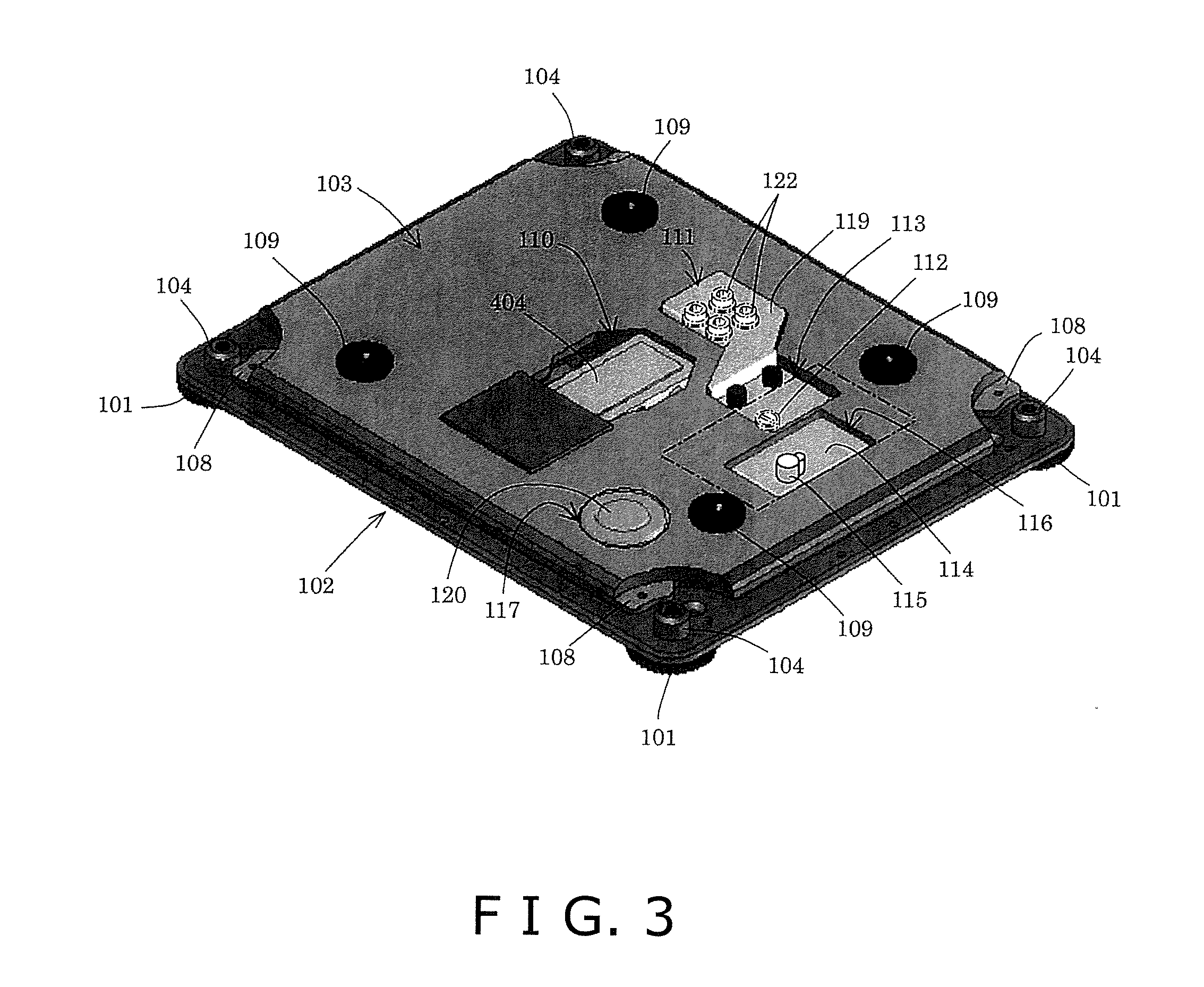

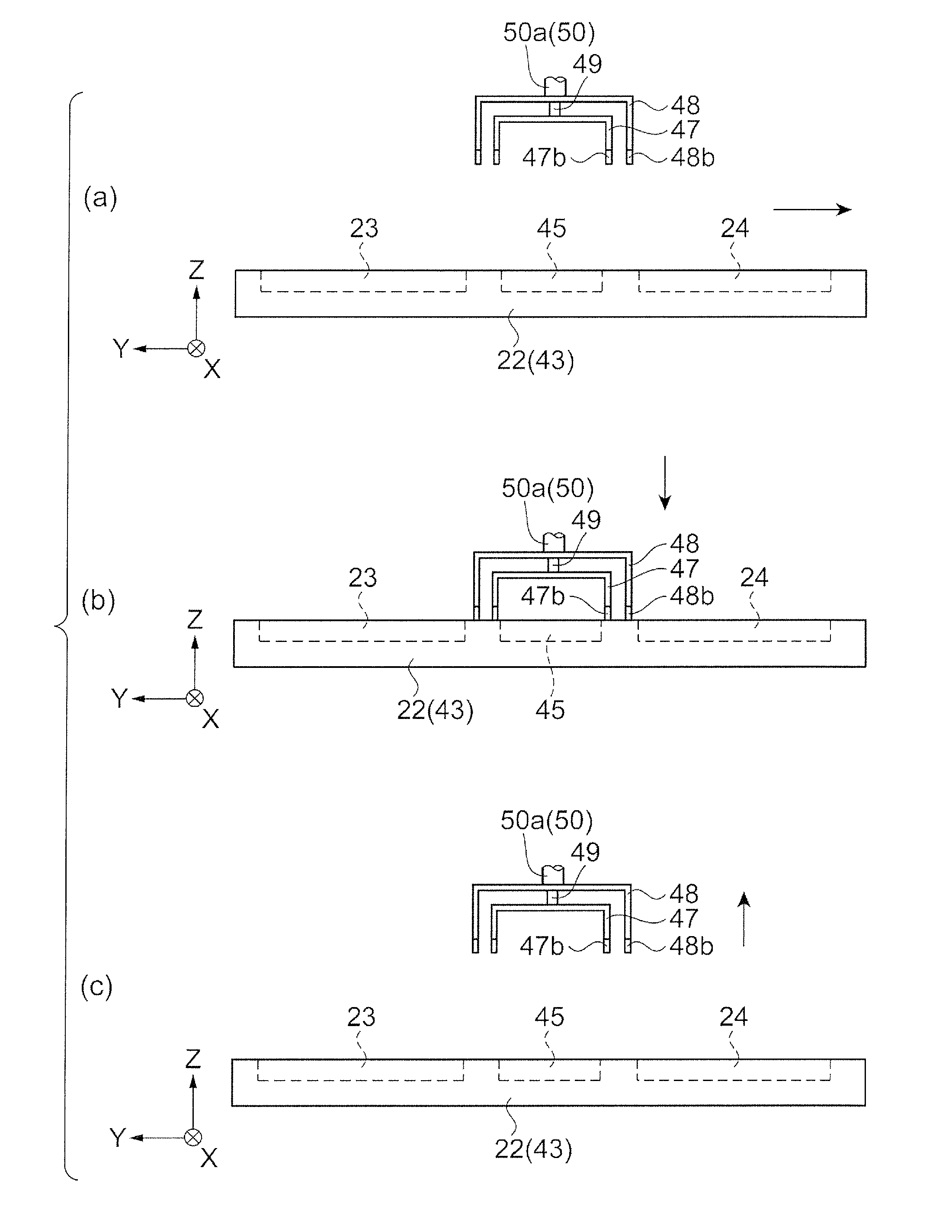

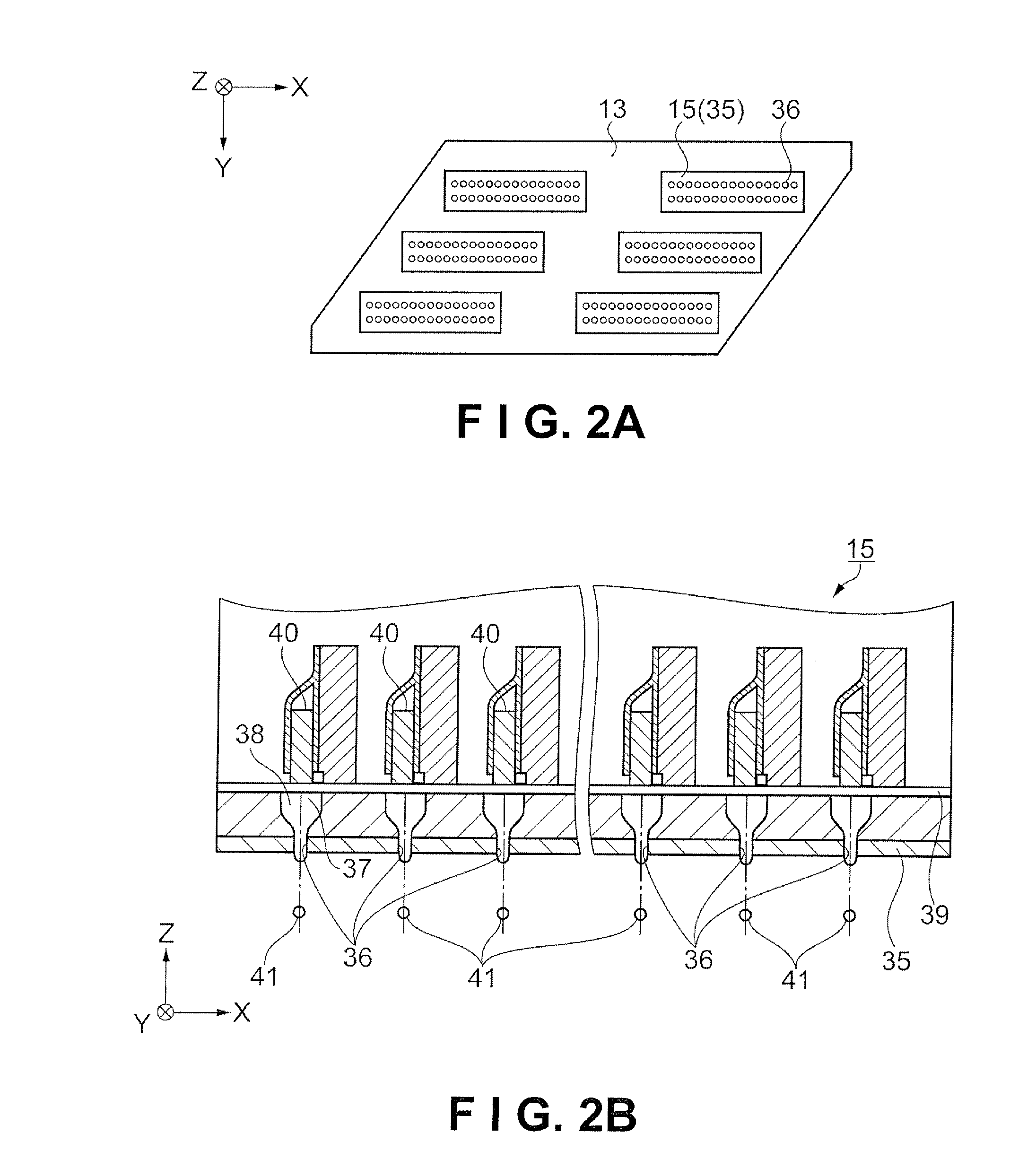

Label printing scale device

InactiveUS9091587B2Limited manufacturing costWidth of device can be made moreWeighing indication devicesWeighing temperature-compensating arrangementsEngineeringElectrical and Electronics engineering

A label printing scale device includes separable casings that are vertically overlaid in two levels, one on top of the other. Specifically, the label printing scale device includes an upper casing housing at least a load cell and a circuit part, and a lower casing housing at least power-generation circuit, a printer, and a control part.

Owner:ISHIDA CO LTD

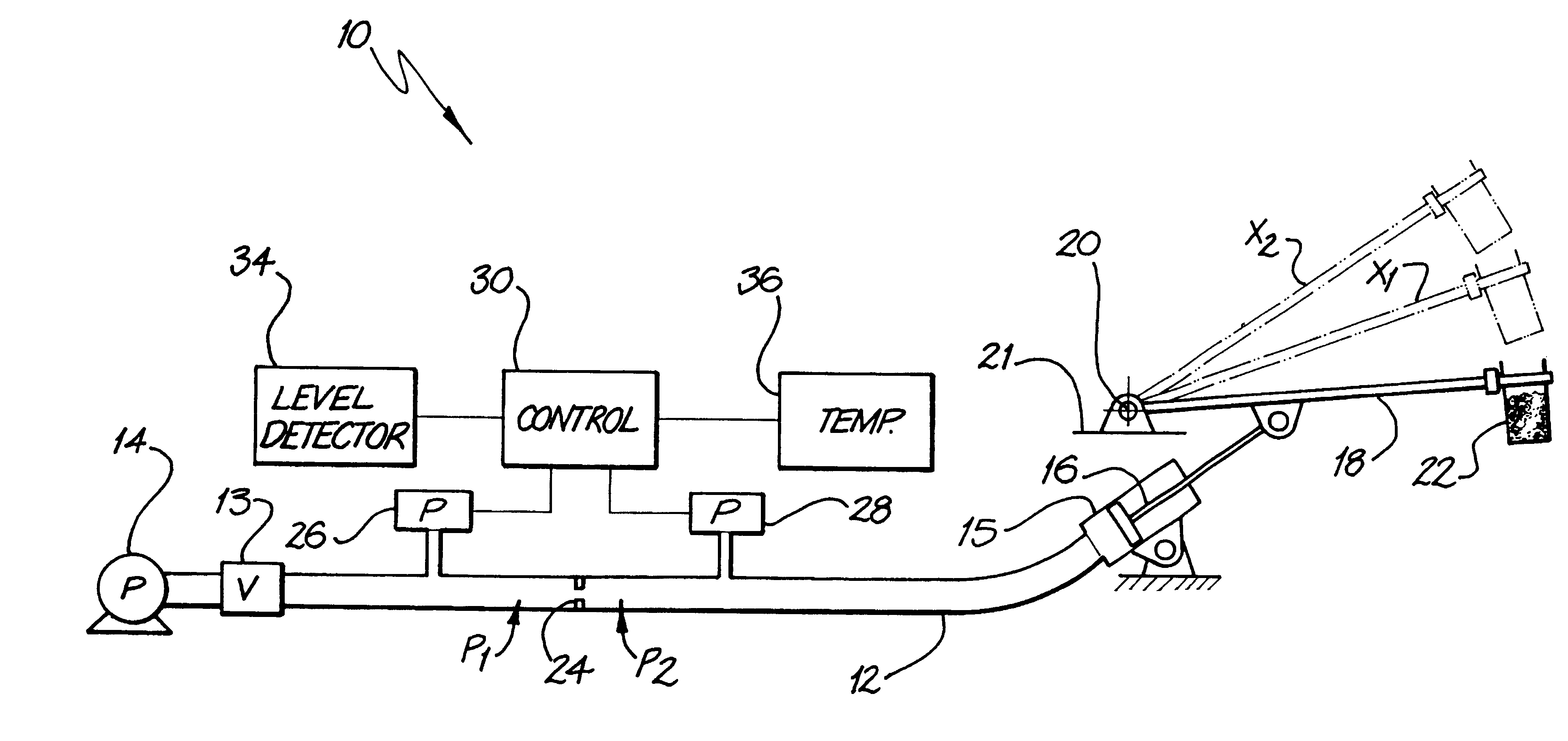

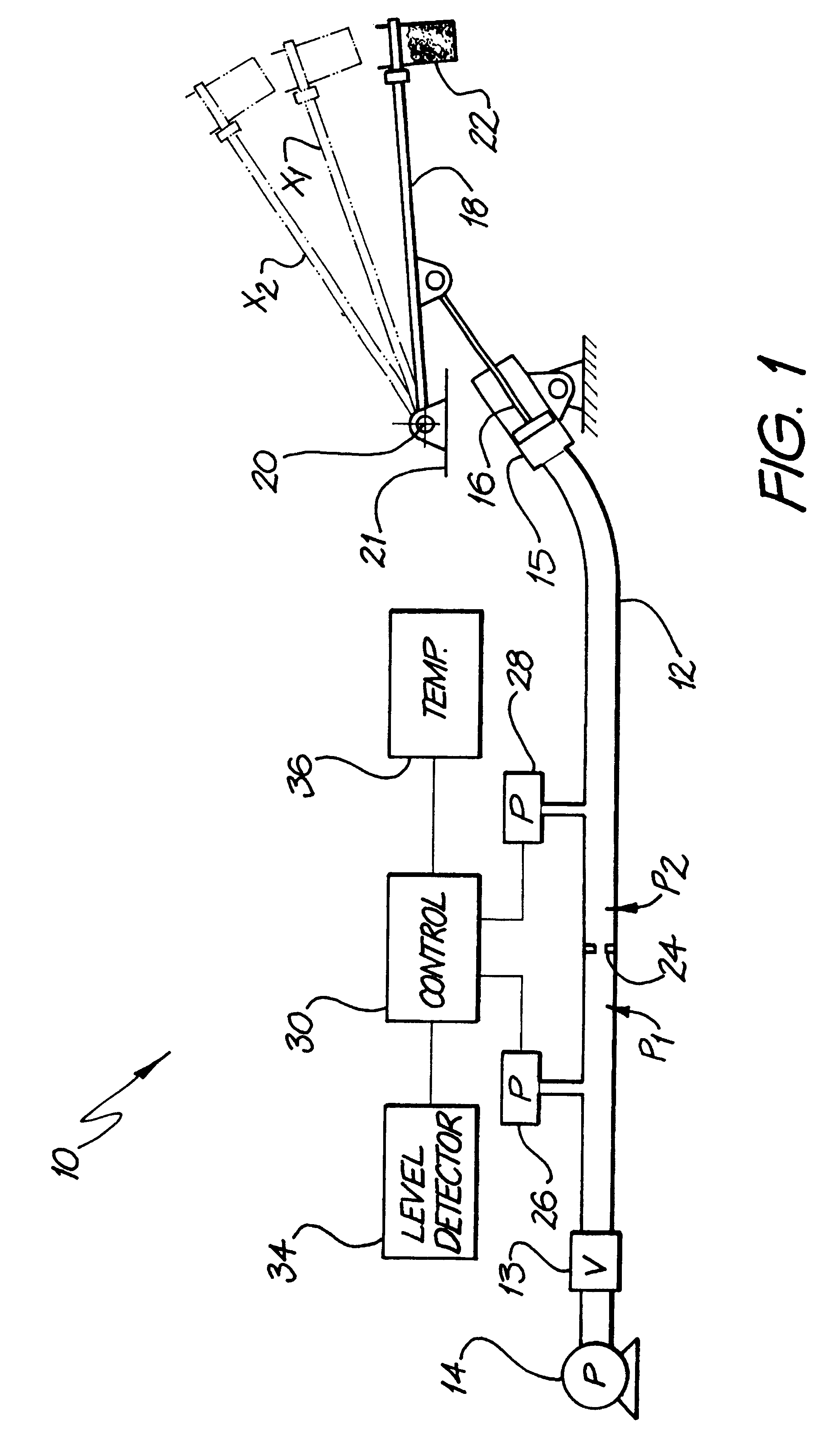

Hydraulic weighing apparatus and method

InactiveUS6627825B1Constant rateForce measurement using counterbalancing forcesWeighing apparatus testing/calibrationRefuse collectionWaste collection

A hydraulic lifting and weighing system particularly for refuse collection vehicles and the like and includes means for dynamically weighing garbage. The system includes a hydraulic actuator operable to move a lifting arm and takes two measurements of the pressure of the hydraulic fluid in the system as the arm raises a waste bin whose weight is to be measured. The weight of the bin is calculated by multiplying the pressure by a factor determined by calibration with known weights. Weights are calculated based on the measurements of pressure and the result averaged. The system compensates for variations in hydraulic flow characteristics. The system includes means for compensating for variations in the inclination of the vehicle.

Owner:TEK SOLUTIONS

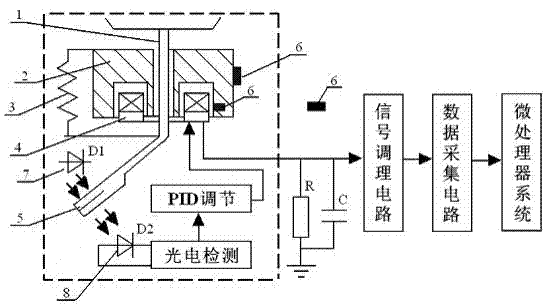

Multifunctional high-accuracy electronic balance

ActiveCN102768060AInnovative designEasy to operateWeighing apparatus using electromagnetic balancingWeighing temperature-compensating arrangementsData acquisitionEngineering

The invention discloses a multifunctional high-accuracy electronic balance. The internal structure of the electronic balance comprises an electromagnetic force balance sensor, a photoelectric detection circuit, a proportion integration differentiation (PID) regulation circuit, a signal modulation circuit, a data collection circuit, a microprocessor master control module and a temperature detection module. The electromagnetic force balance sensor, the photoelectric detection circuit and the PID regulation circuit form a closed system to improve accuracy and stability of the electronic balance. The multifunctional high-accuracy electronic balance is novel in design and convenient to operate. Due to adopting the electromagnetic force balance sensor and utilizing the null method principle to weigh quality of weighed object, the multifunctional high-accuracy electronic balance has excellent performance of being high in measurement accuracy, good in measurement stability and capable of performing continuous and repeated measurement. Besides, the multifunctional high-accuracy electronic balance further has functions of being various in measurement type, and capable of achieving full-automatic calibration and self-diagnosis of breakdown.

Owner:DABAIKE LAB EQUIP ENG JIANGSU

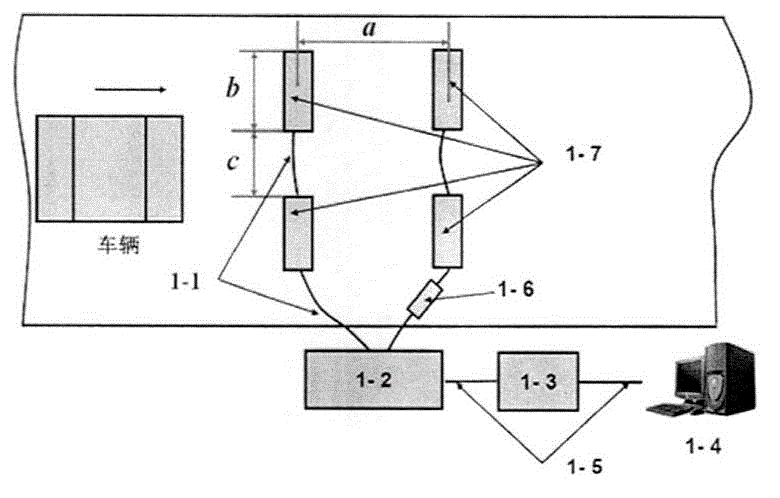

Portable optical fiber dynamic weighing system

InactiveCN104390685AWeighing temperature-compensating arrangementsSpecial purpose weighing apparatusEngineeringComputer science

The invention belongs to an intersected field of optical fiber sensors and traffic management. Specifically, the invention provides a portable instrument and a measurement method for measuring total weight, weight distribution (including weight of each wheel of a vehicle), distance between front and rear axles and distance between left and right wheels of a moving vehicle. Moreover, based on the obtained basic information, the invention also can provide some ''intelligent information'' of the vehicle. Besides, by comparing the obtained information with general parameters of the vehicle and by assistance of some other sensors (such as an infrared temperature sensor), the portable instrument and the measurement method disclosed by the invention can be used for further predicting quantity of passengers in the vehicle, load weight and relative positions thereof in the vehicle. According to the portable instrument and the measurement method disclosed by the invention, optical fiber sensing and transduction are adopted, signal transmission is realized in an optical way only and inside an optical cable only. Therefore, the characteristics require that the optical fiber sensor is especially applicable to occasions with high requirements on safety.

Owner:苏州佳因特光电科技有限公司 +1

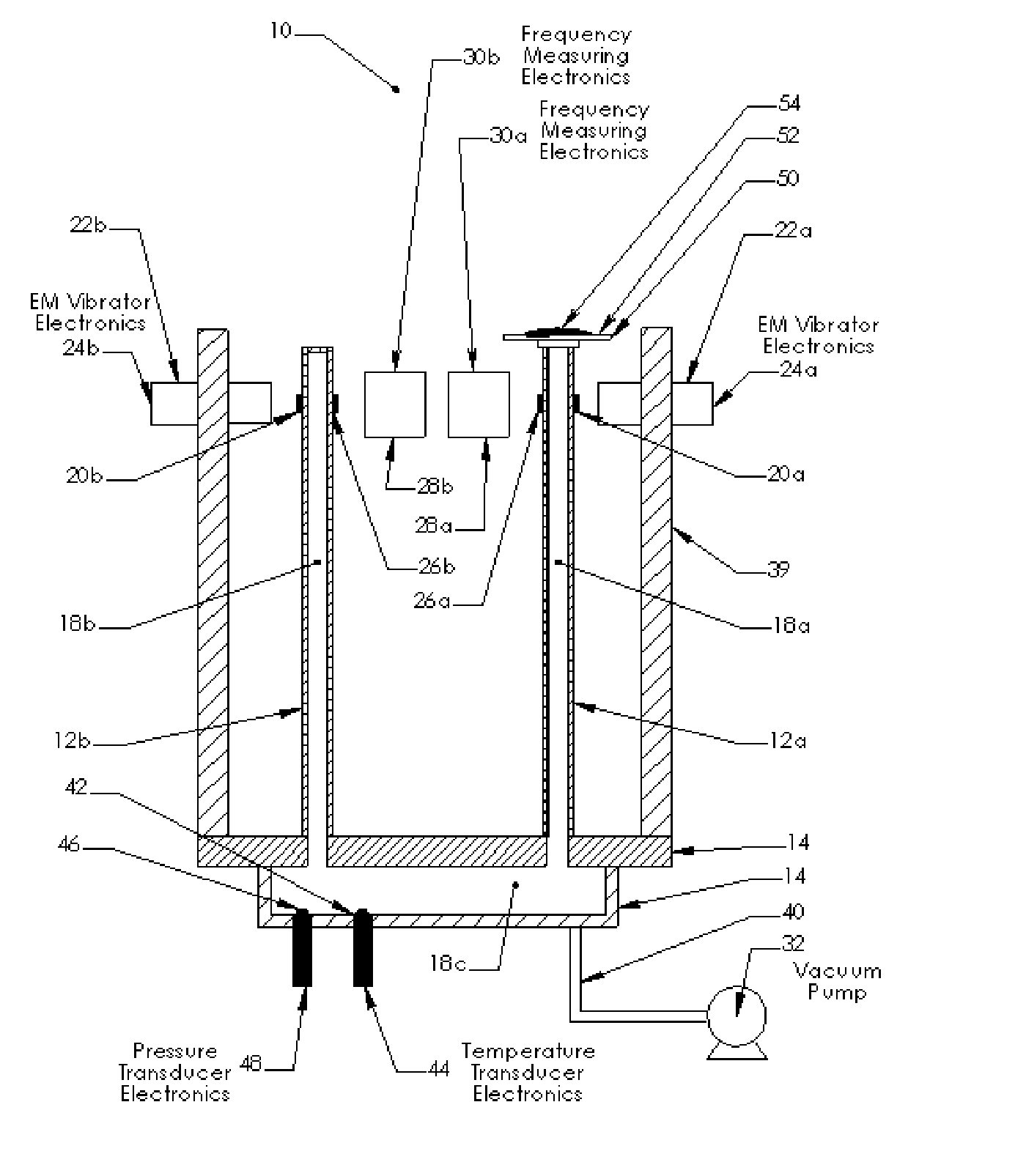

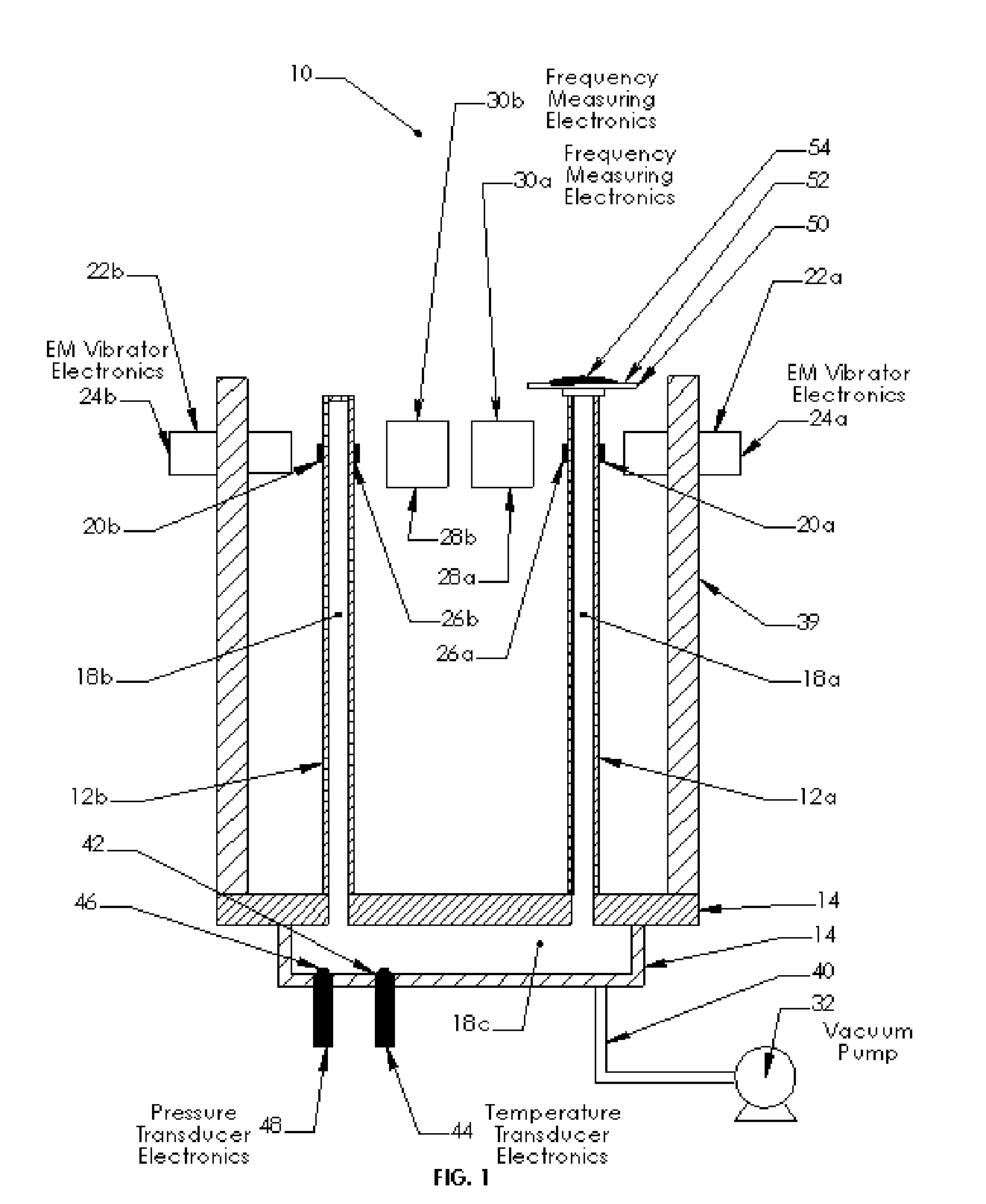

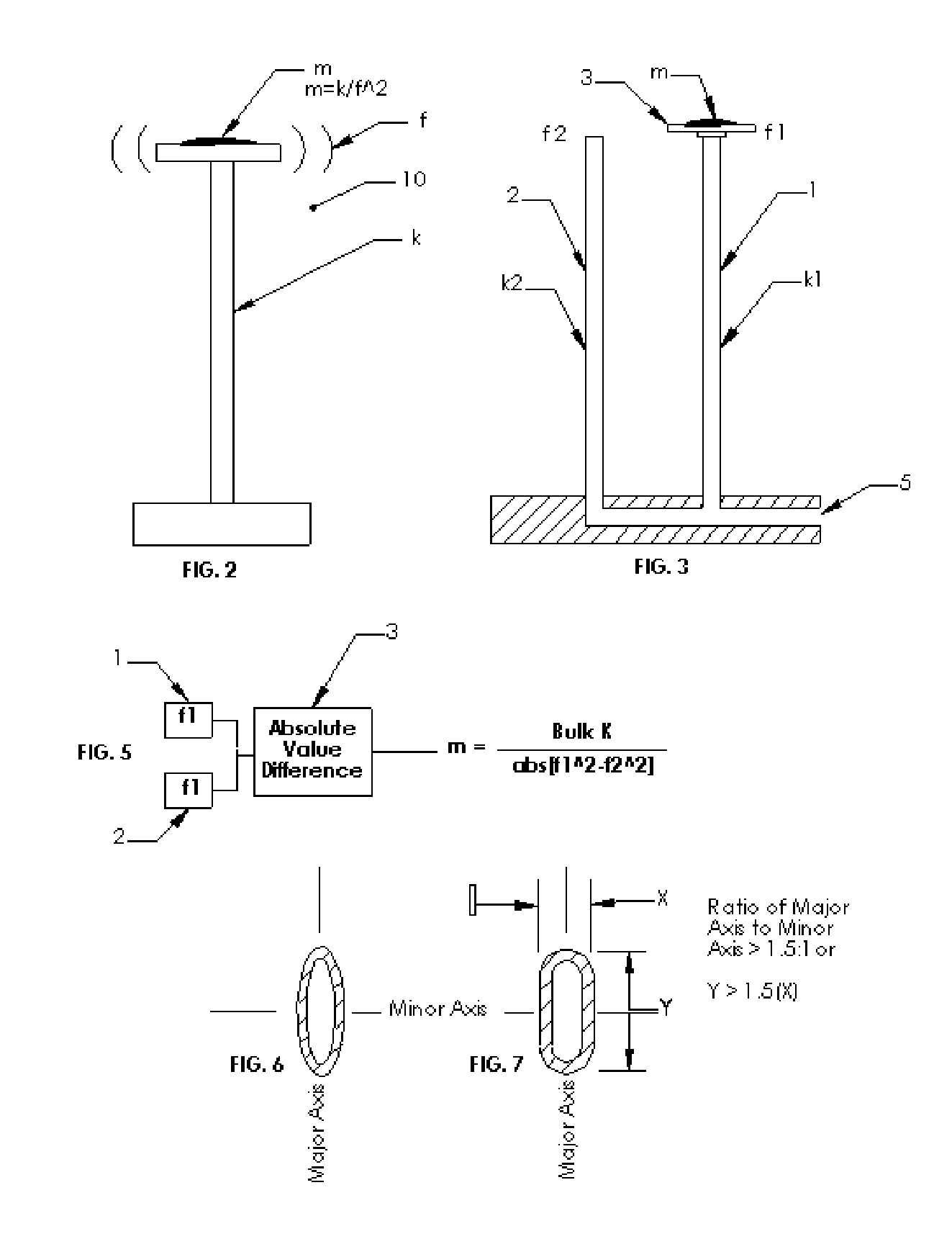

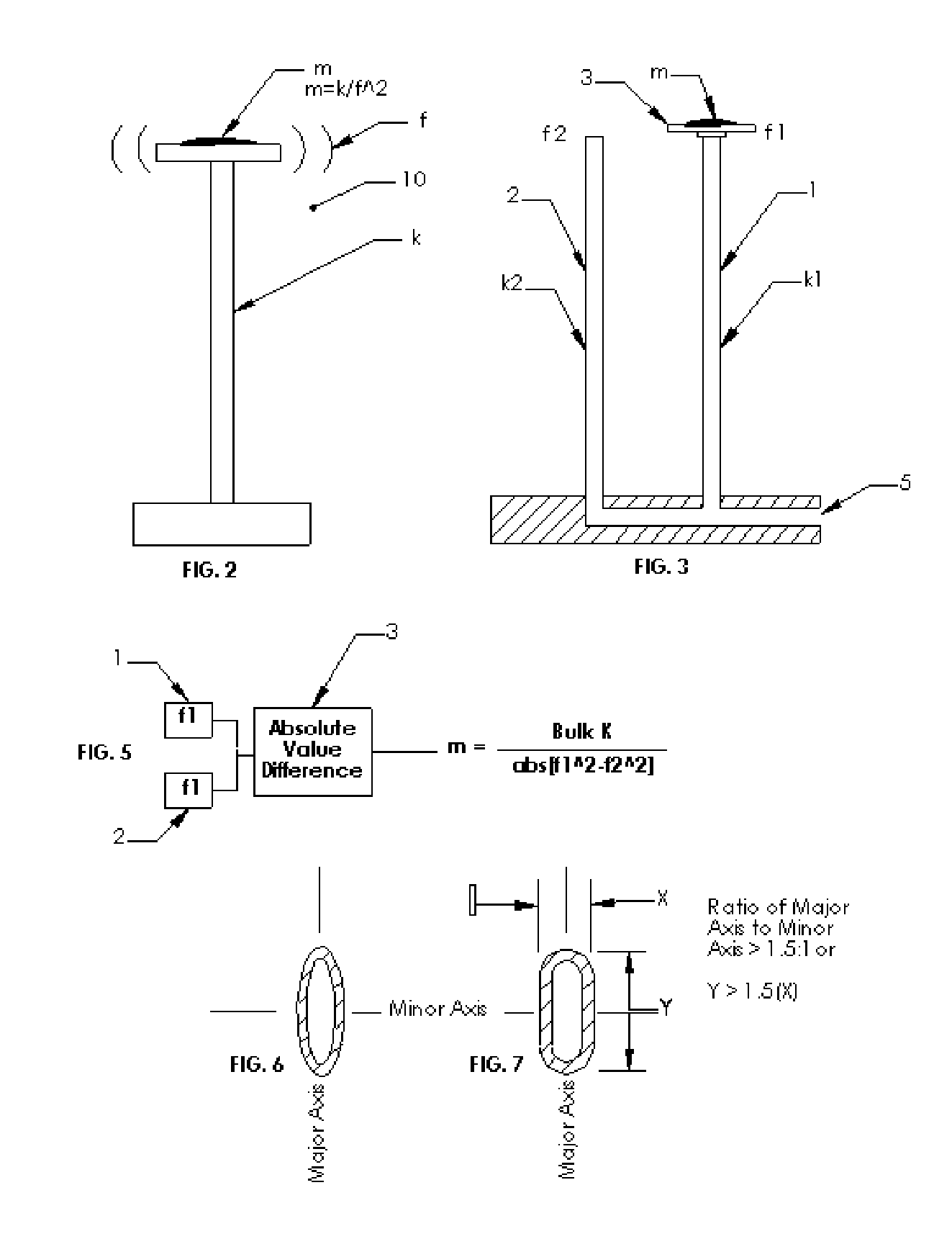

Oscillating Inertial Microbalance and Method of Passive Compensation

ActiveUS20060086174A1Minimize energy transferAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationParticulatesSide effect

The claimed subject matter is directed to a continuous passive temperature, ressure, modulus of elasticity, and force compensated oscillating inertial microbalance and method of using the same. Temperature and / or pressure and / or modulus of elasticity compensation and / or force compensation is achieved by providing two substantially similar oscillating elements wherein only one oscillating element is subjected to the mass collection means. The other oscillating element is subjected to all other factors but does not include a particulate collection means. By taking the difference between the two similar oscillating elements one can substantially remove the undesirable side effects having to do with changing temperature and / or pressure and / or modulus of elasticity. The ratio of the major axis to the minor axis is described as being important to eliminate and or minimize precession of the oscillating elements.

Owner:SIERRA INSTR

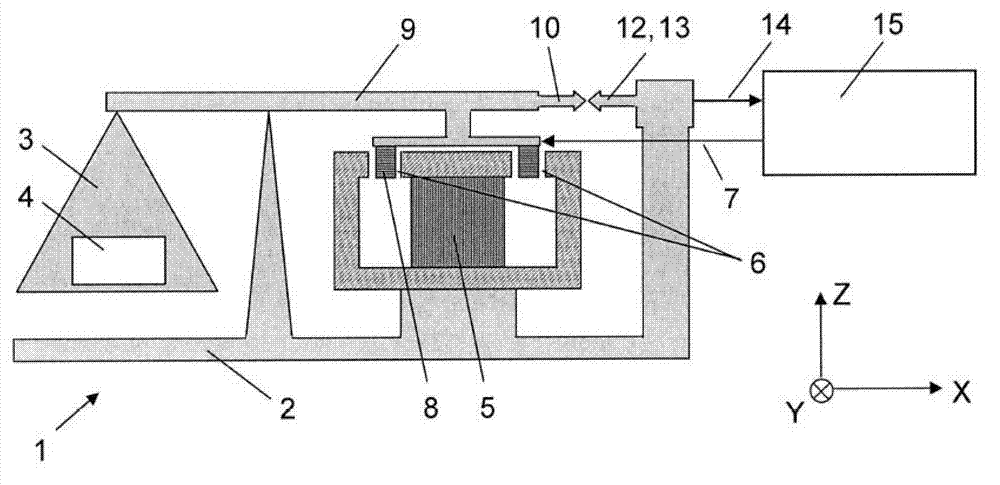

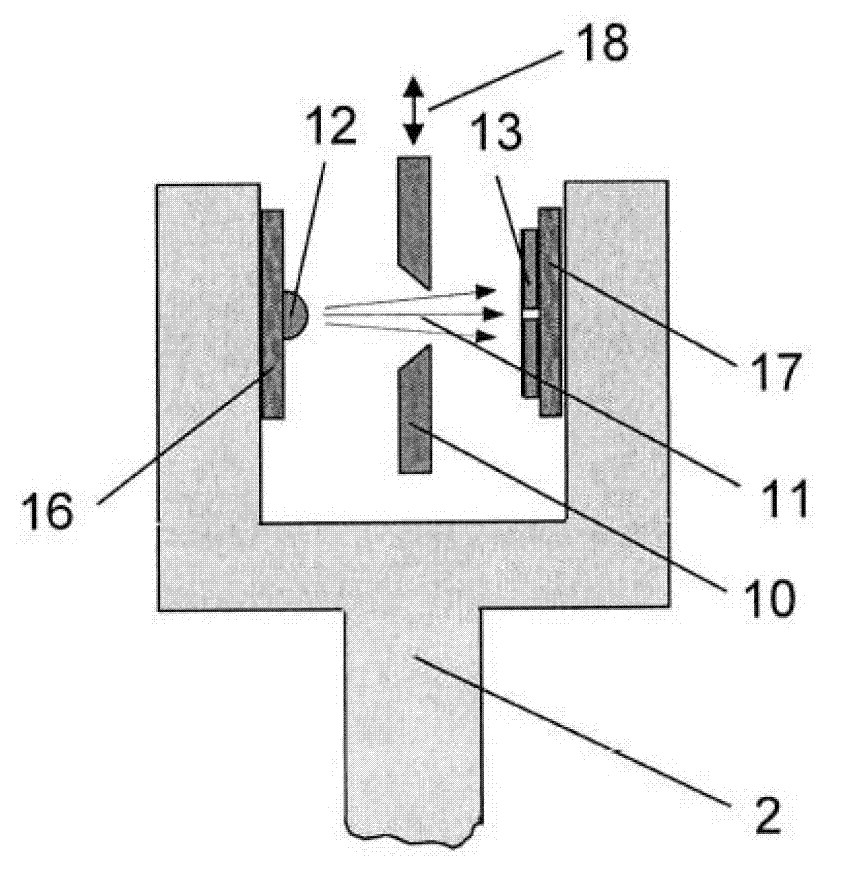

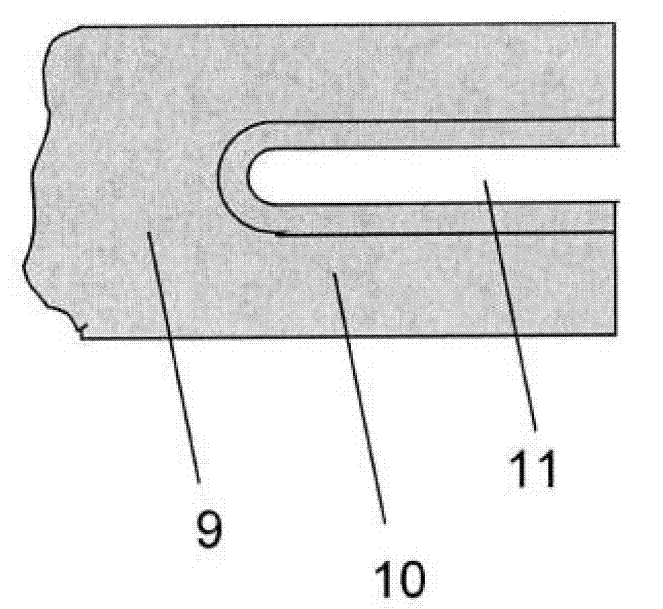

Weighing cell operating on the principle of electromagnetic force compensation with optoelectronic position sensor

ActiveCN103175595AImprove thermal conductivityWeighing apparatus using electromagnetic balancingWeighing temperature-compensating arrangementsClosed loopOpto electronic

A weighing cell based on the principle of electromagnetic force compensation. A permanent magnet system is mounted on a base part and includes an air gap within which is suspended a coil that is connected to a load receiver through a force-transmitting mechanism. The coil carries an electrical compensation current when the weighing cell is in operation. An optoelectronic position sensor is also included, and its signal corresponds to the deflection of the coil from a zero position which occurs as a result of placing a load on the load receiver. A closed-loop controller regulates the compensation current in response to the sensor signal in such a way that the coil and the load receiver that is connected to it are returned to their zero position by the electromagnetic force that is acting between the coil and the permanent magnet.

Owner:METTLER TOLEDO INC

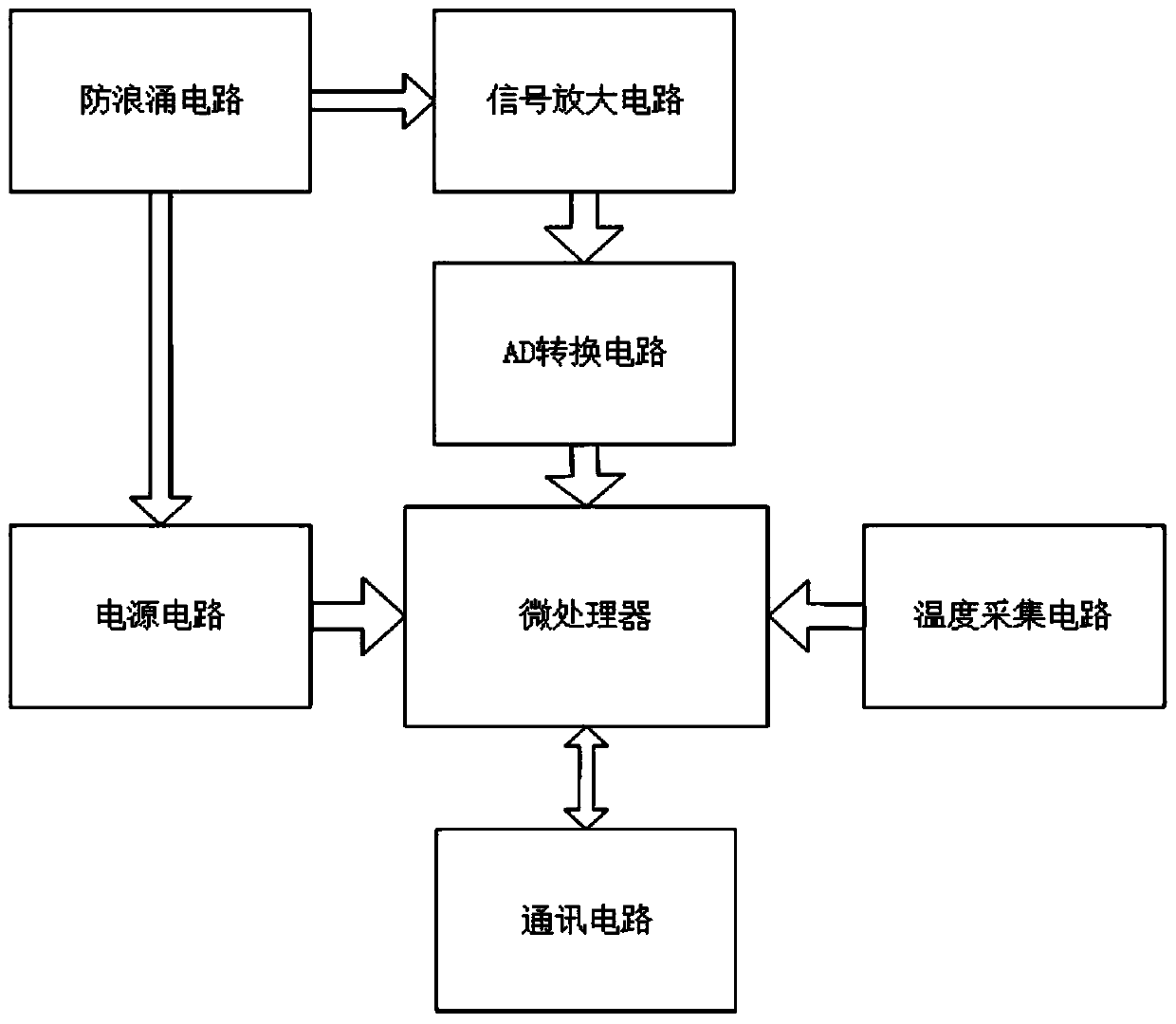

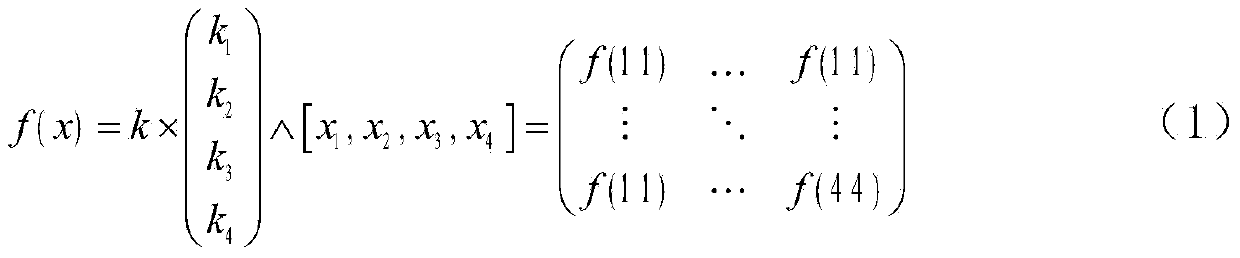

Anti-cheating high-precision intelligent digital weighing module and anti-cheating method thereof

InactiveCN104180881AAvoid changeImprove reliabilityWeighing temperature-compensating arrangementsSpecial purpose weighing apparatusComputer terminalPower circuits

The invention discloses an anti-cheating high-precision intelligent digital weighing module and an anti-cheating method thereof. The digital weighing module comprises a signal amplification circuit, an AD converting circuit, a microprocessor, a temperature collecting circuit, a communication circuit, a power circuit and a surge prevention circuit. The anti-cheating method comprises the following steps that a data receiving terminal transmits a set of random numbers to the digital weighing module; the digital weighing module encrypts the received random numbers and actual measuring weight data through an encryption function f(x) to form encrypted messages; the digital weighing module transmits the encrypted messages to the data receiving terminal through a custom RS-485 communication protocol; the data receiving terminal receives the encrypted messages and then conducts encryption calculation through a decryption function to obtain the actual measuring weight data. The anti-cheating high-precision intelligent digital weighing module and the anti-cheating method thereof can effectively prevent the phenomenon that weight information is changed through signal interference, data tampering and other cheating methods, safety and reliability are achieved, the weight information is not likely to be tempered or stolen, and the reliability of data transmission is improved.

Owner:JINAN JINZHONG ELECTRONICS SCALE

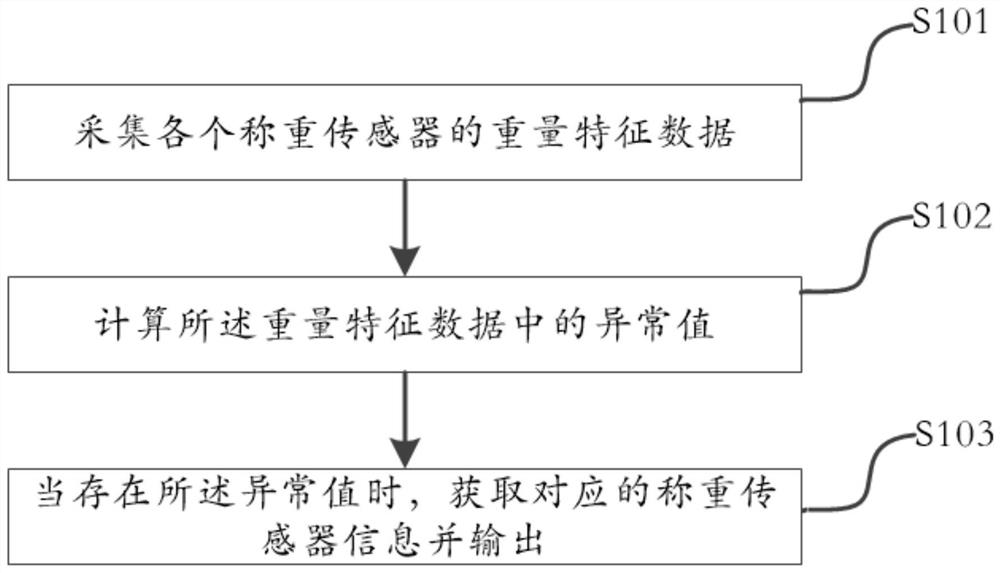

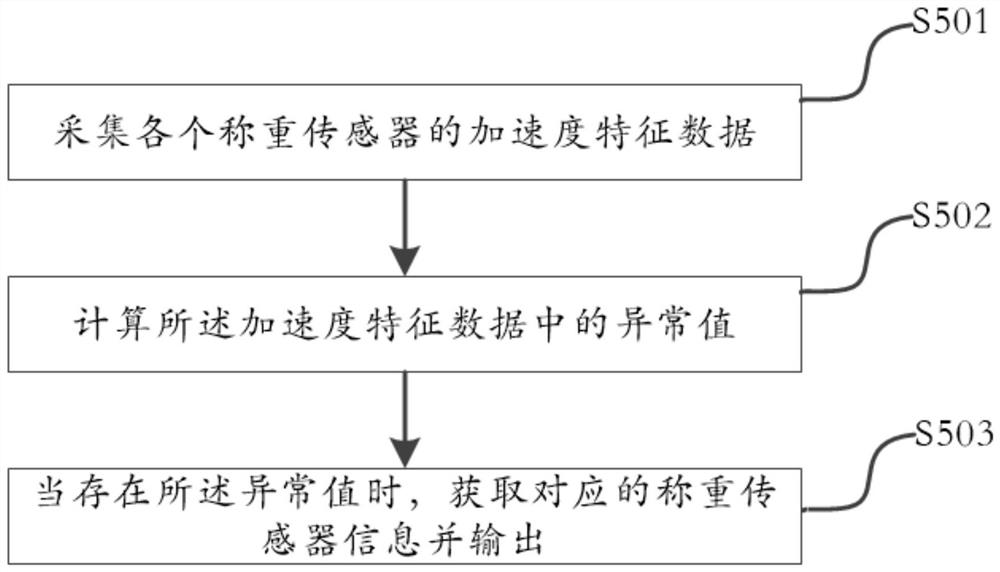

State detection method and device for weighing sensors

InactiveCN112304413AIntuitive Operation InstructionsValuable Operation InstructionsWeighing apparatus testing/calibrationWeighing indication devicesFeature dataReliability engineering

The invention provides a state detection method and device for weighing sensors. The state detection method for weighing sensors is applied to a multi-point weighing system, and comprises the following steps: collecting feature data of each weighing sensor; calculating an abnormal value in the feature data; and when the abnormal value exists, obtaining corresponding weighing sensor information andoutputting the weighing sensor information. By means of the state detection method and device for the weighing sensors, a client can be helped to accurately find out the fault sensor or the potentialfault sensor, measurement errors caused by sensor problems are avoided, and the use satisfaction degree of the user is improved.

Owner:METTLER TOLEDO (CHANGZHOU) PRECISION INSTR CO LTD +2

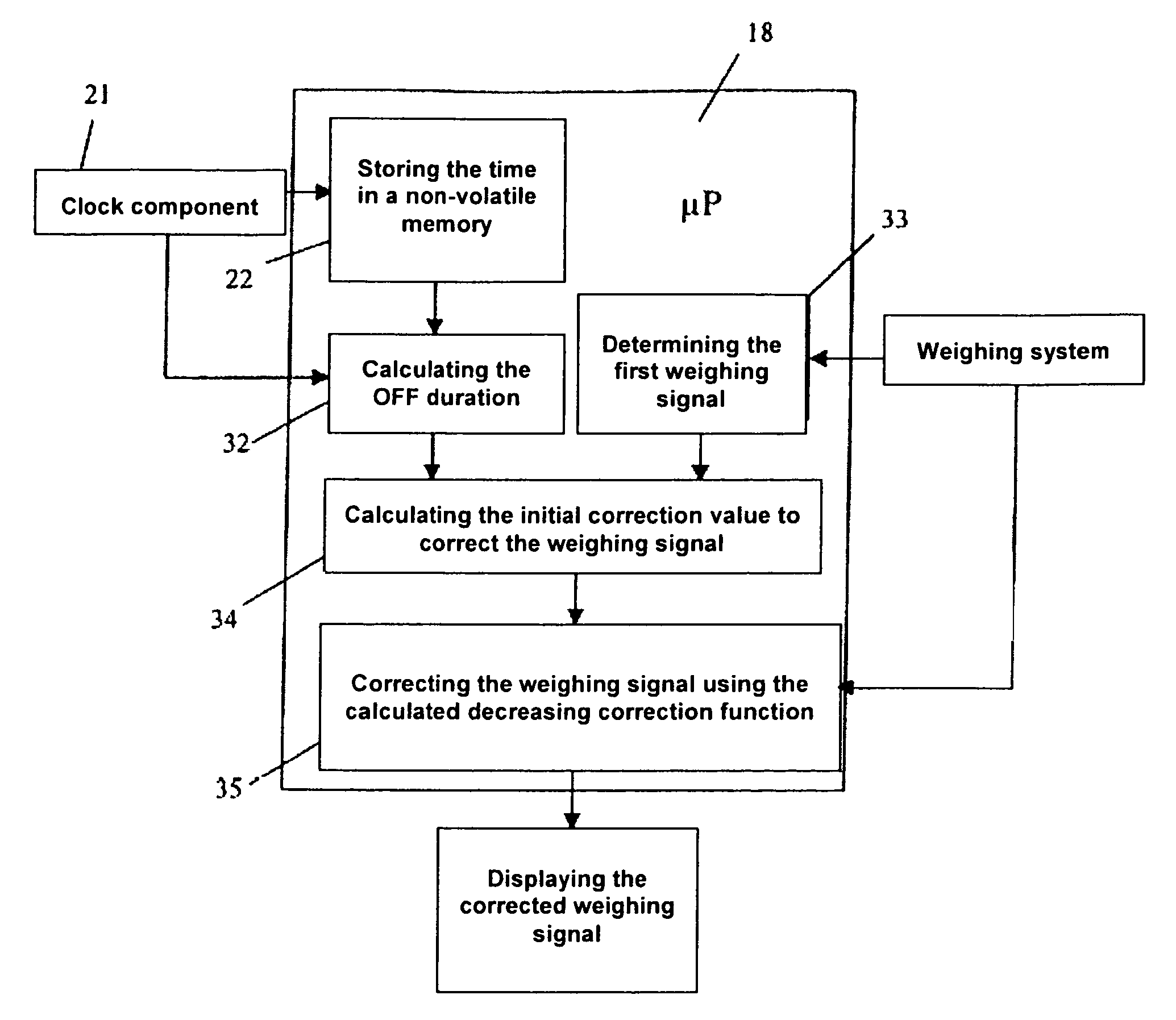

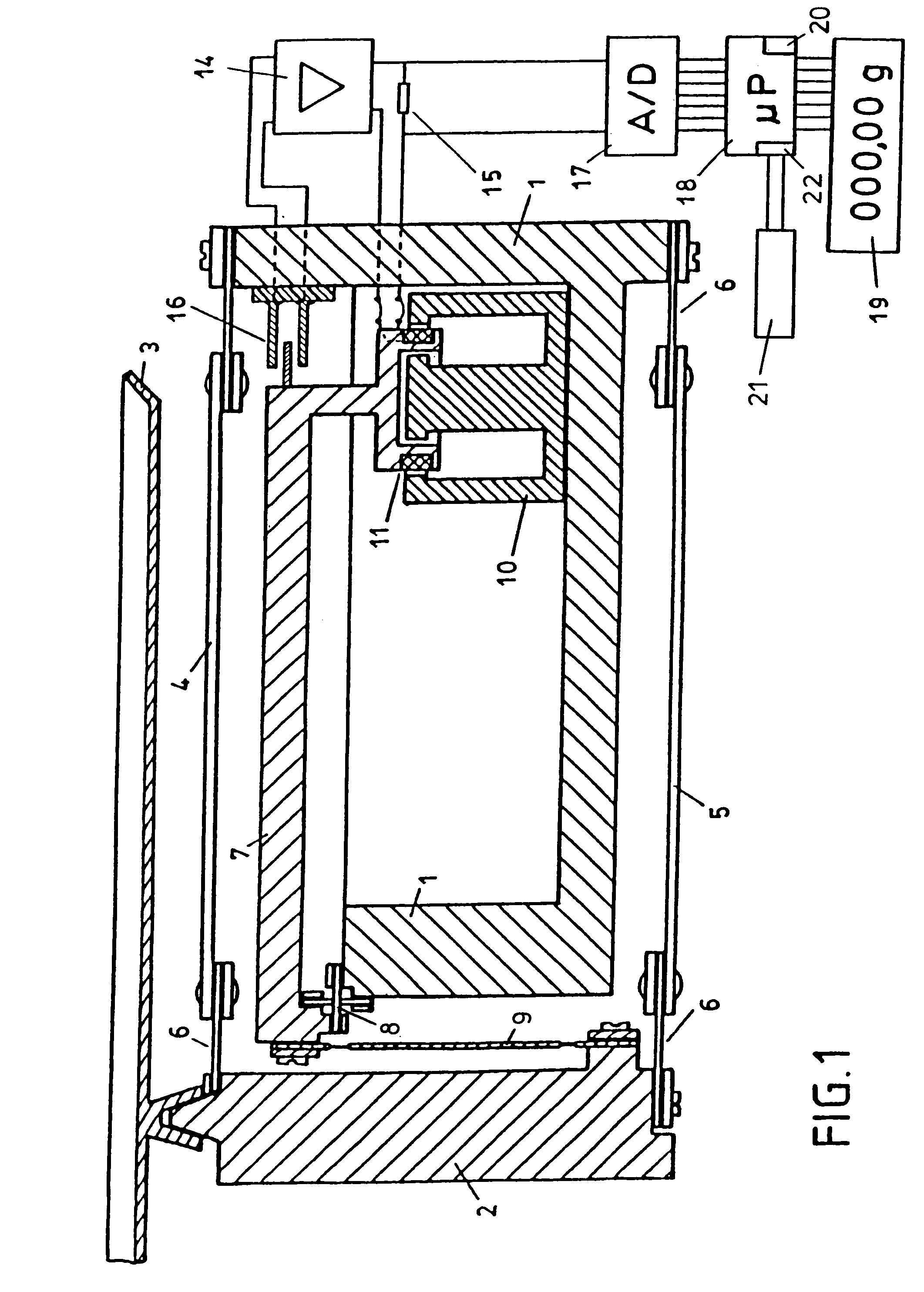

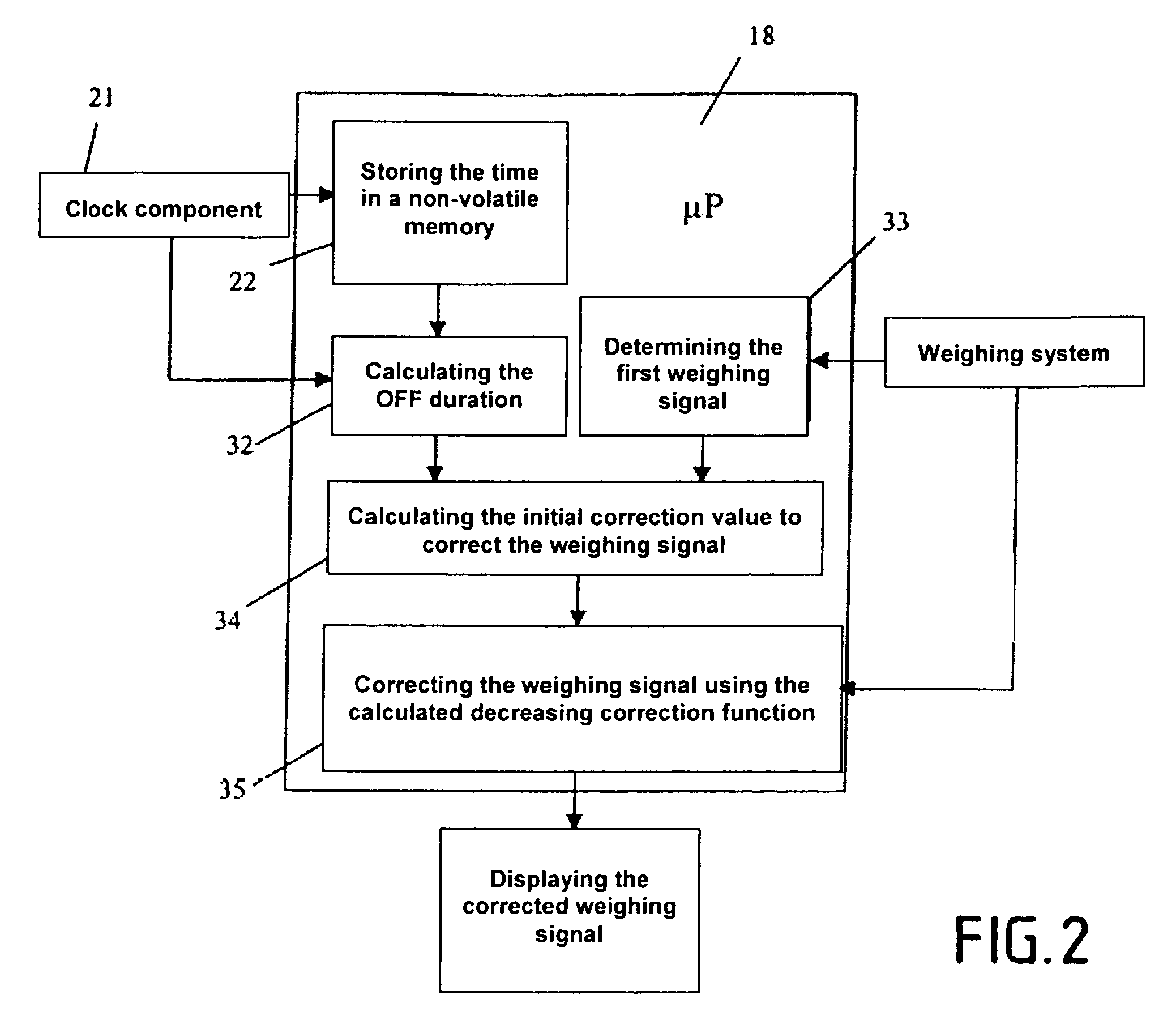

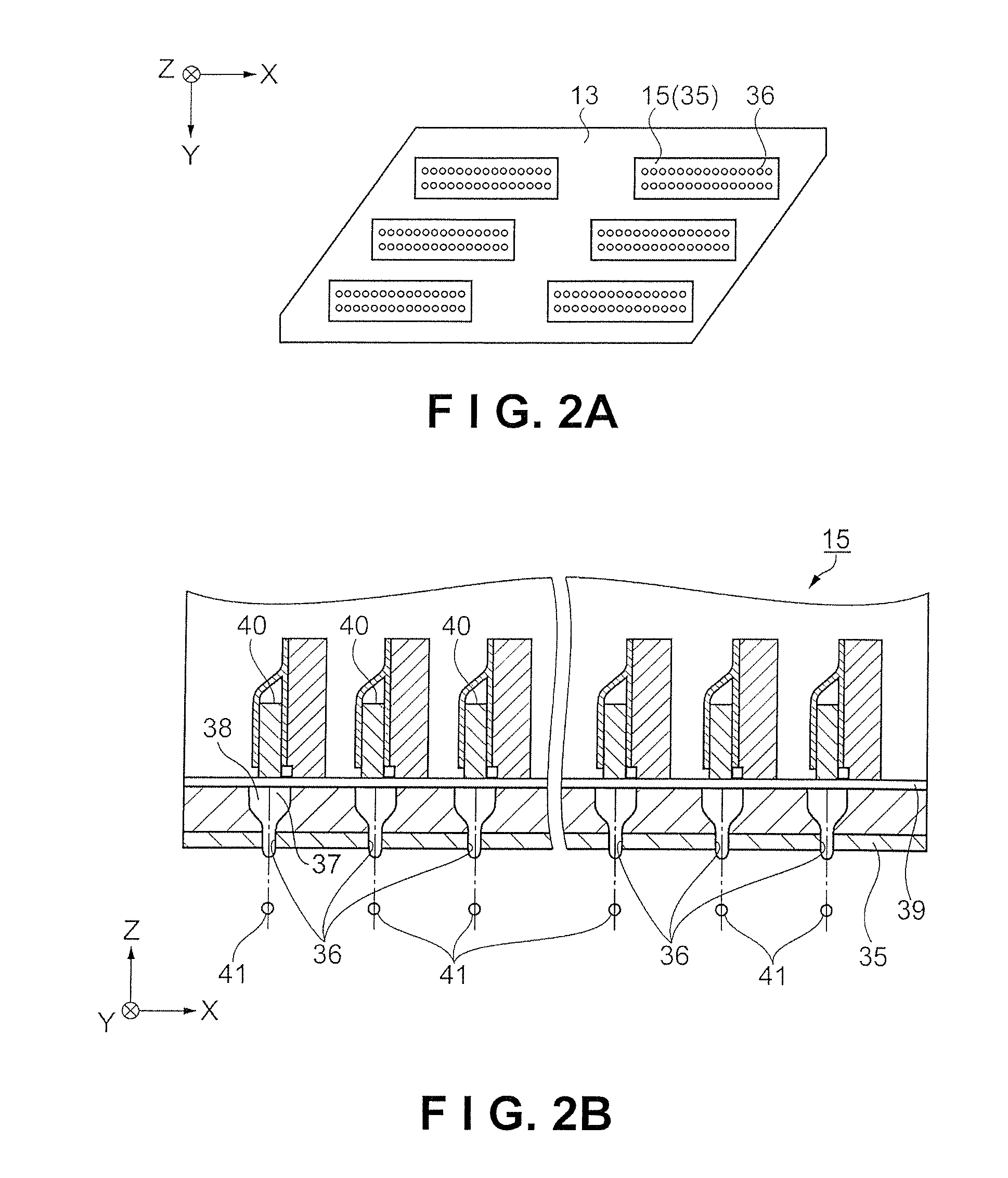

Electronic scale and method for weight measurement including correction means for correcting a weight dependent signal

ActiveUS7361867B2Shorten the timeImprove accuracyElectric heatingHigh-frequency/infra-red heating bakingDigital signal processingVoltage source

A scale having an electronic weighing system to generate a weight-dependent signal and a digital signal processing unit (18). The digital signal processing unit (18) has a circuit or program parts which measure the time elapsed since connection of the voltage to the scale. To dramatically reduce the time required for the scale to reach its full accuracy after connection of the voltage supply, the digital signal processing unit (18) has computation modules (34, 35) that correct the weight-dependent signal generated by the weighing system by a correction value that depends on the time elapsed. The magnitude of this correction value, starting from an initial correction value, converges with increasing time elapsed to a constant end value that differs from the initial correction value.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Oscillating Inertial Microbalance and Method of Passive Compensation

ActiveUS7285736B2Minimize energy transferWeighing apparatus using elastically-deformable membersAnalysing solids using sonic/ultrasonic/infrasonic wavesParticulatesPrecession

The claimed subject matter is directed to a continuous passive temperature, pressure, modulus of elasticity, and force compensated oscillating inertial microbalance and method of using the same. Temperature and / or pressure and / or modulus of elasticity compensation and / or force compensation is achieved by providing two substantially similar oscillating elements wherein only one oscillating element is subjected to the particulate collection means. The other oscillating element is subjected to all other factors but does not include a particulate collection means. By taking the difference between the two similar oscillating elements one can substantially remove the undesirable side effects having to do with changing temperature and / or pressure and / or modulus of elasticity. The ratio of the major axis to the minor axis is important to minimize precession of the oscillating elements.

Owner:SIERRA INSTR

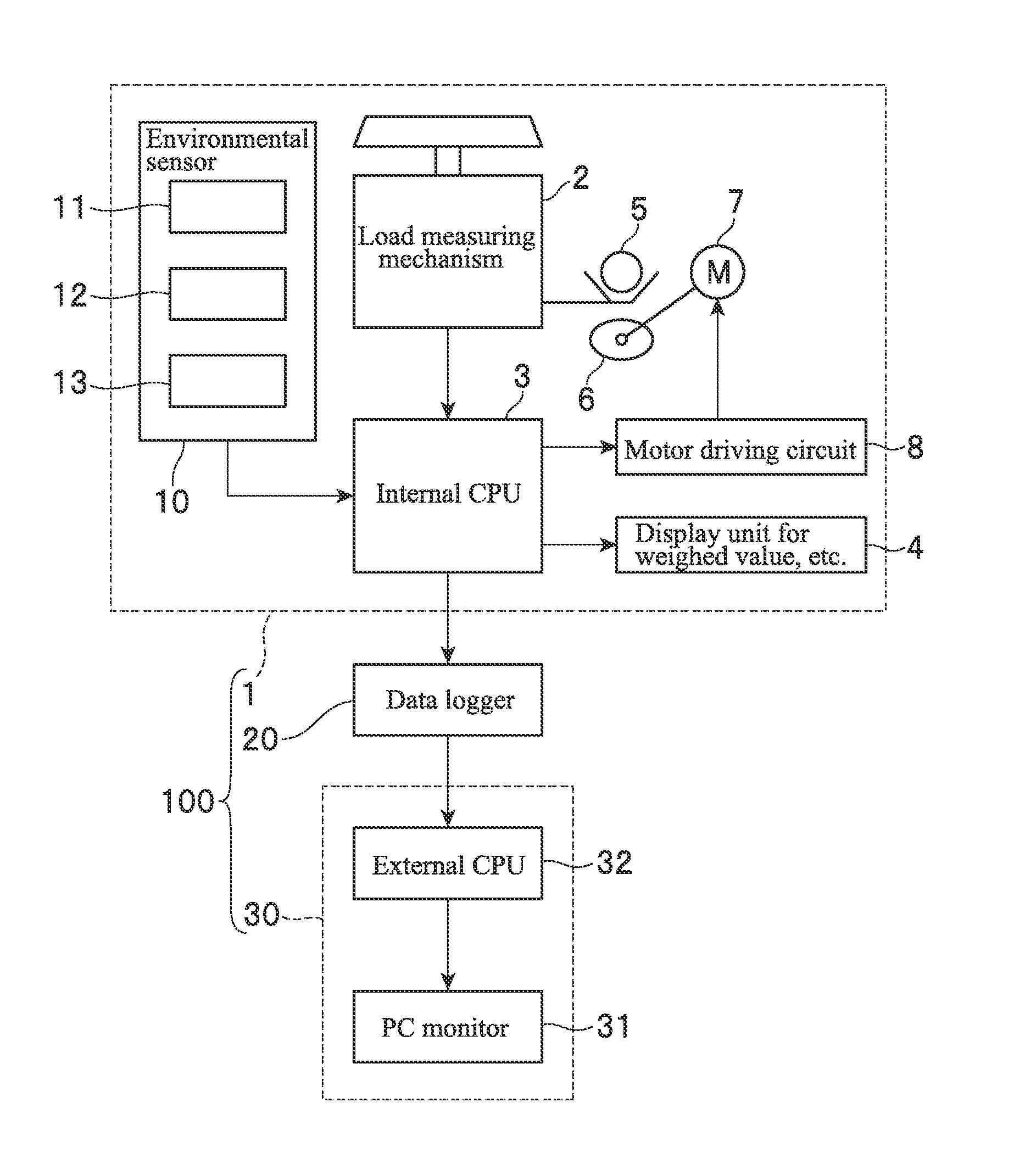

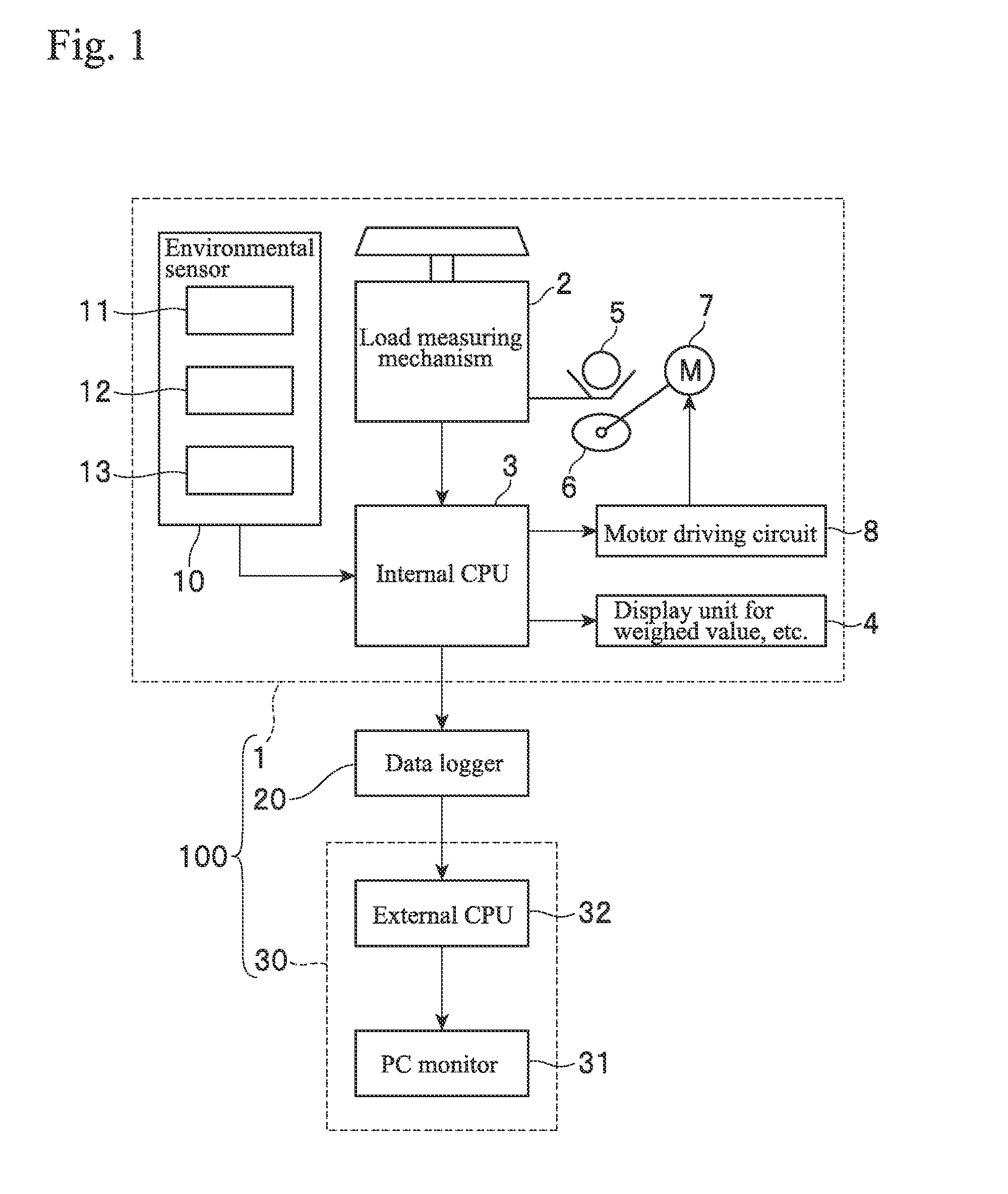

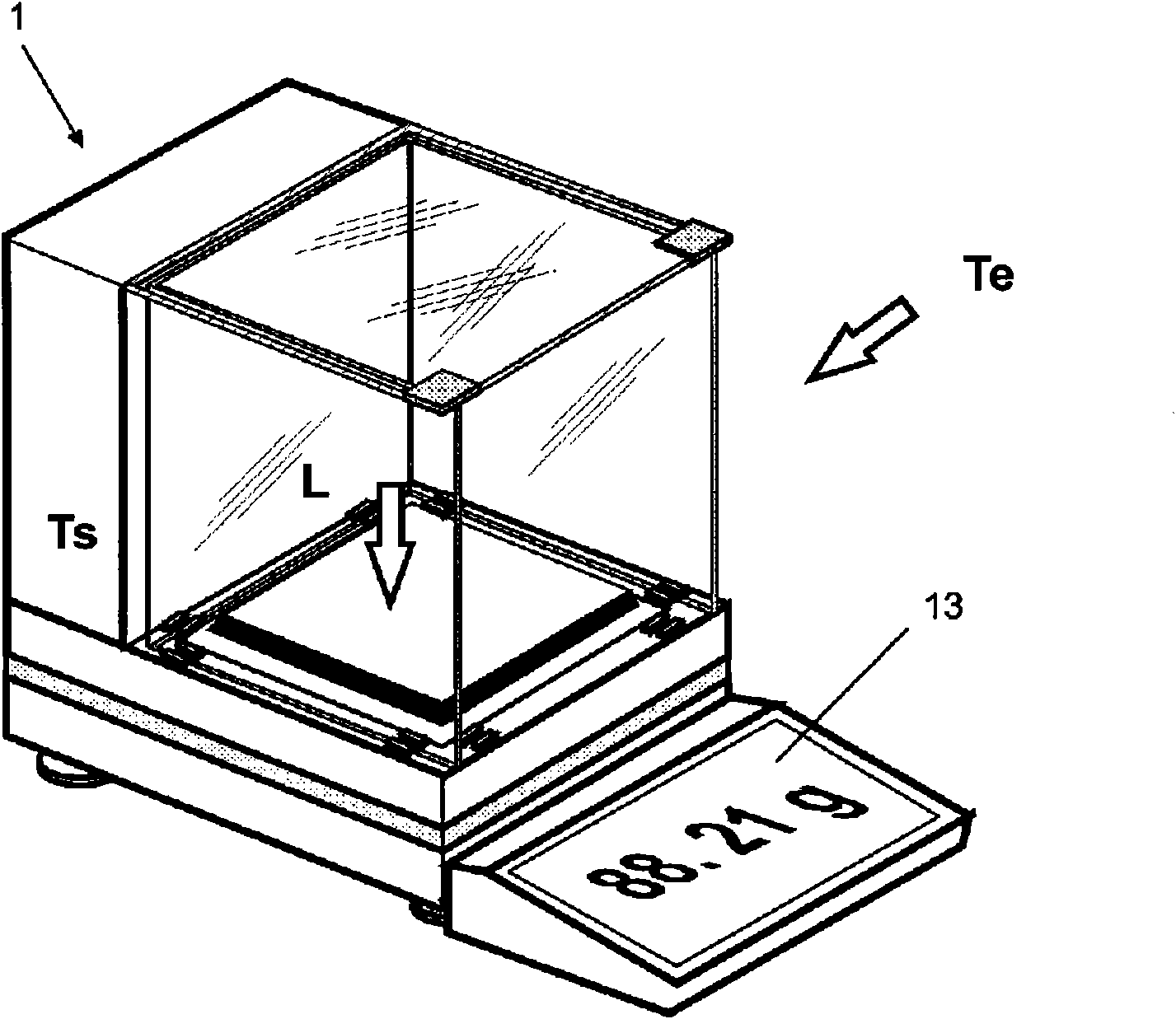

Weighing apparatus

ActiveUS20130306382A1Improve reliabilityImprove the surrounding environmentWeighing apparatus testing/calibrationWeighing indication devicesArithmetic processing unitDependability

To provide a weighing apparatus by which it is possible for a user himself / herself to determine poor performance of the apparatus is a factor attributable to an installation environment, and the weighing accuracy is improved. Respective temporal fluctuations in weighed data detected from a load measuring mechanism 2 and environmental measurement data detected in an environmental measurement means 10 are recorded in a correlative manner in an arithmetic processing unit 32, and the temporal fluctuations are visually recognizable via a display unit 31. Thereby, the correlation between the environmental variations and the weighed data is visually disclosed, which makes it possible for a user to easily recognize that poor performance of the apparatus is attributable to the environmental variations, that increases the reliability of the weighing apparatus. Further, the fundamental performance (accuracy) presented by the apparatus is also assured by allowing the user himself / herself to improve the surrounding environment.

Owner:A&D CO LTD

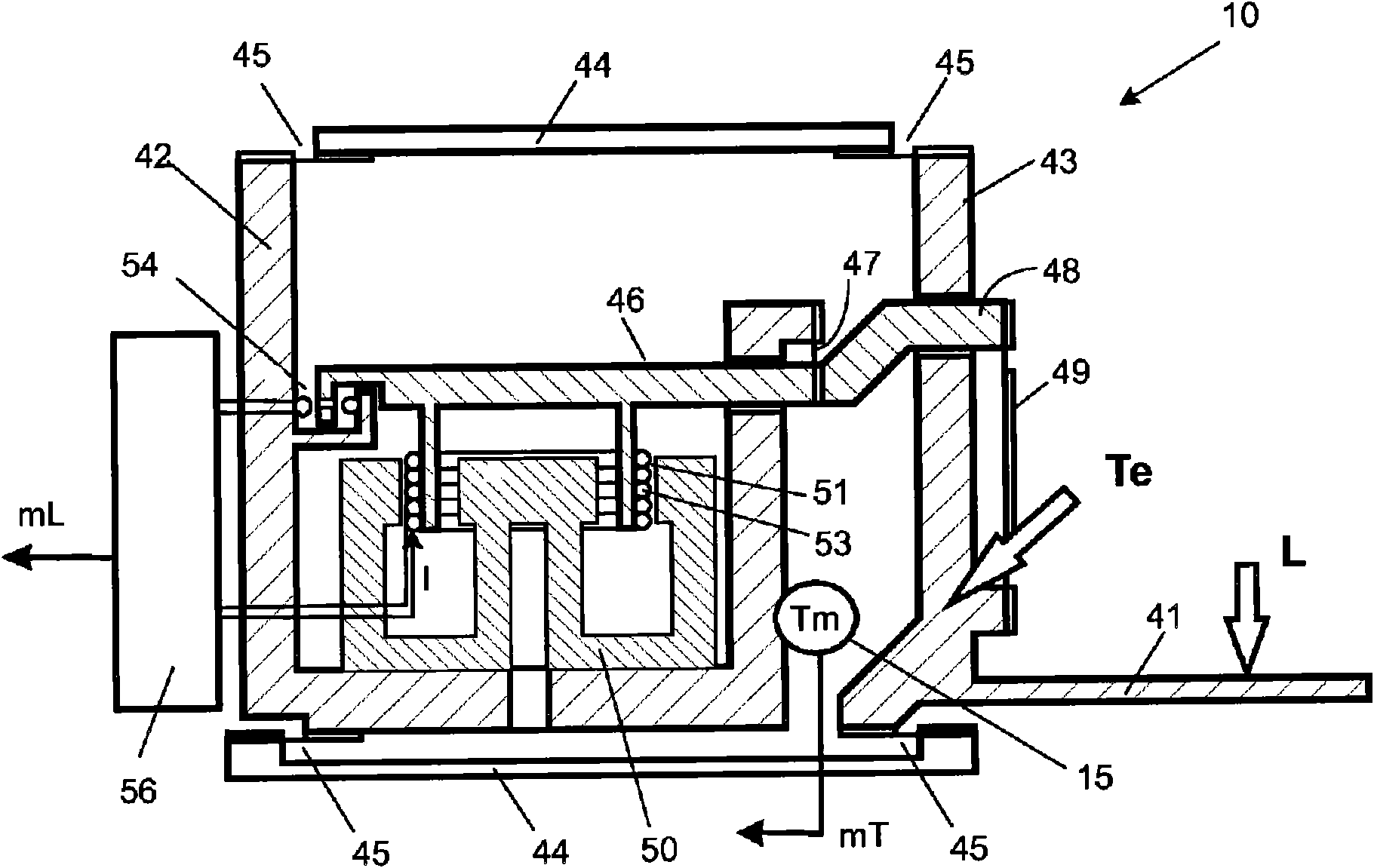

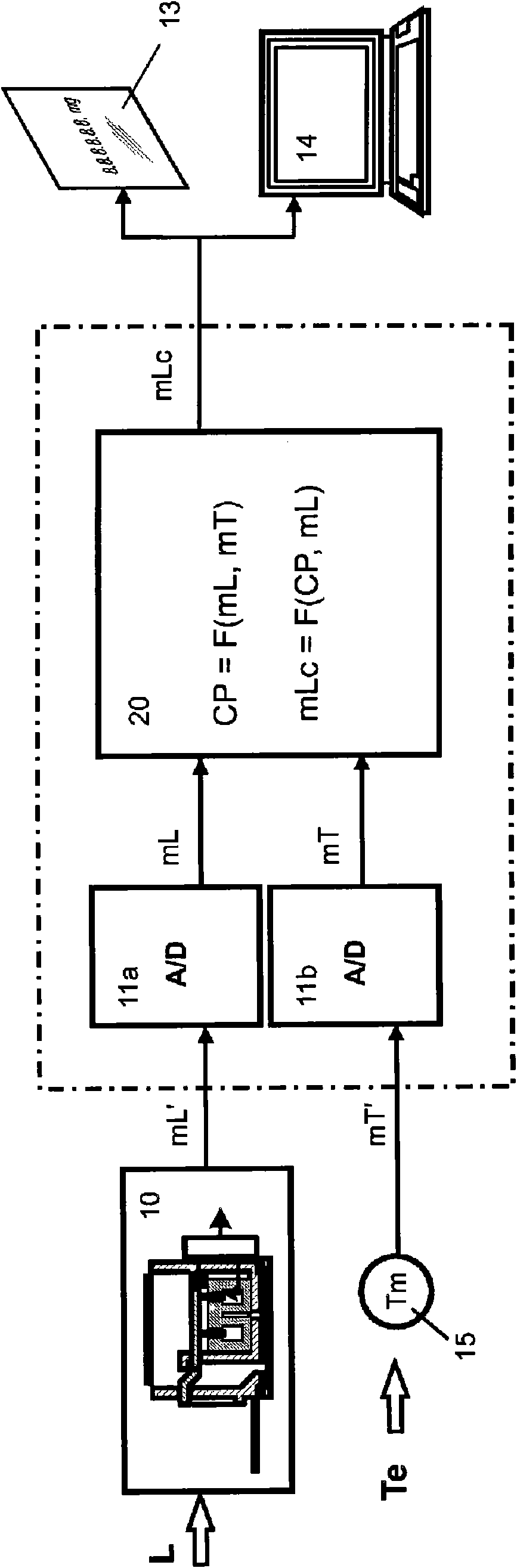

Method For Correcting The Temperature Of A Force Measuring Apparatus And Force Measuring Apparatus

ActiveCN102483345ASimple designLow costWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationElectric forceTemperature difference

The invention relates to a method for correcting the temperature of a force measuring apparatus (1) that is based on the principle of electromagnetic force compensation, particularly a scale, during normal measuring operation, comprising the following steps: generating an electric force measurement signal (mL) corresponding to a force that is acting on the force measuring apparatus using a load cell (10); generating an electric temperature measurement signal (mT) using a temperature sensor (15), which is disposed at a distance from the heat-generating components of the force measuring apparatus (1), said signal corresponding to the ambient temperature (Te) acting on the force measuring apparatus; processing the force measurement signal (mL) on the basis of the temperature measurement signal (mT) and the force measurement signal(mL) into a temperature-corrected output signal (mLc); transmitting the output signal (mLc) to a display unit (13) and / or a further processing unit (14). To this end, during the processing step based on the force measurement signal (mL) and / or the temperature measurement signal (mt), at least one corrective parameter (CP) used to correct the output signal (mLc) is calculated using a thermodynamic model, said parameter characterizing a temperature difference (dTr, dT1, dT2) that exists between a system temperature (Ts, Ts1, Ts2) and the ambient temperature (Te), or between a first system temperature (Ts1) and a second system temperature (Ts2).

Owner:METTLER TOLEDO INC

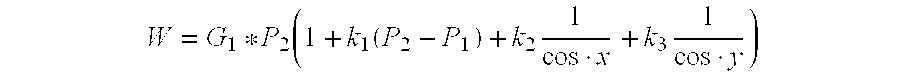

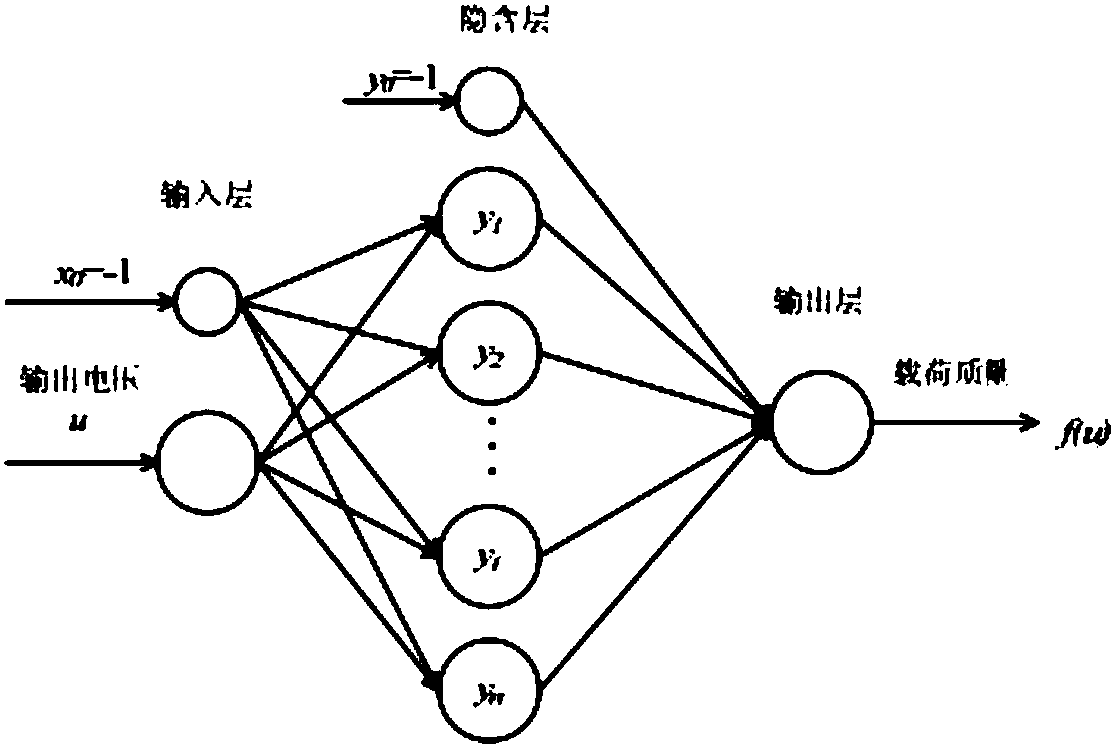

BP neural network based temperature gain compensation method applied to electronic scale

InactiveCN108332837AAccurate temperature compensationWeighing apparatus testing/calibrationWeighing temperature-compensating arrangementsMicrocontrollerMicrocomputer

The invention discloses a BP neural network based temperature gain compensation method applied to an electronic scale. The method comprises the steps of: 101, establishing a neural network model for temperature gain correction of a weighing sensor; 102, obtaining learning training sample data of the network; 103, pre-processing the sample data; 104, performing network training on the number of samples; 105, testing the network prediction effect; and 106, writing a compensation formula into a firmware program of a single-chip microcomputer. The method of the invention can correct a temperaturesensor by using the neural network method, can quickly and accurately realize the temperature compensation of the weighing sensor, not only makes the accuracy of the compensation link reach the measurement allowable error range, but also has a prediction compensation effect for temperature points without training.

Owner:CHIPSEA TECH SHENZHEN CO LTD

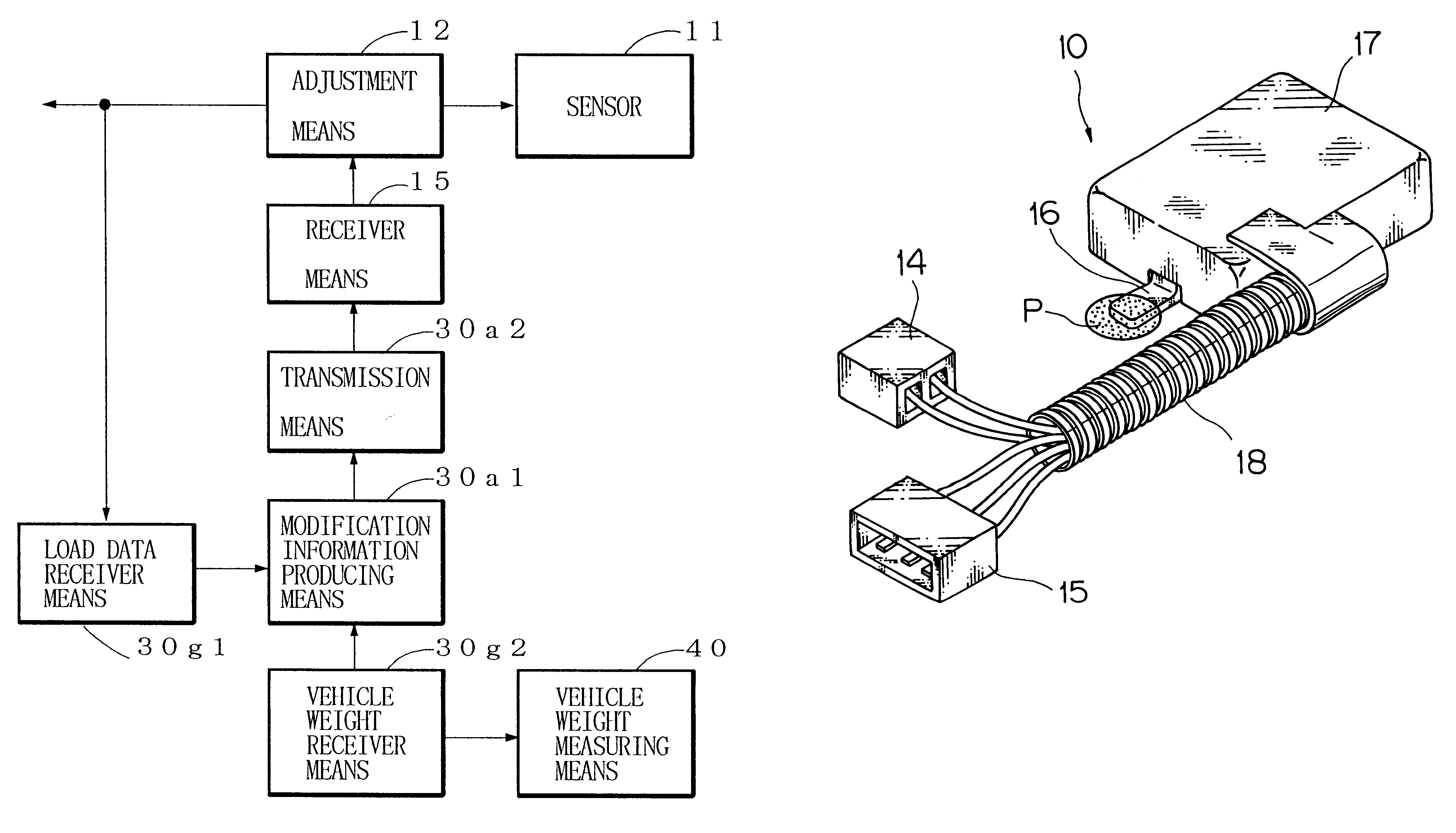

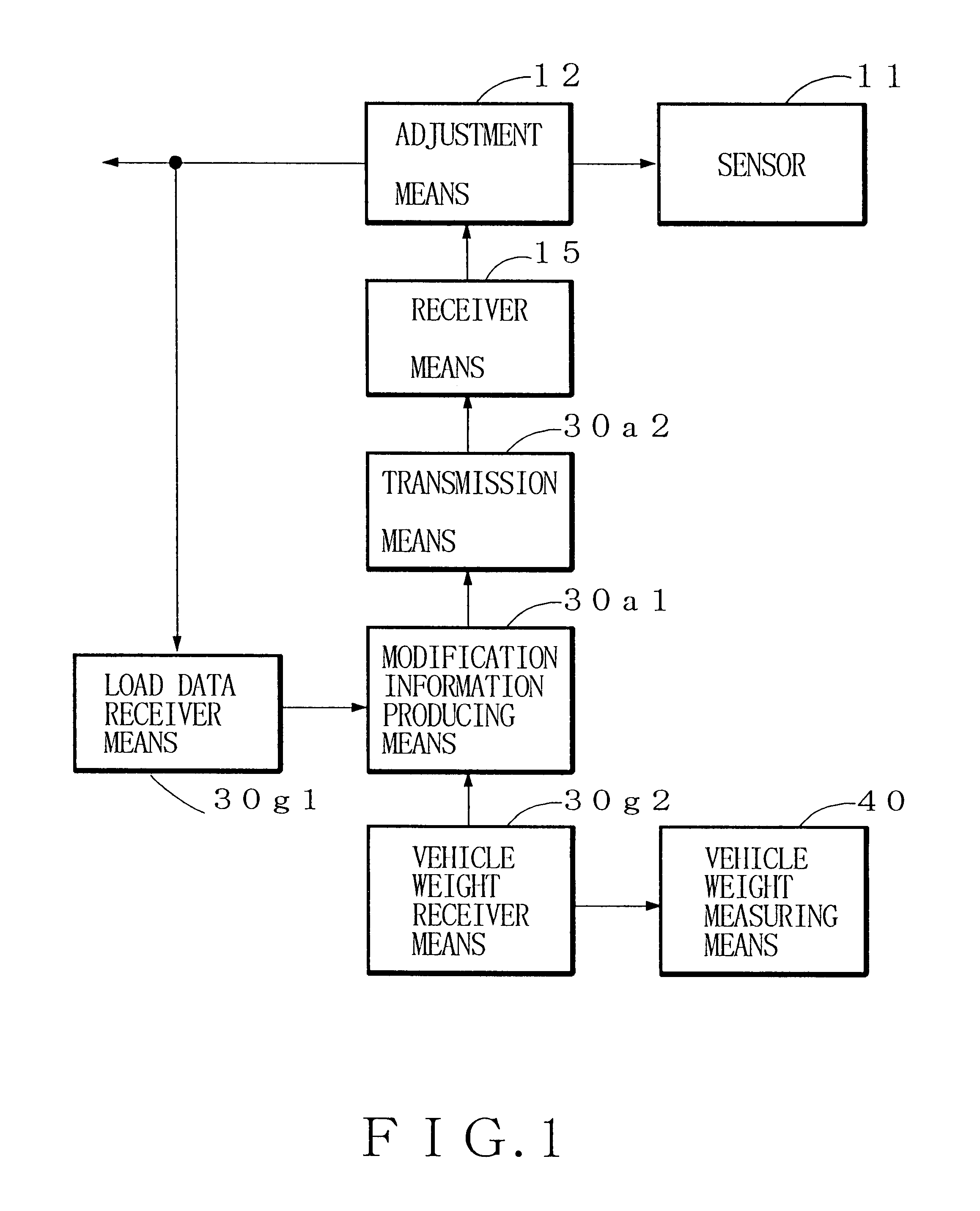

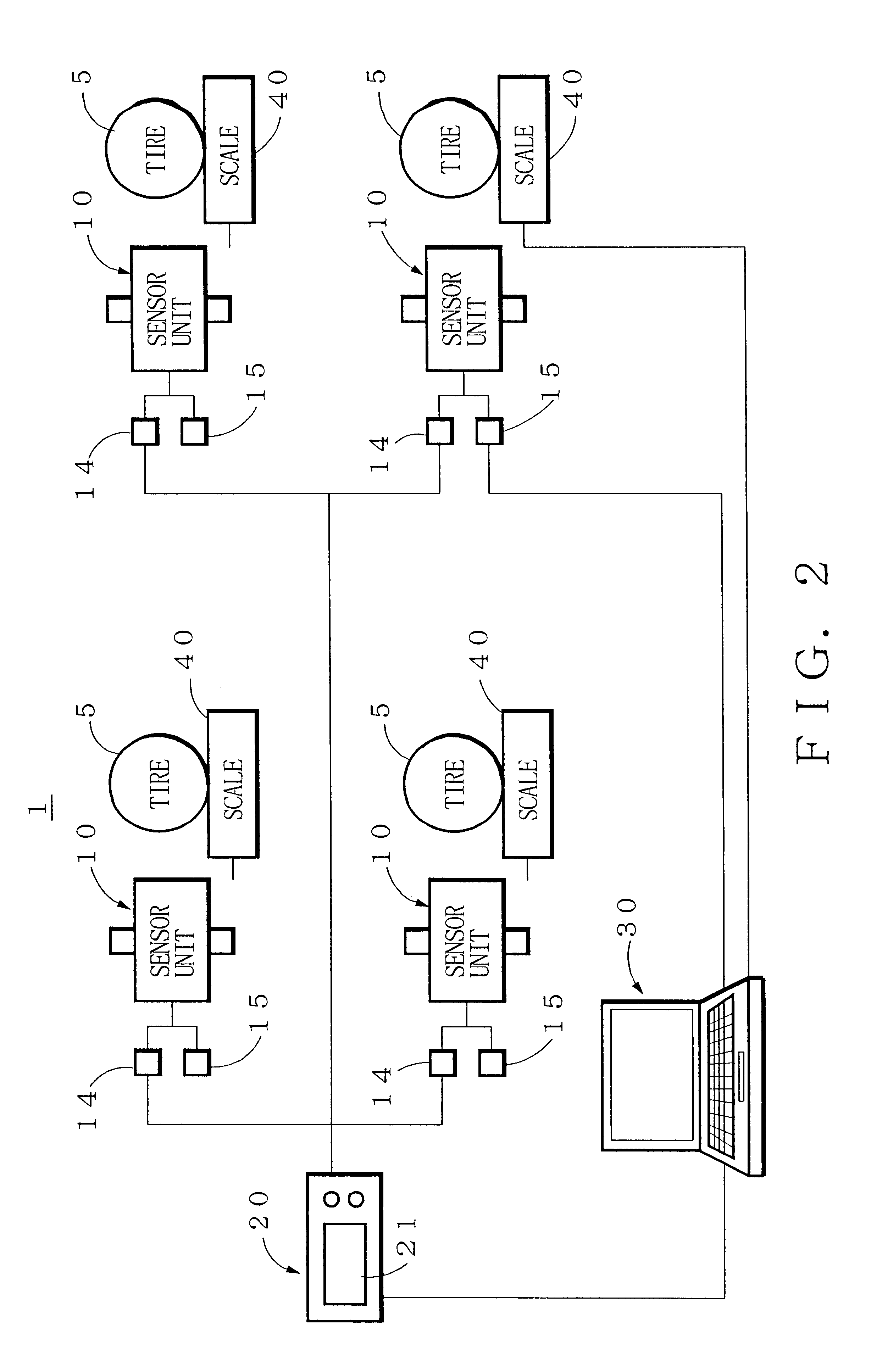

Sensor unit and control system of the same

InactiveUS6653576B2Weighing apparatus testing/calibrationWeighing indication devicesControl systemEmbedded system

A sensor unit having a sensor and an adjustment unit is welded to a vehicle. After the mounting of the sensor unit, a receiver unit externally receives modification information for modifying the load signal adjustment. Thereby, the load signal outputted from the sensor is adjusted by the adjustment unit responsive to the modification information to be externally outputted. Thus, alter the mounting of the sensor unit, the receiver unit receives the modification information, and the adjustment unit adjusts the load signal supplied from the sensor based on the modification information. This allows the sensor unit to unitarily have the sensor and the adjustment unit. Thereby, the adjustment unit can be modified by the modification information externally supplied. Accordingly, the sensor unit with the adjustment unit can be applied to various types of vehicles.

Owner:YAZAKI CORP

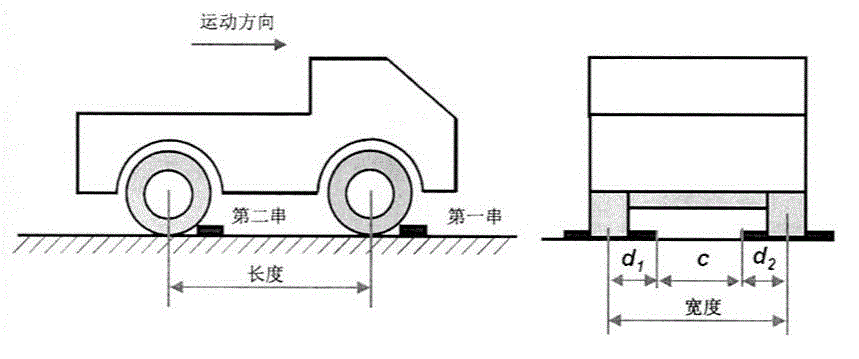

Continuous weight meter and continuous weight metering method

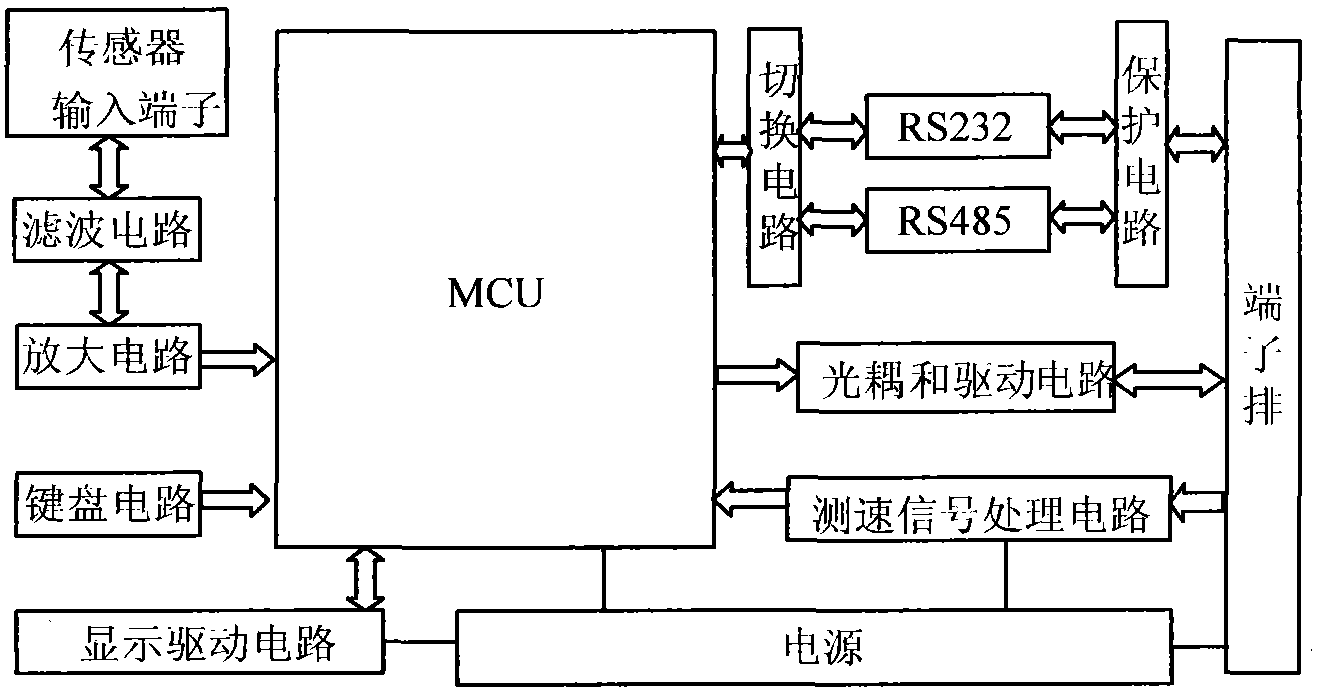

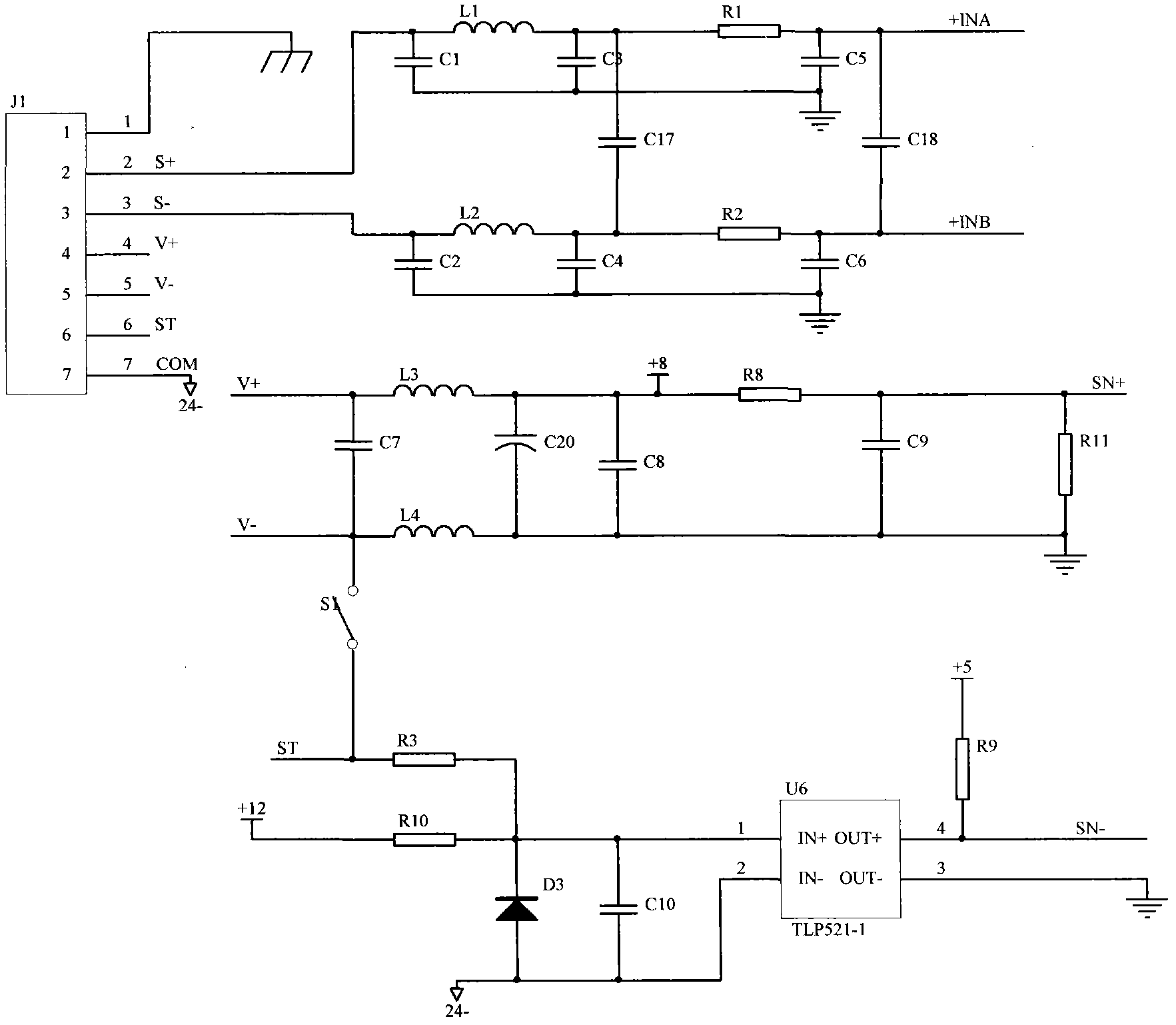

InactiveCN102305659AImprove anti-interference abilityImprove stabilityWeighing temperature-compensating arrangementsWeighing apparatus for continuous material flowSignal processing circuitsEngineering

The invention discloses a continuous weight meter and a continuous weight metering method thereof. The continuous weight meter comprises a sensor input terminal, a filter circuit, an amplifying circuit, a velocity measurement signal processing circuit, a micro controller unit (MCU), a display drive circuit, an optical coupler, a drive circuit and a keyboard circuit, wherein, the MCU is internally provided with a temperature measuring module and can be used for carrying out temperature compensation on the continuous weight meter according to the external temperature. Temperature compensation and anti-interference filtering treatment are carried out, sensitivity of the continuous weight meter to variation of the outside temperature is reduced, and the anti-interference capability of the continuous weight meter is improved, thus stability and reliability of the whole continuous weight meter are enhanced on the whole.

Owner:LUDONG UNIVERSITY

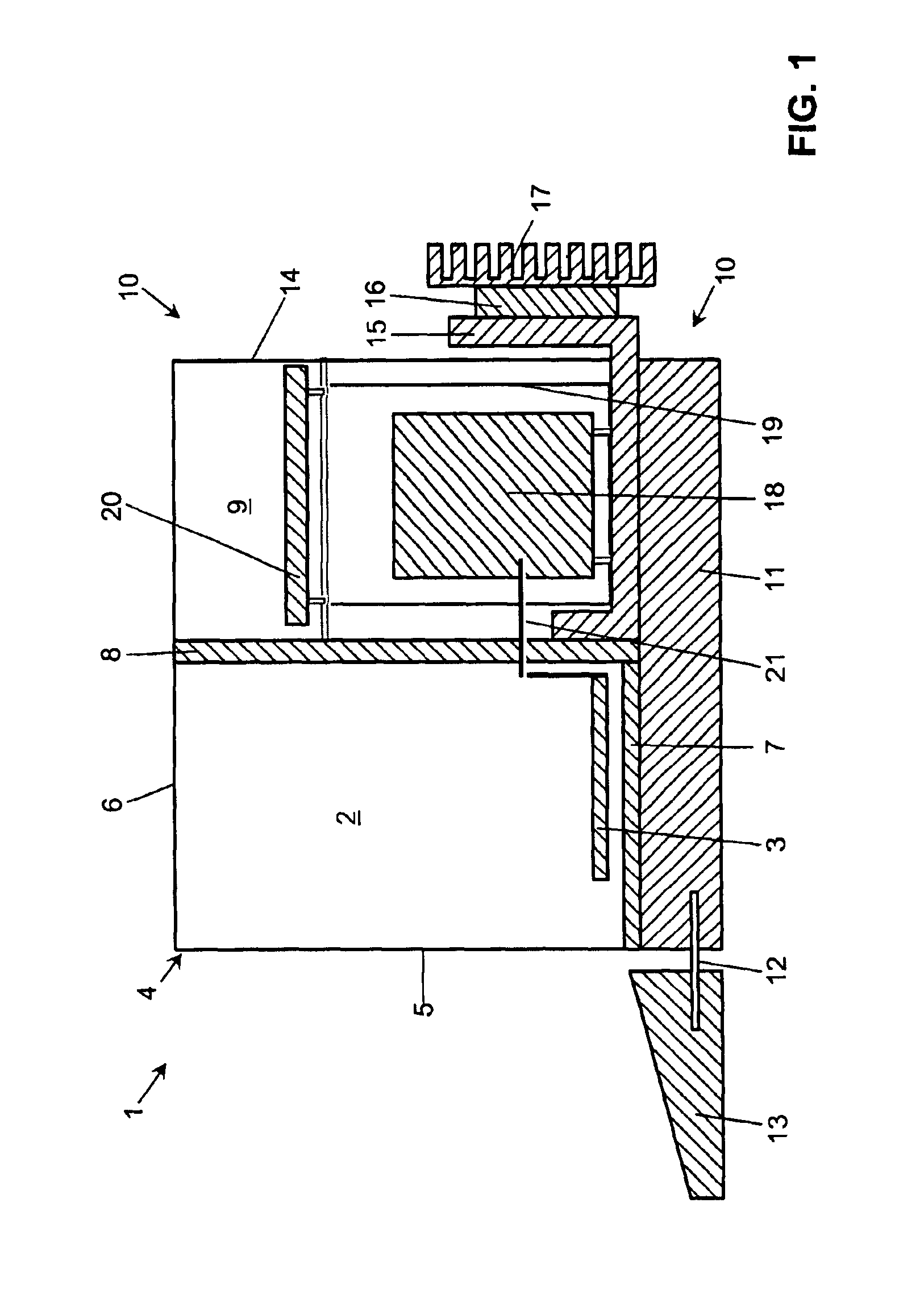

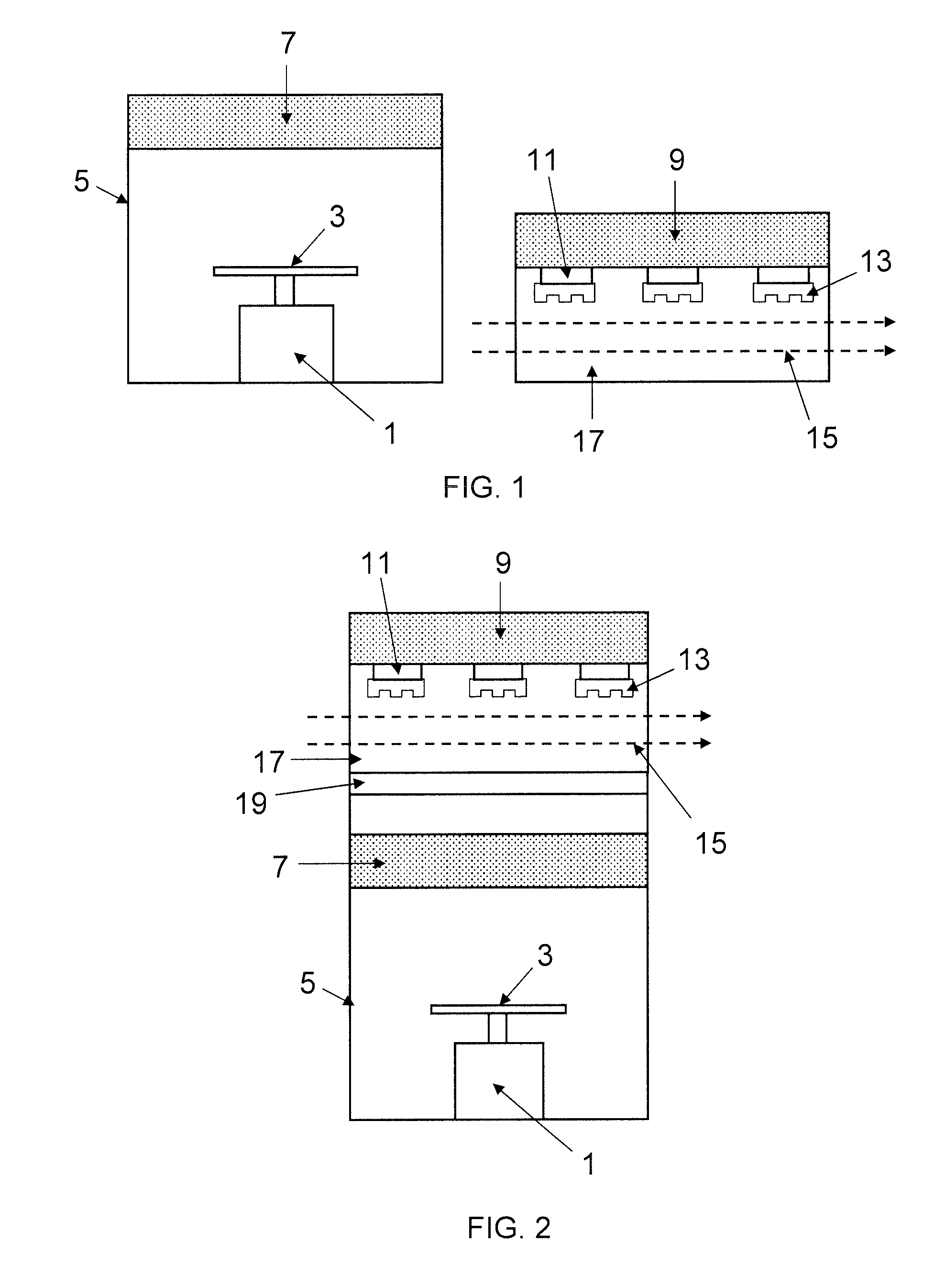

Balance with a heat removing device

ActiveUS6951989B2Stable stratification of airThe result is stableWeighing temperature-compensating arrangementsEngineeringTemperature gradient

A balance (1) with a weighing pan (3) inside a weighing compartment (2) enclosed by a draft shield (4) has at least one thermoelectric module (16) that is arranged outside of the weighing compartment (2) and thermally connected to a stationary part of the balance (1). At least one vertical wall (8) of the draft shield (4) has a lower end portion in thermal connection with the thermoelectric module (16). The vertical wall (8) is configured in such a way that a temperature gradient develops in the vertical wall (8), wherein the temperature increases from the bottom to the top of the wall (8).

Owner:METTLER TOLEDO GMBH

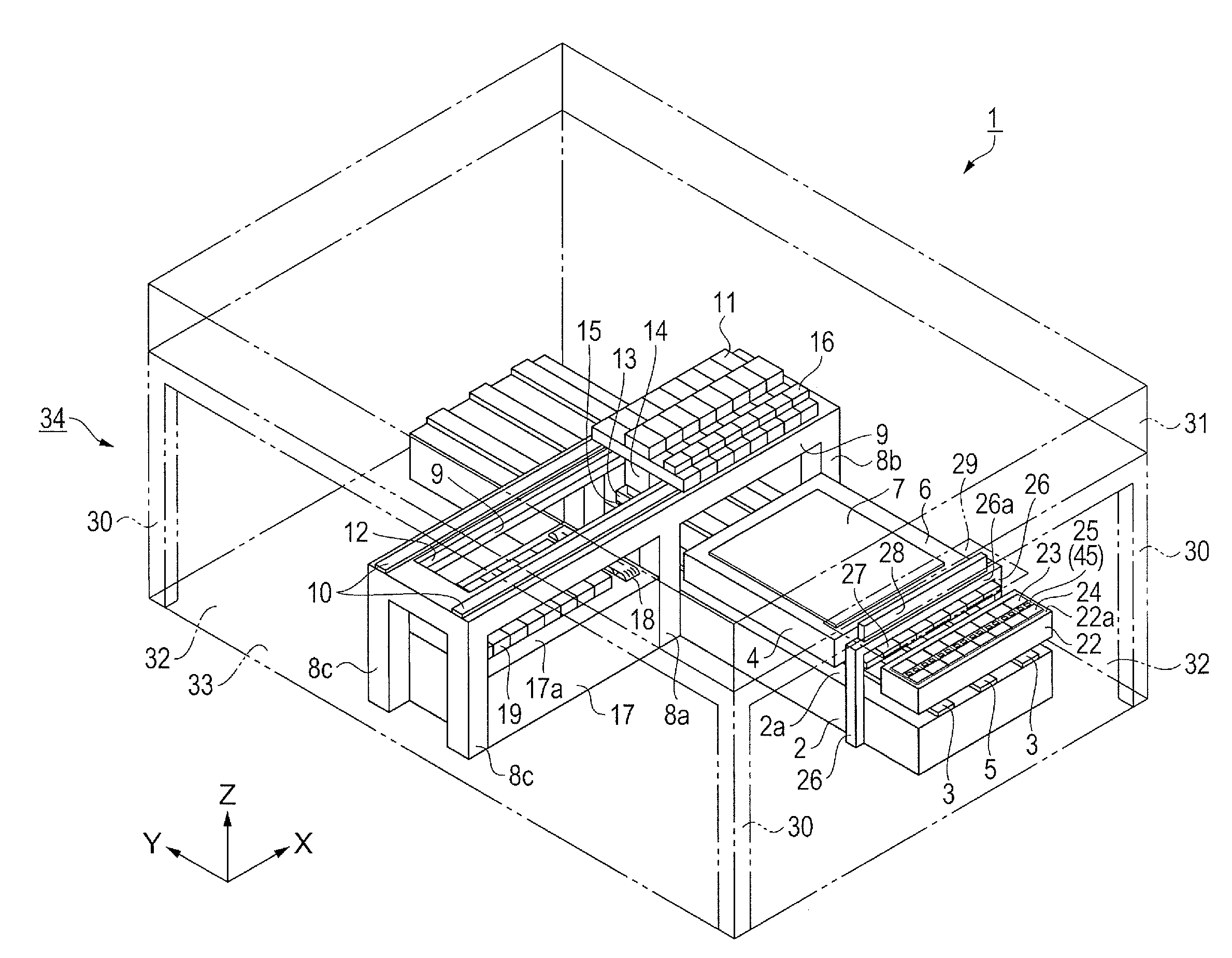

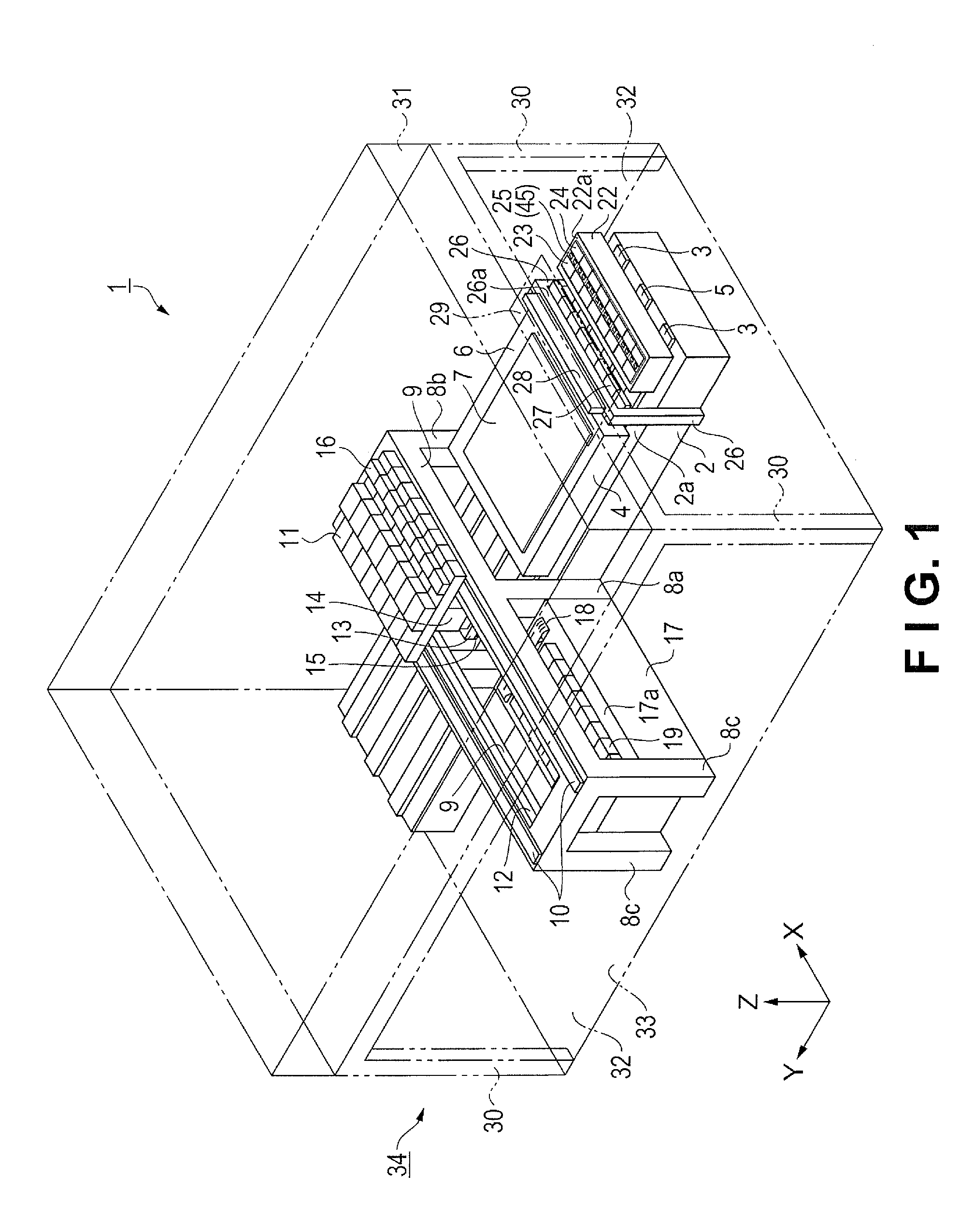

Label printing scale device

InactiveUS20120217069A1Limited manufacturing costWidth of device can be made moreWeighing indication devicesWeighing temperature-compensating arrangementsEngineeringElectrical and Electronics engineering

A label printing scale device includes separable casings that are vertically overlaid in two levels, one on top of the other. Specifically, the label printing scale device includes an upper casing housing at least a load cell and a circuit part, and a lower casing housing at least power-generation circuit, a printer, and a control part.

Owner:ISHIDA CO LTD

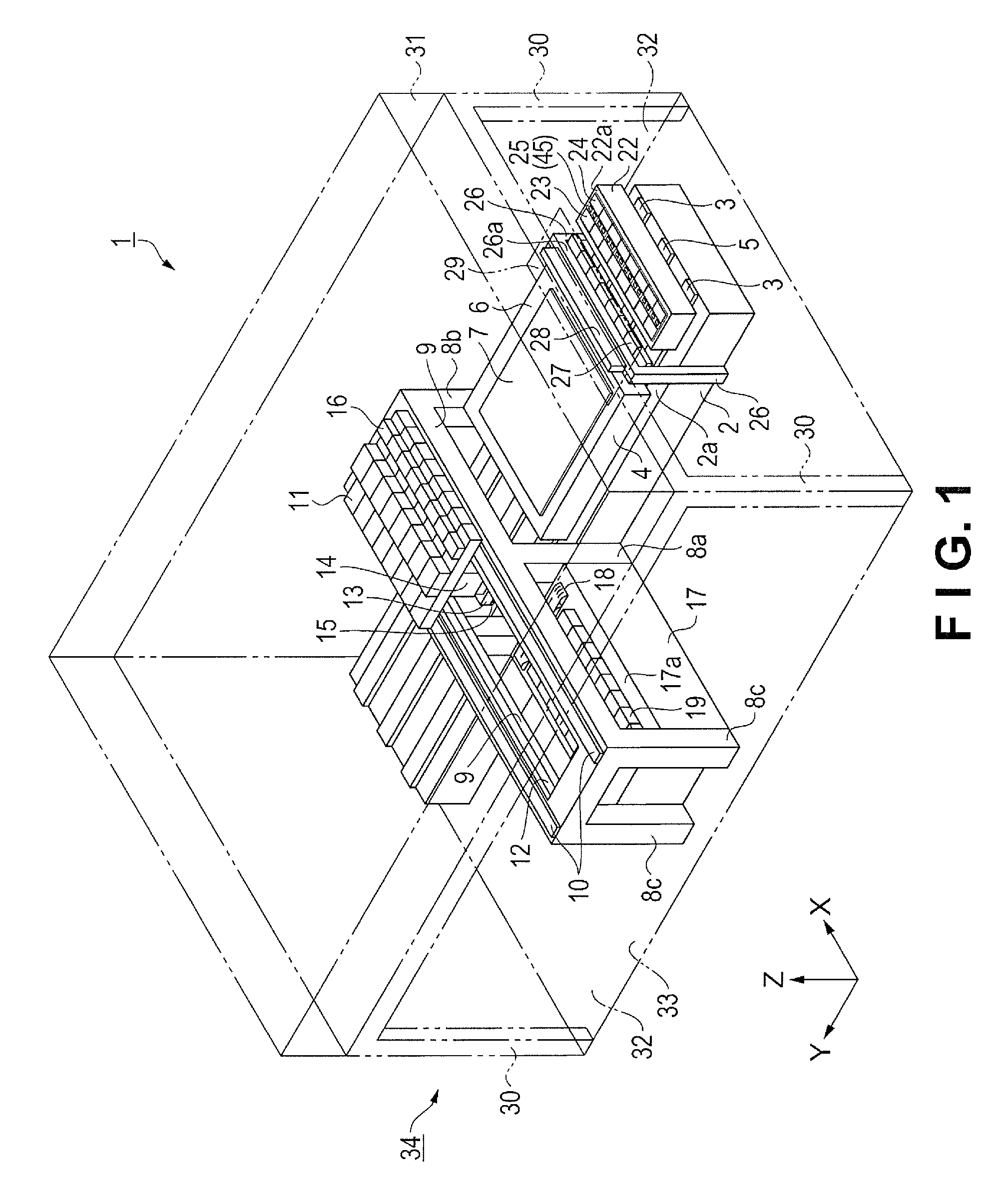

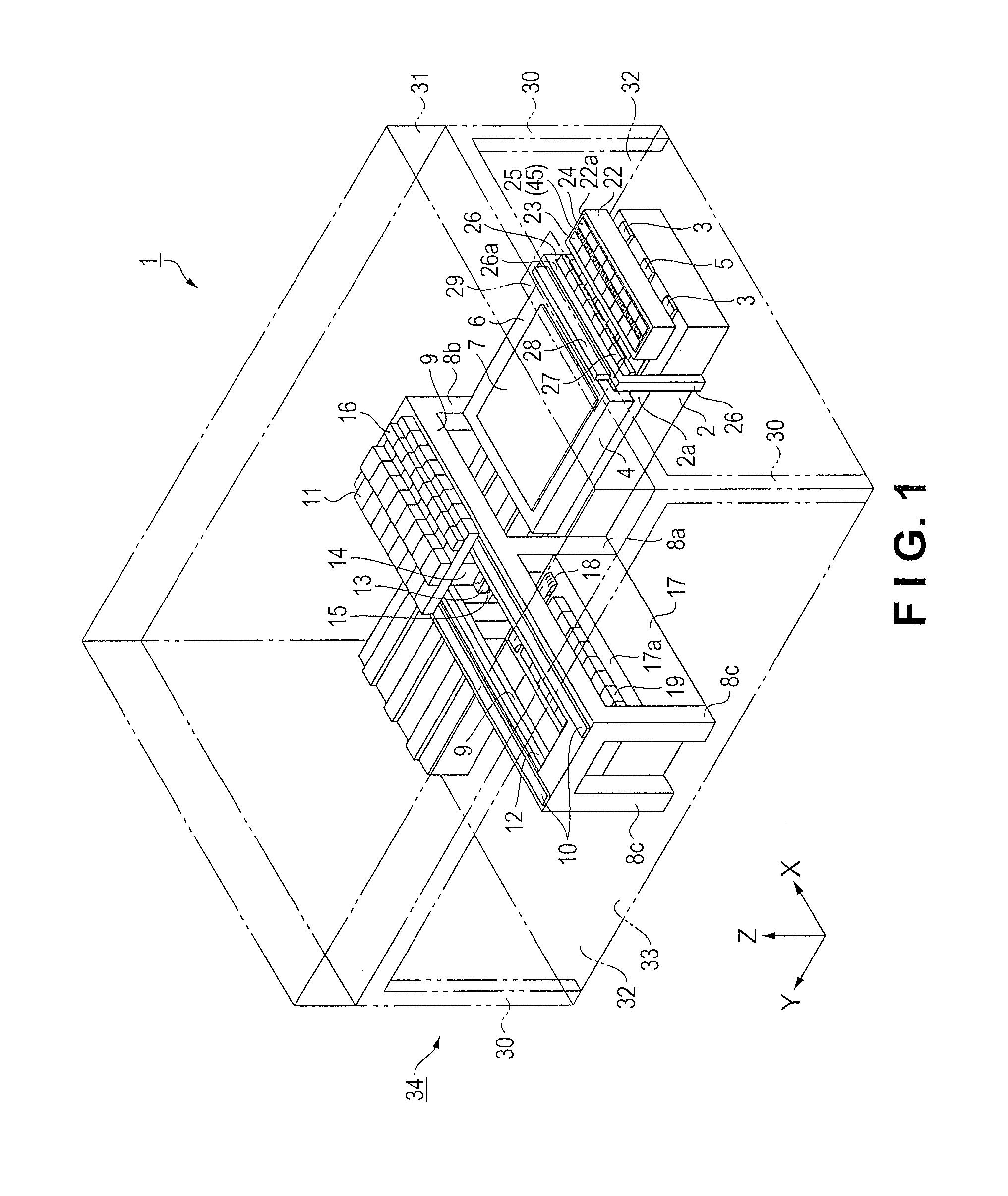

Weight measurement device, droplet discharge device, and weight measurement method

InactiveUS7893368B2Accurate weighingAvoid measuringWithdrawing sample devicesMaterial check-weighingMeasurement deviceTransverse plane

A weight measurement device is configured and arranged to measure the weight of a measurement object. The weight measurement device includes a container and a wind-guard cover. The container is configured and arranged to receive the measurement object therein. The wind-guard cover is configured and arranged to selectively cover an upper space of the container. The wind-guard cover has a transverse air-blocking part configured and arranged to block an air flow flowing in a transverse direction with respect to the container. The container also is equipped with an air control device that injects temperature-adjusted air into a chamber that accommodates the container and the wind-guard cover.

Owner:KATEEVA

Droplet discharge device

ActiveUS20110100725A1Material check-weighingWeighing temperature-compensating arrangementsMeasurement deviceMaintenance stage

A droplet discharge device for discharging a liquid material onto a workpiece includes a droplet discharge head, a guide rail, a stage, a maintenance stage and a weight measurement device. The droplet discharge head discharges the liquid material. The guide rail extends in a prescribed direction. The stage, on which the workpiece is mounted, moves on the guide rail along the prescribed direction. The maintenance stage moves on the guide rail along the prescribed direction. The weight measurement device is disposed on the maintenance stage, the weight measurement device measuring weight of droplets discharged from the droplet discharge head and is able to be disposed at a location opposite the droplet discharge head when the maintenance stage moves along the guide rail.

Owner:KATEEVA

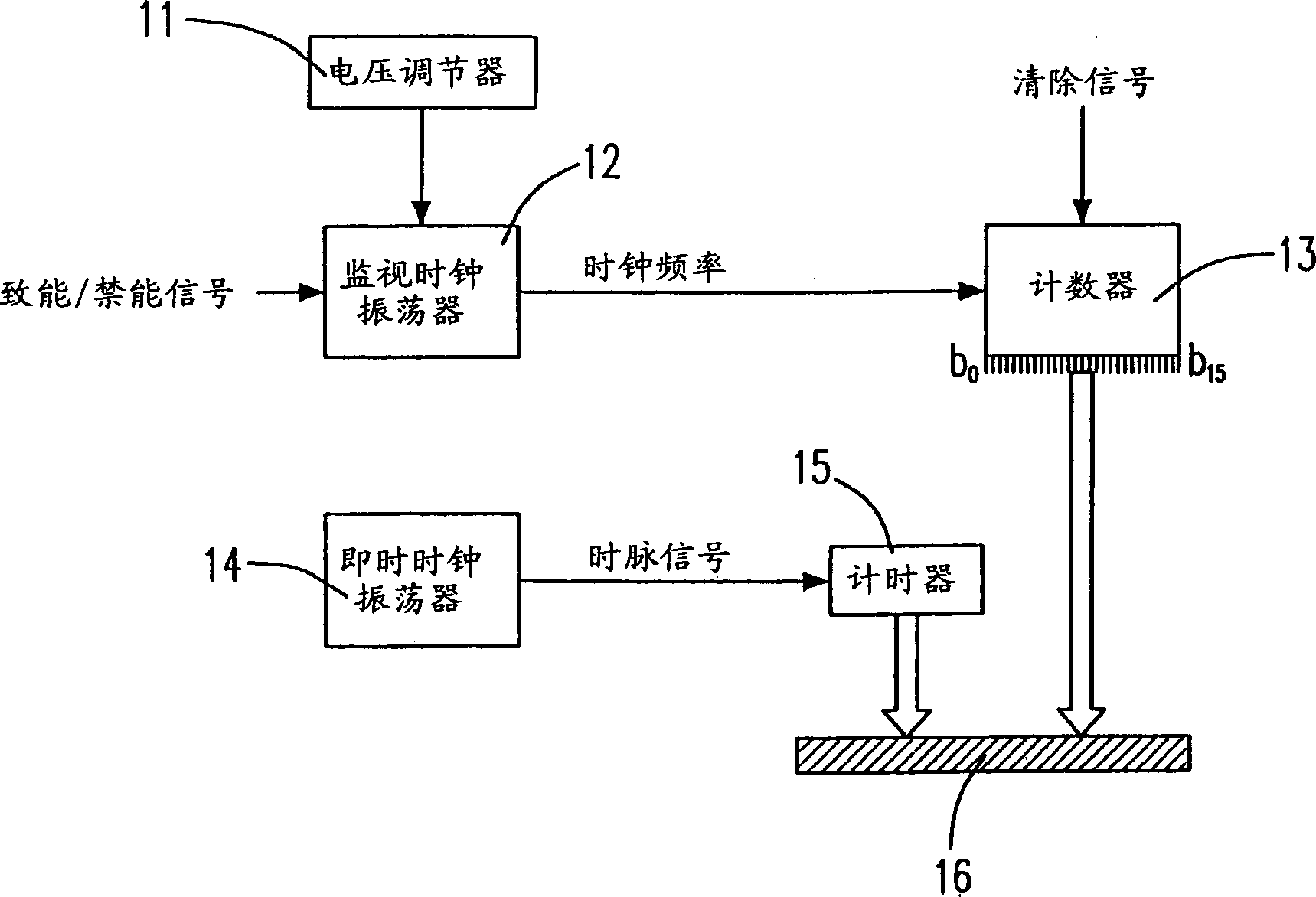

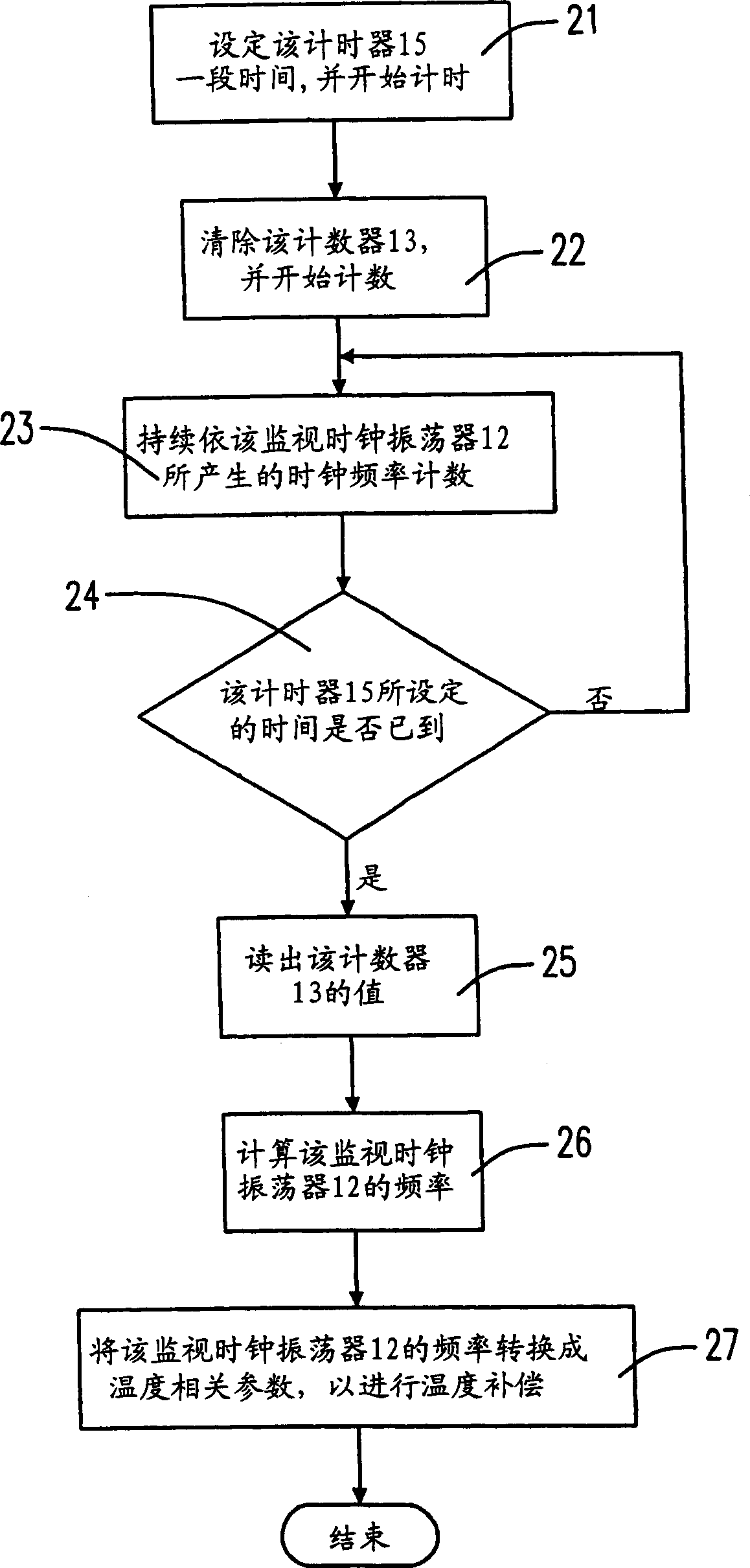

Temp. compensating circuit and method

InactiveCN1825065ATo achieve the function of temperature compensationMitigation of undesired influencesWeighing temperature-compensating arrangementsElectricityVoltage regulation

The invention relates to a temperature compensation circuit and the method. The temperature compensation circuit includes a first oscillator to supply a first impulse signal, a timer electrically connecting to the first oscillator, a voltage regulator to generate a fixed voltage, a second oscillator electrically connecting to the voltage regulator, and a counter that electrically connects to the first oscillator to gain a counting value and the frequency of the second oscillator to take temperature compensation.

Owner:HOLTEK SEMICON

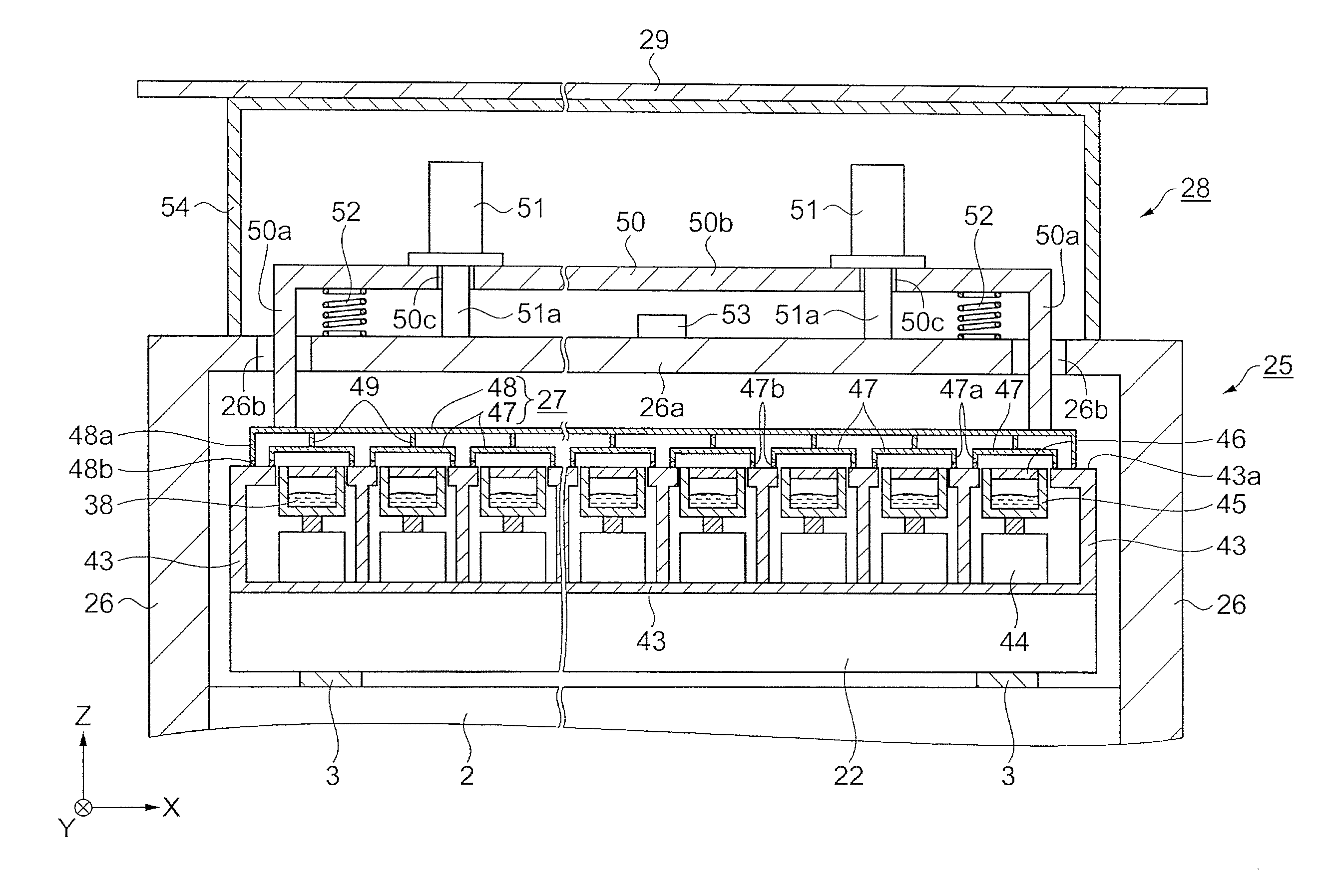

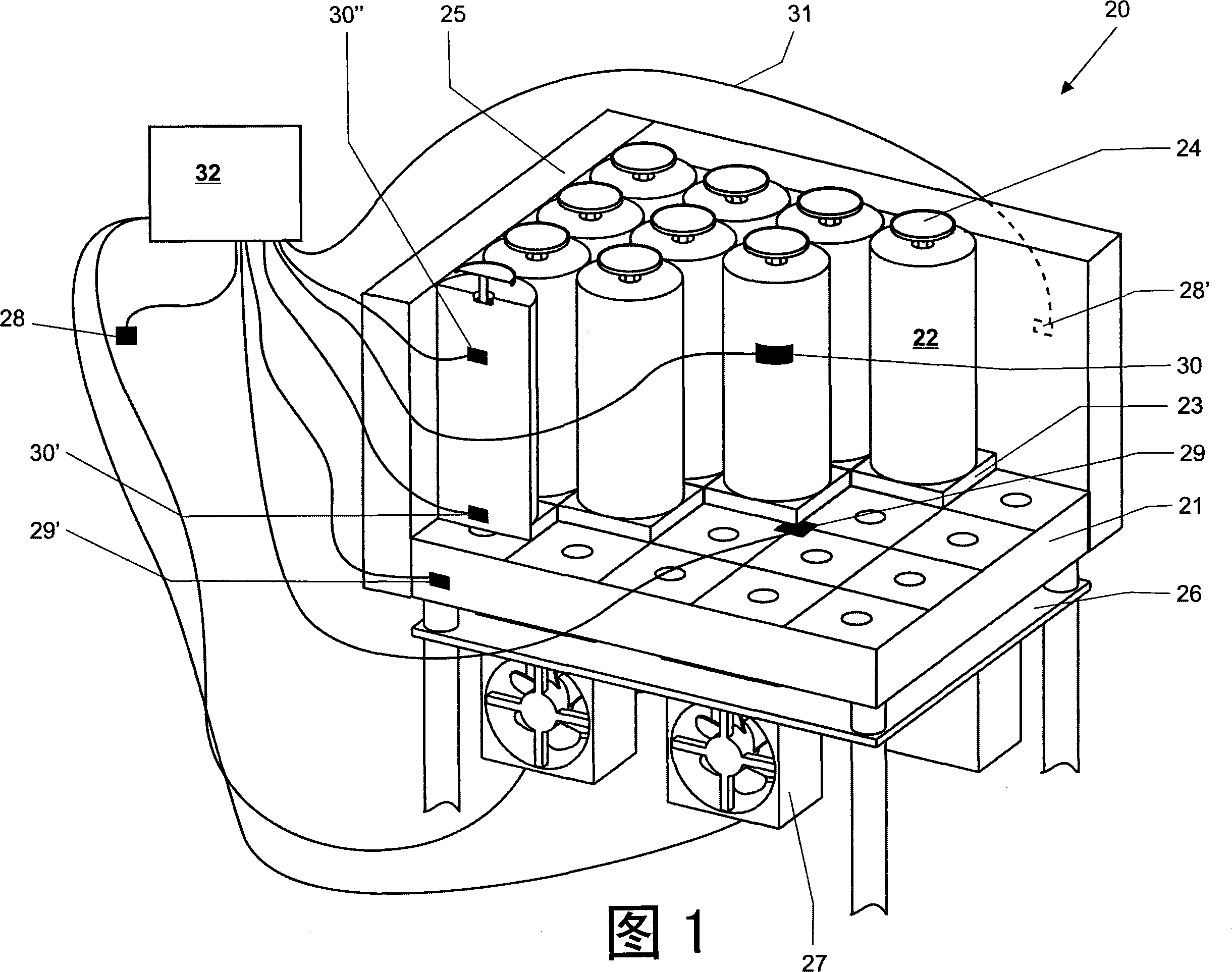

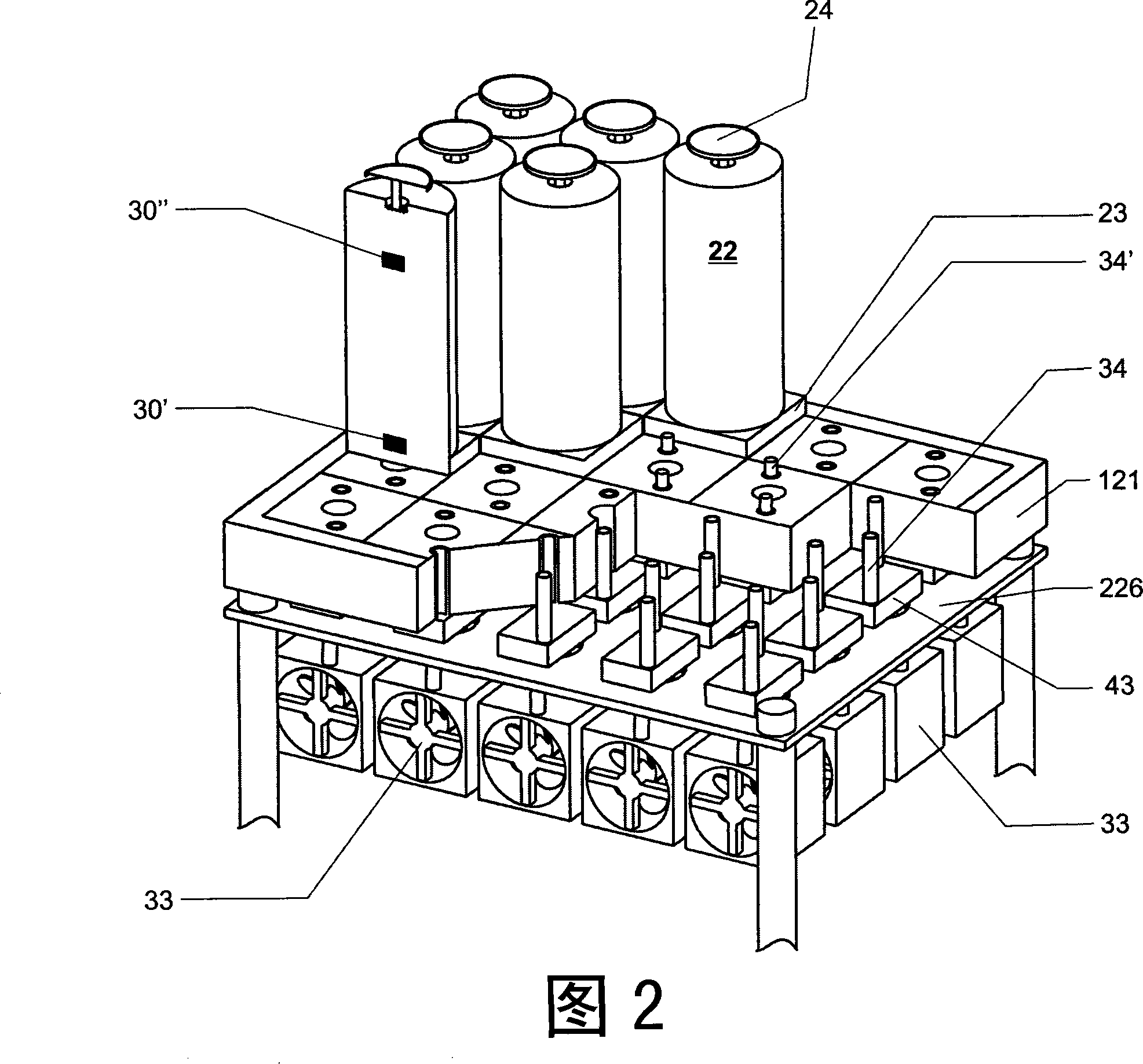

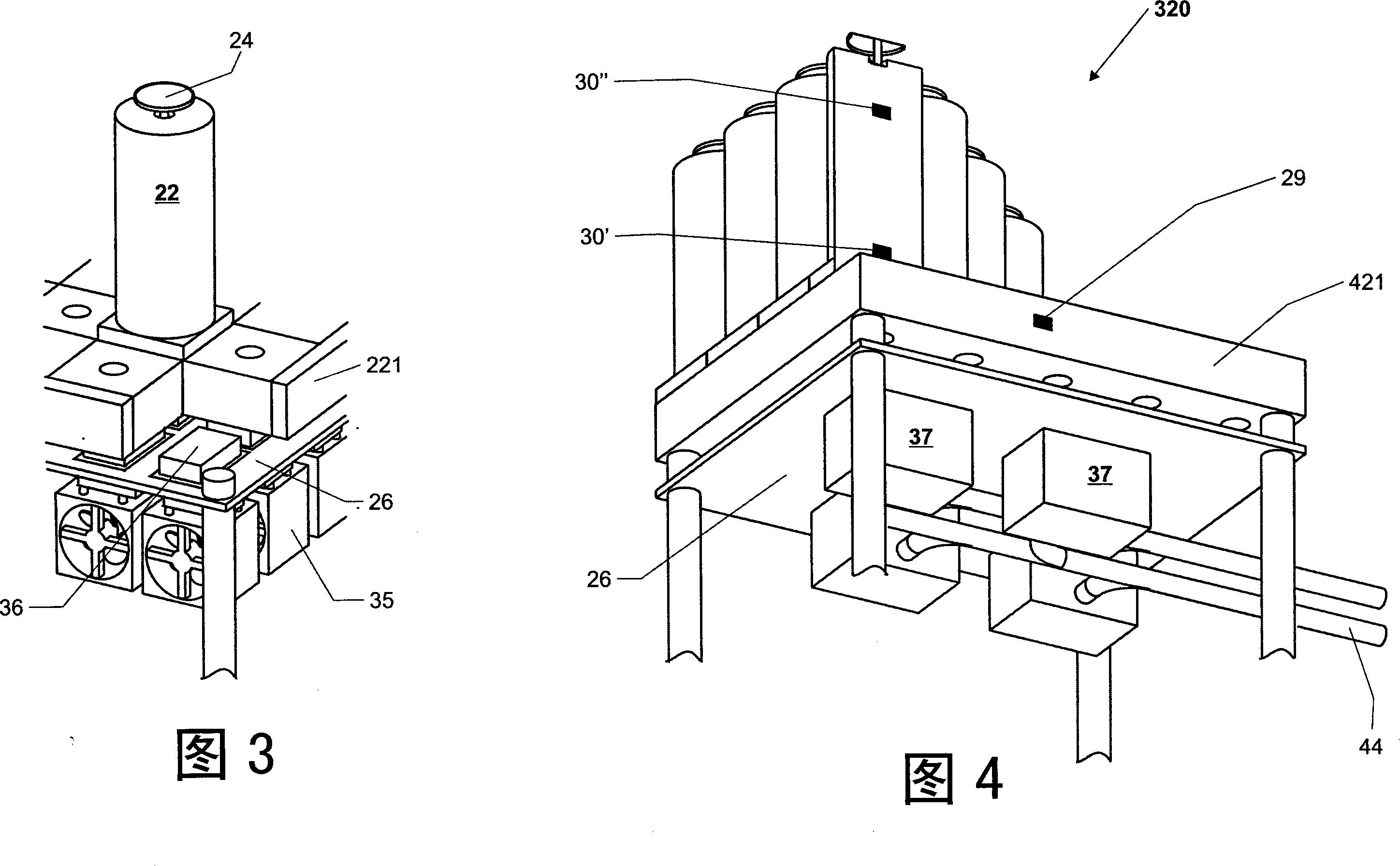

Multi-module weighing system with temperature control

InactiveCN101187584AWeighing temperature-compensating arrangementsTemperature controlElectrical and Electronics engineering

Multi-module weighing system with a holding structure(21) serving to receive a plurality of weighing modules(22) which are rigidly connected to each other in a given spatial arrangement and are operable independently of each other, wherein each weighing module(22) comprises at least one load receiver(5), wherein the multi-module weighing system is connected to a temperature control device which is in thermal connection with each of the weighing modules(22).

Owner:METTLER TOLEDO INC

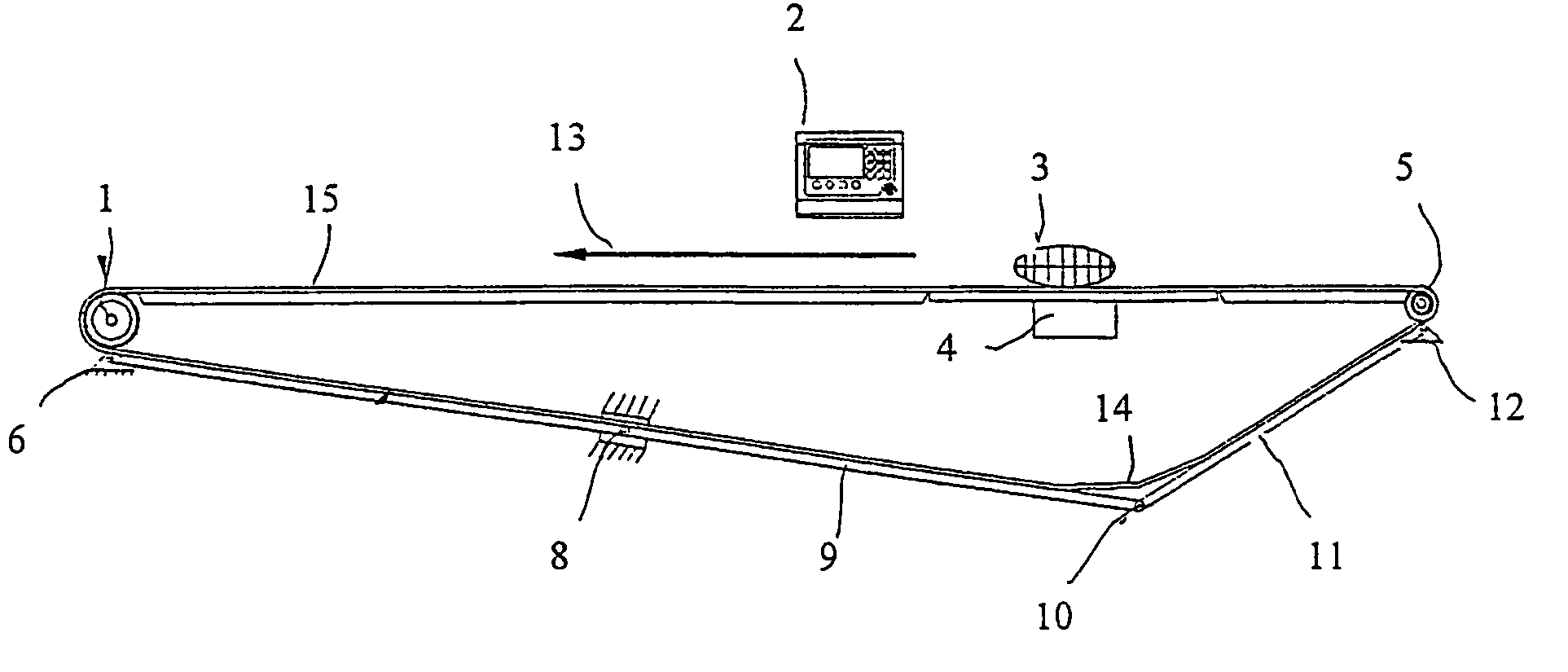

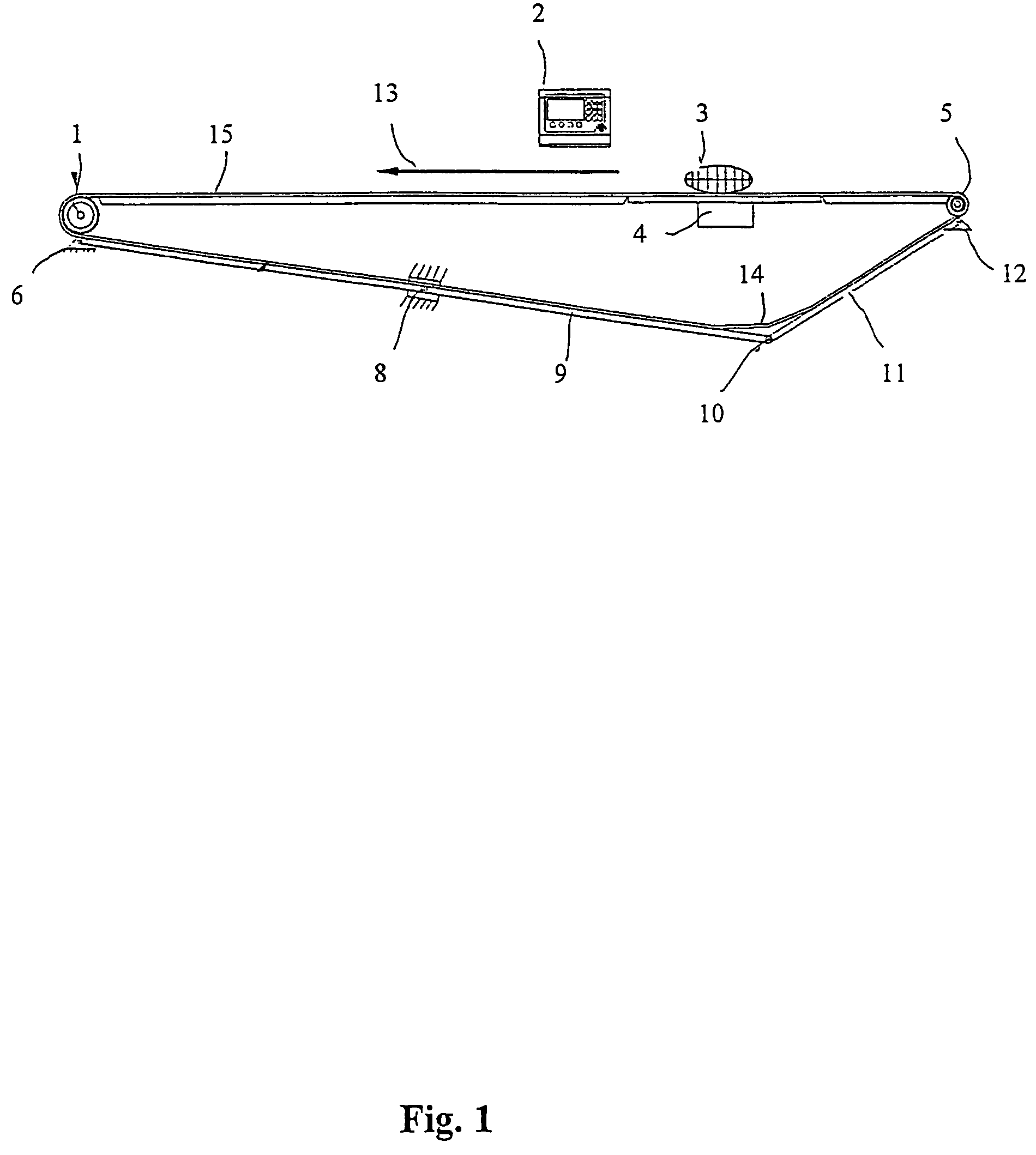

Apparatus and method for controlling the belt tension of a belt weigher

A belt weighing apparatus for maintaining high accuracy in weighing by way of maintaining a fixed tension in the belt and preventing the belt from oscillating. The belt conveyor is comprised of a supporting frame, an upper guiding unit arranged on the supporting frame, a first and a second end-supporting device arranged on the supporting frame in proximity to the opposite ends of the upper guiding unit, a motor unit, at least one weighing platform arranged in-between the first and a second end-supporting devices, a lower guiding unit having a first property arranged on the supporting frame, and an endless conveyor belt having a second property is extended between said first and a second end supporting devices. At any instant of time an upper part of the belt rests on the upper guiding unit and the weighing platform defining a conveying pad of the belt weighing apparatus, and the lower part of the belt defining the return way of the belt weighing apparatus rests partly on the lower guiding unit that acts as a support for part of the lower run while another part of the belt hangs freely. The accuracy in the weighing is maximized by matching the first and the second properties such that any heat expansion or contraction of the belt will be compensated at least partly through expansion or contraction of the lower guiding unit.

Owner:MAREL HF

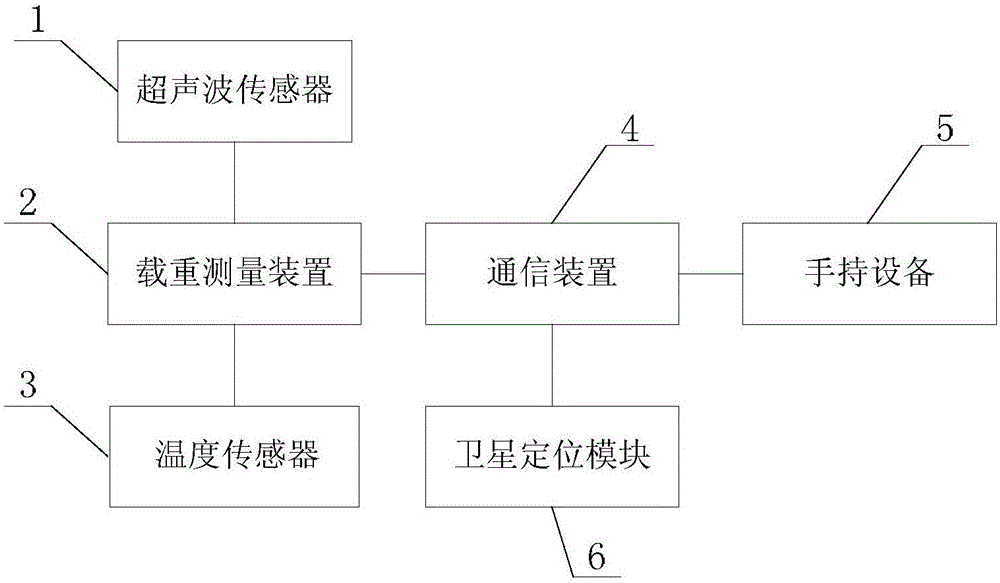

Multi-function vehicle-mounted overload monitoring system

InactiveCN106644008AKnow the loadServe as a reminderWeighing temperature-compensating arrangementsSpecial purpose weighing apparatusMeasurement deviceUltrasonic sensor

The invention provides a multi-function vehicle-mounted overload monitoring system. The system comprises at least one ultrasonic sensor, a temperature sensor, a load-carrying measurement apparatus, a communication apparatus and hand-held equipment. The temperature sensor, the load-carrying measurement apparatus and the communication apparatus are fixed to one vehicle body. The ultrasonic sensor is fixed to one suspension frame of the vehicle body. The ultrasonic sensor and the temperature sensor are connected to the load-carrying measurement apparatus in a communication connection mode respectively. The load-carrying measurement apparatus is connected to the hand-held equipment and a monitoring center in the communication connection mode through the communication apparatus. By using the multi-function vehicle-mounted overload monitoring system, any structure components of a vehicle do not need to be changed, and the system possesses advantages that reliability is high; stability is good; cost is low; and dynamic real-time monitoring of the vehicle can be realized.

Owner:SHANGHAI DIANJI UNIV

Digital module with temperature compensating function and temperature compensating method thereof

ActiveCN102353439AOvercoming random errorsHigh precisionWeighing temperature-compensating arrangementsMicrocontrollerMicrocomputer

The invention discloses a temperature compensating method of a digital module with a temperature compensating function. The digital module comprises a one-chip microcomputer interface circuit, and a temperature measurement and reference voltage circuit connecting with the one-chip microcomputer interface circuit. An interface of the temperature measurement and reference voltage circuit is in external connection with a digital temperature sensor. The temperature compensating method includes a zero temperature compensating method and a sensitivity temperature compensating method, and is characterized in that the zero compensation adopts a point-slope form formula: AD compensation dosage=K(TX-T Fsign)+AD Z; the sensitivity compensation adopts the formula: N<output>=N<actual measurement>-((N<actual measurement>-N<datum point>)*K<per Kg>+K<datum point>*(T<actual measurement>-T<datum point>).

Owner:KELI SENSING TECH NINGBO CO LTD

Weight measurement device, droplet discharge device, and weight measurement method

InactiveUS20090008159A1Accurate weighingAvoid measuringBurettes/pipettesMaterial check-weighingMeasurement deviceTransverse plane

A weight measurement device is configured and arranged to measure the weight of a measurement object. the weight measurement device includes a container and a wind-guard cover. The container is configured and arranged to receive the measurement object therein. The wind-guard cover is configured and arranged to selectively cover an upper space of the container. The wind-guard cover has a transverse air-blocking part configured and arranged to block an air flow flowing in a transverse direction with respect to the container.

Owner:KATEEVA

Semiconductor wafer processing methods and apparatus

ActiveUS20170005019A1Increase temperatureClosely matchedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTemperature controlProcess region

A semiconductor wafer processing method comprising controlling the temperature of a semiconductor wafer to be within a predetermined processing temperature range by: causing a first temperature change of the semiconductor wafer using a first temperature changing unit; and subsequently causing a second temperature change using a second temperature changing unit; wherein the first change is greater than the second change; and subsequently loading the semiconductor wafer on a processing area of a semiconductor wafer processing apparatus. Also, a semiconductor wafer processing method comprising controlling the temperature of a semiconductor wafer to be within a predetermined processing temperature range by causing a temperature change of the semiconductor wafer using a temperature changing unit; transporting the semiconductor wafer from the temperature changing unit to a processing area of a semiconductor wafer processing apparatus; and controlling the temperature of the semiconductor wafer during the transporting step.

Owner:METRYX

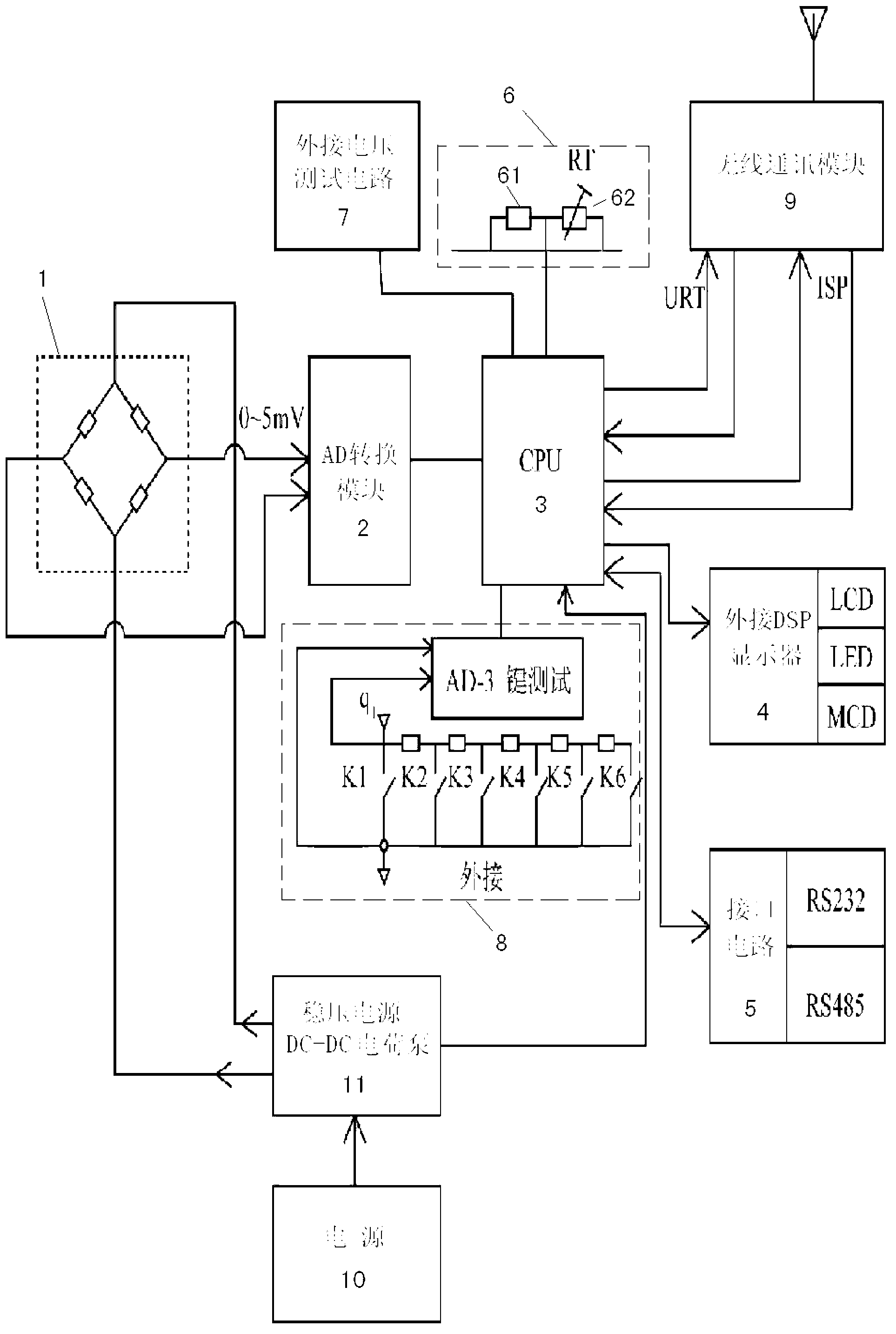

Remote-control digital weighing machine with temperature compensation function and temperature compensation method for remote-control digital weighing machine

InactiveCN103234617AImprove pass rateAvoid electromagnetic interferenceWeighing temperature-compensating arrangementsDigital signal processingDisplay device

The invention relates to a remote-control digital weighing machine with a temperature compensation function and a temperature compensation method for the remote-control digital weighing machine. The remote-control digital weighing machine comprises a weighing sensor, an AD (analog and digital) conversion module, a CPU (central processing unit), an external DSP (digital signal processing) display, an interface circuit, a temperature compensation circuit, an external voltage testing circuit, a keyboard circuit, a wireless communication module, a power supply and a DC-DC charge pump of a stabilized voltage supply; an equal-arm bridge of the weighing sensor comprises four resistance strain gauges, and various components are powered by the power supply and the DC-DC charge pump of the stabilized voltage supply; after force signals detected by the weighing sensor are converted into analog electric signals, the analog electric signals are inputted into the AD conversion module and are converted into digital signals, and the digital signals are inputted into the CPU to be processed, so that a weight value of a measured object is obtained; output ends of the CPU are respectively connected with the external DSP display and the interface circuit, an input end of the CPU is connected with the temperature compensation circuit, and another output end of the CPU is connected with the wireless communication module; the power supply outputs two power supply channels via the DC-DC charge pump of the stabilized voltage supply, and the AD conversion module and the CPU are respectively powered by the two power supply channels. The remote-control digital weighing machine and the temperature compensation method can be applied to different service places.

Owner:唐令弟

Popular searches

Weighing apparatus for materials with special property/form Weighing by absorbing component Moisture content investigation using microwaves Weighing apparatus using fluid action balancing Fluid pressure measurement by mechanical elements Tension measurement Hydraulic/pneumatic force measurement Material analysis using microwave means Material analysis by optical means Specific gravity measurement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com