Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250results about "Weighing apparatus using electromagnetic balancing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

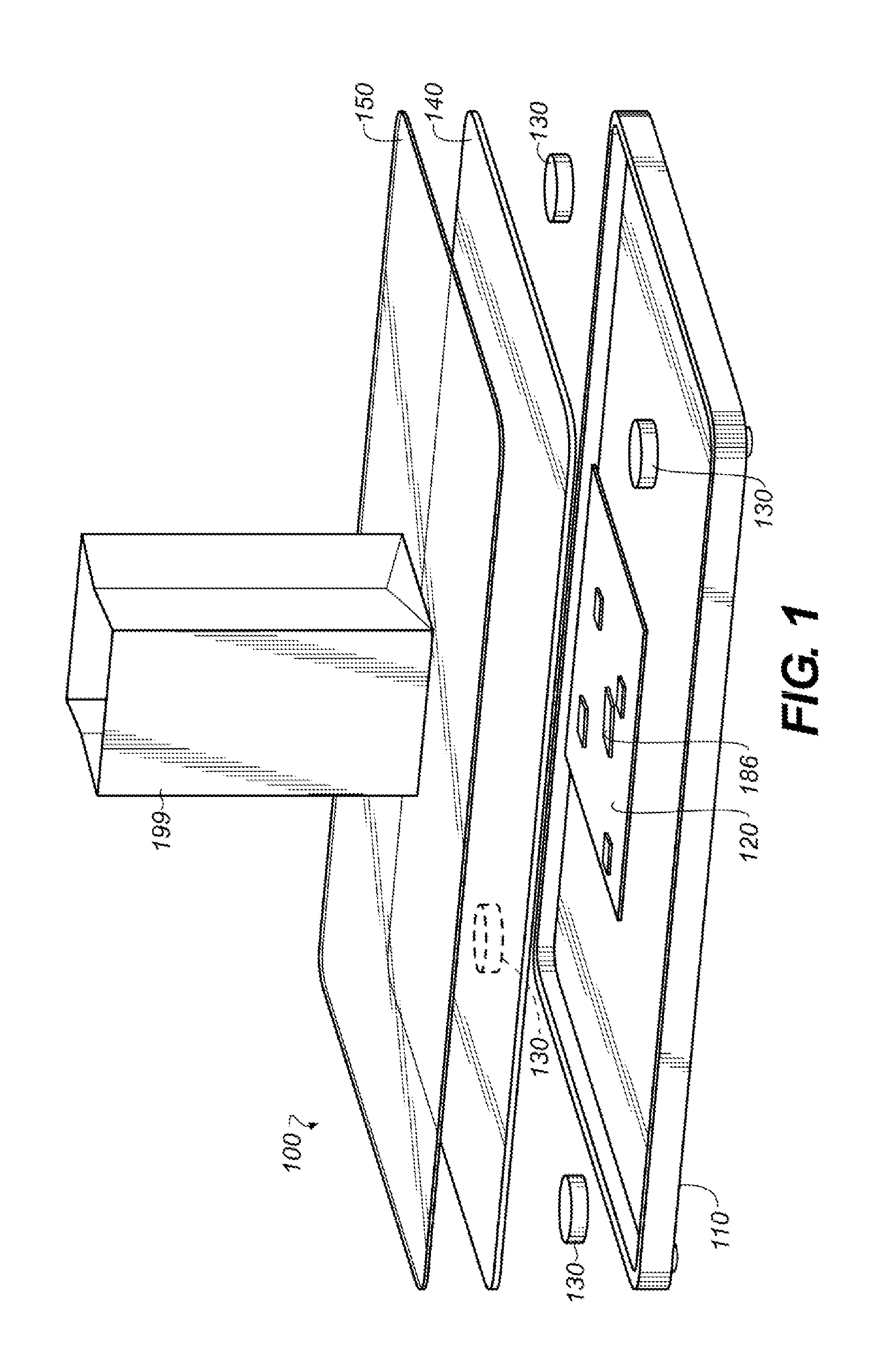

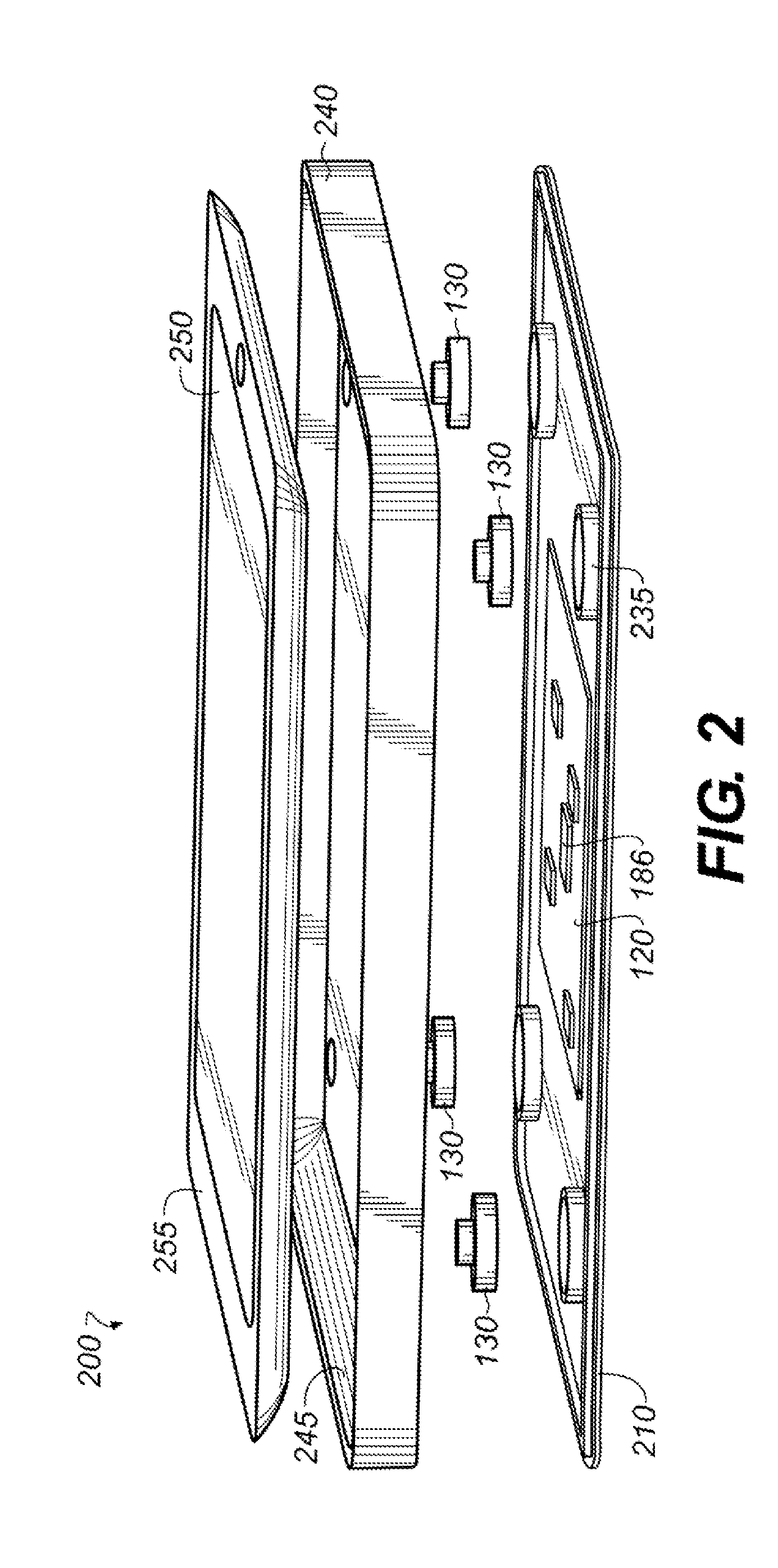

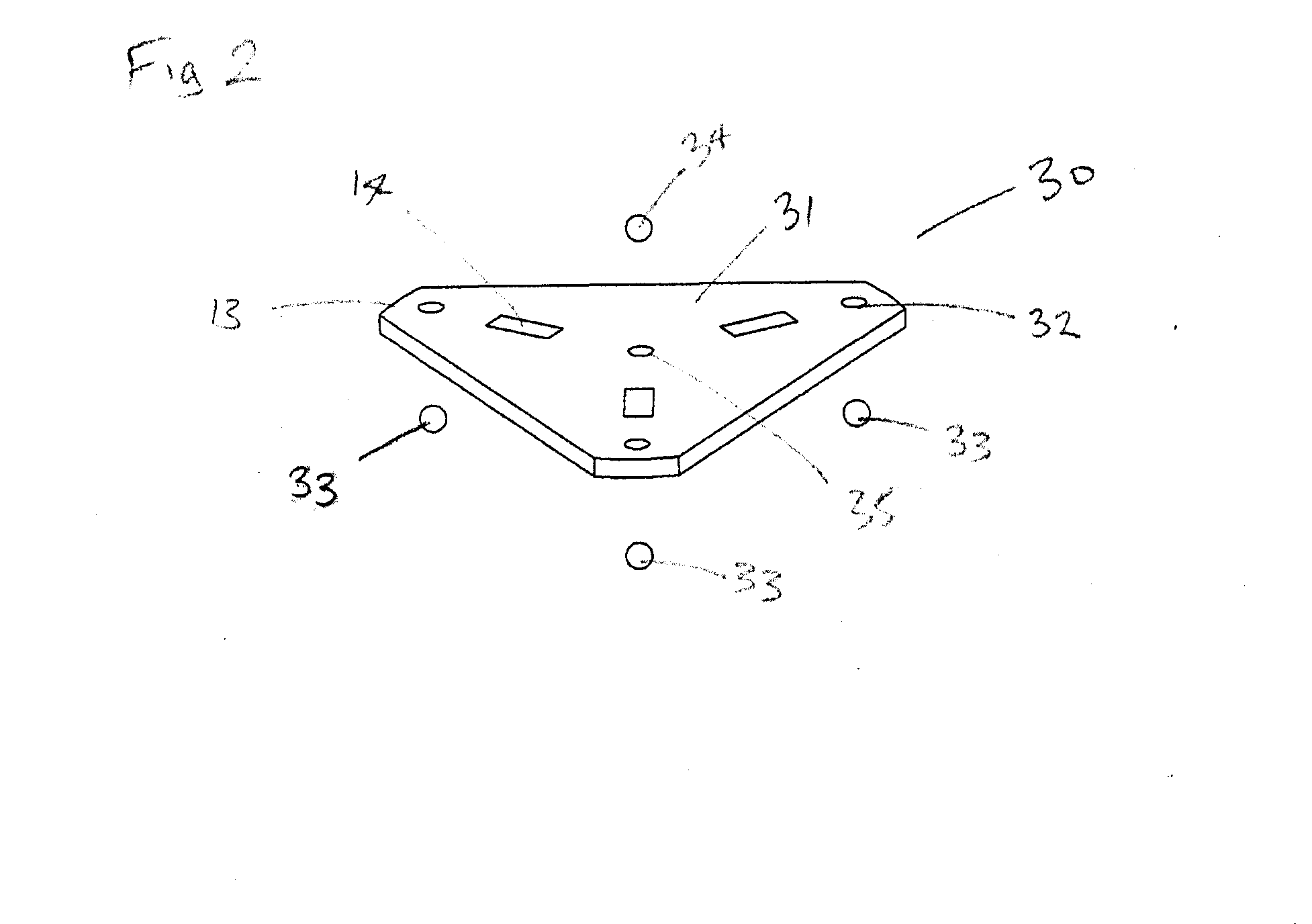

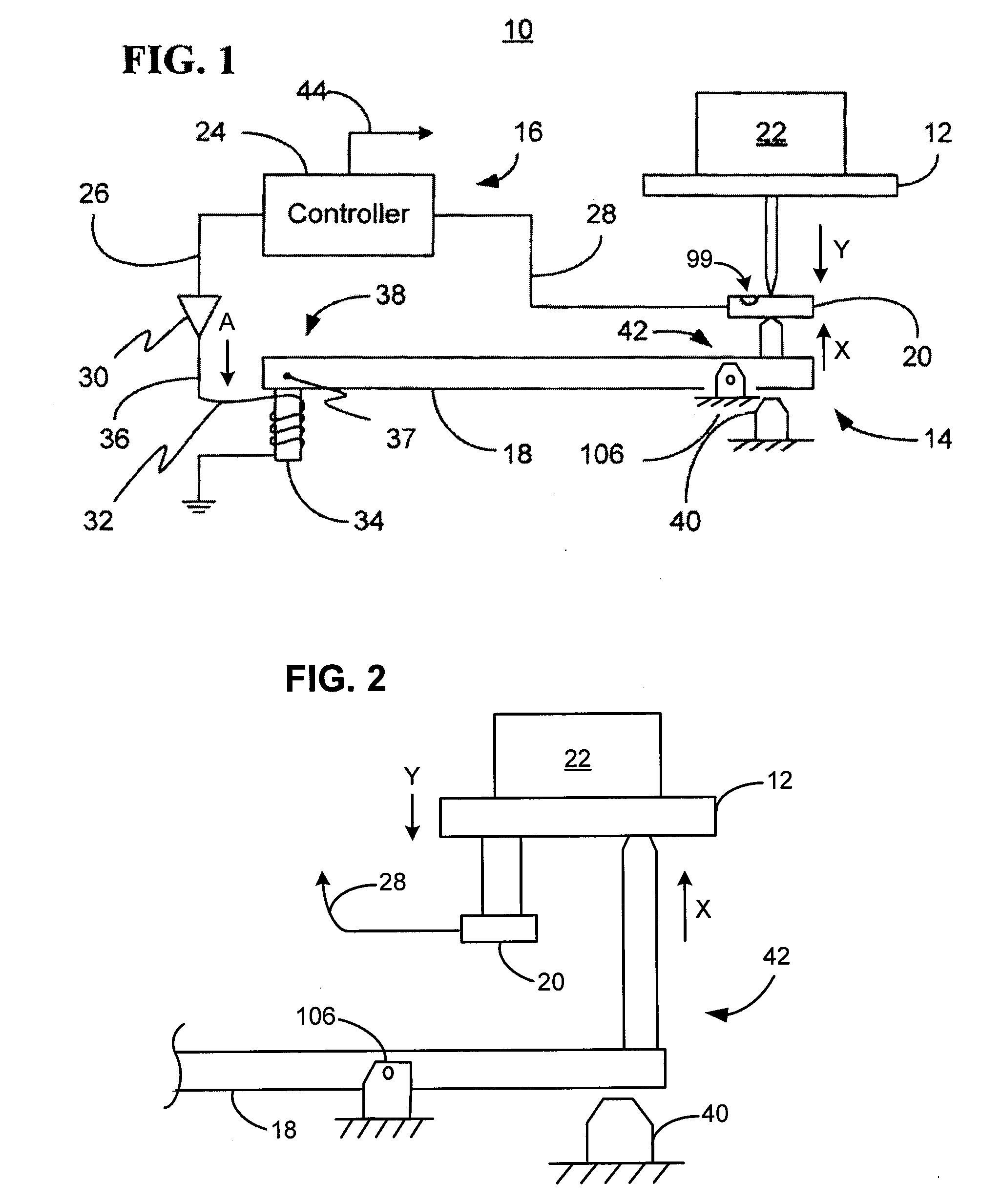

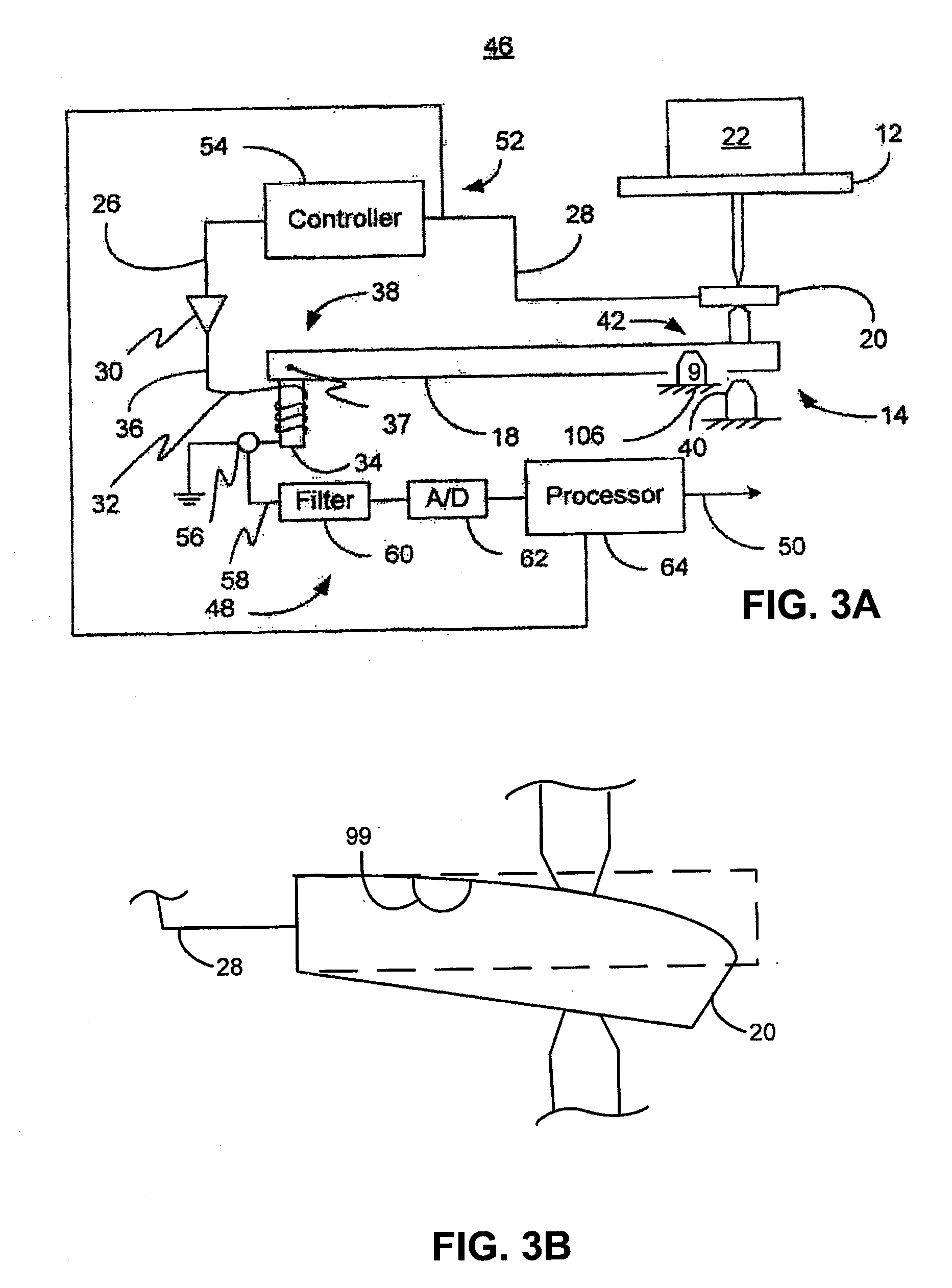

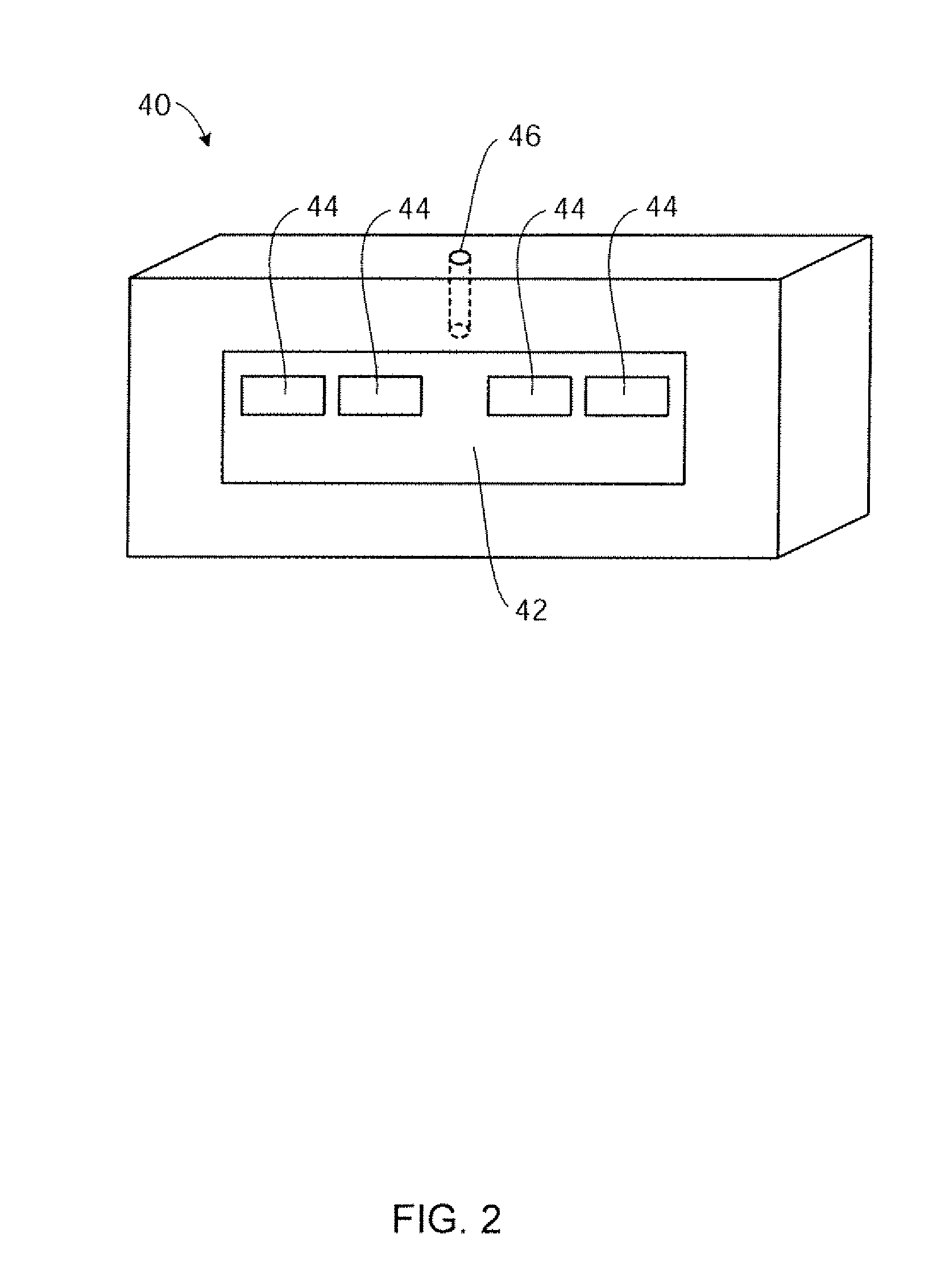

Devices, systems and methods to determine area sensor

ActiveUS20150168205A1Improve accuracyWeighing apparatus using elastically-deformable membersForce measurementTransducerEngineering

A weighing scale includes a platform supporting a load. Force transducers beneath the platform output respective transducer force signals of the load. An area sensor above the platform outputs area force signals of load forces applied to respective spatial areas of the platform. A processor is configured to determine the load's weight and location on the platform based on the transducer force signals and the area force signals. A method of weighing the load is also described. A method of monitoring the load includes measuring first transducer force signal(s) and first area force signal(s) of the load, and then repeatedly measuring second force signal(s) of the load using the transducer(s) or area sensor until the first and second signal(s) indicate a change in a weight or location of the load. A changed weight or changed location of the load is then determined using the measured second force signal(s).

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

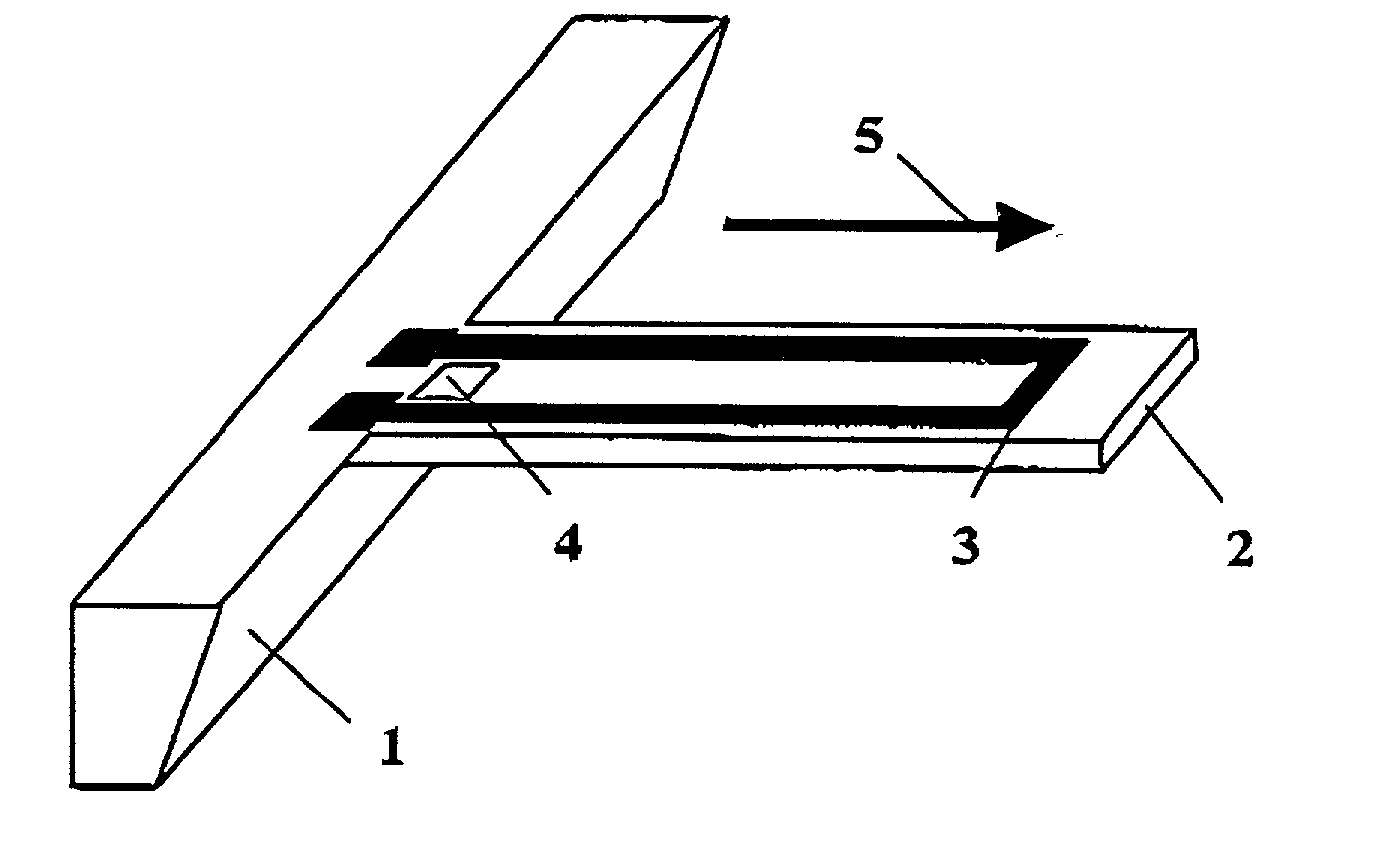

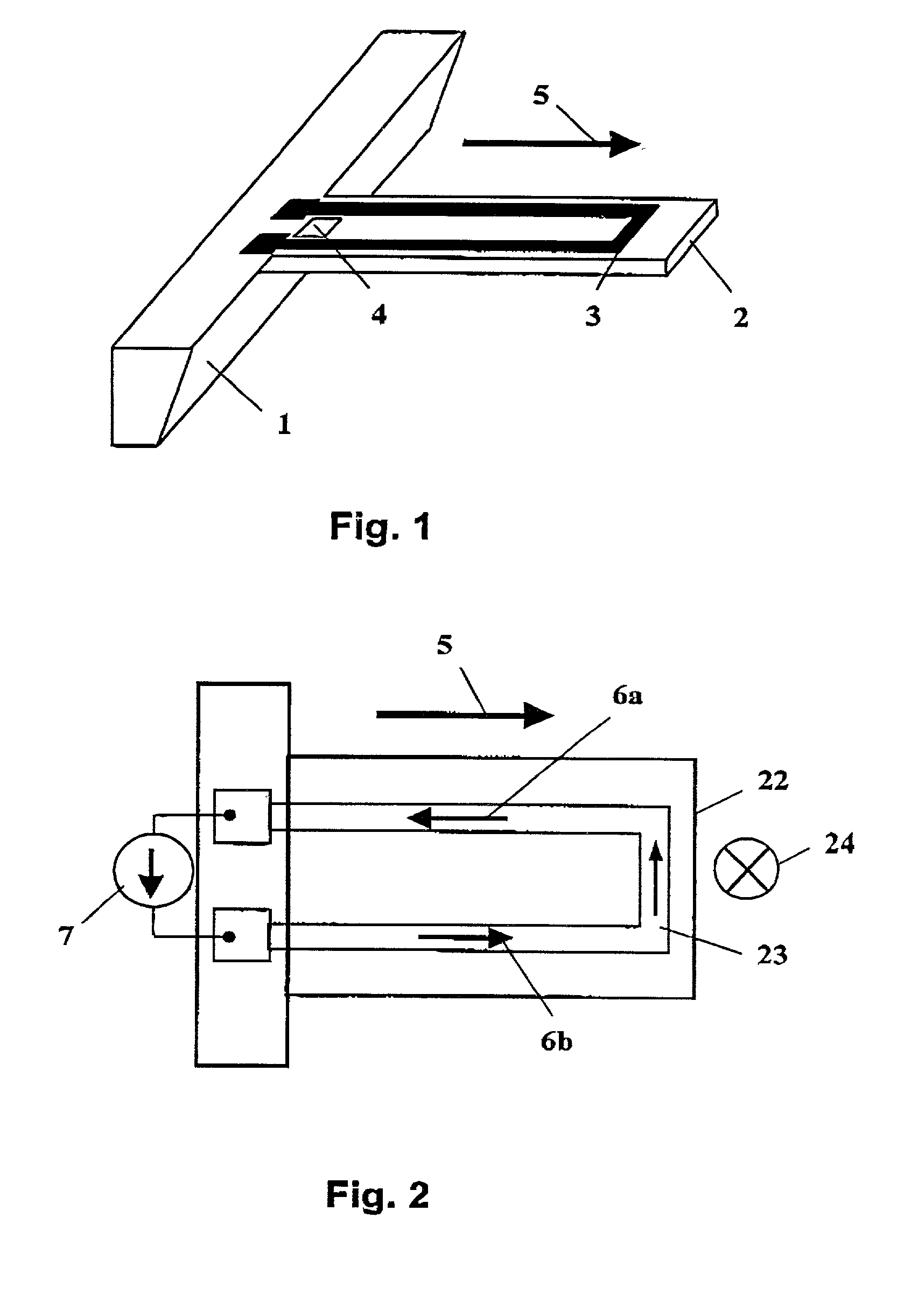

Sensor apparatus and cantilever for it

InactiveUS20020092359A1Highly sensitive chemicalEasy to adaptNanotechForce measurementSelective excitationCondensed matter physics

A magnetically excited, resonant cantilever sensor apparatus has a cantilever as the transducer element. A static magnetic field is directed in the plane of the cantilever(s) cooperating with a current loop in / on the latter. Orienting the magnetic field along or perpendicular to the cantilever axis and controlling the current apprpriately allows for selective excitation of resonance or non-resonance modes and / or in a self-oscillation mode. The deflection of the cantilever is detected using piezoresistive or magnetic readout. The apparatus may be used as gas sensor, scanning force microscope, mechanical filter, temperature sensor or the like.

Owner:SWISS FEDERAL INST OF TECH ZURICH

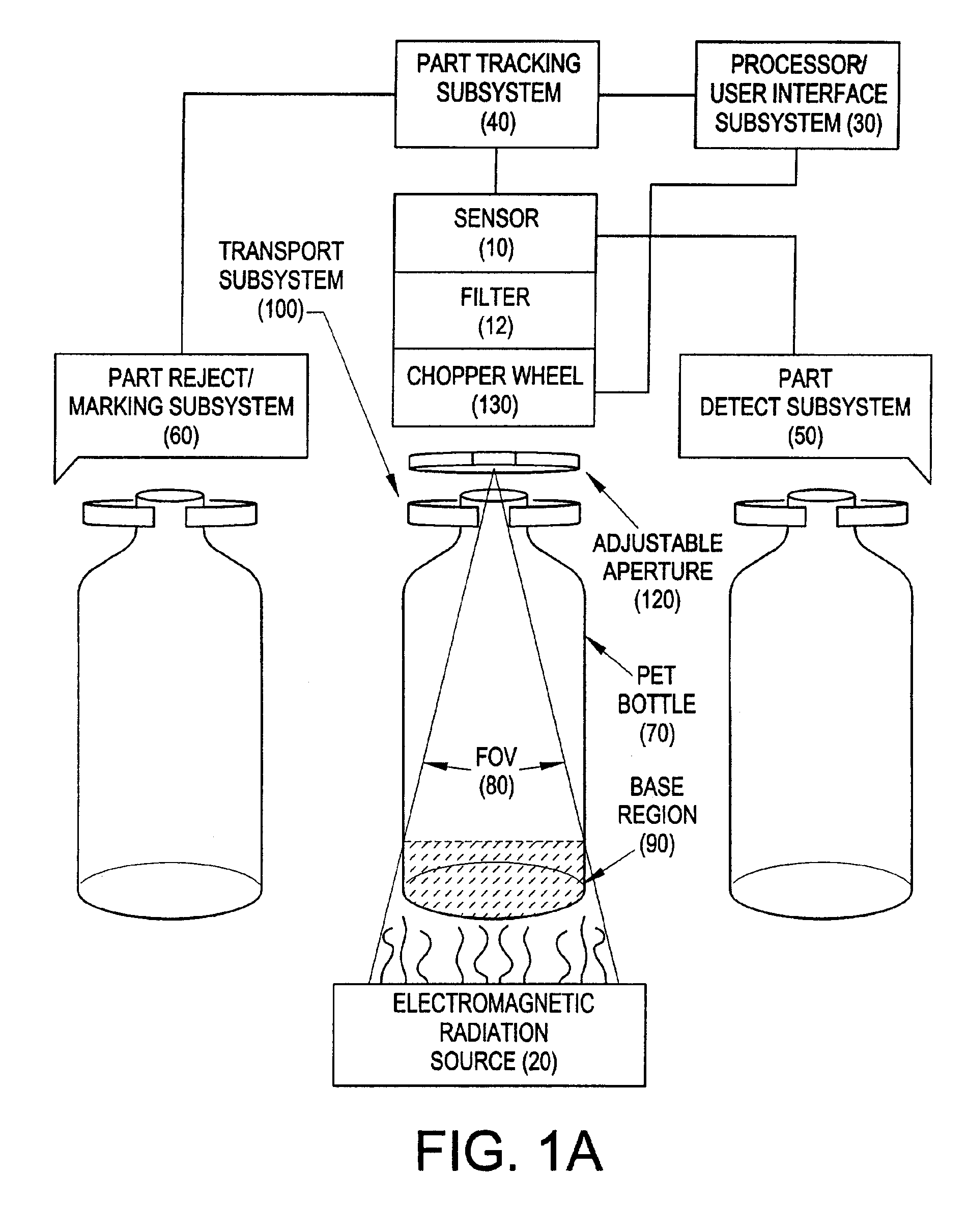

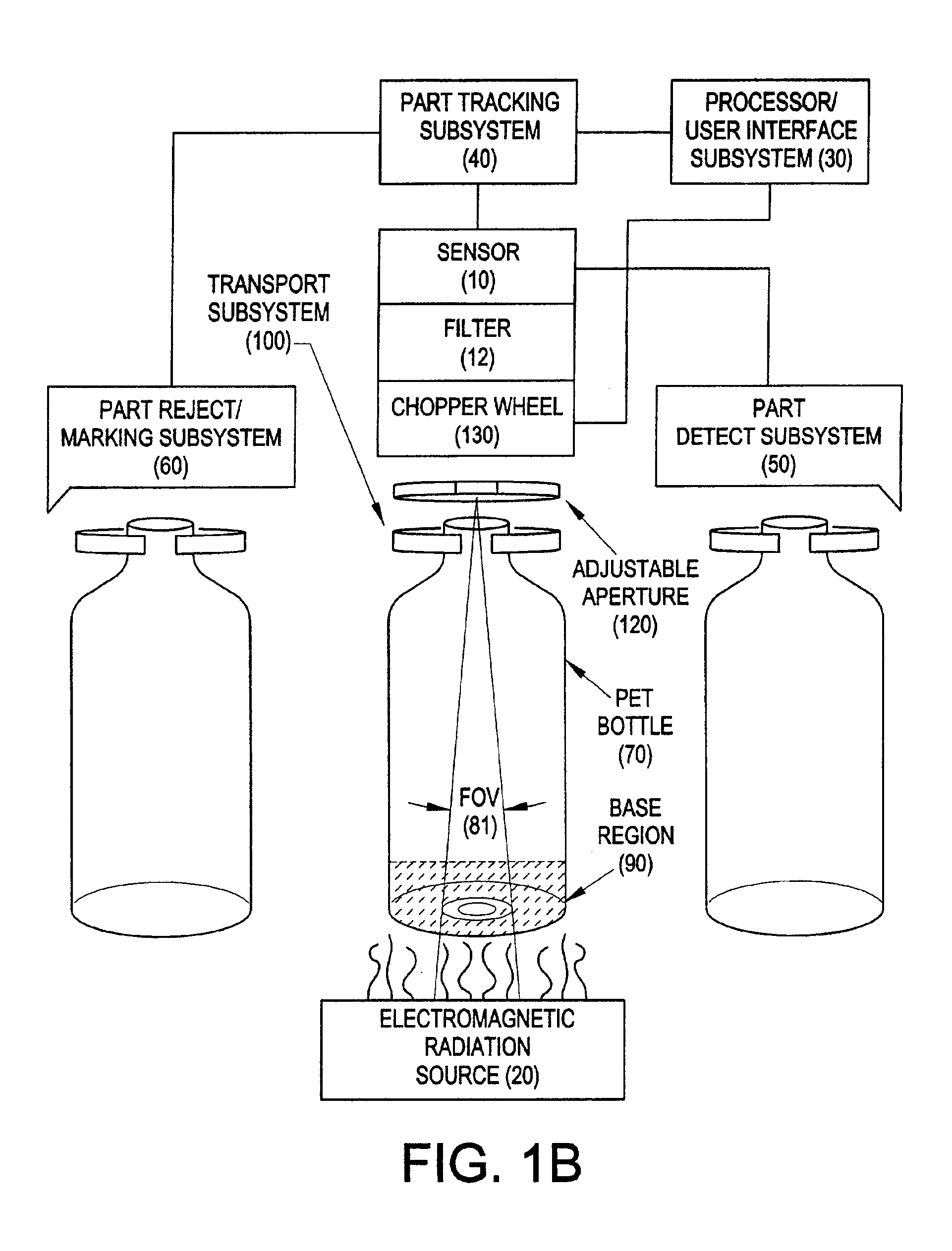

Apparatus and method for providing spatially-selective on-line mass or volume measurements of manufactured articles

InactiveUS6872895B2Material analysis by optical meansMaterial check-weighingVolume measurementsQuality control

This invention relates to a method and apparatus for mass and / or volume measurements of manufactured articles. More particularly, this invention relates to a method and apparatus for mass and / or volume measurements that can be performed on-line in a part manufacturing process. On-line measurement of the mass or volume of material contained in a specific region of interest of the manufactured items is performed 100% on-line. Real-time process control information is based on real-time measurement of the mass or volume of material contained in a specific region of interest of a manufactured item. Automated quality control inspection for manufactured articles is based on real-time measurement of the mass or volume of material contained in a specific region of interest of manufactured items. A manufacturing closed-loop process is directly corrected to keep it within control limits based on real-time measurement of the mass or volume of material contained in a specific region of interest of manufactured items soon after these items are manufactured.

Owner:PRESSCO TECH INC

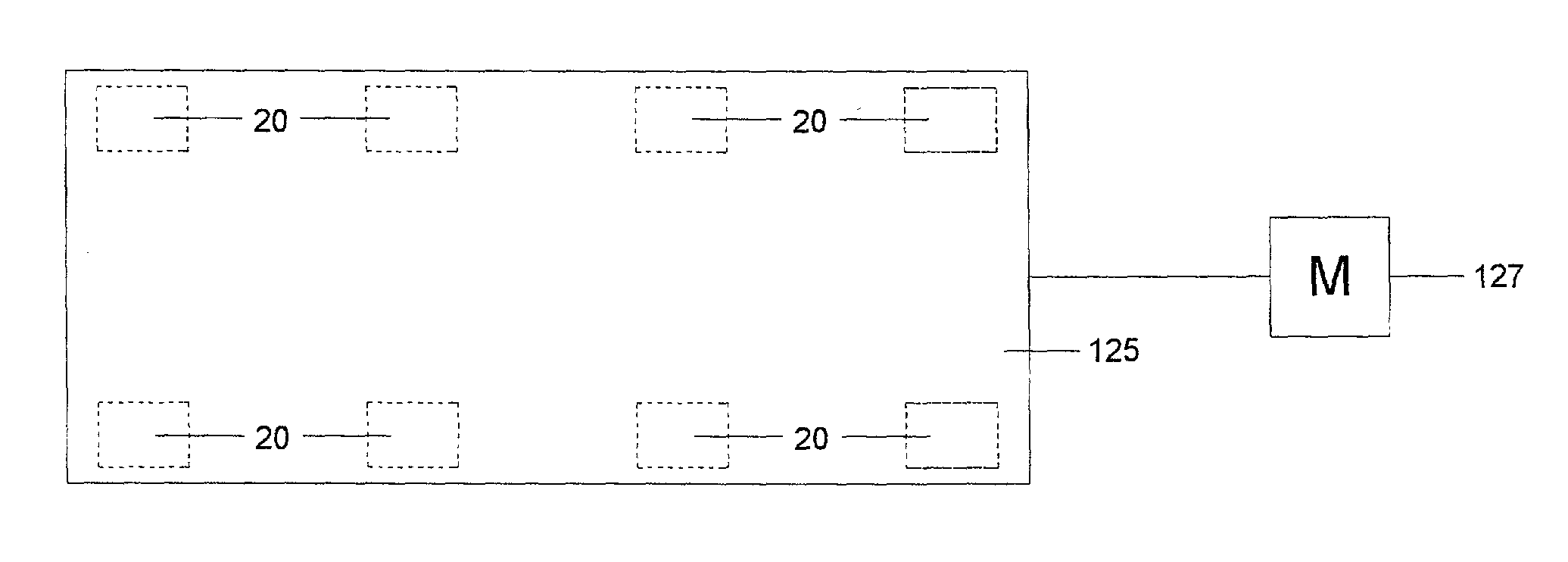

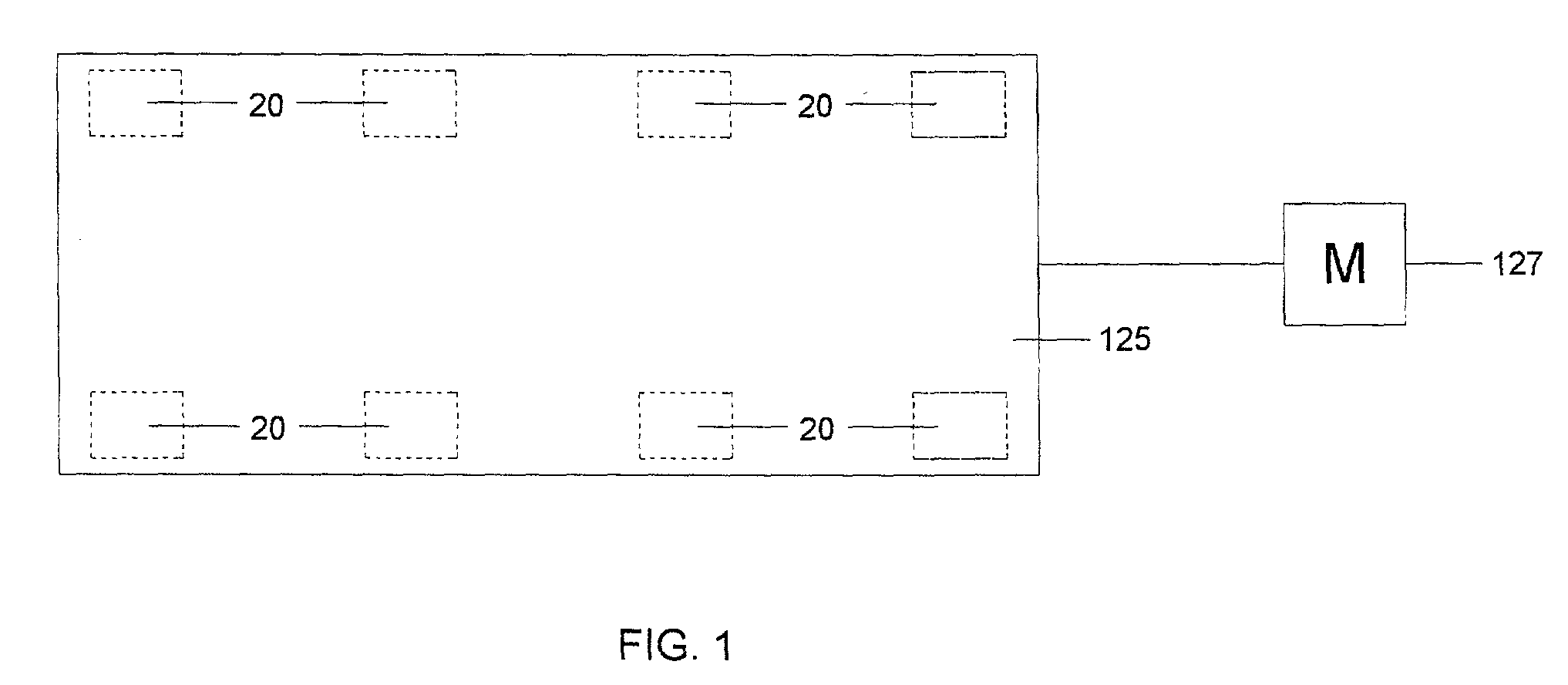

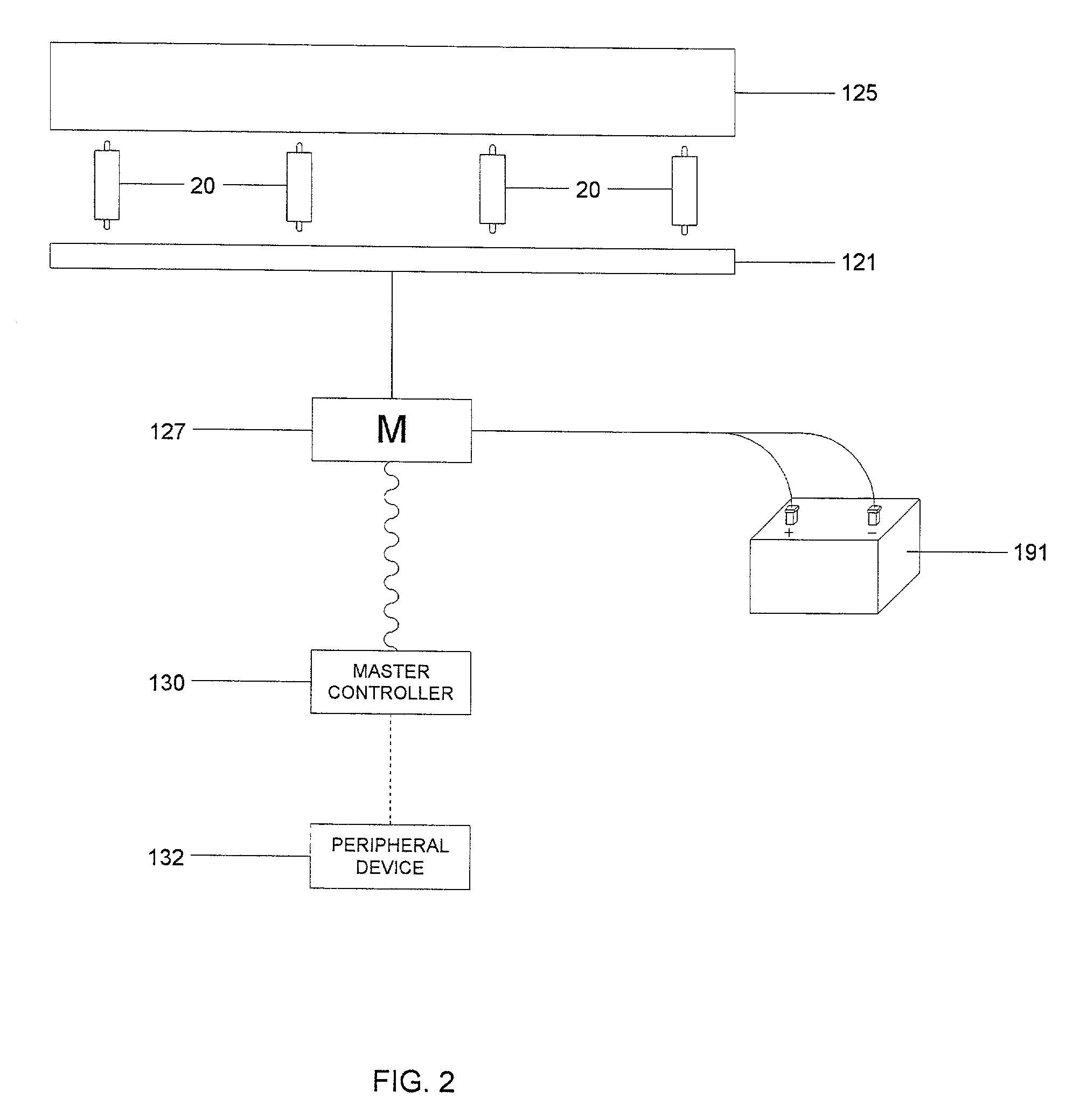

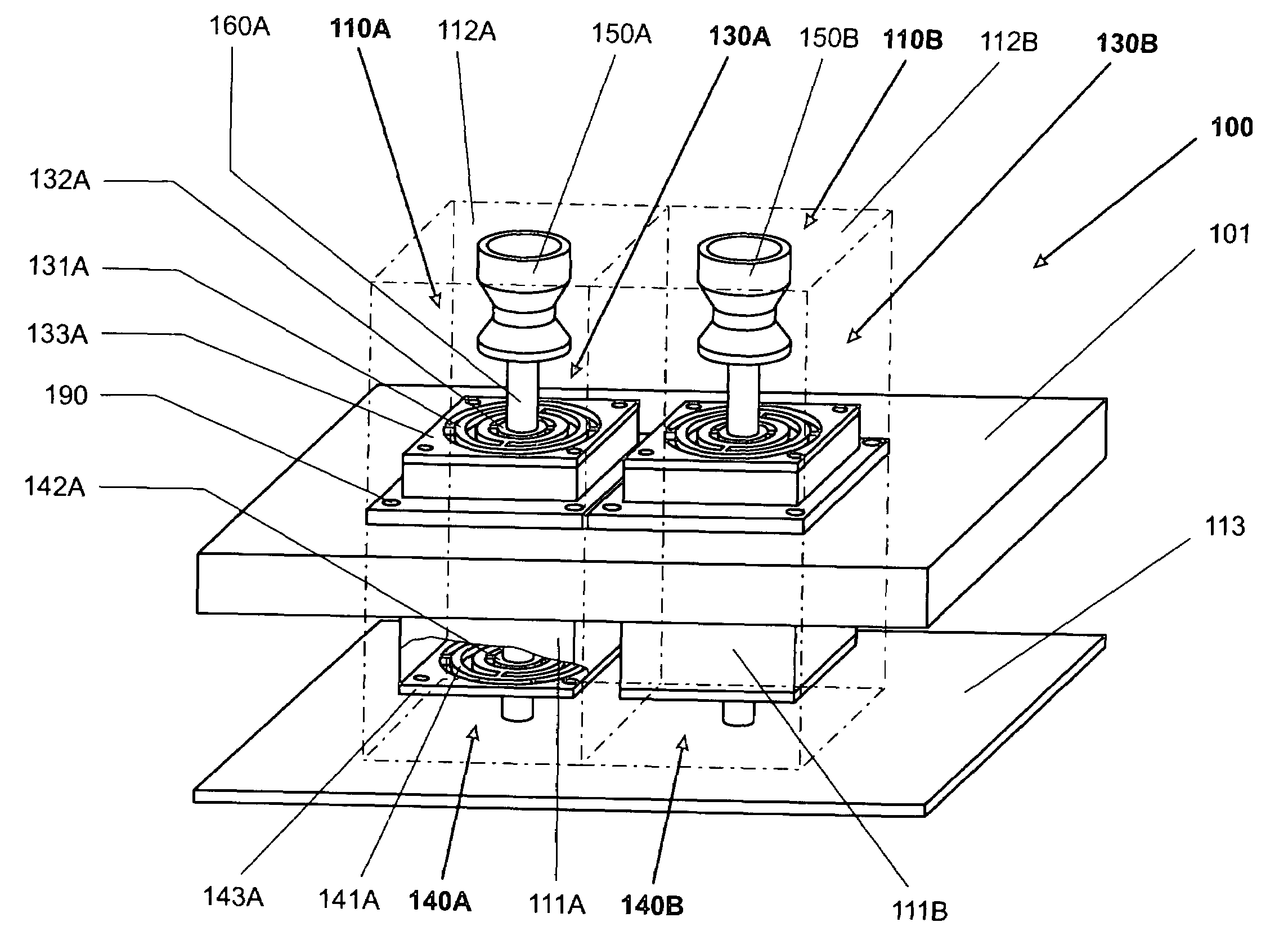

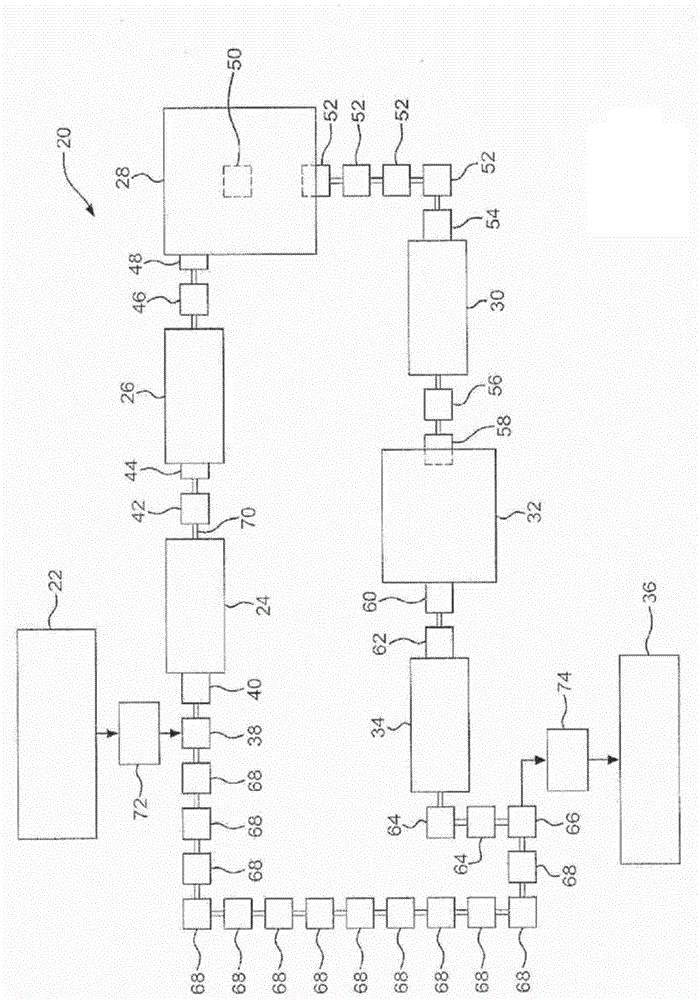

RF multiple load cell scale

InactiveUS20040026135A1Eliminate needEnergy efficient ICTWeighing apparatus using elastically-deformable membersMicrocomputerTransceiver

Load cells forming one or more weighing scales are connected to each other and to a common concentrator which communicates to a master controller in the control house via RF wireless communication. The load cells are polled by and provide weight reading to concentrator to the master controller. A digital load cell is used which includes a rocker pin, guided beam, torsion ring or other counterforce, a circuit board mounted on the counterforce and an enclosure sealing the circuit board and all but the load bearing surfaces of the counterforce and a mounded antenna. The circuit board includes a microcomputer and a transceiver. RF communication is provided with the circuit board through a antenna mounted on the enclosure. One or a number of load cells may be connected to a computer or controller to form one or more weighing scales with one or more weighing scales connect to a control house through wireless RF communication. The preferred embodiment uses passive receivers for receiving the signals and waveguide to minimize power requirements.

Owner:METTLER TOLEDO INC

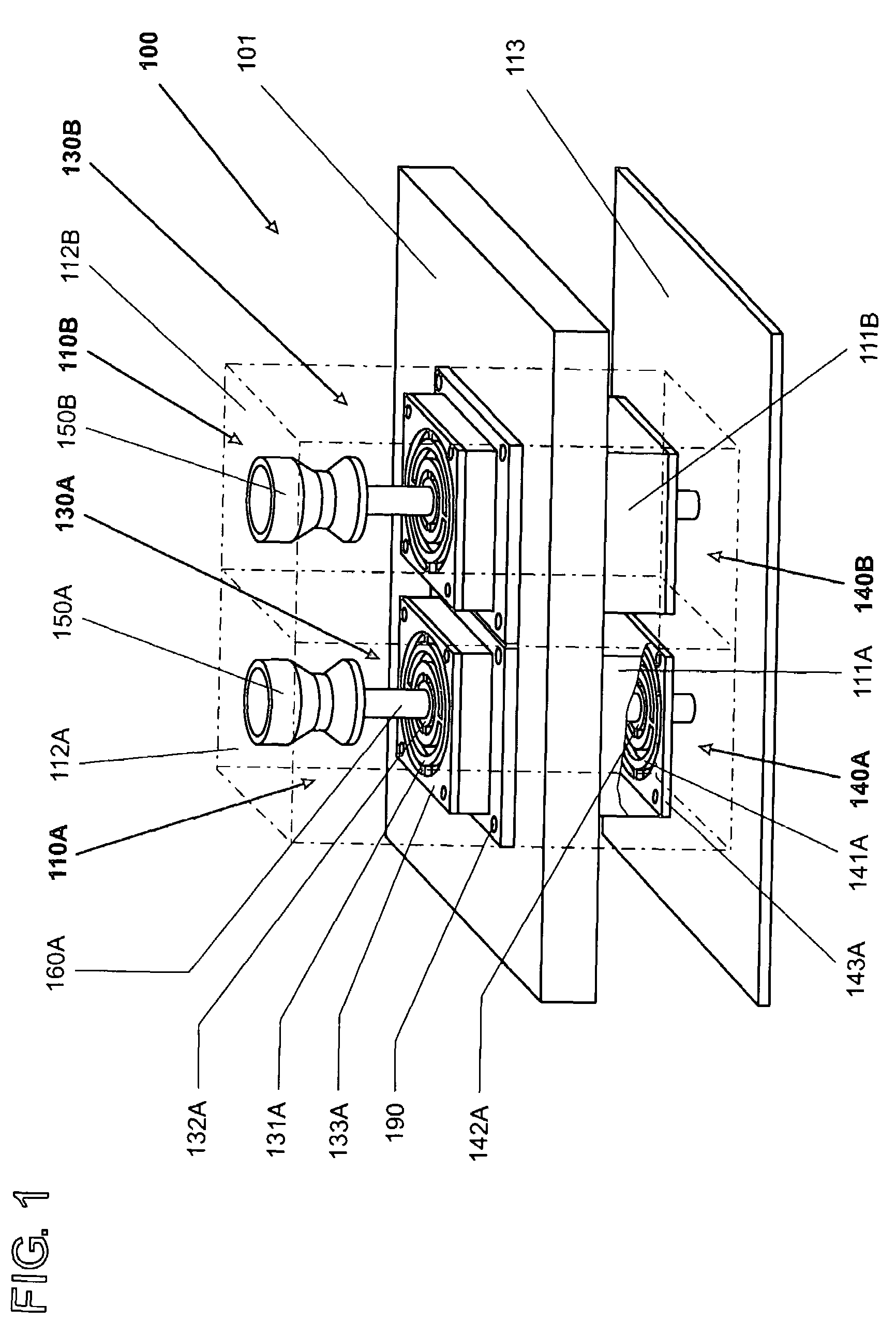

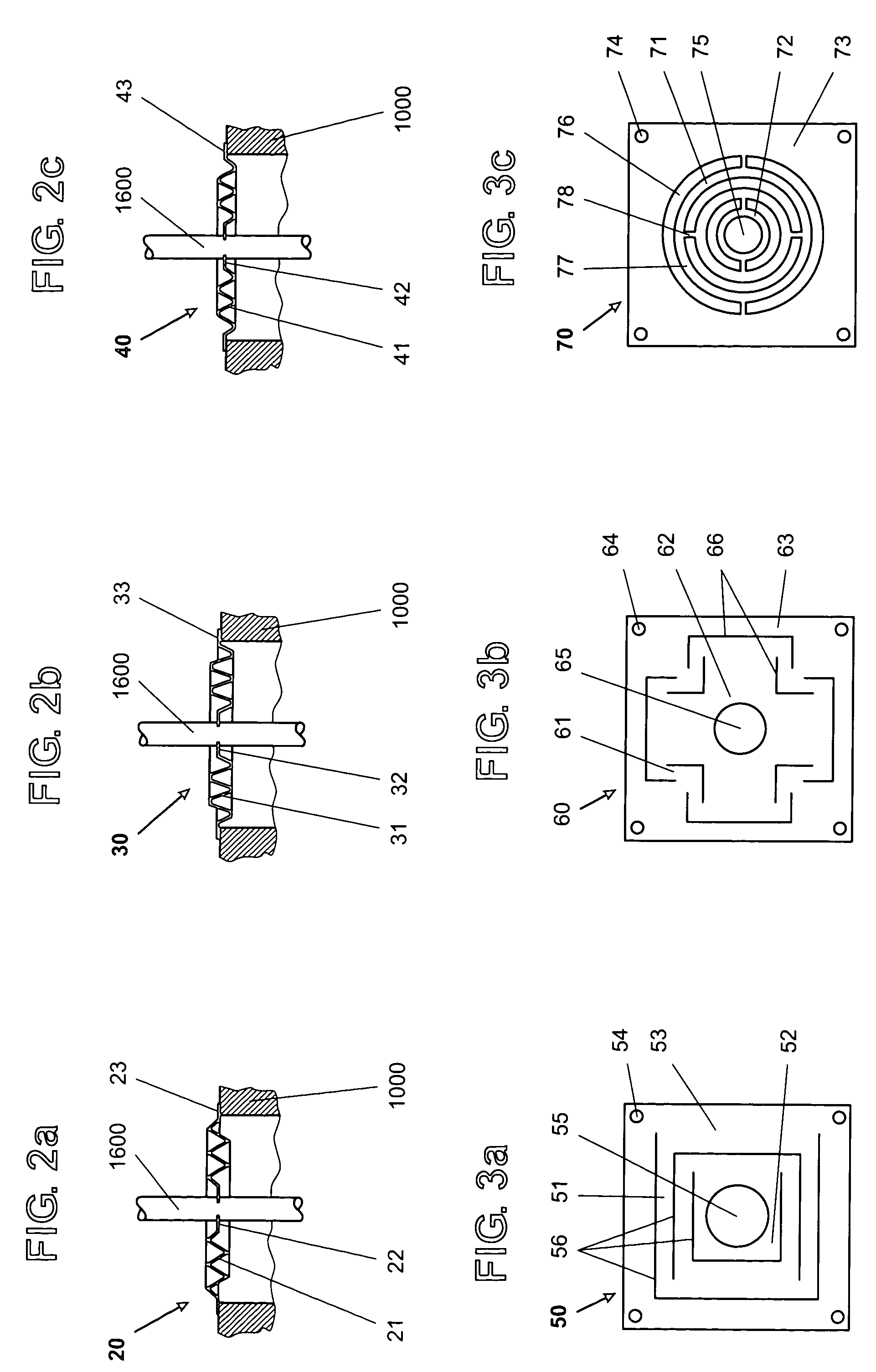

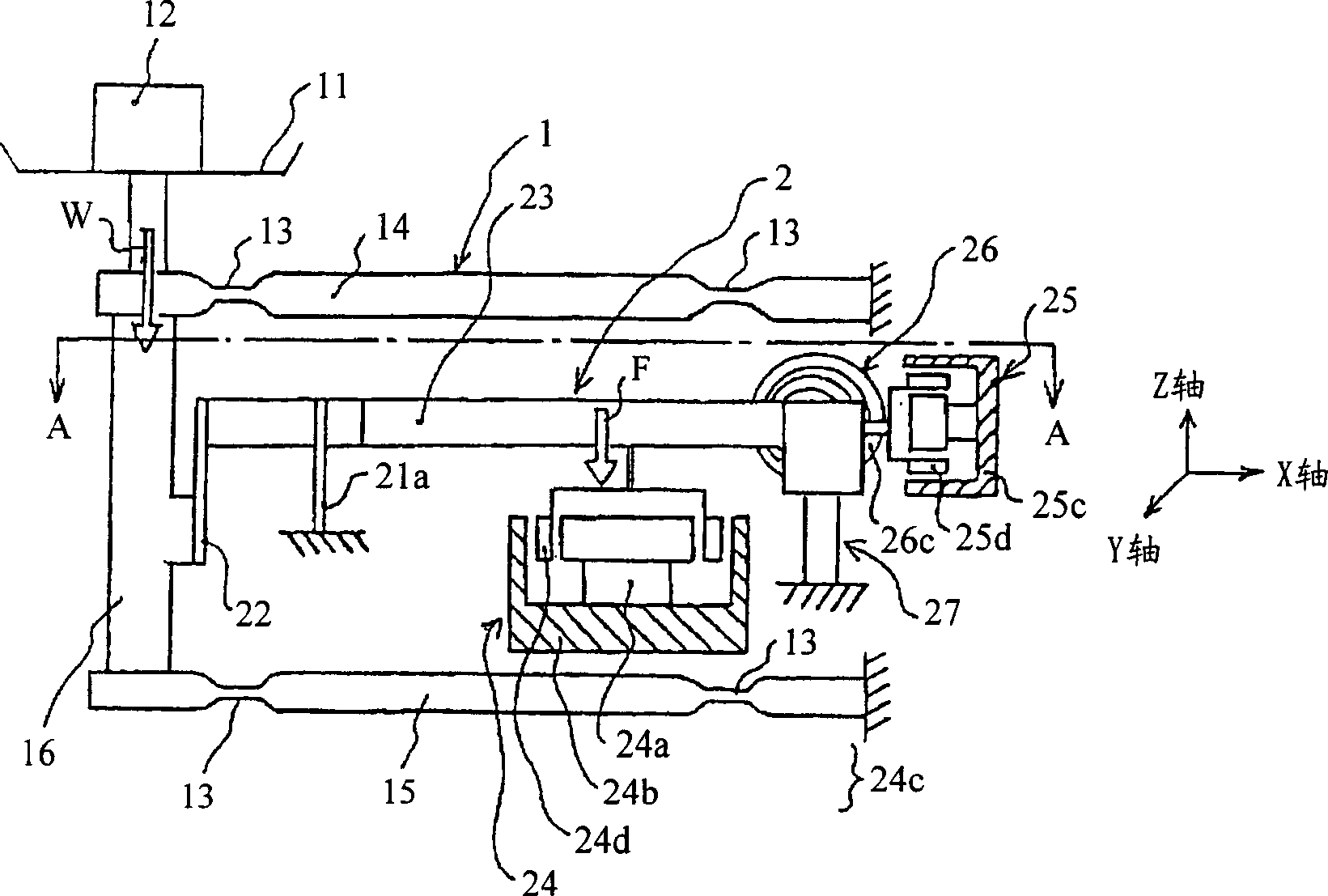

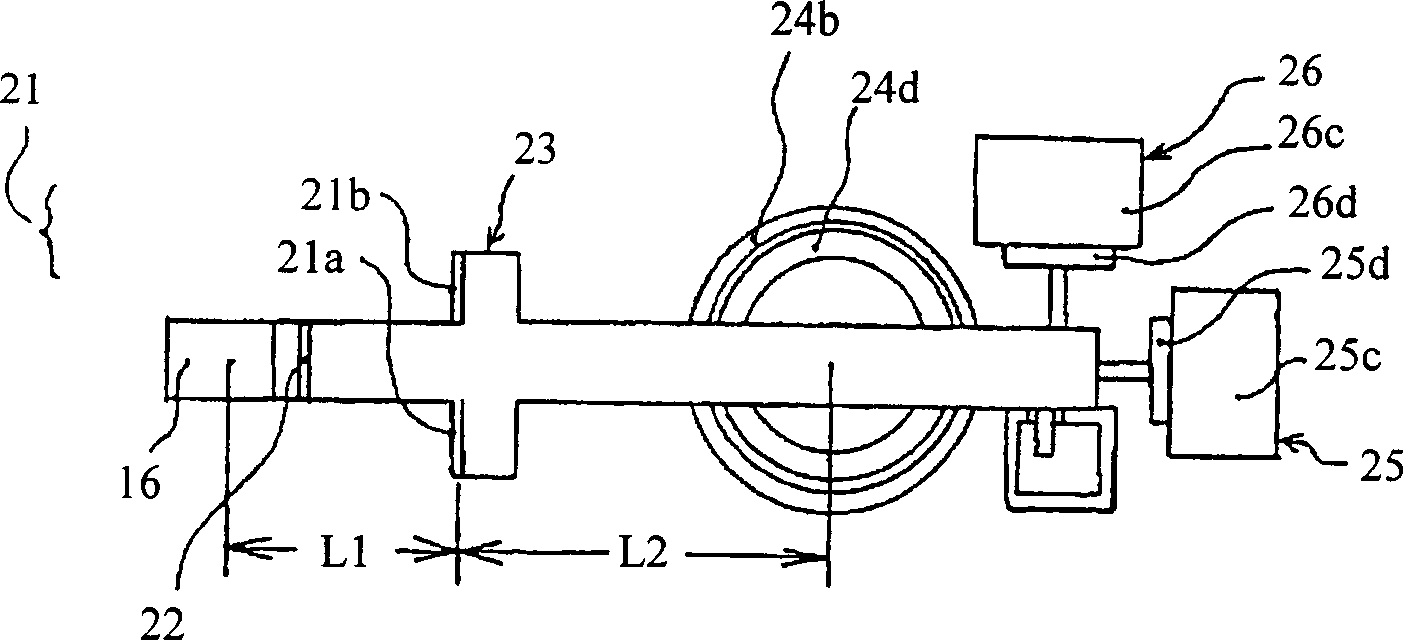

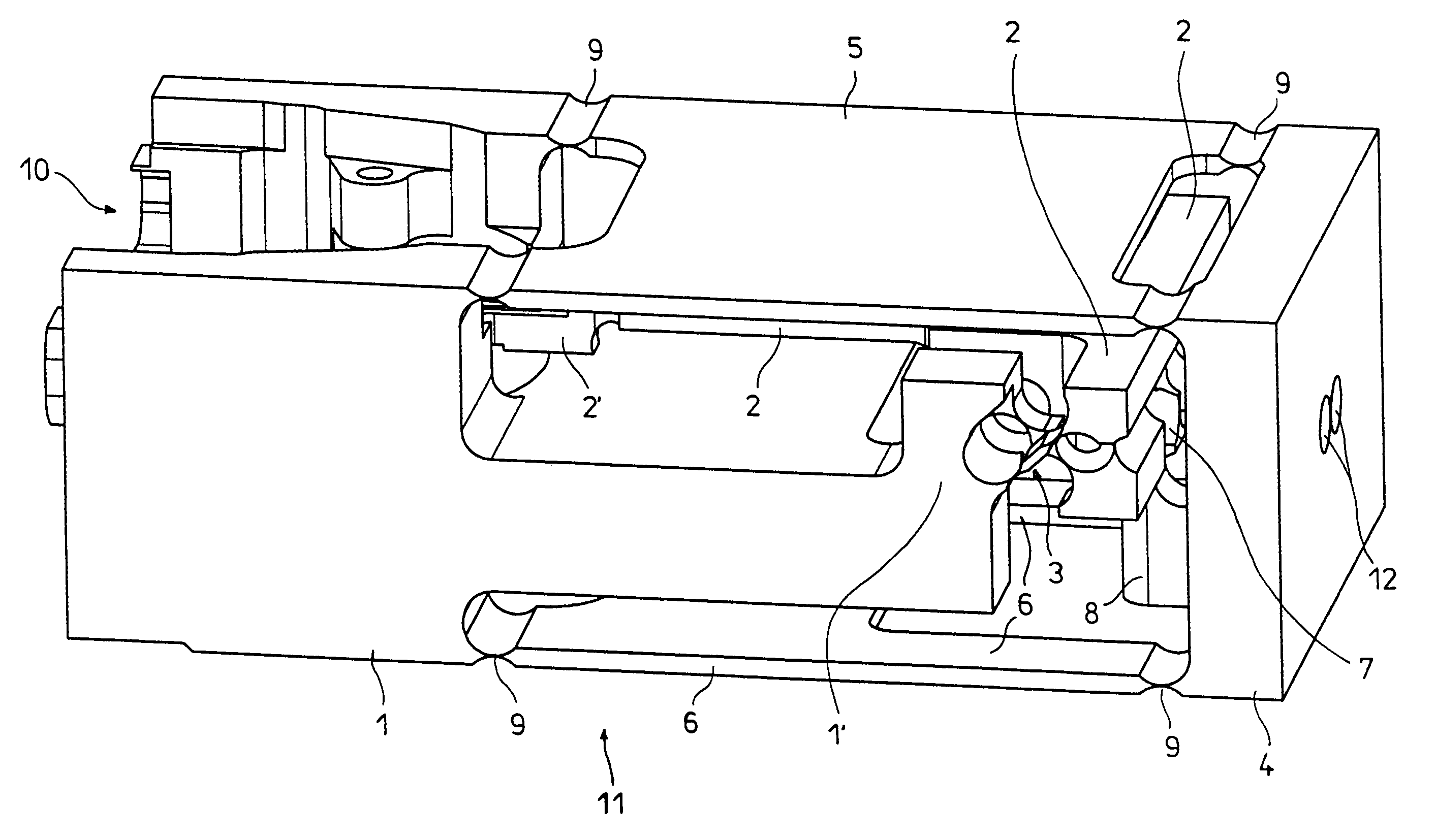

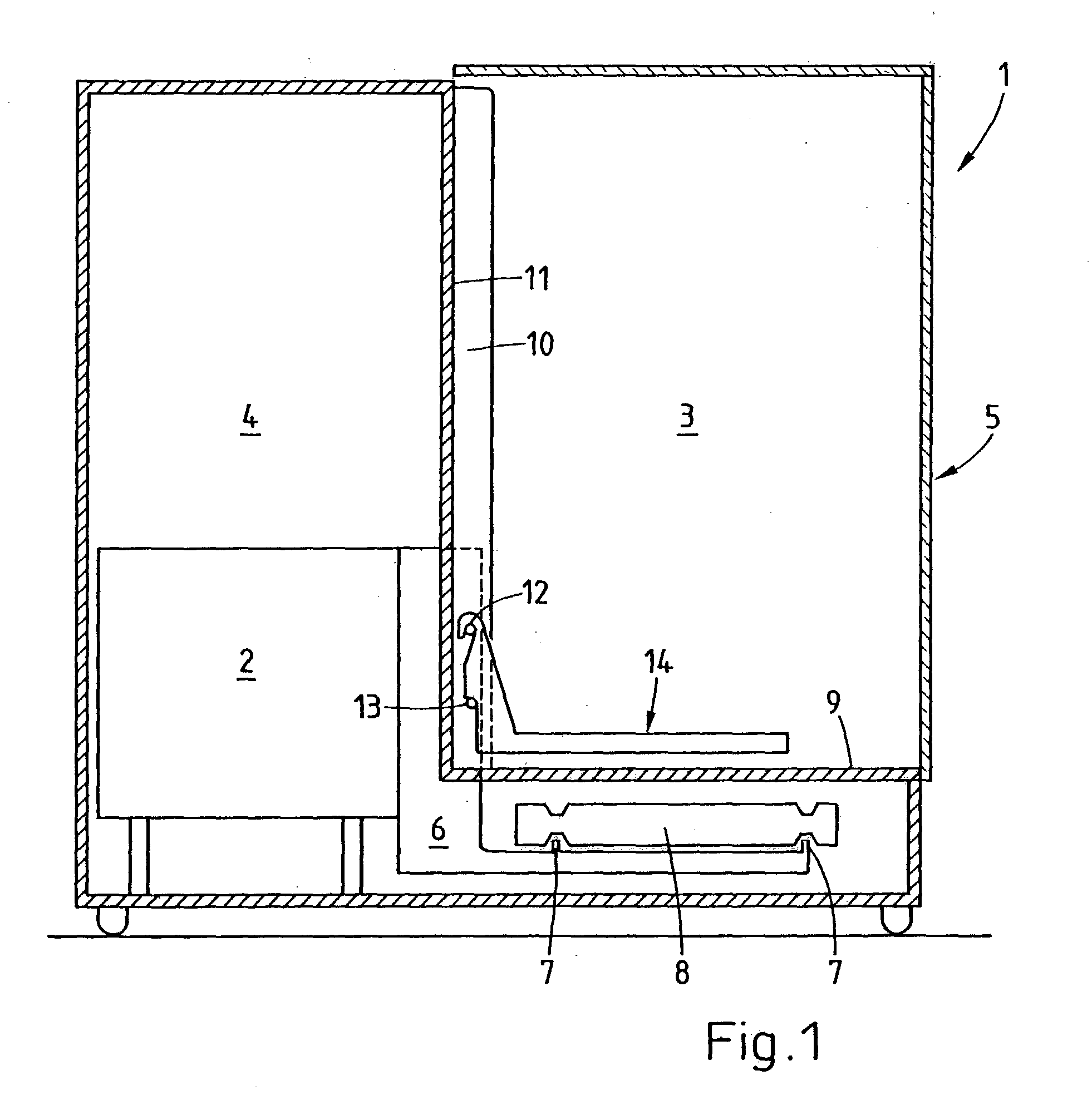

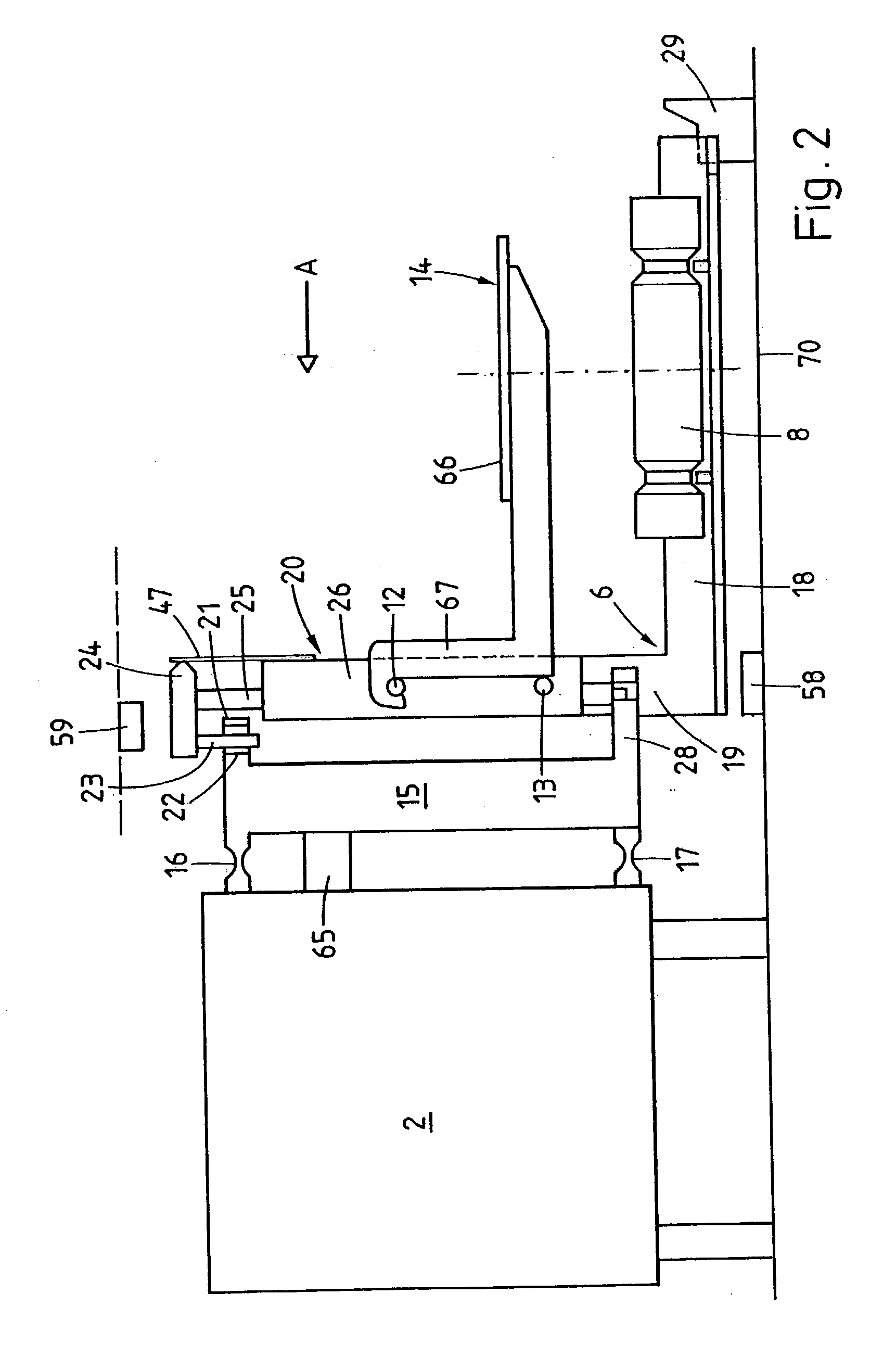

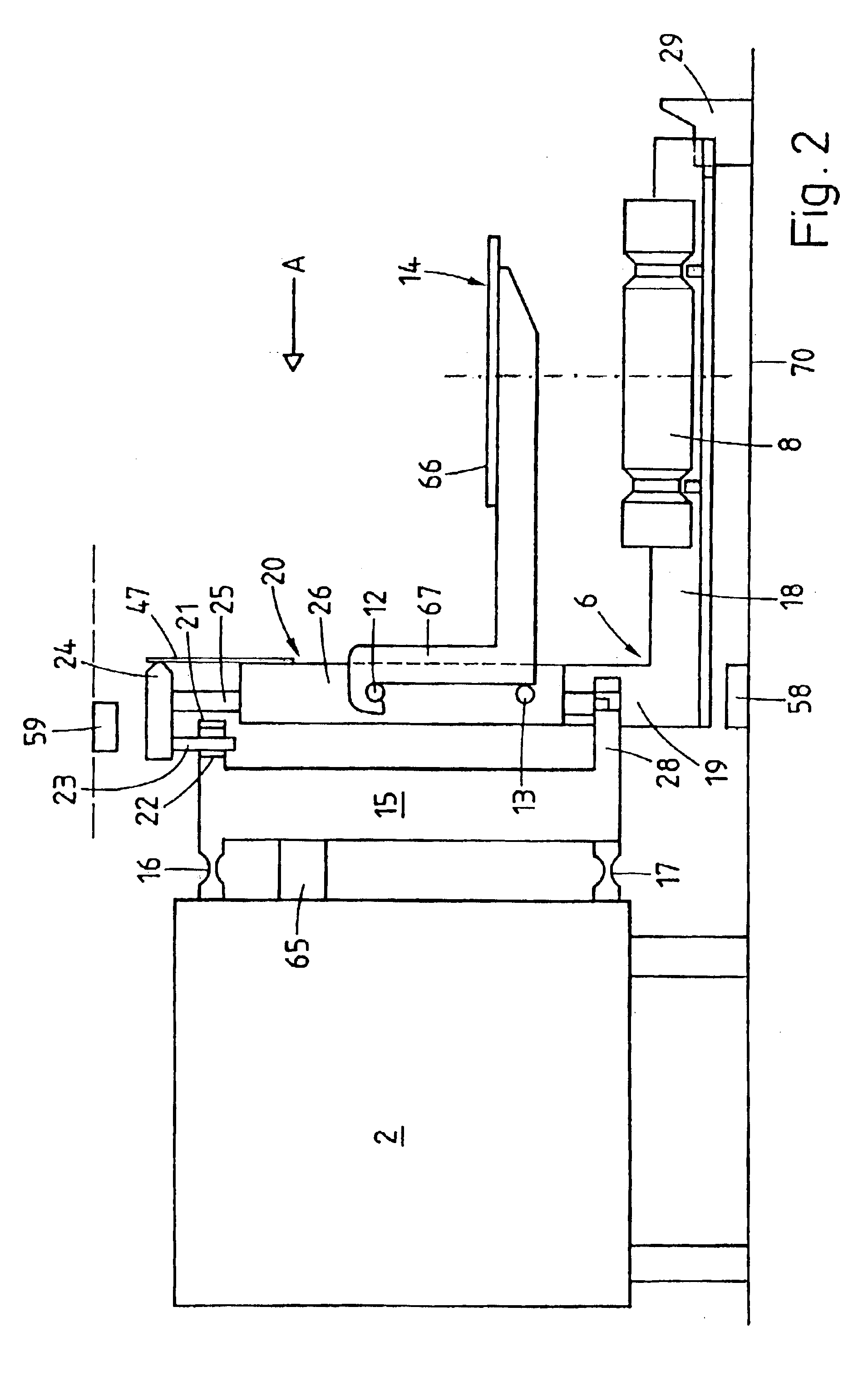

Parallel-guiding mechanism for compact weighing system

ActiveUS7429705B2Lightweight stiffnessBending stiffness of a very thin stationary parallel leg can be markedly increasedWeighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersEffective lengthEngineering

An exemplary weighing module is disclosed which has a load receiver and a weighing cell that are connected to each other by a force-transmitting rod, wherein the weighing module is arranged inside a design space whose dimensions in a plane extending orthogonal to the load direction are limited by the design spaces occupied by neighboring weighing cells or represent the largest dimension of the weighing cell in said plane. An exemplary weighing cell has a parallel-guiding mechanism in which at least one movable parallel leg which is connected to the force-transmitting rod and at least one stationary parallel leg are arranged with a predefined guiding distance from each other, connected to each other by at least one upper parallel-guiding member and at least one lower parallel-guiding member. The effective length of the parallel-guiding members is larger than the guiding distance, and the movable parallel leg does not protrude out of the design space.

Owner:METTLER TOLEDO AG

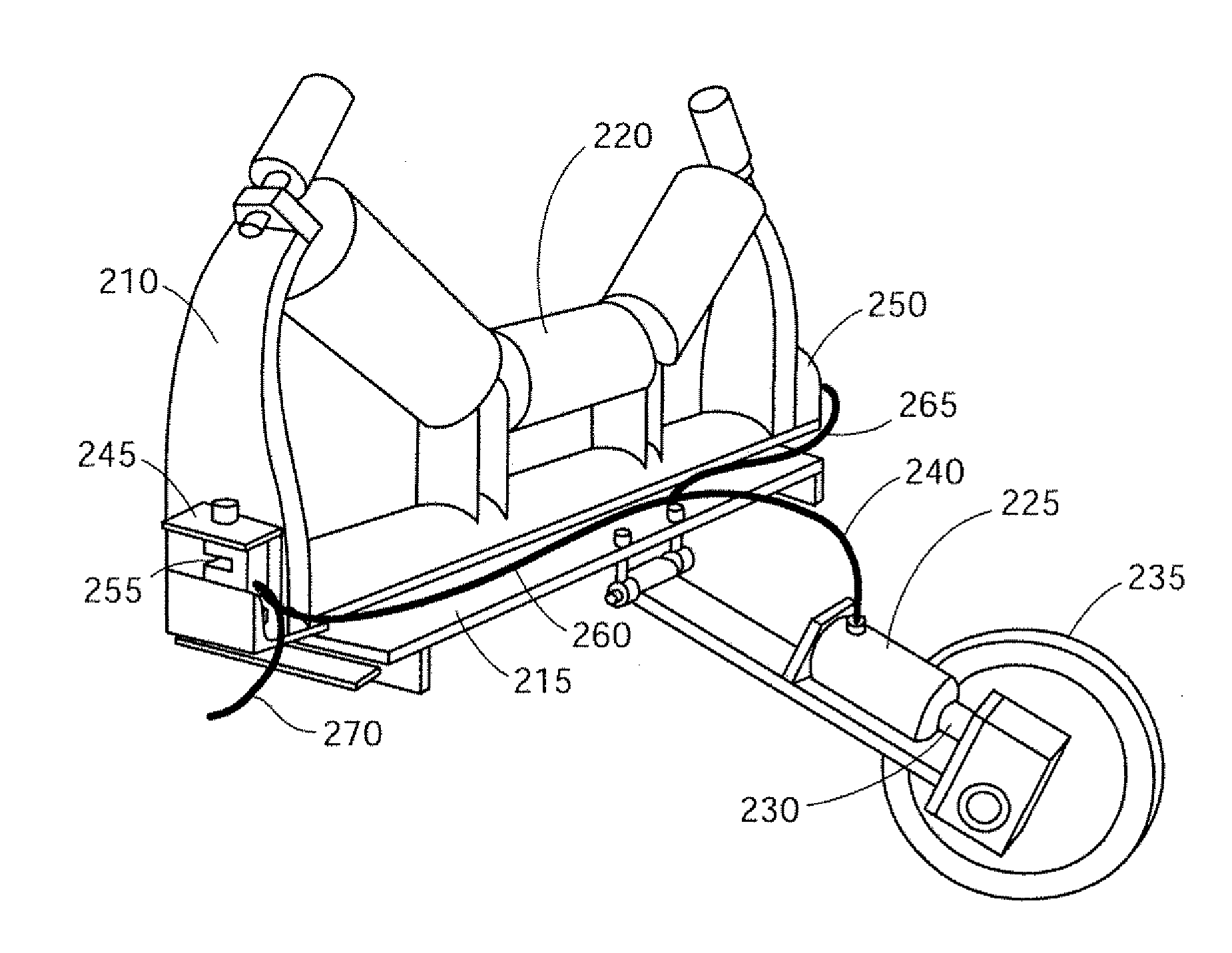

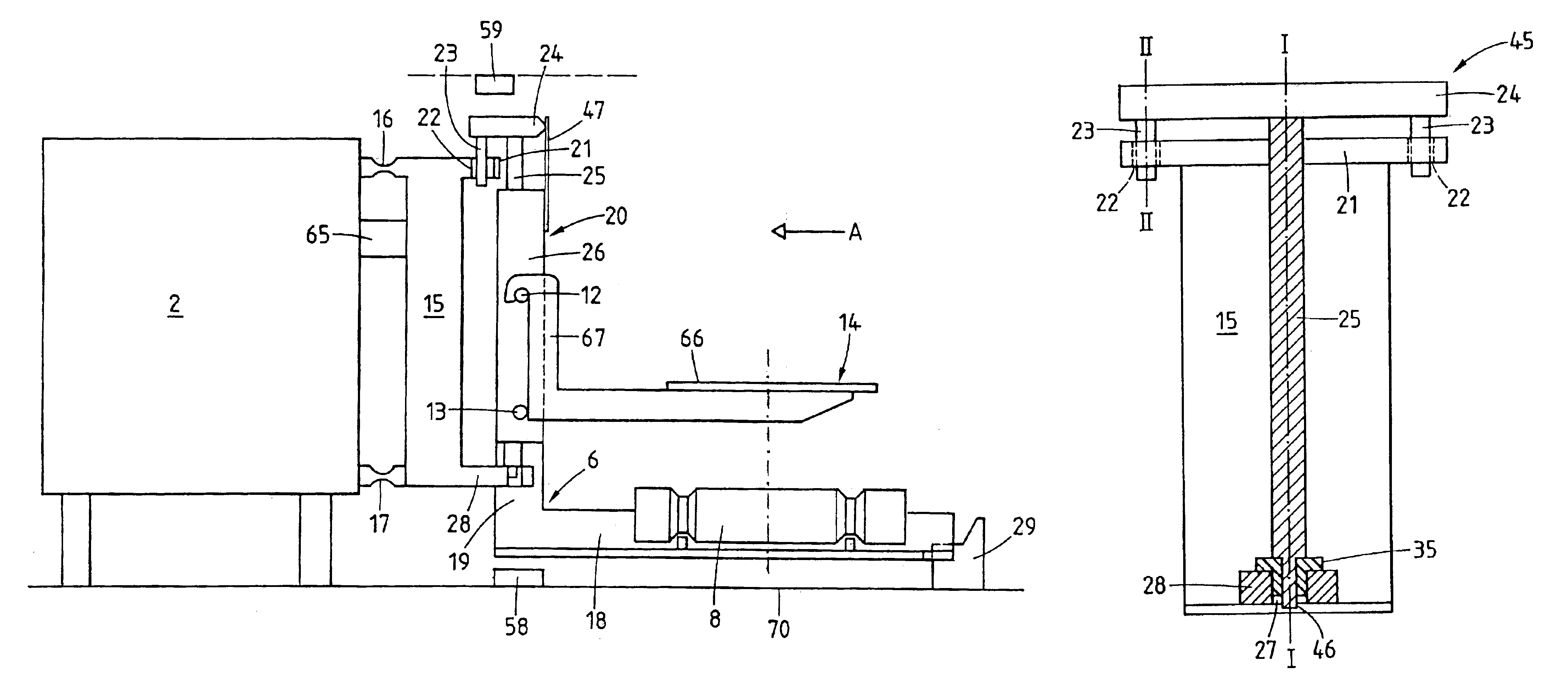

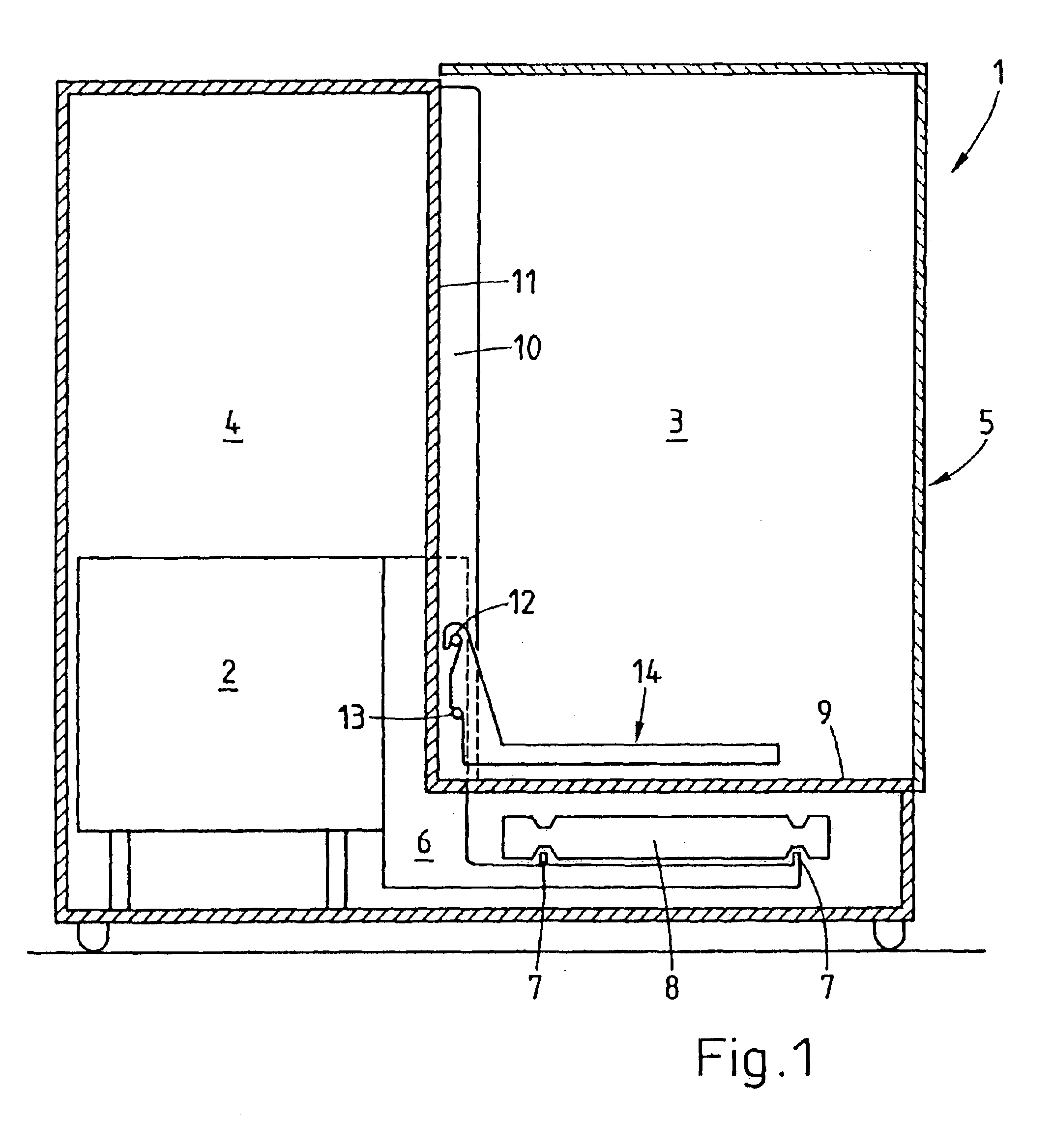

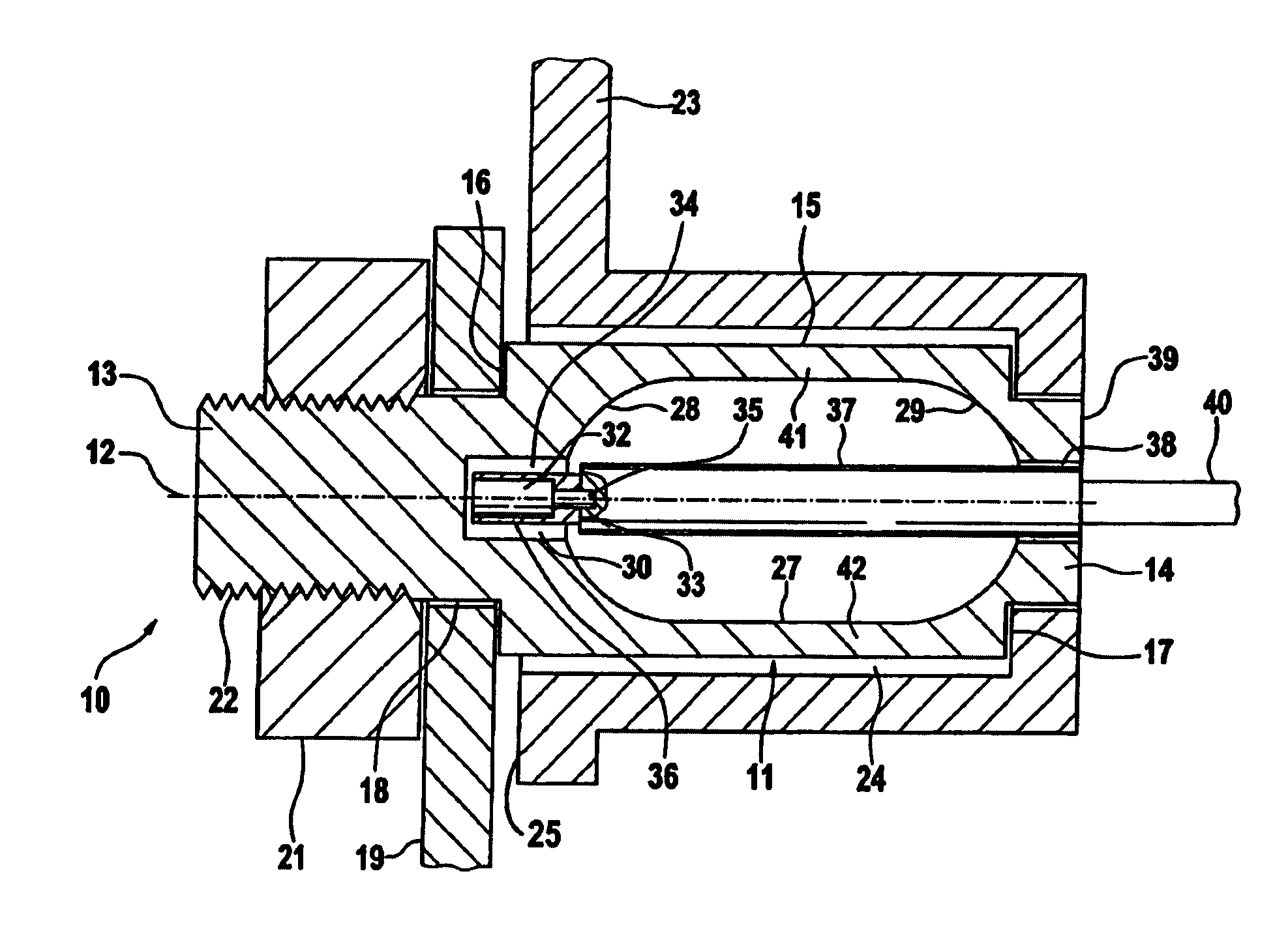

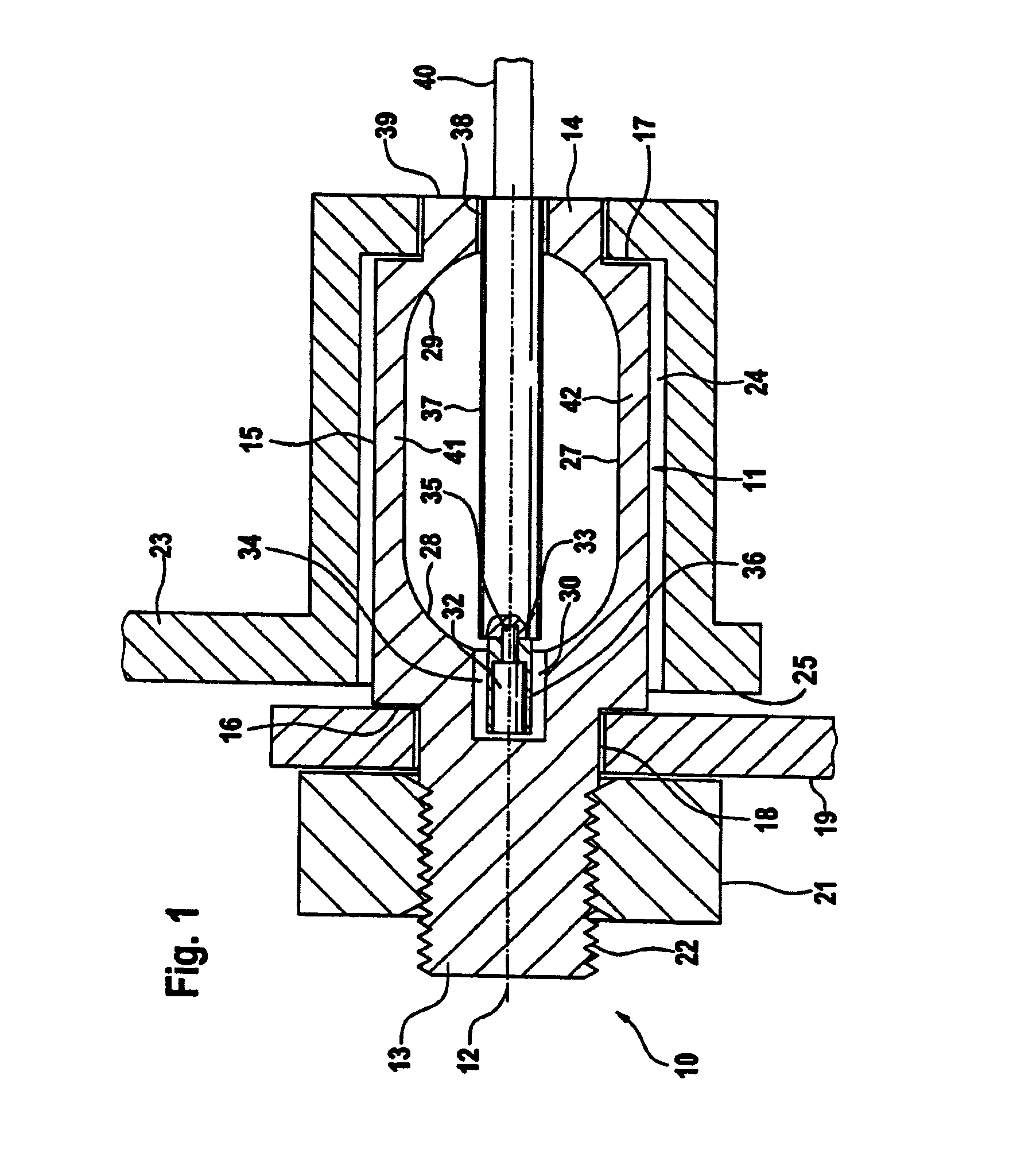

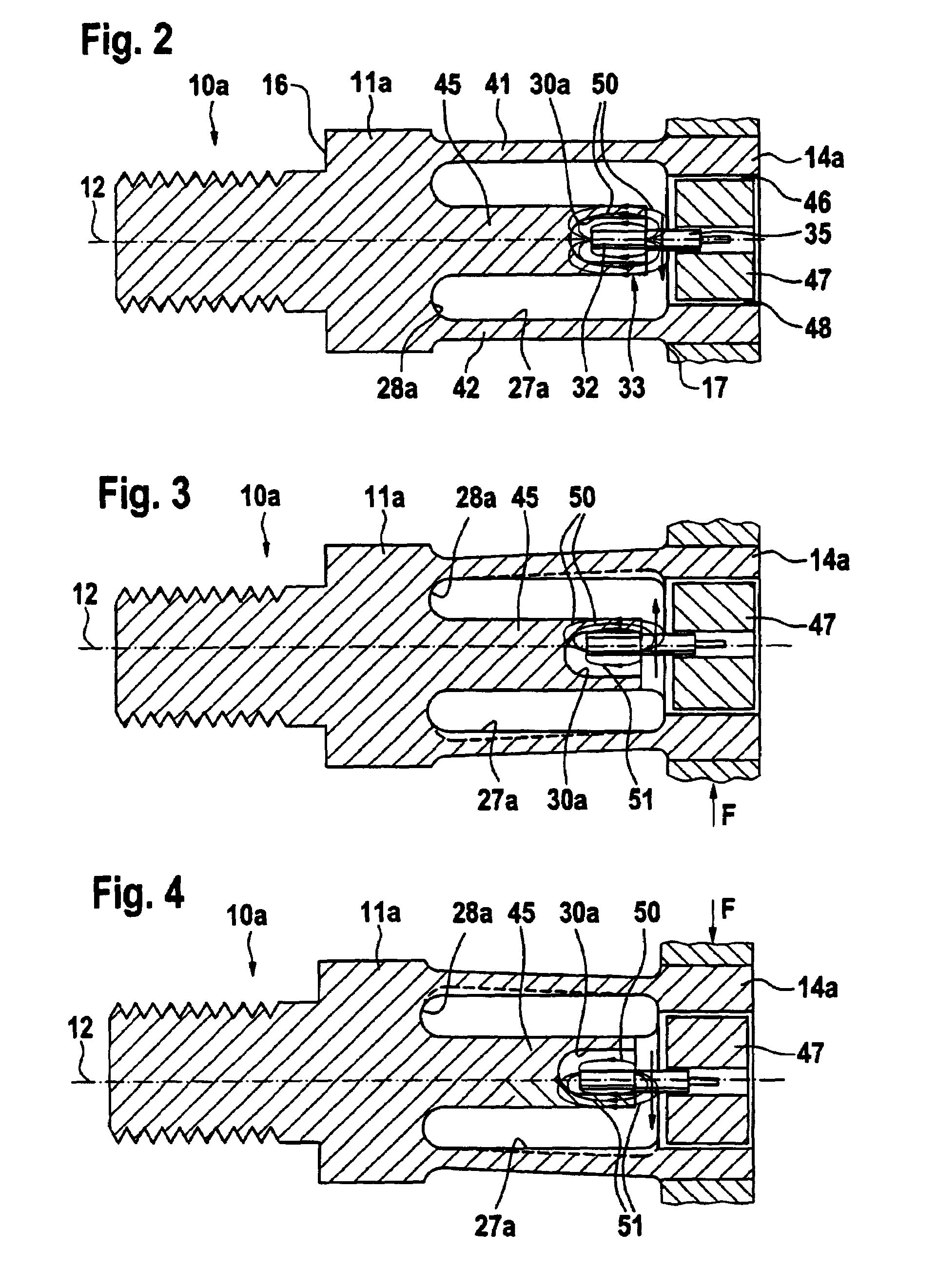

Measurement device and seating arrangement

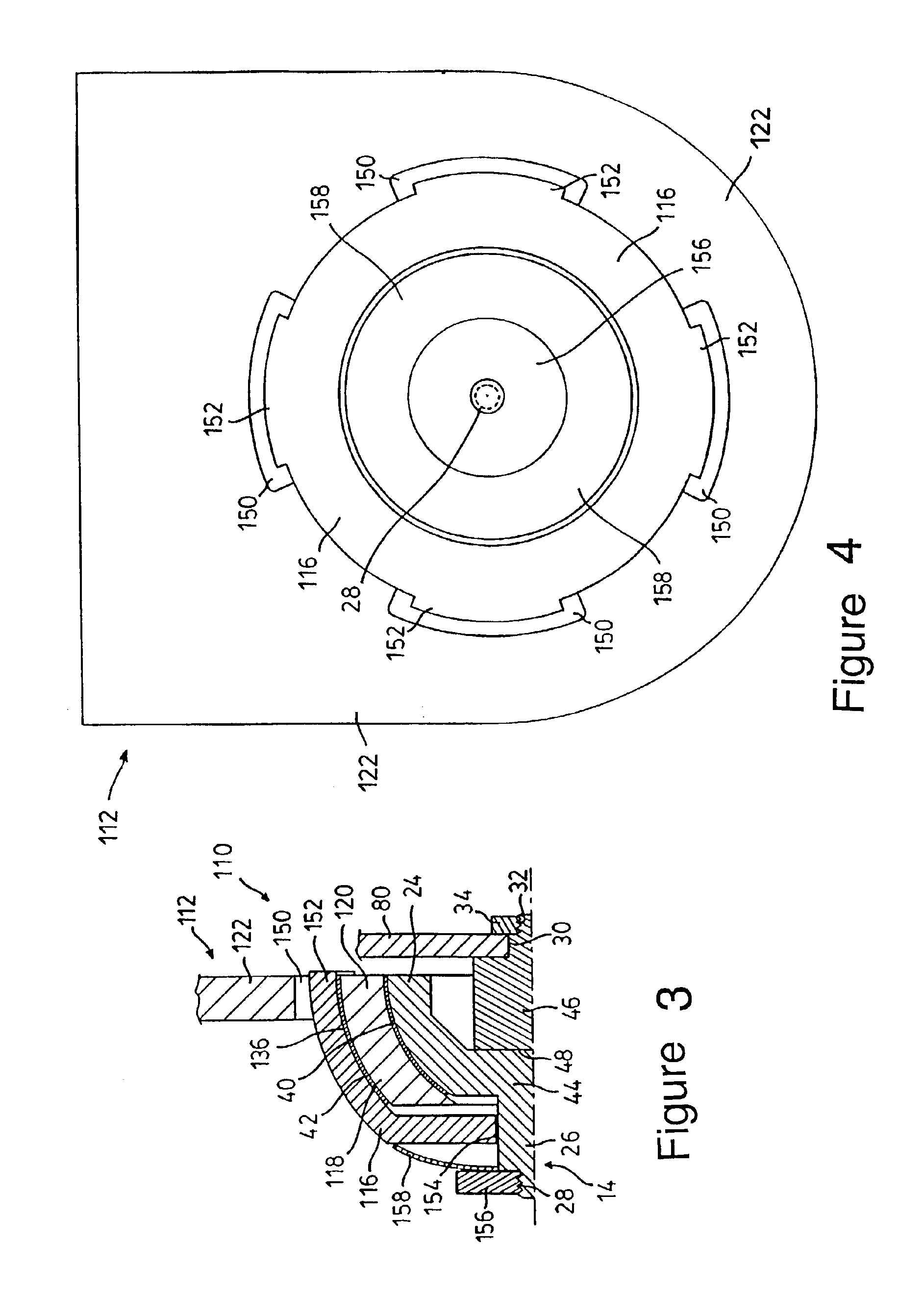

InactiveUS6931947B2Precise and reliable measurement of the force conductedForce measurementSimultaneous indication of multiple variablesMeasurement deviceEngineering

A measurement device (10; 110; 210) and associated seating arrangement, in particular for measuring a weight acting on a vehicle seat, that includes: a force transmission element (12; 112; 212), which is connectable to a first unit, preferably a vehicle seat, and a measurement assembly (14; 50; 114; 214), which is rigidly connectable to a second unit (80), preferably a vehicle body part. The force transmission element (12; 112; 212) is pivotable about at least one axis around the measurement assembly (14; 50; 114; 214).

Owner:SARTORIUS WEIGHING TECH CO LTD

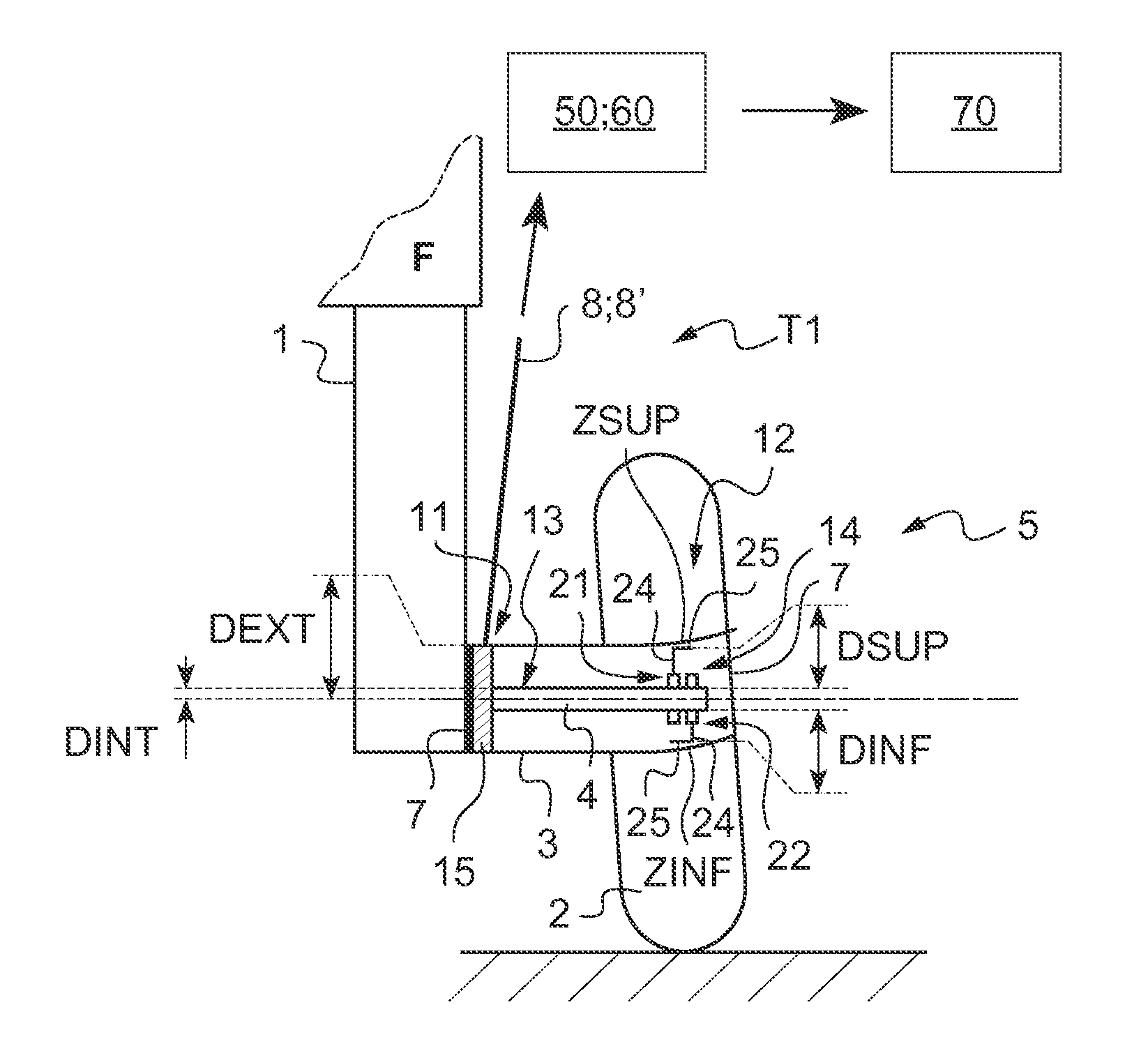

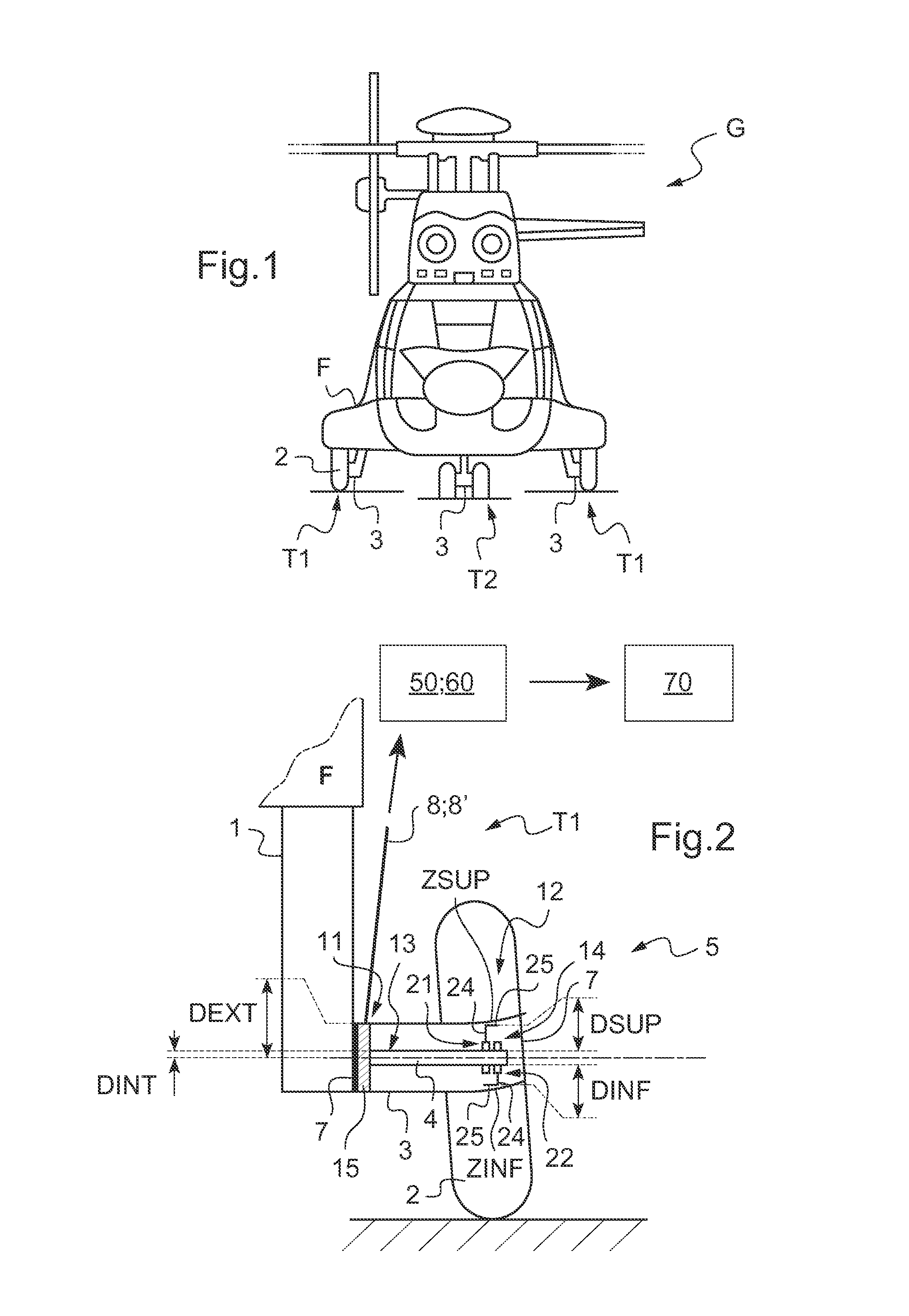

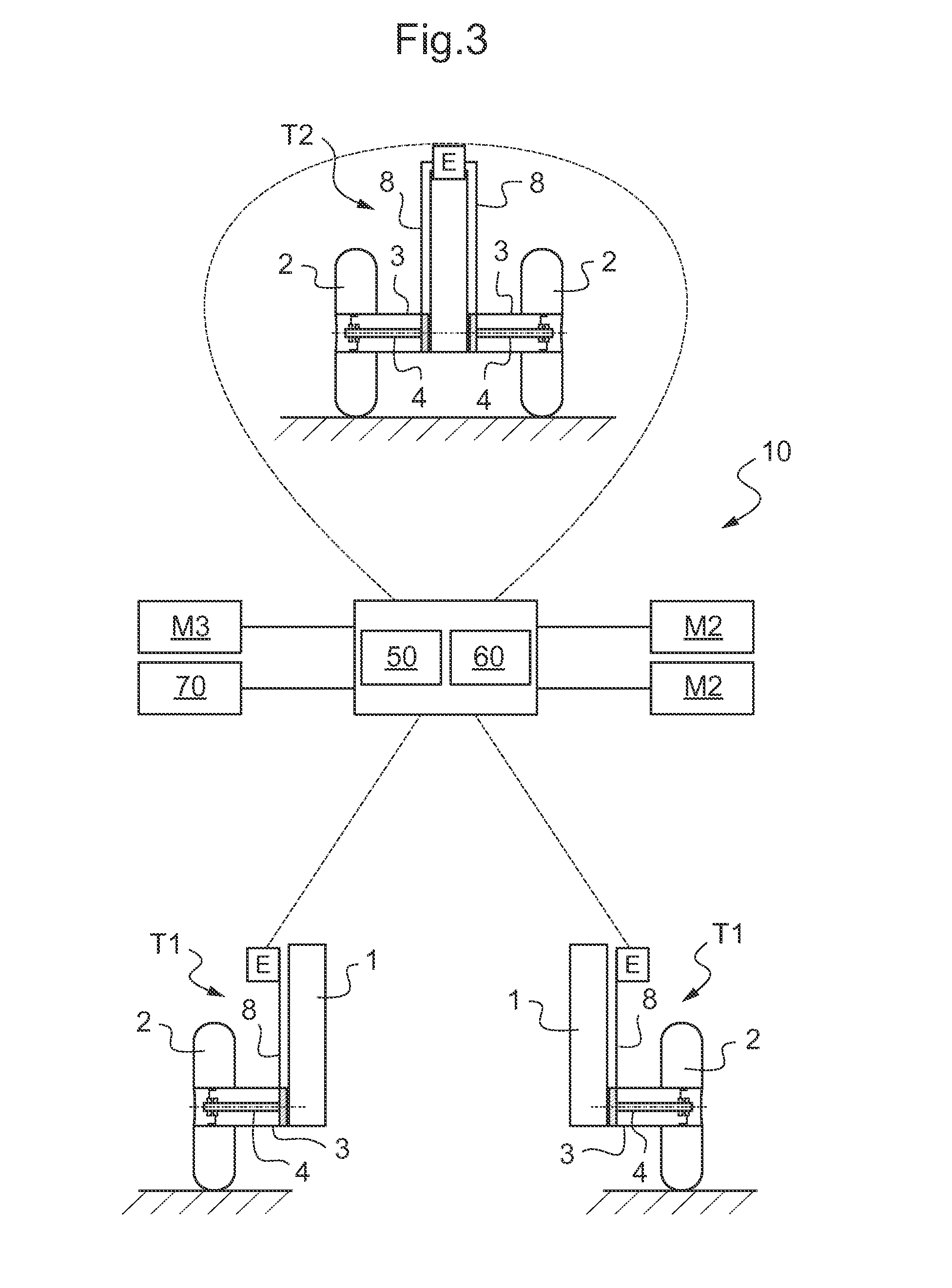

On-board device for measuring the weight of an aircraft and the position of its center of gravity

ActiveUS20130192903A1Reliable and verifiedAccurately determineWeighing apparatus using electromagnetic balancingWeighing apparatus for materials with special property/formOn boardEngineering

Owner:EUROCOPTER

Weight sensing

ActiveUS20150101870A1Reduce weightWeighing apparatus using elastically-deformable membersMicrobiological testing/measurementEngineeringLoad cell

A weight sensor may include a weighing platform and a load cell coupled to the platform to sense a weight applied to the platform. The load cell may include a deformable plate with one or more strain gauges arranged to provide an electrical signal representing the weight applied to the platform, and a base supporting the load cell, wherein the deformable plate is movably mounted to the base at only three contact points, the contact points allowing lateral movement of the plate relative to the base when the plate deforms in response to a weight applied to the platform. The weight sensor makes it possible to independently monitor the weight and weight shifting of two people sharing the same bed. The weight sensor is self-centering when a load is applied off-centre to the platform, which is particularly beneficial when such a weight sensor is used underneath a bed, e.g., under a bed leg or other support member which may not be aligned centrally over the weight sensor. Beneficially the sensor is not unduly affected by minor misalignment of the leg of a bed relative to the load cell.

Owner:CARDE CHRIS

High Capacity and High Resolution Scale

ActiveUS20090090564A1Weighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersImage resolutionEngineering

A scale can include a low capacity sensing mechanism operatively coupled to a load, wherein the low capacity sensing mechanism may detect movement of the load. A transfer mechanism can be operatively coupled to the low capacity sensing mechanism, wherein the low capacity sensing mechanism may enable the scale to weigh both relatively heavy loads and relatively light loads to a minor division resolution associated with the low capacity sensing mechanism.

Owner:QUADIENT TECH FRANCE

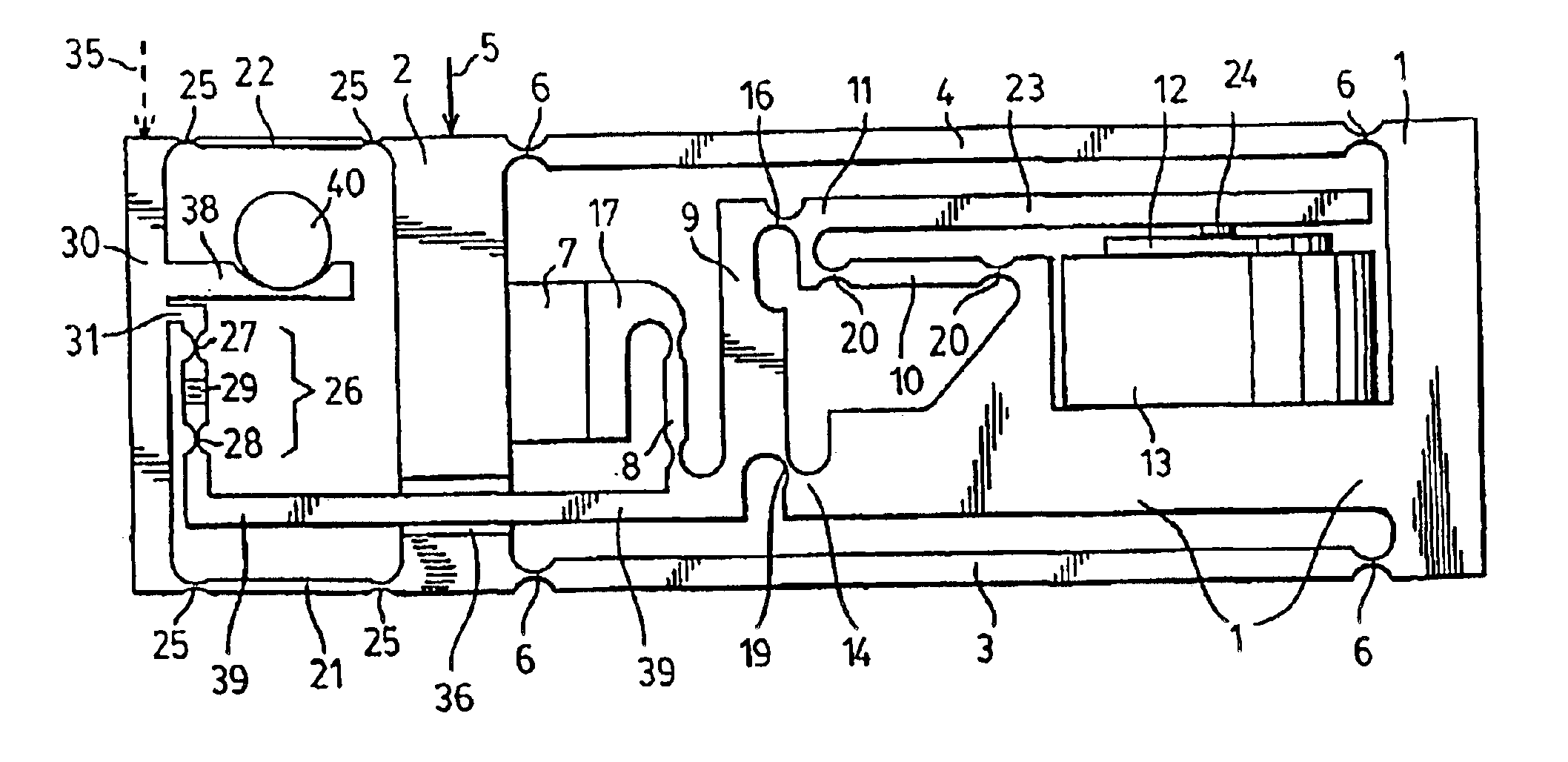

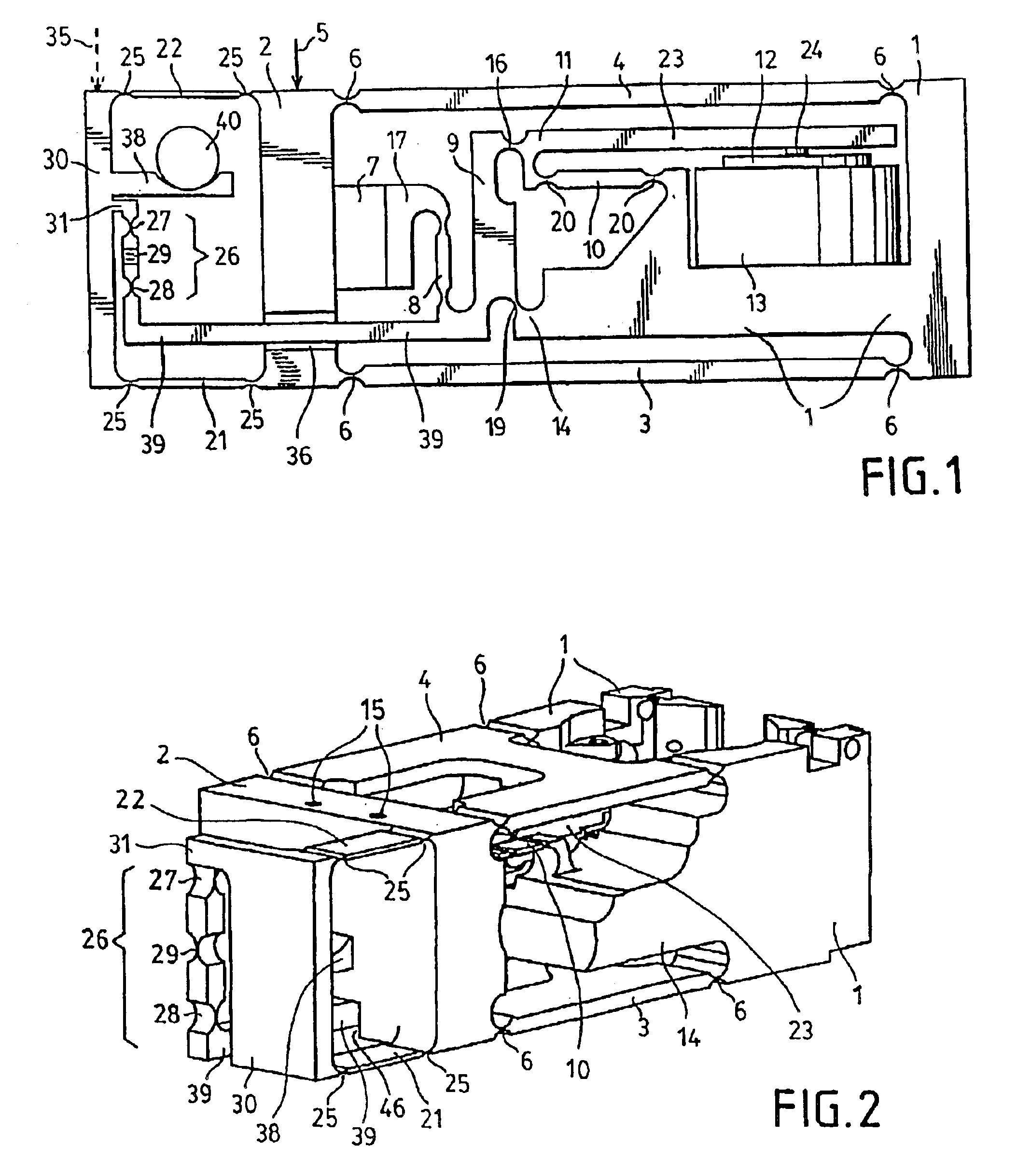

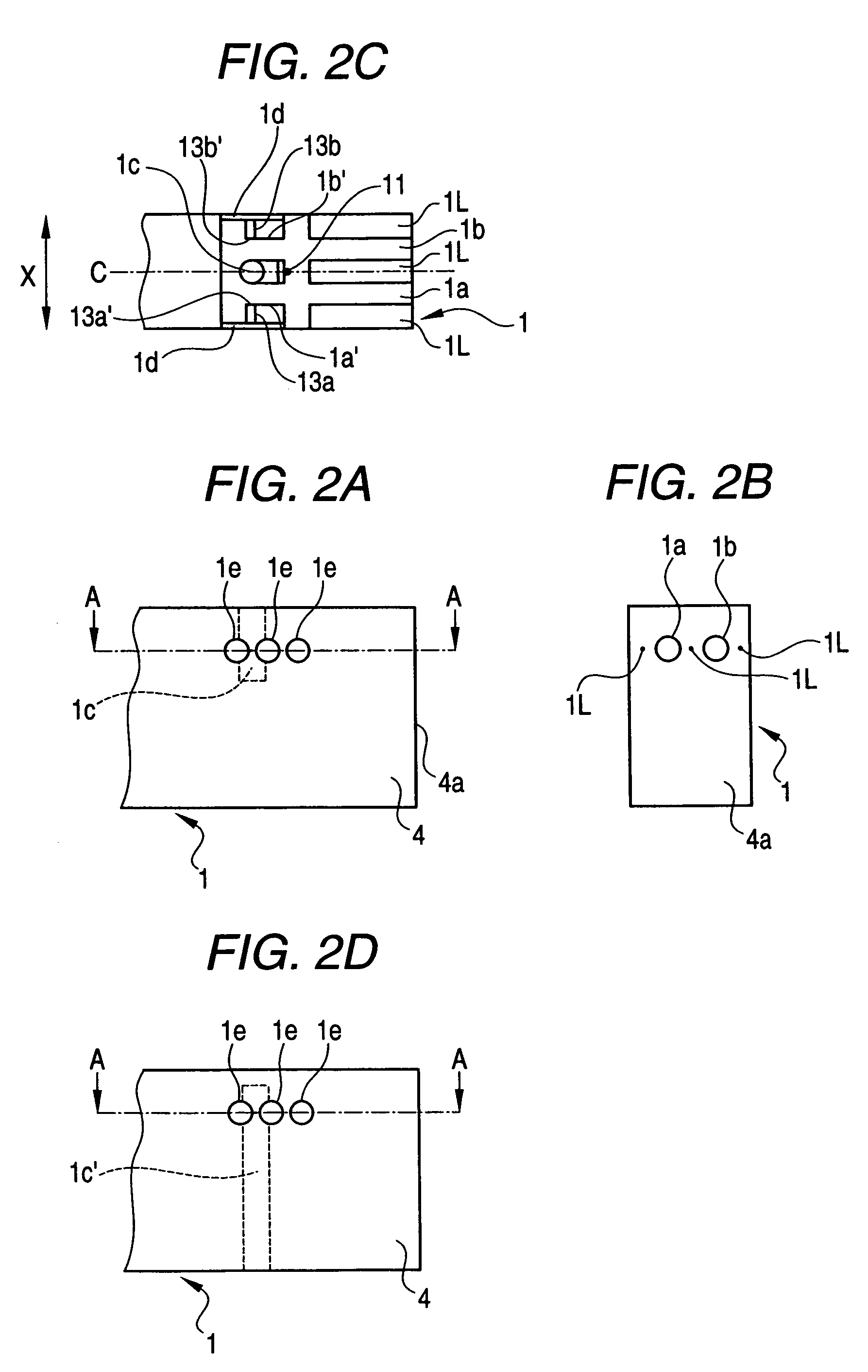

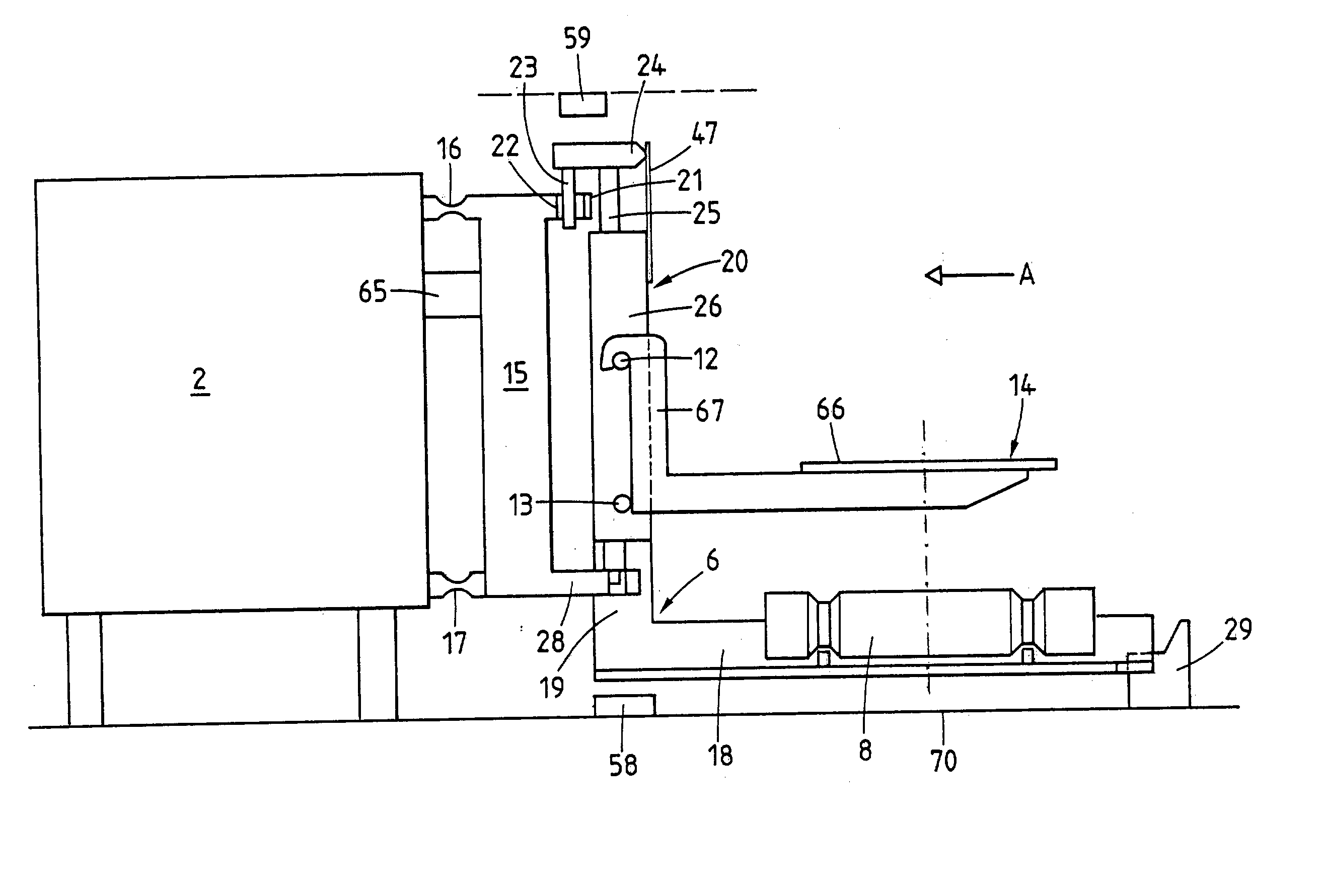

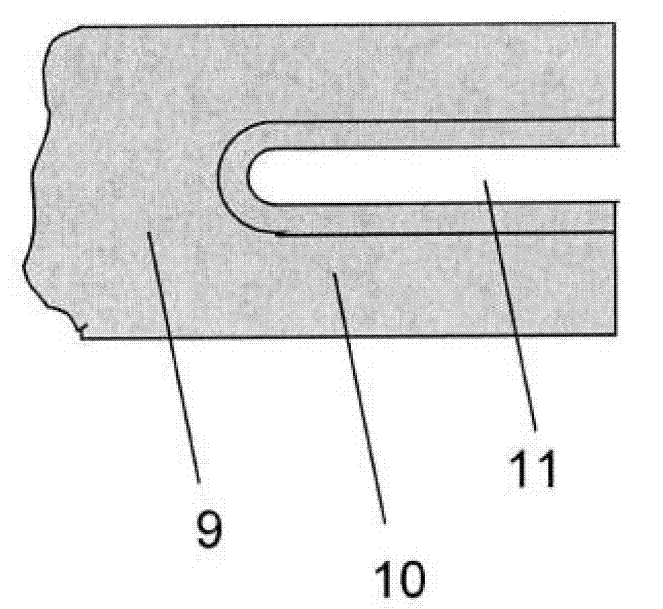

Weighing sensor with calibration weight

InactiveUS6861593B2Eliminate the problemWeighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersCouplingControl engineering

A weighing sensor including a base (1) fixed to a housing, a load sensor (2) connected to the base in a displaceable manner via two arms (3, 4), a lever system (8 . . . 11) having at least one lever and transmitting the load acting on the load sensor to a transducer (12, 13), and a built-in calibration weight (40) which may be lowered onto a support region (30 / 38) for checking and / or calibrating the sensitivity of the weighing sensor. The support region is guided in a parallel manner by two additional arms (21, 22) and is connected to a lever (9 / 39) of the lever system (8 . . . 11) via a coupling element (26). Relatively large loads on the weighing sensor may be simulated with relatively small calibration weights, without the need for complicated lifting devices. The two additional arms (21, 22) are connected on the one hand to the support region (30 / 38) and on the other hand to the load sensor (2) and are located on the side of the load sensor (2) opposite from the lever system (8 . . . 11).

Owner:SARTORIUS LAB INSTR GMBH & CO KG

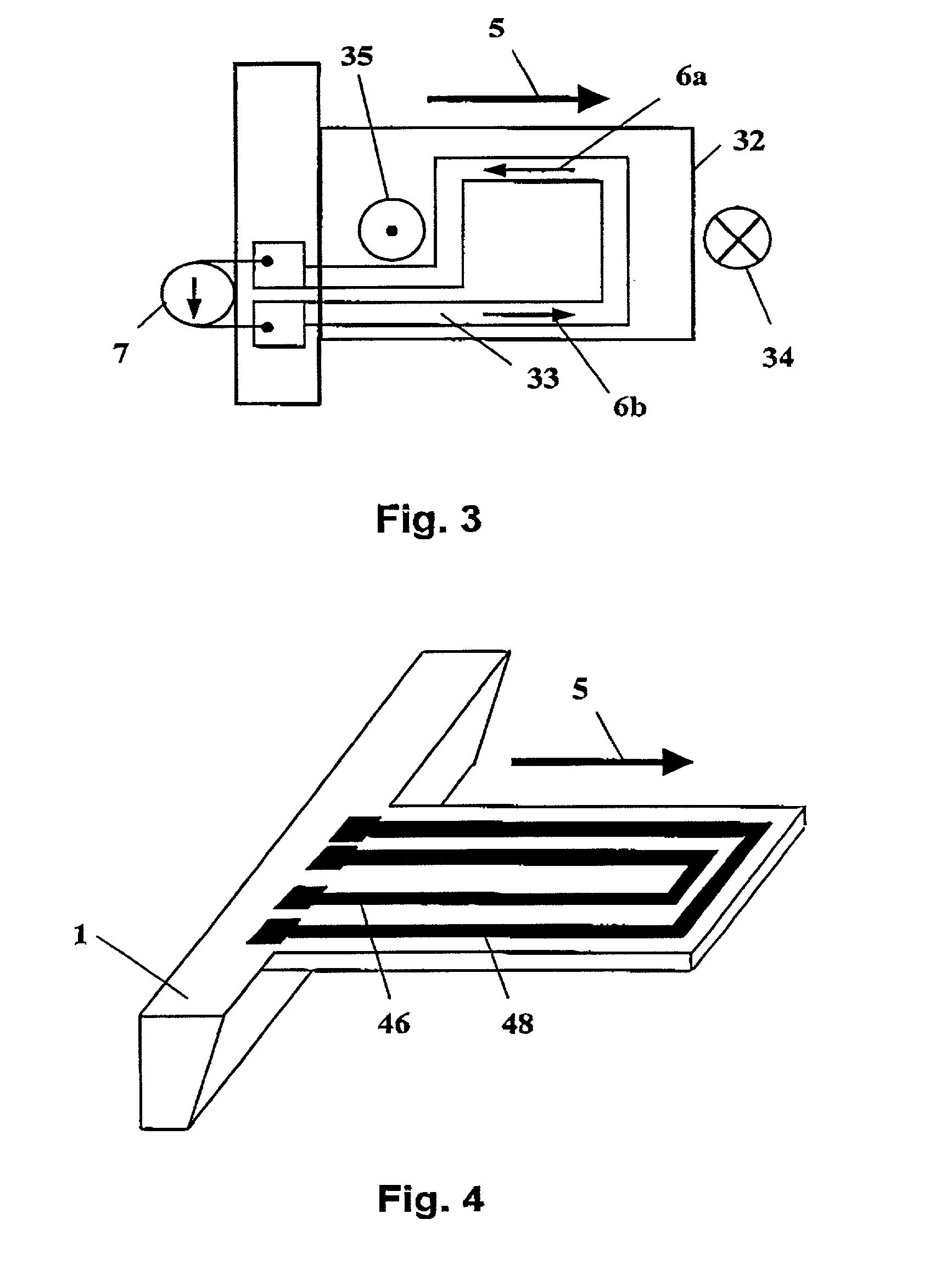

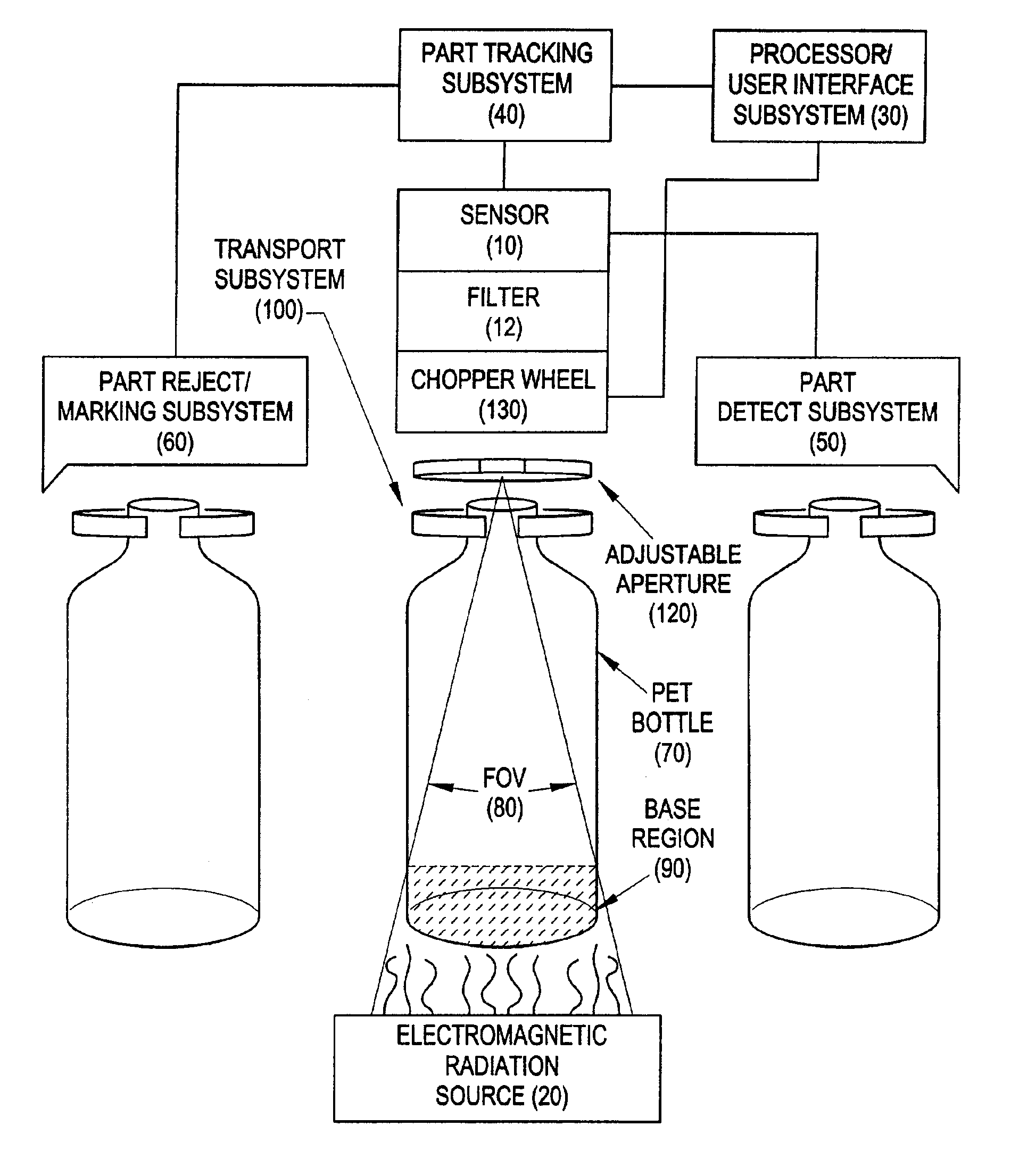

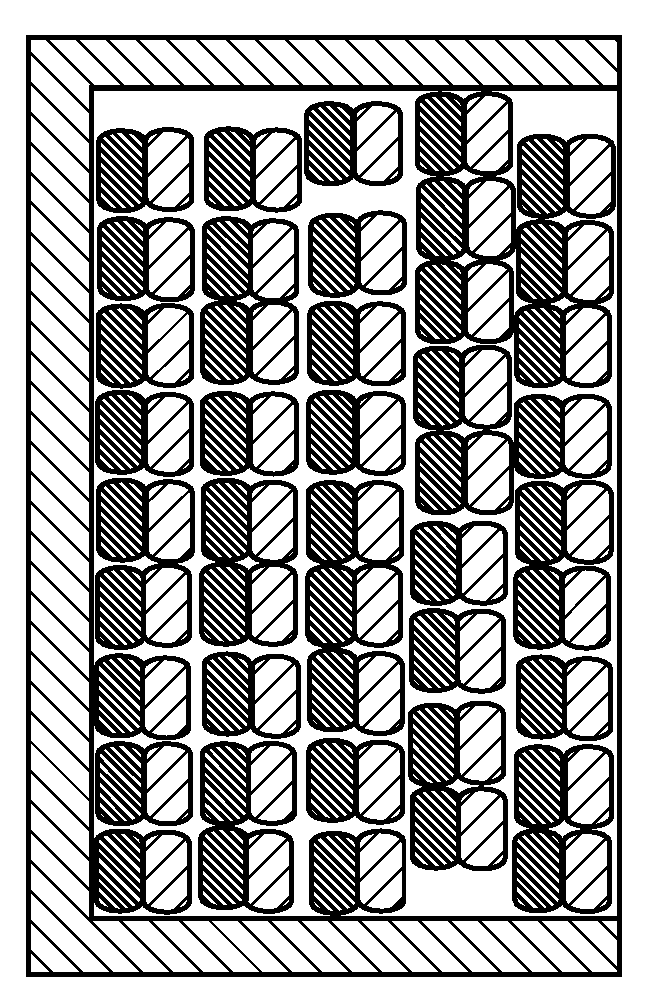

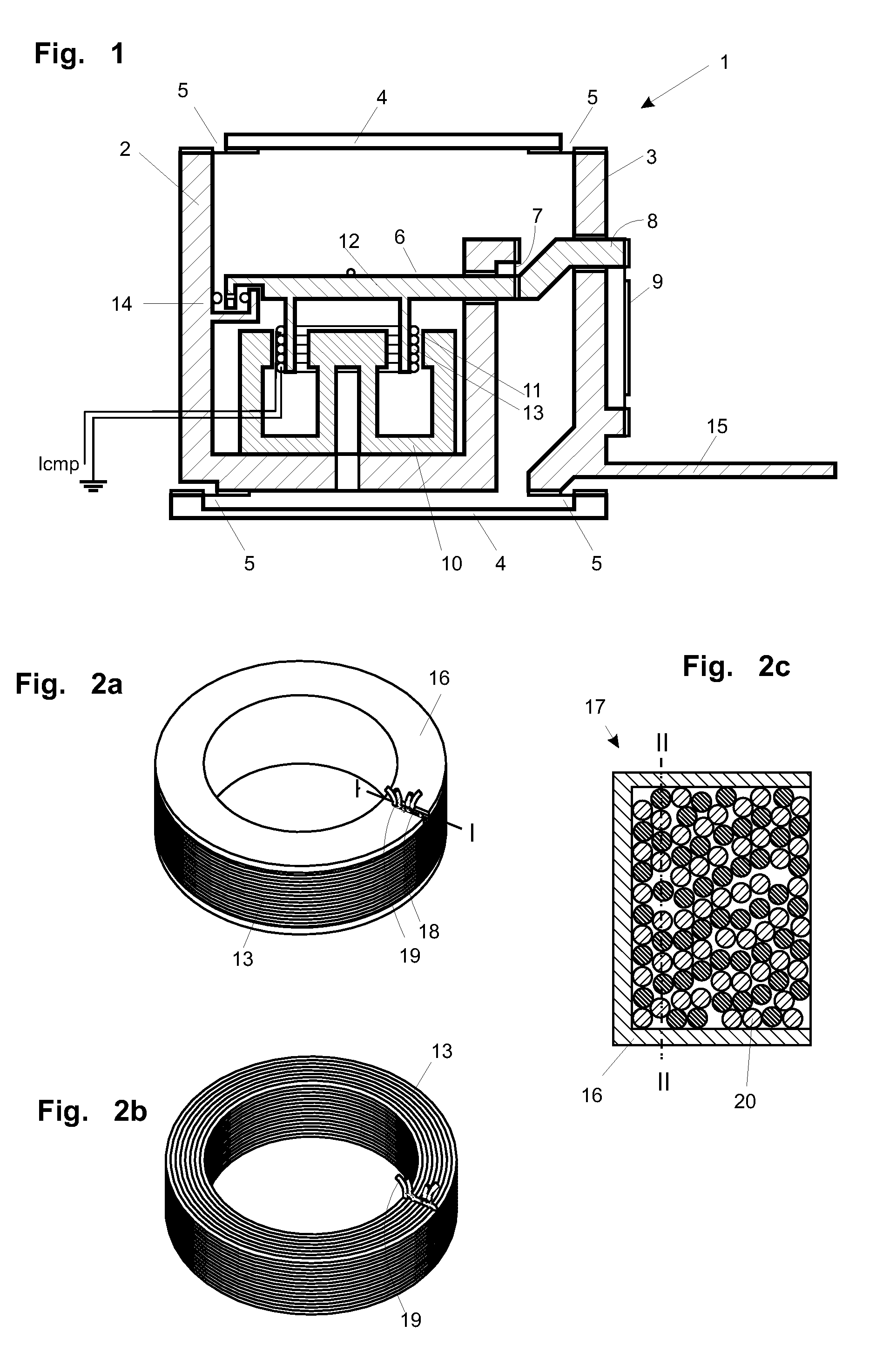

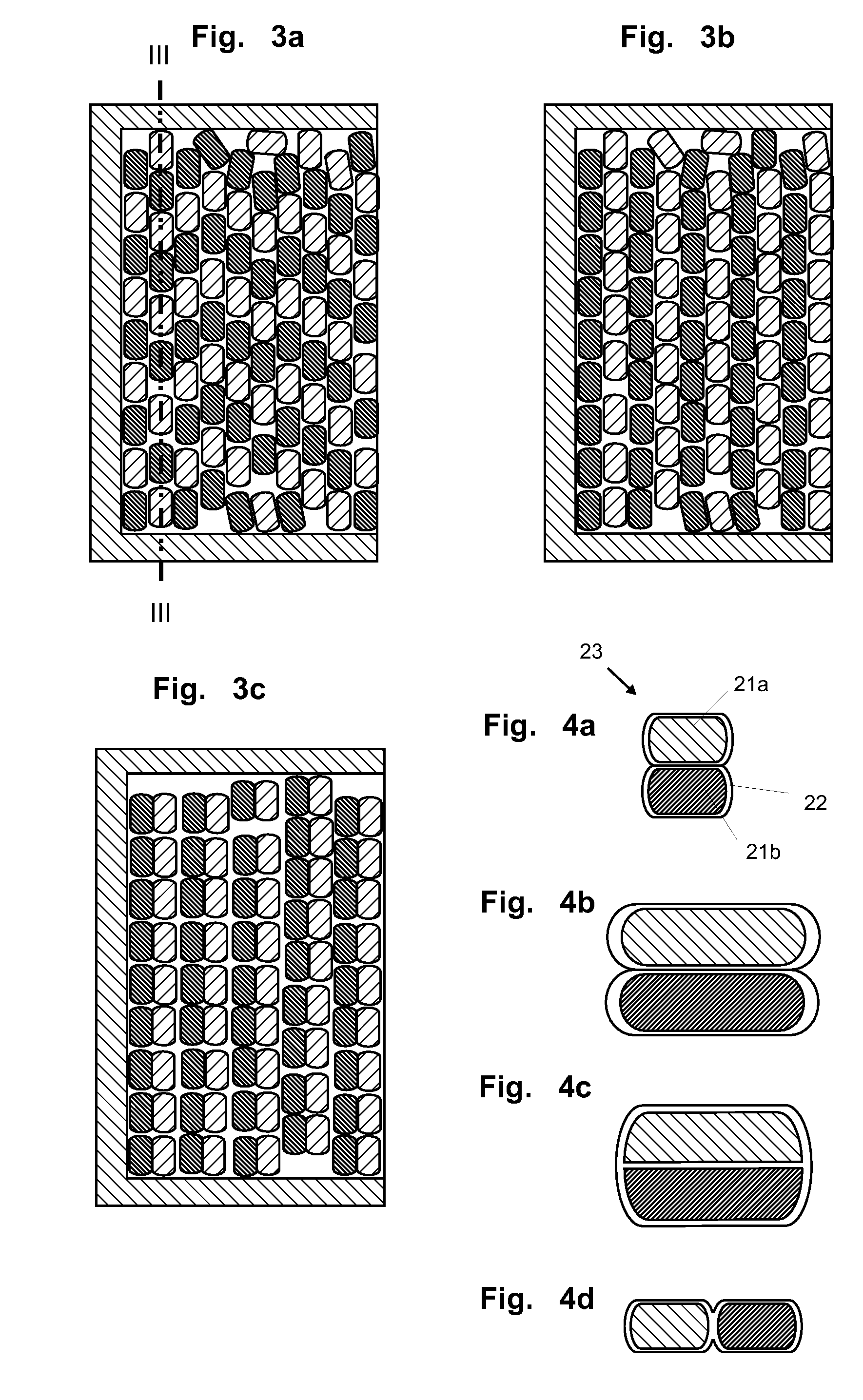

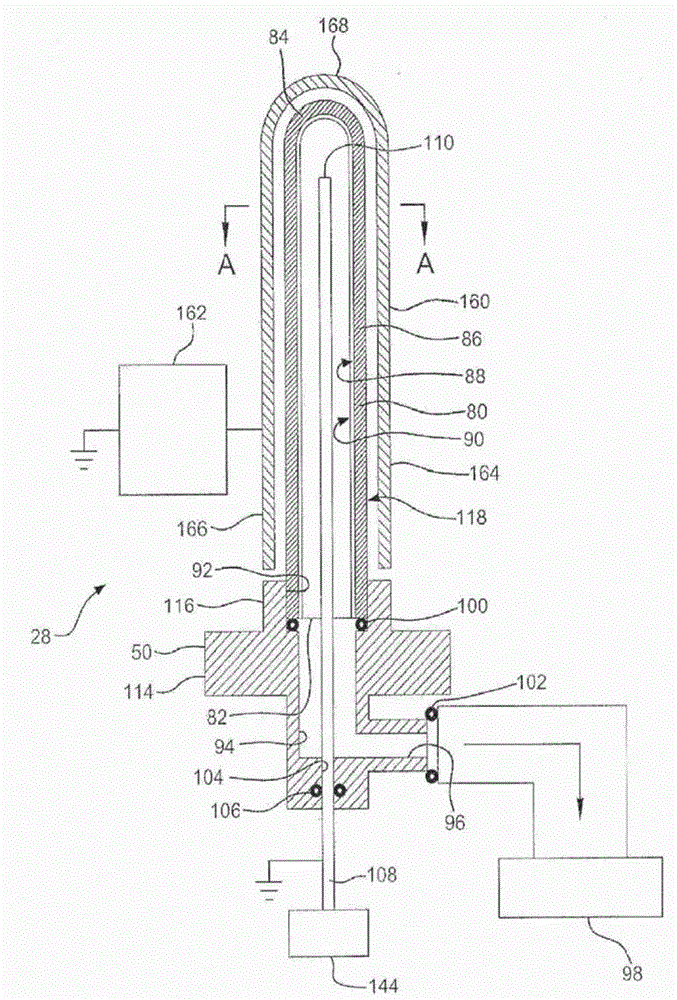

Coil of a force-measuring system, and method of manufacturing the coil

InactiveUS20080218303A1Improve fill rateAvailable spaceTransformers/inductances coils/windings/connectionsWeighing apparatus using electromagnetic balancingEngineeringConductor Coil

A multi-layered electromagnetic coil for a force-measuring system is based upon the principle of electromagnetic force compensation, as is a method for manufacturing the coil. The coil has a multifilar, specifically bifilar, wiring arrangement of coil wires. Preferably, the coil wires have a substantially rectangular cross-sectional profile. The cross-sectional profile of the coil wire is designed for achieving the densest possible packing of the windings in the coil can be achieved.

Owner:METTLER TOLEDO AG

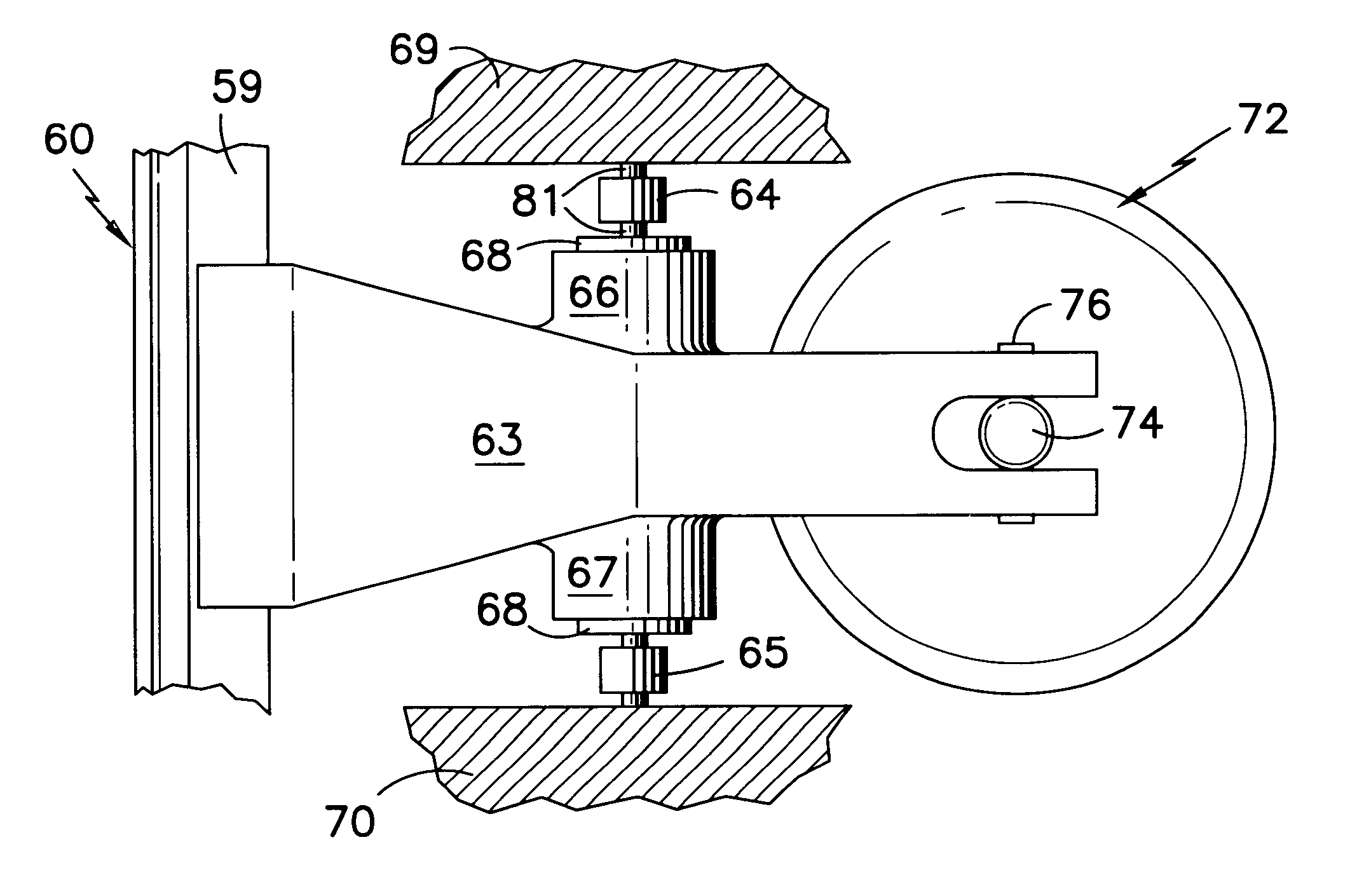

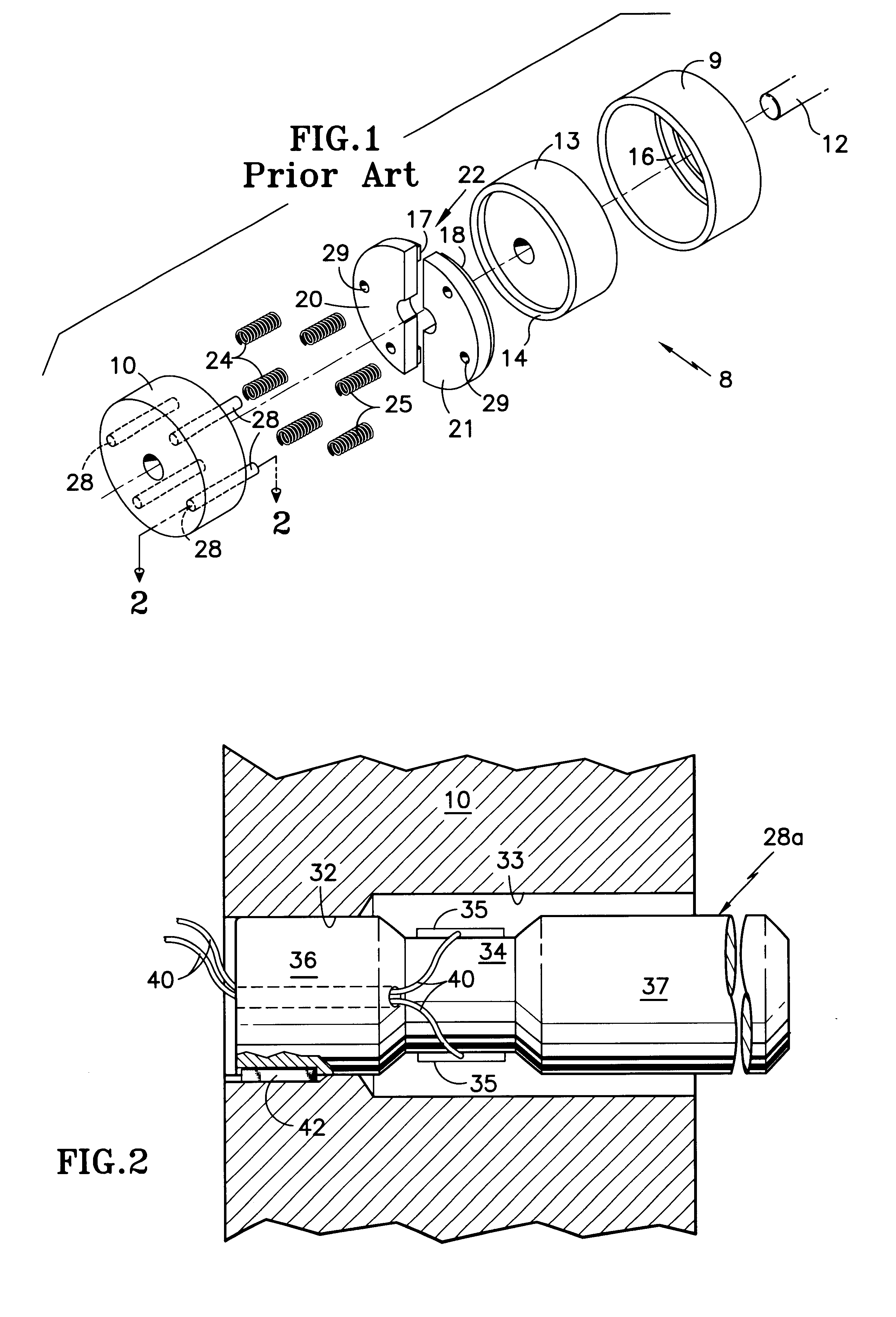

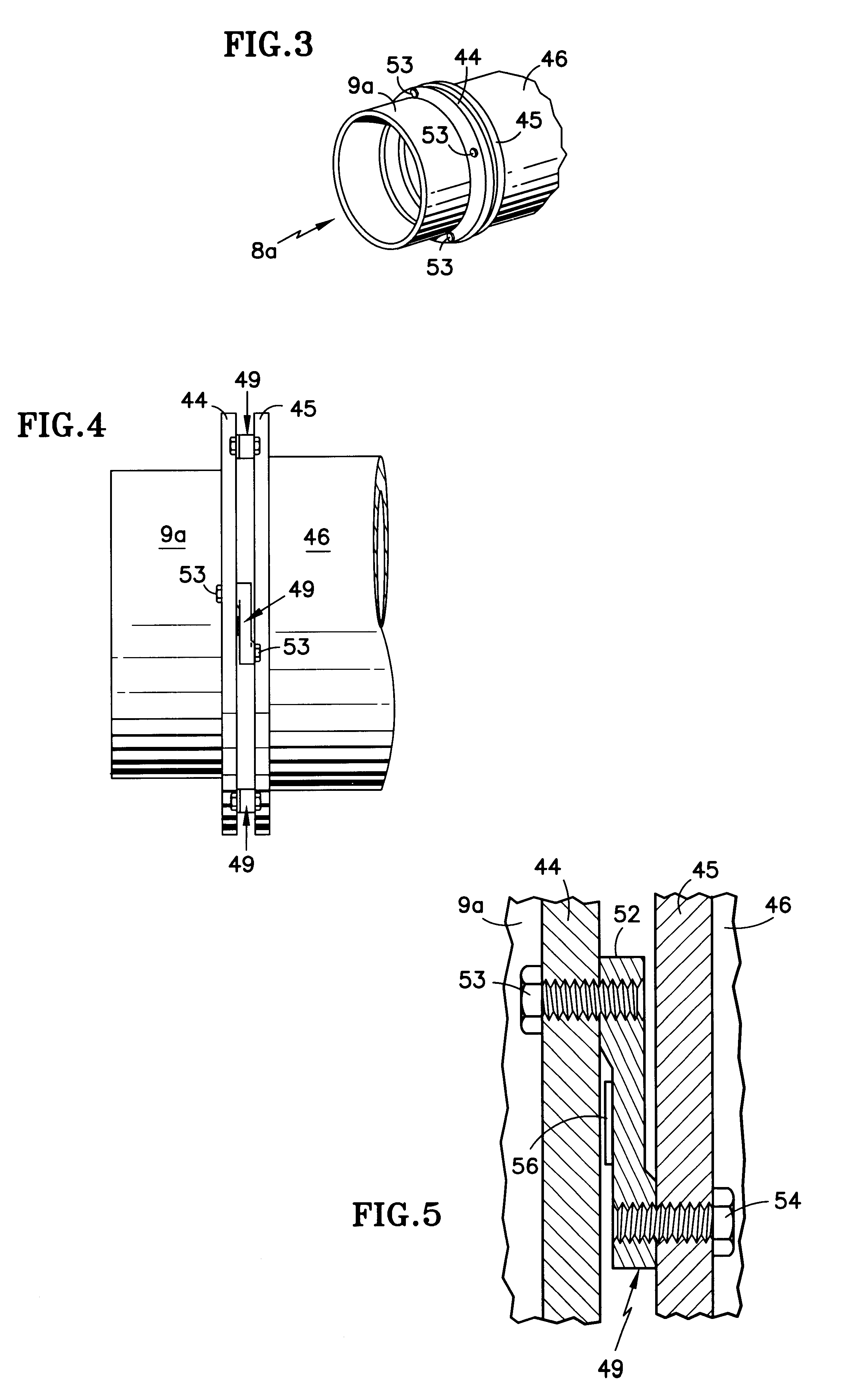

Elevator brake load weighing system

InactiveUS6483047B1Inexpensive and reliableLittle maintenanceWeighing apparatus using electromagnetic balancingWeighing indication devicesEngineeringVertical load

Load cells 35, 56 on antirotation dowel pins 28a or load mounts 49 indicate brake reaction forces in the disk brake 8, 8a of an elevator. Vertical load cells 72, 73 on bending load cell 80 indicate vertical brake reaction loads on a rail 60. A table indicating the load of an empty car at each of the landings served by the car permits subtracting load components relating to ropes, chains and cables to provide a live load indication prior to brake release; this may be used to determine if the load exceeds the maximum permissible load for the car.

Owner:OTIS ELEVATOR CO

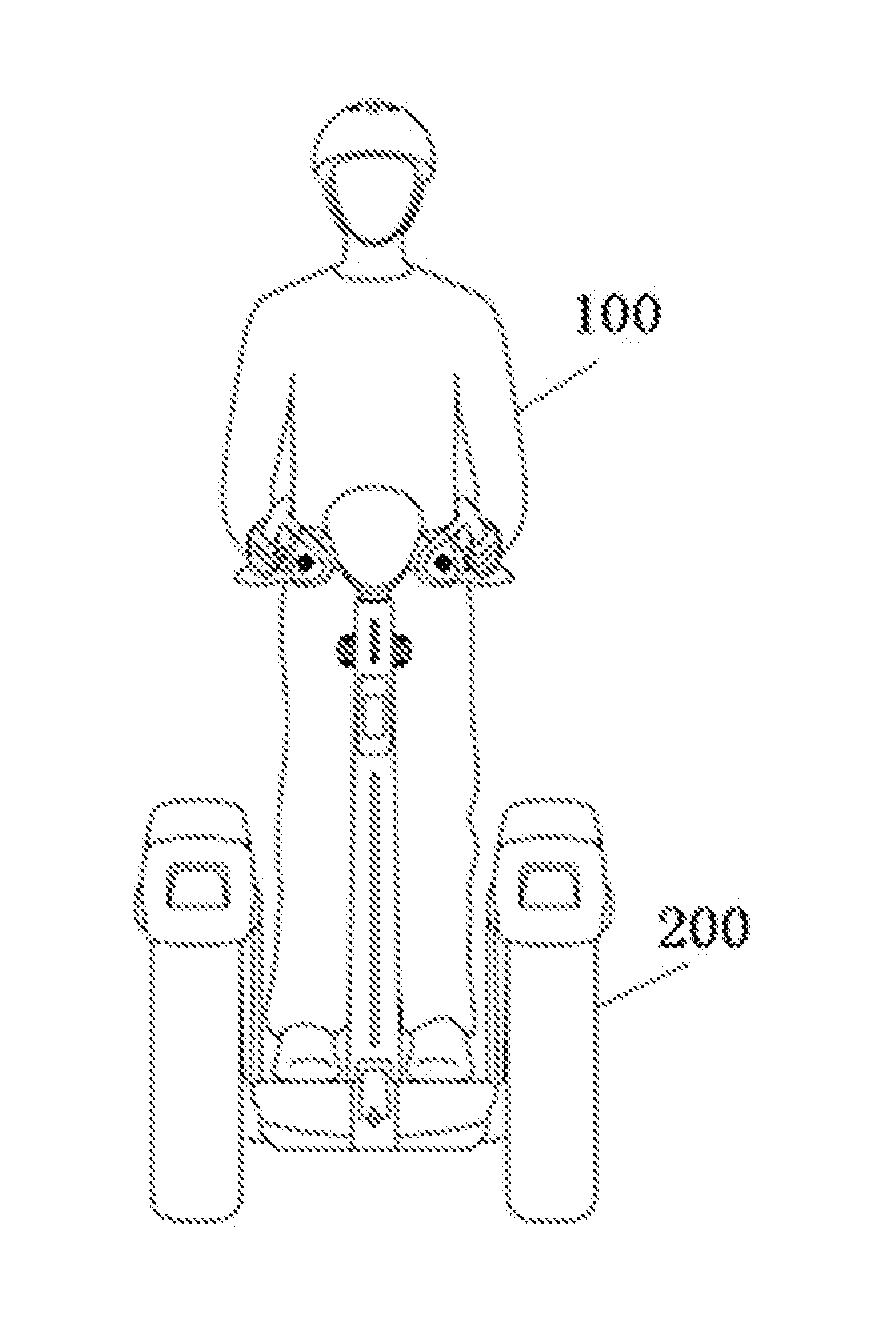

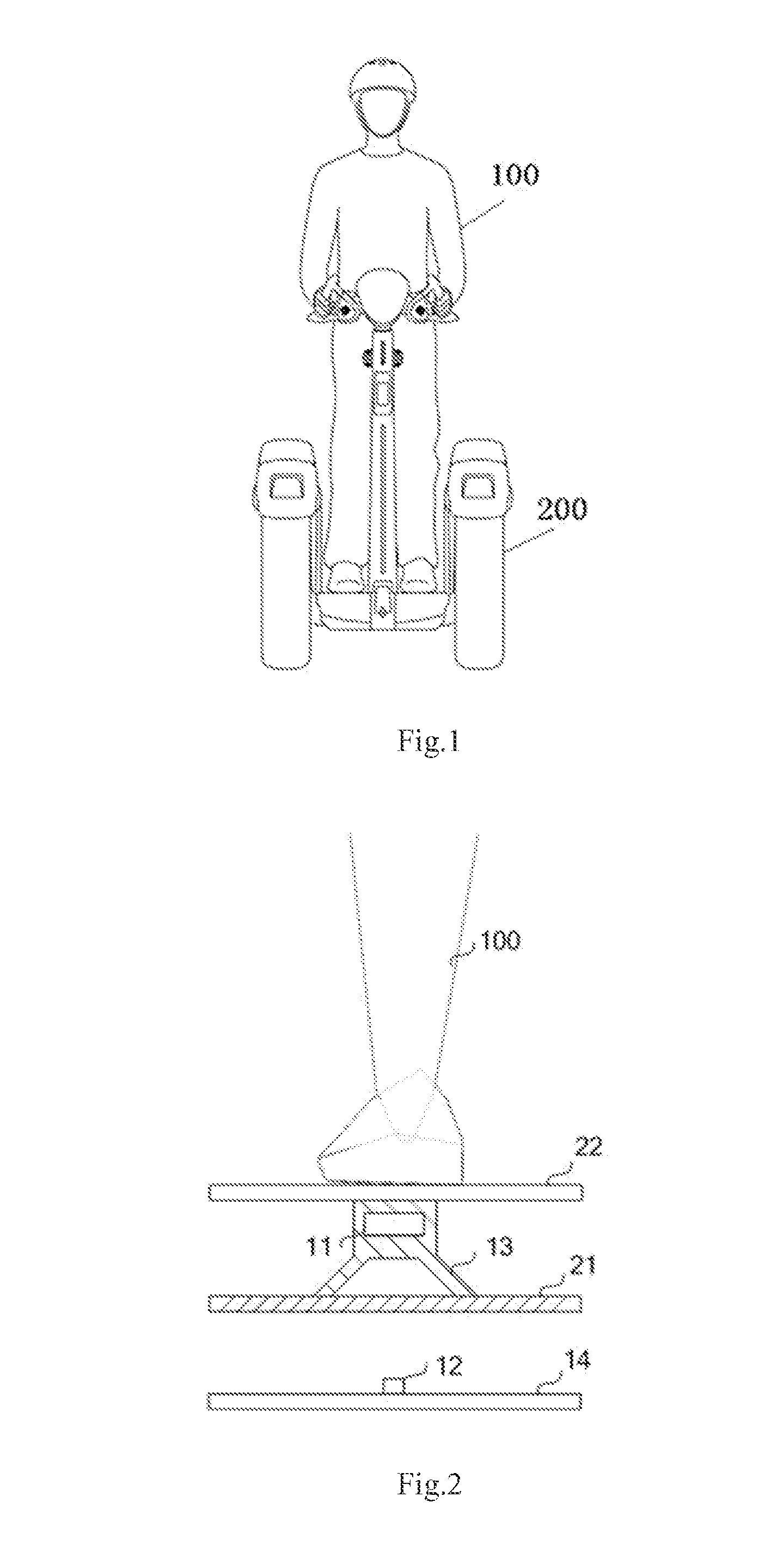

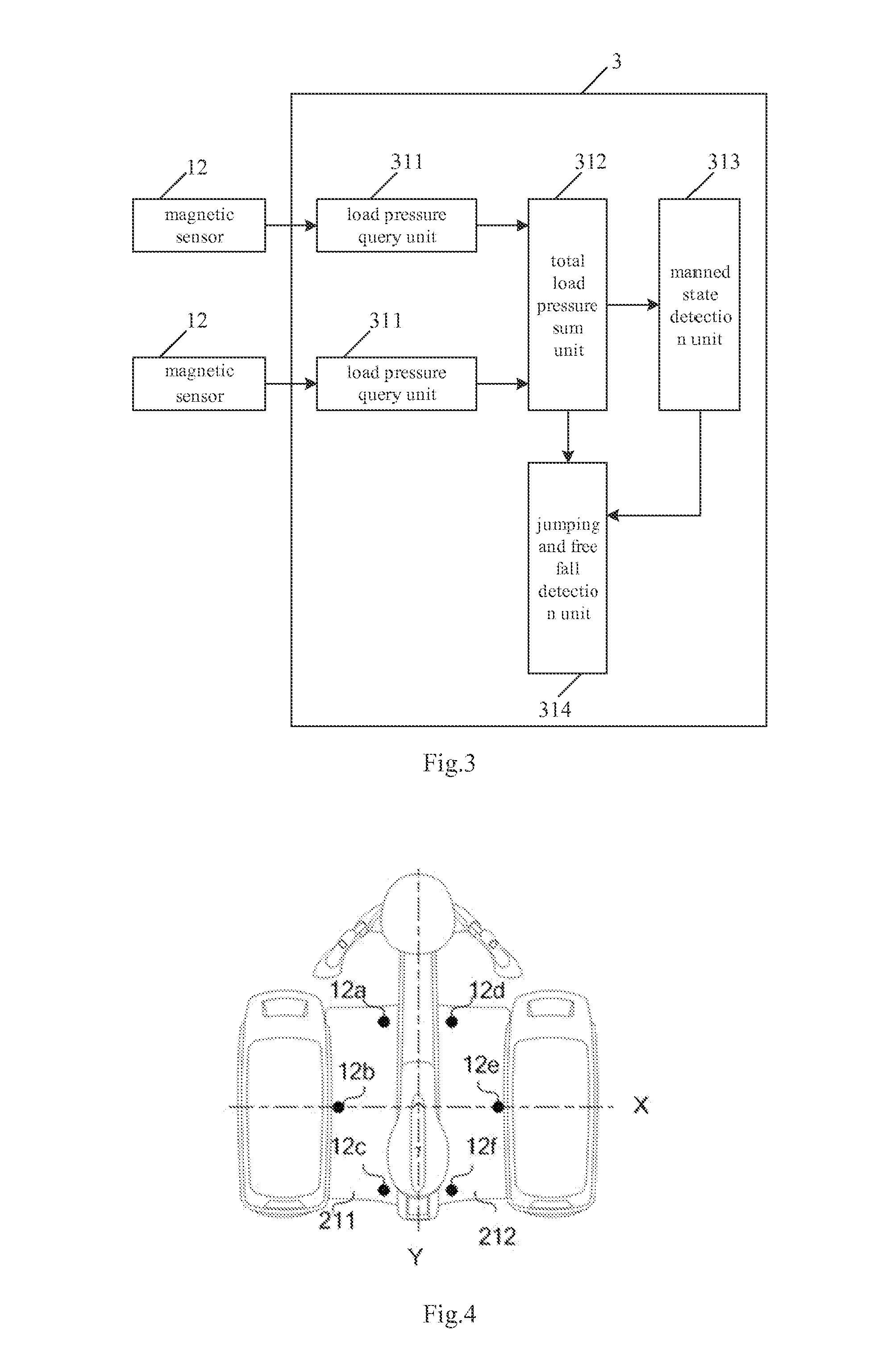

Online load detection device for self-balancing two-wheel vehicle

ActiveUS20150239499A1Inhibit wearExtended service lifeVehicle testingRegistering/indicating working of vehiclesRelative displacementEngineering

An online load detection device for a self-balancing two-wheel vehicle, comprising a support platform load detection device: the support platform load detection device comprises at least a group of magnetic detection devices; each group of magnetic detection devices comprise a permanent magnet and a magnetic sensor; the permanent magnet is supported on a support platform via an elastic member; the magnetic sensor is disposed in the easing of the support platform, and is used to detect the magnetic field change caused by the relative displacement between the permanent magnet and the magnetic sensor and output a detection signal. The detection device further comprises a seat pressure sensor disposed on a seat. The detection device detects the load pressure of the support platform in a non-contact manner, and can avoid wear, judge and warn the driving attitude of a driver.

Owner:NINGBO CHIKEWEI ELECTRONICS CO LTD

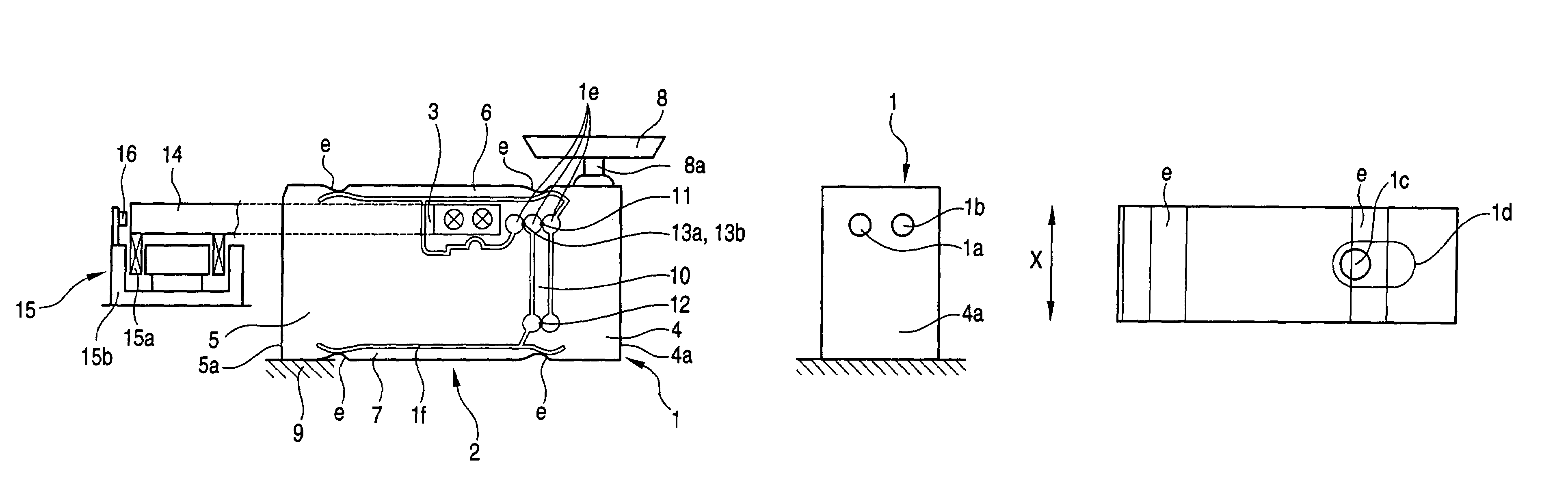

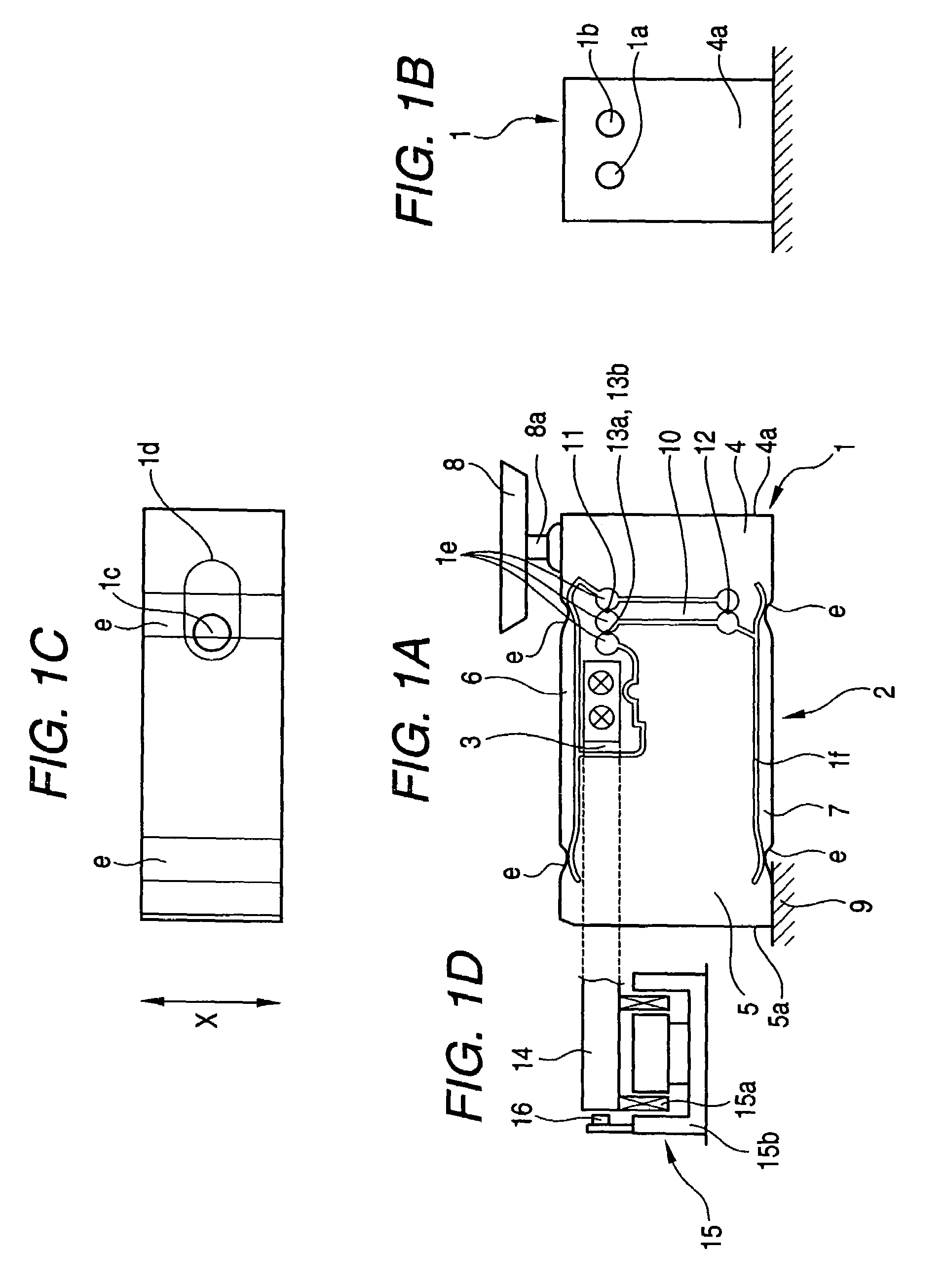

Electronic balance having a vibration reducing mechanism

InactiveUS7307226B2Reduce impactReduce widthWeighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersEngineeringSupport point

Two horizontal holes are processed at the end face of a movable pillar of a load measuring cell in a block shape. A power-point spring is formed between the horizontal holes, and the internal side faces of the horizontal holes constitute the internal end faces of supporting-point springs. Further, from above or below the load measuring cell, a vertical hole is processed so that the supporting-point springs are separated by the vertical hole extending in a vertical direction and are formed on both side faces in the longitudinal direction of load measuring cell.

Owner:SHIMADZU CORP

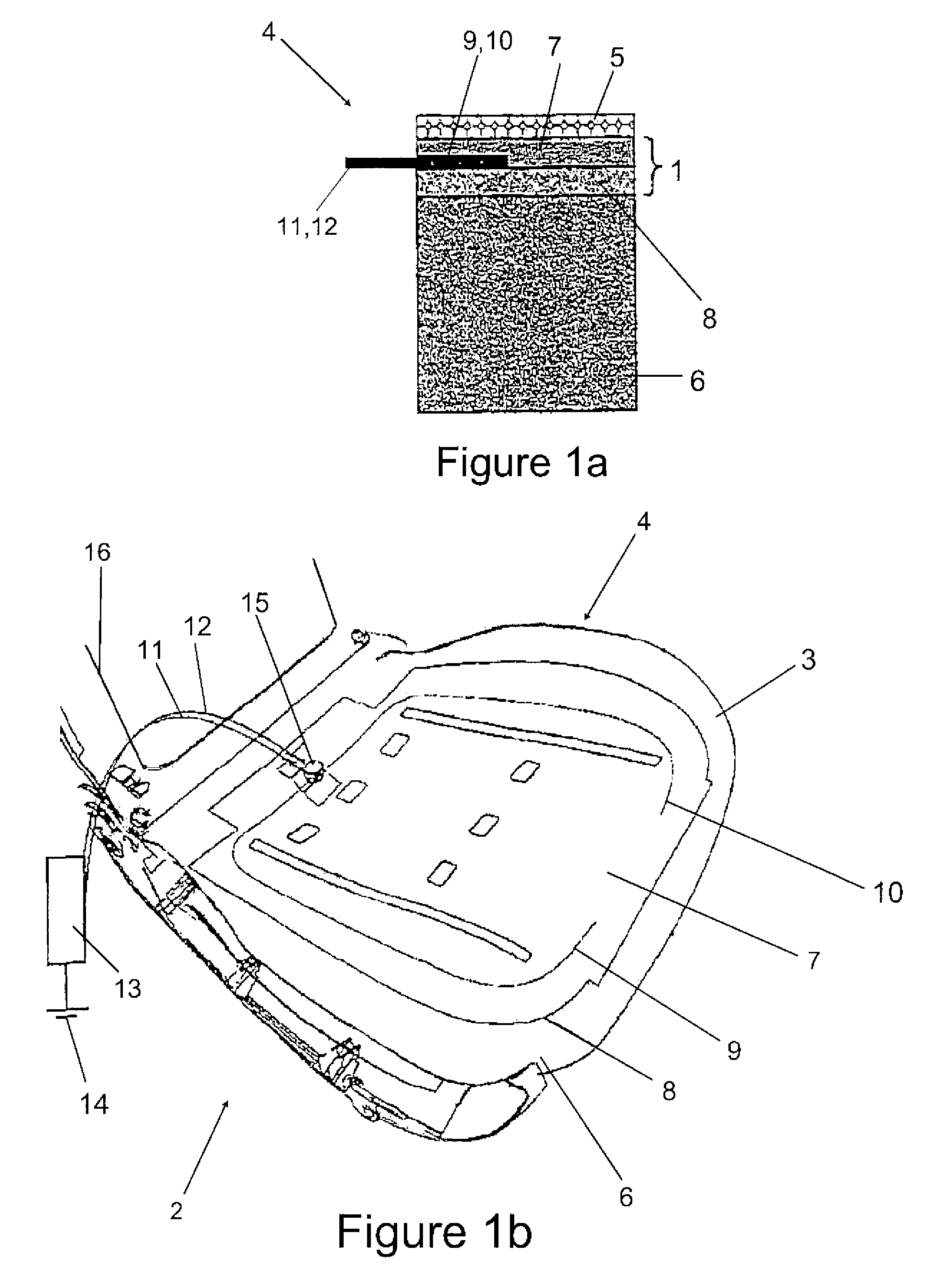

Surface heating, method for its production, and heatable object, and seat occupancy recognition, seat with it, and seat occupancy recognition method

InactiveUS7205505B2Simple and low-costHeating safetySeat heating/ventillating devicesElectric devicesElectrical resistance and conductanceSynthetic materials

A system for recognizing the occupancy of a seat, containing elements made of electrically conducting synthetic material, especially strips made of electrically conductive polyurethane. A seat equipped with the system. A method for recognizing seat occupancy whereby an alteration in resistance of the electrically conductive material occurring in a change of weight is detected.

Owner:BRAINSTOCK COM

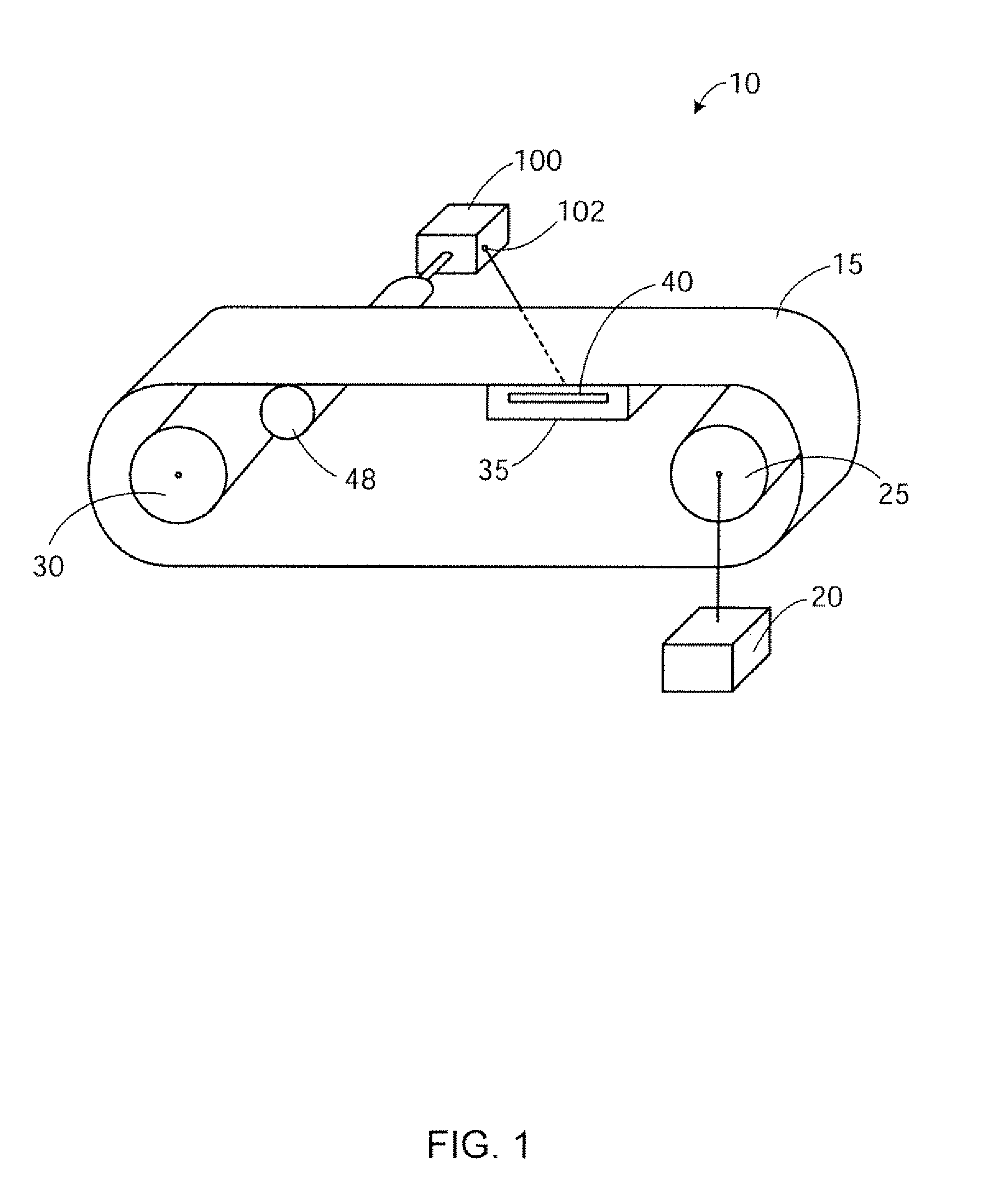

Conveyor belt scale system

ActiveUS20070215391A1ConveyorsWeighing apparatus using electromagnetic balancingMechanical energyEngineering

A scale may include a conveyor belt that carries a load, where the load has a weight. A generator is included that receives mechanical energy arising from movement of the conveyor belt and outputs electrical energy that corresponds to a rate of movement of the conveyor belt. At least one load cell receives the electrical energy from the generator, senses the weight of the load, and outputs a voltage that corresponds to the weight of the load and the rate of movement of the conveyor belt.

Owner:MFR & TRADERS TRUST

Electronic balance

InactiveCN1782678AAvoid sensitivityReduce vibrationWeighing apparatus using electromagnetic balancingElectromagnetic interferenceEngineering

Owner:SHIMADZU SEISAKUSHO CO LTD

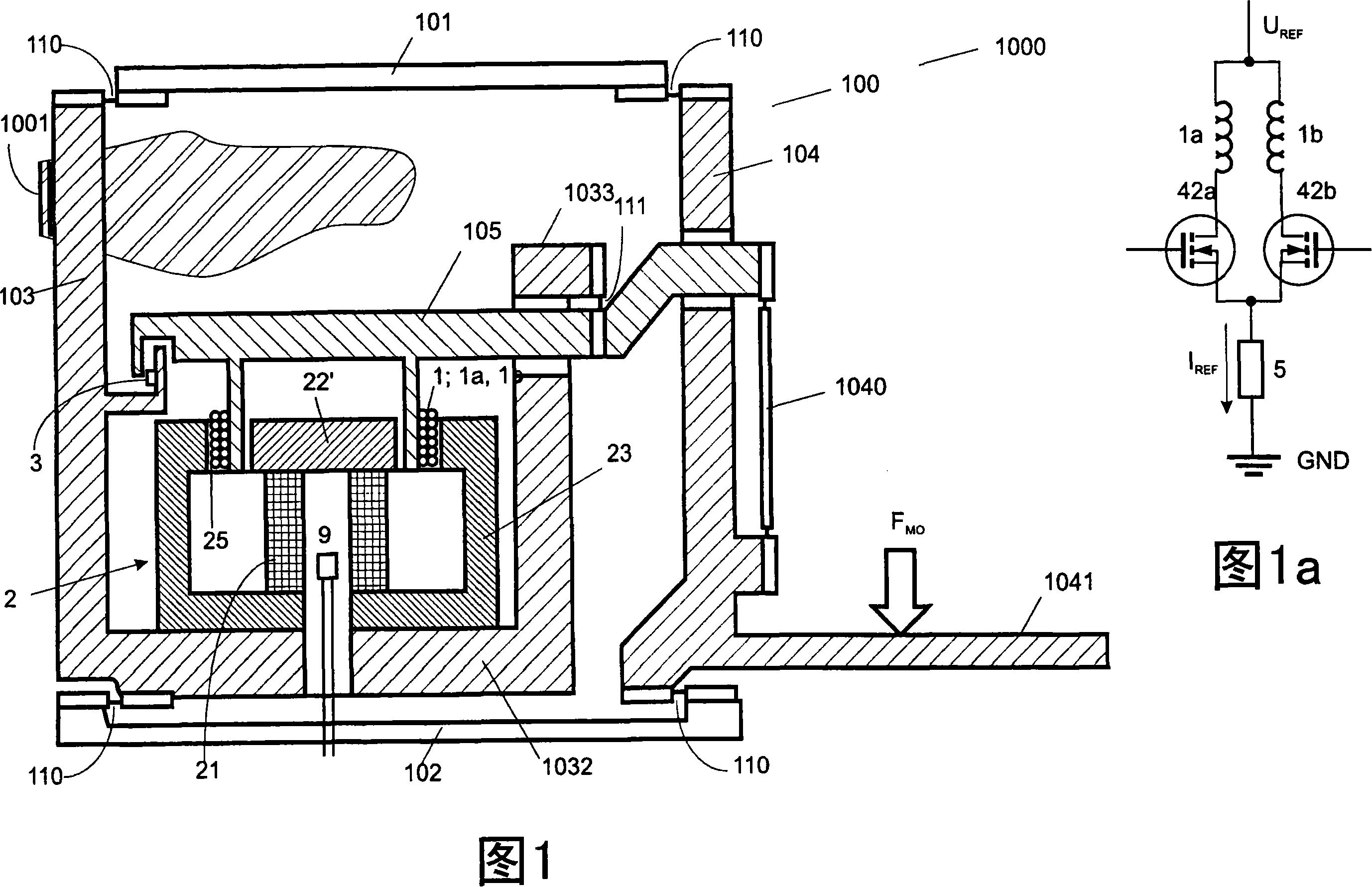

Force measuring device and reference unit

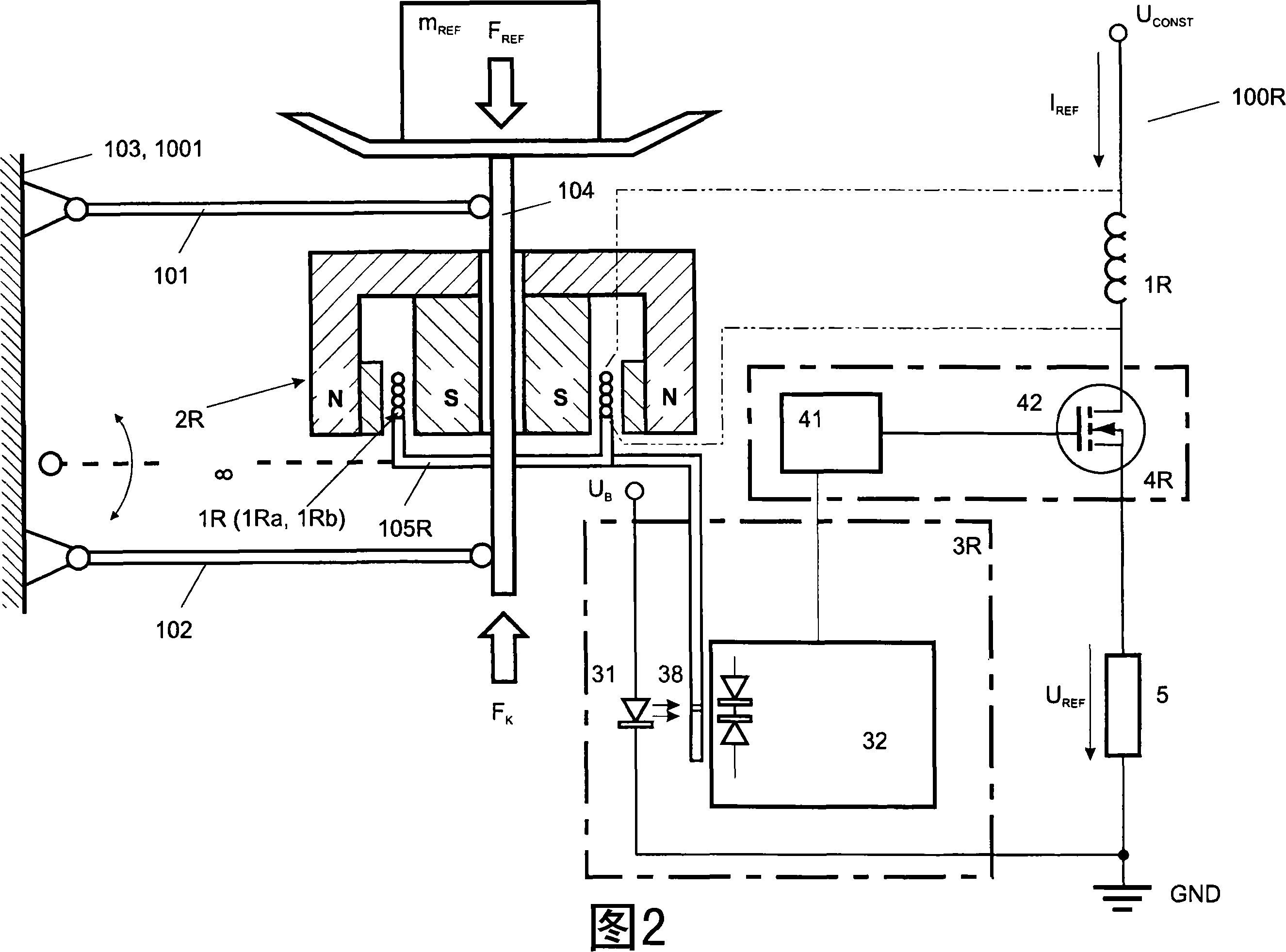

ActiveCN101140182ALow costCompact designWeighing apparatus testing/calibrationOscillations damping for weighingMagnetic tension forceReference current

A force-measuring device (1000) includes a measuring unit (100) and a reference unit (100R), wherein the reference unit (100R) is used to deliver a reference quantity, a reference current (IREF) or a reference voltage (UREF), by means of which the force (FMO) of a measurement object which is to be determined can be measured by the measuring unit (100). According to the invention, the reference unit (100) is a force-measuring device which is loaded with a reference mass (mREF) and which in accordance with the principle of electromagnetic force compensation generates a reference current (IREF) that can be regulated by means of a measuring-and regulating device (3R, 4R) in such a way that in a first reference coil (1R;1Ra) which is held by a reference lever (105R), the reference current (IREF) generates a magnetic field which cooperates with the magnetic field of a reference magnet (2R;2-2R) in such a way that a magnetic force is brought to bear on the reference lever (105R), wherein the force (FREF) of the reference mass (mREF) which is likewise acting on the reference lever can be compensated by said magnetic force.

Owner:METTLER TOLEDO INC

Electronic balance

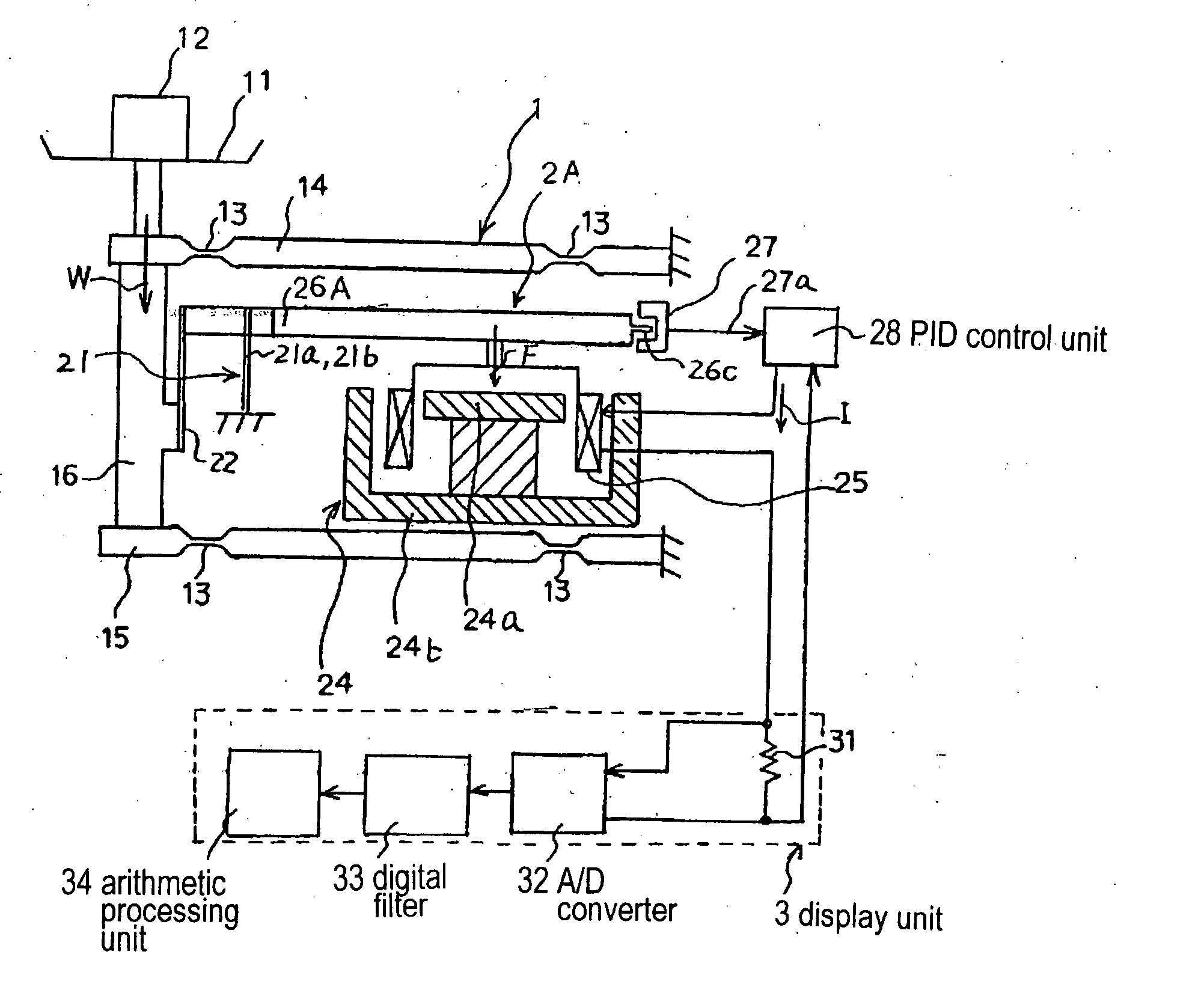

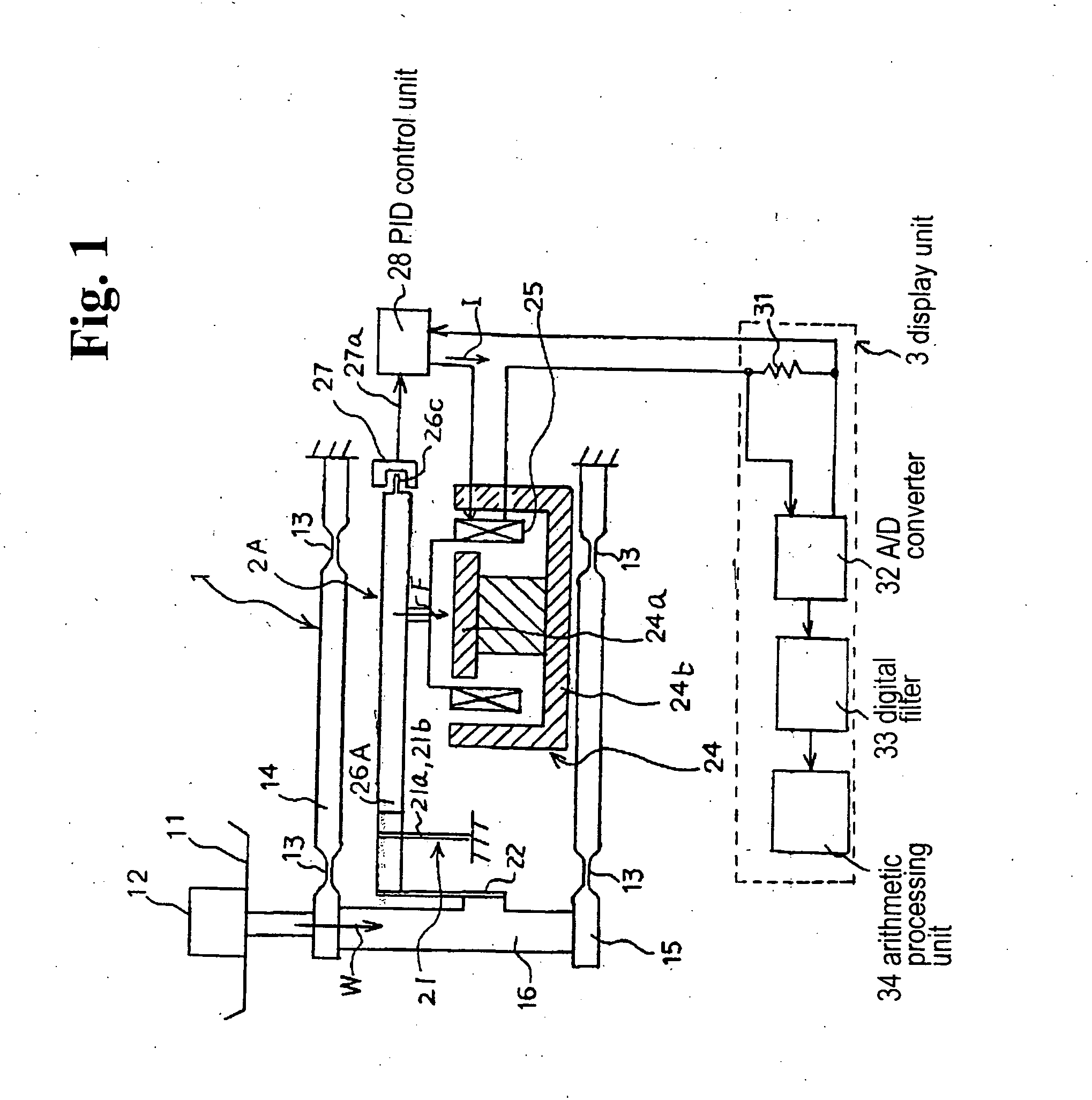

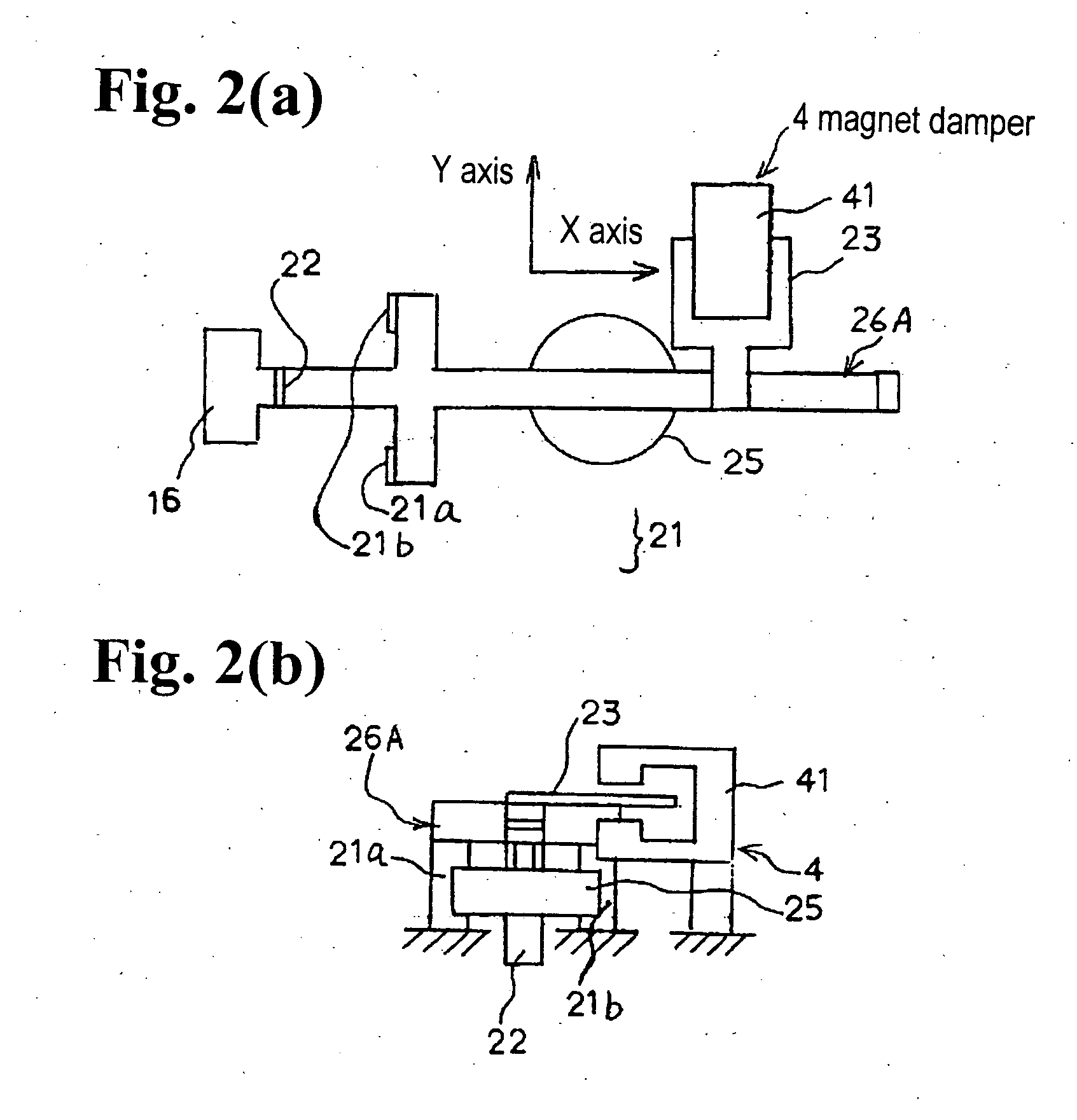

InactiveUS20050205309A1Reduce vibrationEliminate the effects ofWeighing apparatus using counterbalanceWeighing apparatus using electromagnetic balancingEngineeringElectron

An electronic balance includes a load transmission mechanism for receiving an object to be measured, a magnetic field generator having a force coil for generating magnetic field, and a balance beam connected at one end to the load transmission mechanism and disposed adjacent to the magnetic field generator with a fulcrum interposed between a portion connected to the weight section and the magnetic field generator. An electromagnetic force generated by supplying current to the force coil is applied to the balance beam to obtain a weight of the object from the current flowing through the force coil in equilibrium with the load. A damper is attached to the balance beam to control vibration in at least one of a longitudinal direction of the balance beam and a horizontal direction perpendicularly intersecting therewith.

Owner:SHIMADZU CORP

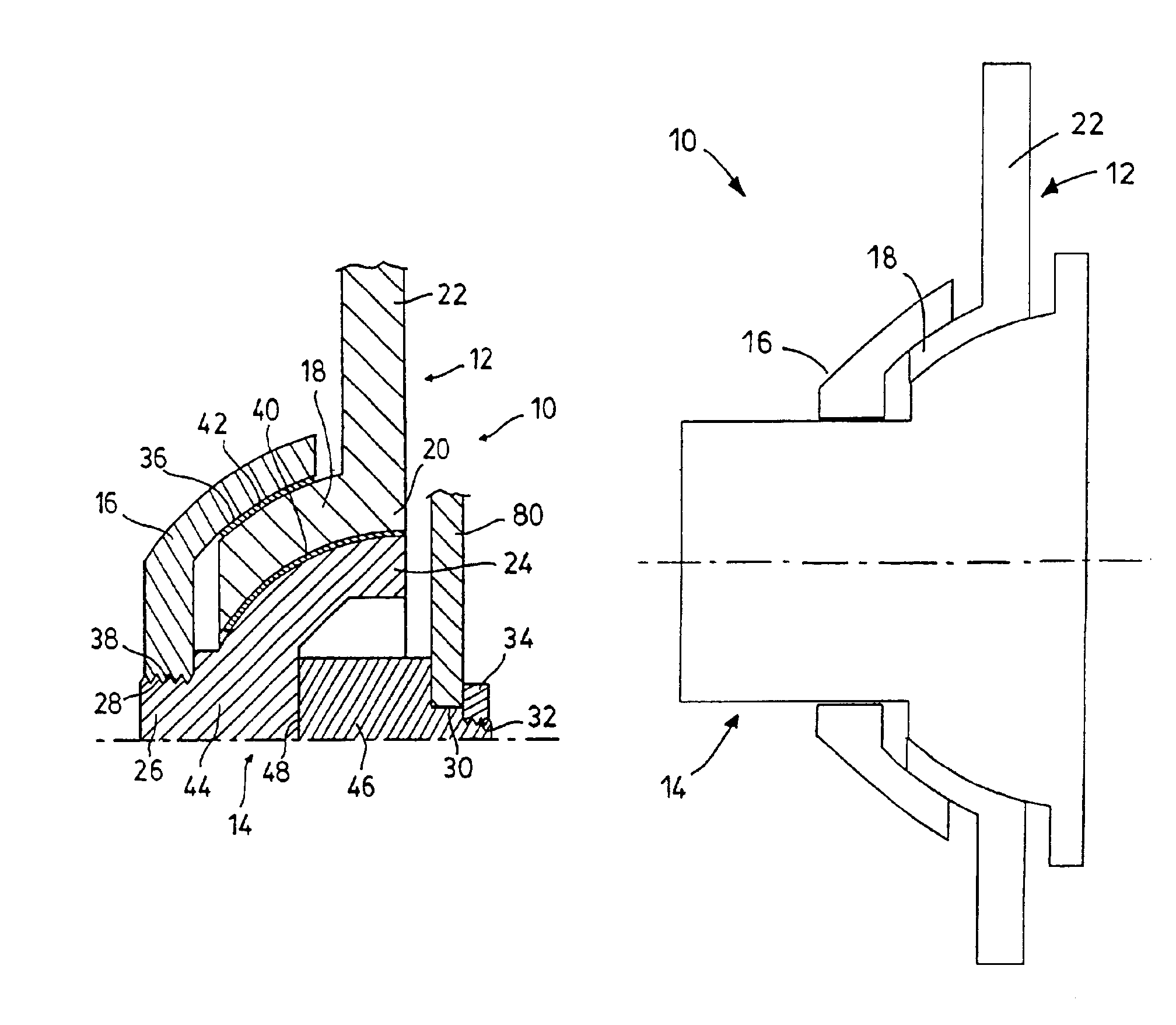

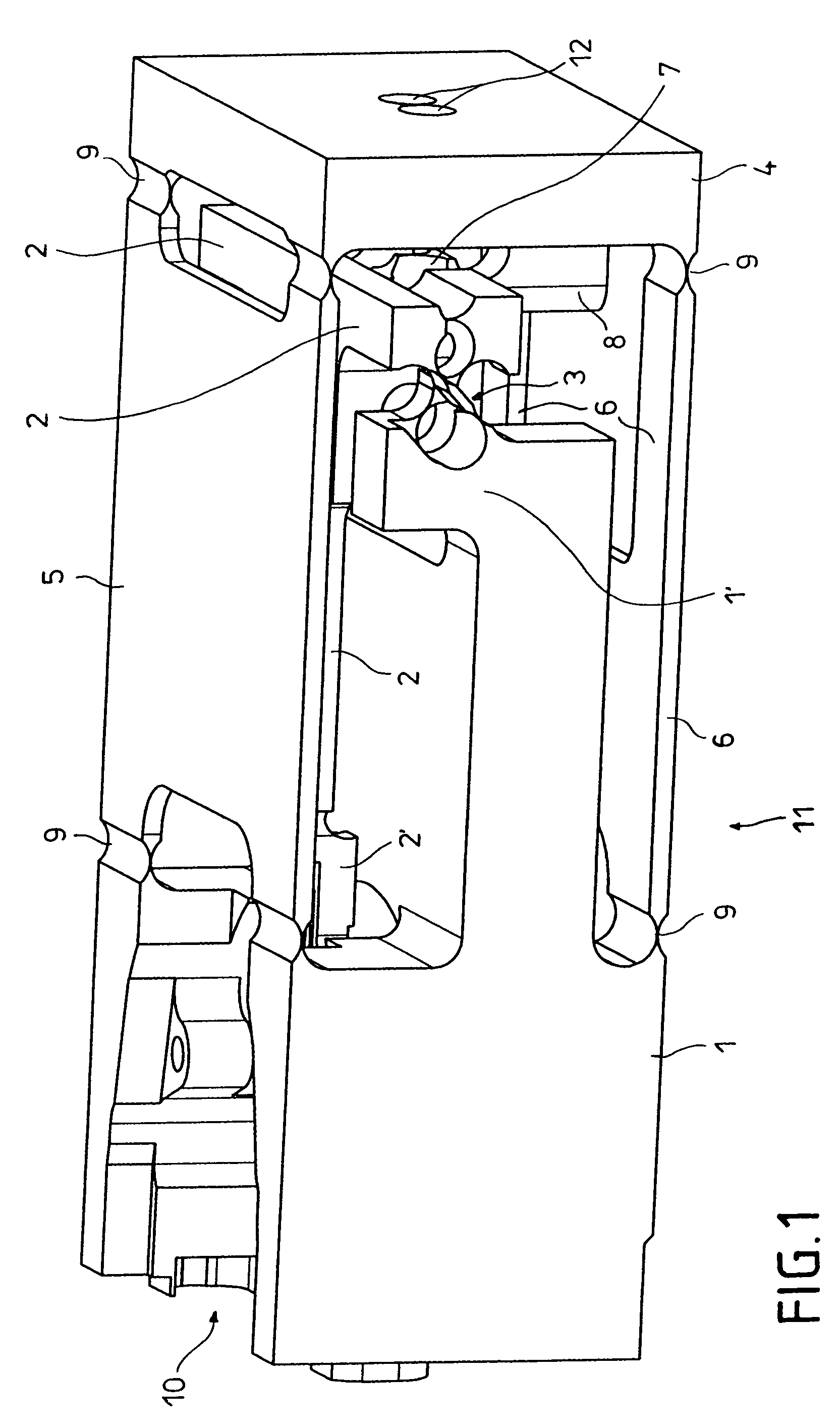

Weighing system of monolithic construction including flexural pivot

ActiveUS7534971B2Easy to manufactureNo hysteresisWeighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersHysteresisCoupling

A weighing system having a base region (1), a parallel-guided load receiver (4), at least one transmission lever (2) that is pivotably mounted on the base region via at least one flexural pivot (3), and a coupling element (7) that connects the load sensor to the short lever arm of the transmission lever. The flexural pivot (3), at least one part of the transmission lever (2), and at least one part of the base region (1′) are monolithically formed from a block. The flexural pivot (3) is separated from the rest of the block by four horizontal parallel bores (31, 32, 33, 34) that are adjacently arranged in an annular manner in such a way as to respectively leave a thin connecting segment (36, 37, 38 39) between adjacent bores, and by additional slots. In this way, a hysteresis-free flexural pivot can be created without the need for separate assembly components.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

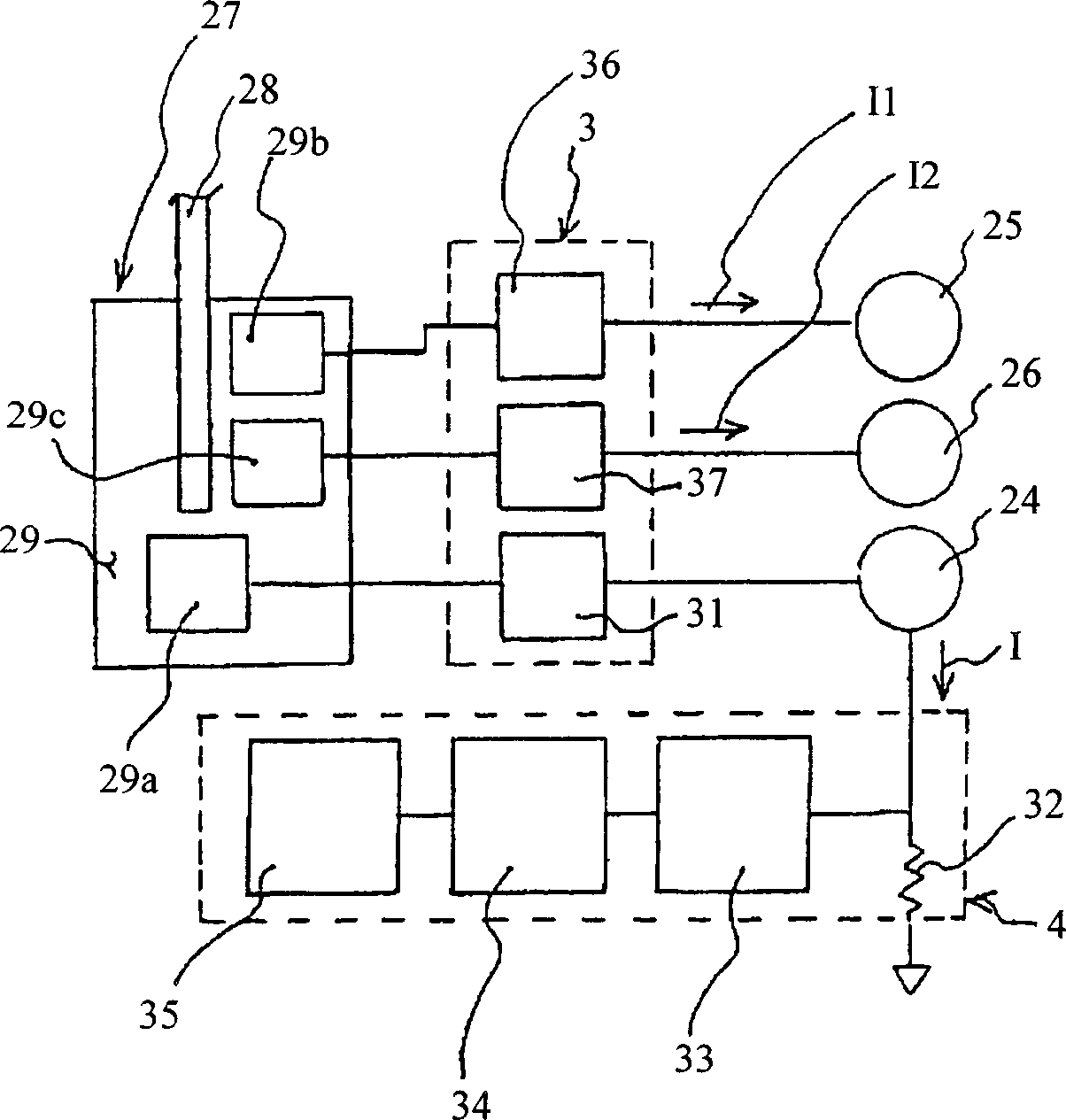

Weighing scales operating method and device

ActiveCN101029844AMultiple guaranteesWeighing apparatus using electrostatic balancingWeighing apparatus using electromagnetic balancingControl theoryMechanical engineering

Owner:METTLER TOLEDO INC

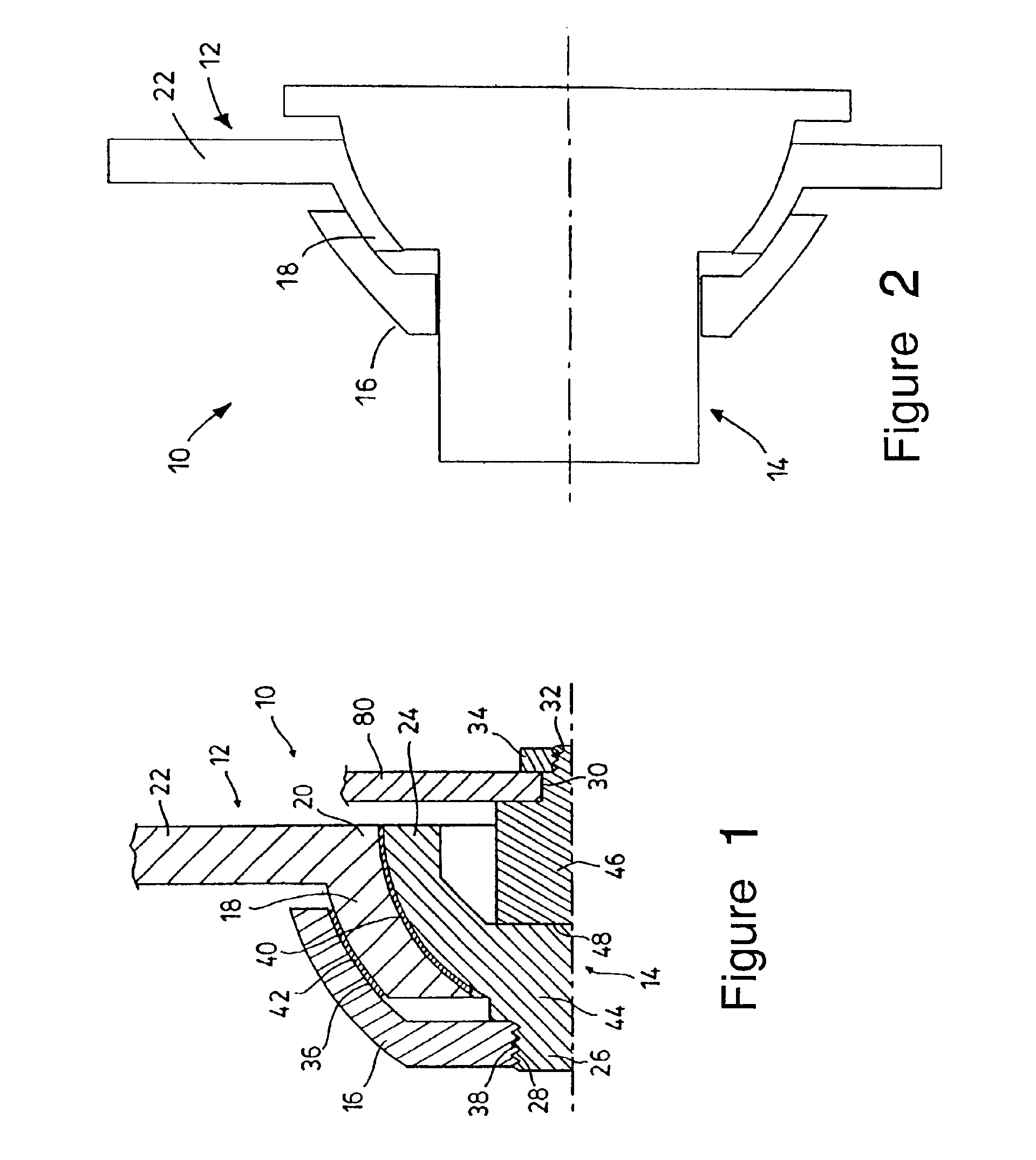

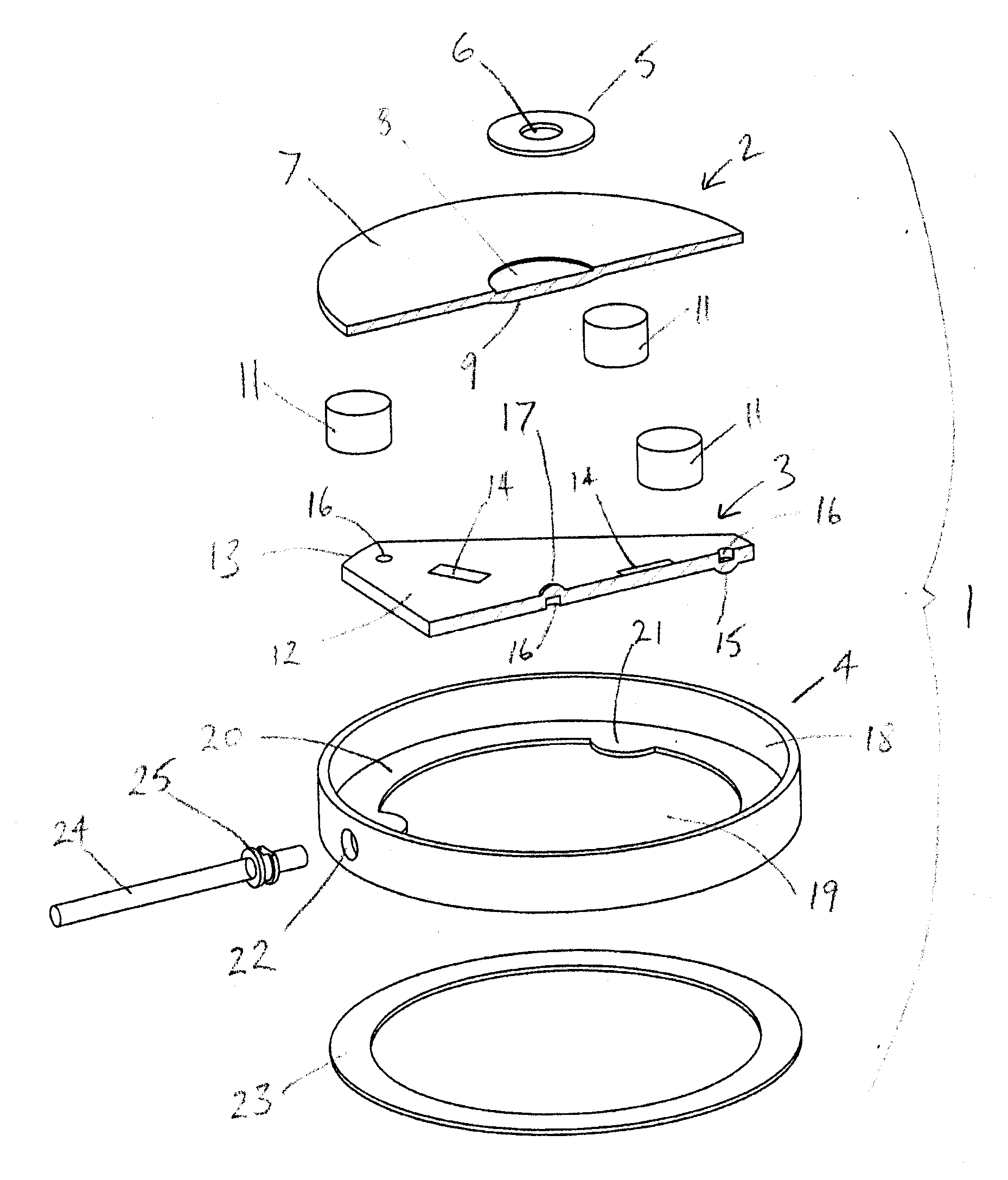

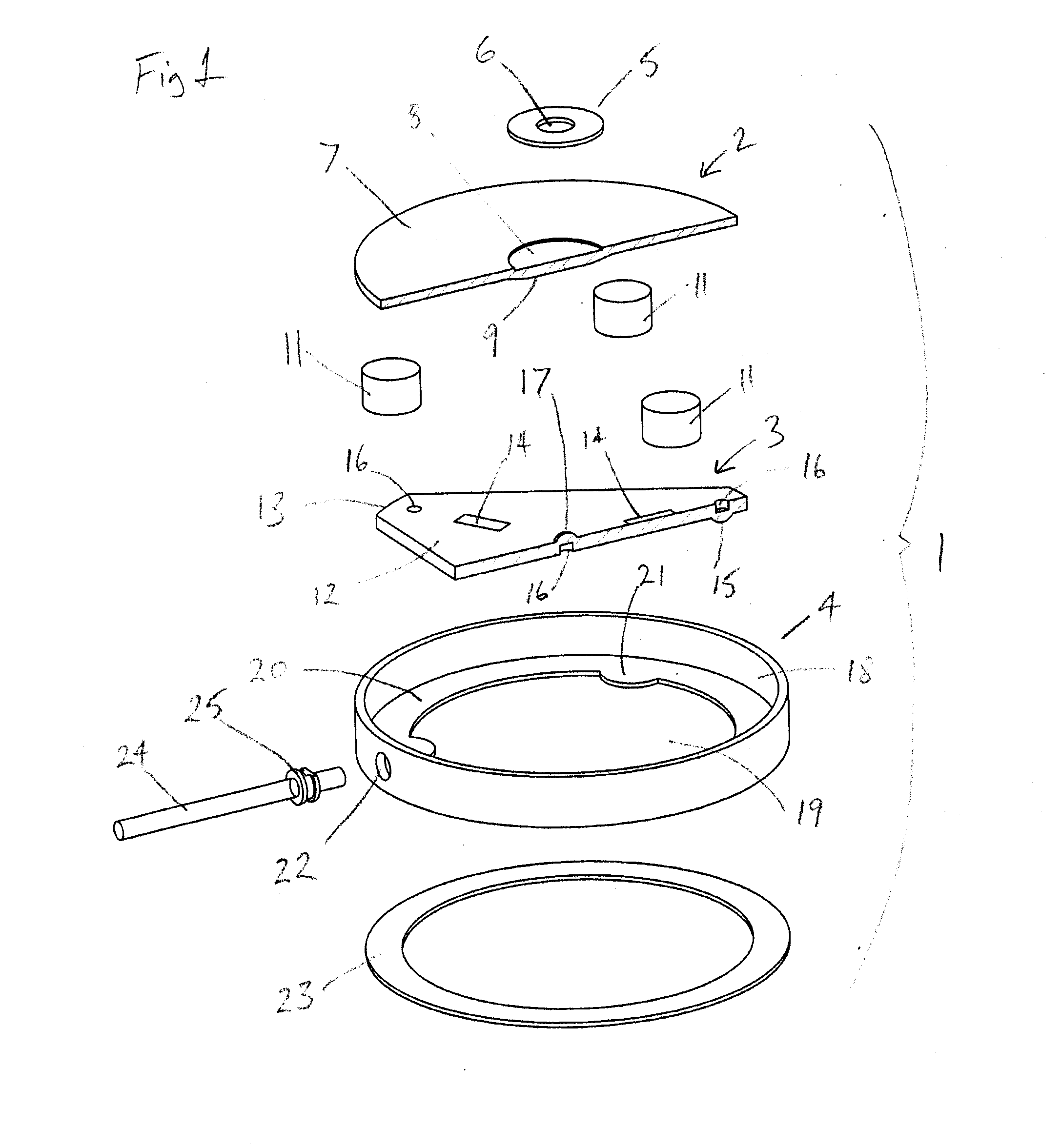

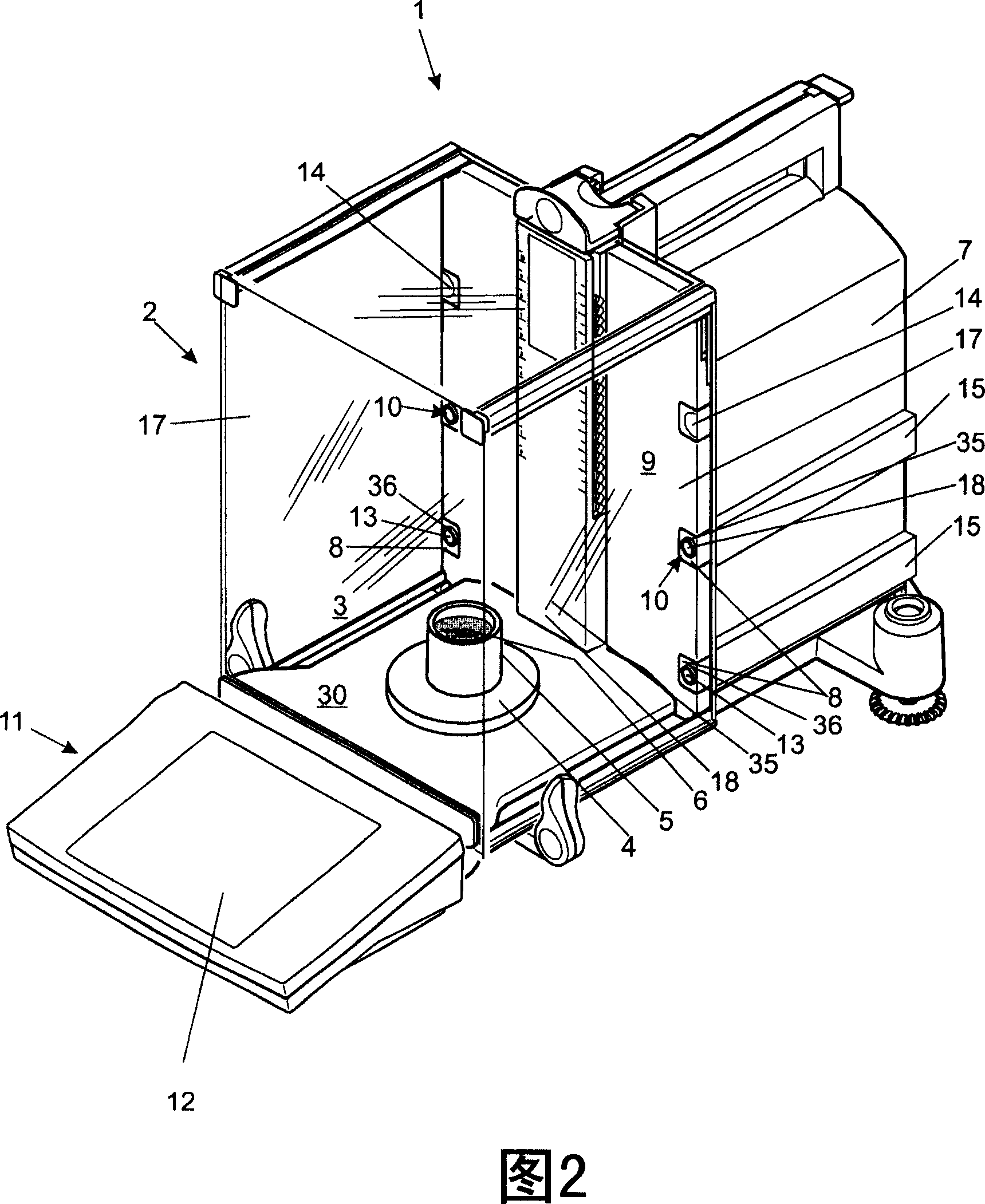

Balance with a support element for coupling a weighing pan to a weighing cell

InactiveUS20030188897A1Yield easilyPrevent residual torquesWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingCantilever

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

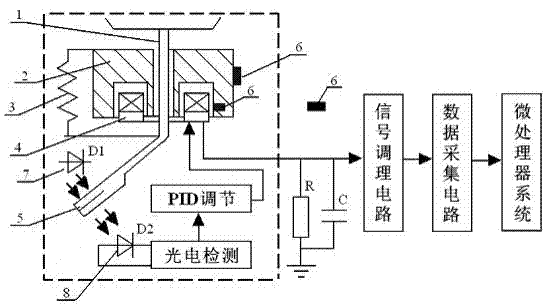

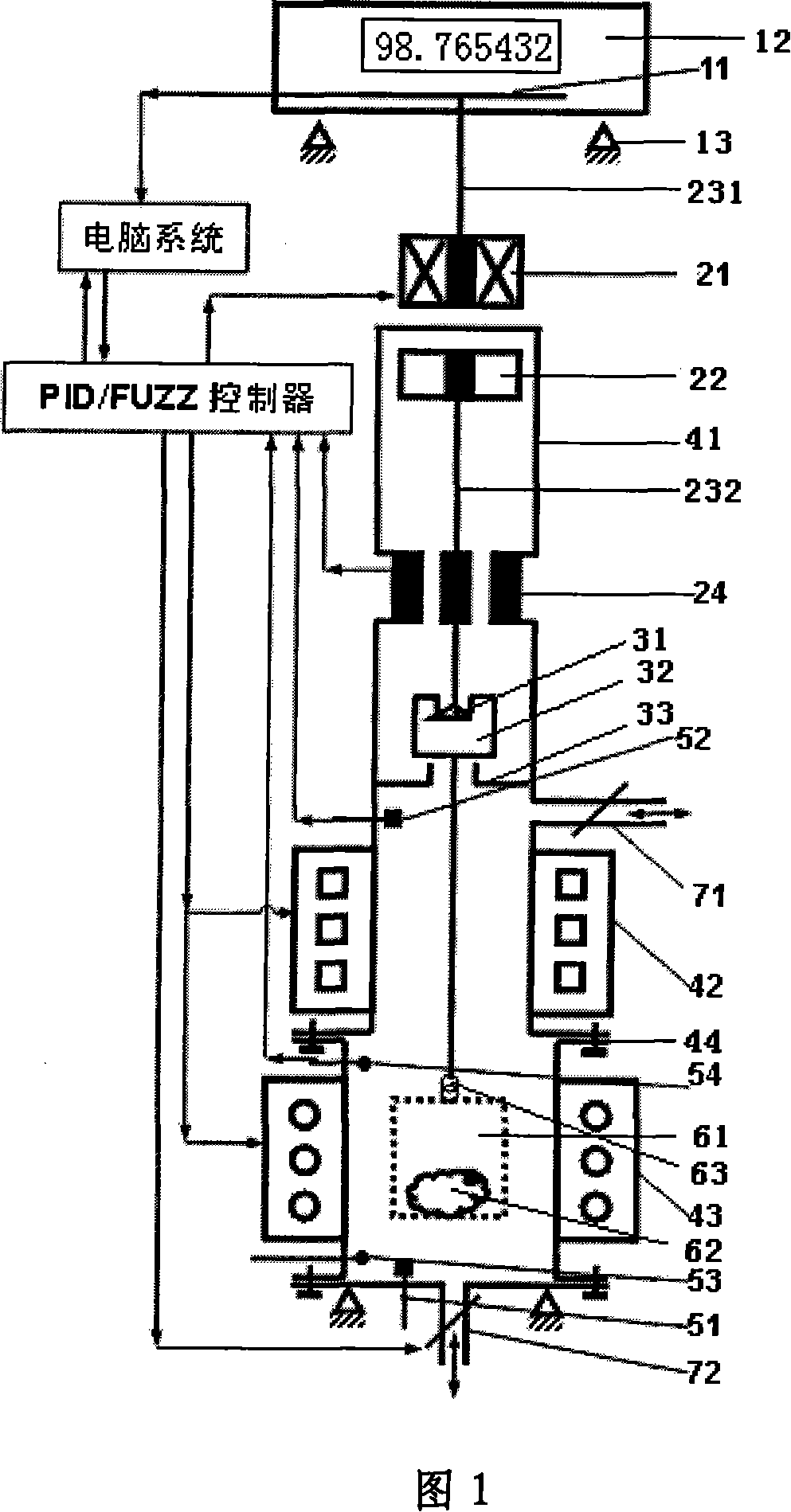

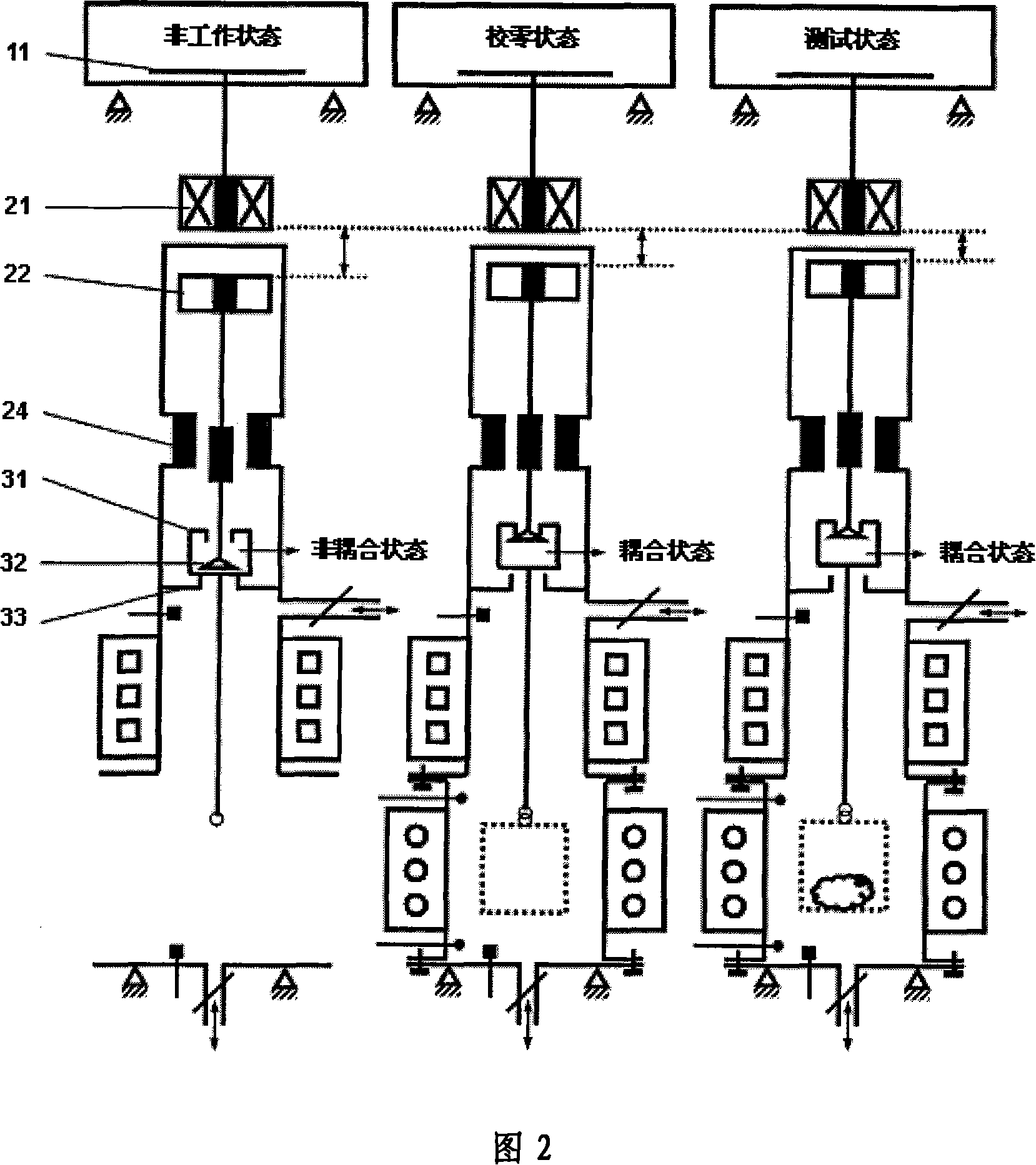

Multifunctional high-accuracy electronic balance

ActiveCN102768060AInnovative designEasy to operateWeighing apparatus using electromagnetic balancingWeighing temperature-compensating arrangementsData acquisitionEngineering

The invention discloses a multifunctional high-accuracy electronic balance. The internal structure of the electronic balance comprises an electromagnetic force balance sensor, a photoelectric detection circuit, a proportion integration differentiation (PID) regulation circuit, a signal modulation circuit, a data collection circuit, a microprocessor master control module and a temperature detection module. The electromagnetic force balance sensor, the photoelectric detection circuit and the PID regulation circuit form a closed system to improve accuracy and stability of the electronic balance. The multifunctional high-accuracy electronic balance is novel in design and convenient to operate. Due to adopting the electromagnetic force balance sensor and utilizing the null method principle to weigh quality of weighed object, the multifunctional high-accuracy electronic balance has excellent performance of being high in measurement accuracy, good in measurement stability and capable of performing continuous and repeated measurement. Besides, the multifunctional high-accuracy electronic balance further has functions of being various in measurement type, and capable of achieving full-automatic calibration and self-diagnosis of breakdown.

Owner:DABAIKE LAB EQUIP ENG JIANGSU

Inspection methods for pecvd coatings

A method for inspecting the product of a coating process is provided. In certain embodiments, the release of at least one volatile species from the coated surface into the gas space adjacent to the coated surface is measured and the result is compared with the result for at least one reference object measured under the same test conditions. Microbalance weighing methods are also disclosed to detect and distinguish among PECVD coatings. Thus the presence or absence of the coating, and / or a physical and / or chemical property of the coating can be determined. The method is useful for inspecting any coated articles, e.g. vessels. Its application on the inspection of PECVD coatings made from organosilicon precursors, especially of barrier coatings, is also disclosed.

Owner:SI02 MEDICAL PRODS

Balance with a T-shaped coupling arrangement that guides the support element onto a load receiver at three points forming a triangle

InactiveUS7012198B2Reduce frictionEasy to cleanWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingEngineering

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

Method for measuring substance weight in special surroundings

InactiveCN101082517AFulfill measurement requirementsWeighing apparatus using electromagnetic balancingMeasuring instrumentCoupling

This invention discloses a kind of material weight metering method under special environment, it forms a metering system with a kind of magnetic suspension metering device, intelligent control device and computer system for dividing the sample circumstance and the measuring circumstance; with the adjusting and controlling of the position sensor and intelligent control device, realizing magnetic suspension situation; after realizing zero adjusting under the normal environment, setting the needed temperature and pressure, the intelligent control device intelligently adjusts and controls the temperature adjusting device and the pressure adjusting device according to the adjusting temperature and adjusting pressure command the computer system exports, to realize the zero adjusting under the set environment; after the environment in the adjusting environment pipe getting the set temperature and pressure, the material weight in the environment pipe is delivered to the measuring device of the out pipe non-touched by the magnetic force coupling function that are produced by the permanent-magnet in the environment and the electromagnet out of the environment, and the measuring device of the out pipe put the measuring signal into the computer system.

Owner:上海中晨数字技术设备有限公司

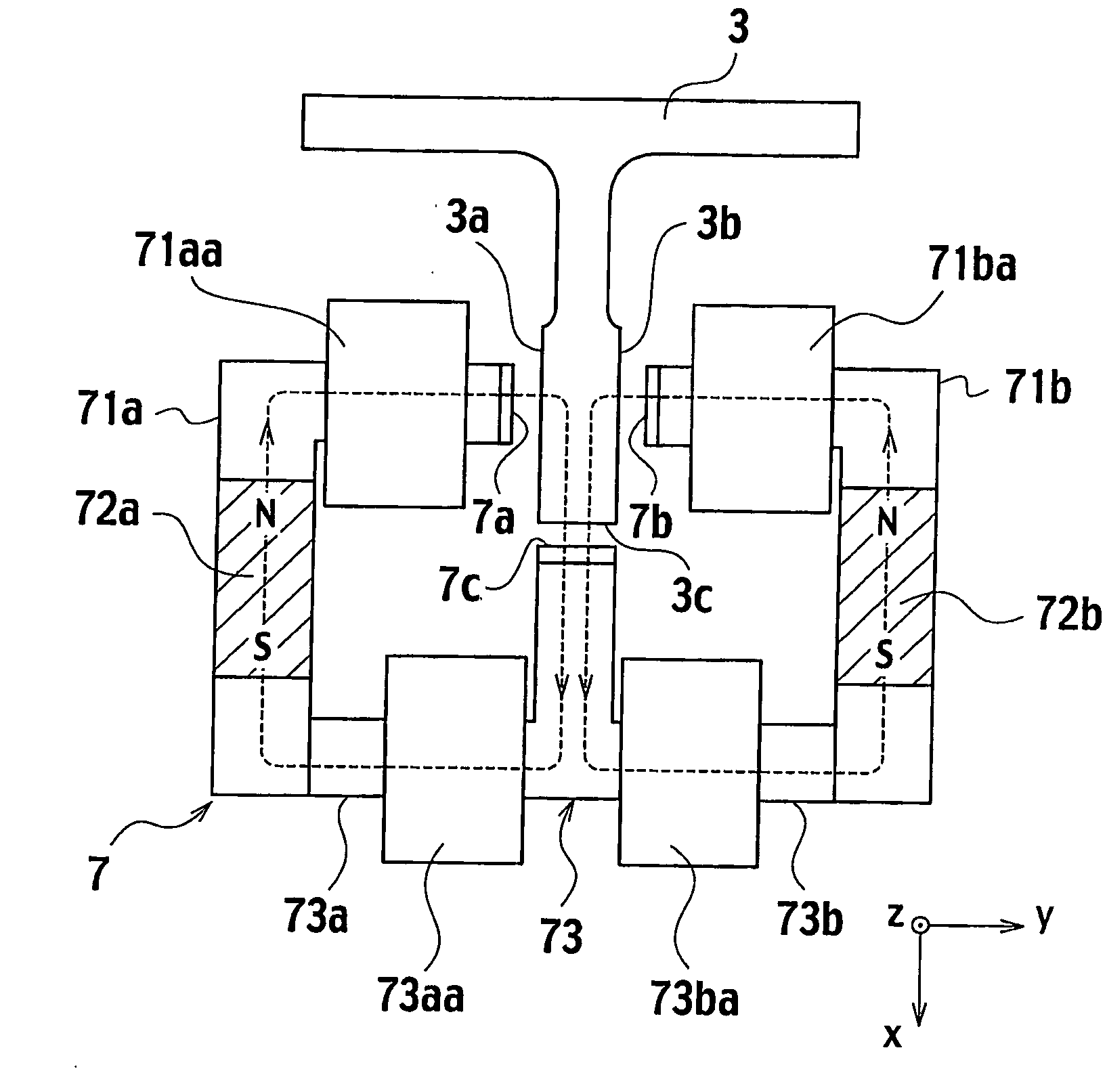

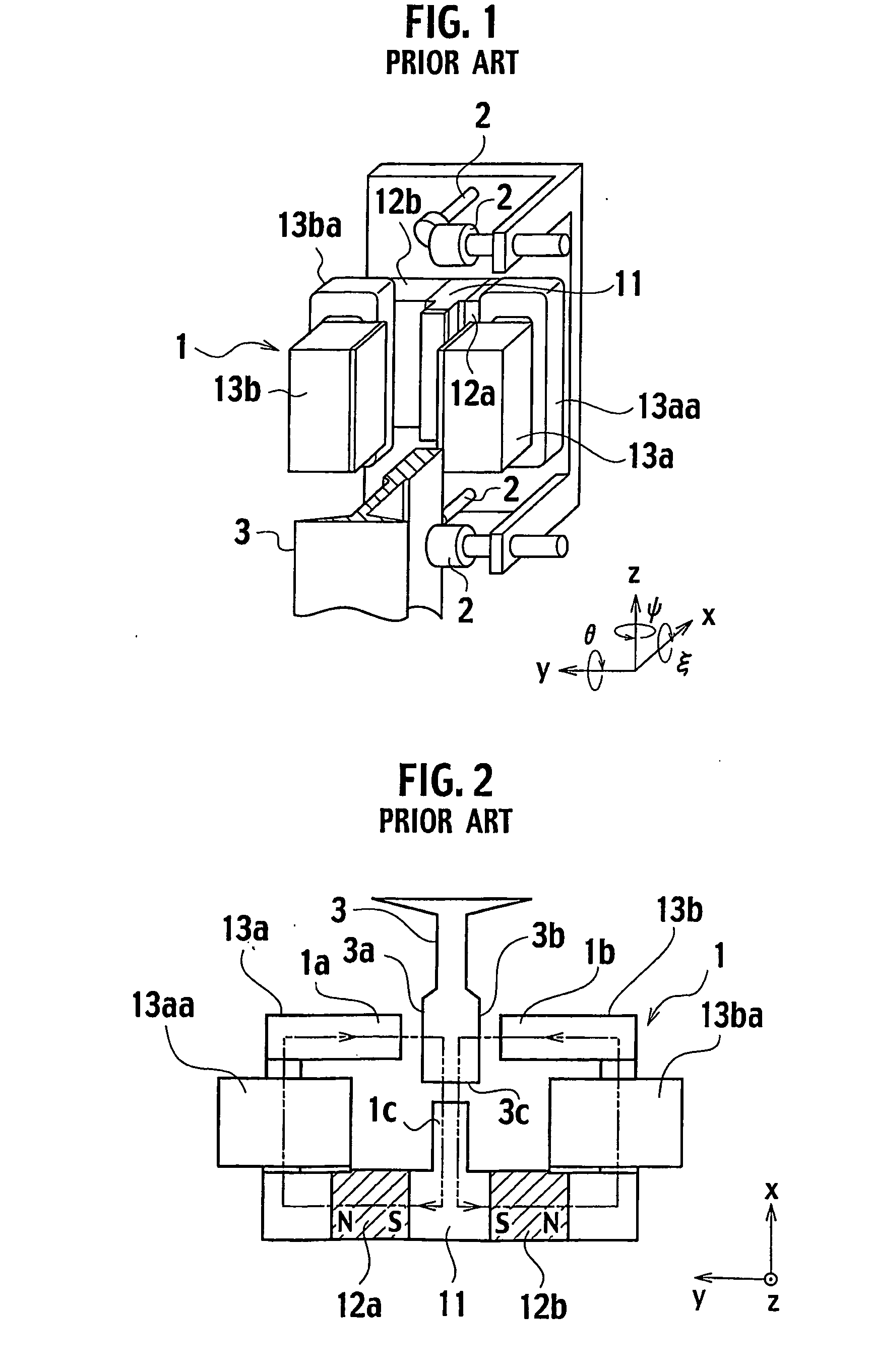

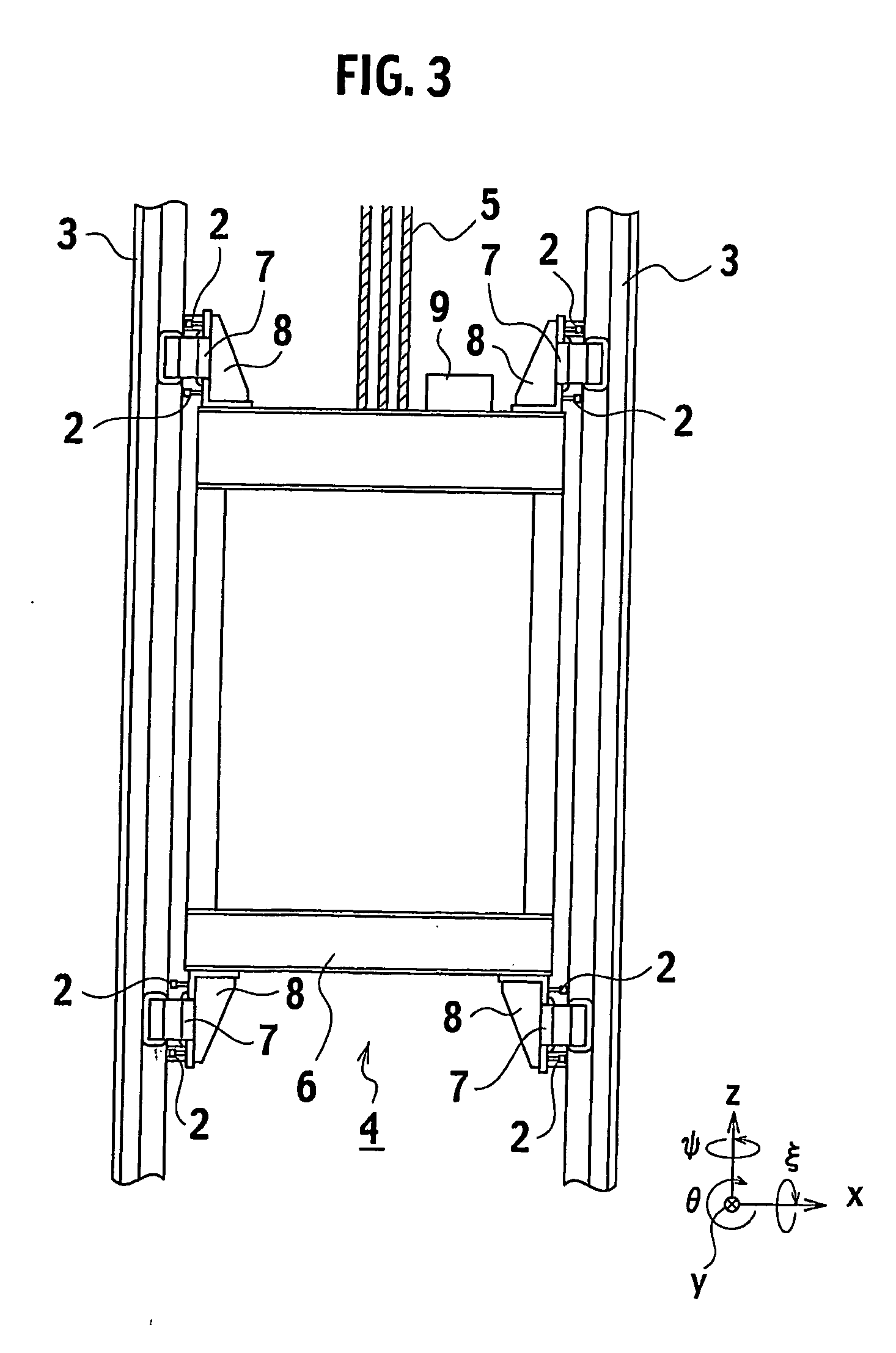

Magnet Unit, Elevator Guiding Apparatus and Weighing Apparatus

InactiveUS20080257655A1Less attractiveHigh operating requirementsWeighing apparatus using electromagnetic balancingMagnetic materialsMagnetic polesElectromagnet

A magnet unit includes a first magnetic pole (7a), a second magnetic pole (7b) and a third magnetic pole (7c) at a center between the first magnetic pole (7a) and the second magnetic pole (7b), providing an E-shaped configuration. In the magnet unit, a first magnet is defined between the first magnetic pole (7a) and the third magnetic pole (7c) by connecting two electromagnets (71aa, 73aa) with each other through a permanent magnet (72a), while a second magnet is defined between the second magnetic pole (7b) and the third magnetic pole (7c) by connecting two electromagnets (71ba, 73ba) with each other through a permanent magnet (72b). With this configuration, it is possible to reduce a deviation in the length of respective magnetic paths from the permanent magnets (72a, 72b) up to their respective magnetic poles. By controlling exciting currents to the respective magnetic poles. By controlling exciting currents to the respective electromagnets (71aa, 73aa, 71ba, 73ba), it is also possible to adjust fluxes (or flux density) in respective directions x, y individually.

Owner:TOSHIBA ELEVATOR KK

Monitor and methods for characterizing airborne particulates

InactiveUS7947503B2Readily moved and carried and attachedLess intrusiveMaterial analysis by electric/magnetic meansMaterial analysis by optical meansParticulatesAnalyte

Owner:UNITED STATES OF AMERICA

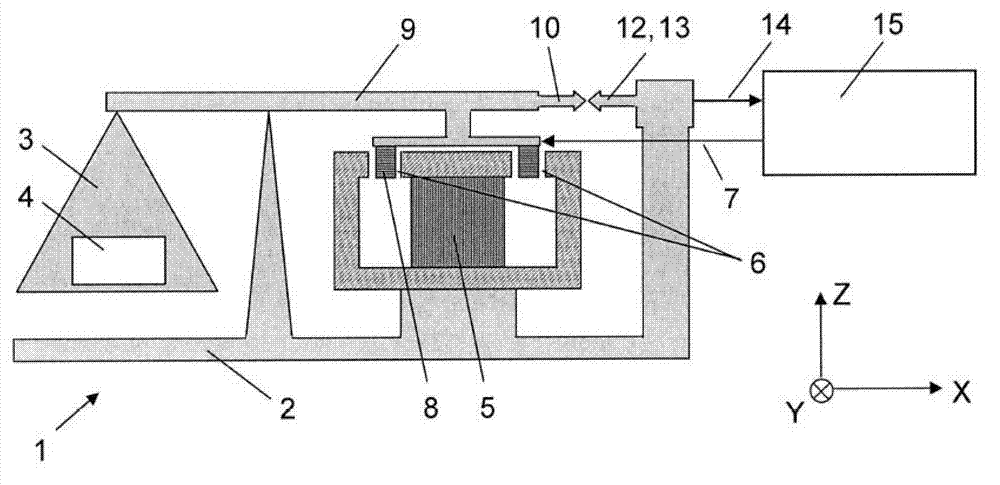

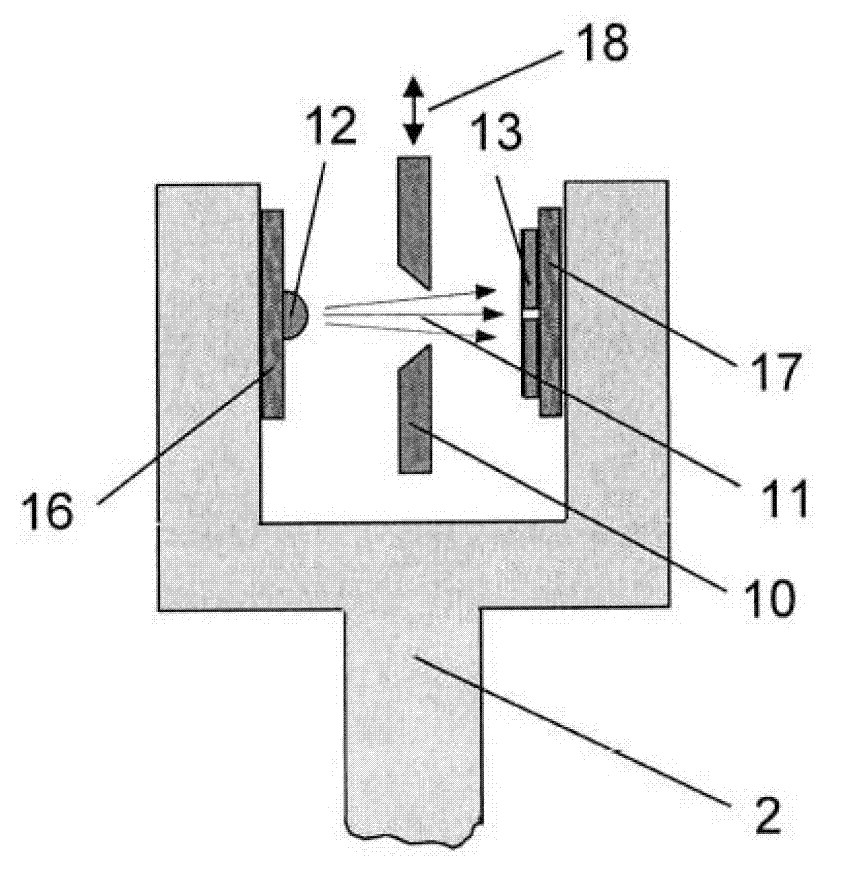

Weighing cell operating on the principle of electromagnetic force compensation with optoelectronic position sensor

ActiveCN103175595AImprove thermal conductivityWeighing apparatus using electromagnetic balancingWeighing temperature-compensating arrangementsClosed loopOpto electronic

A weighing cell based on the principle of electromagnetic force compensation. A permanent magnet system is mounted on a base part and includes an air gap within which is suspended a coil that is connected to a load receiver through a force-transmitting mechanism. The coil carries an electrical compensation current when the weighing cell is in operation. An optoelectronic position sensor is also included, and its signal corresponds to the deflection of the coil from a zero position which occurs as a result of placing a load on the load receiver. A closed-loop controller regulates the compensation current in response to the sensor signal in such a way that the coil and the load receiver that is connected to it are returned to their zero position by the electromagnetic force that is acting between the coil and the permanent magnet.

Owner:METTLER TOLEDO INC

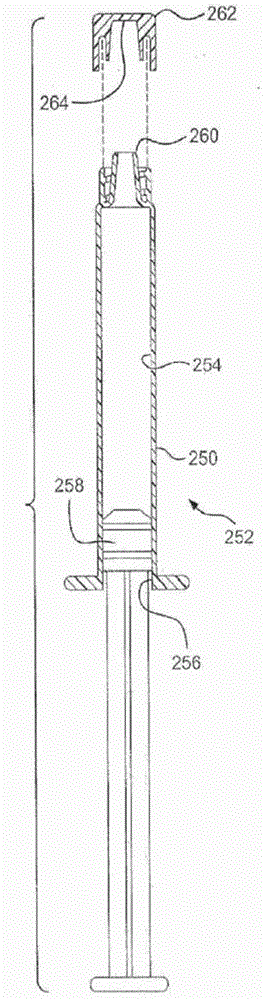

Force measuring device, in particular for seat weight determination in a motor vehicle

InactiveUS6986293B2Improve accuracyAccurate detectionVehicle seatsWeighing apparatus using elastically-deformable membersMobile vehicleMeasurement device

A force measuring device for seat weight determination in a motor vehicle includes a taking up element which has at least two bearing points. The device further includes a mechanism forming a first recess in the taking up element in a region between at least two bearing points and a rod-shaped element which extends in the longitudinal axis of the taking up element and is not loaded by bending forces. The rod-shaped element has a free end which deviates from the longitudinal axis of the taking up element when a force to be measured acts on the taking up element, and a measuring unit with a magnet and a magnetic field-sensitive sensor The magnet and the magnetic field-sensitive sensor are arranged immovably relative to one another so that the distance from the magnet to a ferromagnetic material changes under loading with the force.

Owner:ROBERT BOSCH GMBH

Popular searches

Devices with sensor Telephone set constructions Special purpose weighing apparatus Using electrical means Electrical/magnetic solid deformation measurement Scanning probe microscopy Mechanical roughness/irregularity measurements Level indicators by physical variable measurement Special data processing applications Mechanical solid deformation measurements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com