Remote-control digital weighing machine with temperature compensation function and temperature compensation method for remote-control digital weighing machine

A weighing device and weighing sensor technology, applied in the direction of weighing temperature compensation device, etc., can solve the problems of calibration, inability to operate on site, and inability to directly see the readings, etc., to achieve the effect of improving the pass rate and overcoming electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

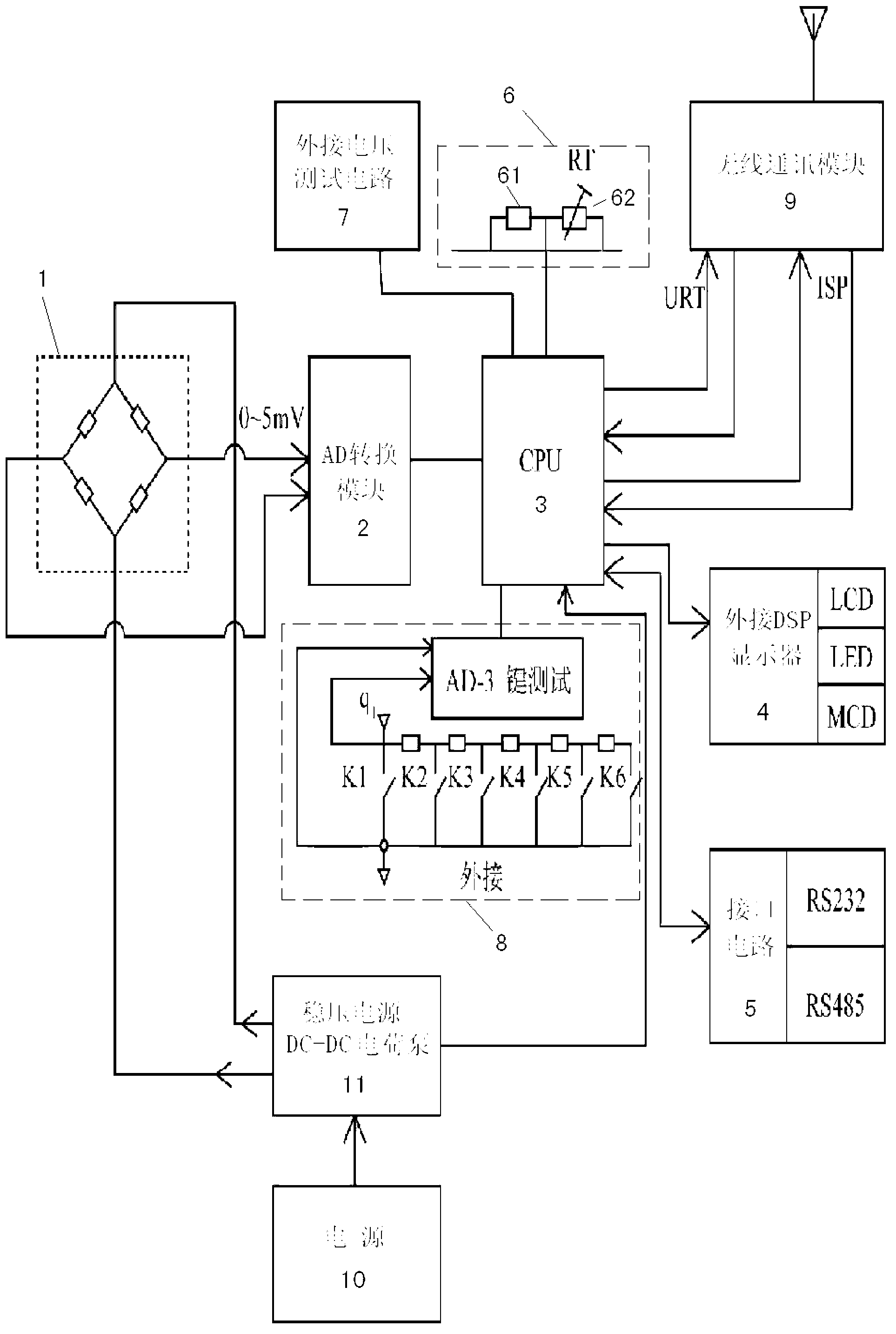

[0016] Such as figure 1 As shown, a remote temperature compensation digital weighing device provided by the present invention is to set the weighing instrument on a smaller double-sided printed circuit board (for example, a 1.6×1.6cm double-sided printed circuit board), and package it with Various sensors. The present invention includes a load cell 1, an AD conversion module 2, a microprocessor (CPU) 3, an external DSP display 4, an interface circuit 5, a temperature compensation circuit 6, and an external voltage tester composed of four resistance strain gauges. Circuit 7, keyboard circuit 8, wireless communication module 9, and power supply 10 and regulated power supply DC-DC charge pump 11 for supplying power to the above-mentioned components.

[0017] After the load cell 1 converts the detected force signal into an analog electrical signal, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com