Multi-module weighing system with temperature control

A weighing system, multi-module technology, applied in the field of weighing system, can solve the problem of not implementing constant temperature control and temperature adaptation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

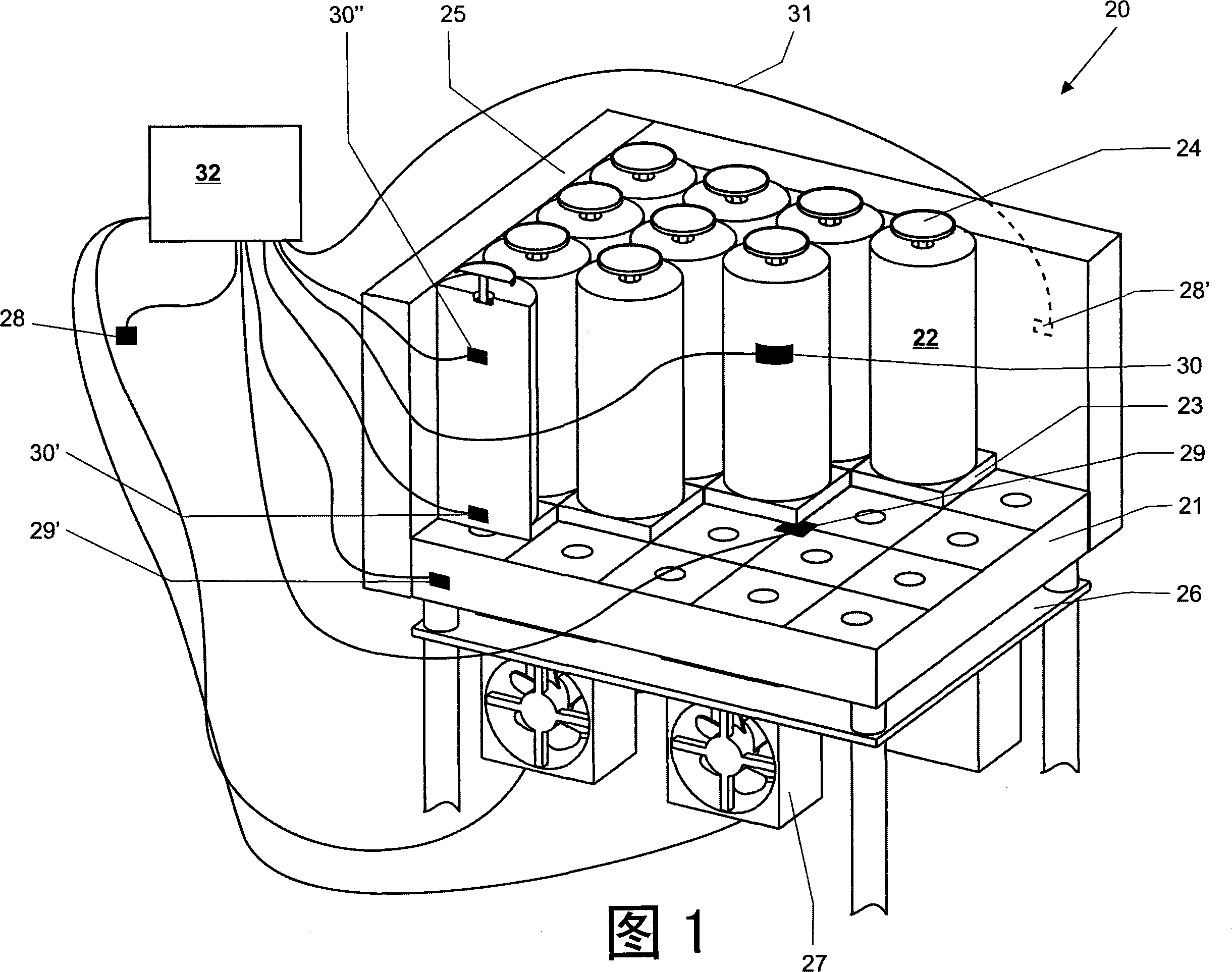

[0043] In Fig. 1, a multi-modular weighing system 20 is shown in a simplified manner. The multi-module weighing system 20 has a holding structure 21 for a maximum of twenty weighing modules 22, of which ten weighing modules are visible in the figure. Each weigh module 22 is connected to the holding structure 21 by a socket 23 and has a load receiver 24 . The load receiver 24 is connected by a suitably configured linkage to a weighing cell (not shown), which is housed within the weighing module 22 . As shown in FIG. 1 , the multi-module weighing system 20 can be insulated, in particular with respect to temperature, from the surrounding environment by at least one housing element 25 , two of which are visible in the figure. It is also possible for the multi-module weighing system 20 to be surrounded on all sides by the housing element 25 . The housing element 25 protects the multi-module weighing system 20 against thermal influences and also, for example, against contamination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com