Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

340results about "Signal inductance without magnetic core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

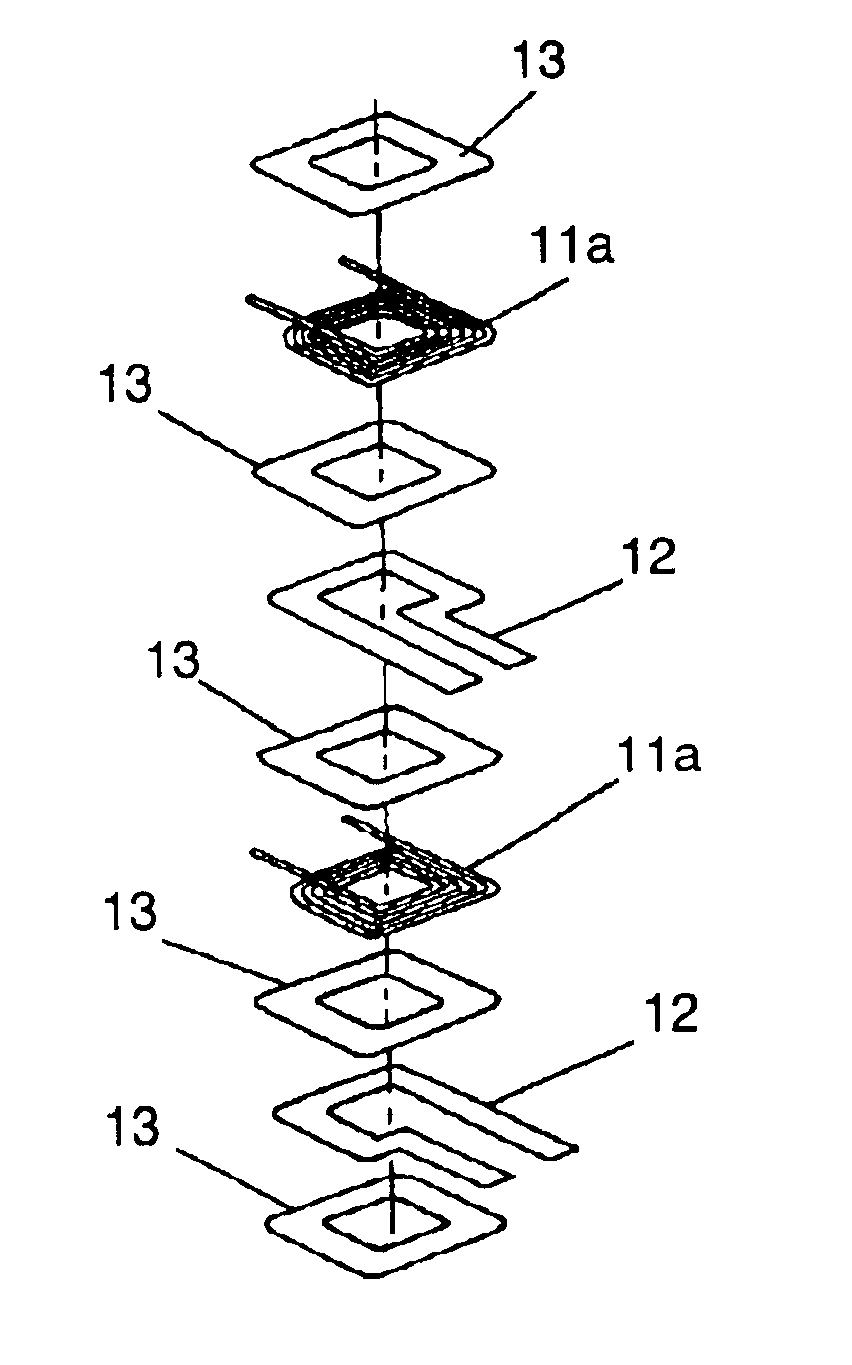

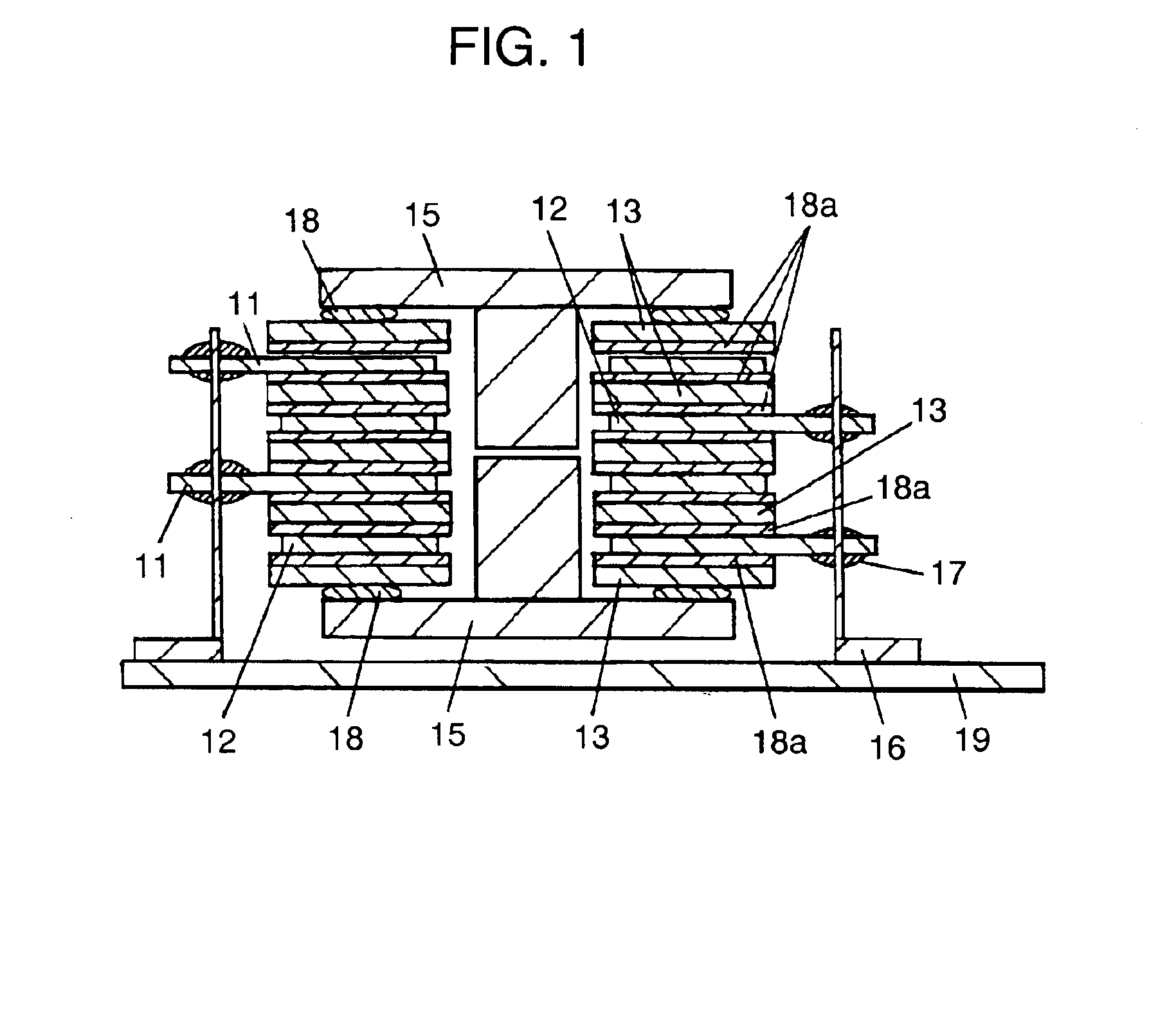

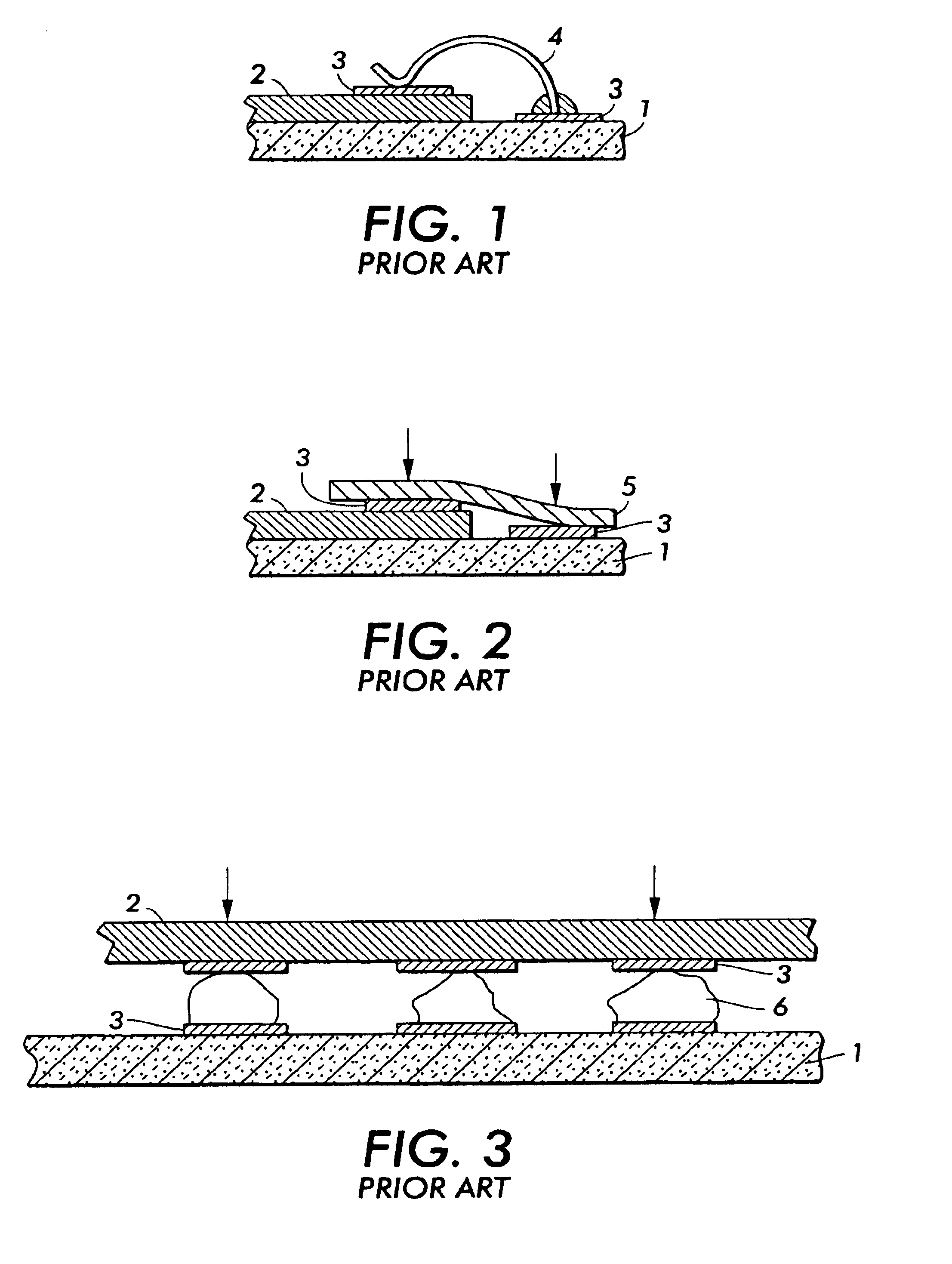

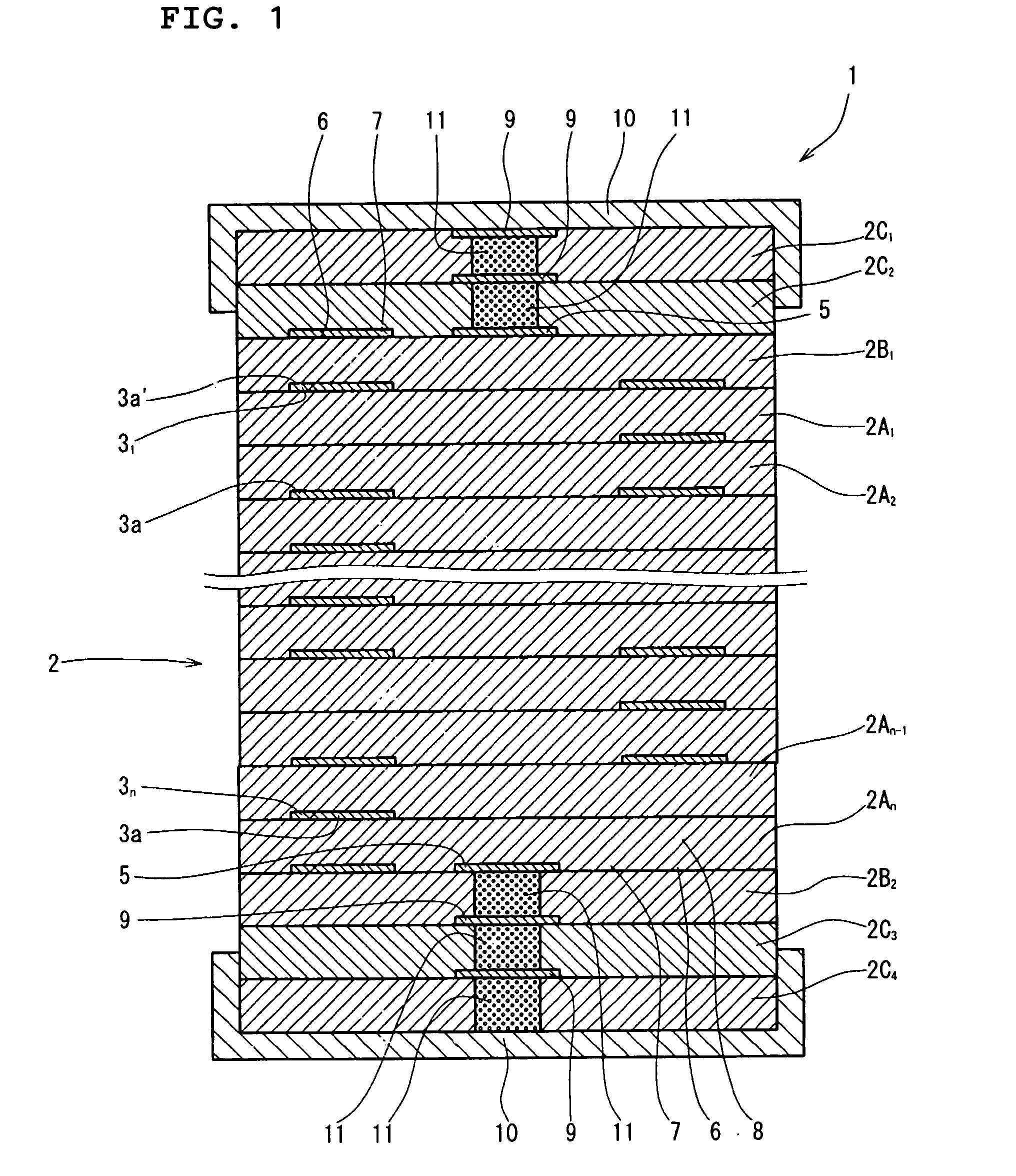

Low-profile transformer and method of manufacturing the transformer

InactiveUS6859130B2Improve productivityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerSwitching power

A multilayered coil is formed by inserting insulating paper 13 having either a pressure sensitive adhesive or an adhesive disposed on both faces thereof into at least one place between thin coil layers and then magnetic cores 15 are mounted to the multilayered coil from above and below. Thus, a thin transformer for a switching power supply is provided, in which variation in distance between coil 11 and coil 12, of which one is disposed over the other, variation in distance of coil 11 and coil 12 from magnetic core 15 and the like are suppressed.

Owner:PANASONIC CORP

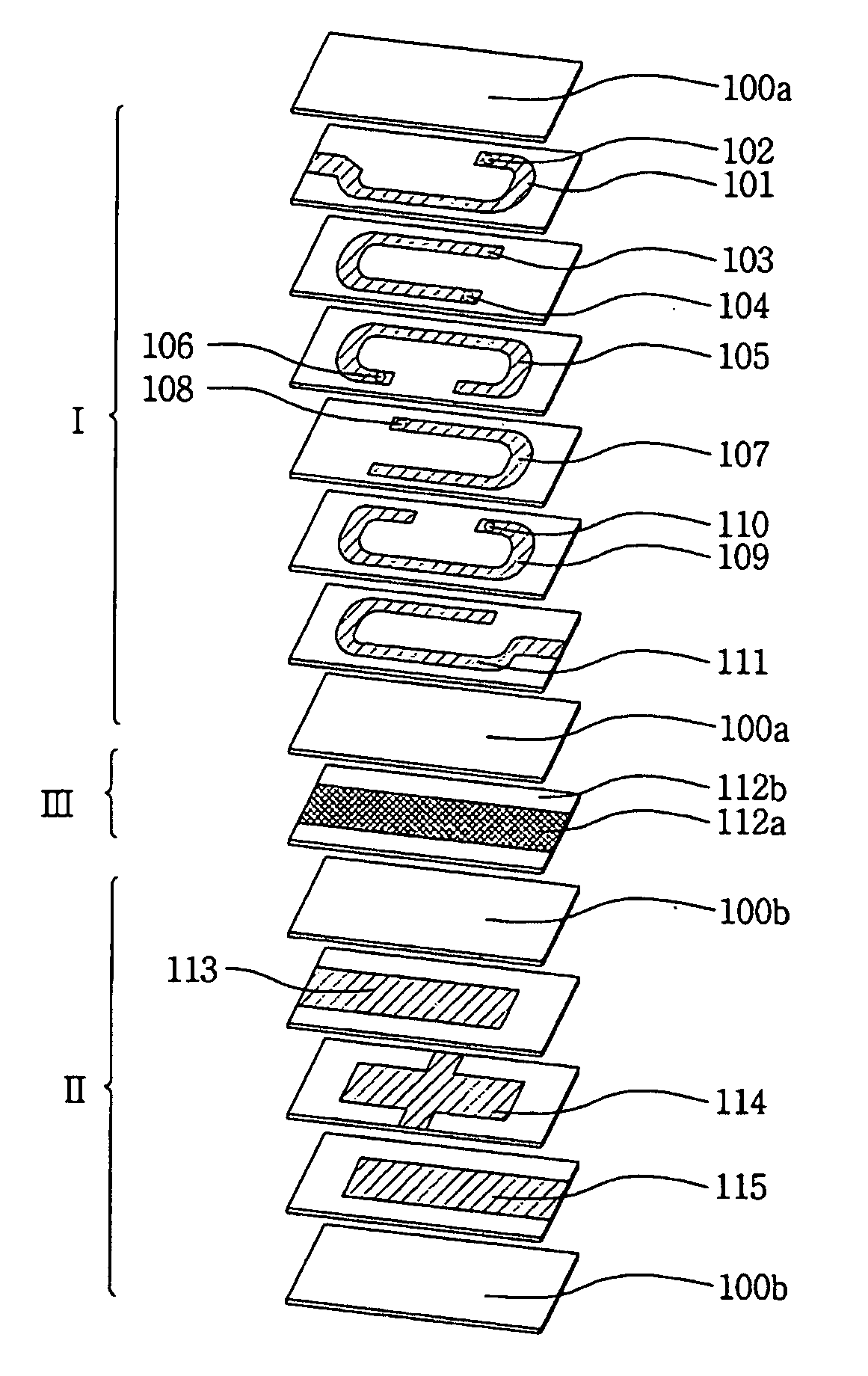

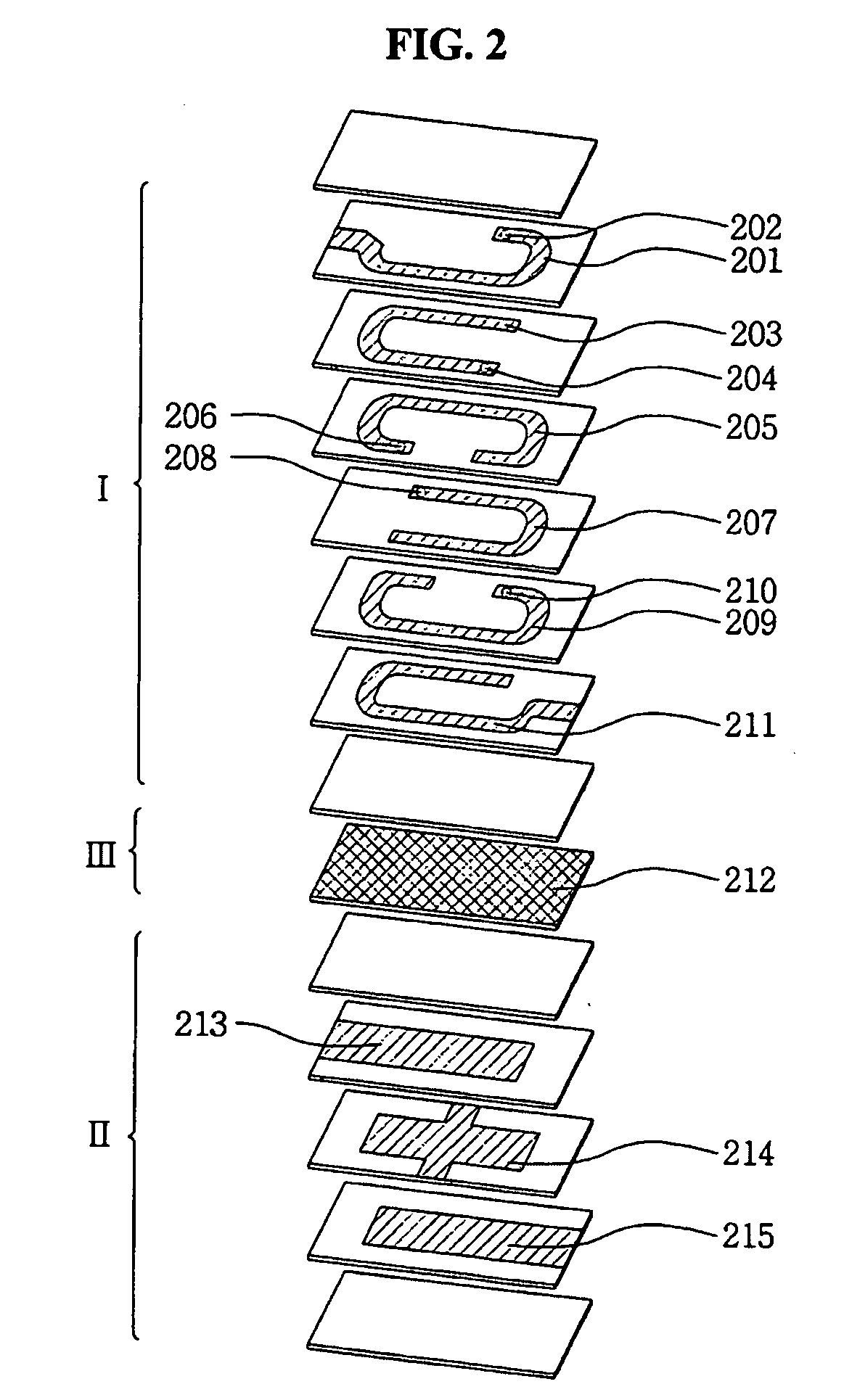

Magnetic and dielectric composite electronic device

InactiveUS20090097219A1Simple processMultiple-port networksPrinted electric component incorporationElectricityLow-pass filter

There is a provided a magnetic and dielectric composite electronic device, comprising: a first region with a plurality of magnetic material sheets being layered; a second region with a plurality of dielectric material sheets being layered; and a third region as a middle layer interposed between the first region and the second region, including a Zn—Ti based material to prevent diffusion of the materials during co-firing of the first region and the second region, and the first region, the second region and the third region are integrally formed in a single body. In accordance with the present invention, the low pass filter including the function of the varistor is realized to obtain the EMI function and the ESD control effect. Furthermore, the one chip electronic device having the composite functions is manufactured by a simple process, and the interdiffusion between the different materials forming the magnetic and the dielectric parts is prevented to secure the durability and electrical characteristics of the product.

Owner:CERATECH

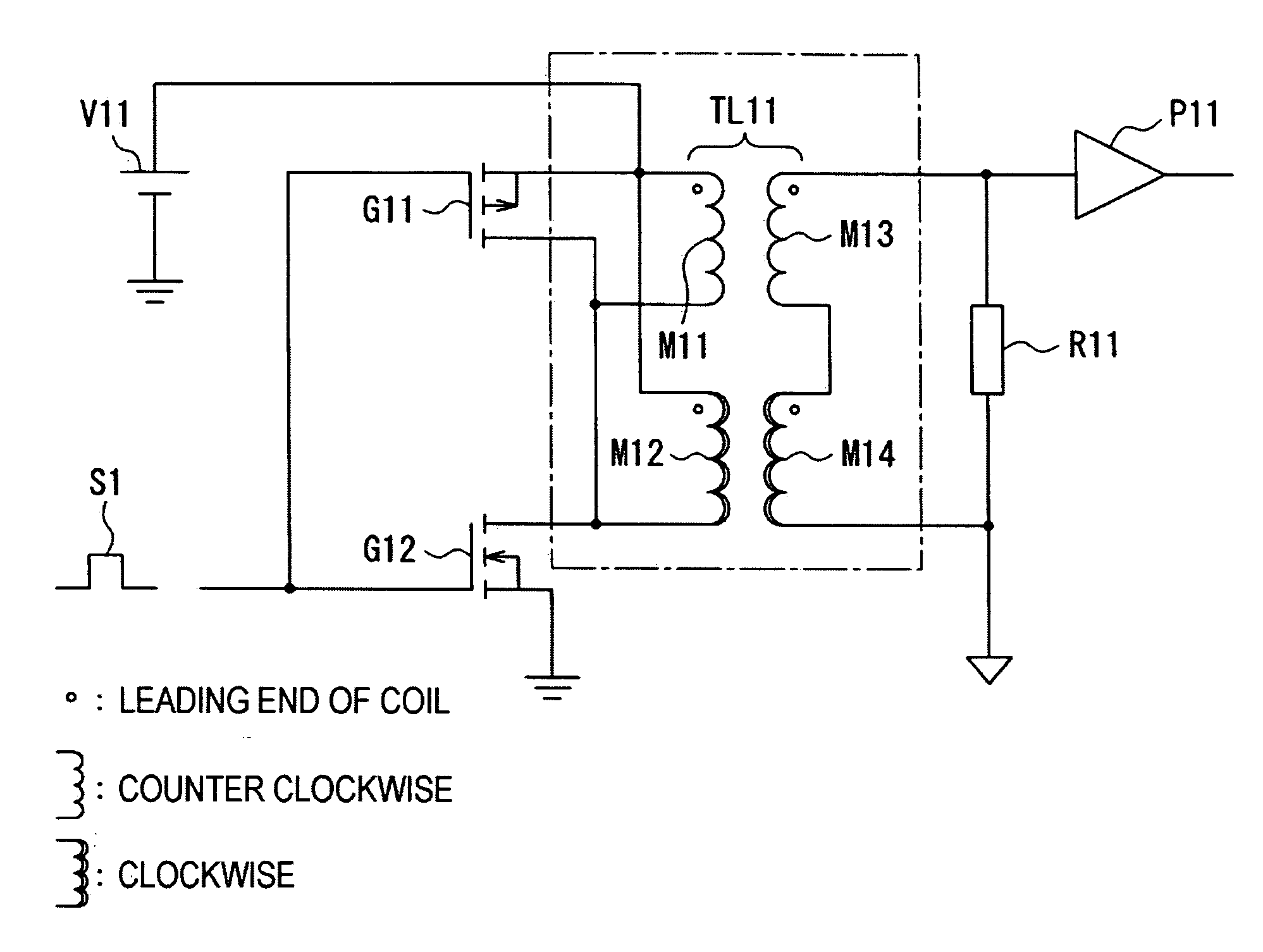

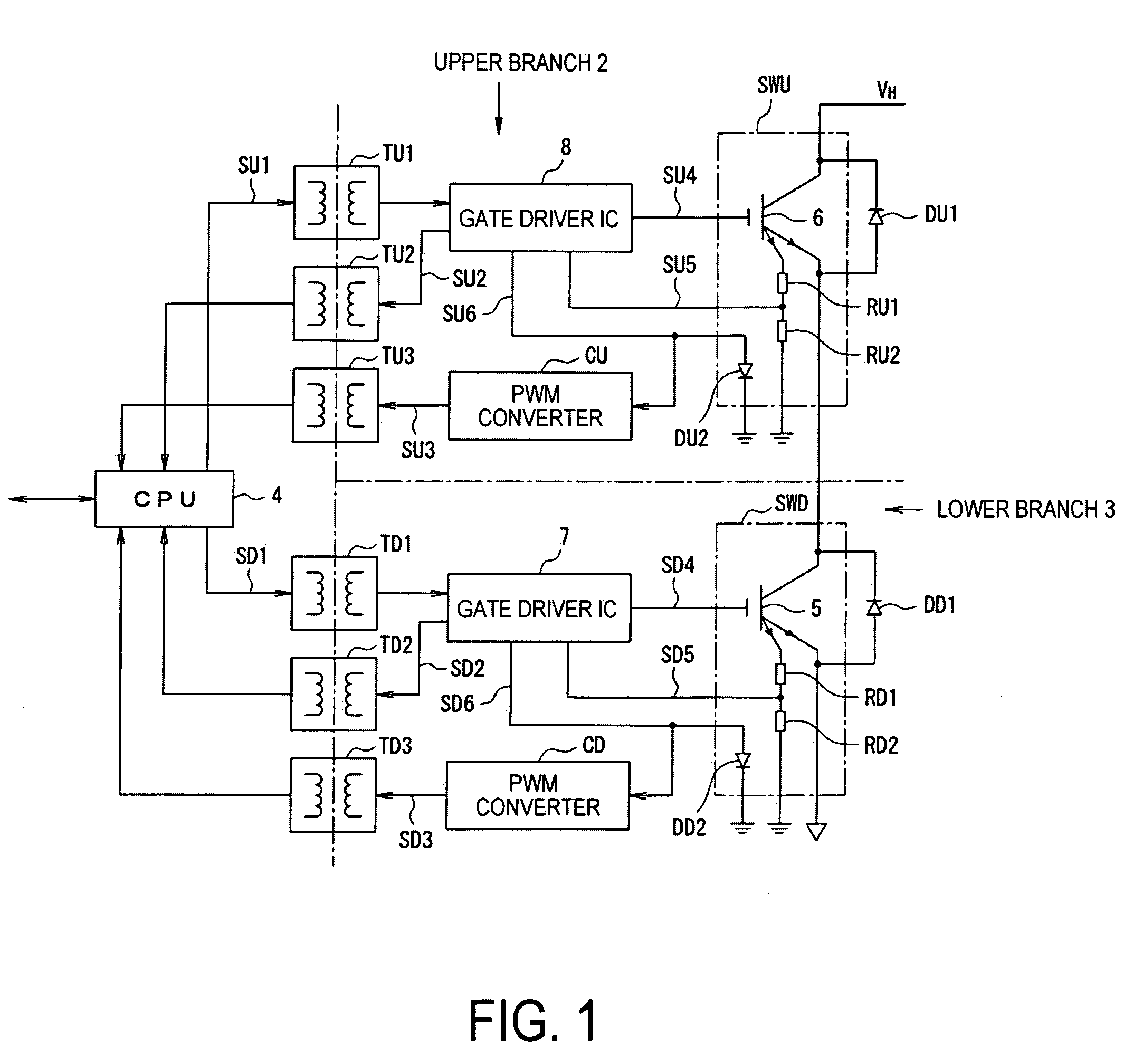

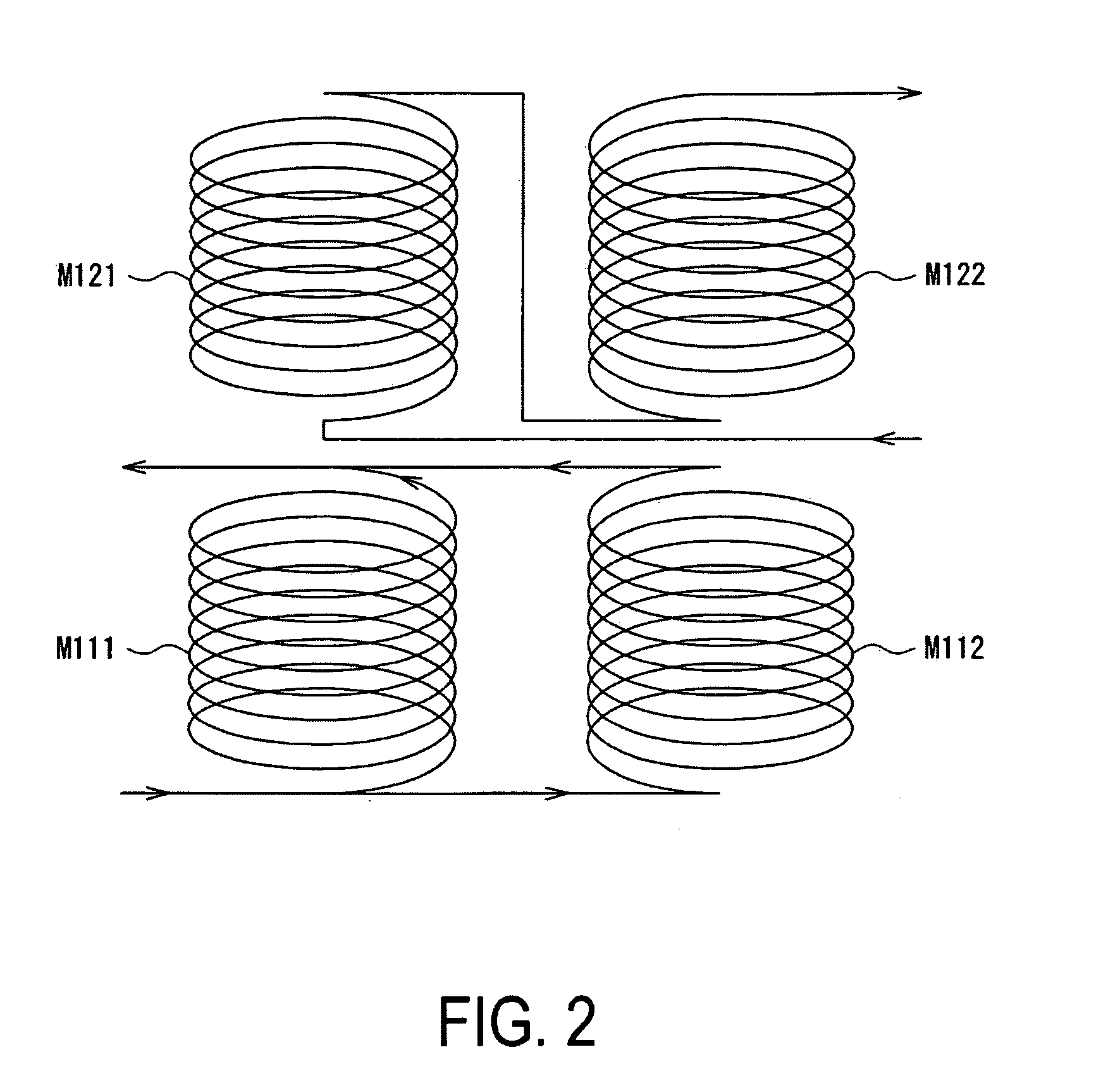

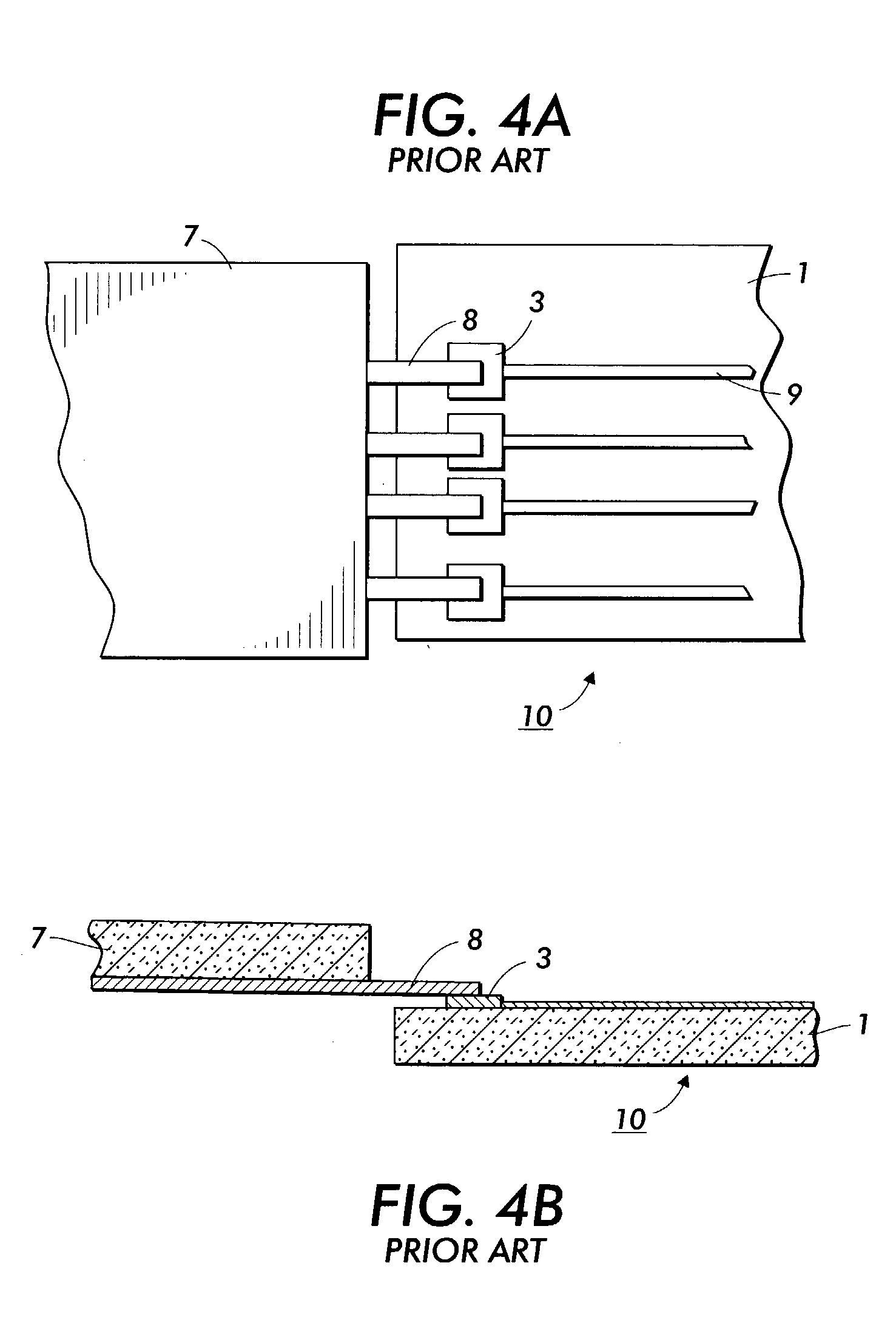

Transformer unit, and power converting device

InactiveUS20080266042A1Reduce overlayLow costDc-dc conversionSolid-state devicesLow voltageTransformer

A transformer unit and a power converting device, which lessen the influence of noise caused by an external magnetic flux, while reducing the temperature dependency of a coupling coefficient, and which transfer signals while insulating a low-voltage and a high-voltage side electrically. Air-core type insulated transformers have a first and second winding of a primary winding as a sending side and a first and second winding of a secondary winding as a receiving side. The windings of the primary winding are connected in parallel and are wound so that the directions of magnetic fields generated by an exciting current oppose each other. The windings of the secondary winding are wound so that electromotive forces to be generated by an external magnetic flux cancel each other, and are connected in series so as to raise the electromotive forces by a signal magnetic flux generated by the primary winding.

Owner:FUJI ELECTRIC CO LTD

Photolithographically-patterned variable capacitor structures and method of making

InactiveUS6922327B2Speed and easeEliminate needAnti-noise capacitorsMechanically variable capacitor detailsCapacitanceDielectric layer

A new type of high-Q variable capacitor includes a substrate, a first electrically conductive layer fixed to the substrate, a dielectric layer fixed to a portion of the electrically conductive layer, and a second electrically conductive layer having an anchor portion and a free portion. The anchor portion is fixed to the dielectric layer and the free portion is initially fixed to the dielectric layer, but is released from the dielectric layer to become separated from the dielectric layer, and wherein an inherent stress profile in the second electrically conductive layer biases the free portion away from the dielectric layer. When a bias voltage is applied between the first electrically conductive layer and the second electrically conductive layer, electrostatic forces in the free portion bend the free portion towards the first electrically conductive layer, thereby increasing the capacitance of the capacitor.

Owner:XEROX CORP

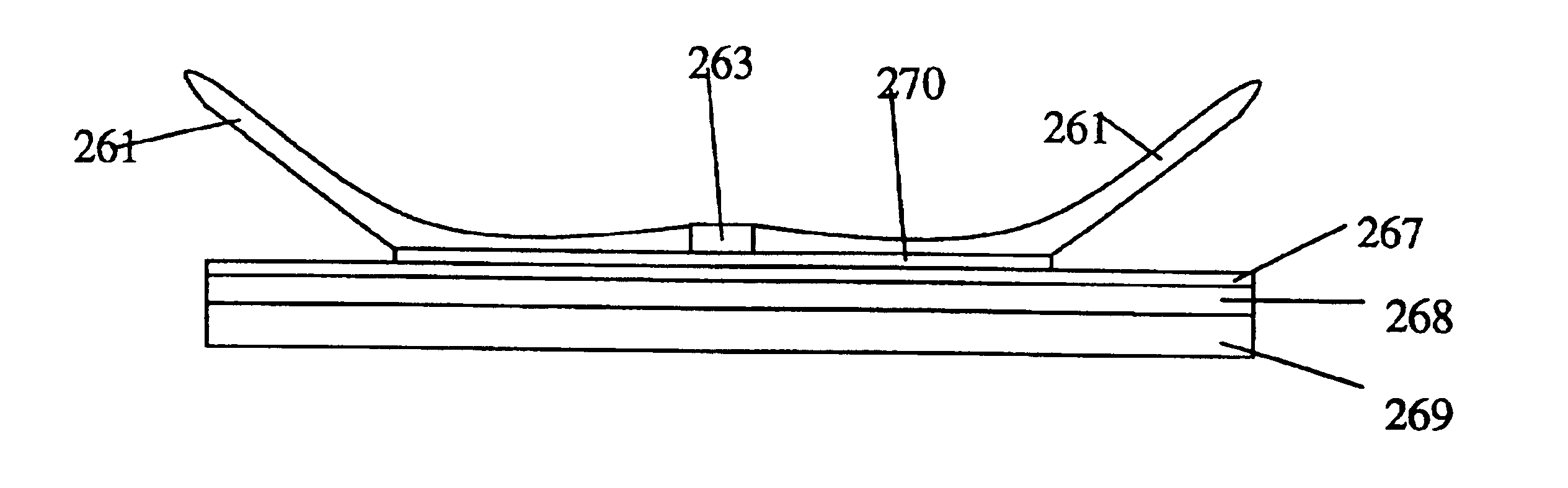

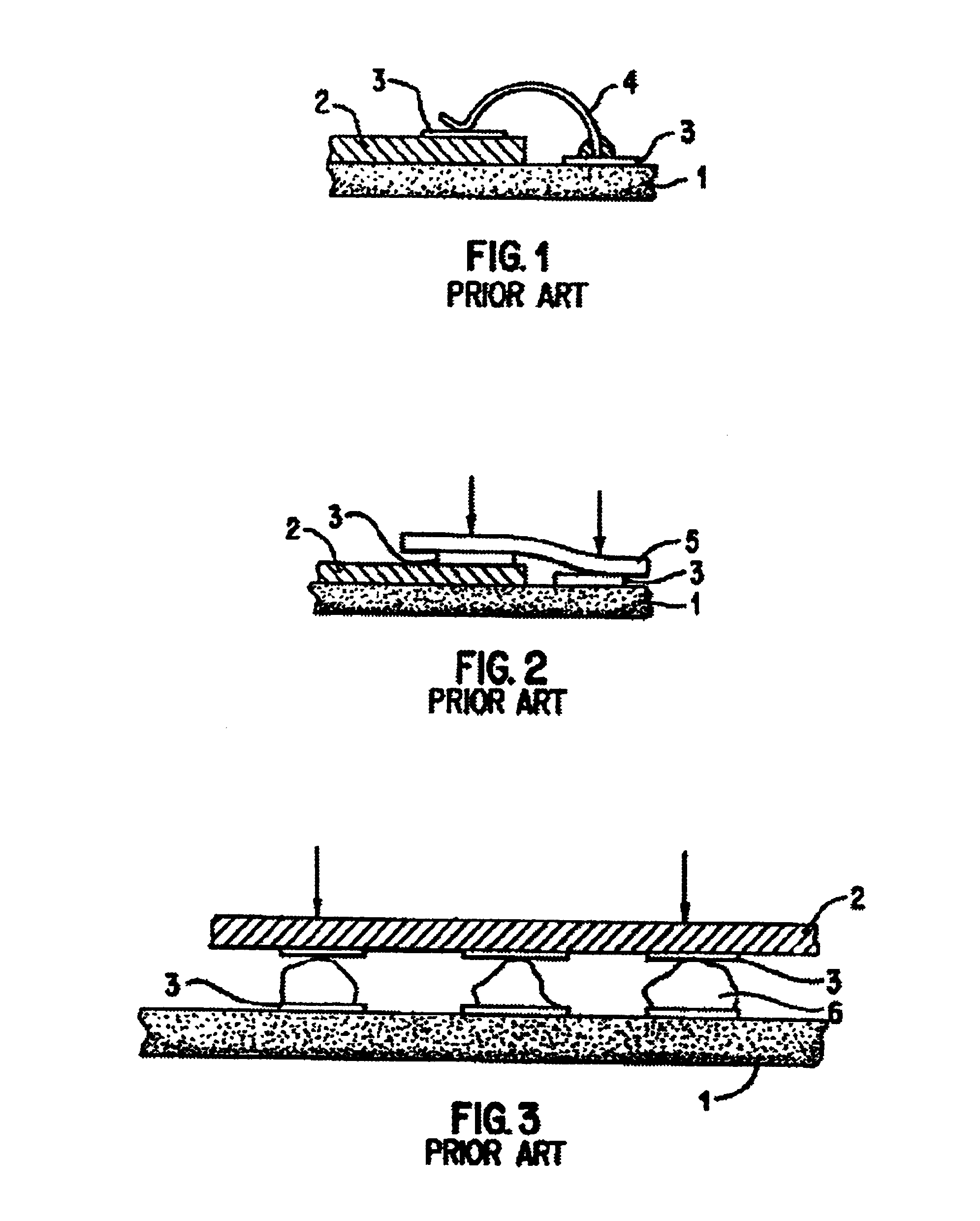

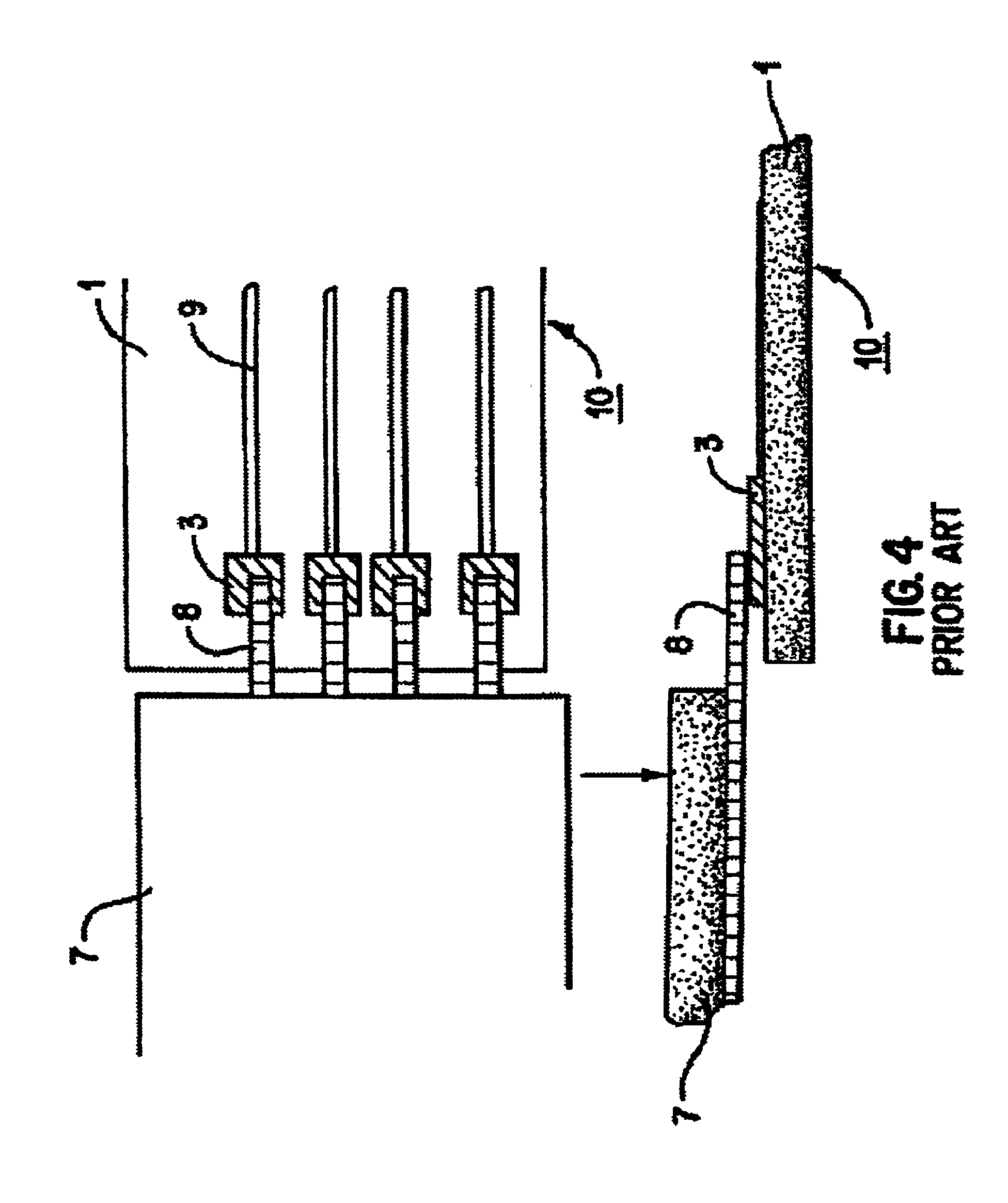

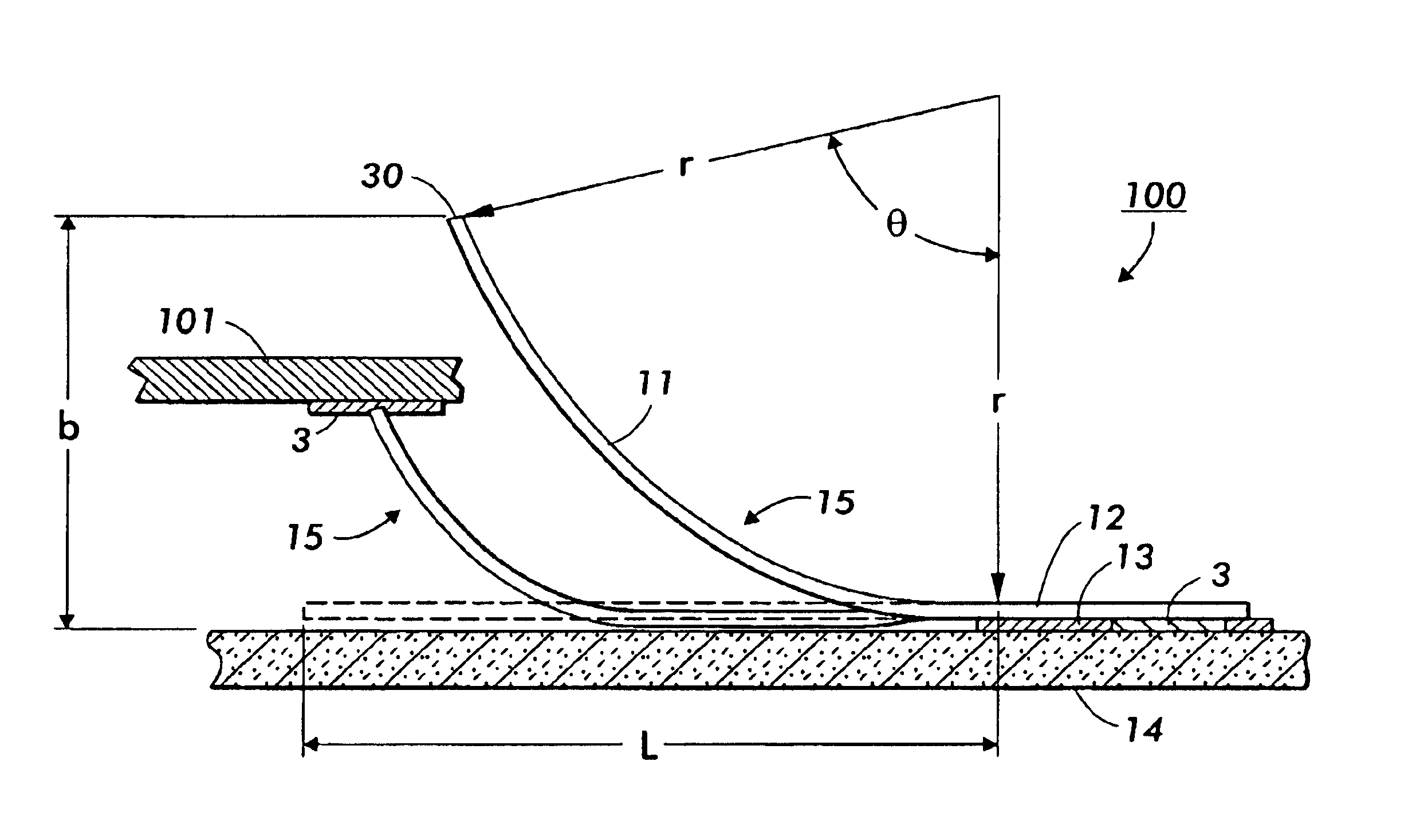

Photolithographically-patterned out-of-plane coil structures and method of making

InactiveUS6856225B1Reduce speedEliminate needSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsMicro structureTransformer

An out-of-plane micro-structure which can be used for on-chip integration of high-Q inductors and transformers places the magnetic field direction parallel to the substrate plane without requiring high aspect ratio processing. The photolithographically patterned coil structure includes an elastic member having an intrinsic stress profile. The intrinsic stress profile biases a free portion away from the substrate forming a loop winding. An anchor portion remains fixed to the substrate. The free portion end becomes a second anchor portion which may be connected to the substrate via soldering or plating. A series of individual coil structures can be joined via their anchor portions to form inductors and transformers.

Owner:XEROX CORP

Inductor and production method thereof

InactiveUS6104272ALower internal resistanceImprove reliabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

The present invention provides a system and method for producing a reliable inductor having an internal conductor with a small electric resistance. A metal wire formed in a nonlinear shape is used as the internal conductor. In an exemplary embodiment of the invention, the internal conductor has a coil-like shape with portions adjacent to each other with respect to the axial direction of the coil being positioned in a substantially cylindrical gap formed in the axial direction of the coil. By providing a gap around the internal conductor, stress between the internal conductor and a ceramic material surrounding the conductor can be eliminated. As a result, the characteristic deterioration or crack generation in the inductor chip is eliminated. Moreover, the leakage flux among the coil pitches of the conductor is reduced, thereby improving the characteristics of the inductor.

Owner:MURATA MFG CO LTD

Photolithographically-patterned out-of-plane coil structures and method of making

InactiveUS6582989B2Capacitor with electrode distance variationSolid-state devicesMicro structureTransformer

An out-of-plane micro-structure which can be used for on-chip integration of high-Q inductors and transformers places the magnetic field direction parallel to the substrate plane without requiring high aspect ratio processing. The photolithographically patterned coil structure includes an elastic member having an intrinsic stress profile. The intrinsic stress profile biases a free portion away from the substrate forming a loop winding. An anchor portion remains fixed to the substrate. The free portion end becomes a second anchor portion which may be connected to the substrate via soldering or plating. Alternately, the loop winding can be formed of two elastic members in which the free ends are joined in mid-air. A series of individual coil structures can be joined via their anchor portions to form inductors and transformers.

Owner:XEROX CORP

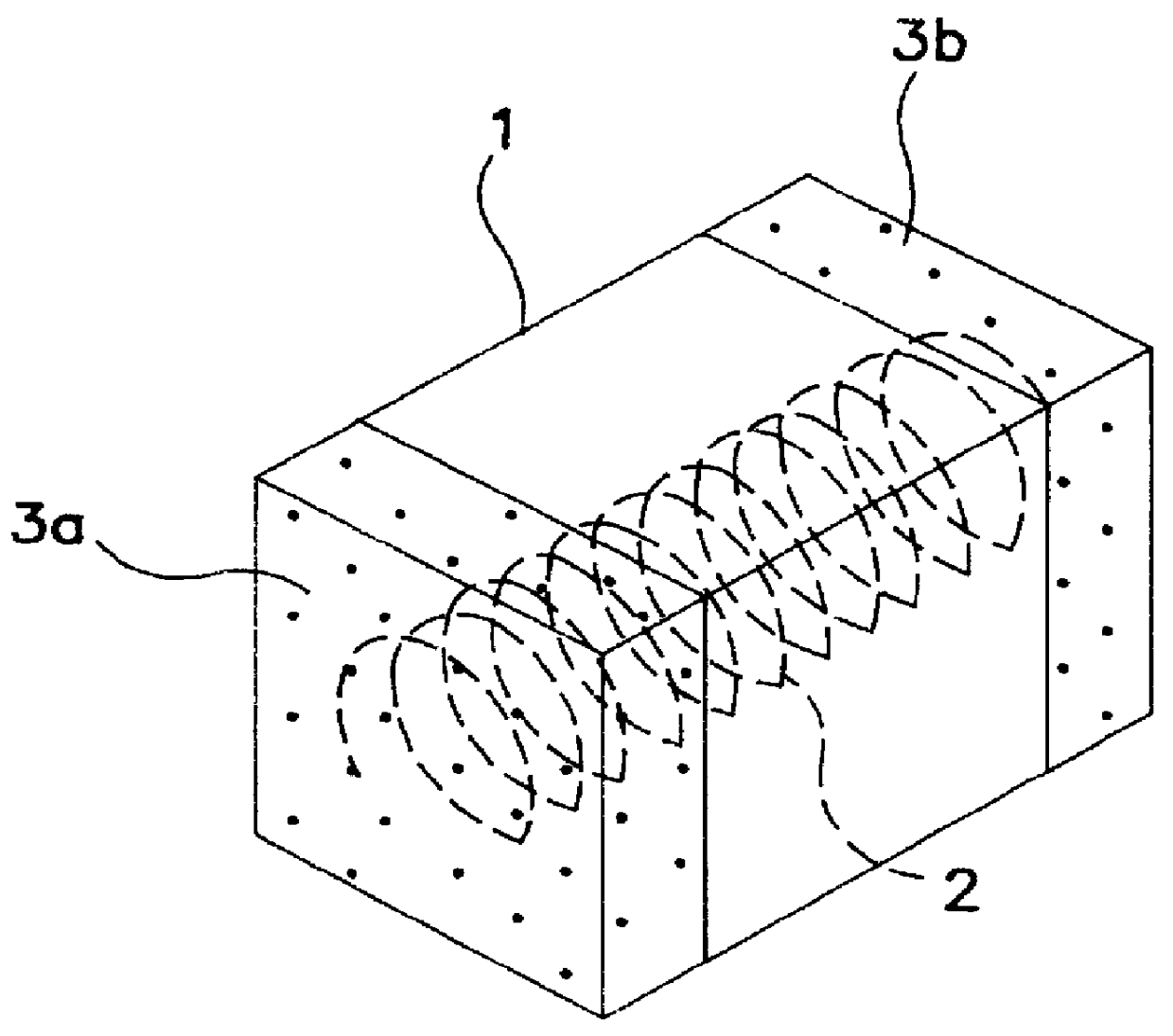

Inductance element, laminated electronic component, laminated electronic component module and method for producing these element, component and module

InactiveUS7081803B2Easy to mass produceAvoid large displacementVehicle cranksPrinted circuit aspectsElectrical conductorHelical coil

A laminated electronic component including at least one inductance element and produced from a laminate having electrical insulators and electrical conductors laminated alternately. The inductance element is formed as a helical coil having a plurality of turns each constituted by four sides. The inductance element has pairs of parallel conductor pieces and pairs of bridging conductor pieces. Each pair of parallel conductor pieces form two of the four sides of one turn of the coil. Each pair of bridging conductor pieces form the other two sides of one turn of the coil. Grooves are formed in the laminate to thereby form the parallel conductor pieces. The grooves are filled with an electrically insulating material. The bridging conductor pieces are formed on the electrically insulating material.

Owner:TDK CORPARATION

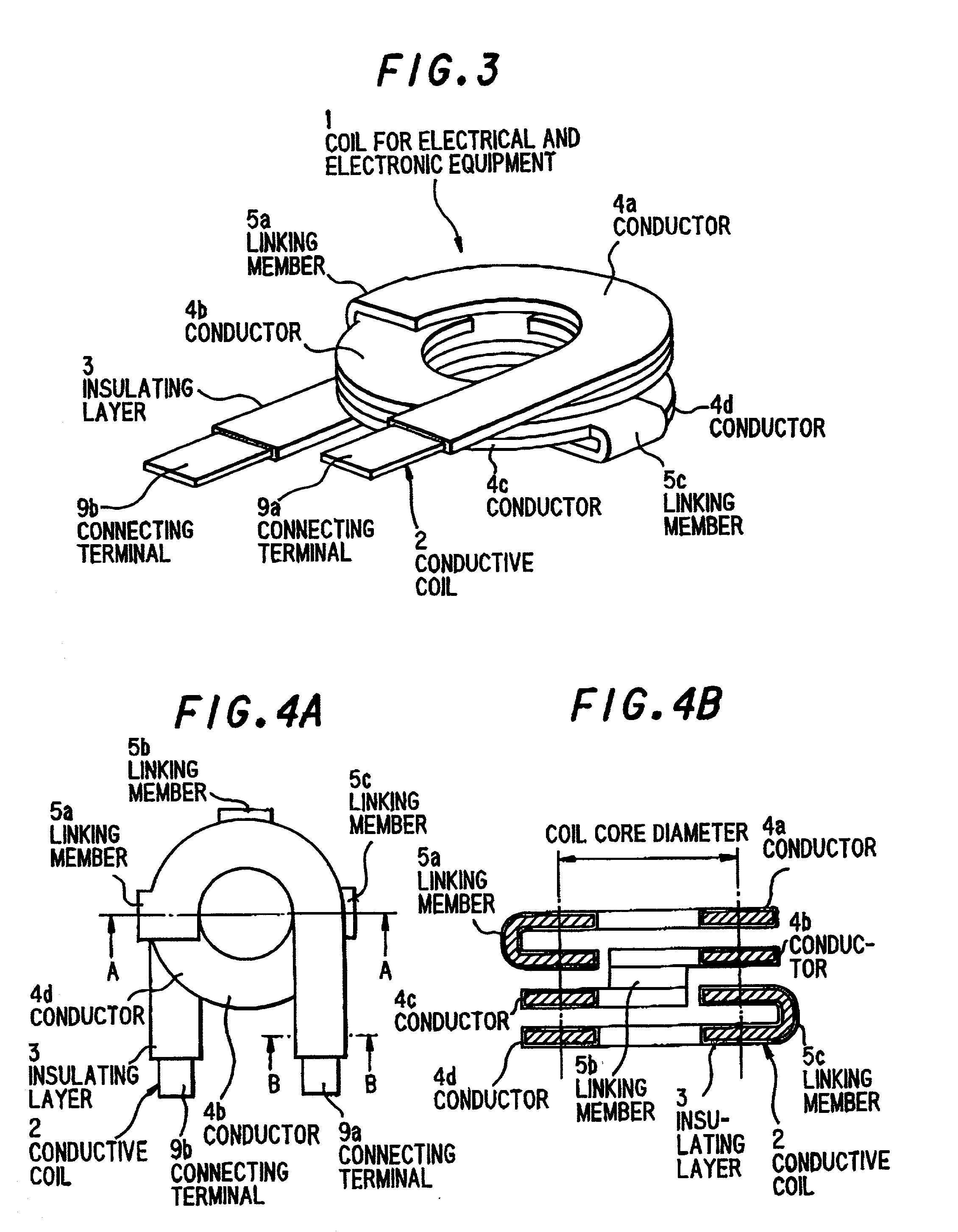

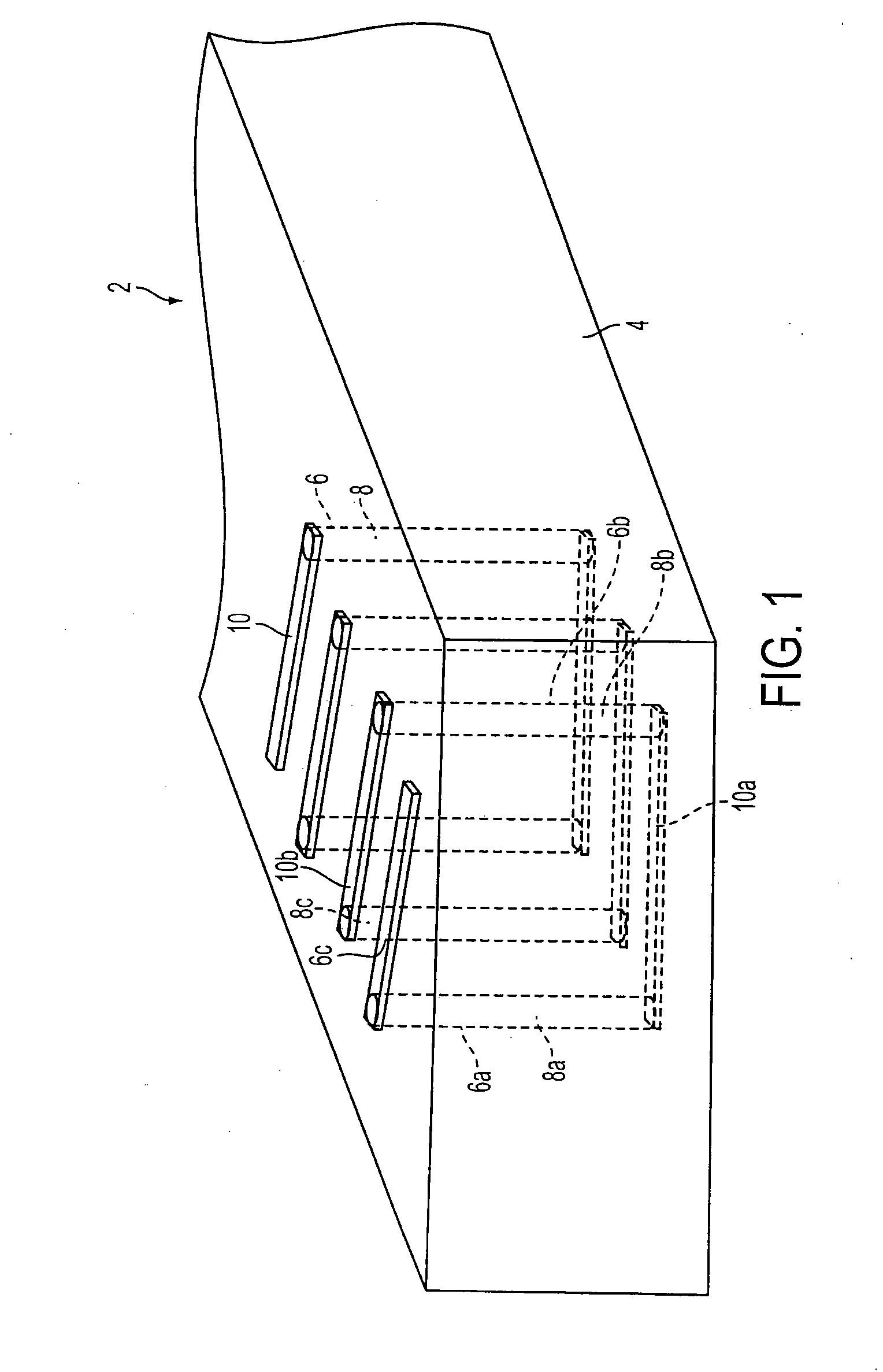

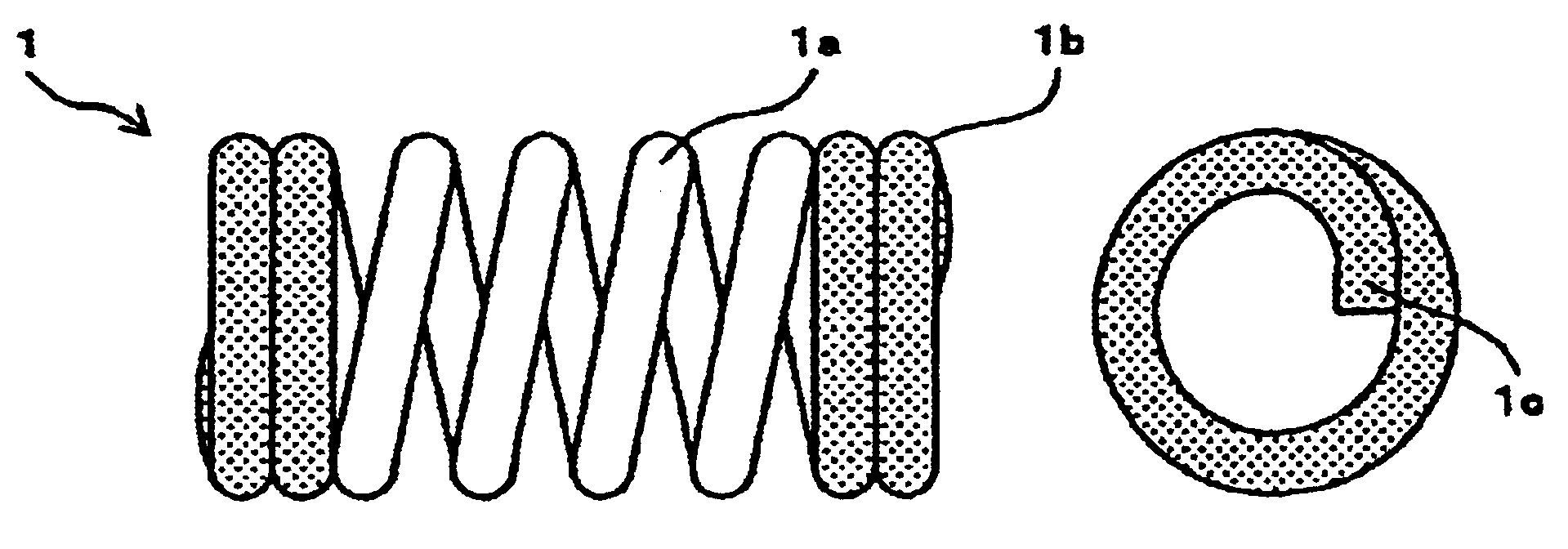

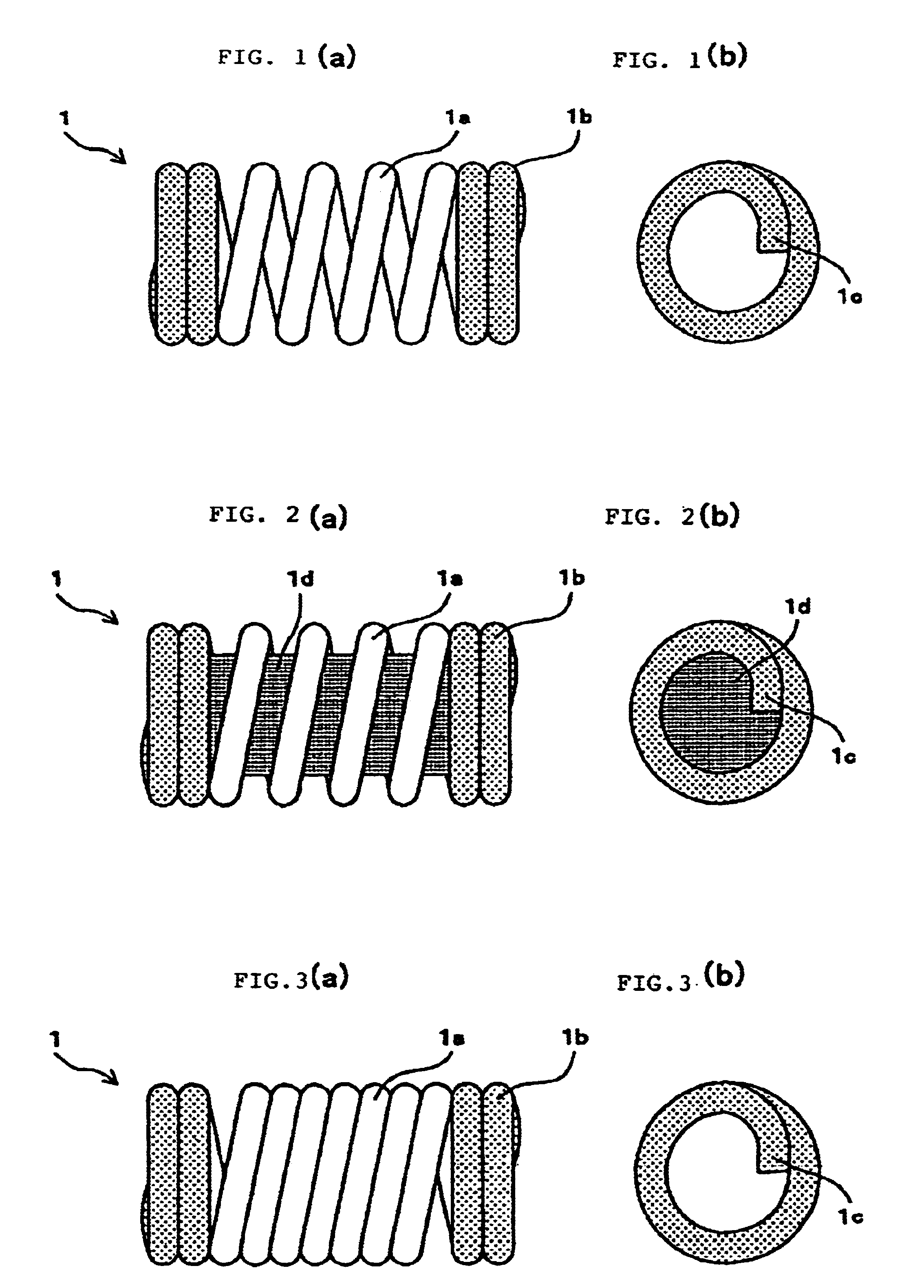

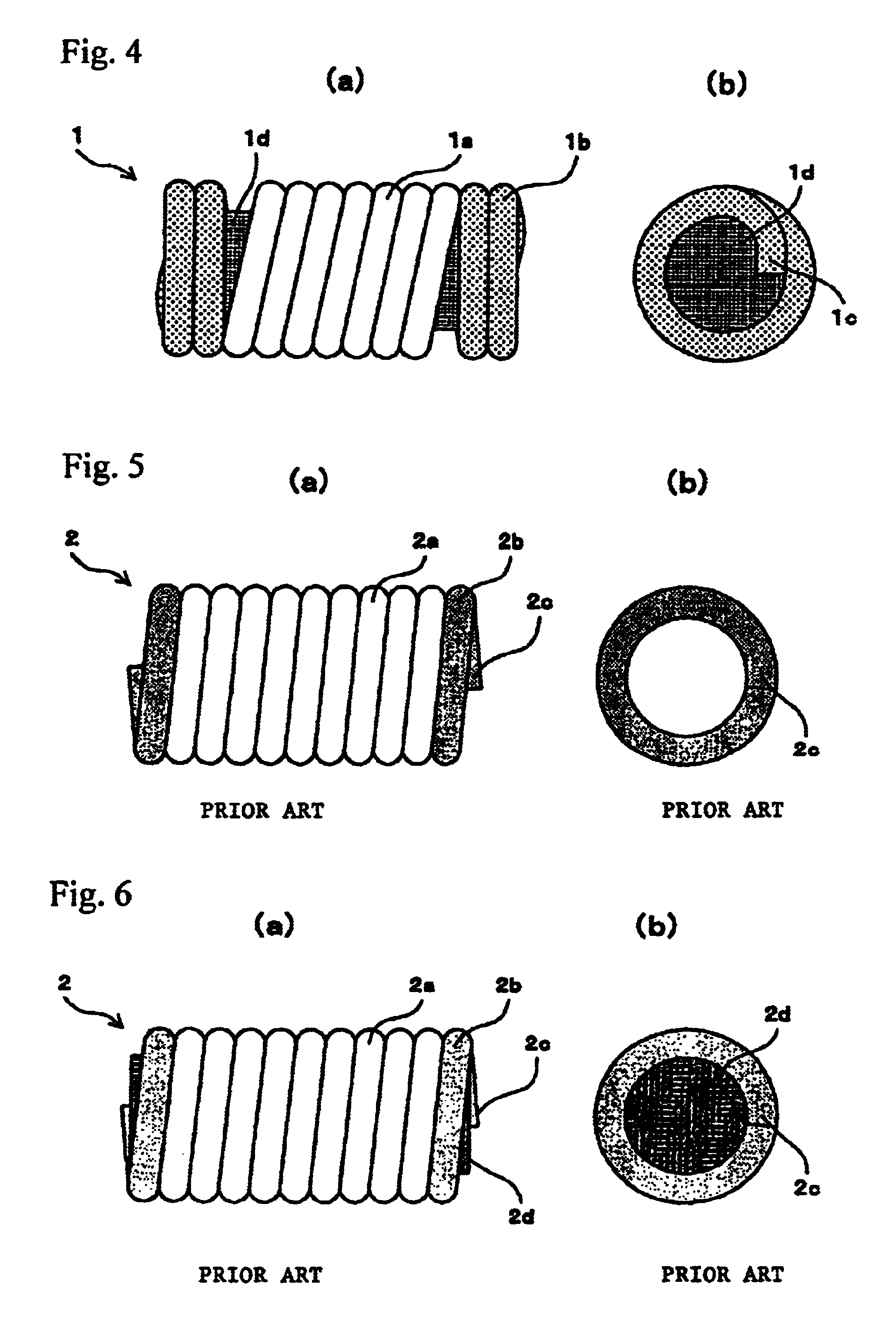

Coil for electrical and electronic equipment as well as process for production thereof

InactiveUS20030052767A1Transformers/inductances coils/windings/connectionsCoils manufactureElectrical conductorEngineering

A coil for electrical and electronic equipment comprises a spiral conductor coil 2 prepared by disposing coaxially a plurality of conductors 4a through 4d each having a flat circular arc-shaped configuration in multiple stages along a vertical direction, and linking sequentially ends of these conductors 4a through 4d to each other by means of linking members 5a through 5c in the vertical direction; and an insulating layer 3 covering the surface of the conductor coil 2, so that a relationship between a conductor width and a coil core diameter does not depend mutually, it becomes possible to increase and decrease optionally the conductor width and the coil core diameter, and as a result, a wider conductor width and a smaller coil core diameter in the conductor coil 2 than that of a conventional coil can be achieved.

Owner:HITACHI CABLE

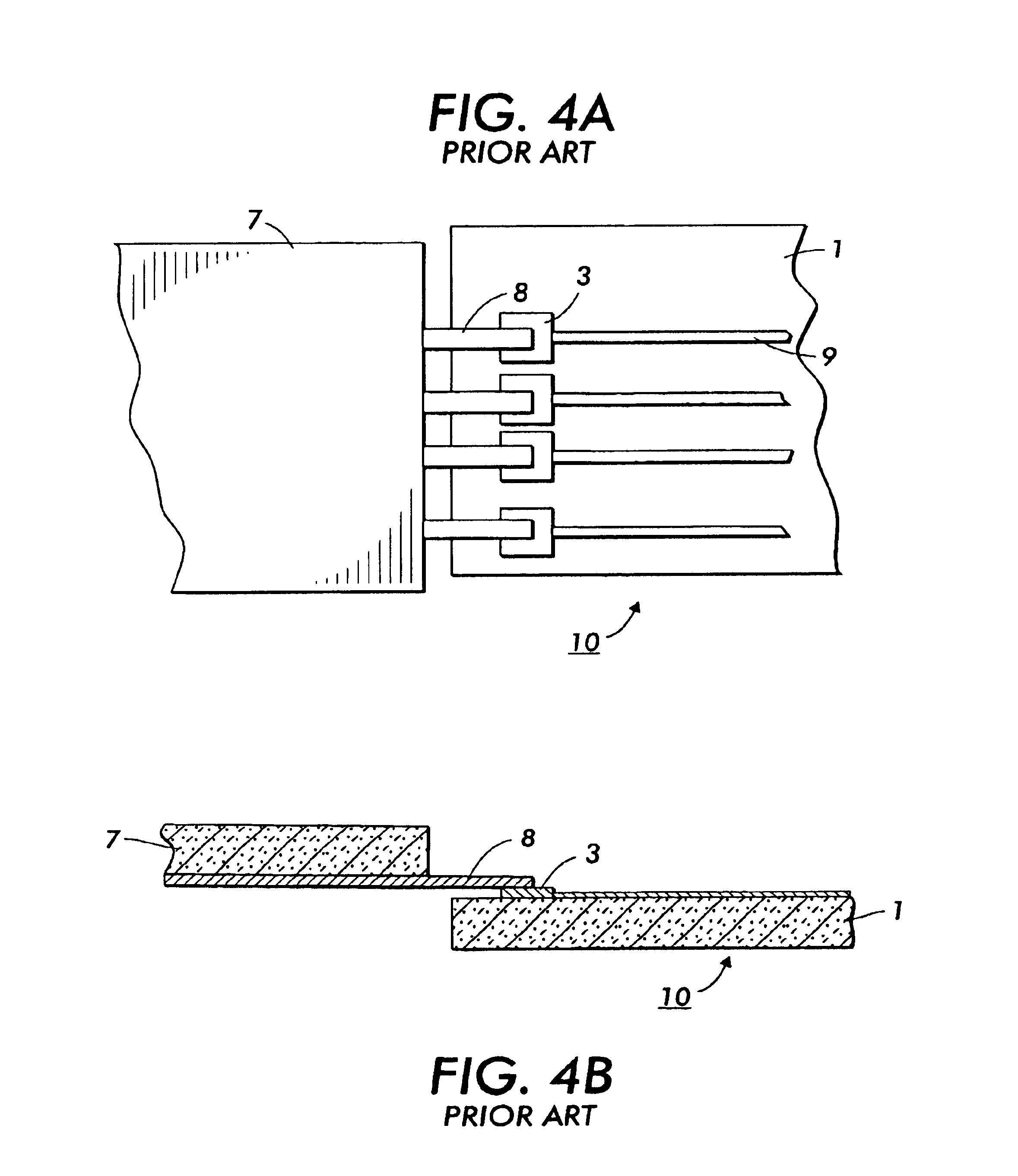

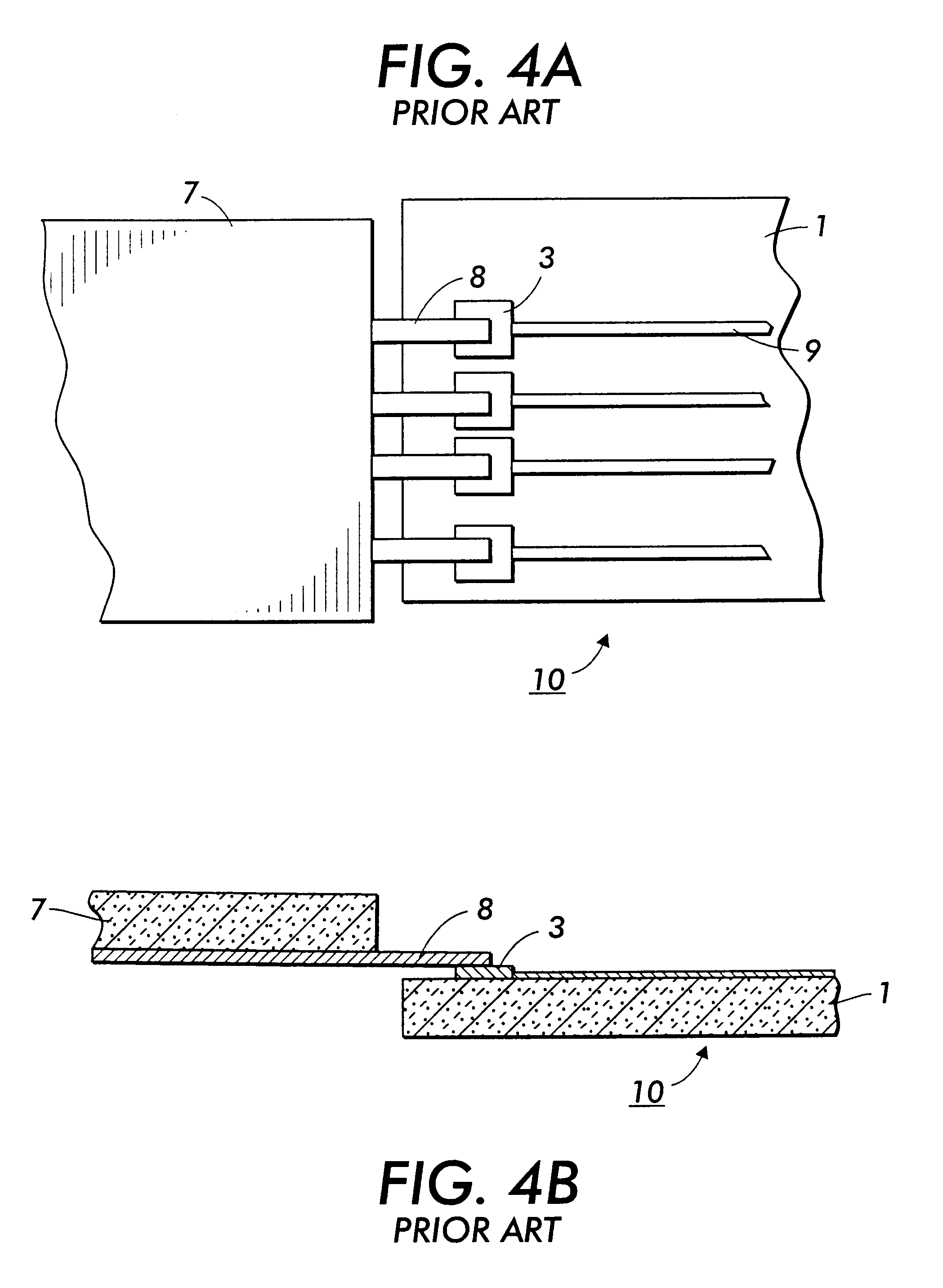

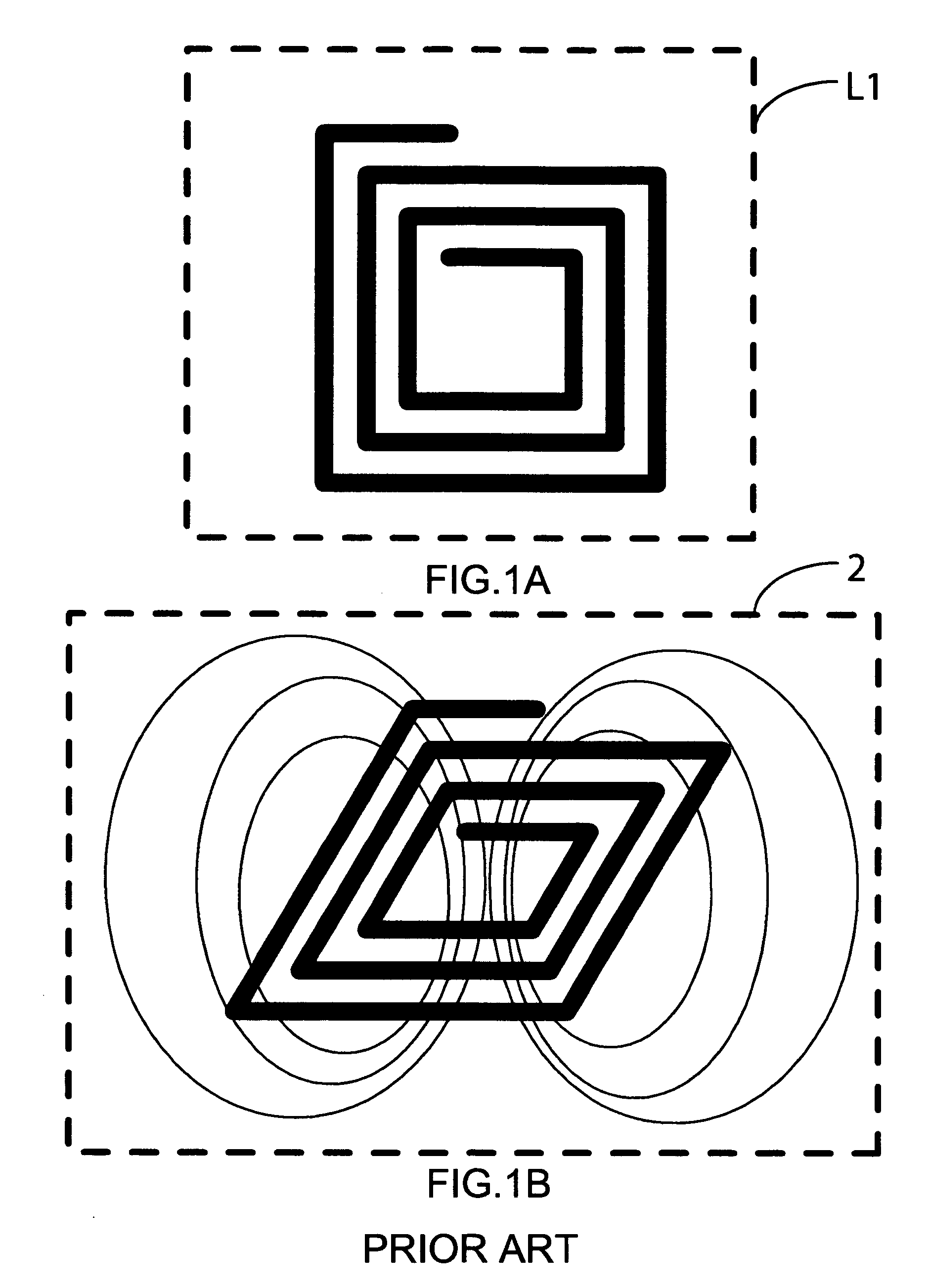

Air core inductive element on printed circuit board for use in switching power conversion circuitries

InactiveUS7221251B2Negative impact on efficiencyEliminating the magnetic lossesTransformers/inductances coils/windings/connectionsPrinted inductancesVoltage converterElectromagnetic interference

A low cost, low EMI air core inductor fabricated on printed circuit board for power conversion circuits is described. The inductive element combines the advantages of high efficiency and minimum board height requirements. It allows high frequency switching without adding undesired magnetic losses and minimizing the electro-magnetic interferences in form of radiated energy. The absence of any magnetic layer adds to the simplicity of the manufacturing process resulting in lower cost. This inductive element allows operation for the conventional and higher frequency step-up and step-down switching voltage converters minimizing the size and cost of output capacitors and reducing the output voltage ripple.

Owner:SEMTECH CORP

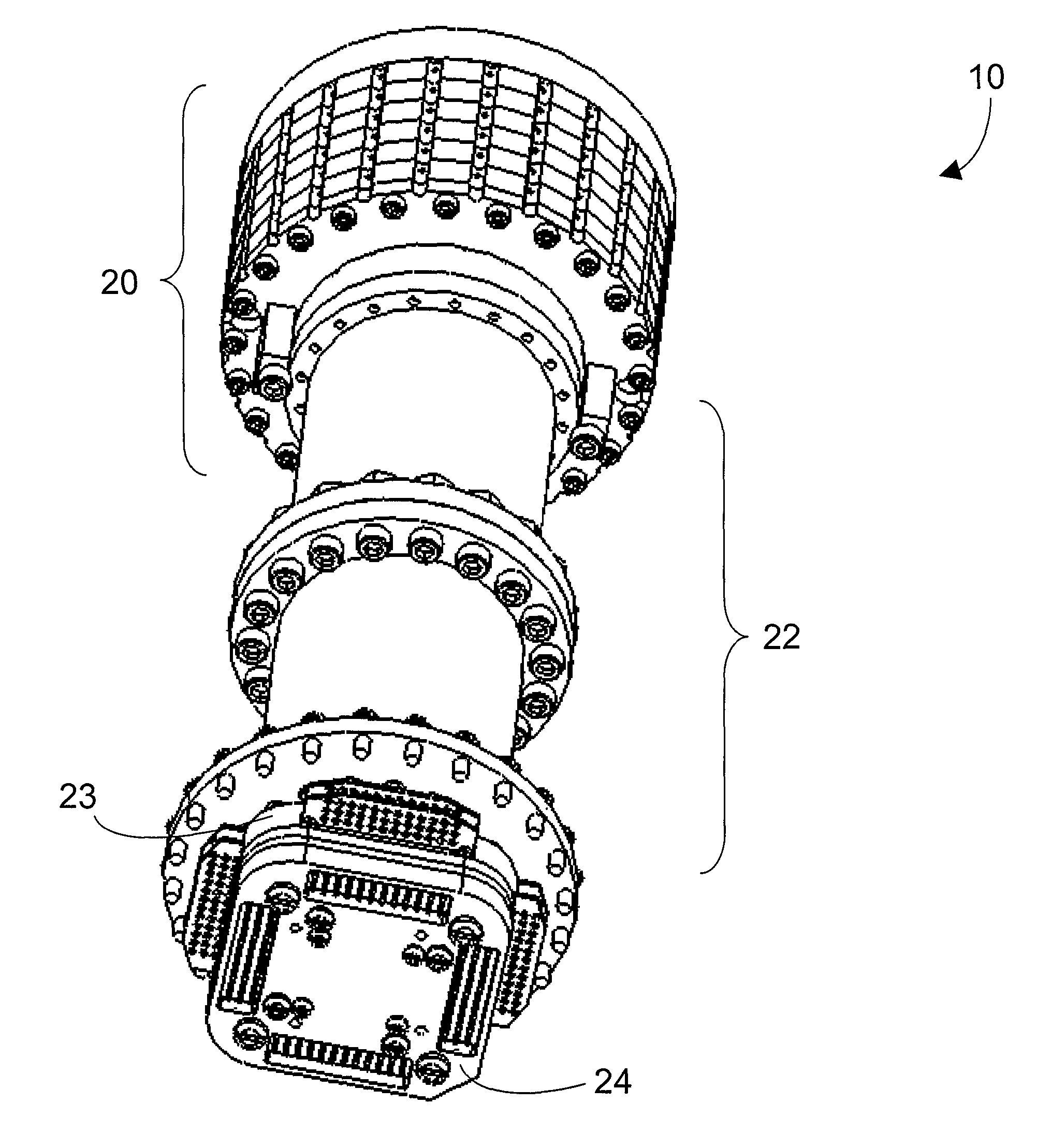

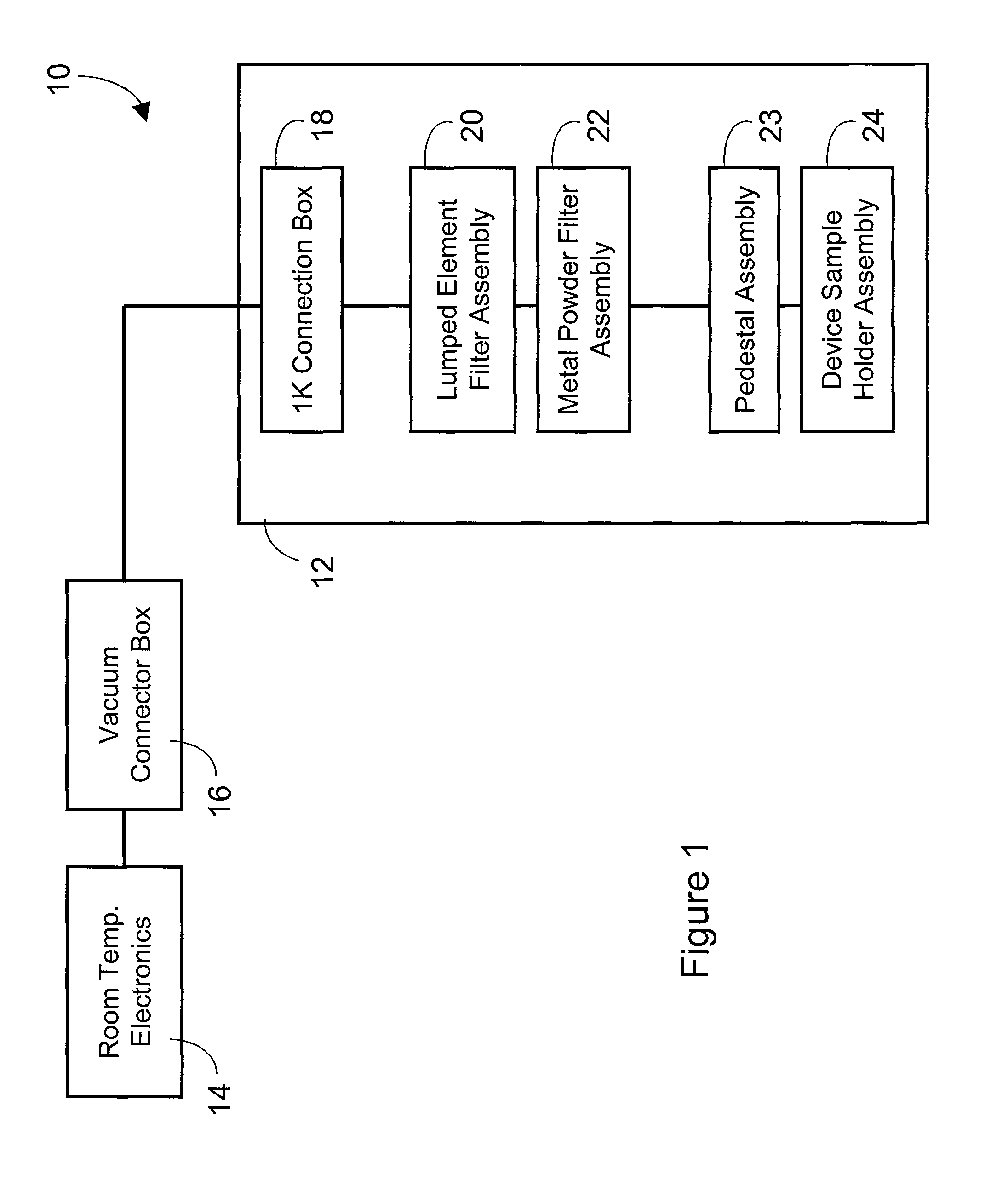

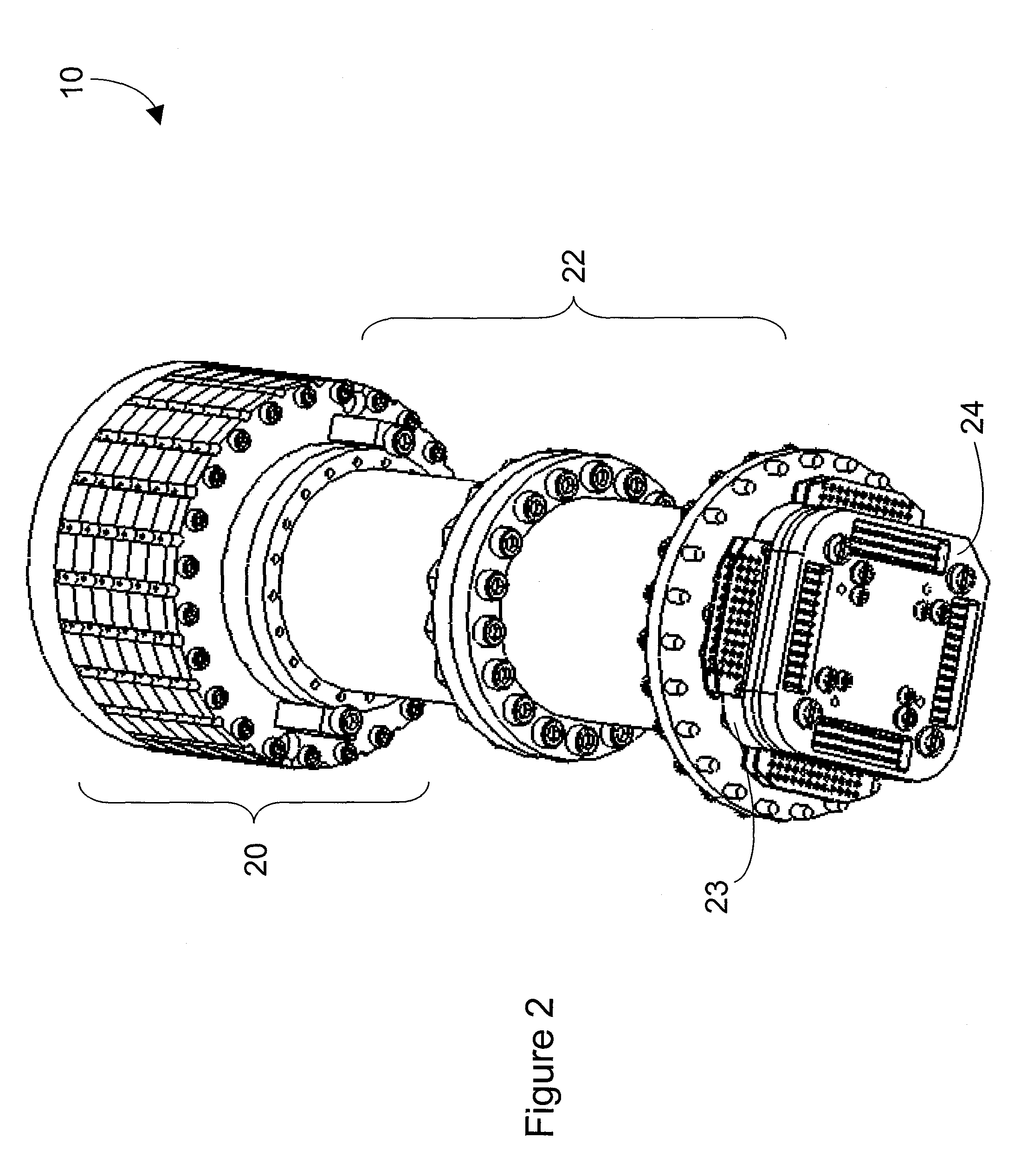

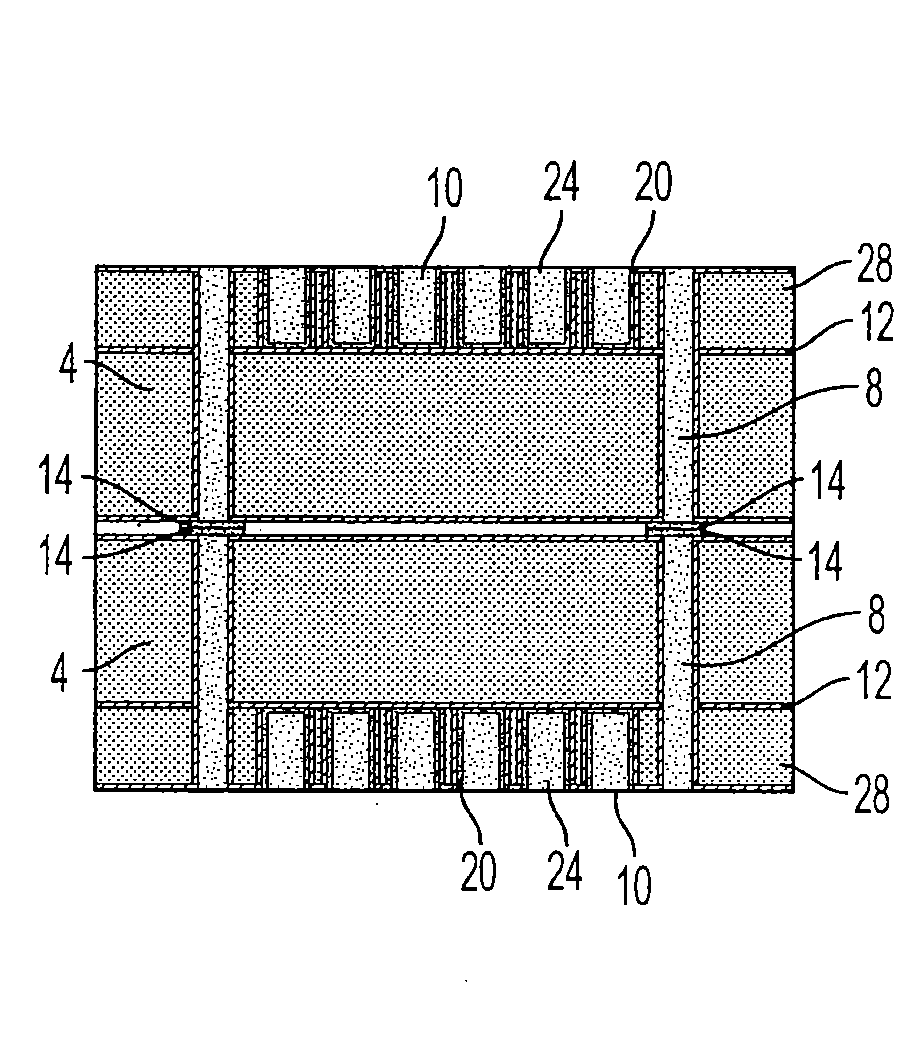

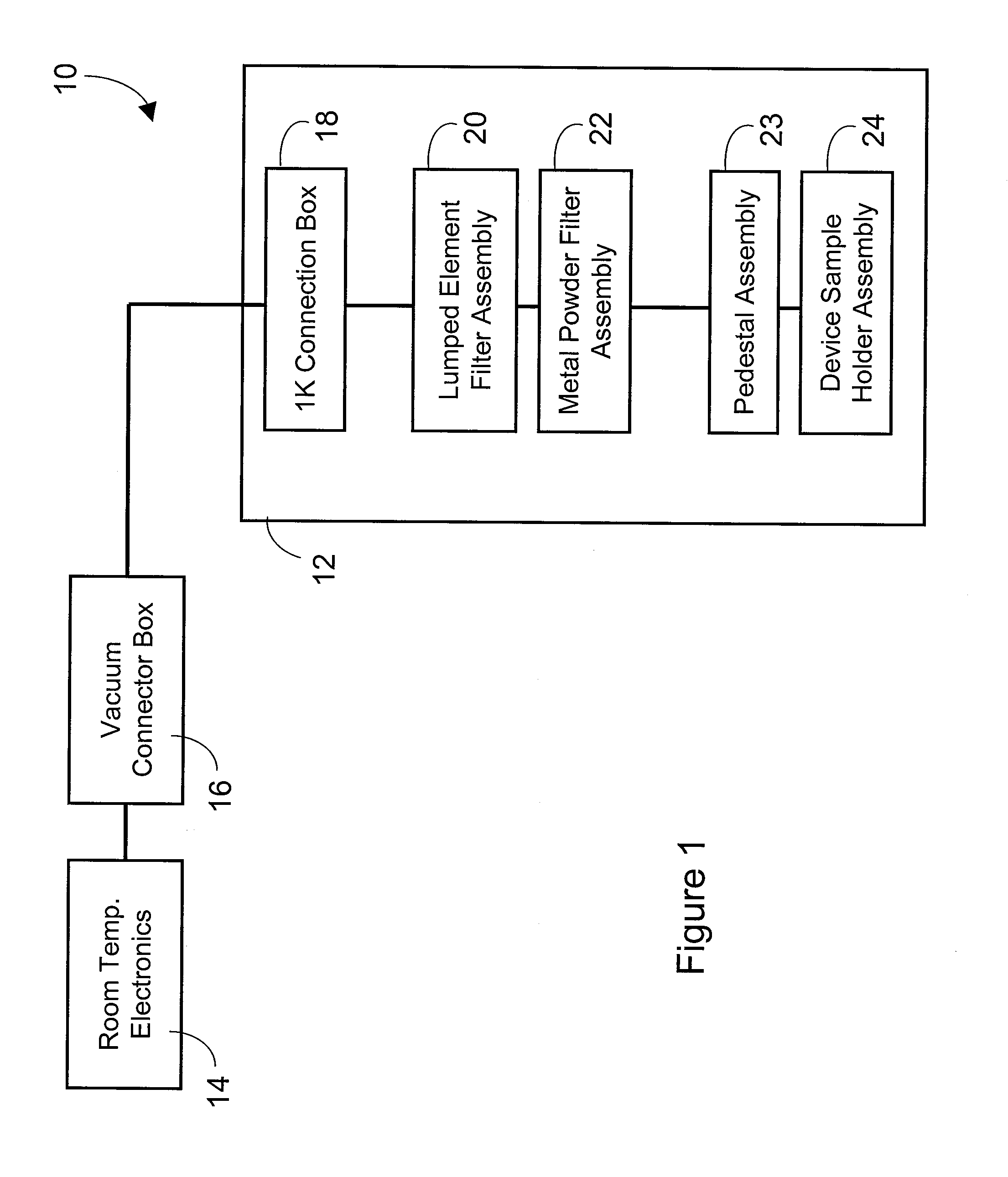

Input/output system and devices for use with superconducting devices

An I / O system and device for use with superconducting device provides multi-stage filtering using superconducting electrical pathways, while providing good thermal conductivity to maintain low temperature of the various components and allowing the easy mounting and dismounting of a device sample from a refrigerated environment. Filtering may include a lumped element filter assembly including multiple plates each carrying a number of lumped element filters. Filtering may include a metal powder filter assembly including multiple metal power filters formed in passages of a substantially non-magnetic portions. A device sample holder assembly secures a device sample, for example a superconducting quantum processor, and provides signals, ground and good thermal conduction.

Owner:D WAVE SYSTEMS INC

Multilayer coil component

ActiveUS20130257576A1Suppress generationLarge thicknessTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical conductorElectrode

Owner:TDK CORPARATION

Microfabricated inductors with through-wafer vias

InactiveUS20100225436A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingElectrical conductorInductor

The present invention relates to microfabricated inductors with through-wafer vias. In one embodiment, the present invention is an inductor including a first wafer, a first plurality of metal fillings located within the first wafer, and a first plurality of metal conductors connecting the first plurality of metal fillings together to form a first spiral with a first plurality of windings. In another embodiment, the present invention is a method for producing an inductor including the steps of forming a first plurality of vias in a first substrate, filling the first plurality of vias in the first substrate with a first plurality of metal fillings, forming a first plurality of metal conductors, and connecting pairs of the first plurality of metal fillings together using the first plurality of metal conductors to form a spiral.

Owner:TELEDYNE SCI & IMAGING

Input/output system and devices for use with superconducting devices

An I / O system and device for use with superconducting device provides multi-stage filtering using superconducting electrical pathways, while providing good thermal conductivity to maintain low temperature of the various components and allowing the easy mounting and dismounting of a device sample from a refrigerated environment. Filtering may include a lumped element filter assembly including multiple plates each carrying a number of lumped element filters. Filtering may include a metal powder filter assembly including multiple metal power filters formed in passages of a substantially non-magnetic portions. A device sample holder assembly secures a device sample, for example a superconducting quantum processor, and provides signals, ground and good thermal conduction.

Owner:D WAVE SYSTEMS INC

Balun transformer

InactiveUS20090039977A1Reduce energy lossHigh strengthMultiple-port networksOne-port networksElectromagnetic couplingTransformer

A balun transformer includes a first conductive pattern having one end provided as an input / output port of an unbalanced signal, a second conductive pattern electromagnetically coupled to the first conductive pattern and having both ends provided as input / output ports of a balanced signal, and a first variable capacitor connected between a ground part and a middle part of an electrical length of the second conductive pattern.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Inductor devices

An inductor device comprising a first conductive pattern on a first layer of a substrate, a second conductive pattern on a second layer of the substrate, and a first region between the first layer and the second layer through which at least one hole is coupled between the first dielectric layer and the second dielectric layer, wherein a magnetic field induced by at least one of the first conductive pattern or the second conductive pattern at the first region is more intensive than that induced by at least one of the first conductive pattern or the second conductive pattern at a second region between the first conductive layer and the second conductive layer.

Owner:IND TECH RES INST

High quality factor, low volume, air-core inductor

InactiveUS20080174397A1Improve the immunityIncrease surface areaElectromagnets without armaturesElectric heatingElectrical conductorAir core

A spirally-wound inductor having a tapered conductor. The height of the conductor increases from a smaller height near the center of the inductor to a greater height at the outer edge of the inductor. A spherically-shaped inductor and methods for manufacturing the spherically-shaped inductor. The spherically-shaped inductor has a series of coils that increase in diameter from each end toward the middle.

Owner:GENERAL ELECTRIC CO

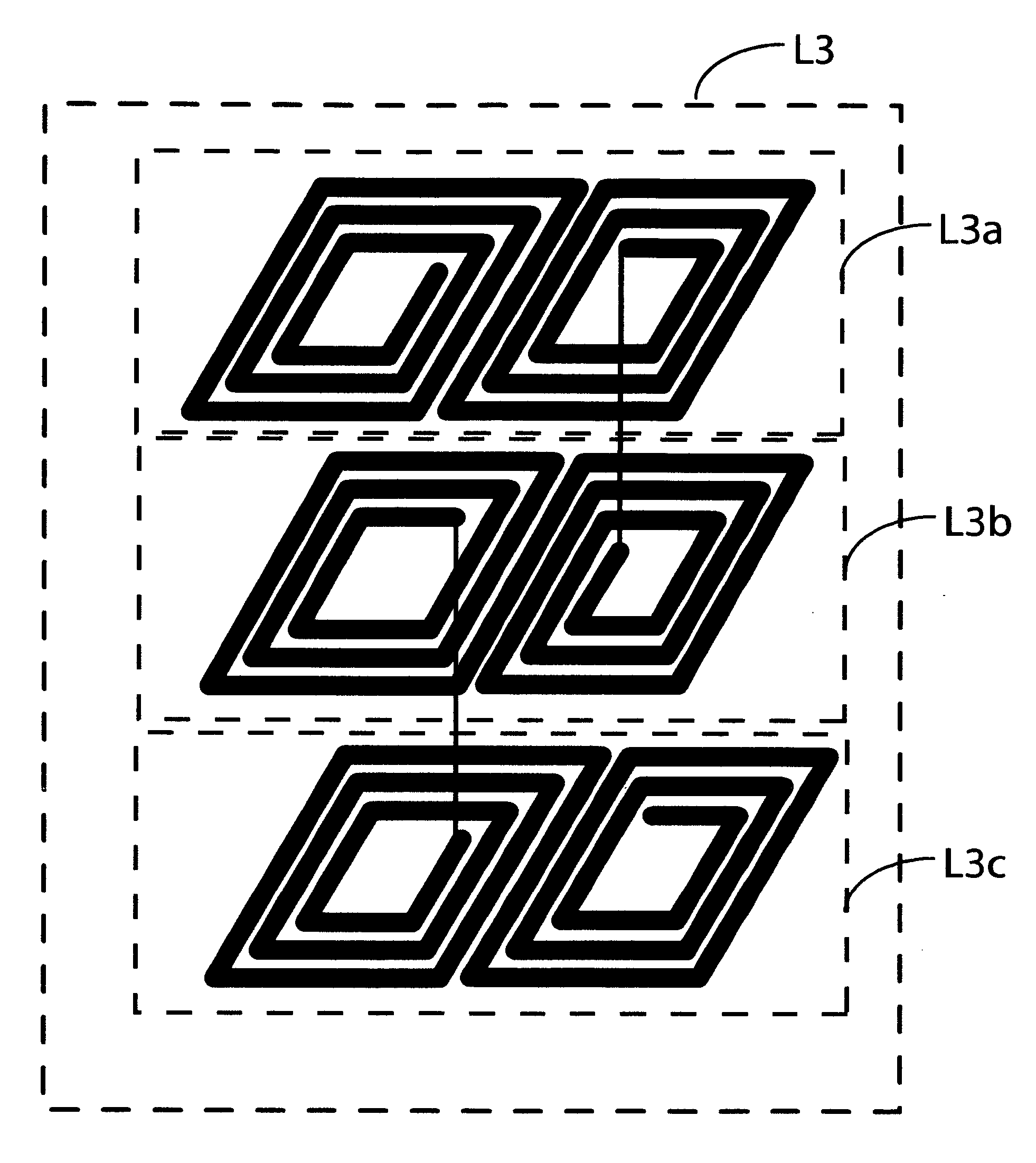

Air core inductive element on printed circuit board for use in switching power conversion circuitries

InactiveUS20060214760A1Increase inductanceLower radiated magnetic energyTransformers/inductances coils/windings/connectionsPrinted inductancesVoltage converterElectromagnetic interference

A low cost, low EMI air core inductor fabricated on printed circuit board for power conversion circuits is described. The inductive element combines the advantages of high efficiency and minimum board height requirements. It allows high frequency switching without adding undesired magnetic losses and minimizing the electromagnetic interferences in form of radiated energy. The absence of any magnetic layer adds to the simplicity of the manufacturing process resulting in lower cost. This inductive element allows operation for the conventional and higher frequency step-up and step-down switching voltage converters minimizing the size and cost of output capacitors and reducing the output voltage ripple.

Owner:SEMTECH CORP

Method of making photolithographically-patterned out-of-plane coil structures

InactiveUS20030179064A1Contact member manufacturingContact member assembly/disassemblyMicro structureTransformer

An out-of-plane micro-structure which can be used for on-chip integration of high-Q inductors and transformers places the magnetic field direction parallel to the substrate plane without requiring high aspect ratio processing. The photolithographically patterned coil structure includes an elastic member having an intrinsic stress profile. The intrinsic stress profile biases a free portion away from the substrate forming a loop winding. An anchor portion remains fixed to the substrate. The free portion end becomes a second anchor portion which may be connected to the substrate via soldering or plating. A series of individual coil structures can be joined via their anchor portions to form inductors and transformers.

Owner:XEROX CORP

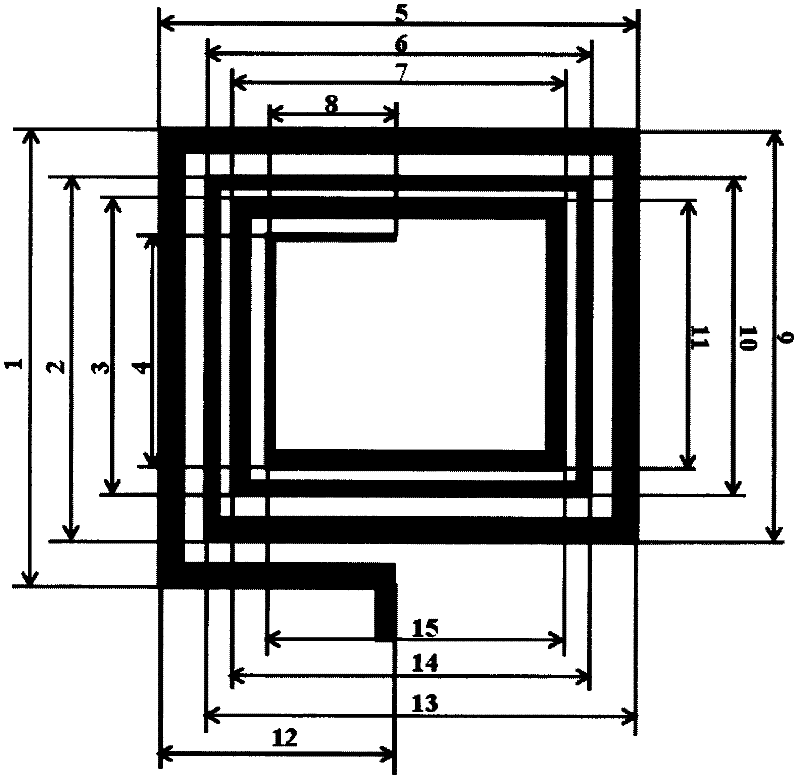

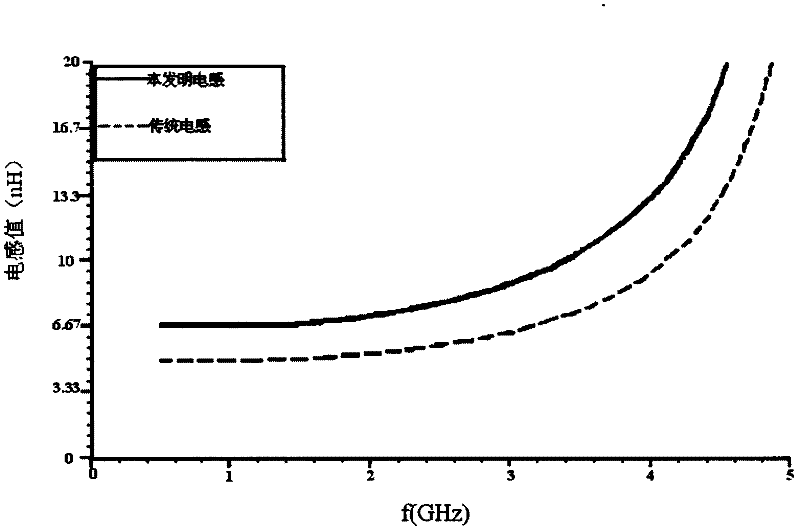

Planar spiral inductor with wide-narrow-alternatingly line width and space

InactiveCN102522181AReduce ohmic lossesOvercome the defect of low Q value of inductanceSignal inductance without magnetic coreElectrical resistance and conductanceInsulation layer

The invention discloses a planar spiral inductor with wide-narrow-alternatingly line width and space, which can be used for an RF integrated circuit. The planar spiral inductor adopts the structure that a spiral inductive insulation layer is arranged on a silicon substrate; the metal thin film is coated on the insulation layer to etch an inductive bottom layer metal layer, so the insulation layeris deposited on the bottom layer metal layer; through holes are formed on the insulation layer so as to connect the bottom layer metal layer and the spiral inductor layer; and the metal thin film is coated on the insulation layer to etch a spiral inductive metal layer with a multi-turn coil; and the pattern of the coil is formed through conductive metal. According to the invention, the metal coilis alternately changed in width form the outer ring to the inner ring, whereas the space is alternately changed in width form the inner ring to the outer ring, thereby reducing the Ohm wastage causedby equivalent resistors connected in series, lowering the proximity effect of the metal wires, improving the quality factor Q value of the spiral inductor, increasing the mutual induction of the wirecoils, and also improving the inductance value of the spiral inductor.

Owner:XIDIAN UNIV

Coil filter and method for manufacturing the same

InactiveUS6940366B2Multiple-port networksTransformers/inductances coils/windings/connectionsSurface mountingWide band

The present invention provides a coil filter suitable for surface mounting on an electronic circuit board by automatic mounting and capable of realizing wide band isolation excellent in high-frequency characteristics without requiring consideration for the mutual position of parts. The coil filter functions to block electromagnetic waves or high-frequency signals propagating while being superimposed on a DC power supply, signal, or the like of an electronic apparatus such as an electronic circuit board. Conducting wires are bonded electrically at coil end parts such that a conducting wire part wound by one turn or more constitutes a short ring conducting in a ring shape on both sides of an intermediate part in which electrically insulated conducting wires are wound. End parts of the conducting wire are positioned on the inner side of the outermost circumferential part of the coil-shaped end faces.

Owner:KOMIYA KUNIFUMI

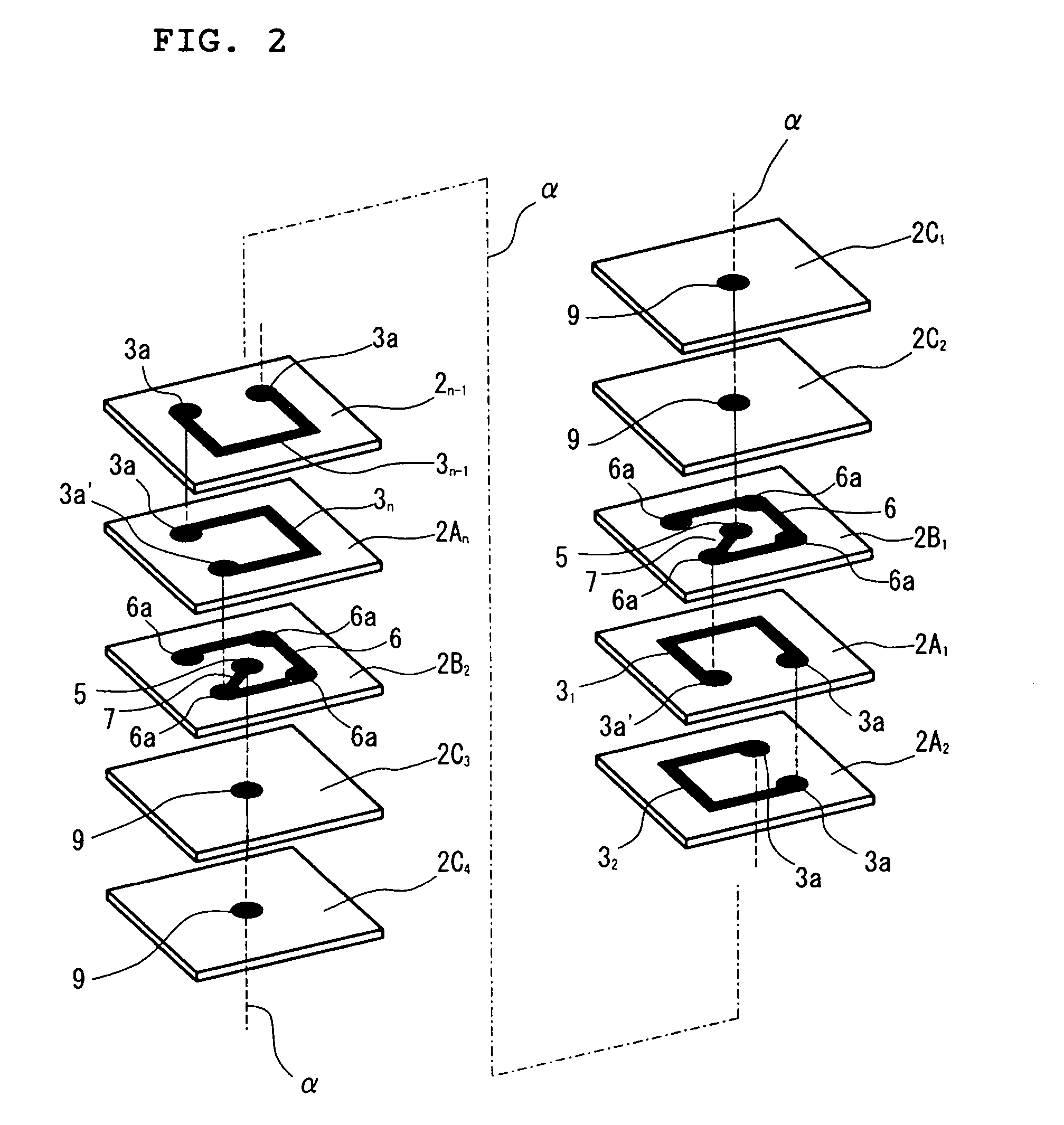

Method of manufacturing multilayered electronic component and multilayered electronic component

ActiveUS20050122699A1Easy to manufactureExcellent electrical propertiesPrinted electric component incorporationConductive pattern formationElectronic componentElectron

A multilayered electronic component that is easy to manufacture and that has excellent electrical characteristics includes end portions of coil wiring patterns that oppose a coil connection electrode that is displaced on the surface of a second ceramic layer due to an increase or decrease in the number of first ceramic layers. A coil connection electrode has a shape in which surface portions of second ceramic layers or opposed second ceramic layers having the first ceramic layers disposed in between are connected to the end portions of the coil wiring patterns that oppose the respective coil connection electrode, which are displaced due to the increase or decrease in the number of the first ceramic layers. A connection wiring pattern has a shape in which one portion of a coil connection electrode is connected to one portion of an external extension electrode connection pattern.

Owner:MURATA MFG CO LTD

Process for producing inductive coil by printed circuit board

InactiveCN1988069AUniform inductanceImprove performancePrinted circuit assemblingCoils manufactureEngineeringPrinted circuit board

This invention relates to a method for manufacturing inductance coils with PCB including: producing a PCB of 2-20 layers and making a screw coil on each layer CB, designing coil turns and coil diameter according to the inductance, winding adjacent two layers of coils in opposite direction and connecting the adjacent two layers of coils with buried holes through through holes of the CB to ensure the same direction of alternating magnetic fields generated by the two adjacent layers of coils till to the last layer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Implantable lead having multi-planar spiral inductor filter

A multilayer helical wave filter having a primary resonance at a selected RF diagnostic or therapeutic frequency or frequency range, includes an elongated conductor forming at least a portion of an implantable medical lead. The elongated conductor includes a first helically wound segment having at least one planar surface, a first end and a second end, which forms a first inductive component, and a second helically wound segment having at least one planar surface, a first end and a second end, which forms a second inductive element. The first and second helically wound segments are wound in the same longitudinal direction and share a common longitudinal axis. Planar surfaces of the helically wound segments face one another, and a dielectric material is disposed between the facing planar surfaces of the helically wound segments and between adjacent coils of the helically wound segments, thereby forming a capacitance.

Owner:WILSON GREATBATCH LTD

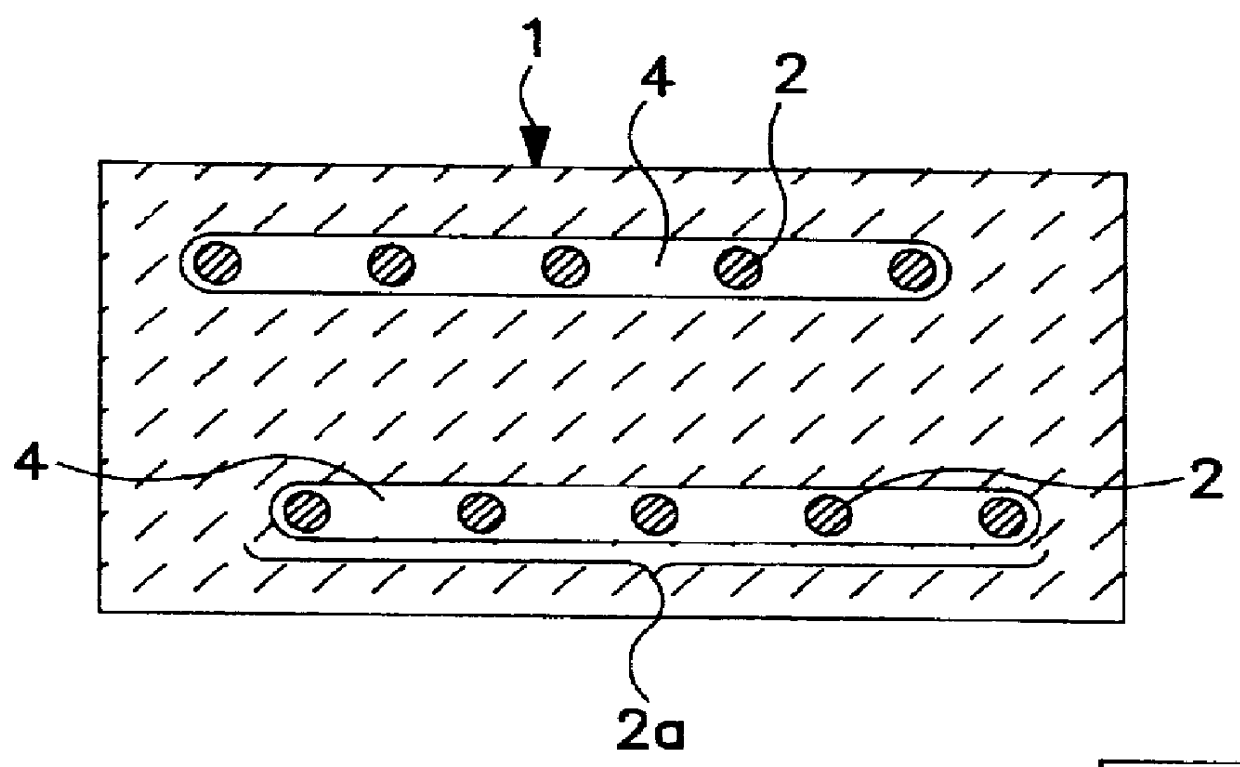

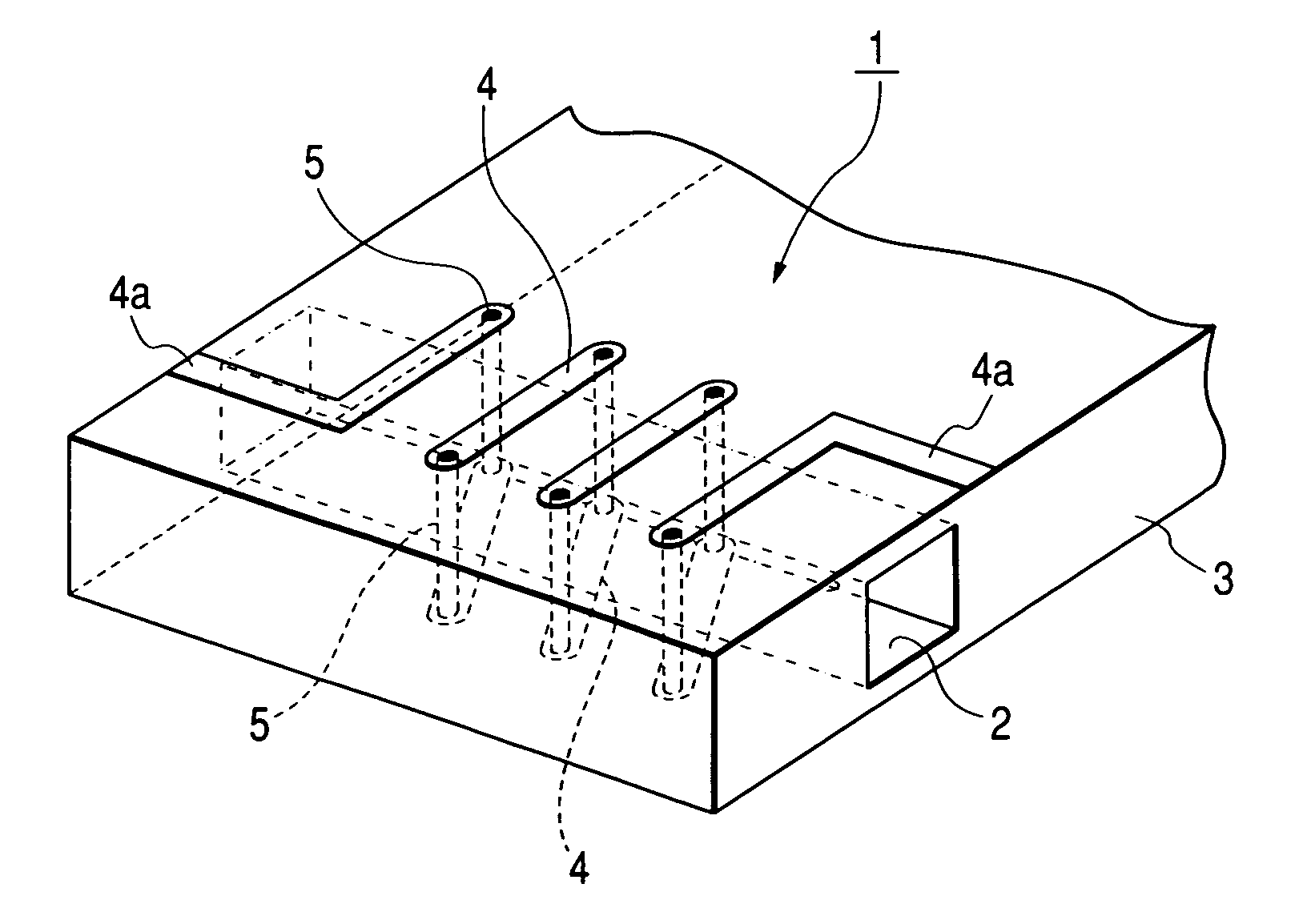

Printed inductor capable of raising Q value

InactiveUS6992557B2Degree of reductionImprove Q valueTransformers/inductances coils/windings/connectionsPrinted circuit aspectsEngineeringInductor

There is disclosed a printed inductor 1 having a spiral coil formed outside a cavity 2 by providing an insulating substrate 3 with the cavity 2 extending in a direction orthogonal to that of the thickness of the insulating substrate 3, forming a plurality of mutually independent printed wiring lines 4 on both the top and bottom faces of the insulating substrate 3 facing each other through the cavity 2, and sequentially and continuously connecting terminals of the printed wiring lines 4 on both the top and bottom faces to each other through a plurality of through holes 5.

Owner:ALPS ALPINE CO LTD

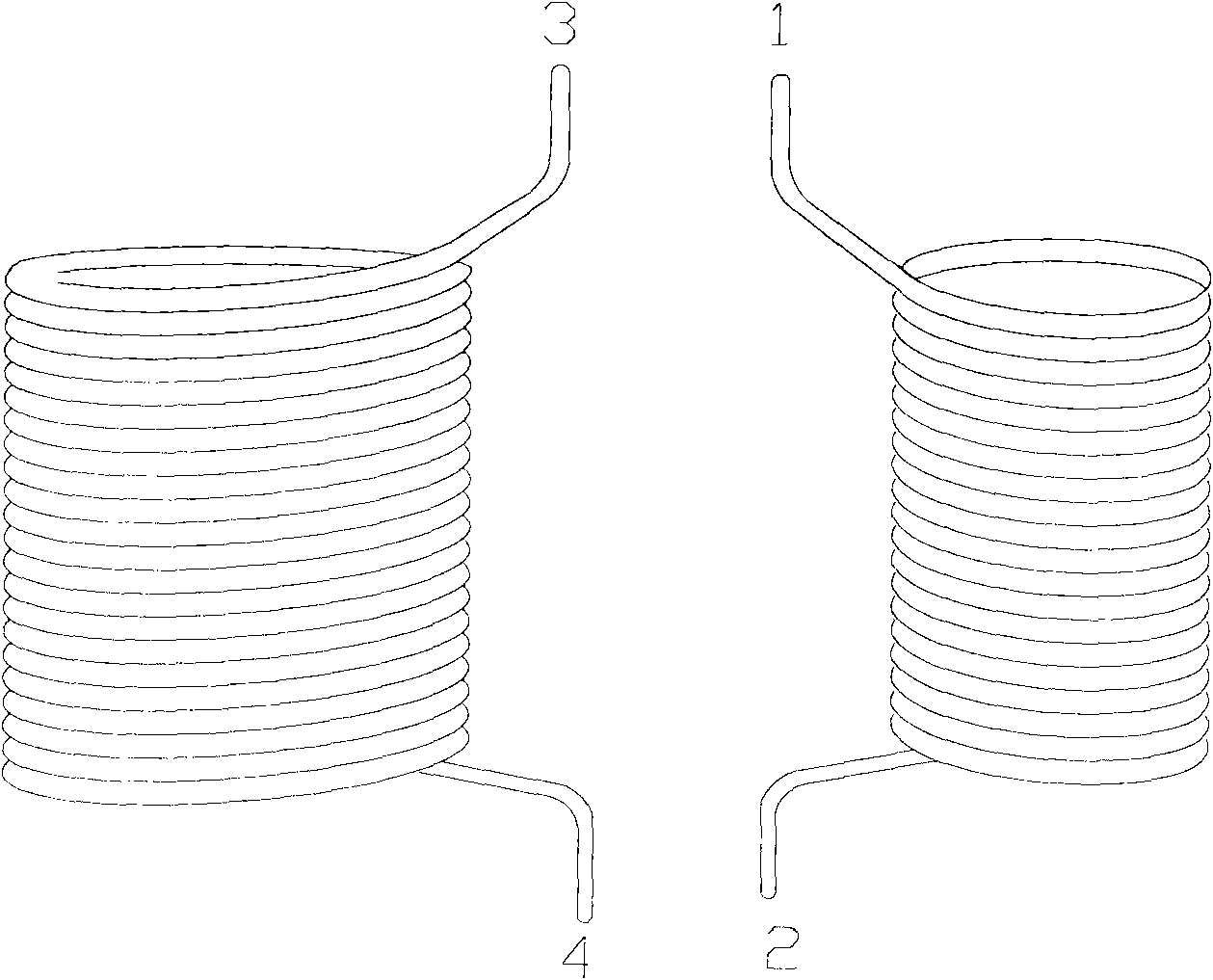

Parallel type circuit breakers based on tightly coupled air reactor

ActiveCN101814402ARealize automatic current sharingAutomatic Current Sharing GuaranteeTransformers/inductances coils/windings/connectionsElectric switchesCurrent limitingEngineering

The invention relates to parallel type circuit breakers based on a tightly coupled air reactor, belonging to the field of high-voltage and high-capacity circuit breaker devices. The invention aims at automatic current sharing and current limiting. Parallel operation of the circuit breakers is realized by adopting the tightly coupled air reactor. The current input ends on two arms of the tightly coupled air reactor are positioned at the same side of the reactor, are short connected and are connected into a system by being welded with a wiring board, the current output ends on the two arms are respectively connected with two circuit breakers after being welded with the wiring board, and the other ends of the circuit breakers are short connected and connected with the system, therefore, the whole parallel type circuit breaker devices based on the tightly coupled air reactor are connected into the system in series, and the wiring board at the output end of the tightly coupled air reactor is supported by a post insulator and is fixed on a prefabricated platform. The circuit breakers are connected in parallel by adopting the tightly coupled air reactor, thereby breaking the short-circuit current by times and improving the entire breaking capability.

Owner:STATE GRID ELECTRIC POWER RES INST +1

Sensor assembly, transformers and methods of manufacture

ActiveUS20080072681A1Fluid pressure measurement using inductance variationFlow propertiesTransformerEngineering

A sensor assembly is provided. The sensor assembly includes a sensor configured to measure an impedance value representative of a sensed parameter and a transformer coupled to the sensor. The transformer includes at least one ceramic substrate and at least one electrically conductive line disposed on the ceramic substrate to form at least one winding. The electrically conductive line includes an electrically conductive material.

Owner:GENERAL ELECTRIC CO

Inductive components, laminated electronic components, laminated electronic components modulars and method for mfg. these components and modulars

A laminated electronic component including at least one inductance element and produced froma laminate having electrical insulators and electrical conductors laminated alternately. The inductance element is formed as a helical coil having a plurality of turns each constituted by four sides. The inductance element has pairs of parallel conductor pieces and pairs of bridging conductor pieces. Each pair of parallel conductor pieces form two of the four sides of one turn of the coil. Each pair of bridging conductor pieces form the other two sides of one turn of the coil. Grooves are formed in the laminate to thereby form the parallel conductor pieces. The grooves are filled with an electrically insulating material. The bridging conductor pieces are formed on the electrically insulating material.

Owner:TDK CORPARATION

Inductive element and manufacturing method of the same

ActiveUS7212095B2Easy to mass produceHigh Q characteristicTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorHelical coil

Conductor layers 2A and insulating layers 4A are alternately stacked so as to prepare a base material 17. A plurality of grooves 18 having a predetermined width are formed in a surface of the base material 17 in such a manner that these plural grooves 18 are located parallel to each other along a stacking layer direction in order to form a coil inner peripheral portion. Embedding materials 5 are filled into the grooves 18. Surfaces 16 of the base material into which the embedding materials 5 have been filled are flattened by polishing. The conductor layers 2A located adjacent to each other are connected to each other, so that helical coils which constitute inductive elements are constructed. Then, both the front plane and the rear plane of the resultant base material are covered by an insulating layer, which is cut so as to obtain respective chips.

Owner:TDK CORPARATION

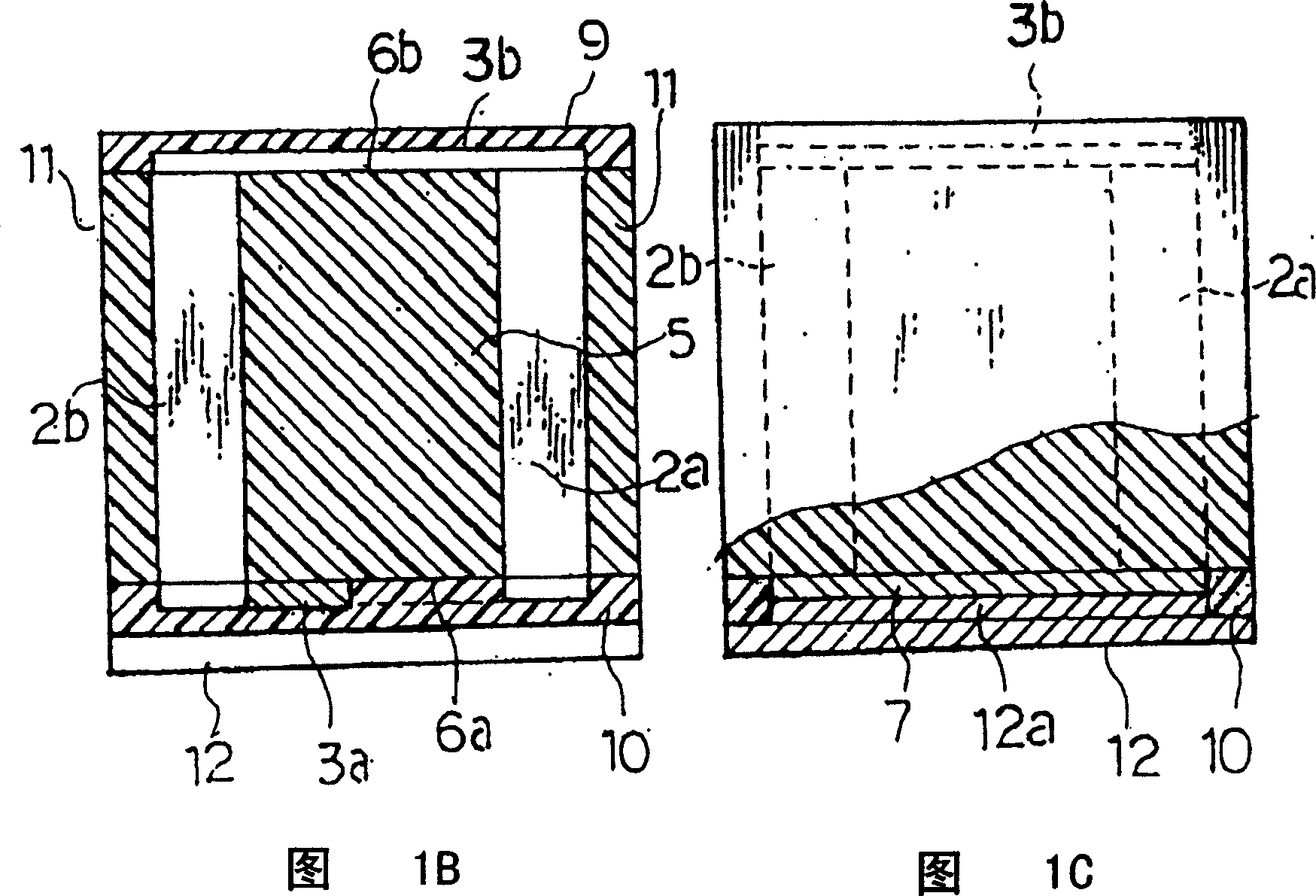

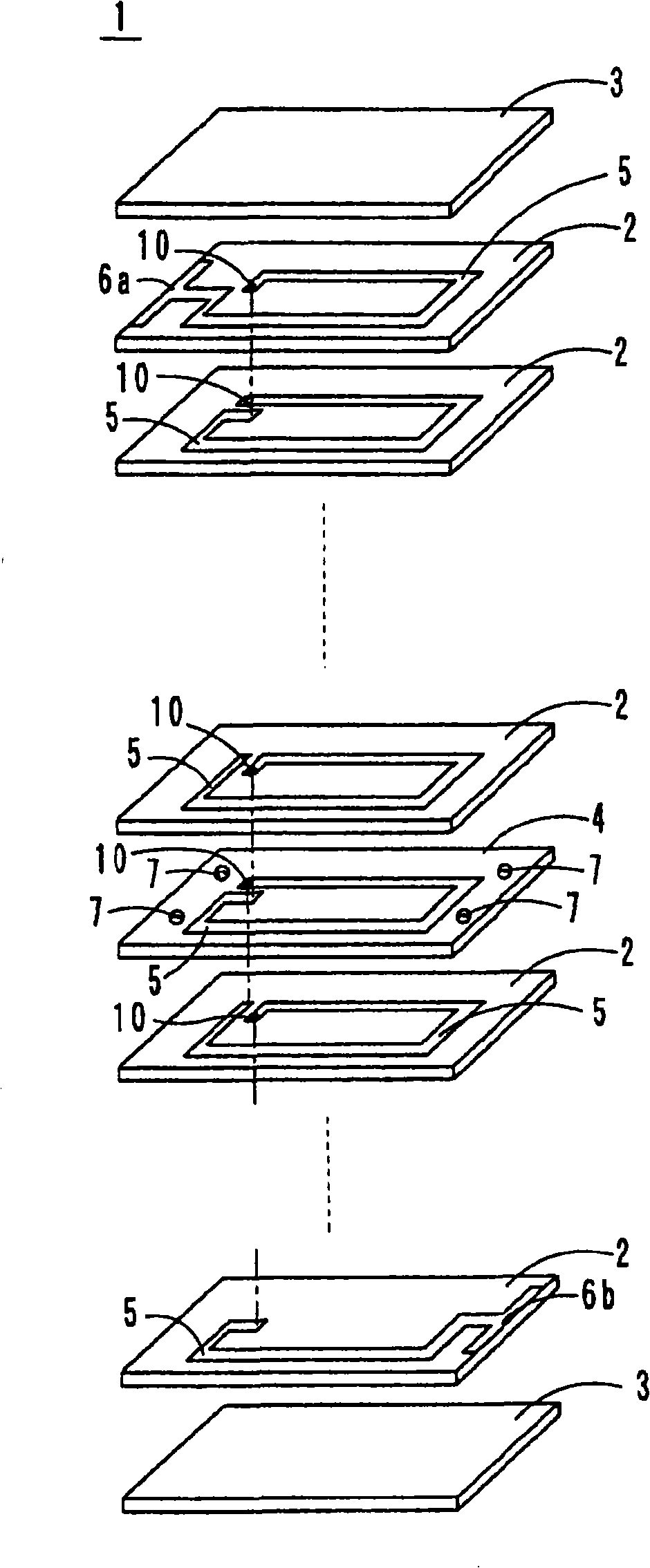

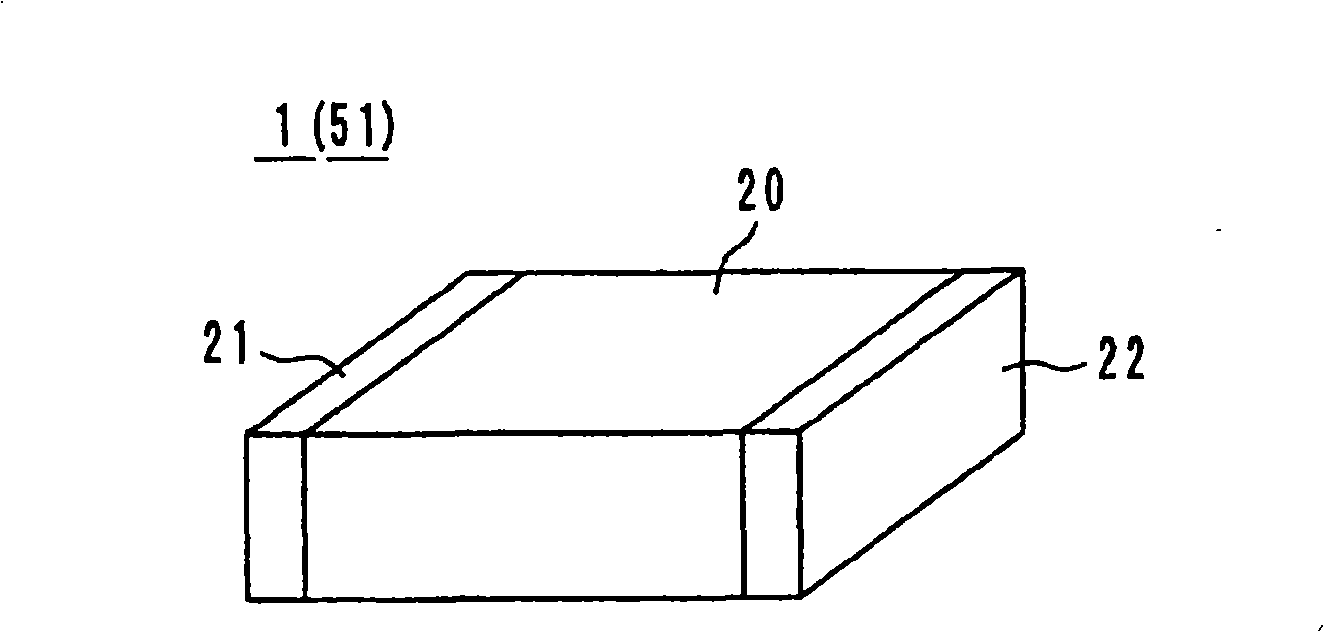

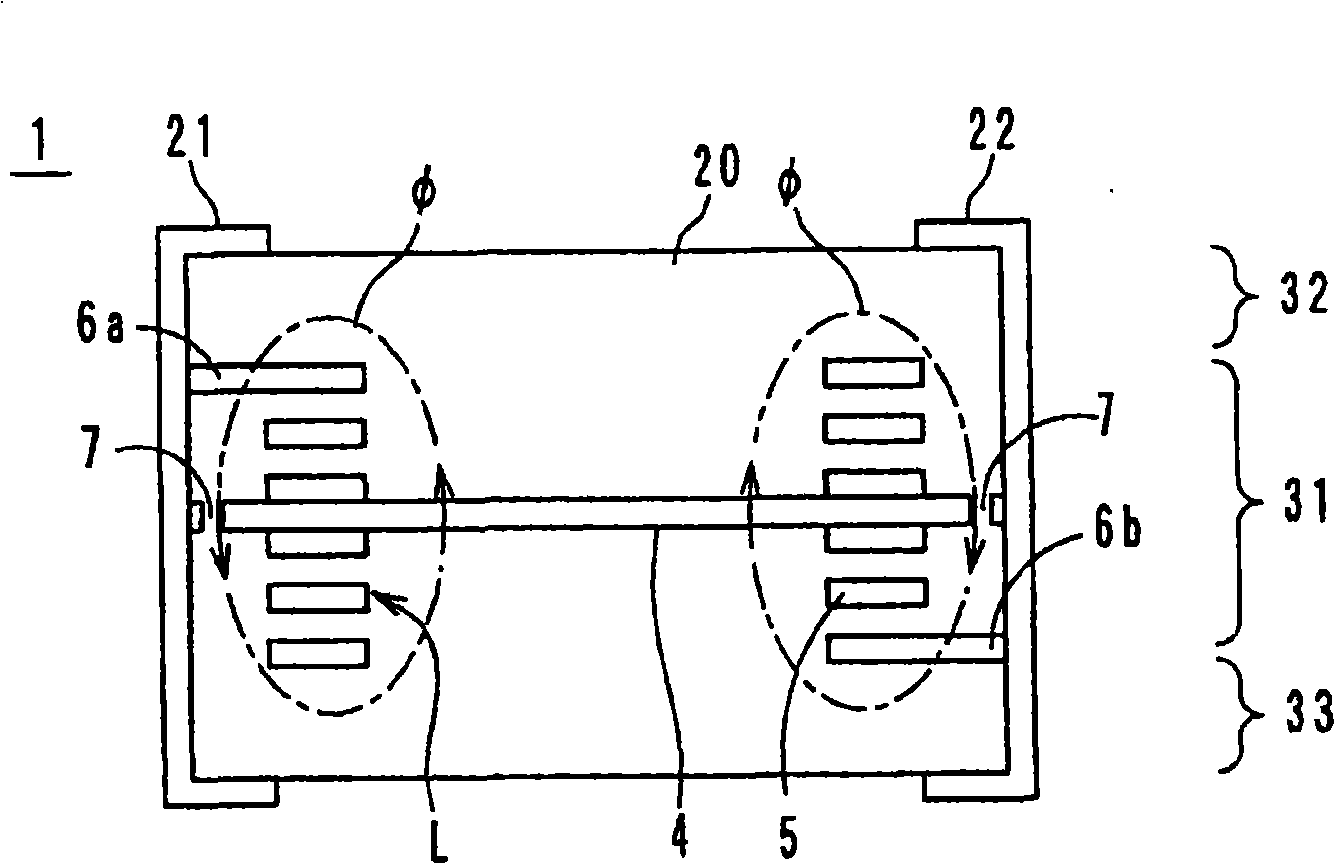

Multilayer coil component and method for manufacturing the same

InactiveCN101356599ACrack suppressionAvoid delaminationCoils manufactureSignal inductance without magnetic coreElectrical conductorMaterials science

A closed magnetic path type multilayer coil component in which cracking or delamination hardly occurs between layers of different permeabilities. A first ceramic sheet (2) on which a conductor pattern (5) for coil is formed and a third ceramic sheet (4) having a permeability lower than that of the first ceramic sheet (2) are laminated, and the conductor patterns (5) for coil are interconnected electrically to constitute a coil being incorporated in a multilayer coil component (1). The third ceramic sheet (4) is sandwiched by the first ceramic sheets (2). A cavity (7) is formed in a major surface of the third ceramic sheet (4) and the first ceramic sheet (2) adjoining the third ceramic sheet (4) is in contact with the inner circumferential surface of the cavity (7).

Owner:MURATA MFG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com