Inductive components, laminated electronic components, laminated electronic components modulars and method for mfg. these components and modulars

A technology of inductive components and electronic components, which is applied in multilayer circuit manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., and can solve problems such as difficulty in obtaining laminated electronic components at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

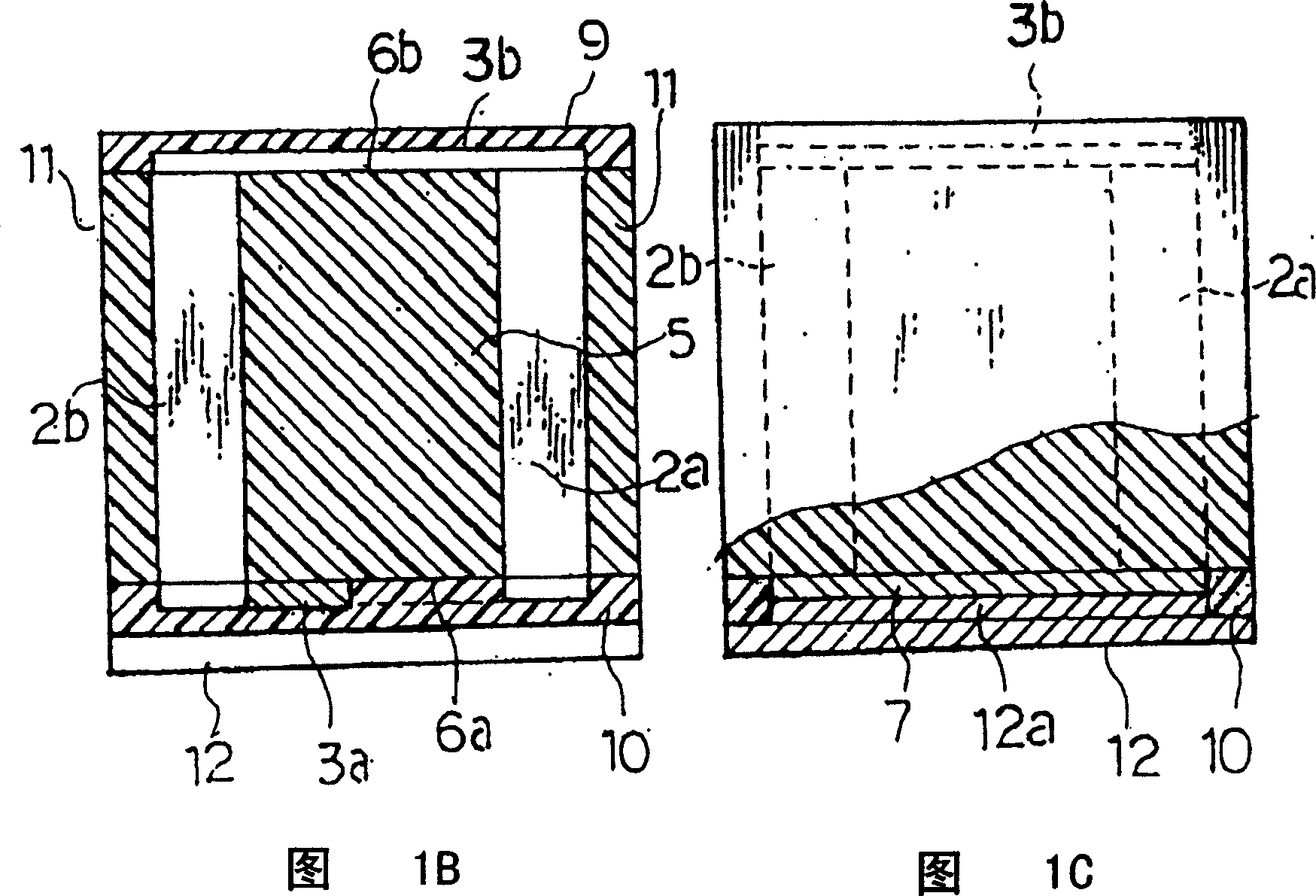

[0086] FIG. 1A shows an embodiment of an inductive element according to the invention in a perspective view. FIG. 1B shows the structure of a coil in the inductor coil in a cross-sectional view. FIG. 1C shows the structure of an electrode in the inductor element in a cross-sectional view. FIG. 2A shows the inductance element in a bottom view. Figure 2B The inductance element is shown in a cross-sectional view.

[0087] In FIGS. 1A-1C and FIGS. 2A and 2B, reference numeral 1 denotes a rectangular spiral coil. The coil 1 includes a pair of parallel conductive members 2a and 2b and a pair of bridging conductive members 3a and 3b. Each pair of parallel conducting members 2a and 2b forms two of the four sides of a turn of the coil 1 . Each pair of bridging conductors 3a and 3b forms the other two sides of a turn of the coil 1 . The rectangular spiral coil is formed by connecting adjacent parallel conductive members 2a and 2b to each other by bridging conductive members 3a and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com