Multilayer coil component and method for manufacturing the same

A technology for stacking coils and components, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc., can solve the problems of easy peeling and poor adhesion, and achieve the effect of suppressing cracks or delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

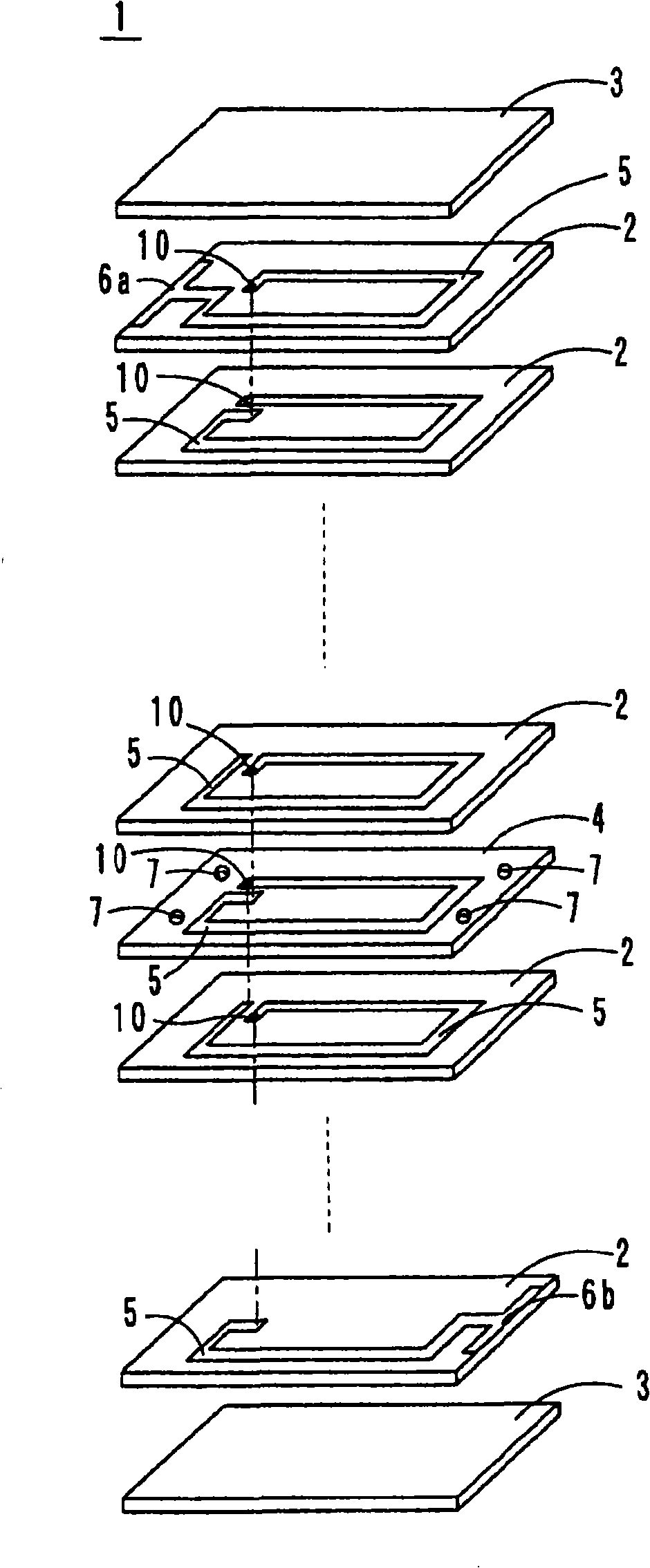

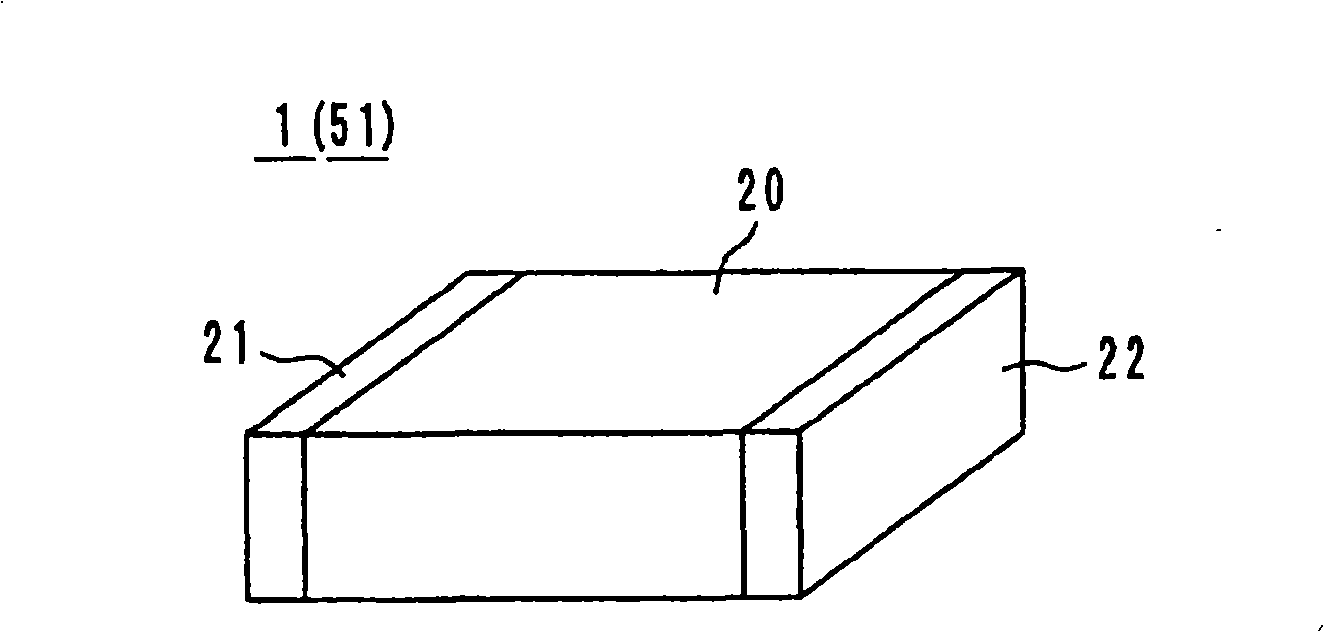

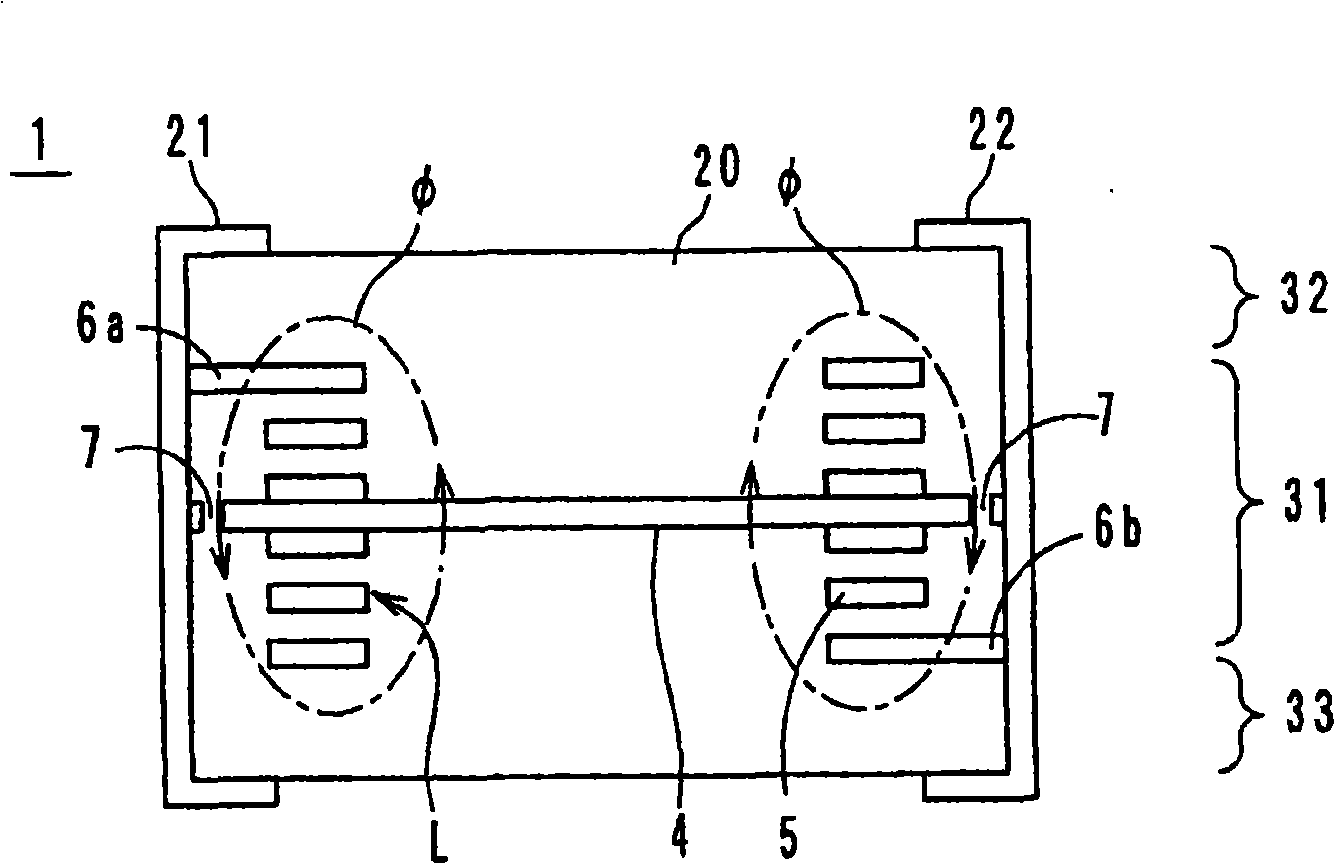

[0027] Hereinafter, an embodiment of an open magnetic circuit type laminated coil component and a manufacturing method thereof according to the present invention will be described with reference to the drawings. The embodiment of the present invention takes the case of a single product as an example, but in mass production, a plurality of internal conductor patterns are printed on the surface of the mother ceramic green sheet, and multiple pieces of the mother ceramic green sheet are laminated and crimped to form Unfired laminate block. Then, the laminated body block is cut according to the configuration of the internal conductor pattern, thereby cutting out laminated ceramic chips one by one, the cut out laminated ceramic chips are fired, and external electrodes are formed on the fired laminated ceramic chips. This is how it goes into production. Alternatively, the mother ceramic green sheets may be laminated and crimped, fired, and then laminated ceramic sheets may be cut o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com