Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about "Non-pressurised lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

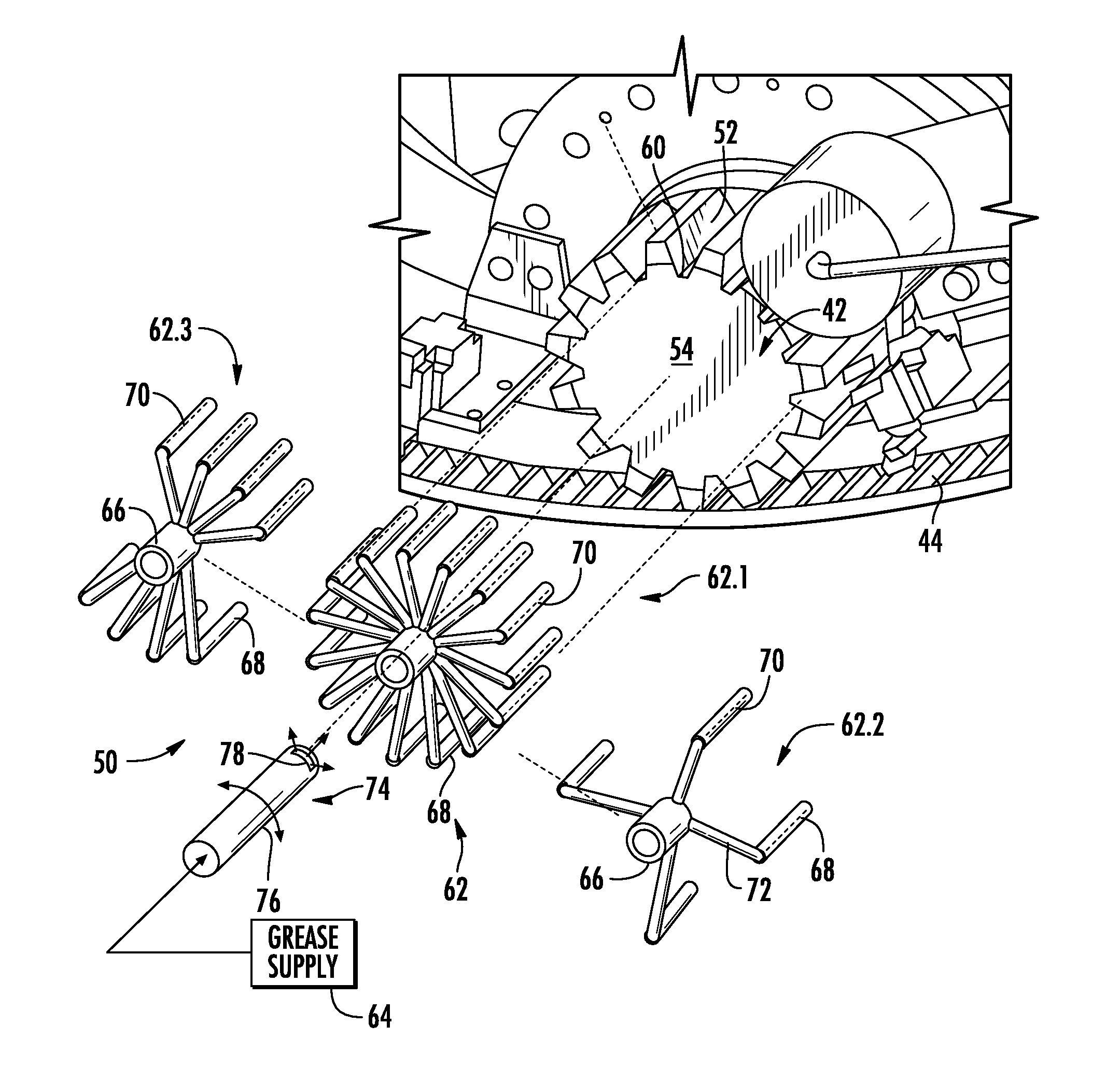

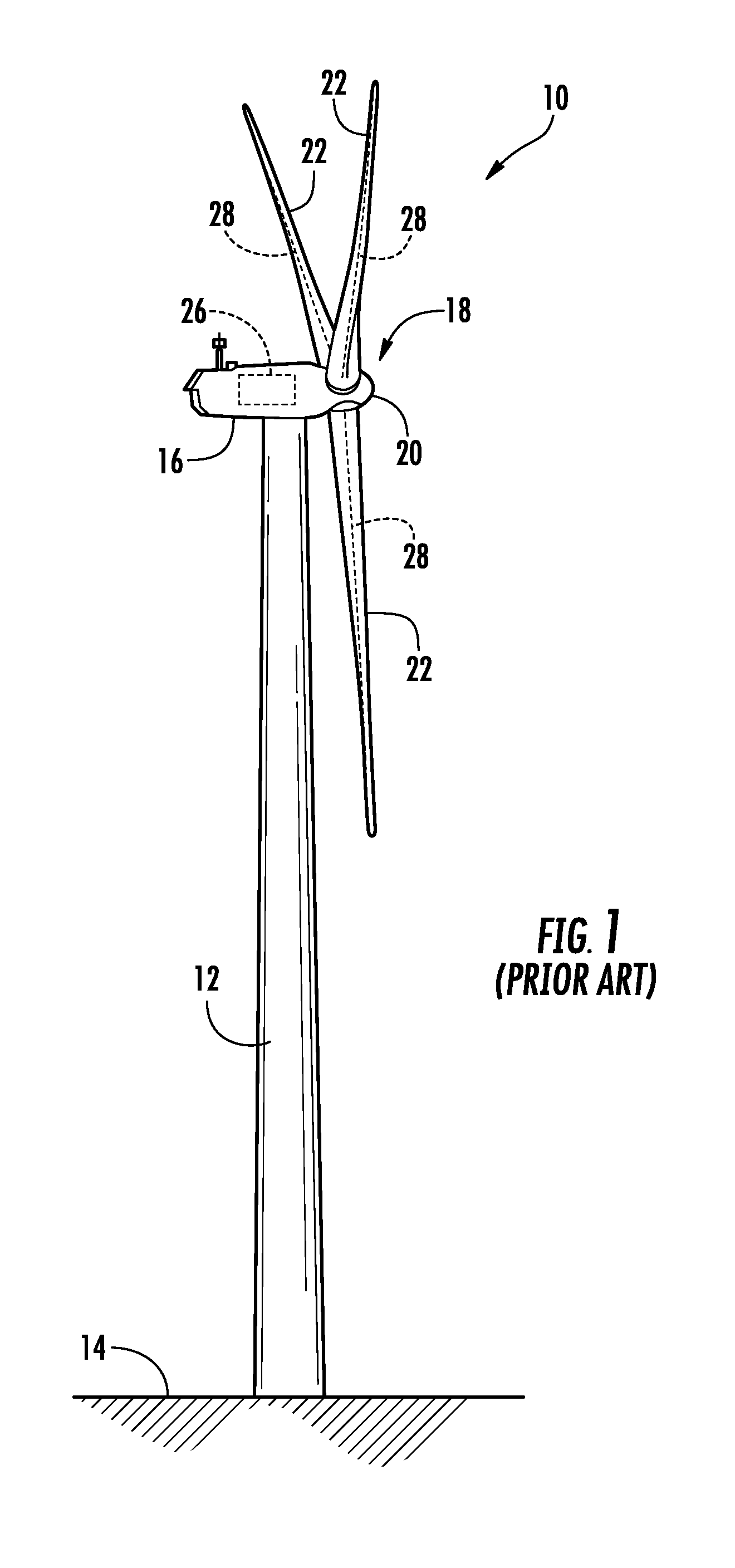

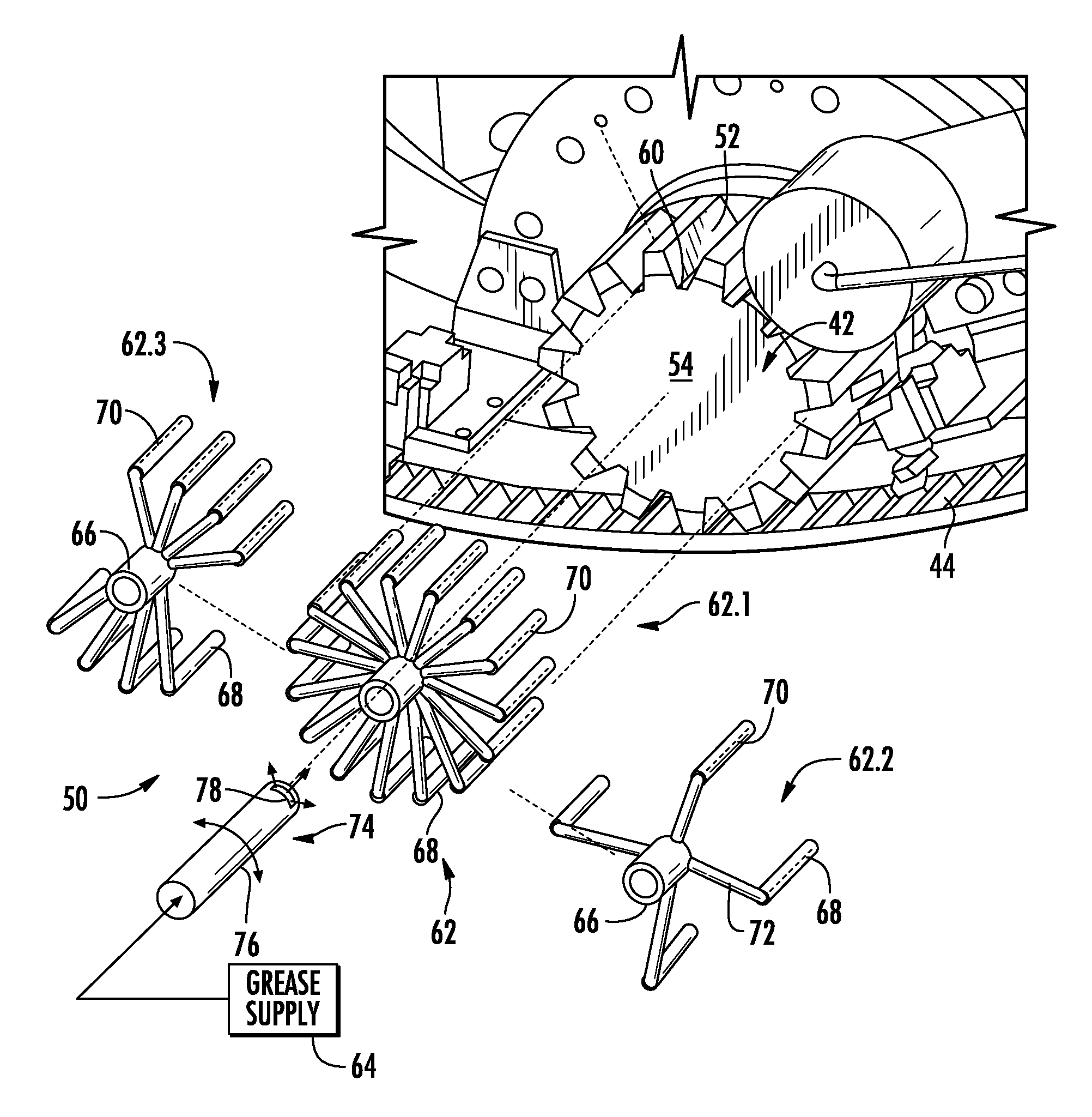

System and method for lubricating gears in a wind turbine

A system and method for lubricating gears in a wind turbine blade pitch drive are provided, wherein the pitch drive comprises a drive pinion gear with gear teeth that engage a pitch bearing gear coupled to a respective wind turbine blade. A grease distributor is configured to mount onto and rotate with the pinion gear, and is configured to deliver grease from an external grease supply to at least one valley defined between adjacent teeth of the pinion gear in a contact area of the pinion gear with the bearing gear without the distributor contacting inter-engaging teeth of the bearing gear.

Owner:GENERAL ELECTRIC CO

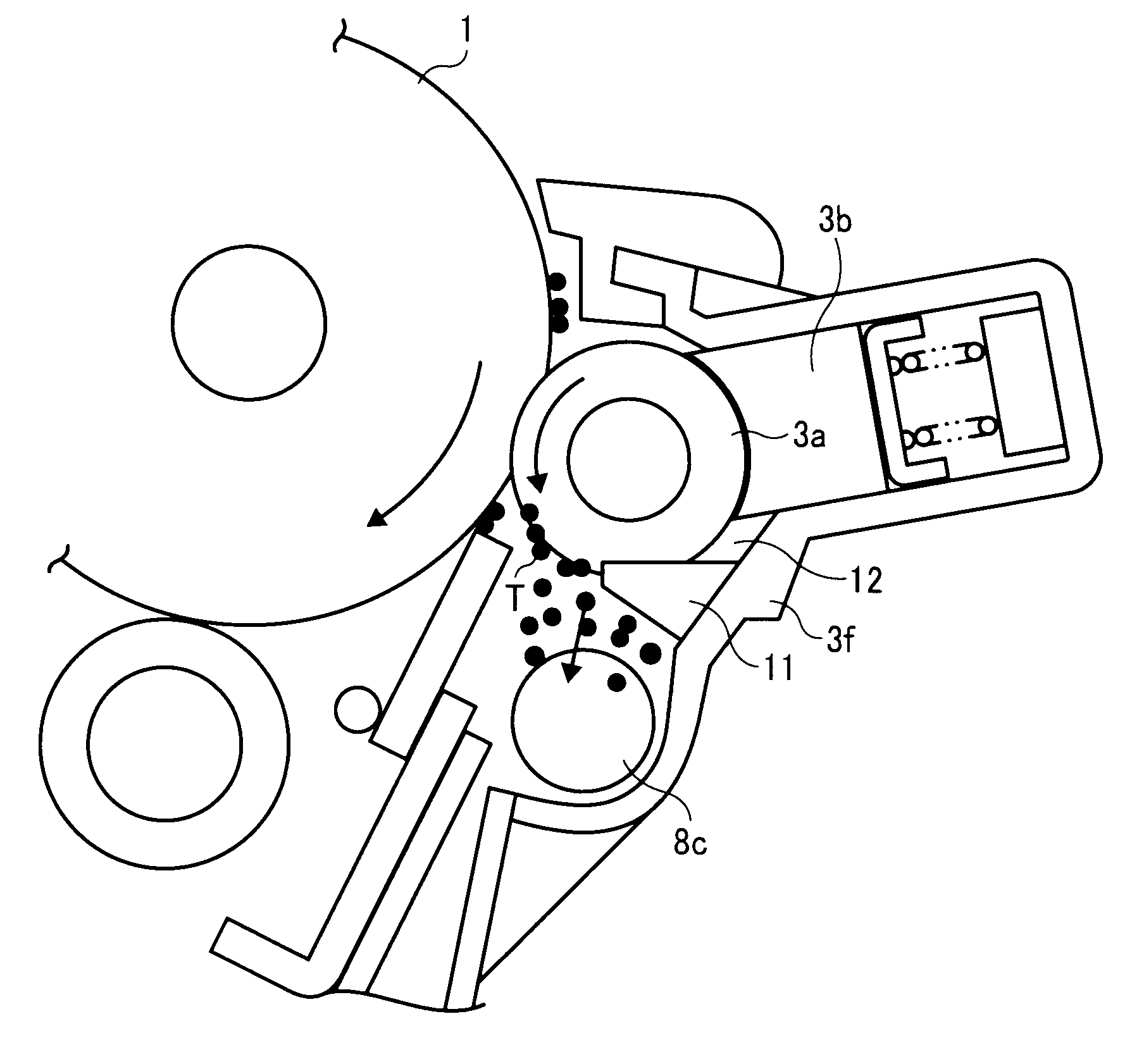

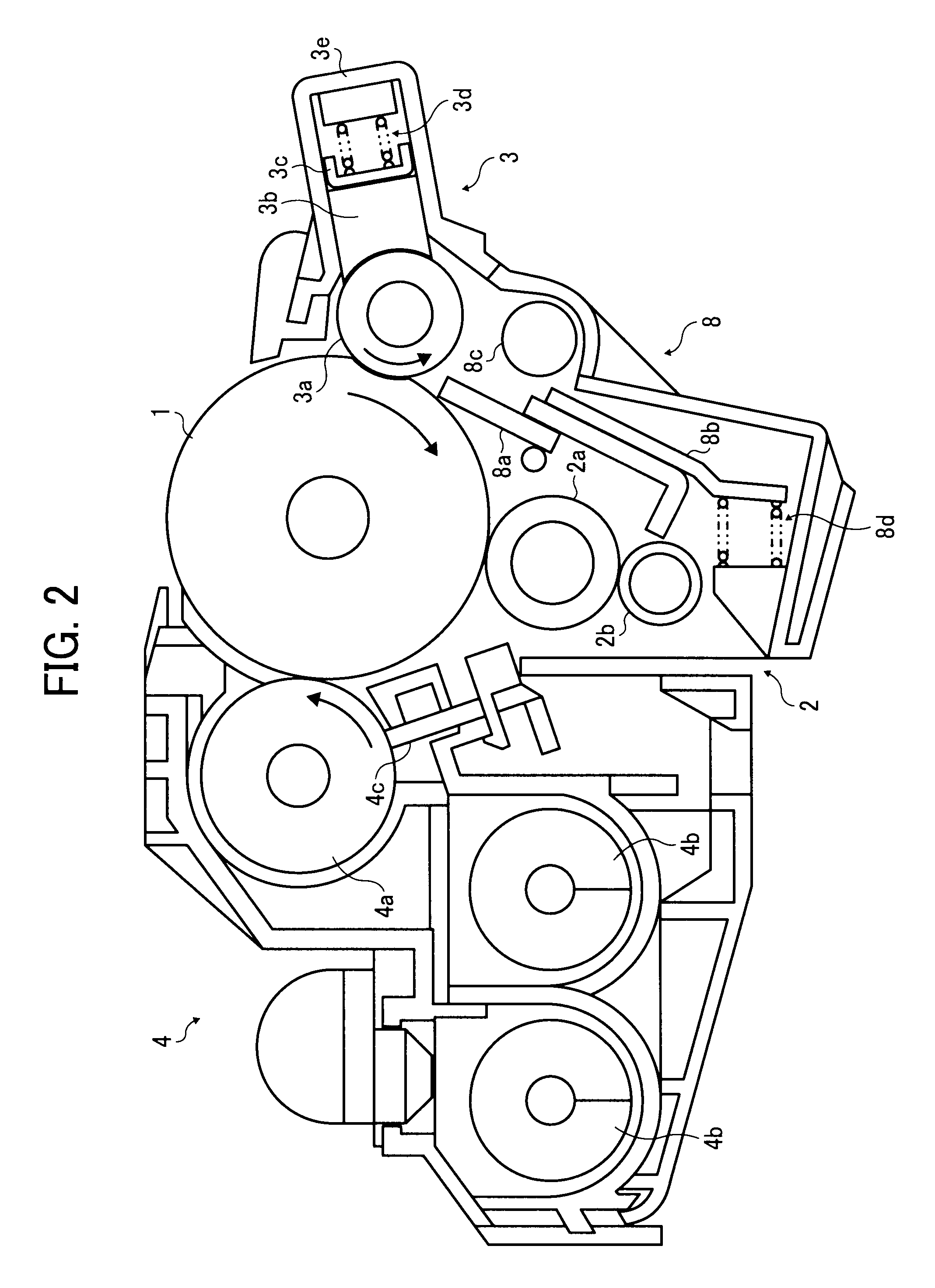

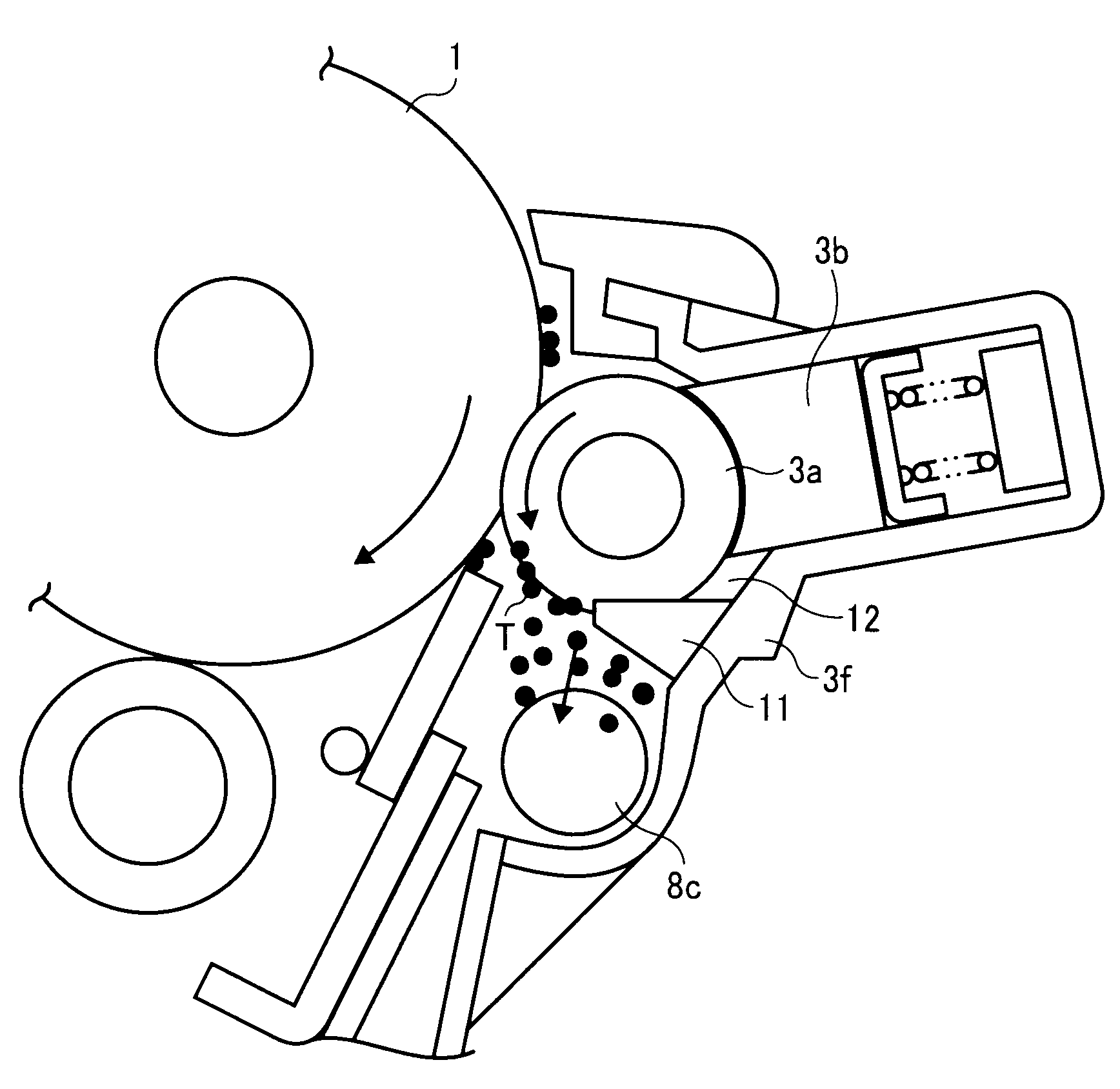

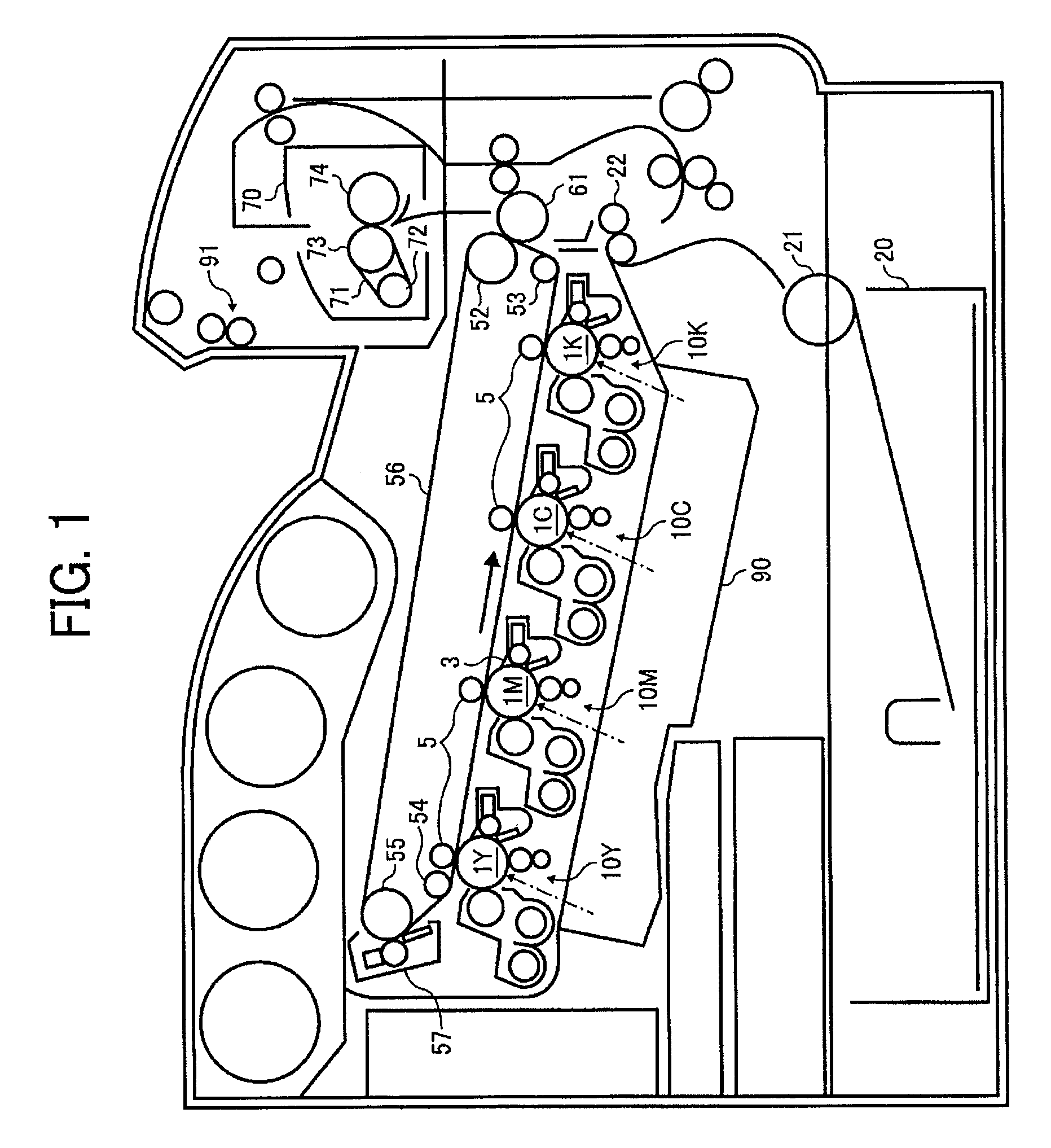

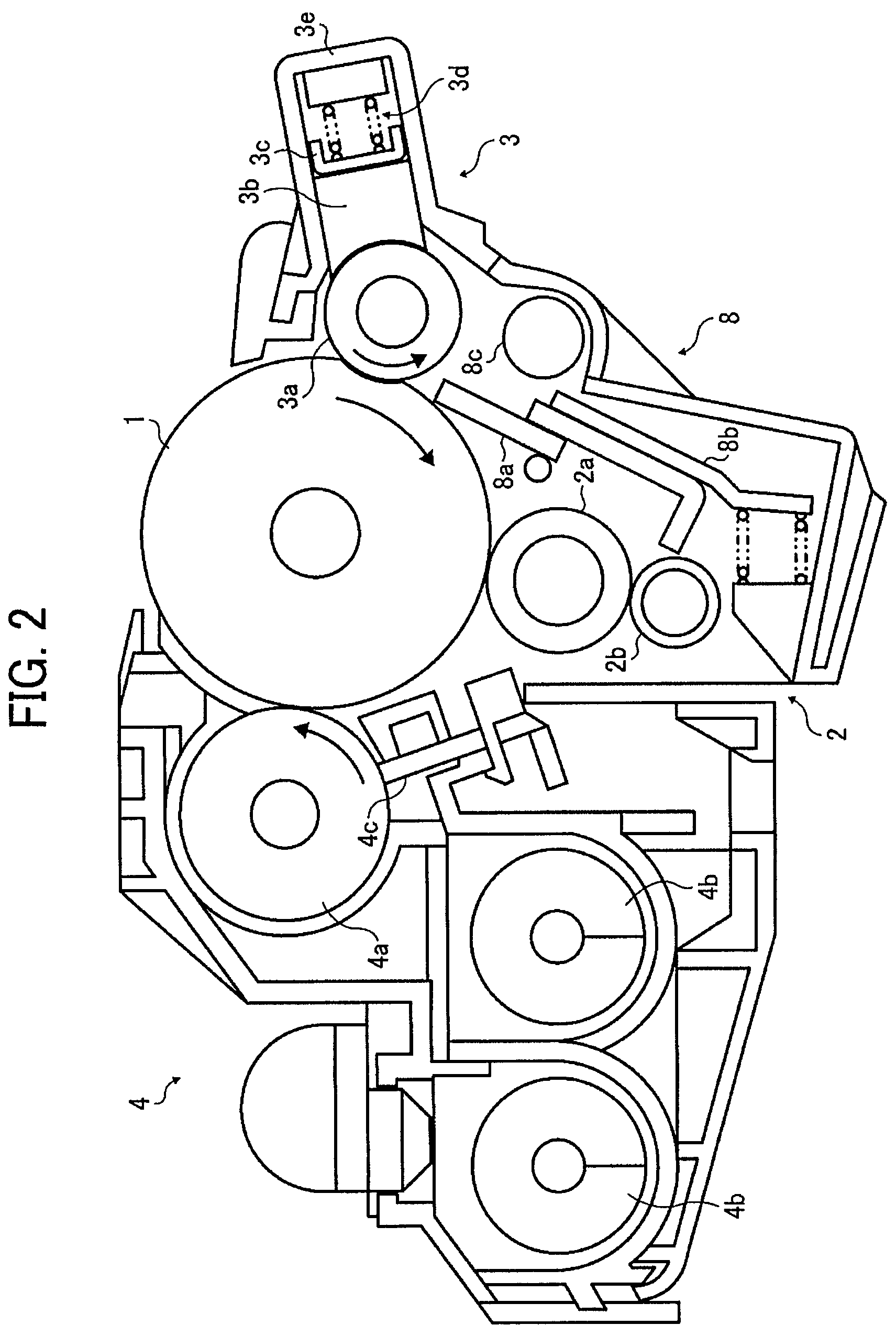

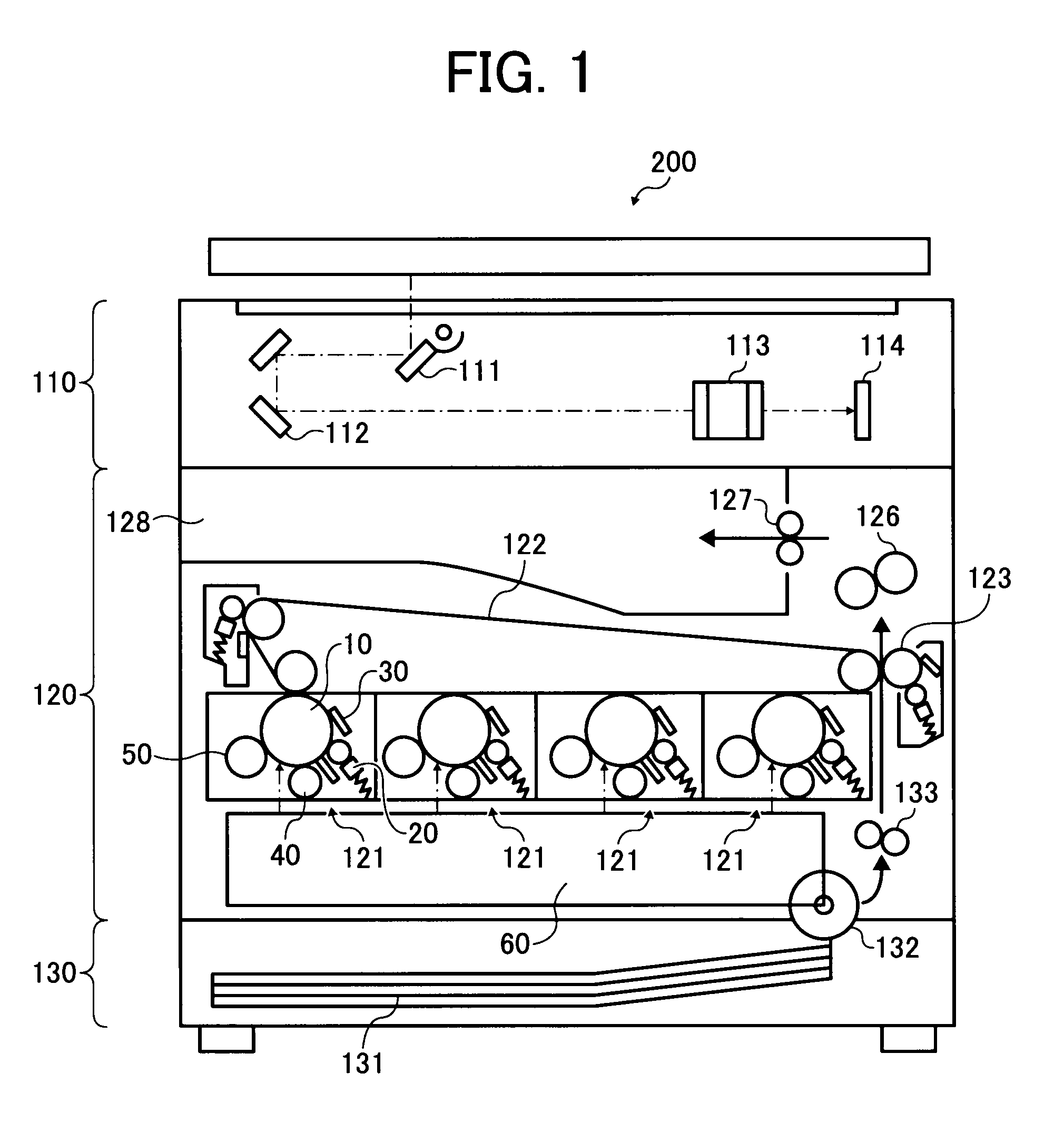

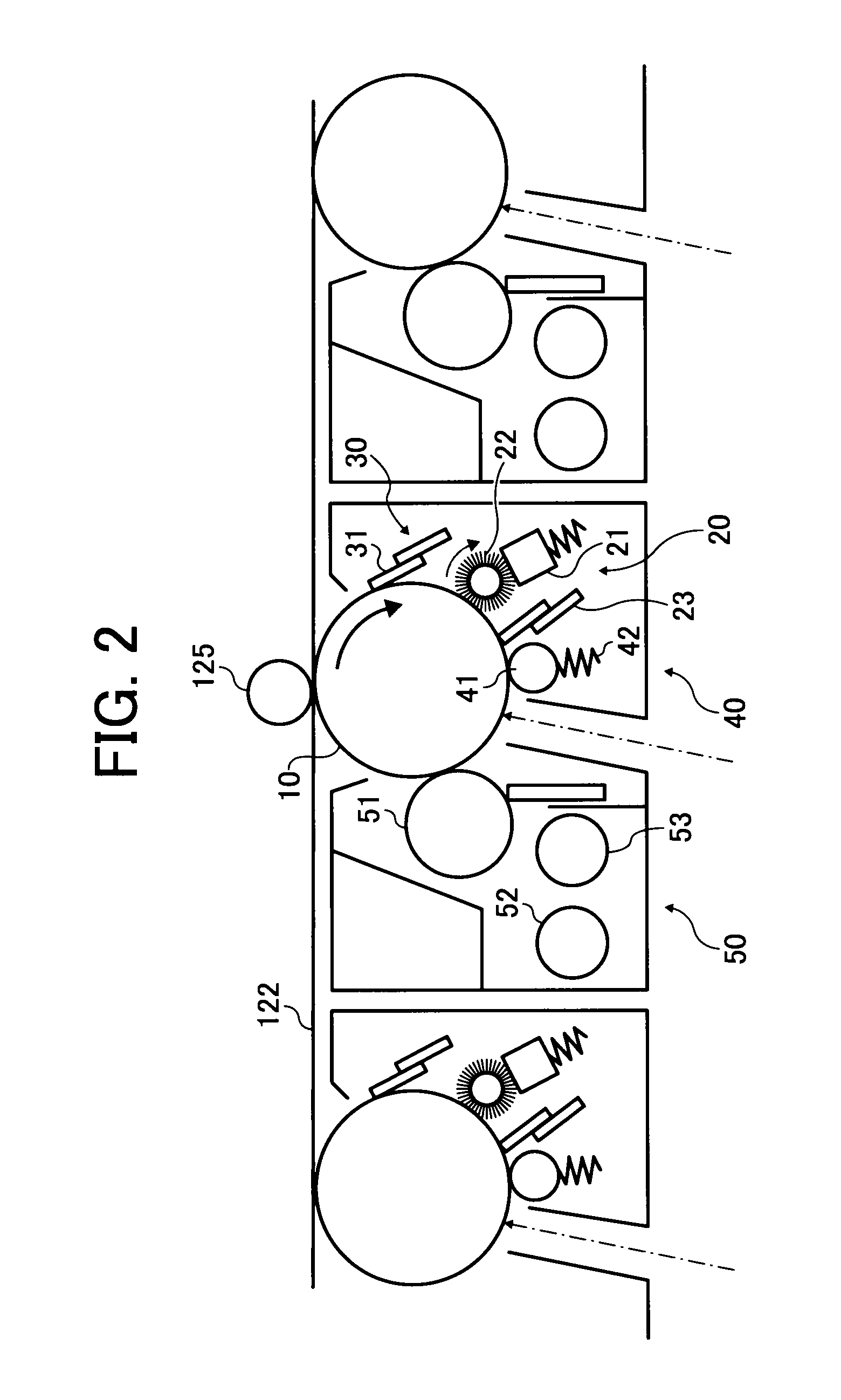

Lubricant applicator and image forming apparatus including same

A lubricant applicator includes a solid mold lubricant, a lubricant application roller, and a flicker member. The lubricant application roller scrapes and applies the lubricant to an image bearing member. The flicker member removes a powder substance adhered to the surface of the lubricant application roller and is disposed upstream of the solid mold lubricant in a direction of rotation of the lubricant application roller. The lubricant application roller, the flicker member, and the solid mold lubricant define a sealed space therebetween. A lubricant applicator includes the solid mold lubricant, the lubricant application roller, the flicker member, and an adherence prevention member that prevents the substance removed by the flicker member from adhering again to the lubricant application roller. A lubricant applicator includes the solid mold lubricant, the lubricant application roller, and a lubricant receiver that receives the scraped lubricant from the lubricant application roller.

Owner:RICOH KK

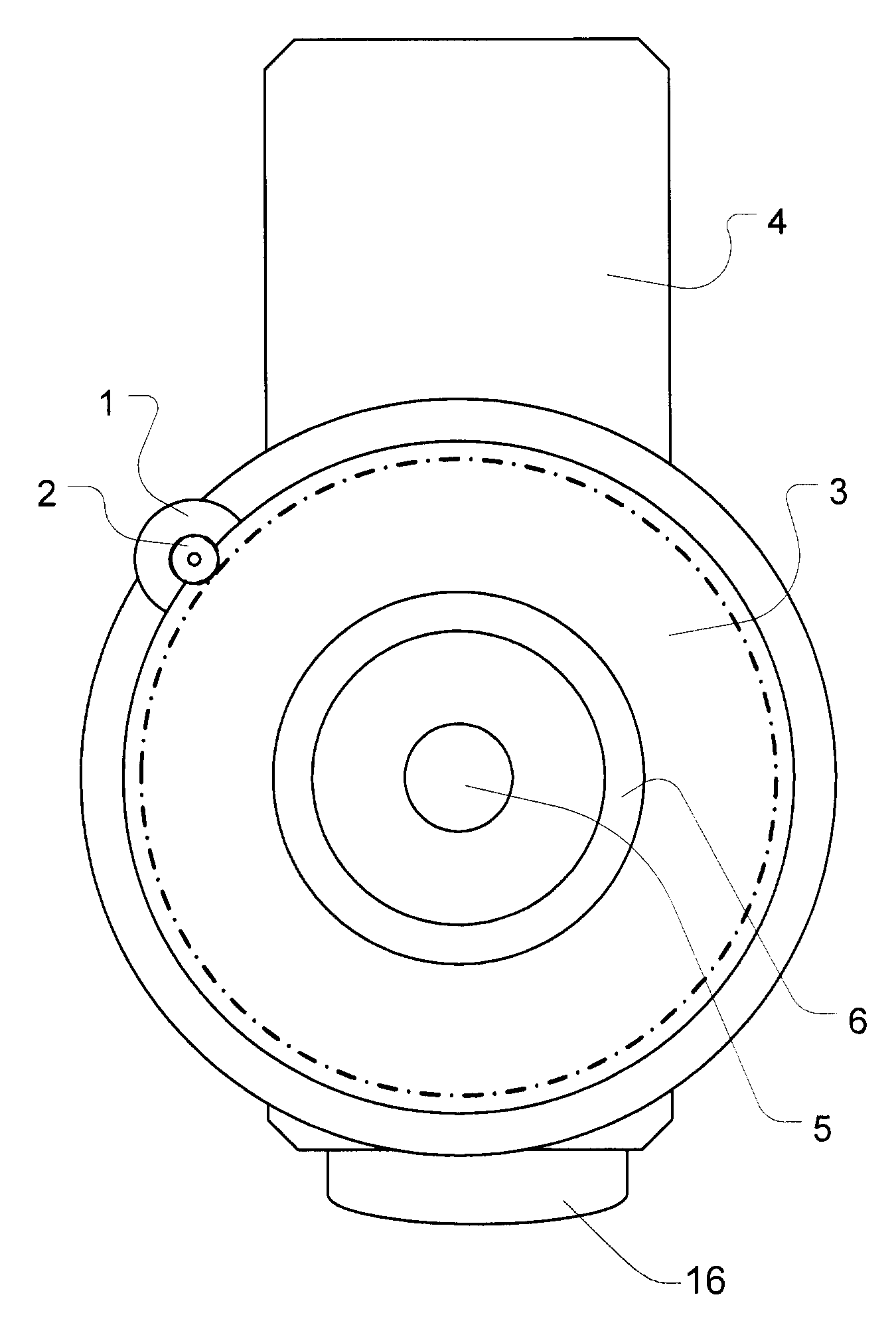

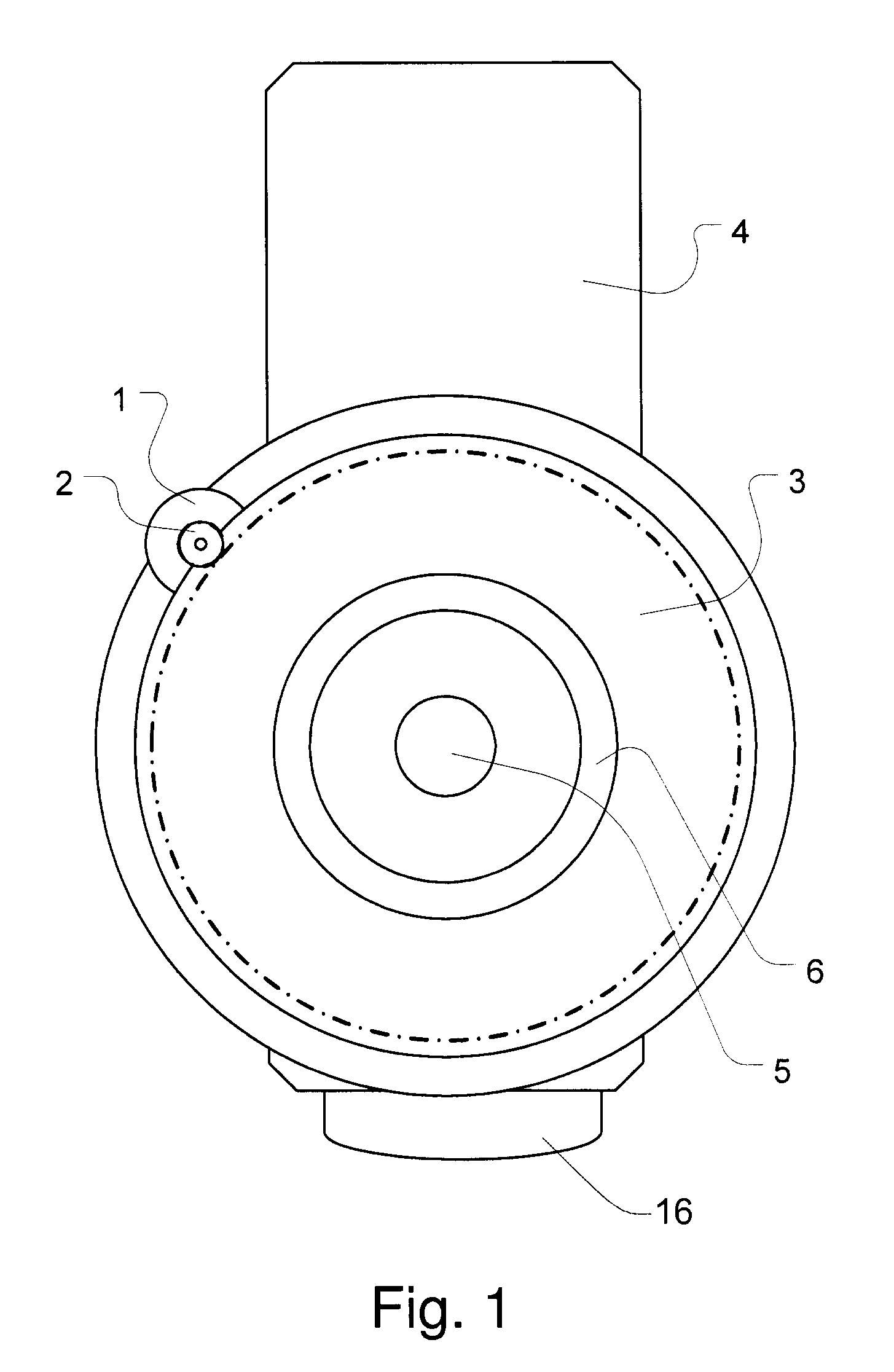

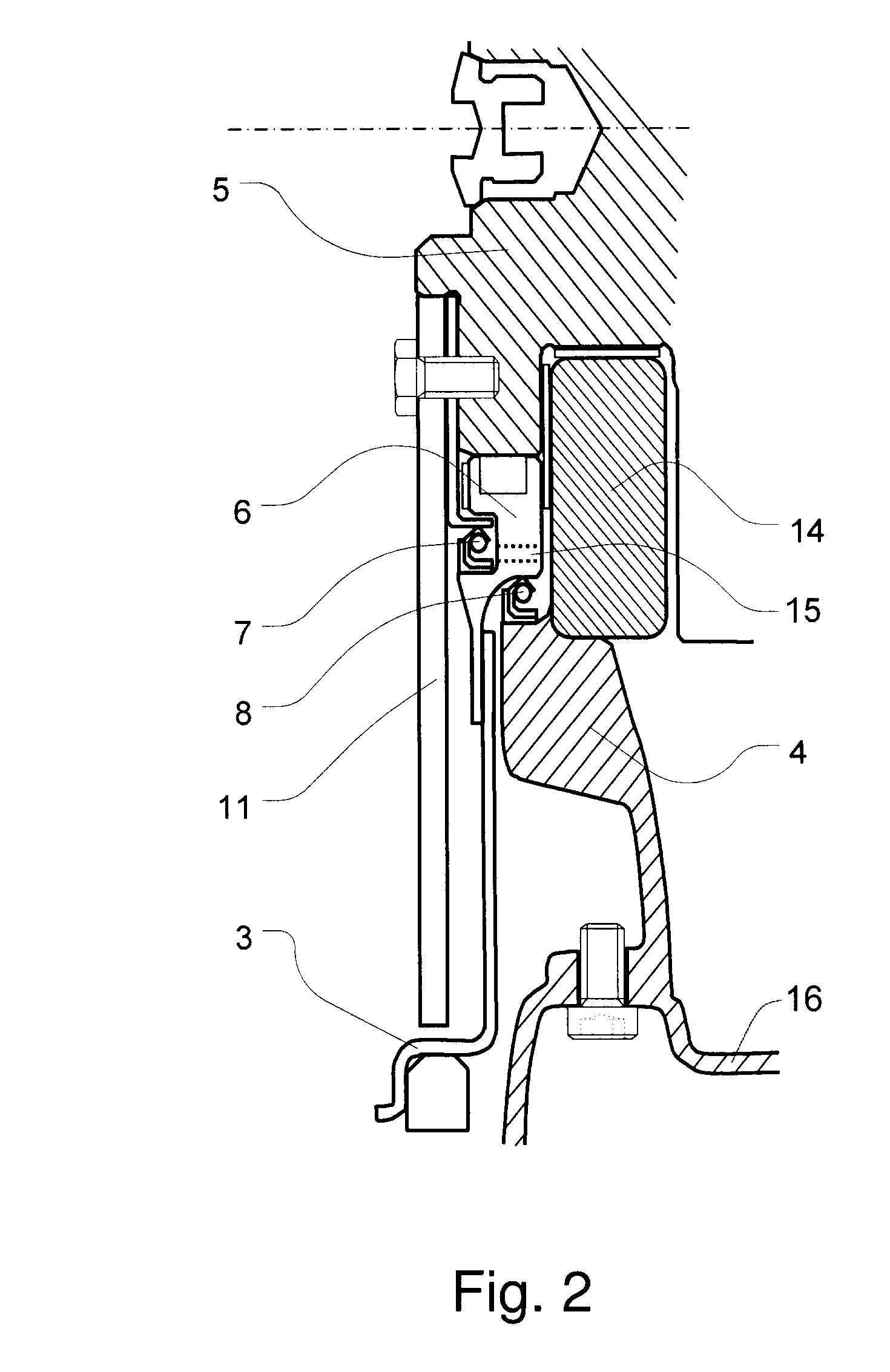

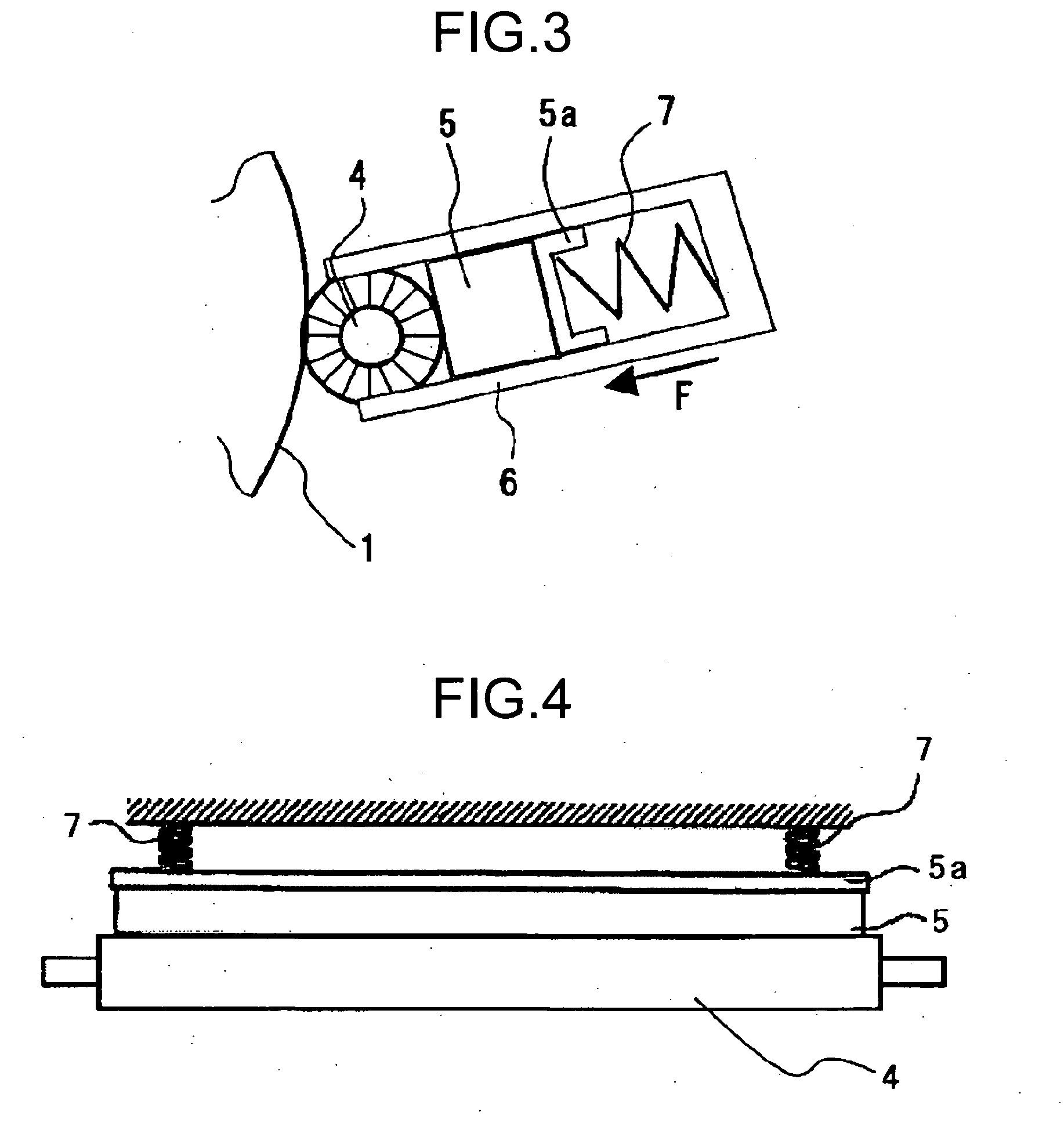

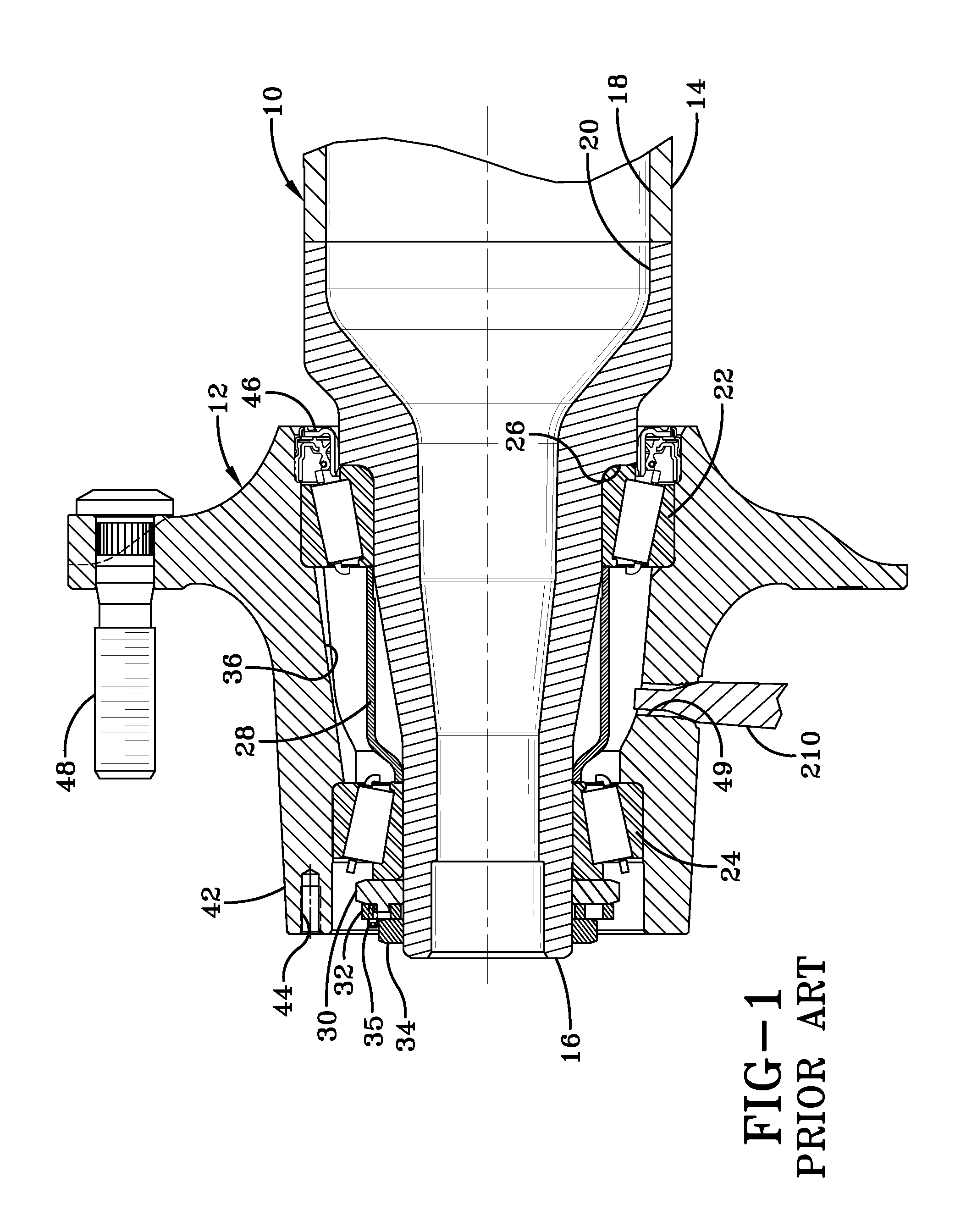

Starter Arrangement for an Internal Combustion Engine

InactiveUS20080163842A1Reduce mechanical strainReduce thermal strainPower operated startersEngine sealsInternal combustion enginePinion

The present invention relates to a starter arrangement for an internal combustion engine. The starter arrangement has a starter motor (1) having a pinion gear (2) at an output shaft. The pinion gear (2) is arranged in constant engagement with a corresponding crank gear of a crank wheel (3) located between an engine block (4) and a flywheel (11) of the engine. The crank wheel (3) is operatively connected to a crankshaft of the engine via a one-way clutch (6). The one-way clutch (6) is arranged at an engine block (4) side of a crankshaft oil seal (7) enabling lubrication and cooling thereof by an engine oil of the engine.

Owner:FORD GLOBAL TECH LLC

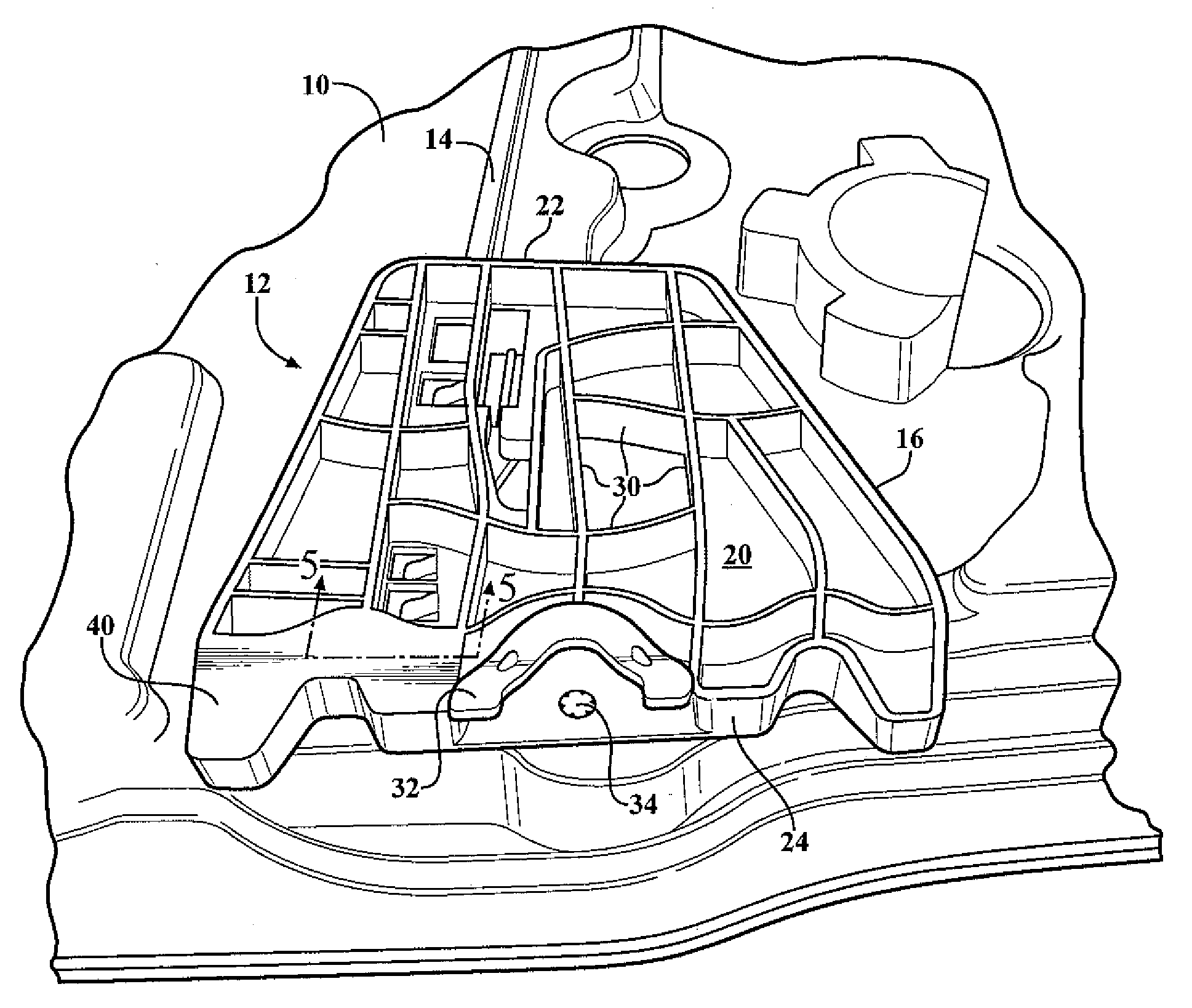

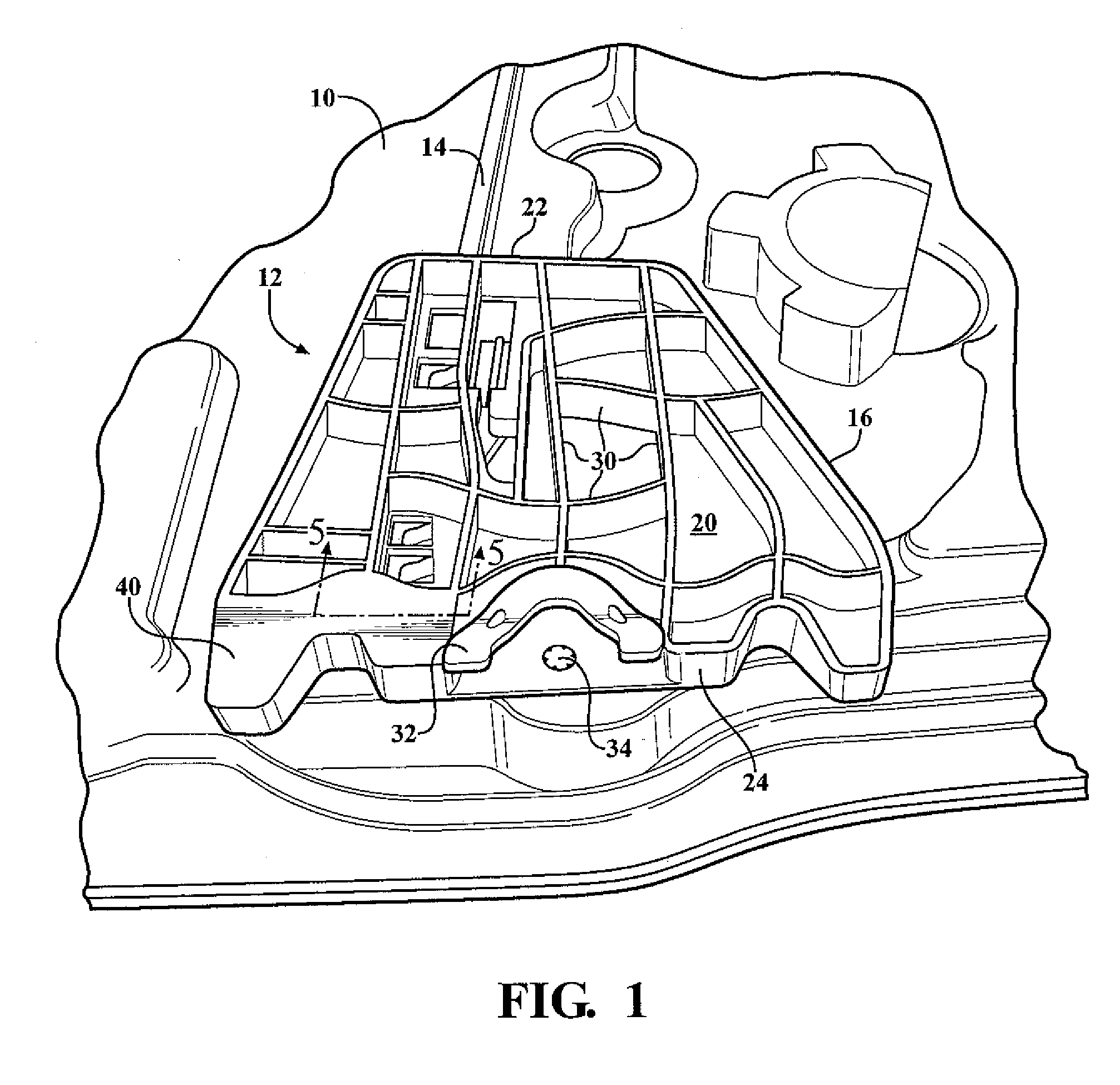

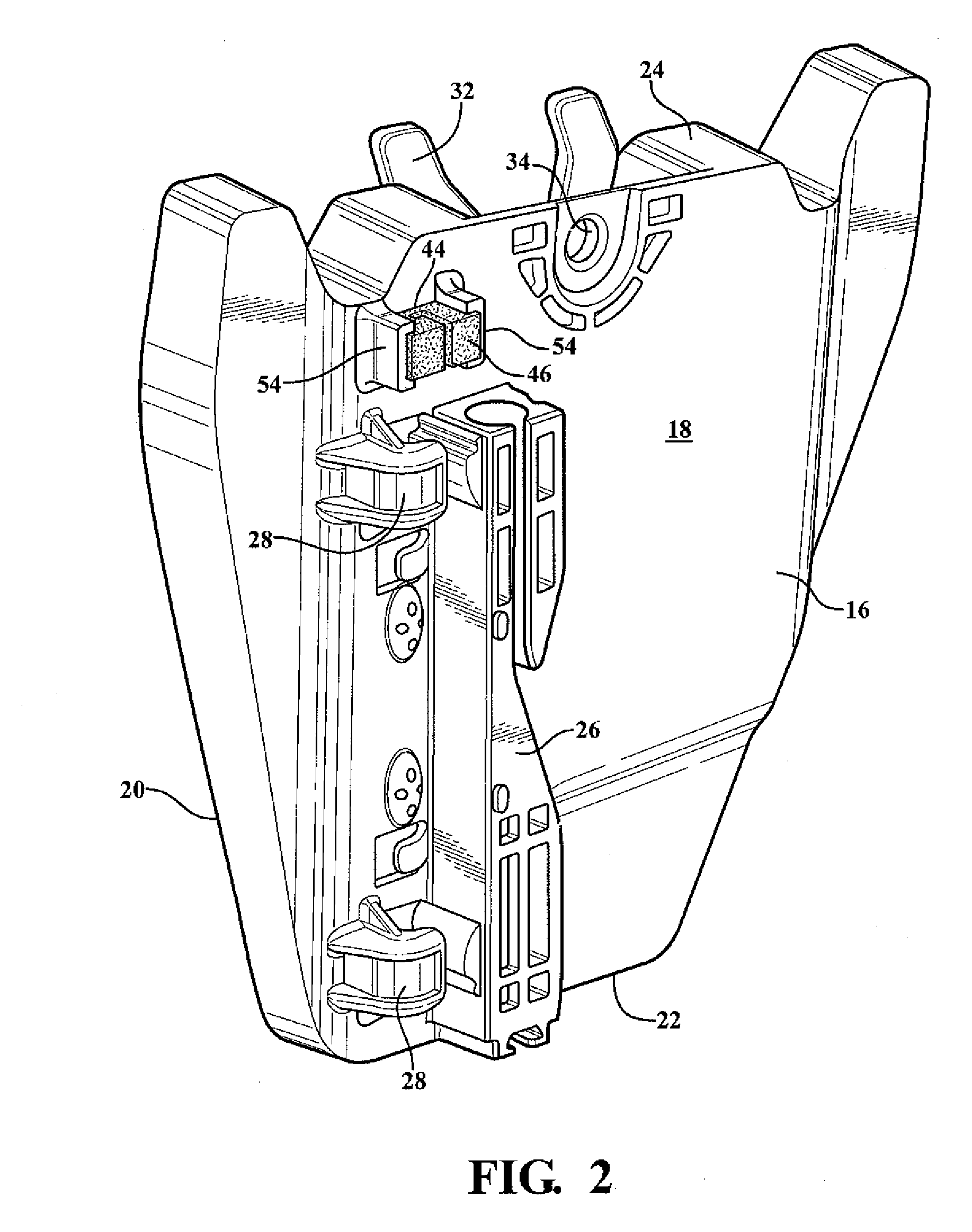

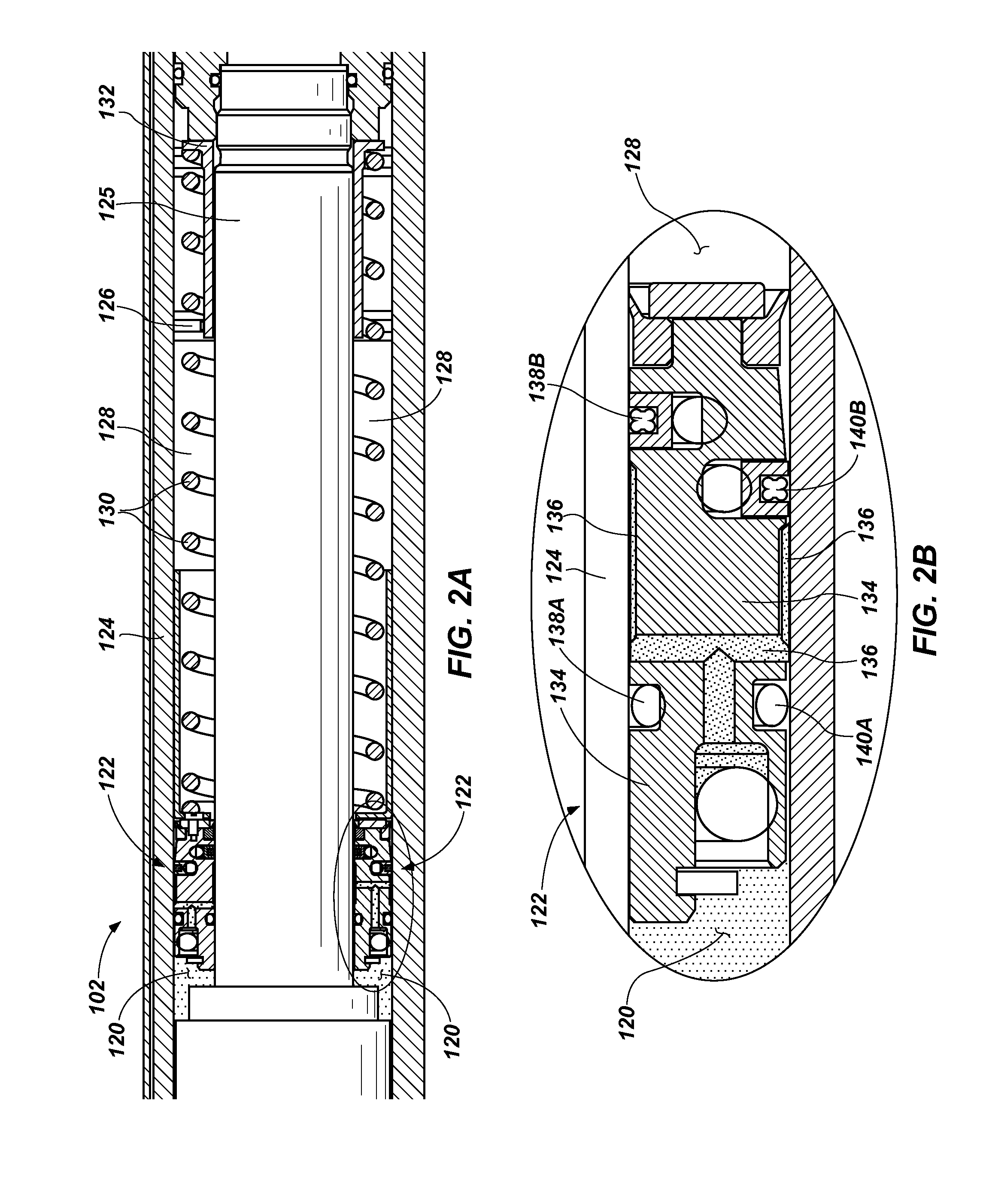

Window Regulator Lifter Plate With Integrated Lubrication System

A window regulator assembly for moving a window pane between an open position and a closed position includes a rail and a lifter plate slidably coupled with the rail. The lifter plate is coupled with the window pane and is guided by the rail to move the window pane between the open and closed positions. A lubrication system lubricates the rail as the lifter plate moves the window pane between the open and closed positions. The lubrication system includes a reservoir contained within the lifter plate, a lubricant storing and releasing material disposed in the reservoir, and an applicator extending from within the reservoir to lubricate the rail.

Owner:PERMAWICK

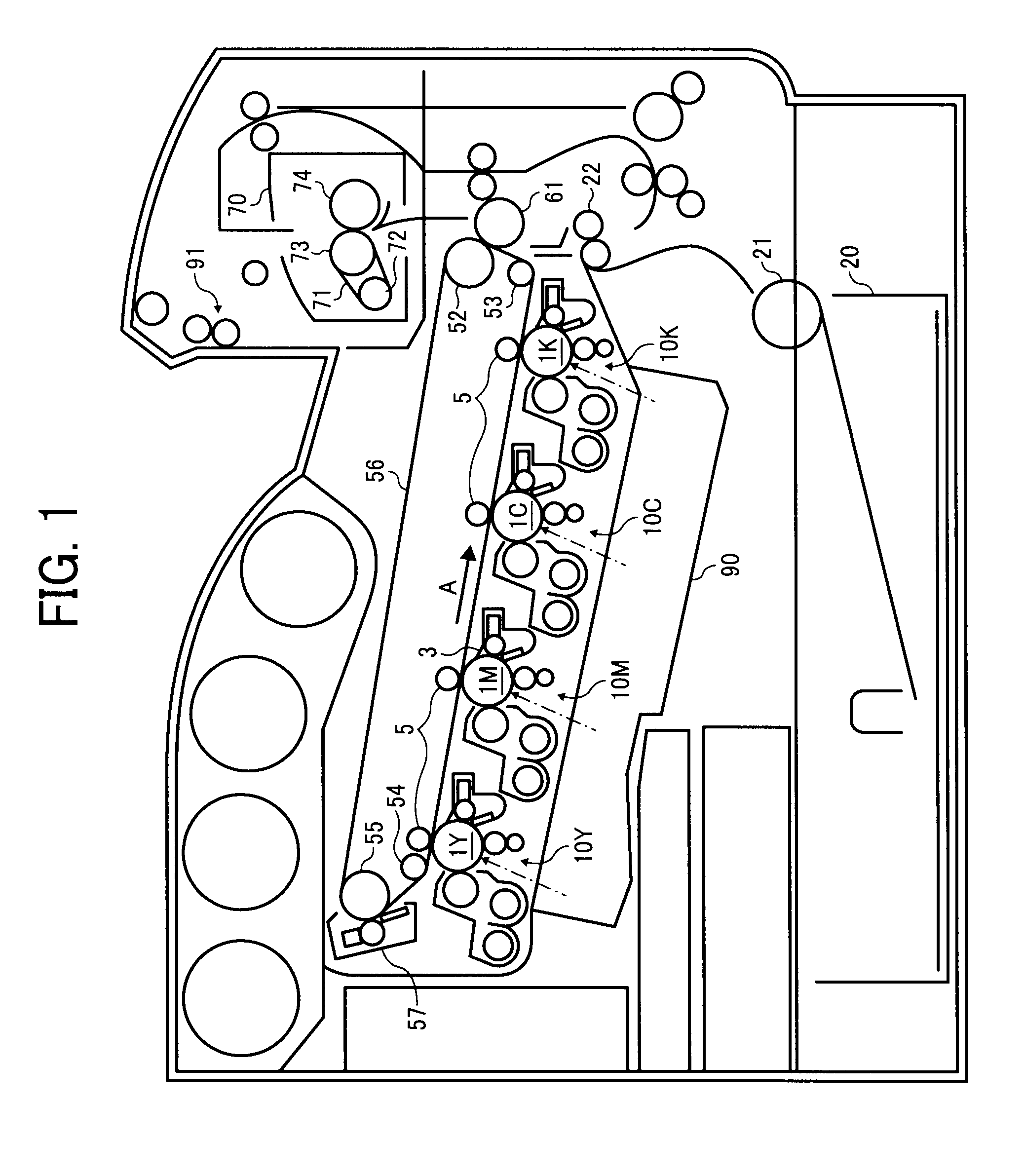

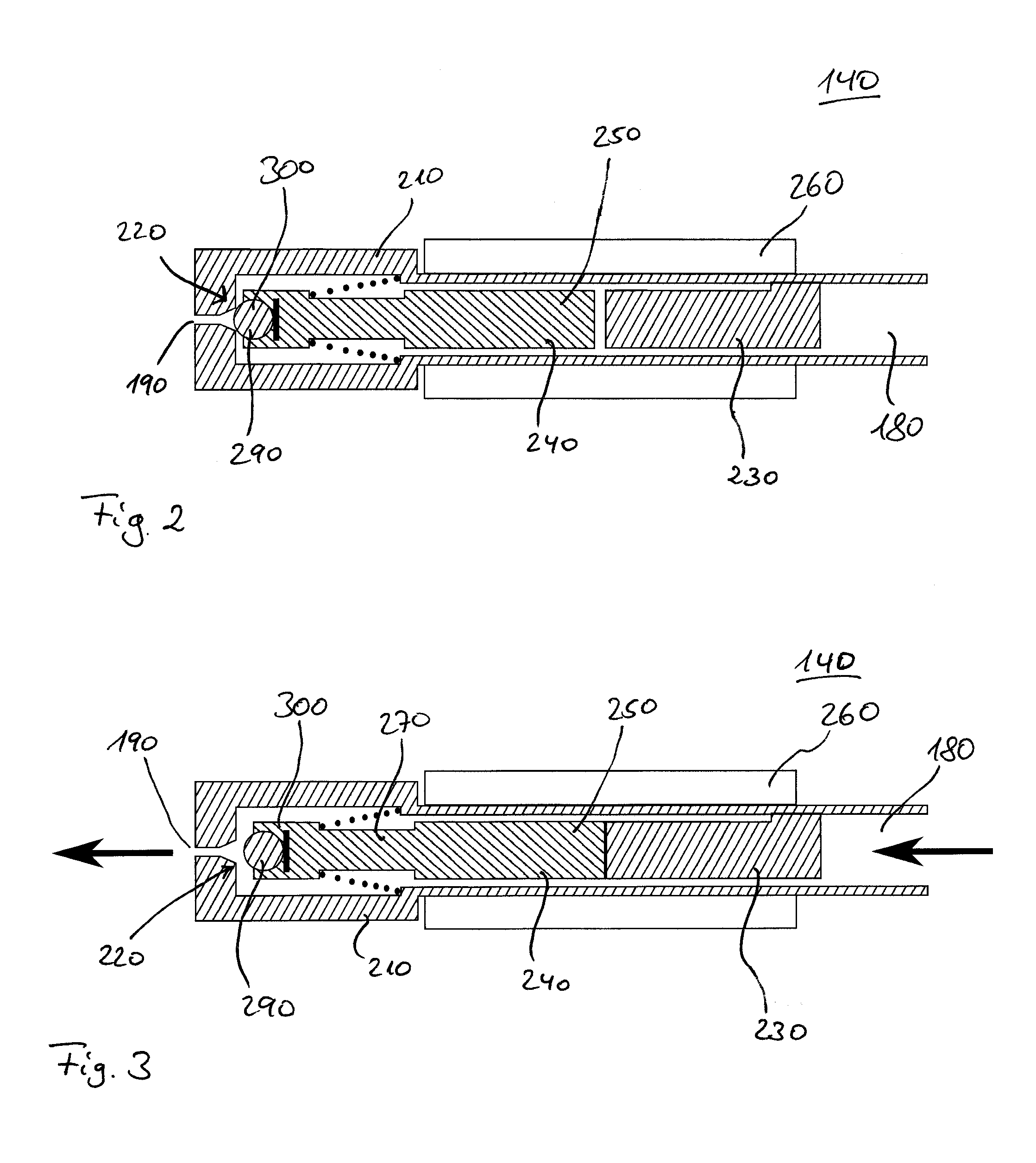

Lubricant applicator, image forming apparatus, and method of mounting lubricant applicator

A lubricant applicator includes: a lubricant application unit that is arranged so as to be in contact with a surface of an image carrier, scrapes a solid lubricant, and applies the solid lubricant onto the surface of the image carrier while moving a surface of the lubricant application unit; a lubricant holding member that holds the solid lubricant; and a lubricant biasing unit that biases the solid lubricant against the lubricant application unit. The lubricant biasing unit is housed in a housing under a state that one end of the lubricant biasing unit is held by the lubricant holding member so that a position of the one end of the lubricant biasing unit is restricted, and another end of the lubricant biasing unit is held by a biasing-unit holding member that is provided to restrict a position of the another end of the lubricant biasing unit.

Owner:RICOH KK

Bushing lubricator and system

A bushing lubricator includes an elongate body having a lubricant passage extending from an inlet opening to an outlet port. The elongate body includes a connection portion at the inlet opening for engaging with a lubricant tray of a lubricating system, a main body portion in a central region, and a bushing lubricator portion of a width to accommodate a bushing with an interior surface of the bushing surrounding the bushing lubricator portion. The outlet port on a periphery of the bushing lubricator portion discharges lubricant onto the interior surface of a bushing.

Owner:BSH HOME APPLIANCES CORP

Pump oil mister with improved service life

A centrifugal environmentally safe pump including a motor driven pump shaft having a fluid pumping impeller affixed thereto. A plurality of annular shaft supporting bearing assemblies are disposed along the shaft adjacent a lubrication chamber, the lubrication chamber housing lubrication fluid (e.g. oil) maintained at a level below rotating portions of the bearing assemblies so as to maintain a low operating temperature within the chamber and adjacent the bearings. A lubricating fluid dispenser having a thin-profile, disc-shaped portion is affixed to the pump shaft within the lubrication chamber for rotation along with the shaft. A plurality of wire-like fluid contacting members are loosely connected along the outer periphery of the disc-shaped portion through respective bearing sleeves, the wire members for dipping into the lubricating fluid when the pump shaft is rotating thereby dispersing or misting the fluid throughout the chamber.

Owner:ENVIRONAMICS

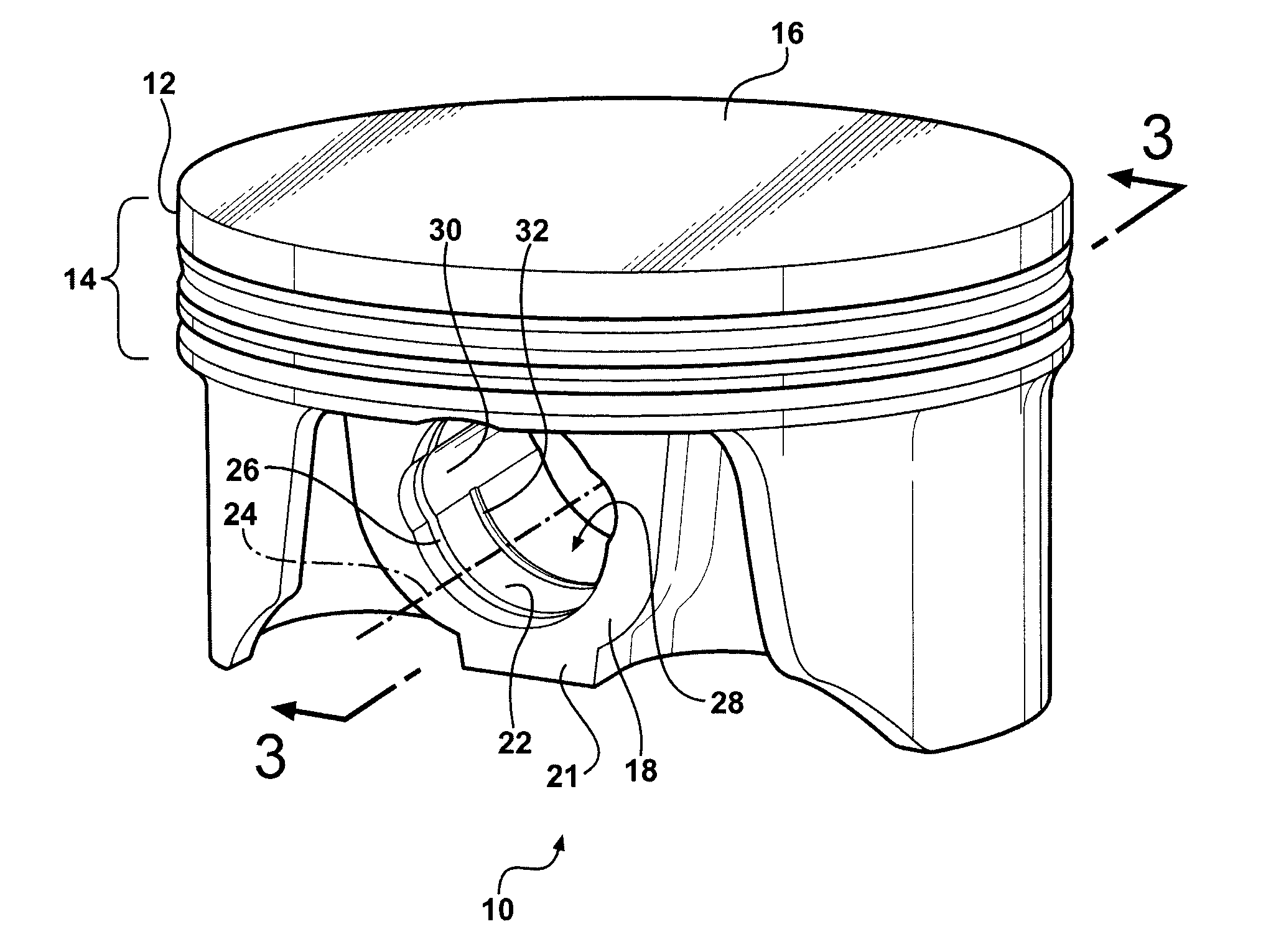

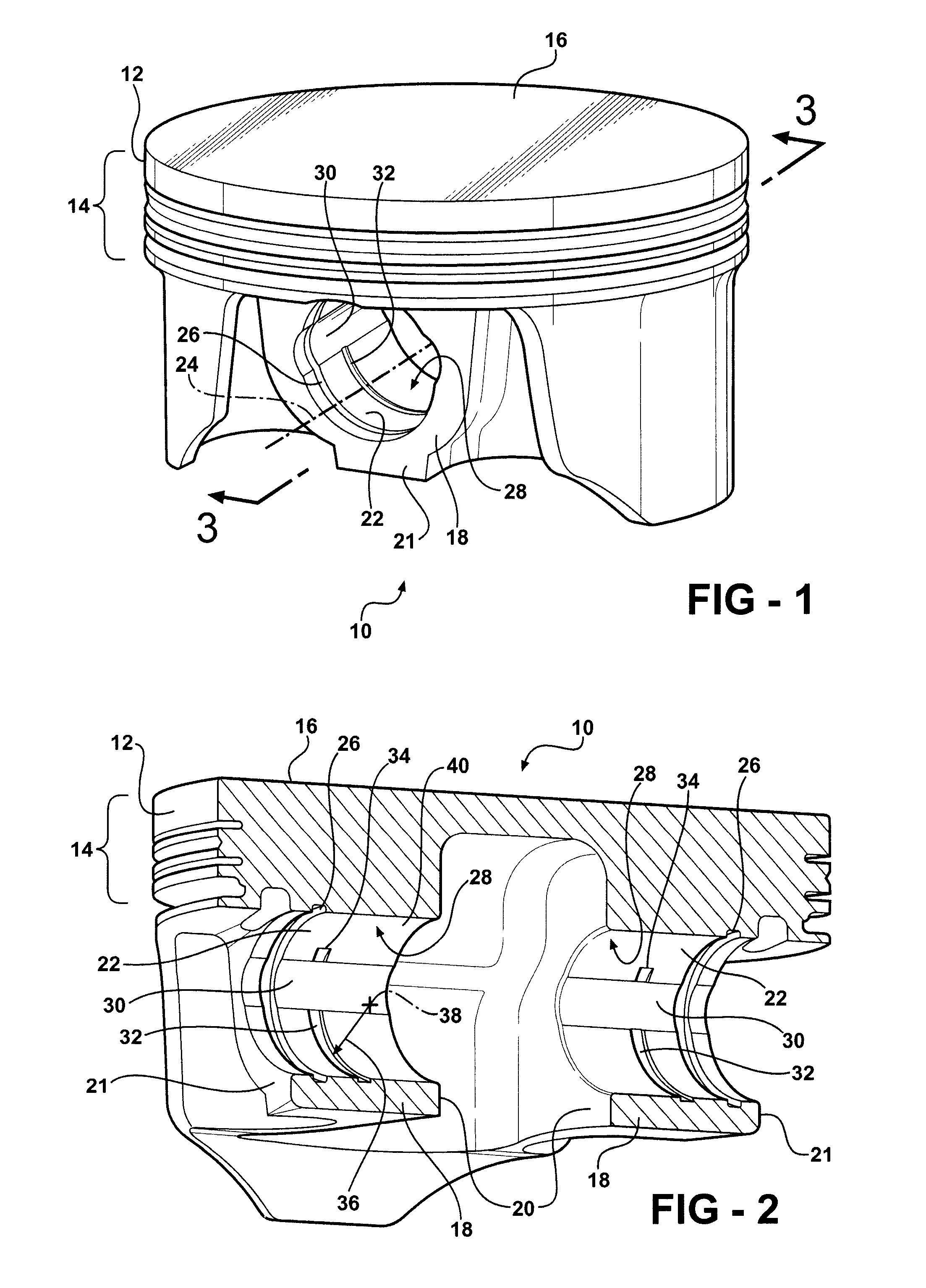

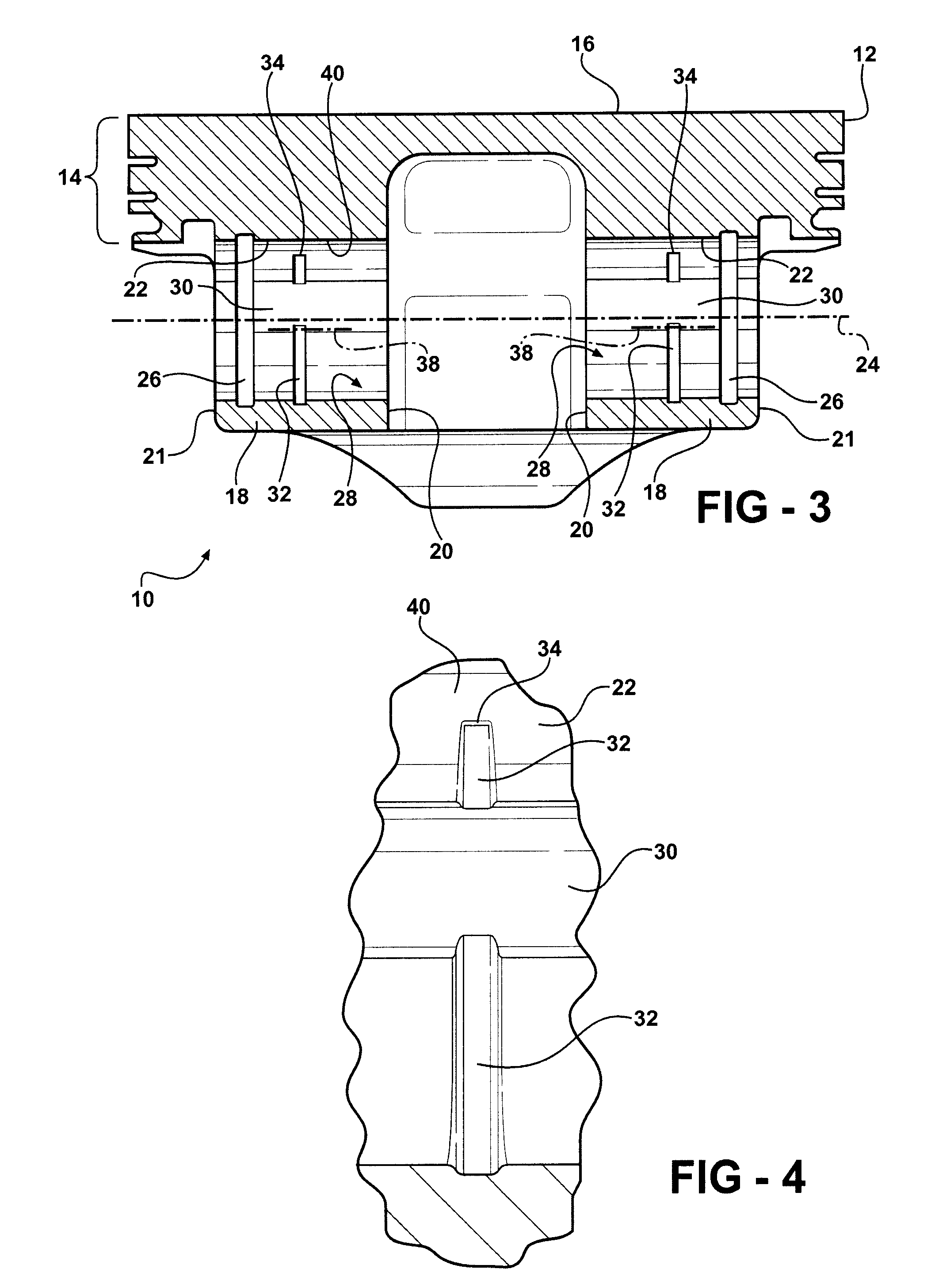

Piston with pin bore lubrication features

ActiveUS20080250922A1Maximizing load capacityReduce manufacturing costPlungersNon-pressurised lubricationBearing surfaceMechanical engineering

A piston has a piston body with a pair of pin bosses having pin bores aligned along a central axis. The pin bores have bearing surfaces, wherein at least one recess extends axially across at least one of the bearing surfaces. A groove extends partially about the bearing surface circumference and is arranged in fluid communication with the recess. The recess and groove provide a lubrication feature to the pin bore, while the bearing surface has an uninterrupted portion for enhanced load carrying capacity.

Owner:FEDERAL MOGUL WORLD WIDE LLC

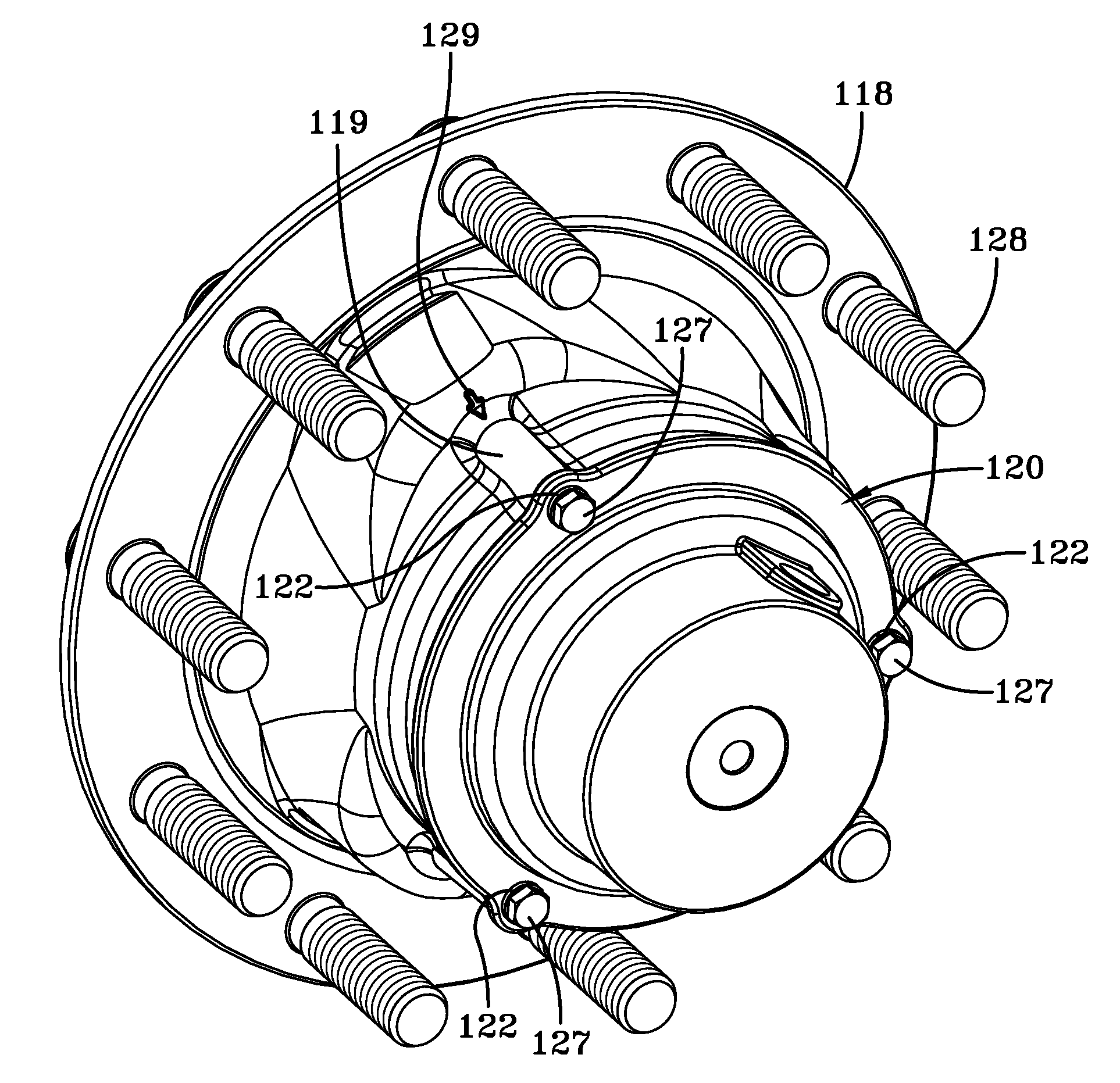

Wheel hub with lubricant fill port

ActiveUS20080024003A1Reduce manufacturing costSimple wayRolling contact bearingsHubsEngineeringHeavy duty

A non-drive axle depends from a heavy-duty vehicle. Each one of a pair of wheel end assemblies is mounted on a respective one of the ends of the non-drive axle. Each wheel end assembly includes a pair of bearings mounted on a spindle of the axle, and a wheel hub rotatably mounted on the bearings. A cavity is formed in the wheel end assembly between the bearings. A port is formed in the wheel hub and extends generally parallel to a central axis of the wheel hub, and communicates with the outboard surface of the wheel hub and the cavity. Lubricant for the bearings is introduced into the cavity by means of the port, and the port is tapped to receive a plug to seal it and contain the lubricant in the cavity. The port also receives a bolt that secures a hubcap to the wheel hub.

Owner:HENDRICKSON USA L L C +1

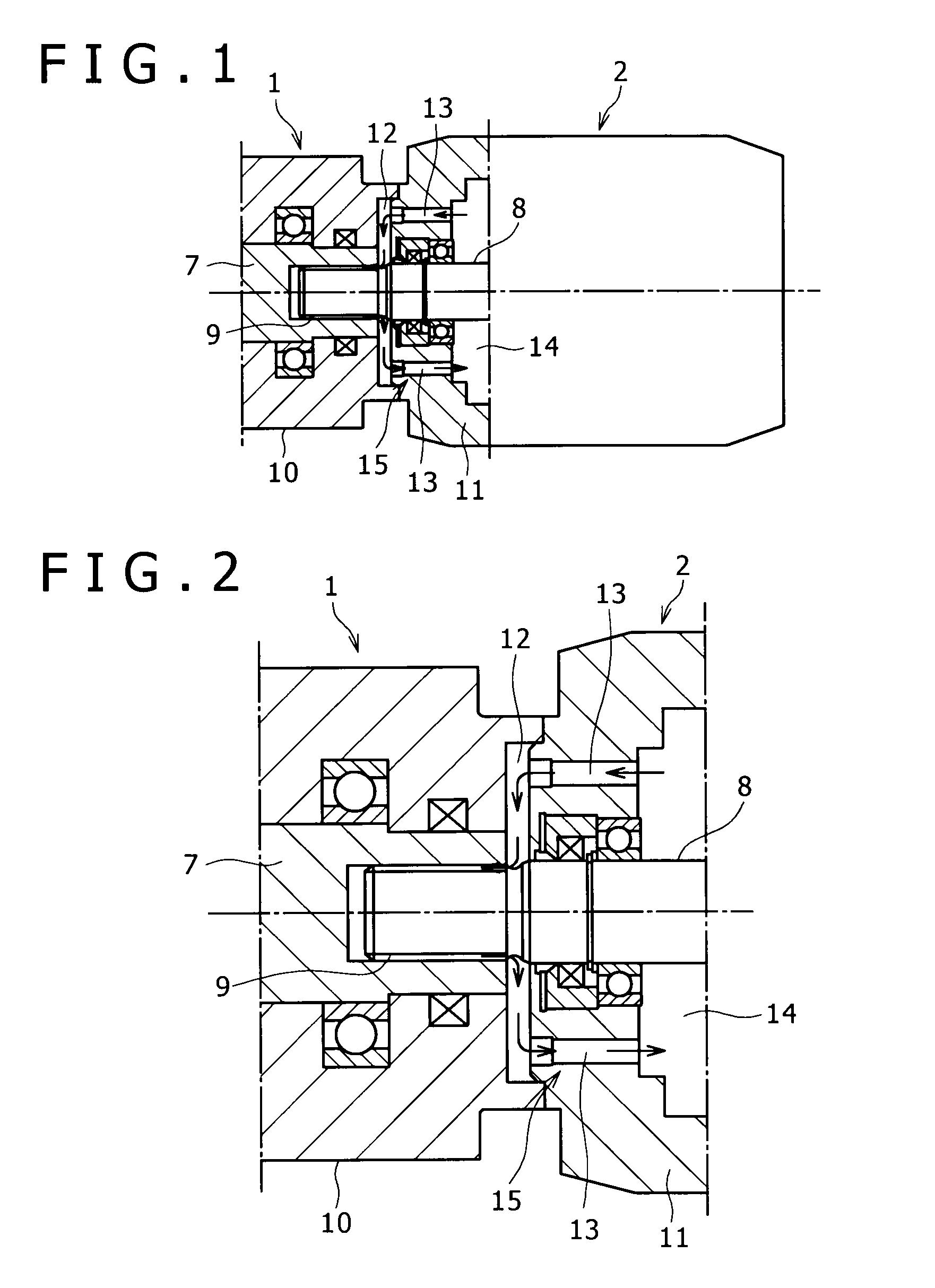

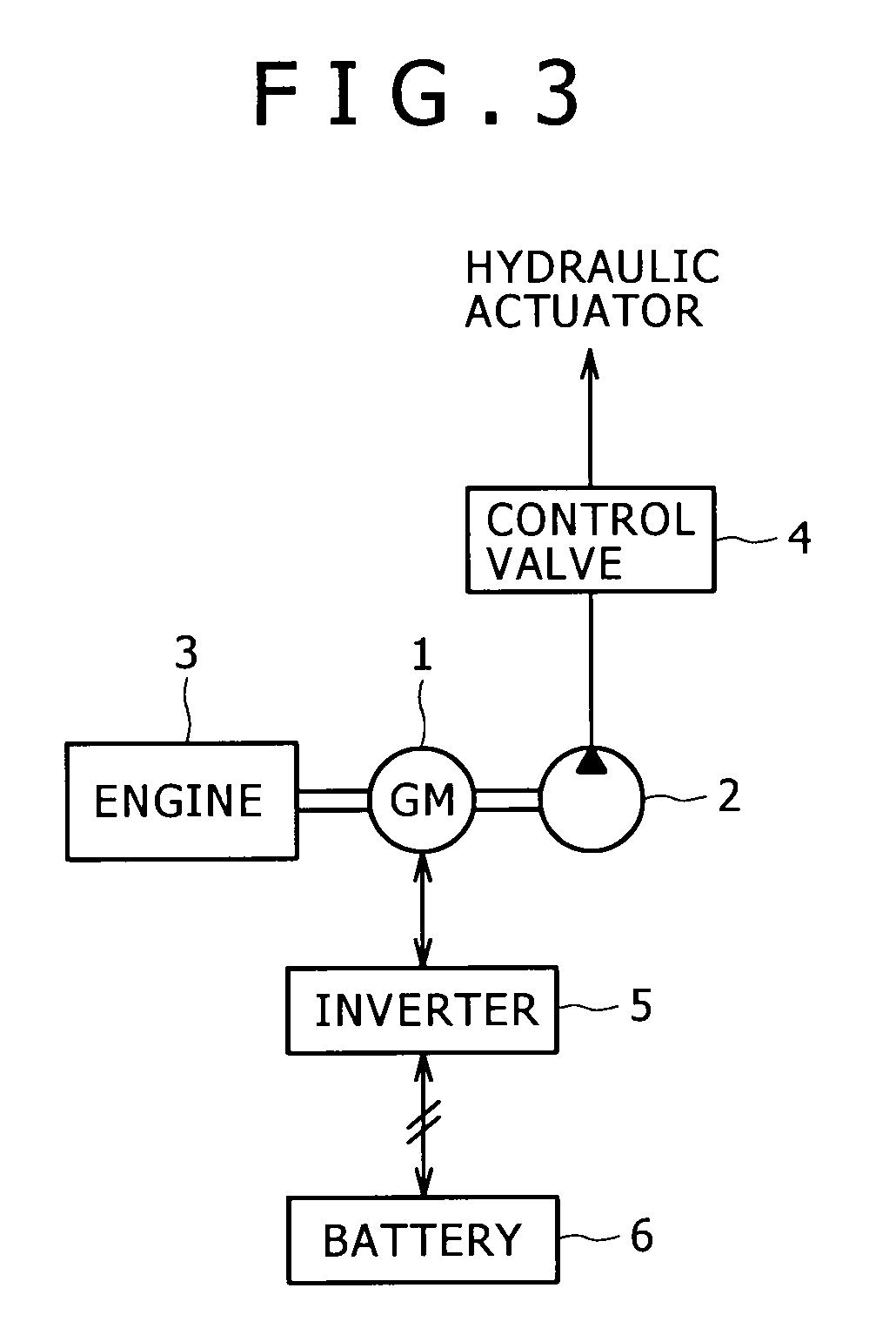

Hybrid working machine

ActiveUS20100193296A1Improve reliabilityInhibit wearClutchesGear lubrication/coolingCouplingHydraulic pump

As lubricating construction for a spline coupling portion for connecting a rotating shaft of a generator-motor and a rotating shaft of a hydraulic pump both actuated by an engine, a lubricating oil chamber communicating with the spline coupling portion is formed within a motor casing of the generator-motor, while in a pump casing of the hydraulic pump there is formed an oil passing hole providing communication between the lubricating oil chamber and an oil chamber in the hydraulic pump on an outer periphery side of the rotating shaft of the hydraulic pump, thereby forming an oil passage for allowing working oil present within the hydraulic pump to circulate through a route including the spline coupling portion.

Owner:KOBELCO CONSTR MASCH CO LTD

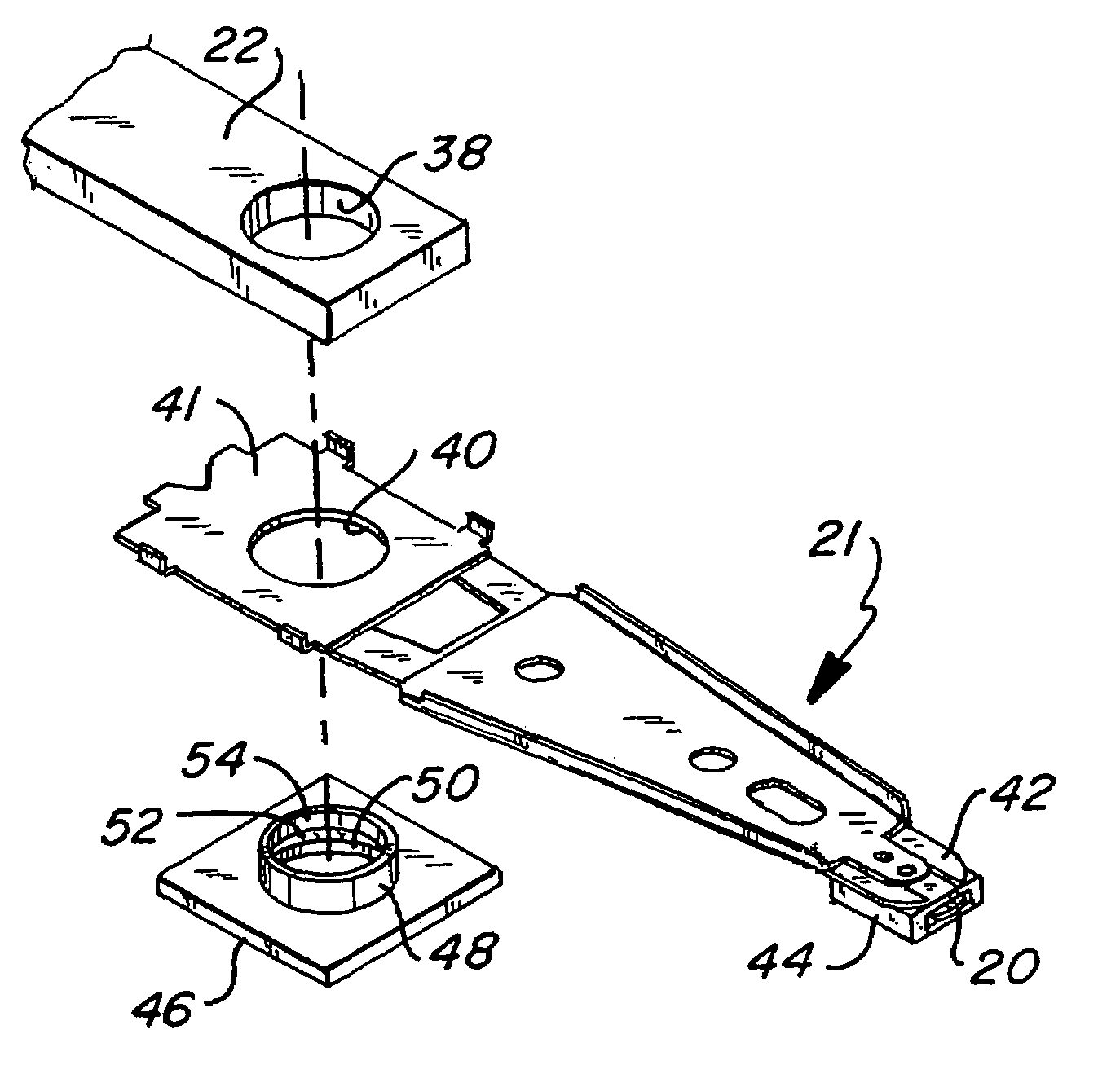

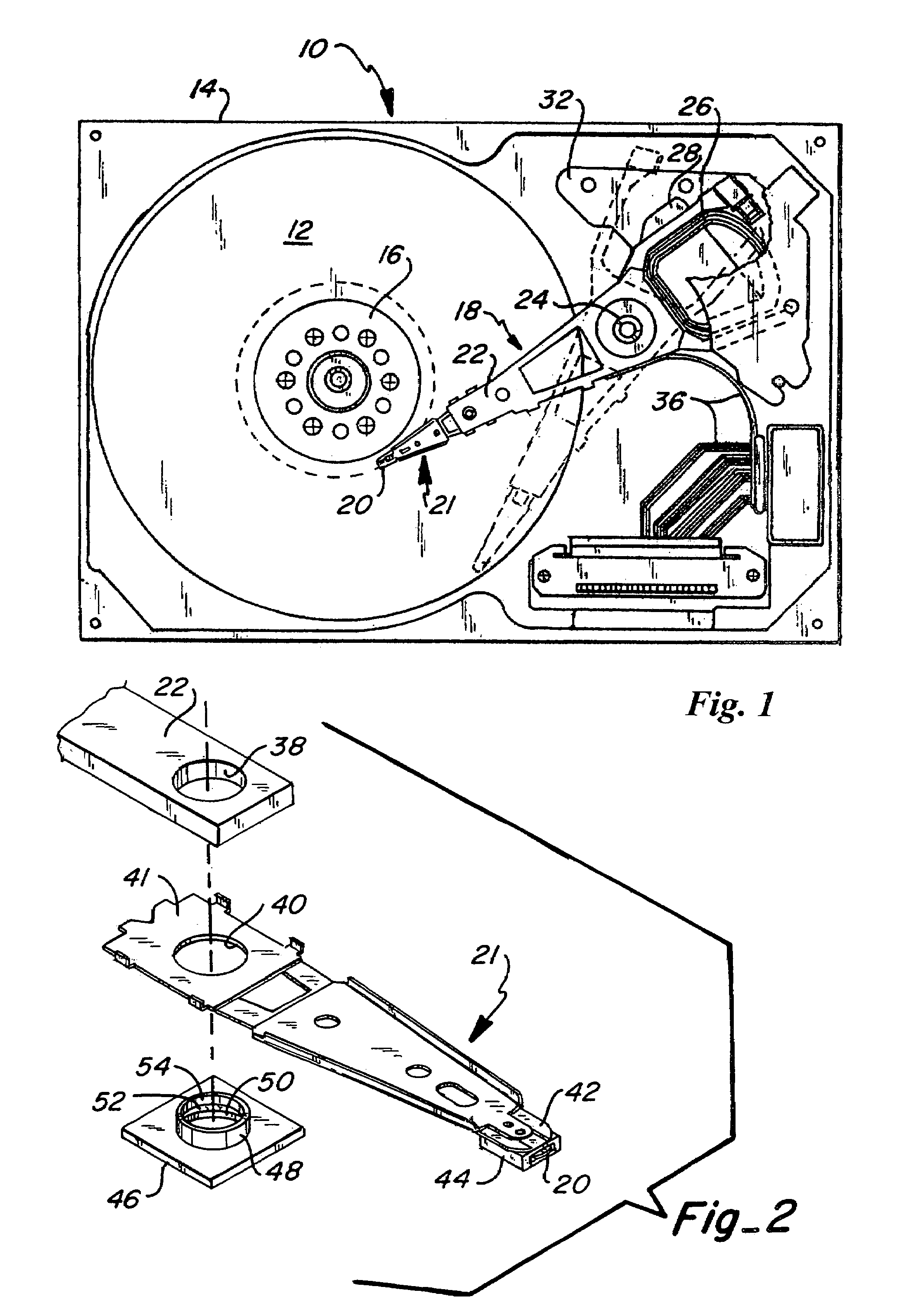

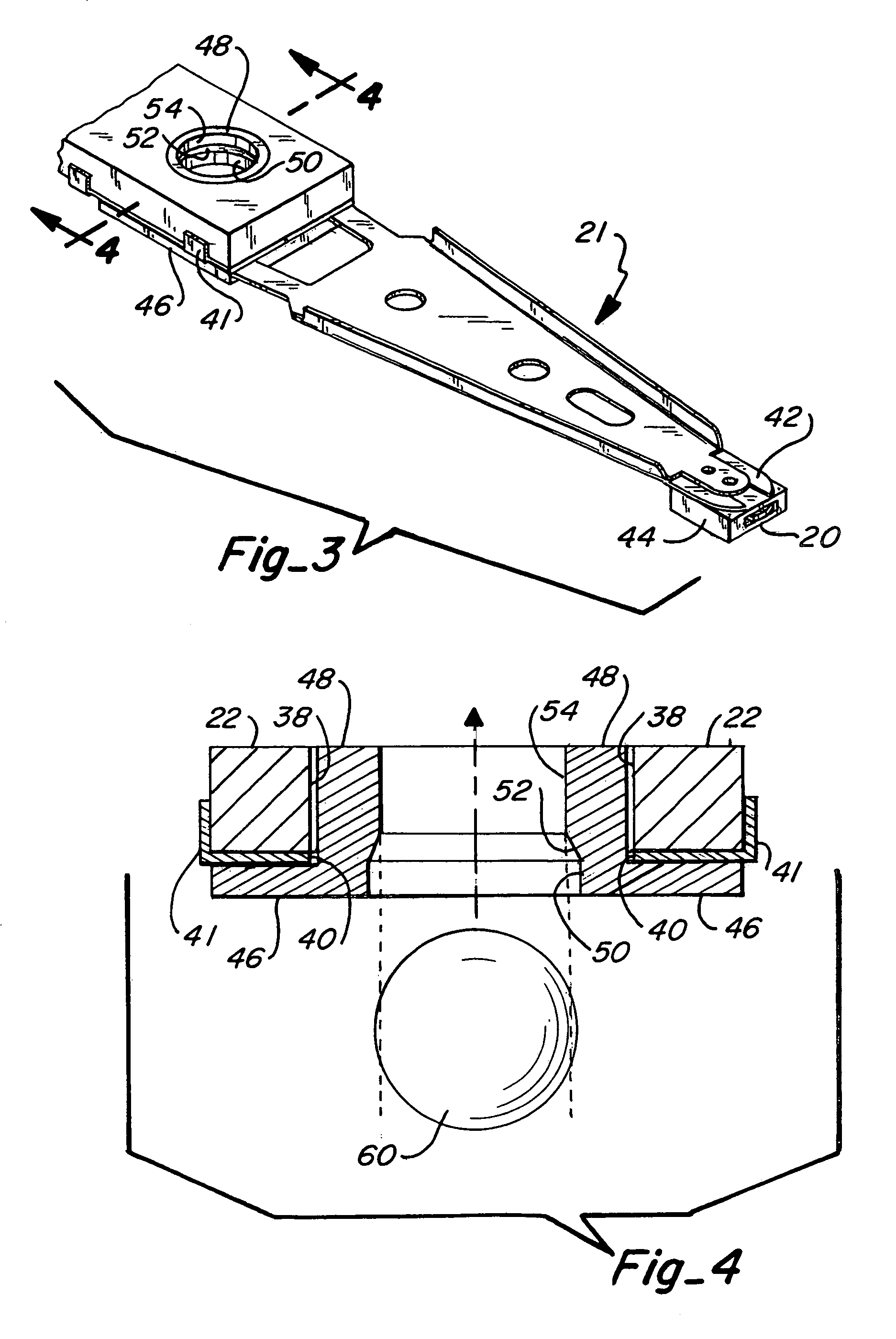

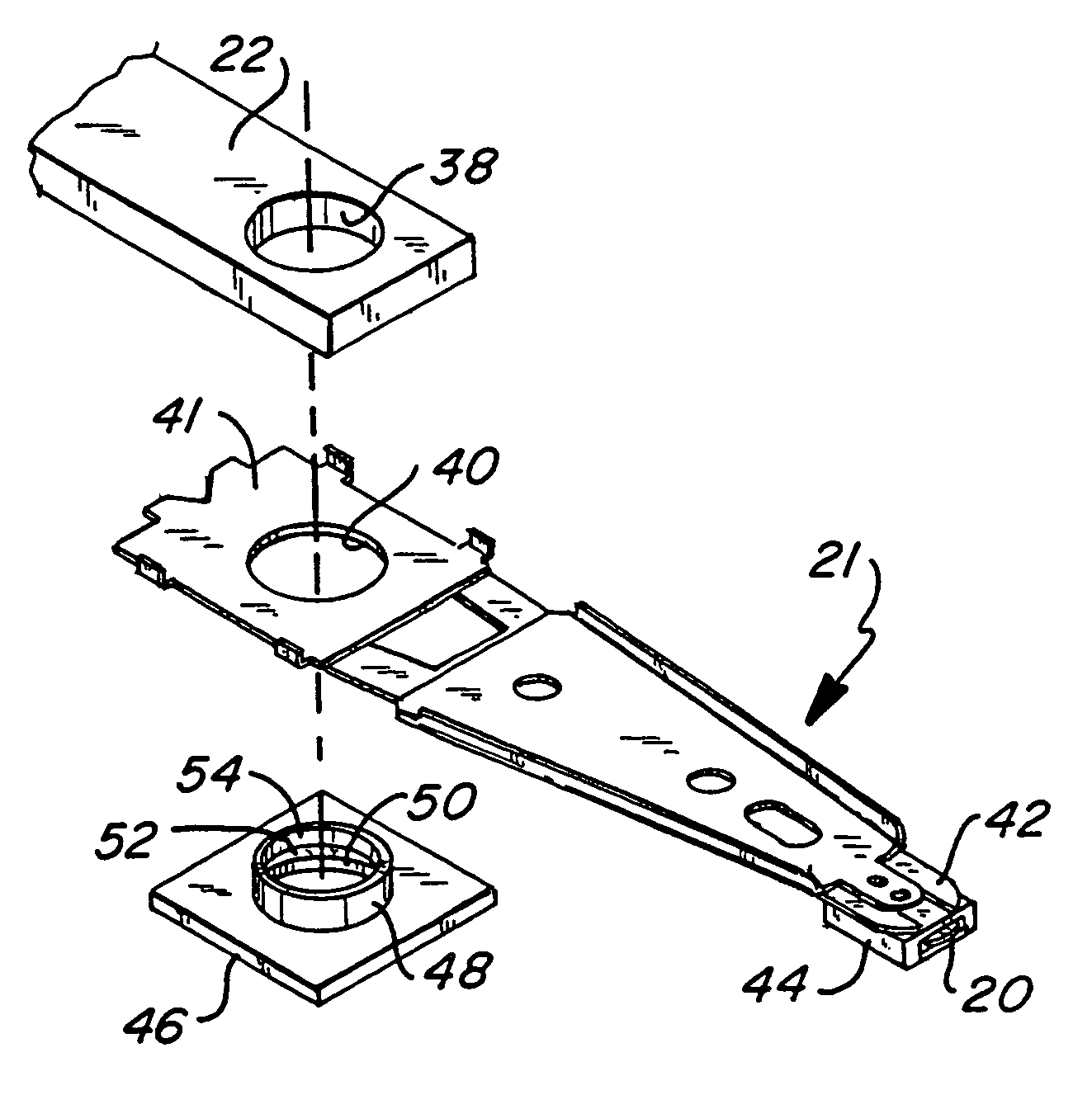

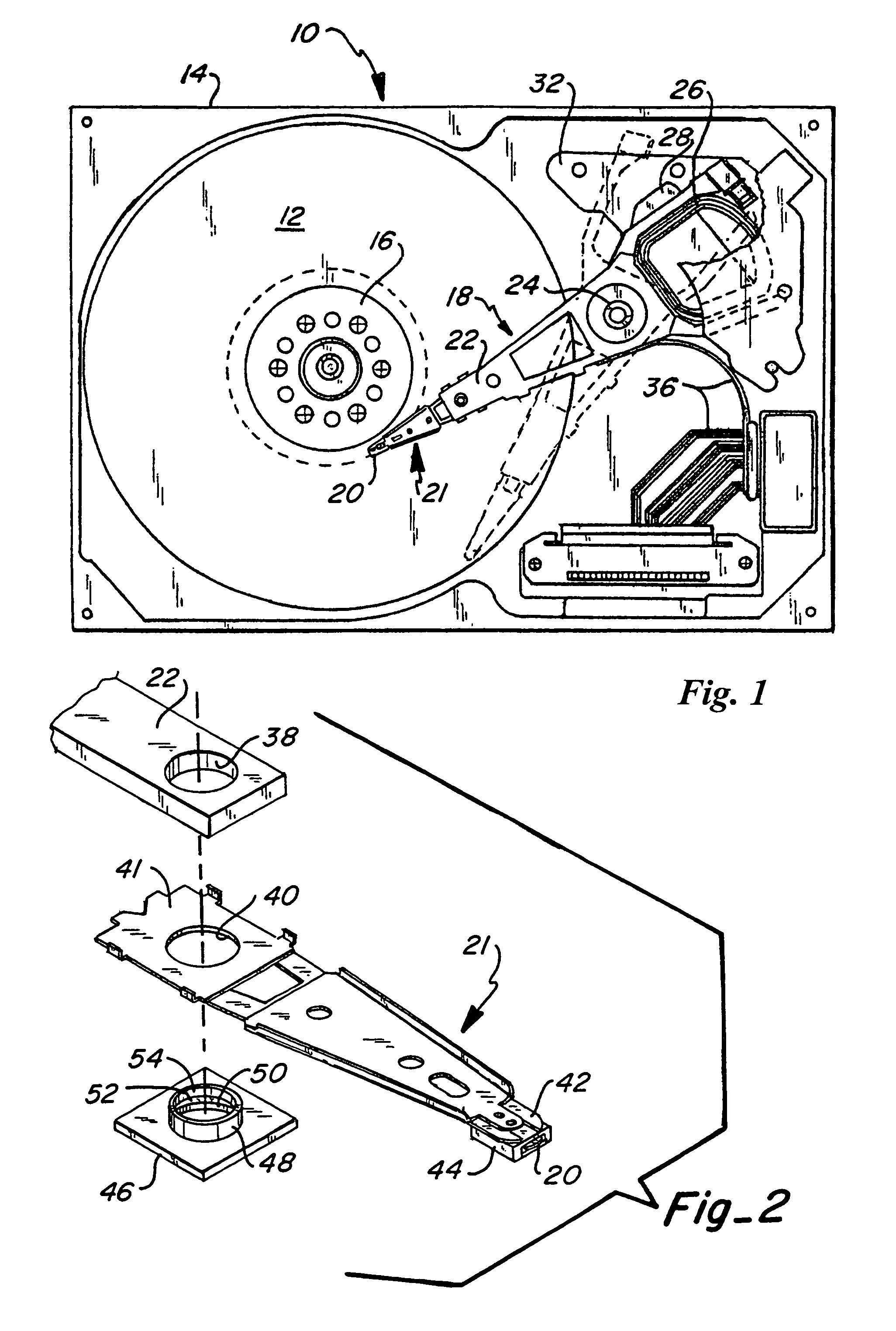

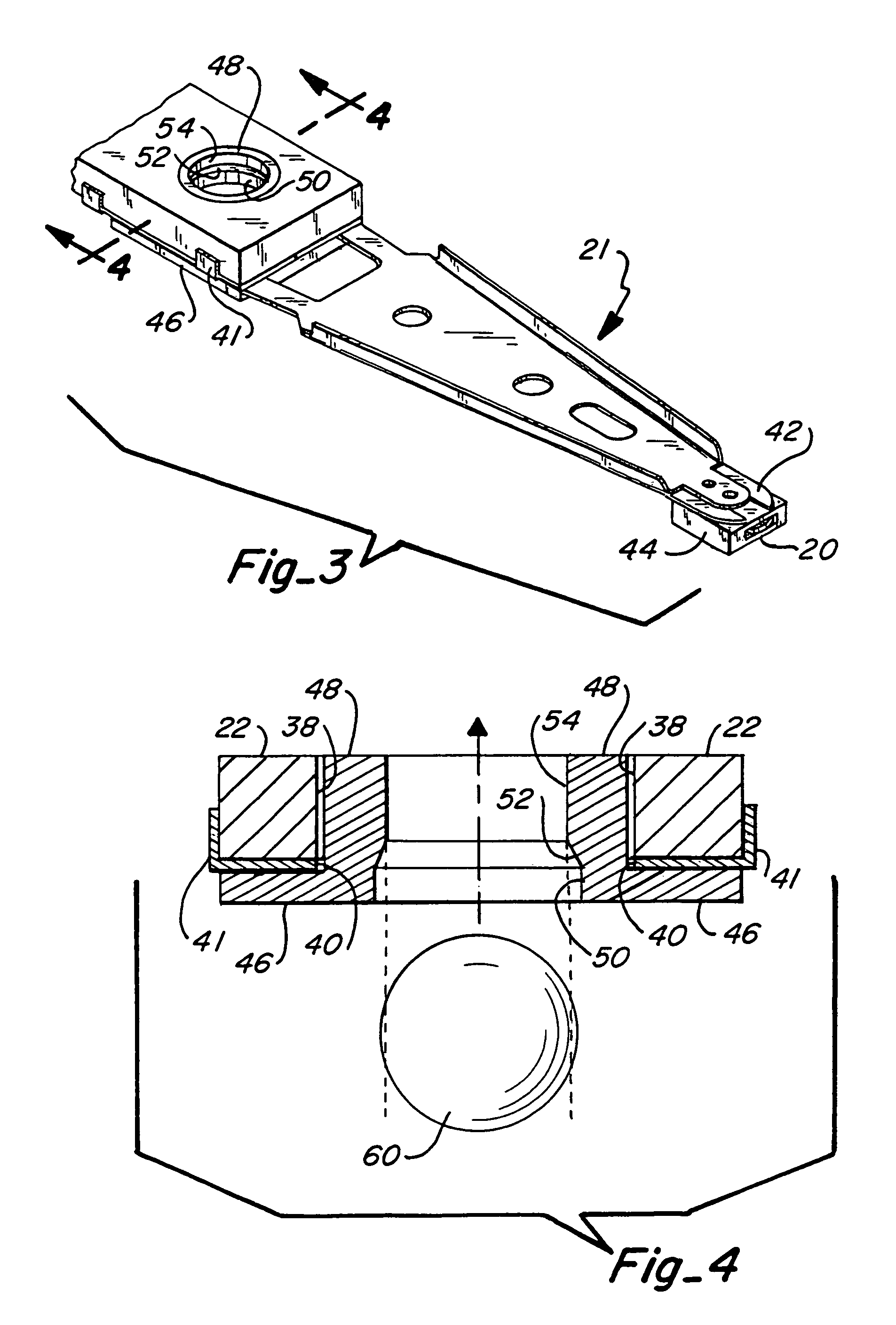

Method of assembling an actuator assembly of a disk drive and of reducing torque out retention values in subsequent de-swaging

InactiveUS7024754B1Reduced retention torqueGood deformation propertiesElectrical transducersManual lubricationGramSwaging

A method is provided for assembling an actuator assembly of a disk drive. The method includes providing an actuator arm, providing a suspension arm, fixing a swage plate to the suspension arm, the swage plate including a swage boss extending therefrom, depositing a film lubricant upon at least an outer surface of the swage boss, and attaching the suspension arm to the actuator arm by swaging. A method is also provided for reducing torque out retention values between the actuator arm and the suspension arm when the actuator arm and suspension arm must be separated in a subsequent de-swaging process. This method includes providing an outer surface of the swage boss, and applying a lubricant film coating to the outer surface of the swage boss. A preferred thin film lubricant may be applied by emersion and draining, localized spraying, or various deposition processes. Application of the lubricant has also shown to improve gram load uniformity and to reduce adverse distortion to the actuator assembly which otherwise occurs during swaging.

Owner:MAXTOR

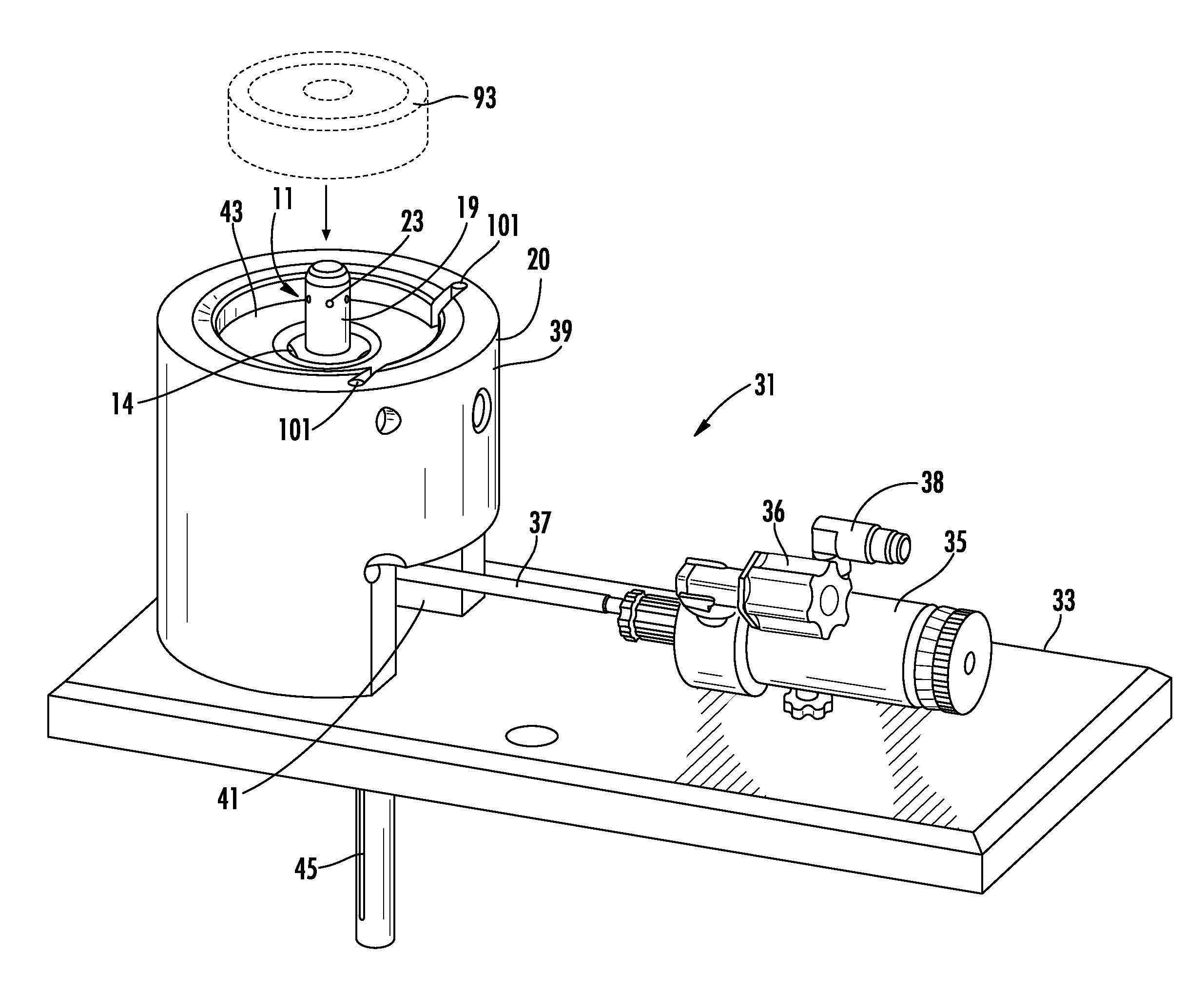

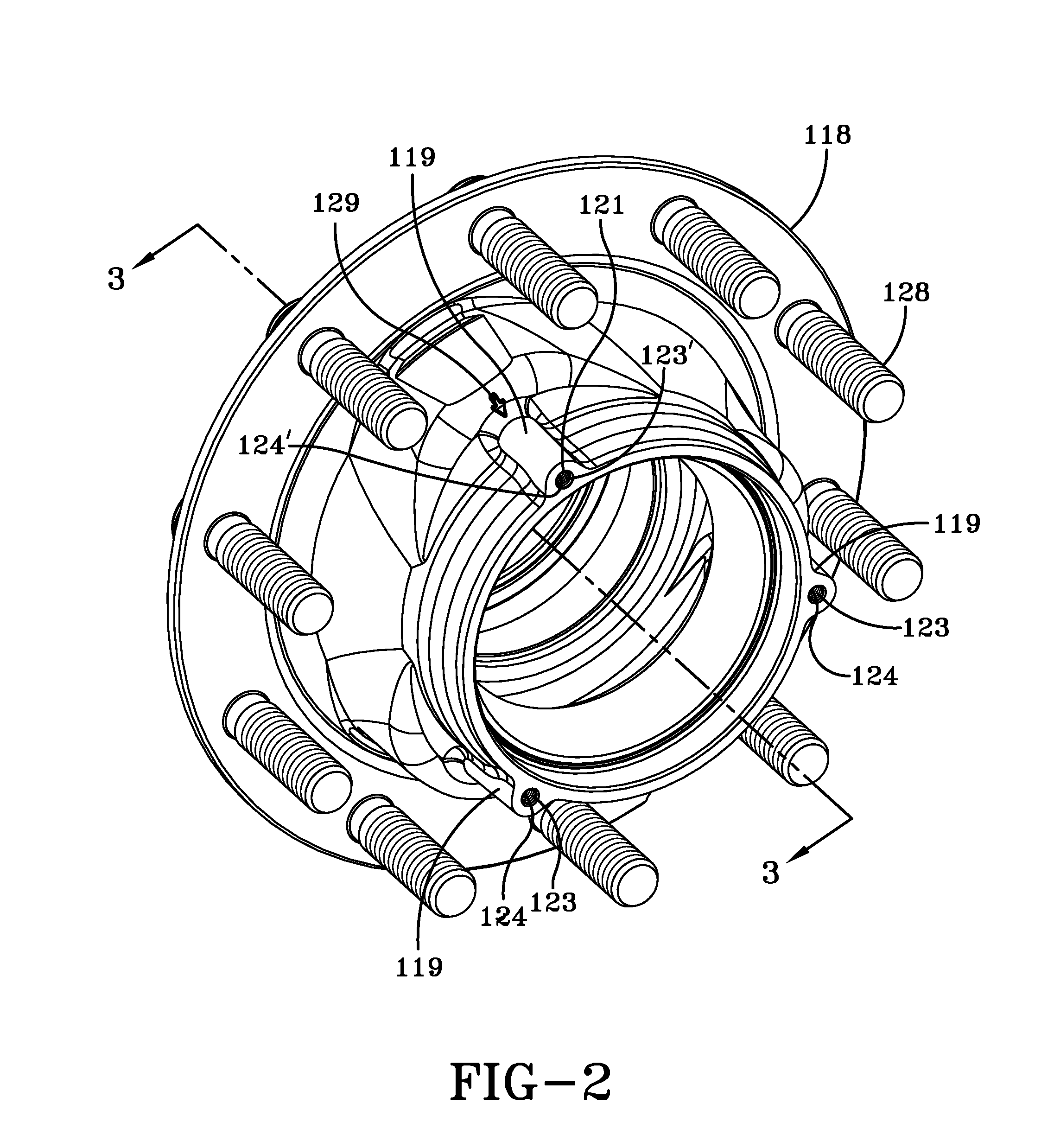

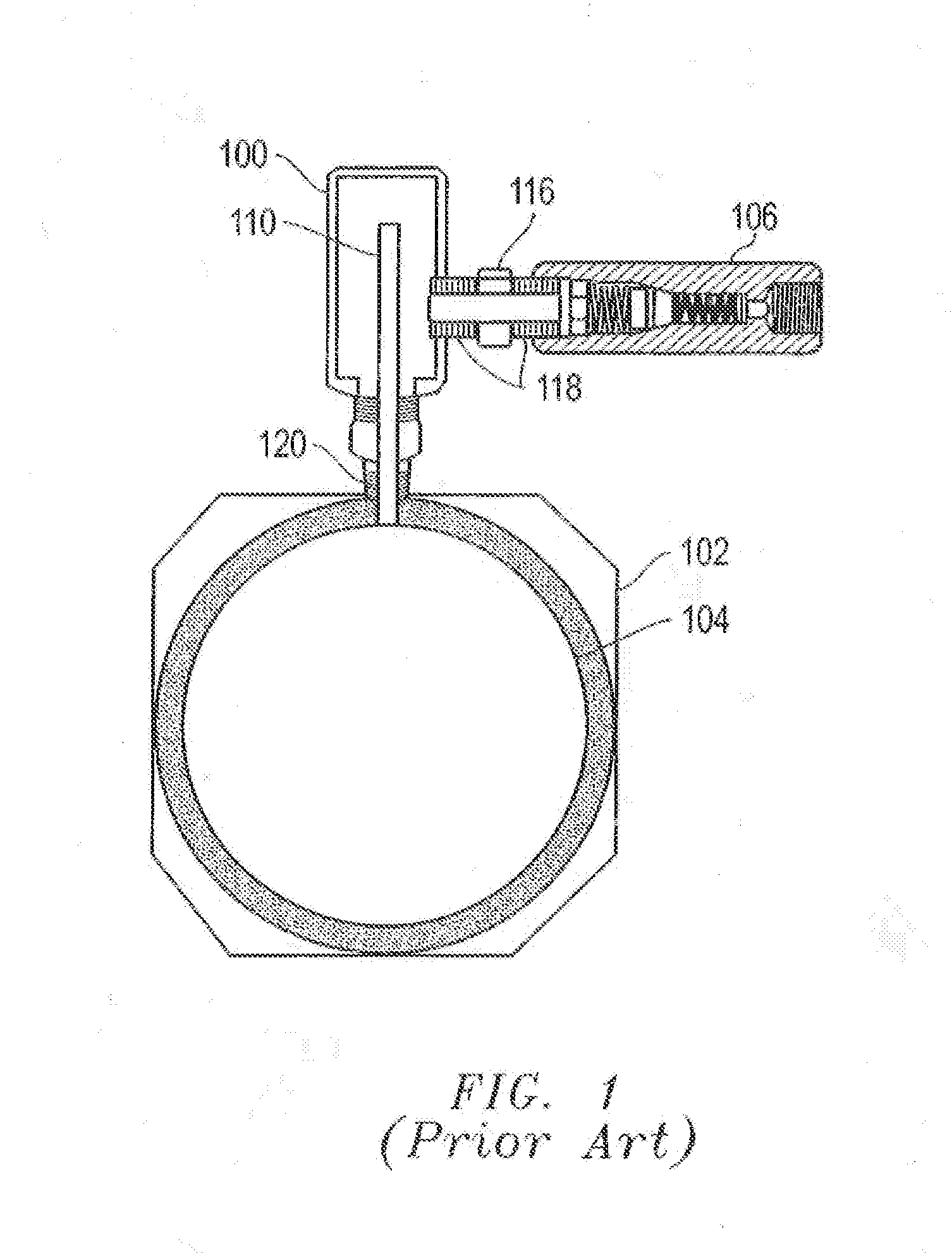

Centrifugal applicator

Methods and apparatus for applying a uniform application of an appropriate quantity of pipe dope to the internal threads of a pipe. In general, the preferred apparatus includes a supply of pipe dope and a centrifugal applicator for evenly applying the pipe dope to internal threads. The system also includes a dosing system to regulate the distribution of pipe dope by dispensing a consistent volume of pipe dope at each application. Potential advantages of the preferred embodiments include the repeatability and consistency of amount of pipe dope on pipe threads (e.g. thickness).

Owner:NAT OILWELL DHT

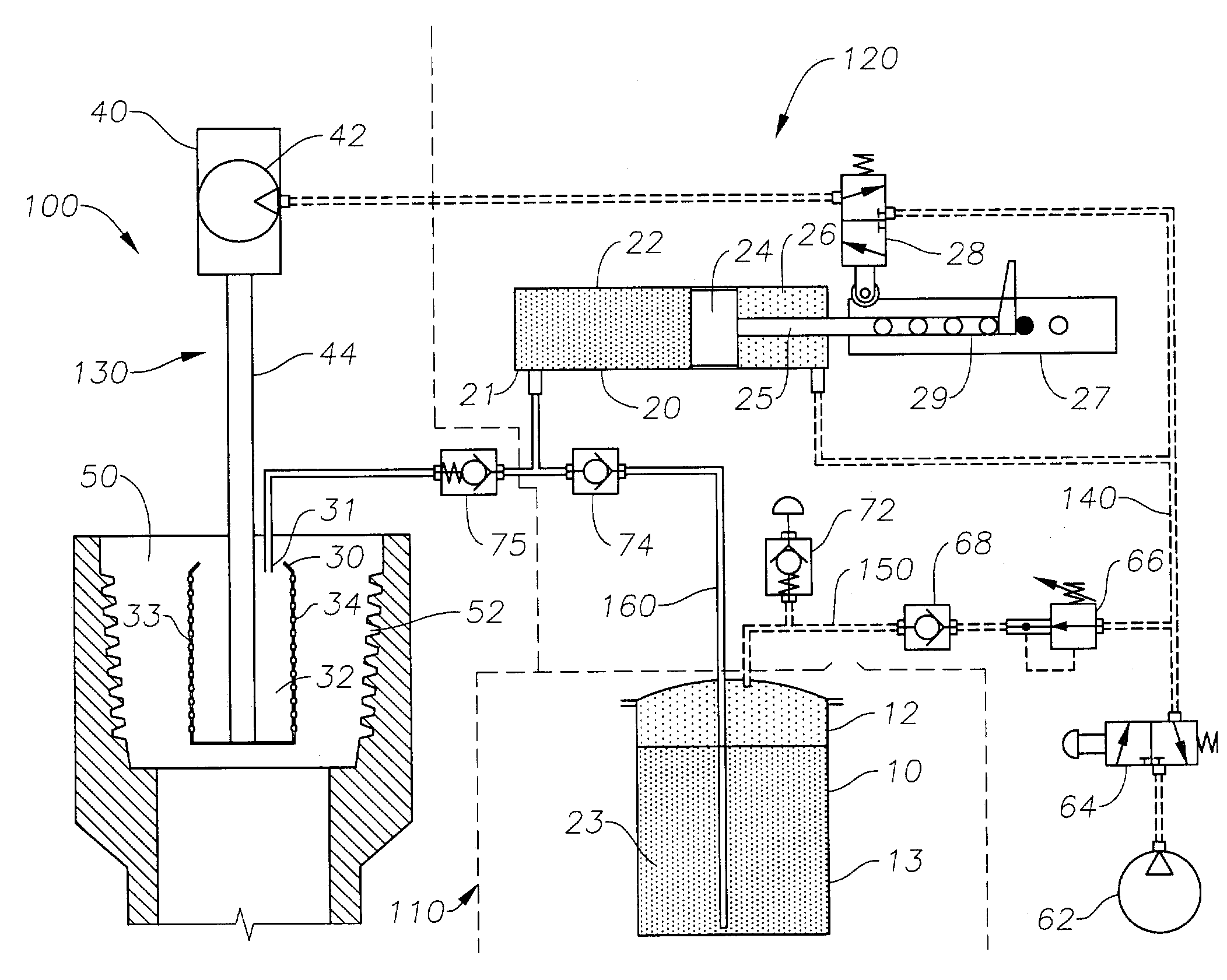

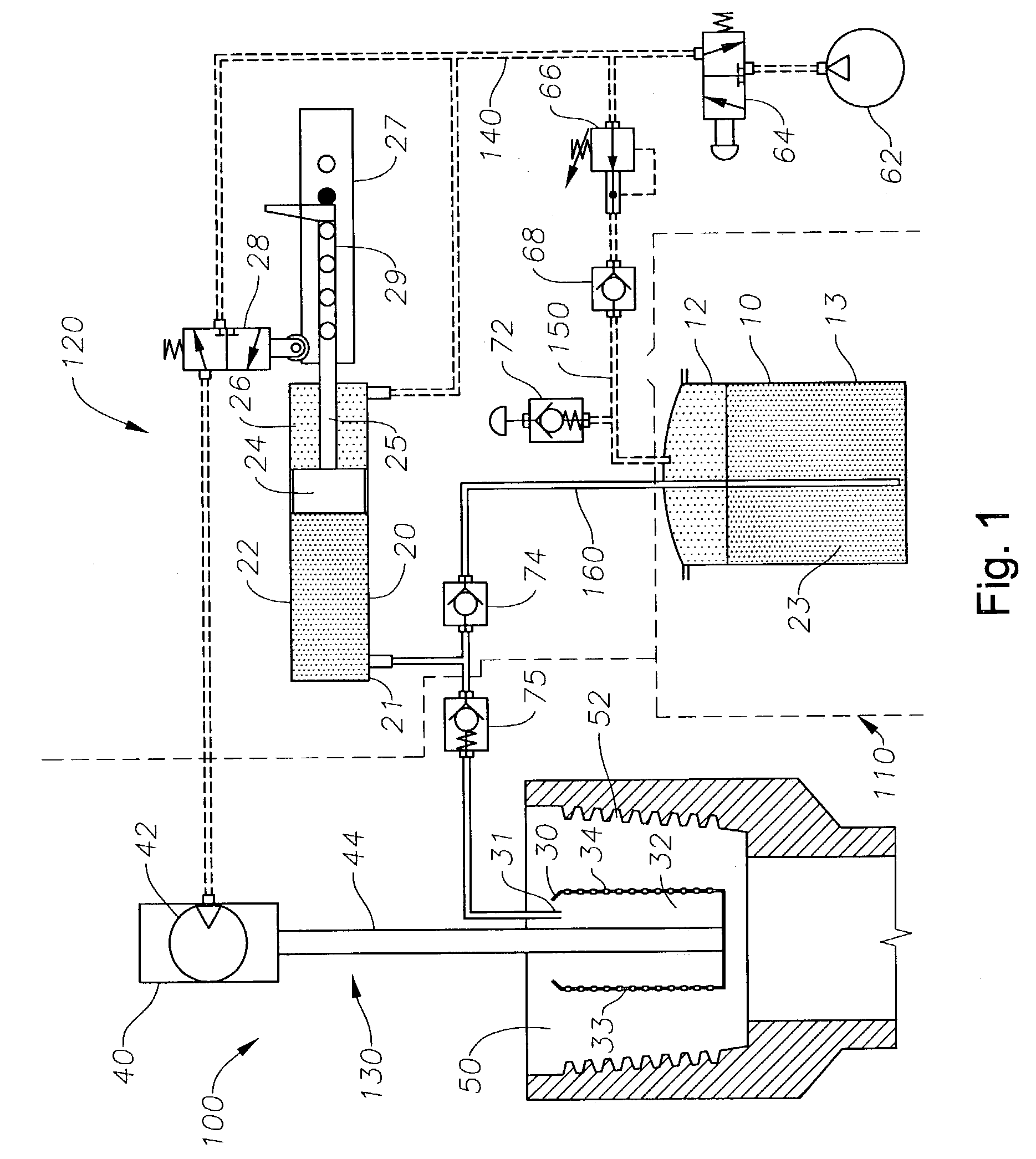

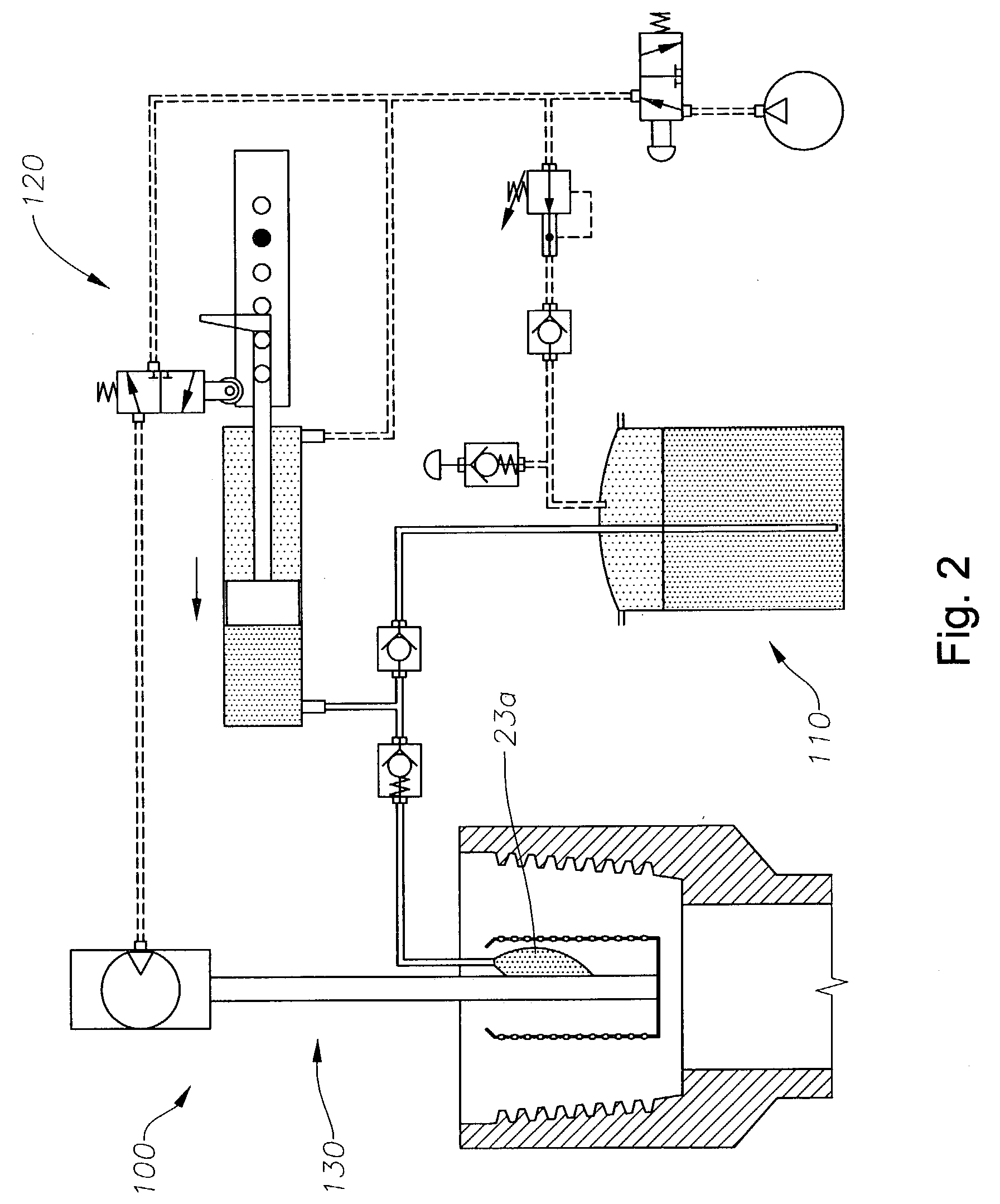

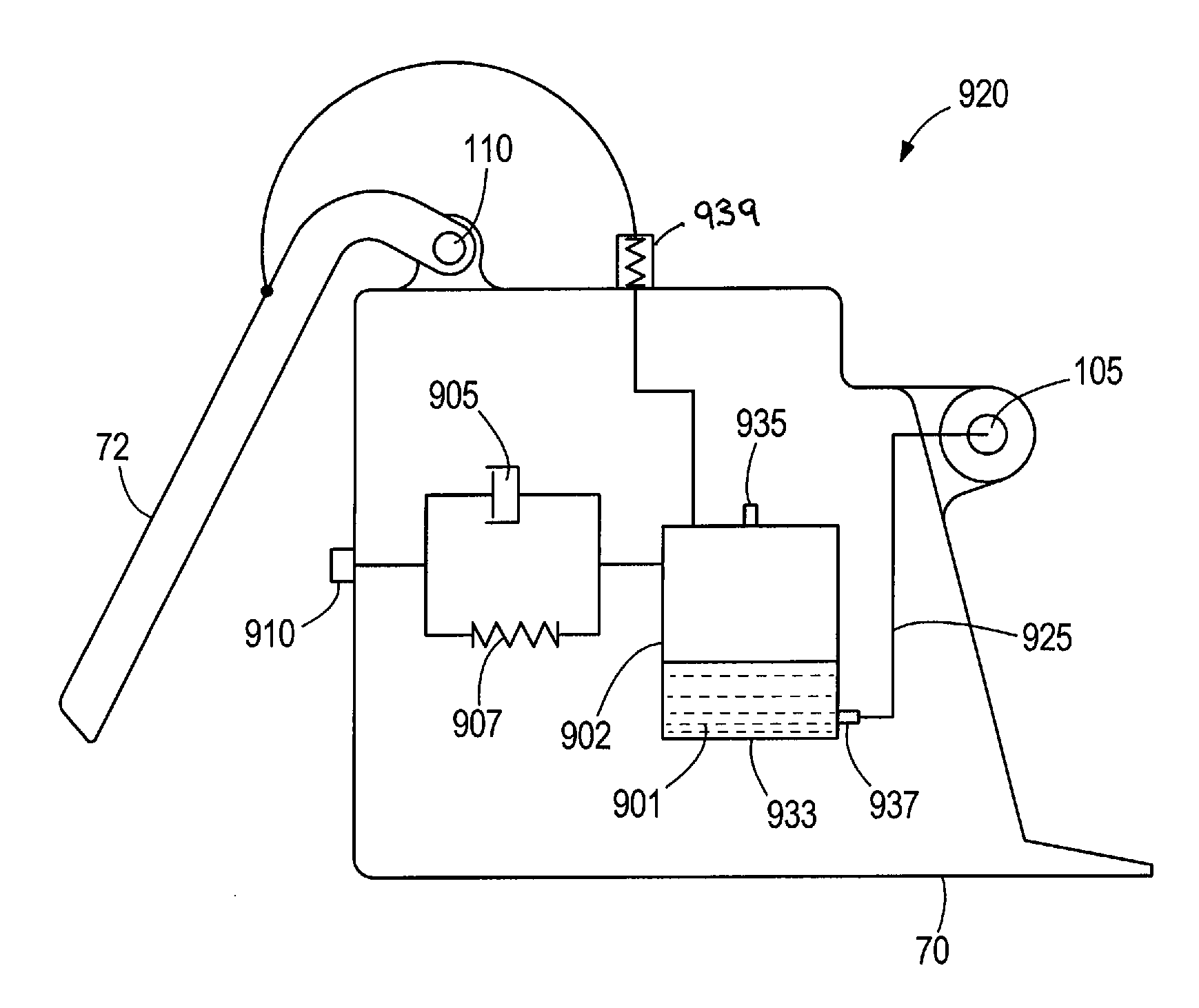

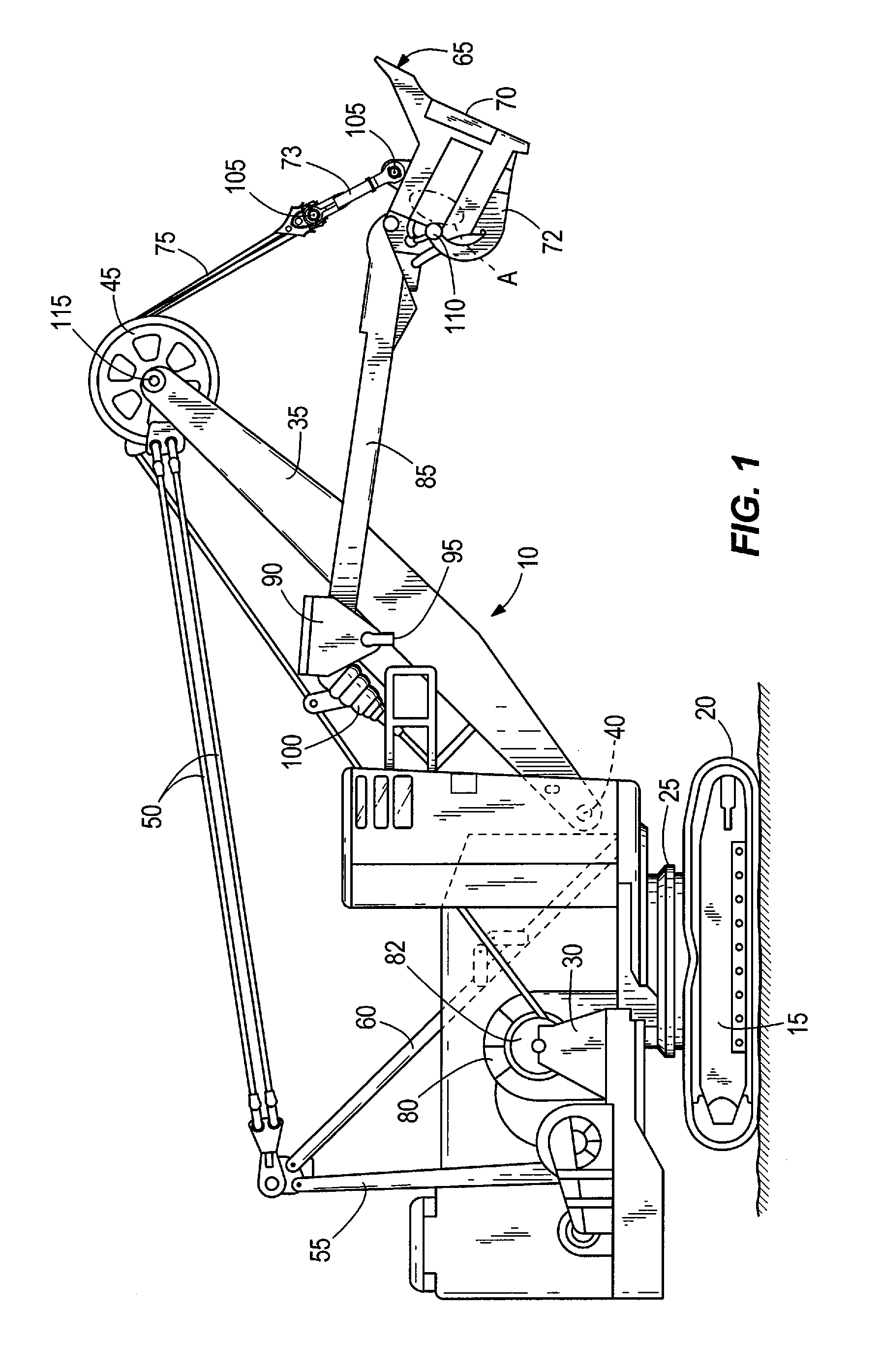

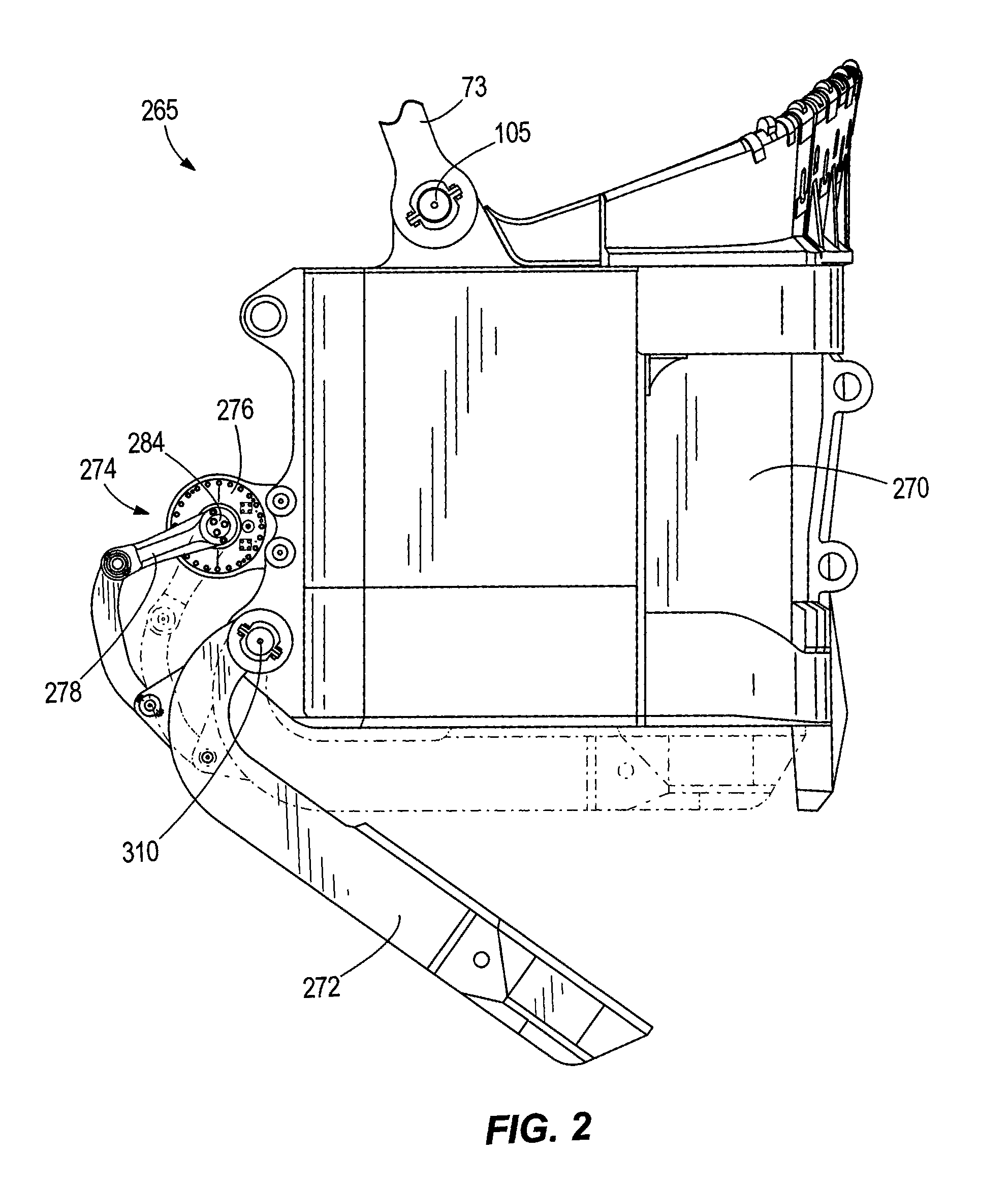

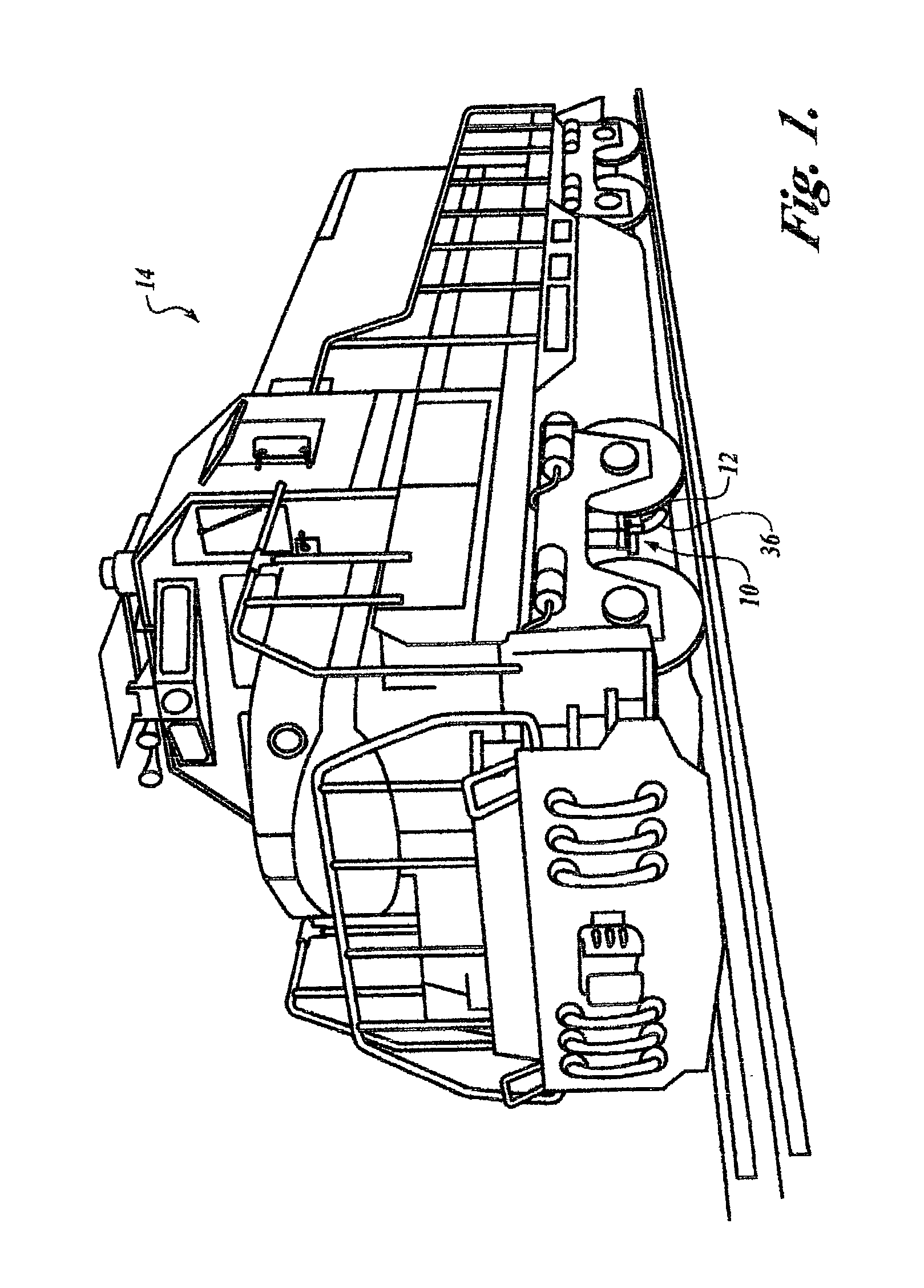

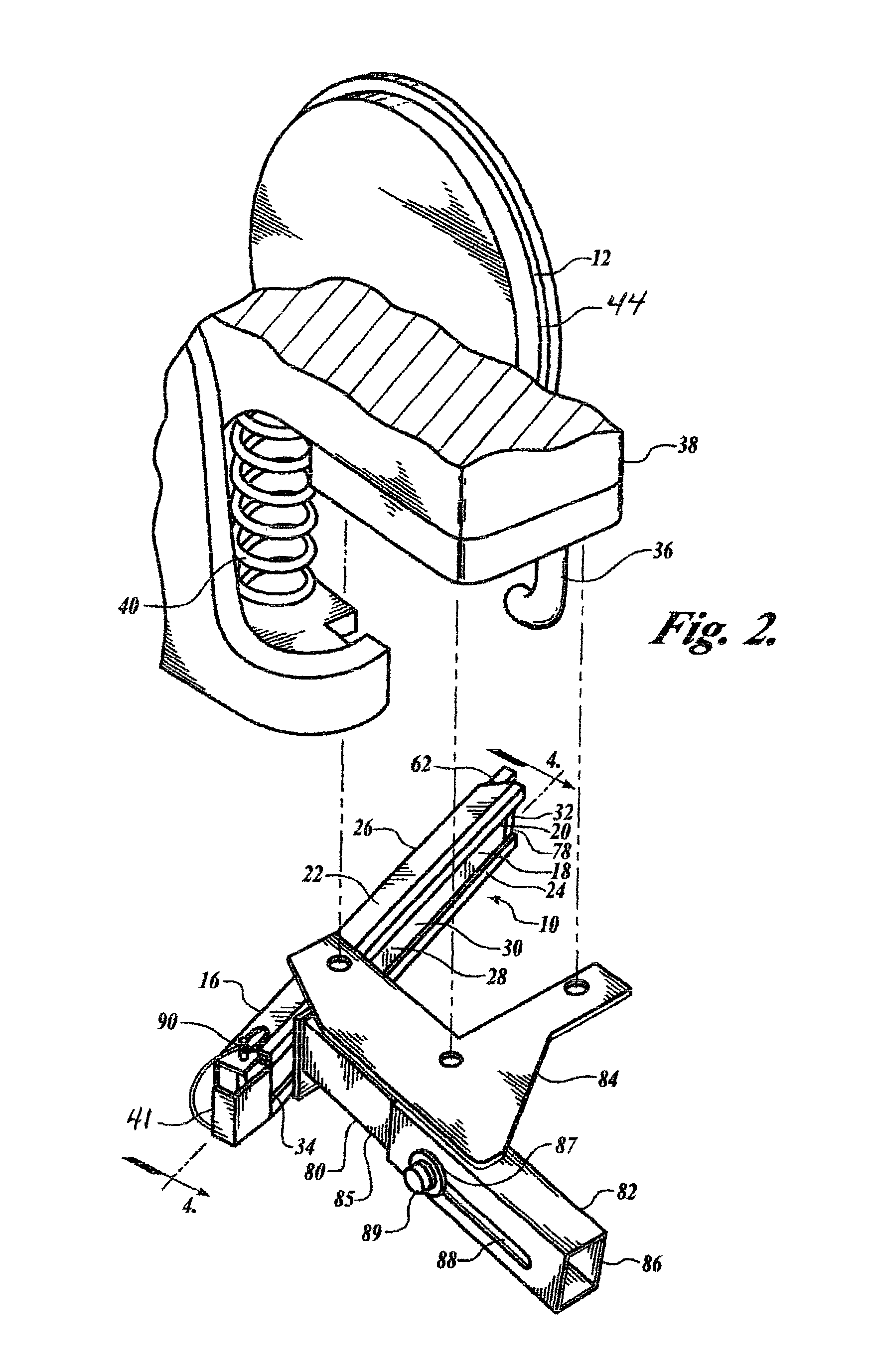

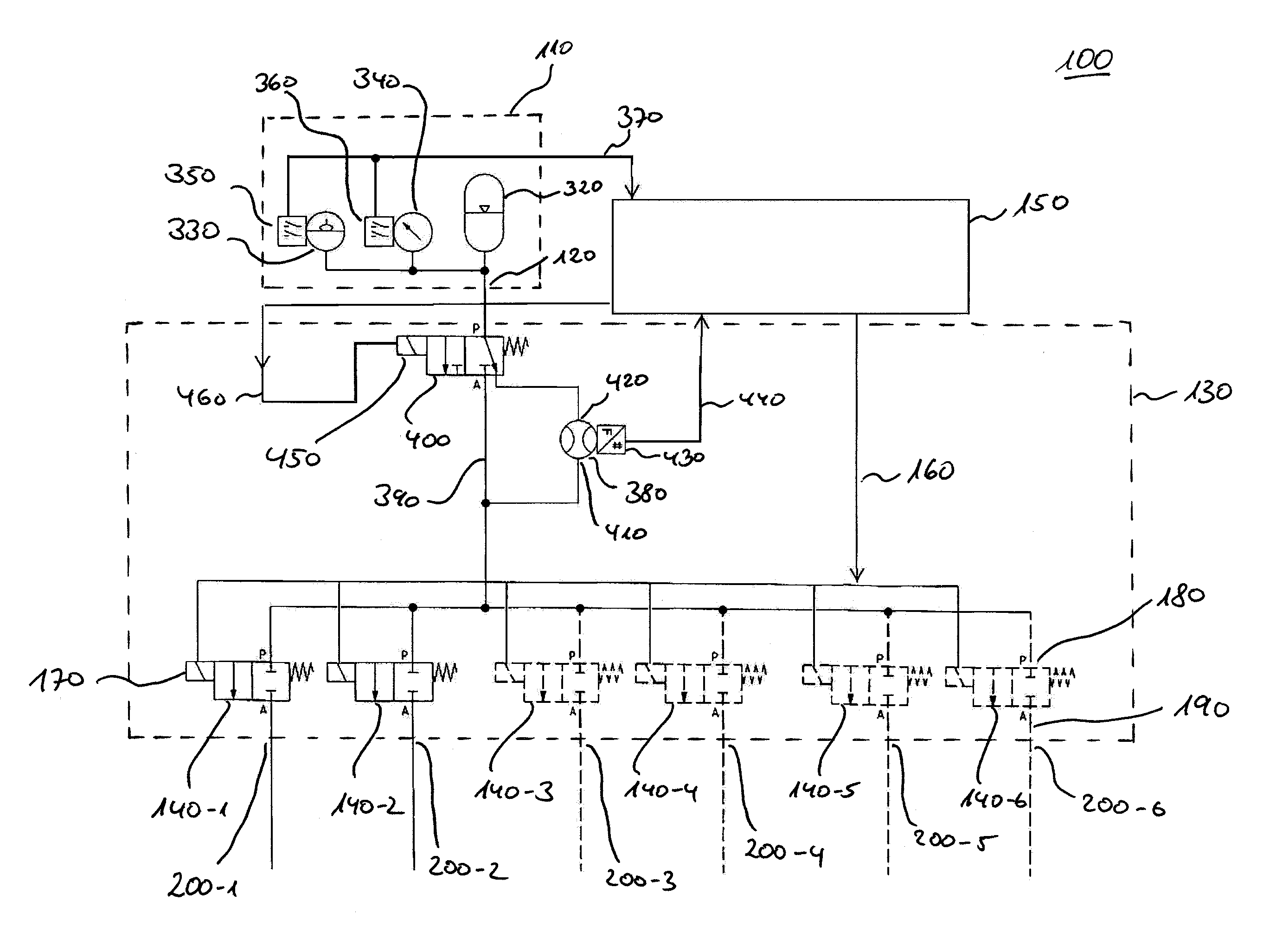

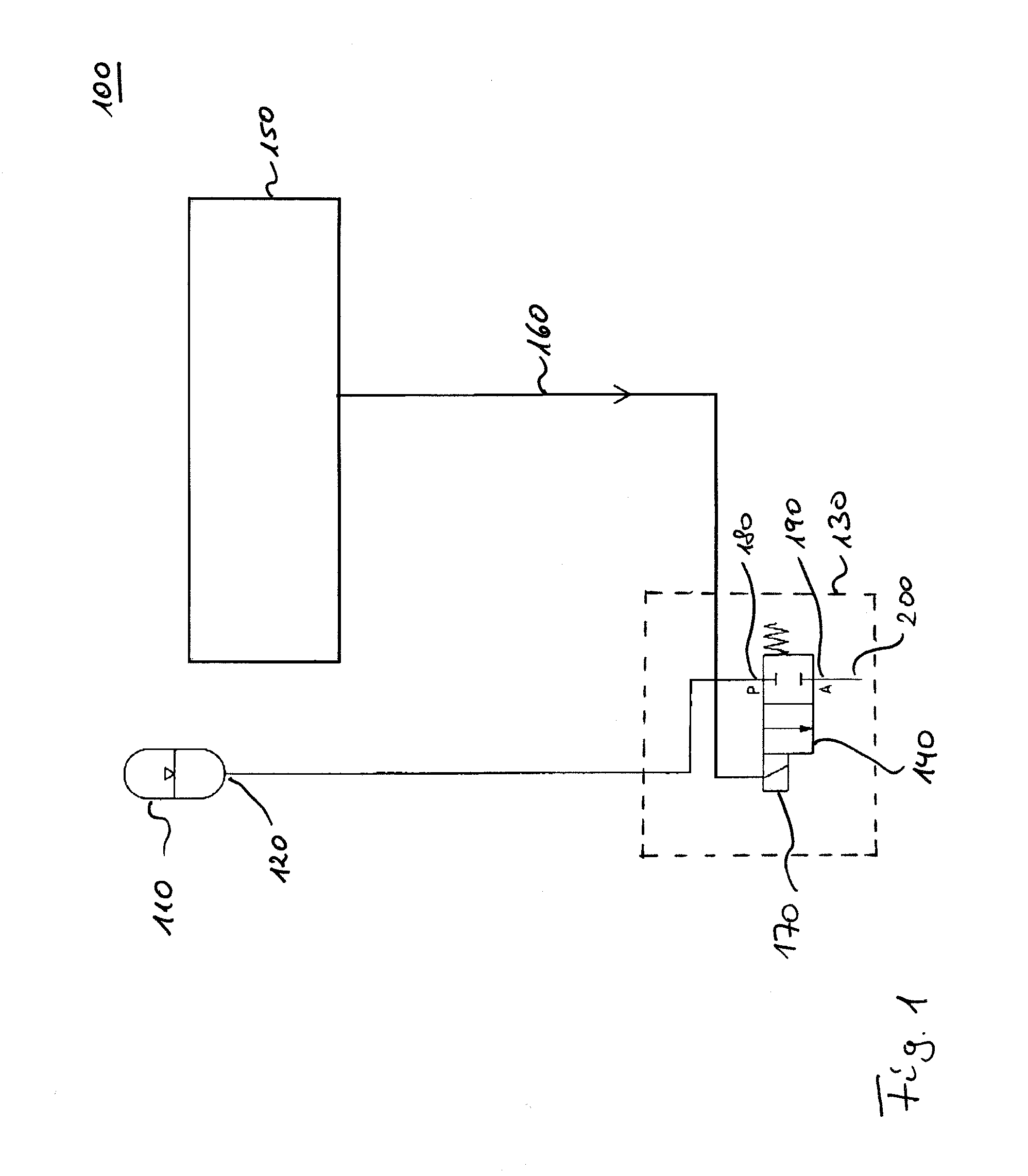

Automatic lubrication system

An automatic lubrication system includes a reservoir configured to be coupled to an industrial machine component, a lubricant line coupled to the reservoir, and a mechanism coupled to the reservoir, the mechanism configured to exact an amount of lubricant from the reservoir based solely on movement of the industrial machine component.

Owner:HARNISCHFEGER TECH

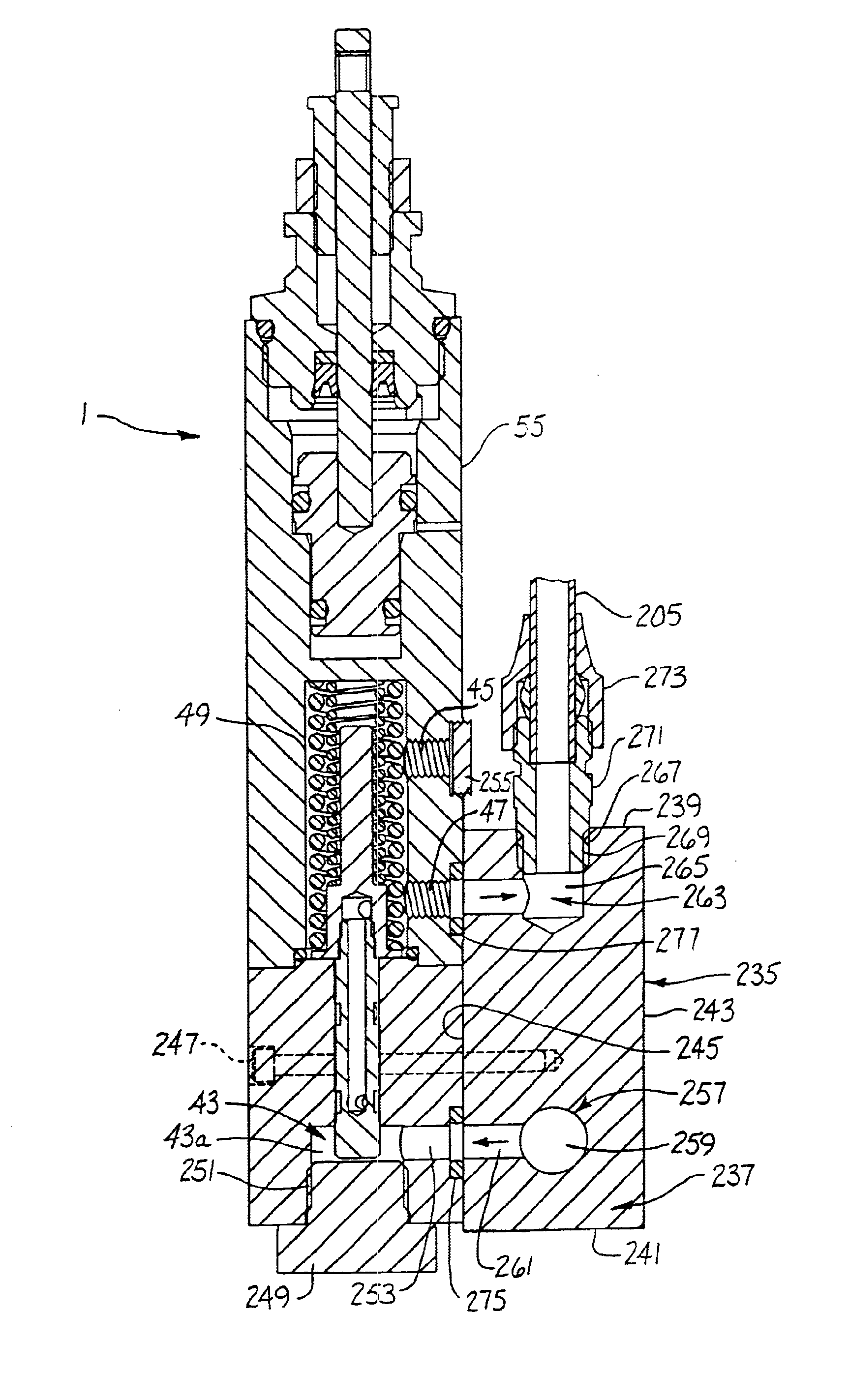

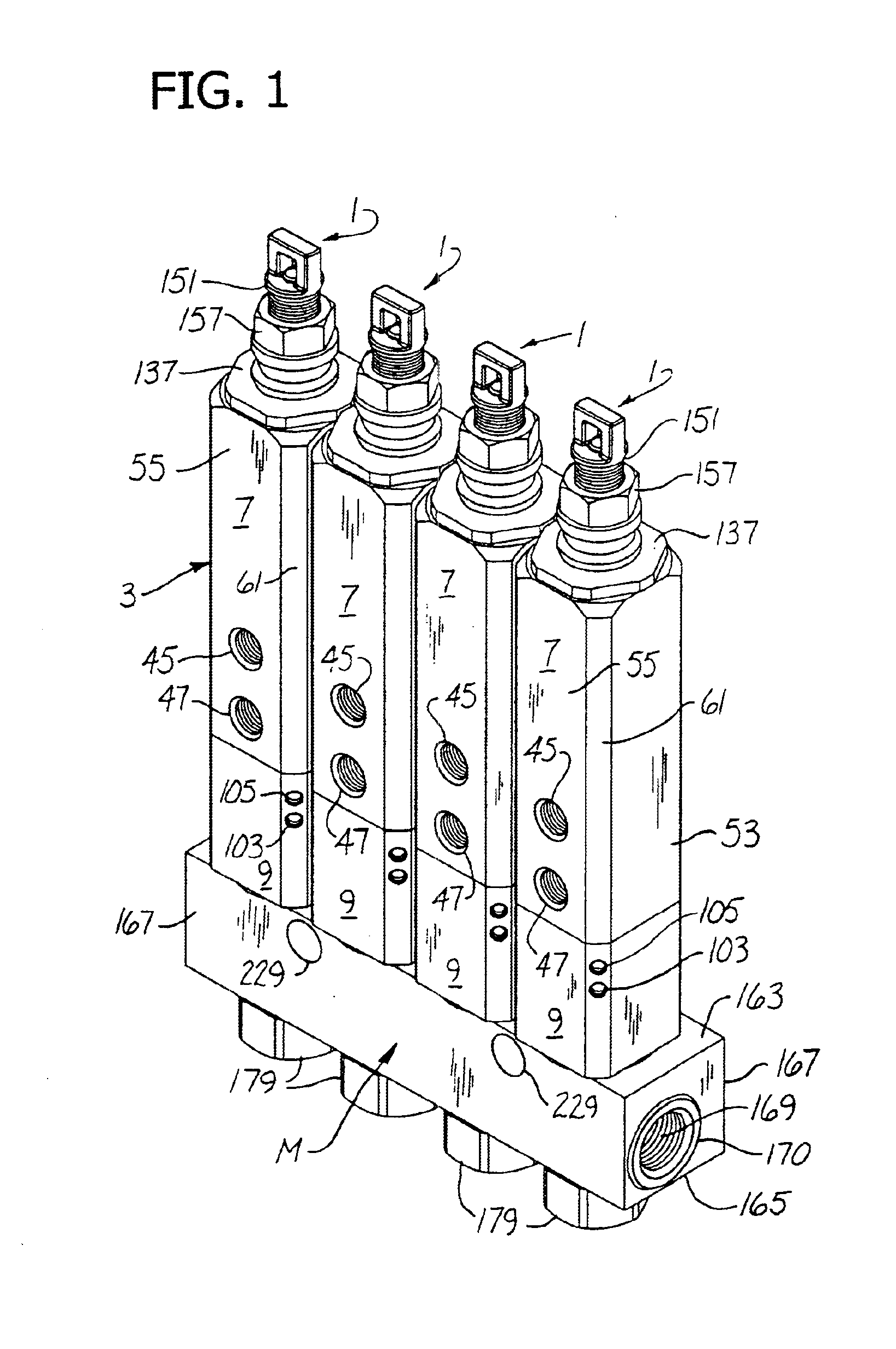

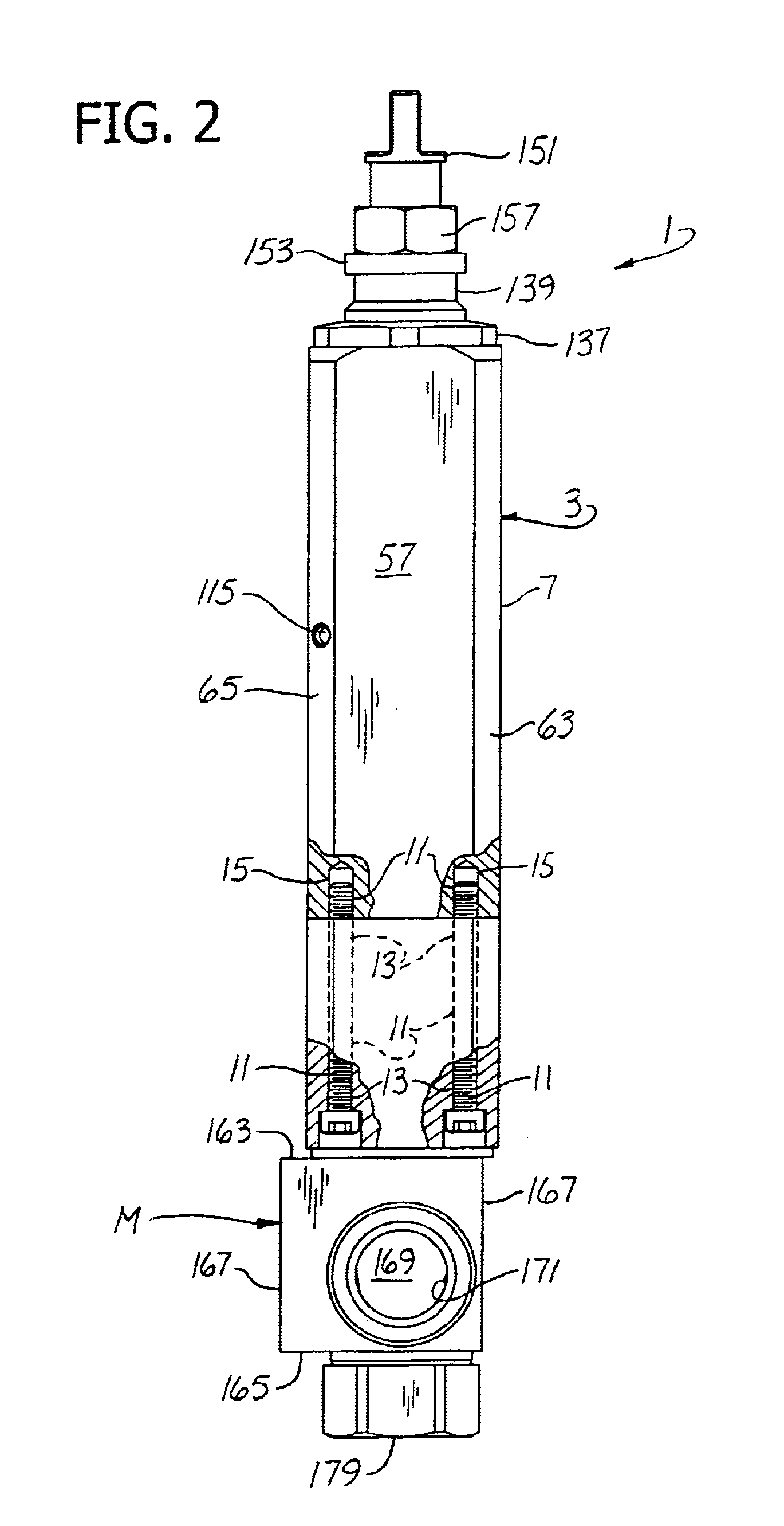

Lubricant injector assembly

InactiveUS6863157B2Improve system performanceReduce ventingProportioning devicesManual lubricationLubricantElectrical and Electronics engineering

A lubricant injector having a measuring chamber, venting of the injector involving transmission of lubricant from its inlet to the measuring chamber, a method of operation of the injector involving such transmission, systems embodying one or more of such injectors, improving the performance of existing systems by use of one or more such injectors, an injector / connector assembly, and an injector sealing assembly.

Owner:LINCOLN INDUSTRIES CORP

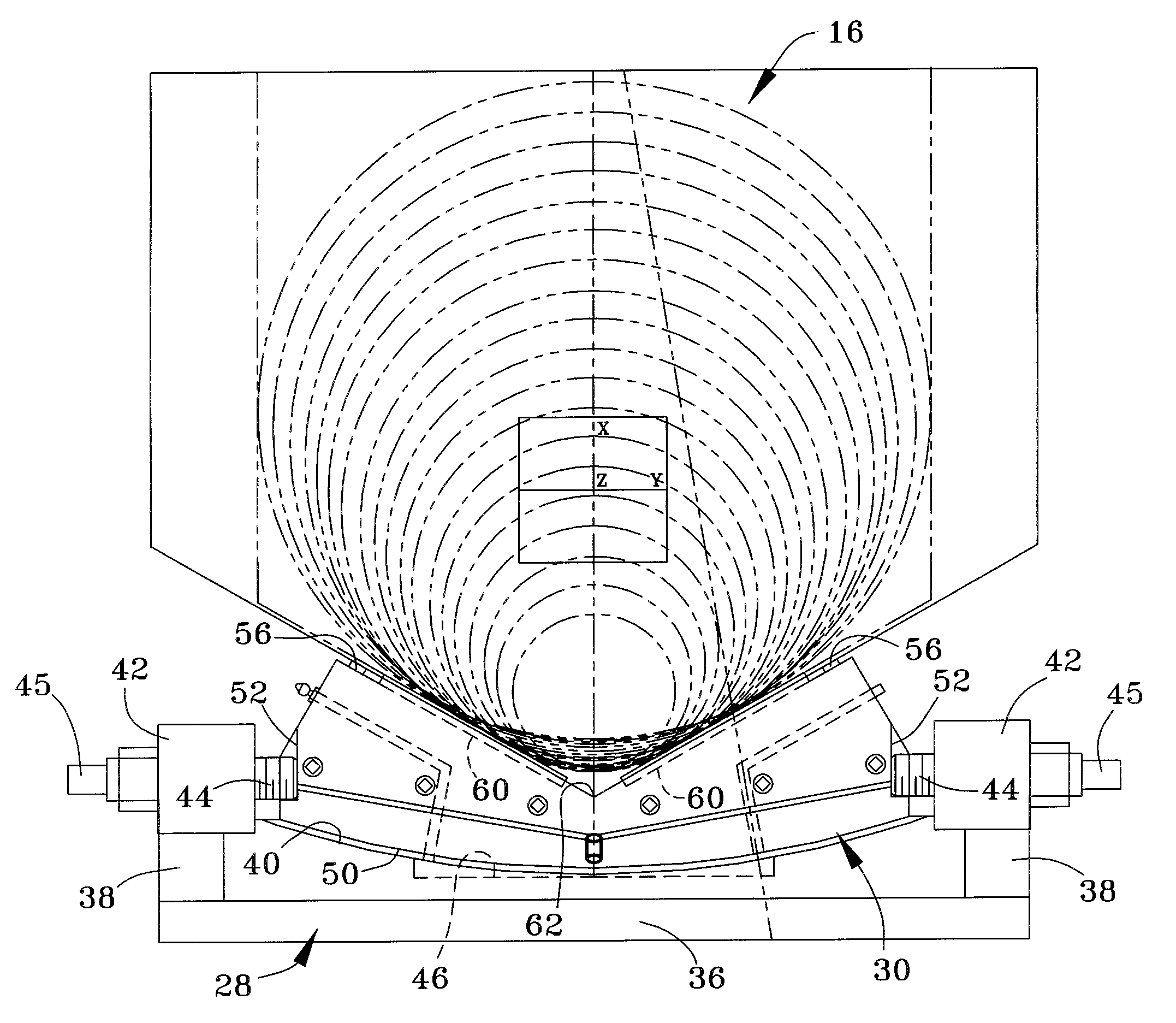

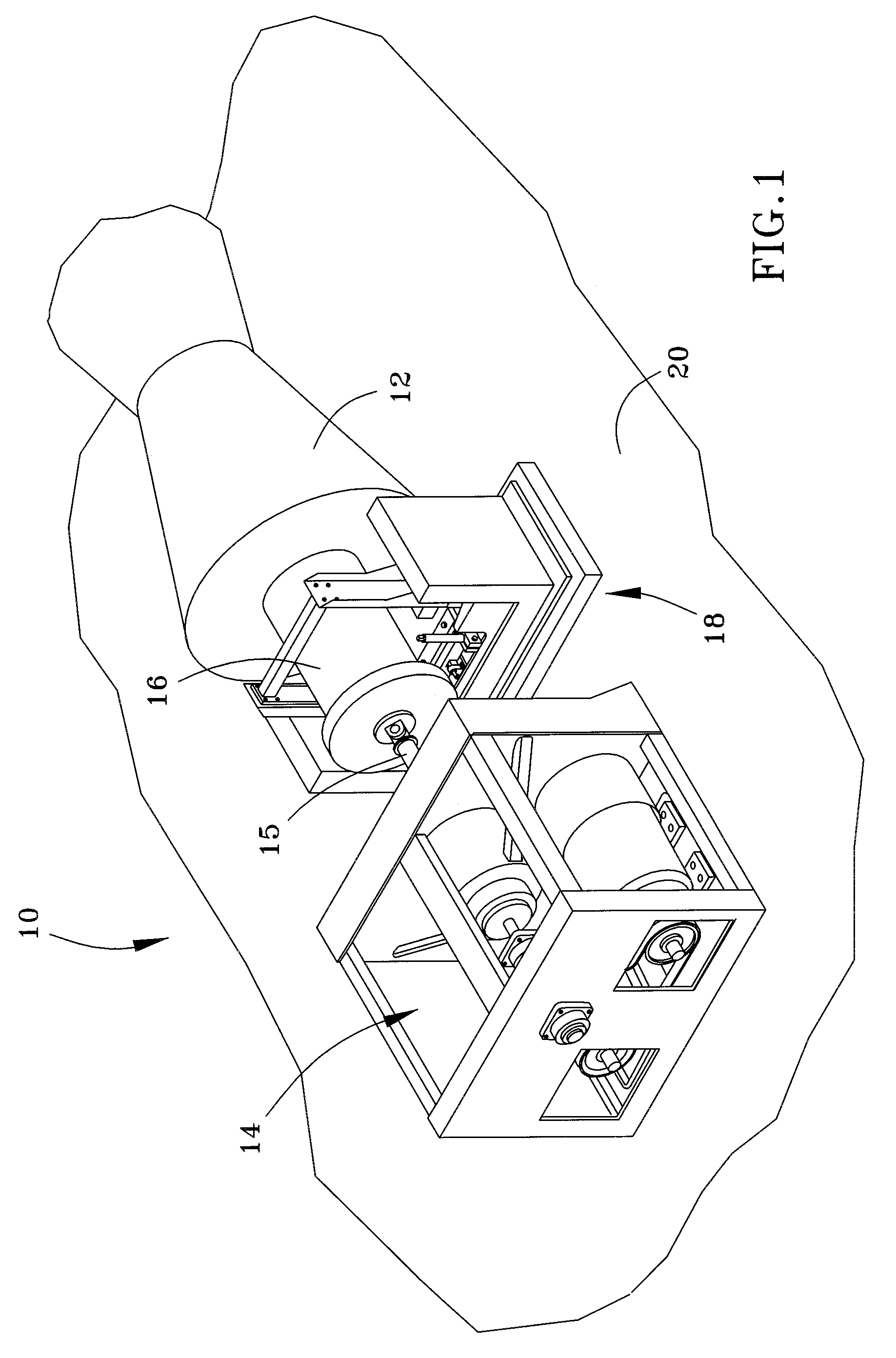

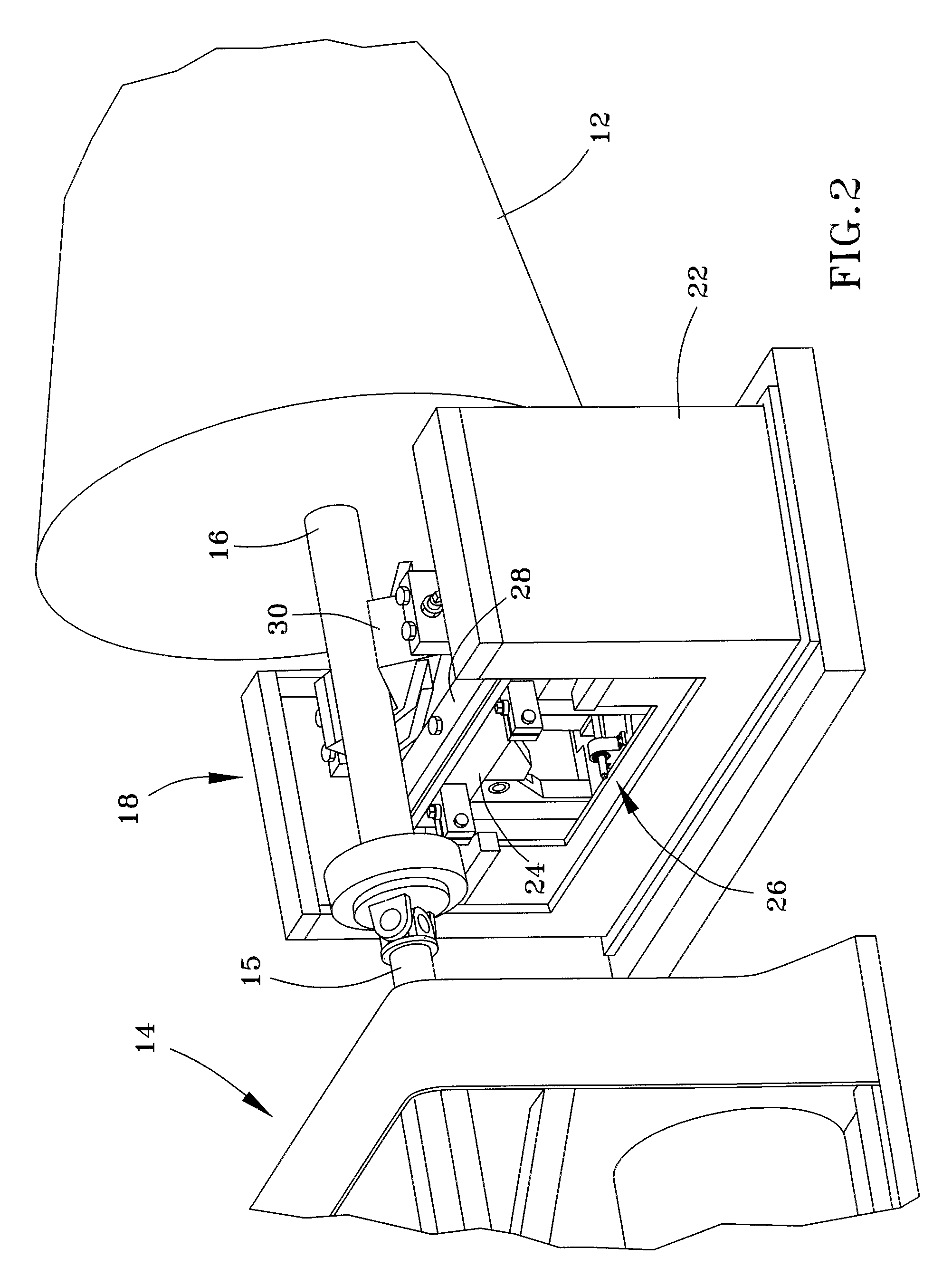

Self-aligning support assembly for rotatable cylindrical components

ActiveUS20100163705A1Easy alignmentReduced dimensional accuracyPortable framesMachines/enginesEngineeringLubricant

An apparatus and method suitable for supporting a cylindrical component. The apparatus includes a pedestal having an upper surface with a semispherical concave shape, and a carriage supported on the upper surface of the pedestal. The carriage has a lower surface and an oppositely-disposed upper surface with elements for contacting and rotatably supporting the cylindrical component. The lower surface of the carriage engages the upper surface of the pedestal and has a semispherical convex shape complementary to the semispherical concave shape of the upper surface of the pedestal. The apparatus further includes a reservoir at and recessed in the upper surface of the pedestal, and a feature for delivering a lubricant to the lubricant reservoir. The lower surface of the carriage and the upper surface of the pedestal define an enclosure around the reservoir.

Owner:GENERAL ELECTRIC CO

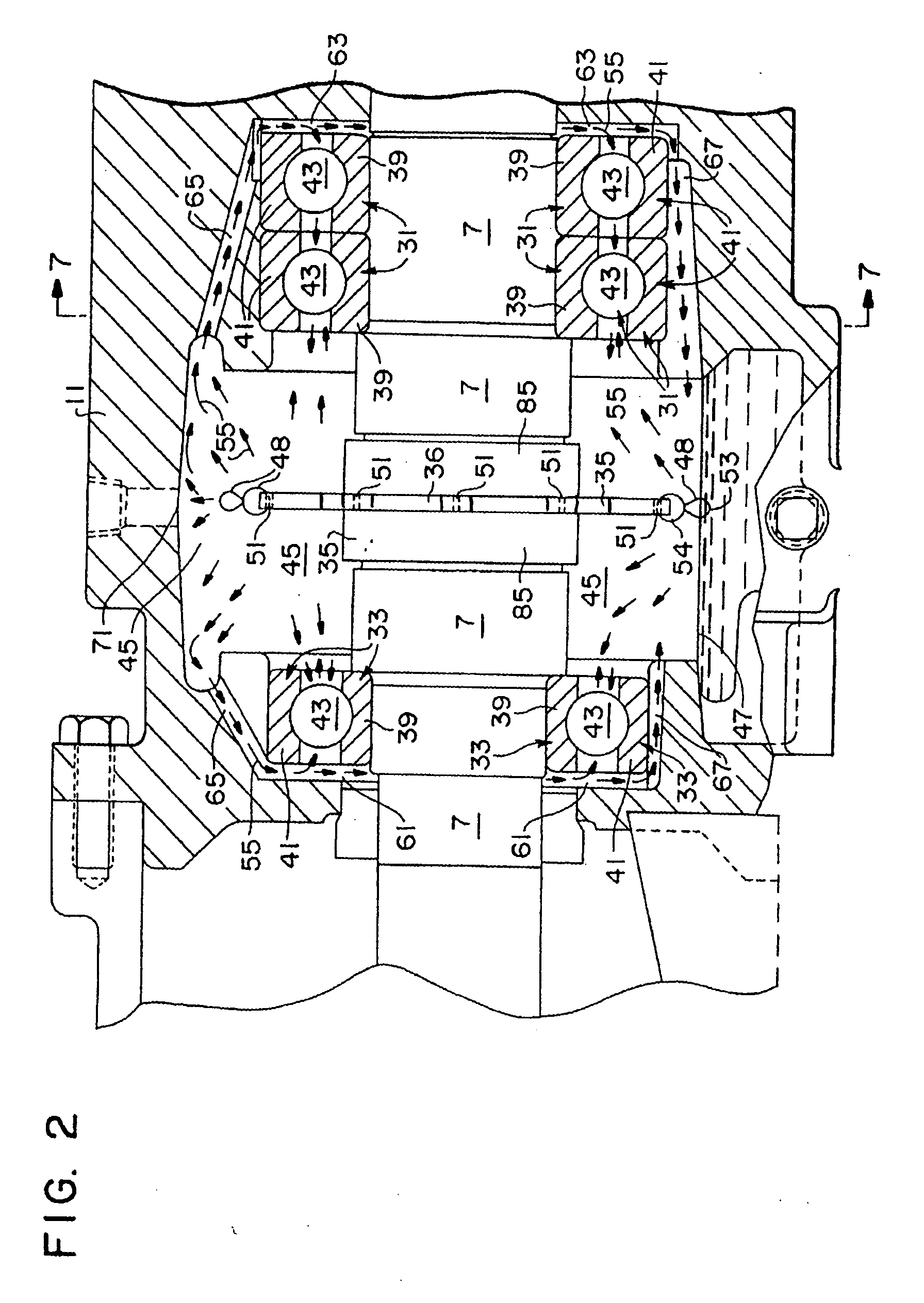

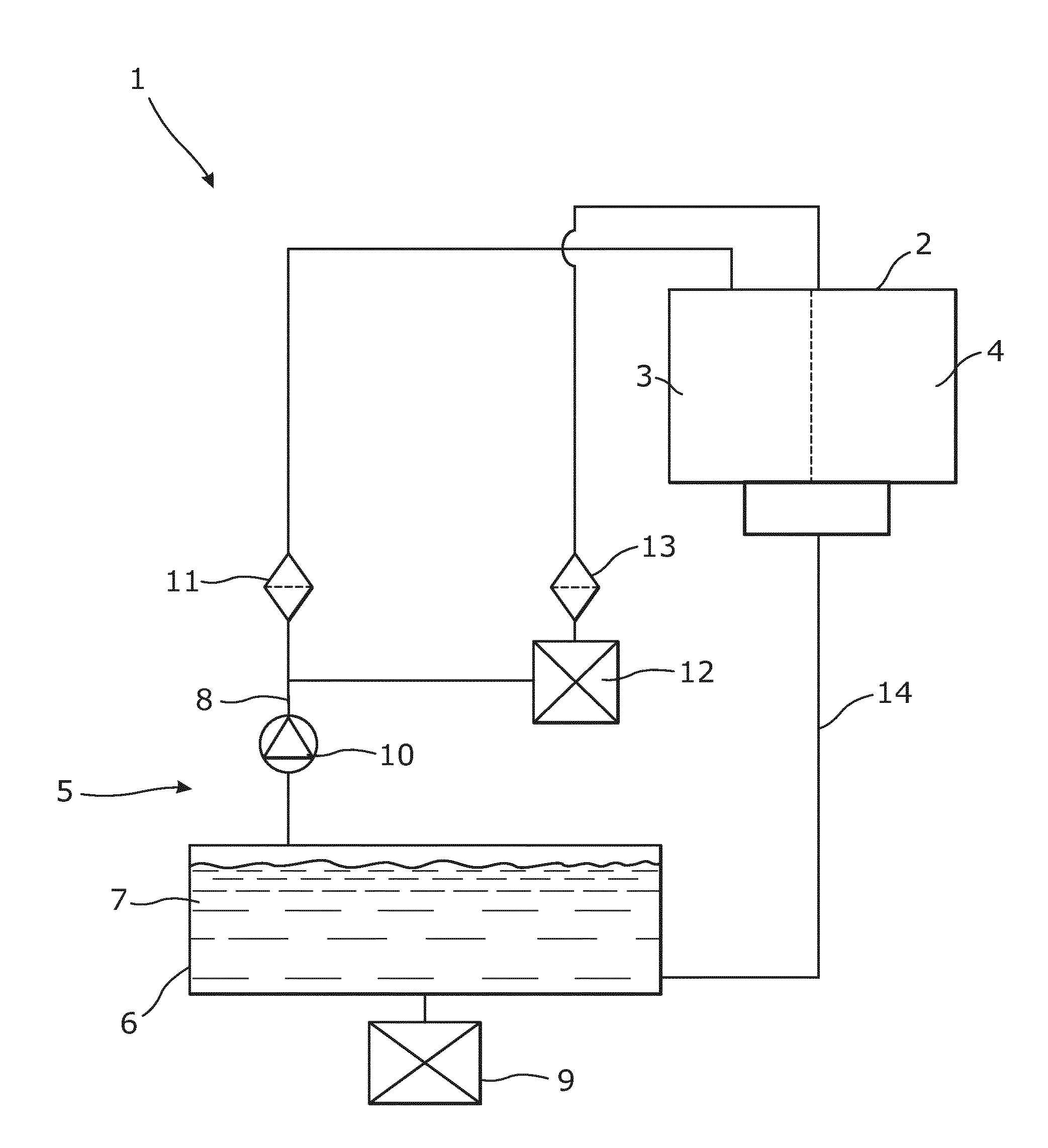

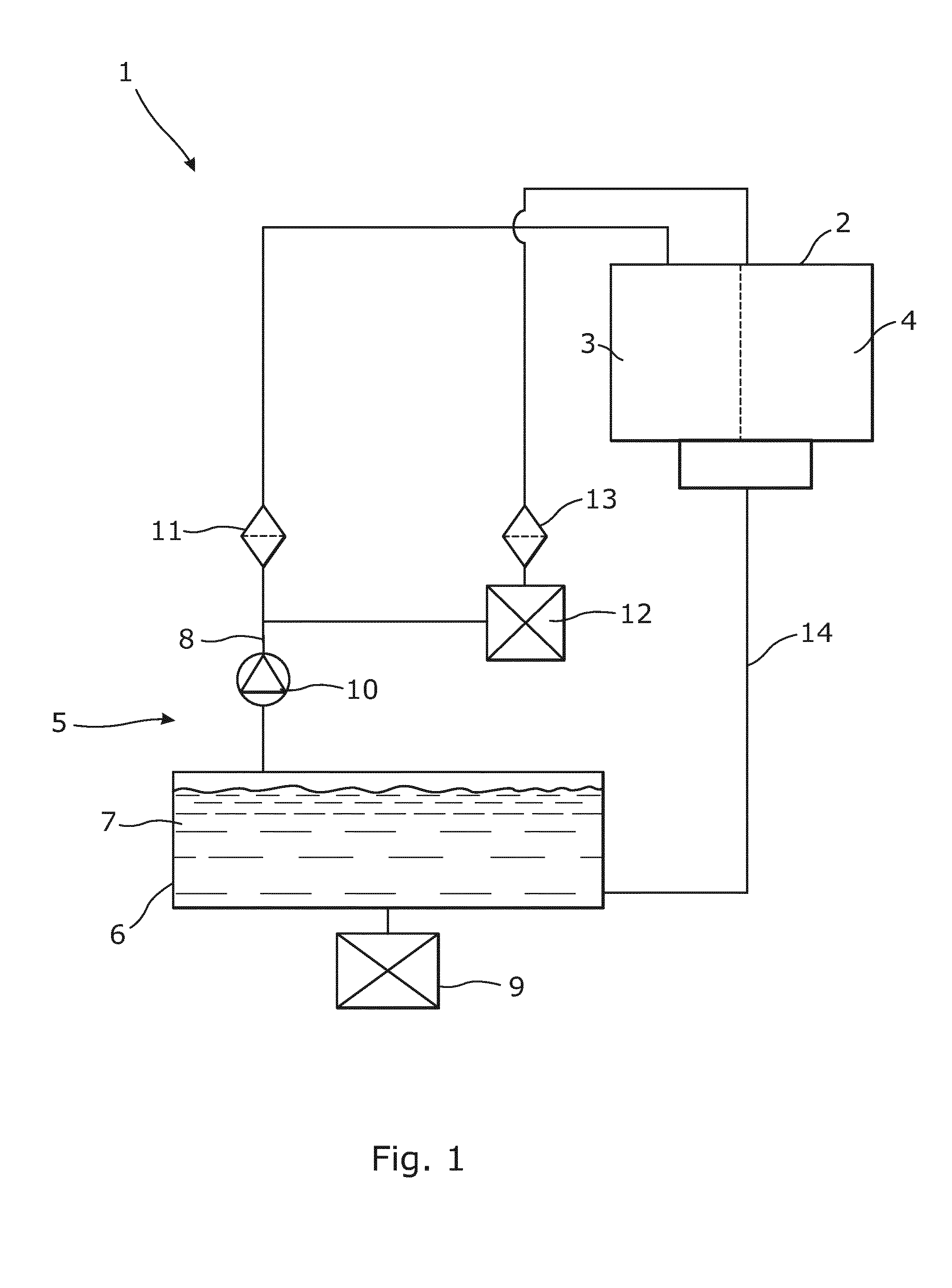

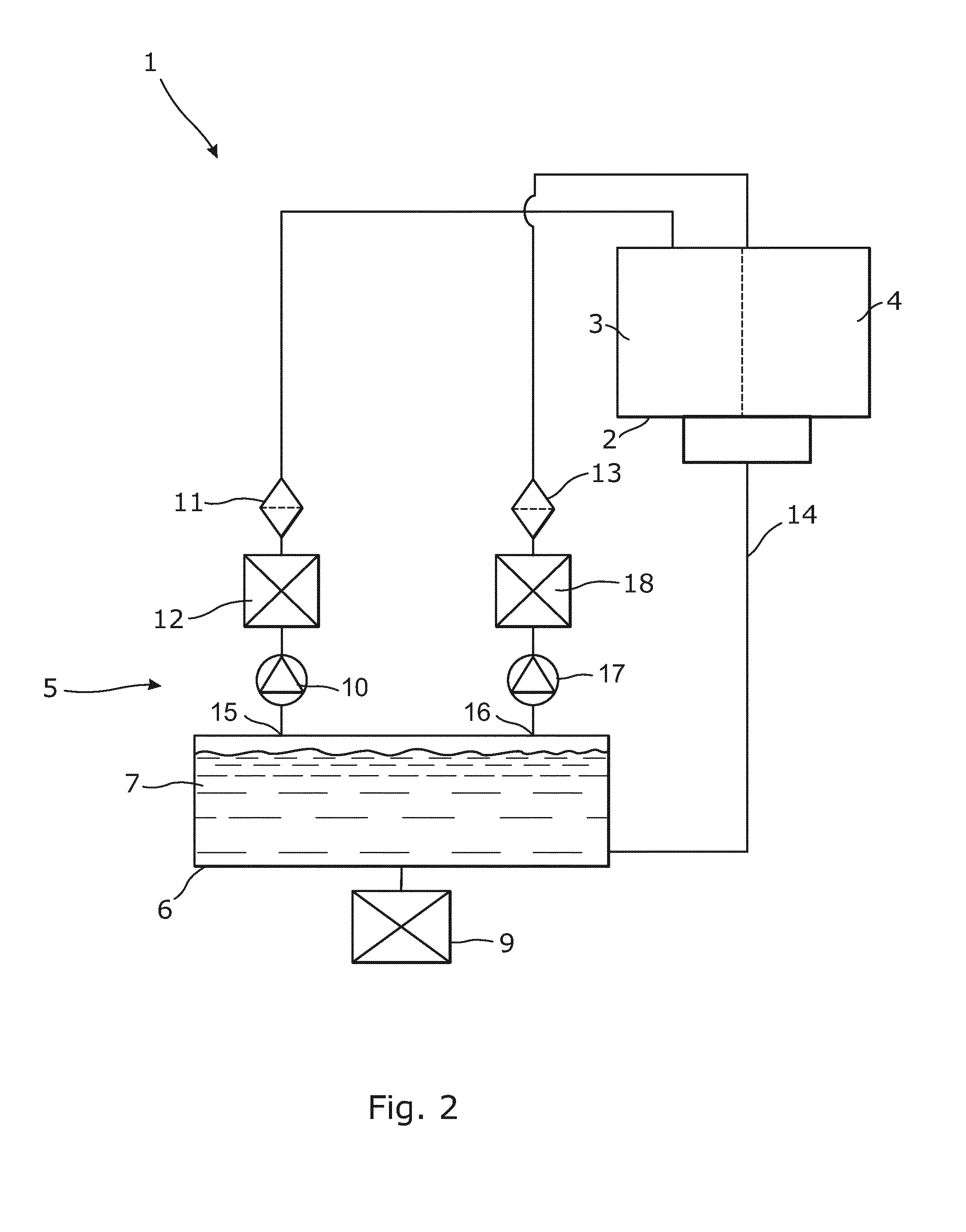

Machine system having a lubrication system

InactiveUS20130288843A1Optimize the lubrication systemExtended service lifeManual lubricationEngine fuctionsEngineeringMachining system

The present invention relates to a machine system comprising a machine having at least a first section and a second section, the first section having a first velocity and the second section having a second velocity, the second velocity being different from the first velocity, and a lubrication system comprising at least one tank having one lubricant, the lubrication system being connected to the first and second sections. Furthermore, the invention relates to a wind turbine comprising the machine system.

Owner:VESTAS WIND SYST AS

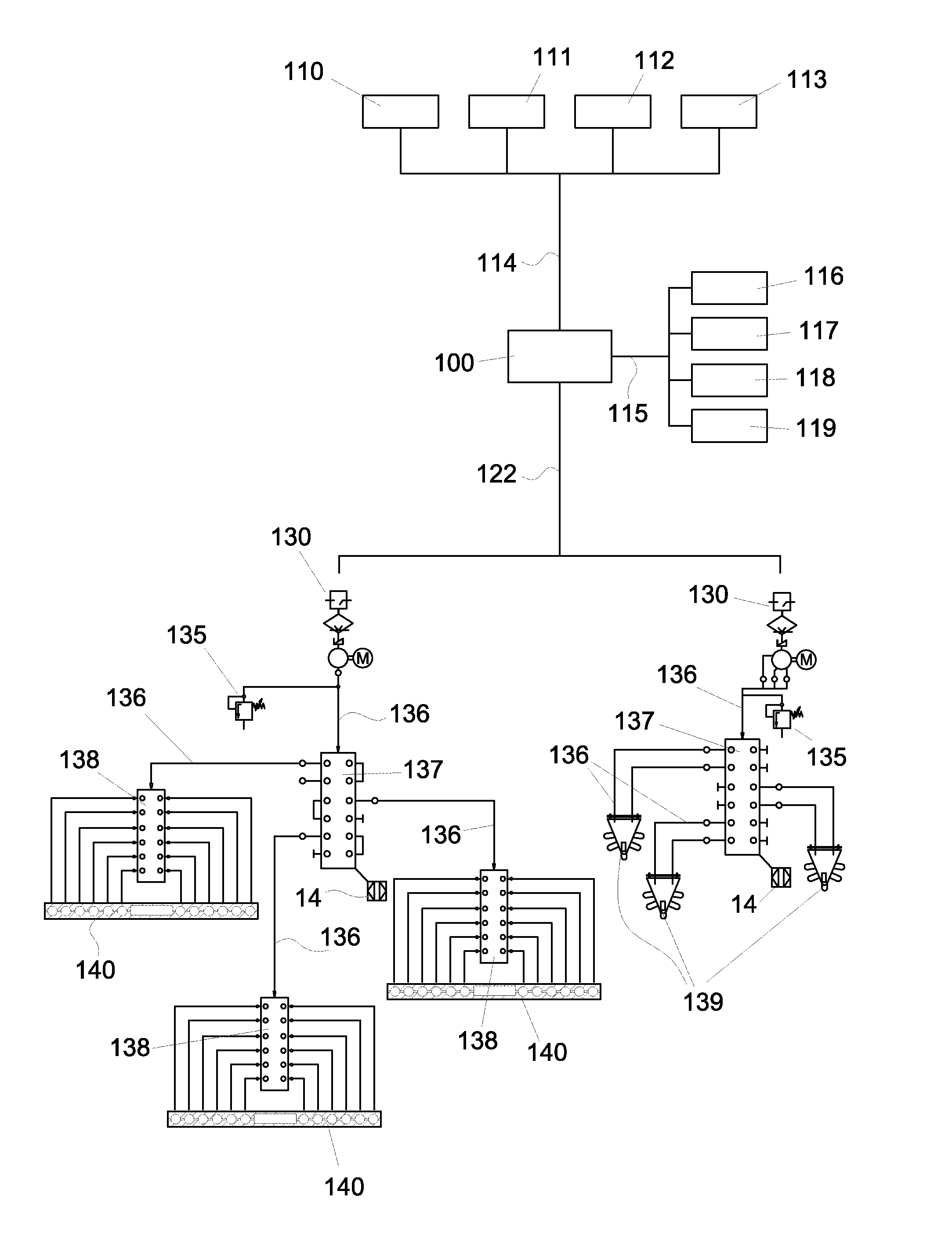

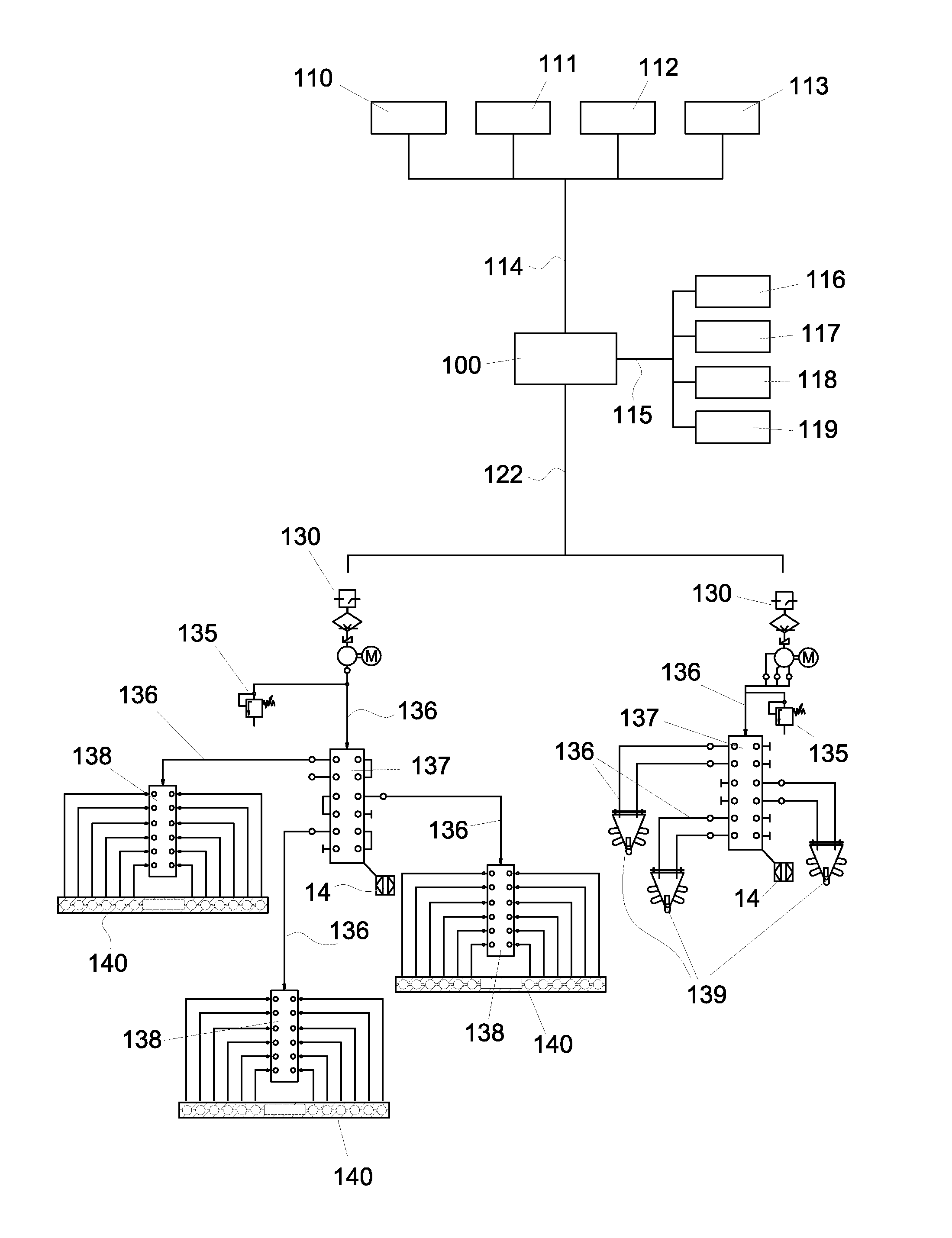

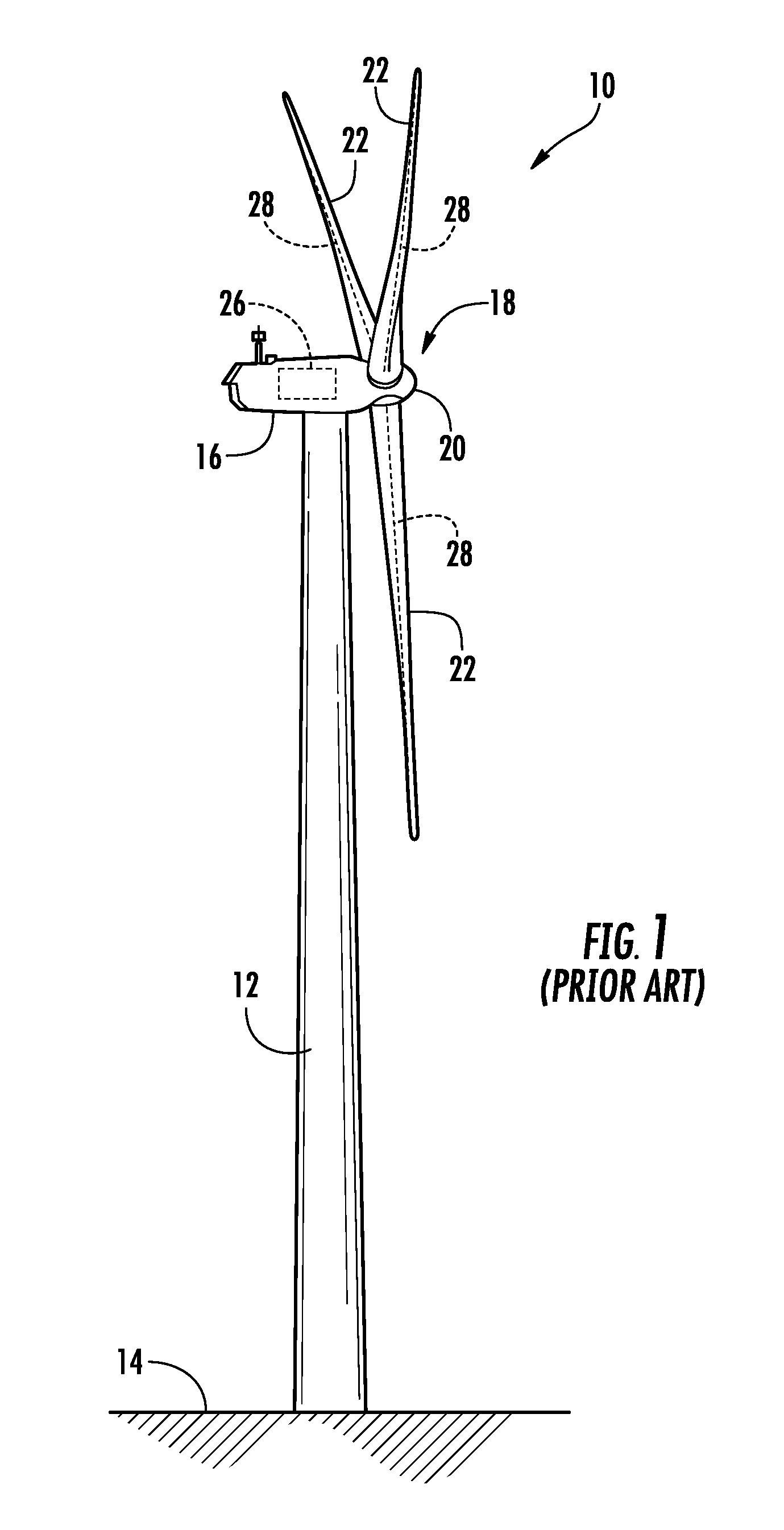

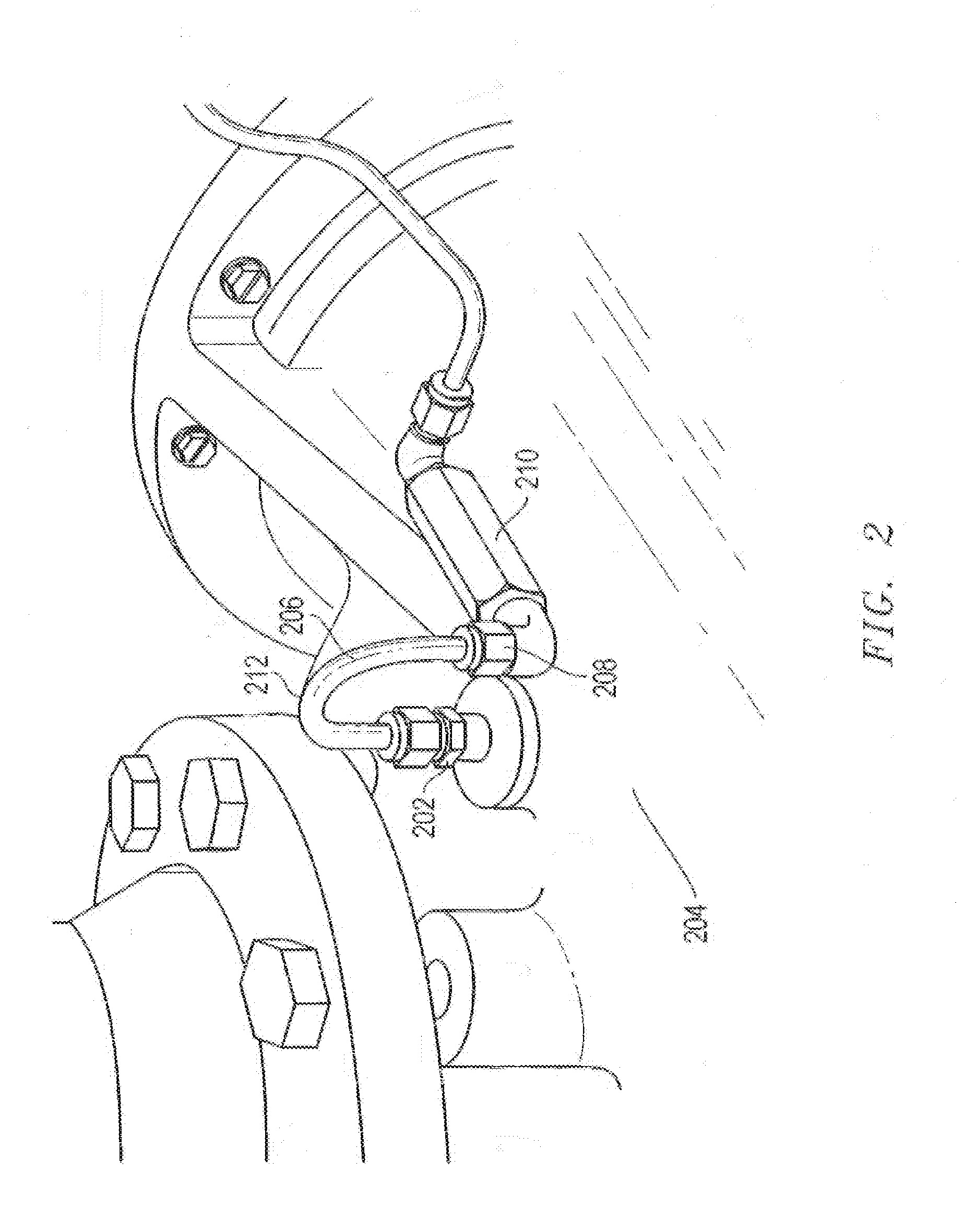

Method for dynamically lubricating a wind turbine pitch blade bearing

ActiveUS20100068055A1Optimized grease consumptionIncreased pitch bearing life-timePropellersWind motor controlTurbineLubrication

The method consists in determining at least one of wind turbine operating conditions or parameters related to pitch activity 116-119; determining if lubrication is needed depending on at least the operating conditions or the pitch activity parameters 116-119; and causing lubrication of the pitch blade bearing if lubrication is determined to be needed. Lubrication may consist in injecting grease during a period of time and causing the blades of the wind turbine to be rotated if necessary during grease injection. The device includes means for determining wind turbine operating conditions, means for determining parameters related to pitch activity, a wind turbine main control 100 for determining if lubrication is needed depending on operating conditions and pitch activity parameters 116-119, and means for causing lubrication of the pitch blade bearing if lubrication is needed.

Owner:GE RENEWABLE TECH WIND BV

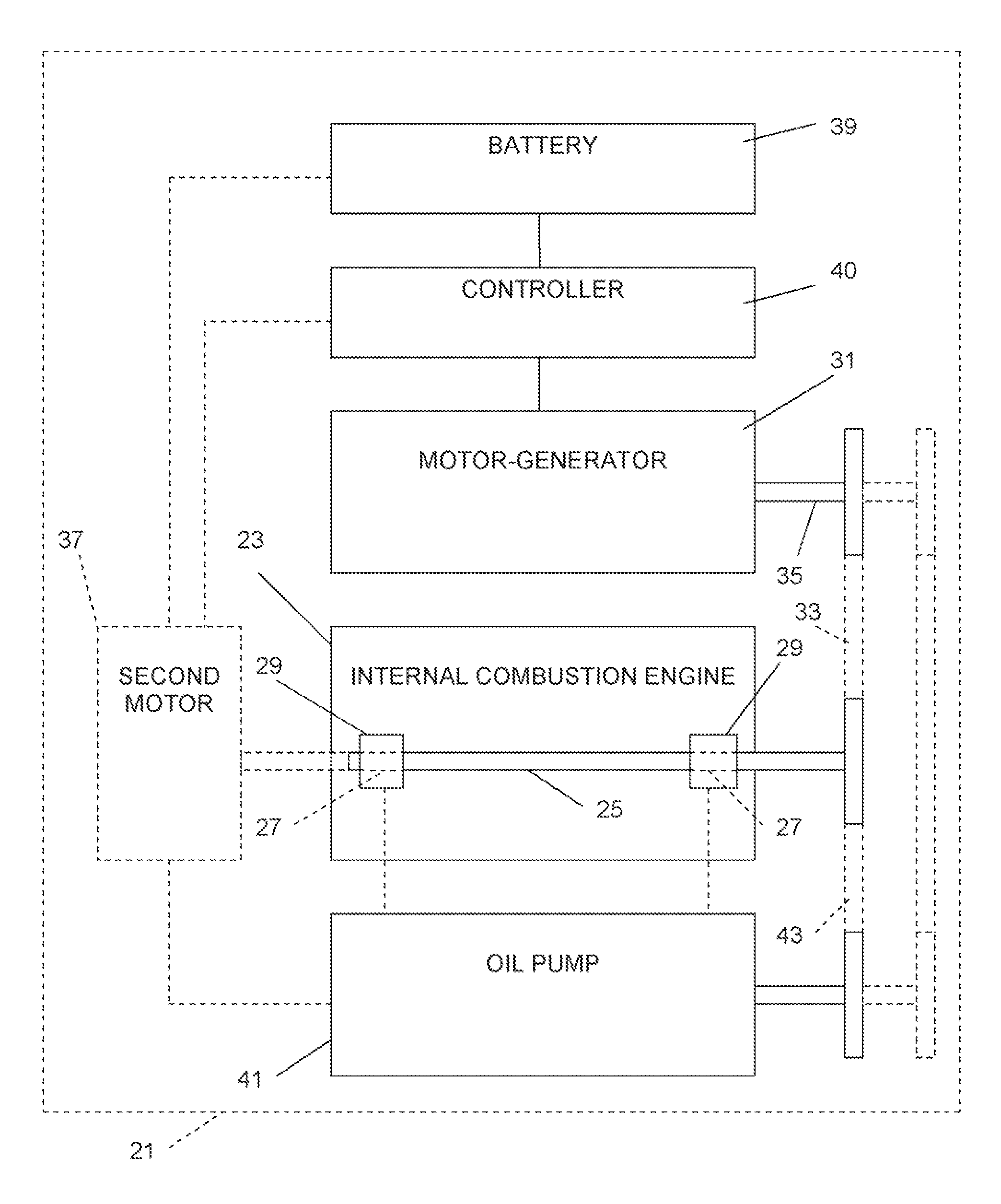

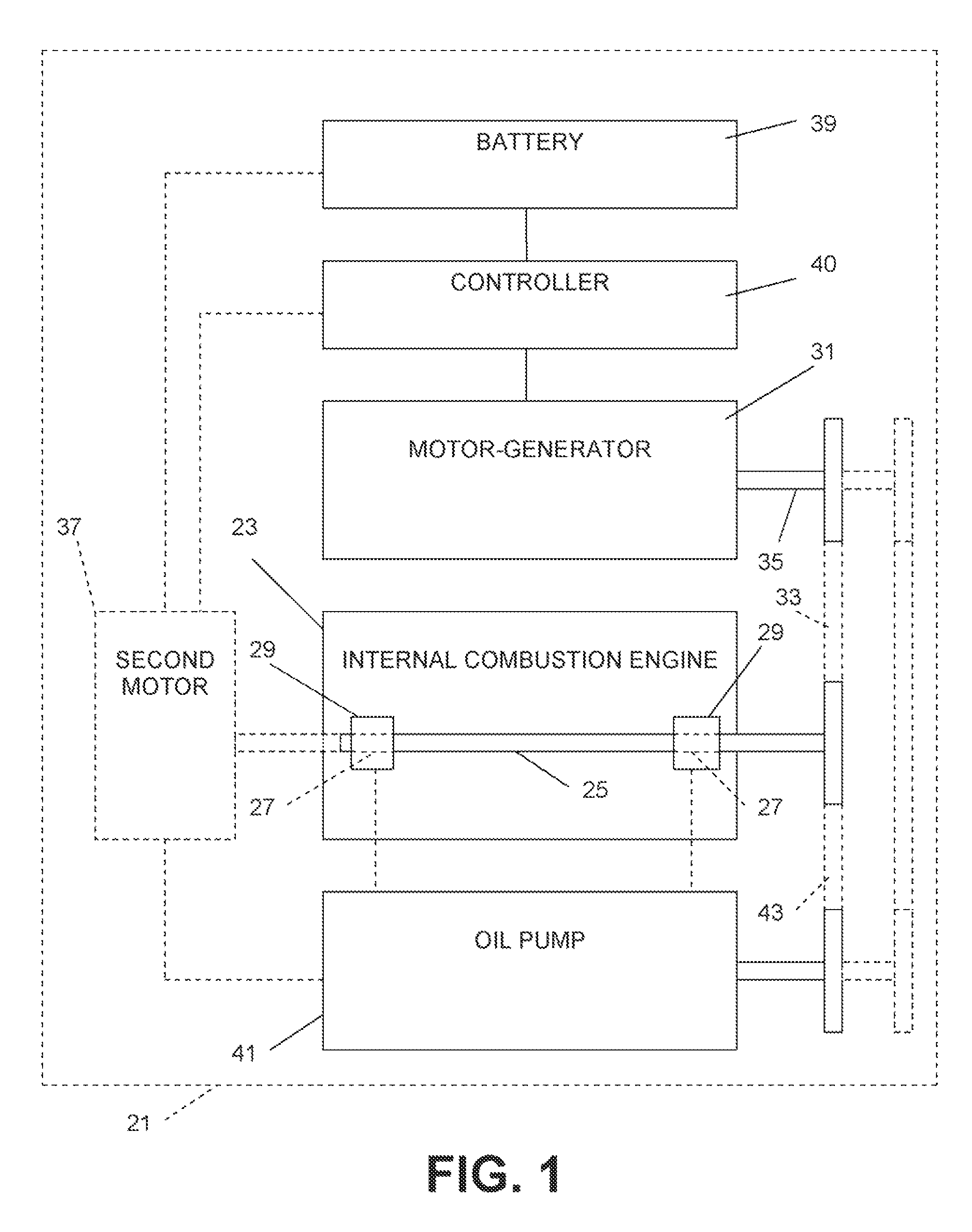

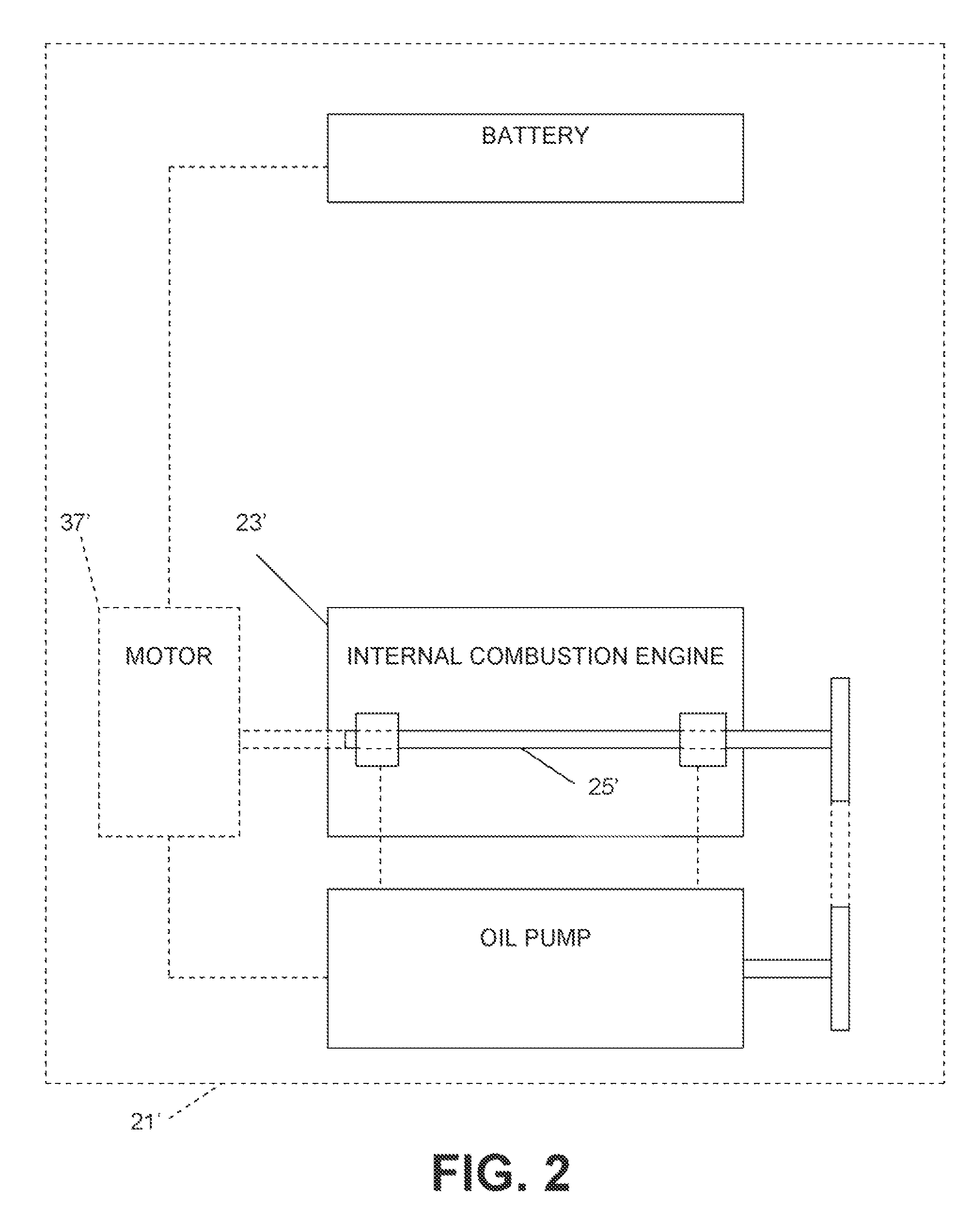

Internal combustion engine including crankshaft that is rotated while engine is in a non-fueled mode and method of operating an engine

ActiveUS9157347B2Analogue computers for vehiclesAuxillary drivesExternal combustion engineInternal combustion engine

A method of operating an engine includes starting and stopping operation of an internal combustion engine that includes a crankshaft having a bearing journal and a bearing in which the bearing journal is rotatable. The crankshaft is constantly turned when the internal combustion engine is in the non-fueled mode. An oil pump can be driven to lubricate the bearing journal and the bearing while the internal combustion engine is in the non-fueled mode to provide hydrodynamic lubrication. An engine is also disclosed.

Owner:VOLVO LASTVAGNAR AB

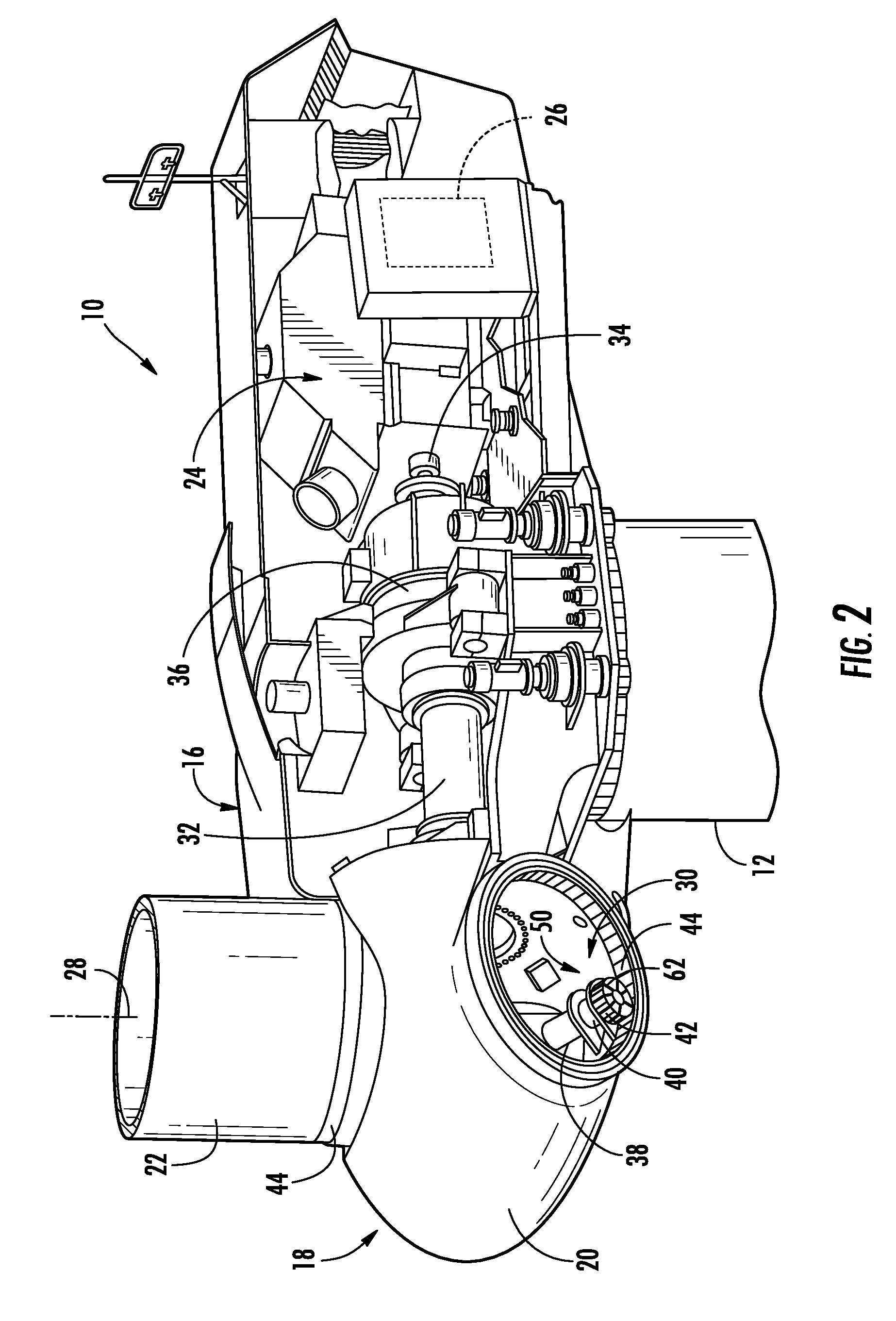

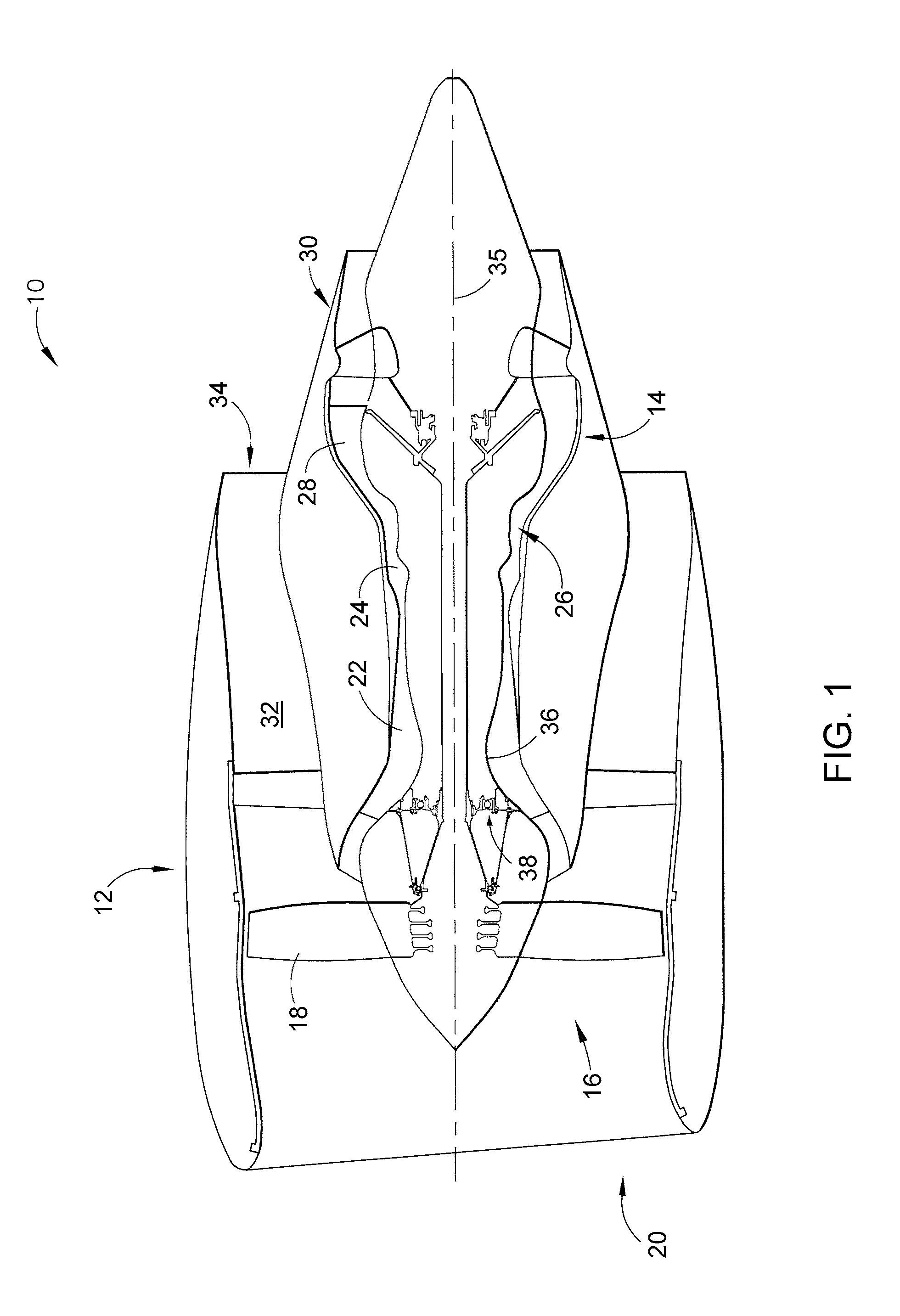

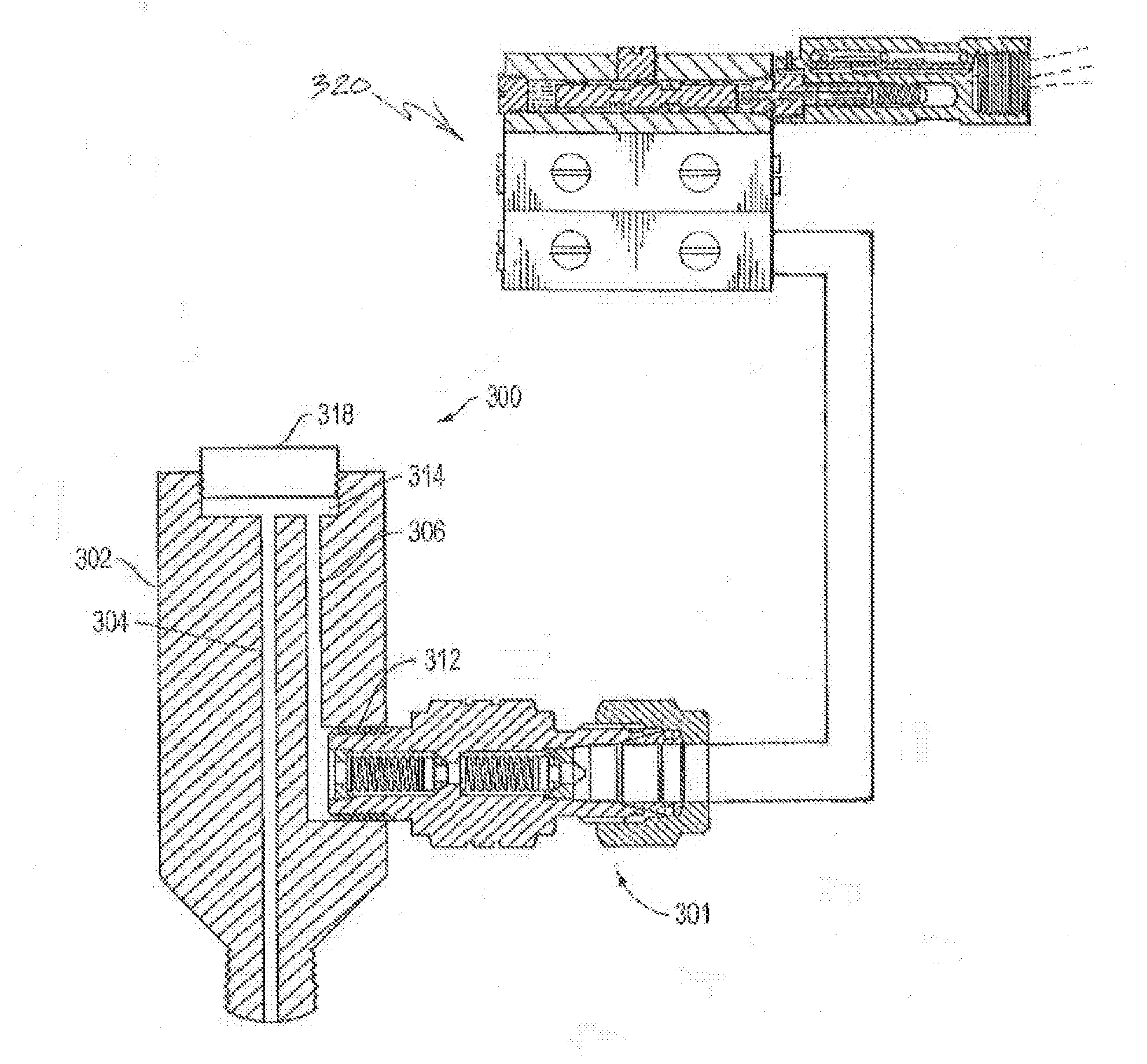

System and method for lubricating gears in a wind turbine

A system and method for lubricating gears in a wind turbine blade pitch drive are provided, wherein the pitch drive comprises a drive pinion gear with gear teeth that engage a pitch bearing gear coupled to a respective wind turbine blade. A grease distributor is configured to mount onto and rotate with the pinion gear, and is configured to deliver grease from an external grease supply to at least one valley defined between adjacent teeth of the pinion gear in a contact area of the pinion gear with the bearing gear without the distributor contacting inter-engaging teeth of the bearing gear.

Owner:GE INFRASTRUCTURE TECH INT LLC

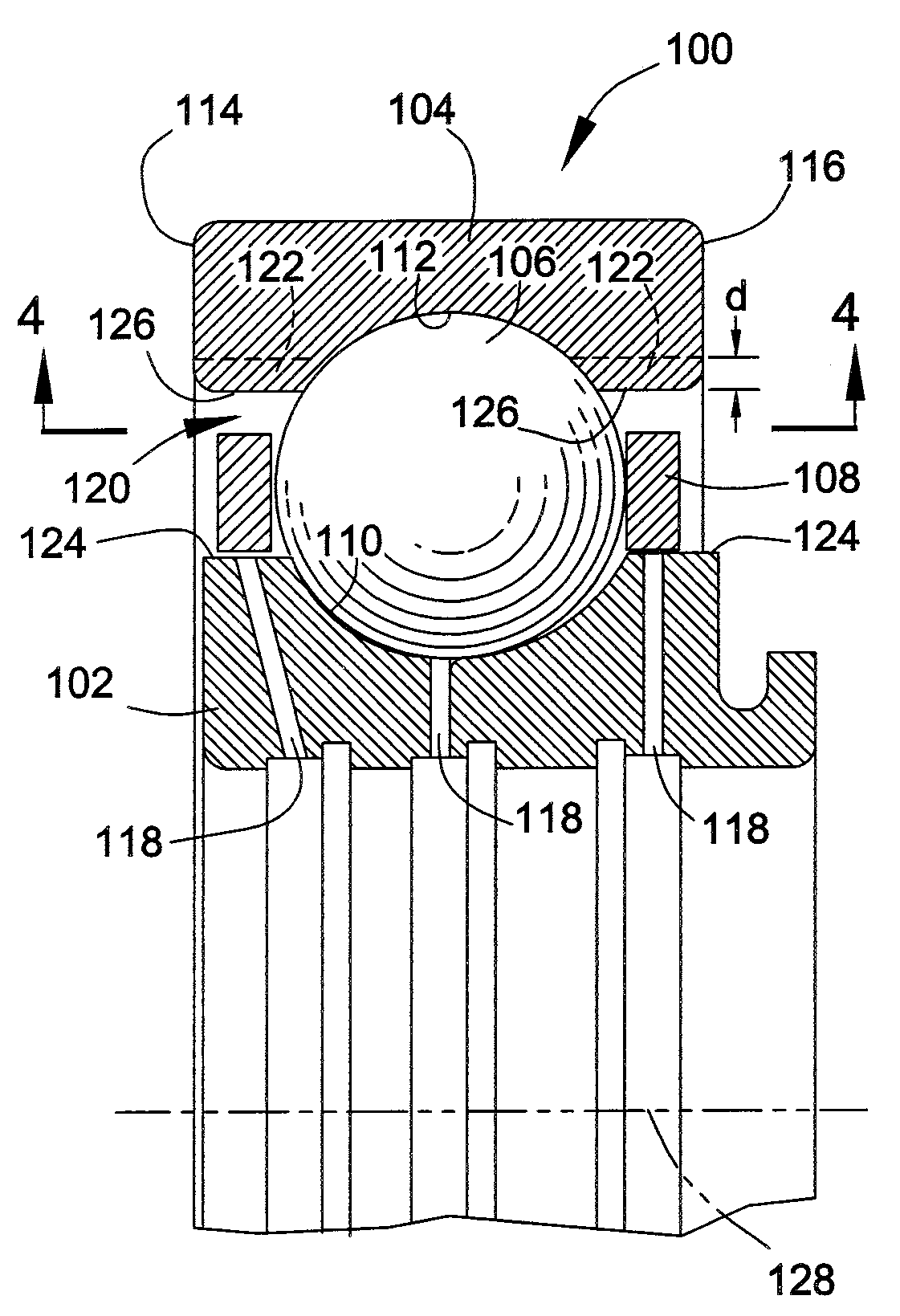

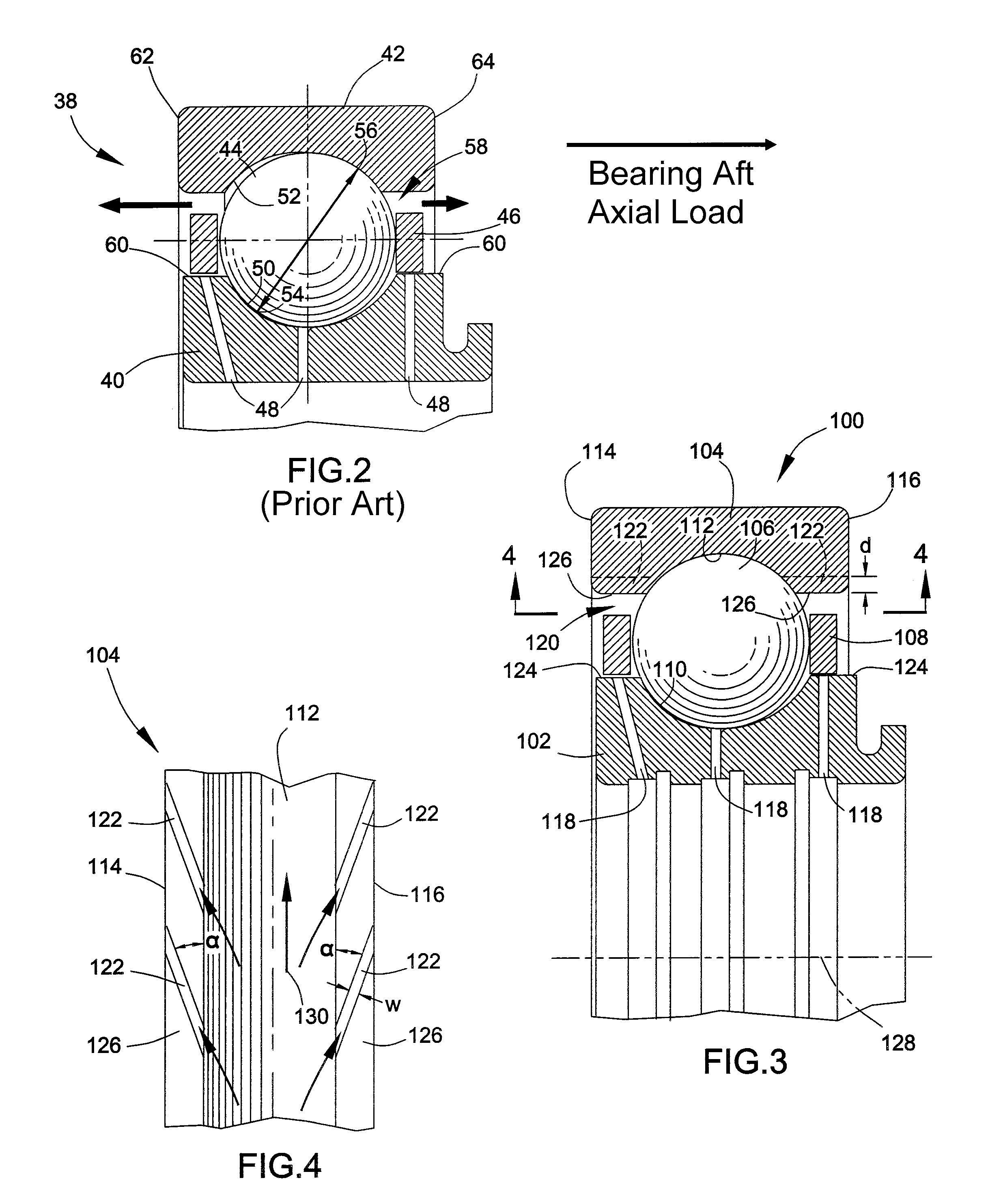

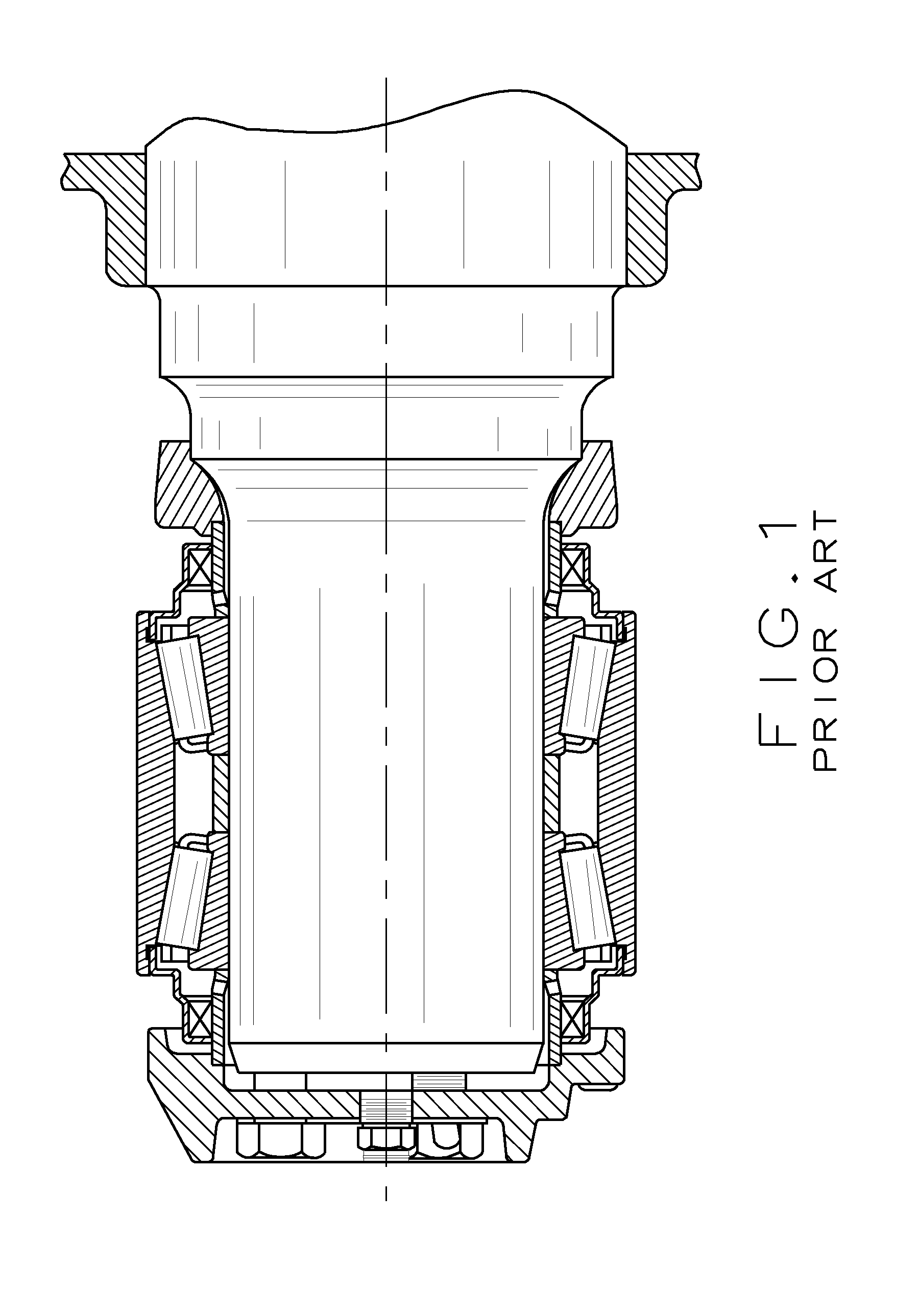

Dynamically-lubricated bearing and method of dynamically lubricating a bearing

InactiveUS9033581B2Low heat generationIncrease speedRolling contact bearingsManual lubricationGas turbinesLubricant

Dynamically-lubricated bearings and methods of dynamically lubricating bearings, including bearings used in gas turbine engines. Such a bearing includes an inner race having an inner race groove between a pair of inner race cage lands, an outer race having an outer race groove between a pair of outer race cage lands and opposes the inner race groove, rolling elements disposed between the inner and outer races and in rolling contact with the inner and outer race grooves, and a cage disposed between the inner and outer races to maintain separation between the rolling elements. A lubricant is introduced into a cavity between the inner and outer races, and rotation of the inner race relative to the outer race causes the lubricant to exit the cavity through recessed surface features in at least one of the inner and outer race cage lands.

Owner:GENERAL ELECTRIC CO

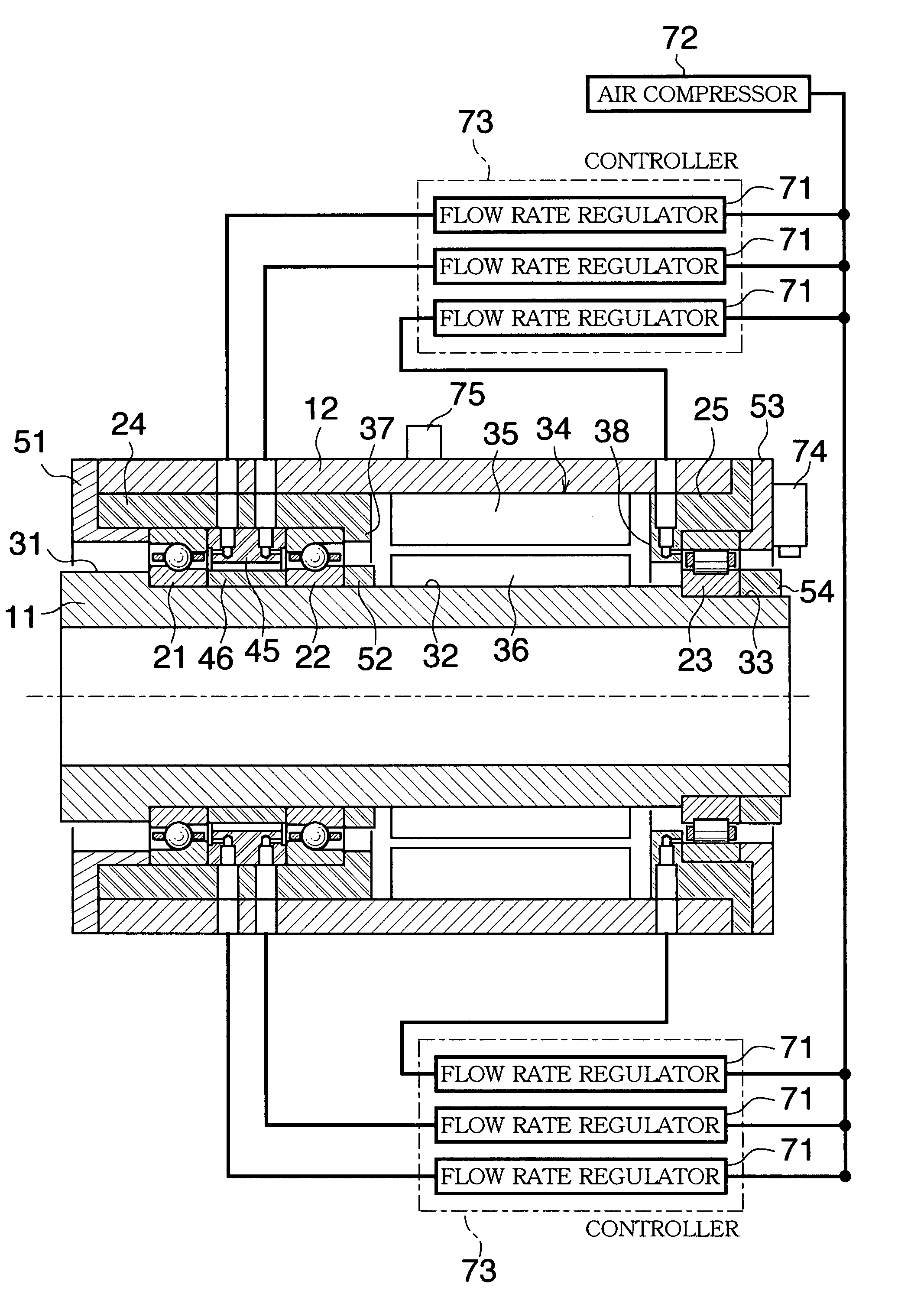

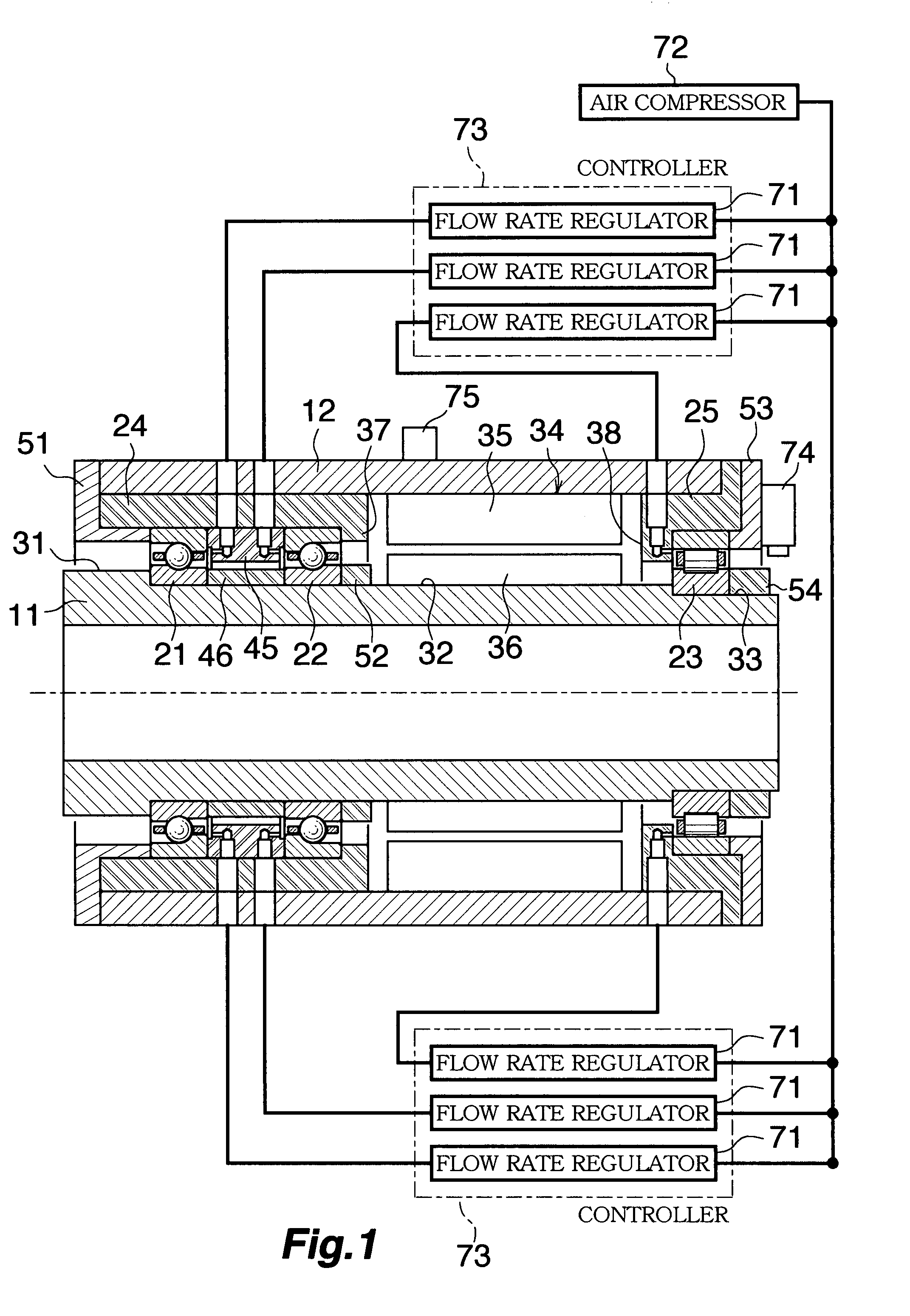

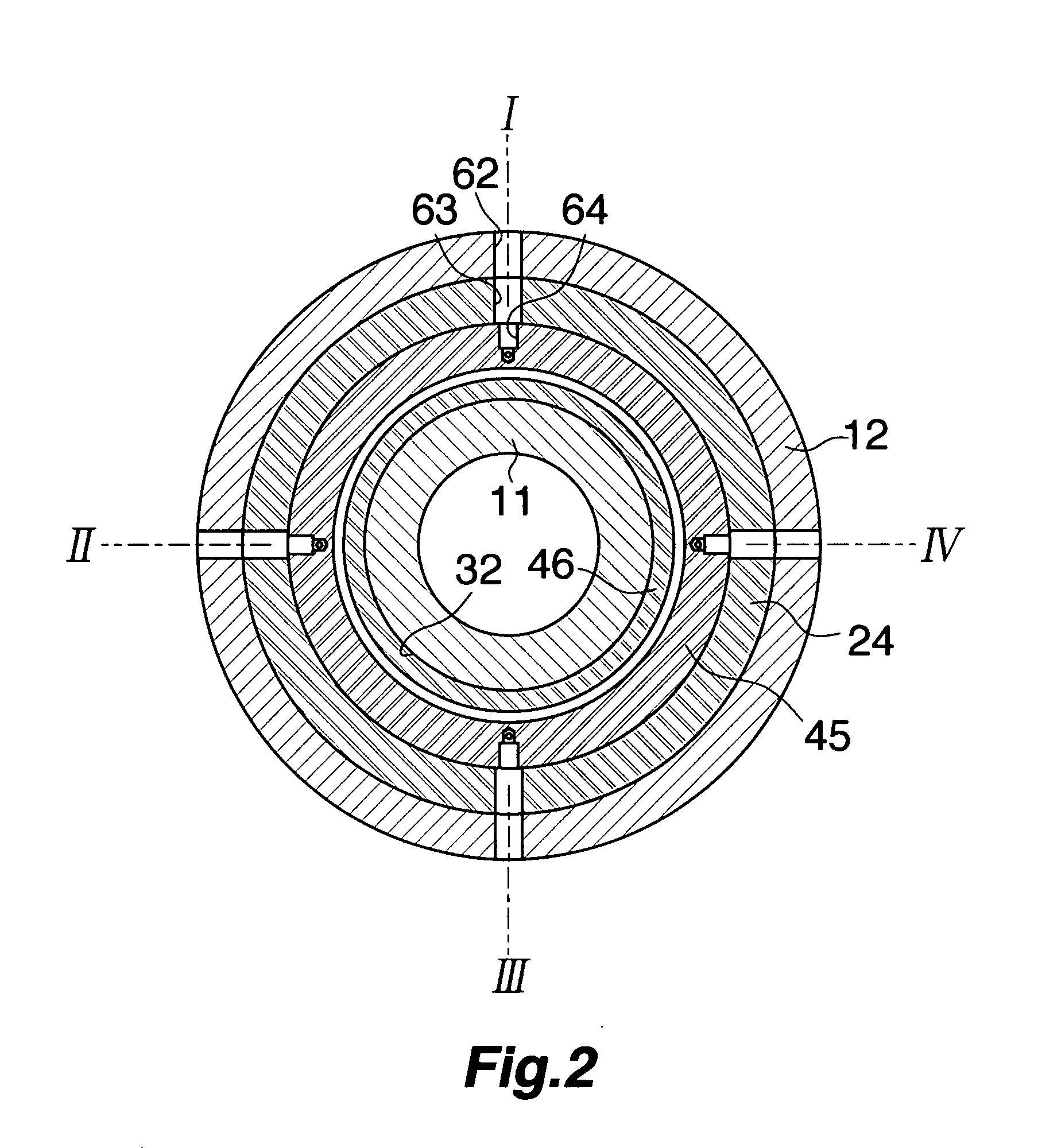

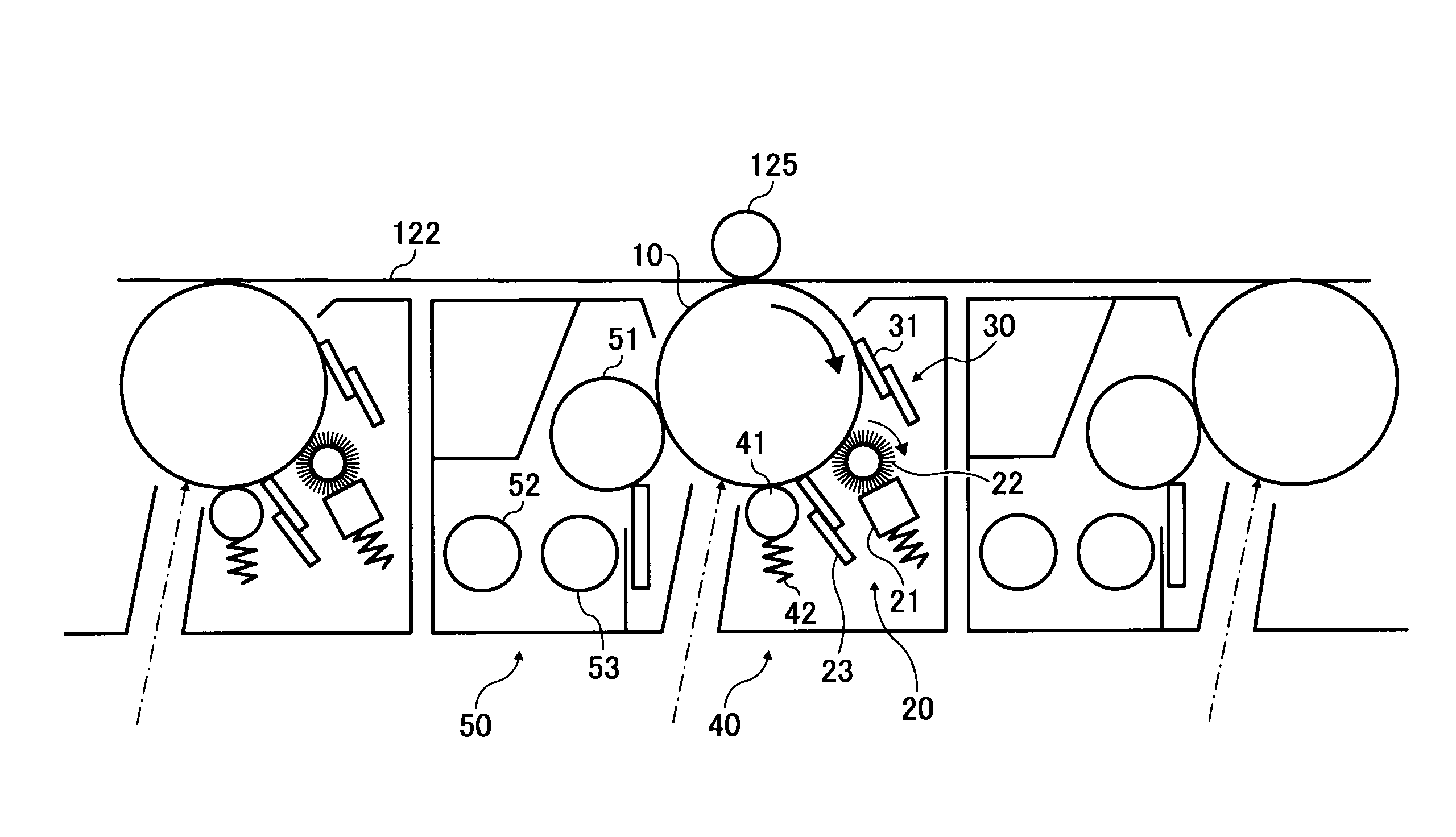

Spindle device

InactiveUS20080093175A1Imbalance in the retainer can be reducedReduce flow rateRolling contact bearingsShaftsEngineeringControl unit

An object of the present invention is to provide a spindle device for stabilizing a retainer with a minimum quantity of air to be supplied to the bearing. A spindle device includes: supplying unit which supplies air from three or more points spaced in a circumferential direction between outer races and inner races of bearings supporting a spindle; and control unit which controls a supply quantity of air supplied by the supplying unit in such a manner as to independently vary the supply quantity at each of the supplying points.

Owner:OKUMA CORP

Lubricant applicator, process cartridge and image forming apparatus including the same

An image forming apparatus includes a lubricant applicator and a process cartridge using the same. The lubricant applicator includes a solid lubricant, a lubricant retainer, a lubricant holder, a lubricant application mechanism, a pressure mechanism, a friction resistance reduction mechanism. The lubricant retainer holds the solid lubricant. The lubricant holder stores the solid lubricant and the lubricant retainer. The lubricant application mechanism applies the solid lubricant to an object. The pressure mechanism is provided between the lubricant retainer and the lubricant holder, and presses the lubricant retainer to push the solid lubricant from the lubricant holder. The friction resistance reduction mechanism is disposed at a position where the lubricant retainer and the lubricant holder come into contact in a frictionally sliding manner. The friction resistance reduction mechanism includes a protrusion provided on at least one of a surface of the lubricant retainer and an inner wall of the lubricant holder.

Owner:RICOH KK

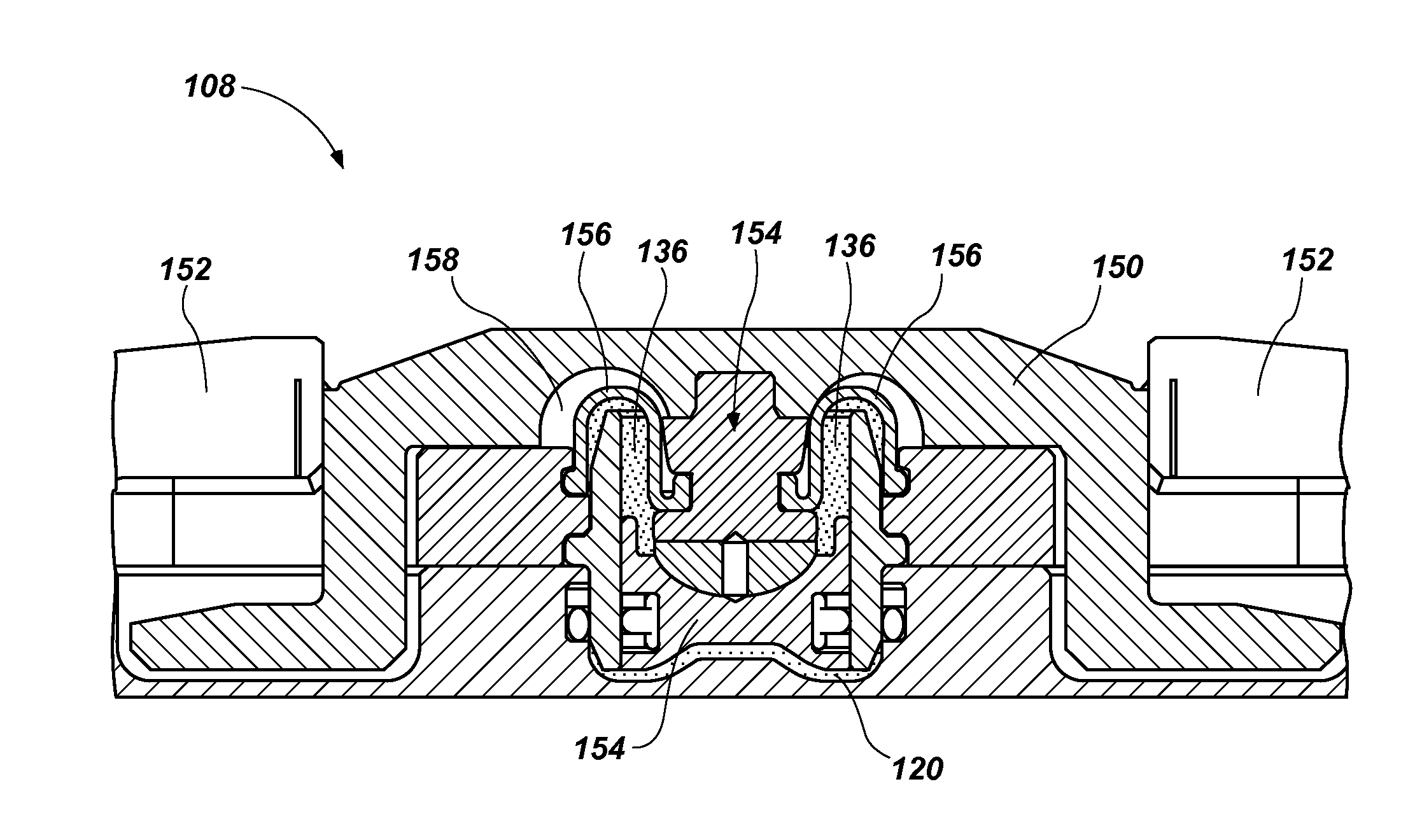

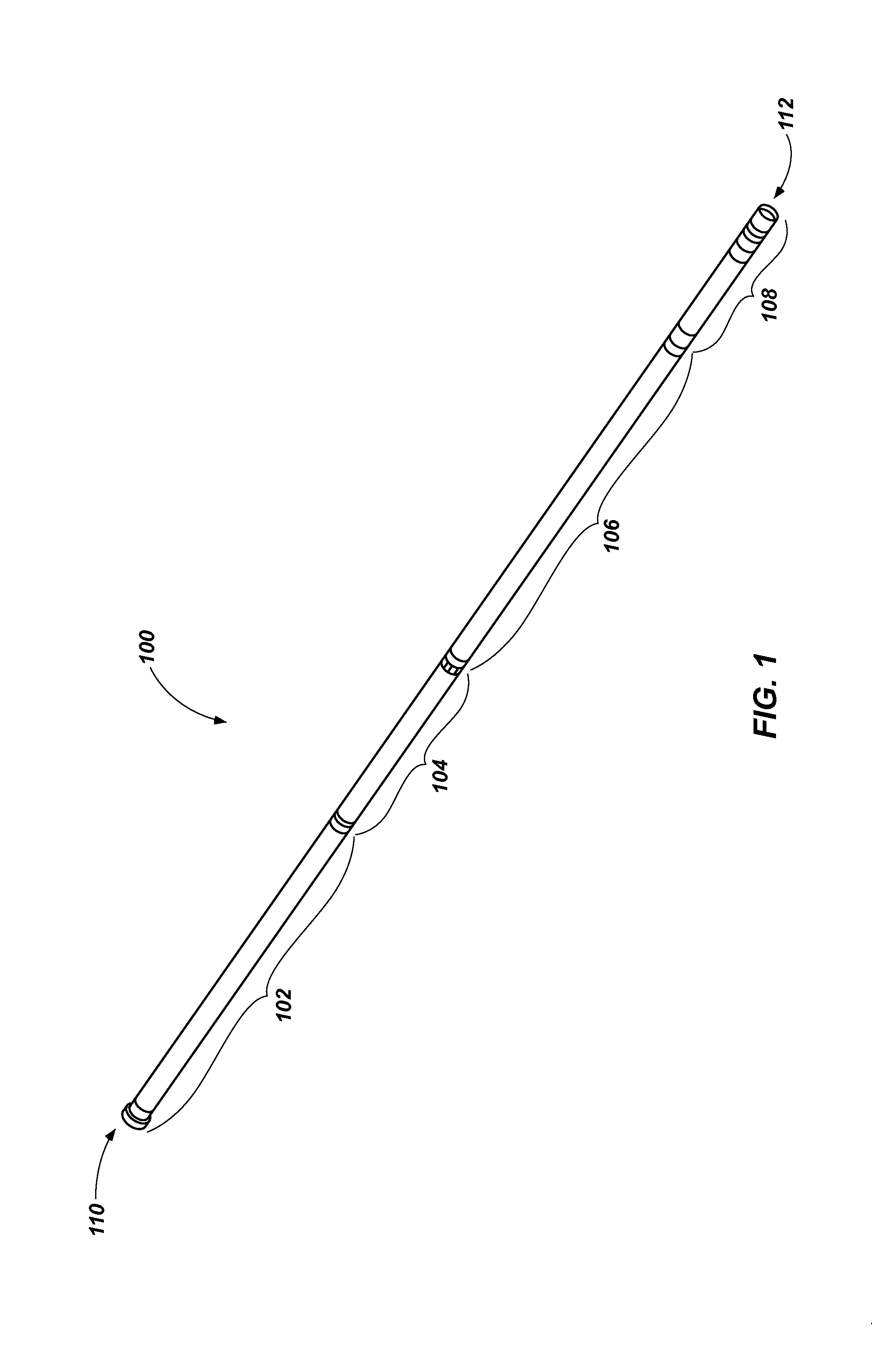

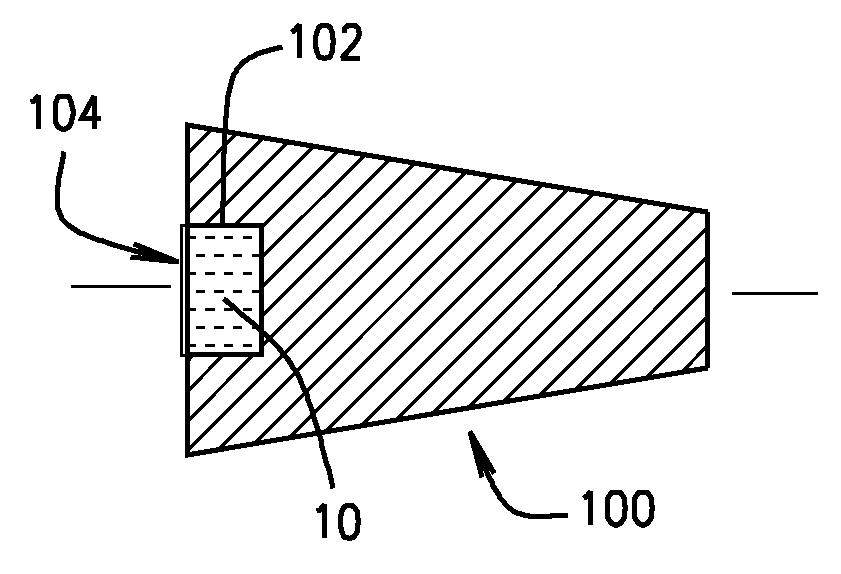

Wellbore tools with non-hydrocarbon-based greases and methods of making such wellbore tools

A wellbore tool includes a non-hydrocarbon-based grease disposed between a first component and a second component. The grease remains substantially impermeable to hydrocarbons at temperatures up to at least about 150° C. and possibly up to at least about 200° C., and pressures up to at least about 27 MPa and possibly to at least about 50 MPa. Methods of forming such wellbore tools include selecting a grease to comprise a non-hydrocarbon-based grease that remains at least substantially impermeable to hydrocarbons at temperatures up to at least about 150° C. and possibly up to at least about 200° C., and pressures up to at least about 27 MPa and possibly to at least about 50 MPa; and disposing the grease at an interface between a first component of a wellbore tool and a second component of a wellbore tool.

Owner:BAKER HUGHES INC

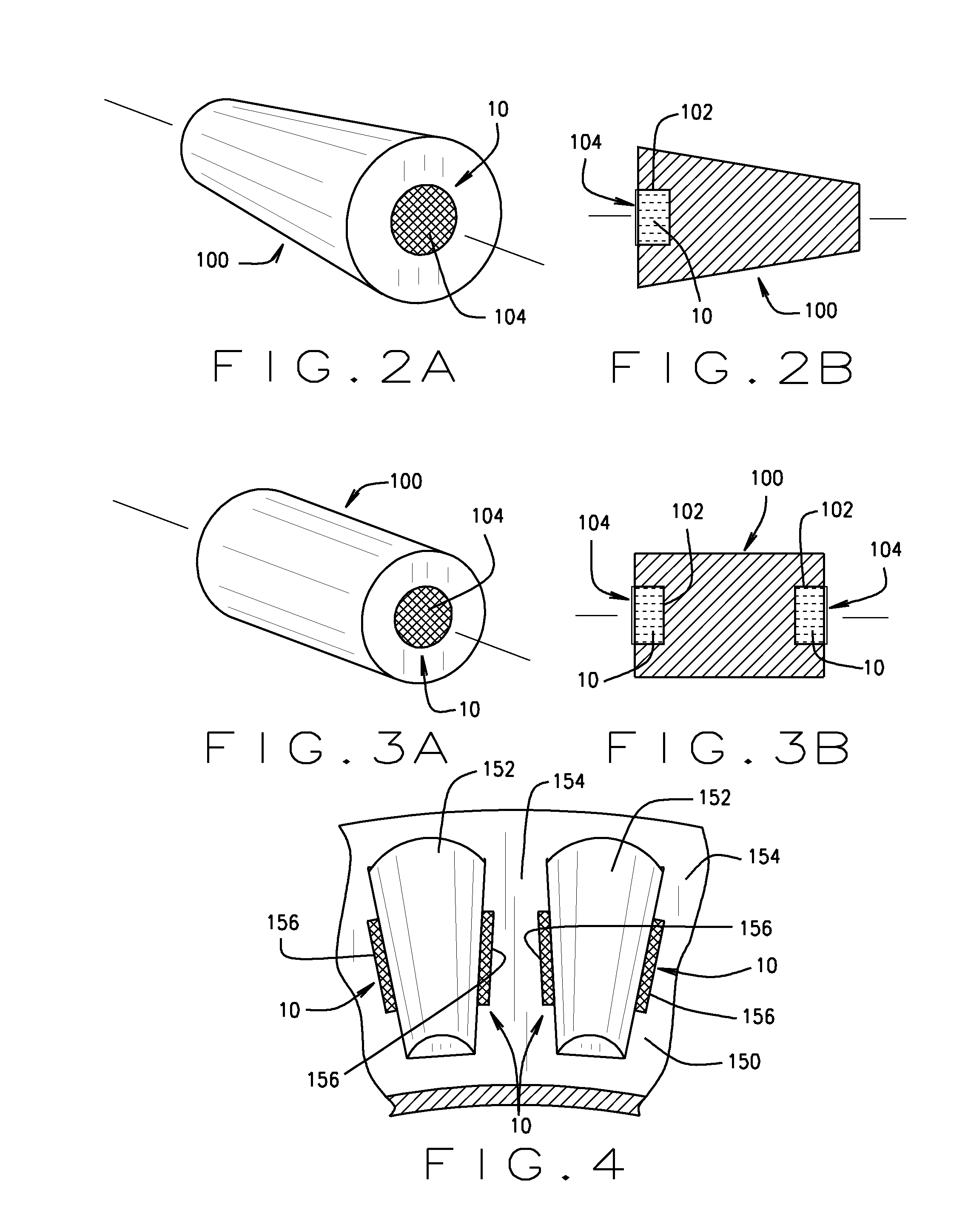

Apparatus and Method for Controlled Release of Lubricant Additives in Bearing and Gear Assemblies

ActiveUS20120170883A1Wear minimizationReduce oxidationRolling contact bearingsManual lubricationControlled releaseOil oxidation

A structure (200) for containing a volume of lubricant additive gel (10) which is disposed within a mechanical system, in close proximity to a wear critical surface, and which is configured to provide a release of the contained additives into a flow of lubricant over time or as a function of temperature in a site-specific manner to minimize wear or reduce oil oxidation due to harsh operating conditions. The structure defines a cage or capsule with screen or mesh sides (202) having multiple perforations or openings through which the flow of lubricant may circulate. Within the contained volume of the structure (200), additives are disposed in a gel matrix (10), and are release over time or as a function of temperature, through the perorations or openings, in close operative proximity to wear critical surfaces of the mechanical system such as a bearing assembly or gear arrangement.

Owner:THE TIMKEN CO

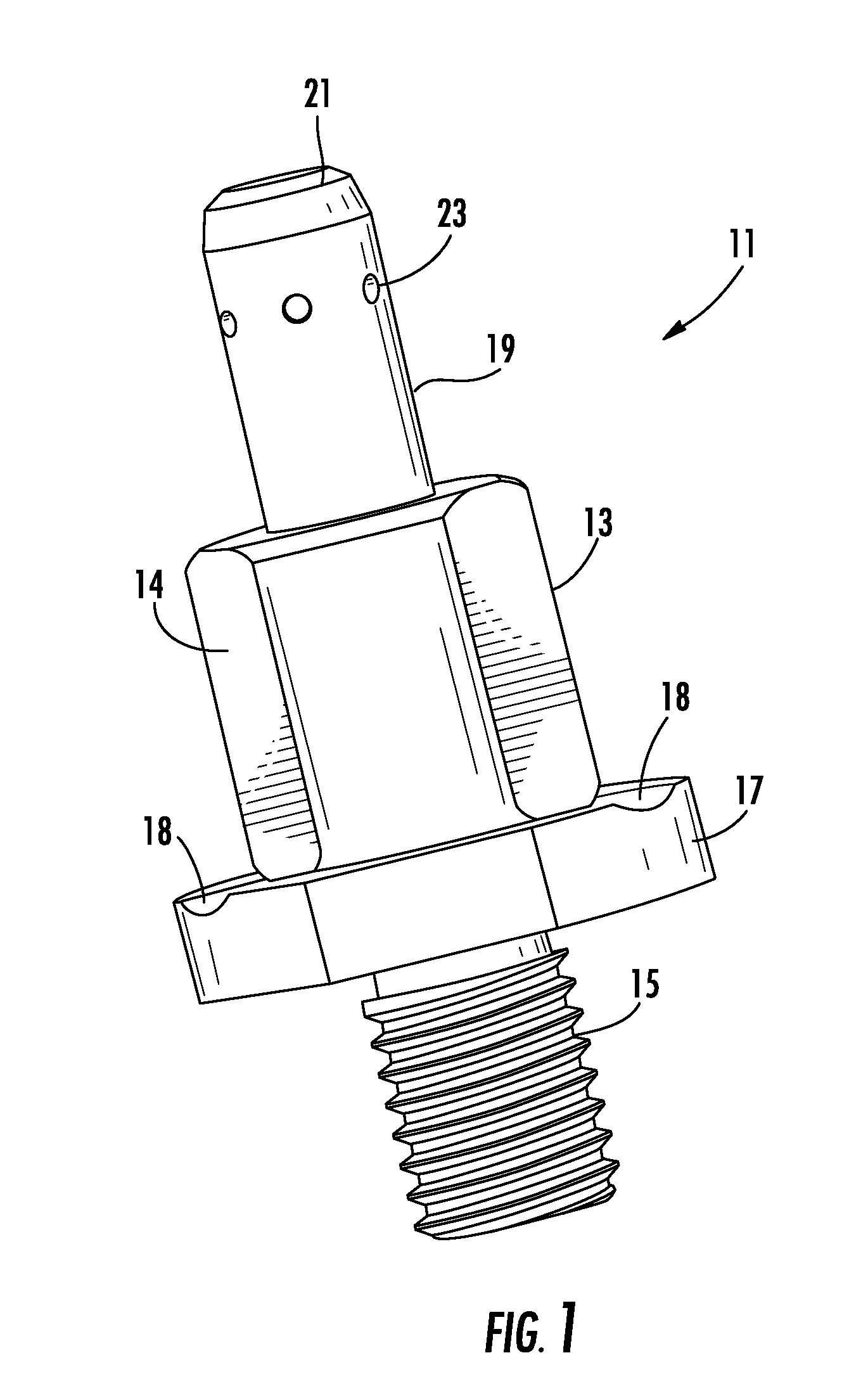

Check Valve and Method and Apparatus for Extending Life of Check Valve

ActiveUS20140000983A1Reduce check valve failureProlong lifePositive displacement pump componentsManual lubricationInjection pointCheck valve

A device and method are described for extending the life of check valves. An improved check valve having a double poppet and tapered guides is more robust, and a check valve protection device between the check valve and the environment into which fluid is injected protects the valve from a contaminating or corrosive environment. The check valve and check valve protection device are small and light weight to prevent vibration-induced failures. The check valve protection device preferably has an interior volume that fills quickly by relatively few cycles of the lubricant pump to reduce delay of lubricant to the injection point.

Owner:COMPRESSOR PROD INT

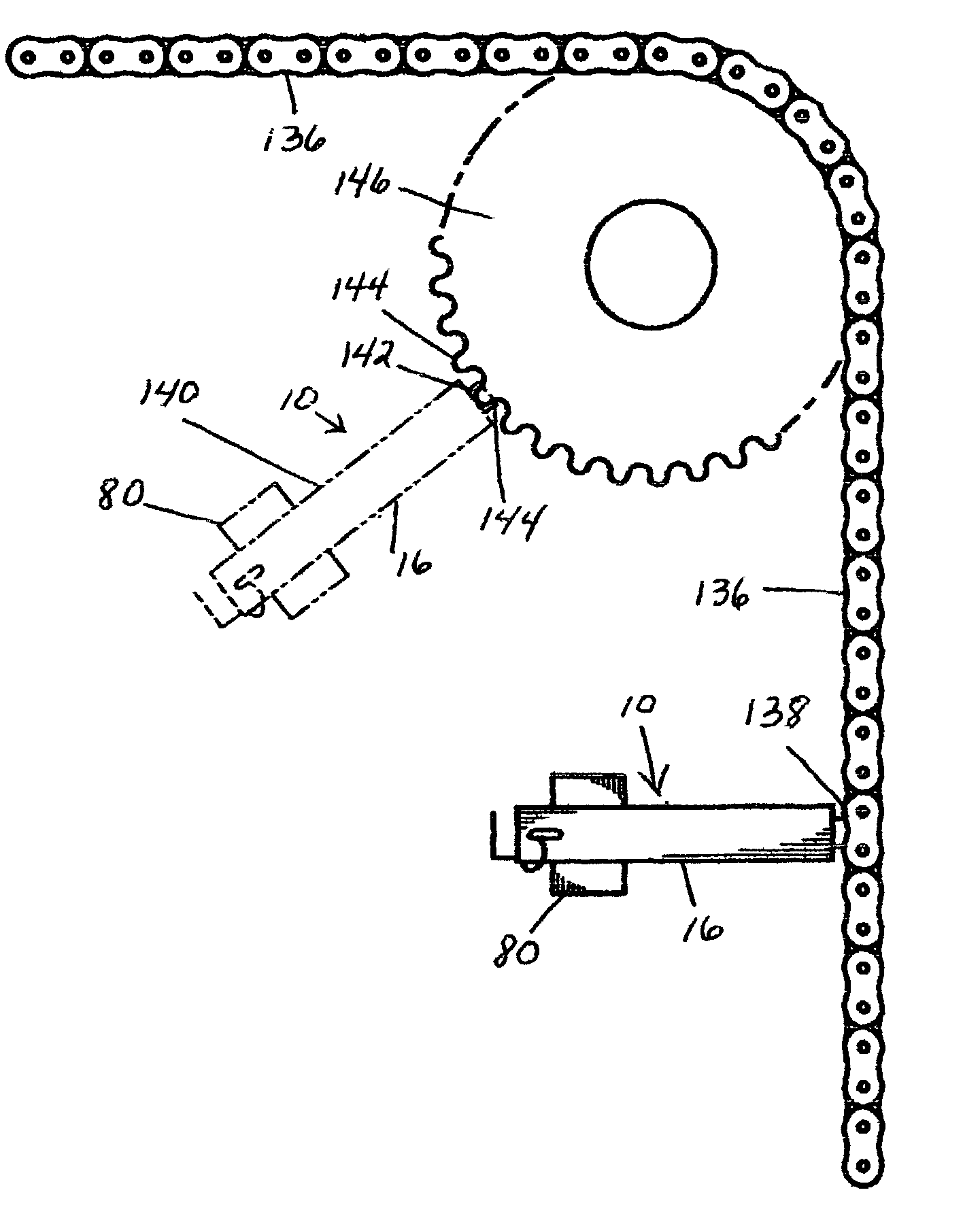

Lubricant applicator

InactiveUS7108104B2For quick replacementWithout usingRailway wheel guards/bumpersNon-pressurised lubricationConstant forceLubricant

A lubricant applicator for disposing lubricant onto a metal surface. The lubricant applicator generally includes a combination holder and dispenser. Lubricant is disposed from the same portion of the combination holder and dispenser as the lubricant was inserted, in the rear portion of the combination holder and dispenser. A dispensing system applies constant force to the rear portion of the combination holder and dispenser so that lubricant is disposed from the rear portion and out of the front portion of the combination holder and dispenser. Lubricant, generally in the form of a stick, can therefore be easily replaced without removing the applicator from its location or without removing its mounting arrangement. Various applications and mounting arrangements for the lubricant applicator are disclosed, as is a method for providing a lubricant applicator.

Owner:MITROVICH MICHAEL J +1

Metering device, lubricating device and method for dispensing a predetermined amount of lubricant

ActiveUS9146006B2Improve accuracyMore installation spaceManual lubricationLeaf springsLubricantMicro valve

A metering device for dispensing a predetermined amount of lubricant includes a lubricant reservoir, which retains a lubricant and dispenses it under pressure via an outlet of the lubricant reservoir, and a metering apparatus, which comprises at least one microvalve. The microvalve is fluidly coupled with the outlet of the lubricant reservoir and dispenses the predetermined amount of lubricant in a defined manner. The metering apparatus is spatially separable from the lubricant reservoir.

Owner:AB SKF

Self-aligning support assembly and method for rotatable cylindrical components

ActiveUS7946554B2Easy alignmentReduced dimensional accuracyPortable framesMachines/enginesLubricantConcave surface

An apparatus and method suitable for supporting a cylindrical component. The apparatus includes a pedestal having an upper surface with a semispherical concave shape, and a carriage supported on the upper surface of the pedestal. The carriage has a lower surface and an oppositely-disposed upper surface with elements for contacting and rotatably supporting the cylindrical component. The lower surface of the carriage engages the upper surface of the pedestal and has a semispherical convex shape complementary to the semispherical concave shape of the upper surface of the pedestal. The apparatus further includes a reservoir at and recessed in the upper surface of the pedestal, and a feature for delivering a lubricant to the lubricant reservoir. The lower surface of the carriage and the upper surface of the pedestal define an enclosure around the reservoir.

Owner:GENERAL ELECTRIC CO

Method of reducing torque out retention values in de-swaging of actuator of disk drive

InactiveUS7624495B1Promote resultsReduce debrisElectrical transducersManual lubricationGramDeposition process

A lubricant is applied to swage contact surfaces in a disk drive of the type including a suspension arm connected to an actuator arm by a swaging process. A preferred thin film lubricant may be applied to the contact surfaces by immersion and draining, immersion and raising the part out of the solution, localized spraying, or various deposition processes. Application of the lubricant reduces chipping during de-swaging, particularly with nickel plated metal components. Application of the lubricant has also shown to improve gram load uniformity, reduce adverse distortion to the actuator assembly and reduces torque out retention values. Improved gram load uniformity enhances overall disk drive functioning, reduced distortion preserves intended attitude and flatness of the actions for assembly and reduced torque out retention values improves reworkability of the disk drive.

Owner:SEAGATE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com